External push broach

A technology of pushing and pulling knives and pressure plates, which is applied in the direction of broaching knives, broaching machines, gear teeth, etc., can solve the problems that the cutting consistency of circular blade teeth cannot be guaranteed, the knife rack cannot be repaired and used, and the position accuracy is difficult to guarantee, so as to achieve saving Processing machine tools and equipment, the cost is beneficial to environmental protection, and the effect of high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is mainly used for the processing and molding of columnar body parts, especially gear parts. Since the structural principle of the present invention is designed for all columnar body structure parts, its processing principle is completely consistent for all columnar body structure parts, so this implementation The method only takes the gear as an example, and the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

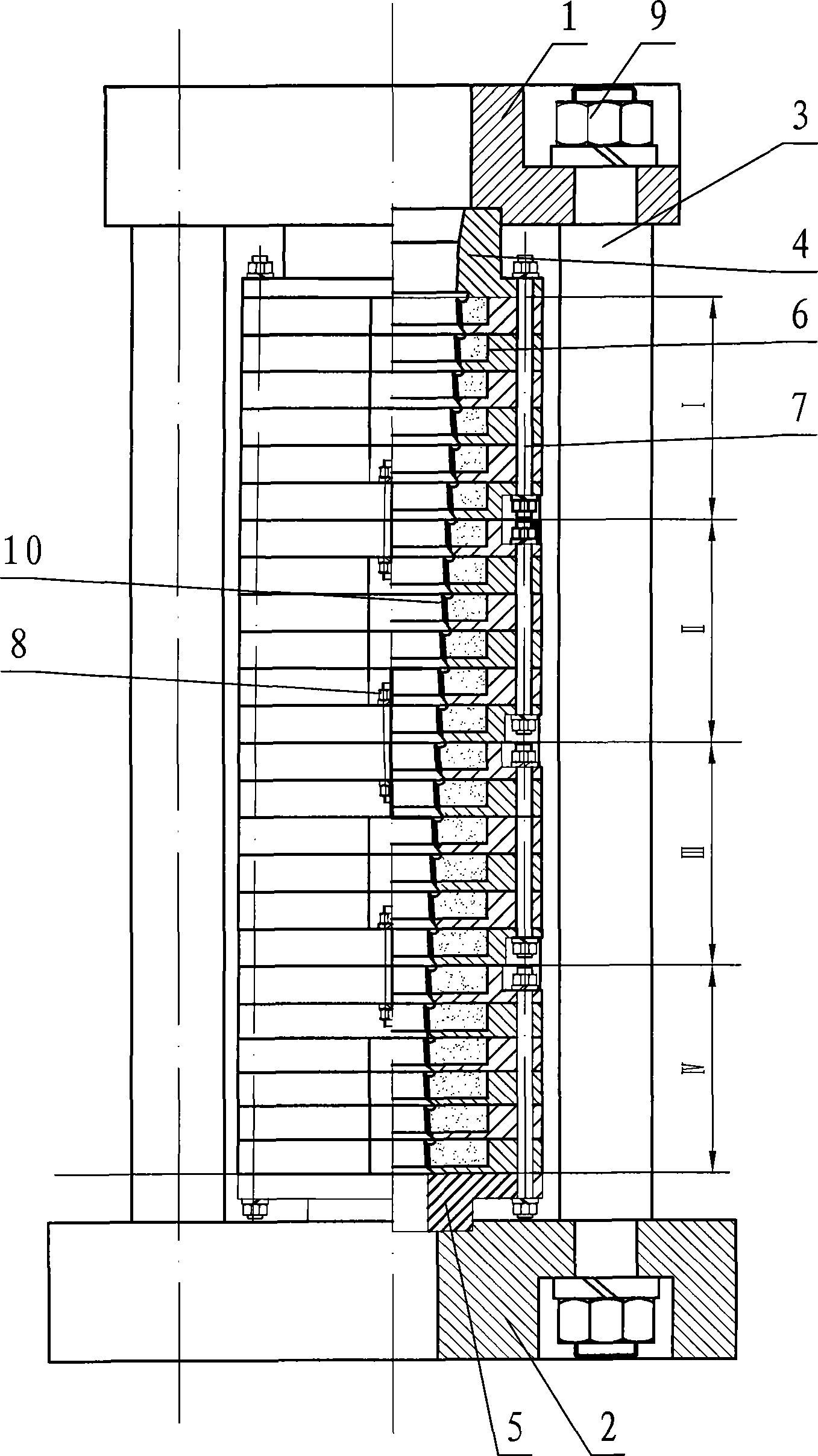

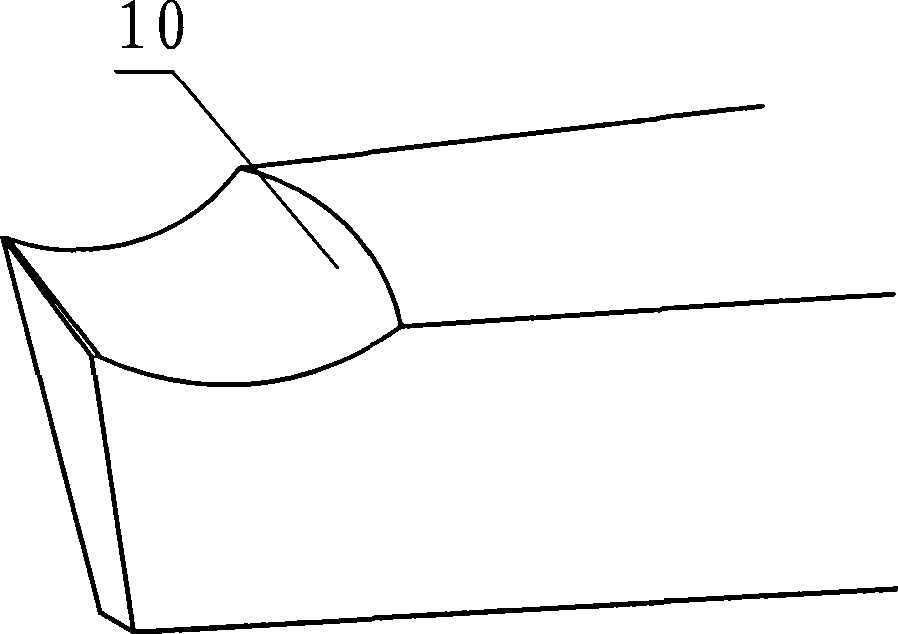

[0031] Such as figure 1 As shown, a push-out broach in this embodiment includes a front guide platen 1, a rear guide platen 2, and a connecting rod 3 connecting the two, and is crimped on the front guide platen 1 and the rear guide platen 2. The cutting part between them, wherein the cutting part is composed of initial cutting tooth part I, transition tooth part II, finishing tooth part III and correction tooth part IV, and each part is composed of a plurality of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com