Efficient drum-shaped profiling end mill

An end mill and drum-shaped technology, which is applied in the field of high-efficiency drum-shaped profiling end mills, can solve the problems of limited tool path, low processing efficiency, and small cutting volume, so as to reduce stress concentration, improve processing efficiency, The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

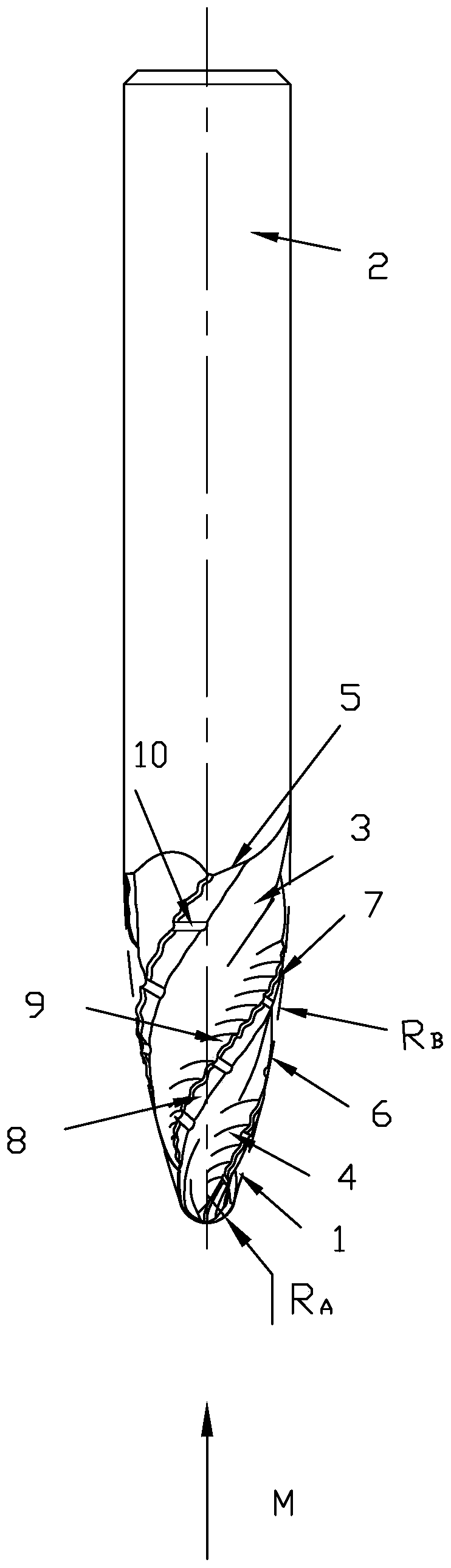

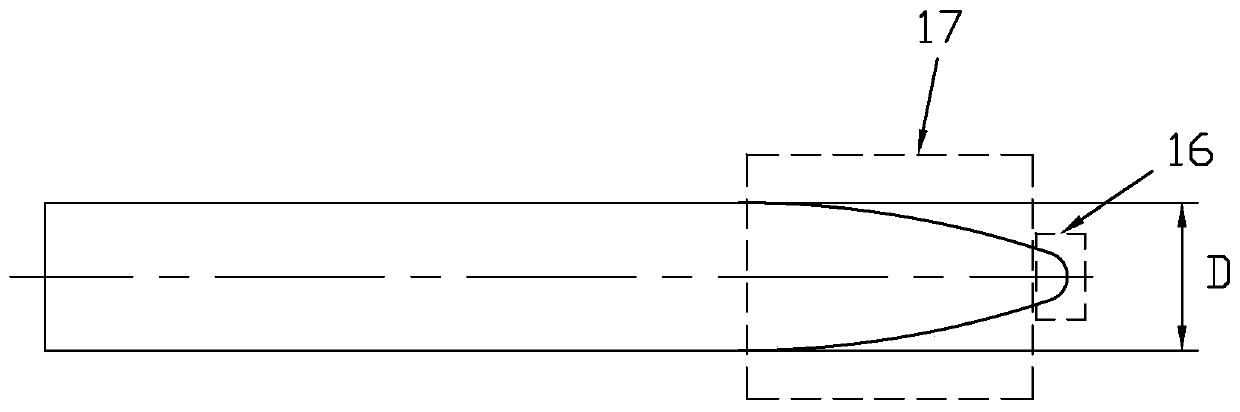

[0028] see Figure 1 to Figure 6 As shown, a high-efficiency drum-shaped profiling end mill of the present invention includes a round rod-shaped body, the lower end of which is provided with a cutting portion 1, and a handle 2 is set from the cutting portion to the top; the entire cutting Part 1 is provided with a plurality of flutes 3 extending spirally in the direction of the handle from the bottom end of the round bar-shaped body. In this embodiment, the number of flutes 3 is 4, but the present invention does not make any adjustments to the number of flutes 3. Restricted, the surface of each flute 3 facing the direction of cutting rotation is set as a rake face 4, and the rake face 4 intersects with the outer peripheral surface of the cutting part 1 to form a cutting edge 5; the cutting edge 5 passes through the The knife face 4 makes it present a wavy cutting edge 9; the cutting edge 5 includes a circumferential cutting edge 17 and a ball-end cutting edge 16, and the ball-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com