Machining method for milling tungsten alloy target material

A processing method and tungsten alloy technology, applied in the field of mechanical processing, can solve the problems of low production efficiency and long processing cycle, and achieve the effects of high production efficiency, short processing cycle and avoiding corner drop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

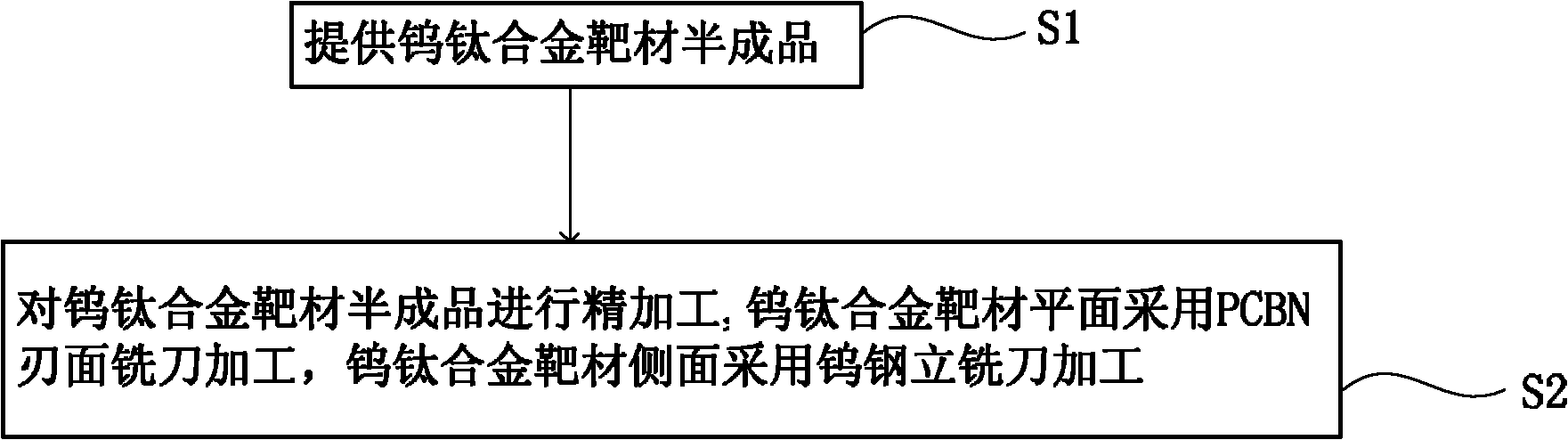

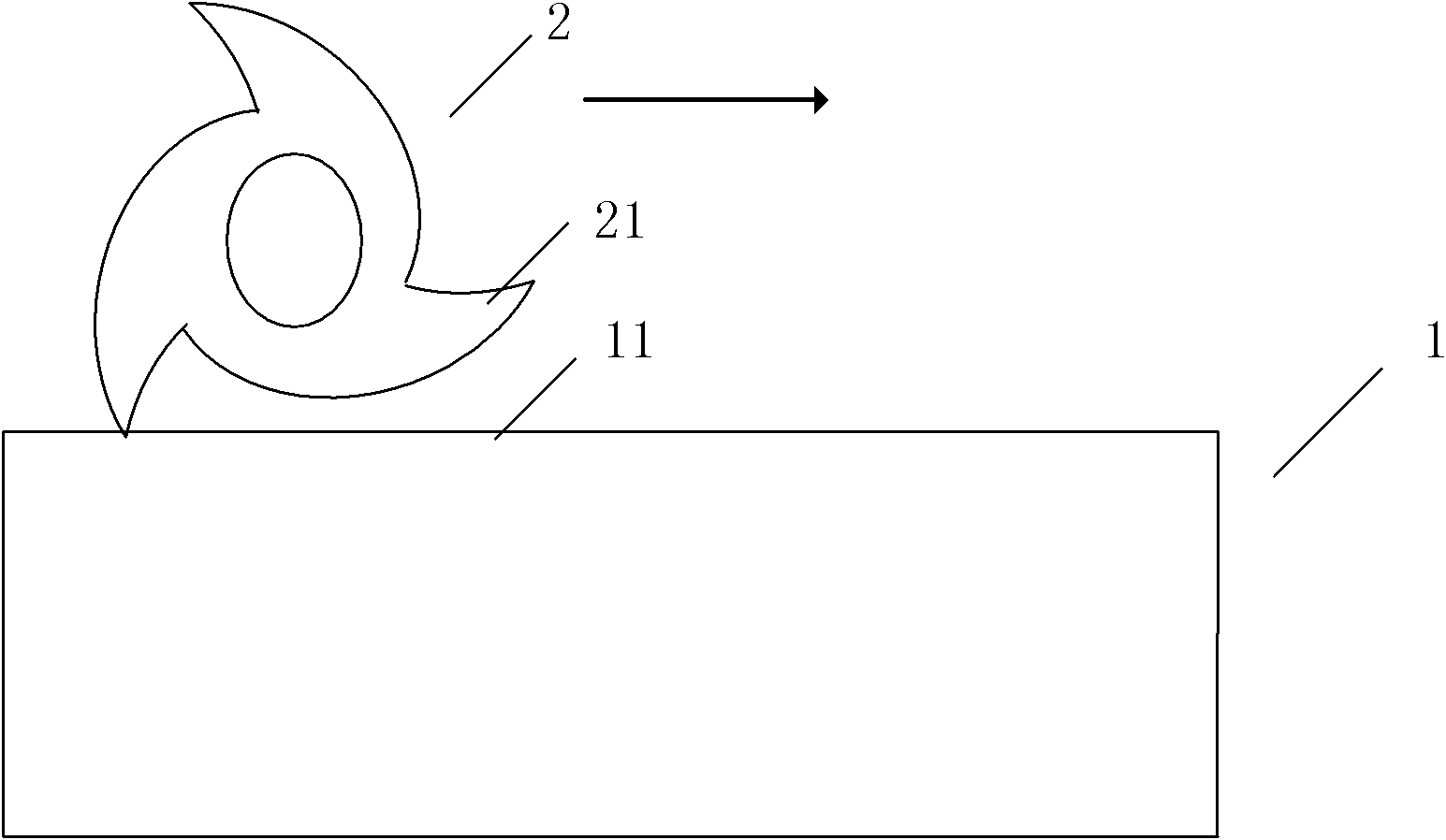

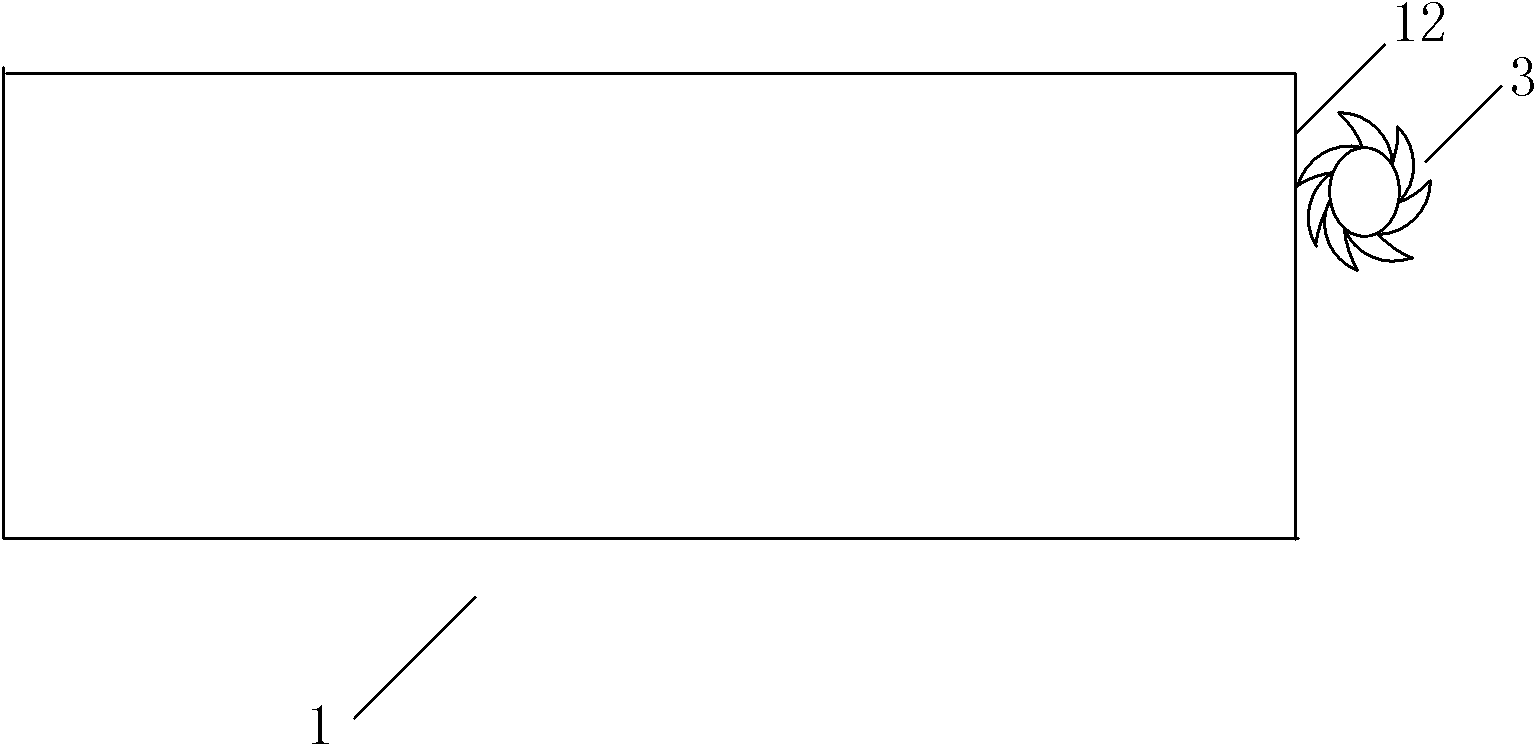

[0033] The present invention aims to process the plane of the tungsten alloy target with a PCBN (cubic boron nitride) edge milling cutter in the finishing step of the tungsten alloy target, and the side of the tungsten alloy target is processed with a tungsten steel end mill, It can avoid corner drop during processing, and at the same time, it can realize the processing of tungsten alloy target with complex curved surface, and solve the problems of long processing cycle and low production efficiency.

[0034] In the processing of tungsten alloy targets, people usually want to use the shortest processing time to improve processing efficiency. At the same time, the hardness of tungsten alloy and the required processing accuracy must be considered. Therefore, it is necessary to select suitable processing tools and High-efficiency processing conditions are used, wherein the processing conditions specifically include: rotation speed, feed speed, back engagement and cooling method. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com