Cutting knife used for thermal cutting of plastic material

A plastic profile, thermal cutting technology, applied in metal processing and other directions, can solve the problems of insufficient smoothness of the end surface of the profile, affect the quality of the profile, loud noise, etc., achieve the effect of not easy to chip, improve the production environment, and reduce cutting noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

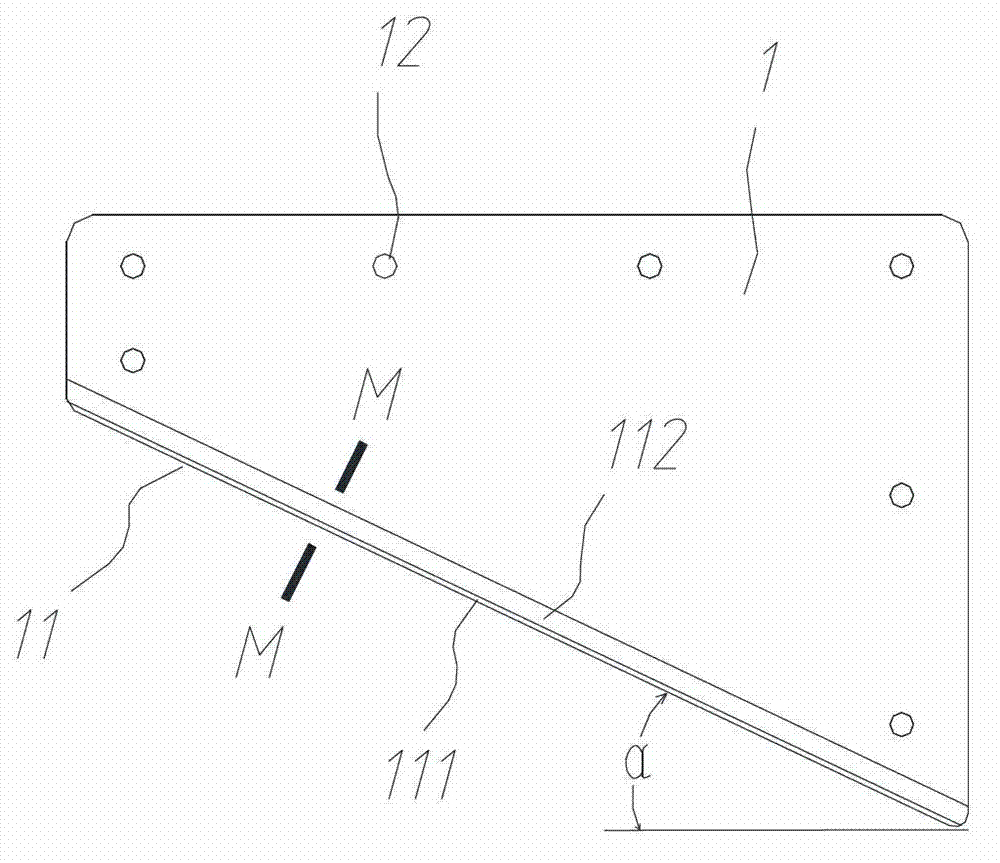

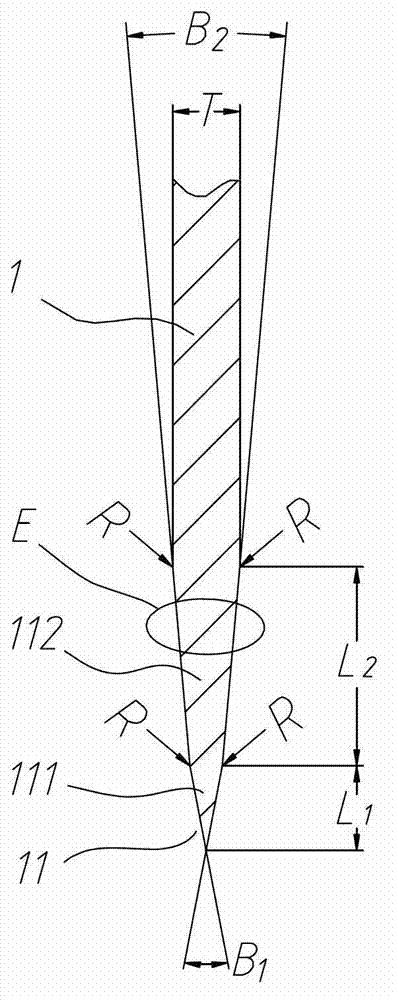

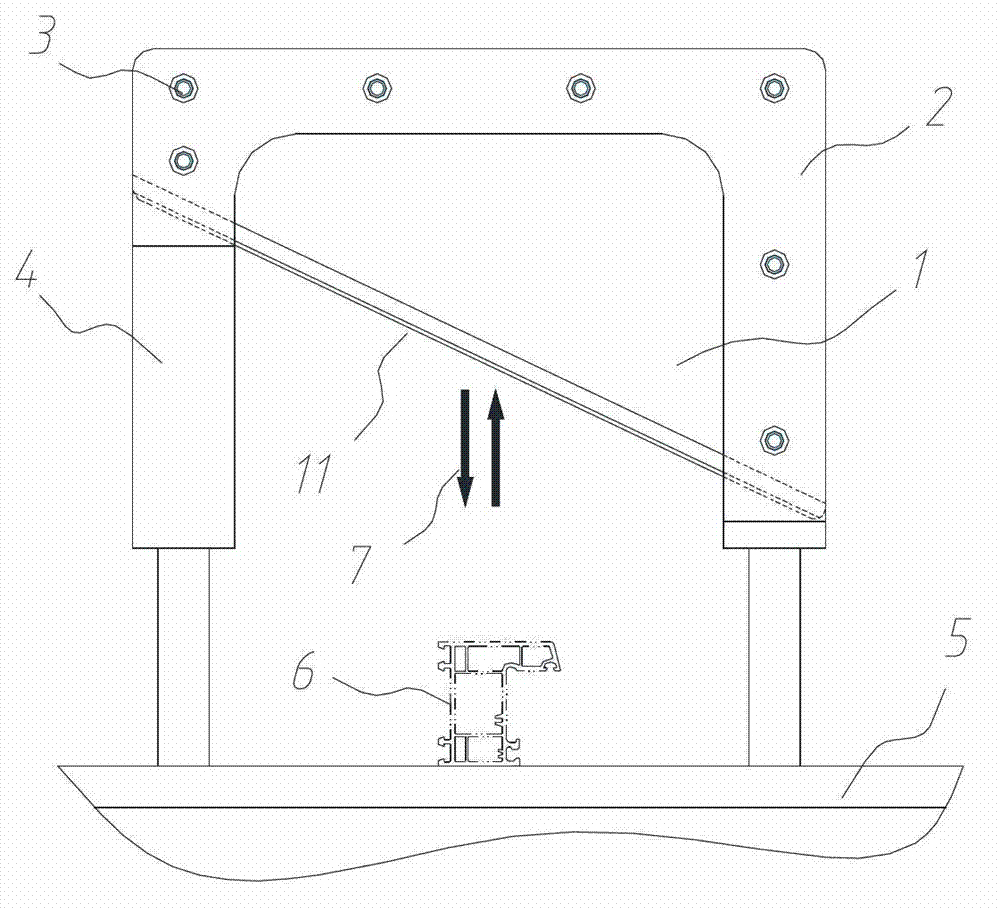

[0014] like figure 1 and figure 2 As shown, the blade body 1 is provided with a mounting hole 12, and the lower end of the blade body 1 is provided with an inclined double-sided cutting edge 11; the inclination angle α of the cutting edge 11 relative to the horizontal line is 22°~28°. The cutting edge 11 includes a first-level cutting edge 111 and a second-level cutting edge 112; the angle of the first-level cutting edge 111 is the angle B between the two sides 1 is 21o~23o, the height L of the first-stage cutting edge 111 1 1.8mm~2.2mm; second-stage cutting edge 112 angle B 2 is 8o~10o, the height L of the second cutting edge 112 2 5mm~8mm, and the thickness T of the blade body 1 is 1.5mm~1.8mm. R smooth transitions exist between the first-stage cutting edges 111 and the second-stage cutting edges 112 , between the second-stage cutting edges 112 , and between the blade body 1 .

[0015] Described first stage cutting edge 111, second stage cutting edge 112 are along bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com