Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Improve section quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

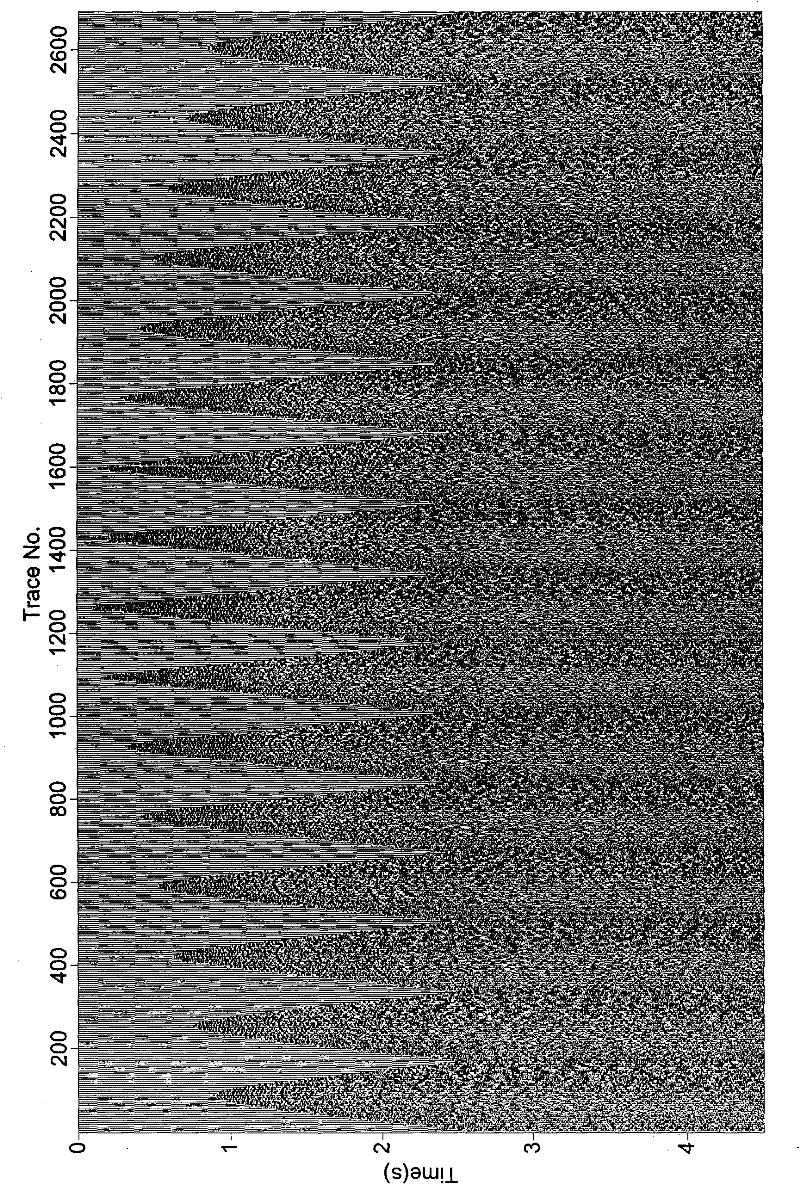

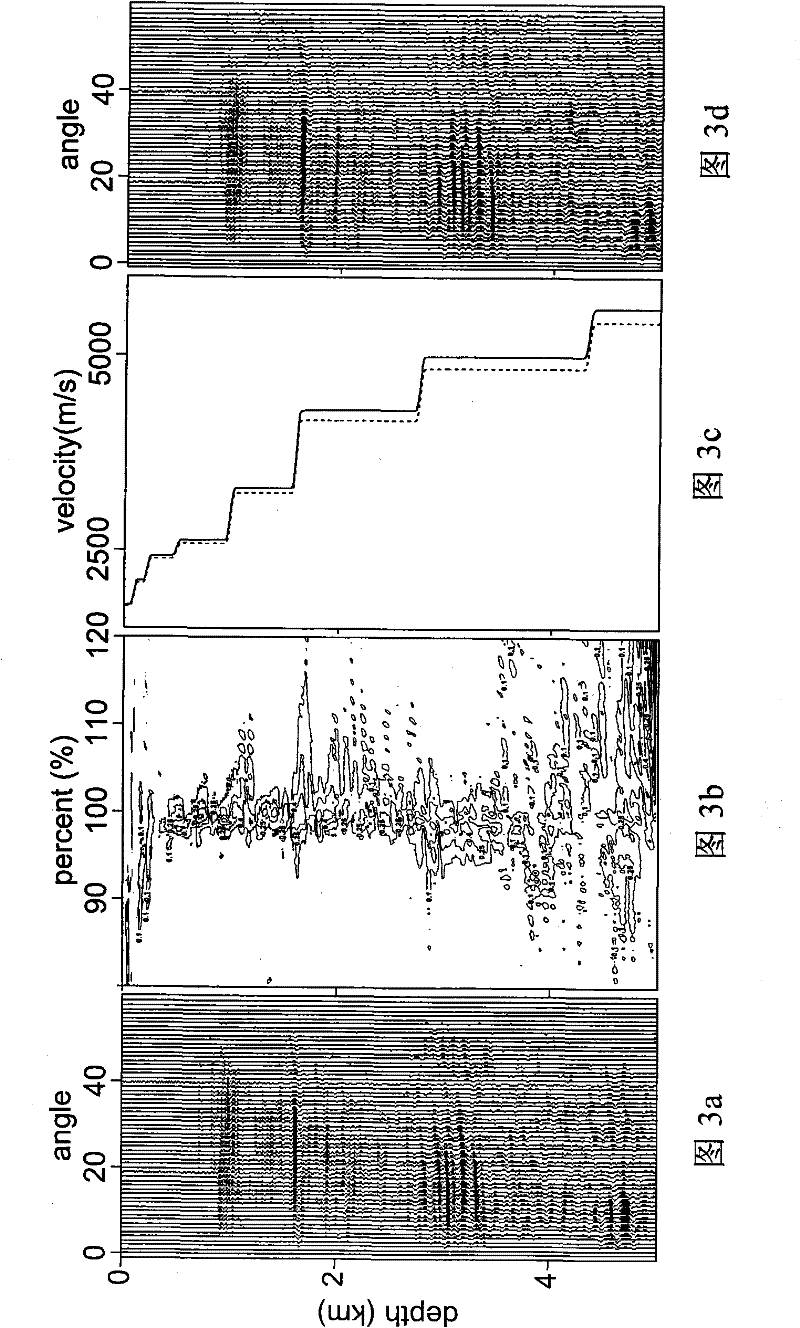

Method for improving imaging effect of wave equation prestack depth migration

InactiveCN102176053AResolve mismatchAvoid multiple offset calculationsSeismic signal processingSeismology for water-loggingSignal-to-noise ratio (imaging)Normal moveout

The invention provides a method for improving the imaging effect of wave equation prestack depth migration, wherein the method is used for processing seismic reflection data in seismic exploration so as to improve the application effect of the wave equation prestack depth migration. The method can be used for improving the imaging effect of the wave equation prestack depth migration by constructing the relationship of residual normal moveout between a depth domain and an angle domain and an interval velocity inversion method to directly update a migration velocity model of the wave equation prestack depth migration based on the residual normal moveout of an angle gather. Based on the relationship of residual normal moveout between the depth domain and the angle domain, the method can be used for removing the residual normal moveout, noise and stretching of a migration gather of the wave equation prestack depth migration, thereby improving the signal-to-noise ratio and resolution of a migration stack profile and improving the quality of the angle gather applied to the prestack inversion. Accordingly, the method can be used for well achieving the direct recognition of underground oil, gas or water, can be used for 2D (two-dimensional) and 3D (three-dimensional) wave equation prestack depth migration of the seismic reflection data, and has important application value for exploration of oil-gas and mineral resources.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

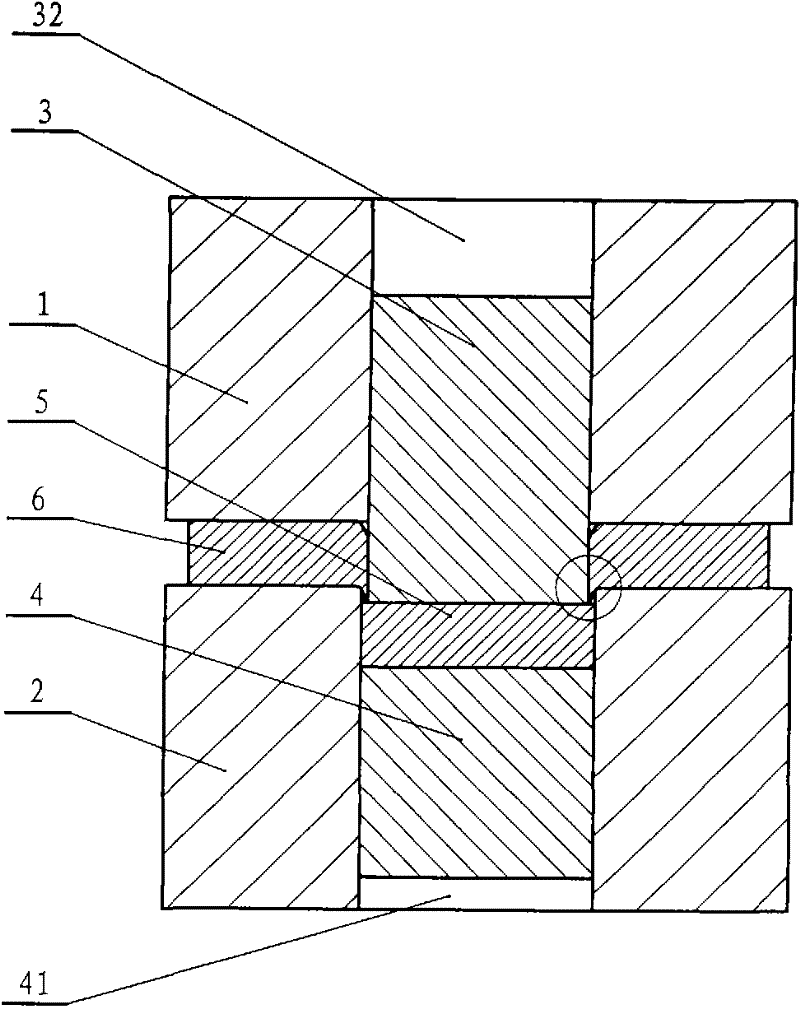

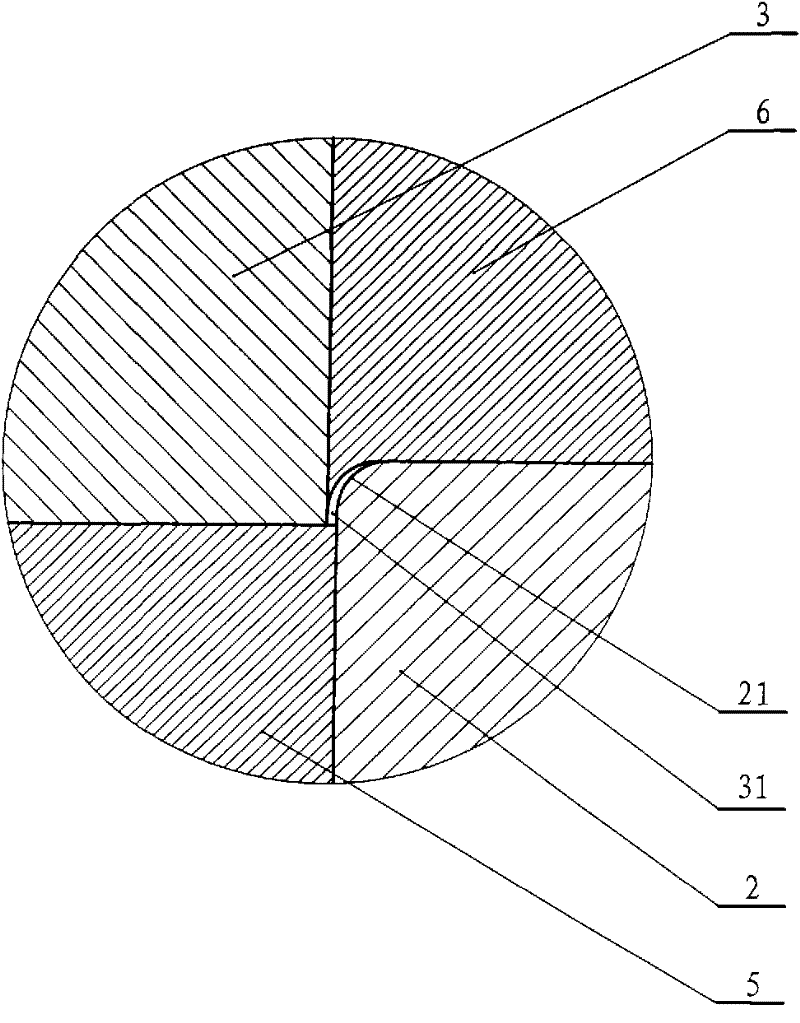

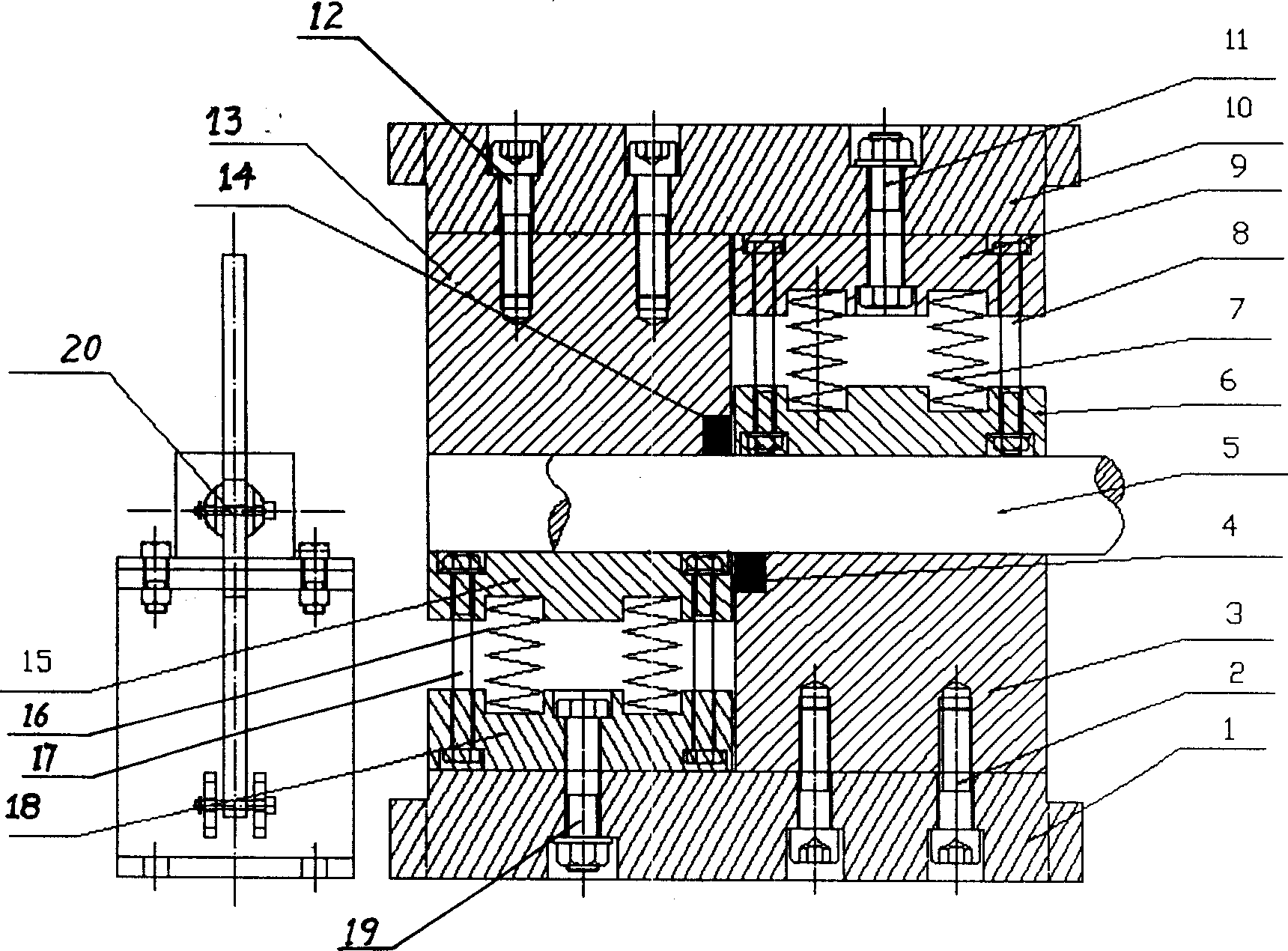

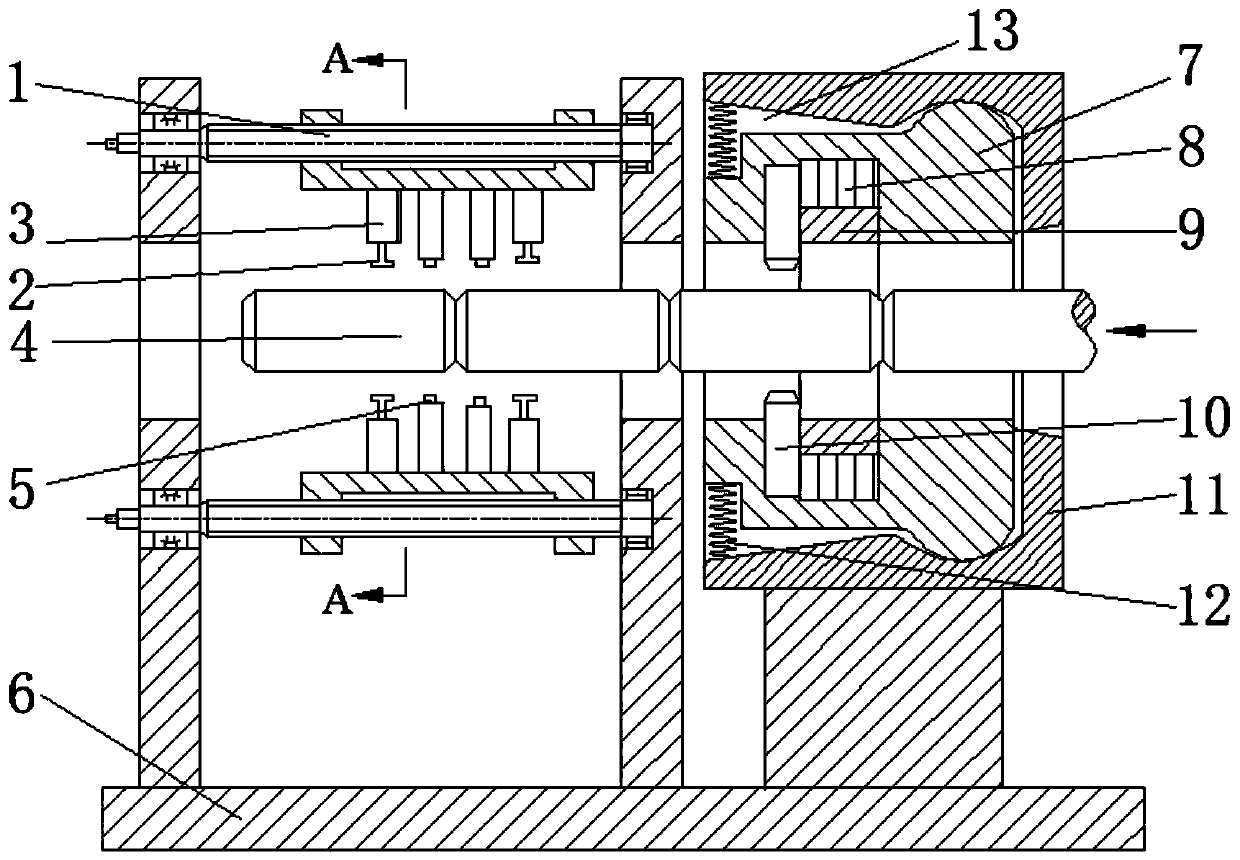

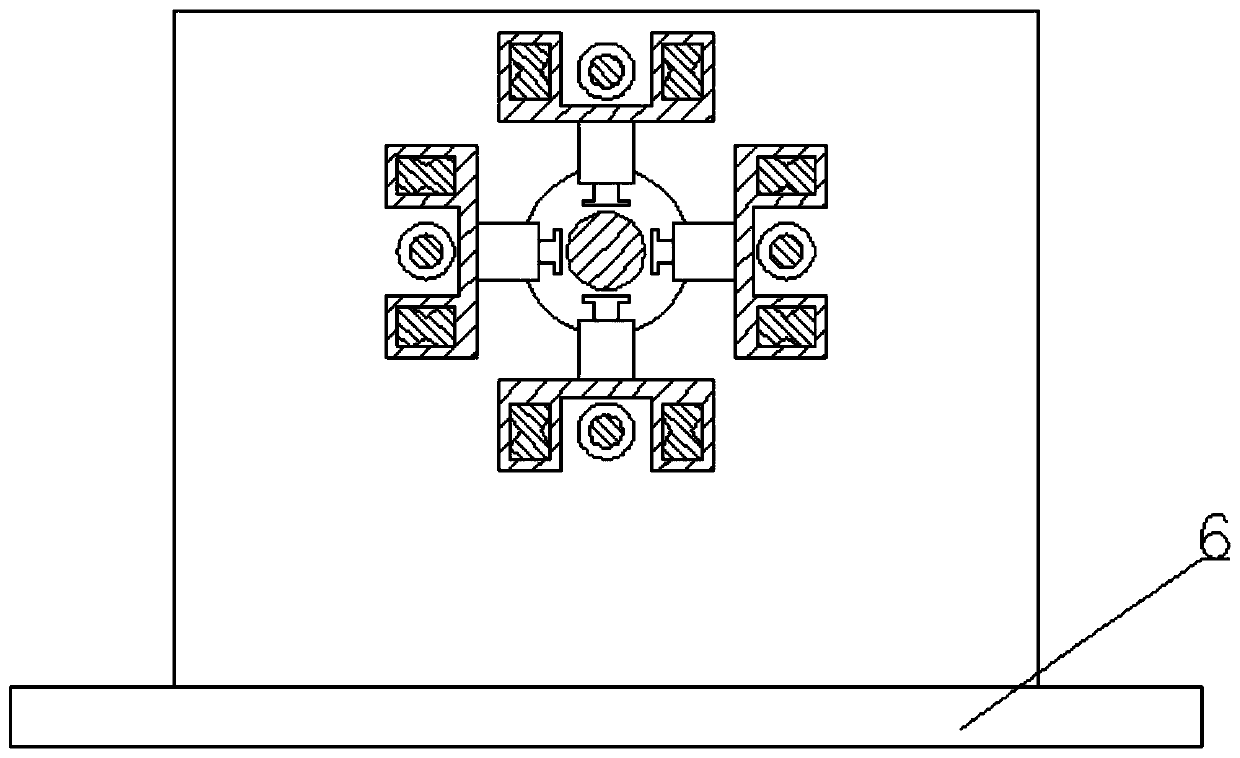

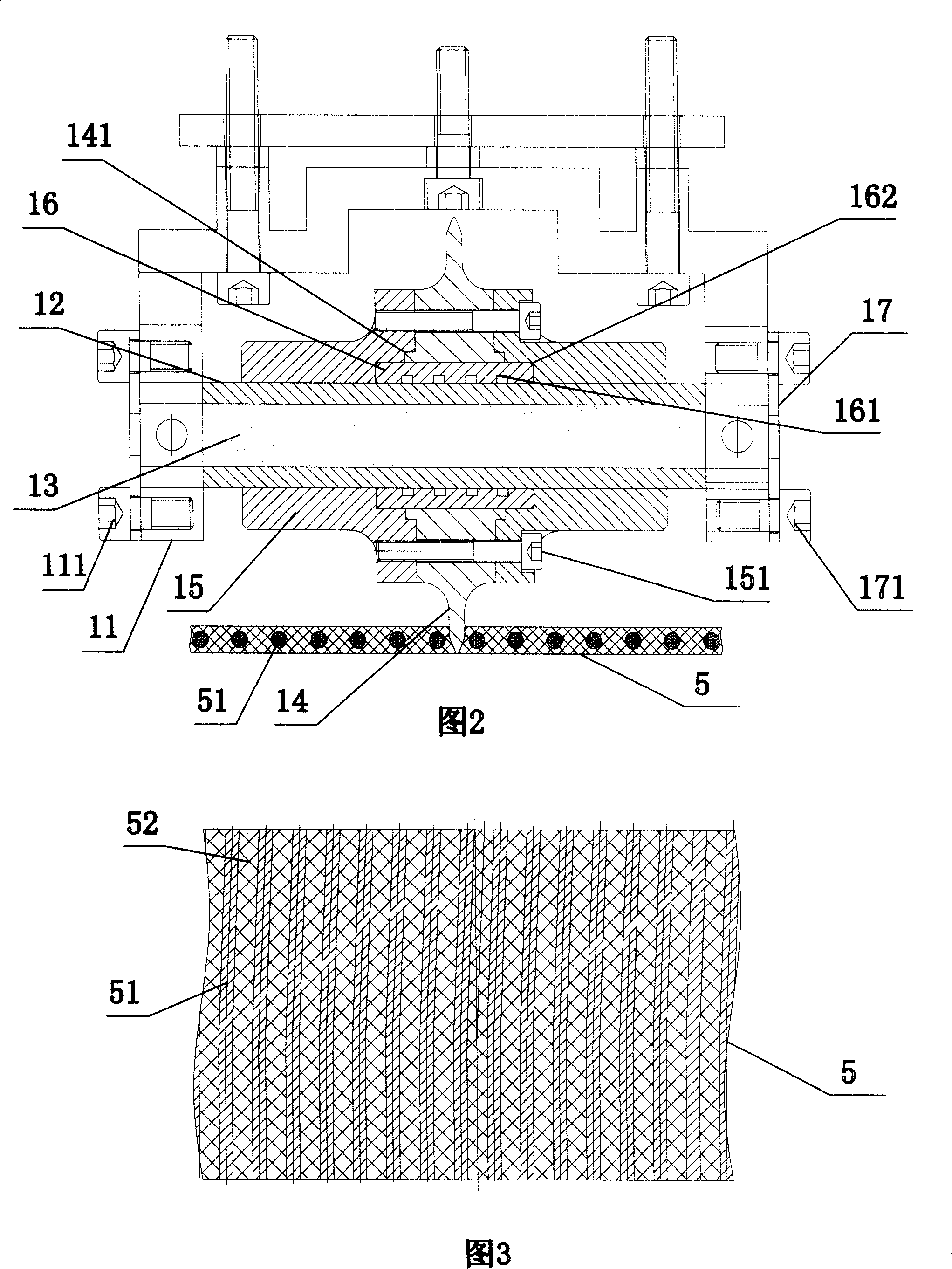

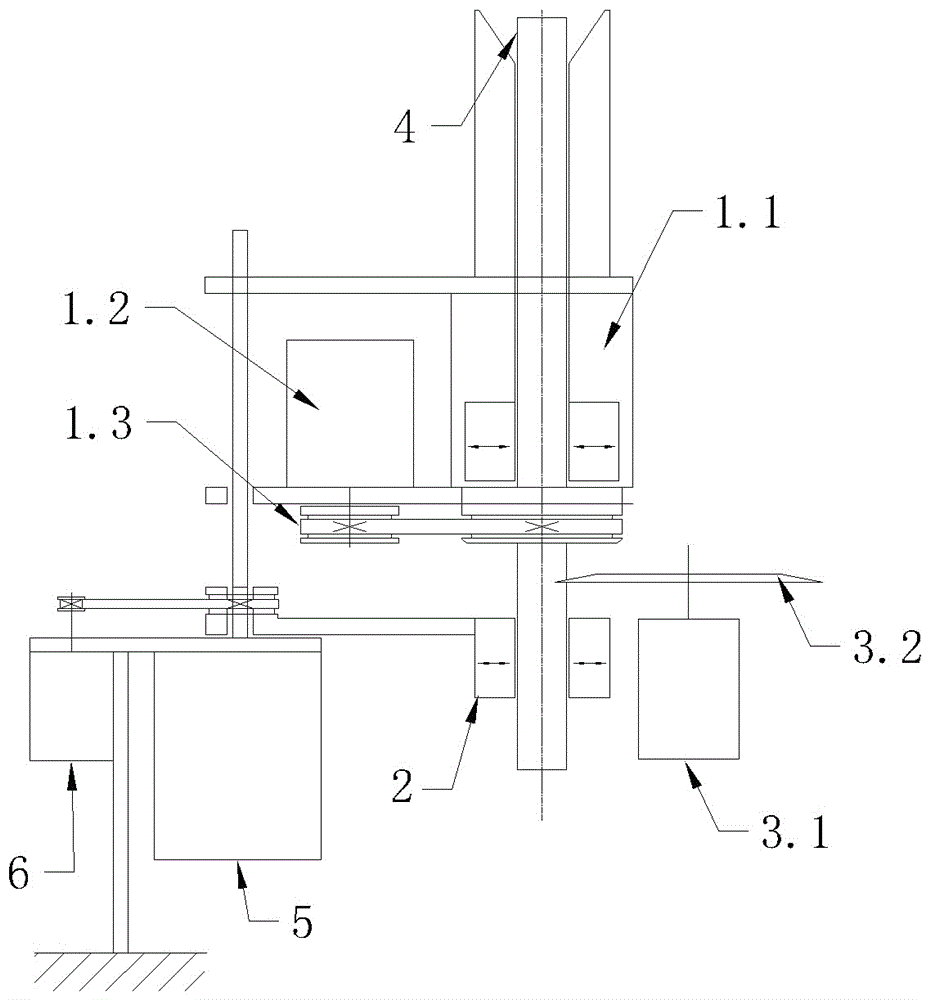

Plane edge-pressing and semi-fine blanking device and method

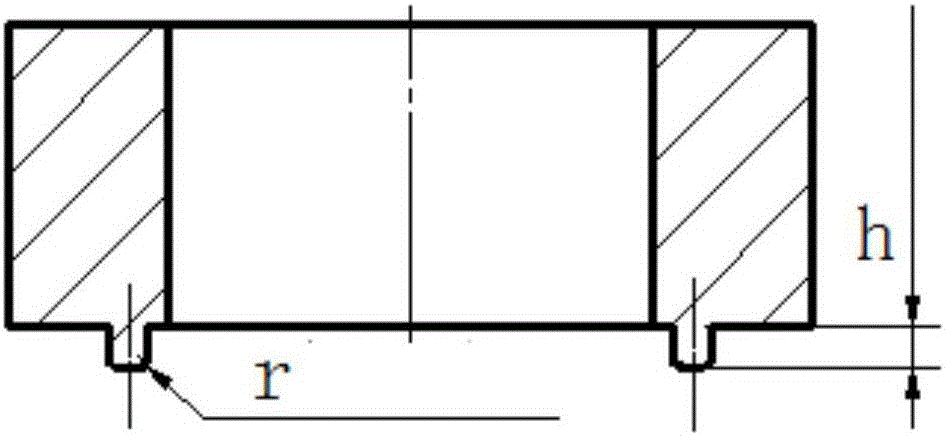

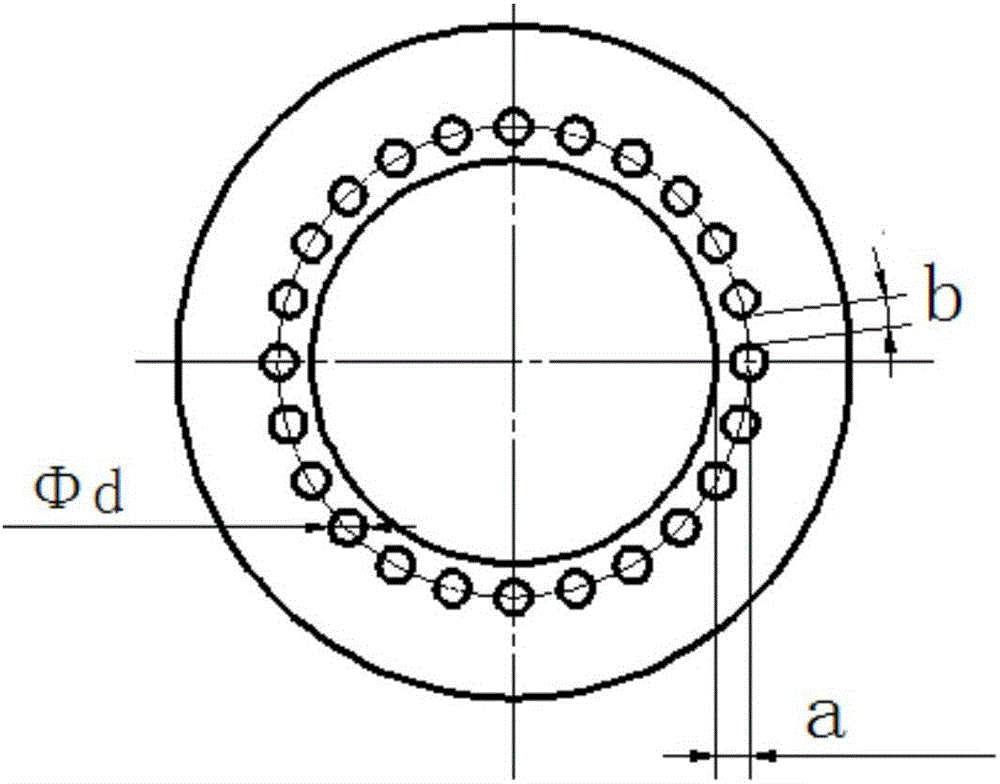

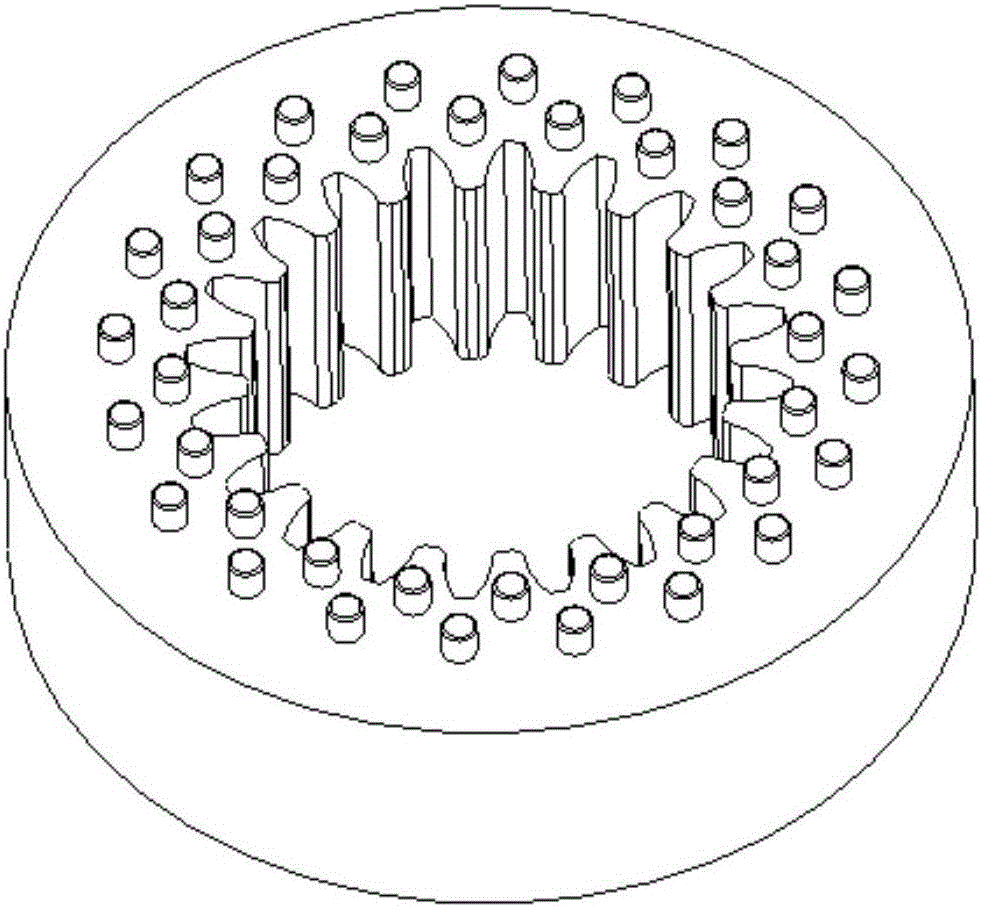

The invention relates to a plane edge-pressing and semi-fine blanking device and a method. The device is provided with a plane pressure plate and a concave die, when a workpiece is punched, the plane pressure plate needs to enable edge-pressing force to press on the outer edge of a profile of the workpiece on a workpiece blank, and the edge-pressing force can generate great friction force betweenthe surface of the workpiece blank and the plane pressure plate and between the surface of the workpiece blank and the concave die, so as to prevent the material of the workpiece blank from flowing out of the profile of the workpiece. The device is matched with punching force, three-dimensional pressure stress is generated in the material of the workpiece blank in an extrusion zone, and plastic flow is generated, so as to enable the numerical values of the pressure stress in the three-dimensional directions to tend to be consistent, enable the material of the workpiece blank in the profile ofthe workpiece to be in the hydrostatic pressure state and have a maximal plastic deformation range, reduce a region for generating tensile stress in a shearing deformation zone and prevent the emergence of cracks on the surface of a cross section of the workpiece. By using the plane edge-pressing and semi-fine blanking device and the method, an ordinary punch can be used, the processing of a die is simple, a pressurization region on the workpiece blank can not cause damages, the processing cost is low, the quality of the workpiece is high, and the device and the method are convenient to popularize and apply in the punching industry.

Owner:CHONGQING UNIV OF TECH

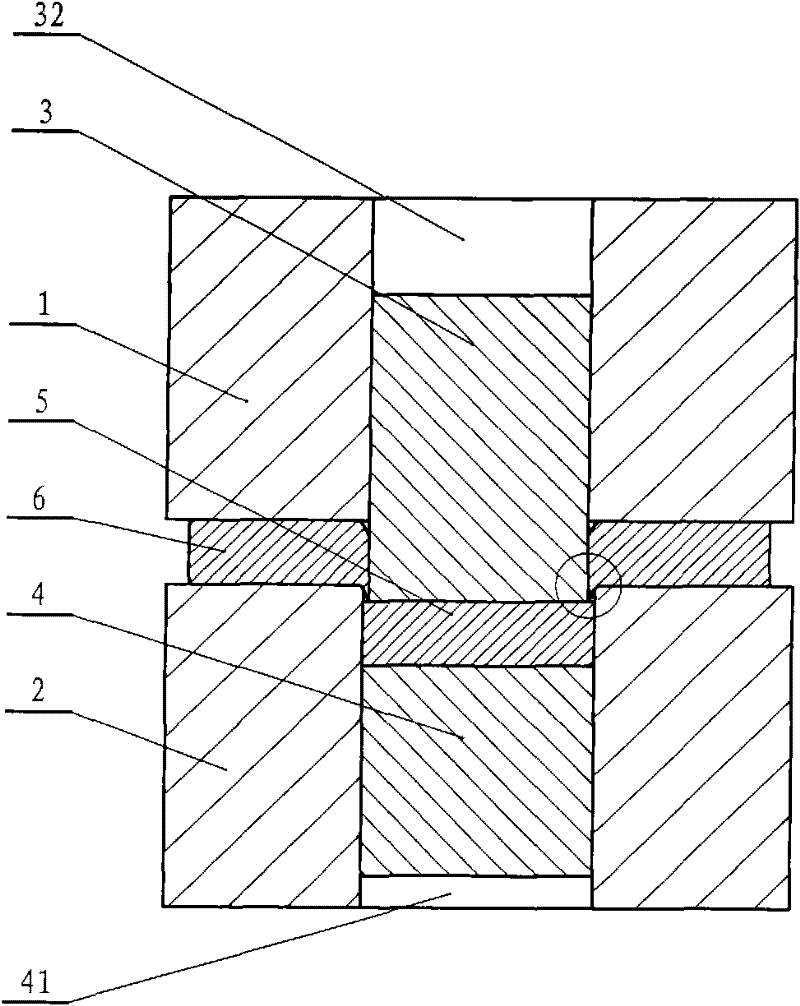

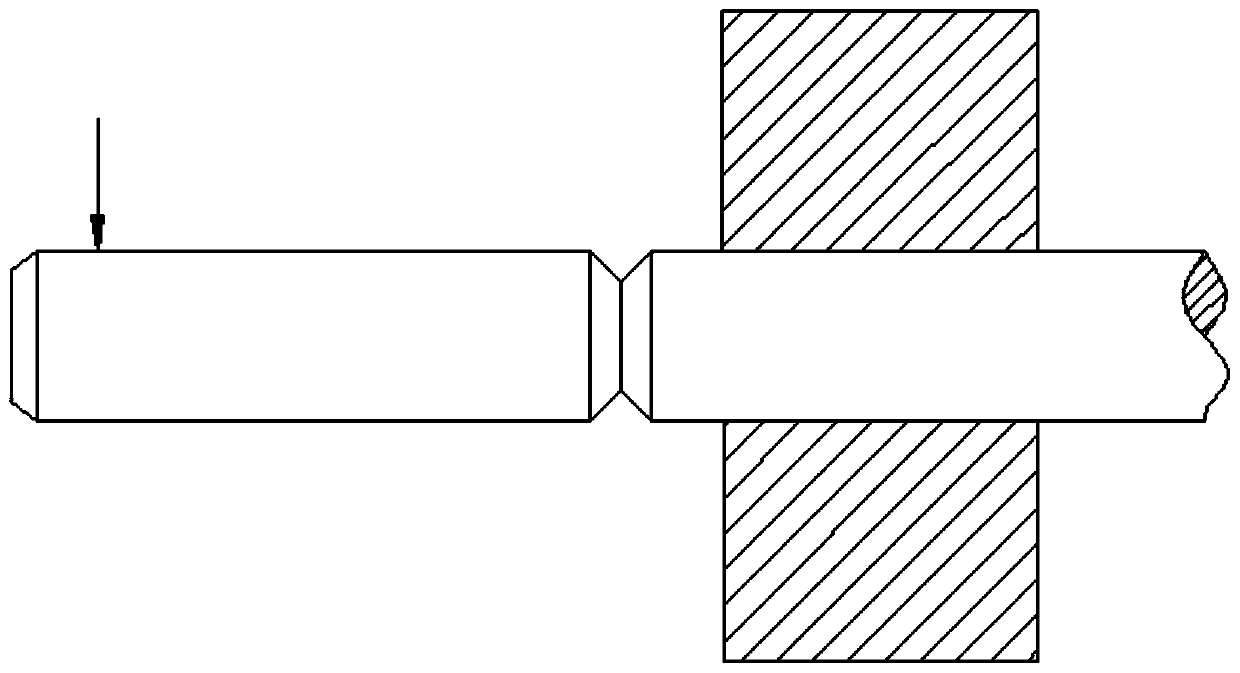

Rod material precision shear mould

InactiveCN1597208AReduce manufacturing costImprove cutting efficiencyShearing machine accessoriesMachine press

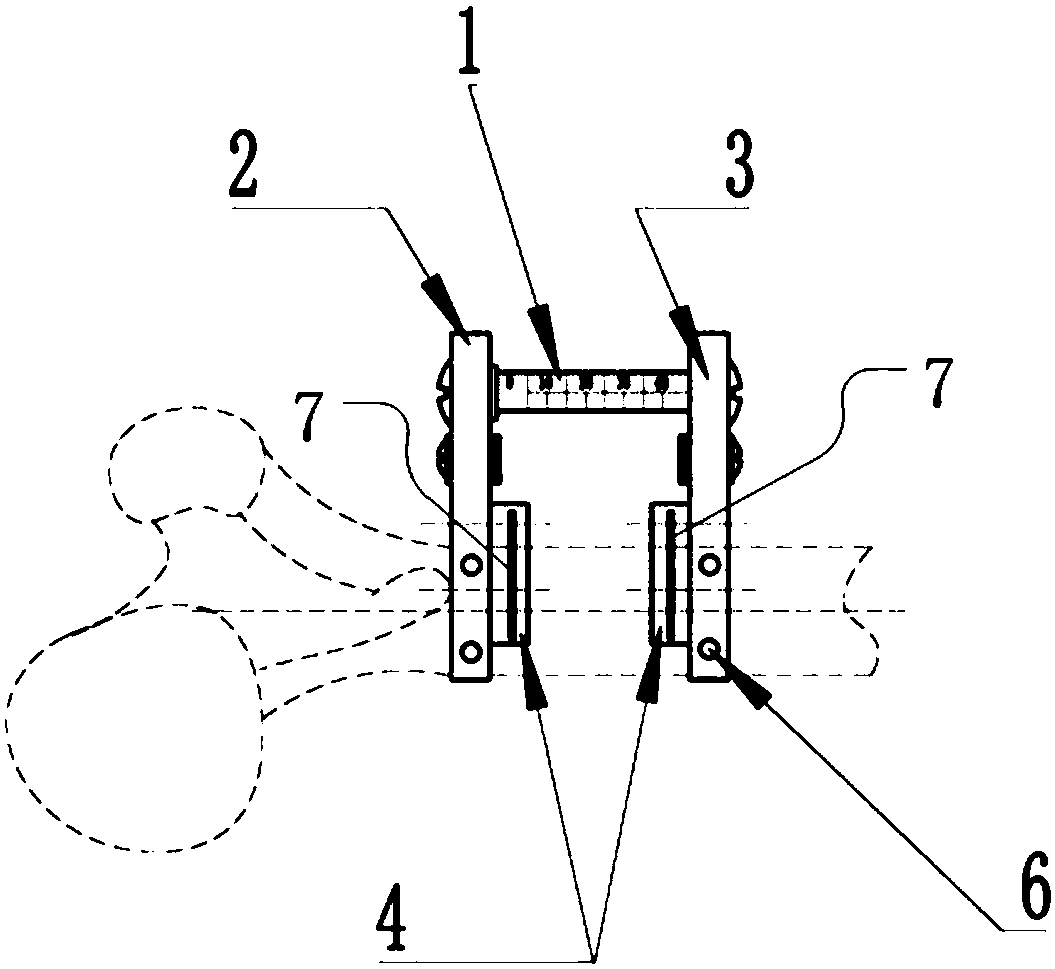

A precision shearing die of rod material for press is composed of upper and lower die plates, upper and lower fixed cutter carriers, upper and lower cutting blades, and the upper and lower clamp units consisting of clamping block, clamping spring, screw bolt and fixed block.

Owner:JINXI AXLE CO LTD

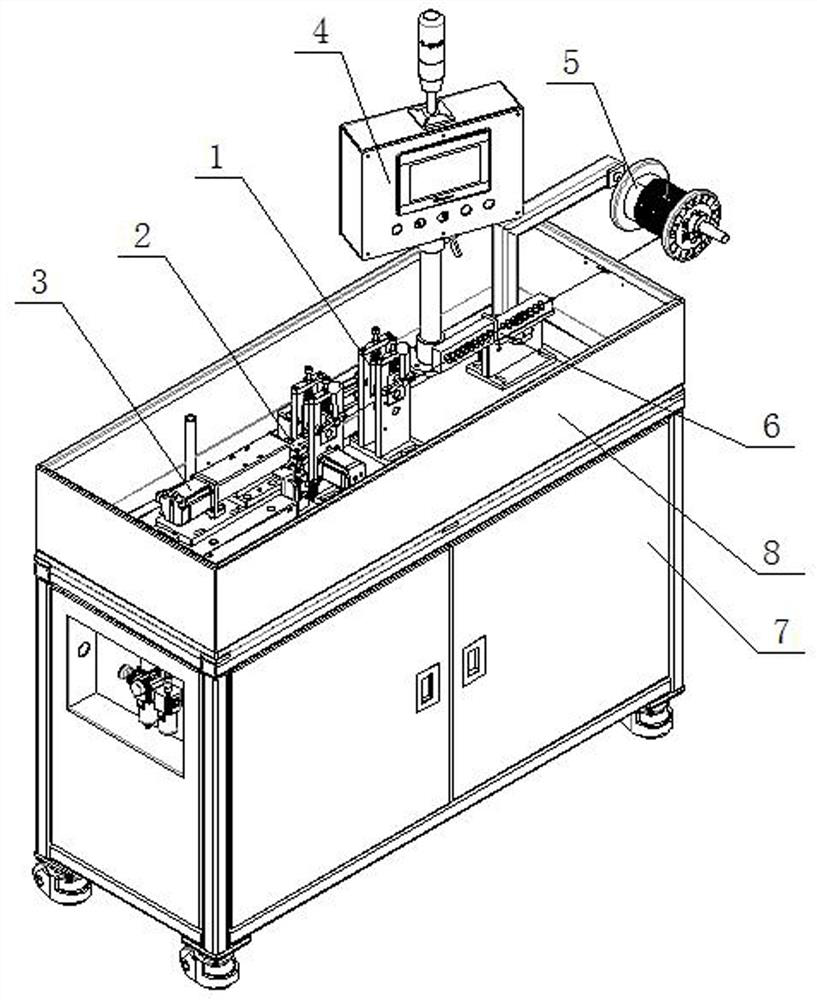

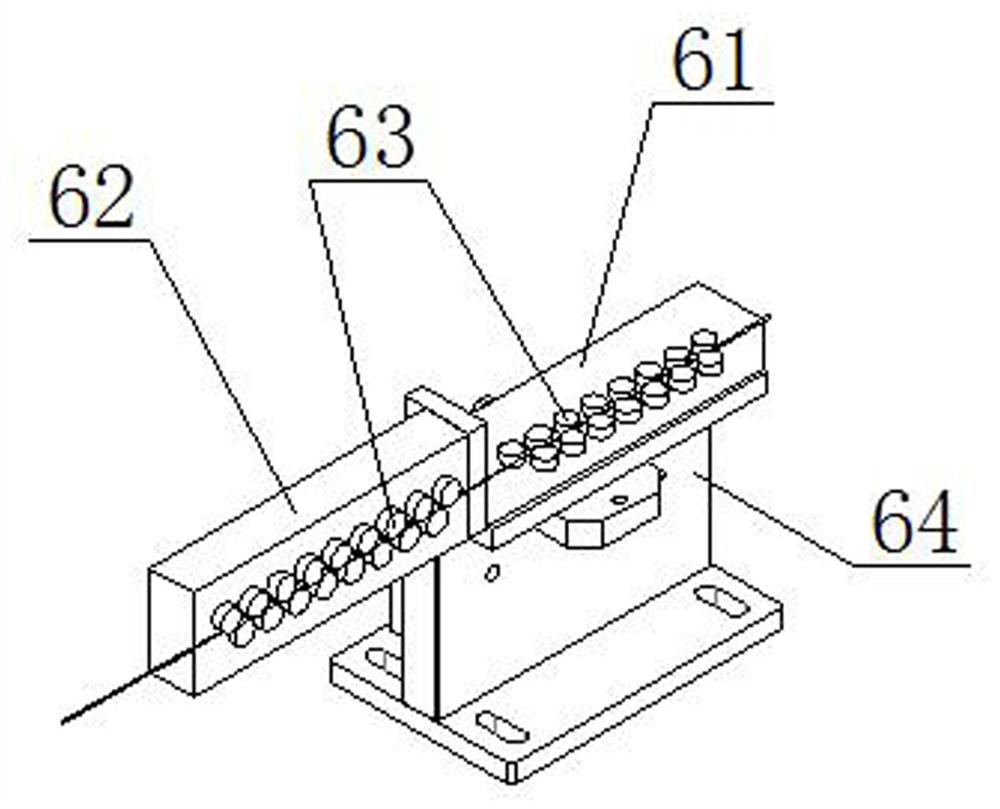

Automatic cutting machine

InactiveCN102554950AWith snap back featureRealize positioning cuttingMetal working apparatusReturn functionEngineering

The invention discloses an automatic cutting machine, relating to a cutting machine. The automatic cutting machine comprises a stand, a cutter plate, a feeding mechanism, an automatic swinging mechanism and an automatic rotating mechanism, wherein the cutter plate, the feeding mechanism, the automatic swinging mechanism and the automatic rotating mechanism are arranged on the stand, the feeding mechanism is provided with a feeding opening, a supporting plate and a discharging opening, the automatic rotating mechanism is used for driving the cutter plate to rotate, and the automatic swinging mechanism is used for driving the cutter plate to swing. According to the automatic cutting machine disclosed by the invention, automatic cutting is realized, influence of manual intervention on a cutting section is avoided and the quality of the cutting section is improved; furthermore, through utilizing the swinging mechanism and the rotating mechanism with combined crankshaft and guide rod, the automatic cutting machine has quick return characteristic, can realize slow-speed cutting and quick returning functions of the cutter plate, and can keep excellent quality of incision section when production efficiency is increased; in addition, the location cutting of the cutter plate on a material is realized by utilizing a material pressing mechanism.

Owner:CHINA AGRI UNIV

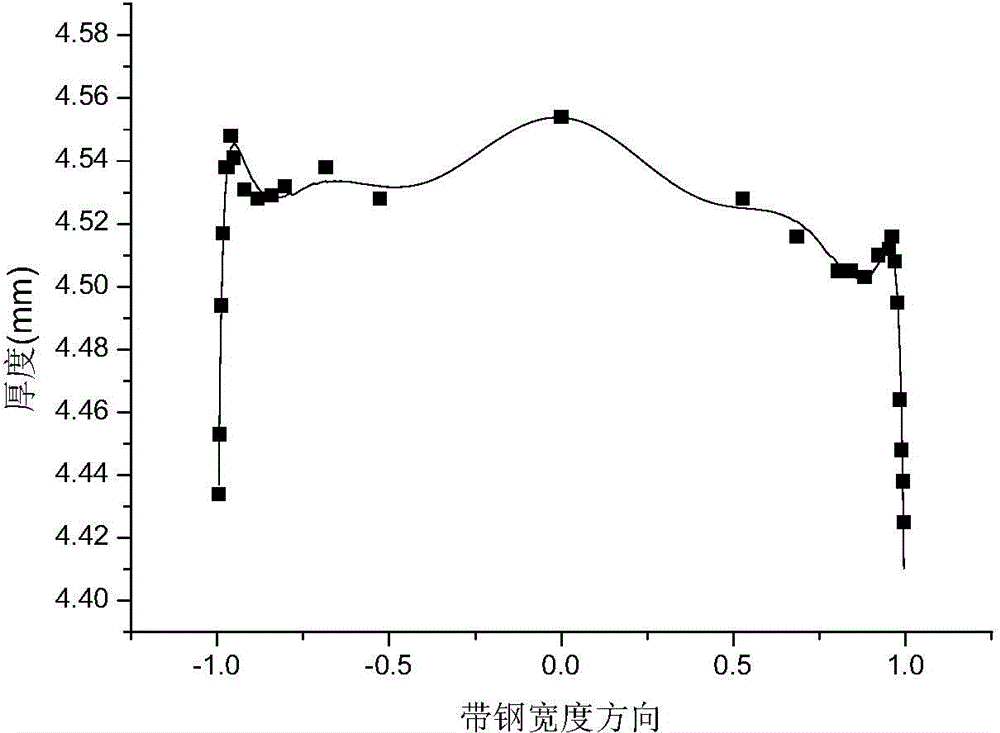

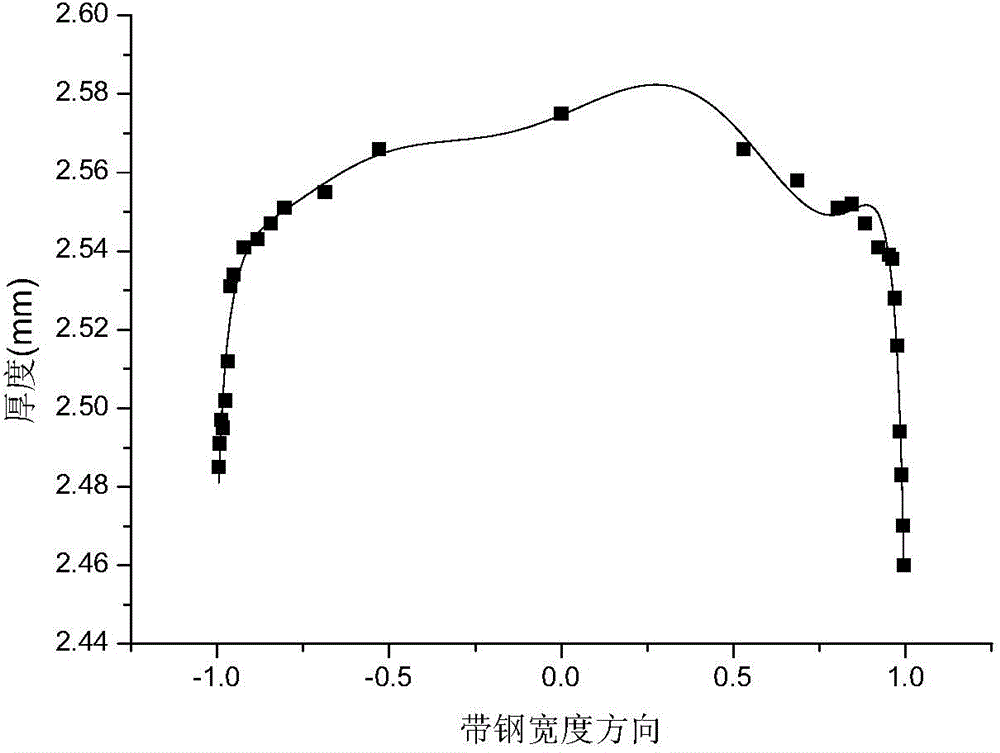

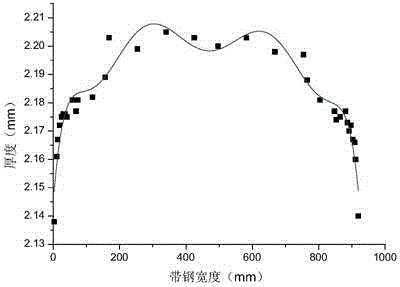

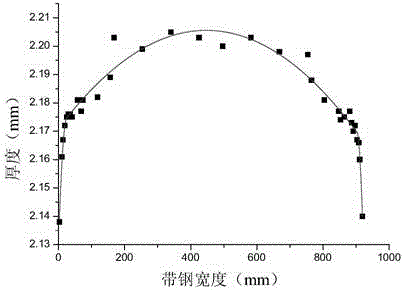

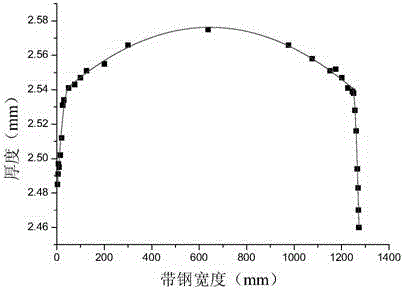

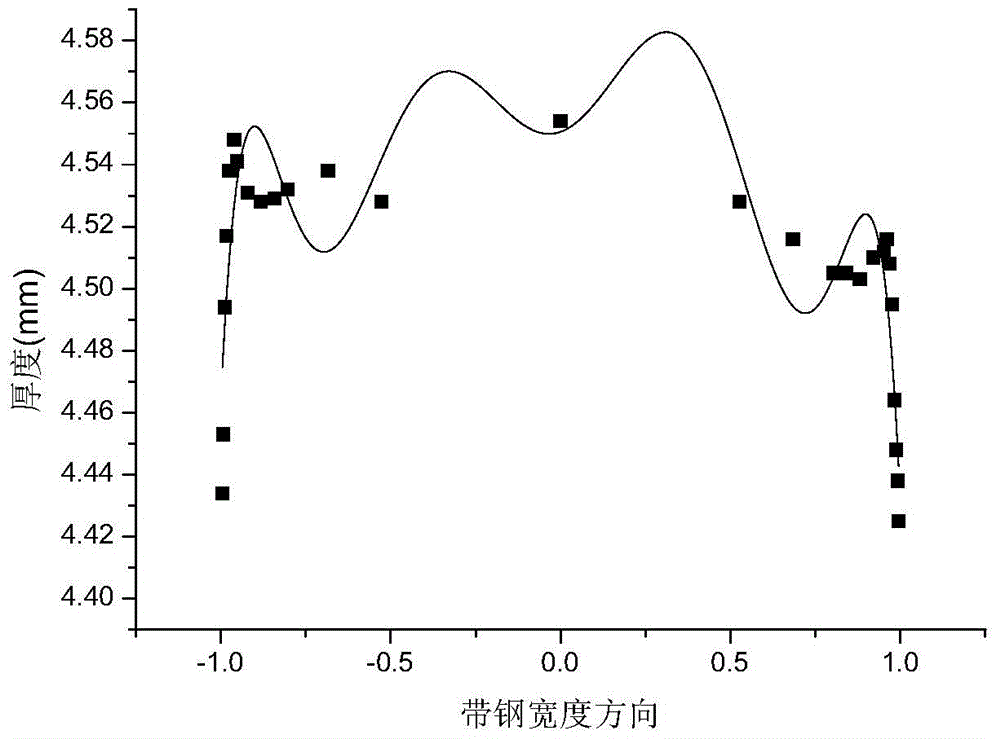

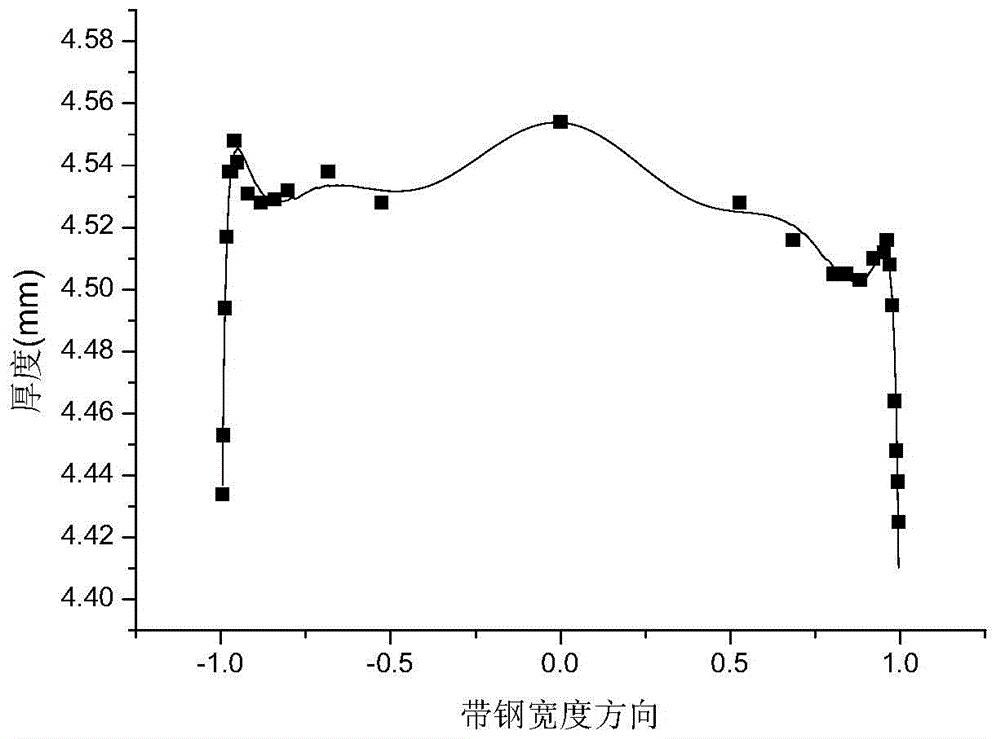

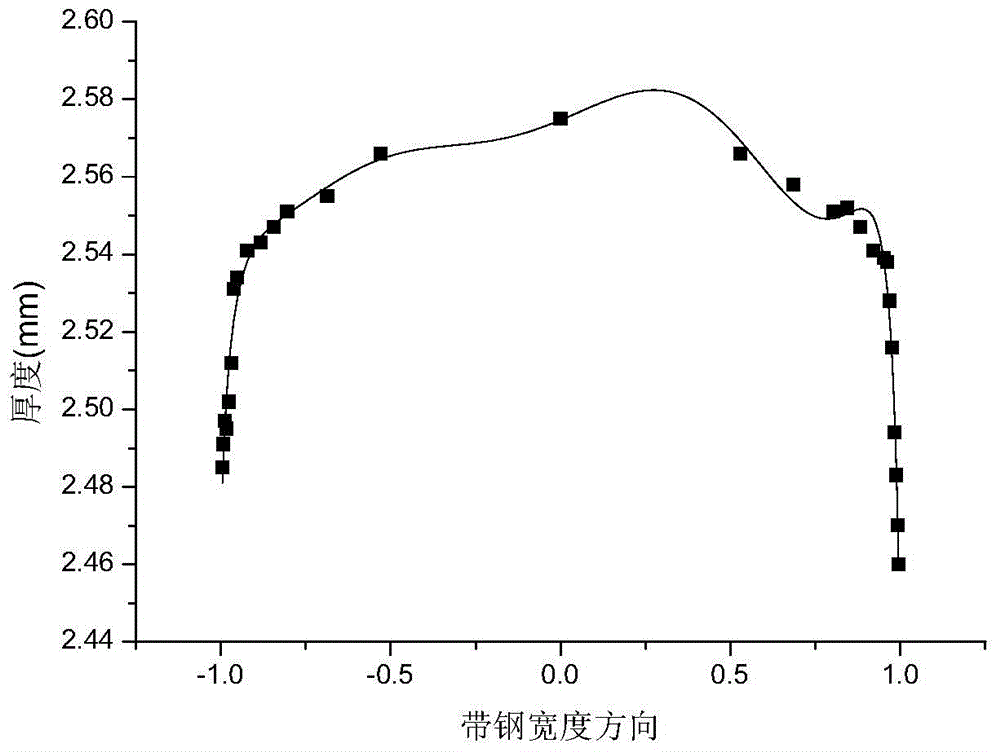

Characteristic parameter identification method of lateral distribution of strip steel thickness on the basis of mechanism

InactiveCN104588417AImprove section qualityImprove shape qualityRoll mill control devicesMeasuring devicesQuality controlStrip steel

The invention discloses a characteristic parameter identification method of the lateral distribution of strip steel thickness on the basis of a mechanism, and relates to the field of strip steel quality control. In the method, one function is adopted to describe the lateral distribution of the strip steel thickness in the whole width direction of the strip steel, the function consists of a basic mode based on an elastic flattening mechanism and a common polynomial, so that the function has few parameters and high precision, and strip steel edge drop can be favorably fitted. The characteristic parameter identification method has an important meaning on the aspects of identifying the section shape of strip materials, lowering influence on the plate shape of a finished product by the shape fluctuation of a material feeding section and improving the quality of the strip steel.

Owner:YANSHAN UNIV

Sectioning device for mounting photoelectric combination cable

InactiveCN111725744ADepth of cut levelImprove section qualityApparatus for removing/armouring cablesEngineeringThreaded rod

The invention relates to the technical field of cable installation equipment and further discloses a sectioning device for photoelectric combination cable installation. The sectioning device compriseshoops , wherein the number of the hoops is two, an annular rail is arranged between the two hoops, rail supporting rods are fixedly connected with two sides of the annular rail, the annular rail is fixed between the two hoops through the rail supporting rods, a sliding block is slidably connected with an outer side wall of the annular rail, and a threaded rod is in threaded connection with the center of the interior of the sliding block. When an outer sheath of the cable is cut, only the sliding block needs to be rotated, the sliding block does circle center motion around the annular rail, therefore, a sectioning knife on the sliding block is used for carrying out annular cutting of the outer sheath, the movement track of the sliding block is a flat circle, a distance between the sectioning knife and the circle center of the annular track is not changed in the cutting process, so a cutting surface and the cutting depth of the outer sheath are relatively flat, and the sectioning quality of the cable outer sheath is greatly improved.

Owner:广西科讯智联科技有限公司

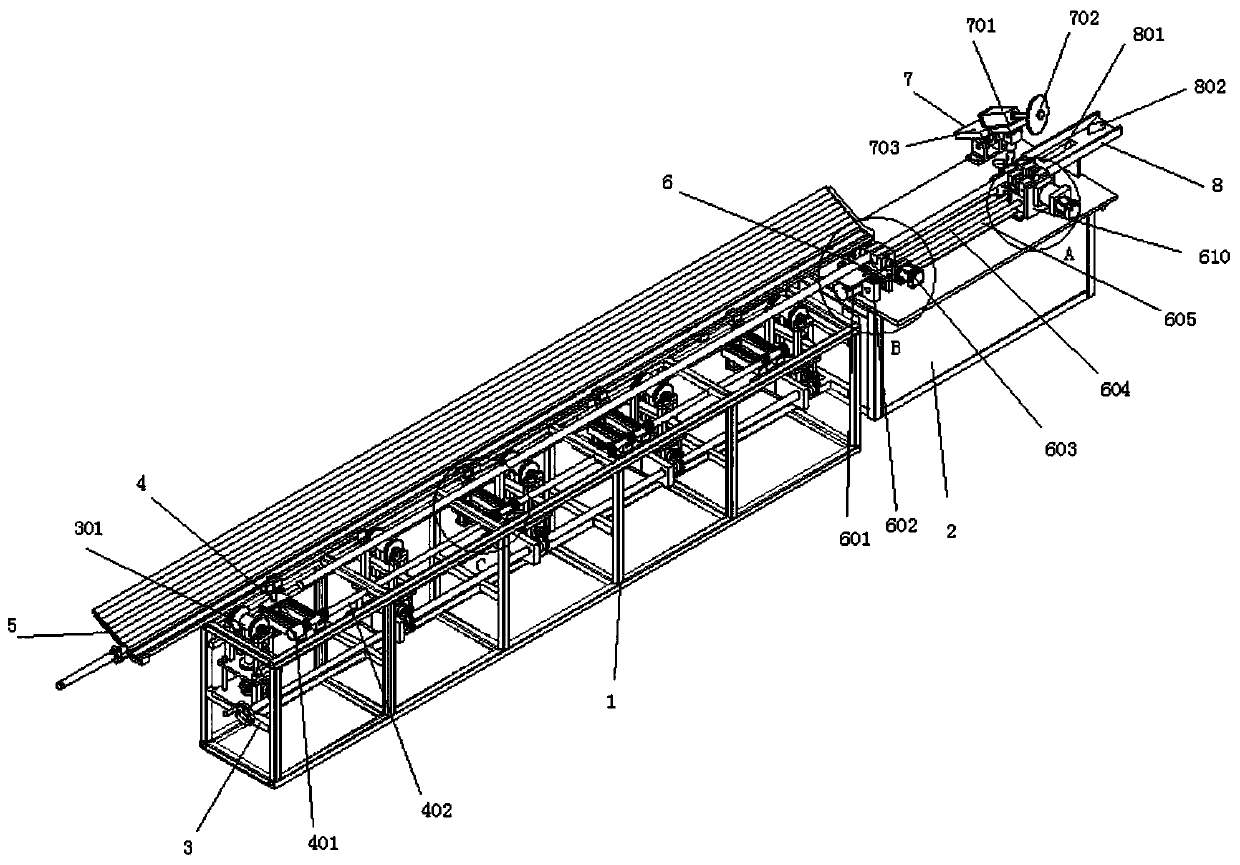

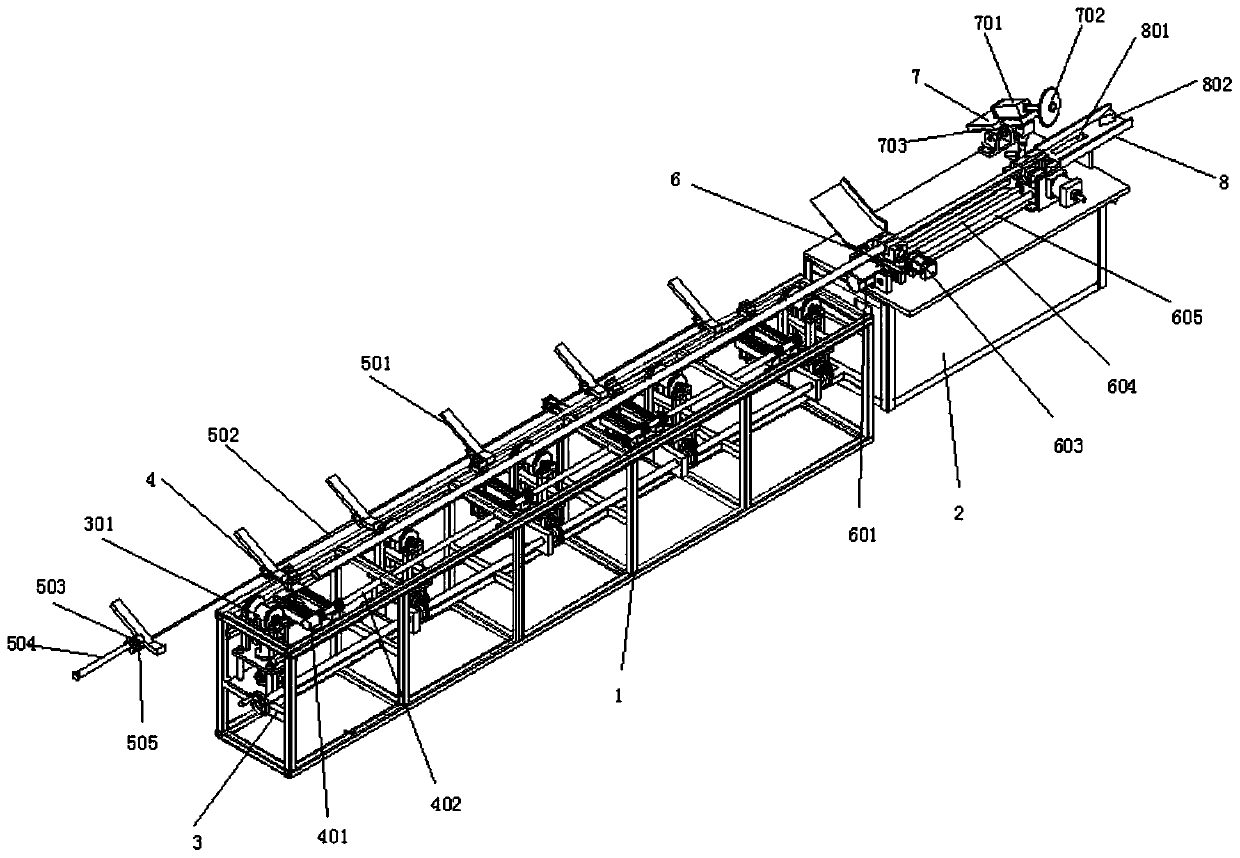

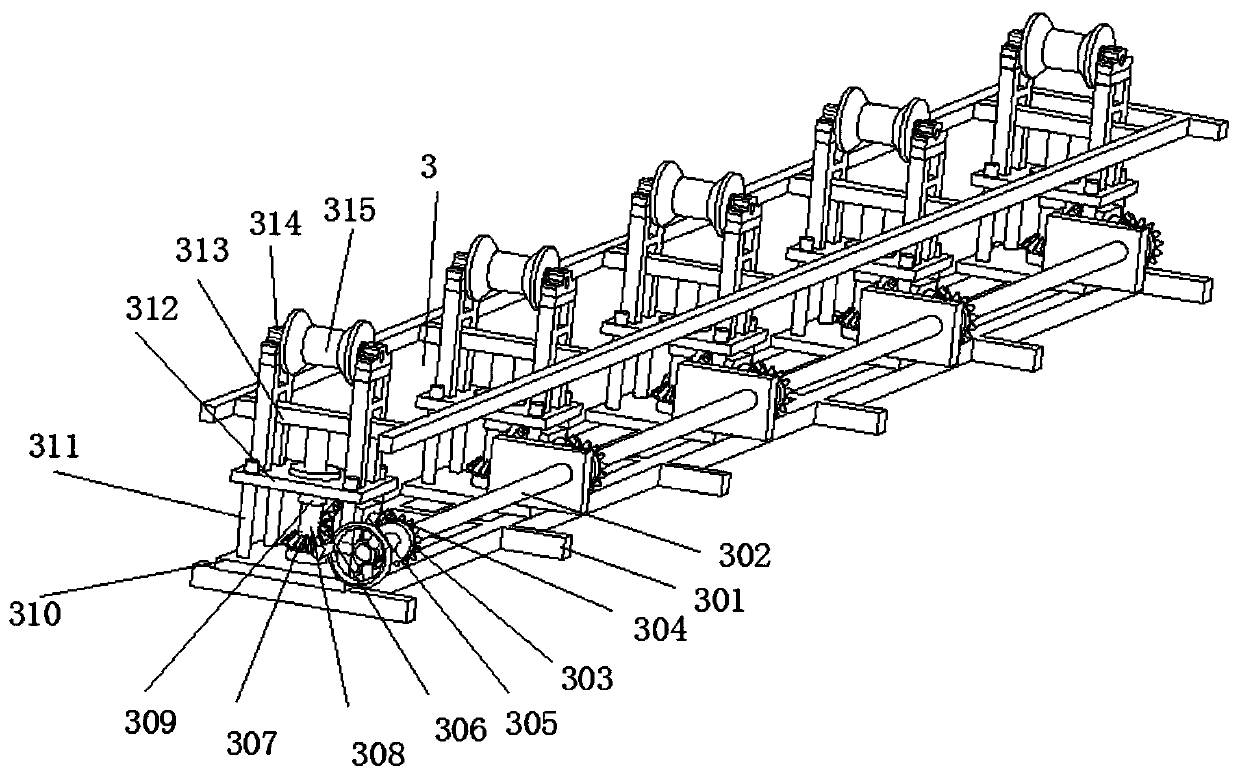

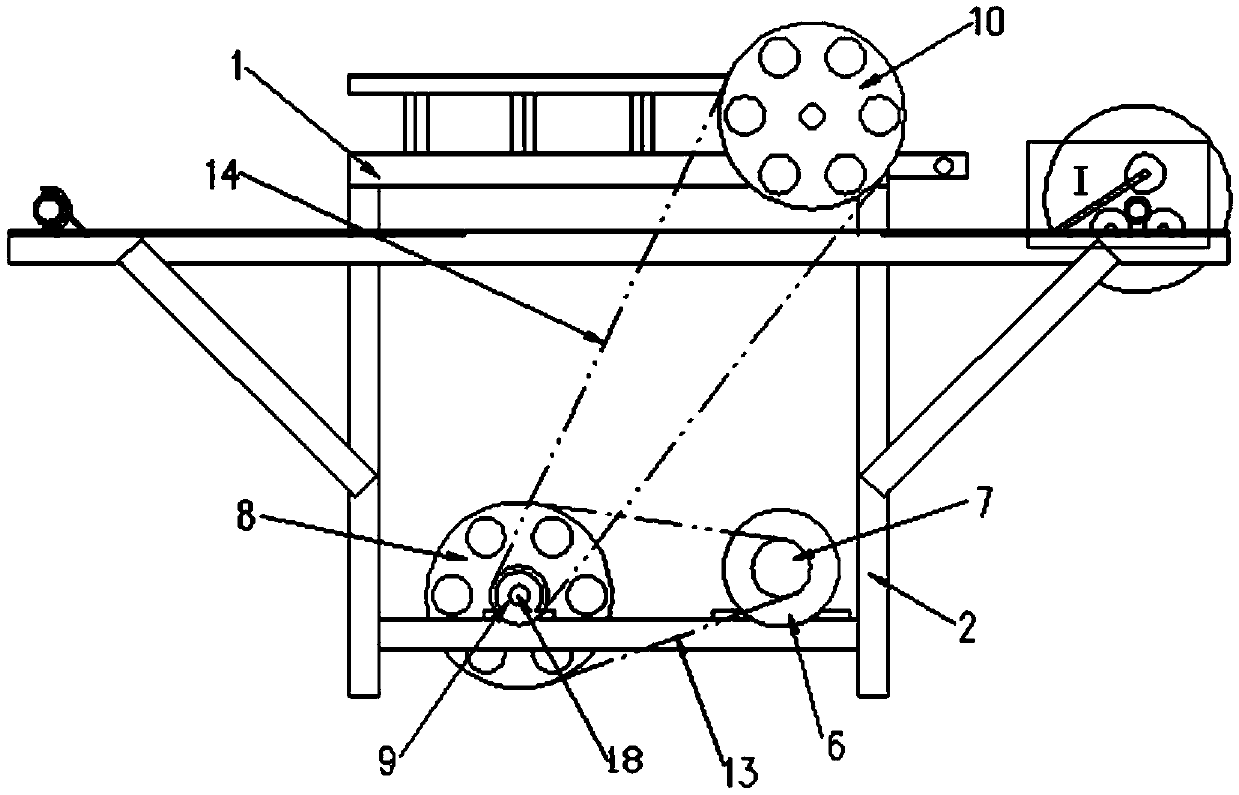

Raw material cutting and slicing equipment for bamboo weaving artware

InactiveCN110962200AFast cutting speedRealize loading and cuttingCane mechanical workingEngineeringWorkbench

The invention discloses raw material cutting and slicing equipment for bamboo weaving artware. The equipment comprises a rack and a workbench, and the rack and the workbench are arranged in the horizontal direction in a collinear mode. The rack is of a quadrilateral frame structure. A workpiece guide frame is fixedly arranged at one side of the top of the rack. A workpiece lifting mechanism is arranged in the rack; a workpiece translation mechanism is further arranged in the rack; and a workpiece conveying mechanism is fixedly arranged on the table top of the workbench. A workpiece cutting mechanism is arranged on the surface of the workbench; position adjustment of bamboo chip workpieces of different sizes is achieved through the workpiece lifting mechanism. Feeding of bamboo chip workpieces is achieved through the workpiece translation mechanism. Bamboo chip workpieces are placed through the workpiece guide frame, connectivity production is achieved, feeding of the bamboo chip workpieces in the sectioning process is achieved through the workpiece conveying mechanism, the pushed bamboo chip workpieces are sectioned through the workpiece cutting mechanism, and the cutting and sectioning equipment is high in automation degree and sectioning efficiency.

Owner:阜南县利民工艺品有限公司

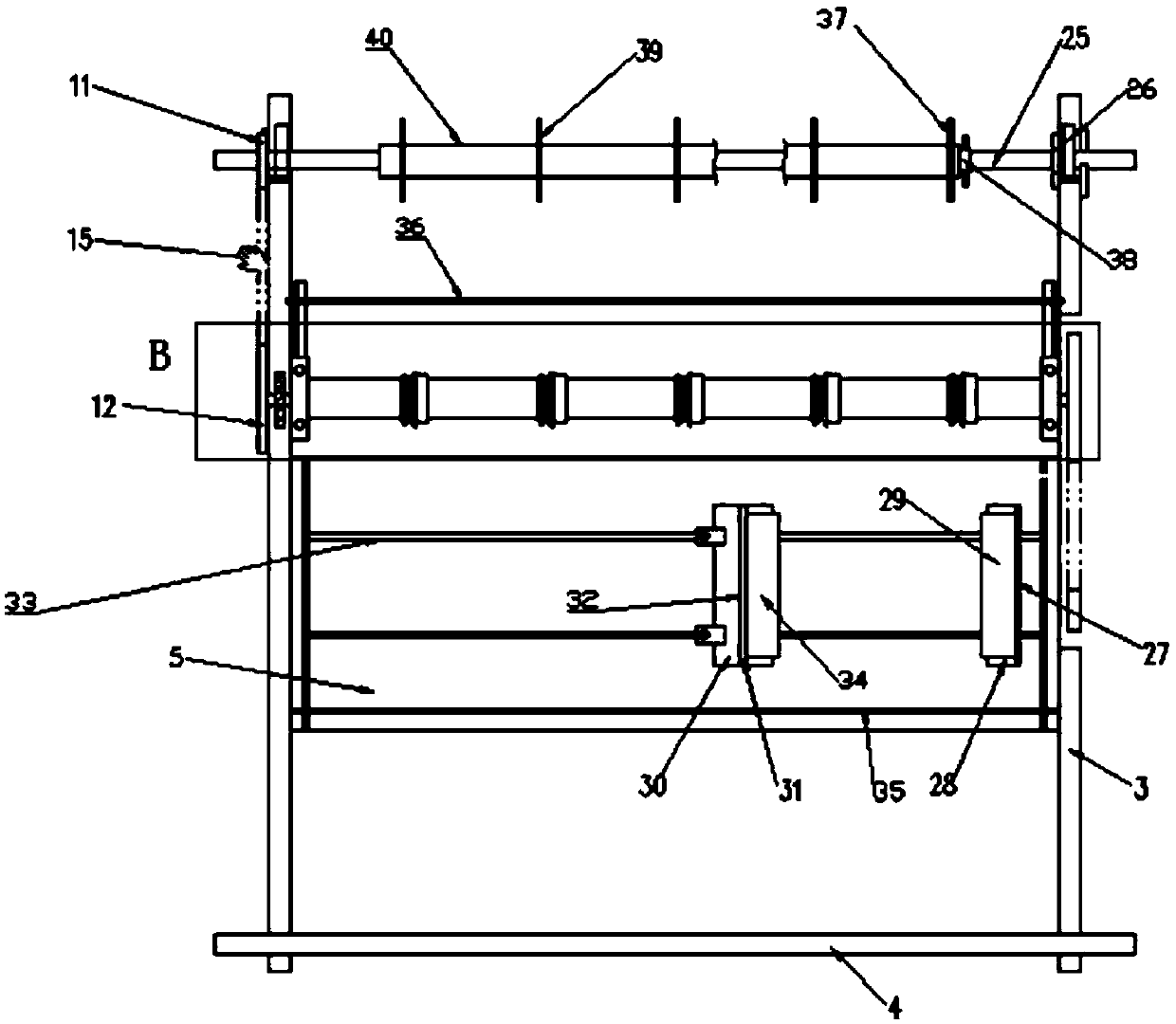

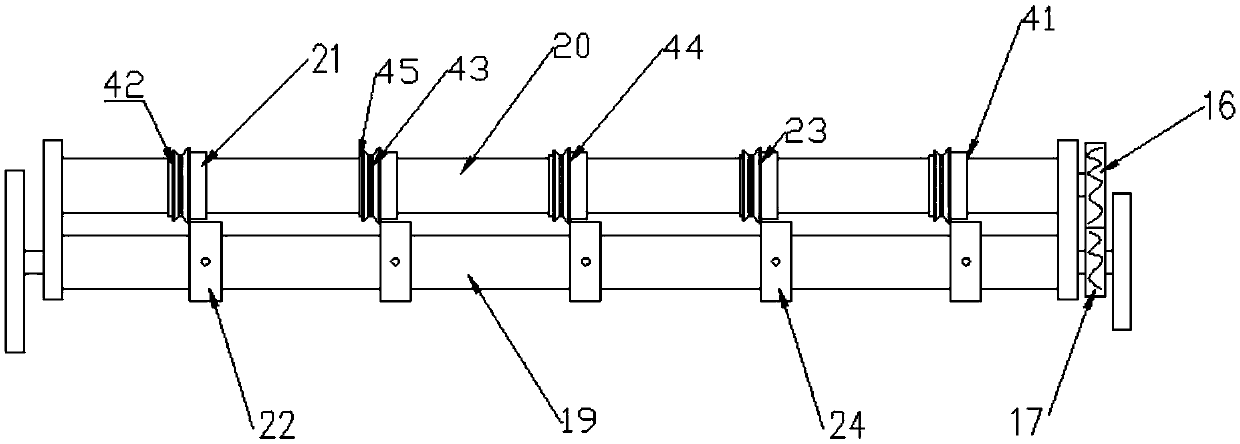

Online servo large-diameter bar hydraulic follow-up fixed-length shearing mechanism

InactiveCN104259548AImprove continuityHigh speed online shearingShearing machinesShearing machine accessoriesHydraulic cylinderEngineering

The invention discloses an online servo large-diameter bar hydraulic follow-up fixed-length shearing mechanism. The online servo large-diameter bar hydraulic follow-up fixed-length shearing mechanism mainly comprises a fixed bracket, a hydraulic shearing machine, a mechanical connecting mechanism and a bearing frame, wherein the fixed bracket mainly comprises a left bracket, a right bracket, a shearing machine guide rail, a guide sleeve, a photoelectric sensor and the like. The hydraulic shearing machine mainly comprises a hydraulic cylinder, an upper cutting knife, a lower cutting knife, a shearing machine roller, a speed measuring support wheel and a bracket. The bearing frame mainly comprises an upper bracket, a lower horizontal rod, a lower bracket, a lower bracket roller, a linear guide rail, a wide guide rail, a baffle rod, a turning arm, a bracket and a fixed-length baffle plate. The mechanical connecting mechanism comprises a servo motor, a gear, a rack, a connecting rod and a touch plate. The online servo large-diameter bar hydraulic follow-up fixed-length shearing mechanism can largely quicken the bar speed to realize high-speed online production, and prevents secondary processing and resource waste to achieve high practical value.

Owner:YANSHAN UNIV

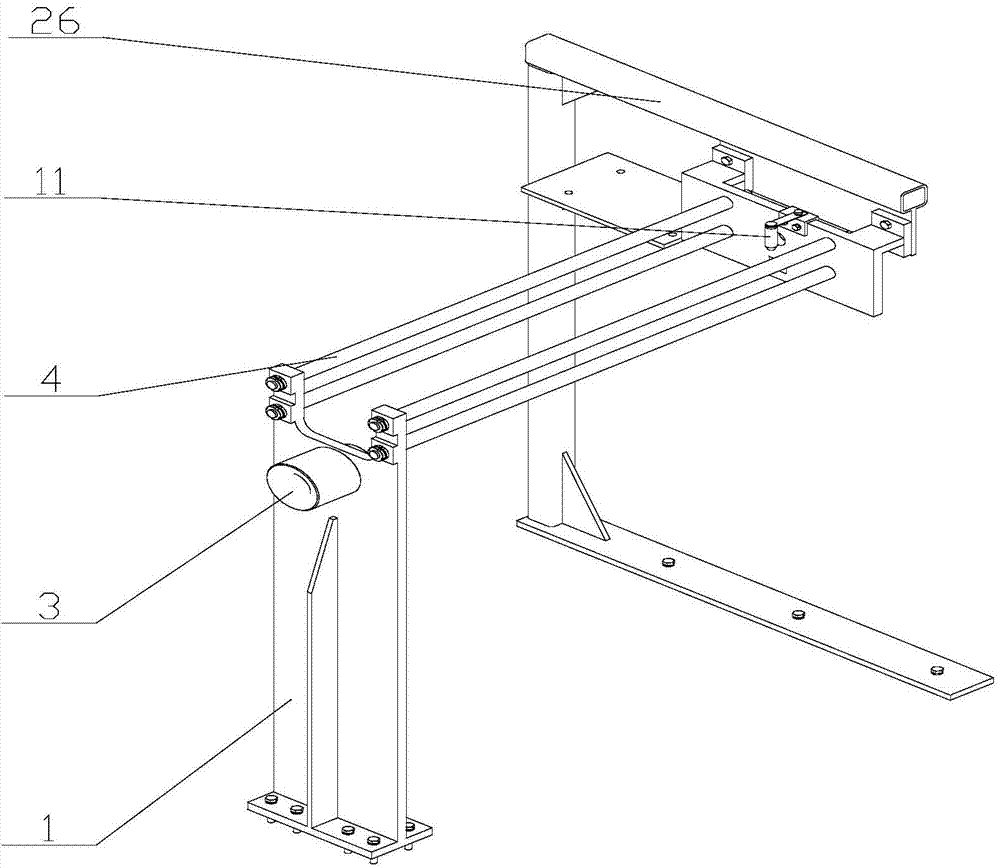

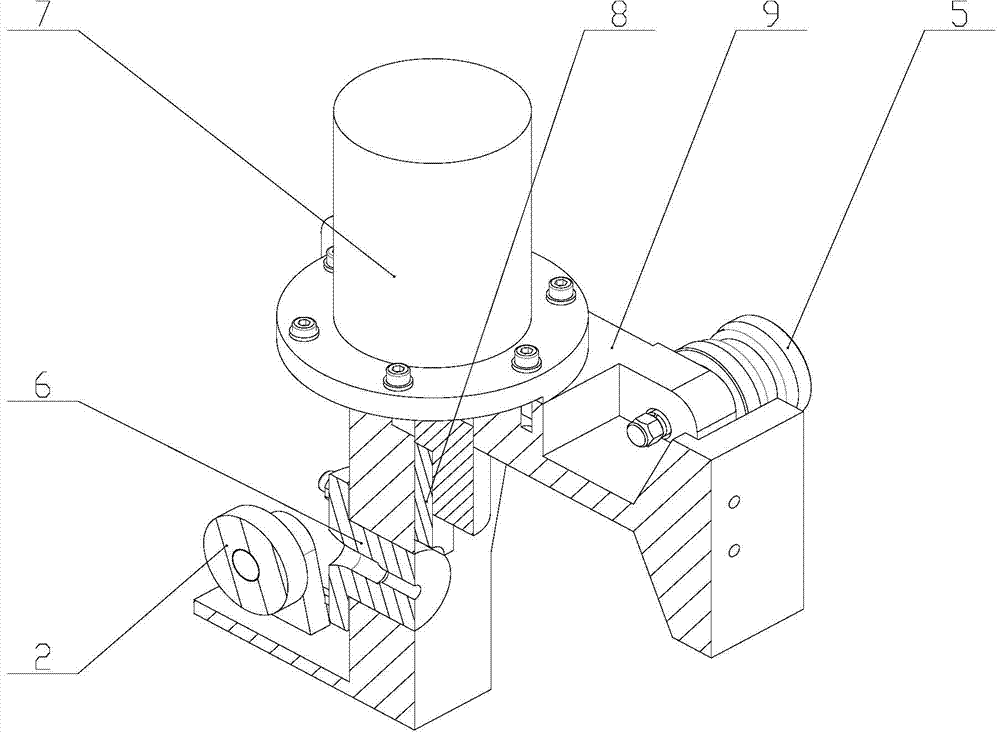

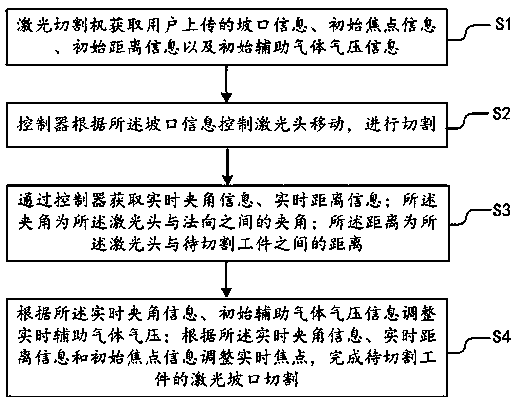

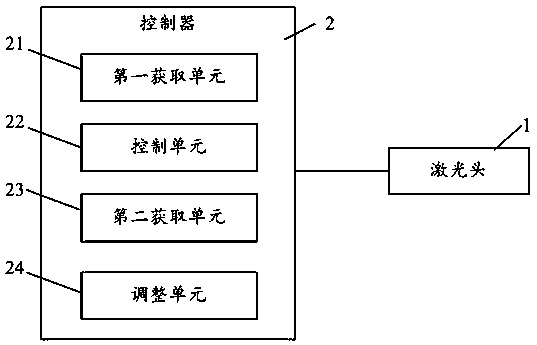

Laser groove cutting method and laser cutting machine

ActiveCN109702361AImprove consistencyImprove section qualityLaser beam welding apparatusEngineeringLaser cutting

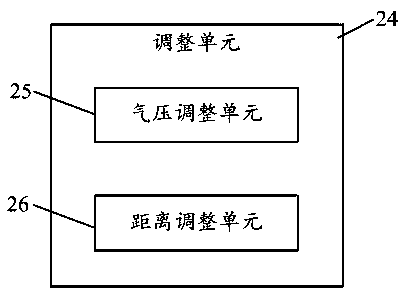

The invention discloses a laser groove cutting method comprises the steps that S1, the laser cutting machine obtains groove information, initial focal point information, initial distance information and initial auxiliary gas pressure information uploaded by a user; S2, a controller controls the laser head to move according to the groove information to conduct cutting; S3, real-time included angleinformation and real-time distance information are obtained through the controller, wherein the included angle is the included angle between the laser head and the normal, and the distance is the distance between the laser head and a workpiece to be cut; S4, according to the real-time included angle information and the initial auxiliary gas pressure information, real-time auxiliary gas pressure isadjusted, according to the real-time included angle information, real-time distance information and initial focal point information, a real-time focal point is adjusted, and then laser groove cuttingof the workpiece to be cut is completed. By the adoption of the laser groove cutting method, the consistency between a straight opening face and a groove face of a groove cutting product can be improved, and the yield of products is greatly improved.

Owner:FOSHAN HONGSHI LASER TECH CO LTD

Universal bone cutting guider for congenital acetabulum maldevelopment femur

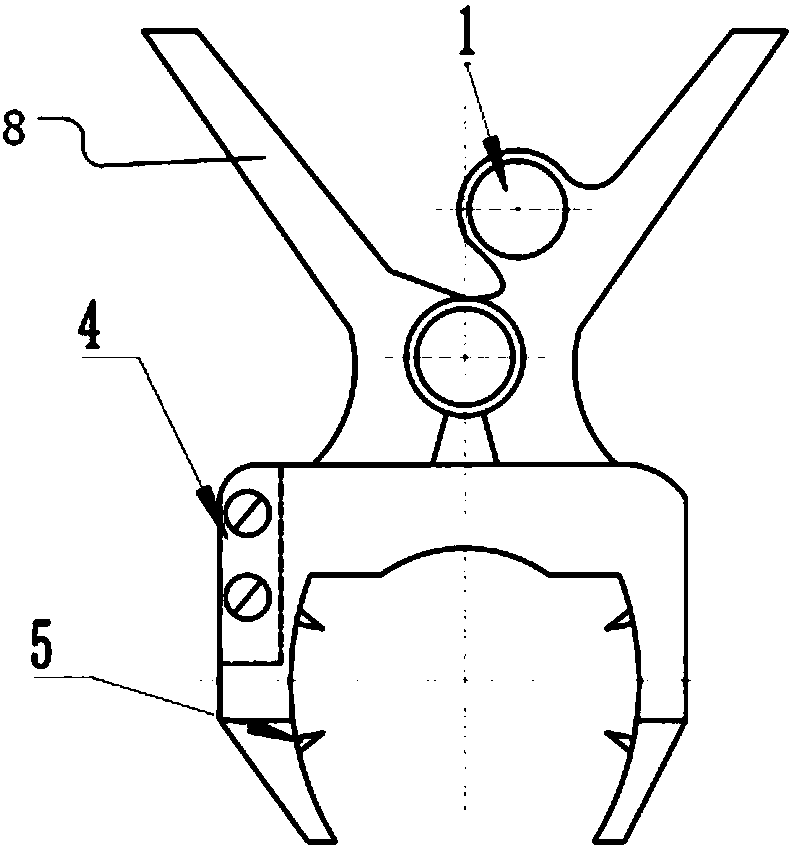

ActiveCN108294805AReasonable structureGuarantee the quality of osteotomyBone drill guidesMaldevelopmentCongenital acetabular dysplasia

The invention discloses a universal bone cutting guider for a congenital acetabulum maldevelopment femur. The guider comprises a front clamping jaw, a back clamping jaw and a locating shaft, and the locating shaft penetrates through fixed holes of the front and back clamping jaws and is perpendicularly connected between the two fixed holes; the front clamping jaw and the back clamping jaw are arranged in parallel, the inner sides of the front and back clamping jaws are provided with bone cutting guide blocks, and the bone cutting guide blocks are provided with bone cutting grooves. According to the universal bone cutting guider for the congenital acetabulum maldevelopment femur, the structure is reasonable, the bone cutting guider is utilized to carry out fixing clamping, locating auxiliary, bone cutting measurement and bone cutting auxiliary on congenital dislocation of hip joint osteotomy, the front and back bone cutting surfaces parallelism and flatness are ensured, it is finally achieved that the bone cutting surfaces are perfectly meshed, the femur medullary cavities in a straight line are ensured after the osteotomy, the risk is reduced that a prosthesis penetrates out of a side face of the femur medullary cavities when prosthesis implantation is carried out, and the achievement ratio of the congenital dislocation of hip joint osteotomy is guaranteed.

Owner:GENERAL HOSPITAL OF PLA

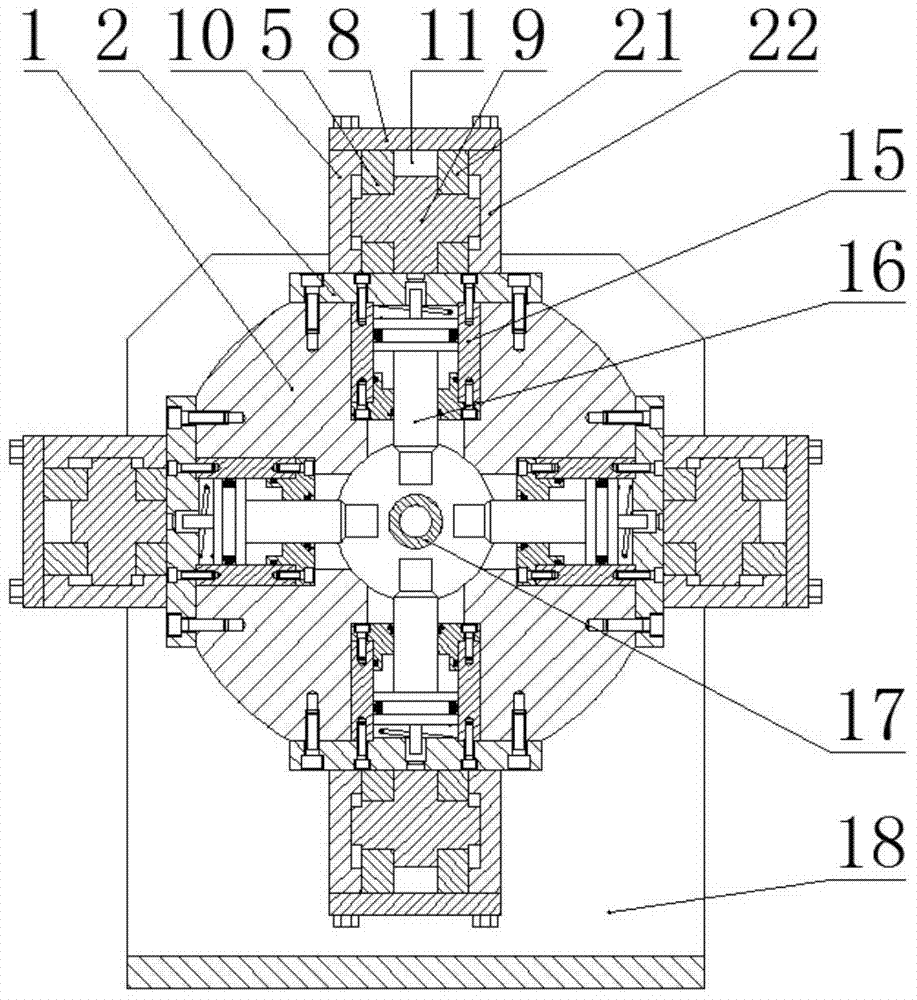

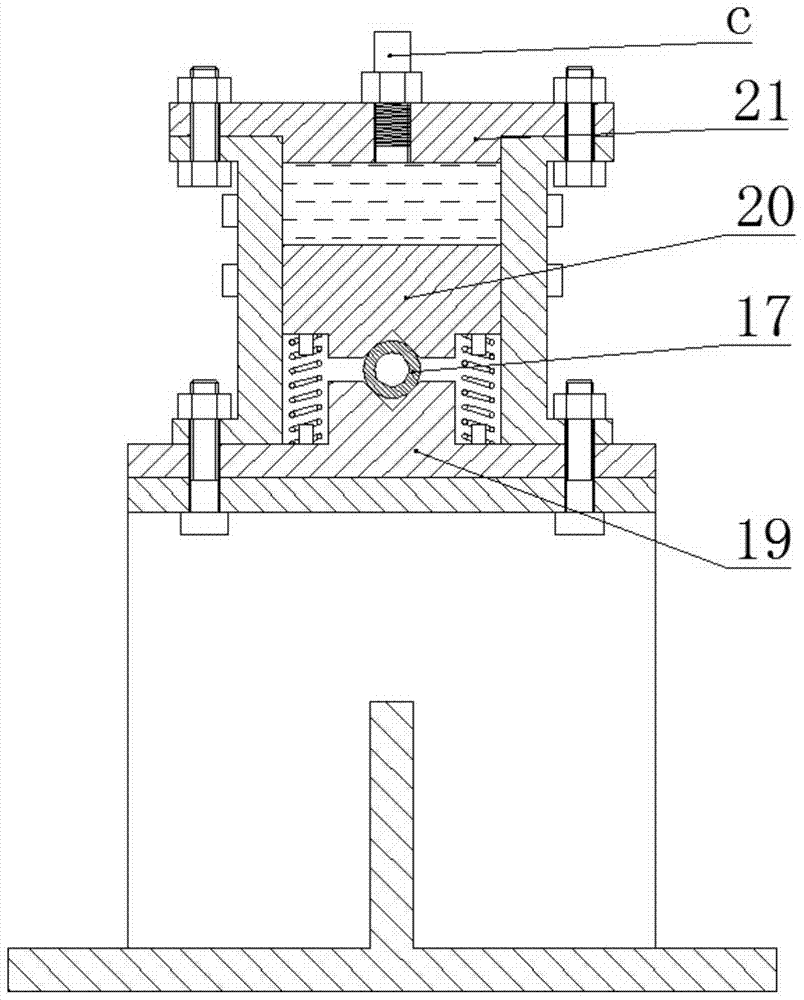

Rod pipe material discharging device driven by explosive slice chemical energy release explosion

ActiveCN104325004AIncrease impact speedSimple structureMetal-working feeding devicesPositioning devicesHigh energyFatigue fractures

The invention relates to a rod pipe material discharging device driven by explosive slice chemical energy release explosion. The rod pipe material discharging device comprises a main machine body, a material clamping mechanism and an explosive charging mechanism, wherein the material clamping mechanism and the explosive charging mechanism are matched with the main machine body, a discharging mechanism consists of four sets of identical forging and beating mechanisms distributed along the radial direction of the main machine body, the explosive charging mechanism charges explosive slices into an explosive charging cavity in a time division way, then, the explosive slices generate explosion through collision and generate high-energy expansion gas, and the generated high-energy gas is gathered into a cylinder tube and pushes a discharging hammer to move, so that a radial unbalance loading force is provided for rod pipe materials; hammers of the four sets of forging and beating mechanisms respectively and sequentially beat the rod pipe materials, so that the rod pipe materials generate fatigue fracture, the discharging process is completed, a great amount of gas generated through explosion of solid explosive slices is used for pushing the discharging hammers to move for discharging, the impact speed of the hammers is high, and the structure of the discharging device is simple. The rod pipe material discharging device has the advantages that the discharging cross section quality is high, the materials are saved, and the production efficiency is high.

Owner:XI AN JIAOTONG UNIV

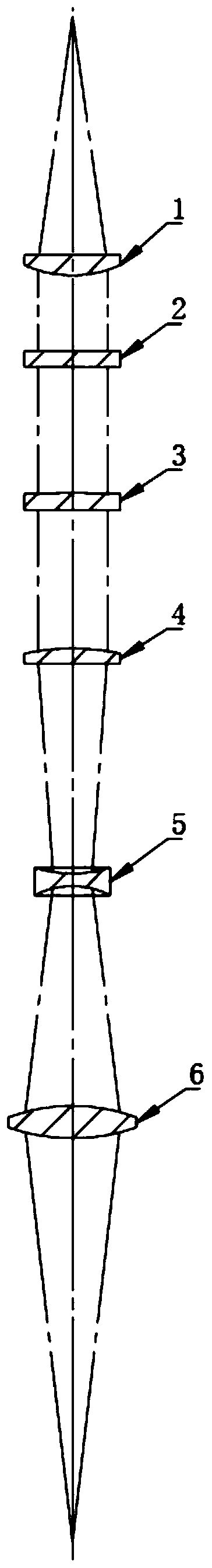

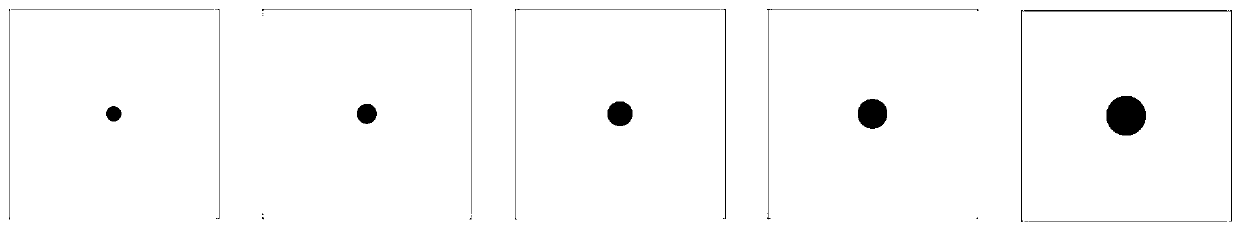

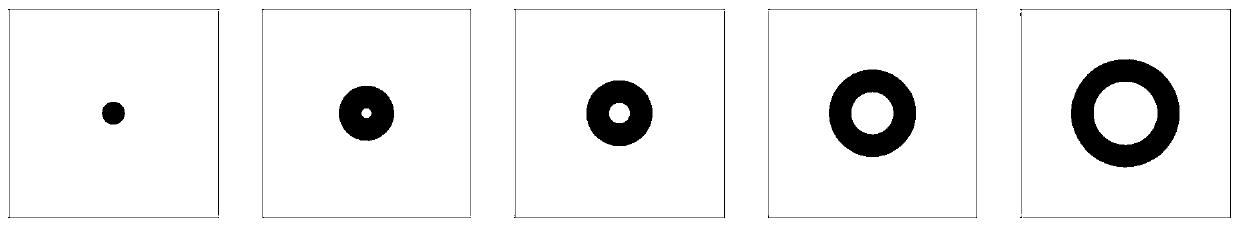

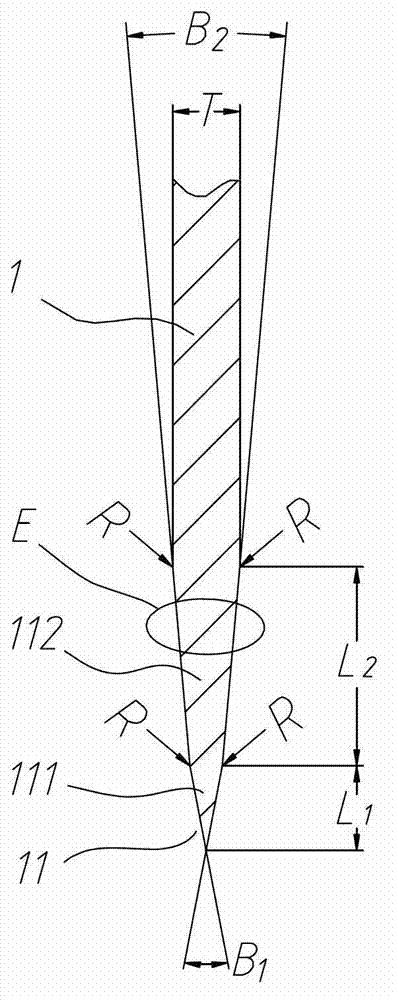

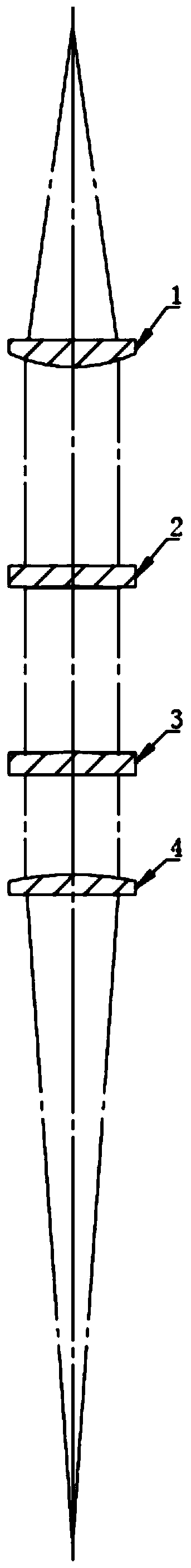

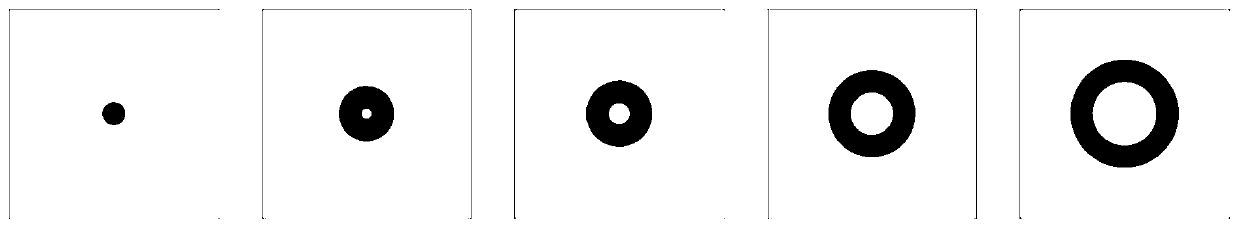

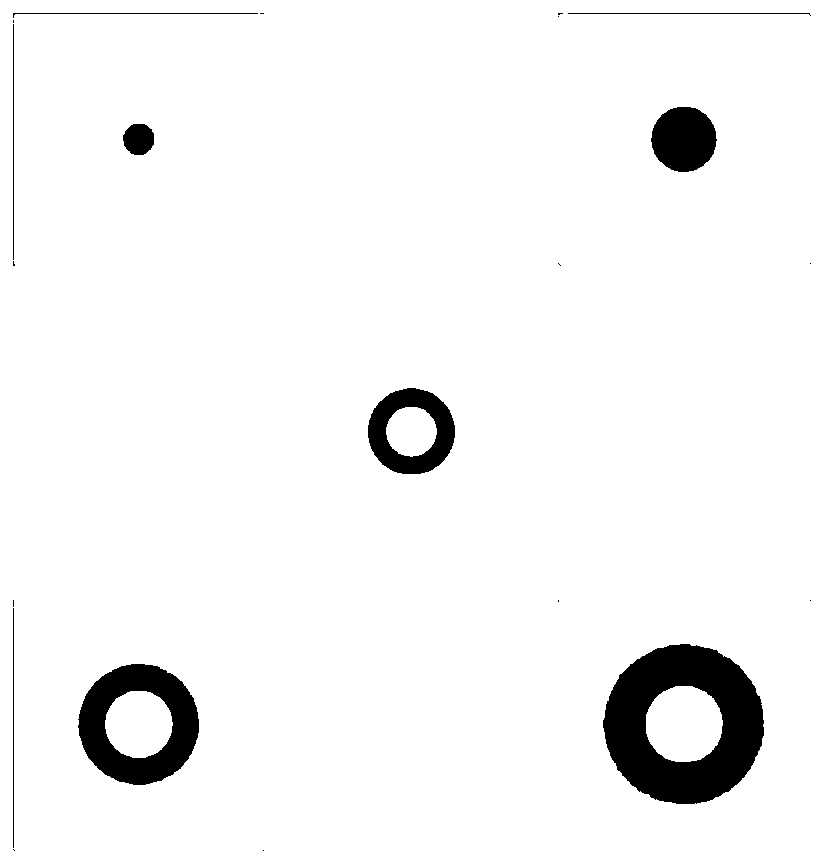

ZOOM cutting device for adjustable ring light spot based on aspheric mirror, and method

InactiveCN110471186ANovel structural designContinuously adjustable middle diameter and thicknessLaser beam welding apparatusOptical elementsAspheric lensEngineering

The invention discloses a ZOOM cutting device for an adjustable ring light spot based on an aspheric mirror, and a method. The device includes an aspheric collimating mirror, a first curved cone lens,a second curved cone lens, an aspheric focusing mirror, a double concave aspheric mirror, and a double convex aspheric mirror. A structure design of the device is novel; characteristics of a ring light spot are achieved based on an axicon lens; compensation characteristics of the size of a focusing light spot, a light beam divergence angle and a focus position are achieved based on a ZOOM opticalsystem; based on characteristics of positive and negative defocus cutting processes of medium and thick boards of different materials, through a mode of moving one of curved cone lenses along a lightbeam transmission axis, and through combination of cooperative adjustment of the ZOOM optical system, a divergence angle of a focused light beam, the size of a focus solid light spot, a solid lightspot to the ring light spot, and the diameter and thickness of the ring light spot are continuously adjustable; and at the same time, based on the need of a laser cutting process, circular energy distribution corresponding to a defocused light beam segment is achieved, and the cutting speed, the section quality, the cutting thickness, and the section verticality of the boards can be greatly improved.

Owner:SHANGHAI EMPOWER AUTOMATION TECH CO LTD

Radially-severing efficient and precise low-stress discharging method

The invention discloses a radially-severing efficient and precise low-stress discharging method, and belongs to the technical field of intelligent manufacturing. Four sets of discharging units symmetrically distributed in the circumferential direction of bars sequentially apply loads to the bars at intervals. Each set of discharging unit comprises discharging clamps arranged at the ends of a firsthydraulic oil cylinder and a second hydraulic oil cylinder, and thrust hammerheads fixed to the ends of piston rods of a third hydraulic oil cylinder and a fourth hydraulic oil cylinder. The discharging clamps and the thrust hammerheads are oppositely arranged, when the bars are severed, after the thrust hammerheads jack the bars, the discharging clamps apply loads to the two ends of V-shaped grooves of the bars simultaneously, the discharging clamps and the thrust hammerheads in the four sets of discharging units cooperate to generate alternating force at the positions of the V-shaped grooves, under the acting force, cracks are produced at the positions of the V-shaped grooves, it is guaranteed that the cracks circumferentially propagate along the sections of the sharp ends of the V-shaped grooves gradually towards circle centers, and the beneficial effects that the efficiency is high, the fatigue crack propagation region area is large, and the fracture surface quality is high are achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

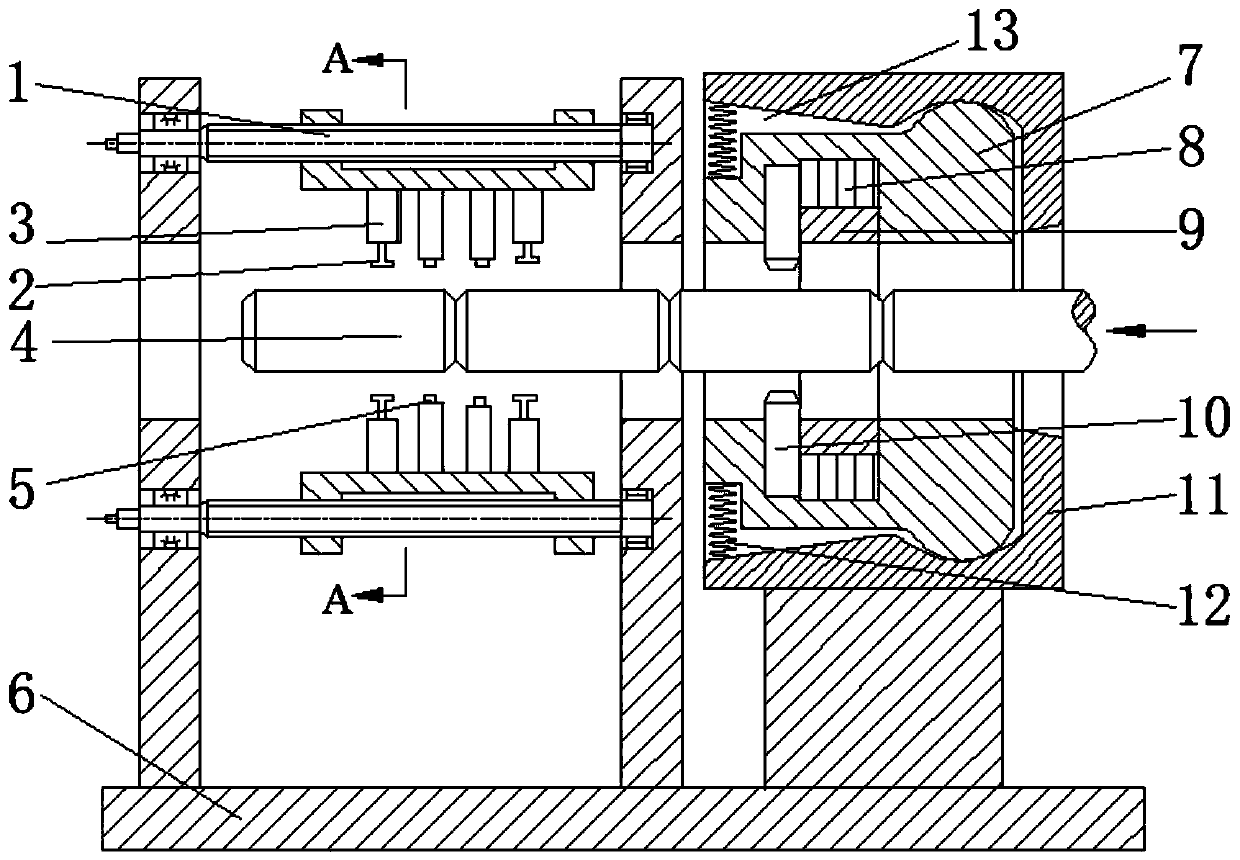

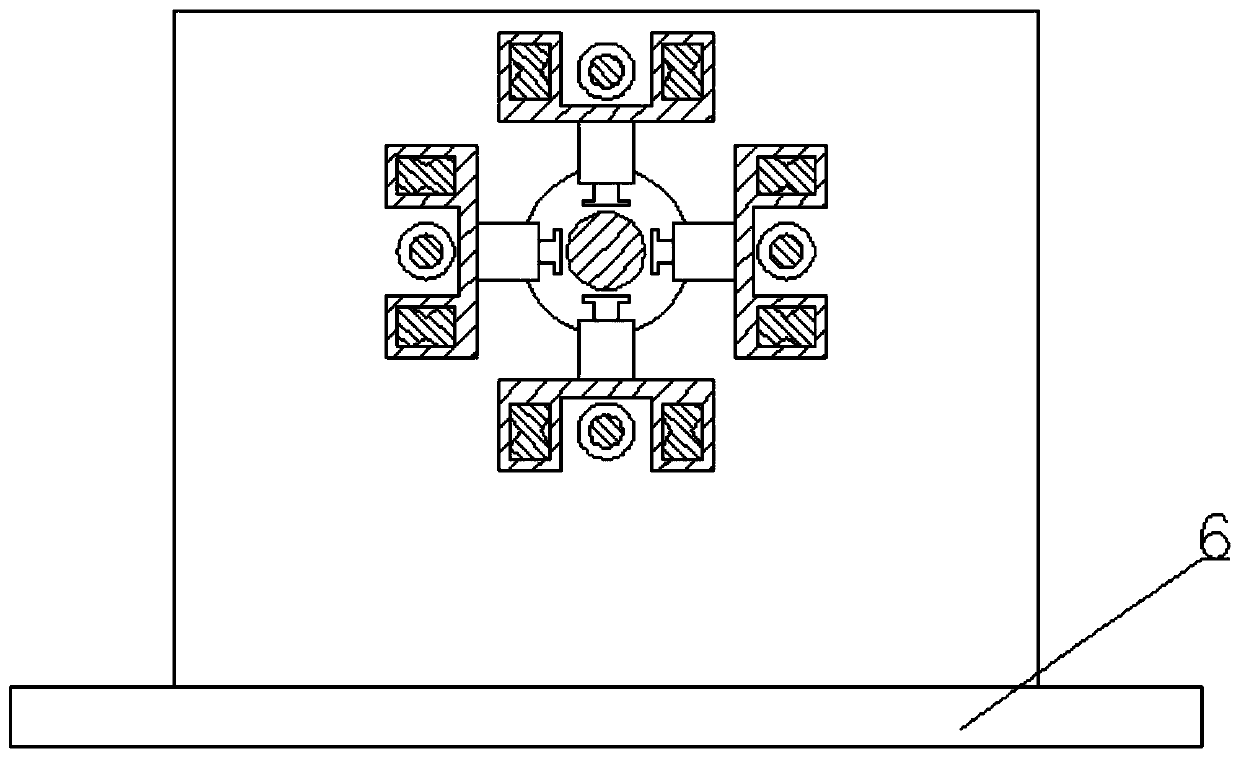

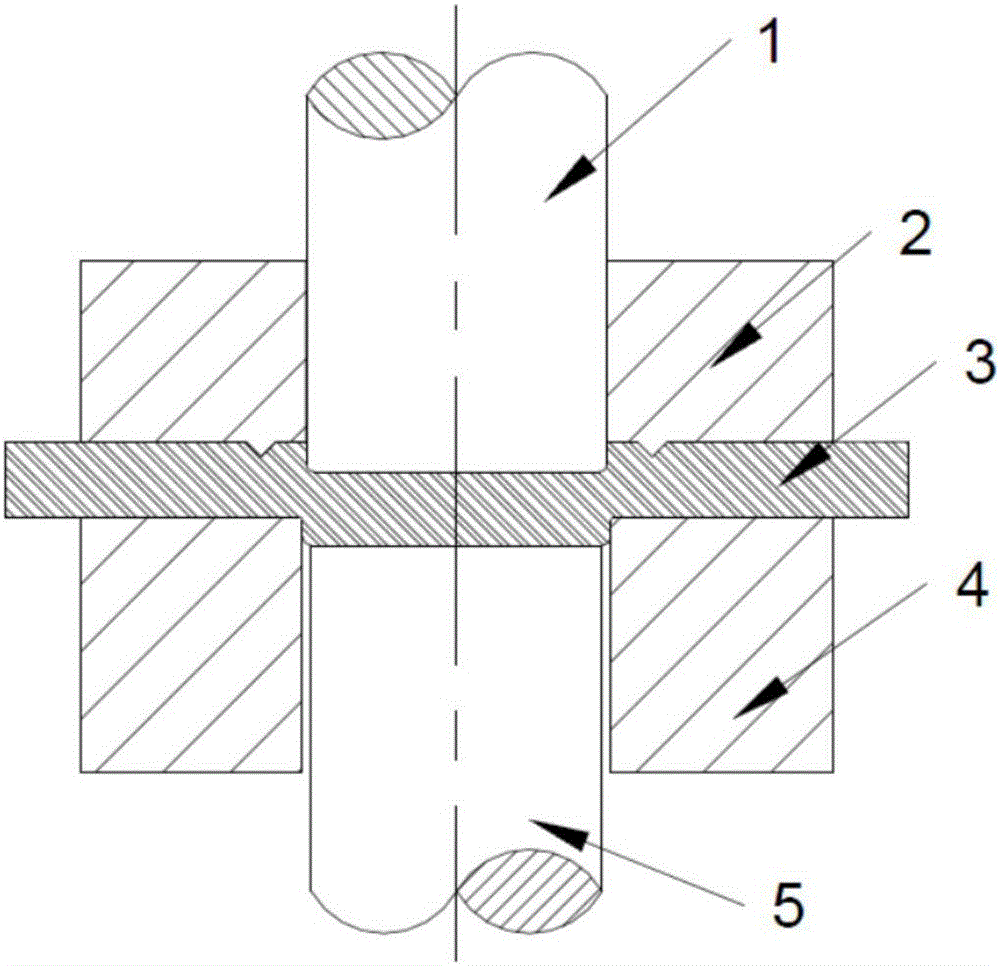

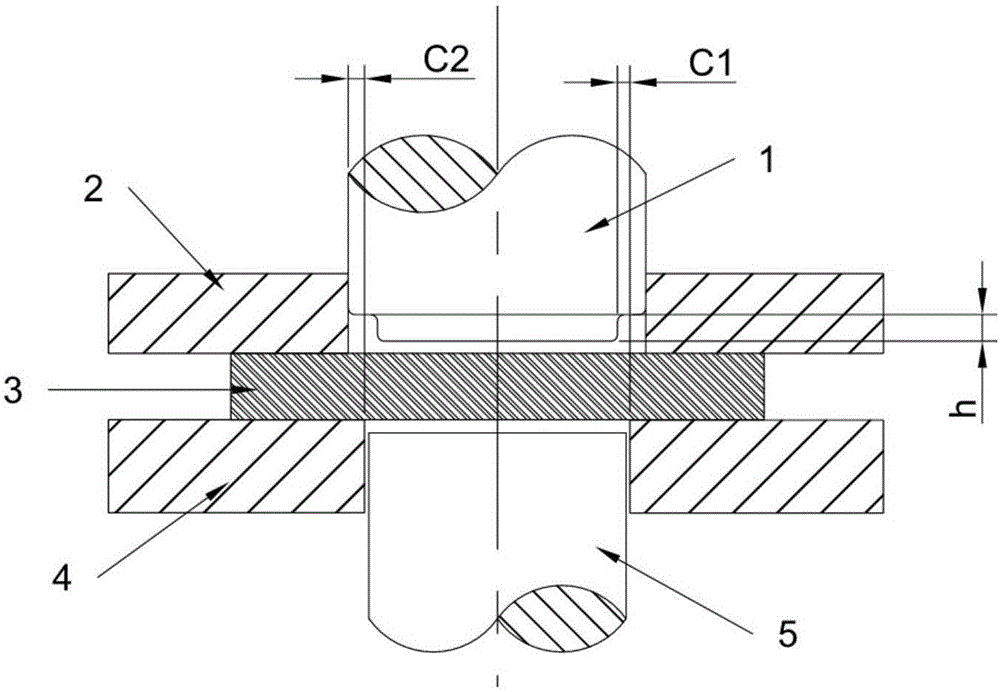

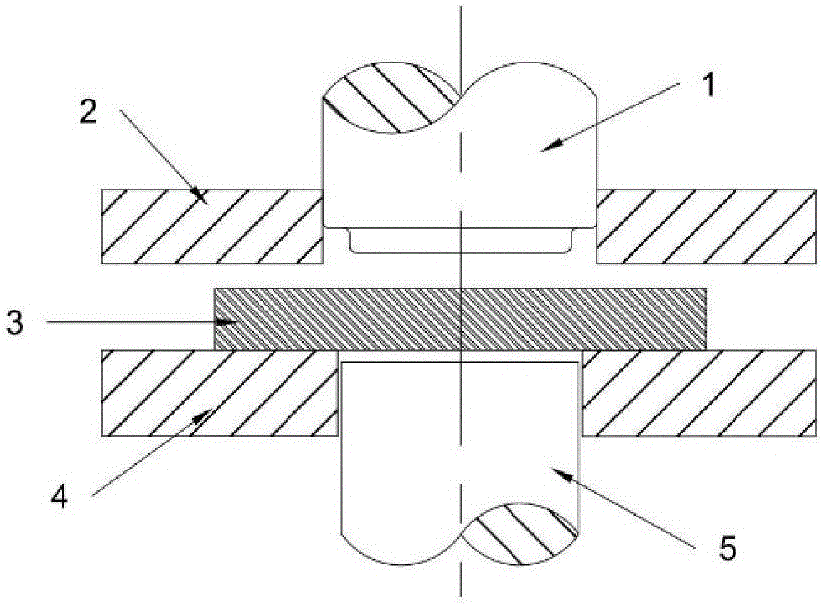

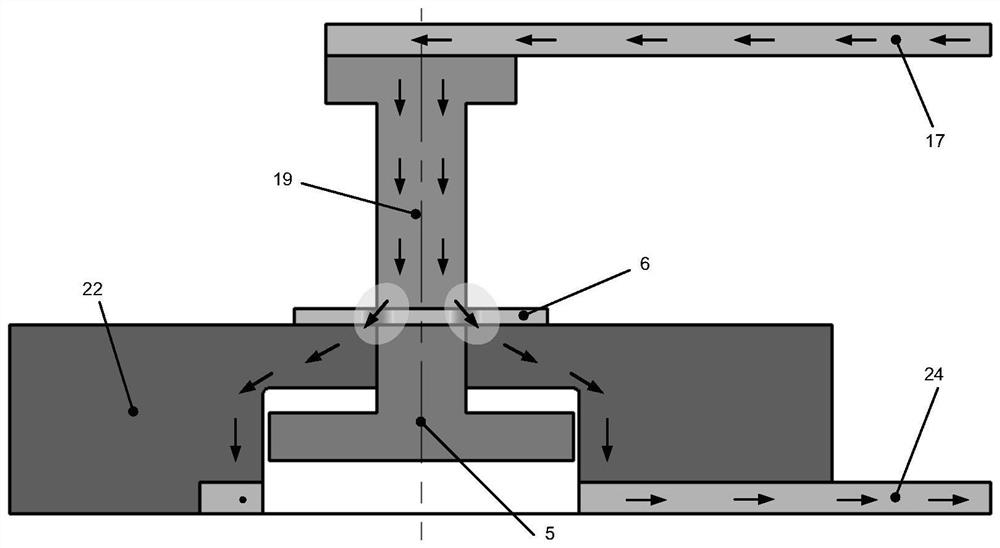

Shear-extrusion type gear-ring-free fine blanking device and method

The invention provides a shear-extrusion type gear-ring-free fine blanking device and method. The device comprises a two-segment male die in a plane pressing plate and a counter-ejector rod which is opposite to the male die and arranged in a female die. The shape of a cavity of the female die is matched with a fine blanking part. The outline size of the outer segment of the male die is larger than the size of the cavity of the female die, and a negative gap is formed by cutting edges of the male and female dies; the outline size of the inner segment of the male die is smaller than the size of the cavity of the female die, and a positive gap is formed by the cutting edges of the male and female dies. By means of the shear-extrusion principle, by designing the two-segment male die and using the action of the plane pressing plate which replaces a V-shaped gear ring in the fine blanking process, compressed stress borne by a deformation area material is increased, separation between the parts and boards is ensured, the fine blanking parts high in section quality can be produced, a V-shaped gear ring pressing plate in a fine blanking die can be omitted, materials are saved, and the machining and maintenance cost of the die is also reduced.

Owner:SHANGHAI JIAO TONG UNIV +1

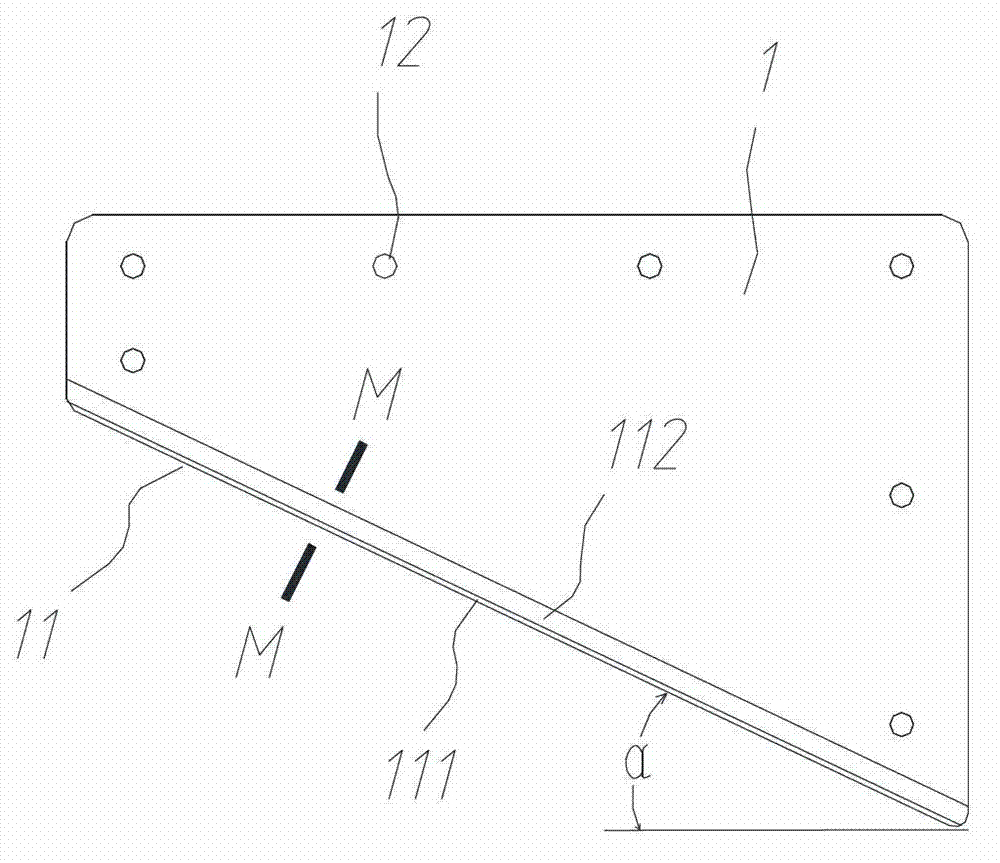

Cutting knife used for thermal cutting of plastic material

ActiveCN103112025AEliminate longitudinal wavy gapsReduce cutting noiseMetal working apparatusPlastic materialsEngineering

The invention relates to a cutting knife used for thermal cutting of plastic material. The cutting knife used for the thermal cutting of the plastic material comprises a blade body, and an inclined double-edged cutting edge which is arranged at the lower end of the blade body, the inclination angle alpha of the cutting edge relative to the horizontal line is 22-28 degrees, and the blade is grinded along the feeding direction of the blade by a grinding appliance to form the cutting edge. The cutting edge at least comprises a first level cutting edge and a second level cutting edge, the angle B1 of the first level cutting edge is 21-23 degrees, and the angle B2 of the second level cutting edge is 8-10 degrees. The plastic material cut by the blade is smooth in end face and free of the appearance of burs and silkings, and cutting end face quality of the material can be improved. Besides, in a cutting process, the resistance stressed on the blade is even, the blade is not prone to tipping, not only is the service life of the blade prolonged, but also cutting noise is reduced observably, and the production environment is improved.

Owner:TONGLING GREAT EXTRUSION TECH

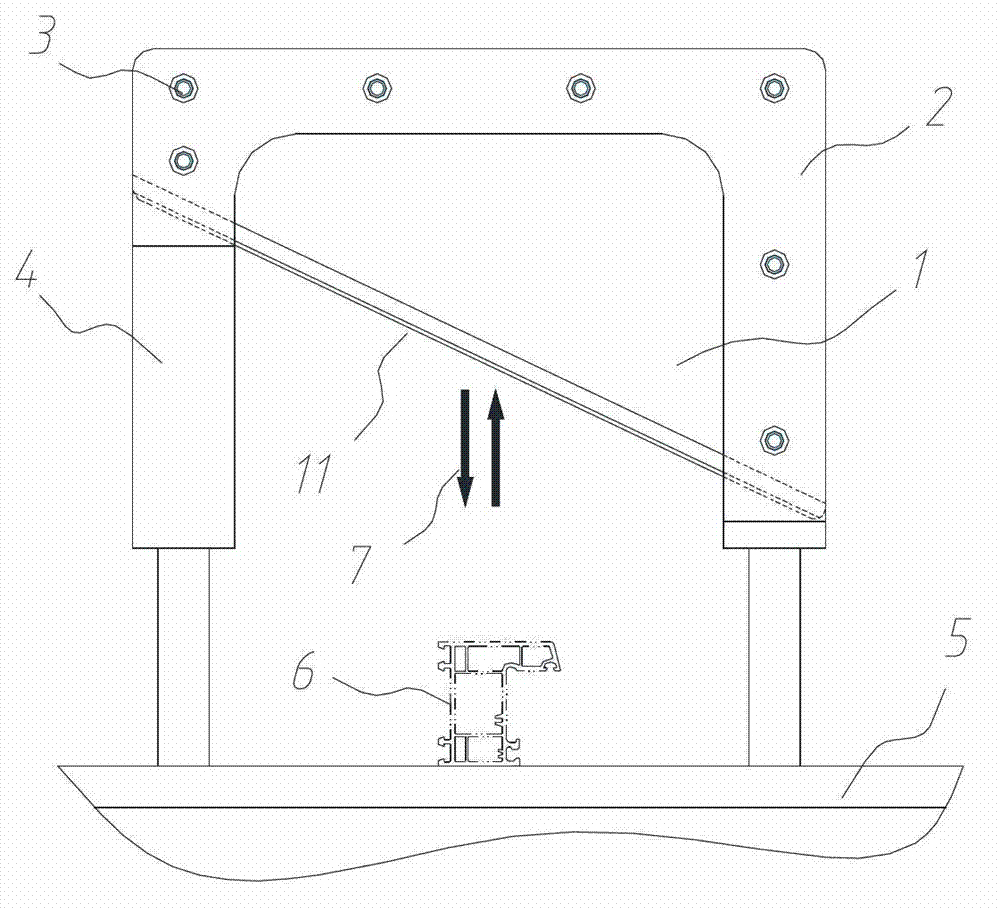

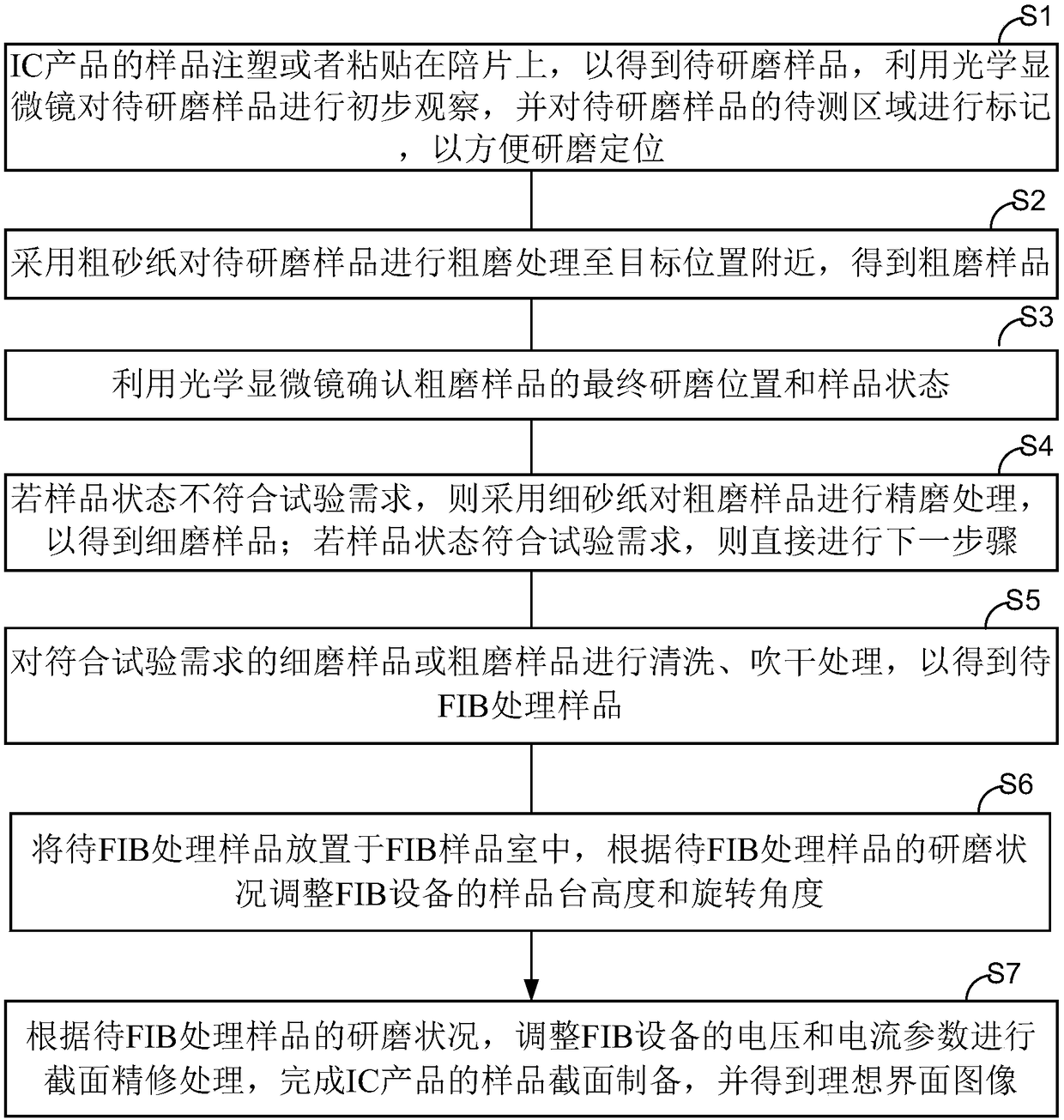

Nanometer-level and high-precision preparation method for cross section of IC product

InactiveCN108267348AImprove section qualityHigh precisionSpecific nanostructure formationPreparing sample for investigationPower flowEngineering

The invention discloses a nanometer-level and high-precision preparation method for the cross section of an IC product sample. The method comprises the following steps: S1, inject-molding or pasting the IC product sample on a detection sheet to obtain a sample to be ground, preliminarily observing the sample to be ground, and marking an area to be tested; S2, coarsely grinding the sample to be ground by flint paper to obtain a coarsely ground sample; S3, confirming the final grinding position and the sample state of the coarsely ground sample; S4, finely grinding the coarsely ground sample byadopting fine sandpaper if the sample state does not meet test demands; S5, performing cleaning and blow-drying treatment on the finely ground sample or the coarsely ground sample meeting the test demands to obtain a sample to be subjected to FIB treatment; S6, placing the sample to be subjected to FIB treatment in an FIB sample chamber, and adjusting the height and the rotation angle of the sample table of an FIB device; and S7, adjusting the voltage and current parameters of the FIB device, and performing cross-section finishing treatment to complete the sample cross section preparation. Thepreparation method has the advantages of high efficiency and high precision, and allows the identification degree of the section sample to reach a nanometer level.

Owner:BEIJING SMARTCHIP MICROELECTRONICS TECH COMPANY +2

Stamping die, stamping forming method and product made by the stamping forming method

InactiveCN101259504AHigh precisionImprove section qualityShaping toolsPressesPunchingManufacturing engineering

A punching die is used for processing a workpiece into a punching product with the section bright area reaching more than 90 percent. The punching die comprises an upper mold and a lower mold; the punching clearance between the upper mold and the lower mold is smaller than one two hundredth of the thickness of the workpiece. A punching shaping method includes the following steps: (1) a low mold is provided and the workpiece is arranged at the lower mold; (2) an upper die is provided and the punching clearance between the upper mold and the lower mold is smaller than one two hundredth of the thickness of the workpiece. The upper mold and the lower mold are matched to carry out punching on the section of the workpiece so as to form the punching product.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Automatic material sectioning device

ActiveCN105364162AImprove section qualityReduce manufacturing costMetal-working feeding devicesShearing machinesEngineeringMechanical engineering

Owner:HUBEI TIANLI HUAJIAN ENG CO LTD

Aspherical lens adjustable annular light spot fixed magnification cutting device

InactiveCN110480186ANovel structural designFast cutting speedLaser beam welding apparatusPhysicsAspheric lens

The invention discloses an aspherical lens adjustable annular light spot fixed magnification cutting device. The device comprises an aspherical collimating lens, a first curved surface conical lens, asecond curved surface conical lens and an aspheric focusing lens, wherein the aspherical collimating lens, the first curved surface conical lens, the second curved surface conical lens and the aspheric focusing lens central axis are coaxial; the aspheric collimating lens and the aspheric focusing lens form a fixed magnification magnifying lens group; and the first curved surface conical lens andthe second curved surface conical lens form an annular adjustable lens group. According to the device, the structural design is novel, the diameter of the focusing focal point solid light spot to an annular light spot and the annular light spot is continuously adjustable; meanwhile, the annular energy distribution of the corresponding off-focal light beam section is realized on the basis of the laser cutting process, so that the cutting speed, the cross section quality and the cutting thickness of the plate are improved; and the device is suitable for laser cutting and application of a kilowatt-watt-grade high-power fiber laser, especially for the cutting application of medium and thick plates in a continuous fiber laser with the fiber core diameter of 50 microns or more.

Owner:SHANGHAI EMPOWER AUTOMATION TECH CO LTD

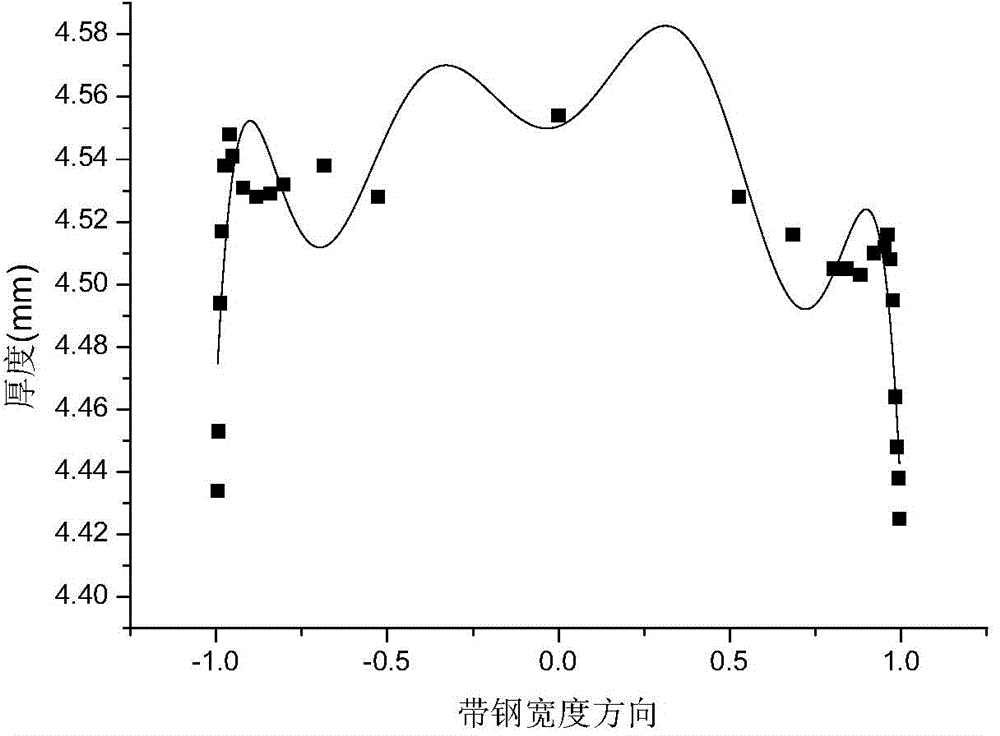

A Method for Extracting Characteristic Parameters of Strip Thickness Transverse Distribution

ActiveCN104550267BDescribe edge thinningImprove section qualityMeasuring devicesMetal rolling arrangementsOriginal dataDistribution characteristic

Disclosed is a strip steel thickness lateral distribution characteristic parameter extraction method. The method is characterized by including: a1, describing a horizontal coordinate of original data, wherein the actually-measured thickness at an xi position is hi; a2, enabling p to be 3, q to be (n-2) and a minimum sum of square of deviations ymin to be 100; a3, taking xp and xq as boundary points; a4, listing fitting functions; a5, taking the situations that two-section function values are equal and first derivative values are equal as constraint conditions; a6, taking coefficients as variables, setting fitting curves and functions of sums of square of deviations and taking a minimum function value of the sums of square of deviations as a constraint condition; a7, solving the coefficients according to the simultaneous conditions and recording the sums of square of deviations of the functions and the actually-measured values; a8, enabling q to be (q-1), if q>=n / 2, returning to the step a3, and if q<n / 2, entering step a9; a9, enabling p to be (p+1), if p<=n / 2, returning to the step a3, and if p>n / 2, entering step a10; a10, outputting the coefficients as optimum strip steel thickness lateral distribution characteristic parameters. By the strip steel thickness lateral distribution characteristic parameter extraction method, steel strip edge drop is described, equipment provided with a profiler can be improved in the aspect of the fitting functions, and after equipment without the profiler performs lateral distribution extraction of the thickness offline, applying the method to online production enables strip steel sectional quality and fitting precision to be improved.

Owner:重庆攀华板材有限公司

A Mechanism-Based Identification Method for Characteristic Parameters of Strip Thickness Transverse Distribution

InactiveCN104588417BImprove section qualityImprove shape qualityRoll mill control devicesMeasuring devicesQuality controlStrip steel

The invention discloses a characteristic parameter identification method of the lateral distribution of strip steel thickness on the basis of a mechanism, and relates to the field of strip steel quality control. In the method, one function is adopted to describe the lateral distribution of the strip steel thickness in the whole width direction of the strip steel, the function consists of a basic mode based on an elastic flattening mechanism and a common polynomial, so that the function has few parameters and high precision, and strip steel edge drop can be favorably fitted. The characteristic parameter identification method has an important meaning on the aspects of identifying the section shape of strip materials, lowering influence on the plate shape of a finished product by the shape fluctuation of a material feeding section and improving the quality of the strip steel.

Owner:YANSHAN UNIV

Discontinuous point type blank holder for fine blanking die and design method of technological parameters of discontinuous point type blank holder

ActiveCN105880350AIncreased hydrostatic stressImprove plastic deformation abilityMetal-working feeding devicesPositioning devicesEngineeringDesign methods

Owner:WUHAN UNIV OF TECH

Radial breaking high-efficiency precise low-stress discharging machine

The invention discloses a radial breaking high-efficiency precise low-stress discharging machine, and belongs to the technical field of intelligent manufacturing. The radial breaking high-efficiency precise low-stress discharging machine comprises four groups of discharging units symmetrically distributed in the circumferential direction, each group of discharging units includes a first hydrauliccylinder, a second hydraulic cylinder, discharging fixtures disposed at the end parts of piston rods of the first hydraulic cylinder and the second hydraulic cylinder, a third hydraulic cylinder, a fourth hydraulic cylinder and thrust hammers separately fixed to the end parts of piston rods of the third hydraulic cylinder and the fourth hydraulic cylinder; the discharging fixtures and the thrust hammers are oppositely arranged; when a bar material is subjected to breaking, after the thrust hammers abut against the bar material, the discharging fixtures apply loads to both ends of a V-shaped groove of the bar material, and alternating force is generated at the V-shaped groove. Under the force, cracks are formed at the V-shaped groove, it is ensured that the cross section of the tip end of the V-shaped groove gradually expands toward the center of the circle in a circumference mode, and the quality and flatness of the cross section of the bar material are improved by changing the loadingmode of the bar material.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Die blanking process utilizing matching of large clearance and small clearance

InactiveCN102554012AEliminate sharp burrsEliminate secondary shearStructural engineeringReliability engineering

The invention discloses a die blanking process utilizing matching of large clearance and small clearance, which includes: (1) blanking a product primarily by a first punch to form a processed cut; and (2) blanking the product secondarily by a second punch to complete the blanking process of the product, wherein the clearance between the first punch and a first die cut at the processed cut formed in the primary blanking is smaller than the clearance between the first punch and the first die cut at the other positions. By the die blanking process utilizing matching of large clearance and small clearance, the contradiction between the requirement of increasing clearance in secondary shearing of blanking sections of medium-thickness plates and the requirement of reducing clearance so as to reduce point burrs at cutting joints is overcome, point burrs at the cutting joints are eliminated by means of small-clearance local blanking at the processed cut, and secondary shearing is omitted by large-clearance blanking at other positions, so that section quality is improved. Accordingly, the die blanking process is simple and convenient for operation.

Owner:FINEFORMING PRECSION ENG

Battery piece cutting device and cutting method

ActiveCN113714656AReduce Fragmentation RateReduce heat damage areaFinal product manufactureLaser beam welding apparatusElectrical batteryCell fabrication

The embodiment of the invention belongs to the technical field of solar cell manufacturing, and relates to a battery piece cutting device and a cutting method. The battery piece cutting device comprises a mounting base, a conveying device, a first laser emitting assembly, a second laser emitting assembly, a first moving device, a jig and a cooling assembly. The first laser emitting assembly, the second laser emitting assembly and the first moving device are all mounted on the mounting base; and the jig is driven to move through the conveying device. First laser emitted by the first laser emitting assembly is used for forming a cutting groove in a battery piece installed on the jig, and second laser emitted by the second laser emitting assembly is used for carrying out radiation heating on the cutting groove of the battery piece. The cooling assembly is slidably arranged on the first moving device; and the cooling assembly comprises a nozzle, and a cold source sprayed by the nozzle cools the cutting groove of the battery piece along with the second laser so that the battery piece can be broken along the cutting groove. According to the battery piece cutting device, the fragment rate of the battery piece in the cutting process can be reduced, the thermal damage area of the battery piece is reduced, and low-loss cutting is achieved.

Owner:HANS LASER TECH IND GRP CO LTD

Automatic steel wire product cutting-off equipment

The invention discloses automatic steel wire product cutting-off equipment which comprises a rack platform. A straightening assembly, a feeding assembly, a clamping assembly and a cutting assembly are sequentially installed on the rack platform from right to left, and a wire disc for winding a steel wire is installed at the end, close to the straightening assembly, of the rack platform. The steel wire on the wire disc sequentially passes through the straightening assembly, the feeding assembly and the clamping assembly and is automatically cut off through the cutting assembly. Through cooperative operation of the straightening assembly, the feeding assembly, the clamping assembly and the cutting assembly, a whole set of automatic operation procedures such as automatic product straightening, wire feeding, positioning and clamping and automatic product cutting and falling are achieved, the automatic steel wire product cutting-off equipment can adapt to cutting of products of different lengths and diameters, the section quality is high, and stability and high efficiency are achieved. Compared with CNC equipment, the machining time is short, manual clamping and material taking operation are omitted, and the production capacity, the yield, the personnel operation environment and the other aspects are remarkably improved.

Owner:SHANGQIU JINZHENYUAN ELECTRONICS TECH CO LTD

Wirecord fabric heat hob cutting device and method thereof

InactiveCN101200119AComply with processing requirementsReasonable structureTyresMetal working apparatusBody rollEngineering

The invention relates to a crop device and method of the wire-cord fabric hot hob, in which the technical scheme of hot hob crop is adopted. Through the heat of the cutter body, the sizing compound is separated. Moreover in the crop process of the cutter body, the body rolls along the axial direction of the wire. Between the cutter body of the hot hob and the fixed axis, a small gap is arranged so that the cutter body can be in the left and right movement along the fixed axis. Thus the tilting and bending issue of wires targeted is resolved. With the adoption of the hot hob and the method, the sizing compound is separated through the heat of the body to complete the crop of the wire-cord fabric. The cross section of the cropped sizing compound is smoother, which is more in line with the cord-processing requirement of the follow up tire ply forming process. Moreover, through the hot hob crop device in which the body can be in self-adaptive adjustment along the fixed axis, when the tilting or bending is occurred on the steel wire, the cutter body can be in rolling crop along the axial direction of the steel wire.

Owner:MESNAC

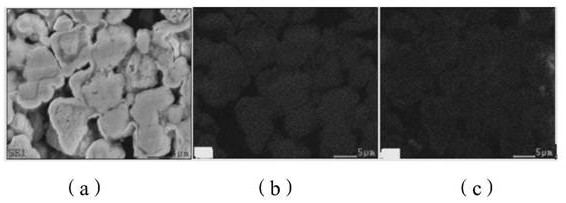

Preparation method of sample for characterizing element distribution uniformity

InactiveCN112798630AObtain element distribution uniformitySolve the problem of insufficient distribution uniformityMaterial analysis using wave/particle radiationNon-aqueous electrolyte accumulator electrodesIon beamTest analysis

The invention discloses a preparation method of a sample for characterizing element uniformity of a positive electrode material, which comprises the following steps of: step 1, preparing the positive electrode material, and preparing a positive electrode plate; step 2, cutting the positive pole piece to form a cutting section; and step 3, testing the cutting section. The positive pole piece is prepared and cut by an argon ion beam, and the formed section of the positive pole piece is used for electron microscope test analysis. Three argon ion beams are adopted to cut the positive pole piece in different directions to obtain the section of the positive pole piece, and the section sample is subjected to energy spectrum scanning, so that the uniformity degree of material surface and bulk phase element distribution can be effectively observed, and a reliable basis is provided for evaluating the performance of the positive pole material. The method provided by the invention is simple and quick, and the element distribution condition can be intuitively obtained.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

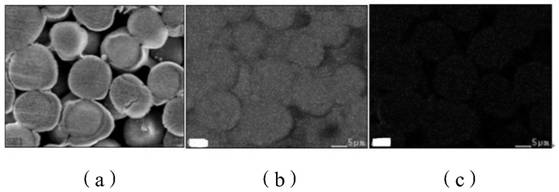

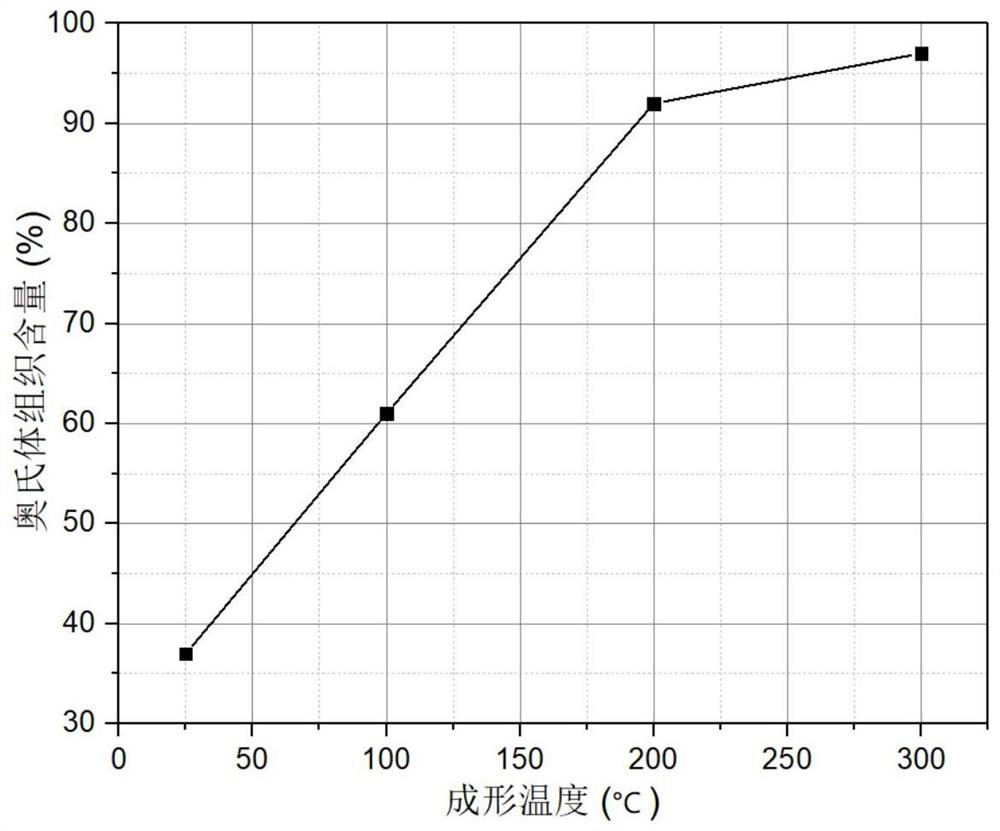

Warm fine blanking die based on current assistance and warm fine blanking method

PendingCN114054600AIncrease temperatureImprove section qualityShaping toolsEjection devicesPulsed DCElectric current flow

The invention relates to a warm fine blanking die based on current assistance and a warm fine blanking method, and solves the technical problems of poor forming quality, serious die abrasion and the like of an austenite 304 stainless steel cold fine blanking part in the prior art. The warm fine blanking die comprises an upper die plate, a lower die plate, a guide column, a guide sleeve, a male die fixing plate, a male die, a female die, an edge pressing plate, an edge pressing plate insert, a reverse ejection rod, a reverse ejection block, a pulse direct-current box, a first electrode and a second electrode, wherein the upper die plate is connected with the lower die plate through the guide column and the guide sleeve; the female die is fixedly connected with the lower die plate, the male die fixing plate is fixedly connected with the upper die plate, and the male die is fixedly connected with the male die fixing plate; and the edge pressing plate is connected with the upper die plate through a limiting bolt, the first electrode makes contact with an upper surface of the male die, the second electrode makes contact with a lower surface of the female die, and two output terminals of the pulse direct-current box are connected with the first electrode and the second electrode respectively. The invention is widely applied to the technical field of metal precision forming.

Owner:WEIHAI HUABANG FINE BLANKING

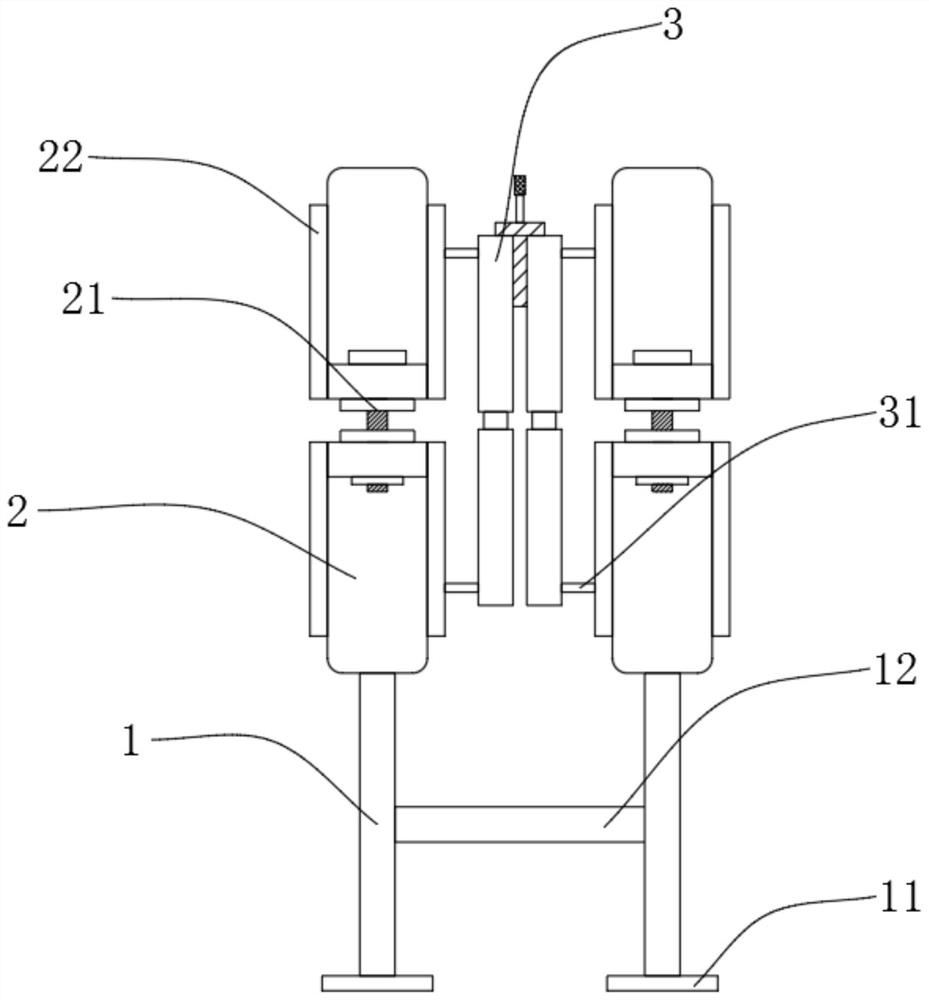

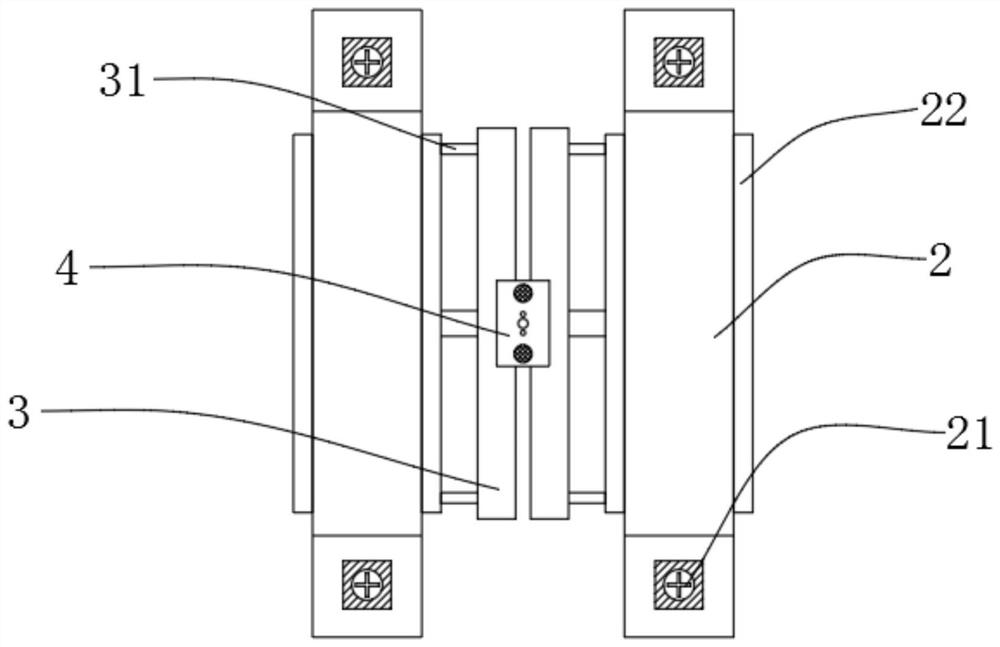

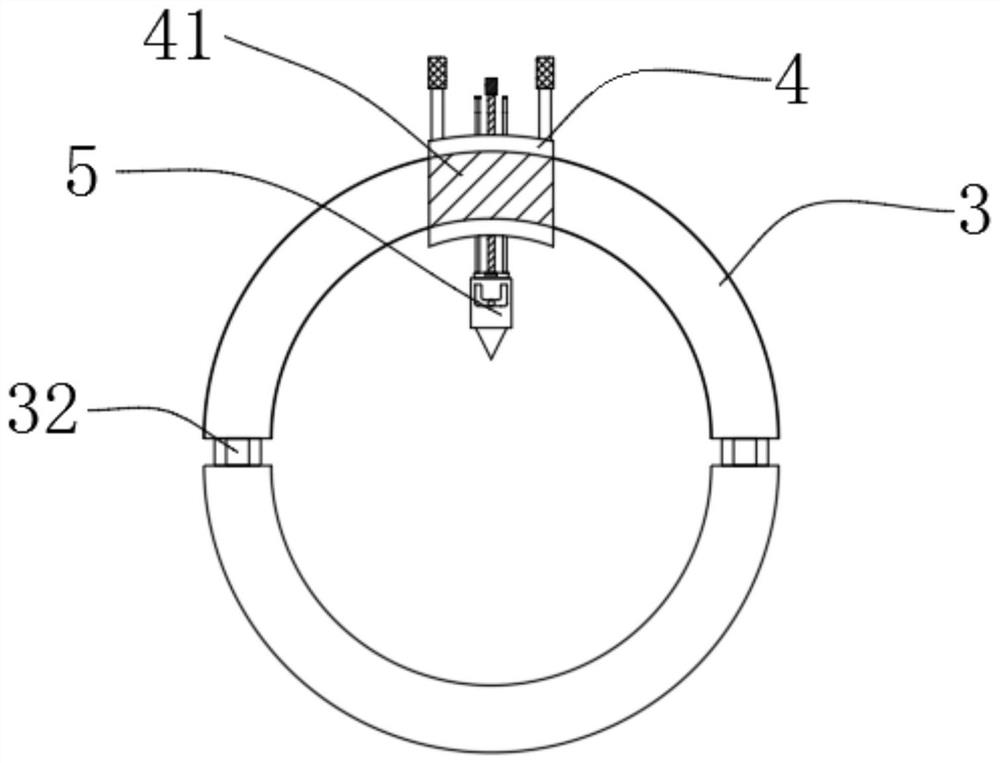

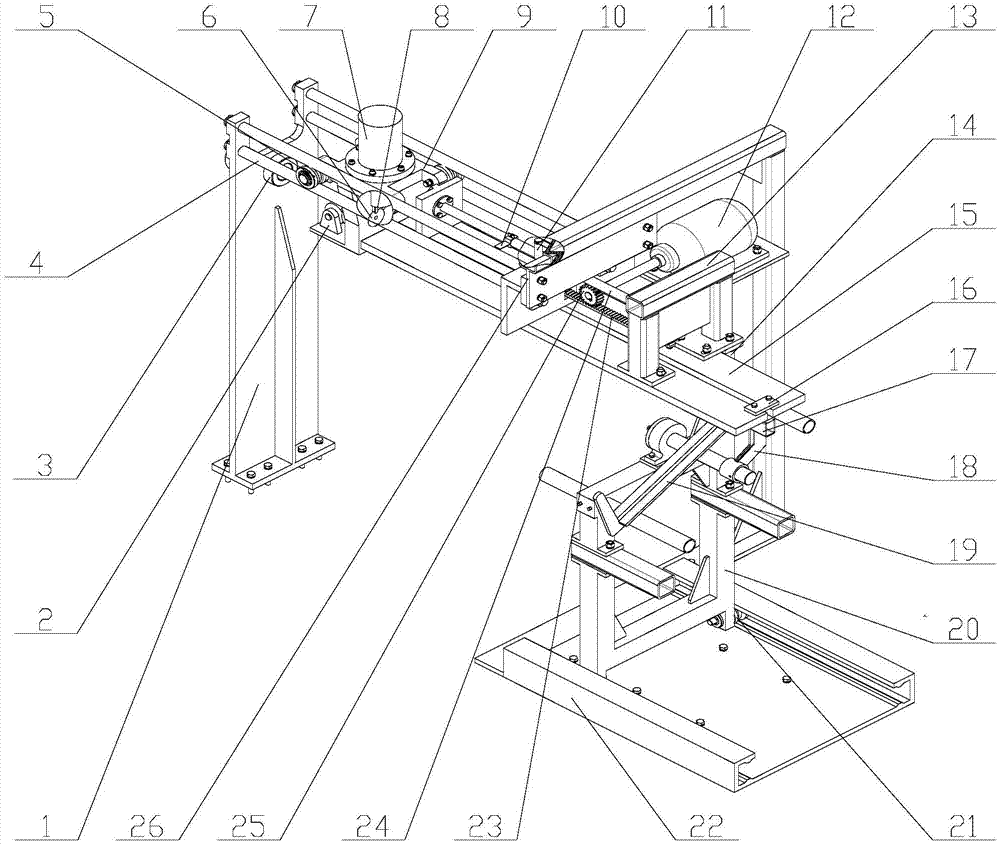

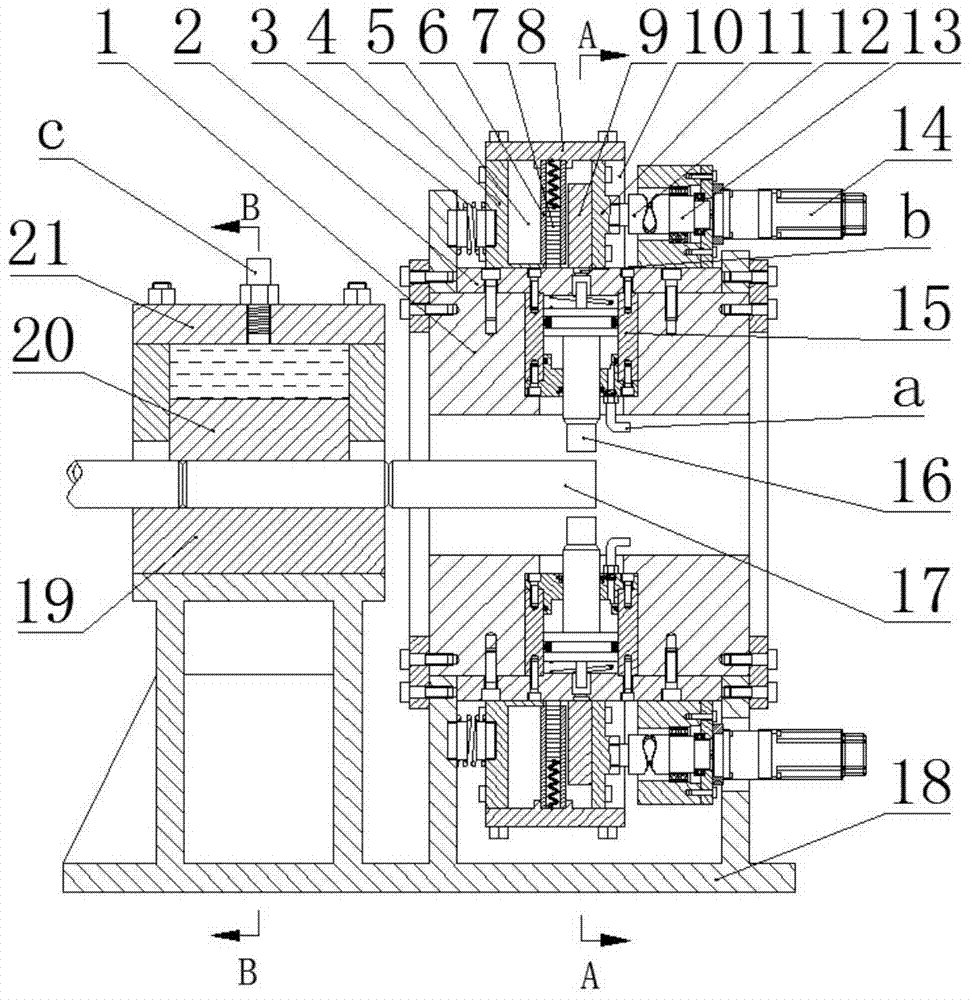

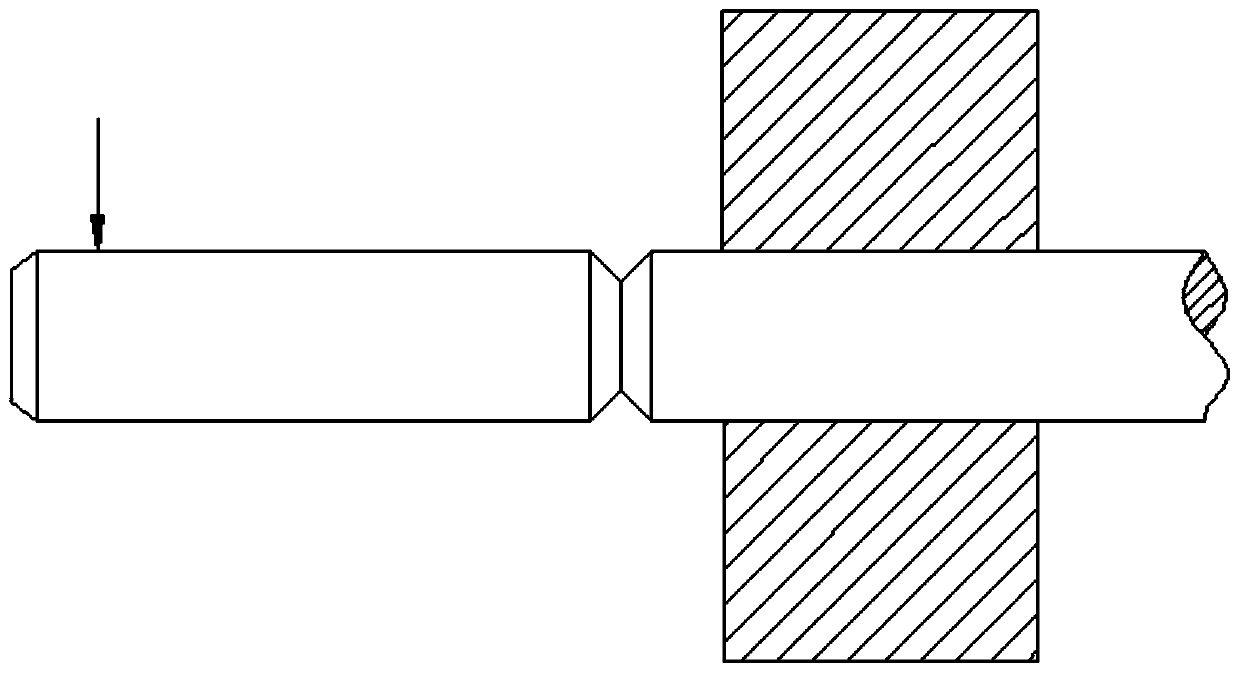

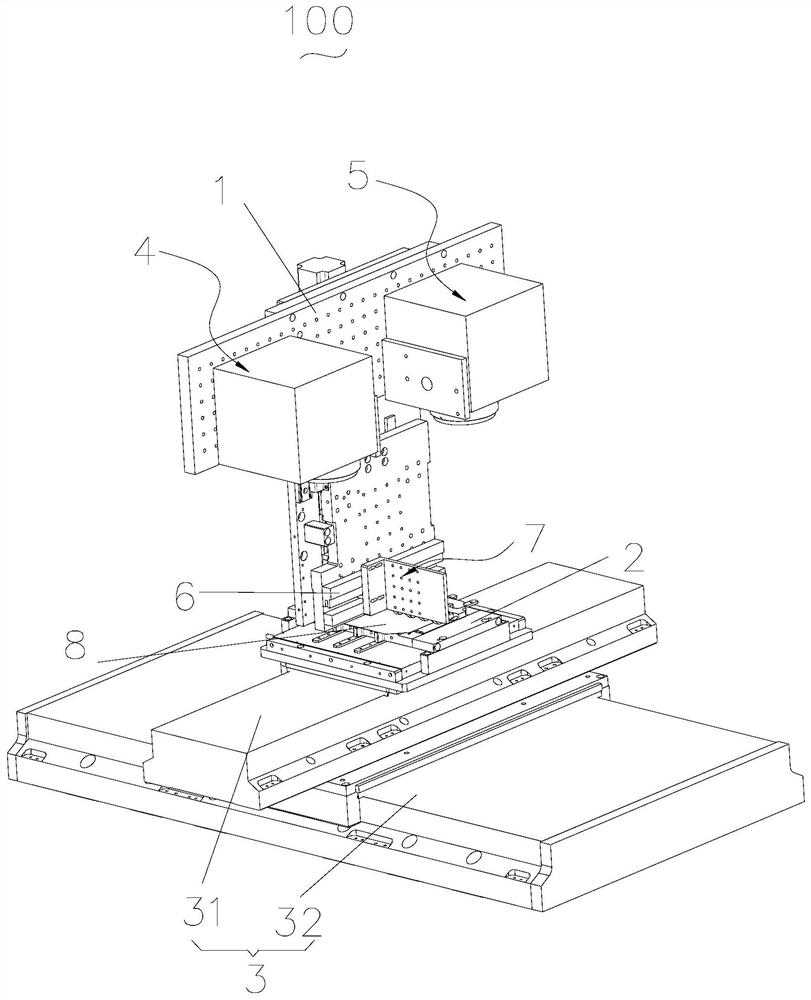

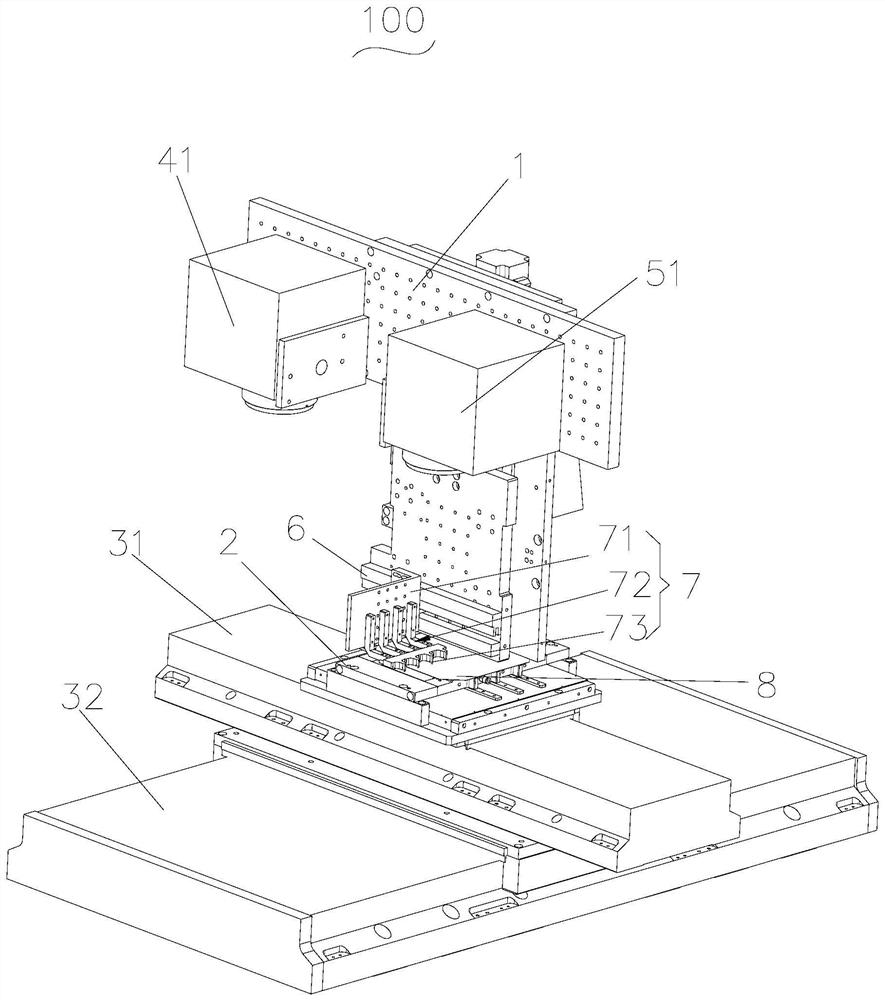

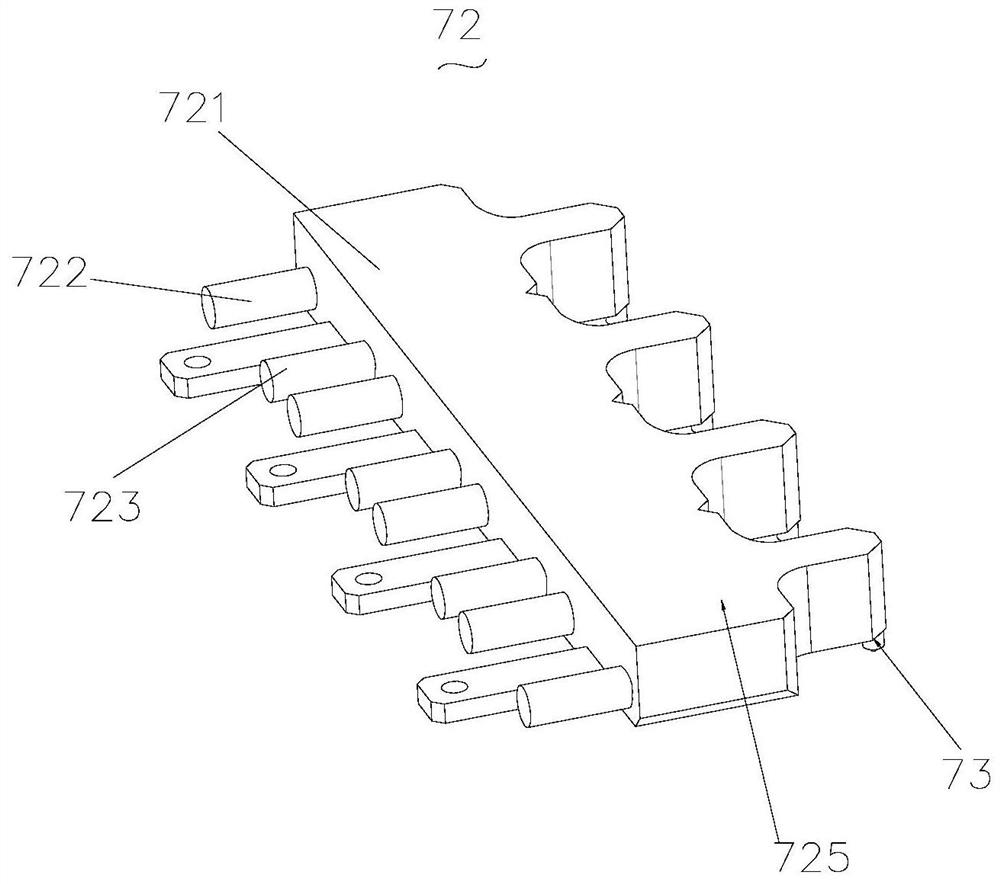

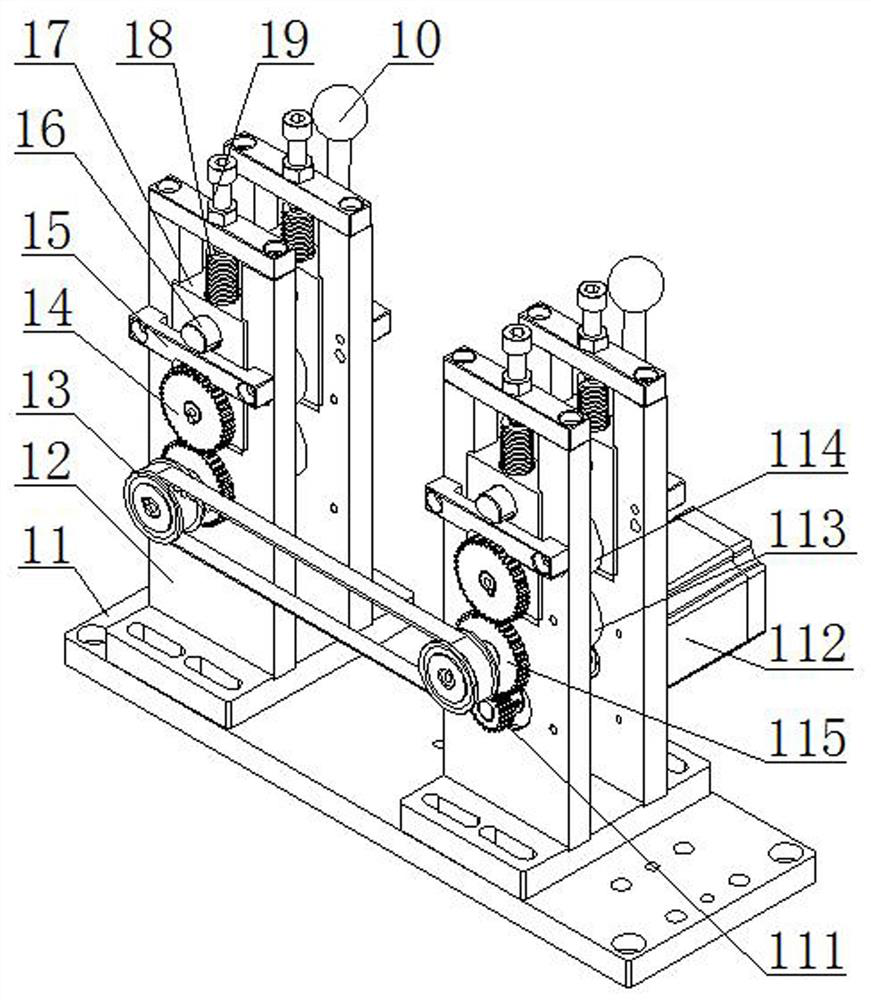

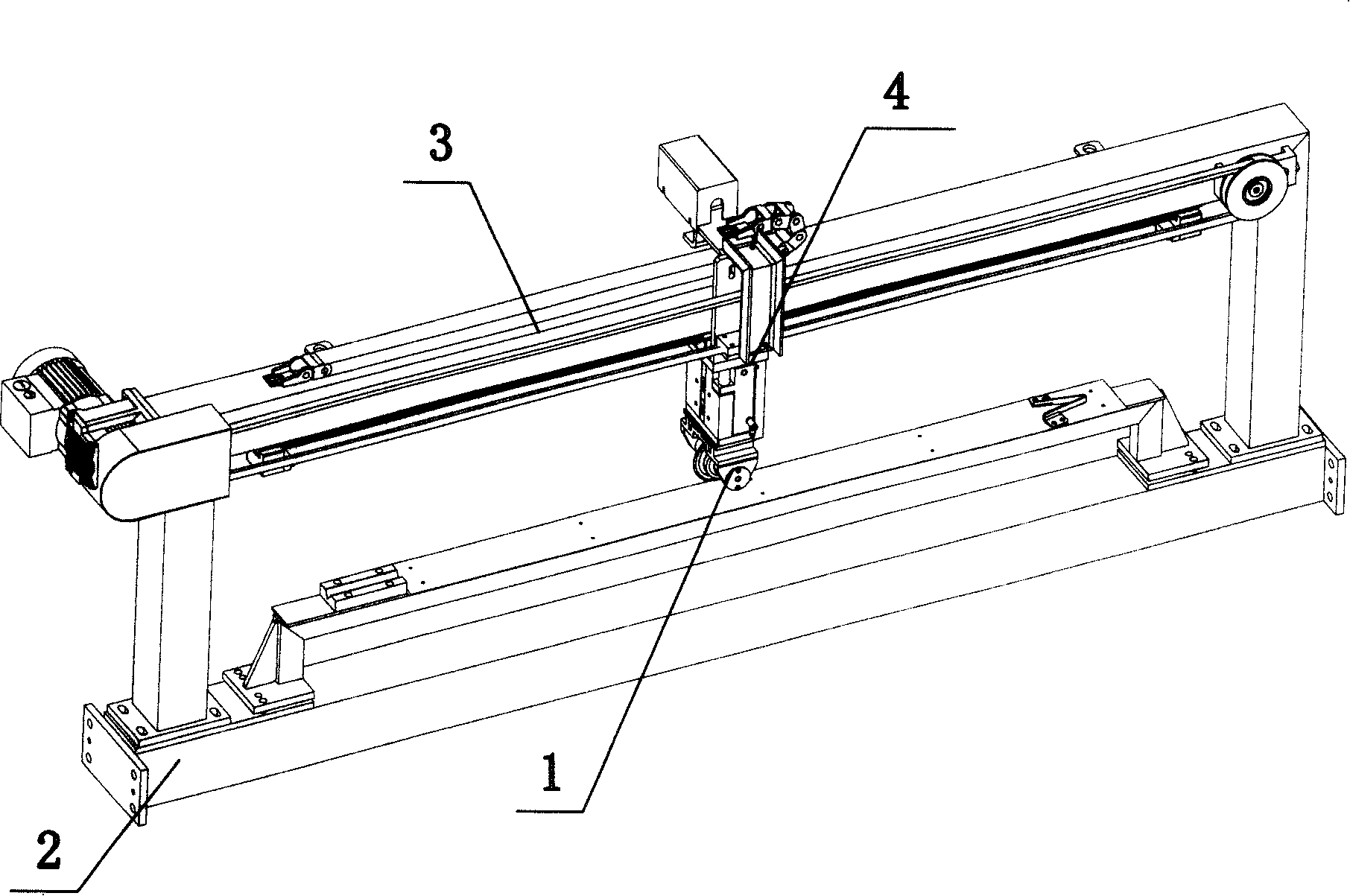

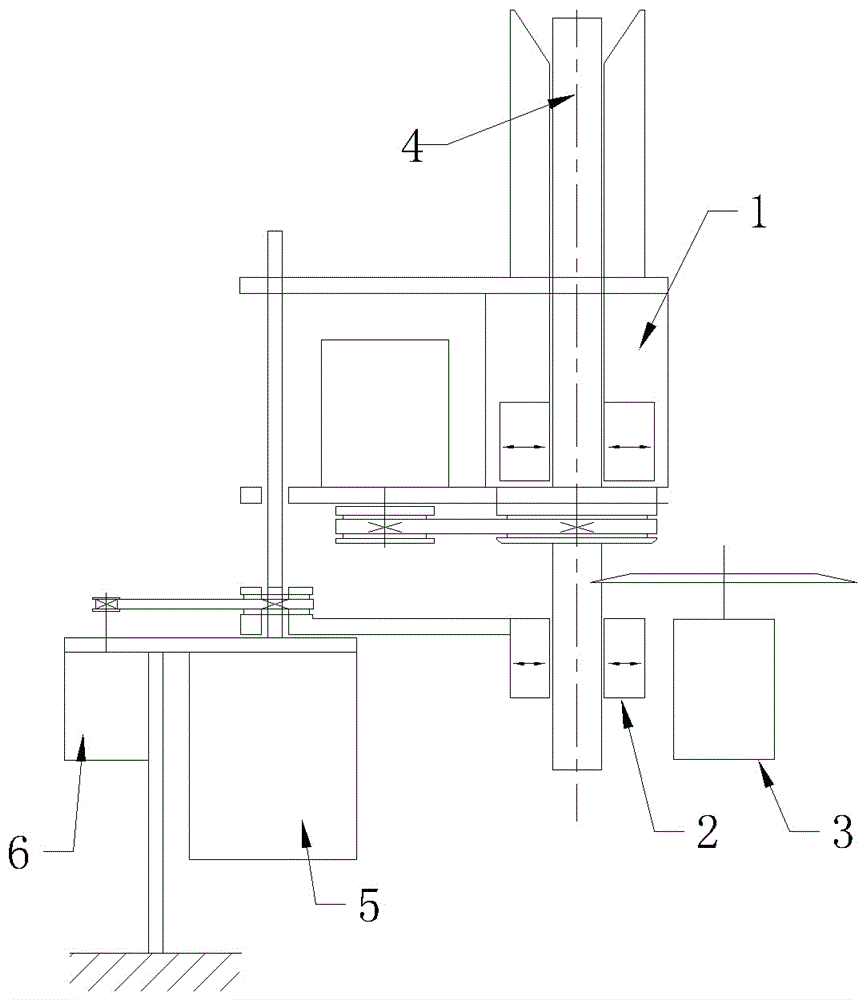

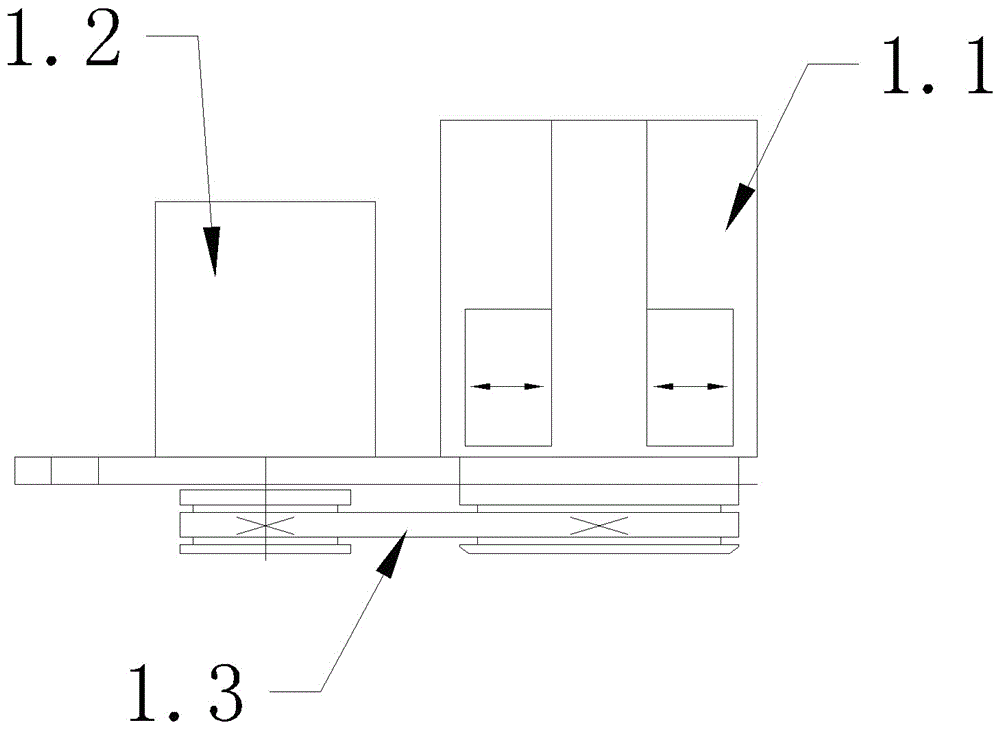

Method and device for obtaining cross-section by rotary cutting of bar material

The invention discloses a method for obtaining cross section through bar material rotary-type cutting and a device for obtaining the cross section through the bar material rotary-type cutting. The method adopts a manner that a bar material and a cutter both adopt active rotations; and, when cutting is performed, the rotary bar material and the rotary cutter contact each other to perform the cutting, and then a cross section is formed through the cutting. The device comprises a rotary clamping mechanism, a cut-off end holding and clamping mechanism, a cutter mechanism and a cutting feeding mechanism; the rotary clamping mechanism is composed of a rack body, a rotary clamp head which is rotatable and is disposed on the rack body, a drive motor disposed on the rack body, and a transmission mechanism connected between the drive motor and the rotary clamp head; and the cut-off end holding and clamping mechanism is composed of a rack body and a cut-off holding clamp disposed on the rack body, the cutter mechanism is composed of a drive motor and a cutter, the rotating axis of the cutter and the rotating axis of the bar material are parallel to each other, and the cutter is disposed at a height between the rotary clamp head and the cut-off holding clamp. The bar material rotating and cutter rotating manner is adopted, and the cross section obtained through the cutting can completely satisfy a high-precision analysis detection requirement.

Owner:SHANGHAI PUSHUO AUTOMATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com