Rod pipe material discharging device driven by explosive slice chemical energy release explosion

A technology of chemical energy and rod and tube material, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problem that explosive gas and gas generating agent are not widely used in industrial production, and achieve high production efficiency, material saving, and high efficiency. The effect of high quality of material section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

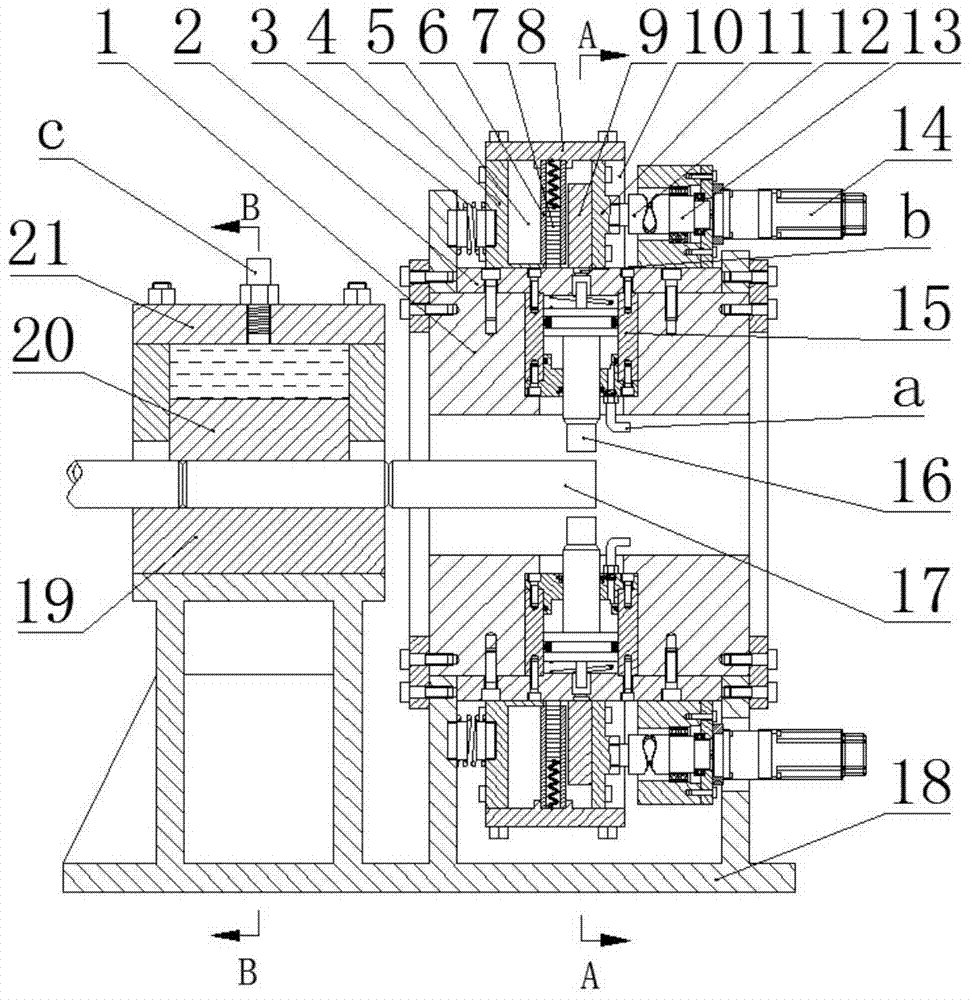

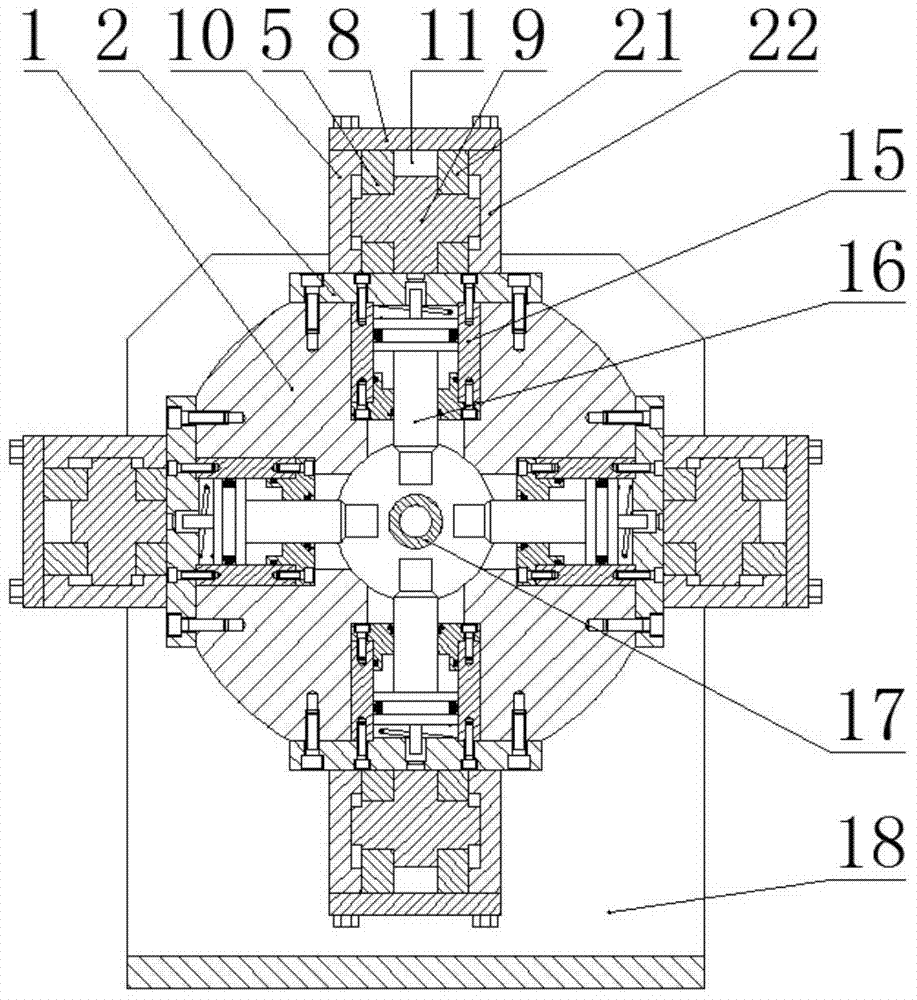

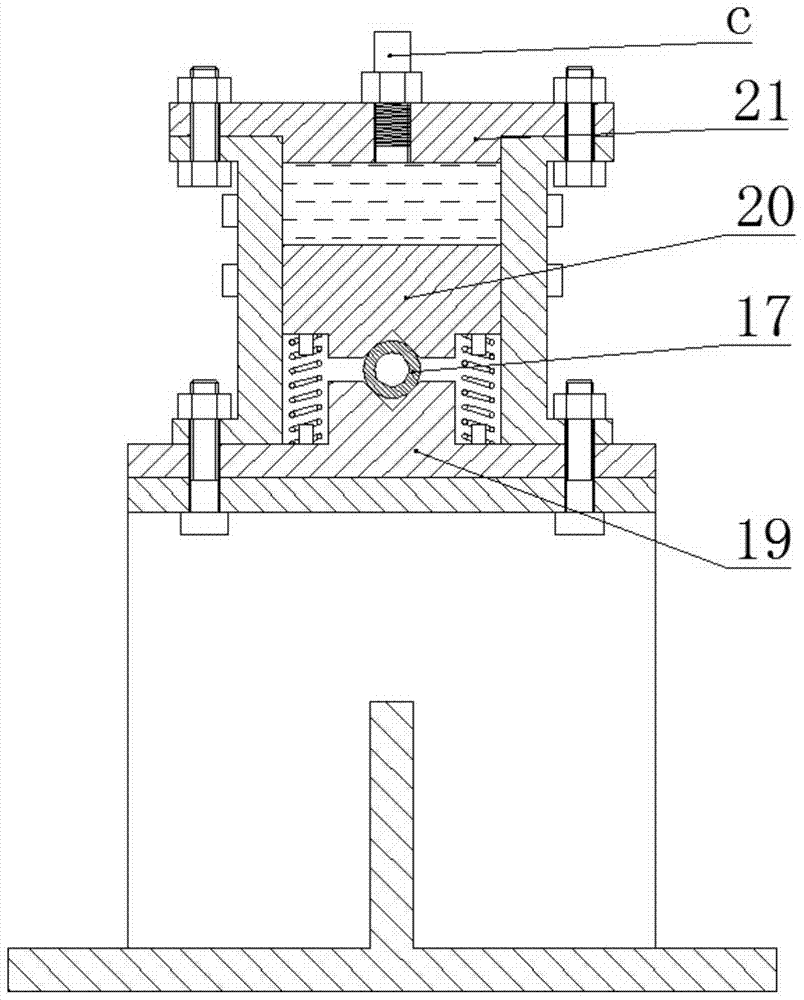

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] Such as figure 1 , figure 2 and image 3 Shown, a kind of stick tube material unloading device driven by the chemical energy release explosion of explosive chips, including the main body and the clamping mechanism and charging mechanism matched with it, wherein the main body includes two cover plates installed on the frame 18 The main cylinder 1, the main cylinder 1 is uniformly distributed along the circumference with four sets of the same forging mechanism composed of cylinder 15, hammer head 16 and pipe joint a, wherein the cylinder 15 is plugged in the main cylinder 1, and the cylinder The lower end of 15 is equipped with a cylinder cover, and a through hole is threadedly connected to the pipe joint a on the cylinder cover. The upper half of the hammer head 16 is installed in the inside of the cylinder barrel 15 and can slide freely in the cylinder barr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com