Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

98results about How to "Increase impact speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

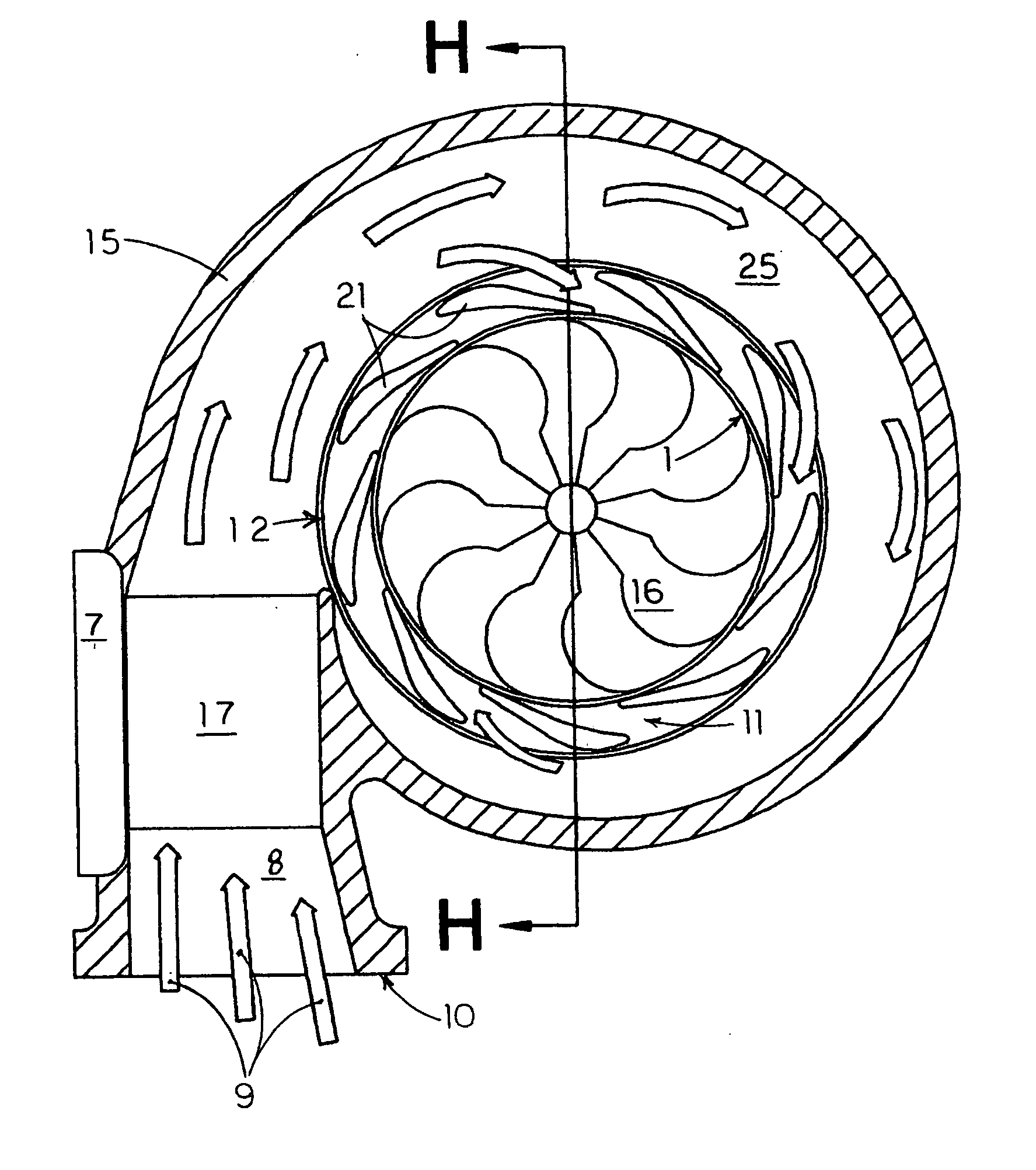

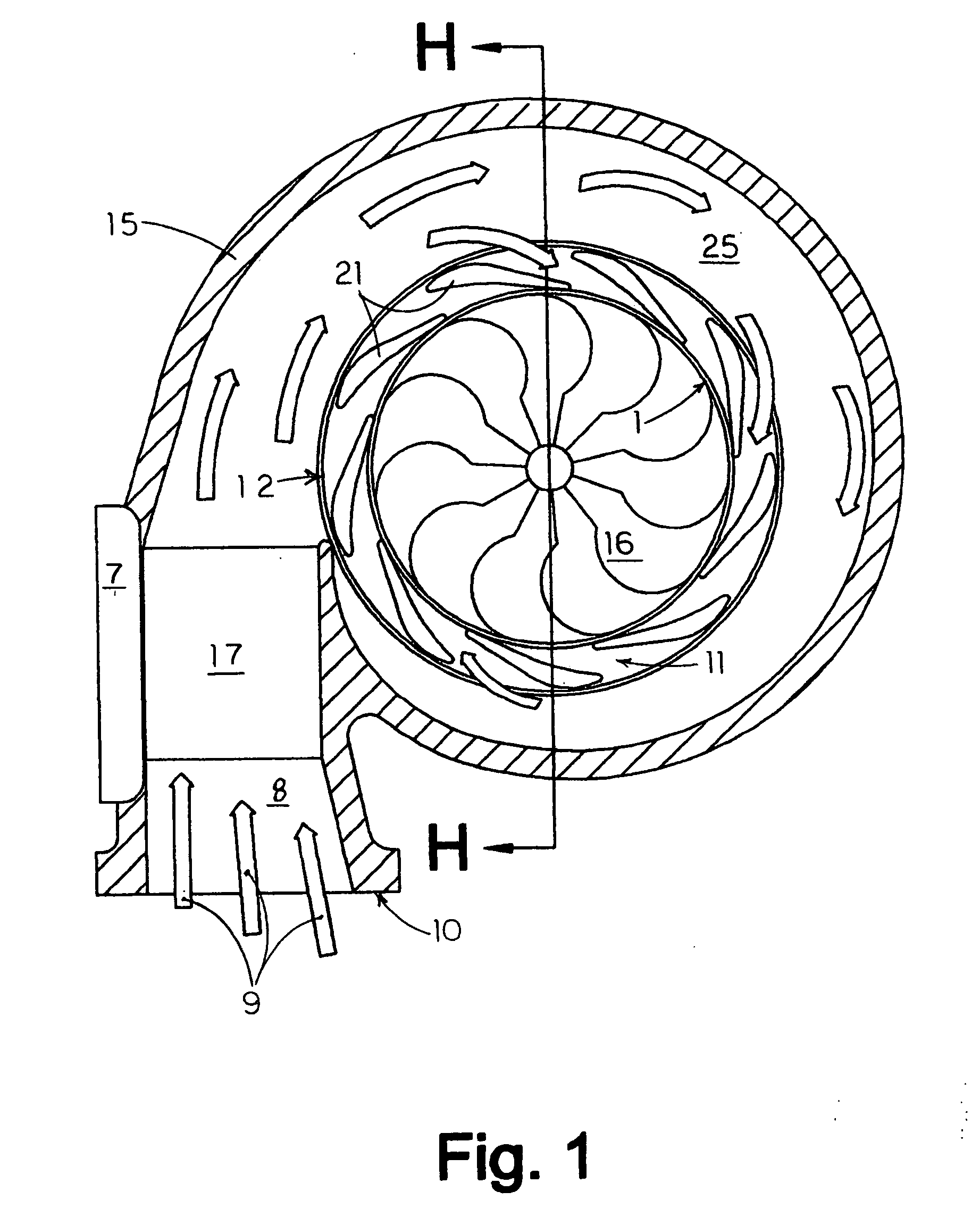

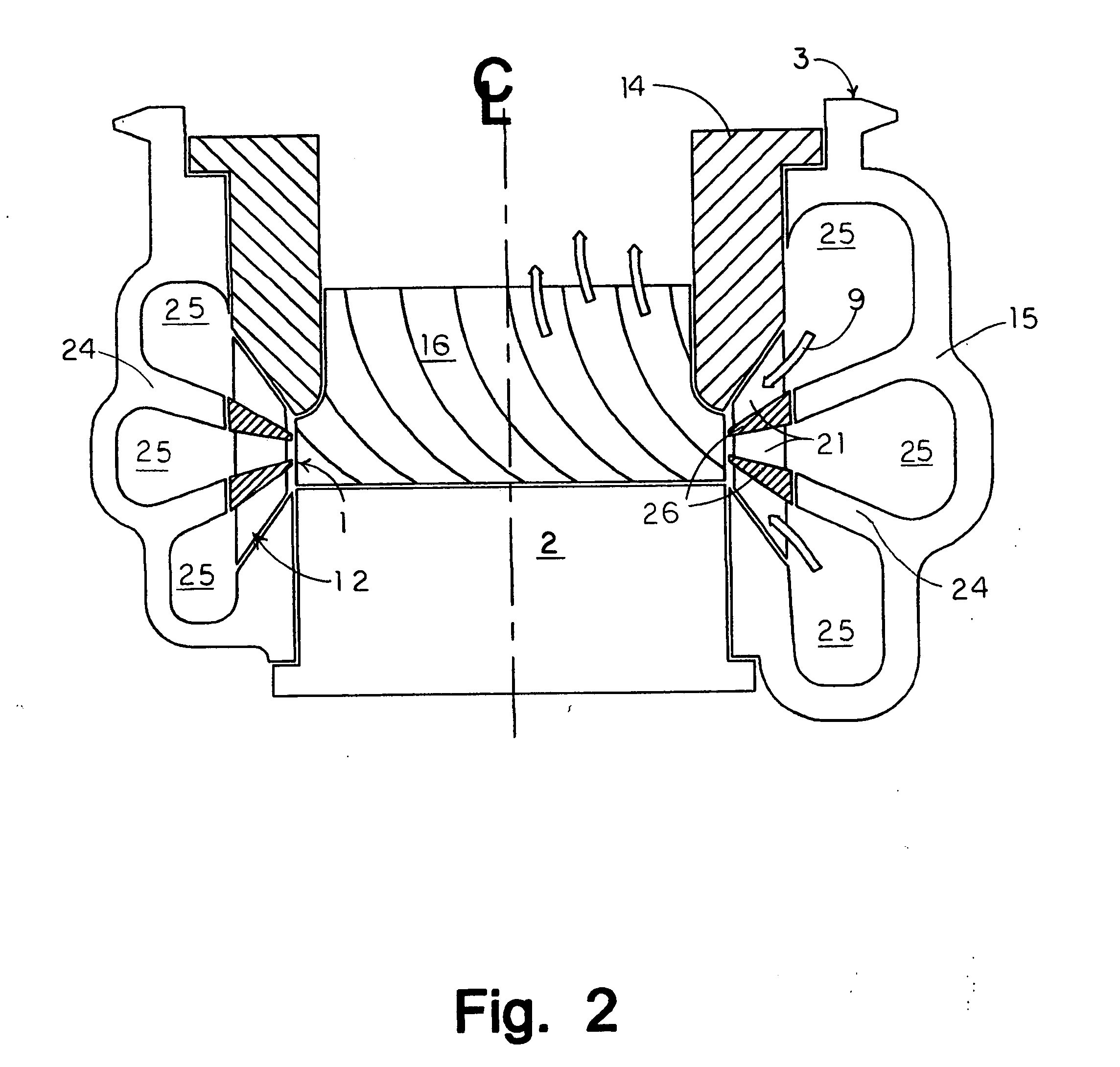

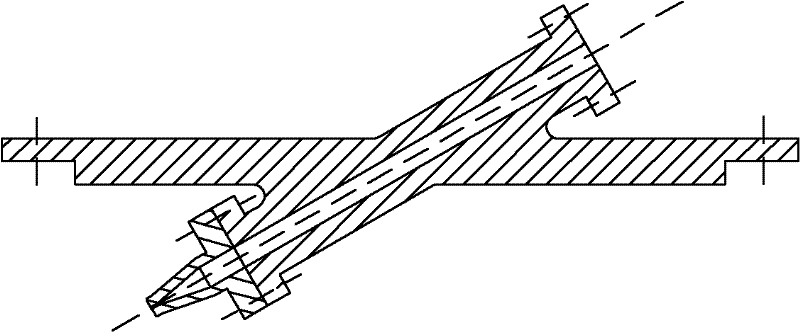

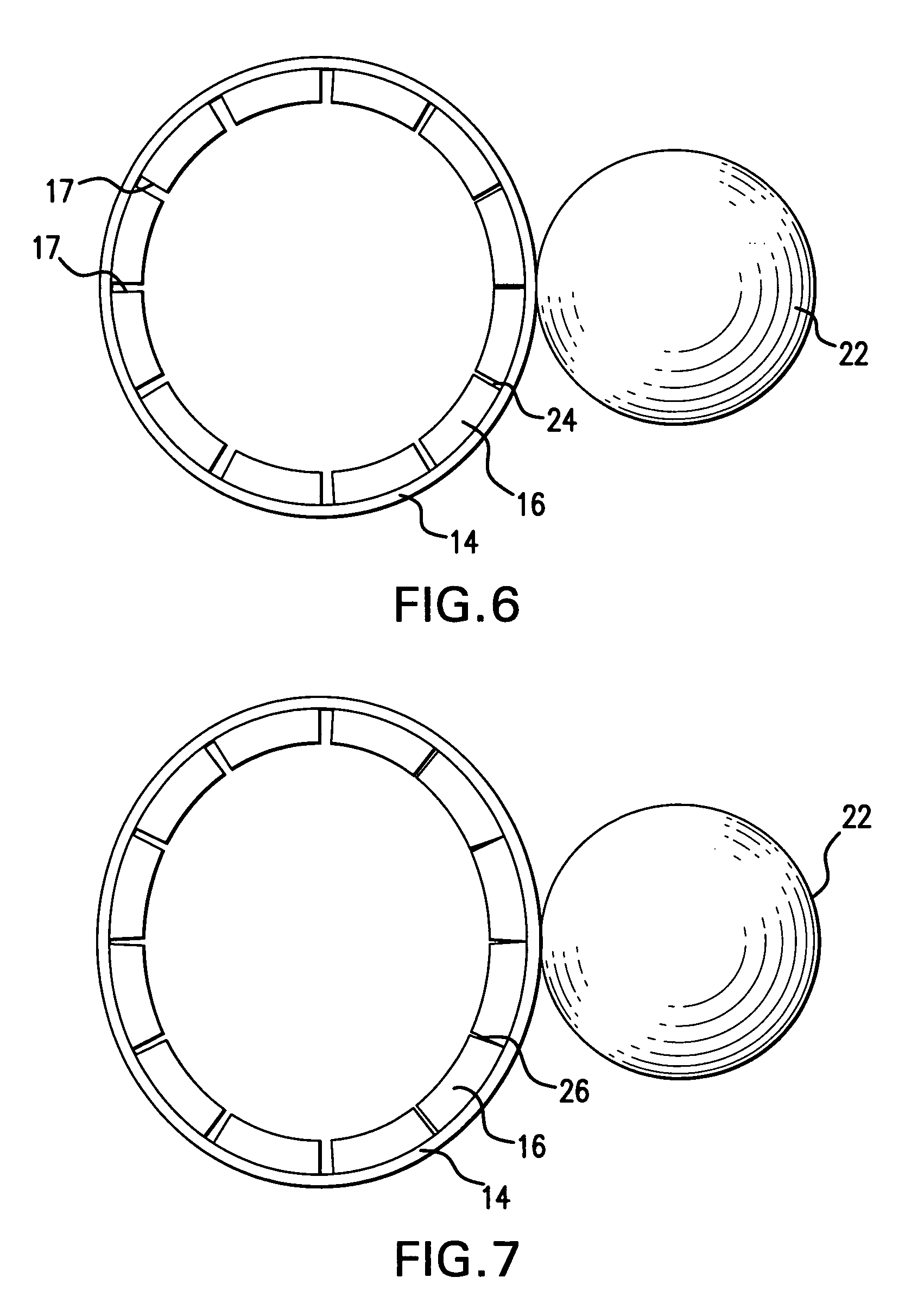

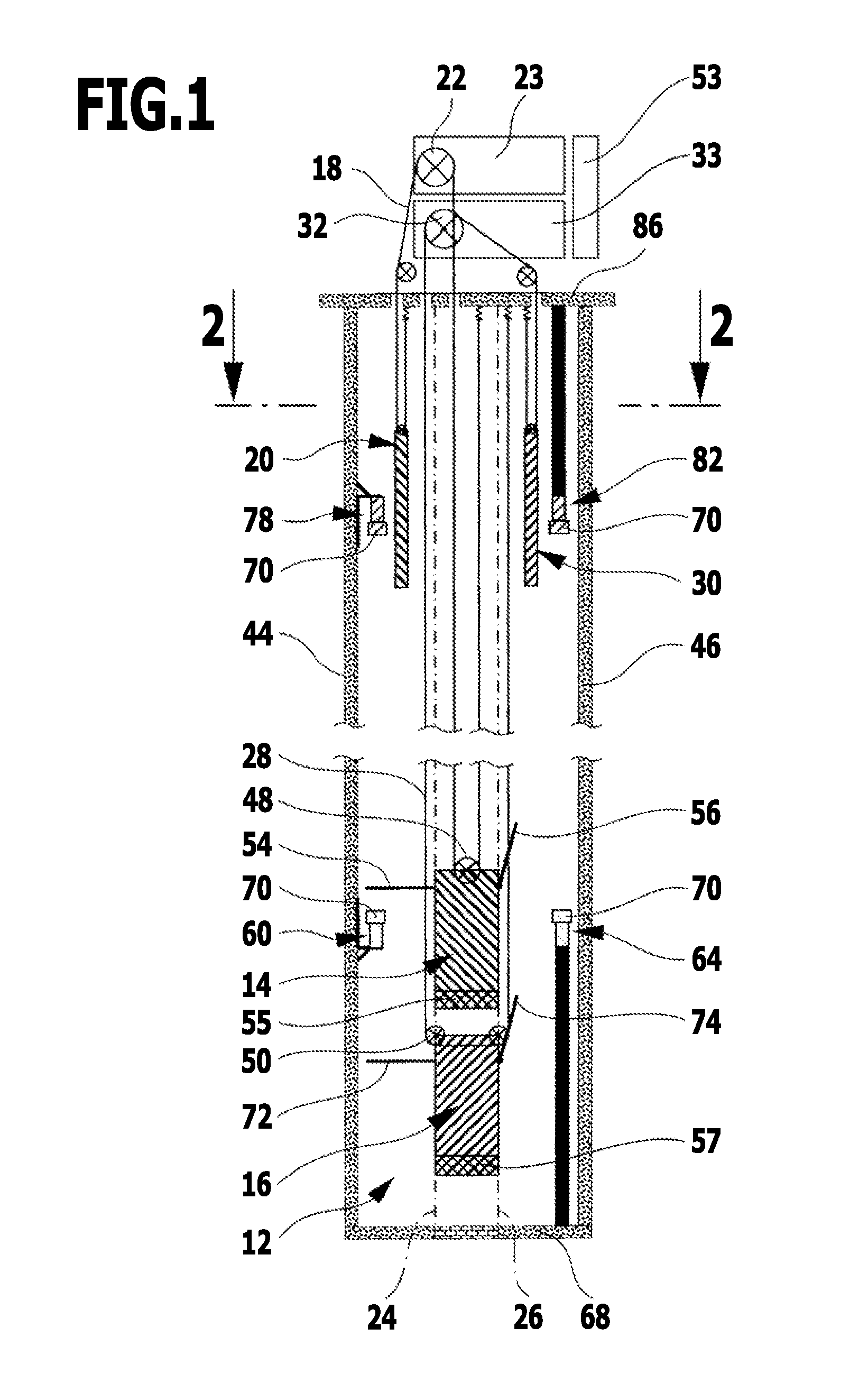

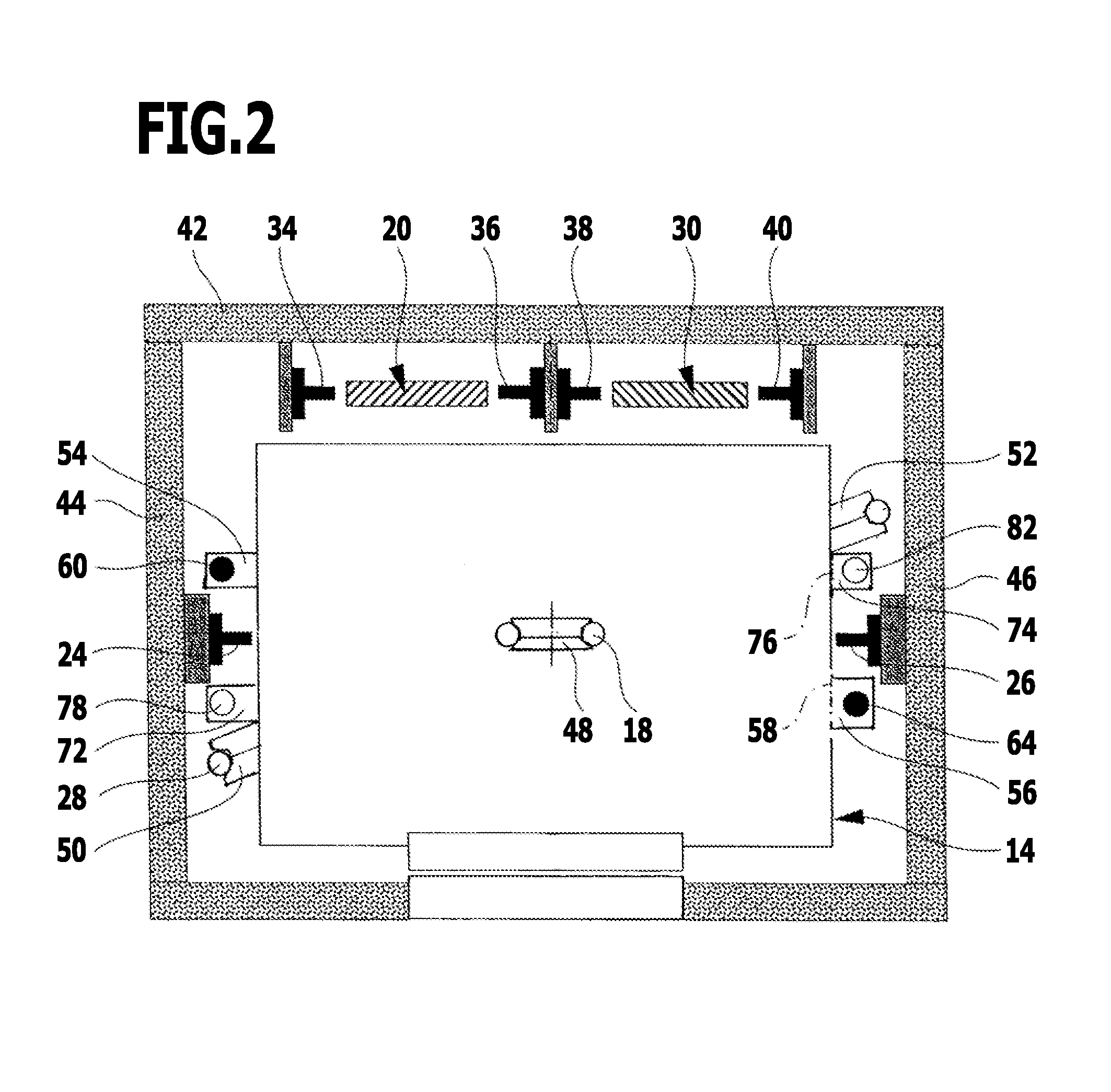

Multiple nozzle rings and a valve for a turbocharger

InactiveUS20070209361A1Increase impact speedReduce back pressureEngine manufactureInternal combustion piston enginesTurbochargerEngineering

A turbocharger turbine housing with at least two volutes utilizing multiple nozzle rings to optimize the turbocharger's proficiency per application, and a valve to control the exhaust flow to selected volutes in the turbine housing.

Owner:PEDERSEN MELVIN HESS +1

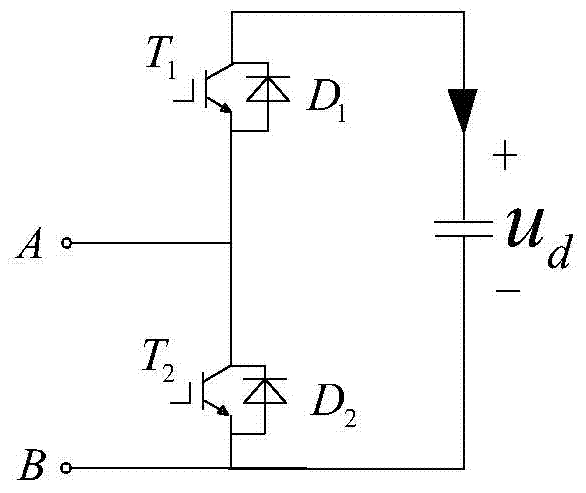

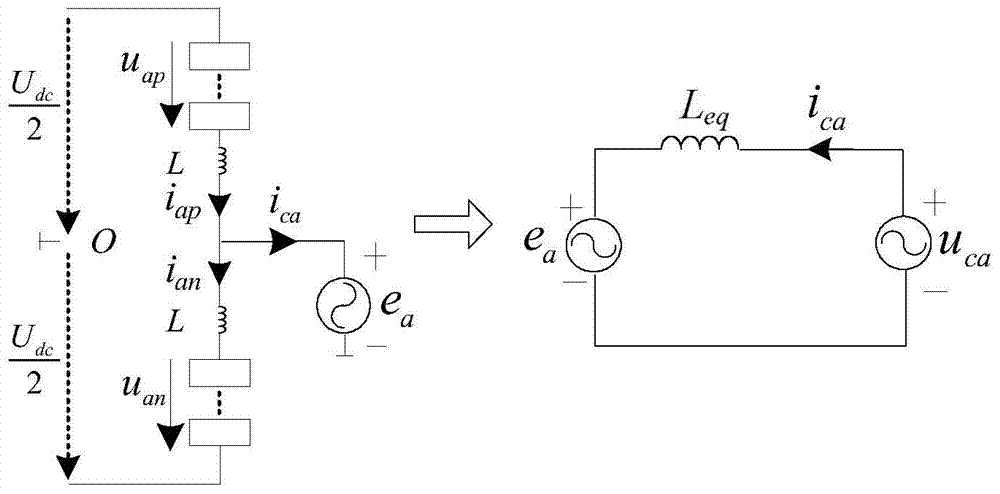

STATCOM unbalance compensation control method based on modular multilevel converter

ActiveCN103532156AImprove efficiencyEliminate imbalanceFlexible AC transmissionAc-dc conversionPower gridModularity

The invention discloses a STATCOM unbalance compensation control method based on a modular multilevel converter (MMC). The method comprises a converter compensation current dead-beat control method and a converter interphase circular current active damping control method. A comprehensive compensation current dead-beat control part is used for compensating active loss in the MMC by controlling active current, reactive current and negative-sequence current which are output by the MMC so as to eliminate unbalance of the current of a power grid and compensate reactive power; the interphase circular current active damping control method is used for summing by detecting the bridge arm current of upper and lower bridge arms of each phase and multiplying by 0.5 to obtain the circular current of each phase, and superposing the output of three-phase current passing through an active damping controller to dead-beat control output so as to inhibit the alternating current component of the circular current, reduce the current stress of converter devices and reduce the loss of the converter. Through the adoption of the method provided by the invention, compensation of the negative-sequence current and reactive current of unbalanced load of the power grid is realized, inhibition of the interphase double frequency circular current of the MMC is simple, the response speed is high and the stability is high.

Owner:HUNAN UNIV

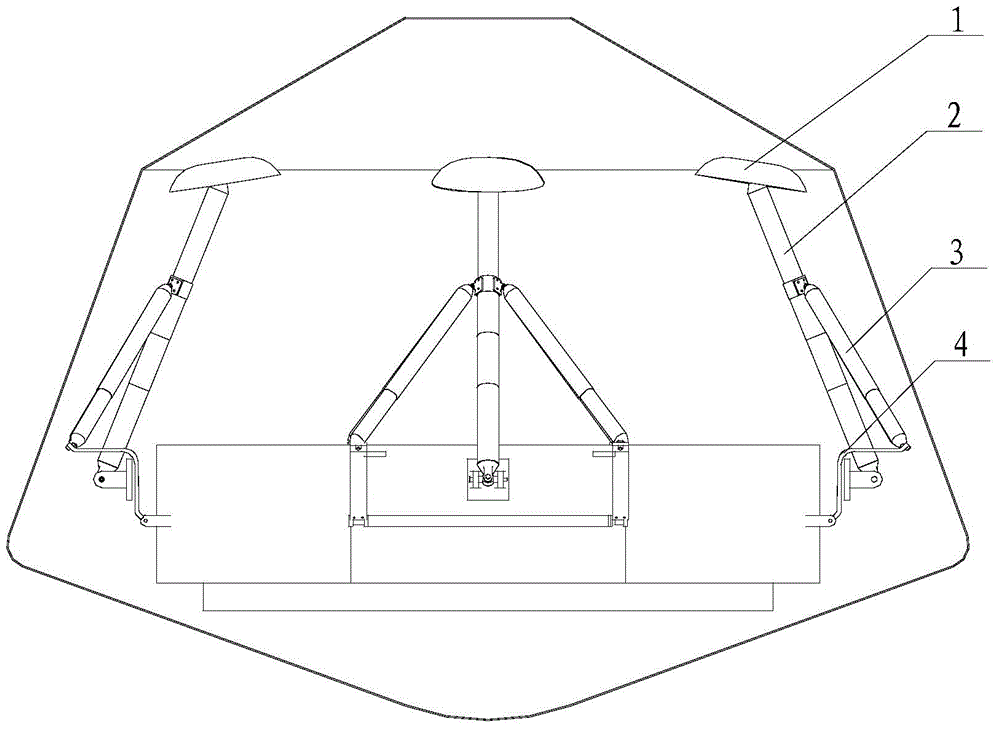

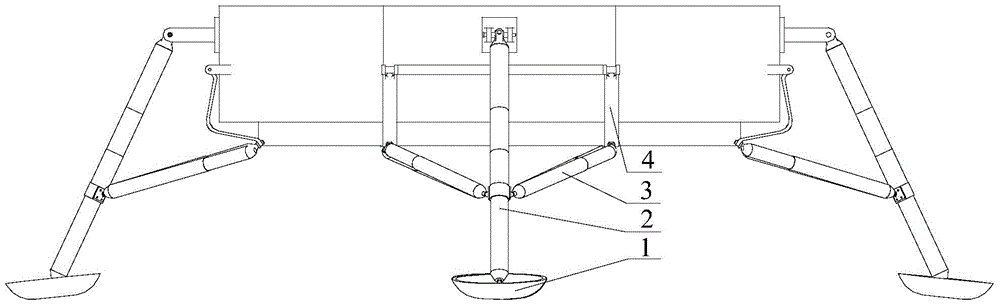

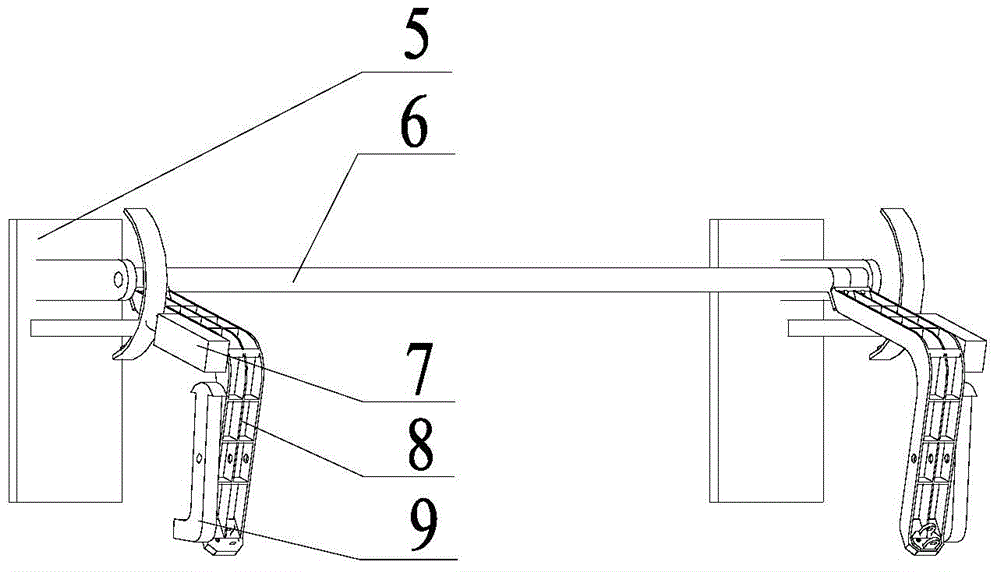

Mars exploration landing buffer device

ActiveCN104627390AIncrease spanImprove motion stabilitySystems for re-entry to earthCosmonautic landing devicesLocking mechanismUniversal joint

A Mars exploration landing buffer device comprises three or four sets of landing legs symmetrically distributed on the periphery of a Mars exploration lander body mechanism. Each set of landing legs is composed of a foot pad (1), a main leg (2), an auxiliary leg (3) and an unfolding locking mechanism (4), wherein the foot pad (1), the main leg (2), the auxiliary leg (3) and the unfolding locking mechanism (4) of the same set of landing legs are connected with one another through universal joints or rotating shafts, and the main leg (2), the auxiliary leg (3), the unfolding locking mechanism (4) of each set of landing legs and the lander body mechanism form a four-bar mechanism so that the landing buffer device can be overturned outwards up and down. The upturning folding structure enables the mass center of the lander to move forwards, the movement stability of the lander in an entering stage is improved, in addition, energy is absorbed through own movement deformation of buffer cellular structures in the main legs (2) and the auxiliary legs (3), soft landing of the lander is achieved, and the device can be applied to design of soft landing buffer mechanisms for landing detection on a planet or a satellite with atmosphere.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

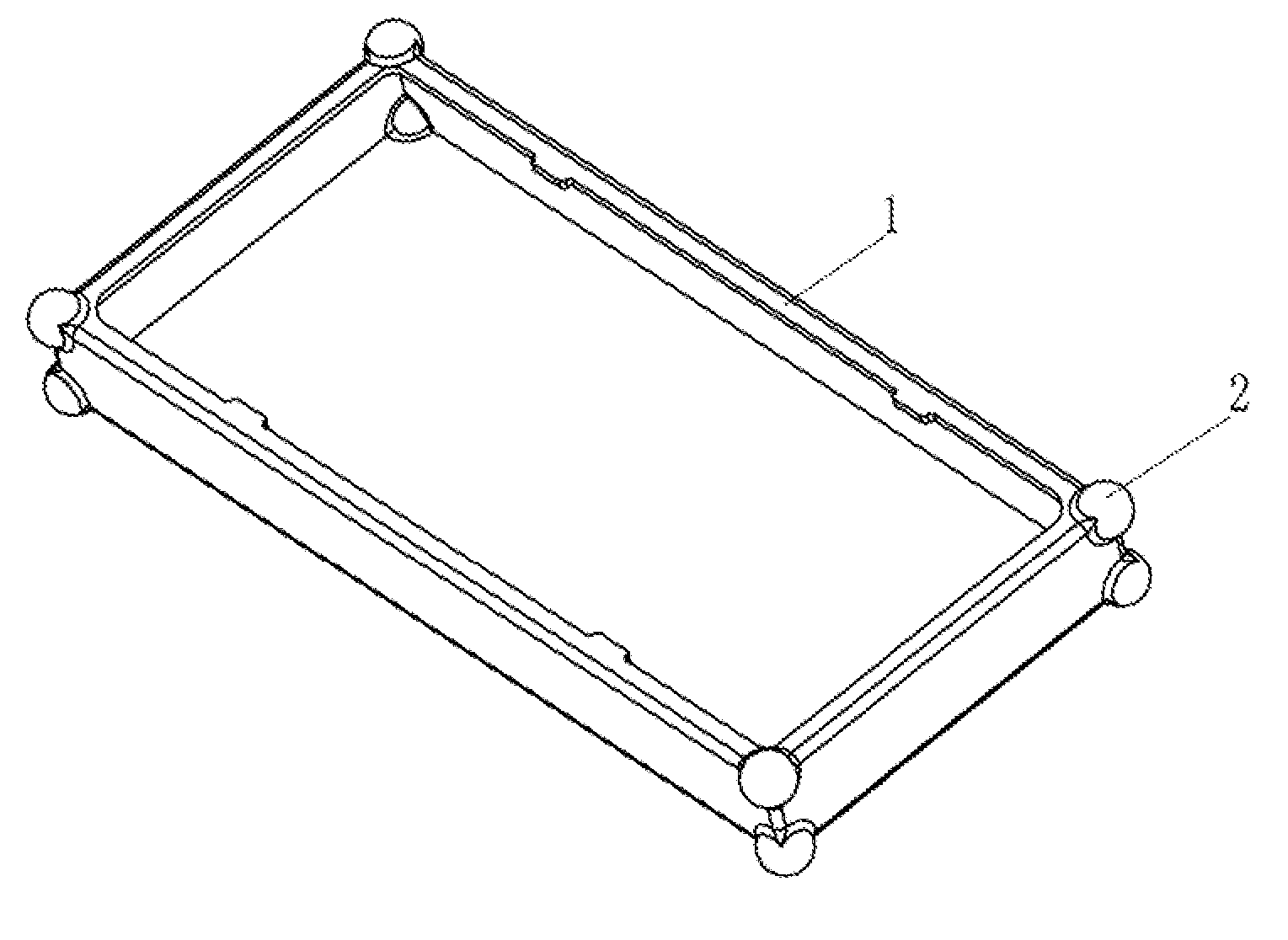

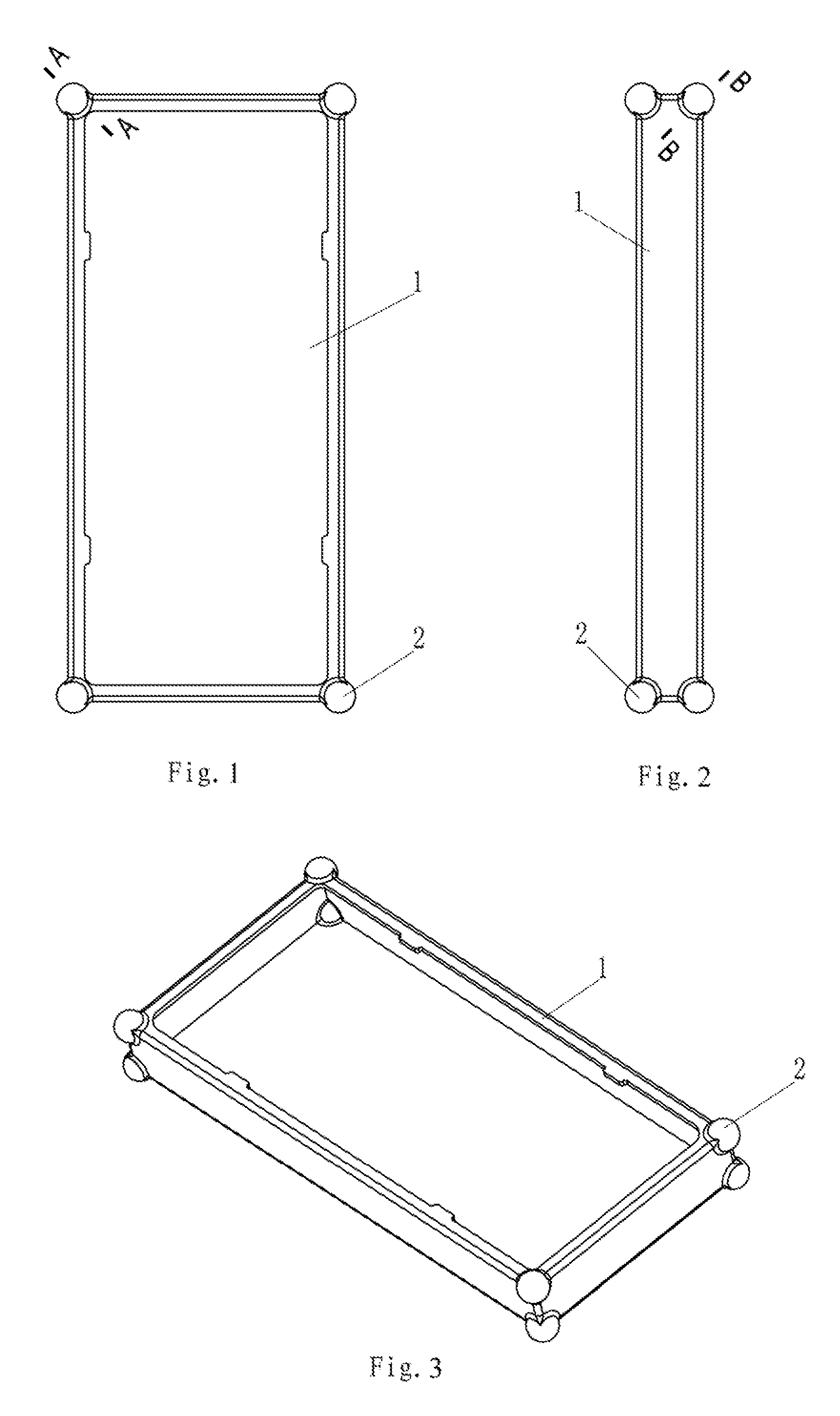

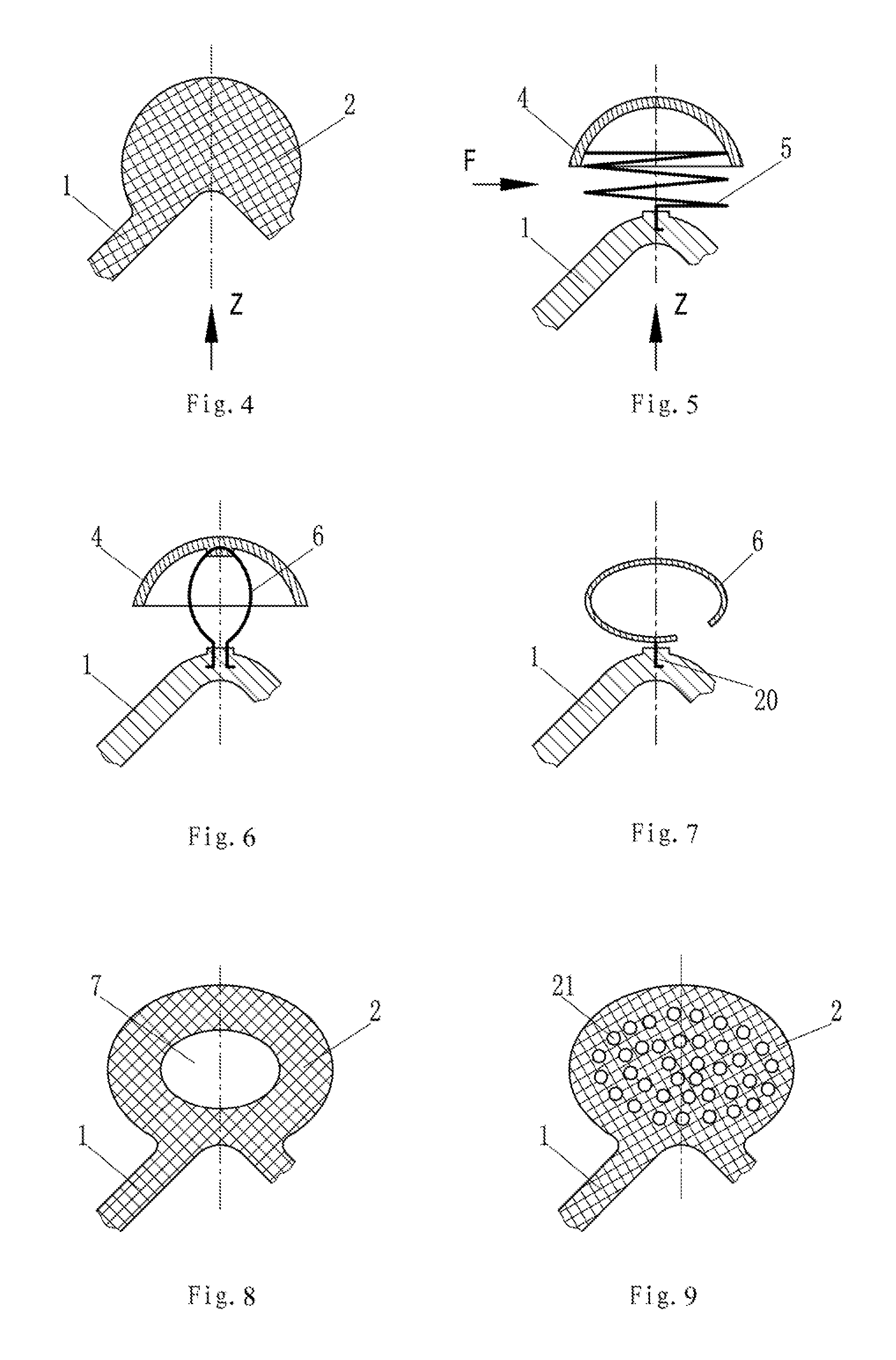

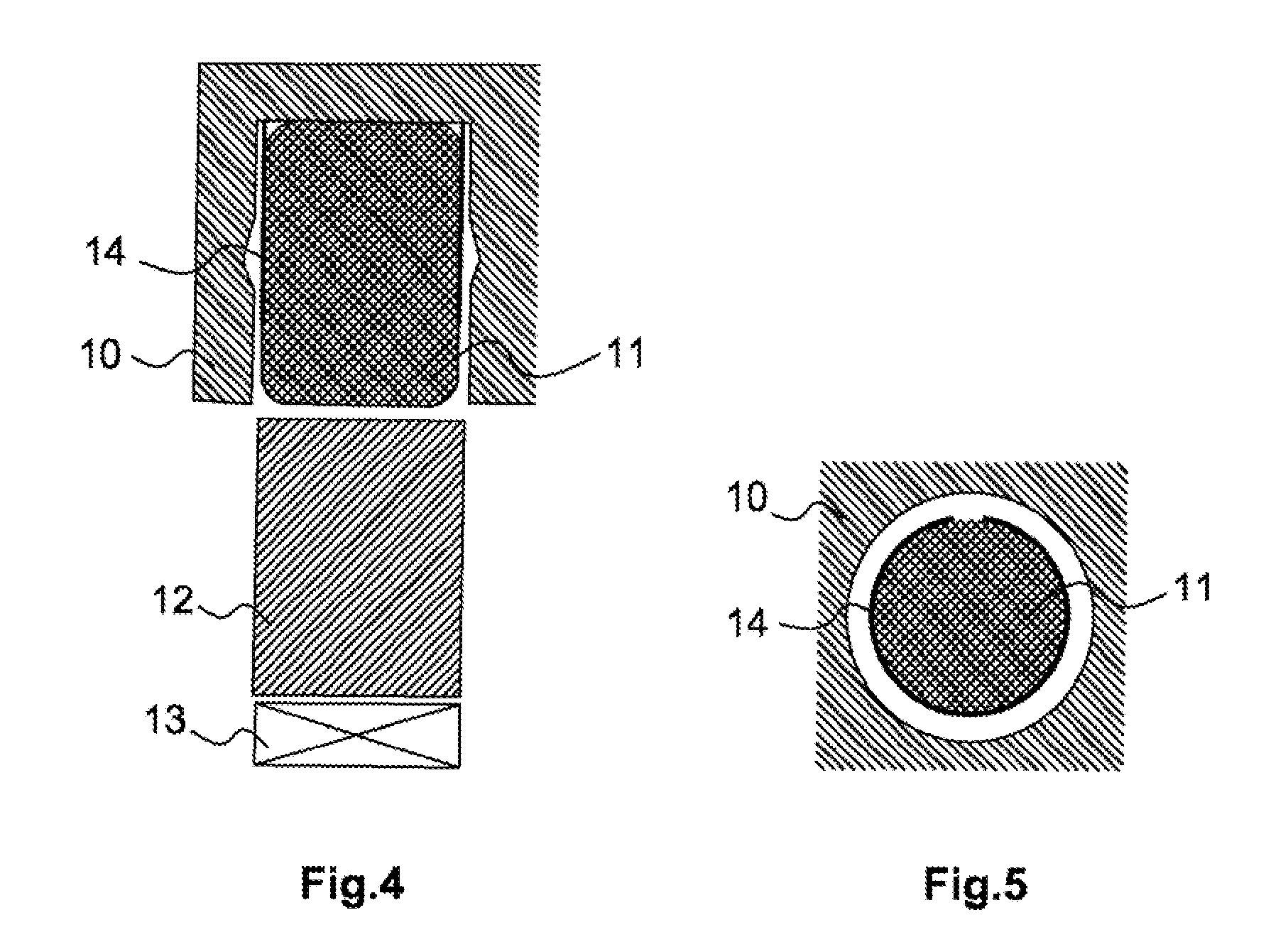

Shock-resistant protective shell of portable appliance

InactiveUS20150108030A1Reduce the cushioning forceImprove protectionCasings/cabinets/drawers detailsOther accessoriesEmbedded systemCapacitor

A shock-resistant protective shell for a portable electric appliance includes a protective shell additionally arranged on a surface of a portable electric appliance and matching the shape of the portable electric appliance, with a buffer body protruding towards an exterior of the protective shell arranged at the corner of the protective shell. A primary buffer axis of the buffer body points to the centroid of the portable electric appliance, or the projection of the primary buffer axis in the principal plane of the electric appliance extends along the angular bisector between two adjacent sides. The buffer body is arranged with a secondary buffer axis arranged perpendicular to the primary buffer axis or perpendicular to the principal plane of the portable electric appliance. The thickness of the buffer body is at least 3 times of the average thickness of the rest parts in the protective shell except for the buffer body.

Owner:QINGDAO CREATE ENVIRONMENT CONTROL TECH +1

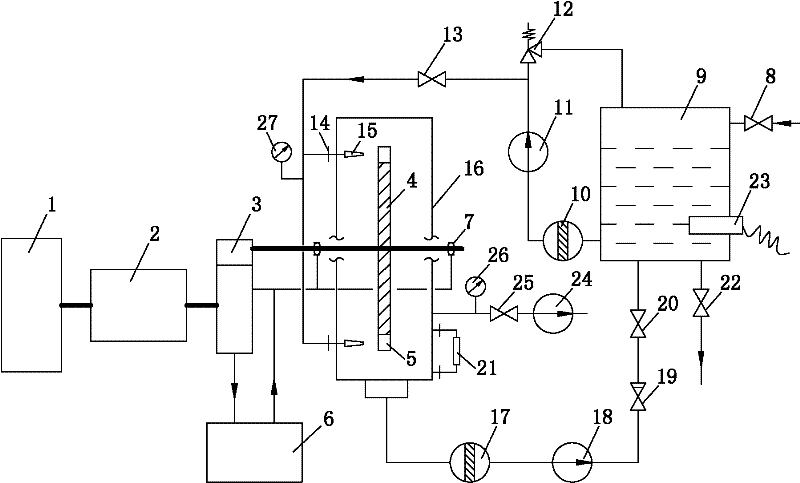

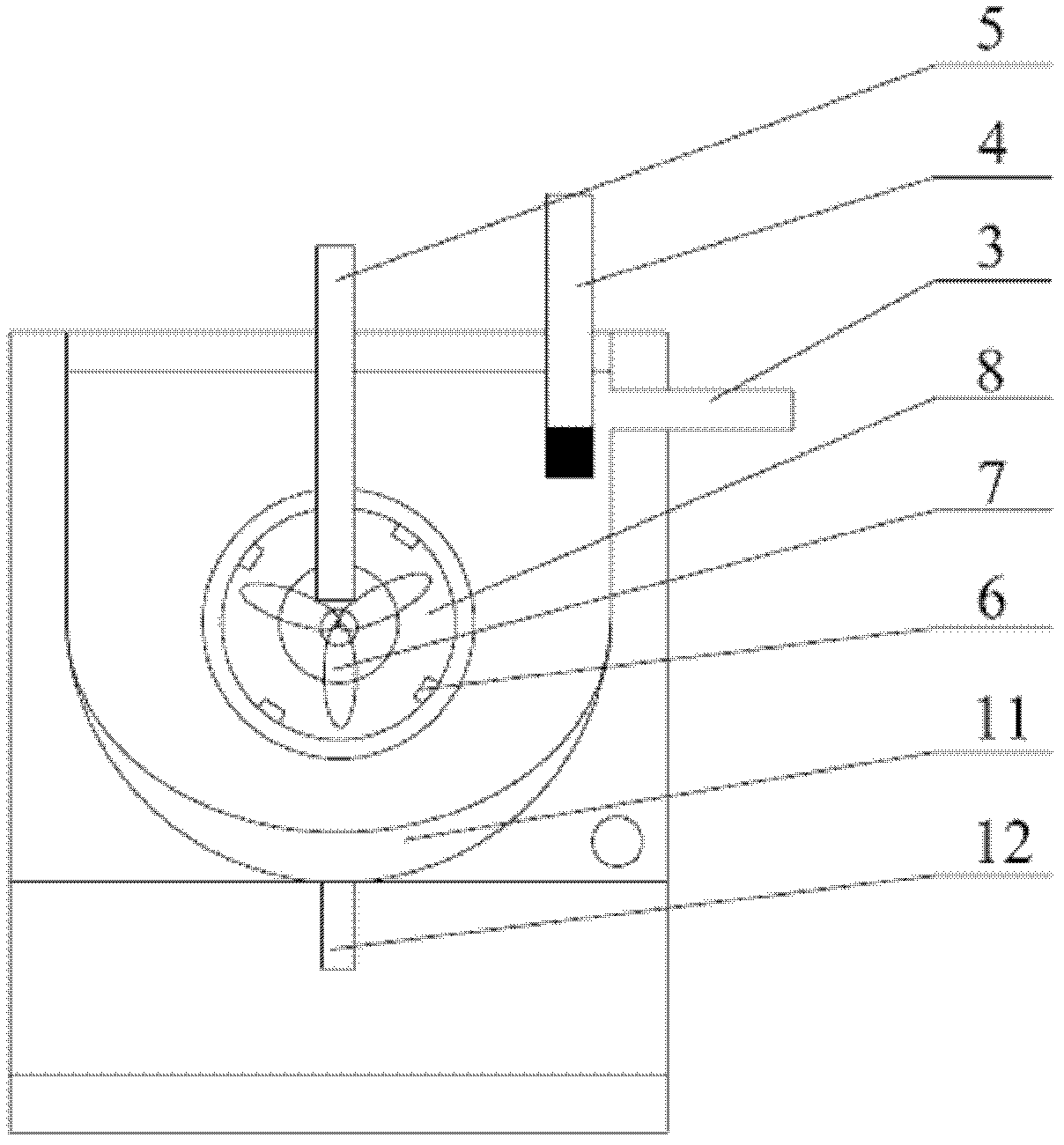

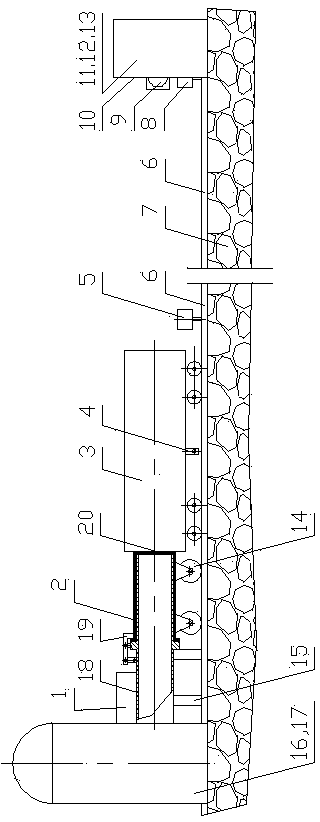

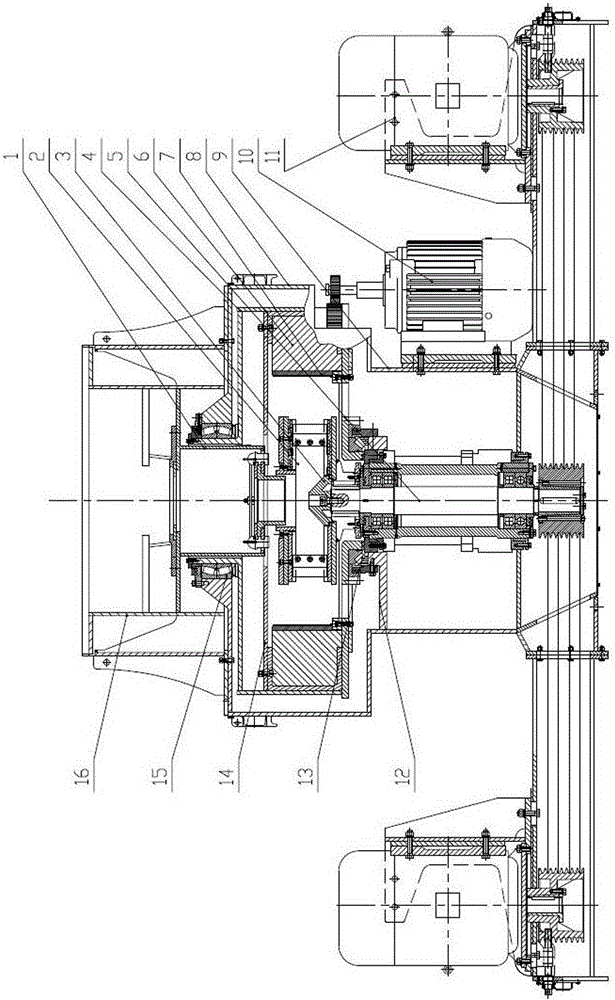

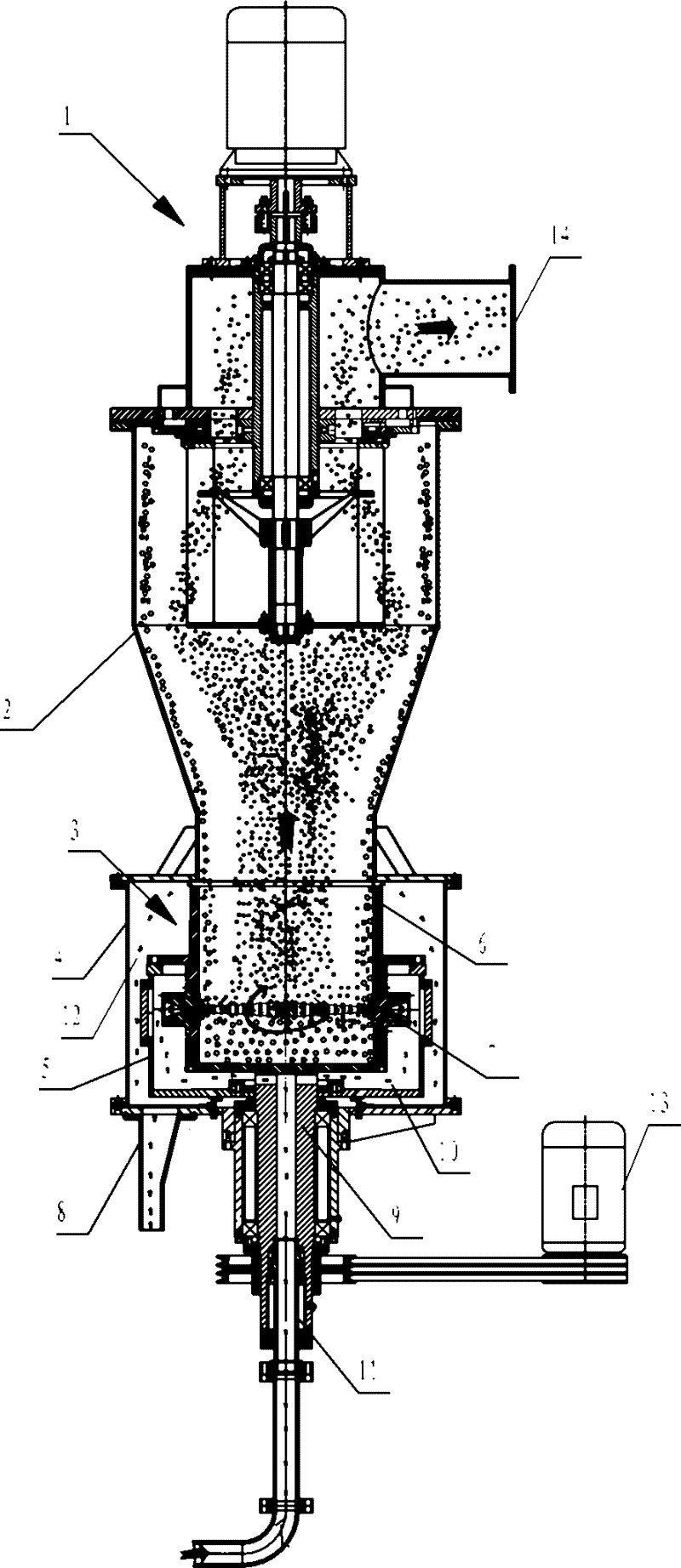

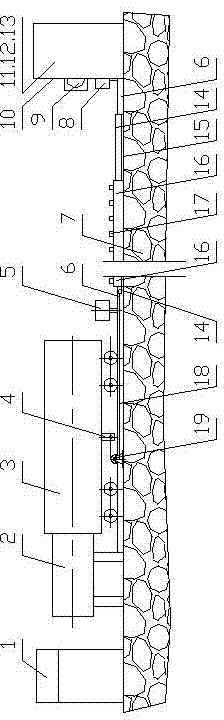

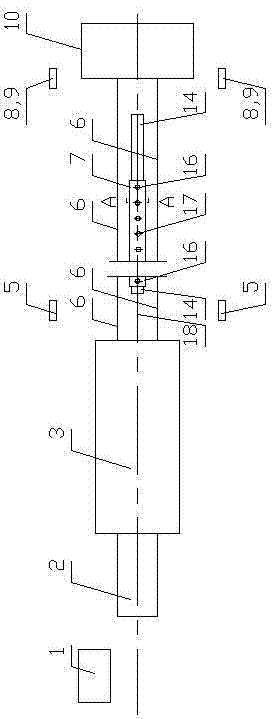

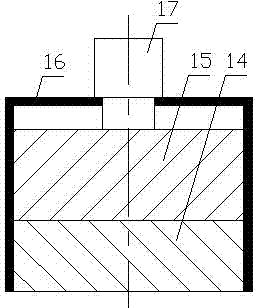

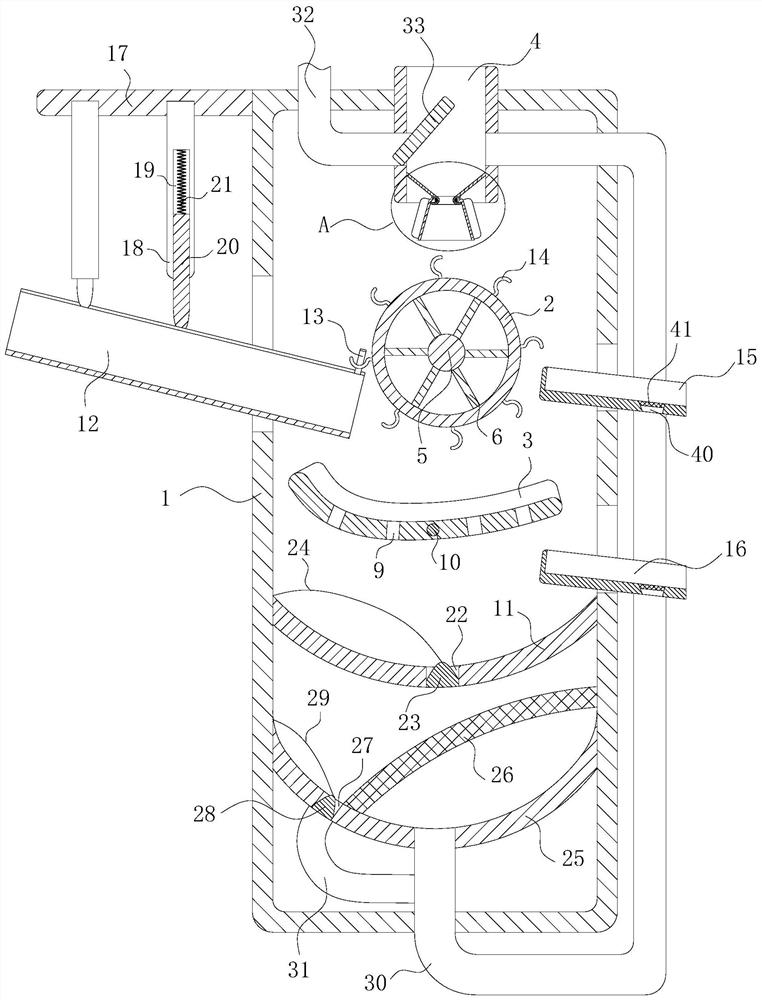

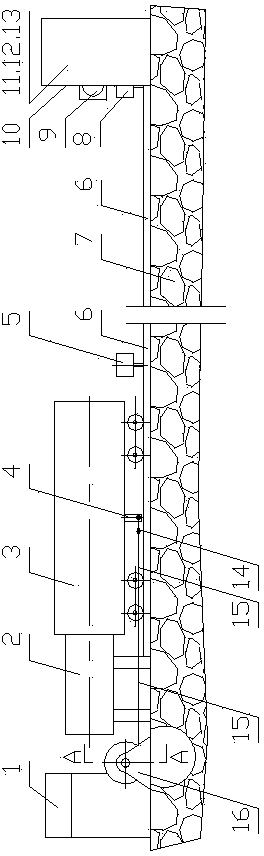

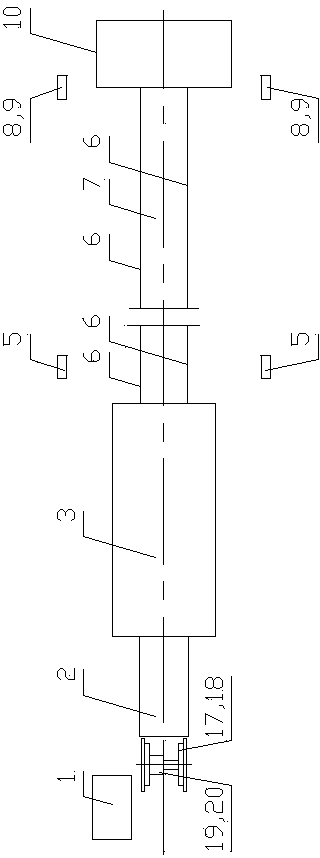

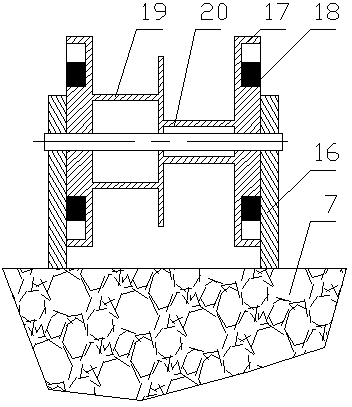

Water erosion experimental facility with/under rotary impact of high-pressure water jet

ActiveCN102252927AIncrease impact speedEasy to controlInvestigating abrasion/wear resistanceElectric machineSteam turbine blade

The invention relates to a water erosion experimental facility with the rotary impact of high-pressure water jet. The facility simulates the blade erosion caused by drops in a steam turbine through the collision between high-speed jet and a rotating test piece. The facility mainly comprises a motor and a motor control cabinet, a gear case, a rotor and a test piece, a high-pressure water pump and nozzle pipelines, etc. While the rotor and the test piece rotate at a high speed, the high-pressure water supplied by the high-pressure water pump can generate high-speed jet through the nozzle. And the jet hits the test piece at a speed of the vector difference between the jet and the test piece, so that hitting speed is greatly improved. Thus, the evaluation of the water erosion resistance of the steam turbine blade material within a short period on an experiment table becomes possible.

Owner:XI AN JIAOTONG UNIV

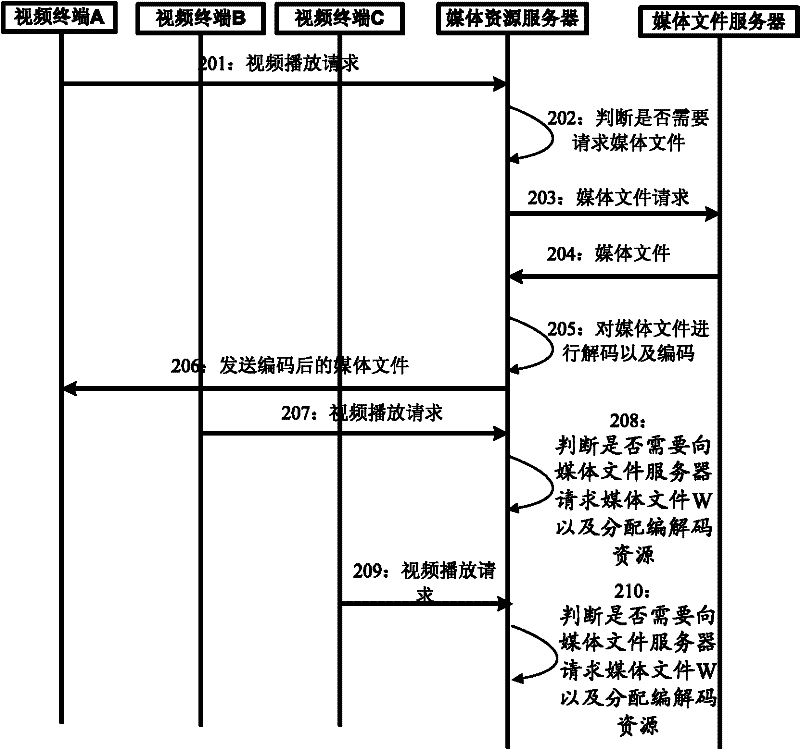

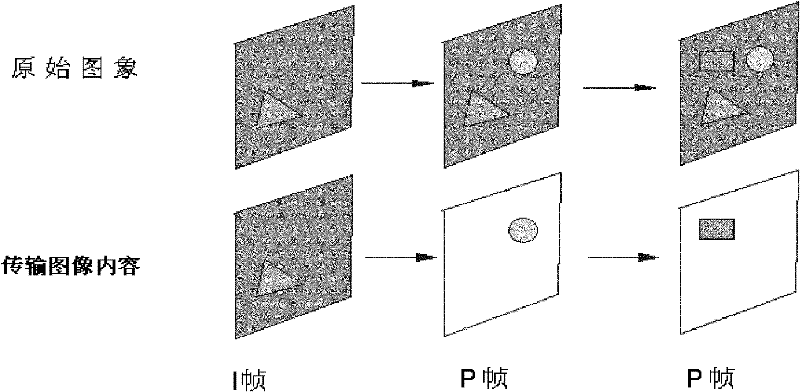

Video file playing method and system and media resource server

ActiveCN102131090AIncrease impact speedImprove utilization efficiencyTelevision systemsTransmissionComputer graphics (images)Computer terminal

The embodiment of the invention provides a video file playing method, device and system. The method comprises the following steps of: receiving a video playing request sent by a video terminal, wherein the video playing request carries a video file identifier and video media ability information of the video terminal; determining that a decoding resource exists to decode a video file corresponding to the video file identifier according to the video file identifier, and decoding the video file corresponding to the video file identifier into a video file in an internal format by using the decoding resource; according to the video media ability information of the video terminal, if a first coding resource is determined to exist to obtain a video file conforming to the video media ability of the video terminal through coding, coding the video file in the internal format into the video file conforming to the video media ability of the video terminal by using the first coding resource, and if the first coding resource is determined to not exist, distributing a second coding resource to code the video file in the internal format into the video file conforming to the video media ability of the video terminal; and sending the coded video file conforming to the video media ability of the video terminal to the video terminal.

Owner:HUAWEI CLOUD COMPUTING TECH CO LTD

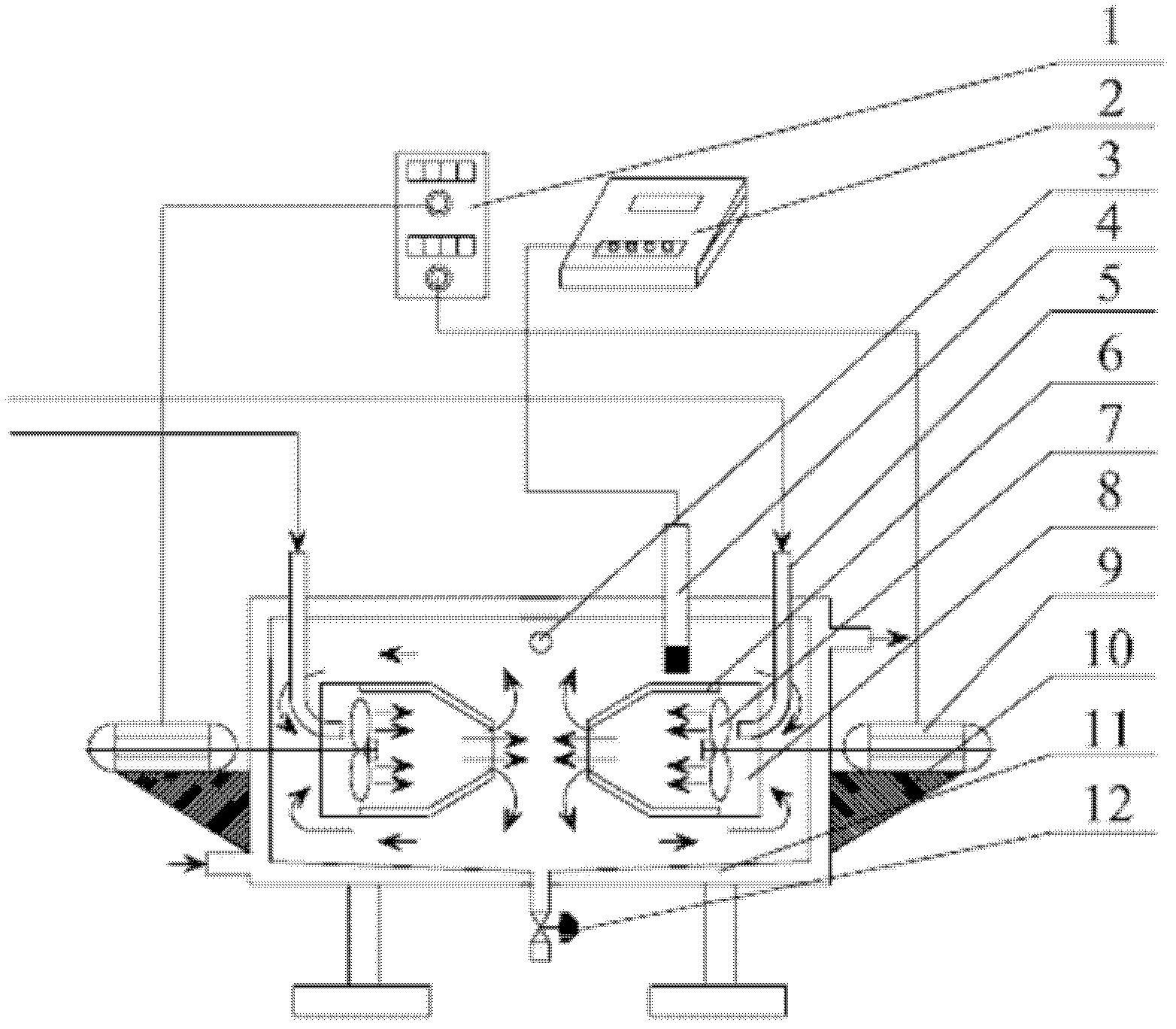

Liquid phase impinging stream reactor with controllable acidity

ActiveCN103203213AIncrease impact speedSuppress swirlChemical/physical/physico-chemical stationary reactorsChemical reactionEngineering

The invention discloses a liquid phase impinging stream reactor with controllable acidity, belonging to the field of chemical reaction technical equipment. In the reactor, 1-6 pairs of draft tubes with changeable diameters are horizontally arranged coaxially and oppositely; raw materials are introduced by feeding tubes with curved nozzles; fluid is accelerated by push-type three-blade stirrers at the entrance of the draft tubes; the rotation speed of the push-type three-blade stirrers is controlled by a controller; rotational flow is inhibited by deflection baffles; the inner diameters of the draft tubes become smaller gradually; cross-section area of a flow channel is decreased; flow speed is increased; the flow speed at the exits of the draft tubes is the maximum; two fluids impinge face to face at a high speed in the container and mixed efficiently and rapidly; the fluids flow to the entrance of the draft tubes from central impinging areas through the outer sides of the draft tubes, thus realizing circulation; motors are fixed and anti-vibrated by triangle support plates, the acidity of a reaction system is on-site monitored by a pH meter probe and displayed in real time by a pH meter display; constant acidity of the reaction system is realized by adjusting liquid inlet flow quantity; and materials in the contained are discharged from a material-discharging port after the reaction is finished. The liquid phase impinging stream reactor can be heated or cooled, and can be operated continuously, intermittently or semi-continuously.

Owner:TSINGHUA UNIV

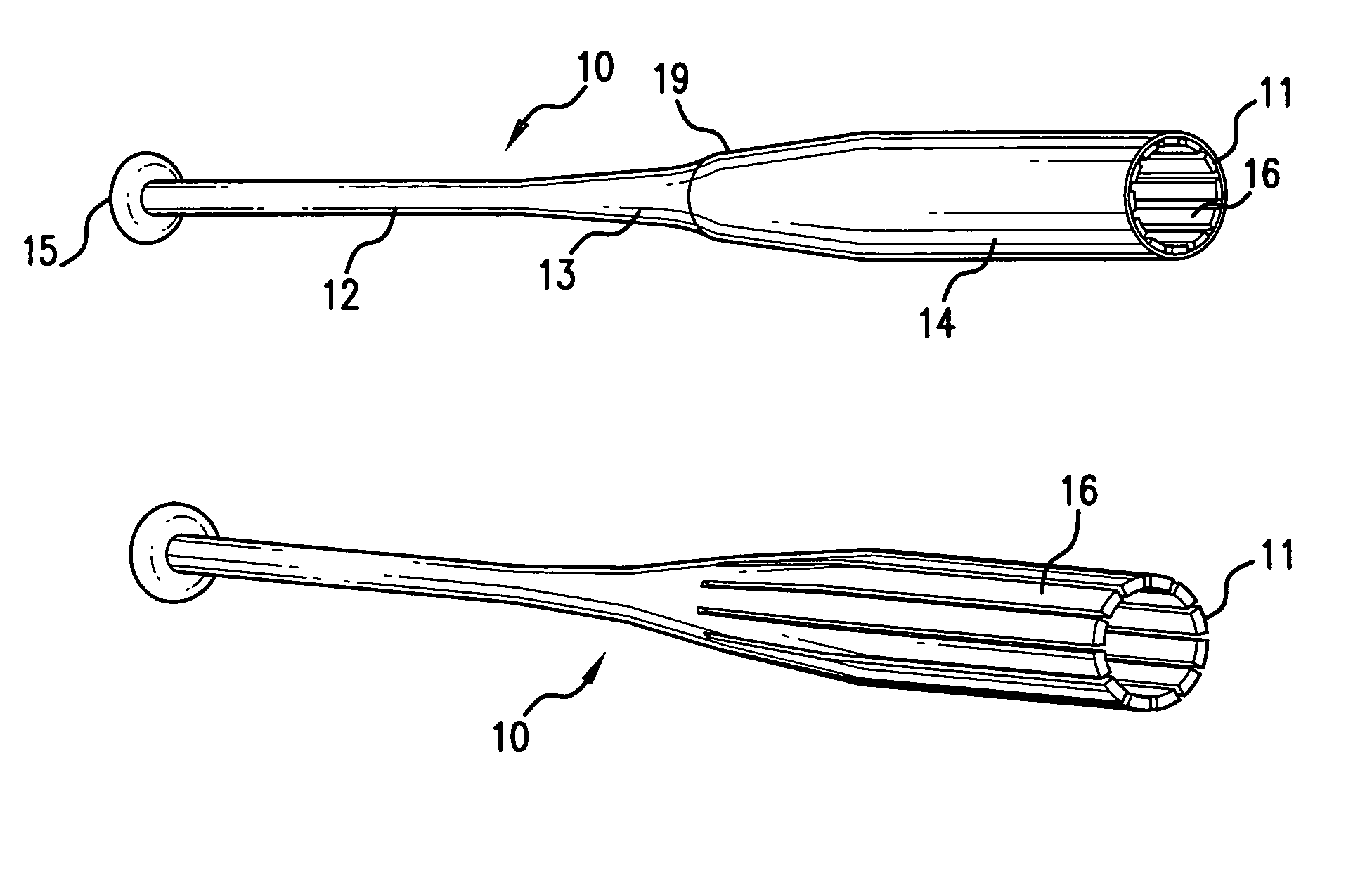

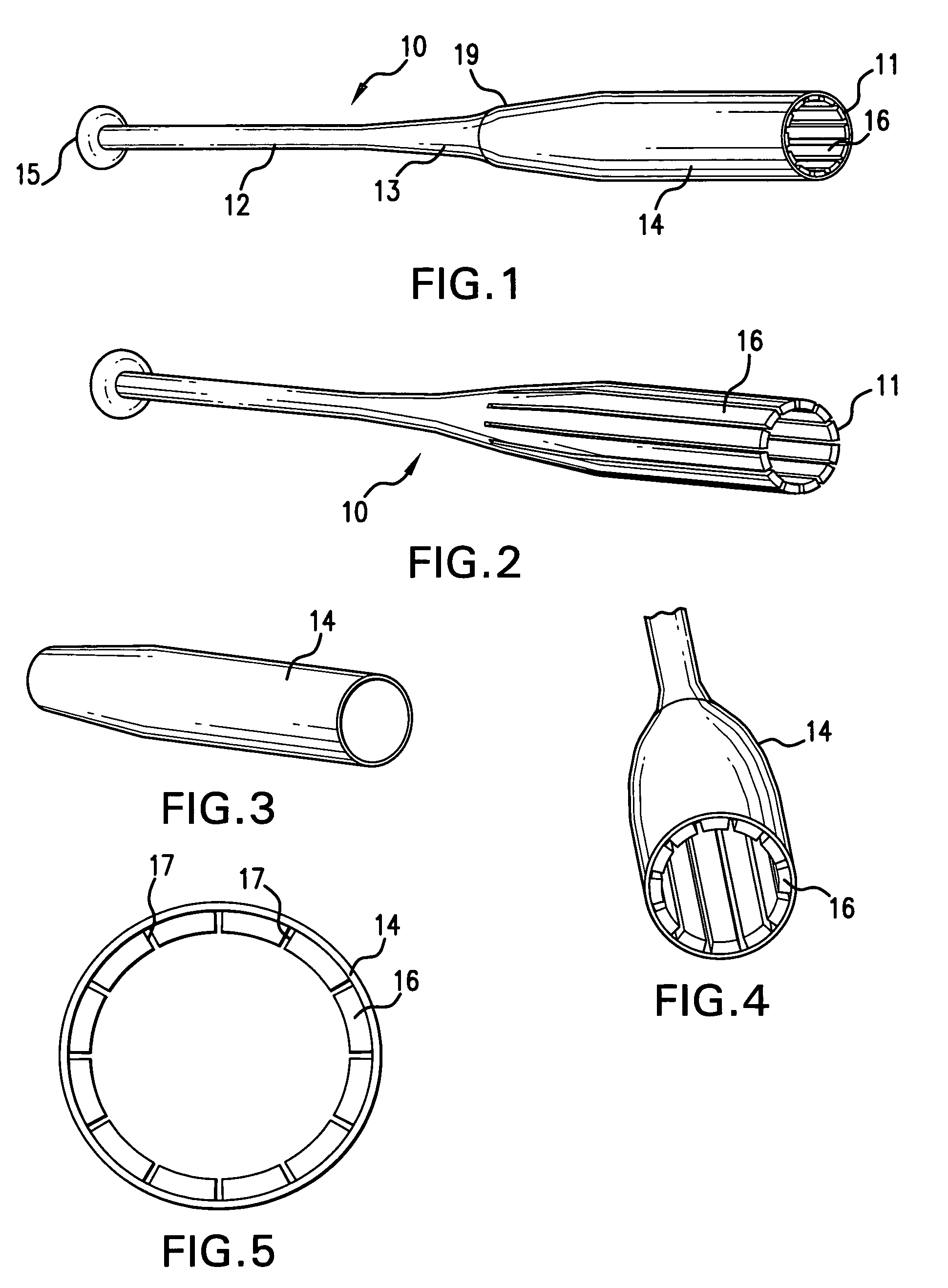

Baseball bat with multiple reinforcing beams

InactiveUS7874946B2Limiting maximum barrel responseMinimizing dampeningMetal working apparatusStringed racketsFiberMechanical engineering

A bat for limiting the maximum barrel response at high impact speeds while minimizing the dampening performance at low impact speeds includes a plurality of separate longitudinal beams extending from the end of the bat to the tapered portion of the bat. These beams, as well as the tapered portion and a handle, are constructed from a composite material, such as fiber reinforced plastic. An external sleeve is then provided around the barrel portion of the bat. The external sleeve is secured around the barrel of the bat using a snap-fit end cap.

Owner:MATTINGLY SPORTS

Elevator installation

InactiveUS20130118837A1Travel path can be limitedReduce impact speedElevatorsBuilding liftsArresting gearAutomotive engineering

An elevator installation is provided. The installation includes a shaft in which at least two cars are arranged above one another and are movable vertically separately. Each car has a drive device and a brake device. A safety device is provided for monitoring the cars. At least one travel path limiting device is provided, comprising at least one stop element arranged on at least a first car and an associated retaining element arranged in the shaft. In a stop position, the stop element protrudes laterally from the car and interacts with the associated retaining element. All other cars movable in the shaft may pass this retaining element unobstructed. The brake device or its braking action is deactivatable if the car falls below a limit speed, and the stop and retaining elements may brake the car to a standstill at speeds up to at most the limit speed.

Owner:THYSSENKRUPP ELEVATOR AG (DE)

Railway vehicle real vehicle bump test system for coupling passenger behavior detection

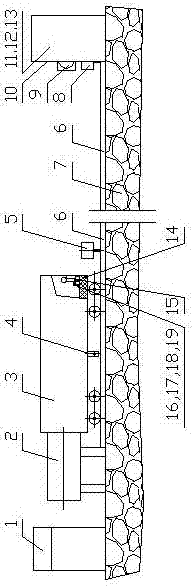

ActiveCN103940624AScientific and reasonable structureEasy to operateRailway vehicle testingShock testingAutomotive engineeringControl table

A railway vehicle real vehicle bump test system for coupling passenger behavior detection comprises a central control table, an emitter, a real vehicle and a bump wall. The real vehicle is arranged on a steel rail between the emitter and the bump wall. A bump speed measuring device and a high speed photography device are installed on the side of the bump wall. Experiment dummies are arranged at two ends and in the middle of a passenger area in a carriage of the real vehicle, the experiment dummies are arranged on seats in a non-restricting sitting posture, and a pressure sensor, a displacement sensor and an acceleration sensor are arranged on a body of each experiment dummy. A brake device, a speed adjusting brake device connector and a debugging speed measuring device are used under the debugging condition. In the bump test process, the brake device deviates from the speed adjusting brake device, and a central control table program controls a relevant device to receive and store data. The power-free free sliding distance of the real vehicle is at least 1.1 times as long as the effective journey of the emitter, and the test bump speed of the real vehicle and the bump wall is not lower than 25kilos per hour. Meanwhile, the coupling passenger behavior detection is conducted.

Owner:CENT SOUTH UNIV

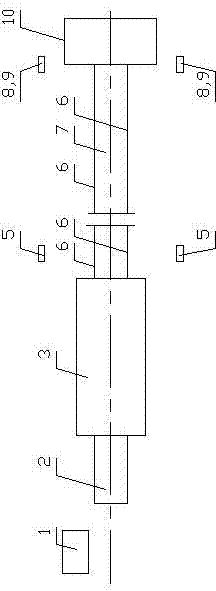

Real vehicle impact test system for pneumatic emission type railway vehicle

ActiveCN103954420AScientific and reasonable structureEasy to operateRailway vehicle testingShock testingAir compressorProcedural approach

The invention relates to a real vehicle impact test system for a pneumatic emission type railway vehicle. The test system comprises a central control desk, an emitter, a real vehicle and an impact wall, wherein the real vehicle is put on a railway between the emitter and the impact wall; the emitter is a pneumatic emitting device and comprises a walking trolley, a support, an air storage tank, an air compressor, a hollow piston, a triggering mechanism and a cylinder sleeve, the hollow piston is installed on the support, the cylinder sleeve is installed on the walking trolley, and the triggering mechanism is arranged between the hollow piston and the cylinder sleeve; an impact speed measuring device and a high-speed photography device are installed on the side face of the impact wall. In the impact test process, the central control desk controls the emitter, the impact speed measuring device, the high-speed photography device and a force measurement and collection device of the impact wall to work through programs, and receives and stores related data; the unpowered free sliding distance of the real vehicle is at least 1.1 times the effective travel of the emitter, the test impact speed of the real vehicle and the impact wall is not smaller than 25 km / h, and after the experiment, analytical calculation is performed to output an experiment result.

Owner:CENT SOUTH UNIV

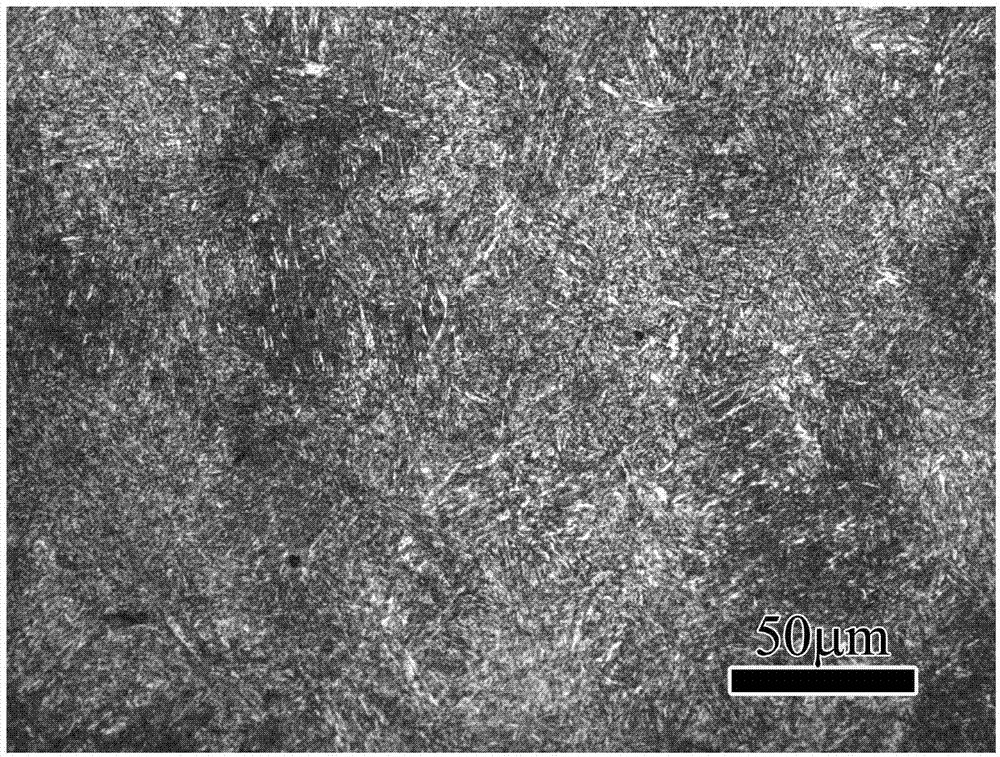

Components of high-toughness ultrahigh-strength steel and preparation process of high-toughness ultrahigh-strength steel

The invention relates to components of high-toughness ultrahigh-strength steel and a preparation process of the high-toughness ultrahigh-strength steel, and belongs to the technical field of alloy steel. The high-toughness ultrahigh-strength steel comprises the components in percentage by mass: 0.25-0.45 percent of C, 0.4-1.2 percent of Si, 0.3-1.5 percent of Mn, 2.0-3.5 percent of Cr, 2.5-4.0 percent of Ni, 2.0-4.5 percent of W, 0.4-0.8 percent of Mo, 0.1-0.4 percent of V, less than or equal to 0.005 percent of P, less than or equal to 0.003 percent of S, less than or equal to 0.002 percent of O, less than or equal to 0.0015 percent of N, less than or equal to 0.05 percent of Cu, and the balance of Fe. A preparation process of the high-toughness ultrahigh-strength steel comprises a smelting process, a forging process and a heat treatment process. According to the high-toughness ultrahigh-strength steel, the use cost is greatly reduced, the mechanical property meets the national standard requirement and the steel has an important popularization and application value.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

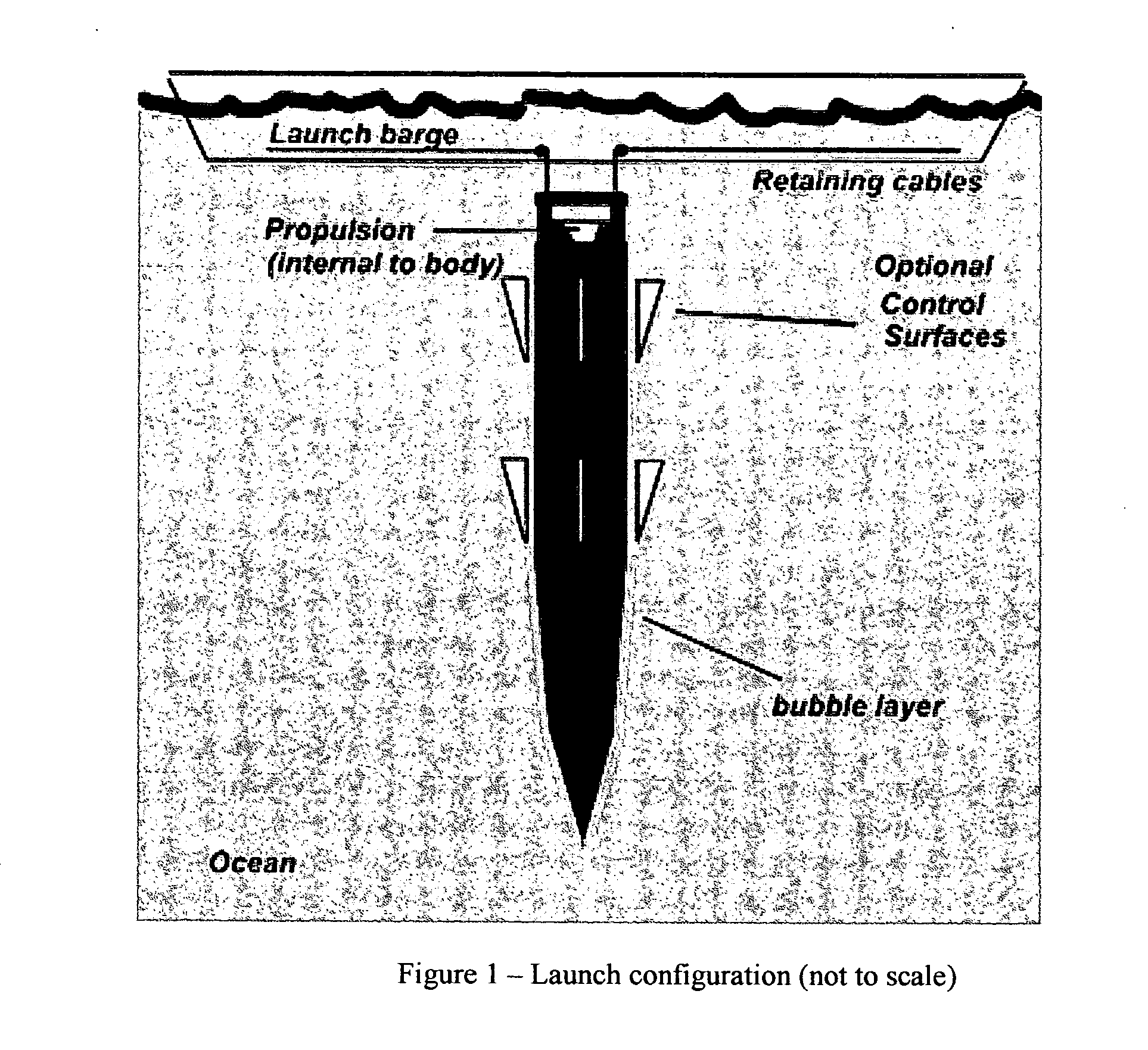

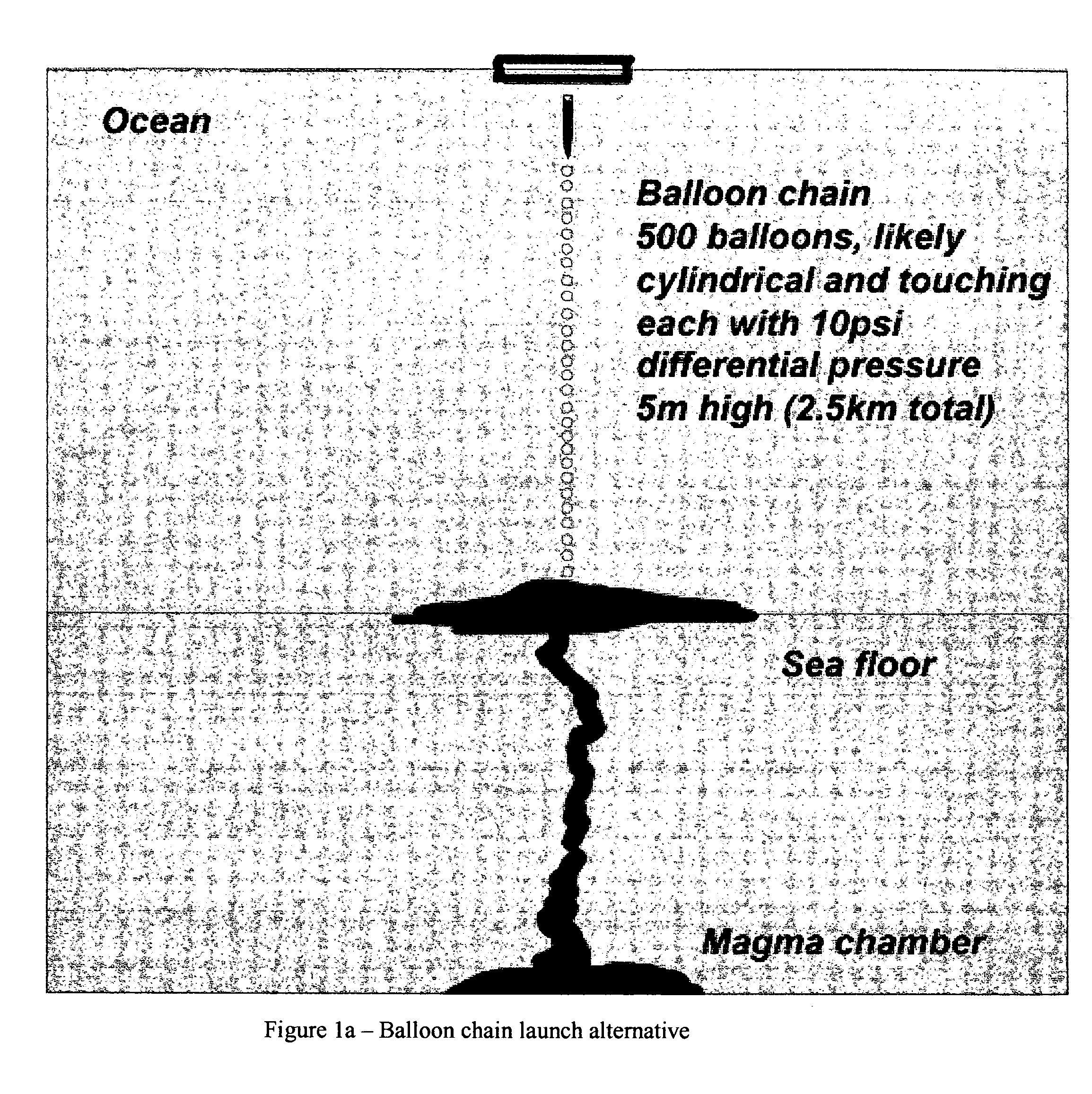

Apparatus for disposal of toxic and radioactive waste

Owner:RODE CHRISTIAN STIG

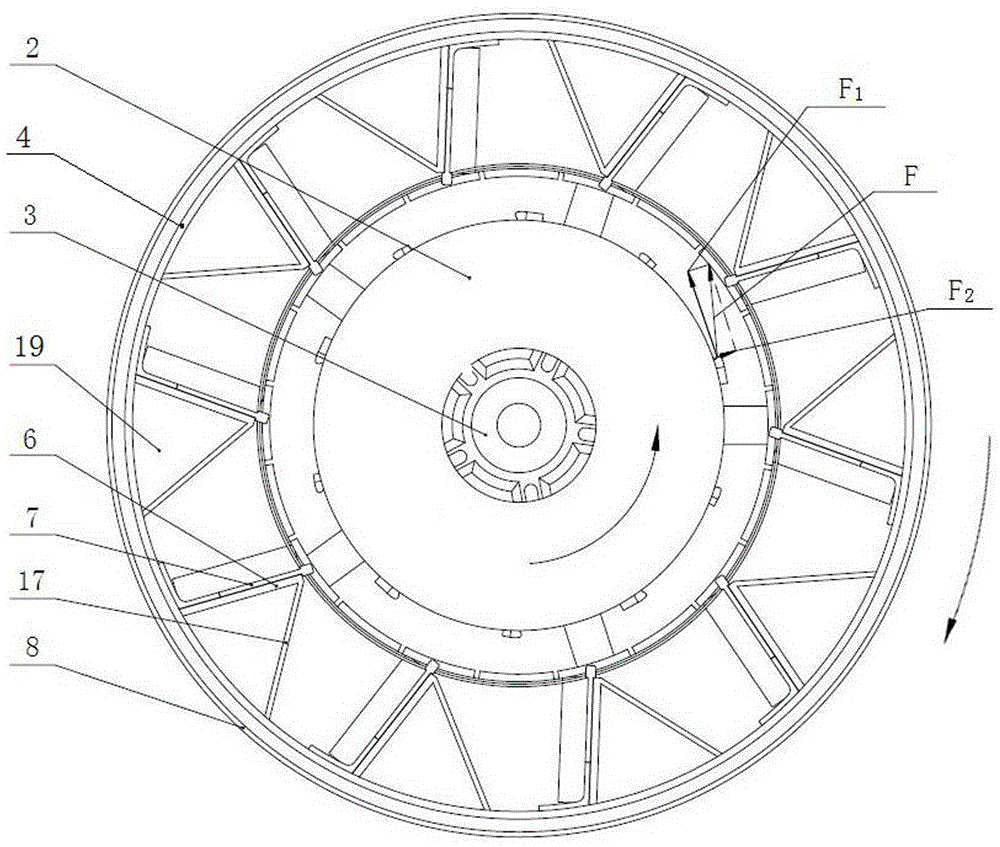

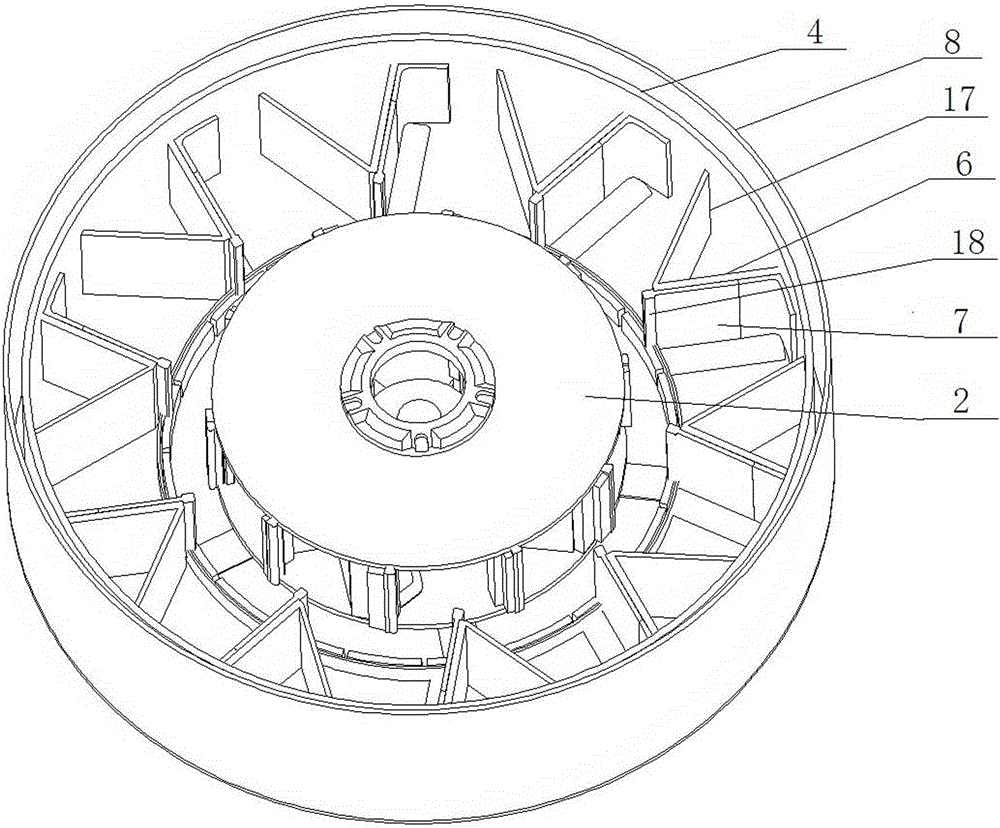

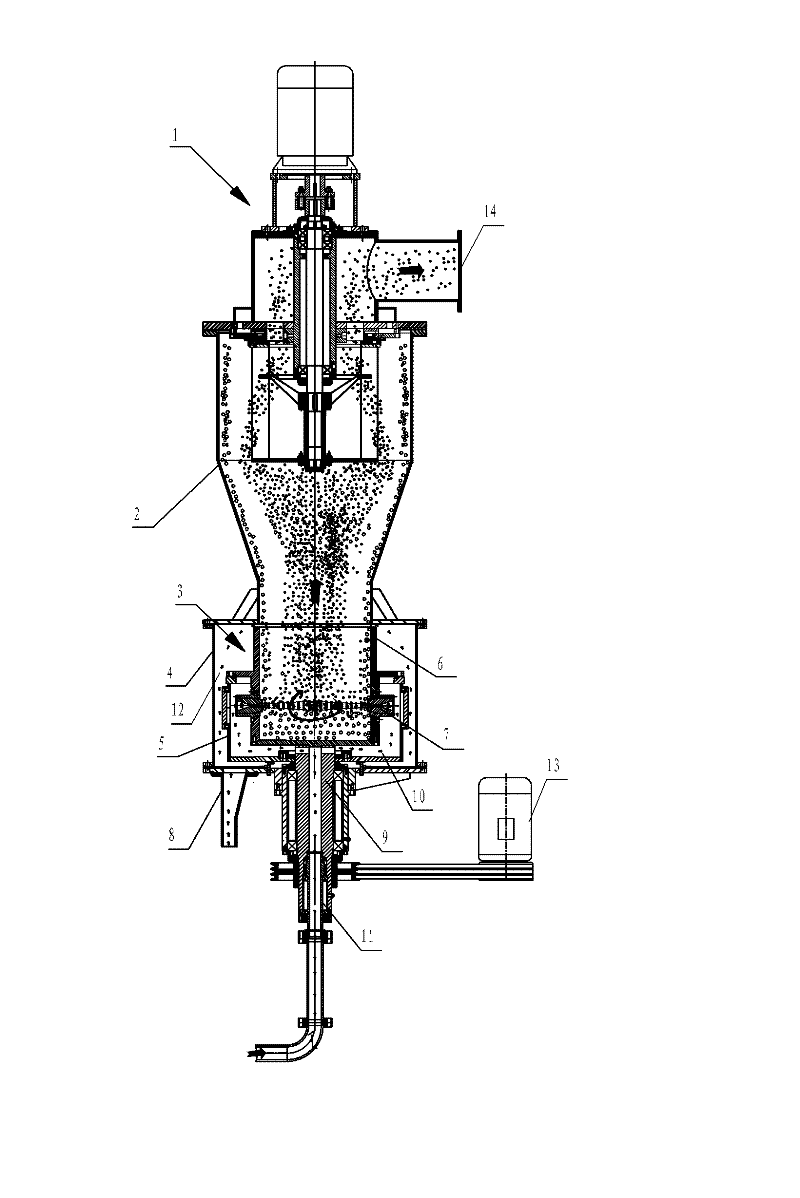

Vertical impact crusher

The invention relates to a crusher, in particular to a vertical impact crusher which comprises a crushing cavity shell, a rotor arranged in the crushing cavity shell and a feeding device used for feeding for the rotor. A crushing cavity is formed by the space between the rotor and the crushing cavity shell. Materials entering the rotor are thrown out from multiple distributing openings formed in the circumferential side wall of the rotor and fly to the crushing cavity shell to be subjected to impact crushing. The crushing cavity shell is rotary, and the rotating direction of the crushing cavity shell is opposite to the rotating direction of the rotor. A plurality of impact plates are arranged in the crushing cavity, rotate along with the crushing cavity shell and impact with the materials thrown out from the rotor. Plate hammers are arranged on the faces, impacting with the materials, of the impact plates, each plate hammer is composed of a wear-resisting plate and a hammer edge arranged at the end, close to the rotor, of the wear-resisting plate, and parts of the hammer edges protrude relative to the faces, impacting with the materials, of the wear-resisting plates. By means of the vertical impact crusher, the impact force and the impact speed of the materials are increased, and the material crushing effect is further improved.

Owner:CITIC HEAVY INDUSTRIES CO LTD

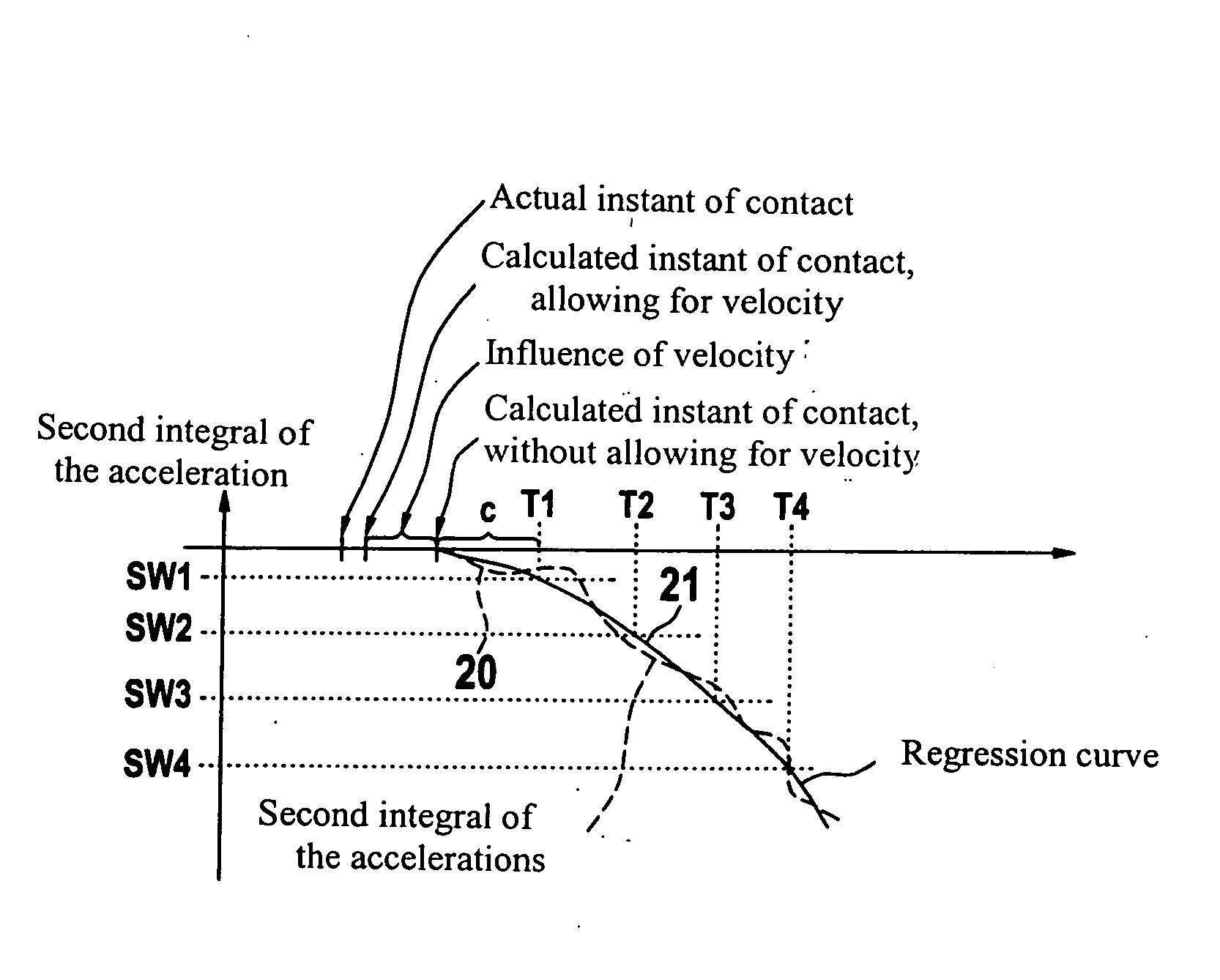

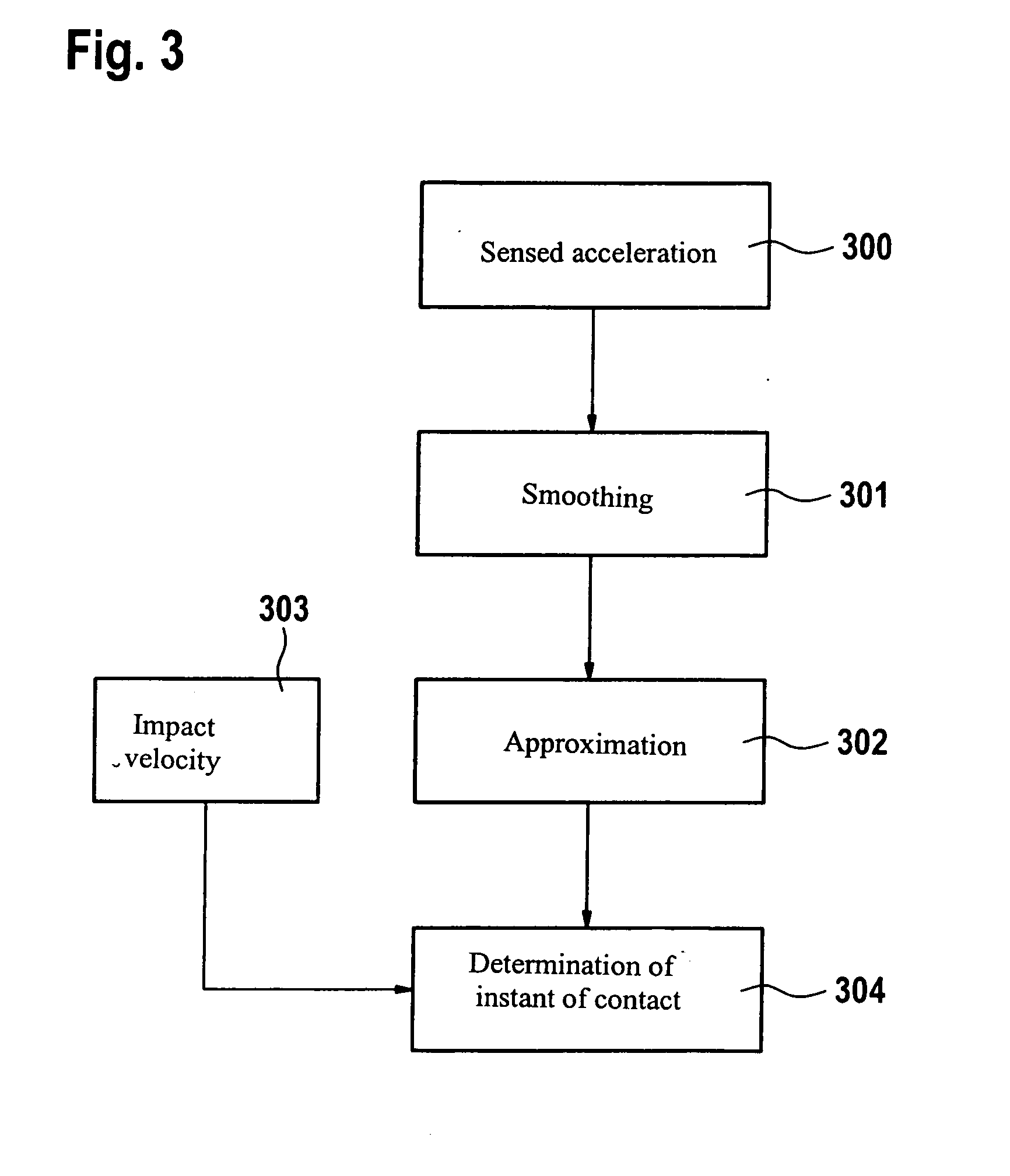

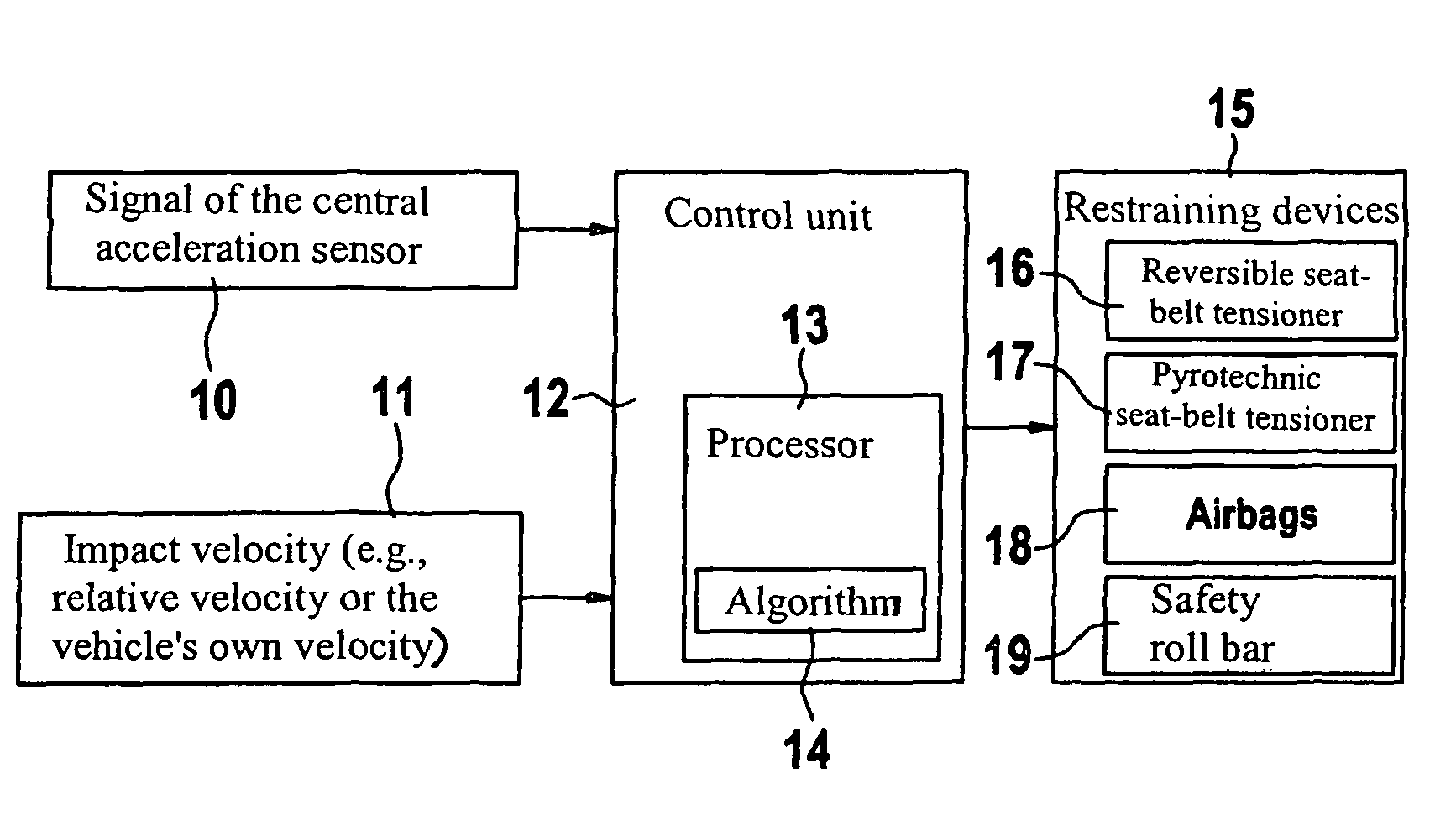

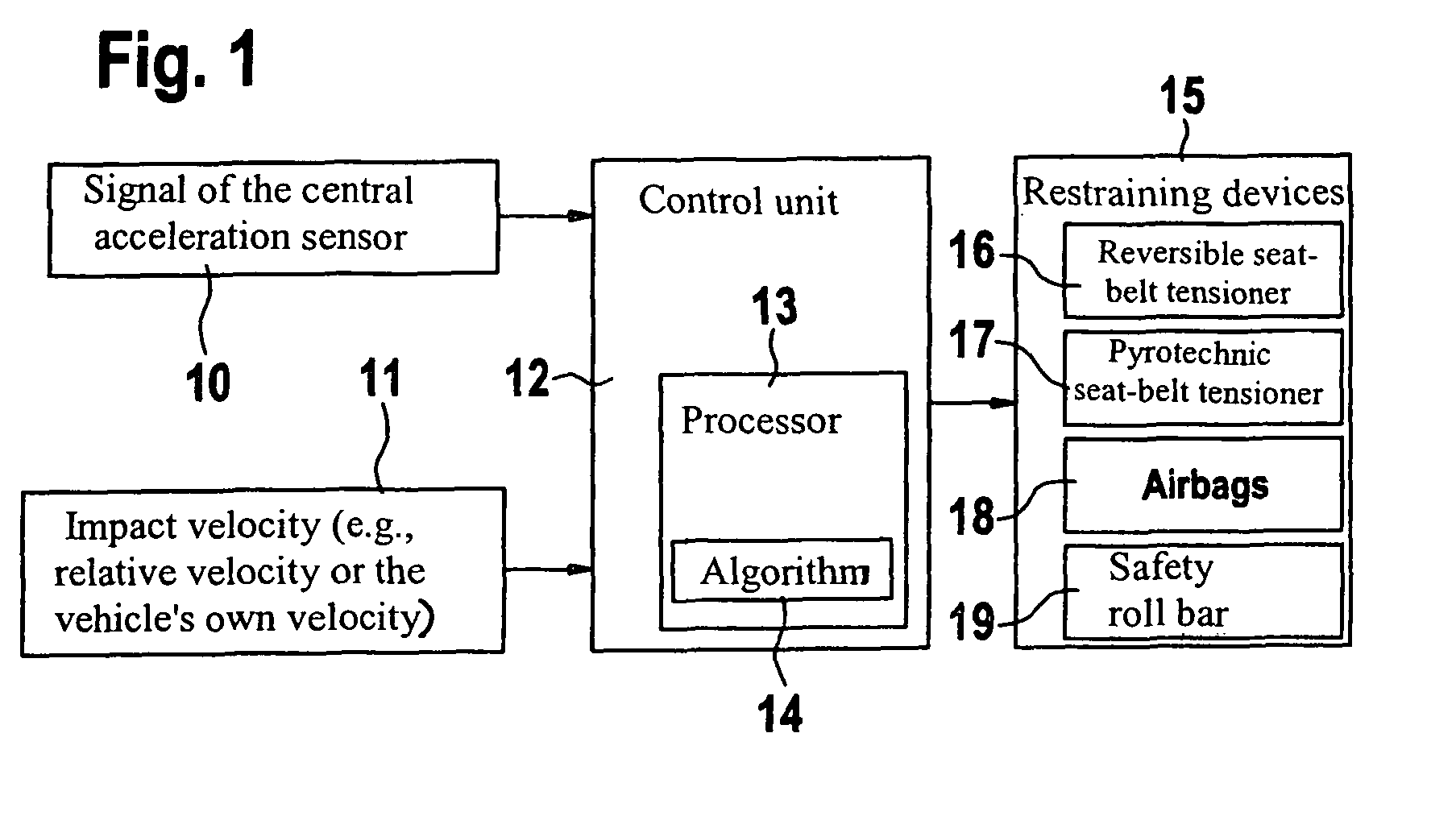

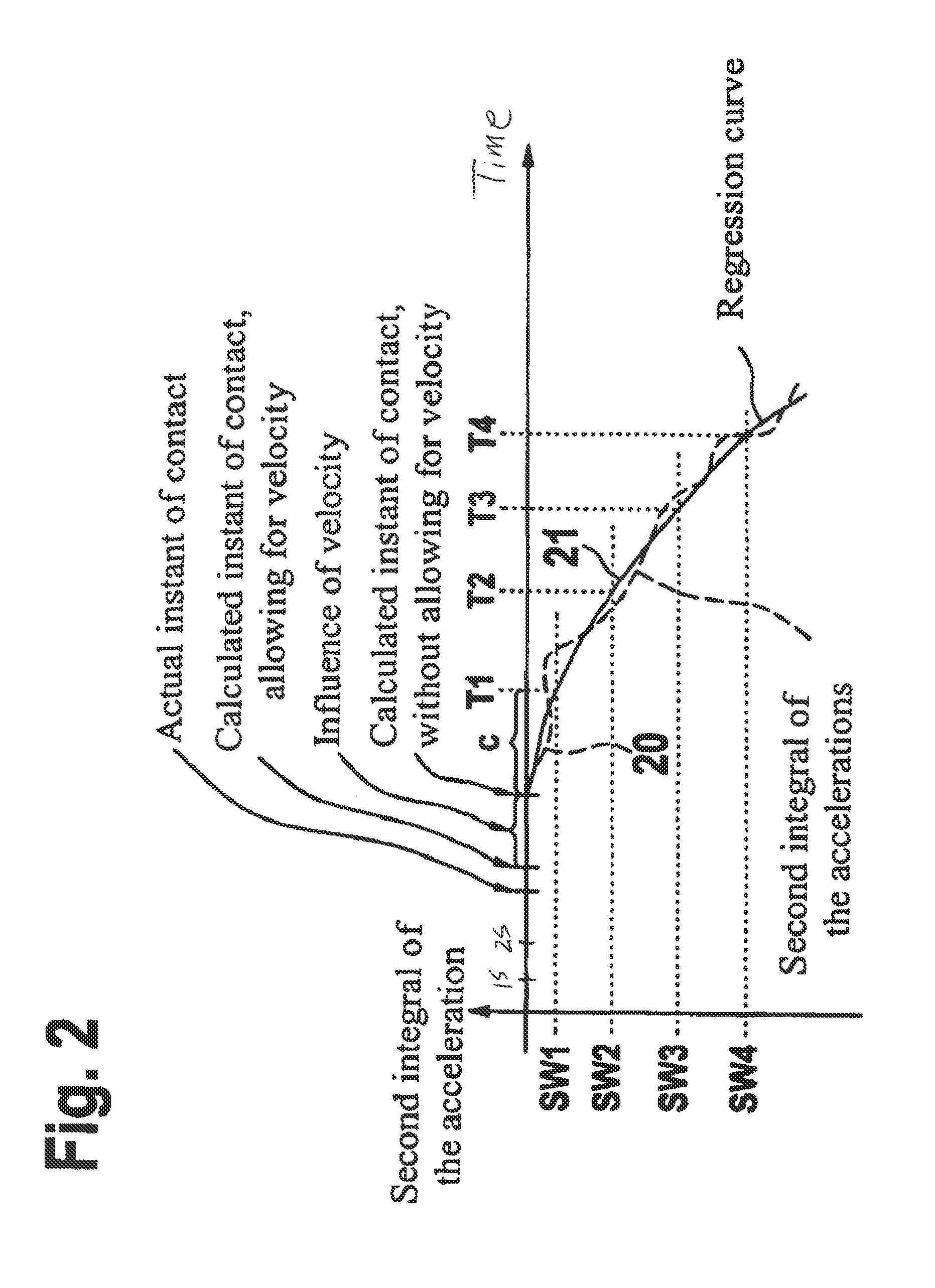

Device for Determining the Instant a Vehicle Makes Contact with an Impact Object

ActiveUS20080204209A1Accurately determineImprove security levelPedestrian/occupant safety arrangementAcceleration measurementEngineeringElectrical and Electronics engineering

Owner:ROBERT BOSCH GMBH

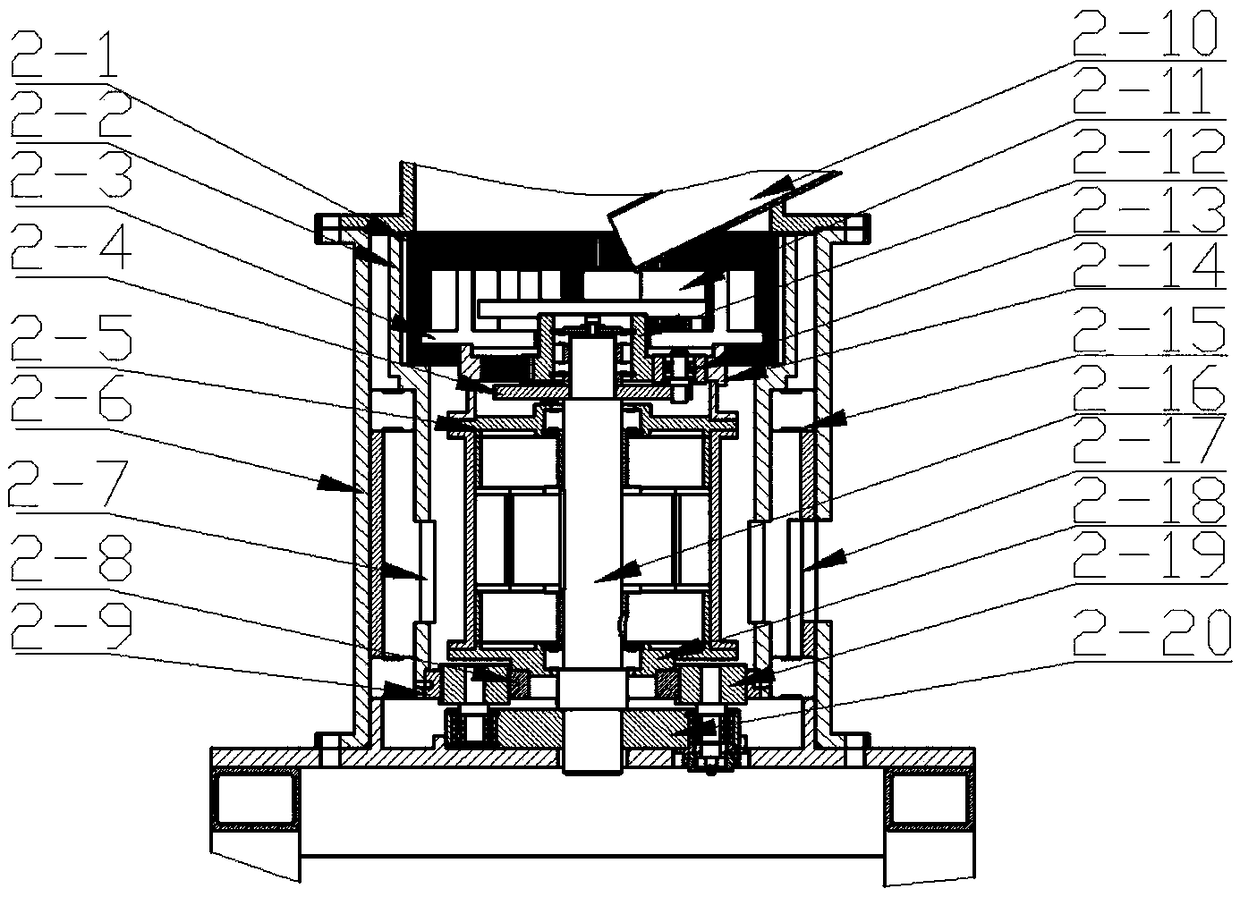

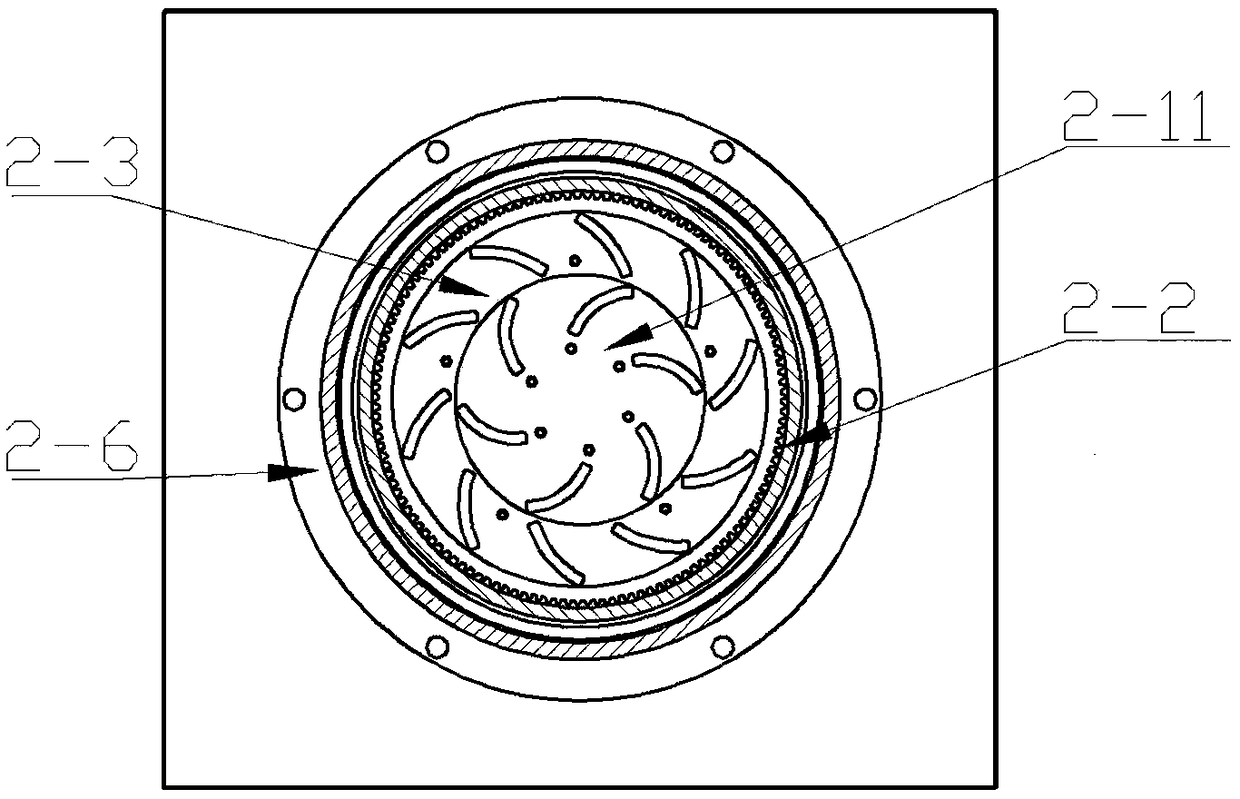

Cyclonic jet mill

The invention discloses a cyclonic jet mill. The jet mill mainly comprises a grader installed on a crushing box; the crushing box is provided with a crushing cavity which is driven by a power unit and is rotatably installed in the crushing box; the crushing cavity comprises an inner column which has a crushing space, an outer column is hermetically installed at the periphery of the inner column, an air flow channel which communicates with a compressed air source is arranged between the inner column and the outer column, an air flow nozzle is provided on the sidewall of the inner column and communicates with the air flow channel and the crushing space. The cyclonic jet mill provided in the invention overcomes the technical problems of formation of a dead space where air flow cannot reach in the crushing space and insufficient crushing of materials, has a reasonable design and is widely applied in ultrafine crushing of raw mineral materials, chemical raw material, heat sensitive substances and the like.

Owner:WEIFANG ZHENGYUAN POWDER ENG EQUIP

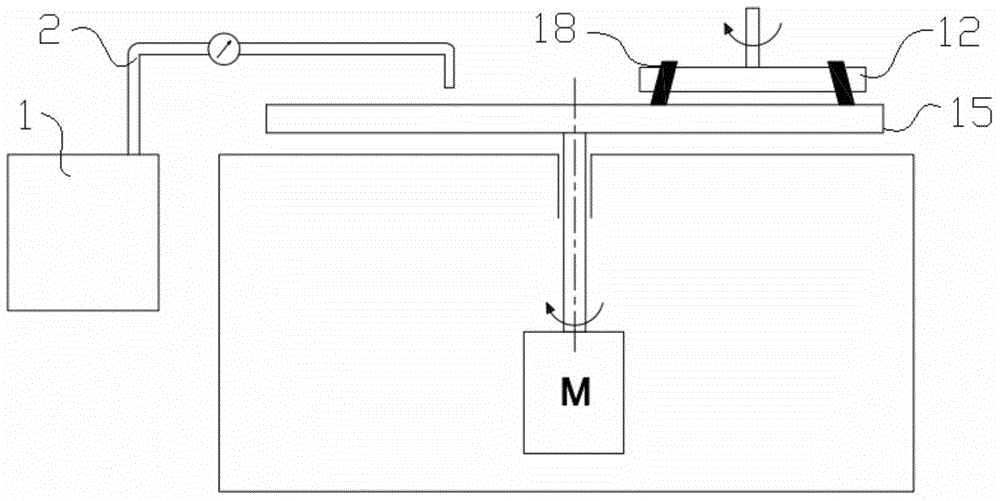

Ultrasonic-vibration-assisted fiber array end face polishing device

The invention discloses an ultrasonic-vibration-assisted fiber array end face polishing device. The device comprises a rotatable polishing cushion and a polishing clamp arranged on the polishing cushion, wherein a workpiece (a fiber array assembly) is clamped on the polishing clamp, a to-be-polished end face of the workpiece is contacted with the polishing cushion under the action of gravity, and a polishing solution is introduced to the polishing cushion; the polishing clamp is arranged on the polishing cushion through a support platform elastically arranged in the vertical direction, the vertical end of the polishing clamp is connected with an ultrasonic transducer through an amplitude-change pole, and the ultrasonic transducer is connected with an ultrasonic generator through a wire. The polishing grinding efficiency of the polishing solution can be improved through chemico-mechanical polishing of an ultrasonic-vibration-assisted fiber array end face, the consumption of the polishing solution is reduced, the production cost is saved, and influences of the polishing solution on the environment are reduced; meanwhile, the polishing effect can be effectively improved, and the device can be widely used in actual production.

Owner:CENT SOUTH UNIV

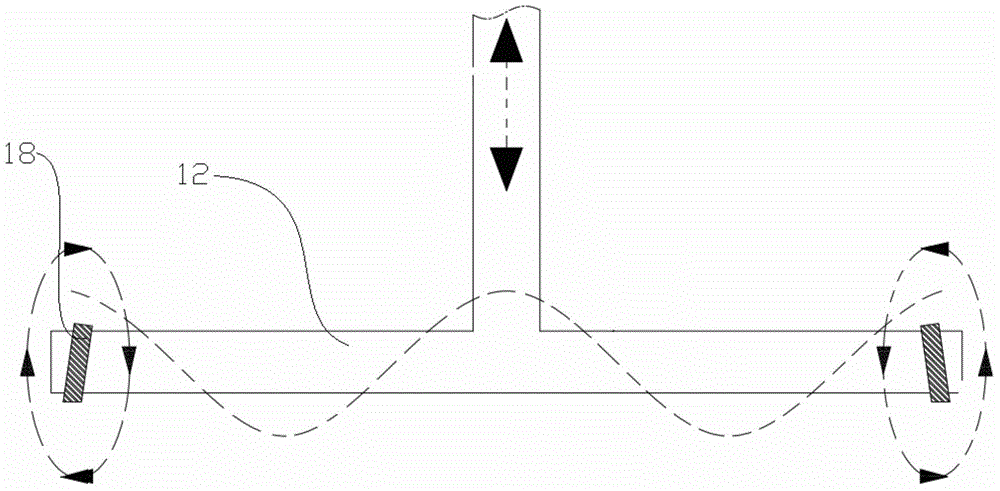

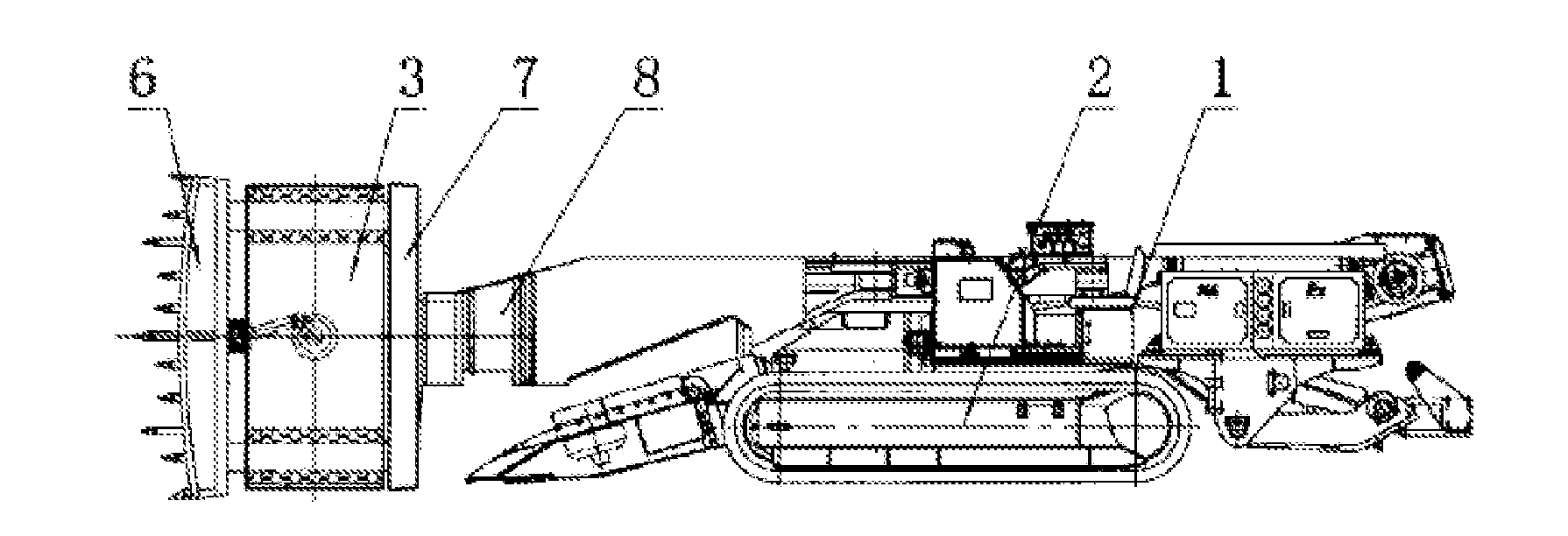

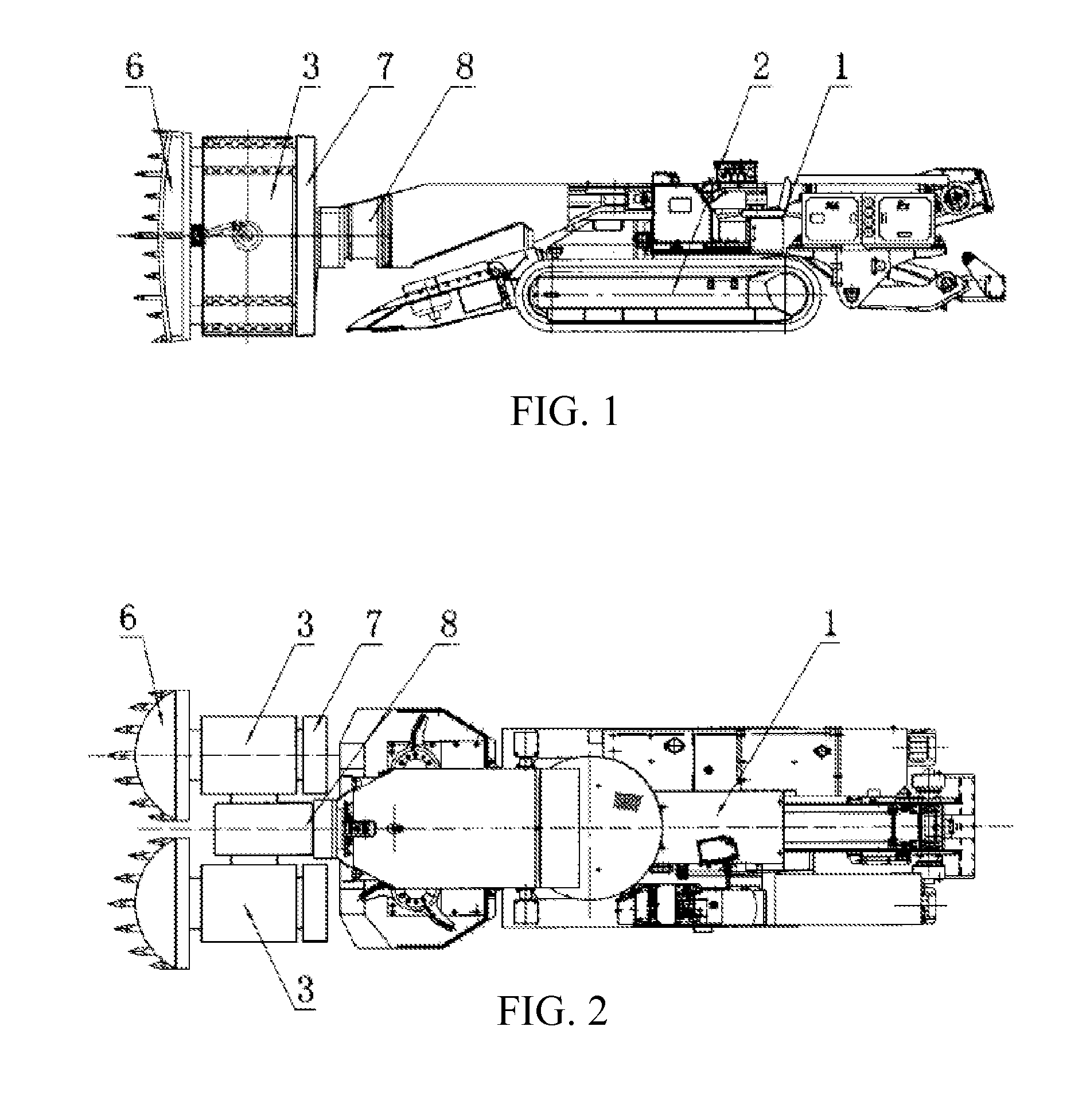

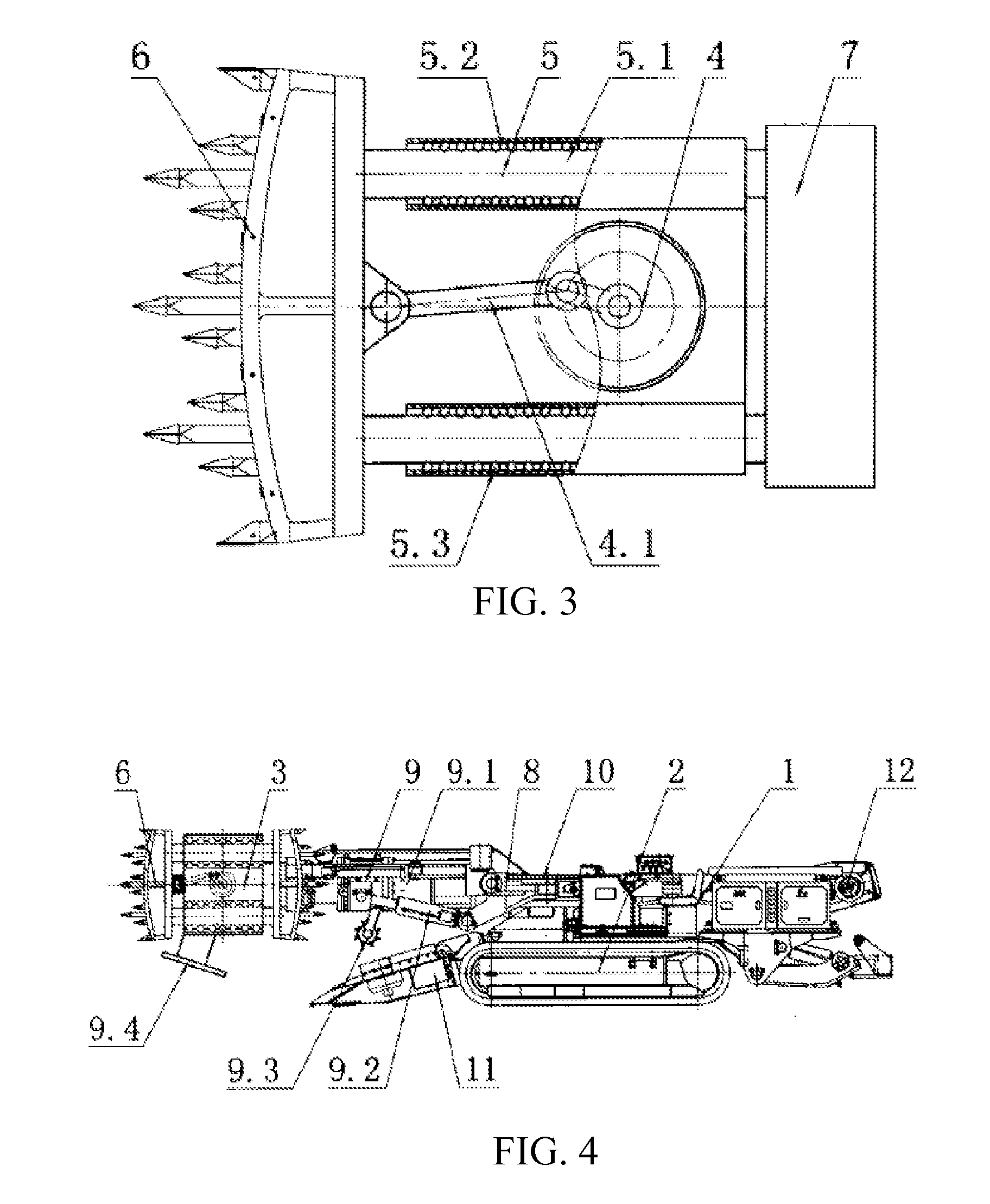

Rolling friction or suspension friction impact mining method and wear-resistant impact mining machine using said method

InactiveUS20150130256A1Increase widthExtended service lifeConstructionsReciprocating drilling machinesWear resistantEngineering

A rolling friction or suspension friction impact mining method and a wear-resistant impact mining machine using said method. The mining machine comprises a reciprocating impact part (3). The reciprocating impact part comprises an impact drive device (4), a rolling reciprocating device, and an impact head (6). The rolling reciprocating device comprises a rubbing body (38), a rubbing body support (39), an impact guiding element (5.1), and a position-limiting mechanism. The rubbing body (5.3) are disposed between the robbing body support (39) and the impact guiding element (5.1), and inside of the position-limiting mechanism to form rolling guiding. The impact drive device is disposed with a damage-prevention mechanism, a rotary power buffer device, and a structural buffer device, such that the impact head reciprocatingly move and have rolling or suspending friction under the support of the impact guiding element, thereby preventing the damage-prevention force to damage a power drive device and a rolling channel guiding device, and preventing the impact vibration caused by the reciprocating impact part to affect the machine body and other parts. The overall stability is therefore enhanced, and the service life is extended.

Owner:LIU SUHUA

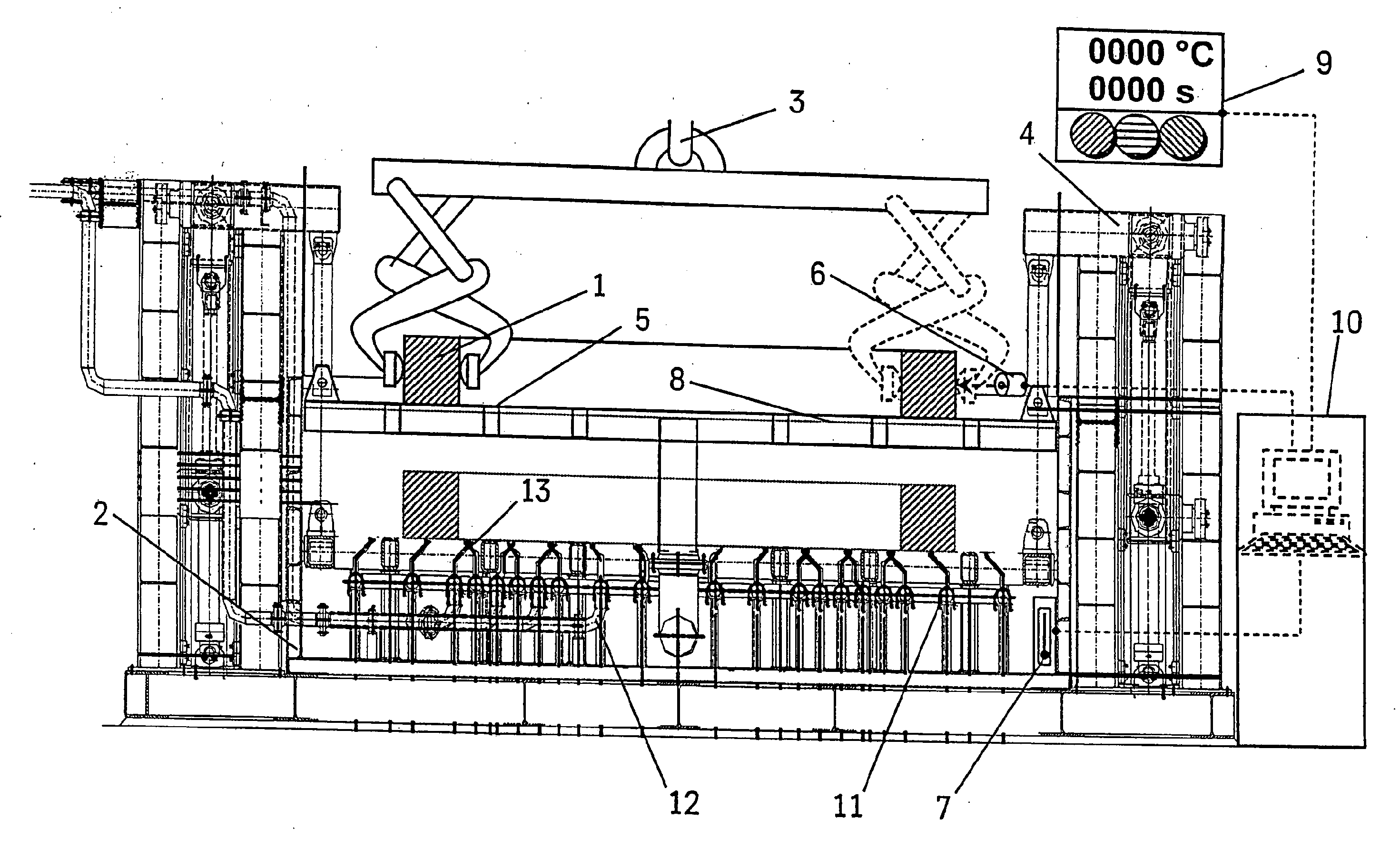

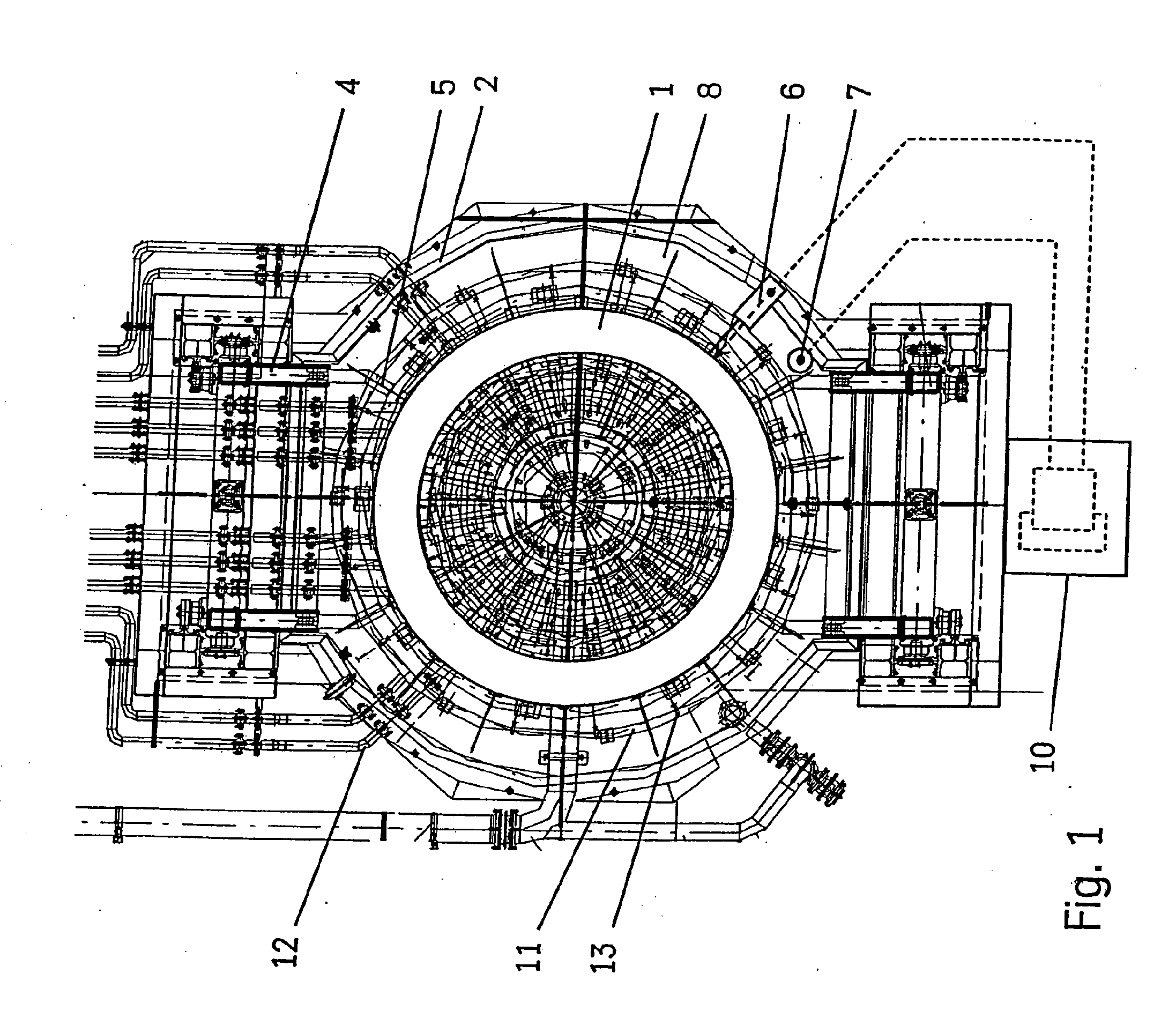

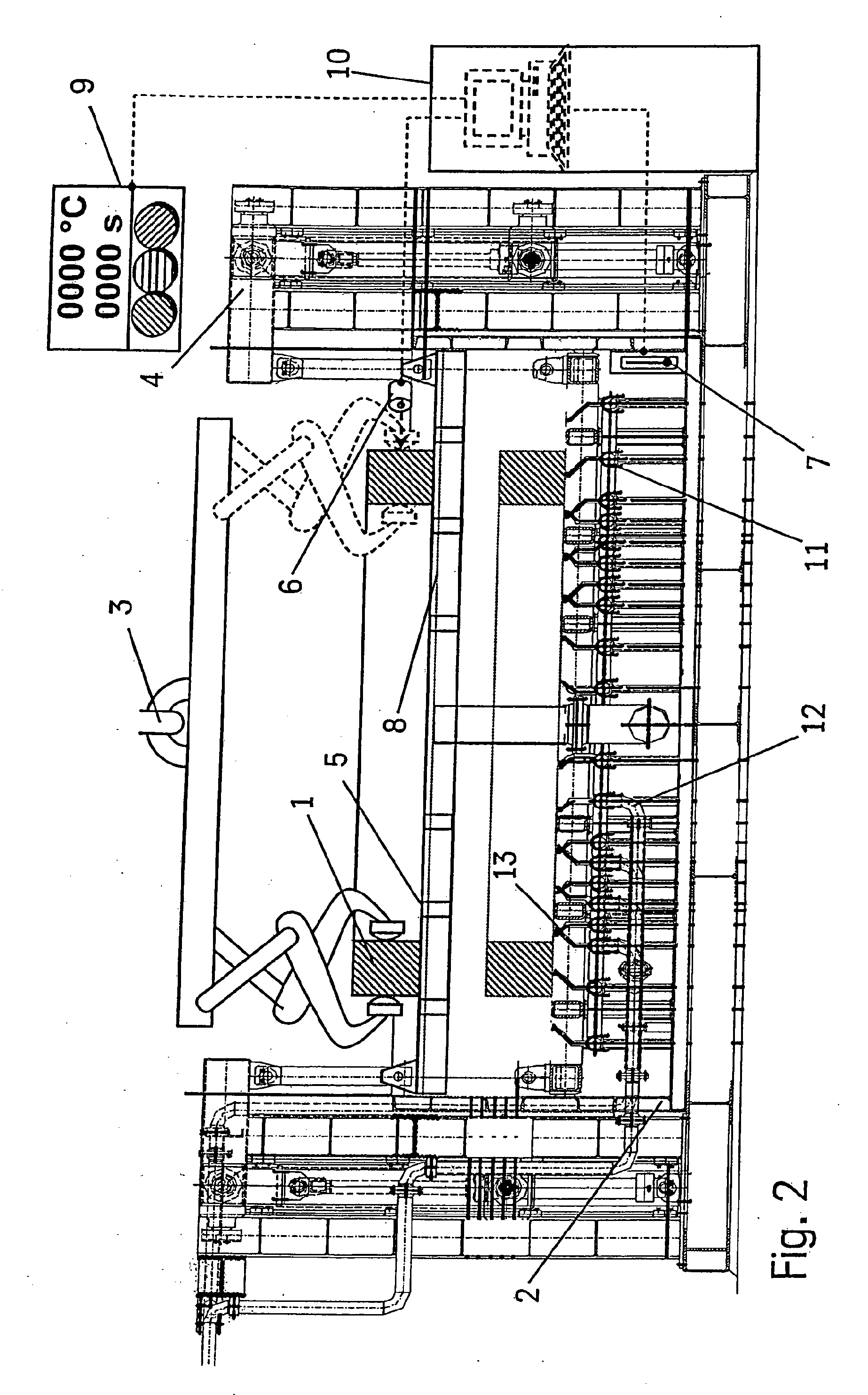

Method for the thermomechanical treatment of seamless rings produced on radial-axial ring rolling machines

ActiveUS20100024929A1Reduce expenditureReduce consumptionFurnace typesHeat treatment furnacesCase hardeningHardened steel

A method and a device are provided for the thermomechanical treatment of seamless steel rings produced on radial-axial ring rolling machines, particularly rings of fine grain steel, heat-treatable steel, case hardened steel, or austenitic steel, preferably of steel tower flanges for wind turbine generators. The ring blank is inserted into the ring rolling machine at a temperature in the range of 900° C. to 1150° C. and is rolled to an outer diameter preferably in the range of 0.2 m to 10 m by a hot forming process. The hot ring (1) is quickly cooled down by a controlled process directly following the rolling, without secondary heating, from a temperature over the conversion temperature in the austenite range to a temperature below 400° C. The device includes a dipping basin filled with cooling liquid (8) or an unfilled cooling container, and a carrier (5) that can be lowered with a hoisting device (4), the rolled ring (1) lying on the carrier. Pressure nozzles (13) are arranged in the dipping basin or the cooling container (2) on one or several ring lines (11), in an equal distribution, for the targeted application of the cooling liquid (8) onto at least one of the ring-shaped surfaces of the ring (1). Measurement of the ring temperature before and / or after the cooldown is carried out, preferably, with a radiation pyrometer.

Owner:ROTHE ERDE GMBH

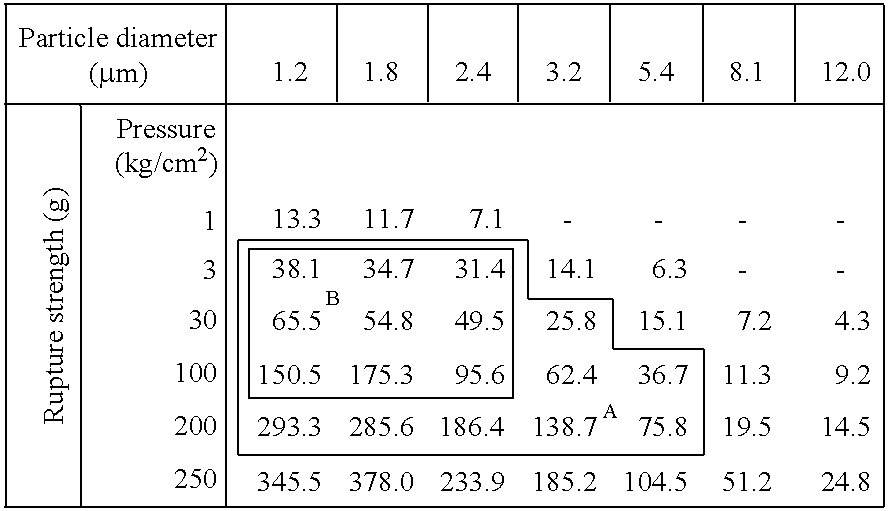

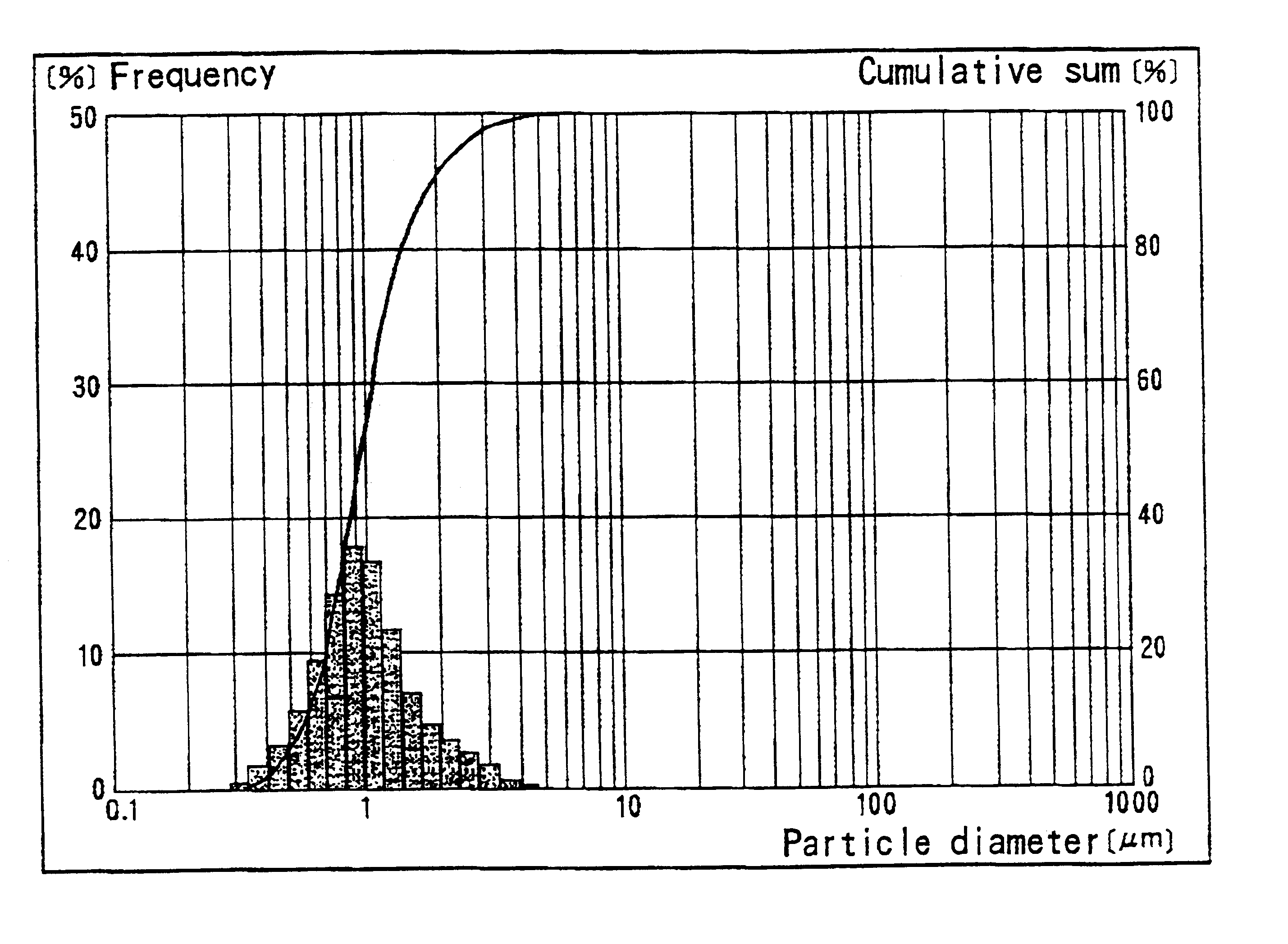

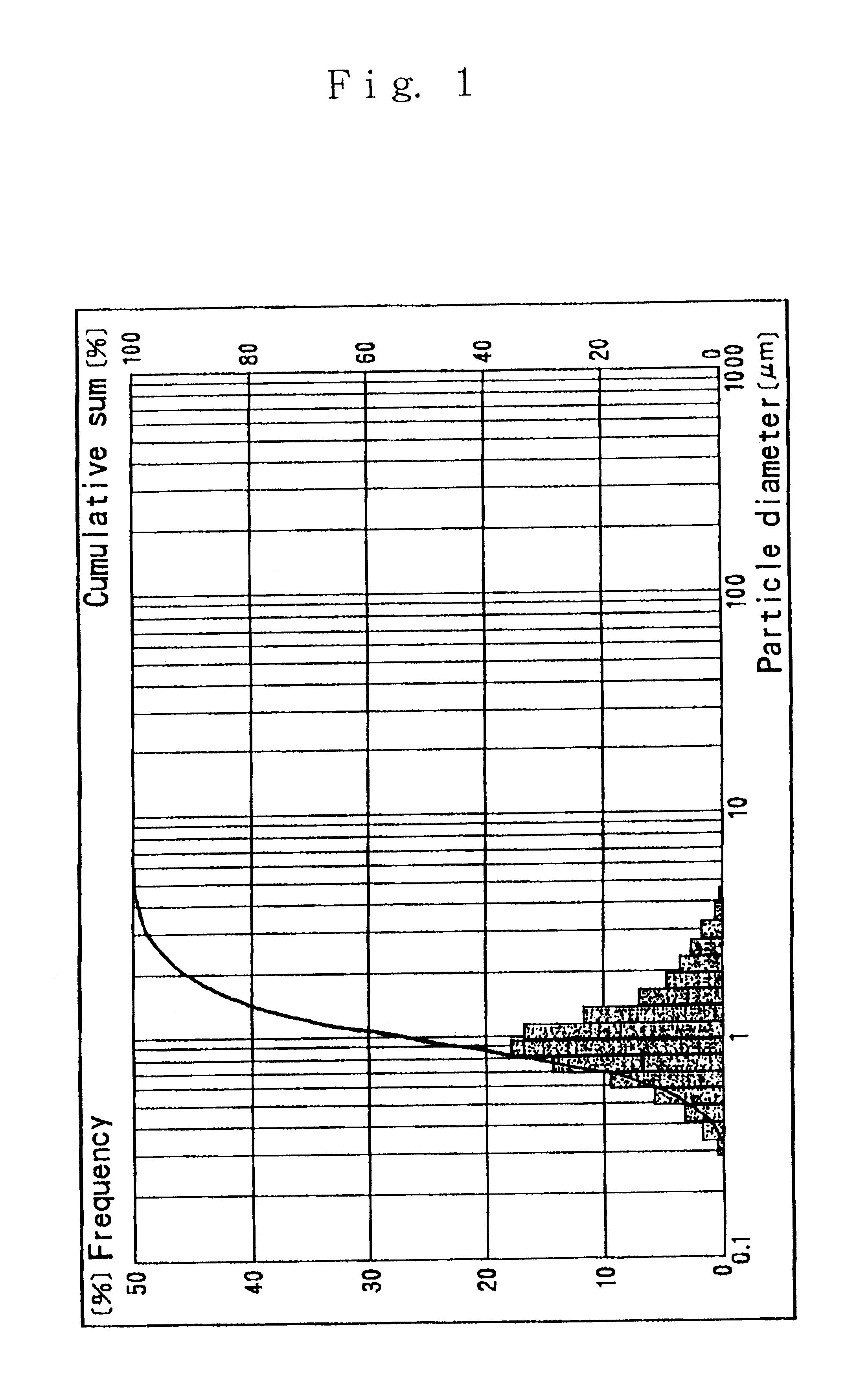

Cosmetic material containing crystalline superfine silk powder

InactiveUS6719985B1Unique glossImprove adhesionPowder deliveryCosmetic preparationsYarnAtmospheric pressure

The invention provides a cosmetic material containing a crystalline superfine silk powder that has the original structure of silk yarn, properties such as an unique gloss, feeling of touch, flexibility, and elasticity; and various properties such as excellent coating power, spreadability, adhesion, feeling of touch, and formability, which are required of an extender powder or color material of cosmetics. The cosmetic material contains a colored crystalline superfine silk powder obtained by the steps of bringing a silk substance into contact with an alkali aqueous solution at temperatures ranging from 100° C. to 150° C. under a pressure ranging from 1 through 5 atmospheric pressures to weaken the silk substance to not greater than 0.02 g / d in tensile strength, dealkalizing and drying the silk substancepowdering the silk substance into a crystalline superfine silk powder below 3 mum in average particle diameter, and dyeing the crystalline superfine silk powder with a natural or synthetic color material, or mixing the crystalline superfine silk powder with a natural or synthetic color material.

Owner:KOZO TSUBOUCHI +2

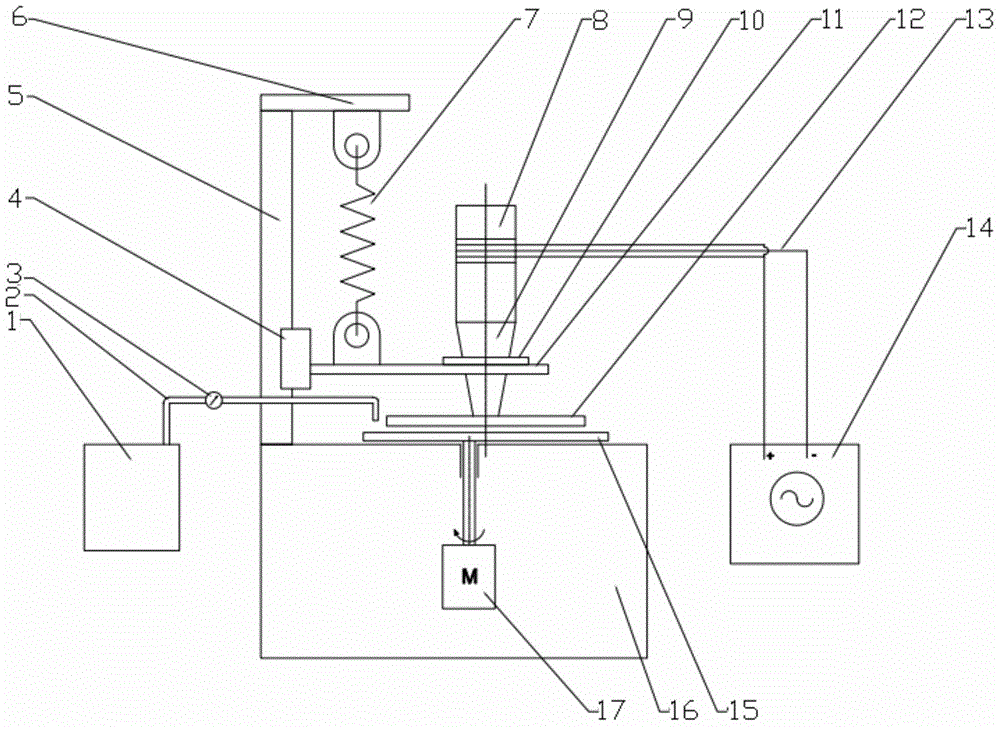

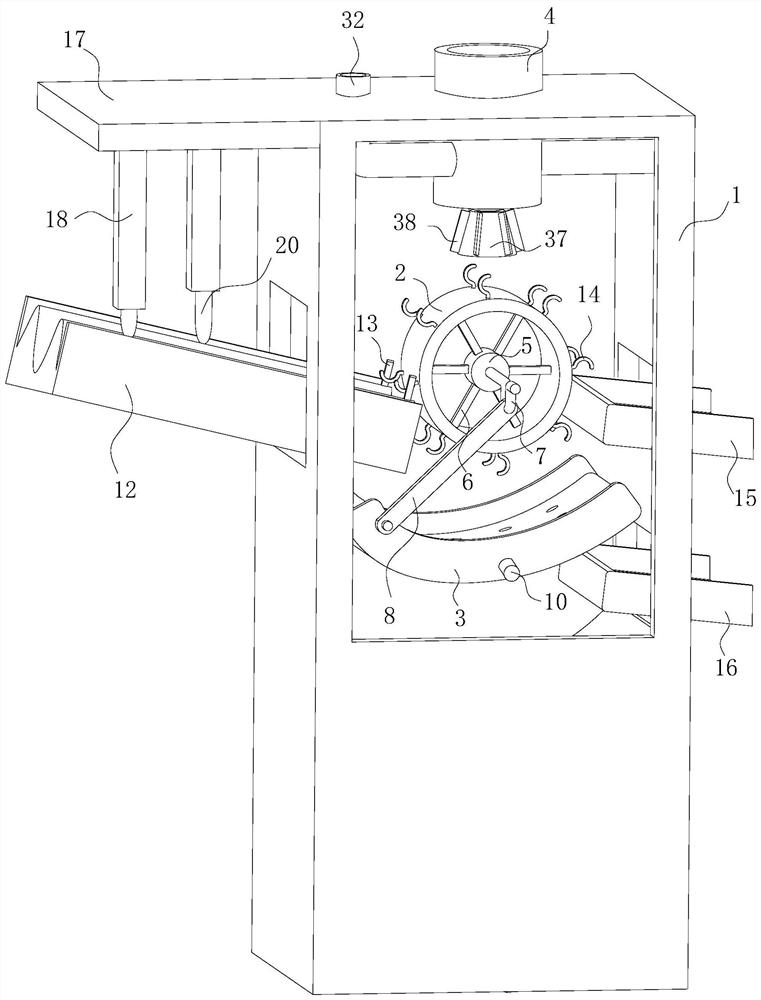

Servo-driven three-cutter mechanical shock high-speed grinder

ActiveCN108906272AEasy to achieve high speedCompact structureGrain treatmentsElectric machineryImpact velocity

The invention relates to a servo-driven three-cutter mechanical shock high-speed grinder which comprises a frame; a smashing device is fixedly arranged at the center of the frame; a grading device isfixedly arranged on the top of the smashing device; the smashing device is composed of an outer rotor servo motor and three rotary cutters; the outer rotor servo motor is used for directly driving a second cutter and utilizes two planetary gear trains to drive a first cutter and a third cutter, so that the first cutter and the second cutter are rotated along the opposite directions and the secondcutter and the third cutter are rotated along the opposite directions. The servo-driven three-cutter mechanical shock high-speed grinder is capable of effectively increasing the relative impact velocity of grains and cutters, forming an anti-abrading material layer on the third cutter surface, delaying the abrasion of the cutters and prolonging the service life of equipment, and has the advantagesof compact structure, high smashing efficiency and convenience in operation.

Owner:XI AN JIAOTONG UNIV

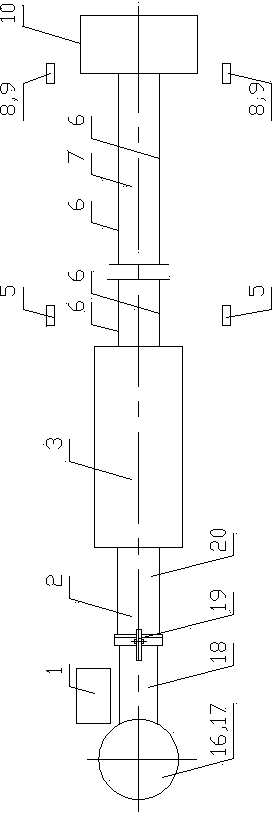

Pressure friction plate braking type real rail vehicle bump testing system

ActiveCN103940622AScientific and reasonable structureEasy to operateVehicle testingAutomotive engineeringPilot system

Disclosed is a pressure friction plate braking type real rail vehicle bump testing system. The pressure friction plate braking type real rail vehicle bump testing system comprises a central control panel, a launcher, a real vehicle and a bump wall. The real vehicle is arranged on the steel rails between the launcher and the bump wall; the side surface of the bump wall is provided with a bump speed measuring device and a high-speed photographing device. A braking device, a speed regulation braking device joint and a testing speed measuring device are configured and used during working condition testing; the braking device is of a pressure friction plate type structure and comprises wedge friction plates, a friction bottom plate, a friction cavity, a pressure unit and steel cables, wherein the pressure unit is a hydraulic, pneumatic, electromagnetic or mechanical adjustable pressure unit. During bump testing, the central control panel controls the working of the launcher, the bump speed measuring device, the high-speed photographing device, and a force measurement collecting device of the bump wall through programs, and receives and stores associated data; the powerless free sliding distance of the real vehicle is at least 0.1 time larger than the effective travel of the launcher; the testing bump speed between the real vehicle and the bump wall is not smaller than 25 kilometers per hour.

Owner:CENT SOUTH UNIV

Device for determining the instant a vehicle makes contact with an impact object

ActiveUS8698611B2Accurately determineImprove security levelDigital data processing detailsAnti-collision systemsAcceleration UnitElectrical and Electronics engineering

Owner:ROBERT BOSCH GMBH

Renovated iron drum production process

InactiveCN110549070AEfficient removalReduce wearOrganic detergent compounding agentsHollow article cleaningPolyethylene glycolHigh pressure

The invention discloses a renovated iron drum production process. Cleaning solvent adopted in high-pressure cleaning comprises 40-60 weight parts of propanediol butyl ether, 16-20 weight parts of xylene, 10-30 weight parts of surface active agent, 6-8 weight parts of polyethylene glycol, 0.5-3 weight parts of coconut oil fatty acid diethanolamide, 3-5 weight parts of corrosion inhibitor, 0.5-1 weight part of modified polyether defoaming agent and 2-4 weight parts of stabilizing agent; then, water is used for washing the internals and the externals of drums; during cleaning, the cleaning solvent is removed by adopting a pressure difference; the shot blasting treatment is performed on the internal and the externals of the iron drums; shots of a shot blasting machine are stainless steel shotsor iron shots with diameters of 1.5-3 mm; a dust removing system is arranged on the shot blasting machine; and the powder spraying, the paint spraying and the drying are performed at 170-180 DEG C. The renovated iron drum production process controls each process link in a refined mode, is not easy to generate leakage at the bottoms of the renovated drums and uniform and beautiful in powder spraying to the surfaces, and only reaches the defective rate of about 2%.

Owner:南通天地和环保科技有限公司

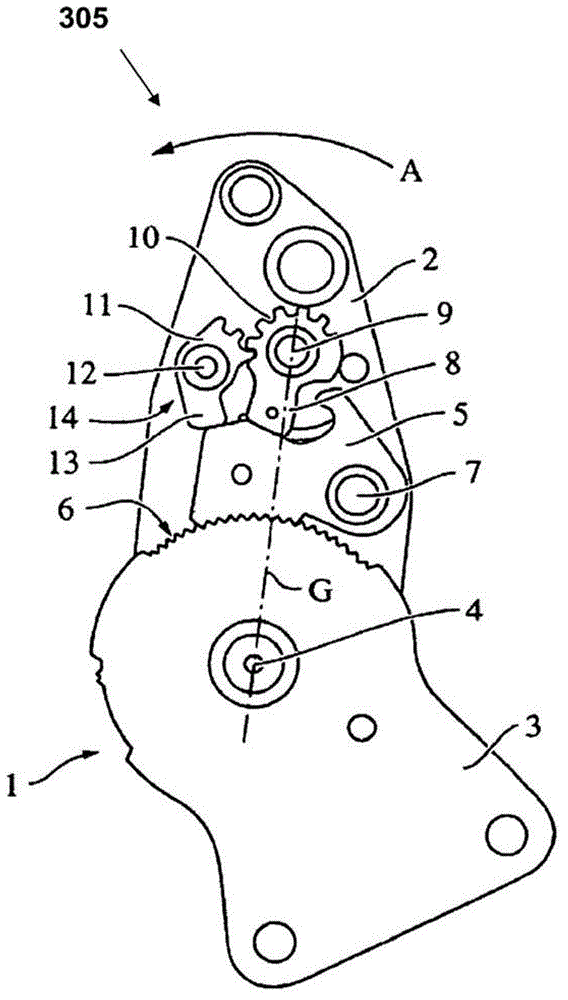

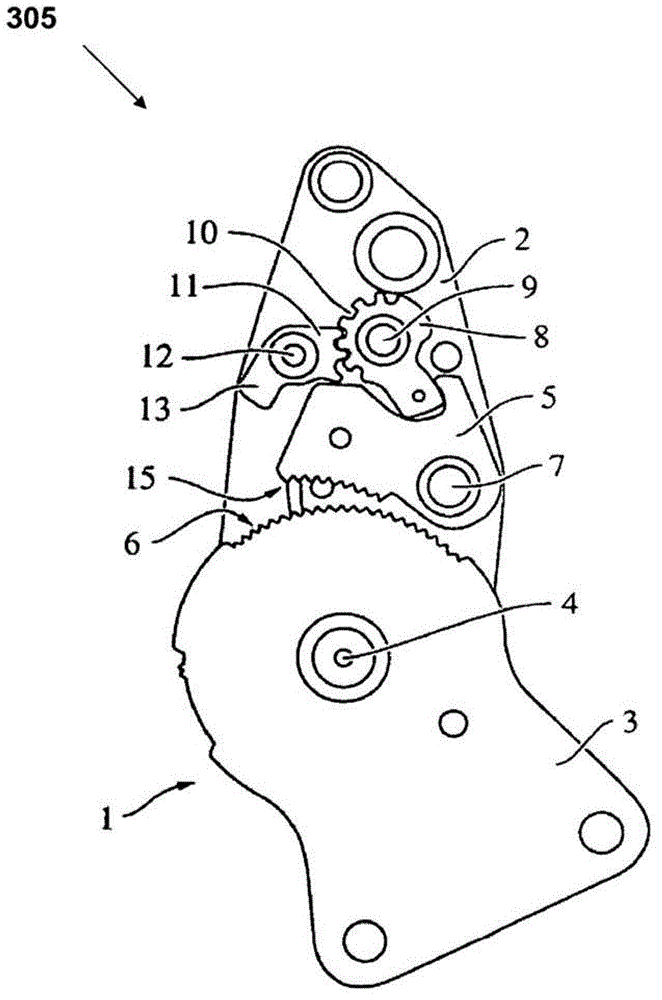

Method for producing high-strength components by means of adiabatic blanking

ActiveCN102753385AReduce weightReduce atomic bondingGear wheelsMovable seatsEngineeringMechanical engineering

Owner:ADIENT LUXEMBOURG HLDG SARL

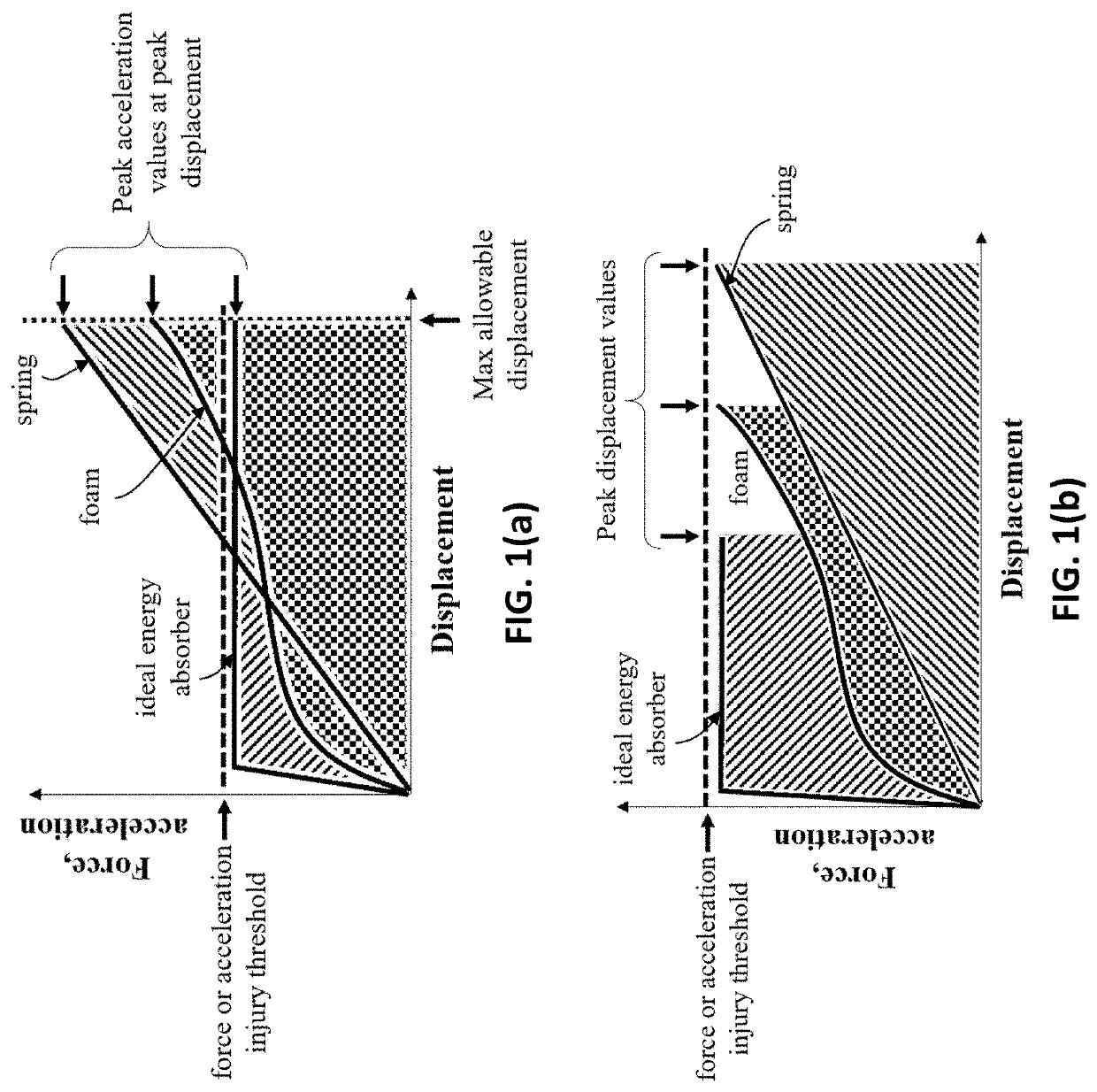

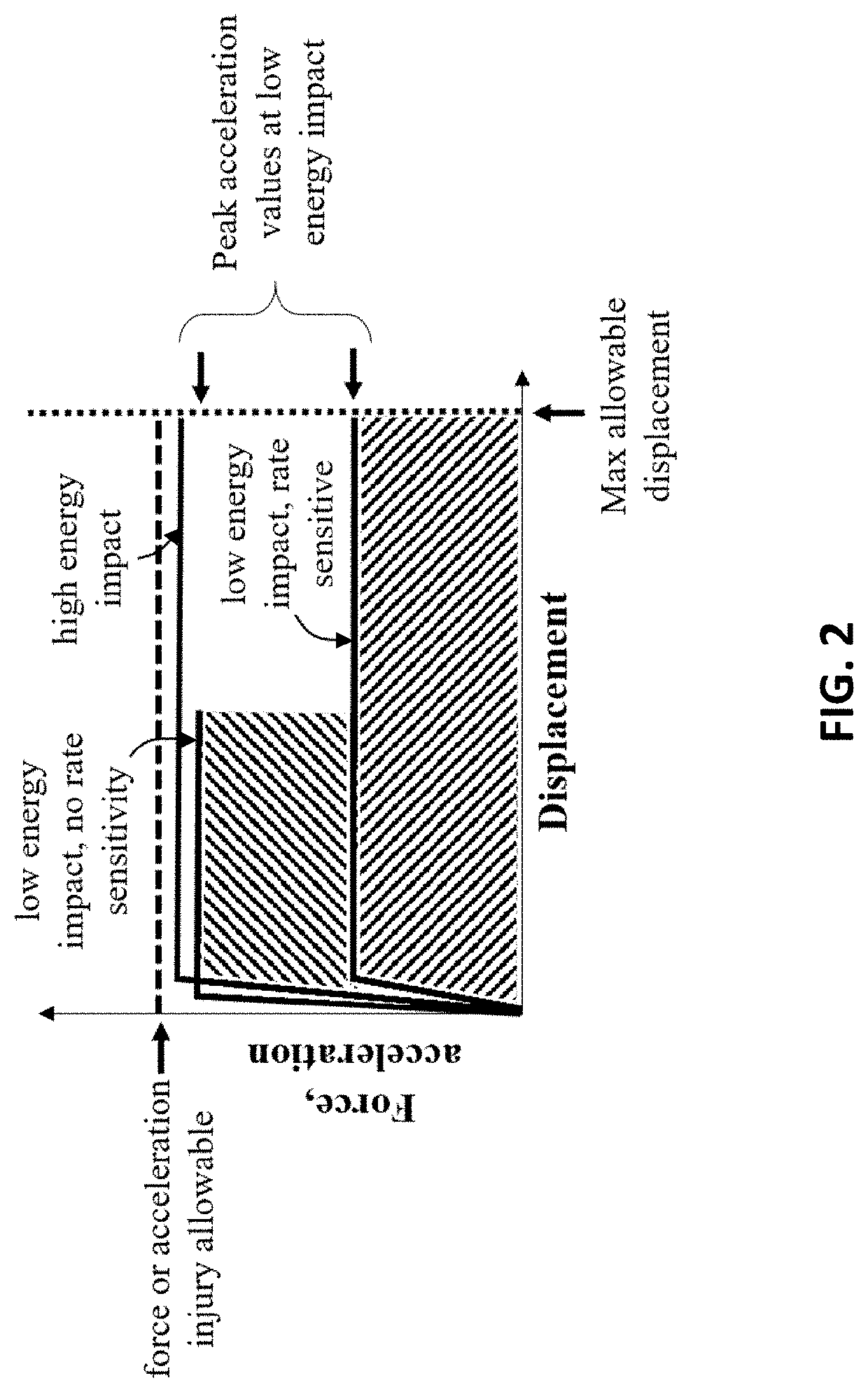

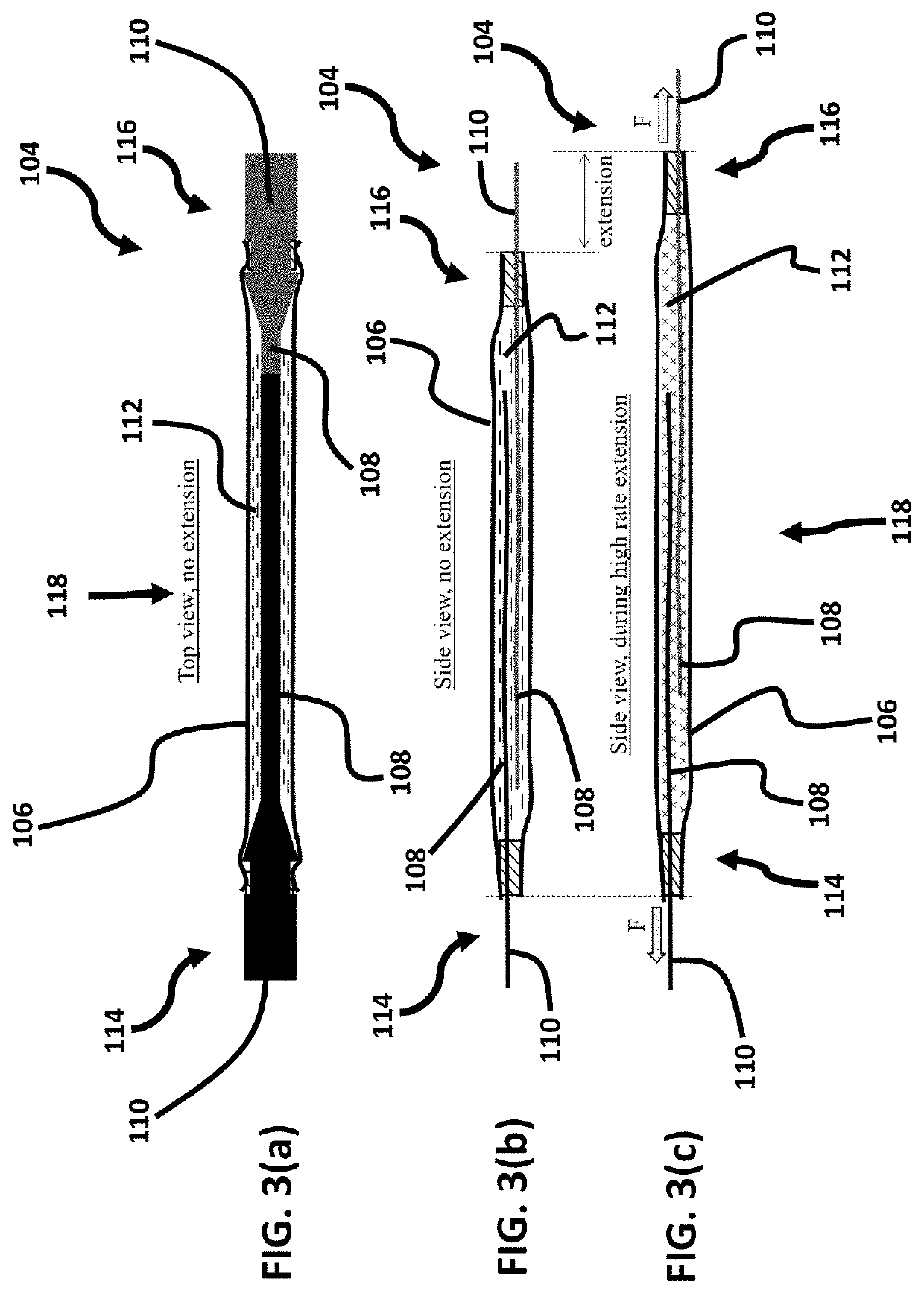

Rate-activated helmet suspension

ActiveUS20200022443A1Decrease head accelerationReduce the possibilitySpringsNon-rotating vibration suppressionStrappingImpact velocity

Impact energy absorbing devices, in some embodiments, may be configured as a helmet having suspension elements employing “rate activated tethers” (RATs), a speed-sensitive flexible strapping material. The RATs are configured to suspend a helmet shell on the head of a wearer, so that impact to the helmet causes extension of the RATs. The RATs provide for: (1) steady force over long strokes, and (2) a stroke force that increases with increasing impact velocity. Standard impact testing of a helmeted headform shows that the RAT suspension decreases head accelerations by 50% relative to a standard suspension system. This decrease in head acceleration is expected to lead to a reduced likelihood of brain and head injury. Because the RATs absorb energy during tensile extension, they offer increases in energy absorption efficiency. These RAT suspensions can potentially replace or complement existing helmet pad and suspension systems in military, sports, and industrial safety-wear.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

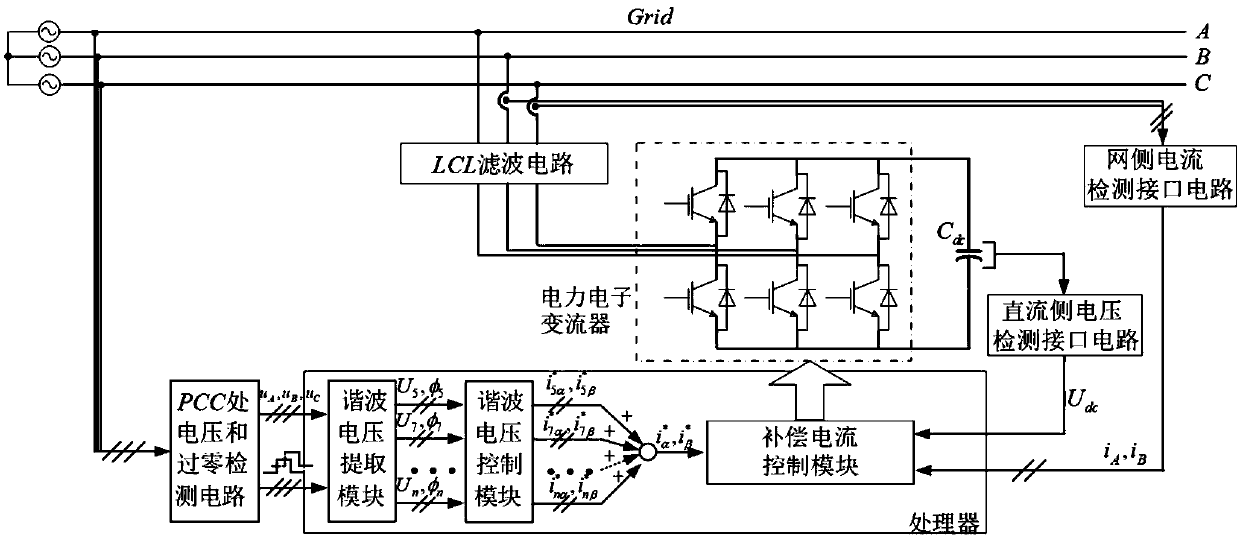

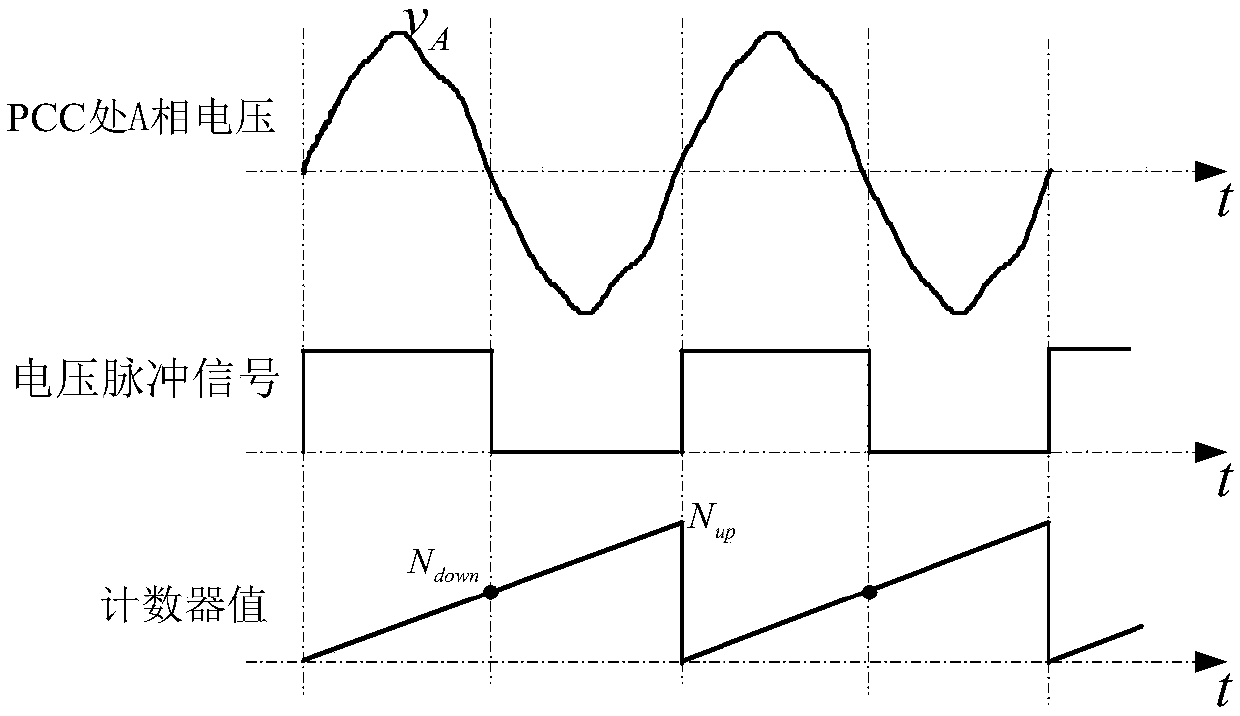

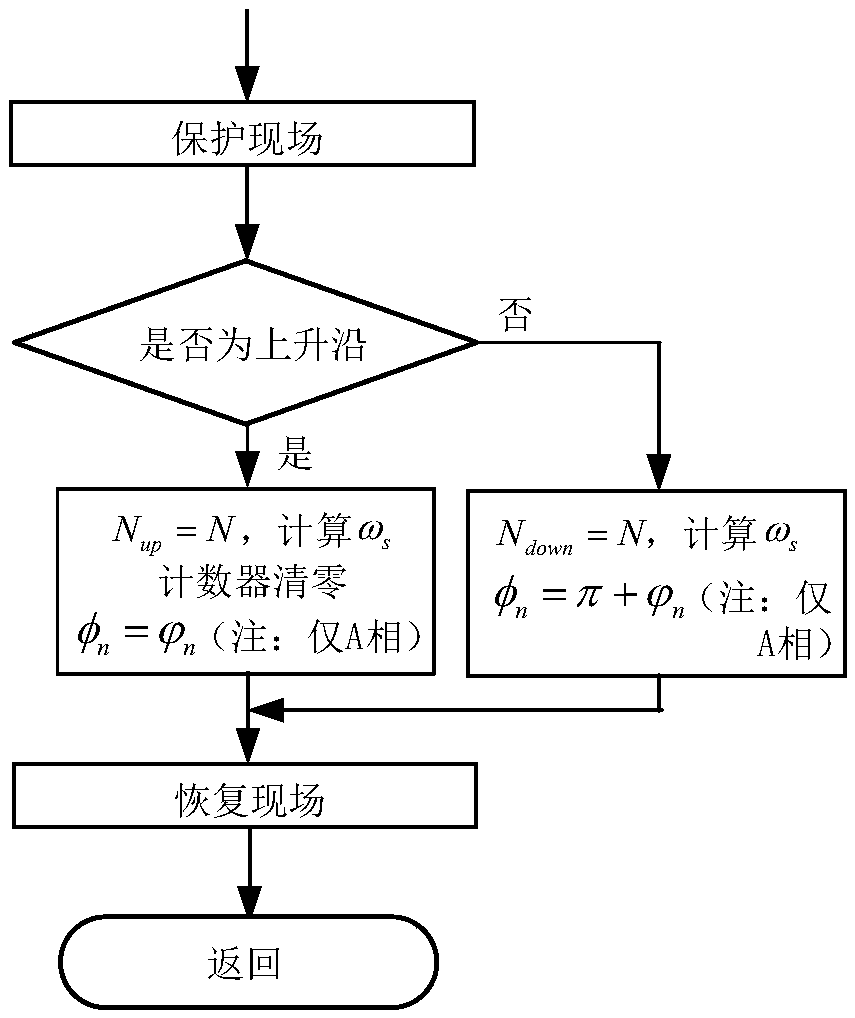

Voltage detection-type active filter for improving electric energy quality of PCC position

ActiveCN109617076AEfficient governanceExtraction is fast and correctReactive power adjustment/elimination/compensationReactive power compensationHardware structureCapacitance

The invention provides a voltage detection-type active filter for improving electric energy quality of a PCC position. The voltage detection-type active filter comprises a power electronic converter,an LCL filtering circuit, a DC-side capacitor, a network-side current detection interface circuit, a DC-side voltage detection interface circuit, a PPC voltage and zero-crossing detection circuit anda processor, wherein the processor is connected with the power electronic converter, the network-side current detection interface circuit, the DC-side voltage detection interface circuit and the PPC voltage and zero-crossing detection circuit, the power electronic converter is connected with the LCL filtering circuit and the DC-side capacitor, the LCL filtering circuit is connected with the network-side current detection interface circuit, and the DC-side capacitor is connected with the DC-side voltage detection interface circuit. By the voltage detection-type active filter, a PCC harmonic voltage is only extracted, a current is not extracted, the hardware structure is simplified, the influence speed is increased, the designated subharmonic voltage can be eliminated, the voltage detection-type active filter is simple to control and simple and convenient to operate, the method is reasonable, and power grid compensation can be performed in real time.

Owner:保定市兆微软件科技有限公司

Full-automatic numerical control shot blasting machine

ActiveCN112571291ARealize cleaning and derustingIncrease the shot blasting areaImpeller wheelsRotor bladesNumerical controlChinese characters

The invention belongs to the technical field of shot blasting machines, and particularly relates to a full-automatic numerical control shot blasting machine. The full-automatic numerical control shotblasting machine comprises a shell, a roller, an arc-shaped plate and a feeding plate, wherein a feeding cylinder is arranged in the center of the upper surface of the shell; the roller is arranged under the feeding cylinder, and a first rotating shaft is arranged in the center of the roller; a rocker designed to be shaped like a Chinese character "gong" is arranged in front of the first rotatingshaft; the arc-shaped plate is arranged under the roller; a connecting rod is hinged between the left end of the arc-shaped plate and the central concave part of the rocker; a collecting plate is arranged below the arc-shaped plate; a feeding opening is formed in the middle of the roller on the left side wall of the shell, and an obliquely designed feeding plate is arranged at the feeding opening;and the cross section of the feeding plate is in a waveform design, and the wave crest of the end, close to the roller, of the feeding plate is fixedly connected with a fixing rod. Through the mutualcooperation of the feeding plate, the roller and the arc-shaped plate, automatic classification of steel bars and other workpieces is achieved, the post-processing time is saved, and resource waste is reduced.

Owner:山东盛德机械有限公司

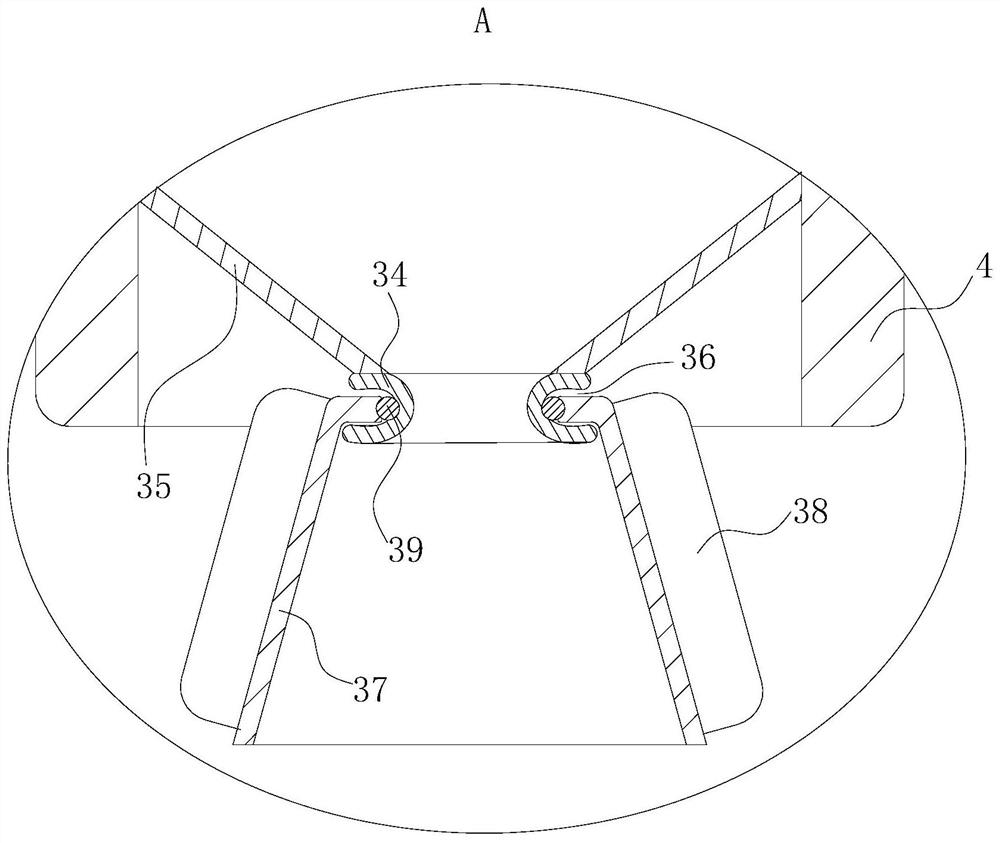

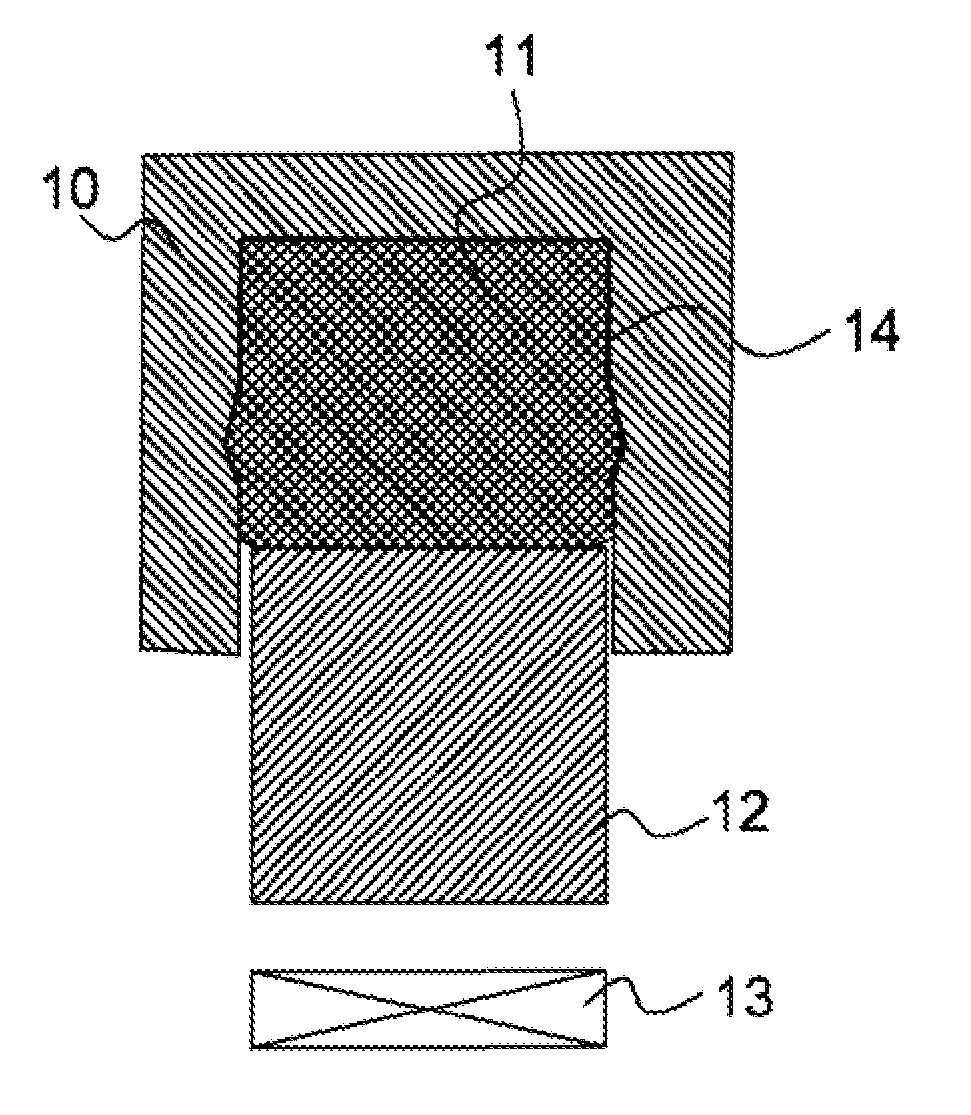

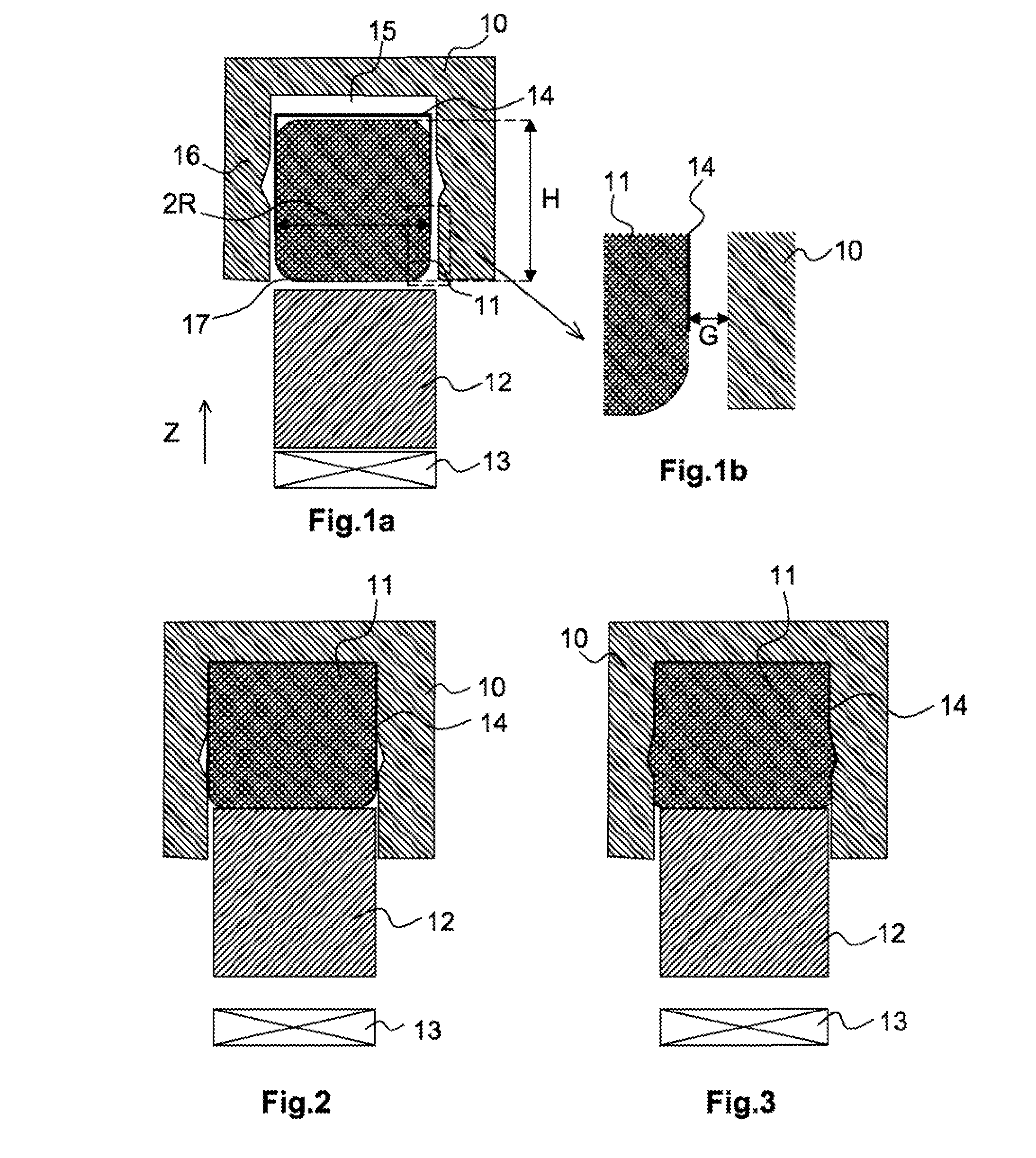

Device and method for forming by stamping at high speed

ActiveUS20150343512A1Efficiently formedReduction of elastic returnMetal-working apparatusPress ramCompressible materialEngineering

A device and a method for forming by stamping a curved metal sheet. The device includes a punch made of deformable and substantially non-compressible material, a hammer configured to strike the punch along the longitudinal axis Z. A generator to generate a magnetic field configured to impart on the hammer a speed greater than a predetermined speed in the Z direction. The device further includes a matrix of predetermined shape, approximately rotationally symmetrical about the longitudinal axis Z. The punch is rotationally symmetrical about the longitudinal axis and configured to be disposed in front of the matrix. The punch has a longitudinal dimension in the same order of magnitude as its dimension perpendicular to the longitudinal axis Z.

Owner:ADM28 S AR L

Real vehicle impact test system for double-roller braking railway vehicle

ActiveCN103954421AScientific and reasonable structureEasy to operateRailway vehicle testingShock testingProcedural approachArresting gear

The invention relates to a real vehicle impact test system for a double-roller braking railway vehicle. The test system comprises a central control desk, an emitter, a real vehicle and an impact wall, wherein the real vehicle is put on a railway between the emitter and the impact wall; an impact speed measuring device and a high-speed photography device are installed on the side face of the impact wall; a brake device, a speed adjusting brake device connector and an adjustment speed measuring device are arranged and used in the working condition adjusting process; the brake device is a brake mechanism with double rollers and comprises a fixed pulley, a steel wire rope, a rack, a brake wheel, a brake mechanism body, the big roller and the small roller, the brake wheel, the big roller and the small roller are of an integrated structure, and the directions of the steel wire rope winding around the big roller and the small roller are opposite. In the impact test process, the brake device breaks away from the speed adjusting brake device connector, and the central control desk controls the relates devices to receive and store data; the unpowered free sliding distance of the real vehicle is at least 1.1 times the effective travel of the emitter, and the test impact speed of the real vehicle and the impact wall is not smaller than 25 km / h.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com