Railway vehicle real vehicle bump test system for coupling passenger behavior detection

A test system and rail vehicle technology, applied in the field of rail vehicle crash test system, can solve problems such as inability to directly use for reference, and achieve the effects of simple and easy operation, scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

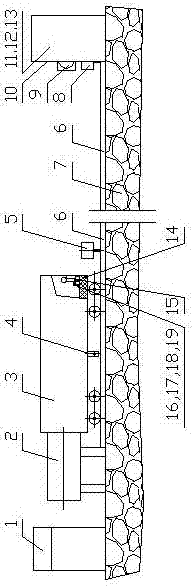

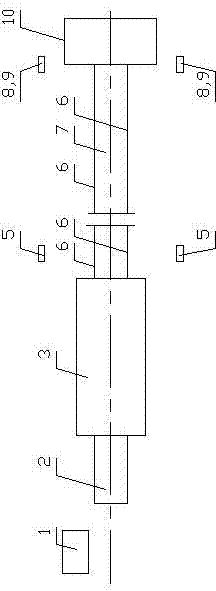

[0056] A steel rail 6 is set on the foundation 7 between the launcher 2 and the impact wall 10; the real vehicle 3 is placed on the steel rail 6, and the launcher 2 is installed on the end of the real vehicle 3 facing away from the impact wall 10; At least one experimental dummy 16 is arranged at both ends and in the middle, and the experimental dummy 16 is placed on the seat 15 in an unconstrained sitting position, and the seat 15 is fixed on the floor 14; the experimental dummy 16 is a standard dummy, and each A pressure sensor 17, a displacement sensor 18 and an acceleration sensor 19 are arranged on the head, neck, chest and back of the experimental dummy 16; the central console 1 is connected to the pressure sensor 17, the displacement sensor 18 and the acceleration sensor 19 by wired or wireless means . During the impact test: the central console 1 controls the work of the transmitter 2, the impact speed measuring device 8, the high-speed photography device 9, the force ...

Embodiment 2

[0058] It is basically the same as in Embodiment 1, except that each experimental dummy 16 is equipped with a rigid frame, and the beams of the frame correspond to the head, neck, back, front chest, abdomen, legs and hands of the experimental dummy 16. The pressure sensor 17, the displacement sensor 18 and the acceleration sensor 19 are arranged at the positions of the parts; the central console 1 is connected with the pressure sensor 17, the displacement sensor 18 and the acceleration sensor 19 by wired or wireless means.

Embodiment 3、4

[0060] They are basically the same as in Embodiment 1, except that the impact wall 10 includes a uniform force plate 11, a force measuring acquisition device and an impact pier 13, the uniform force plate 11 faces the real vehicle 3, and the force measurement acquisition device is located between the uniform force plate 11 and the impacting pier. between the piers 13; the force measurement acquisition device is a force sensor array 12; the central console 1 is electrically connected to the force sensor array 12 and receives impact data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com