Cyclonic jet mill

A jet mill and cyclone technology, applied in the field of solid material crushing devices, can solve the problems of insufficient crushing of materials and insufficient air flow, and achieve the effects of prolonging service life, reducing maintenance and protecting the operating environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

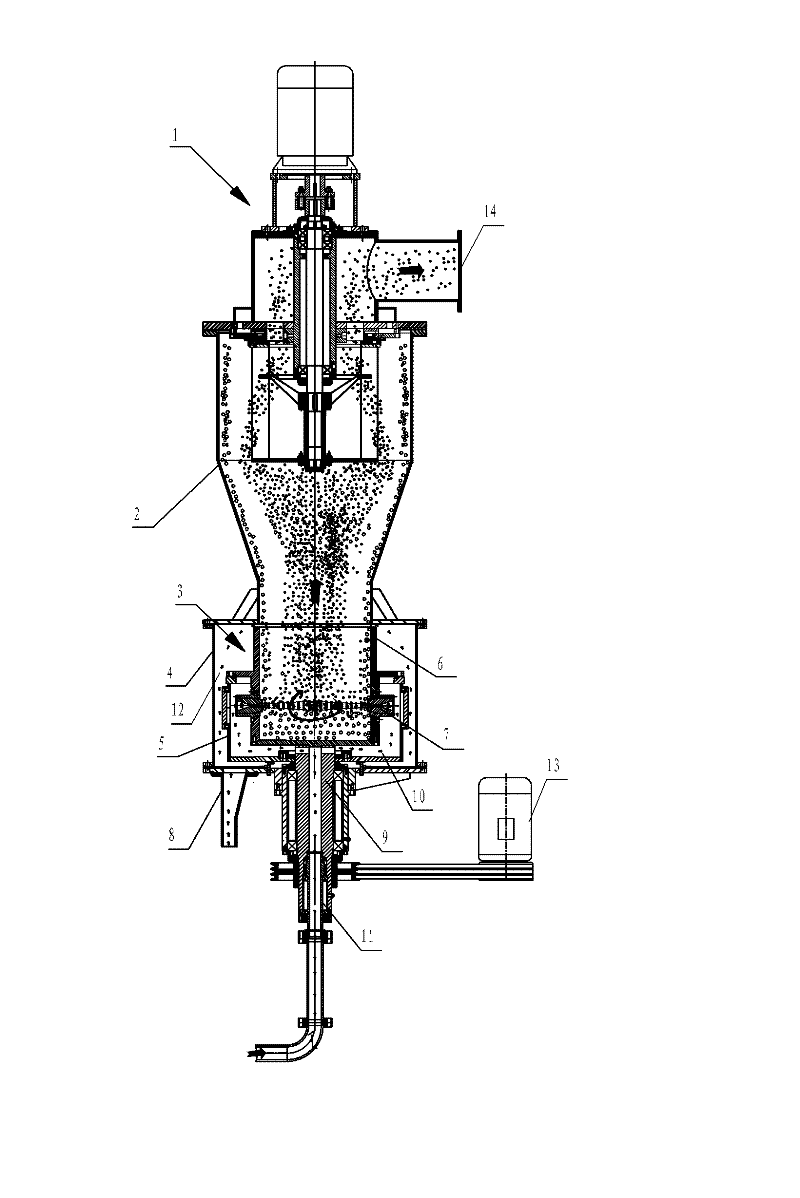

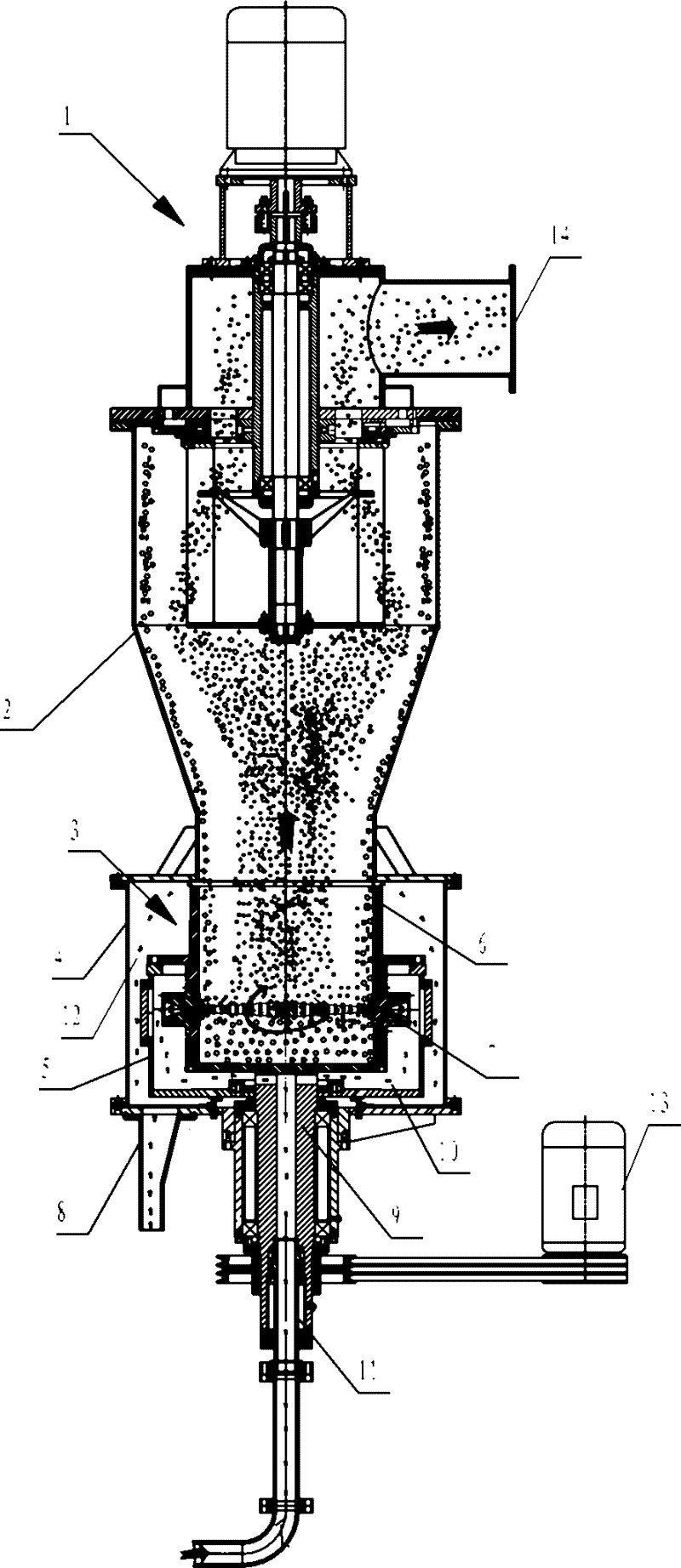

[0016] As shown in the accompanying drawings, a cyclone airflow pulverizer includes a classifier 1 installed on a pulverization box, and the pulverization box is provided with a pulverization cavity 3 driven by a power unit and rotatably installed in the pulverization box , the power device is preferably a motor 13, the crushing cavity 3 includes an inner cylinder 6 with a crushing space, the outer circumference of the inner cylinder 6 is sealed with an outer cylinder 5, and the inner cylinder 6 is connected to the outer cylinder 6. An airflow passage 10 communicating with a compressed air source is provided between the cylinders 5, and an airflow nozzle 7 is provided on the side wall of the inner cylinder 6, and the airflow nozzle 7 communicates the airflow passage 10 with the crushing space. The air flow nozzles 7 are at least one pair and are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com