Composite fixing phase change material of 79-83 deg.c and its preparing method

A technology of shape-setting phase change materials and latent heat of phase change, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems that qualitative phase change materials have not made great progress, and achieve low weight loss rate and stable material properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

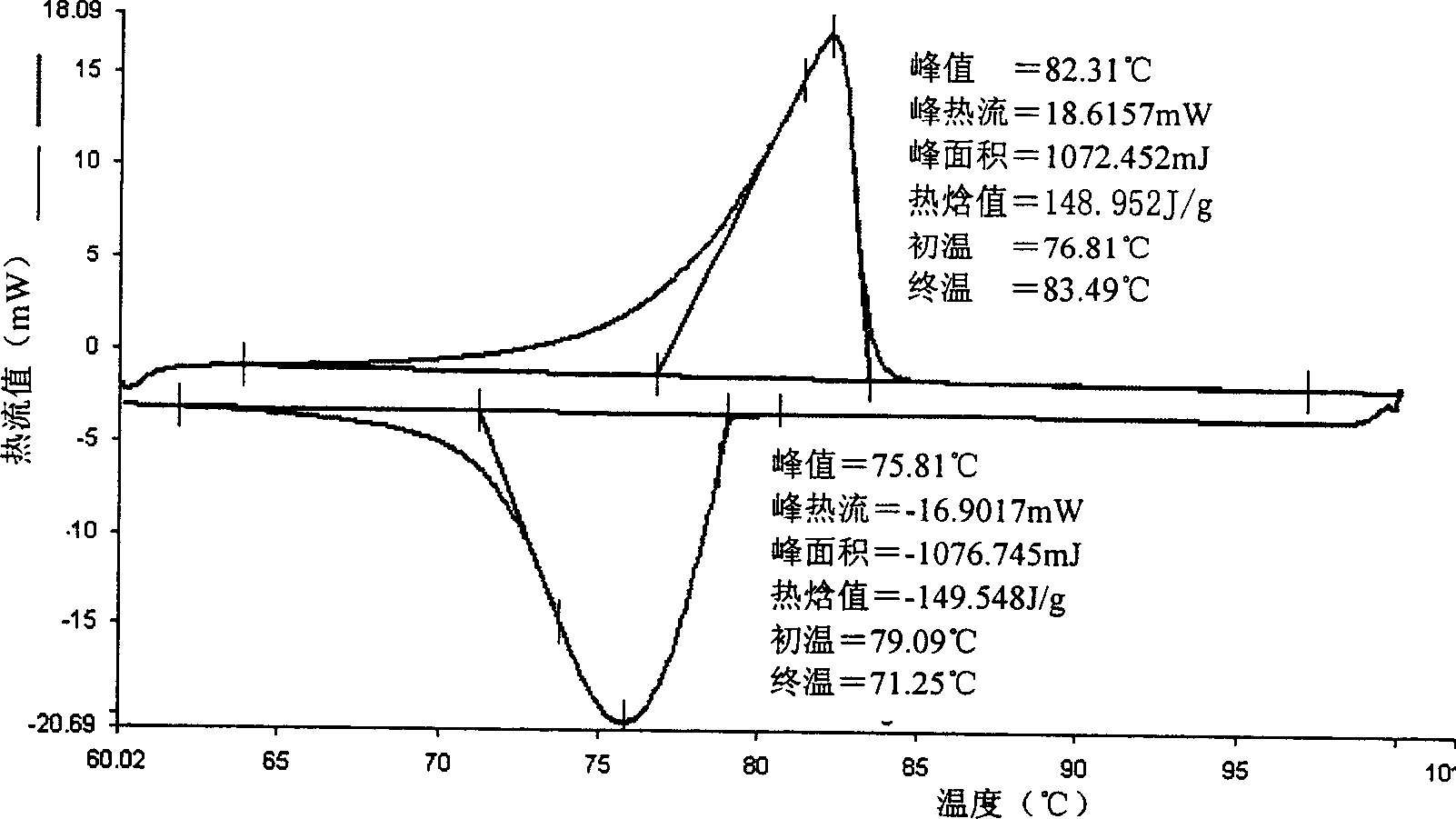

Embodiment 1

[0015] Put 800g of paraffin wax with a melting point of 81.6°C and a latent heat of phase transition of 209.1kJ / kg into the reactor, heat and melt at 100-120°C, put 150g of high-density polyethylene into it, and raise the temperature to 140-160°C , stir at a speed of 100r / min until the paraffin wax and high-density polyethylene are integrated into a viscous liquid, add 100g of SEBS, stir evenly, and finally add 50g of expanded graphite, stir evenly. The blend is taken out and put into a mold of 140*140*10mm, and pressed with a pressure of 300kPa. After cooling, it is taken out from the mold to obtain a fixed-shape phase-change material. Using the Pyris Diamond differential scanning calorimeter of PE Company in the United States, the peak value of the melting curve of the material is 82.31° C., and the latent heat of phase change is 149.2 kJ / kg. Take a 30*30*10mm shaped phase change material and soak it in hot water at 88°C for 200 hours. The material has no obvious deformatio...

Embodiment 2

[0017] Put 800g of paraffin wax with a melting point of 81.6°C and a latent heat of phase transition of 212.5kJ / kg into the reactor, heat and melt at 100-120°C, put 100g of high-density polyethylene into it, and raise the temperature to 140-160°C , Stir at a speed of 120r / min until the paraffin wax and high-density polyethylene are integrated into a viscous liquid, add 50g of SEBS, stir evenly, and finally add 50g of expanded graphite, stir evenly. The blend is taken out and put into a mold of 140*140*10mm, and pressed with a pressure of 200kPa. After cooling, it is taken out from the mold to obtain a fixed-shape phase-change material. Using the Pyris Diamond differential scanning calorimeter of the American PE company, the peak value of the melting curve of the material is 81.62 ° C, and the latent heat of phase change is 168.8. Take a 30*30*10mm shaped phase change material and soak it in 88°C hot water for 200 hours. The material has no obvious deformation. After drying, i...

Embodiment 3

[0019] Put 800g of paraffin wax with a melting point of 81.6°C and a latent heat of phase transition of 212.5kJ / kg into the reactor, heat and melt at 100-120°C, put 150g of high-density polyethylene into it, and raise the temperature to 140-160°C , Stir at a speed of 120r / min until the paraffin wax and high-density polyethylene are integrated into a viscous liquid, add 50g of SEBS, stir evenly, and finally add 50g of expanded graphite, stir evenly. The blend is taken out and put into a mold of 140*140*10mm, and pressed with a pressure of 300kPa. After cooling, it is taken out from the mold to obtain a fixed-shape phase-change material. Using the Pyris Diamond differential scanning calorimeter of PE Company in the United States, the peak value of the melting curve of the material is 83.83° C., and the latent heat of phase change is 153.0 kJ / kg. Take a 30*30*10mm shaped phase change material and soak it in hot water at 88°C for 200 hours. The material has no obvious deformation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com