Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Improve level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

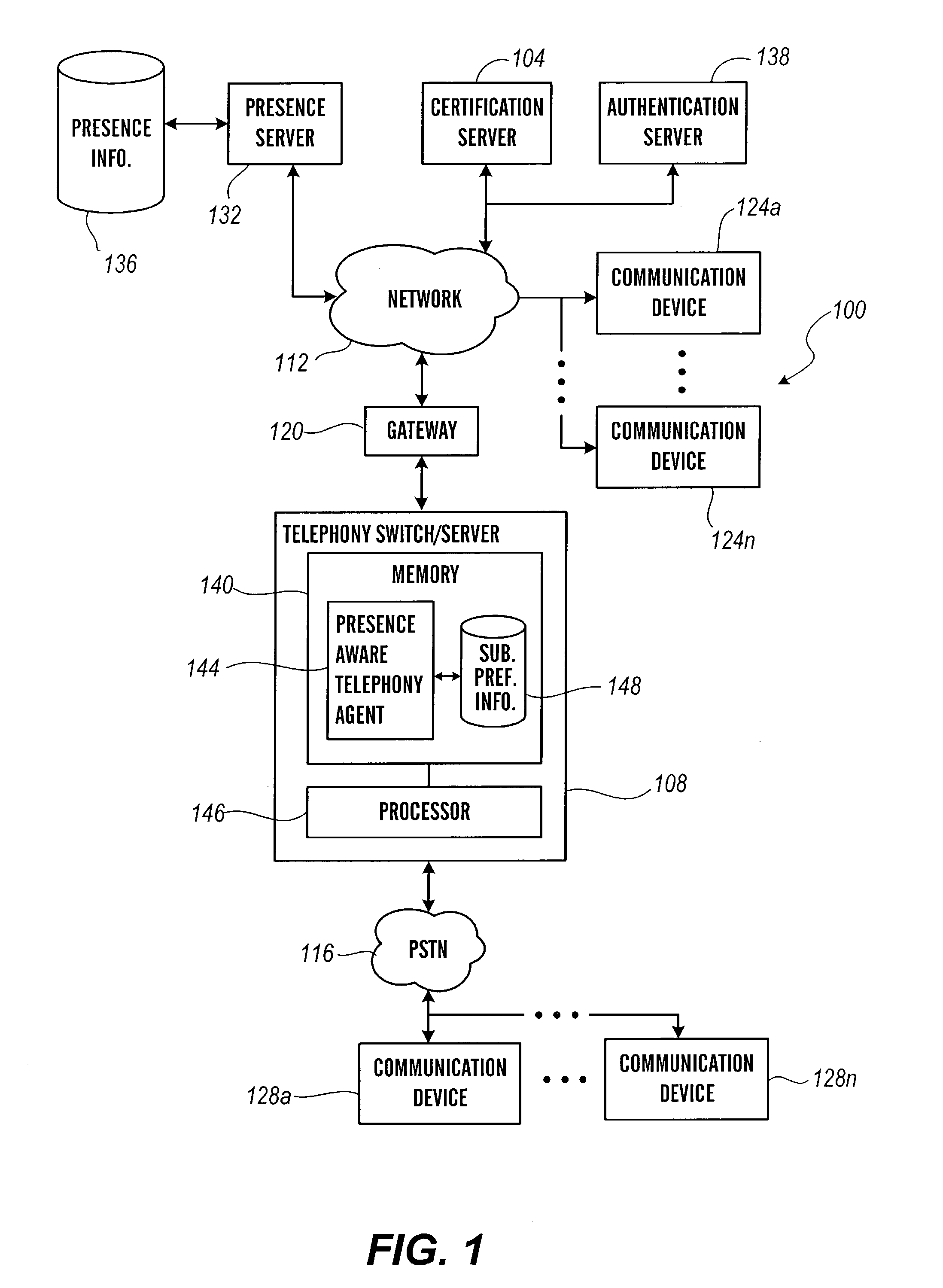

Authentication mechanism for telephony devices

ActiveUS7190948B2Improve levelConducive to useUnauthorised/fraudulent call preventionEavesdropping prevention circuitsAuto-configurationTelephone equipment

The present invention is directed to a presence aware network 100 that includes a plurality of communication devices 124a–n and 128a–n, associated with a plurality of subscribers. Each communication device may be configured automatically according to a first set of preferences associated with a first subscriber when the first subscriber performs a telephony function on the communication device and according to a second set of preferences when a different second subscriber performs the telephony function on the communication device. The first and second sets of preferences are different from one another.

Owner:AVAYA INC

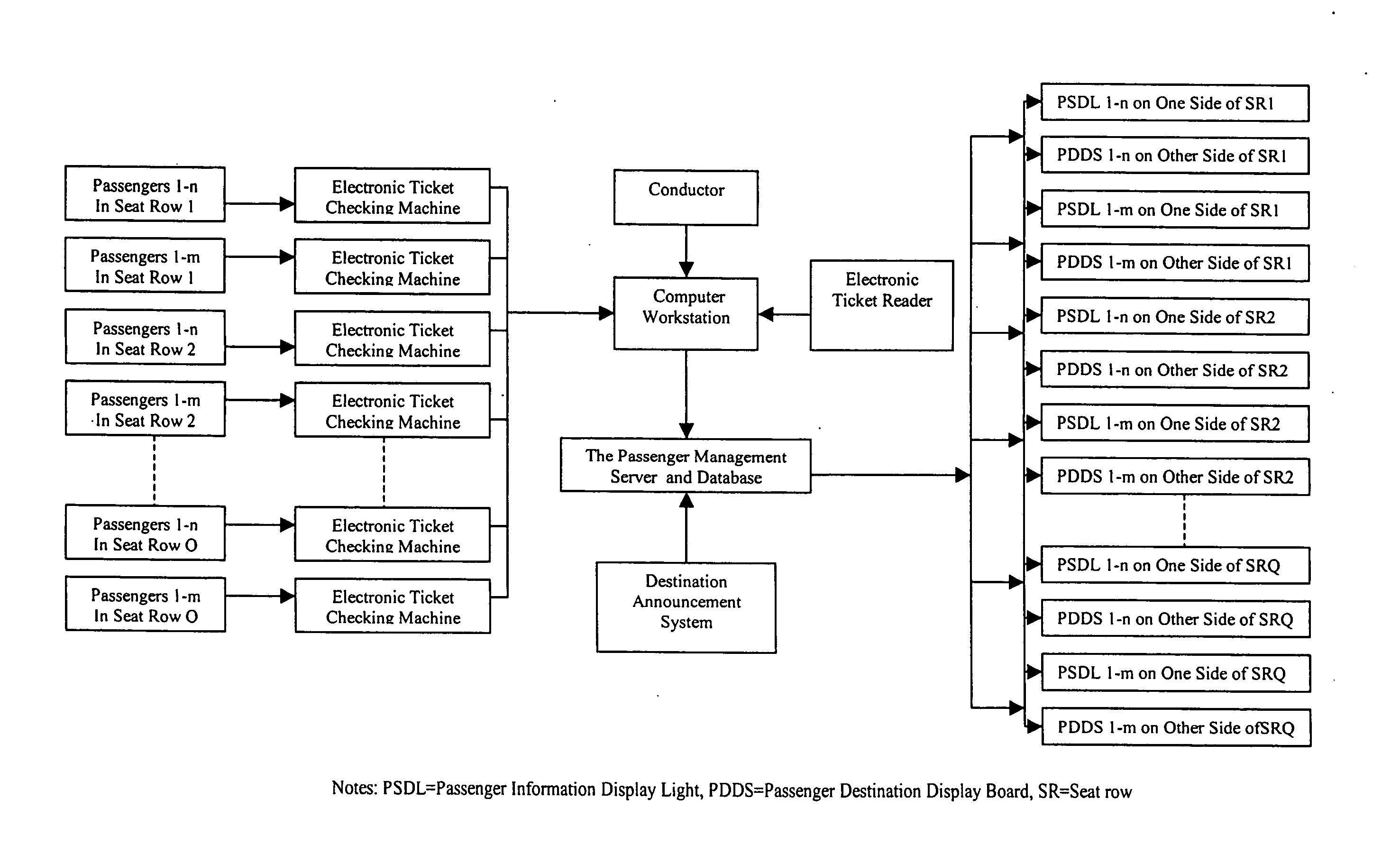

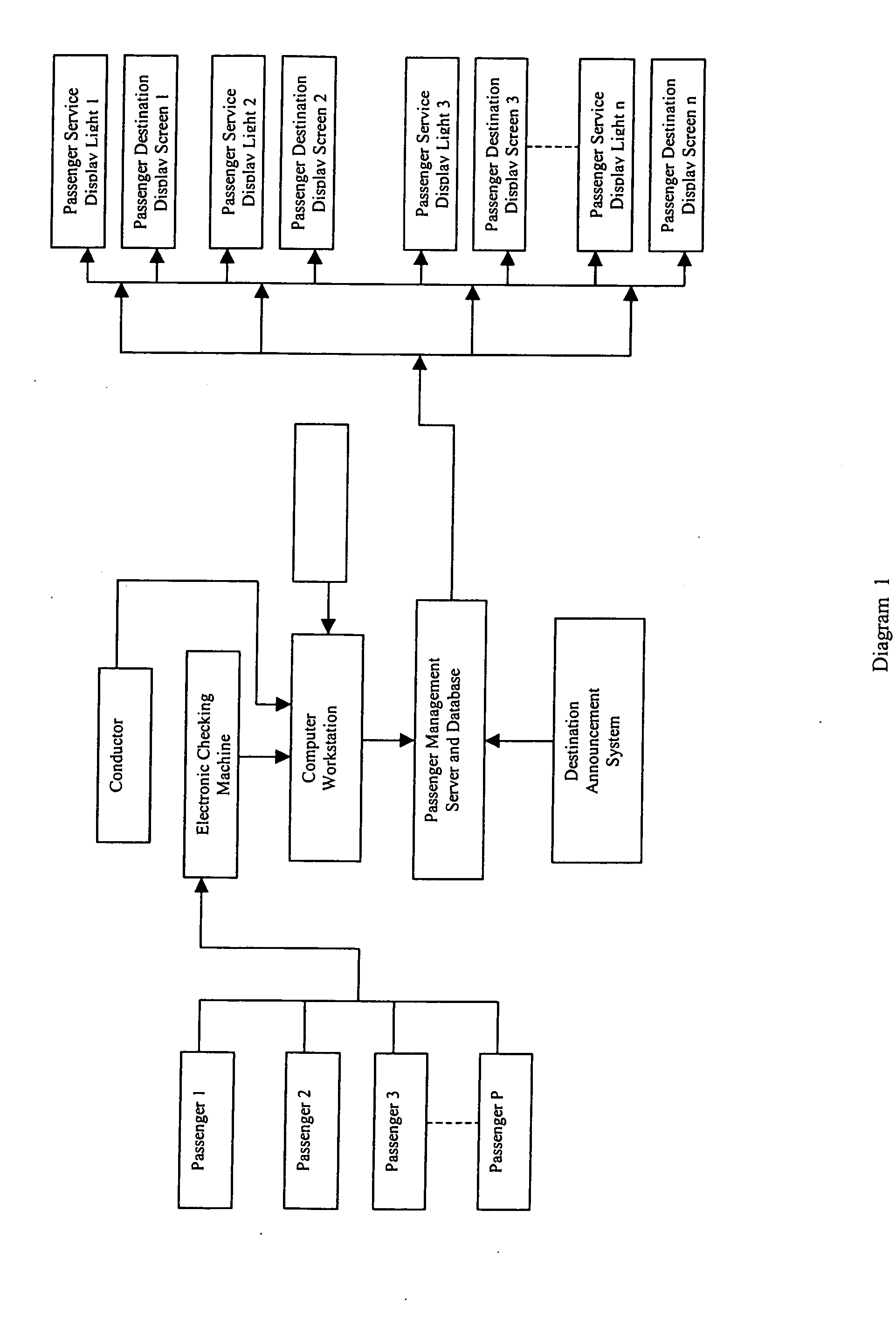

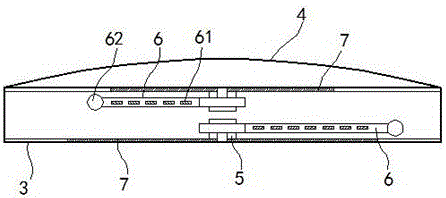

Electronic passenger management method and system in railroad passenger cars/long-distance buses

InactiveUS20070265891A1Improve levelImprove the level ofReservationsDatabase machinePassenger information

This present invention is directed to an electronic passenger management system and its corresponding techniques that can be applied to railroad passenger cars / long-distance buses. The system mainly consists of the following parts: an electronic ticket checking machine, a passenger information display device, a passenger management server and database, a computer workstation, and an electronic ticket reader. The computer network connects passenger management server with the electronic ticket checking machine, the passenger information display device, and the computer workstation. This system can be used to check tickets, assign seats, remind passengers of the arrival of destination, display names of destination, change seats, help passengers to purchase tickets on the spot, conduct data enquiries and statistical analyses. This present invention can redress the unsymmetrical status that widely exists between the advanced railroad system / long-distance bus system and the traditional method of requiring conductors to provide manual information to passengers and to replace the old traditional passive passenger information system with the advanced active electronic passenger management system, resulting in further improvement of passenger management and information levels in railroad trains / long-distance buses for their passengers.

Owner:GUO YIXIN

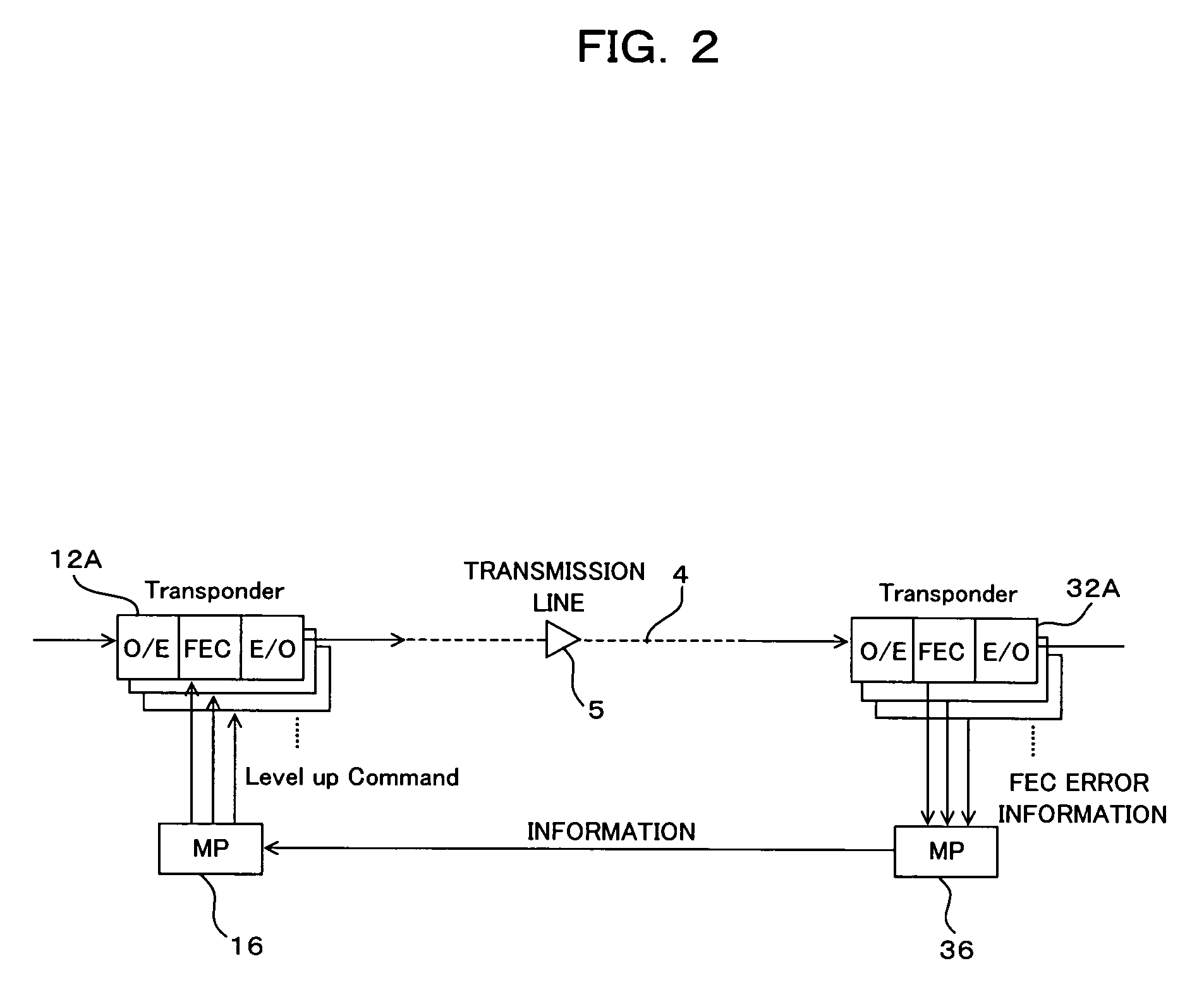

Terminal apparatus and controlling method for optical output power

InactiveUS20050207754A1Improve levelQuality controlWavelength-division multiplex systemsTransmission monitoringPower controlTerminal equipment

A terminal apparatus by which, even where BER data, for example, of an optical signal of an existing wavelength cannot be utilized, the optical output powers of the existing wavelength and an extension wavelength can be adjusted in a short period of time while eliminating quality degradation of the existing circuit. The terminal apparatus includes a level controlling section for controlling a total optical output power of an existing wavelength signal light and an extension wavelength signal light to a fixed level, a monitoring unit capable of monitoring the optical output power for each wavelength, and a controller for controlling the optical output power of the extension wavelength signal light so that the optical output power of the existing wavelength signal light monitored by the monitoring unit may not be lower than a minimum permissible optical output power.

Owner:FUJITSU LTD

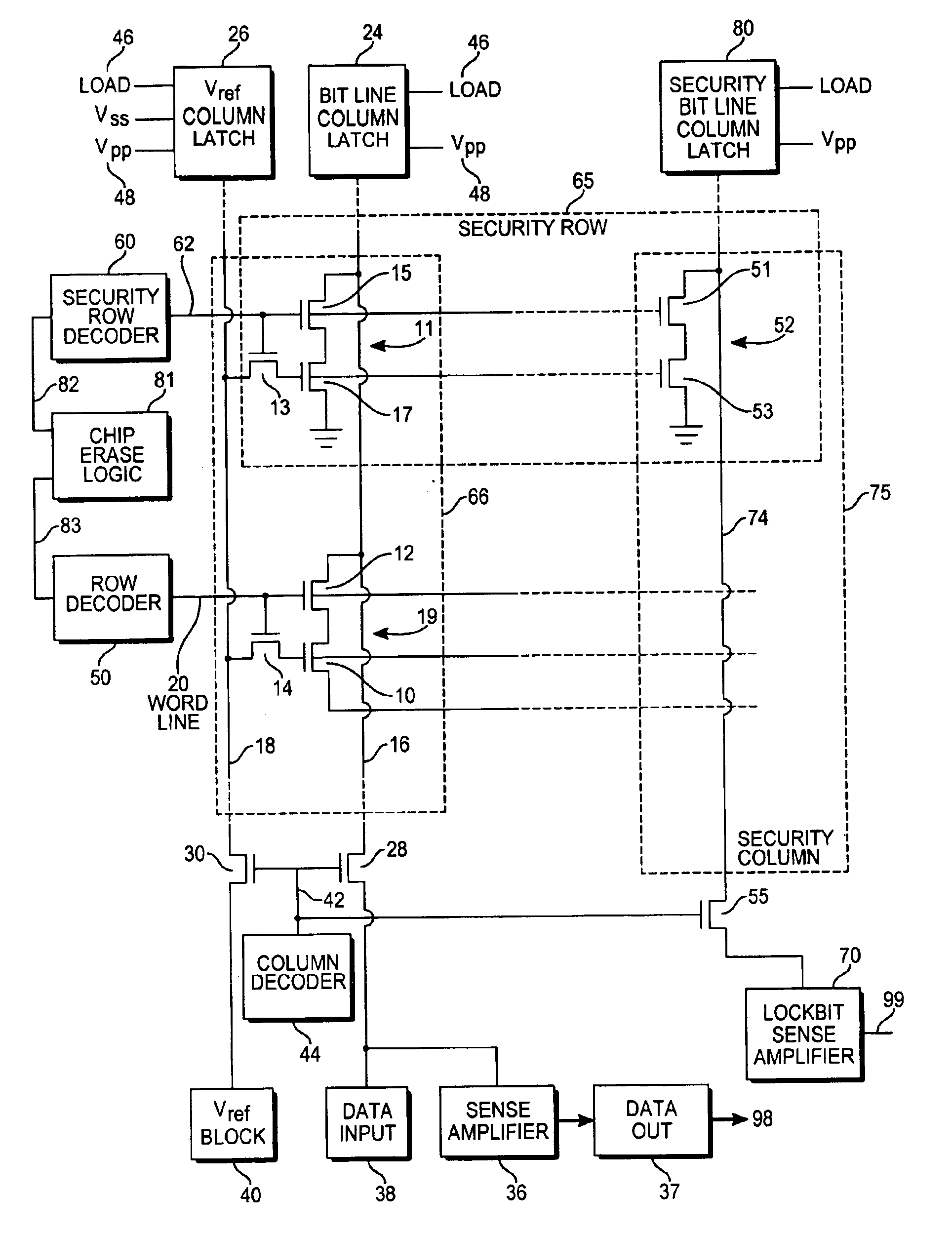

Embedded memory with security row lock protection

ActiveUS6879518B1High levelImprove levelRead-only memoriesDigital storageNon-volatile memoryEmbedded memory

A memory device having a memory array of nonvolatile memory elements also includes one or more security rows (or columns) of security bits that can be programmed to a locked status. External memory access requests are processed by first reading the corresponding security bit. If the requested row or column is locked, a default zero value is returned. Only external requests of unlocked locations, and all internal access requests, return the actual memory contents. Security bits can be erased (unlocked), but the secured contents of the locked row or column is also erased at the same time.

Owner:ATMEL CORP

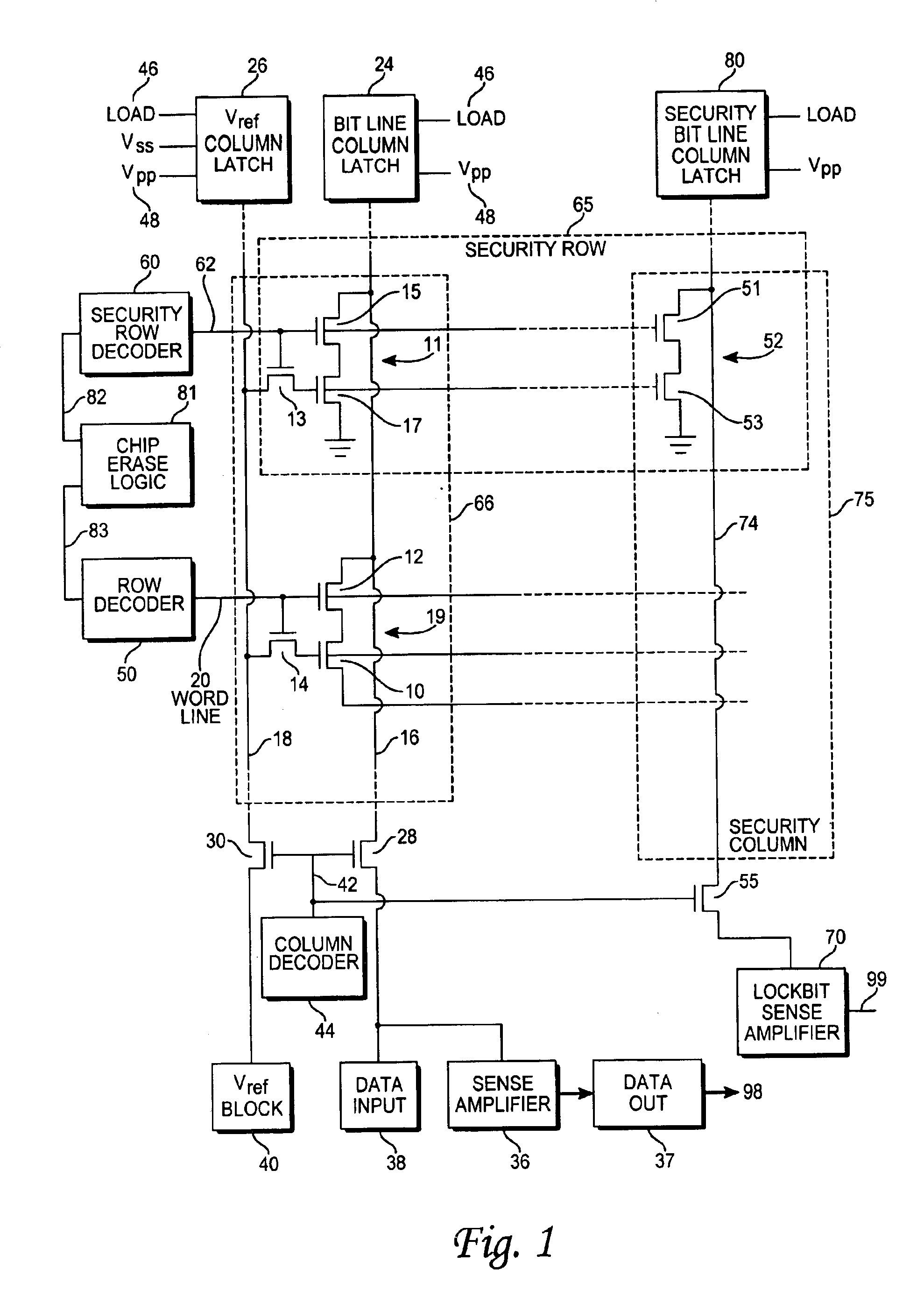

Long-acting growth hormone and methods of producing same

ActiveUS20140371144A1Reduce weight lossImprove levelPolypeptide with localisation/targeting motifPeptide/protein ingredientsChorionic gonadotrophinGrowth factor

Use of a growth hormone protein and polynucleotides encoding same comprising an amino-terminal carboxy-terminal peptide (CTP) of chorionic gonadotrophin and two carboxy-terminal chorionic gonadotrophin CTPs attached to the growth hormone in methods of inducing weight loss or body fat reduction, methods of increasing insulin-like growth factor (IGF-1) levels, and methods of reducing the dosing frequency of a growth hormone in a human subject are disclosed. Pharmaceutical compositions comprising the growth hormone and polynucleotides encoding the growth hormone of the invention and methods of using same are also disclosed.

Owner:OPKO BIOLOGICS

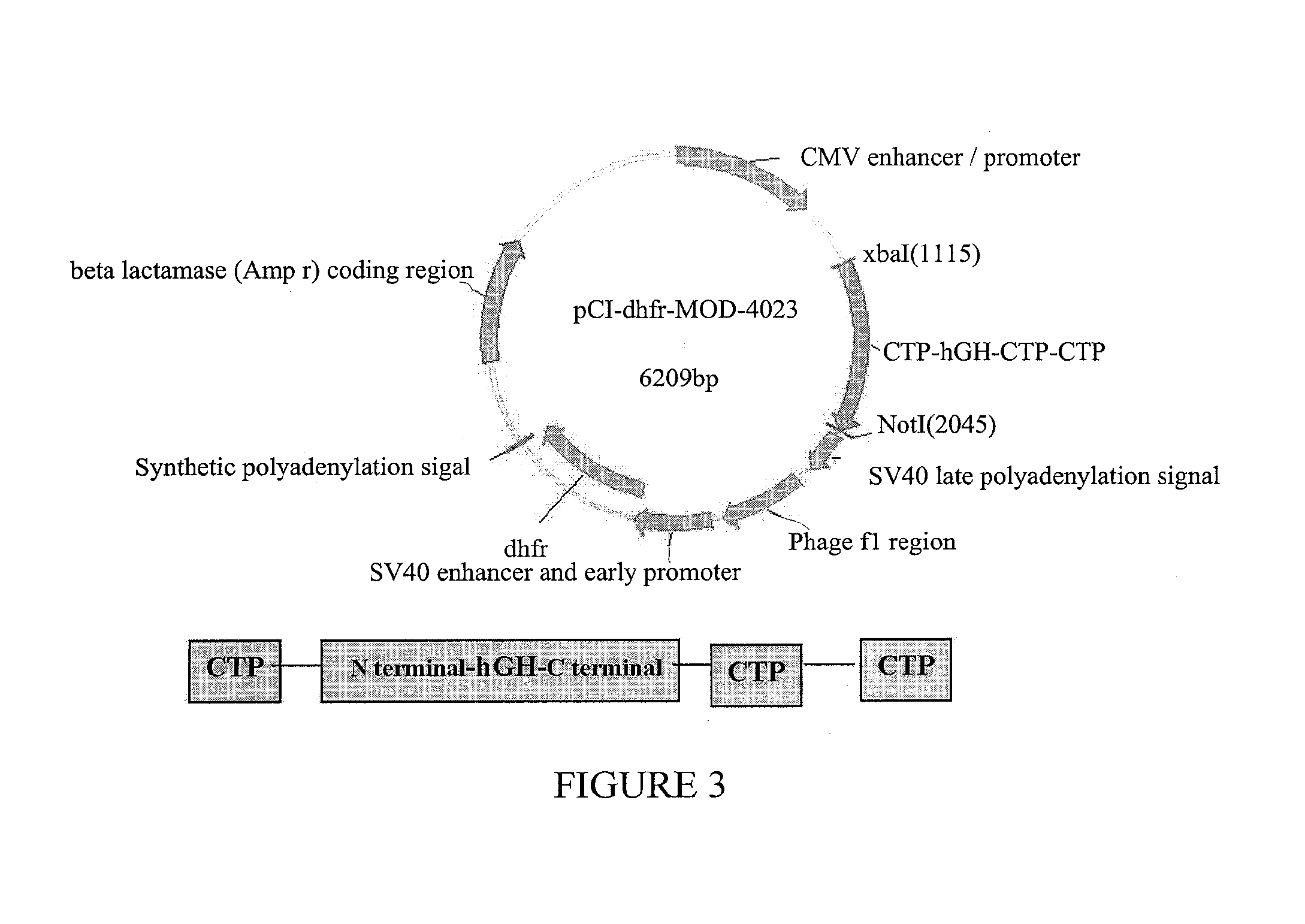

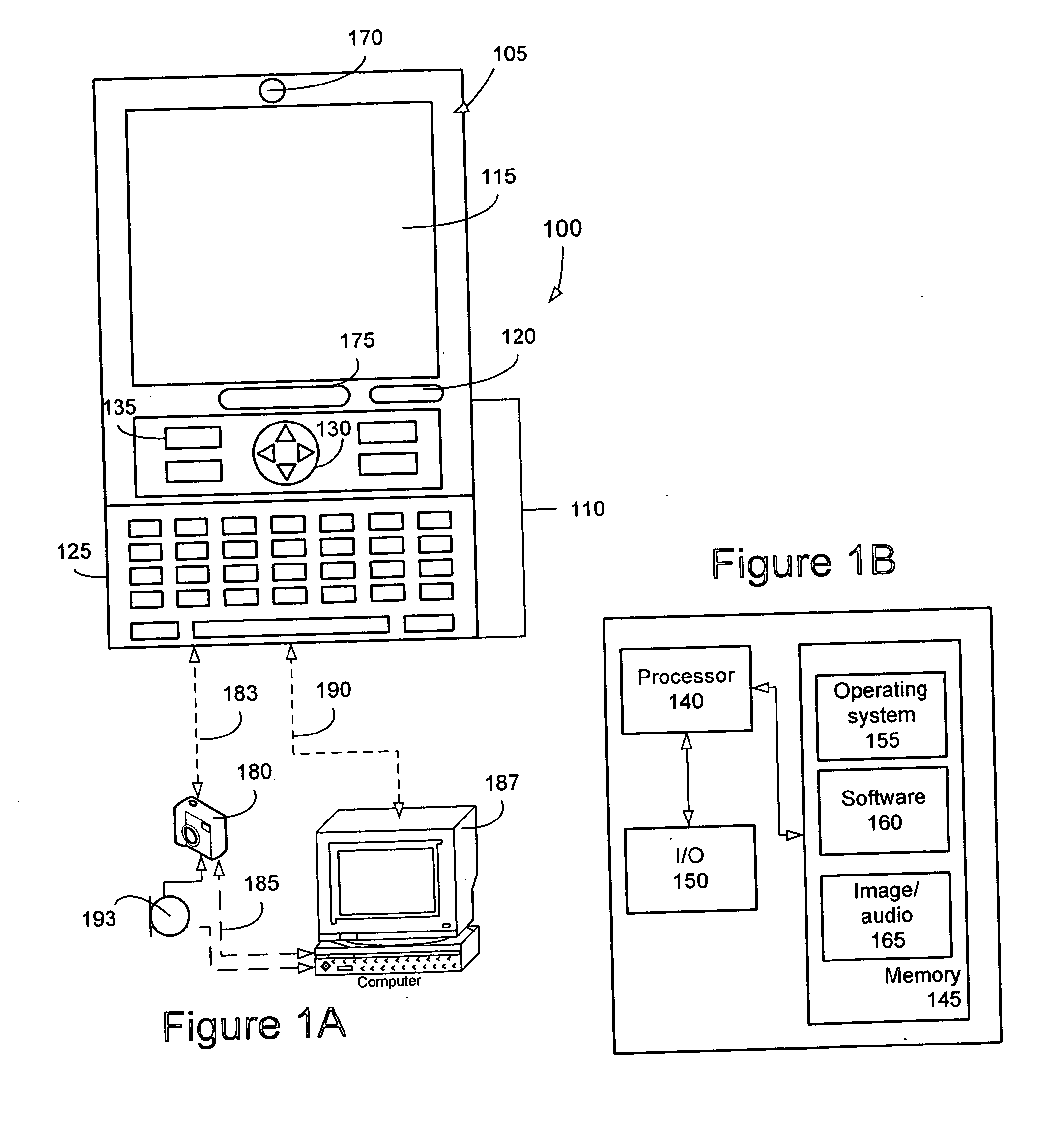

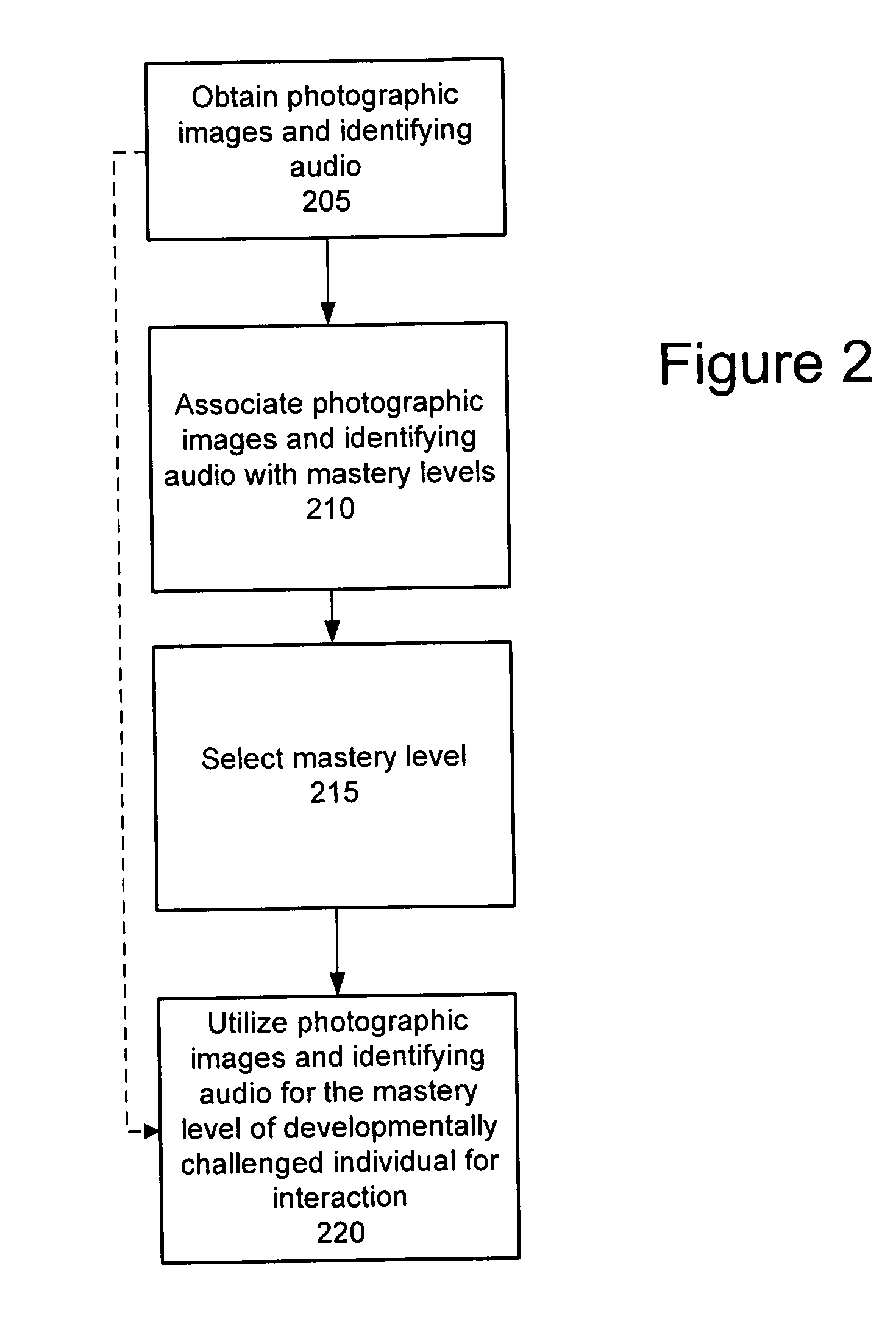

System for interacting with developmentally challenged individuals

InactiveUS20070259318A1Improved communicationImprove levelTeaching apparatusAudio frequencyInput device

An apparatus for interacting with a developmentally challenged individual is set forth. The apparatus includes a user input device, a visual display, an audio output device, and a processing system. The processing system is connected to control the visual display, the input device, and the audio output device and operates to display one or more photographic images on the visual display based on a mastery level of the developmentally challenged individual. The developmentally challenged individual communicates by selecting one of the a predetermined photographic images from the visual display using the user input device. In response to this selection, the processing system controls the audio output device to play audio vocalizations corresponding to the selected photographic image. As the mastery level of the developmentally challenged individual is increased, the photographic images on the visual display may be presented in a hierarchical manner, in effect increasing the communication vocabulary that is available to the developmentally challenged individual. In one example, the user input device, the visual display, the audio output device, and the processing system are integrated with one another to form a handheld unit.

Owner:HARRISON ELIZABETH V

Optical system of atomic oscillator and atomic oscillator

InactiveUS20100002231A1Improve S/N ratioImprove levelPulse automatic controlGaseous masersFluorescencePopulation

An optical system of an atomic oscillator that regulates an oscillation frequency by using an optical absorption property by one of a double resonance method utilizing light and micro waves and a coherent population trapping (CPT) method utilizing a quantum interference effect produced by two kinds of resonance light, includes: a light source emitting the resonance light; a gas cell disposed at an emitting side of the light source, sealing a gaseous metal atom therein and transmitting the resonance light through a metal atom gas; a light detecting unit detecting the transmitted light that is transmitted through the metal atom gas; and a fluorescence blocking unit blocking at least a part of fluorescence, which is emitted from the metal atom gas to the light detecting unit, and disposed between the metal atom gas and the light detecting unit.

Owner:SEIKO EPSON CORP

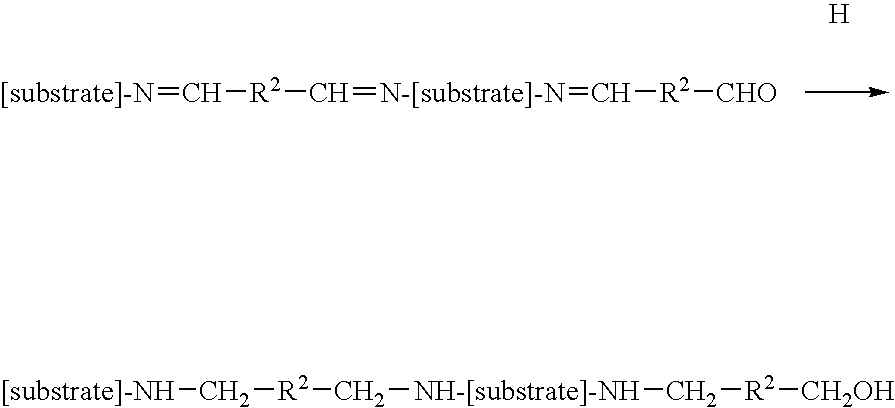

Treatment of implantable medical devices resistant to calcification

InactiveUS20080319166A1Improve levelSuppress occurrenceConnective tissue peptidesFibrinogenBorohydrideBiomedical engineering

Treatment of implantable medical devices resistant to calcification The invention relates to a method for treating an implant comprising a protein-based substrate, including the following steps in which:(A)—the protein-based substrate is treated with a compound containing at least one aldehyde group, then(B)—the substrate is treated with a compound comprising a borohydride, then(C)—the substrate resulting from step (B) is treated with a derivative containing a silane group.The invention also relates to the treated protein-based implant obtained at the end of this method.

Owner:LAB PEROUSE

High position stereo shelf warehouse super-flat terrace construction technology

The invention discloses a high position stereo shelf warehouse super-flat terrace construction technology comprising the following steps: 1, preparation work: setting up support templates and adjustable separate guide rails; 2, casting concrete in sectional warehouses, erecting a vibration beam on the separate guide rail, and using the vibration beam to vibrate and flatten the concrete; 3, manually leveling the surface of the concrete; 4, spraying hardener on the concrete surface after initial set of the concrete so as to form a hardened layer; 5, extracting mud, polishing and shinning the hardened layer until the flatness and levelness of the hardened layer surface complies with a preset precision requirement. The high position stereo shelf warehouse super-flat terrace construction technology can make the terrace with high flatness, levelness, and abradability, so the high position multilayer shelf can be stably mounted, logistic devices can be stably used, and the terrace can remain flat and smooth when the shelf and device are under fullload state.

Owner:CHINA LIGHT IND CONSTR

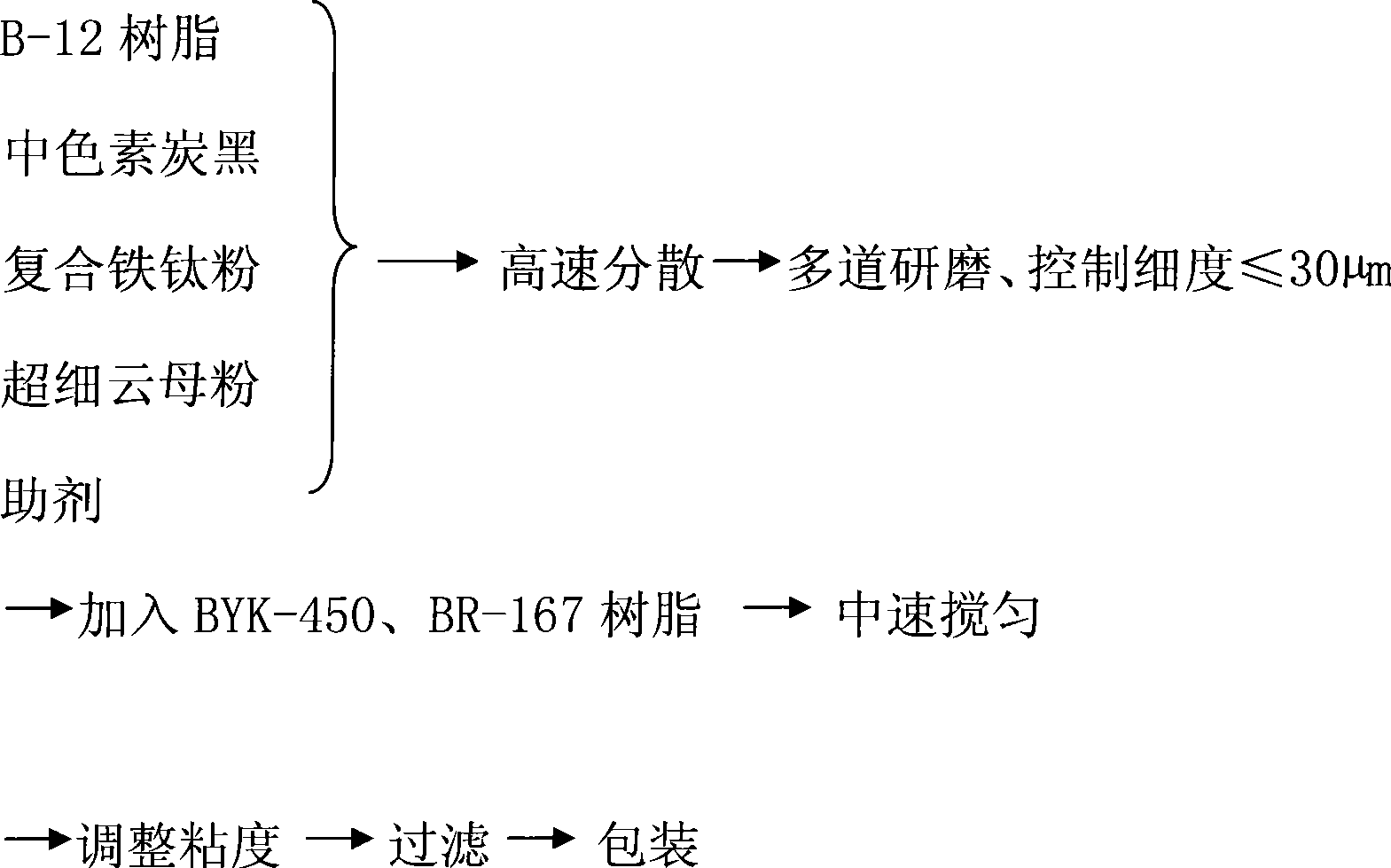

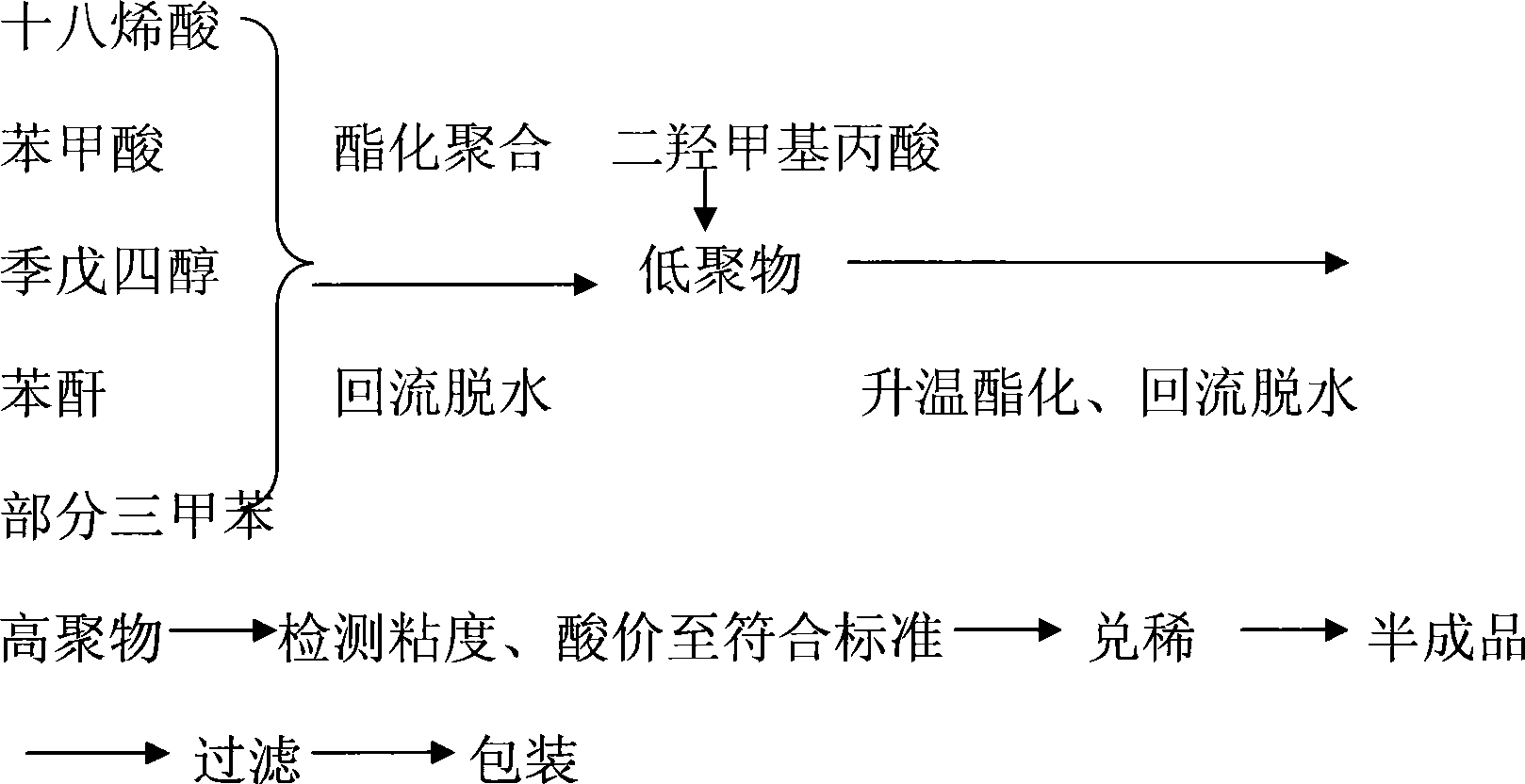

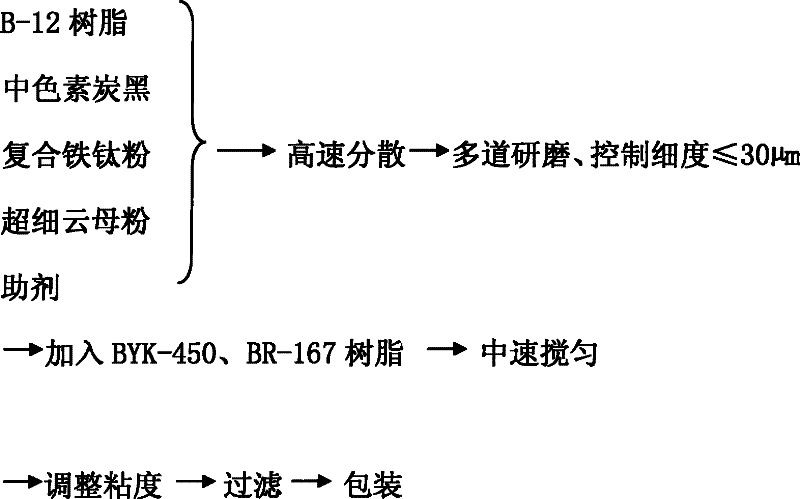

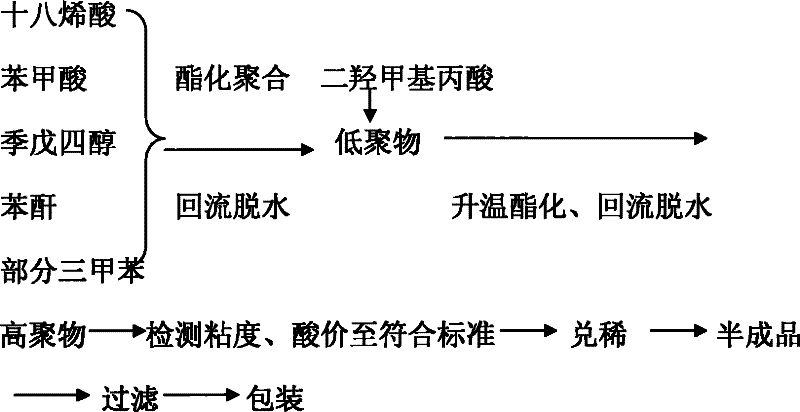

Low temperature quick-drying amino paint for automobile chassis and production method thereof

ActiveCN101434809AImprove efficiencyImprove coating efficiencyPolyester coatingsBenzoic acidPropanoic acid

The invention provides a low-temperature fast-dry amino automobile chassis paint and a production method thereof, wherein, the paint consists of B-12 resin, medium pigment carbon black, compound ferrotitanium powder, ultra-fine mica powder, an auxiliary agent, sealed paratoluenesulfonic acid BYK-450 and BR-167 amino resin; B-12 resin is prepared by octadecenoic acid, benzoic acid, pentaerythritol, phthalic anhydride, dimethylol propionic acid, and trimethyl benzene. The automobile chassis paint adopts special B-12 resin synthetic route to lead the polymer chain to have more active functional groups simultaneously to be matched with the blocked paratoluenesulfonic acid, reduces the baking temperature of the existing amino paint from 130 DEG C to 90 DEG C and reduces the curing film-forming time from 1 hour to half an hour. As the paint film has high crosslinking density, compound ferrotitanium powder and squamous anti-rust pigment are matched for use, and the polyaniline is used for improving the anticorrosive potentials, thus leading the salt spray resistance of the paint to achieve 150 hours and improving the protection performance and the coating efficiency.

Owner:ANQING LINGHU PAINT

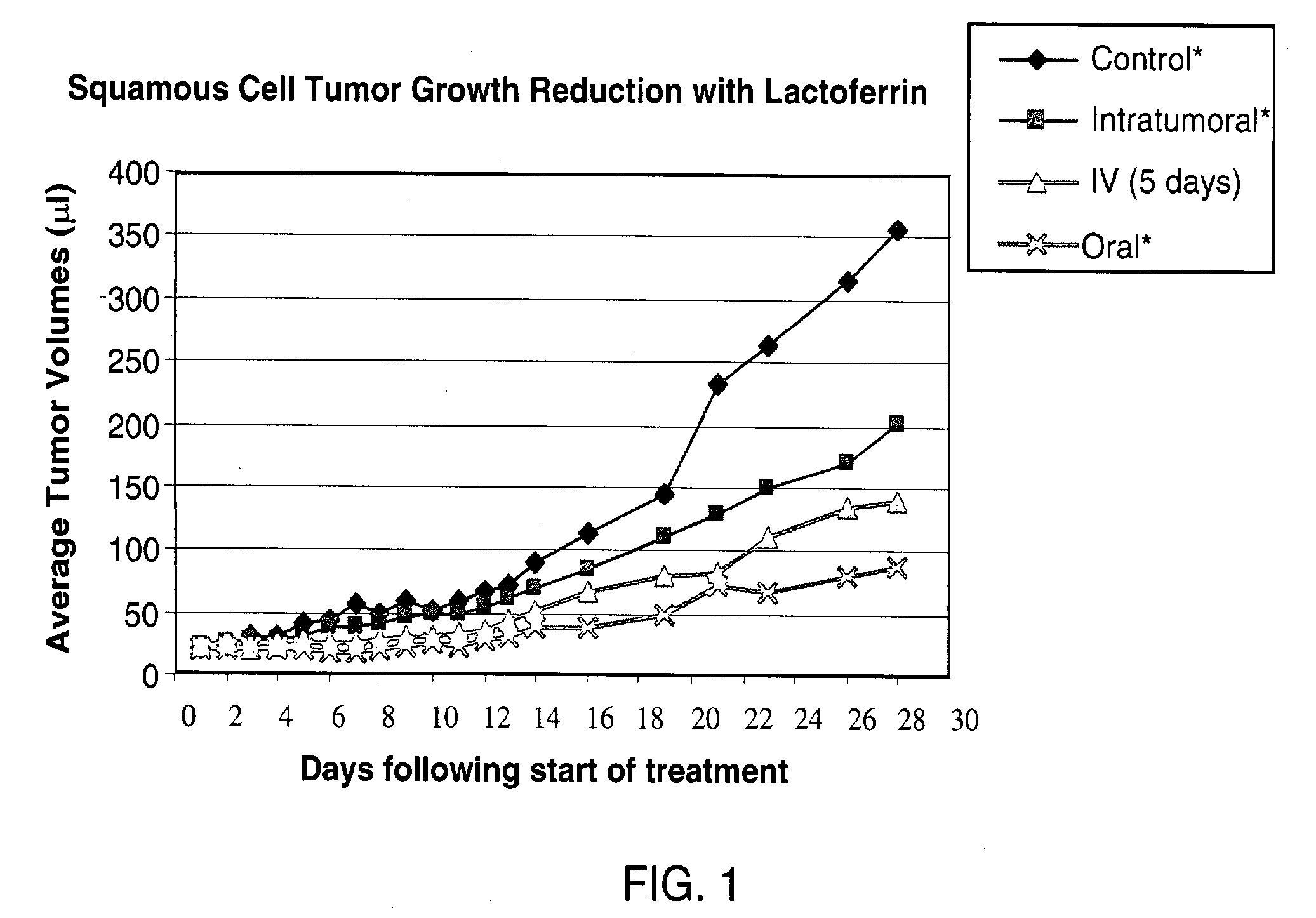

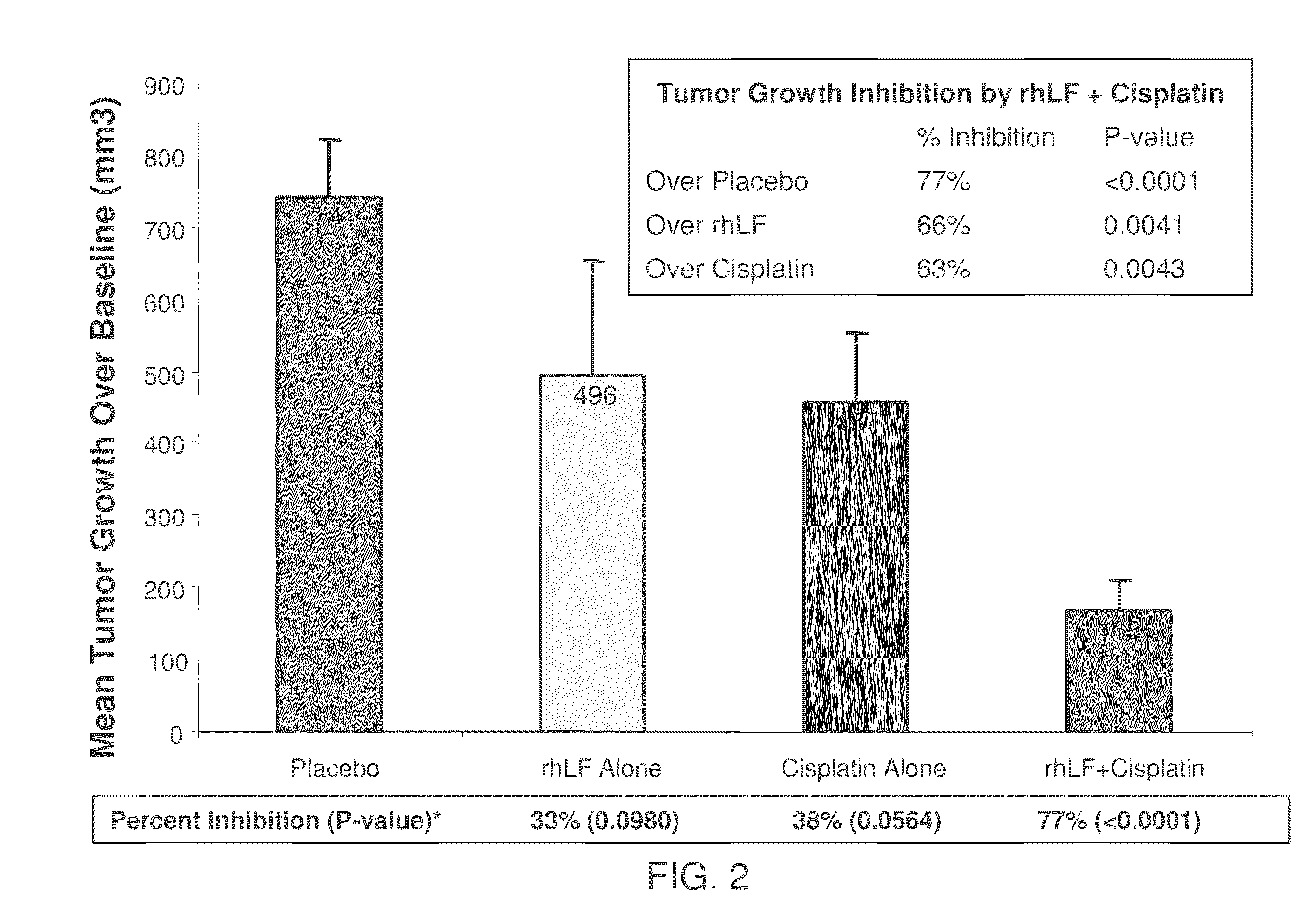

Intratumorally administered lactoferrin in the treatment of malignantneoplasms and other hyperproliferative diseases

InactiveUS20100137208A1Increase in amountImprove levelOrganic active ingredientsHeavy metal active ingredientsCancer therapyLactoferrin

The present invention relates to methods of treating a hyperproliferative disease by administering a composition of lactoferrin alone or in combination with standard anti-cancer therapies.

Owner:AGENNIX

Mortar levelling and paving device

InactiveCN110984585AImprove work efficiencyImprove levelBuilding material handlingMechanical engineeringData connection

The invention provides a mortar levelling and paving device, and belongs to the technical field of building construction equipment. The mortar levelling and paving device comprises a rack, a scrapingmechanism and leveling mechanisms. The scraping mechanism comprises a scraping part and a tilt angle sensor, the tilt angle sensor is arranged on the scraping part, and is used for detecting the tiltcondition of the scraping part, the two ends of the scraping part are each provided with one leveling mechanism, each leveling mechanism is connected with the rack and the corresponding end of the scraping part to form a linkage structure, the leveling mechanisms are used for being in data connection with the tilt angle sensor, according to the tilt condition, detected by the tilt angle sensor, ofthe scraping part, the corresponding ends of the scraping part are driven to lift, the scraping part swings to the leveling state under the linkage effect of the leveling mechanisms, the scraping part and the rack, the scraping part can be automatically leveled to level and pave the mortar, work efficiency is high, after leveling, levelness is high, and the levelness yield of the large-area mortar ground can be well ensured.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

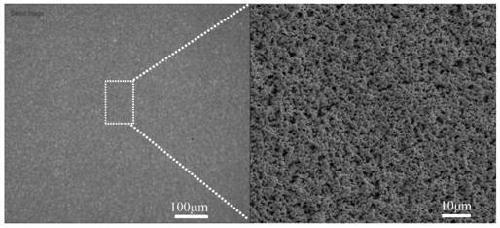

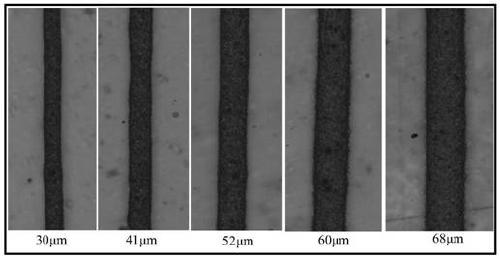

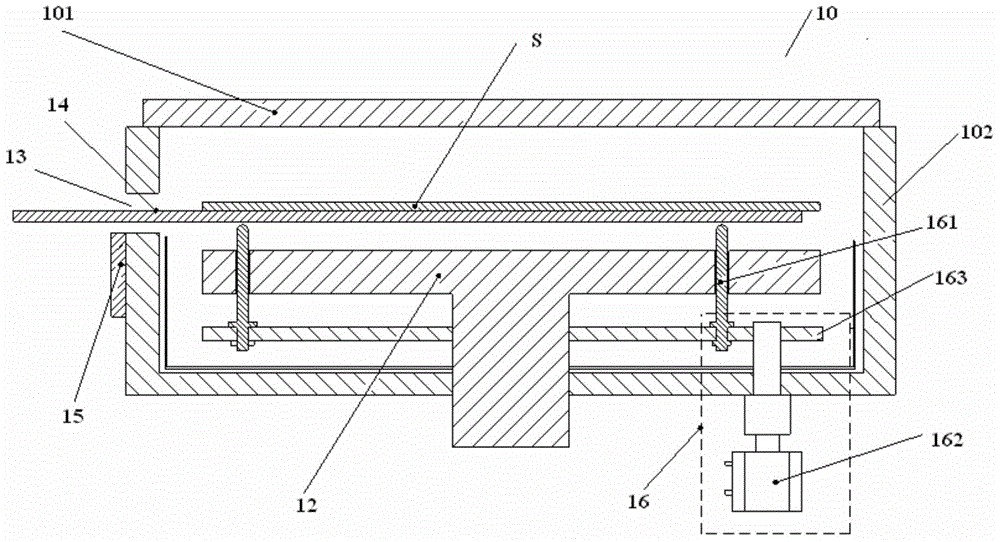

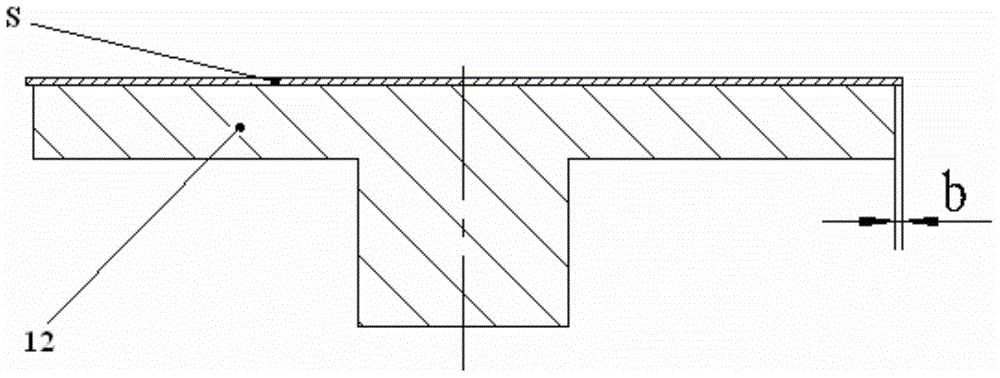

Preparation method of nano-silver paste for electric field driven jet micro-nano 3D printing

ActiveCN111180107AGuaranteed stabilityEvenly dispersedMaterial nanotechnologyNon-conductive material with dispersed conductive materialSilver pastePolymer resin

The invention provides a preparation method of nano-silver paste for electric field driven jet micro-nano 3D printing, and belongs to the technical field of conductive silver paste and micro-nano 3D printing. The nano-silver paste is composed of modified nano-silver powder, an organic carrier and polymer resin, wherein the weight ratio of the modified nano-silver powder to the organic carrier to the polymer resin is 55-75: 15-40: 1-10; and the organic carrier is composed of an organic solvent, a thickener, a plasticizer, a surfactant, a dispersing agent, a leveling agent and an additive, wherein the weight percentage ratio of the organic solvent to the thickener to the plasticizer to the surfactant to the dispersing agent to the leveling agent to the additive is 60-90: 2-10: 3-10: 1-8: 1-10: 1-10: 1-10. By modifying the nano-silver powder and adjusting all the components, the viscosity of the nano-silver powder is matched with electric field driven jet micro-nano 3D printing, ultra-fine large-depth-width-ratio high-performance conductive pattern manufacturing is achieved, and finally, excellent adhesive force and conductive performance are achieved, and particularly, the problem that due to agglomeration of nano silver materials, the use performance is unstable is solved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

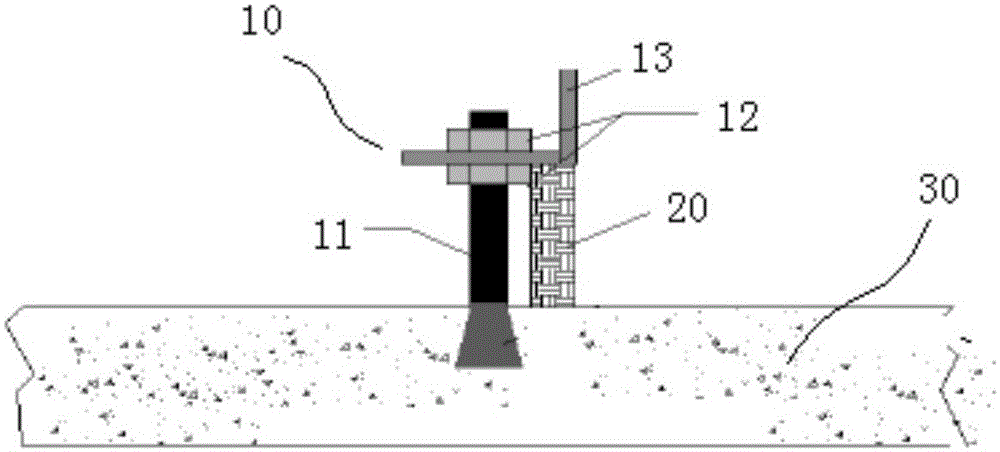

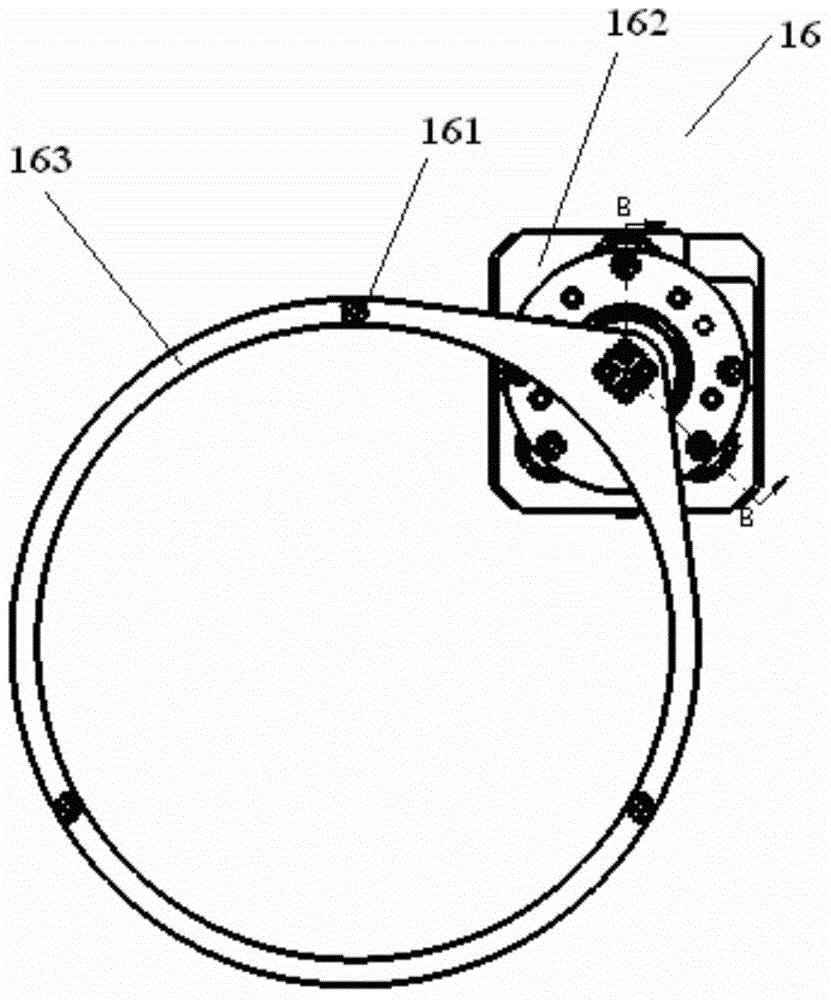

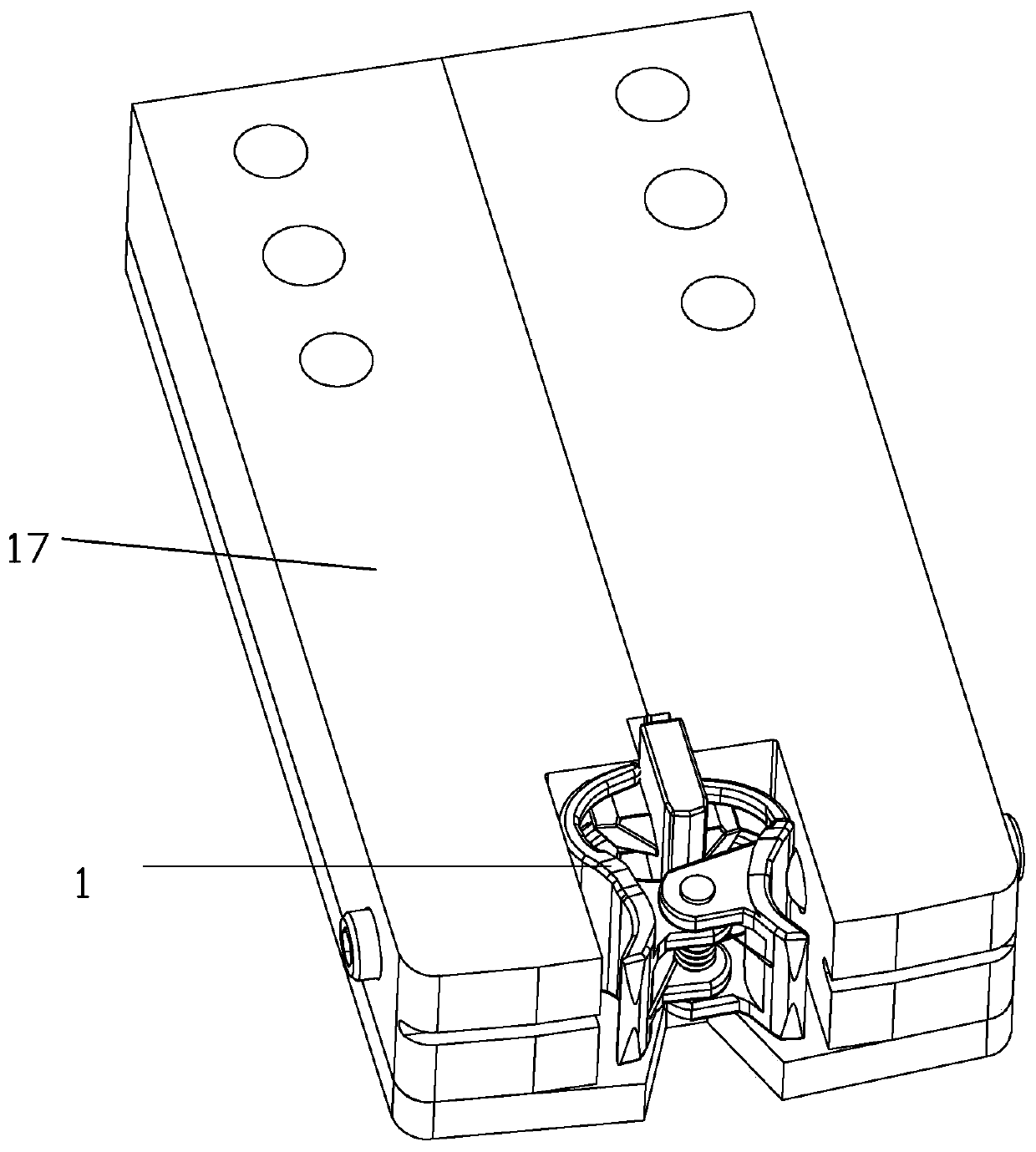

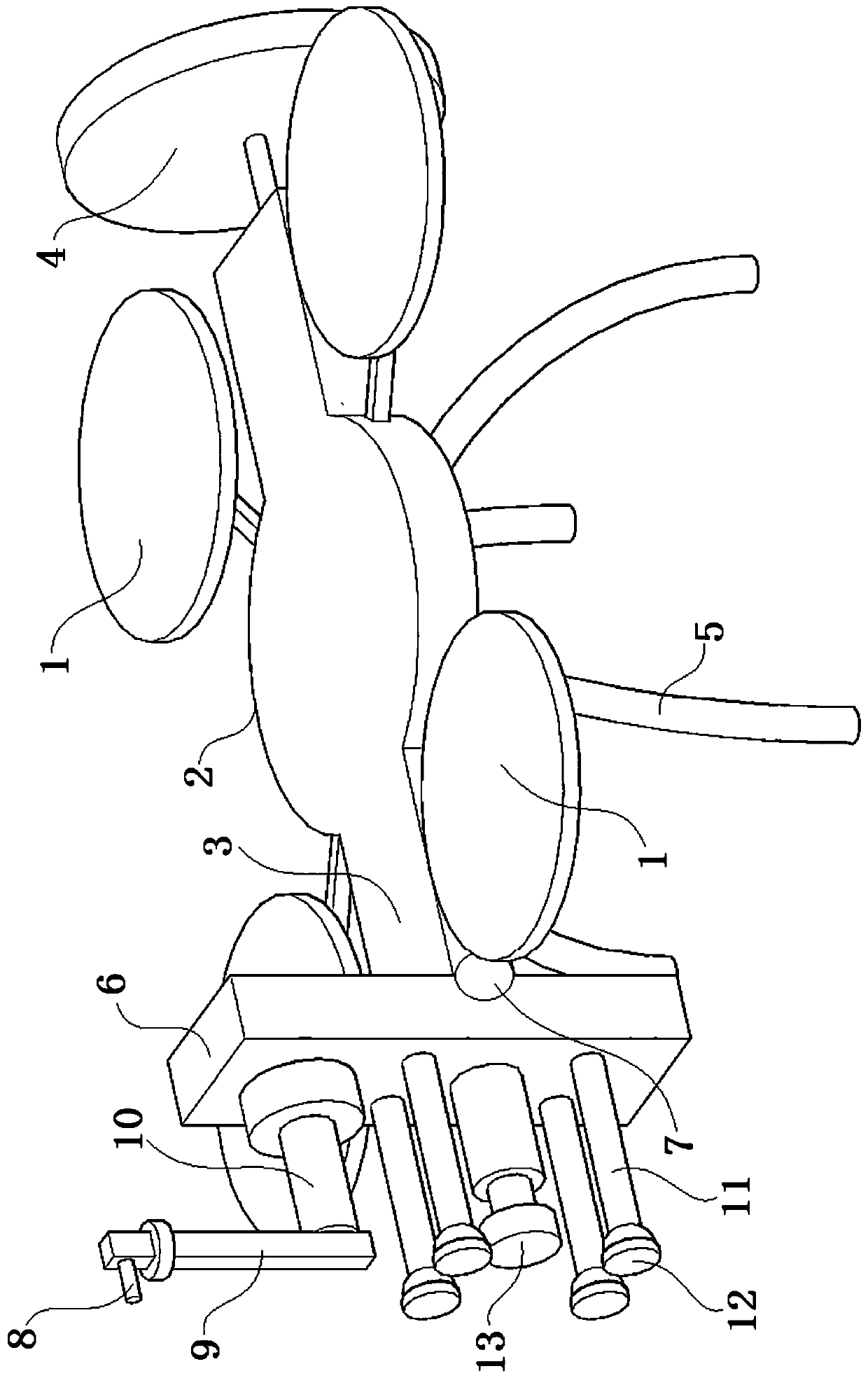

Ejector pin mechanism and plasma processing equipment

ActiveCN104658957AImprove levelImproved leveling accuracyElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma processingElastic component

The invention provides an ejector pin mechanism and a piece of plasma processing equipment. The ejector pin mechanism comprises at least three ejector pins and a holding bracket used for supporting the ejector pins. An elastic component is arranged between each ejector pin and the holding bracket. The heights of the elastic components can change within an elastic range under the action of pressure, which makes the heights of the ejector pins change relative to the height of the holding bracket. The ejector pin mechanism provided by the invention can improve the precision of horizontal adjustment, which enables the machining requirement and the assembly precision requirement on other components of the ejector pin mechanism to be lowered to a certain extent. Moreover, the ejector pin mechanism can help to shorten the time of horizontal adjustment and improve the work efficiency.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

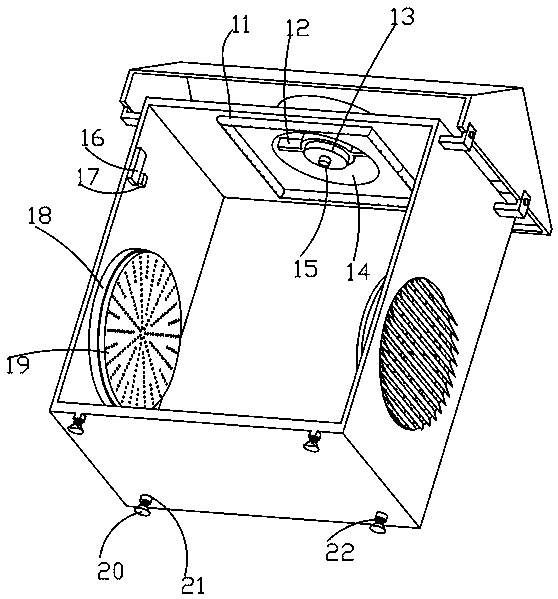

Uniform heating large microwave oven

ActiveCN106524242AIrregular movementSpread evenlyDomestic stoves or rangesLighting and heating apparatusMicrowave ovenEngineering

The invention relates to a uniform heating large microwave oven. The uniform heating large microwave oven includes an oven body and a closed door. Horizontal linings are clamped in the oven body at an equal distance, each lining includes an upper plate and a lower plate, and reflection discs are flexibly placed the upper plate and lower plate. Each reflection disc includes a reflection shell and a reflection mirror, a top plate and base plate in the reflection shell are equipped with spring discs, the two spring discs are over against each other coaxially, and the center shafts of the spring discs are perpendicular to the base plate of the reflection shell. The tightening ends of the two spring discs are exposed out of the reflection shell and are disposed on the surface of the reflection shell. In the reflection shell, the two spring discs are respectively equipped with a rotating pendulum capable of rotating around the center shafts of the spring discs, and the two rotating pendulums are different in length. The microwave oven has a novel structure, can realize uniform heating of food materials within unit time, ensures the quality and qualification rate of the product, and also improves the space utilization rate of the microwave oven at the same time.

Owner:兰溪市市场开发服务有限公司

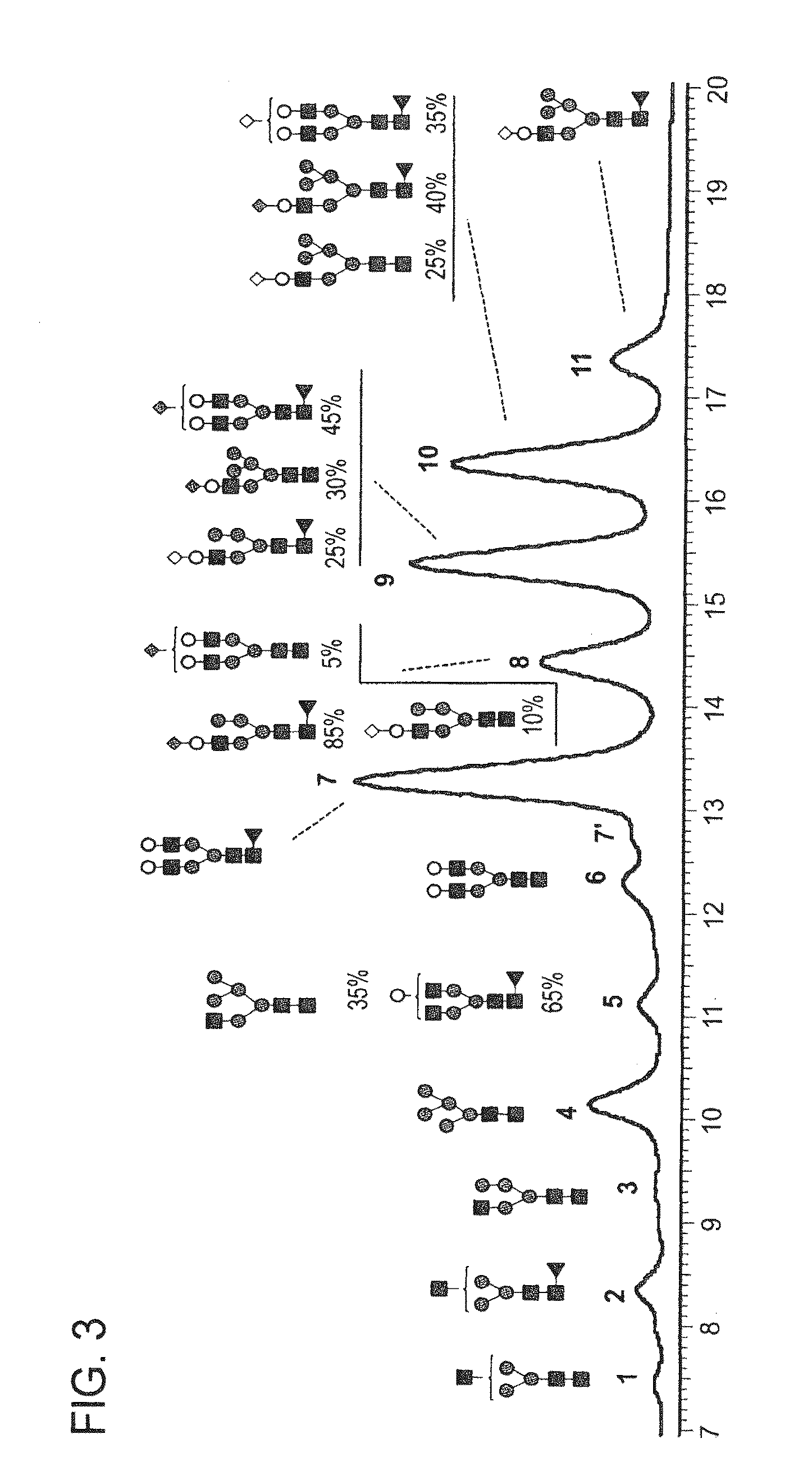

Highly galactosylated Anti-tnf-alpha antibodies and uses thereof

InactiveUS20150368334A1Improved complement dependent cytotoxicityImprove levelAntipyreticMilk immunoglobulinsAdalimumabPopulation

In one aspect, the disclosure relates to highly galactosylated anti-TNF-alpha antibodies and compositions thereof. In one aspect, the disclosure relates to populations of anti-TNF-alpha antibodies with a high level of galactosylation, and compositions thereof. In one aspect, the disclosure relates to methods of production and use of highly galactosylated anti-TNF-alpha antibodies and populations of anti-TNF-alpha antibodies with a high level of galactosylation. In some embodiments, the anti-TNF-alpha antibody is adalimumab.

Owner:LABE FR DU FRACTIONNEMENT & DES BIOTECH SA

Sending device for clip pieces of small jaw clips

PendingCN109909705AAvoid flippingReduce flipMetal working apparatusEngineeringMechanical engineering

Owner:浙江宏日自动化科技有限公司

Composition Comprising Lactobacillus Plantarum 2830 (ECGC 13110402)

ActiveUS20180318364A1Enhanced cholesterol reduction and controlImprove levelPowder deliveryBacteria material medical ingredientsMutant strainLactobacillus plantarum

The present invention relates to compositions comprising Lactobacillus plantarum 2830 (ECGC 13110402), or mutant strain or strains thereof, for use in the treatment or prevention of hypercholesterolaemia, and in particular reducing the total cholesterol (TC) and low density lipoprotein cholesterol (LDL-C) levels, in an individual. Specific dosage regimes and methods of production are also claimed and described.

Owner:PROBIOTIX HEALTH LTD

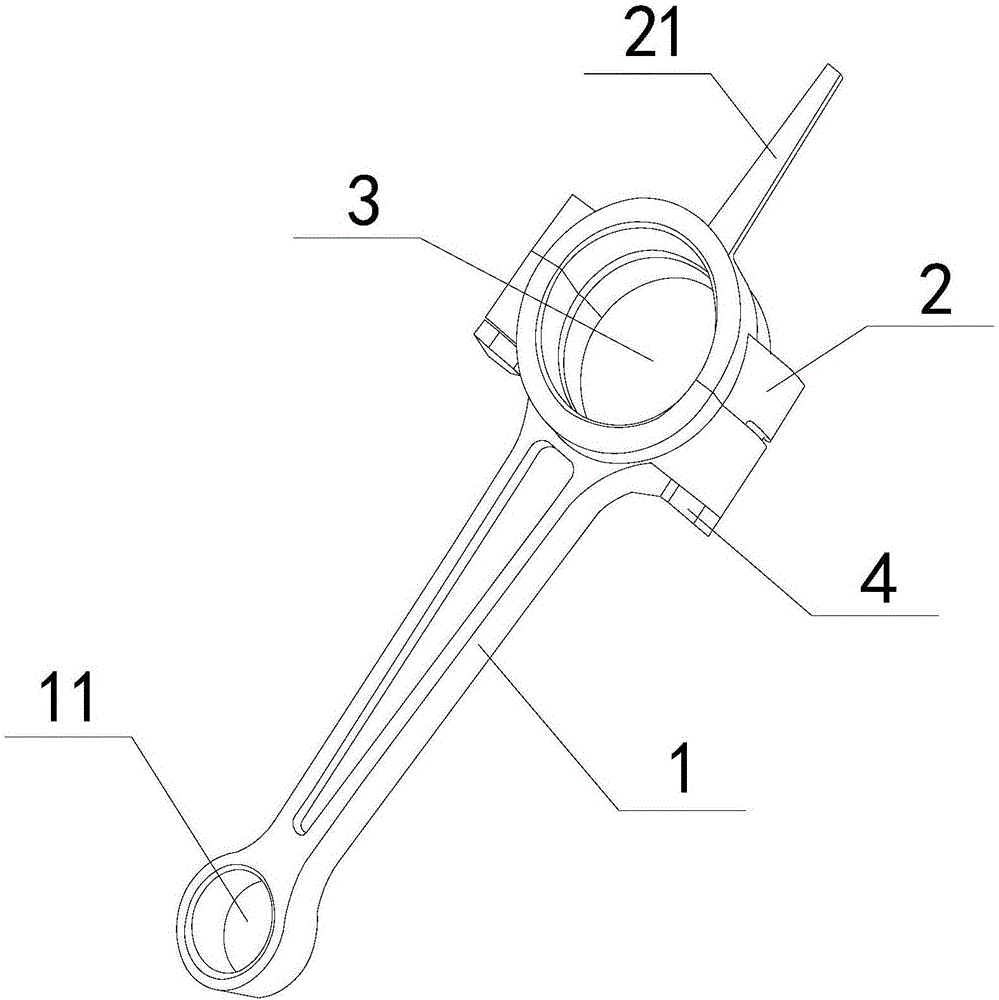

Machining method for engine connecting rod

The invention relates to a machining method for an engine connecting rod. The machining method for the engine connecting rod includes the following steps that (a) the two end surfaces of the connecting rod are subjected to rough grinding, a small-head hole is drilled and enlarged, a large-head hole and the small-head hole are subjected to rough boring, the small-head hole is subjected to semi-finished boring, a bolt boss is milled, a bolt hole is drilled or tapped, and deburring is carried out; (b) linear cutting is carried out on the position, corresponding to a cracking plane, of the inner edge of the large-head hole to form a V-shaped cracking groove, and the V-shaped cracking groove is symmetrical relative to the cracking plane to form an initial cracking source; (c) the connecting rod is heated to 150-250 DEG C, a hydraulic cylinder drives a bidirectional wedge block to move downwards and be pressed into a semicircular movable sleeve, the semicircular movable sleeve is pushed to act on the inner wall of the large-head hole, the large-head hole is cracked instantly, a connecting rod cover and a connecting rod body are separated, and cold water is sprayed; and (d) the cracked connecting rod is subjected to fine machining, and a cracked connecting rod finished product is formed. The connecting rod is heated and sprayed with the cold water after the connecting rod cover and the connecting rod body are separated, the strength of the engine connecting rod can be improved, and the levelness of the cracking plane of the connecting rod cover and the connecting rod body can be improved as well.

Owner:苏州利达铸造有限公司

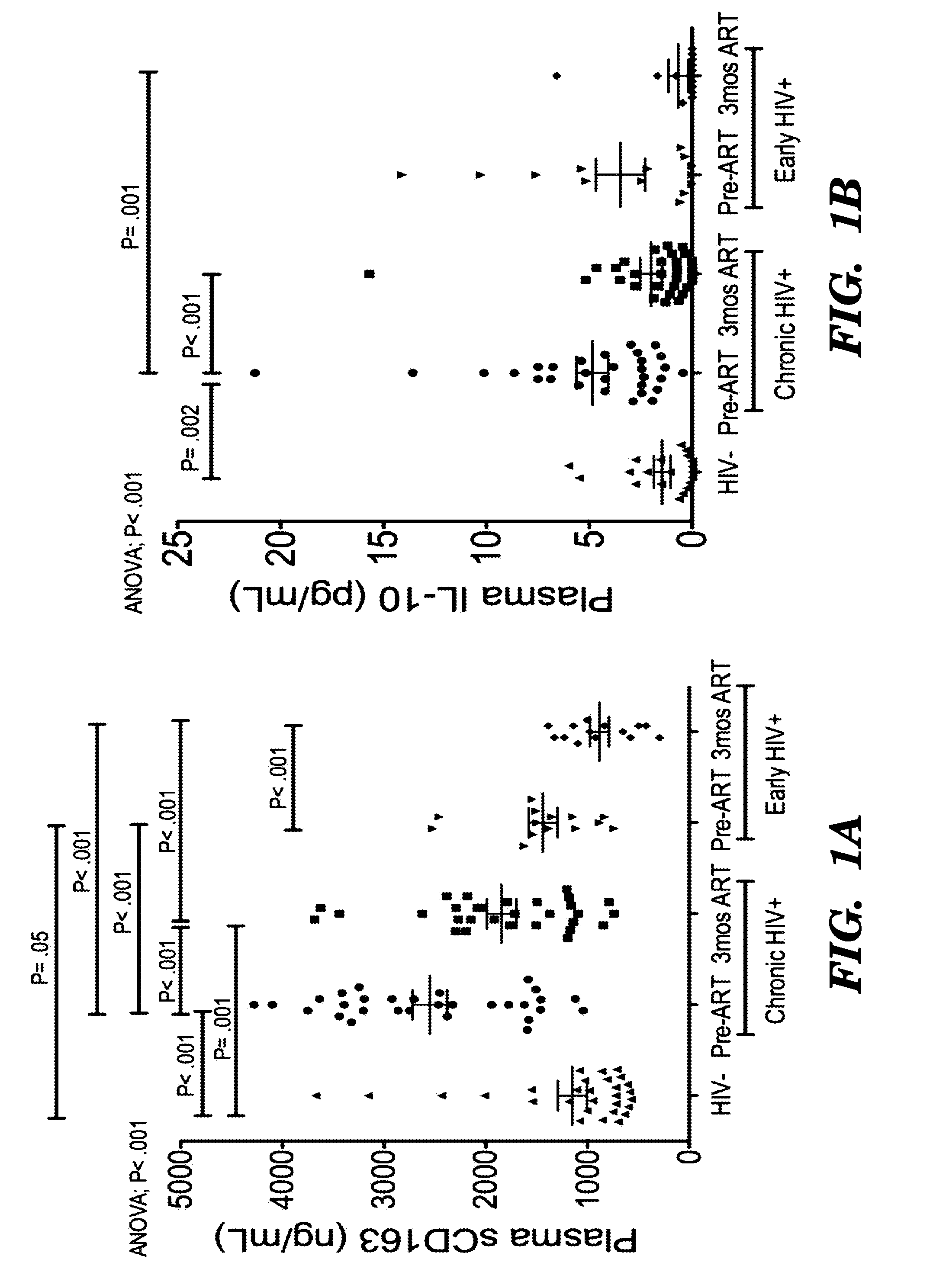

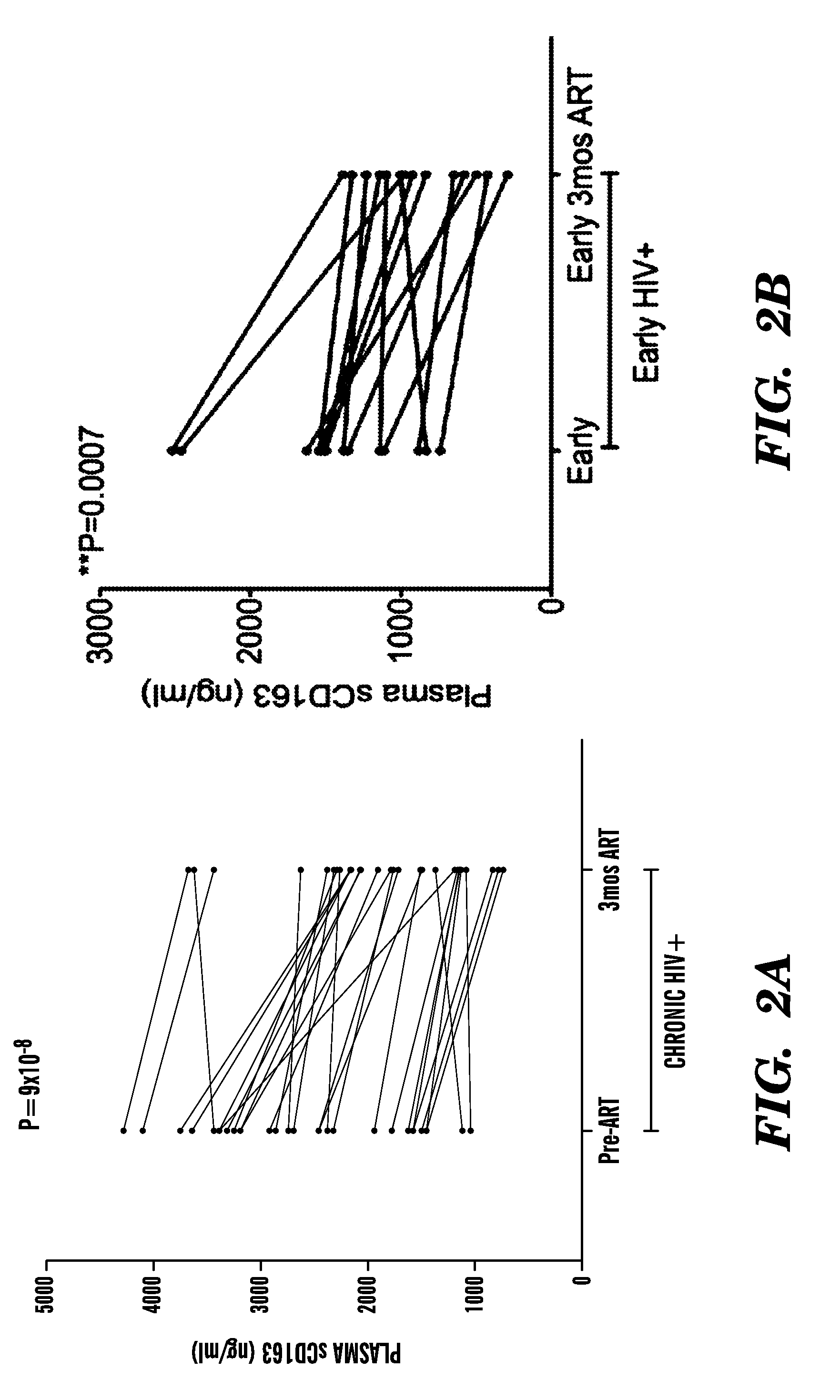

Assays and methods for determining risk of a macrophage-mediated disease development in a subject infected with HIV

InactiveUS20130244965A1Decrease in levelImprove levelBioreactor/fermenter combinationsBiocideDrugOrganism

The invention is generally related to assays and methods for determining the risk of an HIV+ individual for developing a macrophage-mediated disease using measurement of soluble CD163 levels in a biological sample. The invention also provides assays and methods for monitoring efficacy of a treatment or a drug for a macrophage-mediated disease, and assays and methods for screening for agents to treat a macrophage-mediated disease in an HIV+ individual by monitoring soluble CD163 levels.

Owner:THE GENERAL HOSPITAL CORP +1

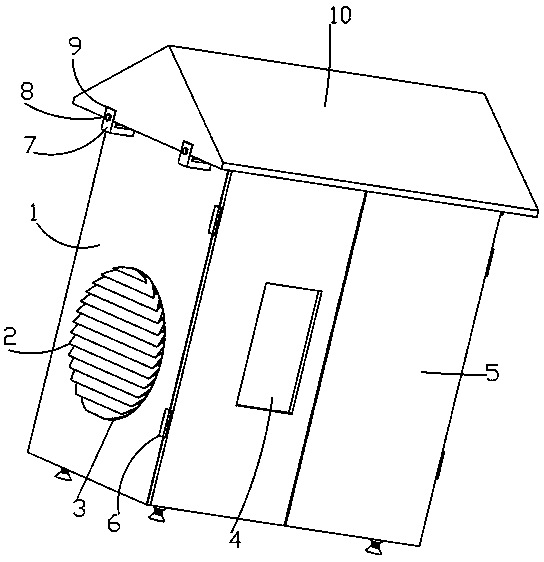

Electrical cabinet with smoke-sensing cooling and dehumidifying device

InactiveCN111211500AAvoid damageImprove securitySubstation/switching arrangement cooling/ventilationFire rescueFire - disastersEngineering

The invention relates to an electrical cabinet with a smoke-sensing cooling and dehumidifying device in the field of electrical equipment. An electrical cabinet is included, and the electrical cabinetis provided with an adjustable supporting structure. An air vent is arranged on the electrical cabinet, and the electrical cabinet is provided with a rain-shielding inclined plate; the electrical cabinet is provided with a threaded sleeve, the threaded sleeve is connected with a circular partition plate; the circular partition plate is provided with a drying agent placing disc filled with a drying agent; through holes are uniformly arranged in side walls of the circular partition plate and the drying agent placing disc; the electrical cabinet is provided with a controller and a protection switch; a straight hole is arranged on the electrical cabinet, the straight hole is provided with a mounting rack, a fan is arranged on the mounting rack, an aerosolizer is arranged on the fan, a fire extinguishing structure is arranged on the electrical cabinet, and the electrical cabinet is provided with a movable installation structure; the movable installation structure is provided with a cabinettop; and the electrical cabinet is provided with a hinge, and the hinge is fixedly connected with a door plate. The electrical cabinet is helpful for reducing a temperature of electrical components in the electrical cabinet, a possibility of fire disasters is avoided, the electrical cabinet is well protected and losses are reduced, and meanwhile, corrosion of damp air to the electrical cabinet made of metal and the electrical components in the electrical cabinet can be avoided, and a service life of equipment is prolonged.

Owner:柴宣何

Unmanned aerial vehicle for measuring coating film thickness of high-rise steel structure

PendingCN110435891ASpace state stabilityWide range of measurementsMeasurement devicesAircraftsEngineeringRotational degrees of freedom

The invention discloses an unmanned aerial vehicle for measuring the coating film thickness of a high-rise steel structure. The unmanned aerial vehicle comprises a flight mechanism, a film measuring mechanism and an adsorption and separation mechanism; the flight mechanism comprises a fuselage connected with a plurality of horizontal rotor wings; the film measuring mechanism comprises an equipmentplate assembled on the fuselage through a rotary shaft, the equipment plate has the rotational degree of freedom at least within the straight angle range around the axis of the rotary shaft, and a film measuring probe is fixed to the equipment plate; and the film measuring mechanism and the adsorption and separation mechanism are both arranged on the same surface of the equipment plate, the adsorption and separation mechanism comprises a vertical rod and a jacking mechanism which are vertically fixed to the equipment plate, a permanent magnet is arranged at the top end of the vertical rod, the jacking mechanism has the linear reciprocating degree of freedom in the direction parallel to the vertical rod, and the vertical distance between the permanent magnet and the equipment plate is within the vertical distance between the top end of the jacking mechanism and the equipment plate when the top end of the jacking mechanism is located at the two limit positions. By adopting the unmannedaerial vehicle, paint film detection can be conducted on the steel structure at the high position which is inaccessible to people, the upper surface, the lateral facades and the lower surface of the steel structure all can be detected, and thus the unmanned aerial vehicle is widely applied.

Owner:NANTONG INST OF TECH

Low temperature quick-drying amino paint for automobile chassis and production method thereof

The invention provides a low-temperature fast-dry amino automobile chassis paint and a production method thereof, wherein, the paint consists of B-12 resin, medium pigment carbon black, compound ferrotitanium powder, ultra-fine mica powder, an auxiliary agent, sealed paratoluenesulfonic acid BYK-450 and BR-167 amino resin; B-12 resin is prepared by octadecenoic acid, benzoic acid, pentaerythritol, phthalic anhydride, dimethylol propionic acid, and trimethyl benzene. The automobile chassis paint adopts special B-12 resin synthetic route to lead the polymer chain to have more active functional groups simultaneously to be matched with the blocked paratoluenesulfonic acid, reduces the baking temperature of the existing amino paint from 130 DEG C to 90 DEG C and reduces the curing film-formingtime from 1 hour to half an hour. As the paint film has high crosslinking density, compound ferrotitanium powder and squamous anti-rust pigment are matched for use, and the polyaniline is used for improving the anticorrosive potentials, thus leading the salt spray resistance of the paint to achieve 150 hours and improving the protection performance and the coating efficiency.

Owner:ANQING LINGHU PAINT

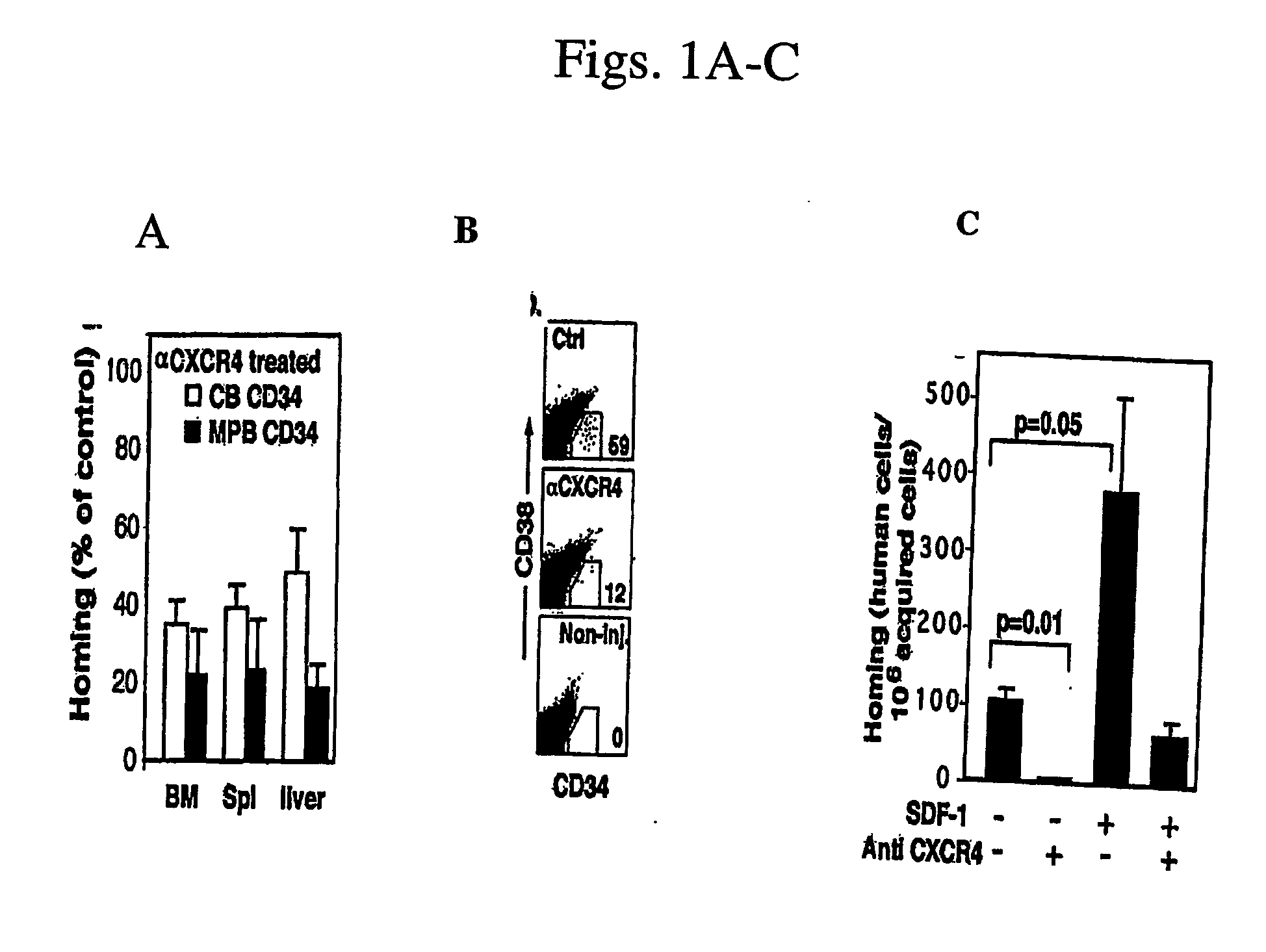

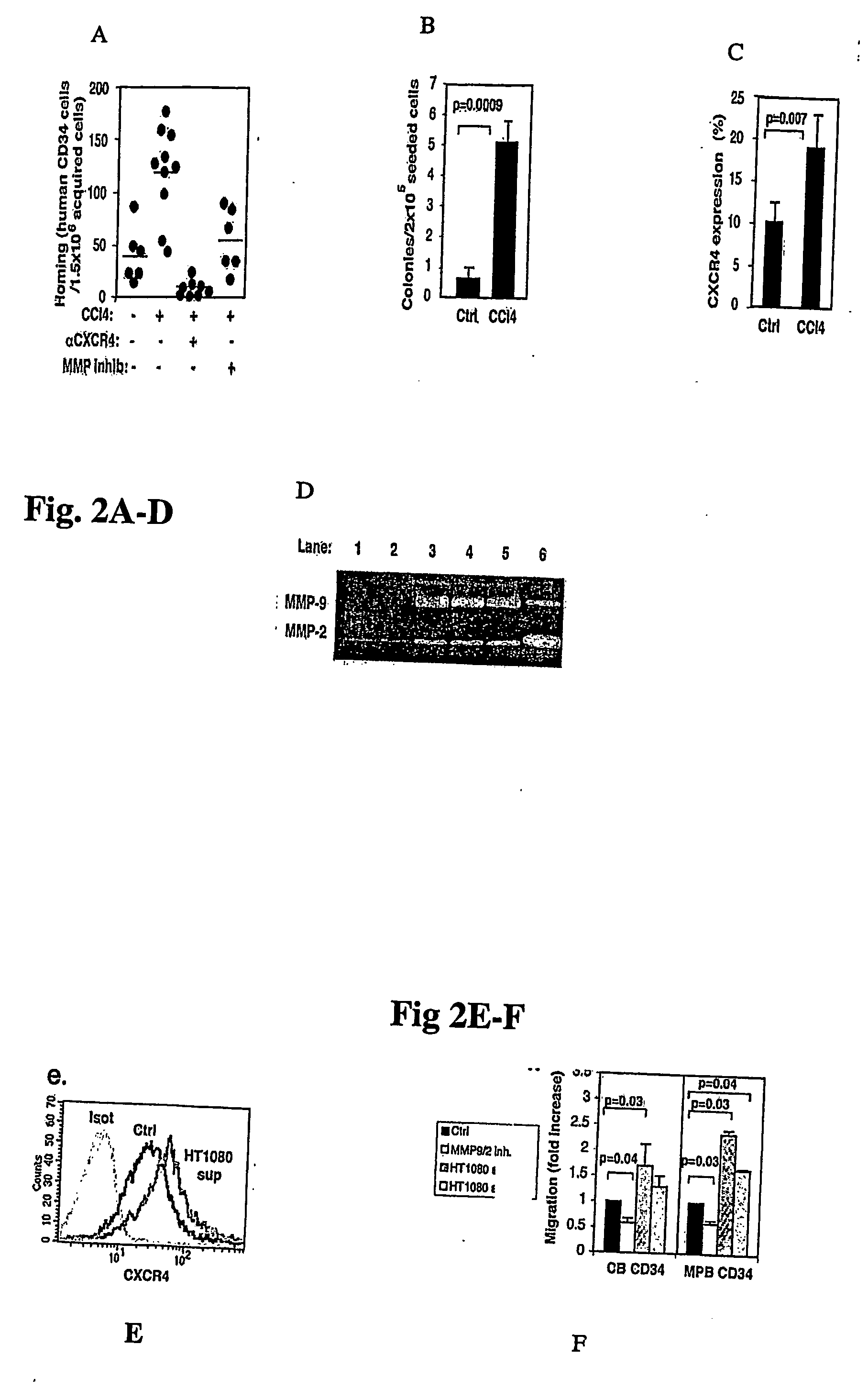

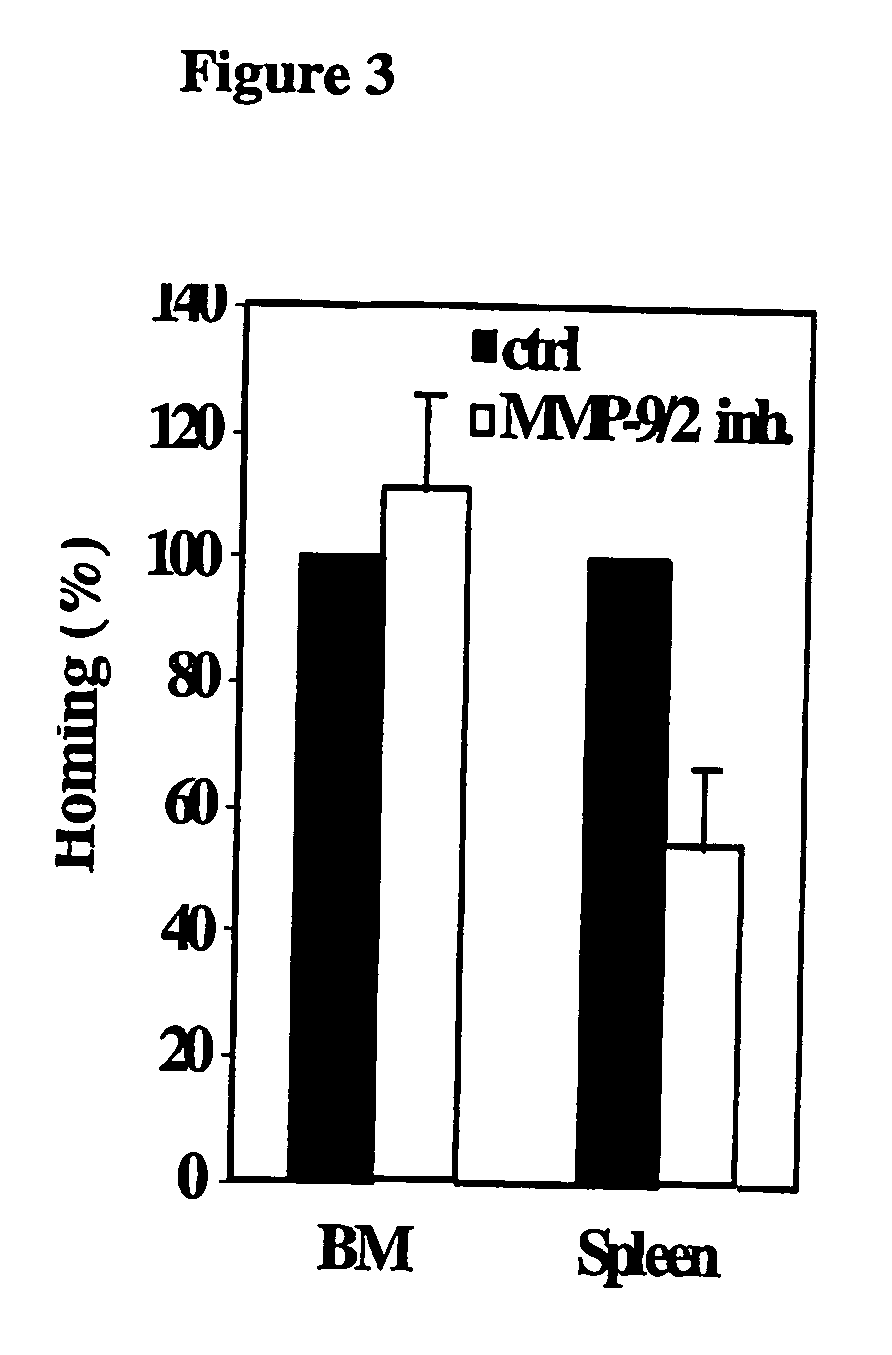

Stem cells having increased sensitivity to sdf-1 and methods of generating and using same

InactiveUS20070003540A1Increased sensitivityImprove levelSugar derivativesPeptide/protein ingredientsMolecular biologyStem cell

The present invention relates to stem cells which exhibit increased sensitivity to a chemoattractant and, more particularly, to methods of generating and using them such as in clinical applications involving stem cell transplantation.

Owner:YEDA RES & DEV CO LTD

Canola variety 45H31

ActiveUS8884103B1Improve levelHigh level of resistanceTissue cultureVector-based foreign material introductionBrassica oleraceaGenetic Materials

A novel canola variety designated 45H31 and seed, plants and plant parts thereof, produced by crossing Pioneer Hi-Bred International, Inc. proprietary inbred canola varieties. Methods for producing a canola plant that comprises crossing canola variety 45H31 with another canola plant. Methods for producing a canola plant containing in its genetic material one or more traits introgressed into 45H31 through backcross conversion and / or transformation, and to the canola seed, plant and plant part produced thereby. This invention relates to the canola variety 45H31, the seed, the plant produced from the seed, and variants, mutants, and minor modifications of canola variety 45H31. This invention further relates to methods for producing canola varieties derived from canola variety 45H31.

Owner:PIONEER HI BRED INT INC

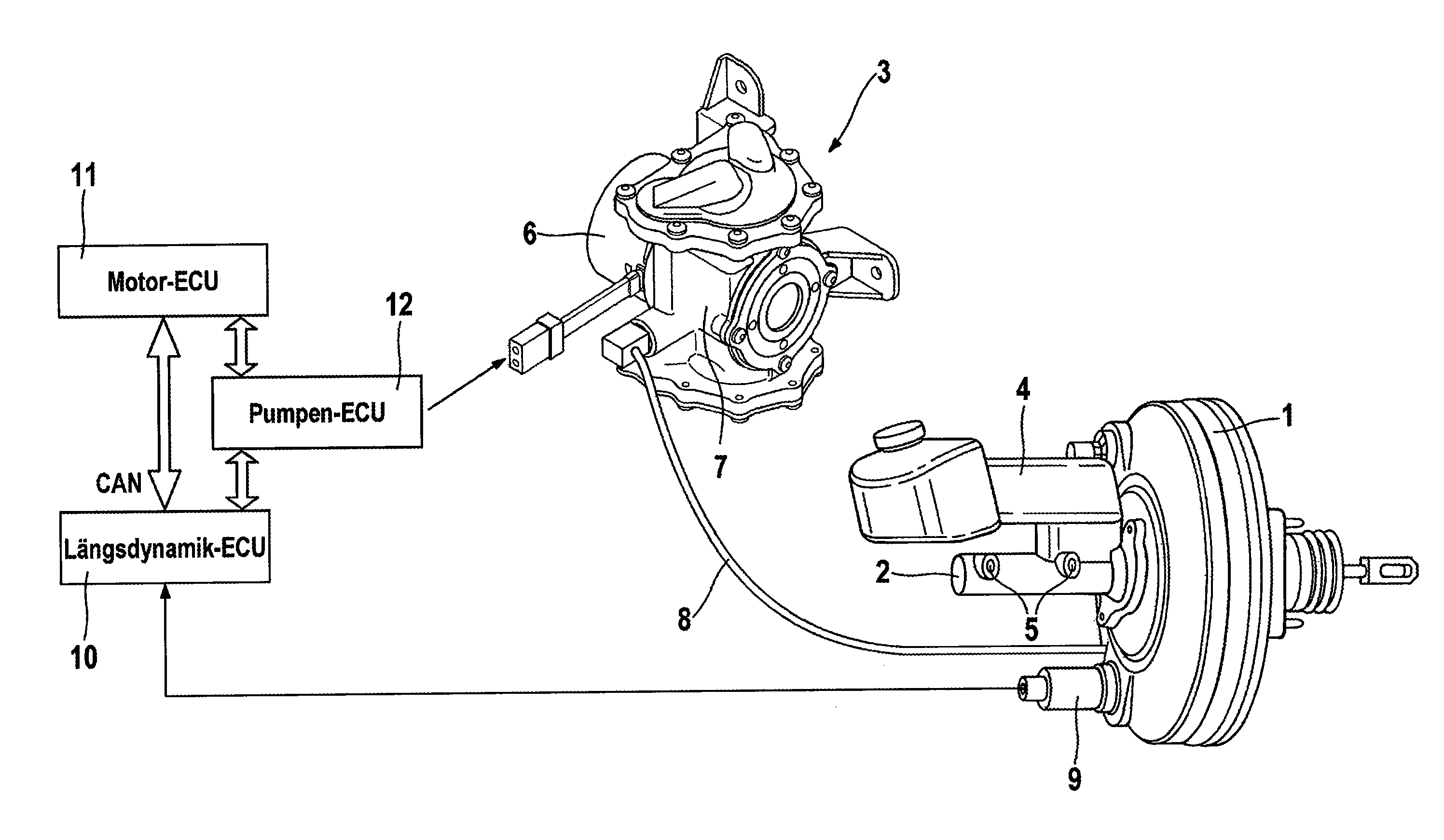

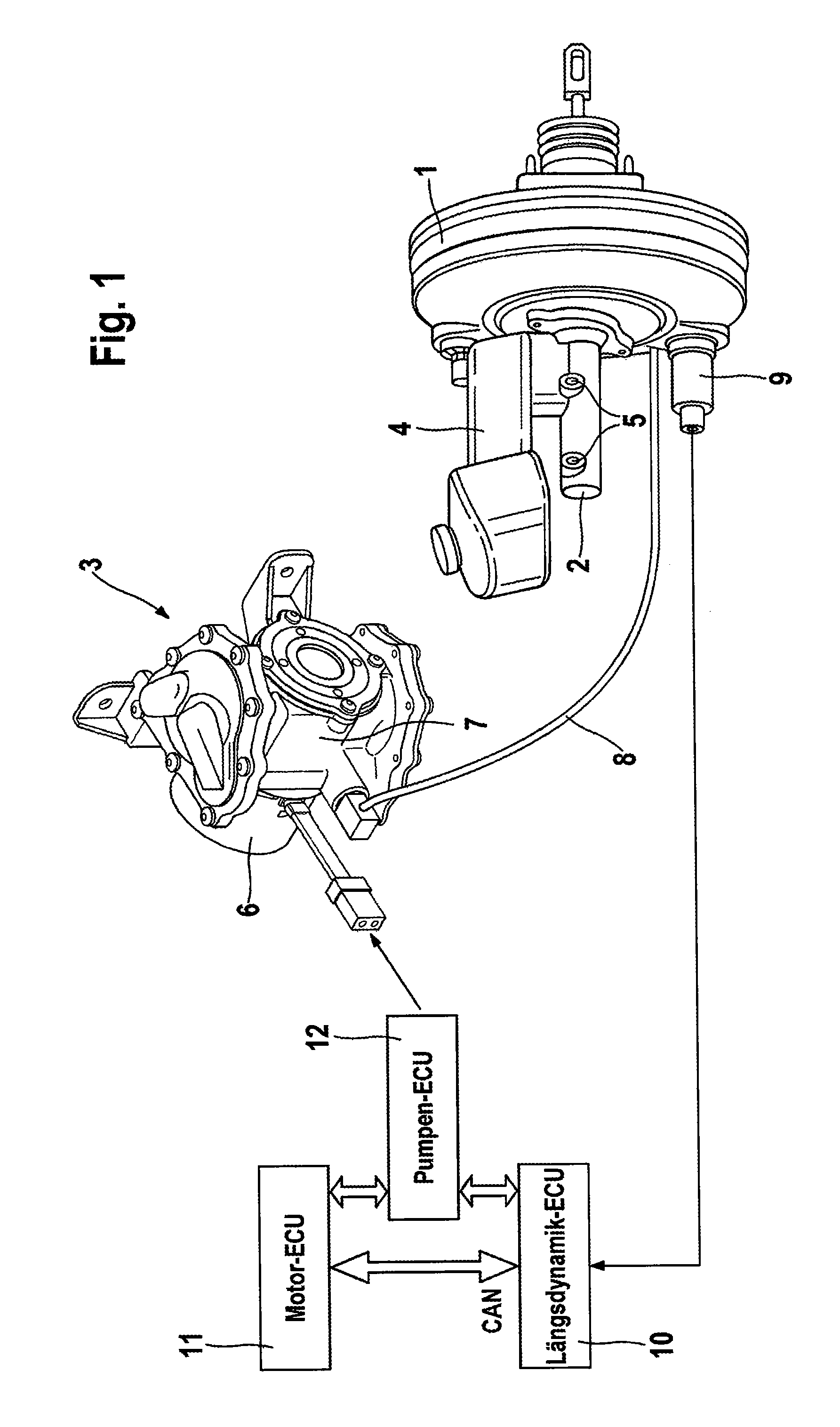

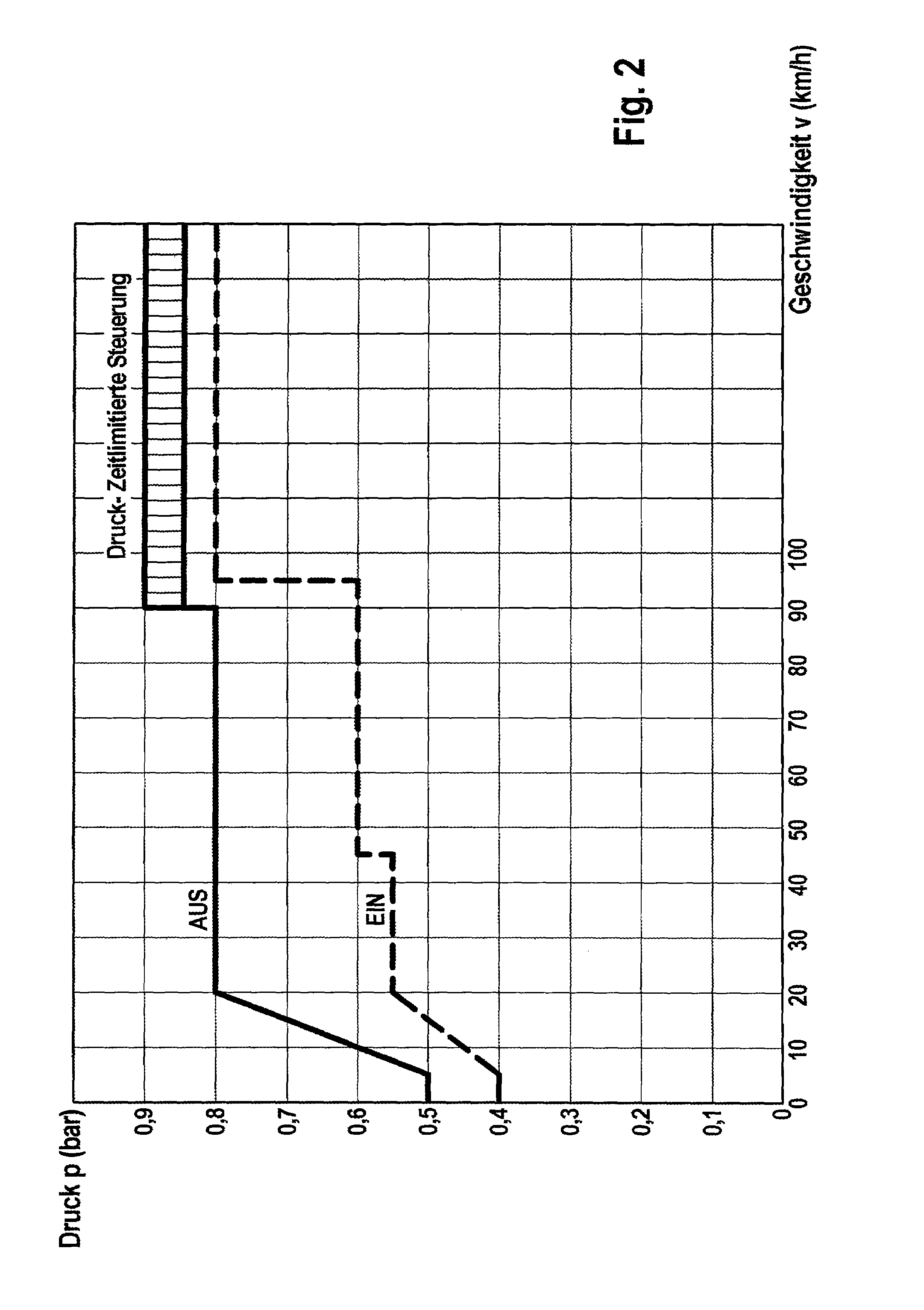

Method for Creating Low Pressure In A Brake Activation Device of a Motor Vehicle Brake System

ActiveUS20100005796A1Improve levelReduce numberBraking action transmissionRotary clutchesElectronic control unitPressure level

A method for creating low pressure in a brake activation device of a motor vehicle brake system, comprising a pneumatic brake force booster the interior of which is divided into at least one low-pressure chamber and one working chamber, a brake master cylinder and a pneumatic motor pump unit for creating the low pressure in the low-pressure chamber, which motor pump unit comprises a low-pressure pump and a motor driving the low-pressure pump, a low-pressure level in the low-pressure chamber or a pressure difference between the low-pressure chamber and the working chamber being detected by a sensor and the motor pump unit being activated by an electronic control unit if the pressure falls below a first predefined, lower low-pressure level Pe in the low-pressure chamber and being deactivated if a second predetermined, upper low-pressure level Pa is reached.

Owner:CONTINENTAL TEVES AG & CO OHG

Retrovirus Packaging Cell

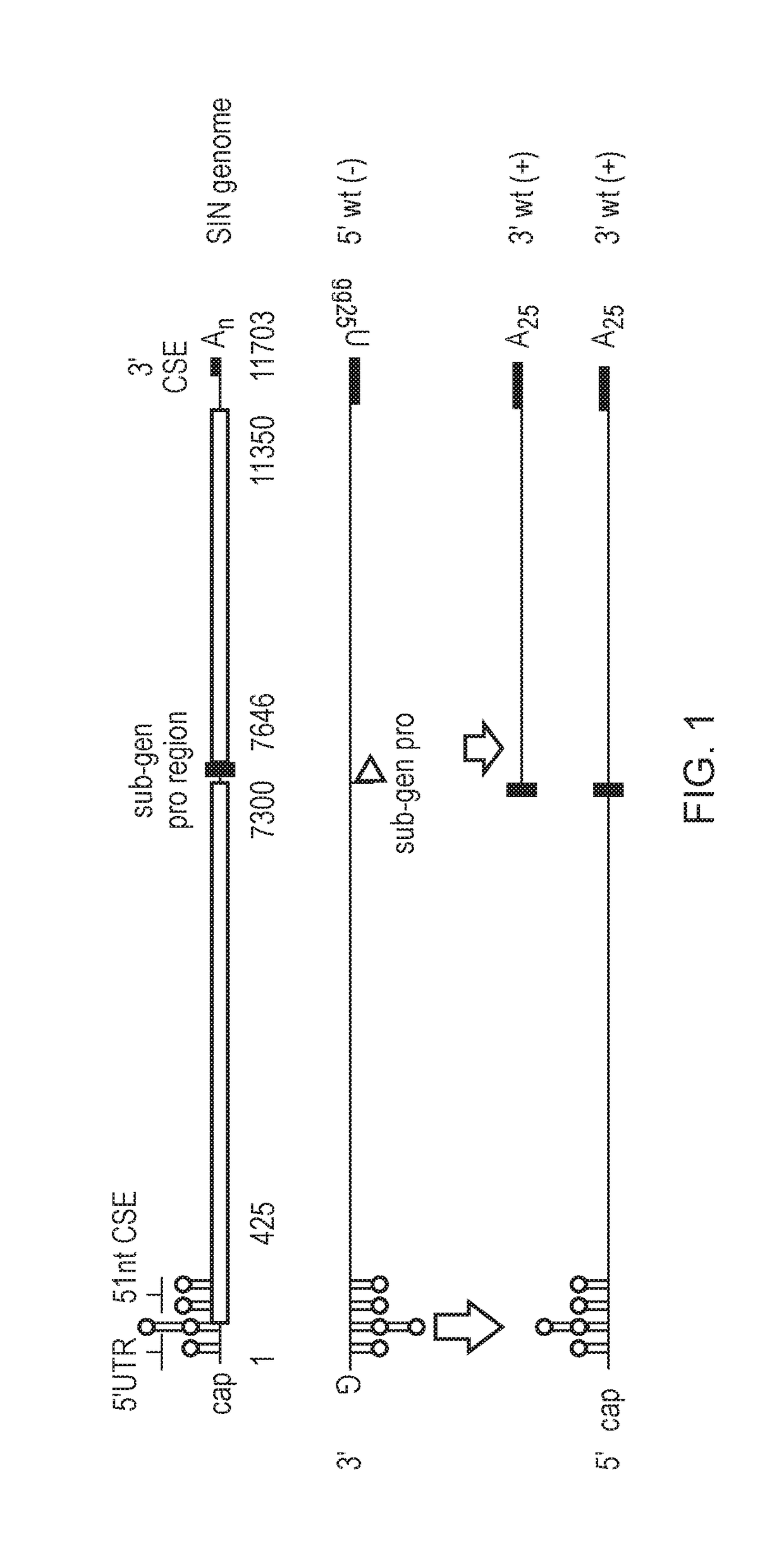

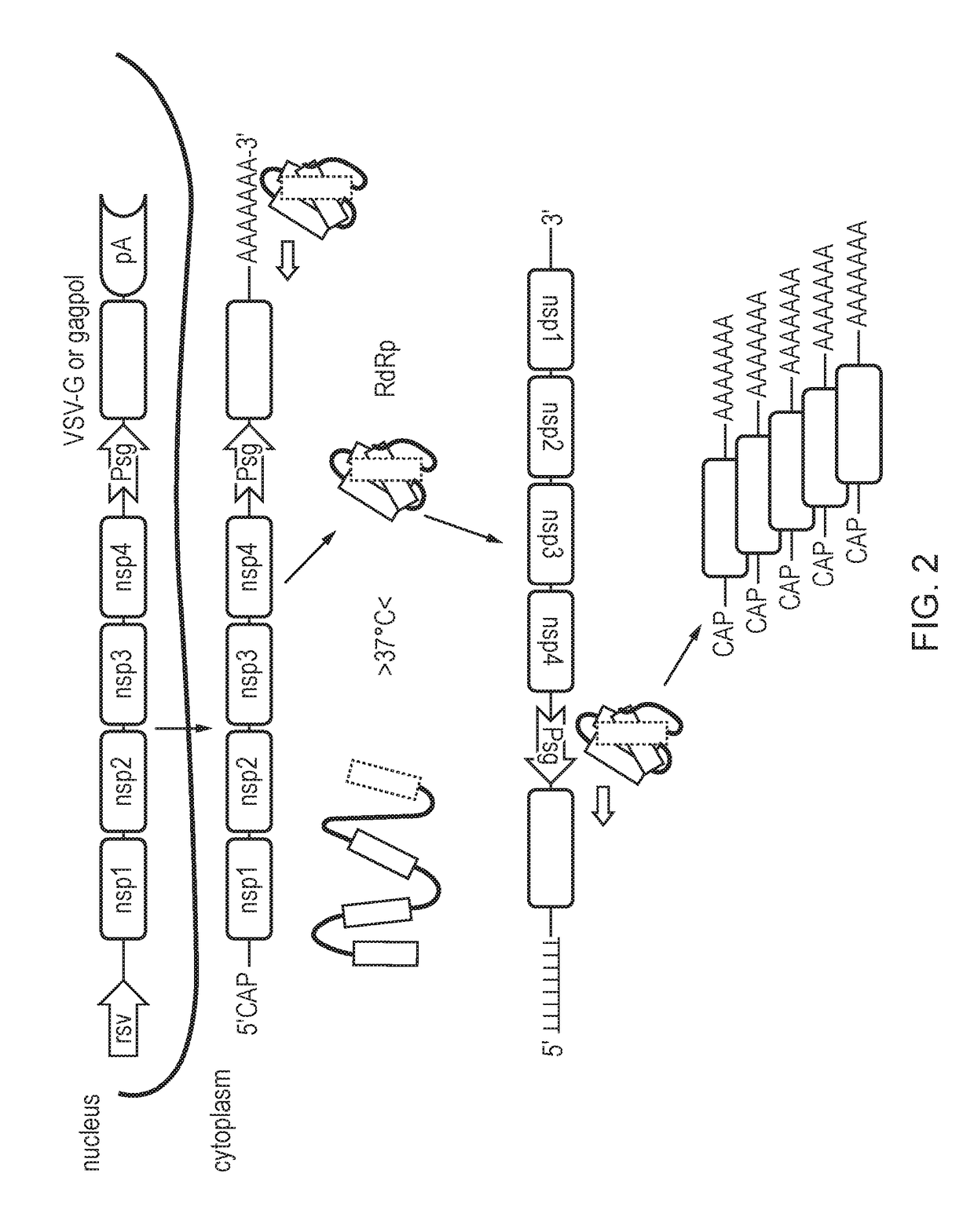

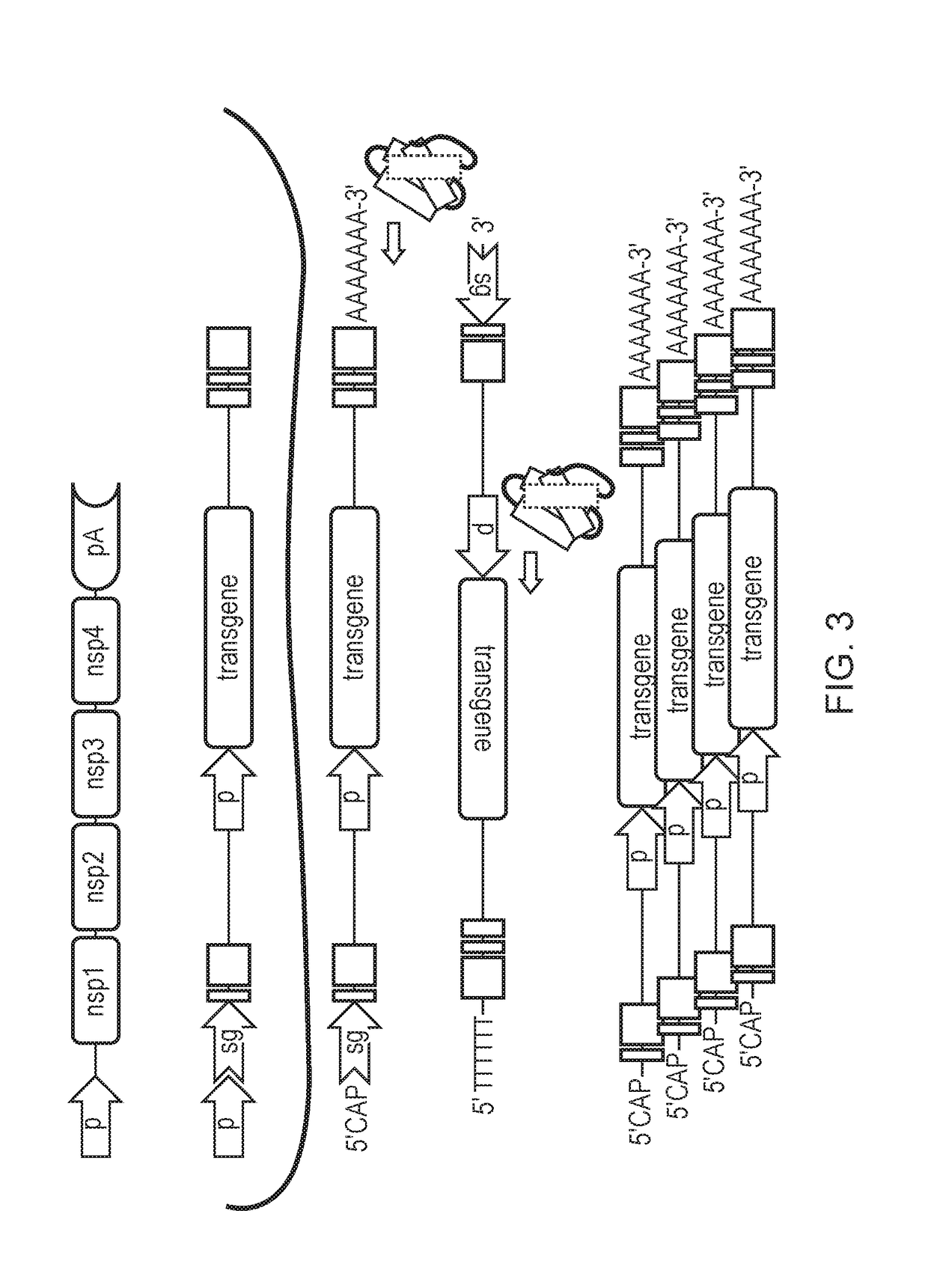

ActiveUS20190055526A1Improve levelImprove the level ofSsRNA viruses positive-senseVirus peptidesRNA-dependent RNA polymeraseRNA polymerase II

The present invention relates to a retrovirus packaging cell which expresses a temperature sensitive RNA-dependent-RNA polymerase (RdRp).

Owner:UCL BUSINESS PLC

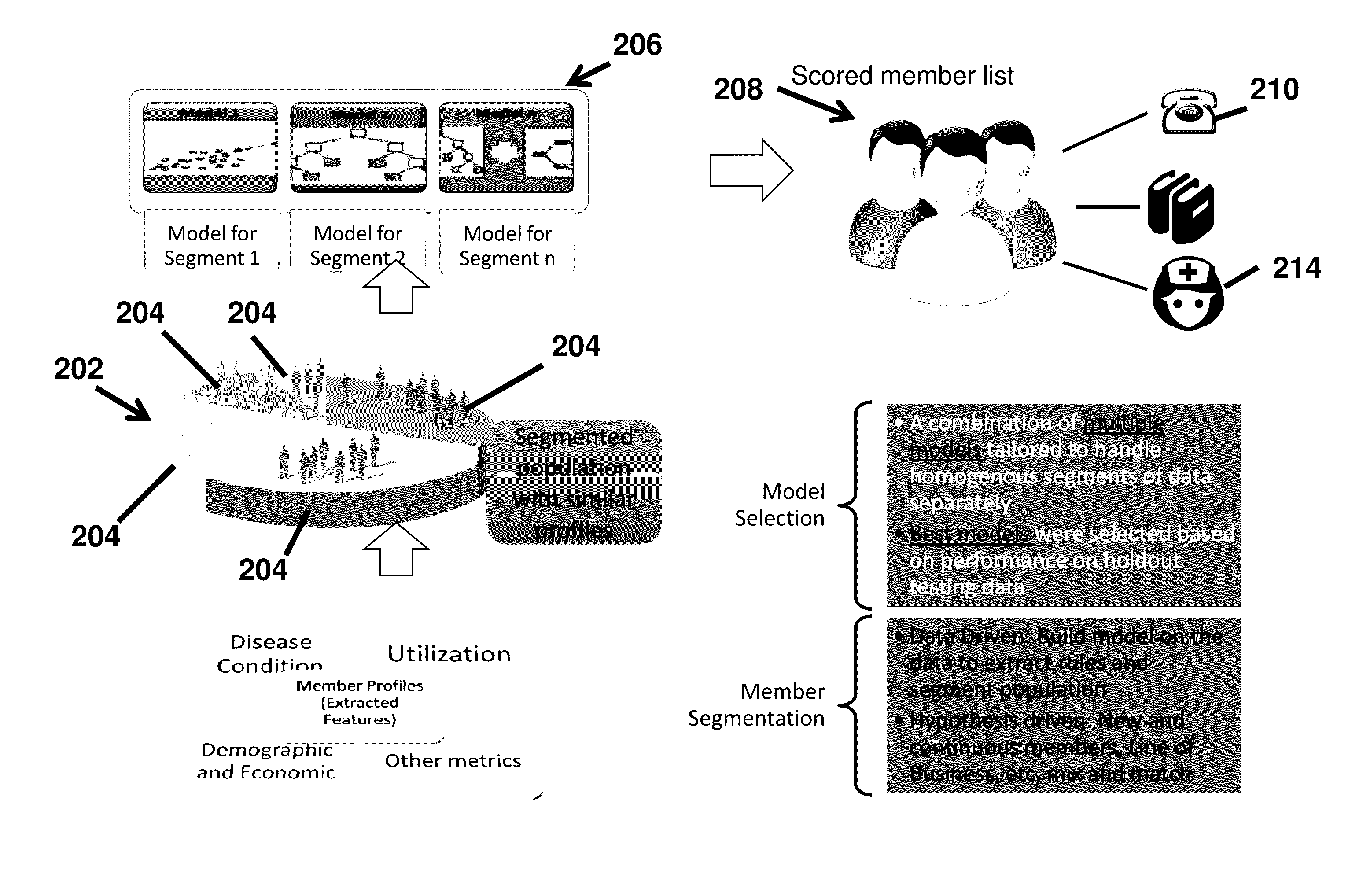

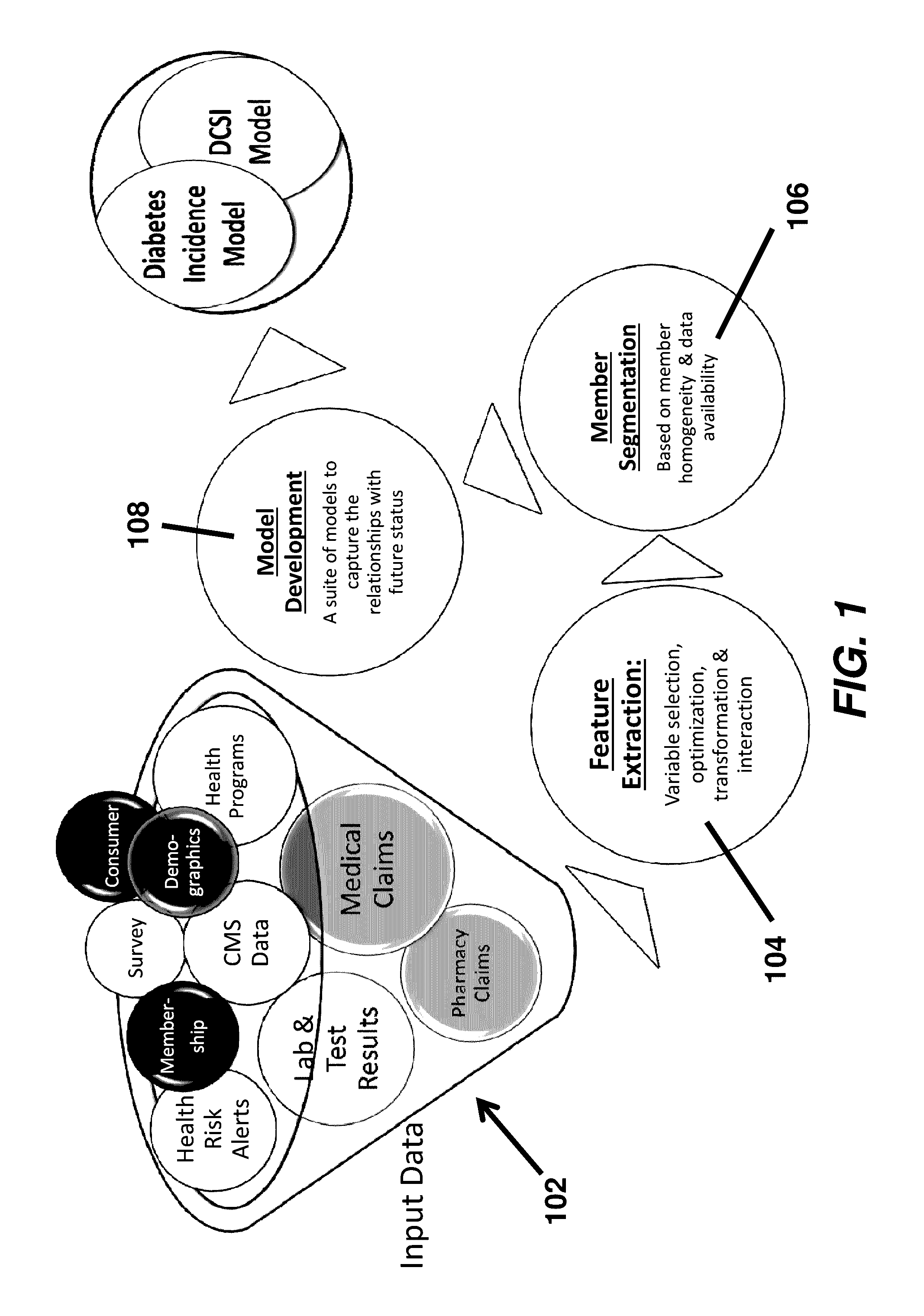

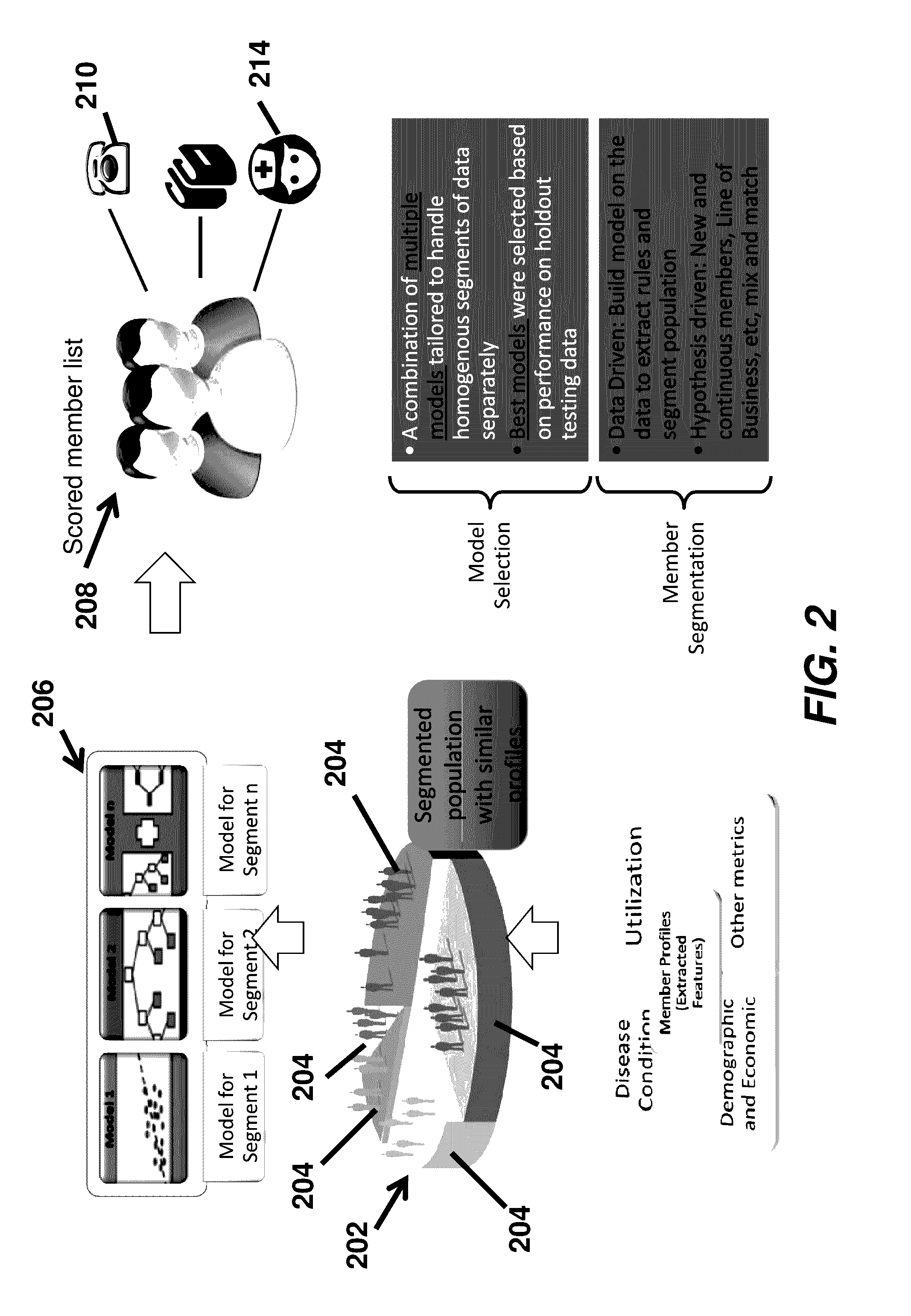

Diabetes onset and progression prediction using a computerized model

InactiveUS20160357934A1Cost reductionImprove levelMedical simulationHealth-index calculationRankingDiabetes mellitus

The disclosed computerized system and method facilitates predicting the onset of diabetes or symptom progression in those patients already suffering from the disease. The computerized system and method applies steps to segment the population by predefined member characteristics. Once segmented, the computerized system and method applies a plurality of prediction models to the segmented population data to provide a ranking of members of the population that indicates the likelihood of onset or progression of diabetes for each member.

Owner:HUMANA INC

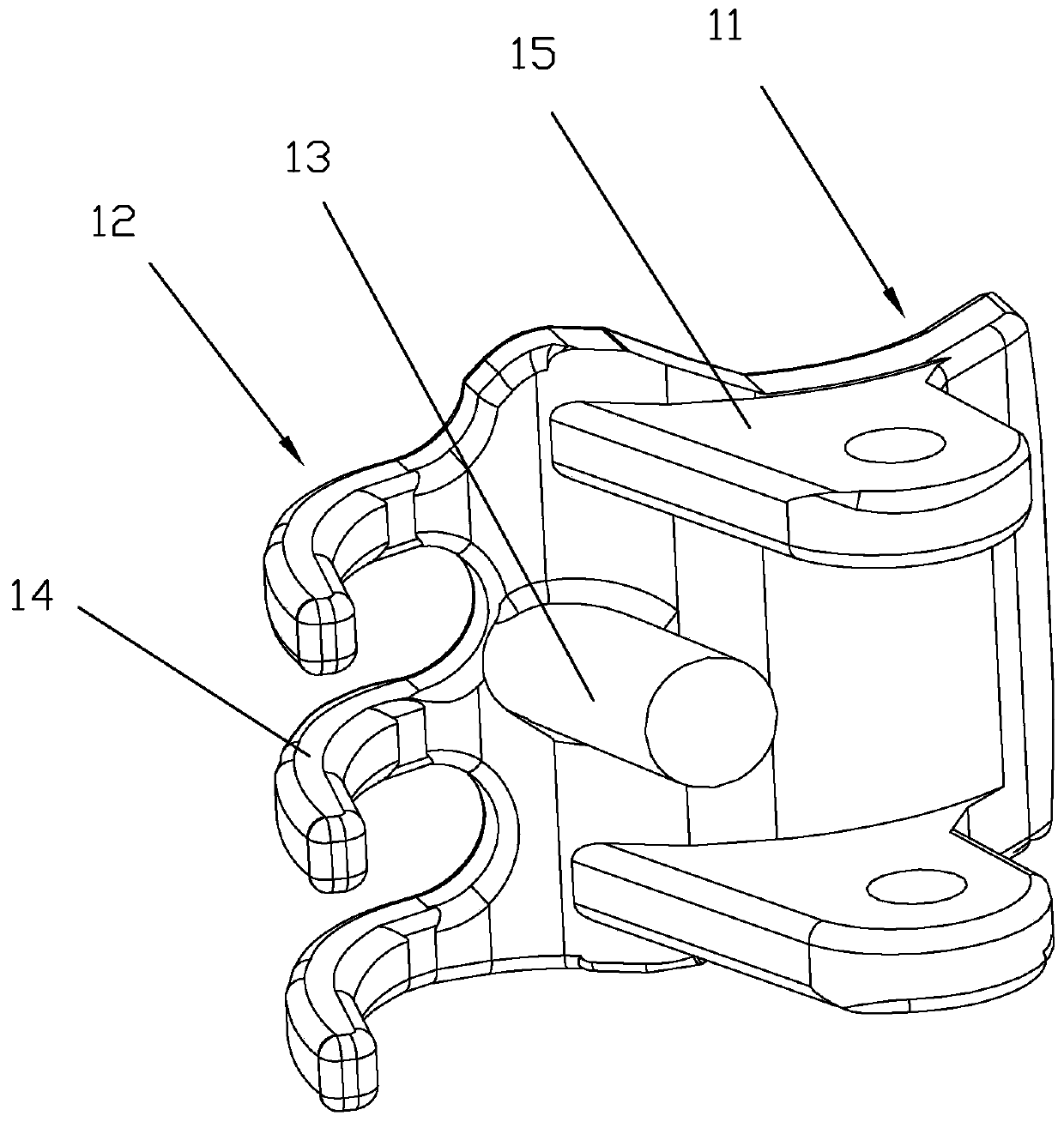

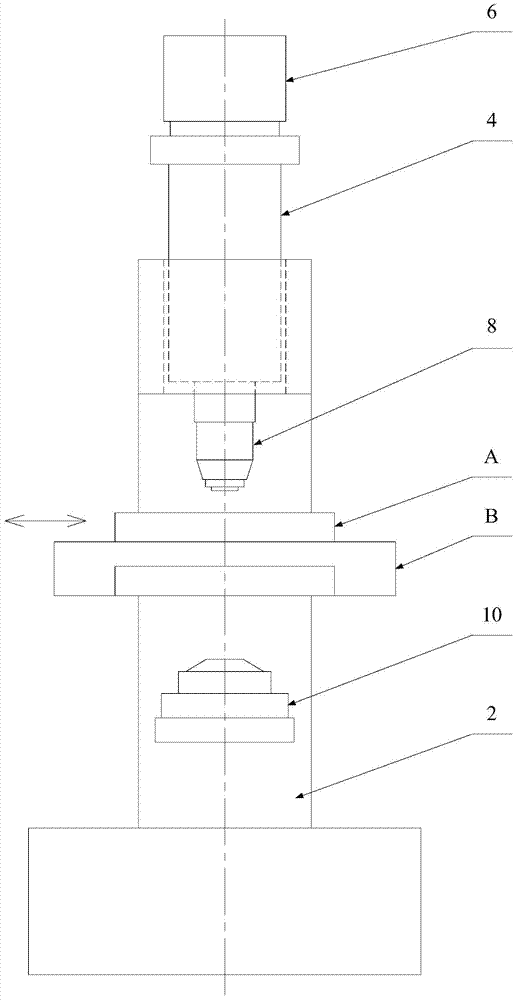

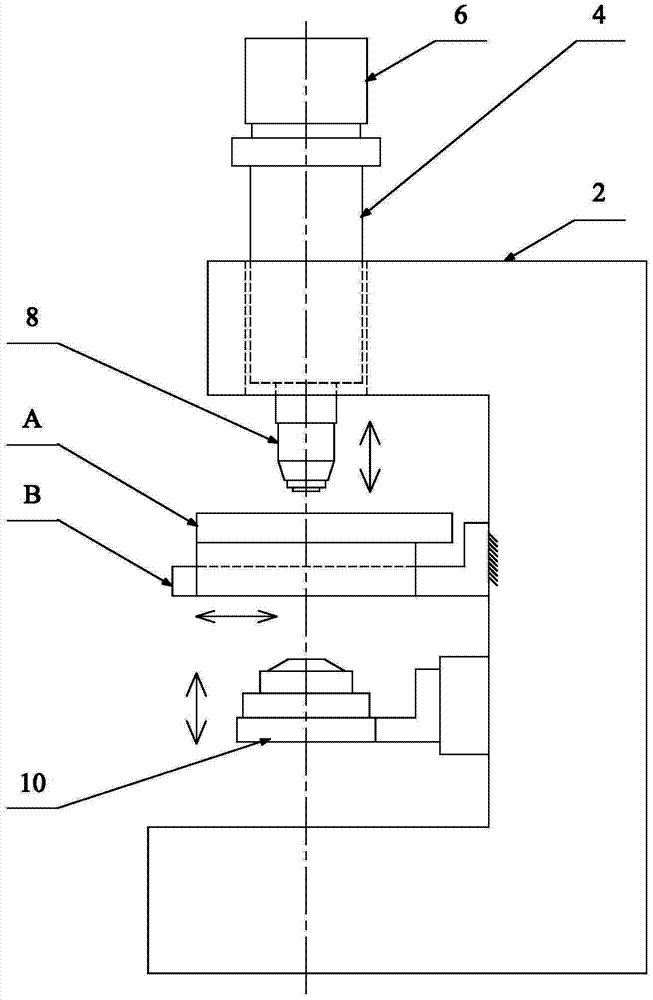

Supporting device for microscope, microscope and microscope carrier

ActiveCN103676127ALess chance of dust accumulationImprove levelLaboratory glasswaresMicroscopesMicroscopeEngineering

The invention discloses a supporting device for a microscope, which is used for supporting a loading device. The supporting device is characterized by comprising a substrate and a plurality of protruding structures arranged on the substrate, and the top ends, used for being contacted with the loading device, of the protruding structures are located on the same horizontal plane. According to the supporting device for the microscope provided by the embodiment of the invention, the loading device is erected above the protruding structures, so that the direct contact area of the loading device and a carrier is reduced as small as possible by the adoption of the protruding structures, and accordingly, the probability of accumulating dust on the top ends of the protruding structures is reduced, the levelness of the loading device is improved, the condition that the loading device has different focus lengths due to the fact that the levelness of the loading device is lowered caused by dust accumulation is reduced, the tedious operation of repeated focusing is greatly reduced, and the use convenience of the microscope is improved. The invention also provides a microscope carrier and the microscope.

Owner:AVE SCI & TECH CO LTD

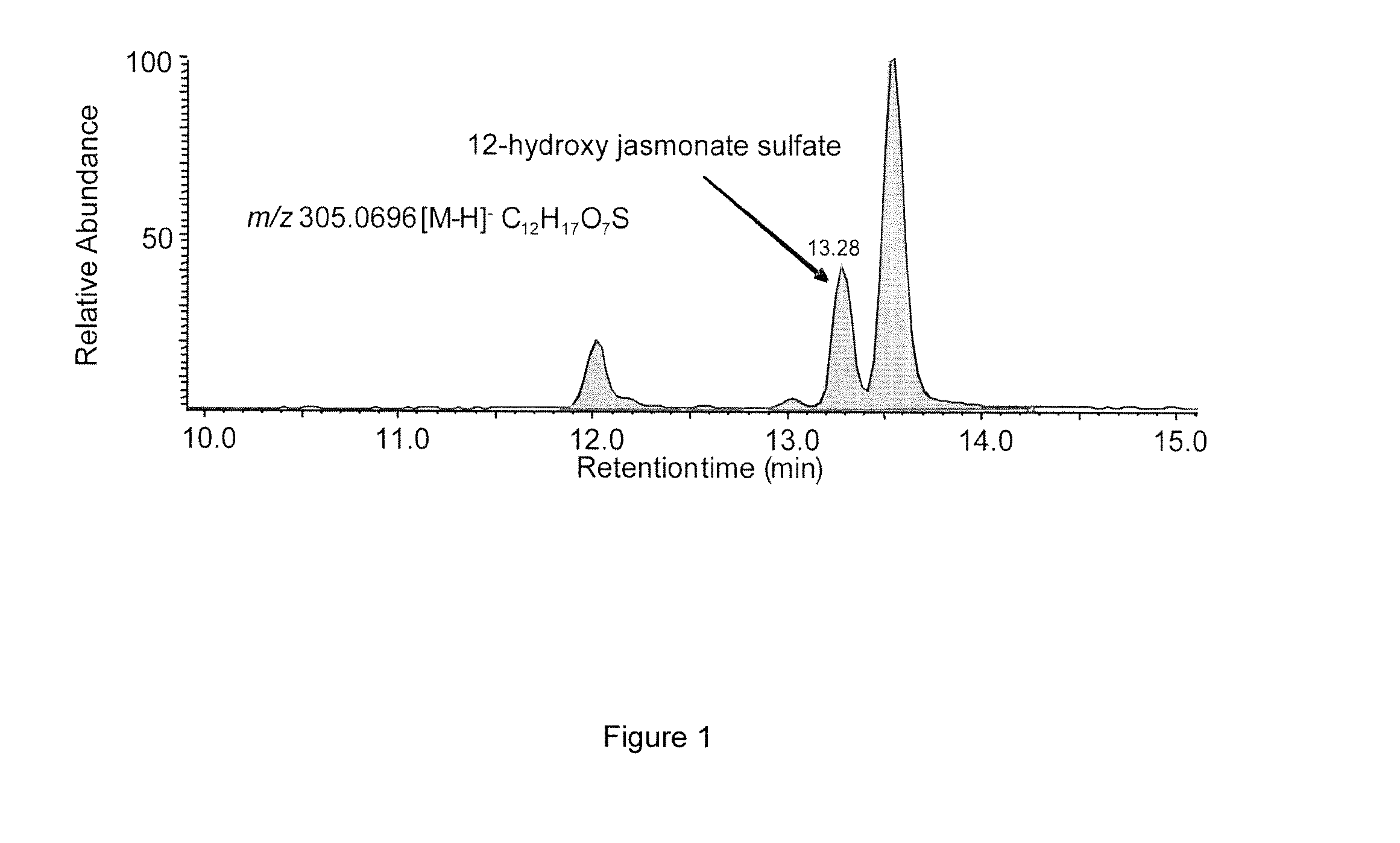

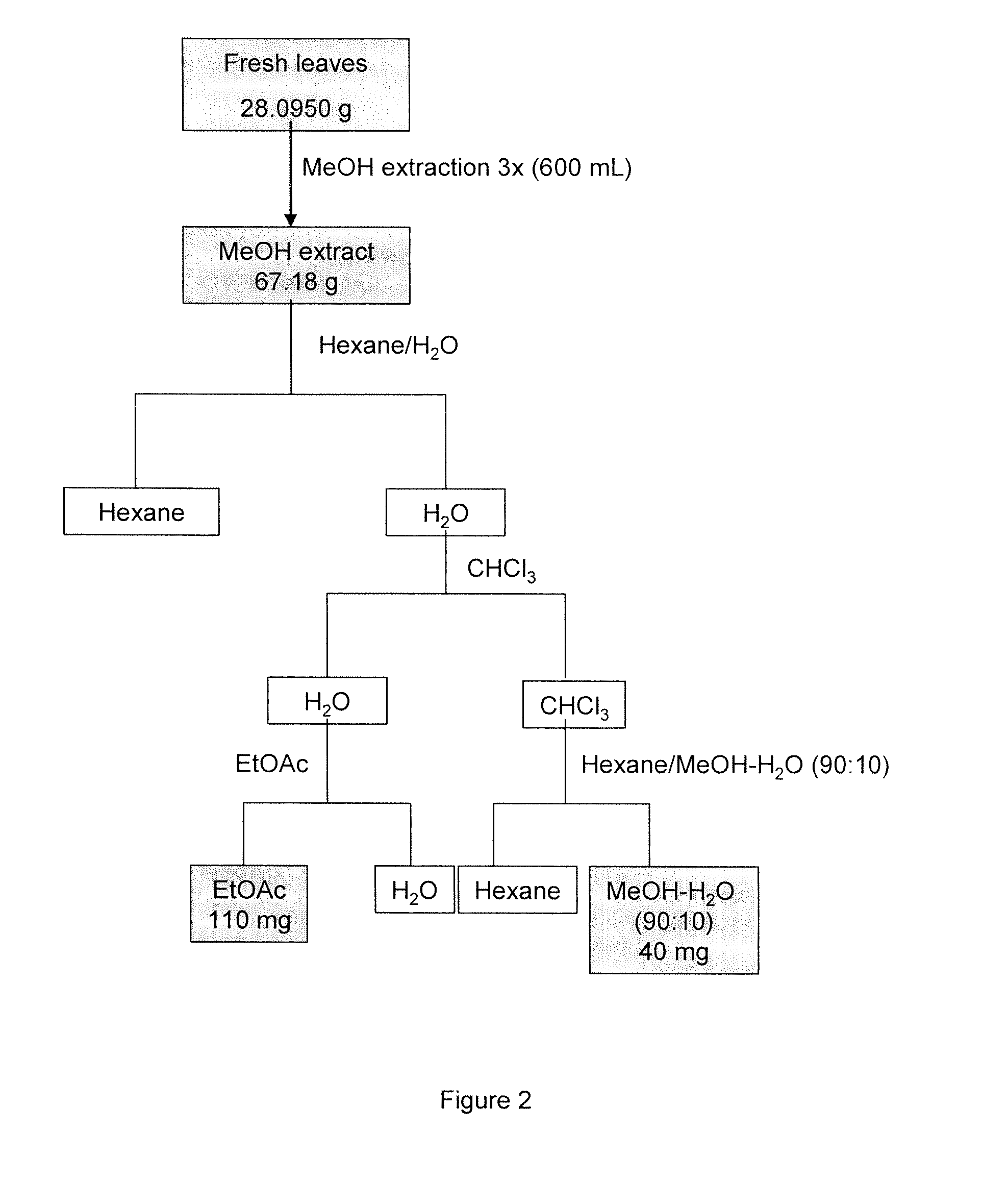

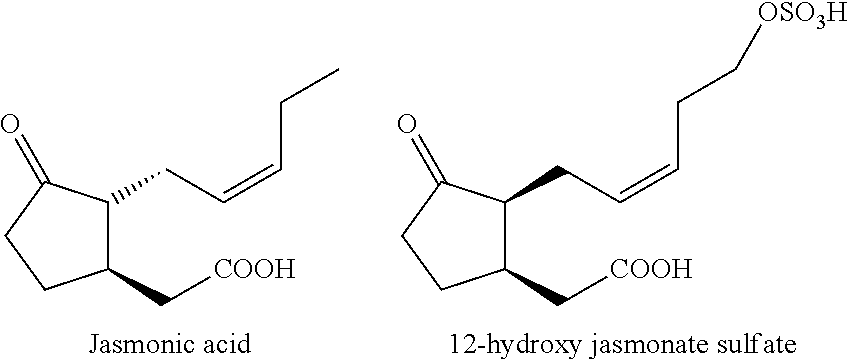

Jasmonic acid compounds in cocoa products

ActiveUS20110257263A1Improve levelEasily treatedOrganic active ingredientsAnimal cellsCacao plantFood products

The invention provides methods for isolating and enhancing the levels of jasmonates from cacao plant sources. In a preferred embodiment, jasmonic acid and 12-hydroxy jasmonate sulfate are detected in various cocoa products, and the levels of these compounds can be manipulated to increase the beneficial health effects of a food product made with the cocoa products The invention includes methods to prepare edible products containing cocoa jasmonates.

Owner:THE HERSHEY COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com