Machining method for engine connecting rod

A technology of engine connecting rods and processing methods, which is applied in the direction of connecting rods, mechanical equipment, shafts and bearings, can solve the problems of reduced reliability and durability of connecting rods, high processing precision requirements, and increased processing costs of connecting rods, etc., to achieve The effect of improving levelness and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

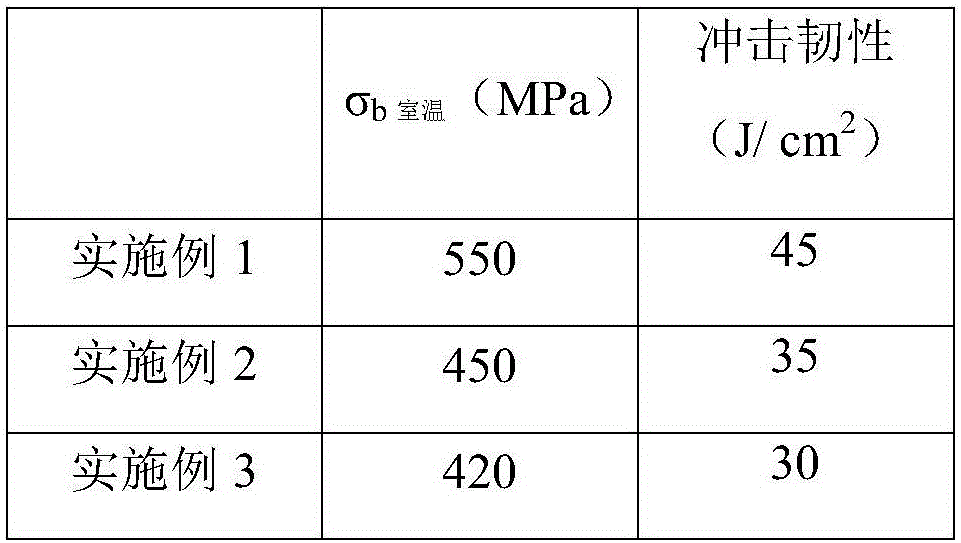

Embodiment 1

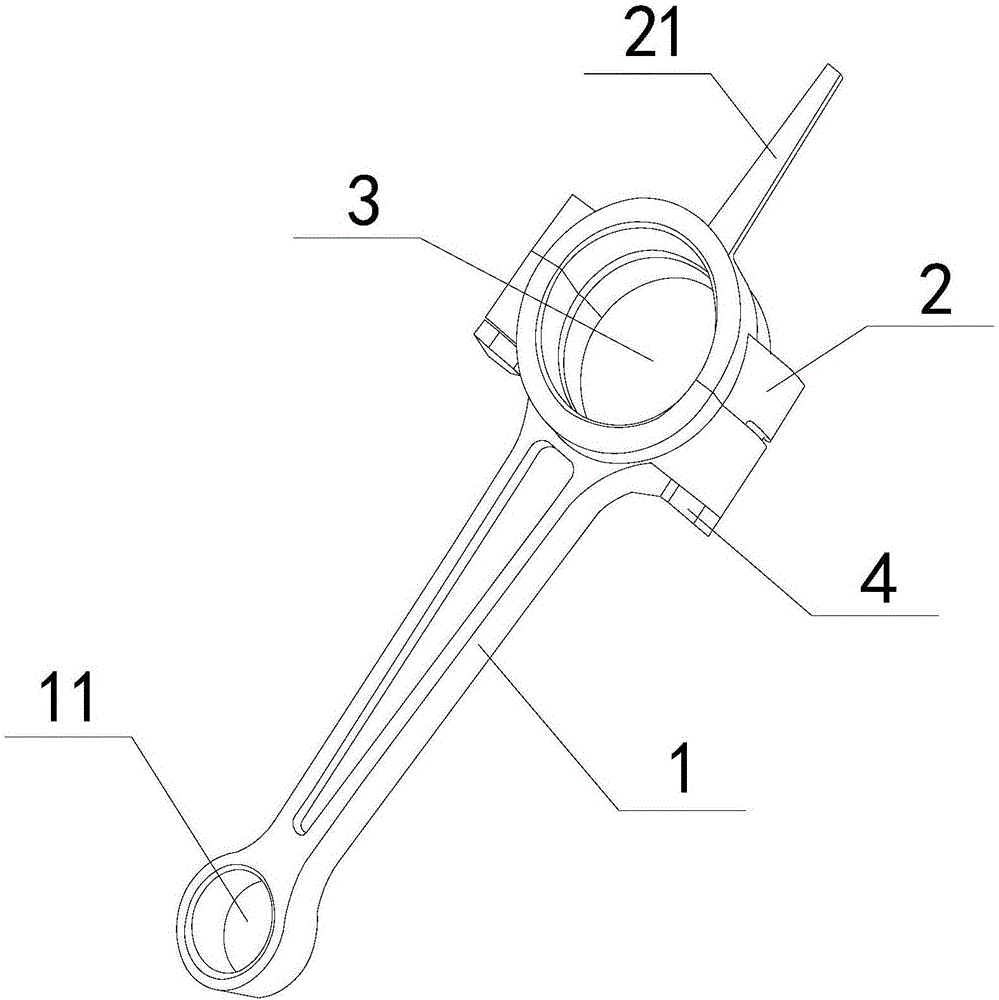

[0017] Such as figure 1 The engine connecting rod shown includes a connecting rod body 1 and a connecting rod cover 2 installed at the end of the connecting rod body 1. The connecting rod body 1 and the connecting rod cover 2 are connected by a plurality of bolts 4 installed on its side. , There is a large head hole 3 between the connecting rod body 1 and the connecting rod cover 2, and the other end of the connecting rod body 1 is provided with a small head hole 11. In the plane; the connecting rod cover 2 is integrally connected with the thimble rod 21 on the same straight line as the connecting rod body 1 .

[0018] The processing method of the above-mentioned engine connecting rod can generally refer to the method and equipment in CN201310021032.5, including the following steps:

[0019] (a) Coarse grinding of both ends of the connecting rod → drilling and expanding the small head hole 11 → rough boring of the big head hole 3 and small head hole 11, semi-fine boring of th...

Embodiment 2

[0024] This embodiment provides a processing method for the engine connecting rod in Embodiment 1, the steps of which are basically the same as those in Embodiment 1, the difference is: the connecting rod is heated to 150°C, and then the hydraulic cylinder drives the two-way wedge downward Move and press into the semicircle movable sleeve, push the semicircular movable sleeve to act on the inner wall of the big head hole 3, the big head hole 3 is instantly broken and the connecting rod cover 2 is separated from the connecting rod body 1, and poured with cold water (30°C).

Embodiment 3

[0026] This embodiment provides a processing method for the engine connecting rod in Embodiment 1, the steps of which are basically the same as those in Embodiment 1, the difference is: the connecting rod is heated to 200°C, and then the hydraulic cylinder drives the two-way wedge downward Move and press into the semicircle movable sleeve, push the semicircular movable sleeve to act on the inner wall of the big head hole 3, the big head hole 3 is instantly broken and the connecting rod cover 2 is separated from the connecting rod body 1, and poured with cold water (20°C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com