Liquid phase impinging stream reactor with controllable acidity

A technology of impinging flow reaction and reaction device, which is applied in the direction of chemical/physical/physical chemical fixed reactors, etc., can solve problems such as unfavorable unloading and cleaning, vibration of propeller and motor shaft, and unsuitability for long-term operation, etc., to achieve Ensure continuous and stable operation, large circulation volume and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

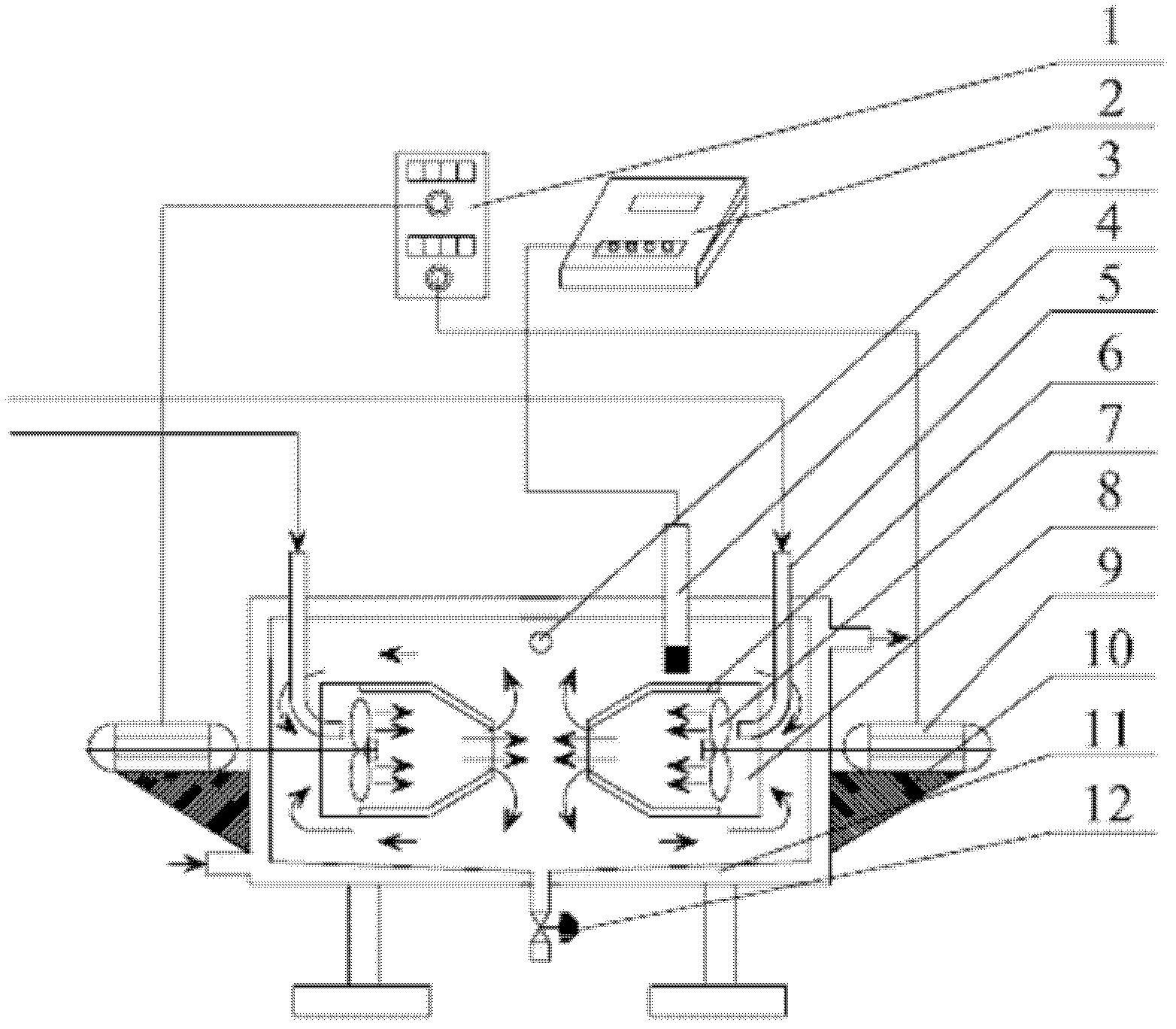

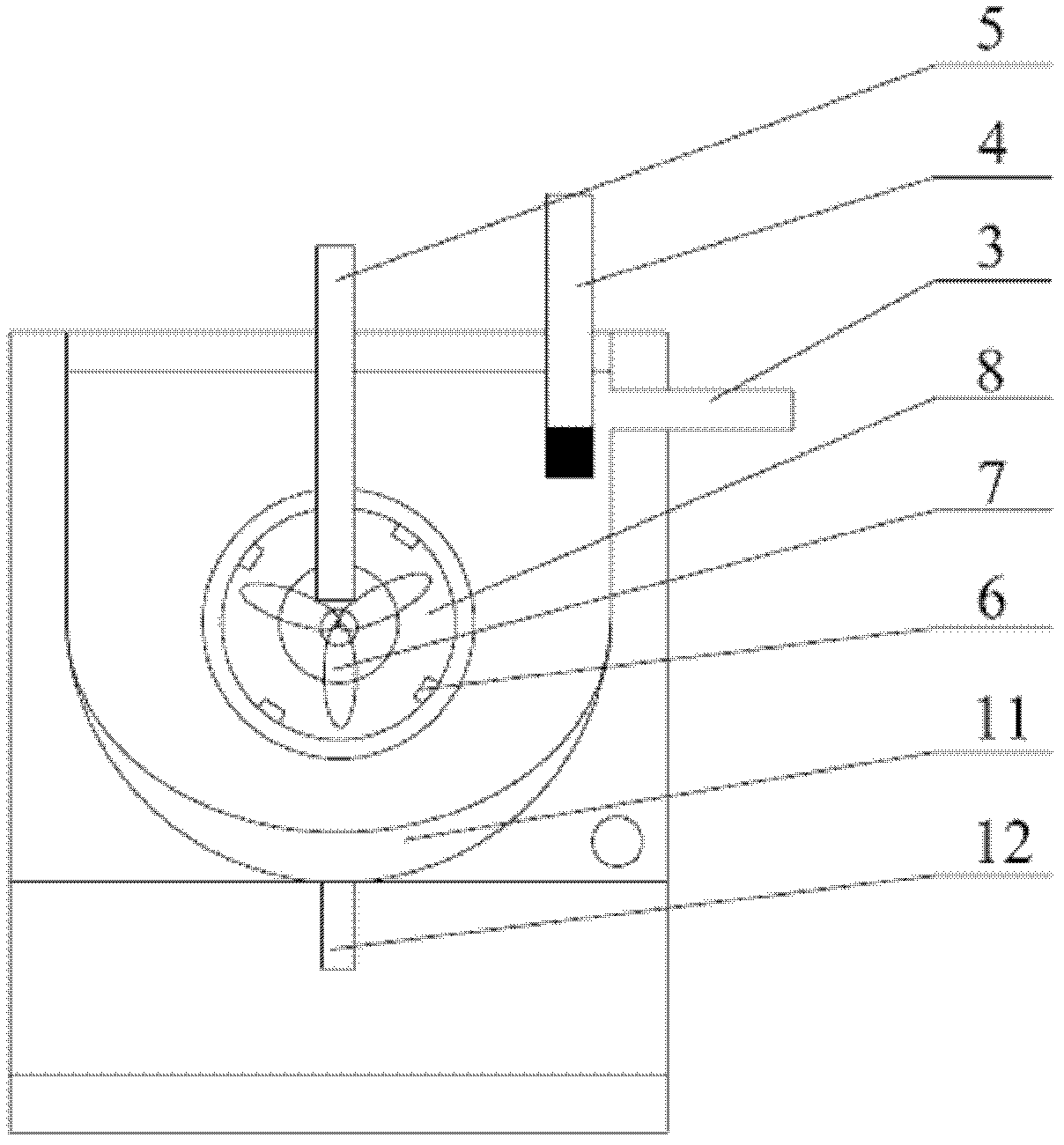

[0029] An acidity controllable liquid phase impinging stream reaction device. The reactor of this device is a horizontal structure, including a reactor shell 11, which is a jacket type, which is convenient for heating or cooling. Two coaxial variable-diameter diversion cylinders 8 are installed symmetrically in the middle of the left and right sides of the reactor shell 11. The diversion cylinders 8 are variable-diameter, and the diameter of the outlet end of the diversion cylinder 8 is 3 / 4 of the diameter of the inlet end. , There is enough space between the inlet of the deflector 8 and the inner wall of the reaction shell 11 to be used as a material circulation flow channel. At the feed end of the deflector 8 are installed a push-type three-blade agitator 7 and two agitators 7 respectively. Coaxial symmetry, used to accelerate the fluid. An elbow feeding tube 5 is provided at the entrance of the deflector 8 and the raw materials are input through the elbow feeding tube 5, whi...

Embodiment 2

[0032] The reaction device is the same as in Example 1.

[0033] Fill the reactor with deionized water, turn on the heat carrier circulation switch, conduct a constant temperature water bath through the jacket of the reactor shell and set the temperature to 60°C, turn on the speed controller 1 so that the motor 9 drives the stirrer 7 and adjust the speed to 2000r·min -1 After the temperature of the working fluid in the reactor reaches 60℃, use a metering pump to reduce the mixed solution of ferric nitrate and phosphoric acid to 0.1L·min -1 The flow rate is fed into the reactor through a feeding pipe with a side elbow, and the concentration of ferric nitrate and phosphoric acid in the mixed solution are both 0.1mol·L -1 , And at the same time input 0.2mol·L through another elbow feeding tube -1 The pH value of the reaction system is controlled by the aqueous ammonia solution to 2.3. After the process is stabilized, the products at 3 outlets of the reactor are collected, and the sphe...

Embodiment 3

[0035] The reaction device is the same as in Example 1. Fill the reactor with deionized water, turn on the heat carrier circulation switch, conduct a constant temperature water bath through the jacket of the reactor shell and set the temperature to 50°C, turn on the speed controller 1 to make the motor 9 drive the agitator 7 and adjust the speed to 2900r·min -1 , After the temperature of the working fluid in the reactor reaches 50℃, use a metering pump to reduce the concentration to 0.1mol·L -1 The mixed solution of ferrous nitrate and phosphoric acid in 0.1L·min -1 The flow rate is fed into the reactor through one side elbow feeding tube, and at the same time, 4mol·L is input through the other elbow feeding tube -1 The pH value of the reaction system is controlled by the aqueous ammonia solution at 4.5. After the process is stabilized, the product at the outlet of the reactor is collected, and the spherical nano-scale iron phosphate is obtained after post-processing procedures s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com