Stamping die, stamping forming method and product made by the stamping forming method

A stamping die and stamping forming technology, which is applied in the direction of forming tools, presses, manufacturing tools, etc., can solve the problems of high manufacturing cost, low production efficiency, and expensive CNC machine tools, and achieve the effect of high section quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

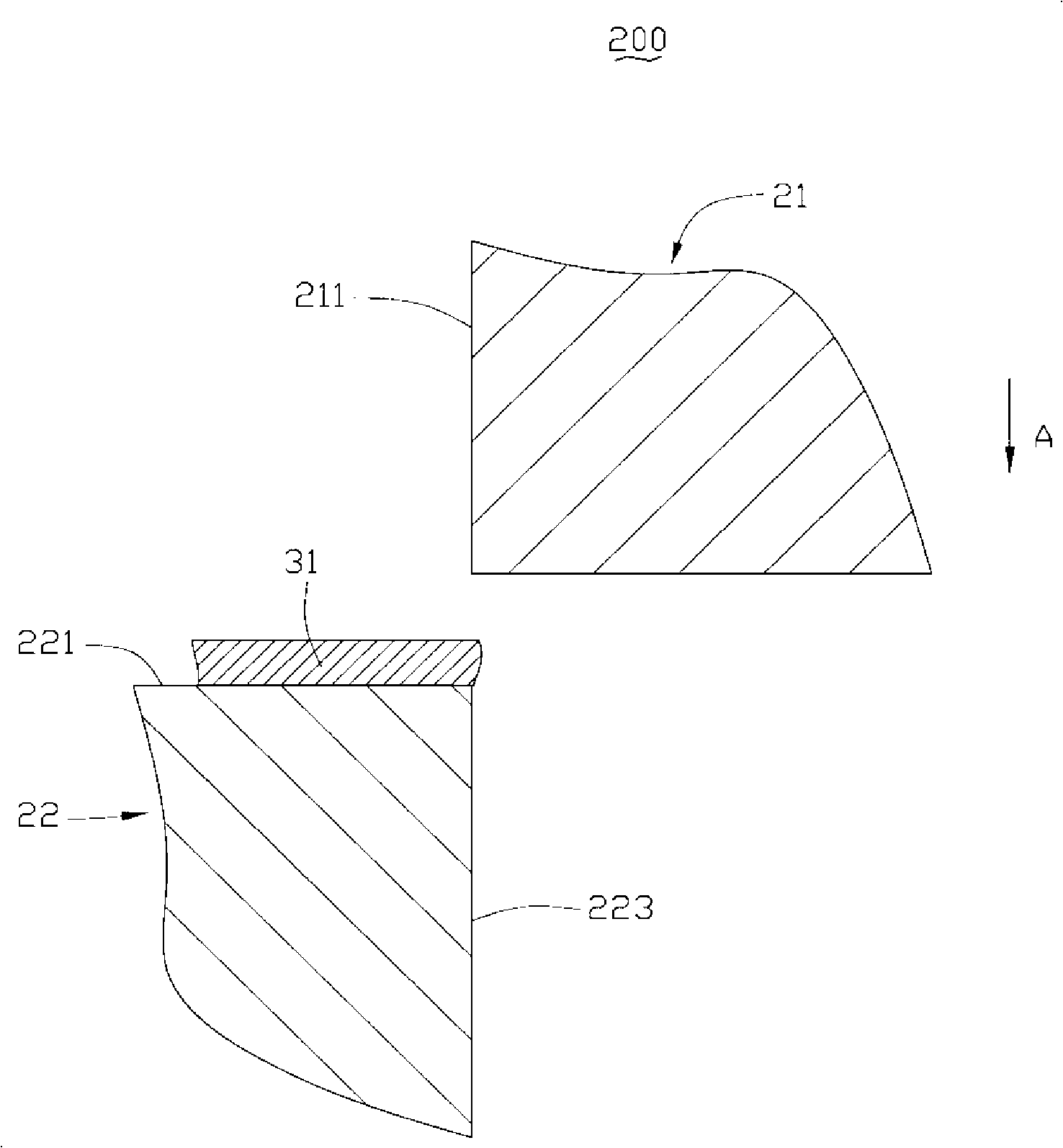

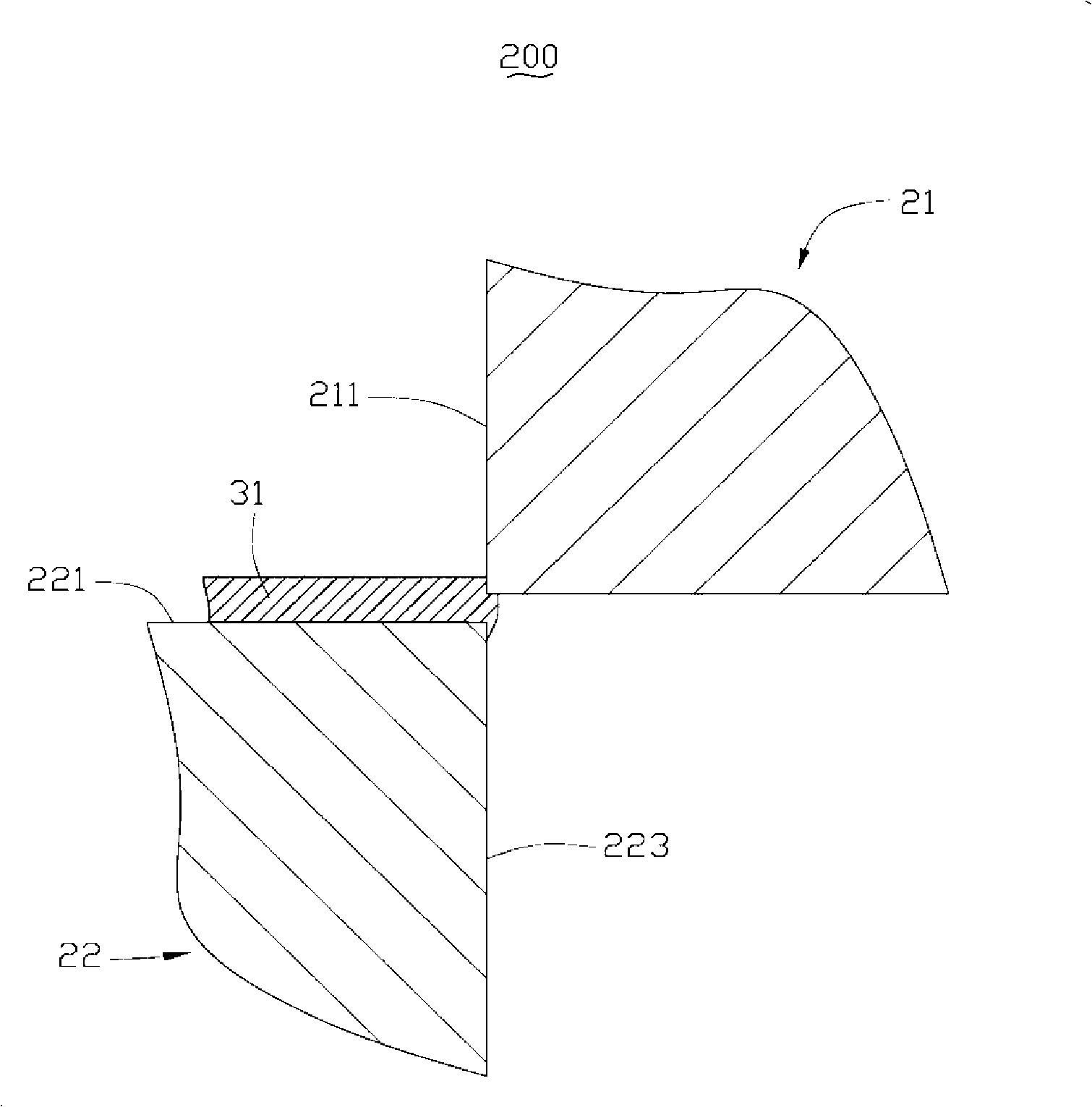

[0014] See also Figure 2 to Figure 4 , The stamping die 200 includes an upper die 21 and a lower die 22 . The upper mold 21 has a working surface 211 . The upper mold 21 shapes the section of the workpiece 31 through the working surface 211 . The lower mold 22 has an operating surface 221 and a side 223 vertically connected to the operating surface 221 . The workpiece 31 is fixed on the operation surface 221 and kept fixed with the lower mold 22 . The stamping gap between the upper die 21 and the lower die 22 is zero, that is, the vertical distance between the working surface 211 of the upper die 21 and the side 223 of the lower die 22 is zero, and the working face 211 and the side 223 are on the same plane.

[0015] During the stamping process, the workpiece 31 is fixed on the operation surface 221 of the lower die 22 and partially protrudes from the operation surface 221 toward the side surface 223 . When the upper die 21 moves in the direction of arrow A, the workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com