Wirecord fabric heat hob cutting device and method thereof

A steel cord and cutting technology, which is applied in other household appliances, tires, metal processing, etc., can solve the problems of inclined or bent cord steel wires, continuous cutting, and unqualified cutting products, etc., and achieves flexible lateral movement and friction The effect of small resistance and high section quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

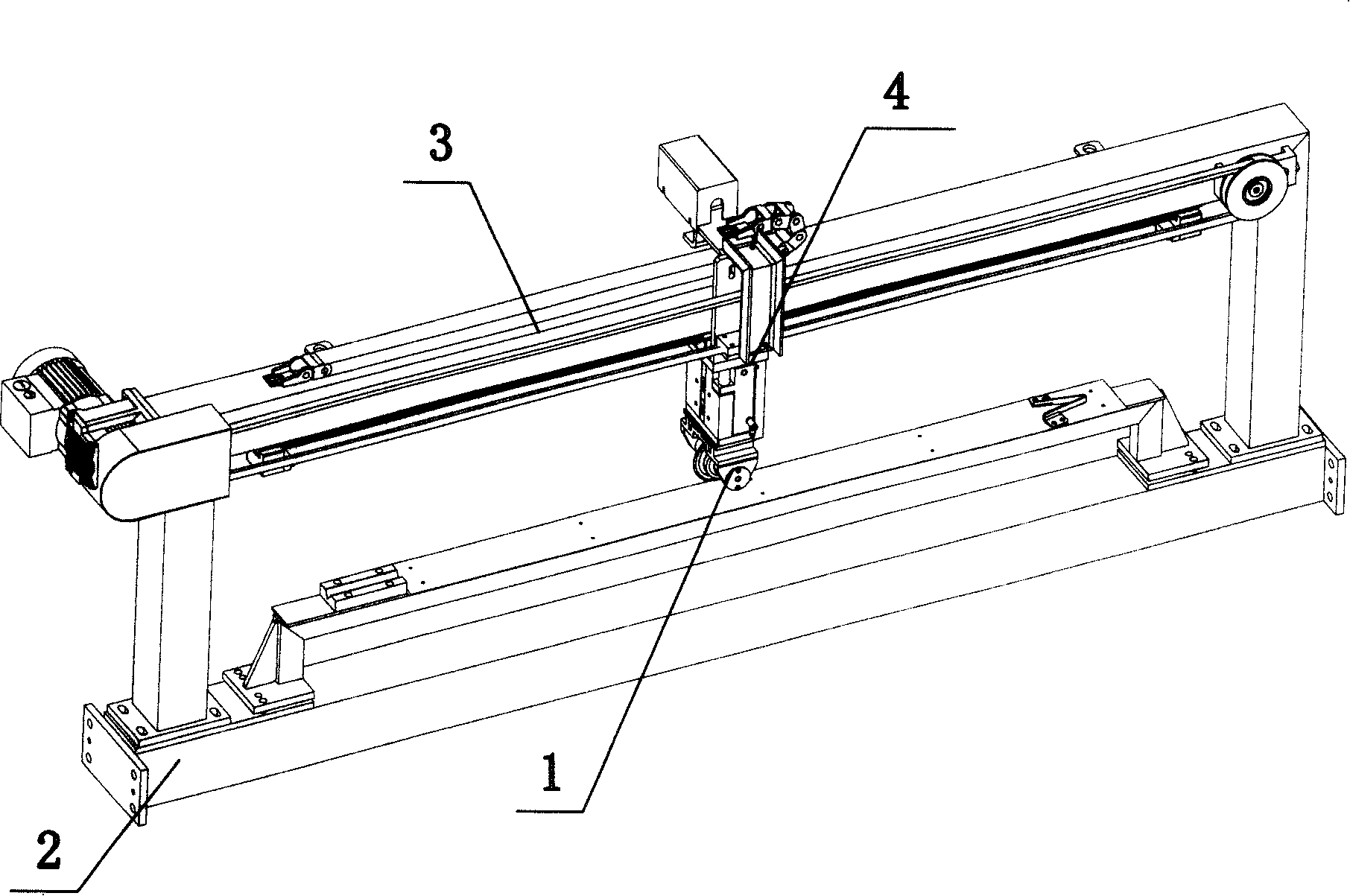

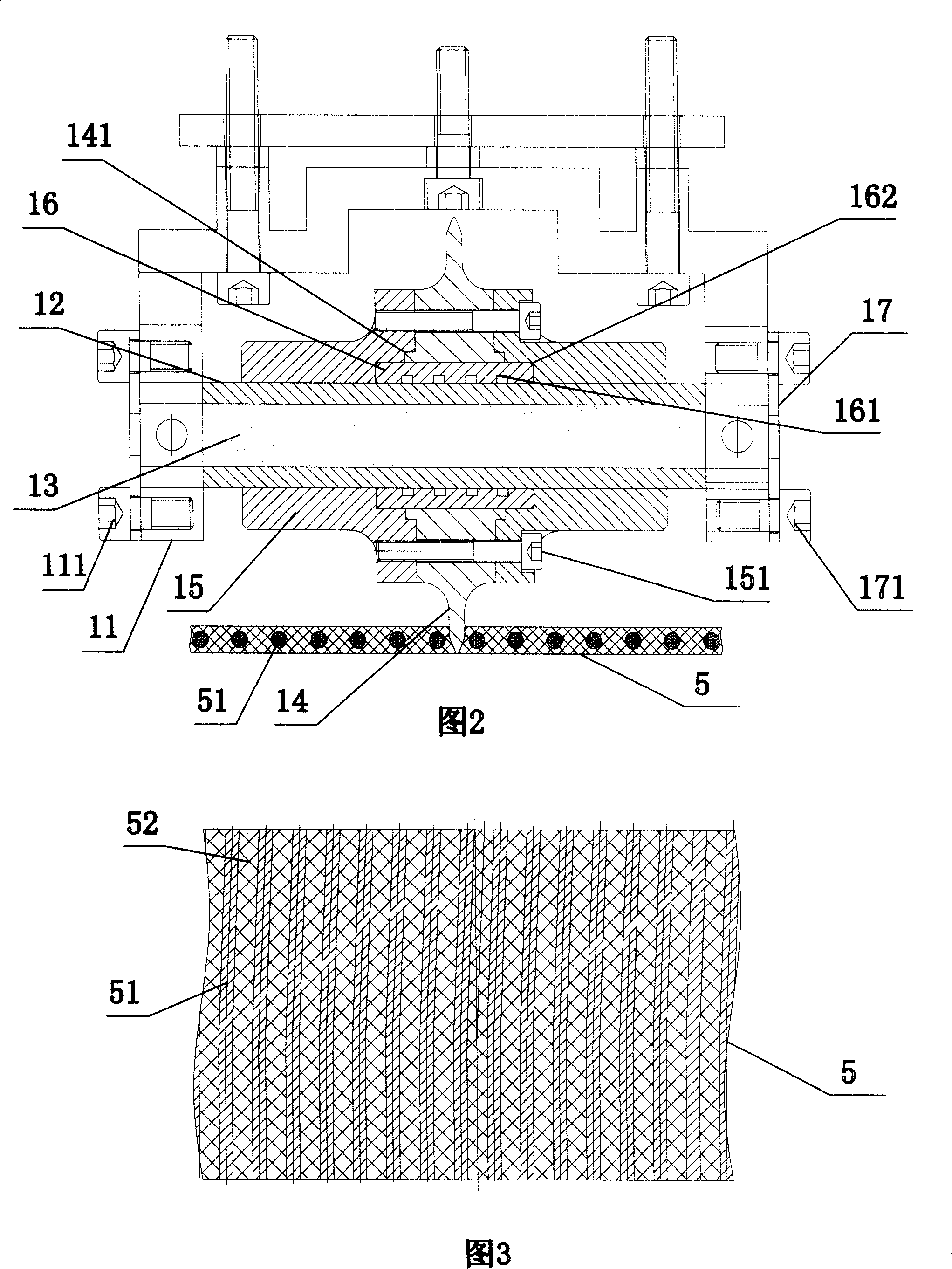

[0047] Example 1, such as figure 1As shown in Fig. 3, the steel cord cutting equipment using the hot hob cutting device 1 has a conveying device 3 horizontally arranged on the frame 2, and a driving hot hob cutting device is arranged on the conveying device 3 1 A driving mechanism 4 extending downwards and cutting the steel cord 5.

[0048] In the steel cord hot hob cutting device 1 , the knife holder 11 is connected upwardly with the driving mechanism 4 through bolts 111 , and the fixed shaft 12 is horizontally sleeved between the two inner walls of the knife holder 11 . The heating tube 13 is sleeved in the inner cavity of the fixed shaft 12, and the heating tube 13 is externally connected with a heating power source with a voltage of 42V and a power of 150W.

[0049] The positioning plate 17 and the bolt 171 are respectively fastened on the outer walls of the two sides of the tool holder 11 to clamp and fix the fixed shaft 12 and the heating tube 13 from both sides.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com