Shearing machine for lens production and processing

A shearing machine and lens technology, applied in metal processing, stone processing tools, stone processing equipment, etc., can solve problems such as increasing difficulty and cycle, affecting shearing quality, and fan blade collision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

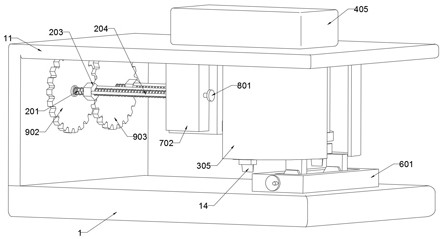

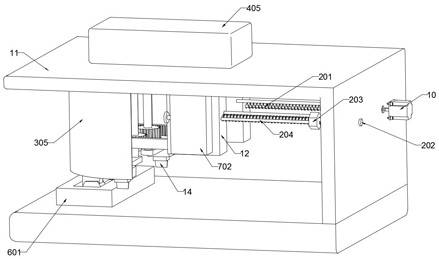

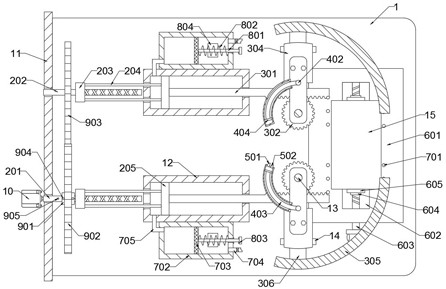

[0026] refer to Figure 1-6 , a shearing machine for lens production and processing, comprising a base 1 and a lens 15, a support plate 11 is fixed on the base 1, the support plate 11 has an inverted L-shaped structure, a box body 12 is symmetrically fixed on the inner wall of the top of the support plate 11, and the box body The inner wall of 12 is slidably connected with a shearing mechanism, and the inner wall of the box 12 is slidably connected with a driving mechanism;

[0027] The shearing mechanism includes a rack 301 slidingly connected to the inner wall of the box body 12. The inner wall of the top of the support plate 11 is rotatably connected to a rotating rod 13. The rotating rod 13 is coaxially fixed with a gear 302. The gear 302 is engaged with the rack 301. The side wall is fixedly connected with a rotating seat 303, the inner wall of the rotating seat 303 is fixedly connected with a support seat 304 by bolts, the bottom wall of the support seat 304 is equipped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com