Separating device and method for enzymatic starch sugar sugar-free grains enrichment

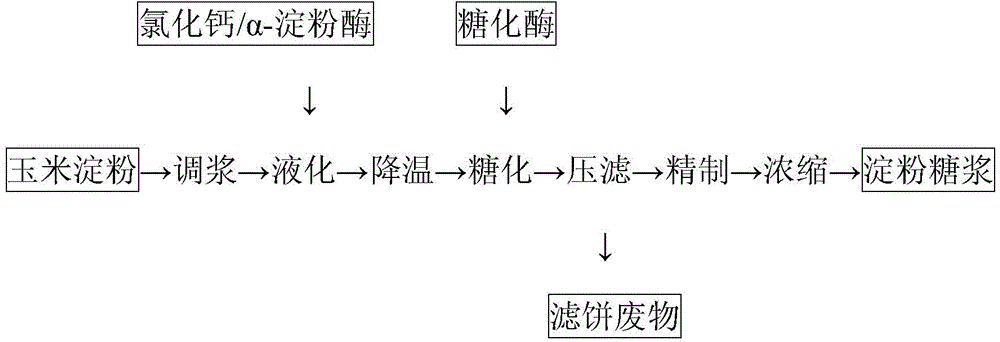

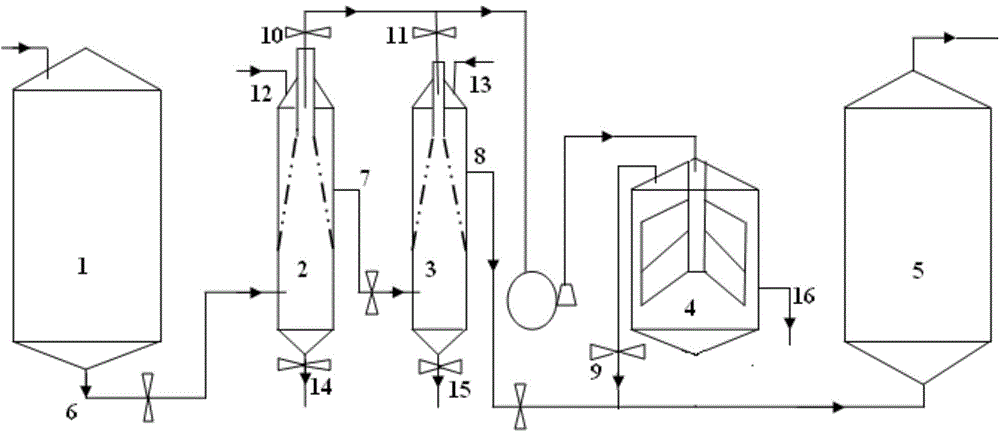

A separation device and technology of starch sugar are applied in the separation of corn starch glutinous grains and sugar liquid, and the field of enzymatic starch sugar glutinous grains enrichment and separation device, which can solve the problem of lowering efficiency of filtering device, lowering efficiency of saccharification, and changing protein content. Low problems, to achieve the effect of reducing processing costs, simple equipment, and no moving parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

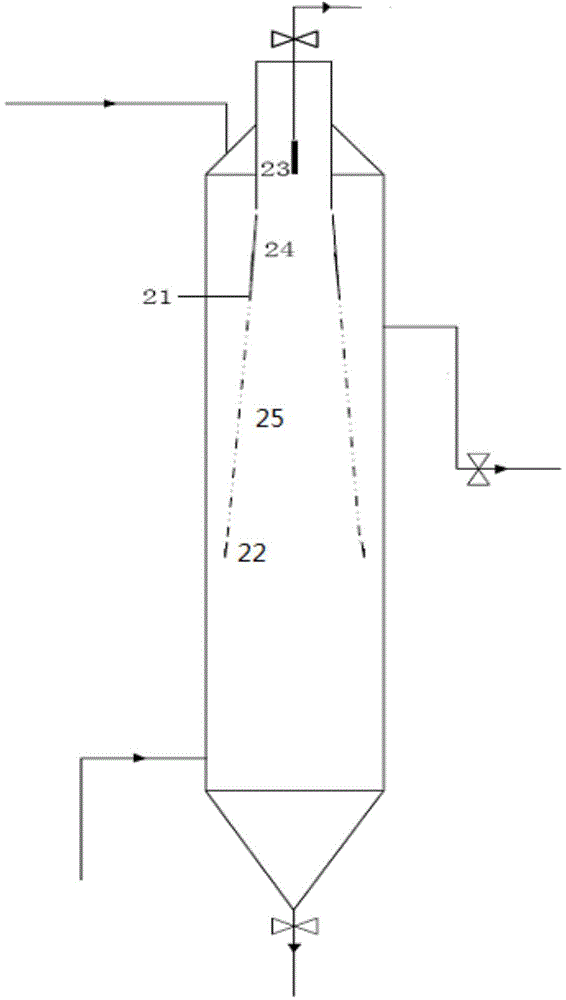

[0043] The tank body diameter of the first sugar grains separator 2 and the second sugar grains separator 3 is 2.0 meters in diameter and 10 meters in height; the diameter of the feed inlet is 0.24 meters, at the position of 0.8 meters above the bottom of the sugar grains separator cylinder; the discharge port 0.24 meters in diameter, located 2.0 meters below the liquid surface.

[0044] The first sugar grains separator 2 is an "upside down" funnel-shaped filter device, the diameter of the grains collection pipeline is 0.8 meters, the bottom level is 1.5 meters below the liquid level of the sugar grains separator, and the top level is higher than the sugar grains separator The liquid level level is 1.0 meters, and the length of the polybasic pipeline is 2.5 meters. The diameter of the waste discharge pipe is 0.20 meters, extending to 0.6 meters below the liquid level of the sugar grain separator; at the position where the bottom of the waste discharge pipe touches the sugar gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com