Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Reduce cutting noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

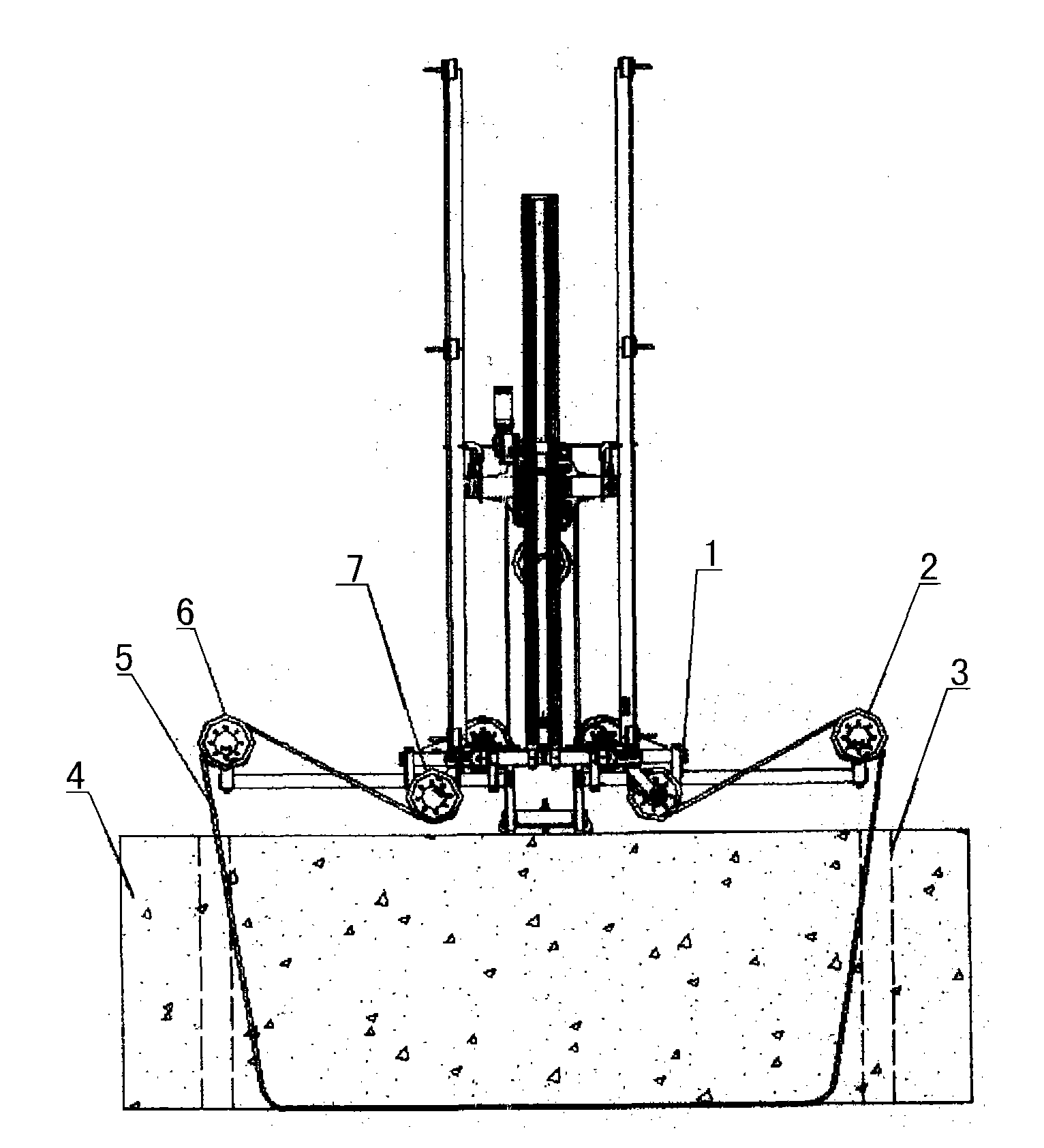

Diamond rope saw static force cutting method

InactiveCN101768926AImprove cutting efficiencySimple construction processBuilding repairsGrinding machinesHydraulic motorReinforced concrete

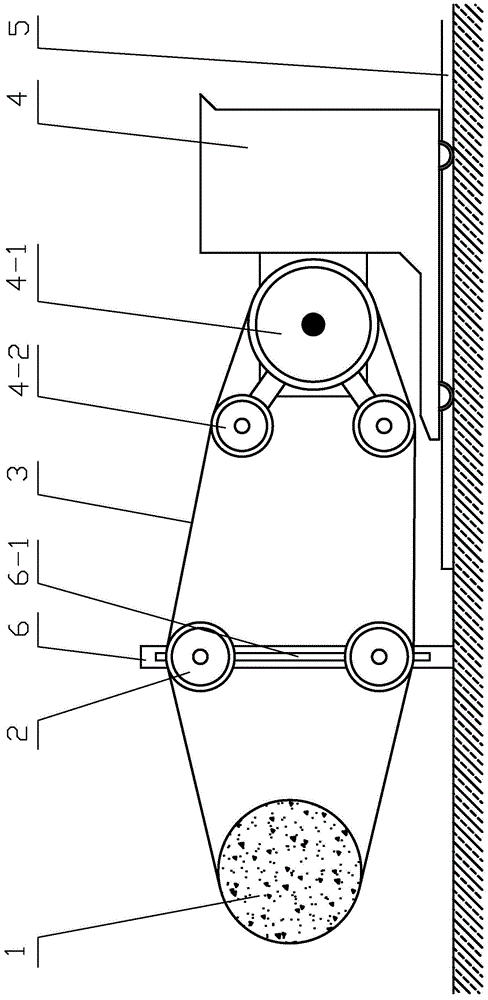

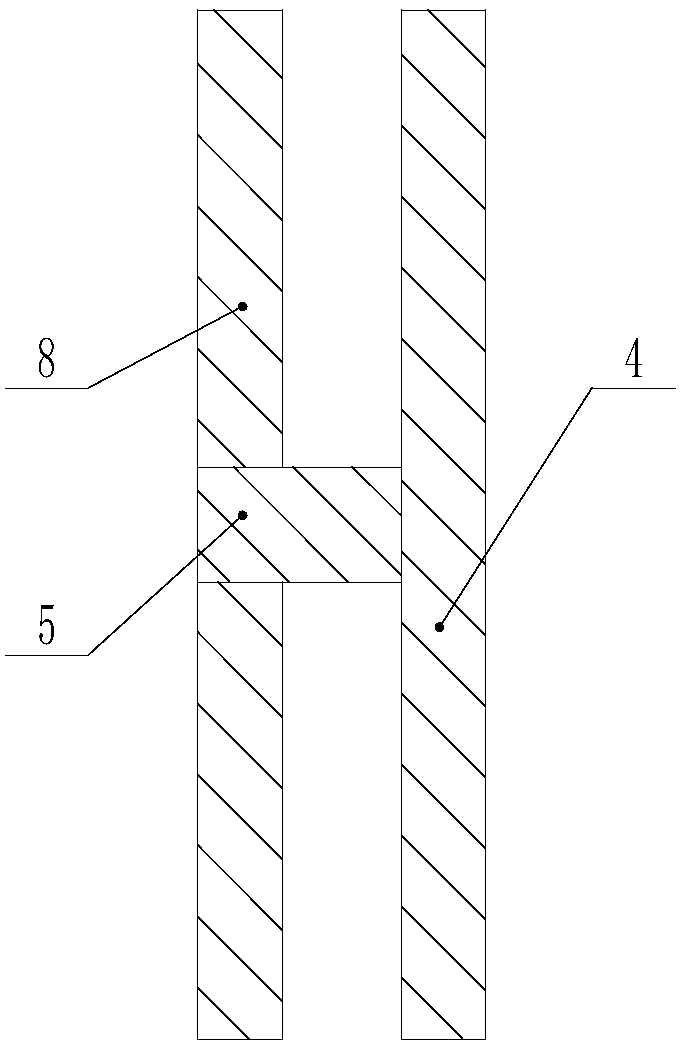

The invention provides a diamond rope saw static force cutting method, relating to a diamond cutting method. In the invention, an adopted hydraulic pressure diamond rope saw is driven by an hydraulic motor to move at a high speed around the cut surface of a cutting object (4) so as to cut the cutting object (4); the grinding material of diamond rope saw (5) is diamond particles, so the diamond rope saw can be used for cutting stone, reinforced concrete or other hard materials; the power source of the cutting is the hydraulic motor, a hydraulic pump is driven by the hydraulic motor to operate smoothly; and the hydraulic motor can be distantly controlled by a high-pressure oil pipe to reduce vibration and noise in cutting process and enable the cutting object (4) is cut and separated stably. The invention has the advantages of high safety and efficiency and environment protection.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

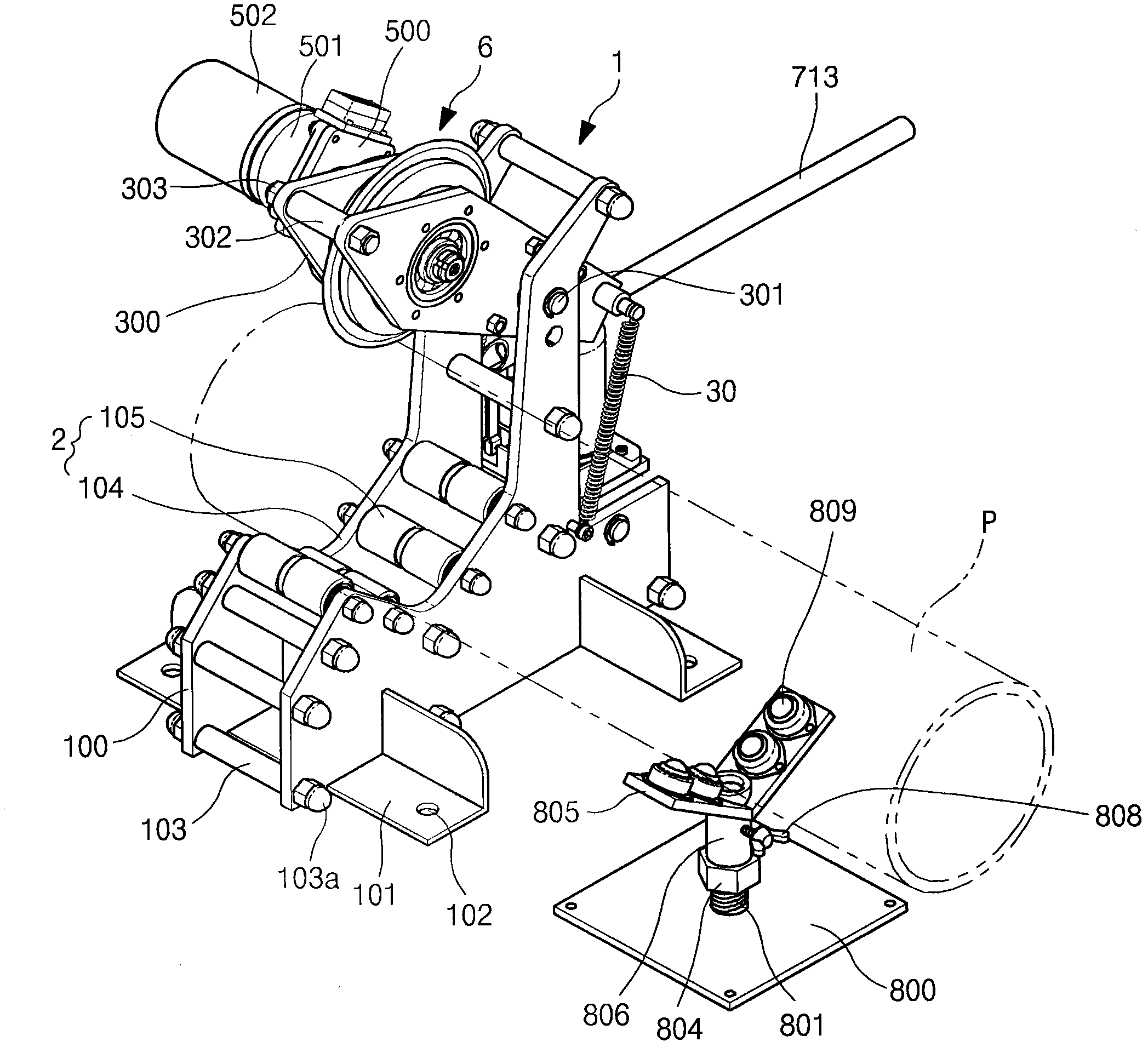

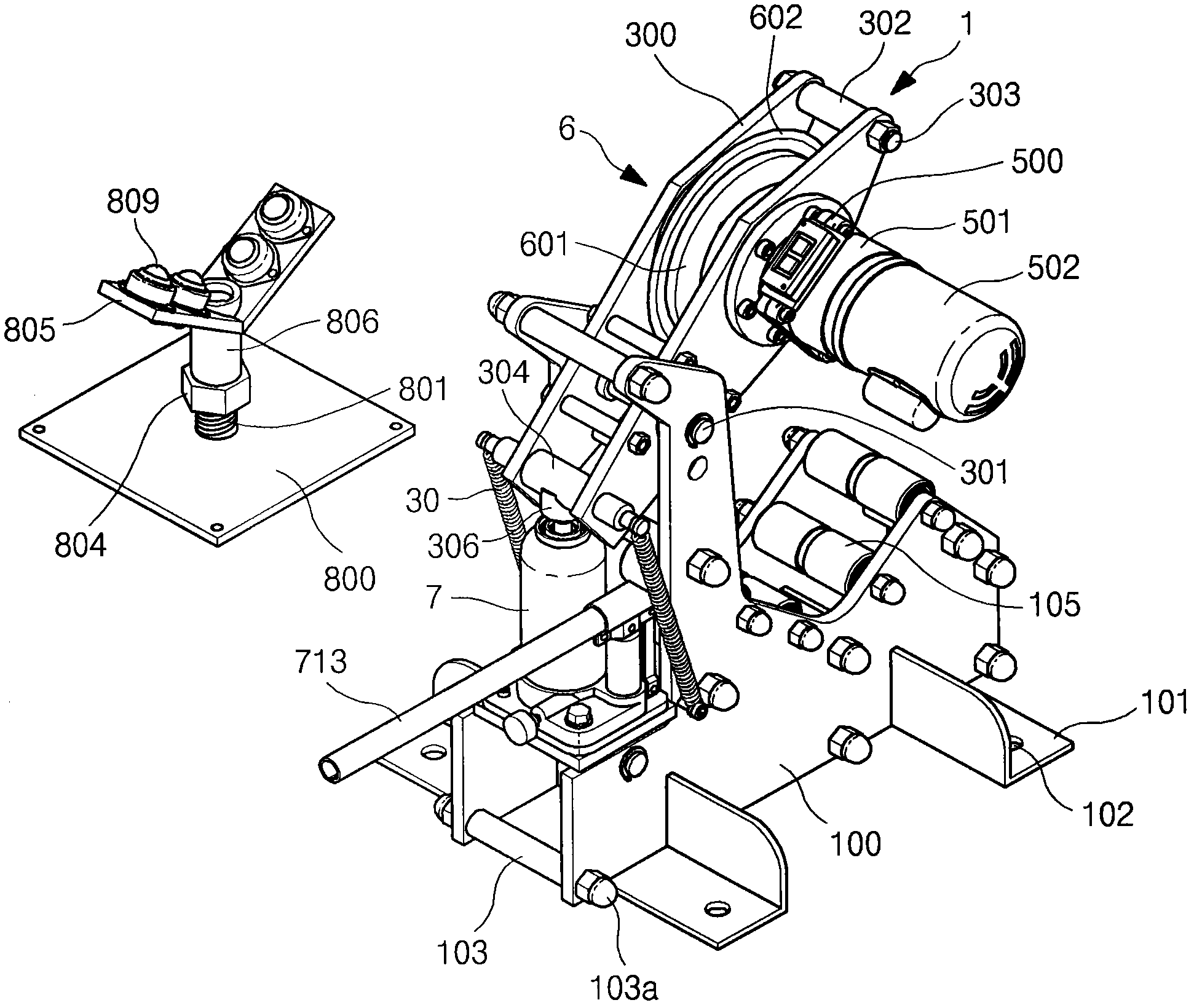

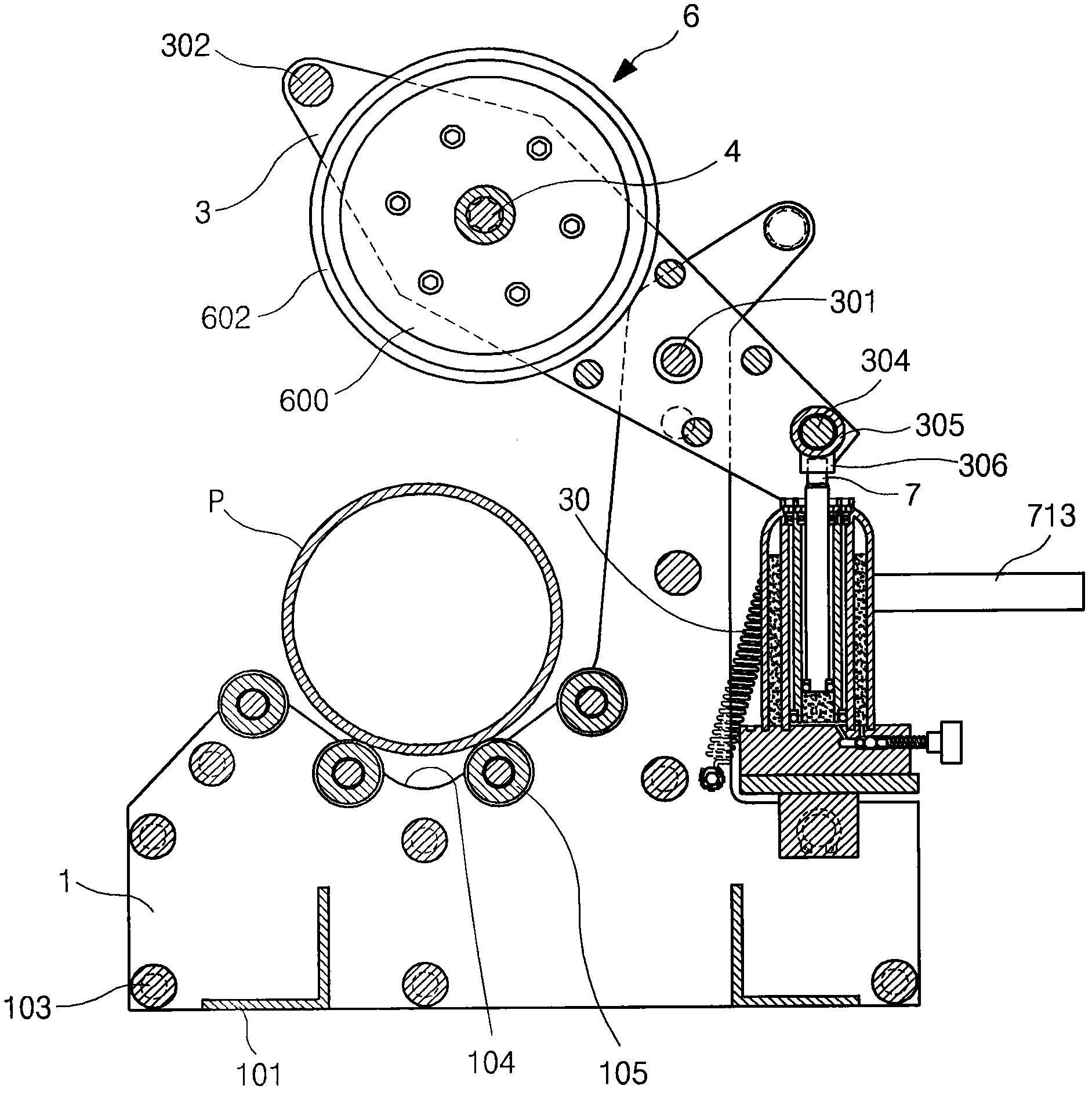

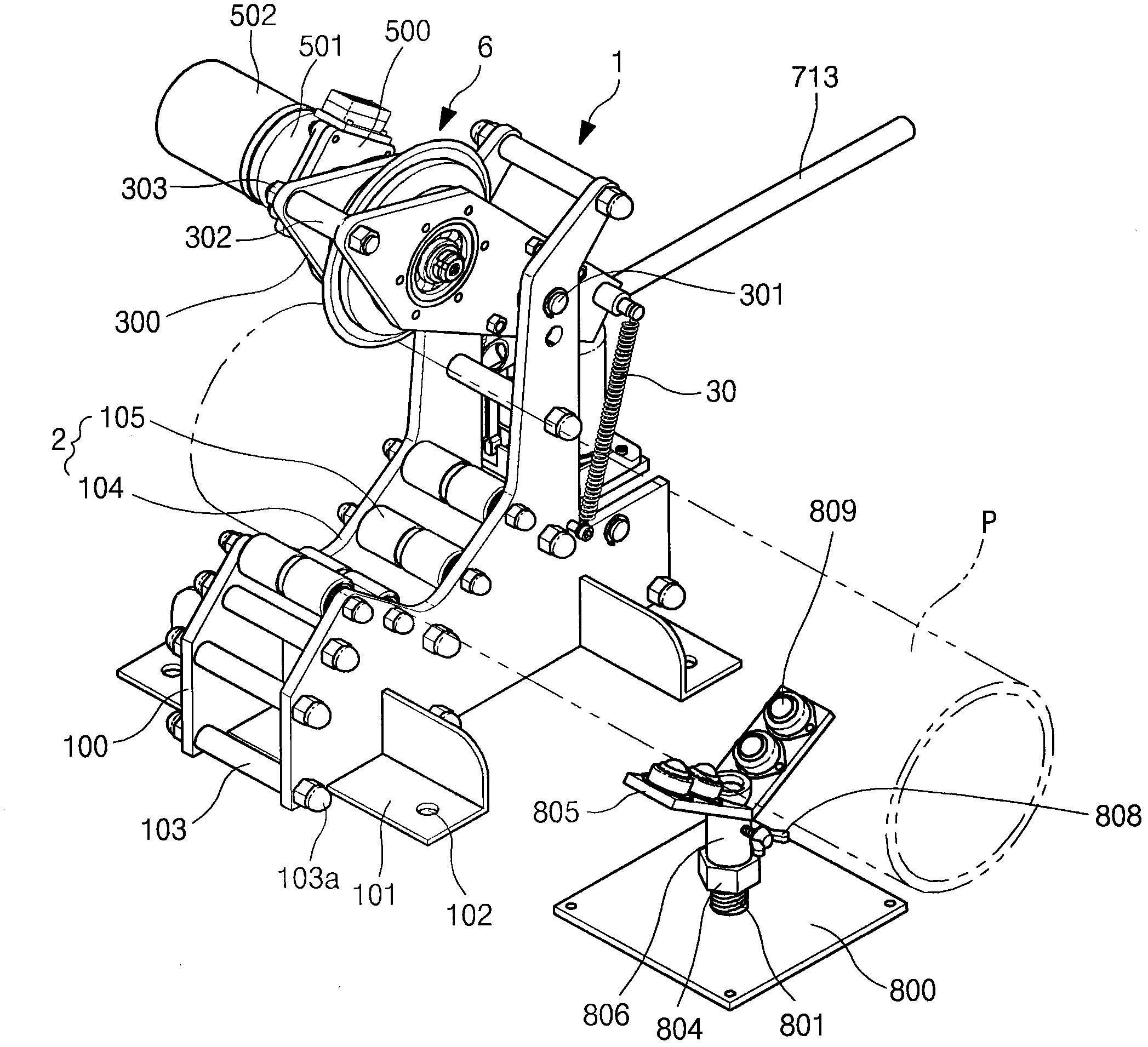

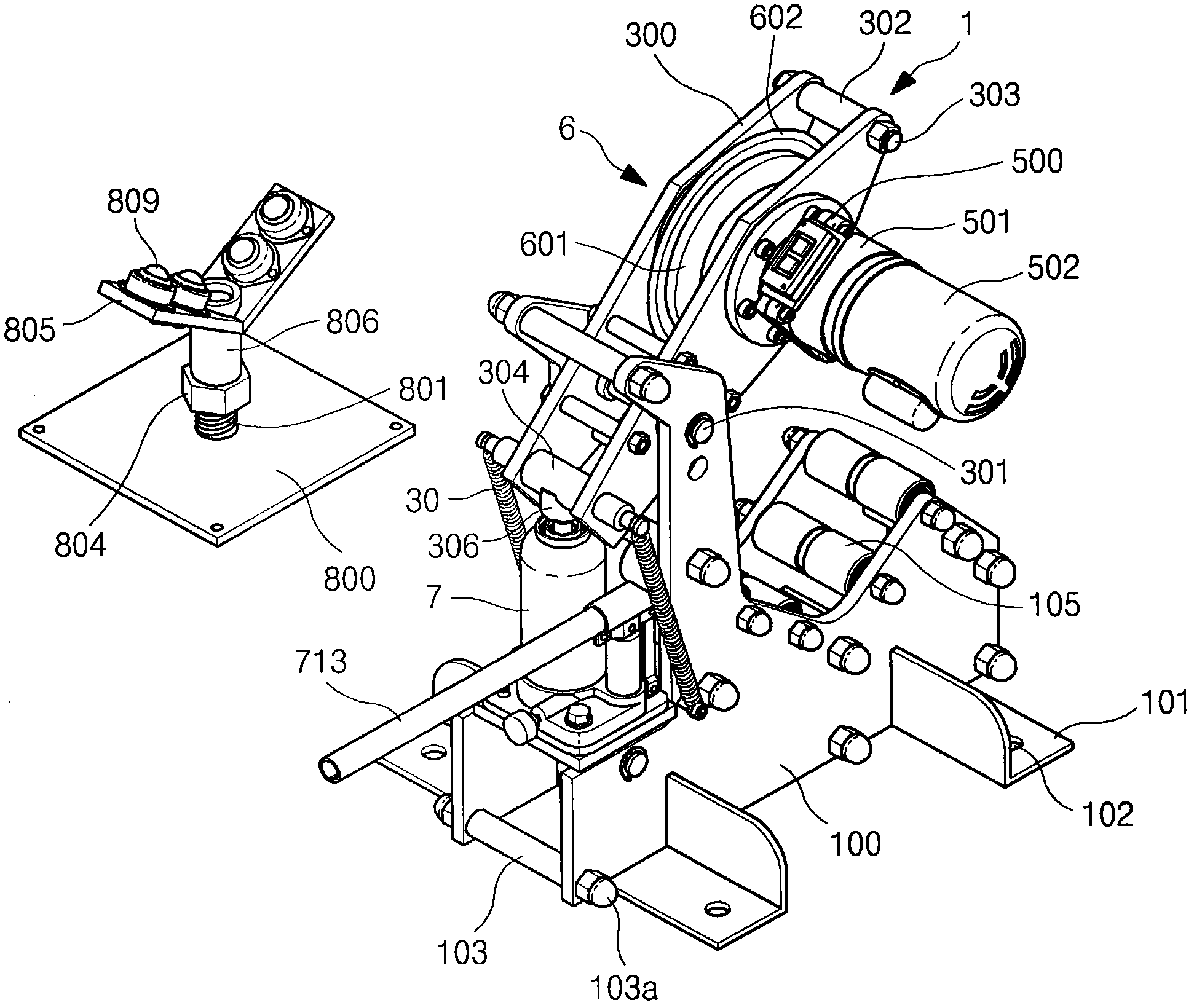

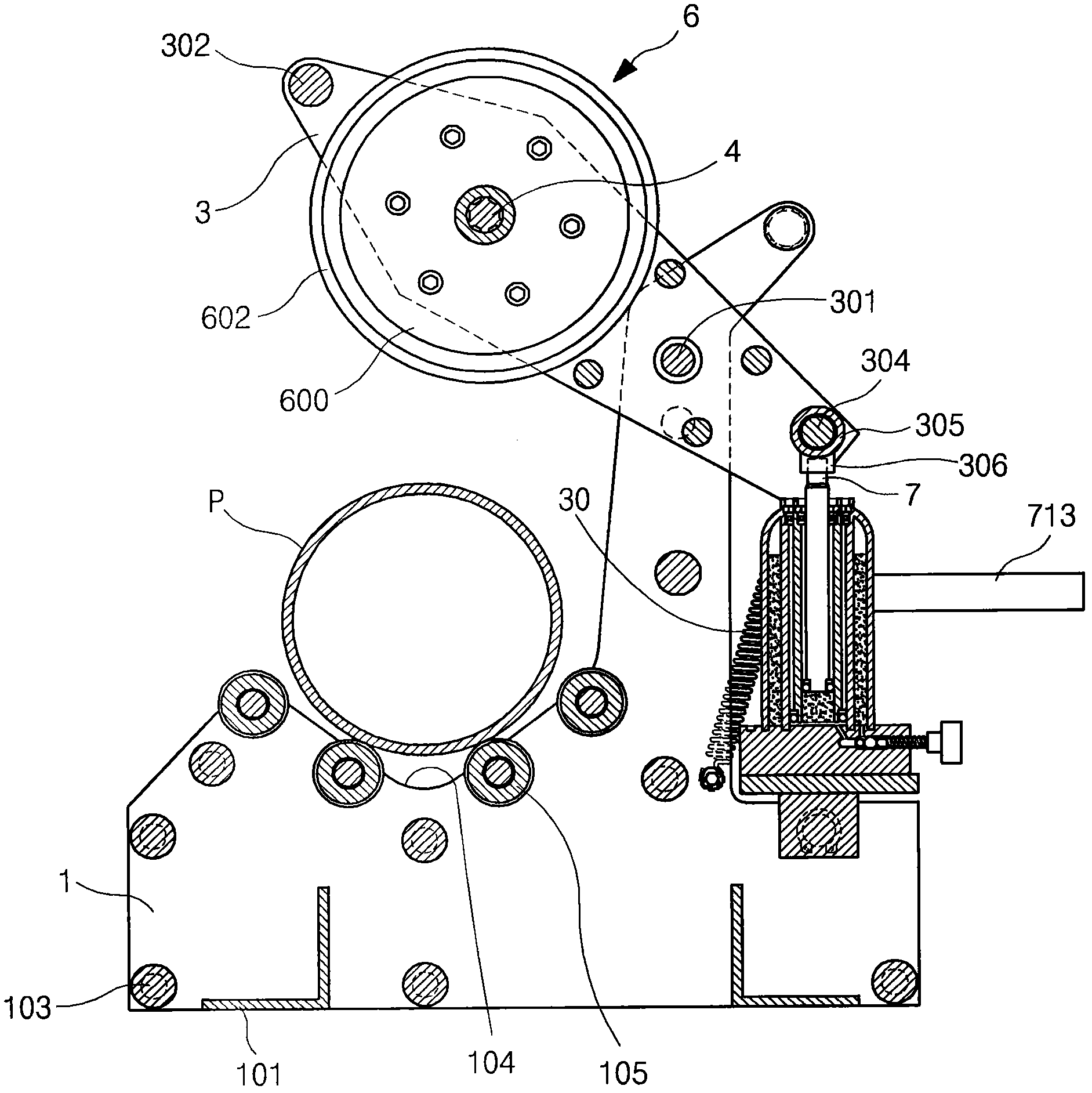

Pipe cutting machine

InactiveCN102574224ASmooth rotationReduce cutting noiseTube shearing machinesBall bearingEngineering

The present invention relates to a pipe cutting machine. The pipe cutting machine of the present invention comprises: a cutting machine body having a cutting board where a pipe to be cut is placed; a pipe mount, which has a mount groove formed in such a manner that the pipe to be cut is mounted thereon in the horizontal direction and includes roller bearings arranged at regular intervals at the inner surface of the mount groove, thereby enabling in-place rotation of the pipe at the mount groove once the pipe to be cut is placed thereon; a rotary blade mount, which includes a hinge shaft installed at the upper side of the pipe mount and a support shaft coupled to the hinge shaft to make a see-saw motion; a motor for driving the rotary blade disposed at the front end side of the rotary blade mount; a piston of a manual hydraulic jack connected to the opposite end to where the rotary blade is disposed, for moving the rotary blade in the vertical direction; and a pipe auxiliary base having an adjustable height disposed at the side of the pipe mount. As such, the pipe is cut as the rotary blade comes in contact with the pipe disposed at the cutting blade and pivots.

Owner:车永俊

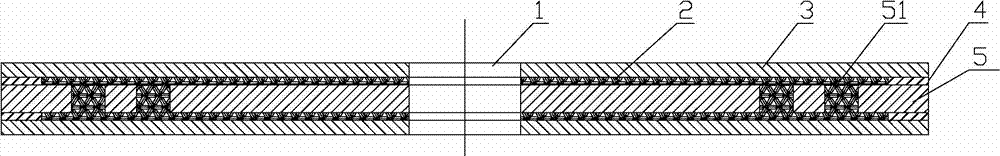

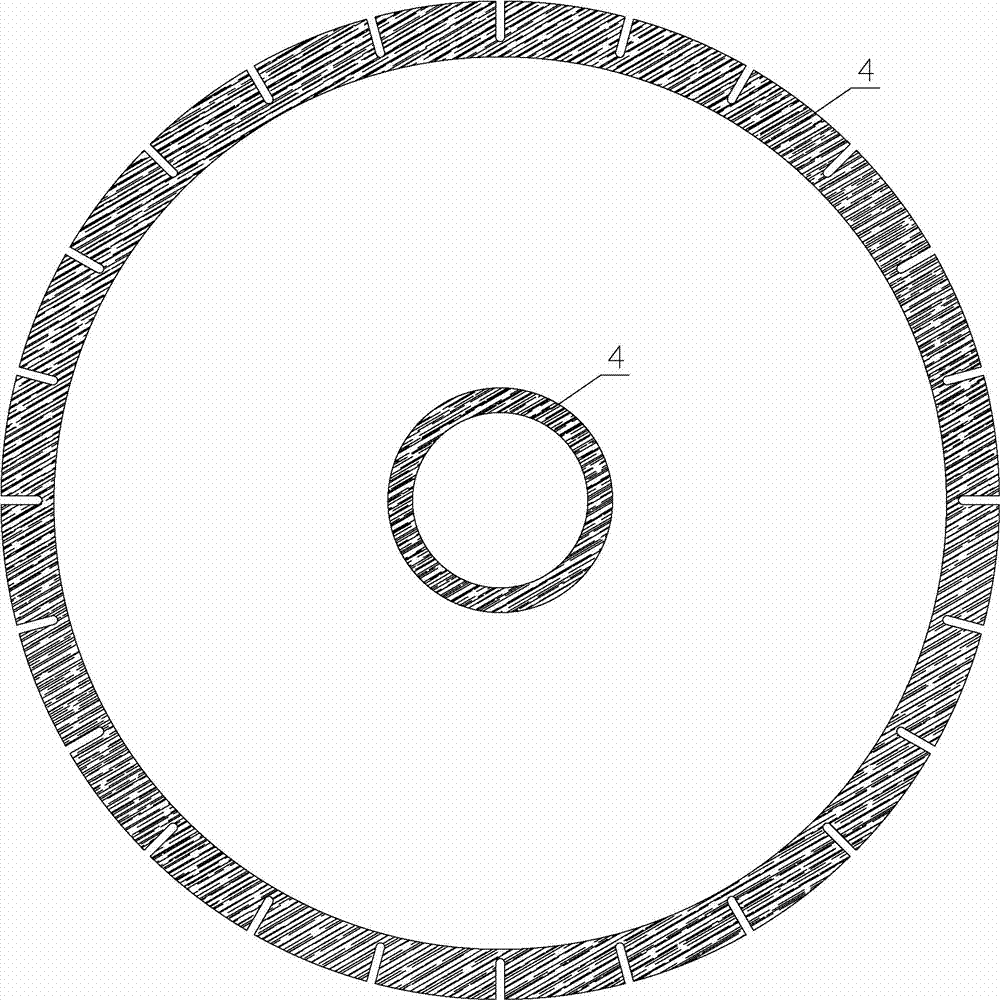

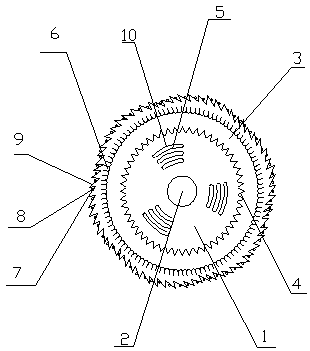

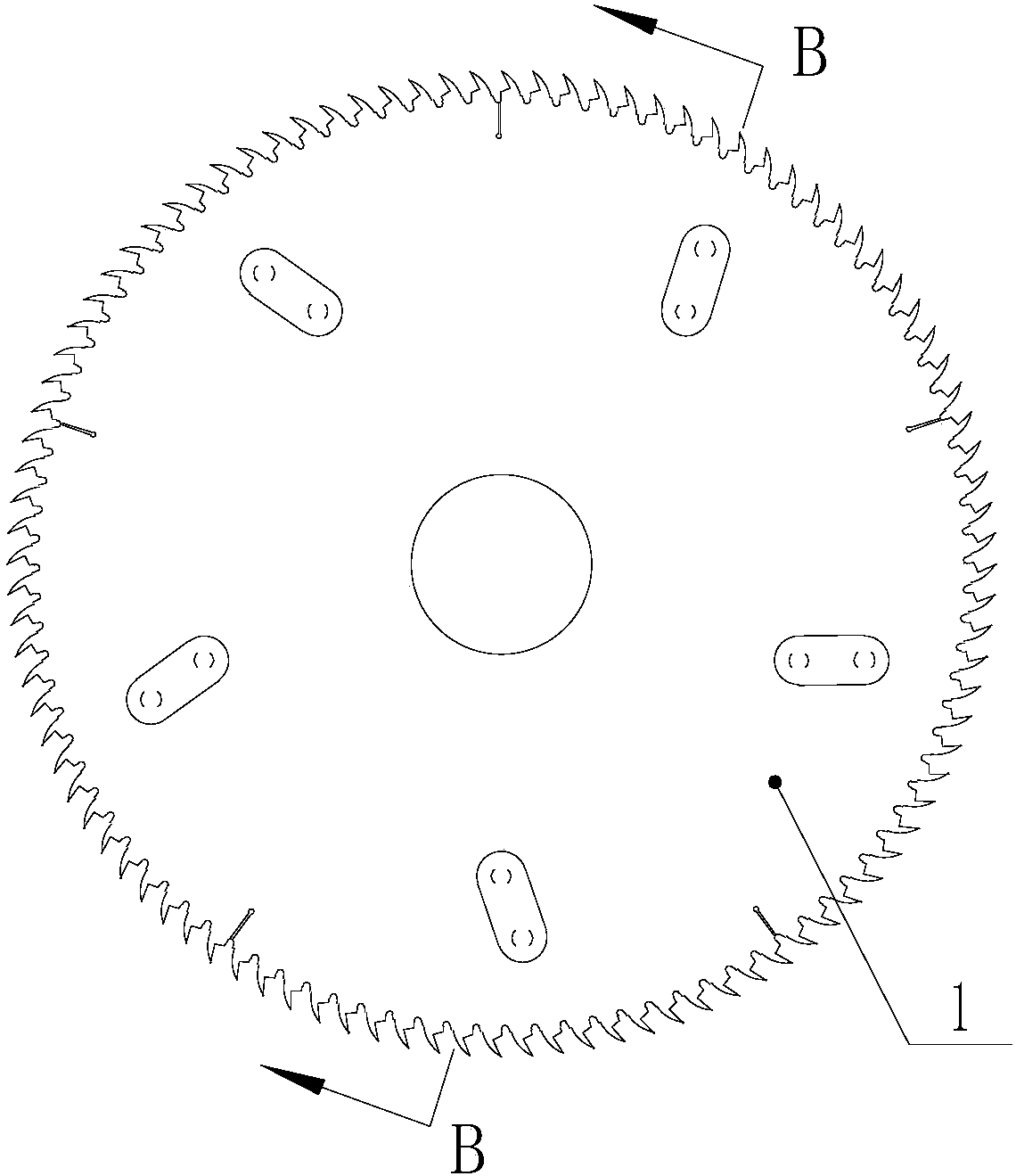

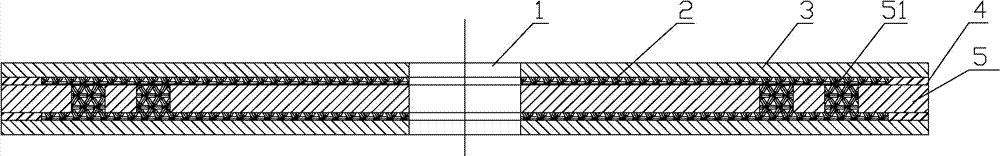

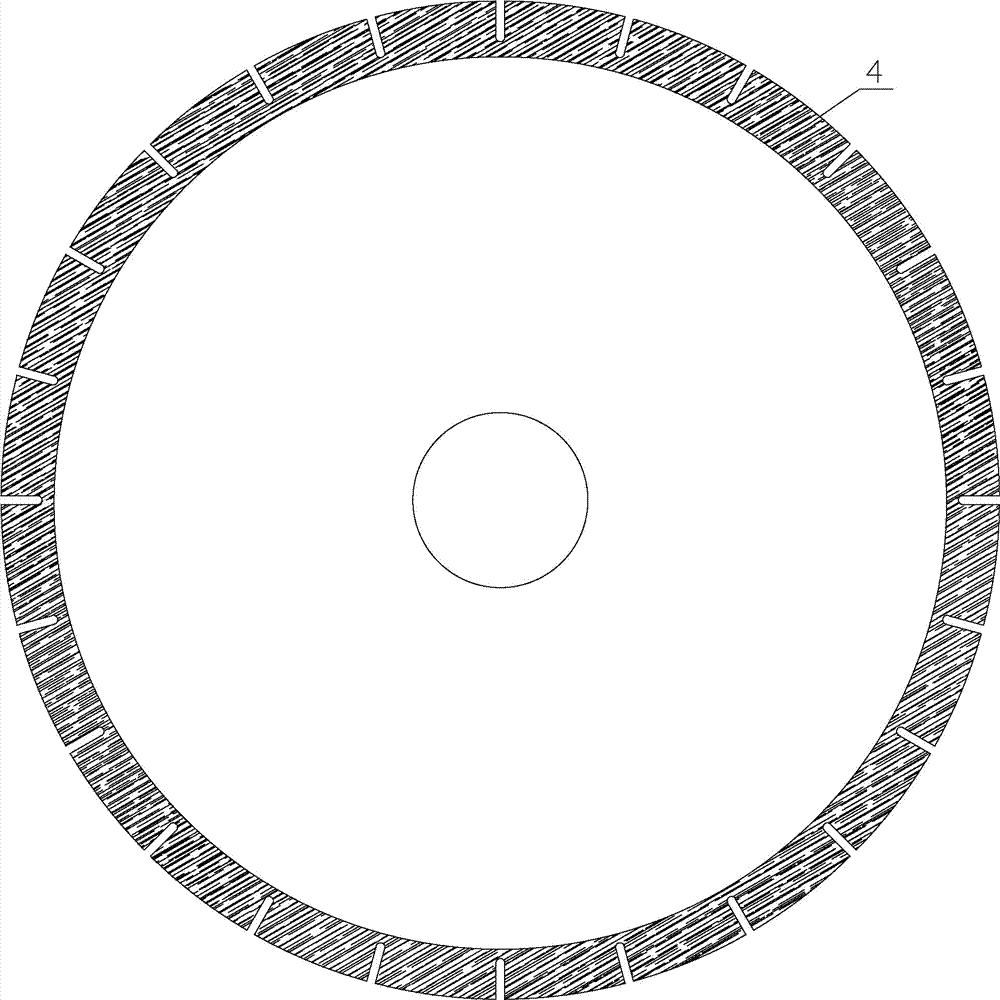

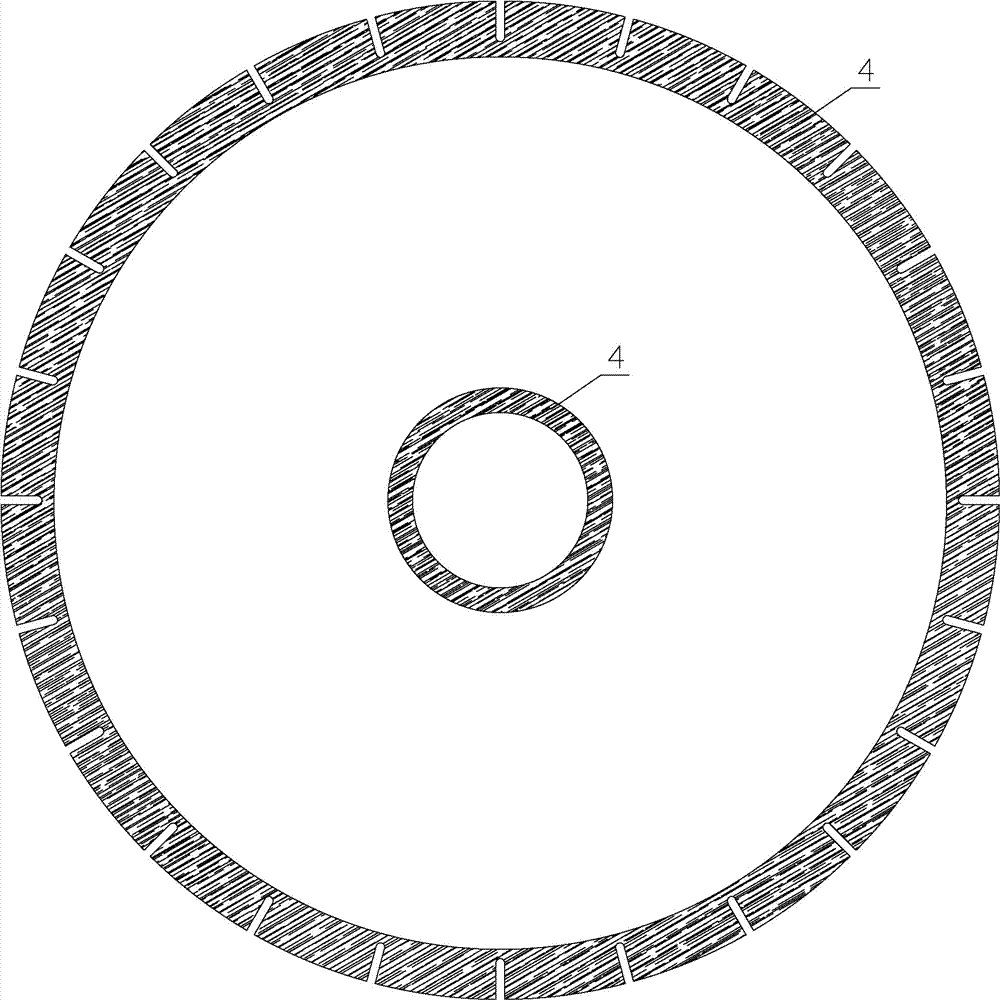

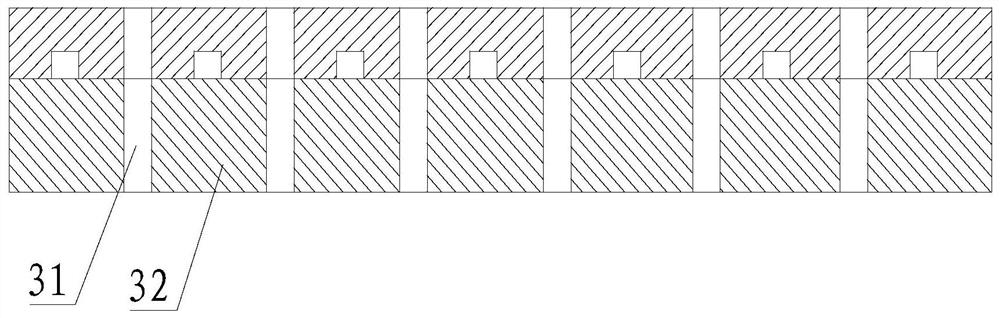

Adhesive composite silencing saw blade primary structure

An adhesive composite silencing saw blade primary structure comprises a saw blade primary structure body, wherein a center hole is formed in the center of the saw blade primary structure body, and the saw blade primary structure body is formed by bonding a plurality of layers of metal plates through adhesive layers. There are three layers of metal plates, and the thickness of the middle layer of metal plate is larger than the thickness of the outer layer primary structure body. A welding layer is further arranged in the adhesive layers. According to the adhesive composite silencing saw blade primary structure, the composite structure formed by bonding the multiple layers of metal plates is adopted for making the saw blade primary structure body have good strength, rigidity and plasticity, and therefore on the one hand, cutting deflection can be effectively reduced, and on the other hand, self-absorbing and buffer performance of cutting vibration can be improved. The arranged adhesive layers serve as damping medium layers to effectively reduce vibration generated in the saw cutting process and lower noise generated in the saw cutting process.

Owner:HEIXUANFENG SAW IND

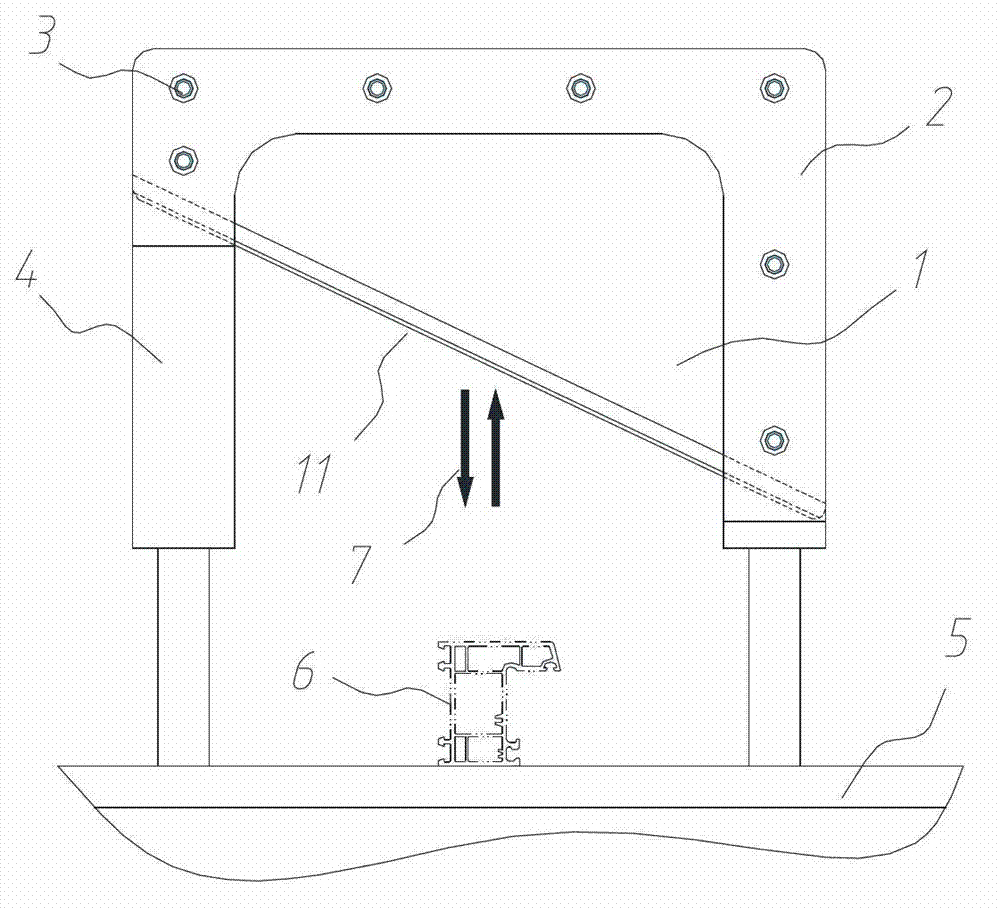

Chipless cutting machine for tubes

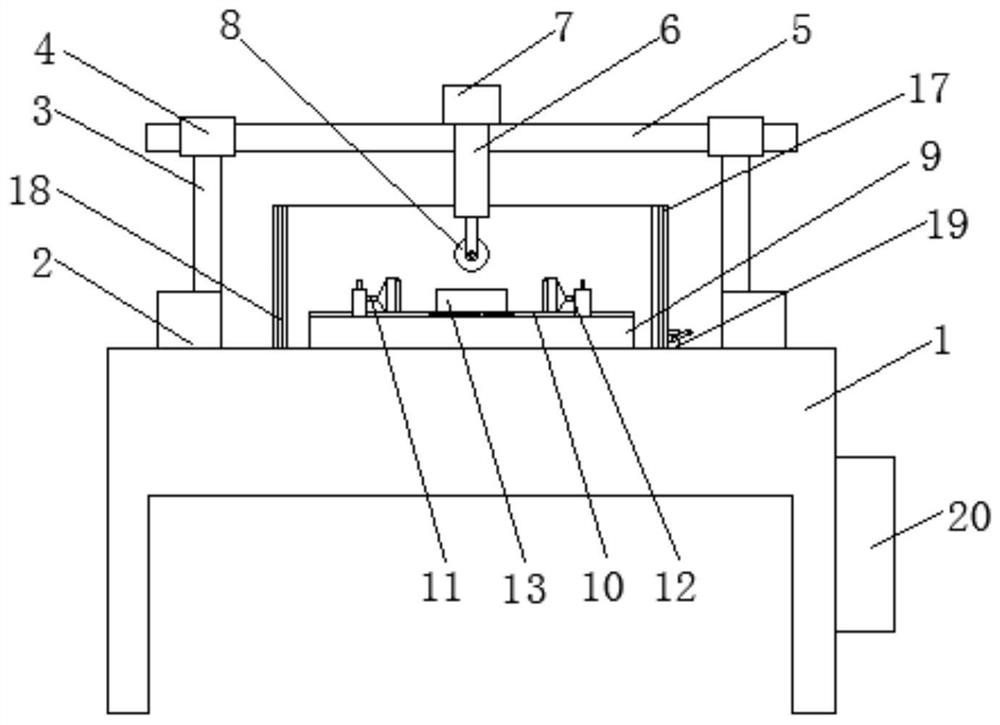

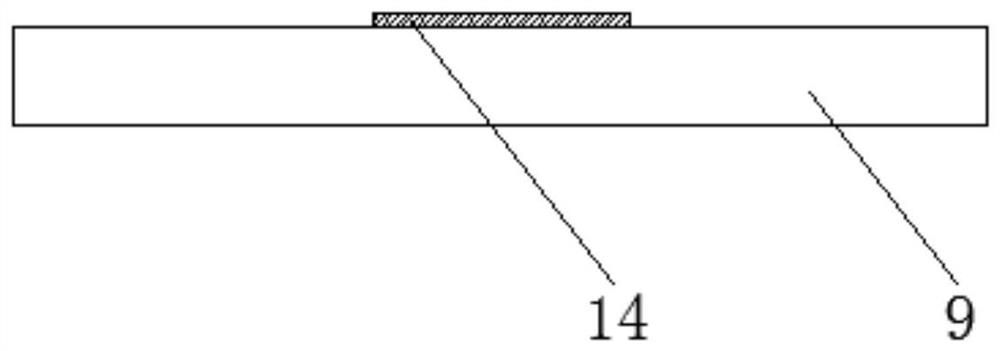

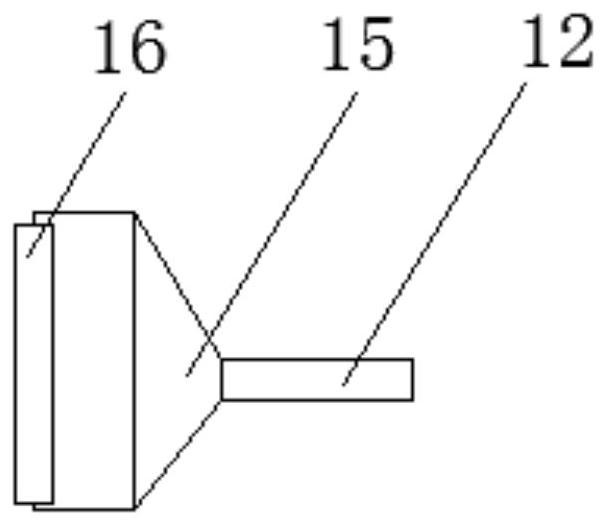

InactiveCN103042549ANo pollutionImprove cutting effectMetal working apparatusMeasurement deviceProgrammable logic controller

The invention relates to a cutting machine, in particular to a chipless cutting machine for tubes. The chipless cutting machine for tubes comprises a machine frame, a tube length measurement device and a PLC (Programmable Logic Controller) control device. When a tube is conveyed, the tube length measurement device sends a length measurement signal to the PLC control device, and the PLC control device controls a cutting device to move along the machine frame according to the length measurement signal and to cut the tube at a fixed length. In the implementation process, a linear sliding rail is arranged on the machine frame and the PLC control device controls the cutting device to move along the sliding rail. A heating device which is used for heating the tube is arranged between the cutting device and the tube length measurement device, the heating device is controlled by a RKC temperature controller to heat the tube to be soft enough to be cut, so that the cutting effect and cutting efficiency can be improved. According to the chipless cutting machine for tubes, the tube is cut by blades to achieve chipless cutting, so that chips from saw cutting used in prior art is avoided, raw materials are saved, and working environment pollution cannot be caused.

Owner:湖南湘光机械模具有限公司

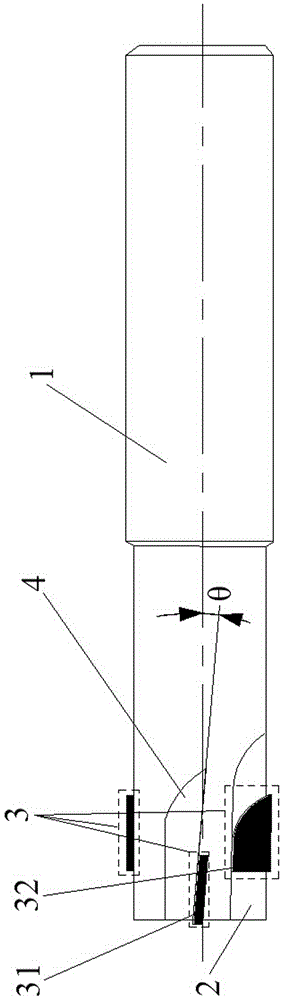

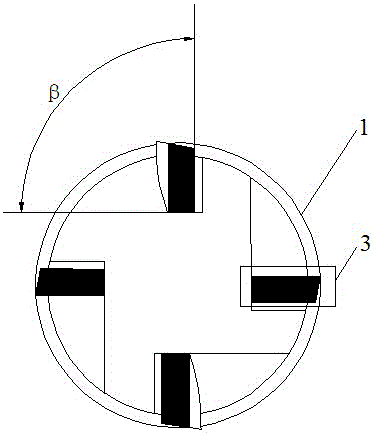

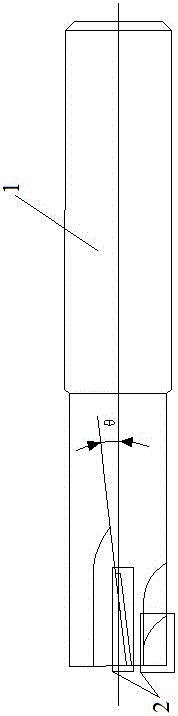

Press-type PCD milling cutter for CFRP milling and manufacturing method

InactiveCN105750604AAvoid stratificationAvoid tearingMilling cuttersWorkpiecesMilling cutterEngineering

The invention discloses a press-type PCD milling cutter for CFRP milling and a manufacturing method and relates to the technical field of milling cutters.When the milling cutter is used for machining a CFRP workpiece, axial cutting force can be offset, vibration can be reduced, and meanwhile layering, tearing and burr defects can be well inhibited.Two front milling cutter grooves are symmetrically formed in the front end of a milling cutter body, and two rear milling cutter grooves are symmetrically formed in the rear portions of the two front milling cutter grooves.The two front milling cutter grooves and the two rear milling cutter grooves are arranged sequentially and alternately, and the rear portions of the two front milling cutter grooves and the front portions of the two rear milling cutter grooves partially coincide in the axial direction.A PCD milling blade is welded in each front milling cutter groove, and a PCD milling blade is welded in each rear milling cutter groove.The four PCD milling blades are all arranged obliquely.The included angles formed between all the PCD milling blades and the center axis of the milling cutter body are the same.Every two adjacent PCD milling blades are opposite in inclining direction.A chip groove is formed in one side of the front surface of each PCD milling blade.The press-type PCD milling cutter is used for CFRP milling, and the defect that an upper surface and a lower surface are layered can be overcome.

Owner:HARBIN UNIV OF SCI & TECH

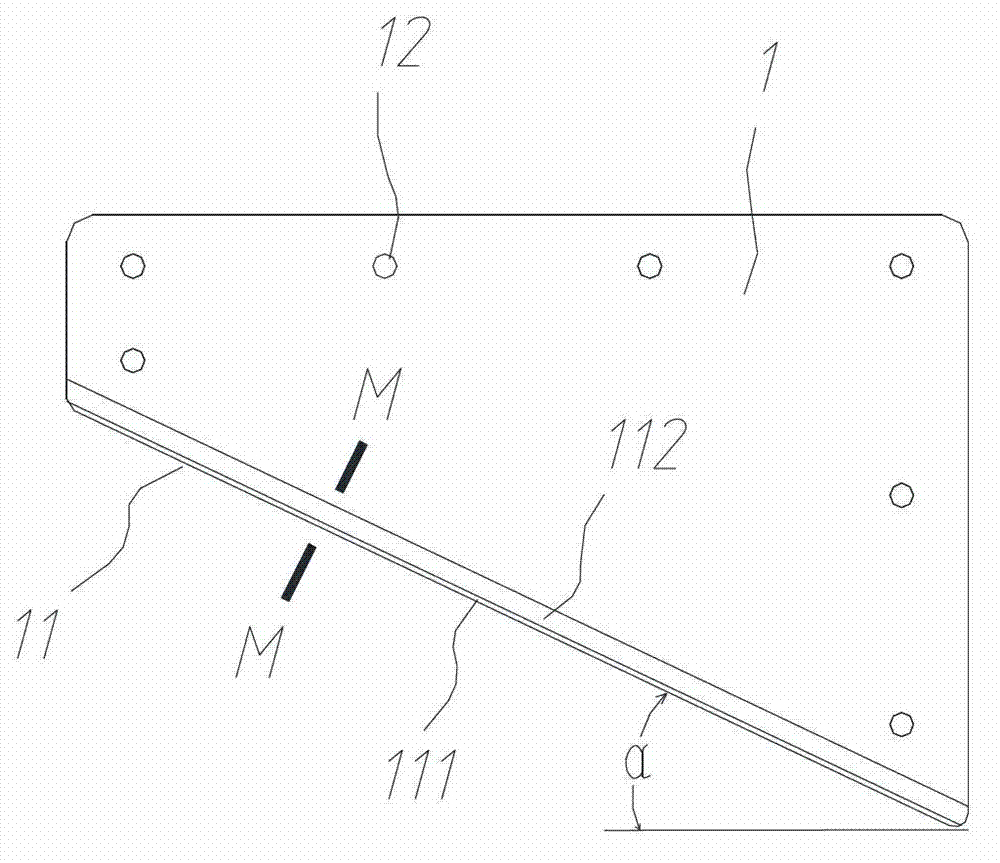

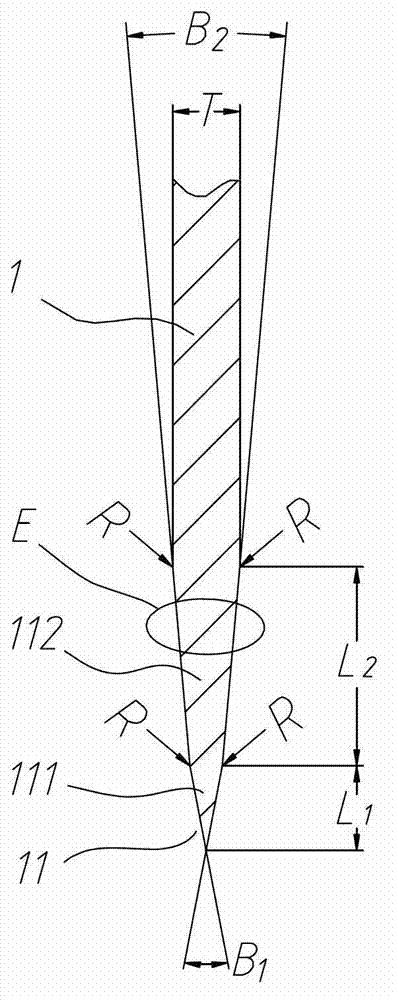

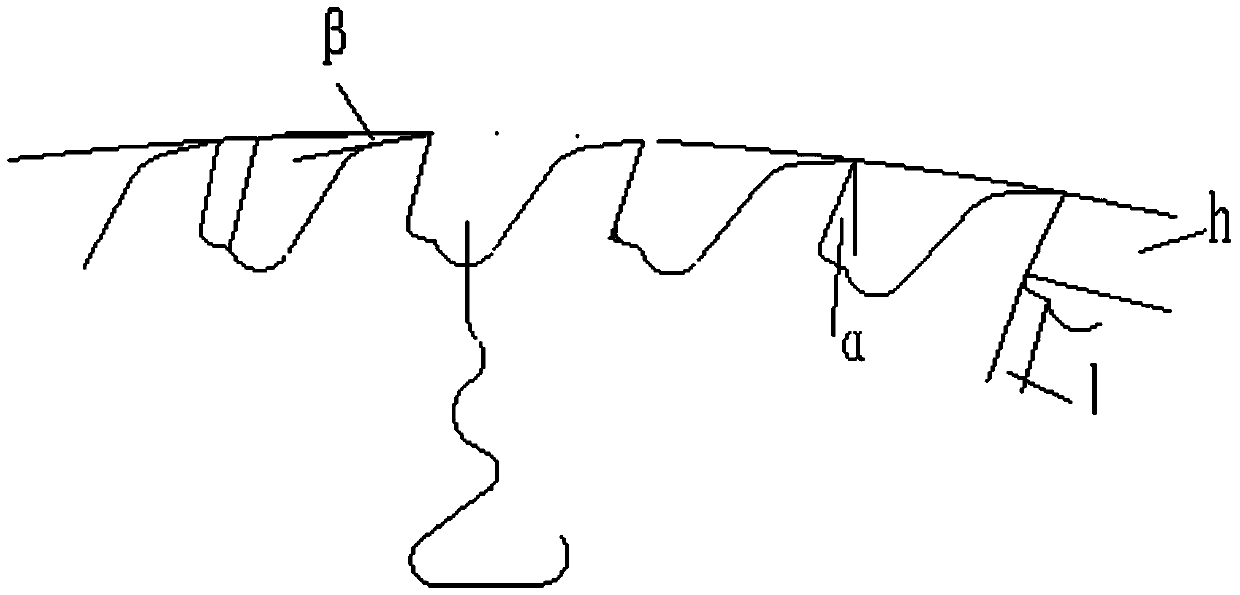

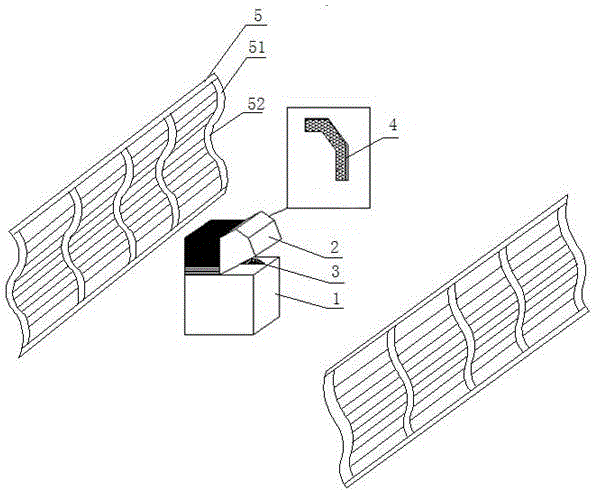

Cutting knife used for thermal cutting of plastic material

ActiveCN103112025AEliminate longitudinal wavy gapsReduce cutting noiseMetal working apparatusPlastic materialsEngineering

The invention relates to a cutting knife used for thermal cutting of plastic material. The cutting knife used for the thermal cutting of the plastic material comprises a blade body, and an inclined double-edged cutting edge which is arranged at the lower end of the blade body, the inclination angle alpha of the cutting edge relative to the horizontal line is 22-28 degrees, and the blade is grinded along the feeding direction of the blade by a grinding appliance to form the cutting edge. The cutting edge at least comprises a first level cutting edge and a second level cutting edge, the angle B1 of the first level cutting edge is 21-23 degrees, and the angle B2 of the second level cutting edge is 8-10 degrees. The plastic material cut by the blade is smooth in end face and free of the appearance of burs and silkings, and cutting end face quality of the material can be improved. Besides, in a cutting process, the resistance stressed on the blade is even, the blade is not prone to tipping, not only is the service life of the blade prolonged, but also cutting noise is reduced observably, and the production environment is improved.

Owner:TONGLING GREAT EXTRUSION TECH

Pipe cutting machine

InactiveCN102574224BSmooth rotationReduce cutting noiseTube shearing machinesBall bearingEngineering

The present invention relates to a pipe cutting machine. The pipe cutting machine of the present invention comprises: a cutting machine body having a cutting board where a pipe to be cut is placed; a pipe mount, which has a mount groove formed in such a manner that the pipe to be cut is mounted thereon in the horizontal direction and includes roller bearings arranged at regular intervals at the inner surface of the mount groove, thereby enabling in-place rotation of the pipe at the mount groove once the pipe to be cut is placed thereon; a rotary blade mount, which includes a hinge shaft installed at the upper side of the pipe mount and a support shaft coupled to the hinge shaft to make a see-saw motion; a motor for driving the rotary blade disposed at the front end side of the rotary blade mount; a piston of a manual hydraulic jack connected to the opposite end to where the rotary blade is disposed, for moving the rotary blade in the vertical direction; and a pipe auxiliary base having an adjustable height disposed at the side of the pipe mount. As such, the pipe is cut as the rotary blade comes in contact with the pipe disposed at the cutting blade and pivots.

Owner:车永俊

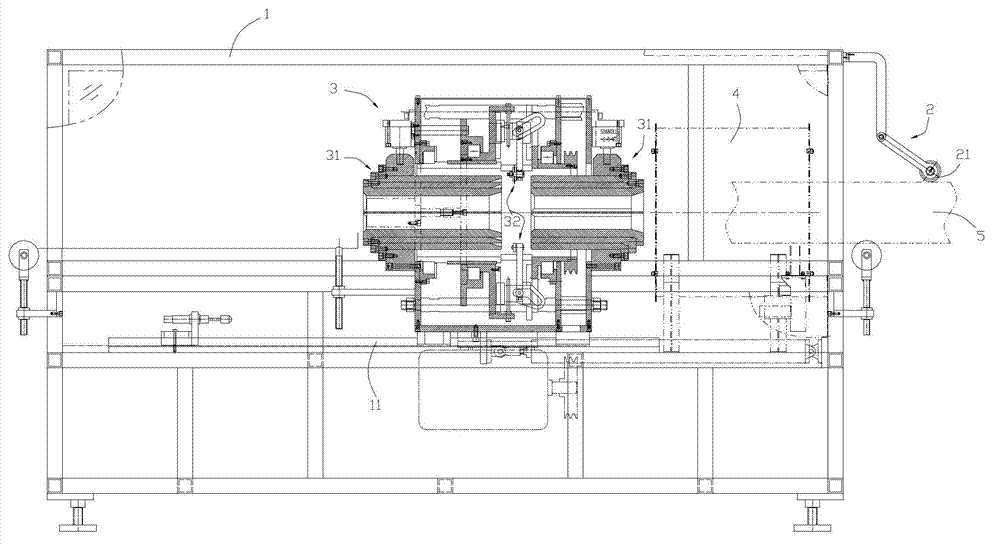

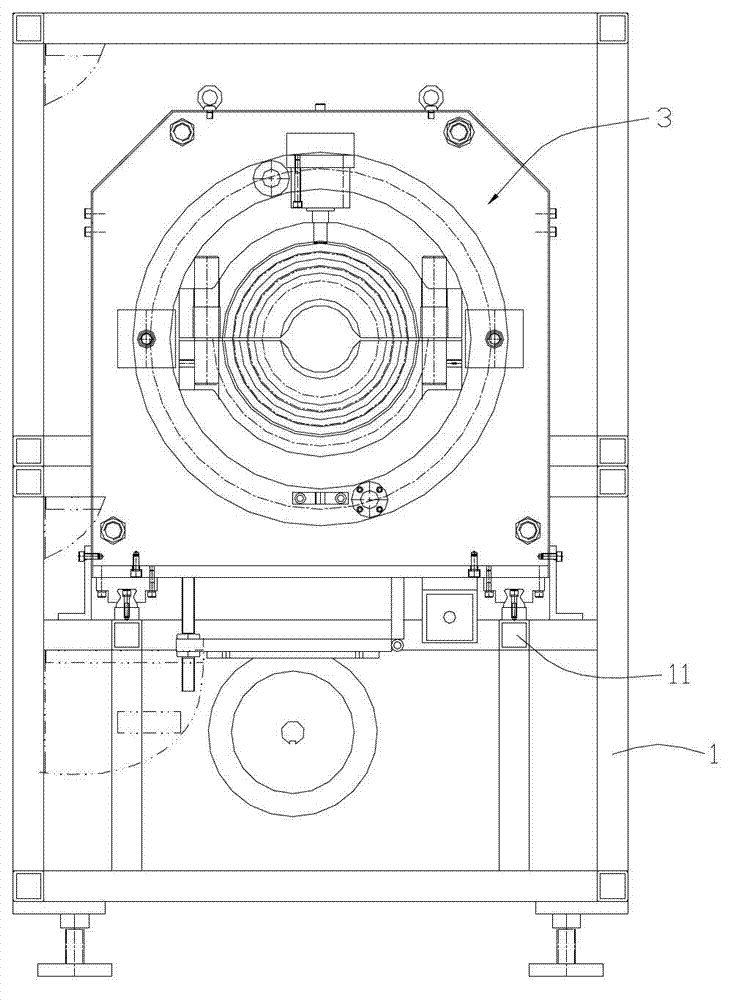

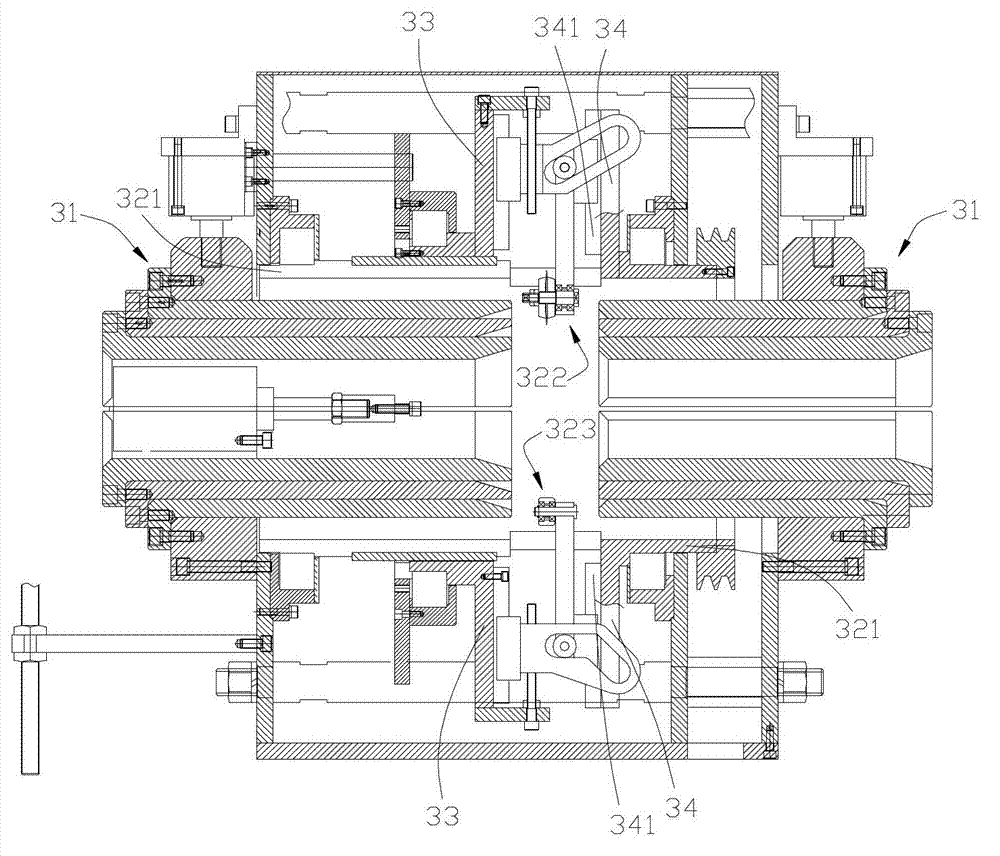

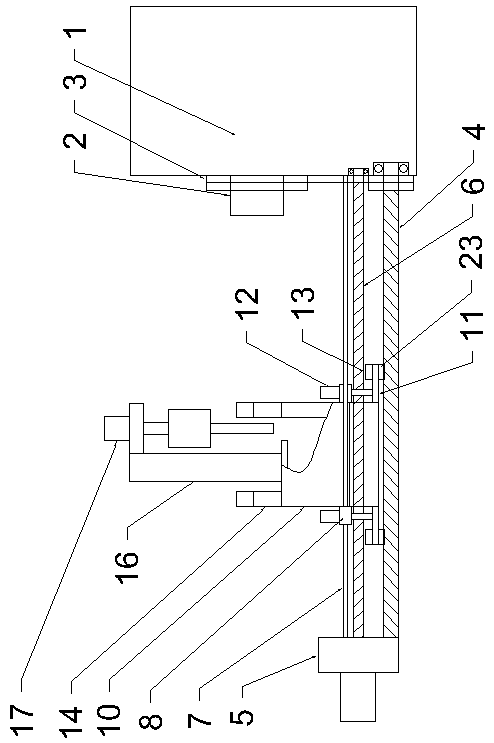

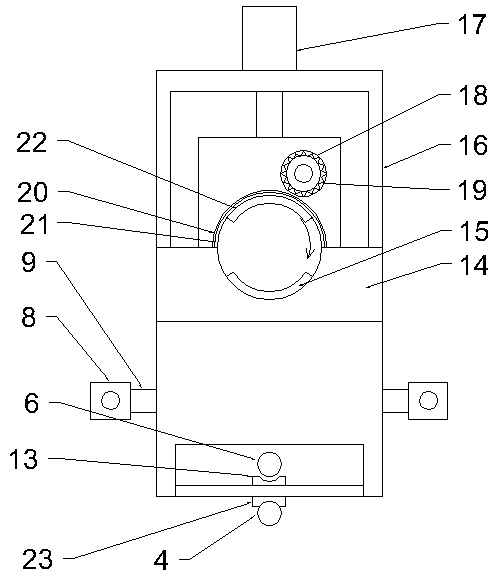

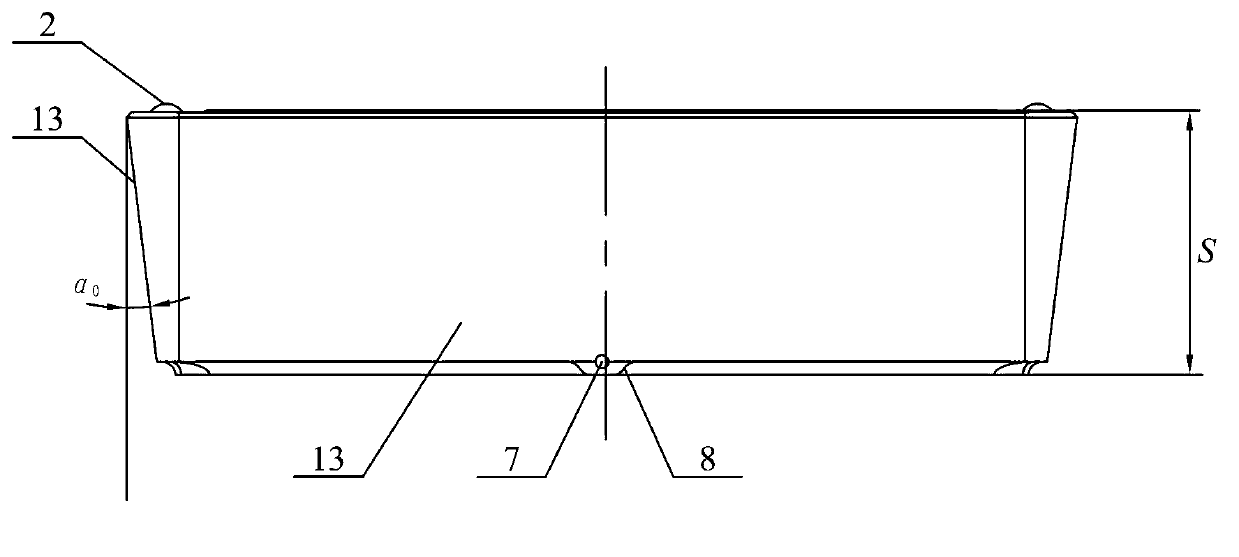

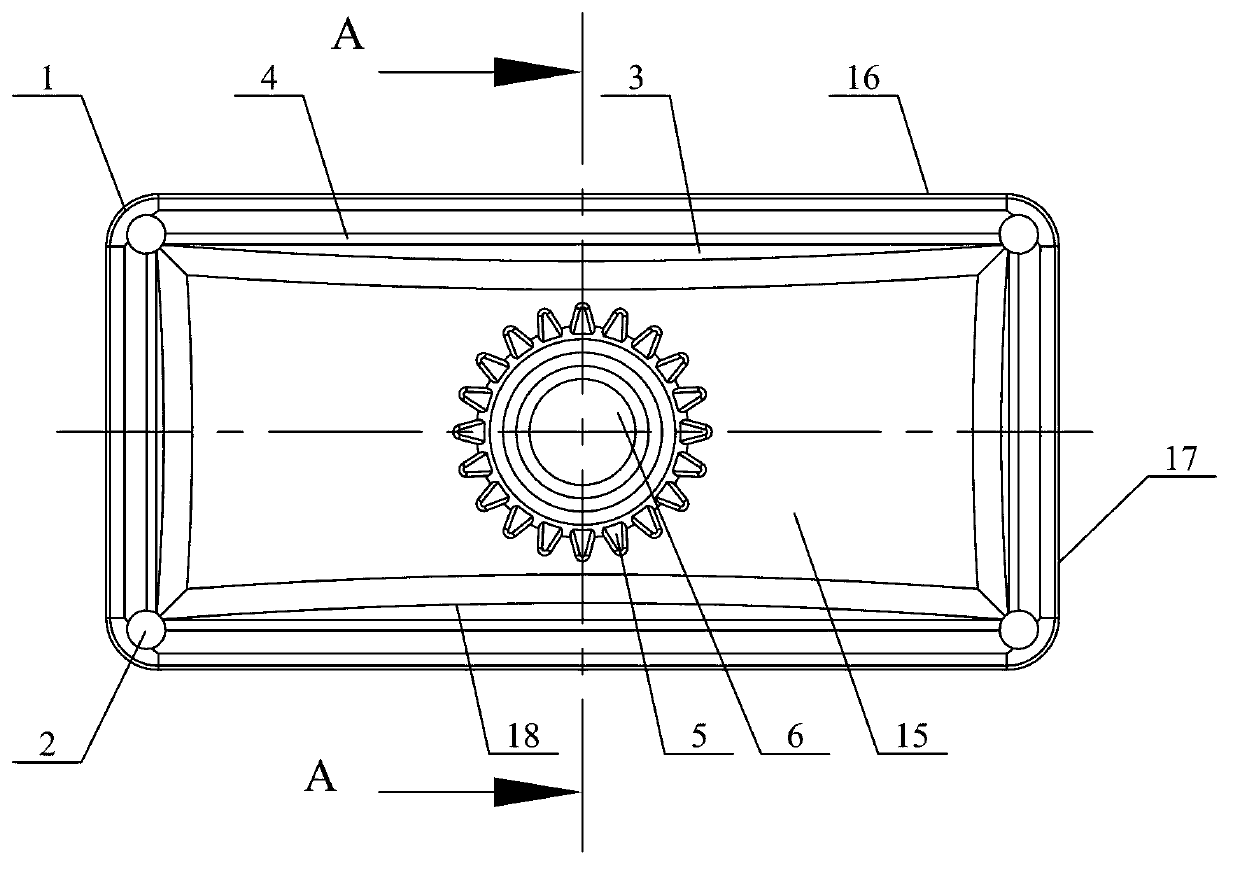

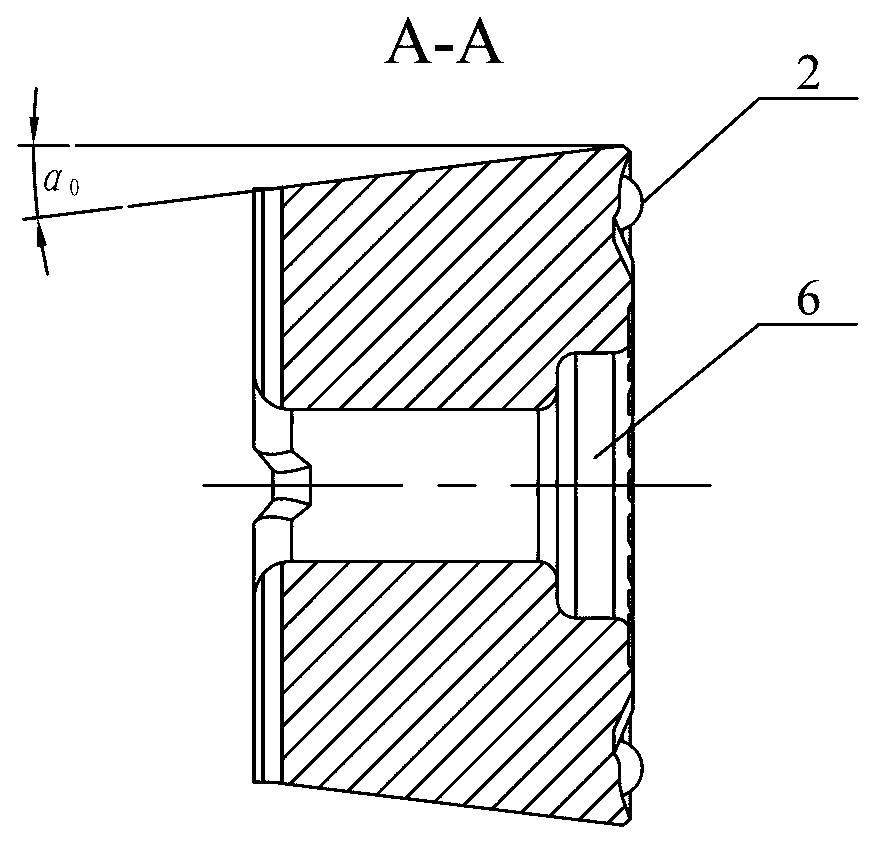

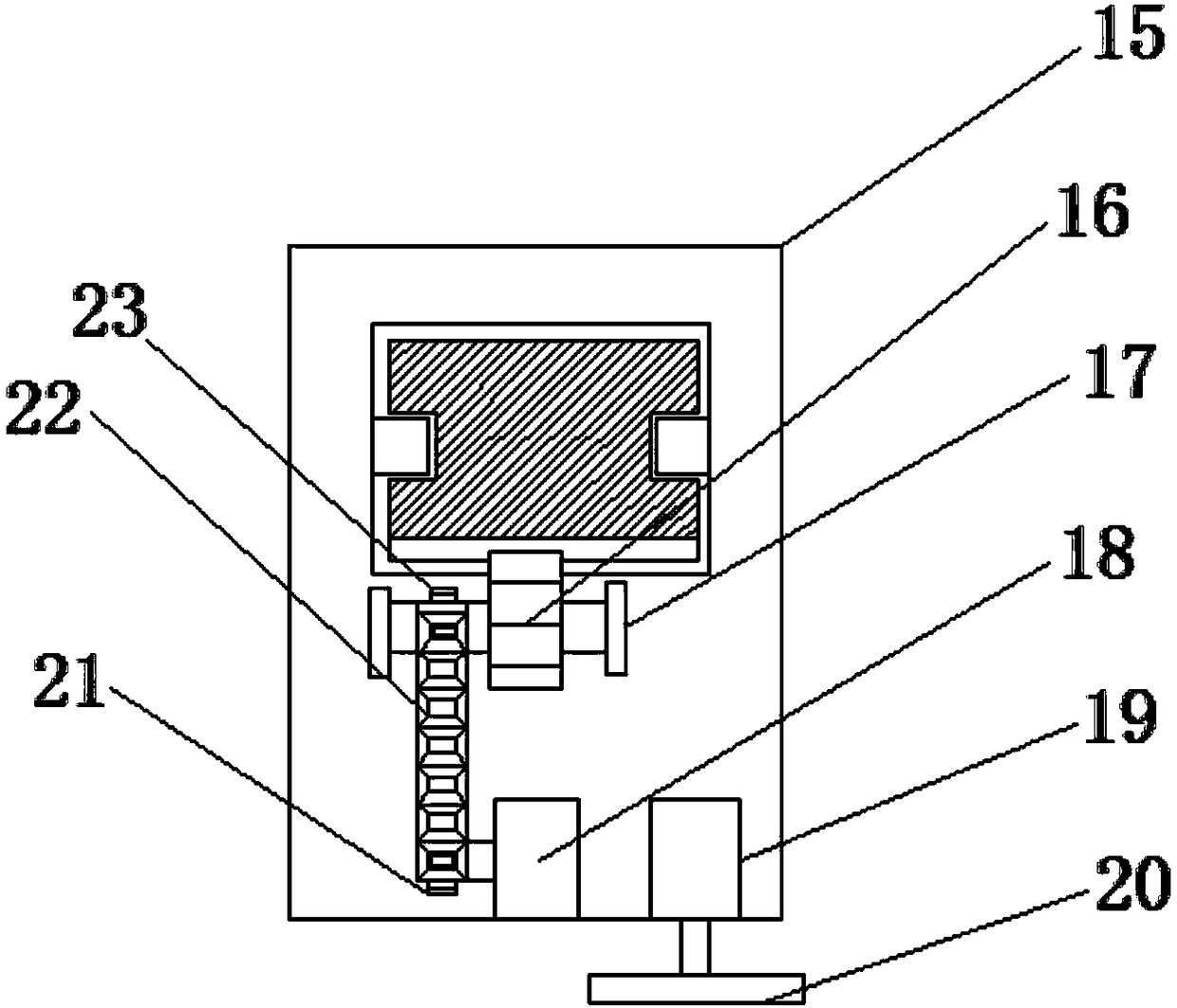

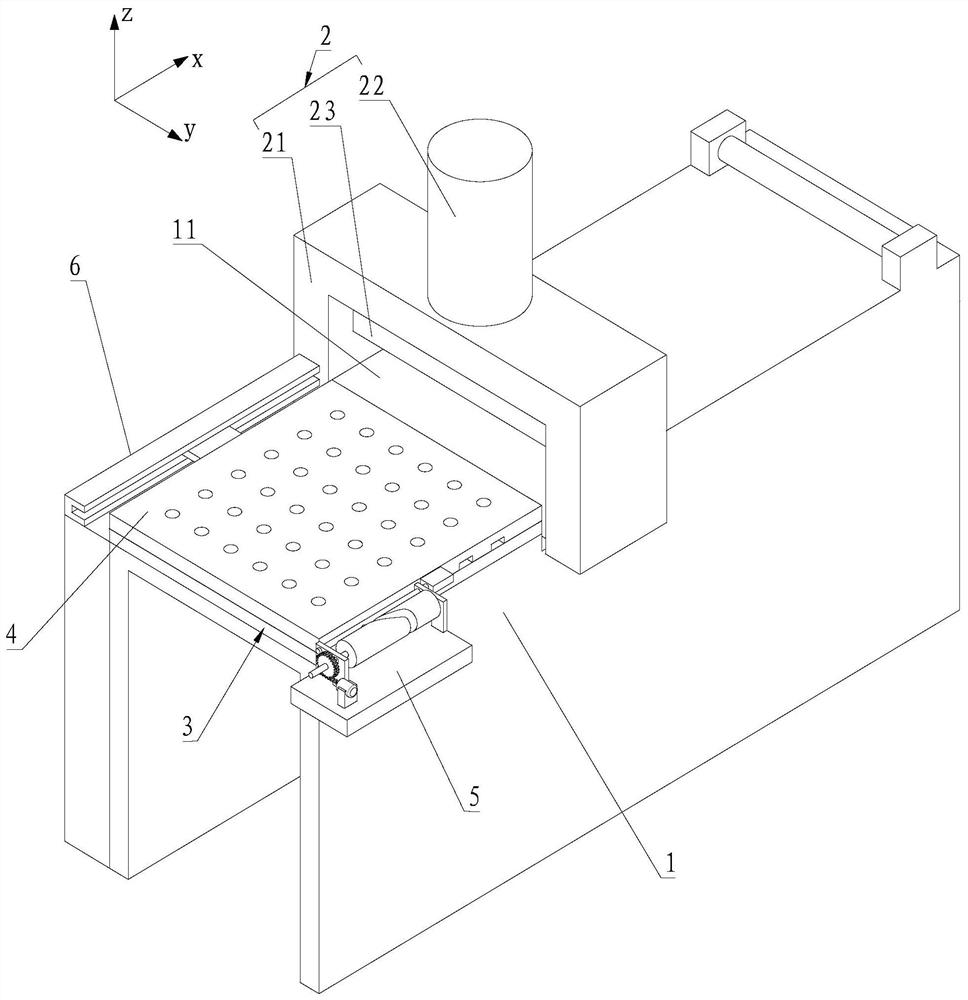

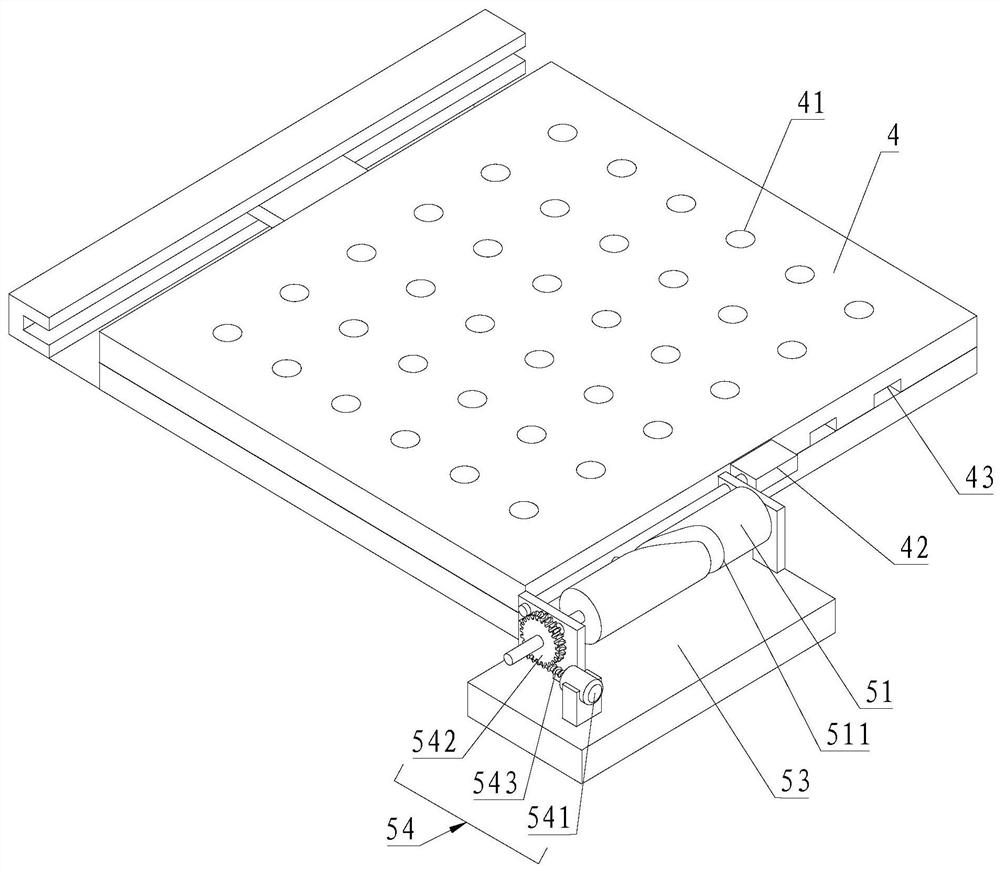

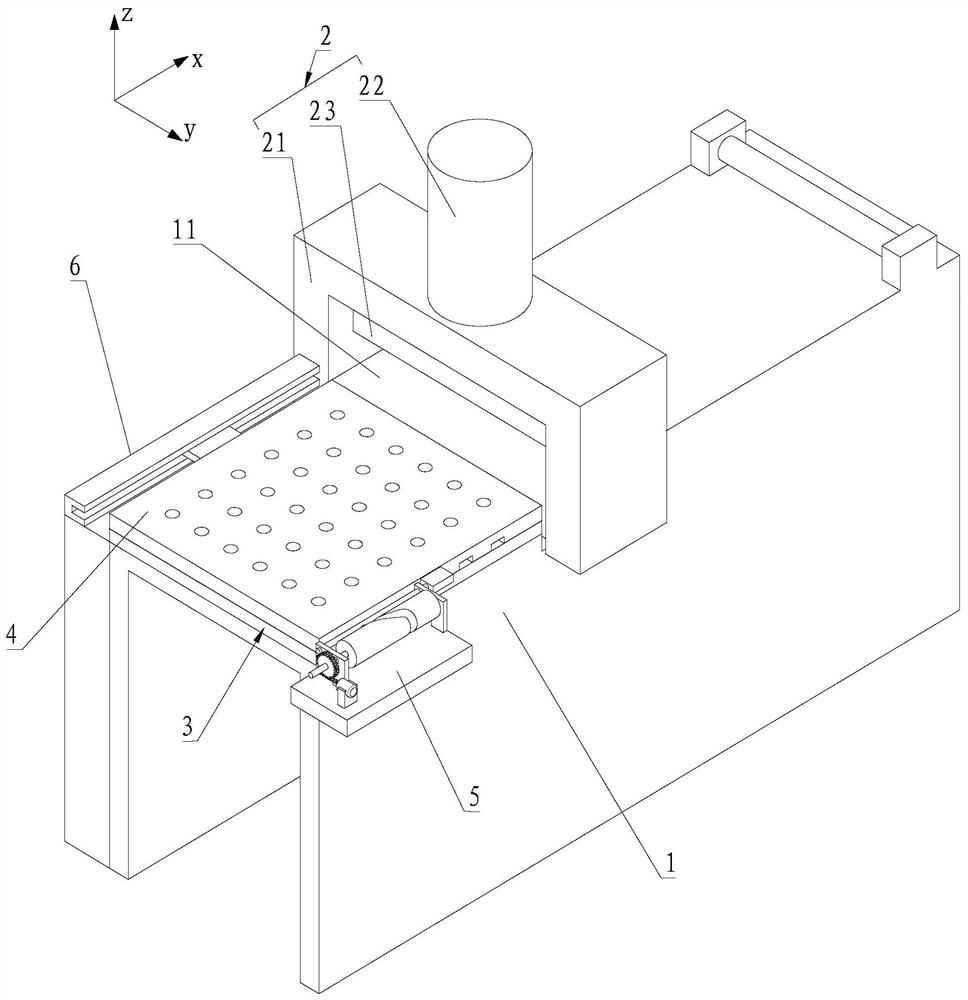

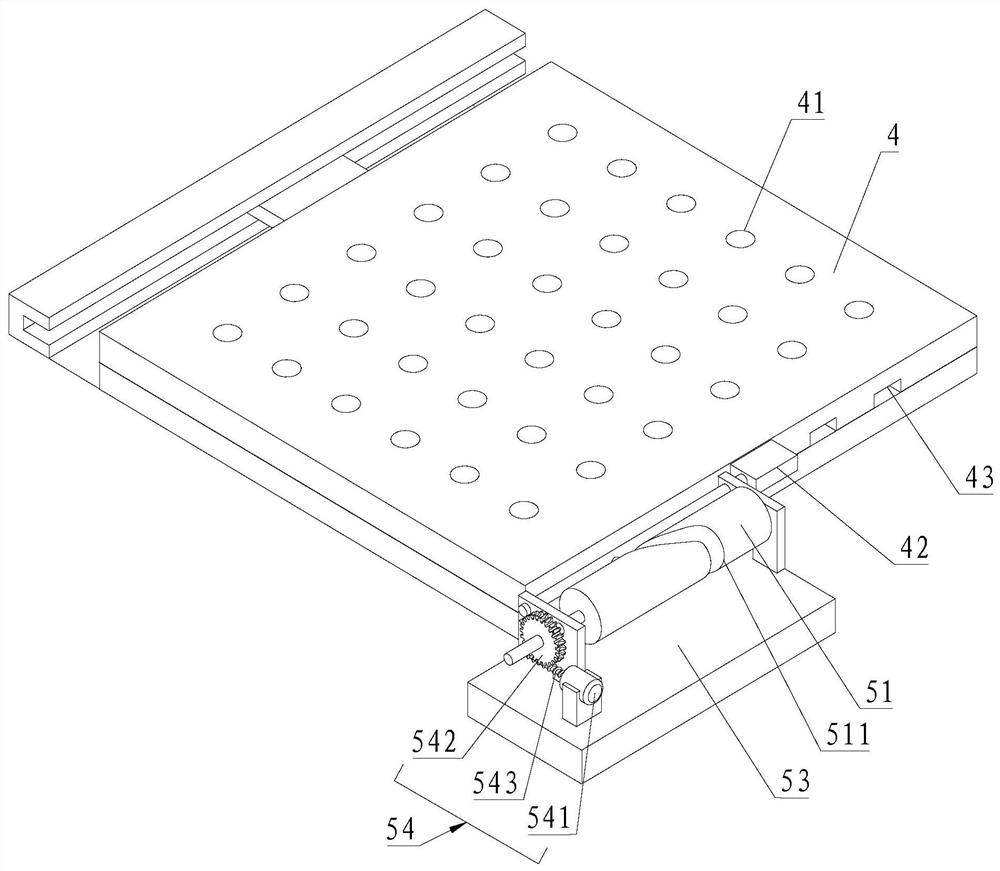

Synchronous cutting system for pipeline extrusion

The invention provides a synchronous cutting system for pipeline extrusion. The synchronous cutting system comprises an extruder; a synchronous gear is mounted on a rotating extruder head of the extruder; a lower transmission screw rod is mounted below the synchronous gear; an upper transmission screw rod is mounted on the position, above the lower transmission screw rod, between the extruder andan outer limiting seat; guiding sliding shafts are arranged on the two sides of the upper portion of the upper transmission screw rod; one ends of the guiding sliding shafts are fixed into the outer limiting seat, and the other ends of the guiding sliding shafts are fixed into the extruder; each guiding sliding shaft is movably sleeved with two sliding sleeves; the two sliding sleeves on the samepositions of the two guiding sliding shafts are connected through a connecting plate; a cutting frame is movably mounted between the two connecting plates; pipeline positioning supporting plates are arranged on the two sides of the top of the cutting frame; and a cutting assembly is mounted on the position, between the two pipeline positioning supporting plates, of the cutting frame. After the synchronous cutting system is adopted, the structure is reasonable, meanwhile, cutting noise is low, burrs are basically avoided, and the using effect is excellent.

Owner:ZHEJIANG JINBO FLUID CONTROL

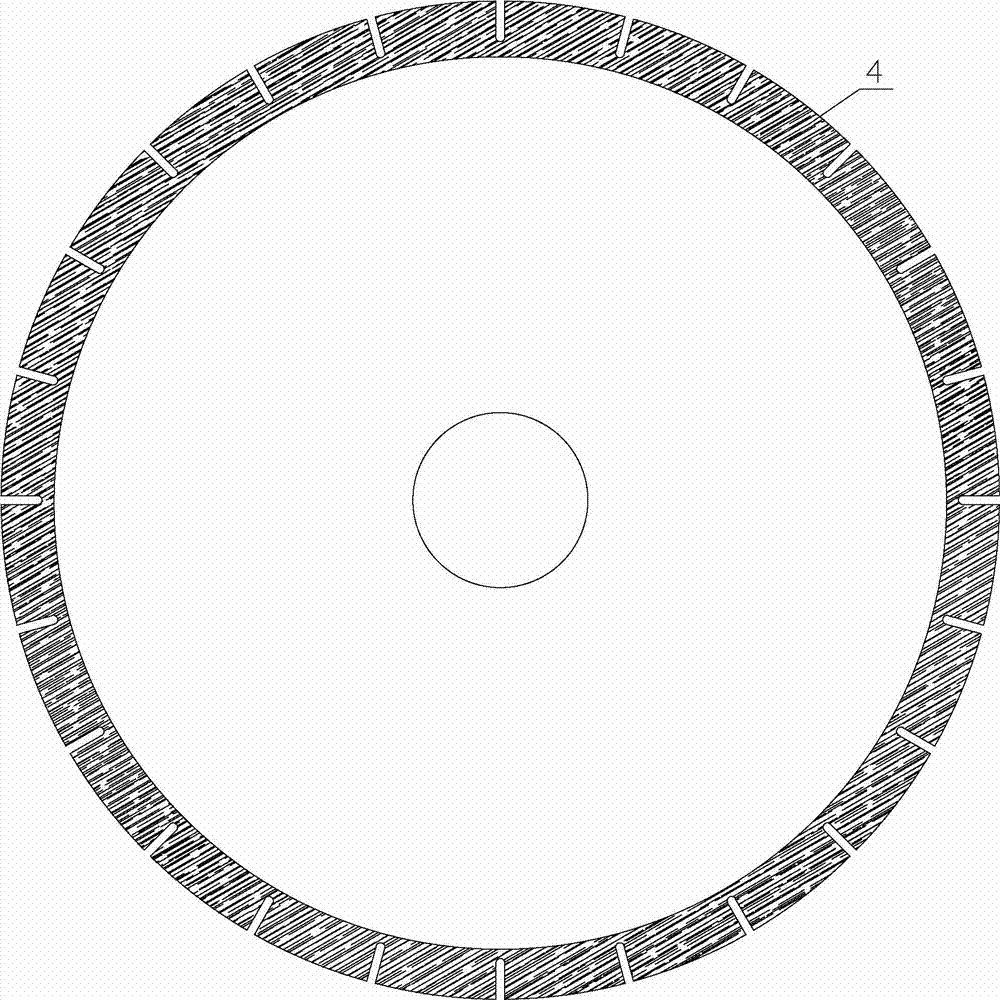

Improved diamond saw blade

InactiveCN107672047ASolve the problem of high friction and cutting blade not sharp enoughSmall cutting resistanceStone-like material working toolsEffective solutionEngineering

The invention discloses an improved diamond saw blade, which comprises a base body and a diamond cutter head. An installation hole is opened in the center of the base body. There are multiple flutes. Its advantage is that: the front end of the diamond cutter head of the present invention is a sawtooth structure, and the sawtooth structure has a working slope, which can reduce the cutting resistance, and effectively solve the problem that the traditional diamond saw blade has a large friction force when cutting and the cutting blade is not sharp enough. problems; by setting up turbine-shaped grooves on the diamond cutter head, chips can be quickly removed and heat dissipation can be improved; the connection between the cutter head and the substrate is connected in a zigzag structure, so that the combination between the substrate and the cutter head is tighter, and it is not easy to drop teeth ;Through the arc-shaped grooves in the fan-shaped area on the substrate, it plays the role of chip removal, reduces cutting noise, and accelerates the cooling of the saw blade.

Owner:南通豪鼎光伏科技有限公司

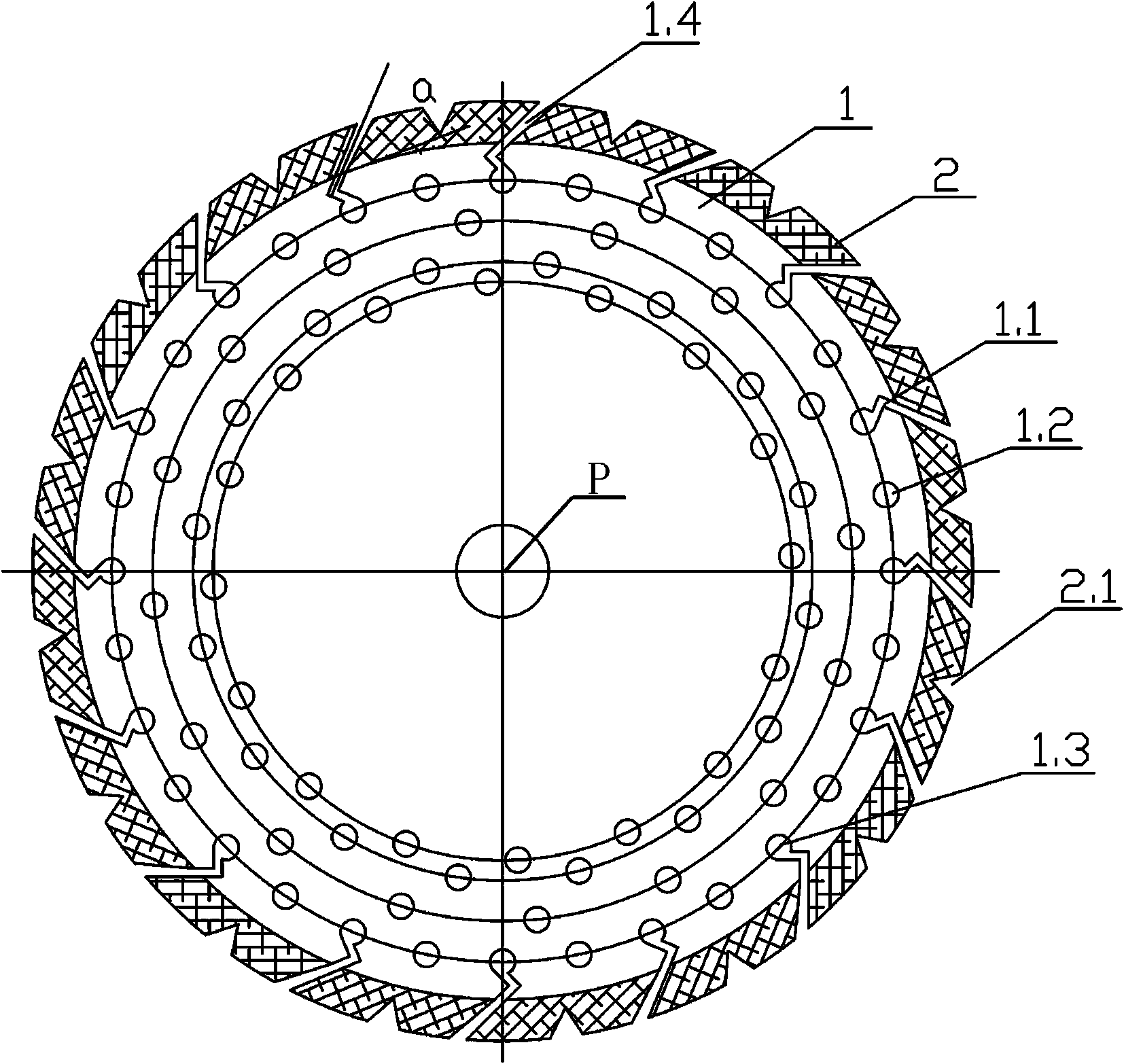

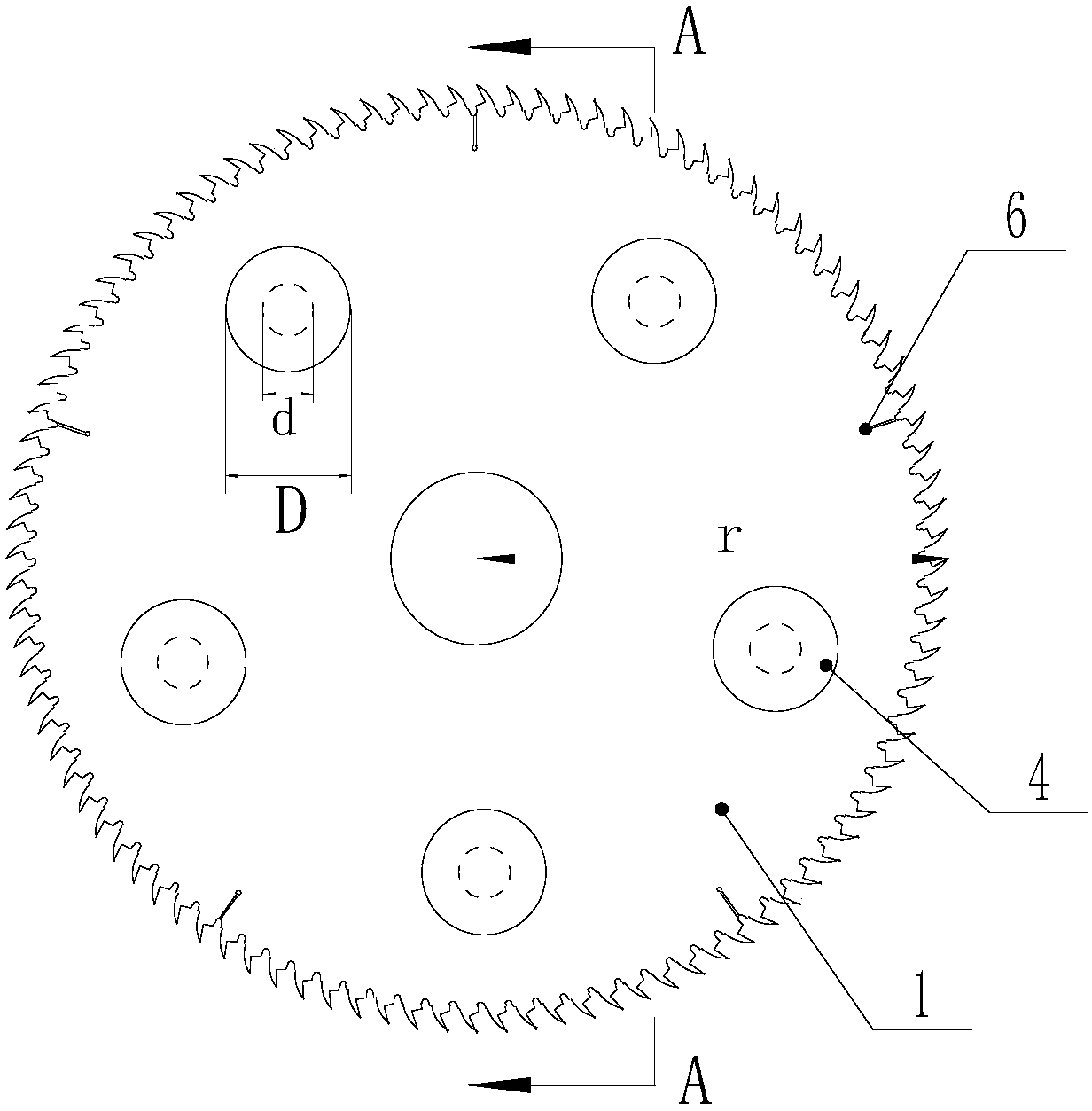

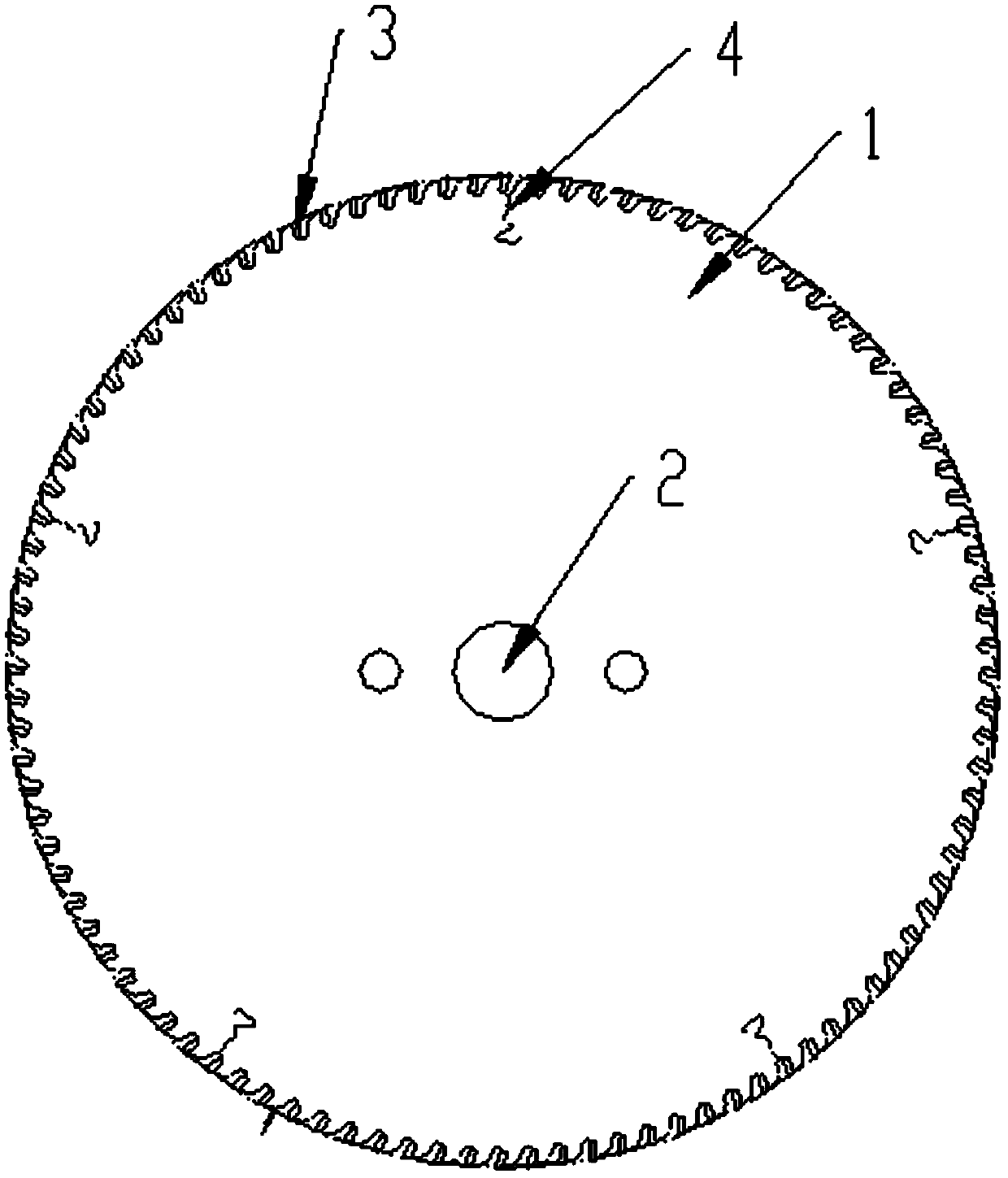

Small low-noise diamond circular saw blade

InactiveCN104108137AReduce cutting vibrationSpeed up coolingMetal sawing toolsStone-like material working toolsTurn angleLow noise

A small low-noise diamond circular saw blade comprises a saw blade base body and a diamond tool bit. The outer edge of the saw blade base body is evenly provided with circular bottom holes and a turn angle water slot with an inclined opening. The cylindrical area of the saw blade base body is provided with holes which are distributed in a staggered mode. The side edge of the diamond tool bit inclines towards the same direction and the tool bit cutting edge is provided with a slot opening. Through the structure, cooling performance is effectively improved when the small diamond circular saw blade conducts cutting at a high speed, the tool bit stress condition and the tooth portion stress condition in the cutting process are improved, cutting noise is lowered, cutting stability is improved, and service life of a blade body is prolonged.

Owner:HEIXUANFENG SAW IND

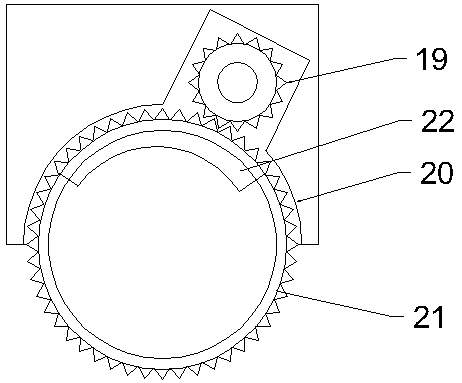

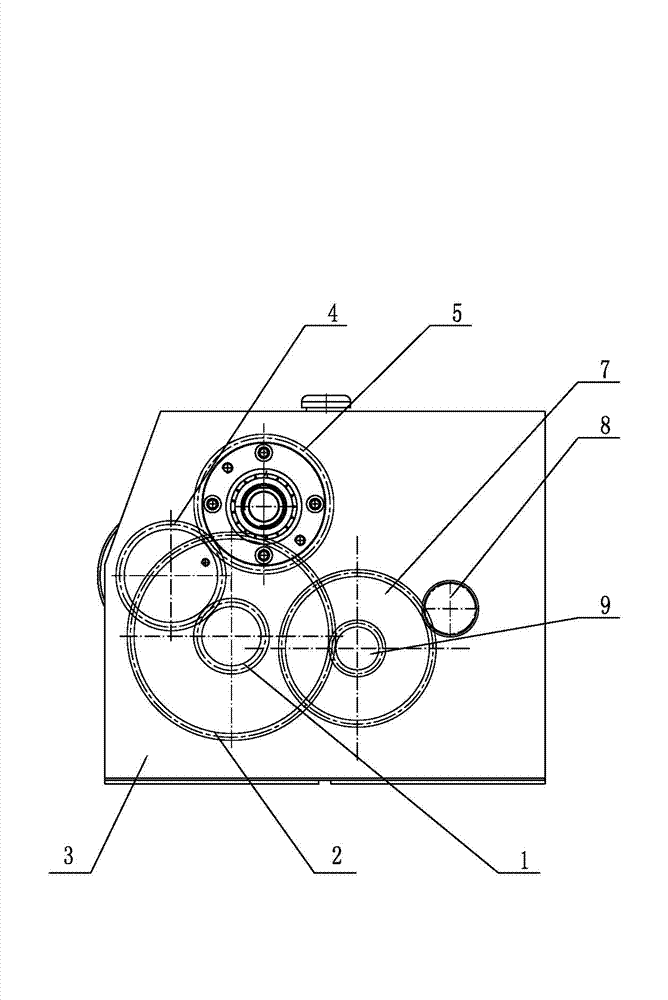

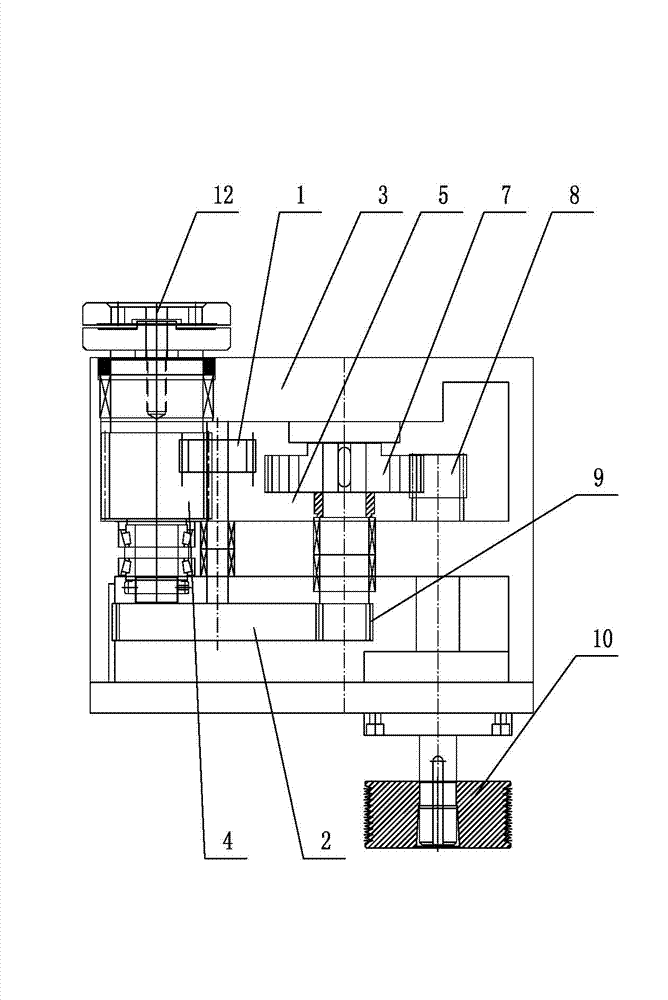

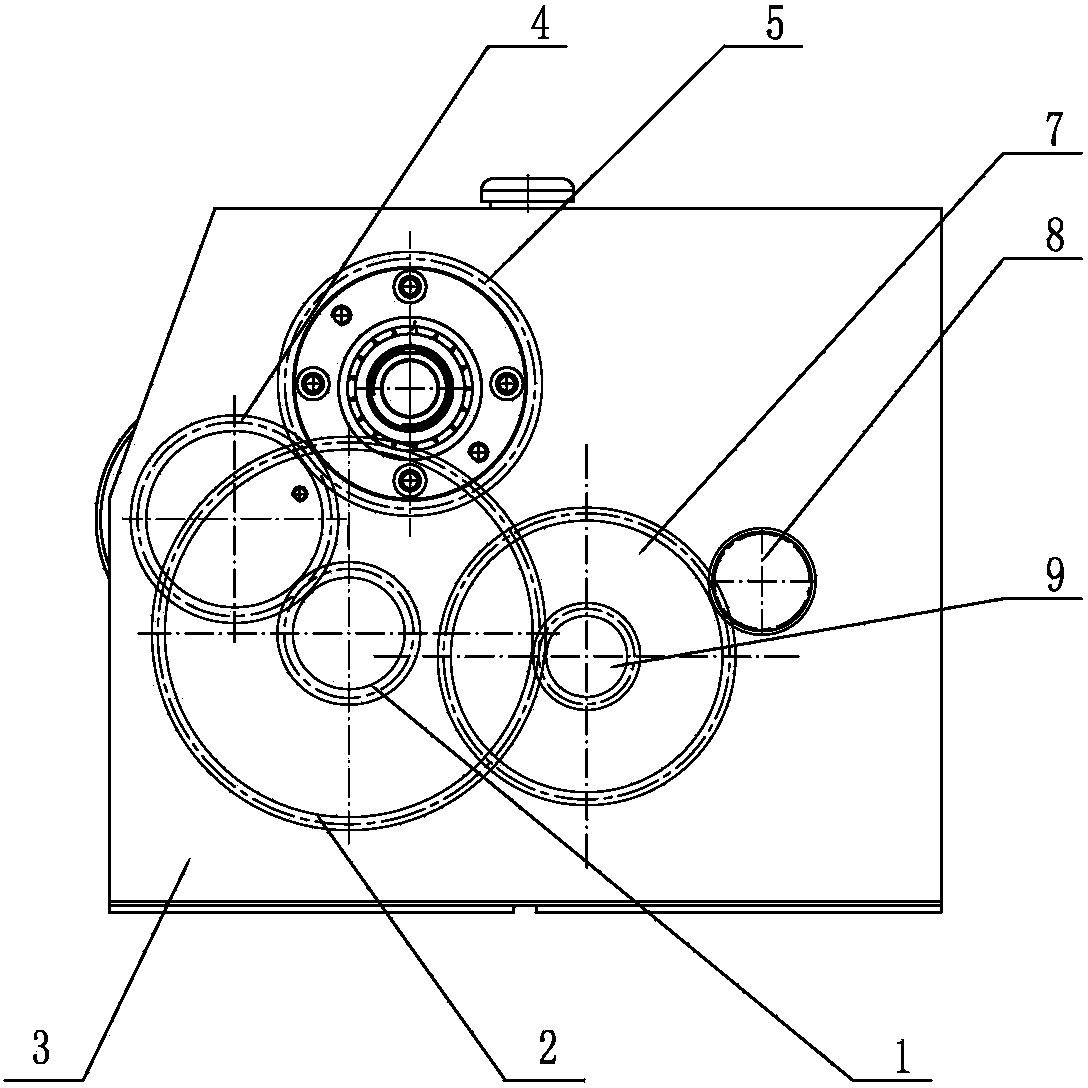

Transmission case for automatically removing backlash and cutting

ActiveCN102825335AEliminate gapsAvoid bouncingMetal sawing devicesMetal working apparatusGear wheelEngineering

The invention discloses a transmission case for automatically removing a backlash and cutting, which comprises a housing, wherein an input shaft and an output shaft are arranged in parallel inside the housing; the shaft end of the output shaft extends out of the housing and is provided with a saw blade clamp; one end of the input shaft extends out of the housing and is provided with a power input component; the input shaft and the output shaft are in transmission connection via a gear set; a damping shaft is also arranged inside the housing; a damping gear is arranged on the damping shaft; the damping gear is meshed with an output gear arranged on the output shaft, and a pneumatic damper is arranged at the shaft end of the damping shaft. Due to the pneumatic damper, the rotation of the output shaft is properly limited by the damping shaft and the damping gear; a gear gap generated when a work-piece is cut is removed; bounce of the output gear is stopped; the cutting noise is reduced; the cutting precision is improved; the abrasion of the gear is reduced; the cutting is more stable; a notch is smooth, and the device can be applied to various cutting machines and also can be applied to a polishing machine.

Owner:江苏省南扬机械制造有限公司

Tin bar cutting machine

PendingCN108097781AAvoid material jamsAvoid stickingMetal-working feeding devicesPositioning devicesButt jointEngineering

The invention discloses a tin bar cutting machine. The tin bar cutting machine includes a rack. The rack is fixedly provided with a fixed module. One side of the fixed module is provided with a movingmodule controlled by a cutting pushing device to move up and down along the side surface of the fixed module. The other side, corresponding to the fixed module, of the rack is provided with a material collecting device capable of jacking out the bin bar and making the bin bar to slide down obliquely. The fixed module is provided with a material pushing through hole horizontally and a material feeding through hole capable of allowing the tin bar to penetrate through horizontally. The feeding through hole is located over the material pushing through hole. The moving module is horizontally provided with a discharging through hole in butt joint with the feeding through hole. According to the tin bar cutting mechanism, when the tin bar horizontally penetrates through the moving module and thefixed module simultaneously, the moving module moves downwards to cut the tin bar, the material pushing device pushes the tin bar out of the moving module horizontally; the material collecting deviceautomatically jacks out the tin bar to conduct material collecting; the phenomenon of material sticking or adhesion is prevented from appearing during cutting; meanwhile, the cutting noise is low, andthe material collecting efficiency is high.

Owner:VICTORY TECH INT

Limitation overload large cutting-in impact resistant type dedicated blade

The invention provides a limitation overload large cutting-in impact resistant type dedicated blade and belongs to the technical field of cutting tools used for lathe work. The limitation overload large cutting-in impact resistant type dedicated blade aims at solving the problems that a cutting tool is prone to breaking when impacted due to the fact that the existing cutting tool used in current lathe work is a single-blade welded type lathe tool, the cutting edge of the cutting tool and chips are prone to producing a tool-chip cementation phenomenon due to the fact that no chip breaker groove is formed in the cutting tool, service life of the cutting tool is short, and production efficiency is seriously restricted. A long cutting edge and a short cutting edge are processed in the edge position of the front tool face of the blade. A double-arc-shaped tool nose is processed in the corner portion of the front tool face of the blade. The side face of a protruding platform of the front tool face of the blade is a round-arc-shaped concave surface. An arc-shaped chip breaker groove is composed of an area which is enclosed by the round-arc-shaped concave surface and the front tool face of the blade. Guide grooves are formed around the bottom portion of the arc-shaped chip breaker groove. Tooth form grooves are processed on the periphery of a fastening screw counter bore. A tool bottom overflow and heat dissipation hole is formed in a protruding pillar in the bottom face of the blade. A tool bottom center heat dissipation groove is formed between two supporting bosses. The limitation overload large cutting-in impact resistant type dedicated blade is used for large cutting-in lathe work in heavy forging blank rough machining.

Owner:HARBIN UNIV OF SCI & TECH

Multifunctional cutting saw blade

InactiveCN107538078AImprove the finishExtended service lifeMetal sawing toolsCircular sawsDeformation effectMaterial type

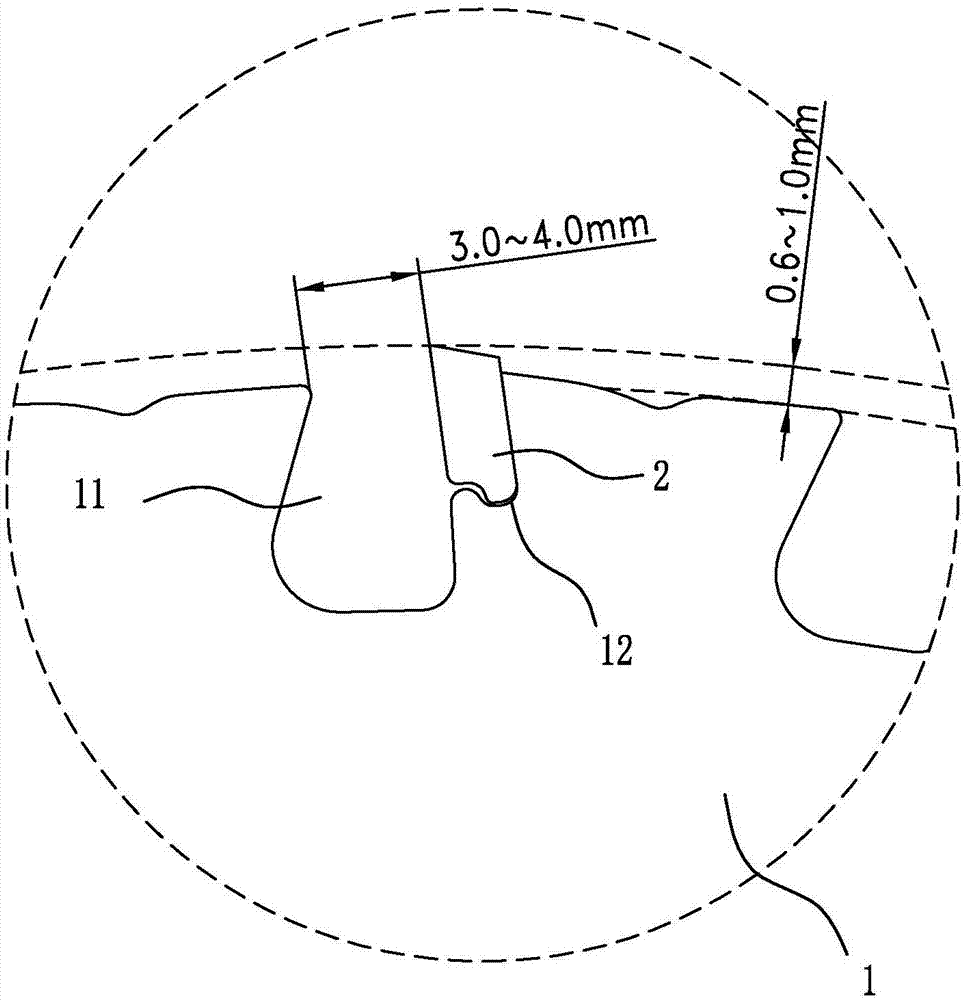

The invention discloses a multifunctional cutting saw blade. The saw blade comprises a circular saw blade, a sunken tooth holder for containing alloy sawteeth is formed in the groove wall of the side,towards the cutting direction, of a saw dust containing groove of the circular saw blade, and the alloy sawteeth are welded to the tooth holder; the saw dust containing groove is designed to gradually expand in the depth direction, the width of an opening is 3.0-4.0 mm, and the cutting feed limit distance of the alloy sawteeth is 0.6-1.0 mm. The multifunctional cutting saw blade is suitable for cutting three main material types such as timber, aluminum material and steel and iron. Meanwhile, the service life of the circular saw blade can be prolonged, the circular saw blade has good noise removal and cutting and heating deformation effects, the saw dust removal ability and impact resistance are remarkably improved, and meanwhile the multifunctional cutting saw blade is suitable for multipurpose and multifunctional cutting.

Owner:FOSHAN NANHAI SUN RISING TOOLS MFG

Automatic feeding type pipe cutting device with noise reduction function

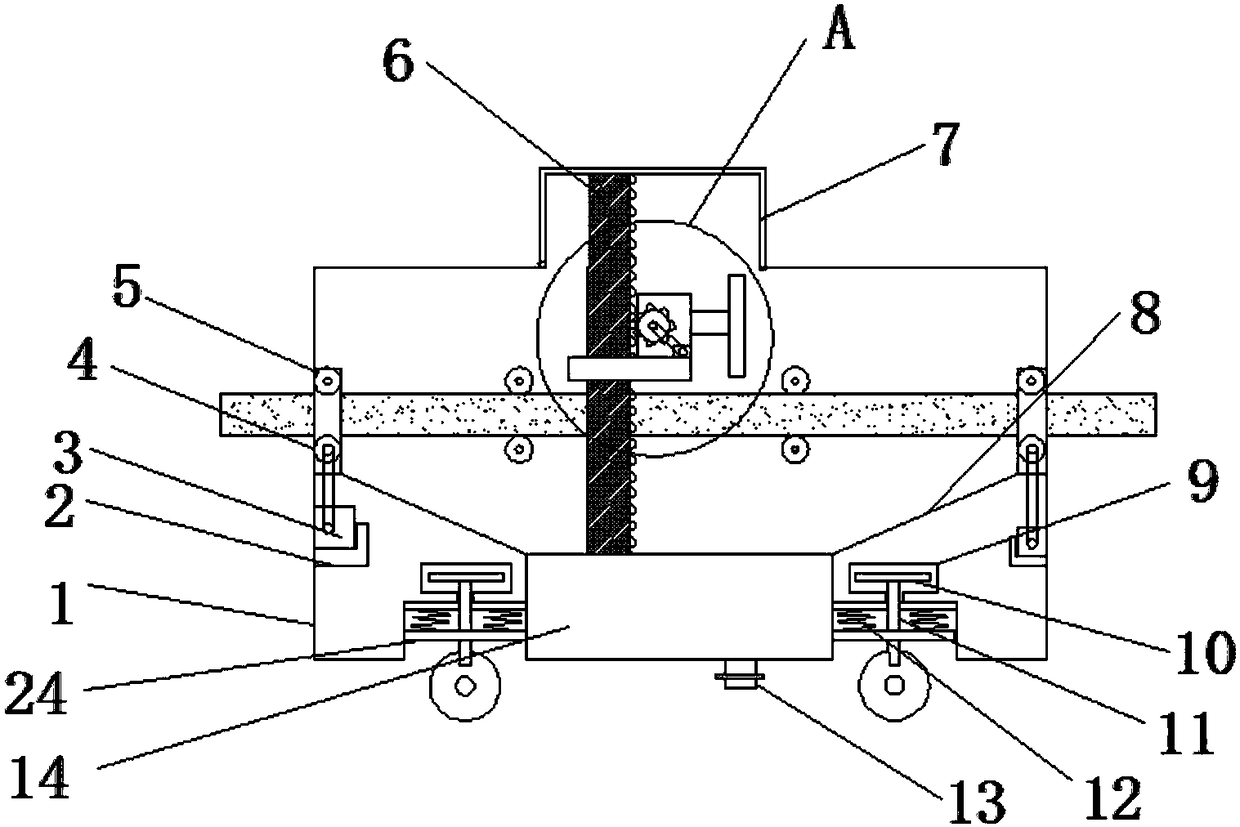

InactiveCN108115196AReduce labor intensityKeep healthyTube shearing machinesShearing machine accessoriesPhysical healthGear wheel

The invention discloses an automatic feeding type pipe cutting device with a noise reduction function. The automatic feeding type pipe cutting device comprises a vehicle body. L-shaped plates are correspondingly and fixedly connected on the two symmetrical side walls in the vehicle body. First motors are correspondingly and fixedly connected to the two L-shaped plates. Driving rolling wheels are correspondingly arranged at the upper ends of the two first motors. The two driving rolling wheels are correspondingly connected with the output ends of the first motors through transmission belts. Driven rolling wheels are correspondingly arranged above the driving rolling wheels. A rack is arranged in the vehicle body. The rack is sleeved with a first support plate. The end, close to rack saw teeth, of the first support plate is fixedly connected with two second support plates. A connecting shaft is arranged between the two second support plates. A gear engaged with the rack is arranged on the connecting shaft. By the adoption of the automatic feeding type pipe cutting device with the noise reduction function, the cutting noise is lowered effectively, the working efficiency is improved remarkably, the labor intensity of the staff is lowered, and the physical health of the staff is safeguarded.

Owner:梁兆寇

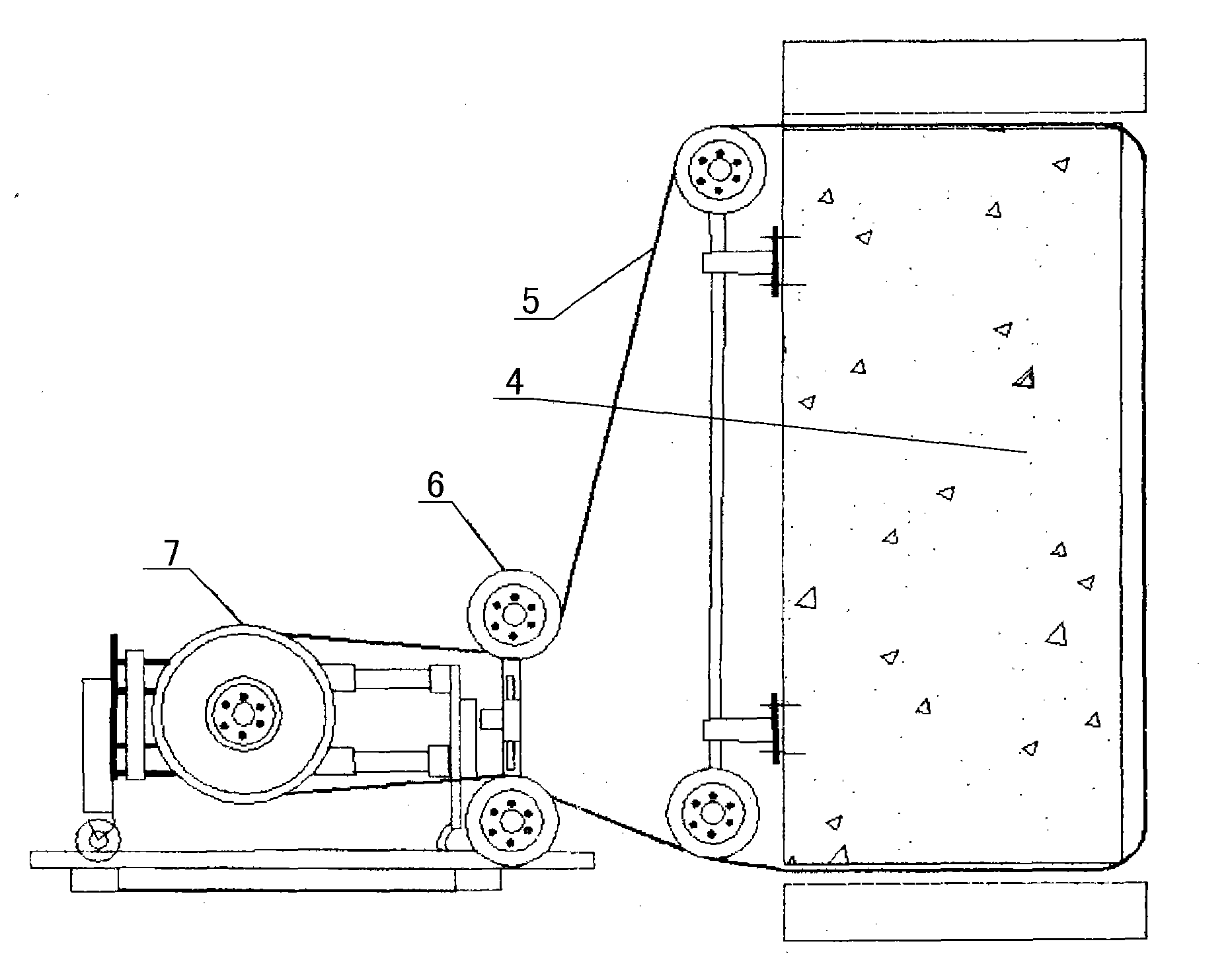

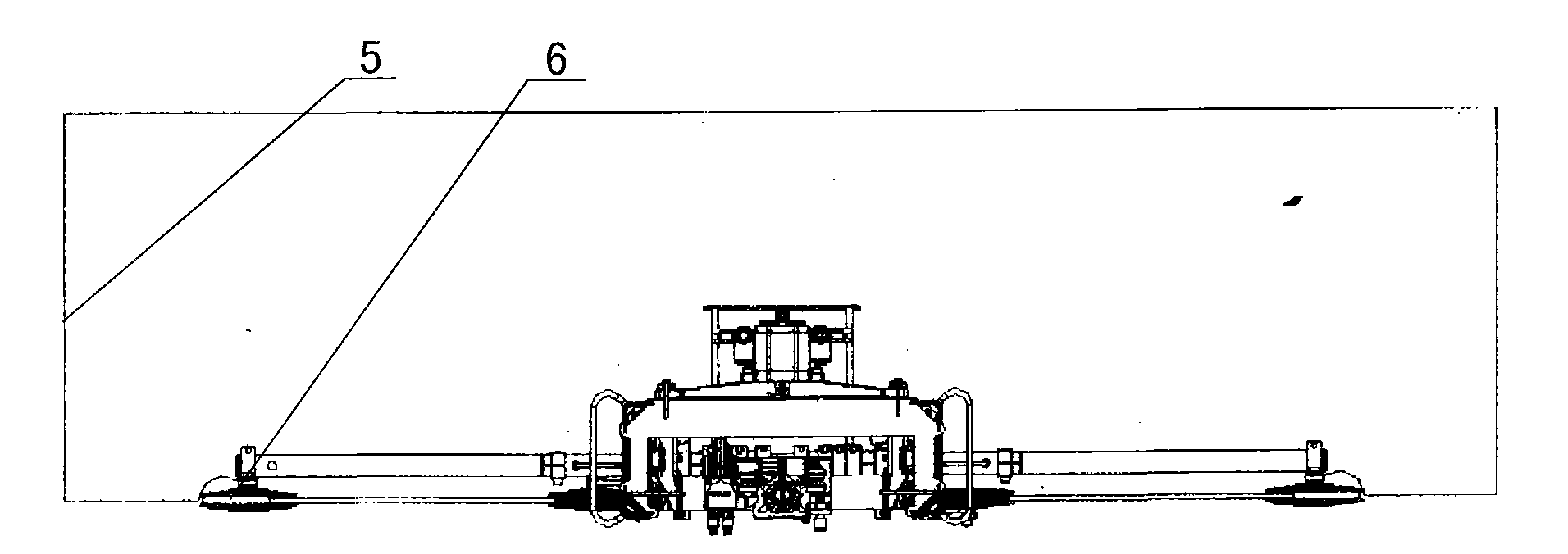

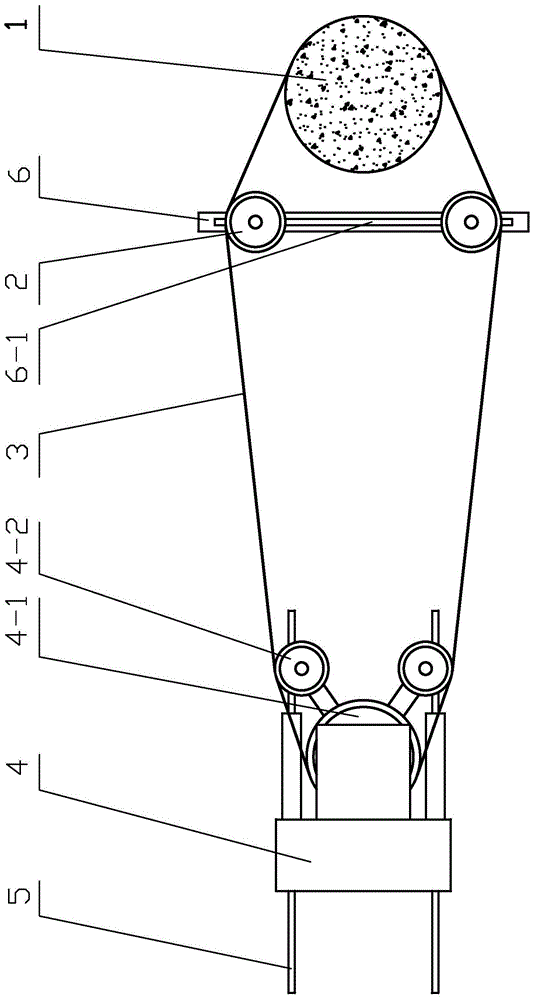

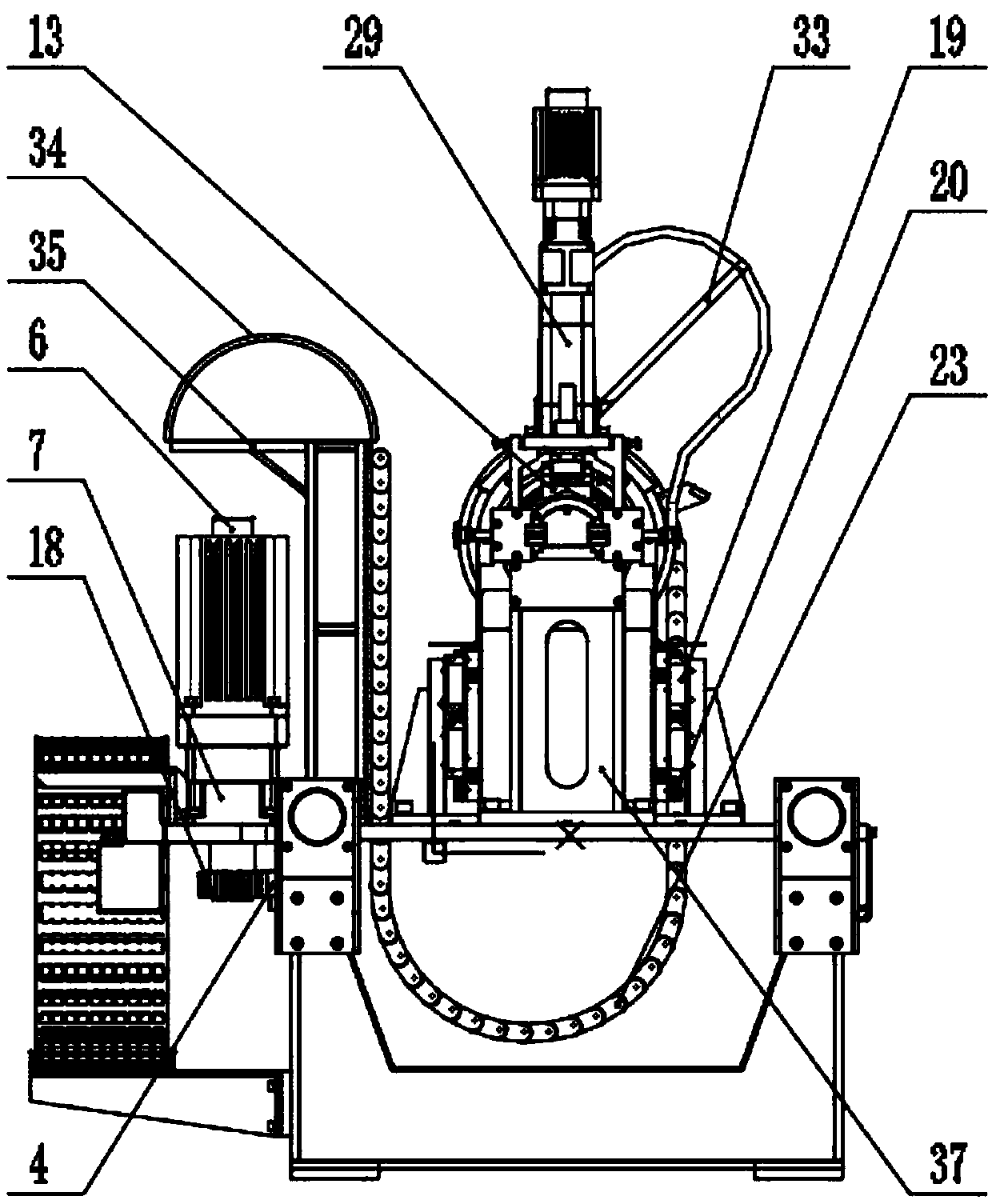

Riser flexible wire cutting method and cutting equipment for steel castings

ActiveCN103521840BImprove manufacturing levelAvoid pollutionMetal sawing devicesCutting forceMechanical engineering

The invention discloses a flexible linear cutting method and cutting device for a dead head of a steel casting. A beaded rope saw is used for cutting the dead head of the steel casting. The method comprises the steps that according to the size of the structure of a dead head cutting face, a rope saw driving device and a beaded rope matched with the rope saw driving device in length are selected; a guiding wheel enabling the cutting direction of the rope saw and the cutting face of the dead head of the steel casting to be consistent is arranged between the dead head of the steel casting and the rope saw driving device; the beaded rope is wound on the dead head of the steeling casting, the guiding wheel, and a machine-mounted guiding wheel and a driving wheel of the rope saw driving device; the rope saw driving device goes forwards and backwards on a track consistent with the cutting direction of the beaded rope, and the cutting force of the beaded rope is adjusted and controlled well; the rope saw driving device is started to drive the beaded rope to rotate at high speed to cut the dead head of the steel casting, and cooling fluid is used for cooling in the cutting process. Beads of the beaded rope are formed through the method that alloy powder is used as a basic blank body and abrasive materials suitable for metal cutting are added, and then the materials are subjected to cold press molding and hot pressed sintering.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

Cutting device of a knurling machine

ActiveCN112775477BLoud noiseHigh precisionShearing machinesShearing machine accessoriesKnurlingPhysics

The invention discloses a cutting device of a knurling machine, which comprises a workbench, a cutting mechanism, an adsorption mechanism, a discharge plate and a discharge mechanism; the top of the workbench has a cutting area; the cutting mechanism is located above the cutting area; the output of the discharge mechanism The fixed end of the discharge mechanism is installed on one side of the adsorption mechanism in the Y-axis direction; the top of the adsorption mechanism is provided with multiple rows of adsorption holes parallel to each other along the Y-axis direction, and the discharge plate is provided with Multiple rows of through holes that can be directly opposite to the adsorption holes; when the steel plate is on the discharge plate and is to be cut, the adsorption holes are directly opposite to and communicated with the through holes, so that the steel plate is adsorbed on the discharge plate; when the steel plate is cut, The discharge plate can move toward a side away from the cutting area, so that the overlapping area of the projection area of the adsorption hole in the Z-axis direction and the projection area of the through hole in the Z-axis direction is reduced. The invention can reduce the noise generated by the collision when the steel plate is cut, and reduce the generation of noise pollution.

Owner:泉州芸台科技有限公司

A low-noise diamond saw blade

ActiveCN109465968BGood shock absorbing functionReduce cutting noiseStone-like material working toolsTool bitMechanical engineering

The invention discloses a low-noise diamond saw blade. The low-noise diamond saw blade comprises a circular base plate, a liquid gallium alloy as well as diamond bit pieces and magnet combinations which are evenly welded on the outer side of the circular base plate; a circular staggered eccentric flow-guiding channel is formed inside the circular base plate; a fixing sleeve is symmetrically weldedin the center of the side wall of the circular base plate in a penetrating manner; the circular staggered eccentric flow-guiding channel comprises a circular channel I and a circular channel II; thin-wall arc-shaped plates are evenly welded on the inner side wall of the circular channel I and the inner side wall of the circular channel II; the circular channel I and the circular channel II are filled with the liquid gallium alloy; and the liquid gallium alloy flows in a communicating manner. According to the saw blade, the thin-wall arc-shaped plates are evenly distributed by the aid of the circular staggered eccentric flow-guiding channel and can absorb shocks produced during cutting of the saw blade, during rotation of the circular base plate, spaces among the thin-wall arc-shaped plates are filled with the liquid gallium alloy, the liquid gallium alloy has the excellent shock-absorbing function, and then the cutting noise can be greatly reduced.

Owner:湖北攀峰钻石科技有限公司

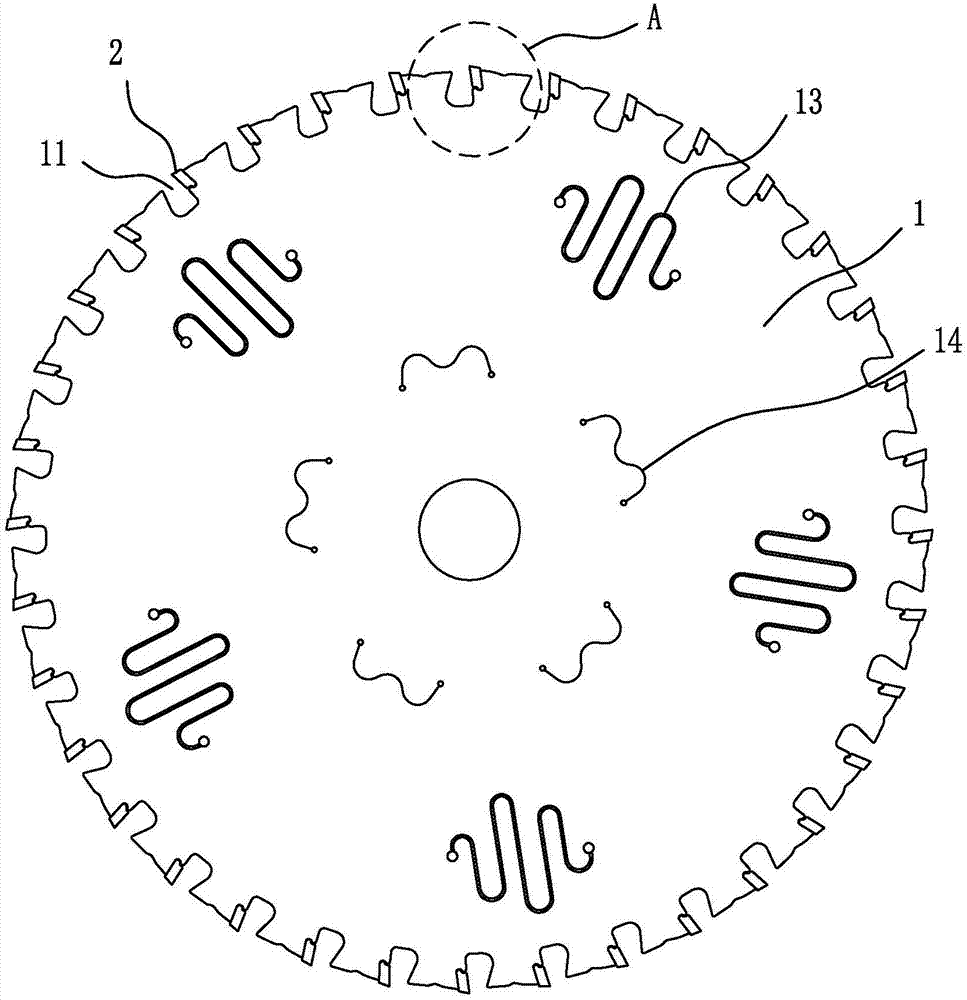

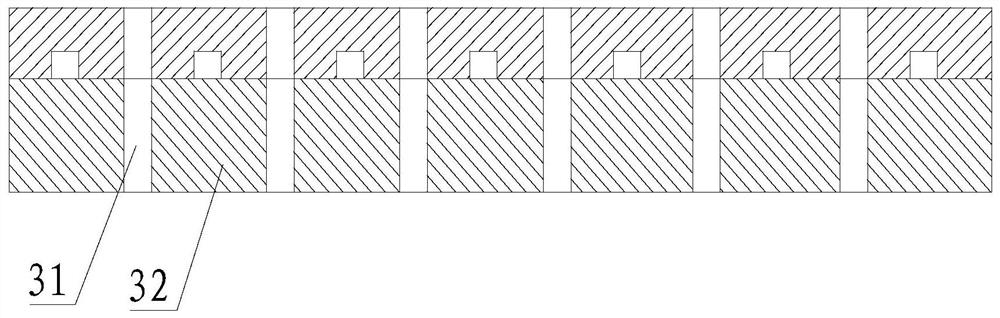

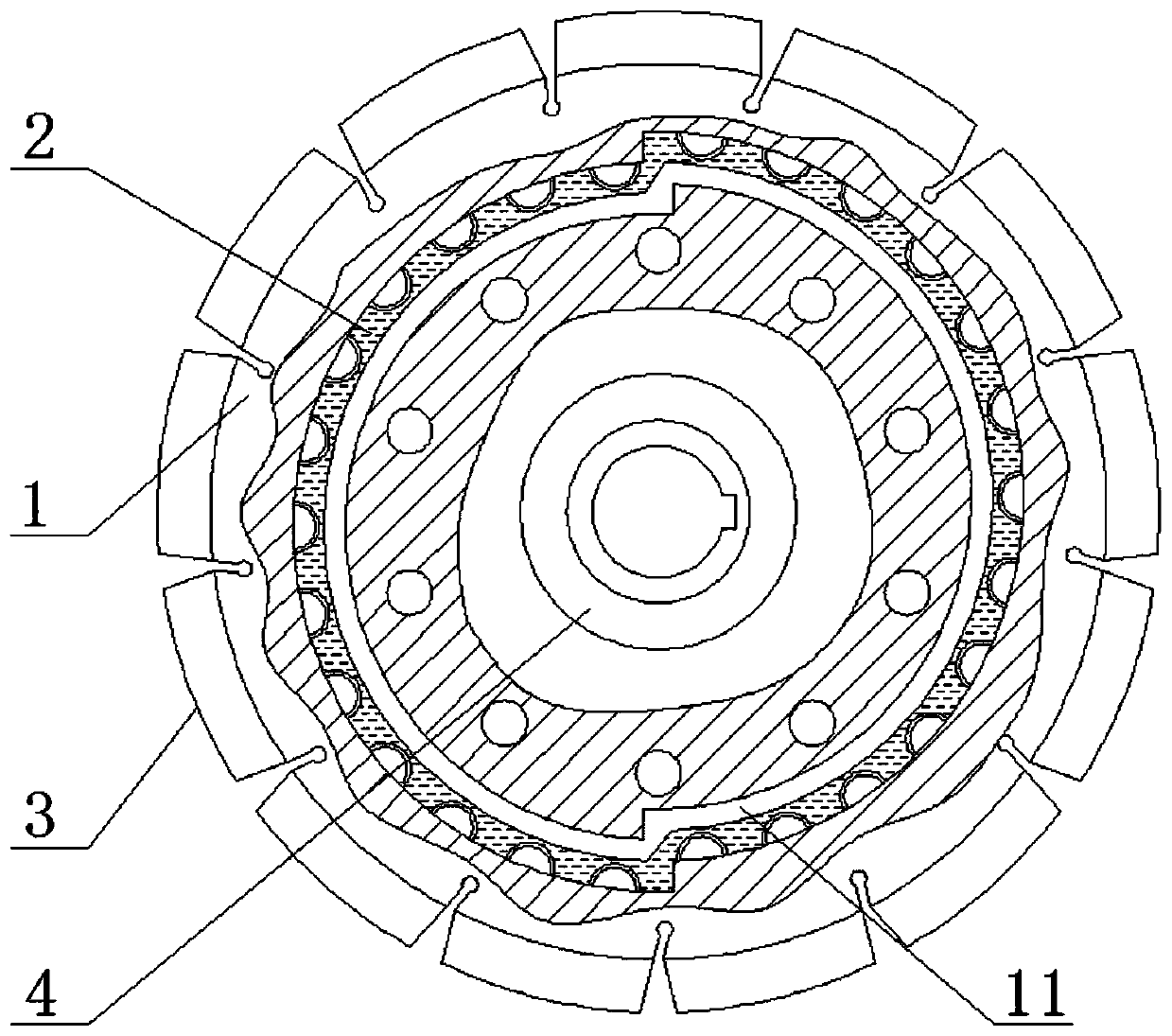

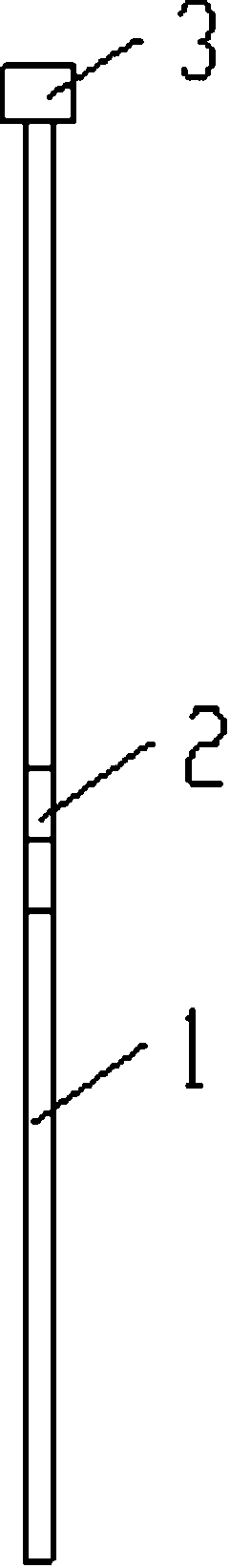

Circular saw web and damping noise reduction structure thereof

ActiveCN107855599AReduce noiseImprove cut qualityMetal sawing toolsFriction dampersInterference fitCircular saw

The invention discloses a circular saw web and a damping noise reduction structure thereof, and belongs to the technical field of cutting equipment. The circular saw web and the damping noise reduction structure solve the defect that in the prior art, a traditional circular saw web is large in noise. A body structure of the circular saw web comprises a saw web base, the saw web base is provided with a first blind hole, a first through hole and the damping noise reduction structure, a first cylinder is installed in the first through hole, and the first cylinder is in interference fit with the first through hole; and a first damping thin sheet is installed in the first blind hole, a gap is reserved between a first arm face on the first damping thin sheet and a second arm face of the first blind hole, and a gap is reserved between a first plane on the first damping thin sheet and a second plane on the first blind hole. The circular saw web and the damping noise reduction structure are mainly used for cutting equipment.

Owner:临沂先行锯业有限公司

Cutting device for glass artware

InactiveCN112174503AAvoid breakingSimple structureGlass severing apparatusGlass coverStructural engineering

The invention relates to the technical field of glass cutting, solves the problems that the glass artware is easy to damage and the production noise is high in the machining process of the traditionalcutting device, and particularly relates to a cutting device for glass artware. The cutting device comprises a cutting base, wherein the top of the cutting base is fixedly connected with a cutting table, the top of the cutting table is fixedly connected with a threaded rod, the threaded rod is in threaded connection with a sliding block, one side of the sliding block is fixedly connected with oneend of a fixing rod, the other end of the fixing rod is fixedly connected with a fixing block, the surface of the fixing block is fixedly connected with a rubber block, a shock pad is fixedly connected to the top of the cutting table, and a glass cover is fixedly connected to the top of the cutting base. According to the invention, a glass material can be prevented from colliding with the fixingblock to be damaged when being fixed, and meanwhile, the glass material can be prevented from being damaged due to rigid collision when the cutting knife makes contact with the glass material.

Owner:扬州市国凤工艺品有限公司

Viscose composite sound-absorbing saw blade matrix

A viscose composite sound-absorbing saw blade base body comprises a saw blade base body, a central hole is arranged in the center of the saw blade base body, and the saw blade base body is formed by bonding multiple layers of metal plates through adhesive layers. The metal plate has three layers, and the thickness of the middle metal plate is greater than the thickness of the outer matrix. The adhesive layer is also provided with a welding layer. The invention provides a viscose compound sound-absorbing saw blade matrix. By adopting multi-layer metal plates to glue the composite structure, the saw blade matrix itself has good strength, rigidity and plasticity, so that on the one hand, it can effectively reduce the cutting deflection, and on the other hand On the one hand, it can improve the self-absorption and cushioning performance of cutting vibration. The set viscose layer acts as a damping medium to effectively reduce the vibration and noise generated during sawing.

Owner:HEIXUANFENG SAW IND

Cutting device of knurling machine

ActiveCN112775477ALoud noiseHigh precisionShearing machinesShearing machine accessoriesKnurlingEngineering

The invention discloses a cutting device of a knurling machine. The cutting device comprises a workbench, a cutting mechanism, an adsorption mechanism, a discharging plate and a discharging mechanism, wherein the top of the workbench is provided with a cutting area, the cutting mechanism is located above the cutting area, the output end of the discharging mechanism is in transmission connection with the discharging plate, the fixing end of the discharging mechanism is arranged on one side of the adsorption mechanism in the Y-axis direction, the top of the adsorption mechanism is provided with multiple rows of adsorption holes parallel to one another in the Y-axis direction, the discharging plate is provided with multiple rows of through holes right opposite to the adsorption holes, when a steel plate is located on the discharging plate and is to be cut, the adsorption holes directly face and communicate with the through holes, and the steel plate is adsorbed to the discharging plate, after the steel plate is cut, the discharging plate can move towards the side away from the cutting area, and the overlapping area of the projection area, in the Z-axis direction, of the adsorption holes and the projection area, in the Z-axis direction, of the through holes is reduced. According to the cutting device, noise generated by collision during steel plate cutting can be reduced, and noise pollution is reduced.

Owner:泉州芸台科技有限公司

Special saw blade for cutting outer water retaining part and bright strip of automobile

PendingCN110153496AReduce cutting noiseExtended service lifeMetal sawing toolsEngineeringNoise reduction

The invention discloses a special saw blade for cutting an outer water retaining part and a bright strip of an automobile. The special saw blade comprises a round saw blade. The thickness of the roundsaw blade is 1.3-1.6 mm, noise reduction lines, the diameters of which are 0.2-0.5 mm, are arranged on the round saw blade, and saw blade tool bits are welded to the round saw blade by using a metalceramic. The thicknesses of the saw blade tool bits are 1.8-2.2 mm, the depths of the saw blade tool bits are 3.0-4.5 mm, the widths of the saw blade tool bits are 1.0-2.0 mm, the angles of the frontangles alpha of the saw blade tool bits are 7-18 degrees and the angles of the back angles beta of the saw blade tool bits are 10-15 degrees. The special saw blade disclosed by the invention reduces the cutting noise effectively, the service life of the saw blade is prolonged, a cutting section is smooth and free of burrs, and the service life of the saw blade is prolonged.

Owner:谷东锯业(山东)有限公司

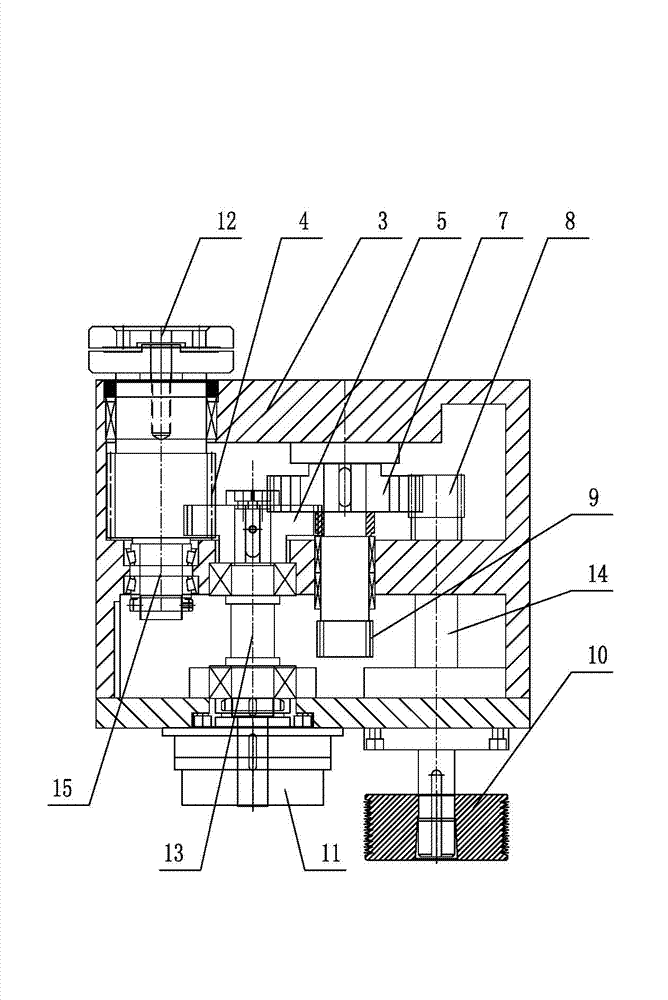

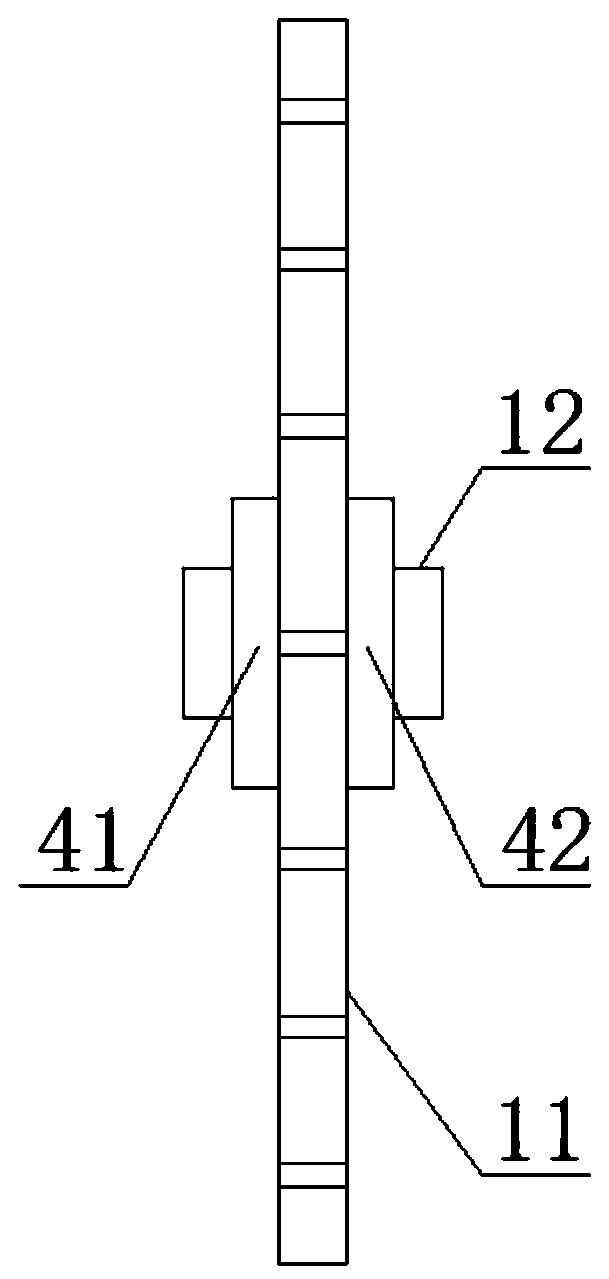

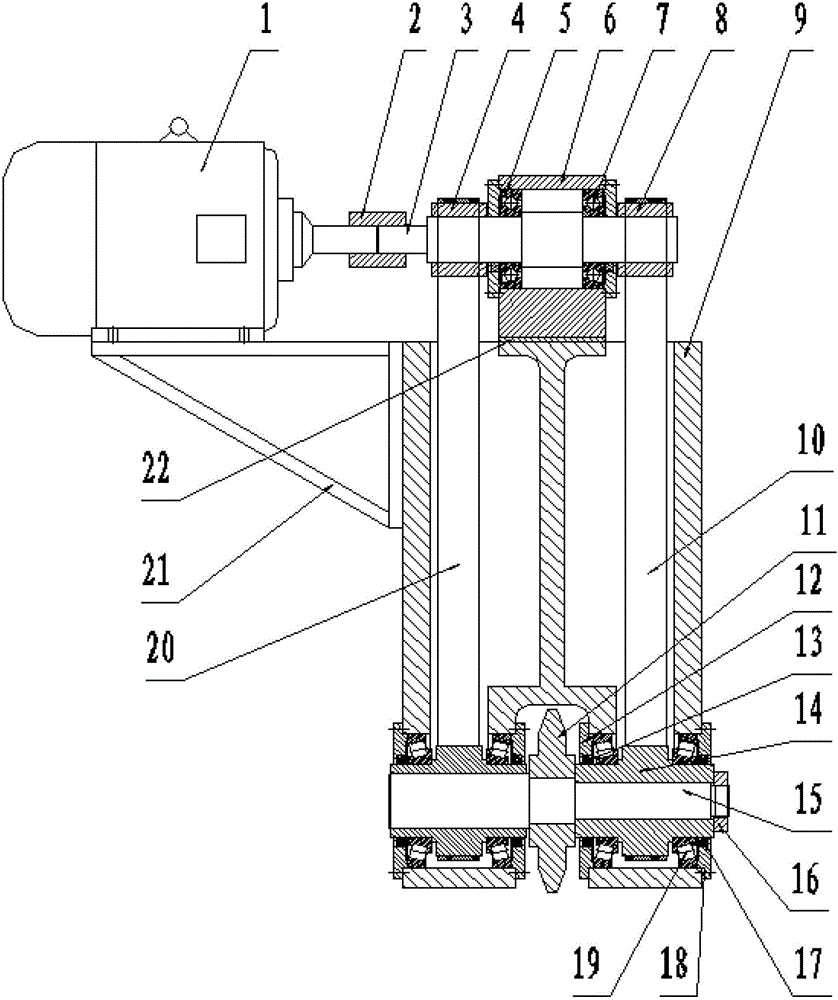

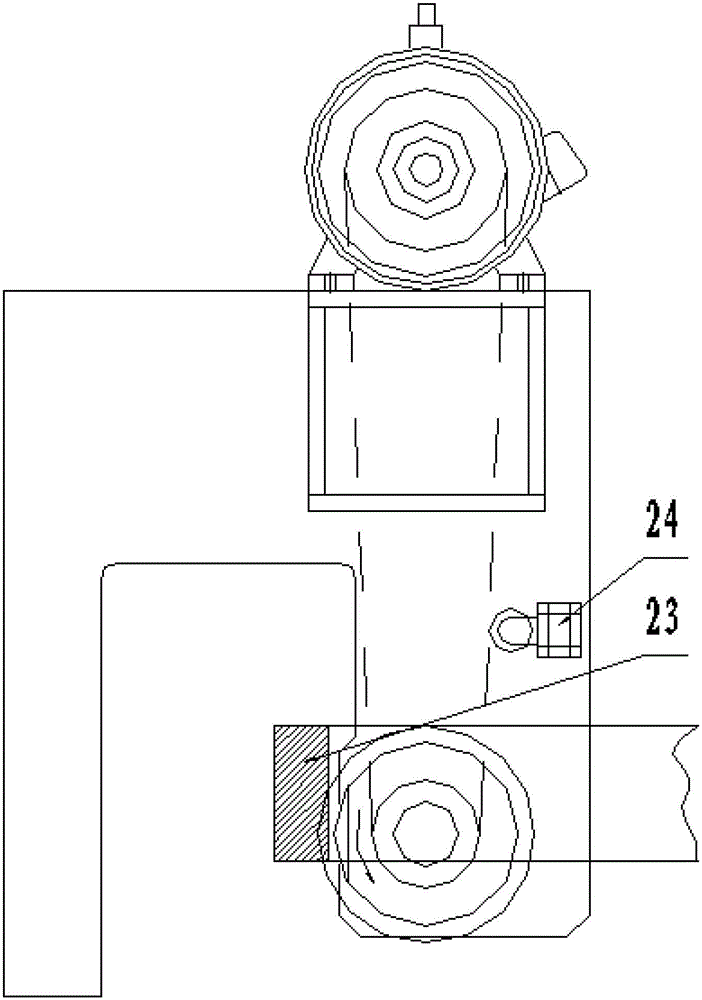

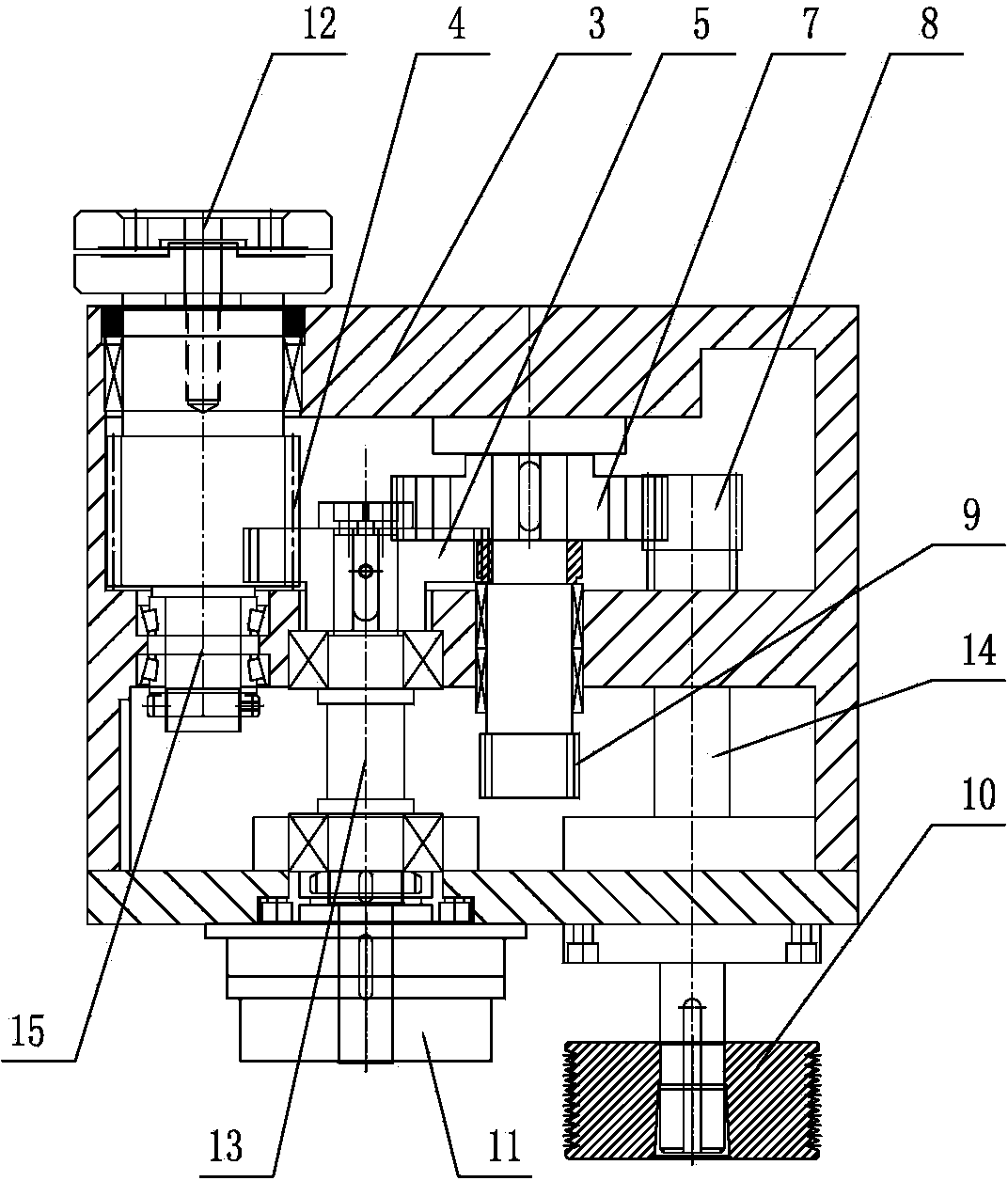

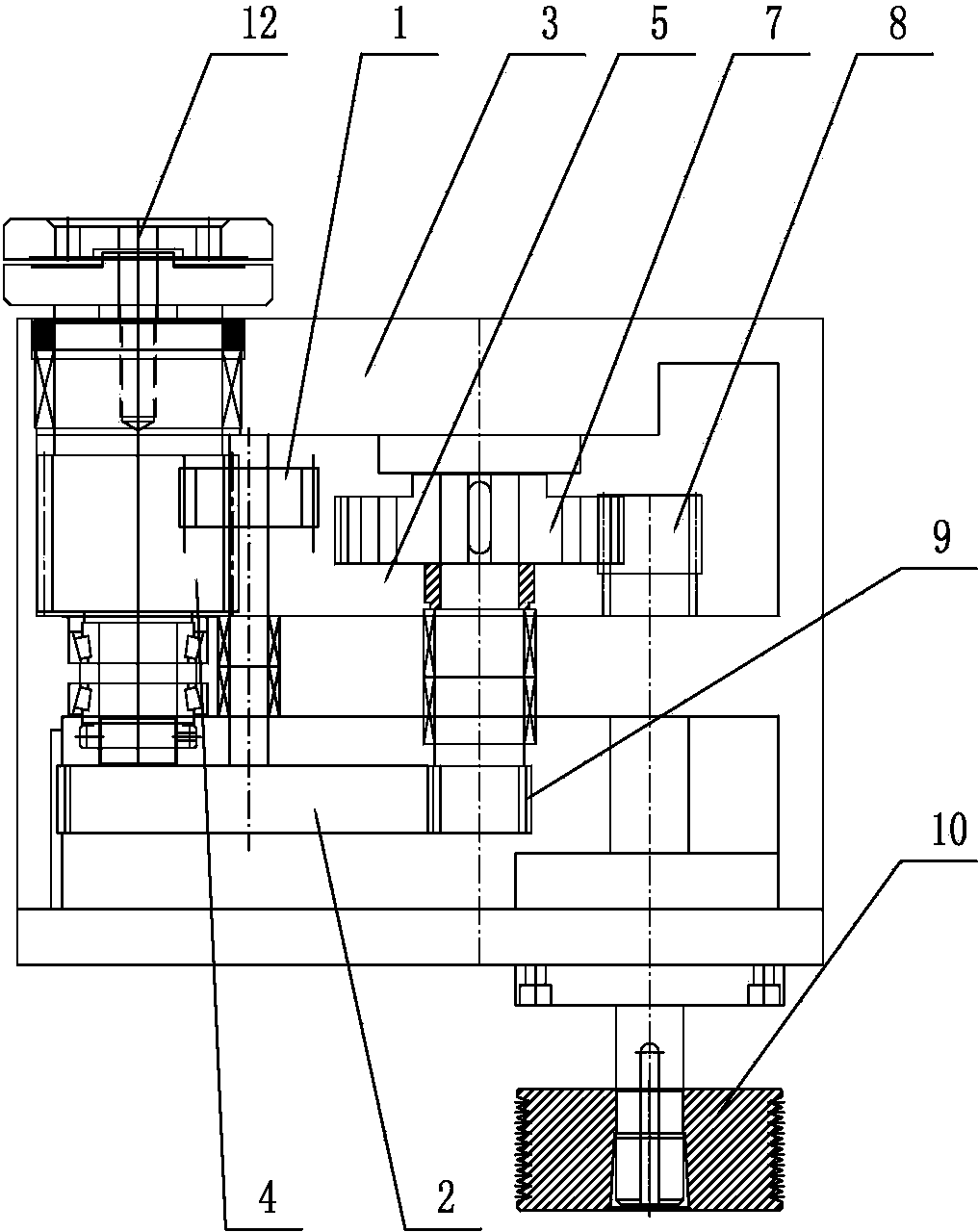

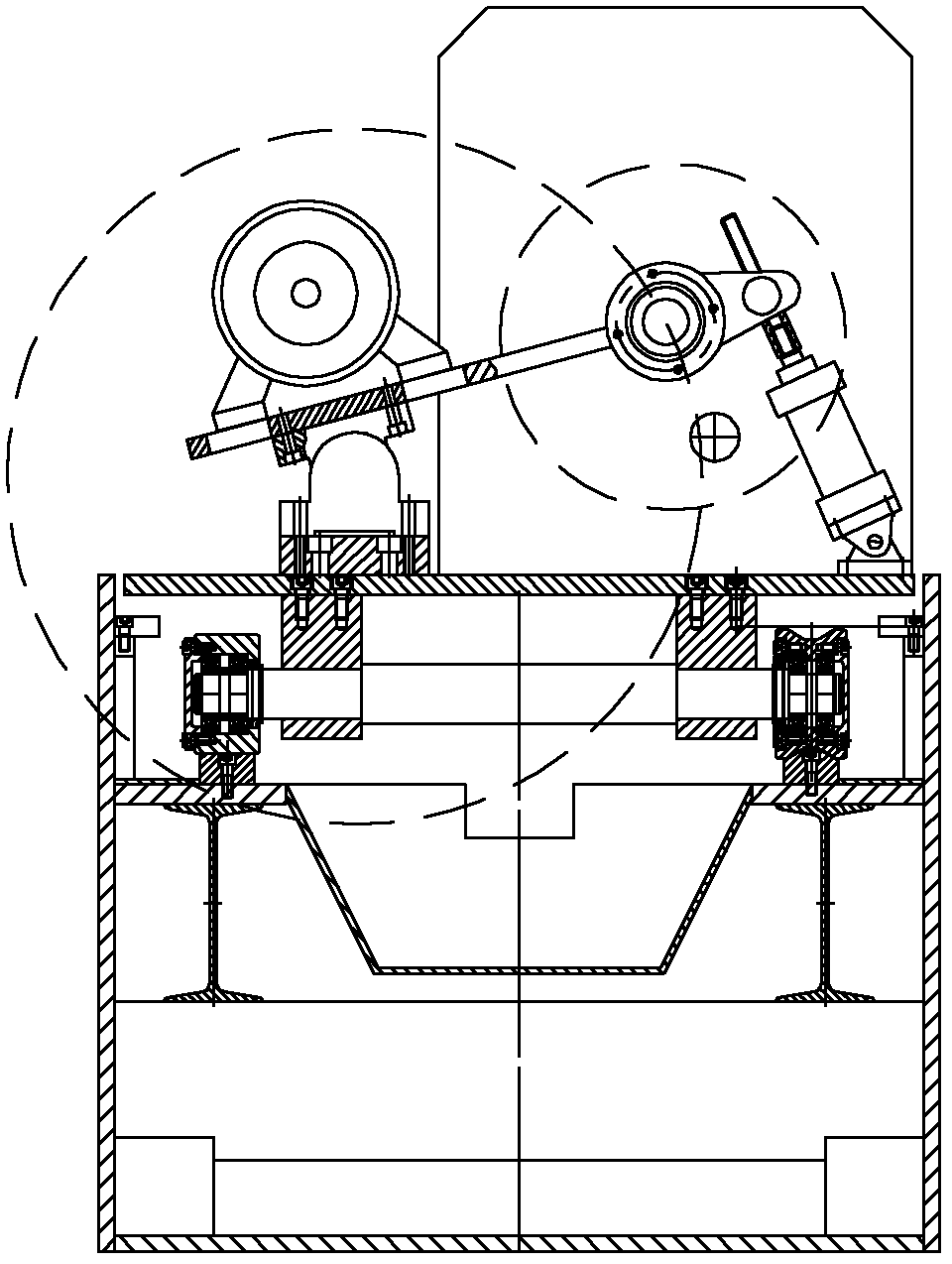

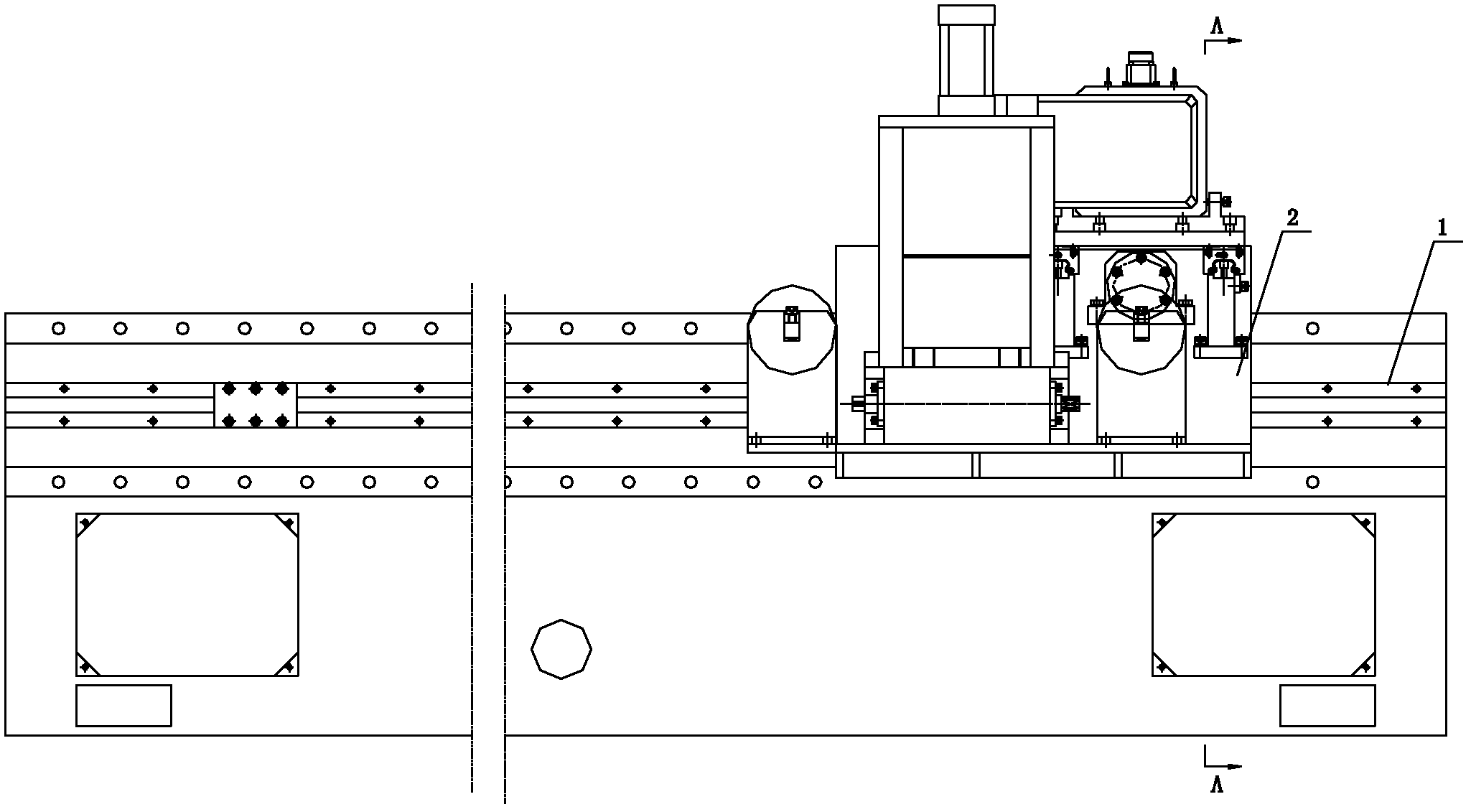

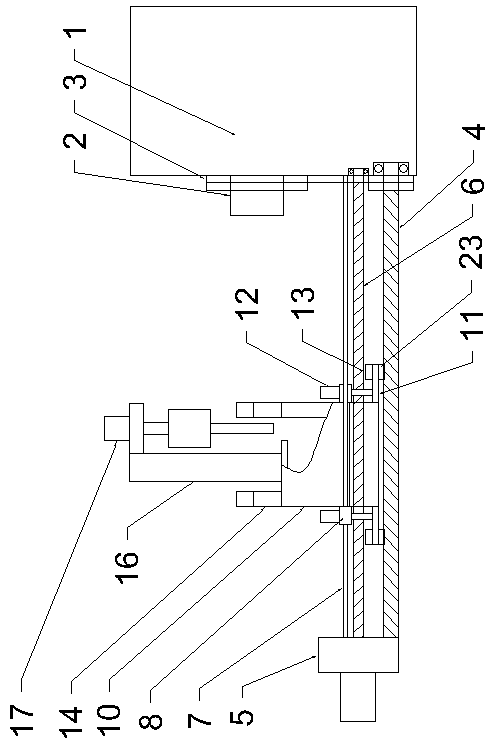

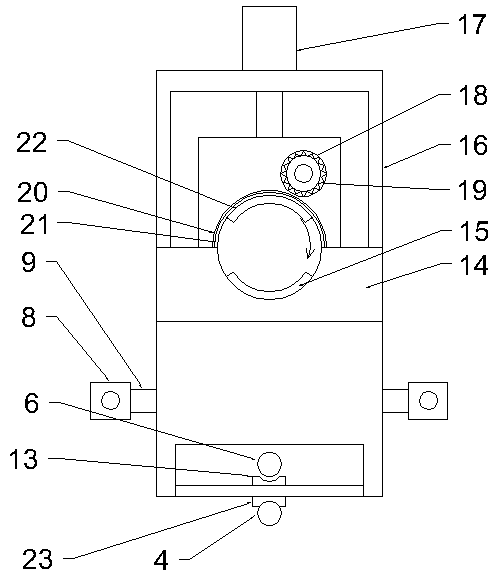

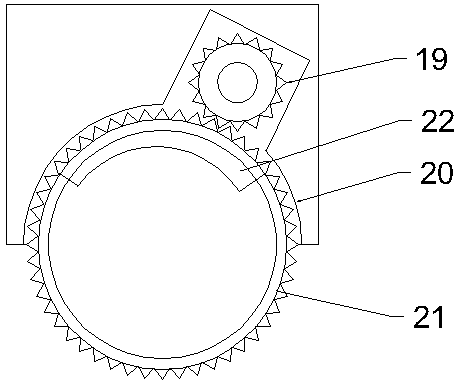

Gear milling spindle box directly driven by torque motor

ActiveCN102717100BImprove surface roughnessShort drive pathDriving apparatusGear teethLow speedGear wheel

A gear milling spindle box directly driven by a torque motor is characterized by comprising the low-speed high-torsion torque motor (1), a driving synchronous belt pulley axle (3), a first driving synchronous belt pulley (4), a second driving synchronous belt pulley (8), a spindle box body (9), a motor support (21), a first synchronous belt (10), a second synchronous belt (20), a disc milling cutter (11), a driven synchronous belt pulley axle (14) and a cutter bar (15). The low-speed high-torsion torque motor is directly connected with the disc milling cutter by the tensioned synchronous belts with arc teeth, a transmission path is short, and transmission efficiency is high. In addition, the tensioned synchronous belts can realize stable transmission without backlashes, nonlinear vibration of a transmission system due to fluctuating cutting load is avoided, cutting noise is lowered, surface roughness of a cut tooth surface is improved, and the risks of impact pitting corrosion of the tooth surface during gear transmission are avoided.

Owner:NANJING GONGDA CNC TECH

Automatic anti-backlash cutting gearbox

ActiveCN102825335BEliminate gapsAvoid bouncingMetal sawing devicesMetal working apparatusEngineeringMechanical engineering

The invention discloses a transmission case for automatically removing a backlash and cutting, which comprises a housing, wherein an input shaft and an output shaft are arranged in parallel inside the housing; the shaft end of the output shaft extends out of the housing and is provided with a saw blade clamp; one end of the input shaft extends out of the housing and is provided with a power input component; the input shaft and the output shaft are in transmission connection via a gear set; a damping shaft is also arranged inside the housing; a damping gear is arranged on the damping shaft; the damping gear is meshed with an output gear arranged on the output shaft, and a pneumatic damper is arranged at the shaft end of the damping shaft. Due to the pneumatic damper, the rotation of the output shaft is properly limited by the damping shaft and the damping gear; a gear gap generated when a work-piece is cut is removed; bounce of the output gear is stopped; the cutting noise is reduced; the cutting precision is improved; the abrasion of the gear is reduced; the cutting is more stable; a notch is smooth, and the device can be applied to various cutting machines and also can be applied to a polishing machine.

Owner:江苏省南扬机械制造有限公司

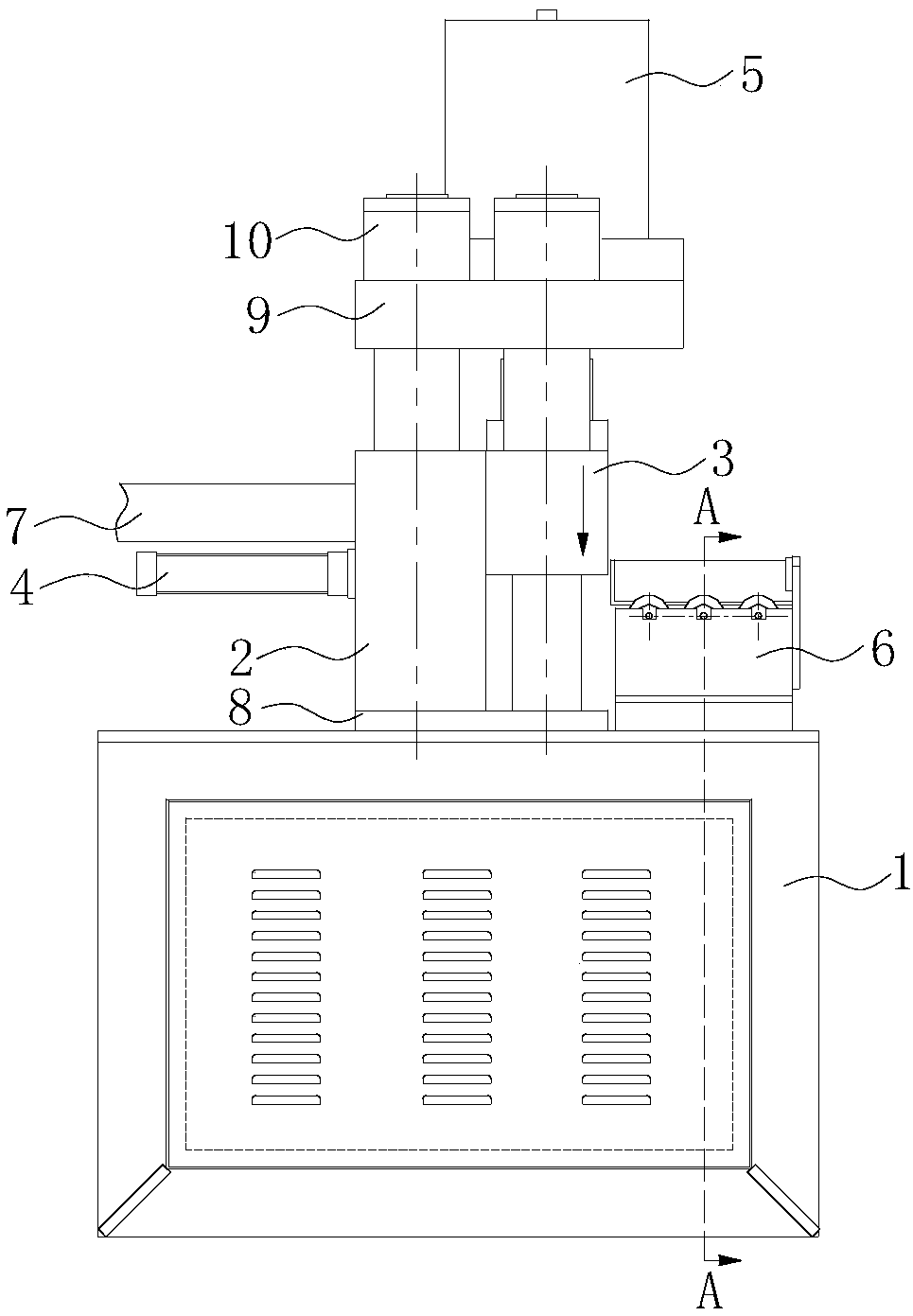

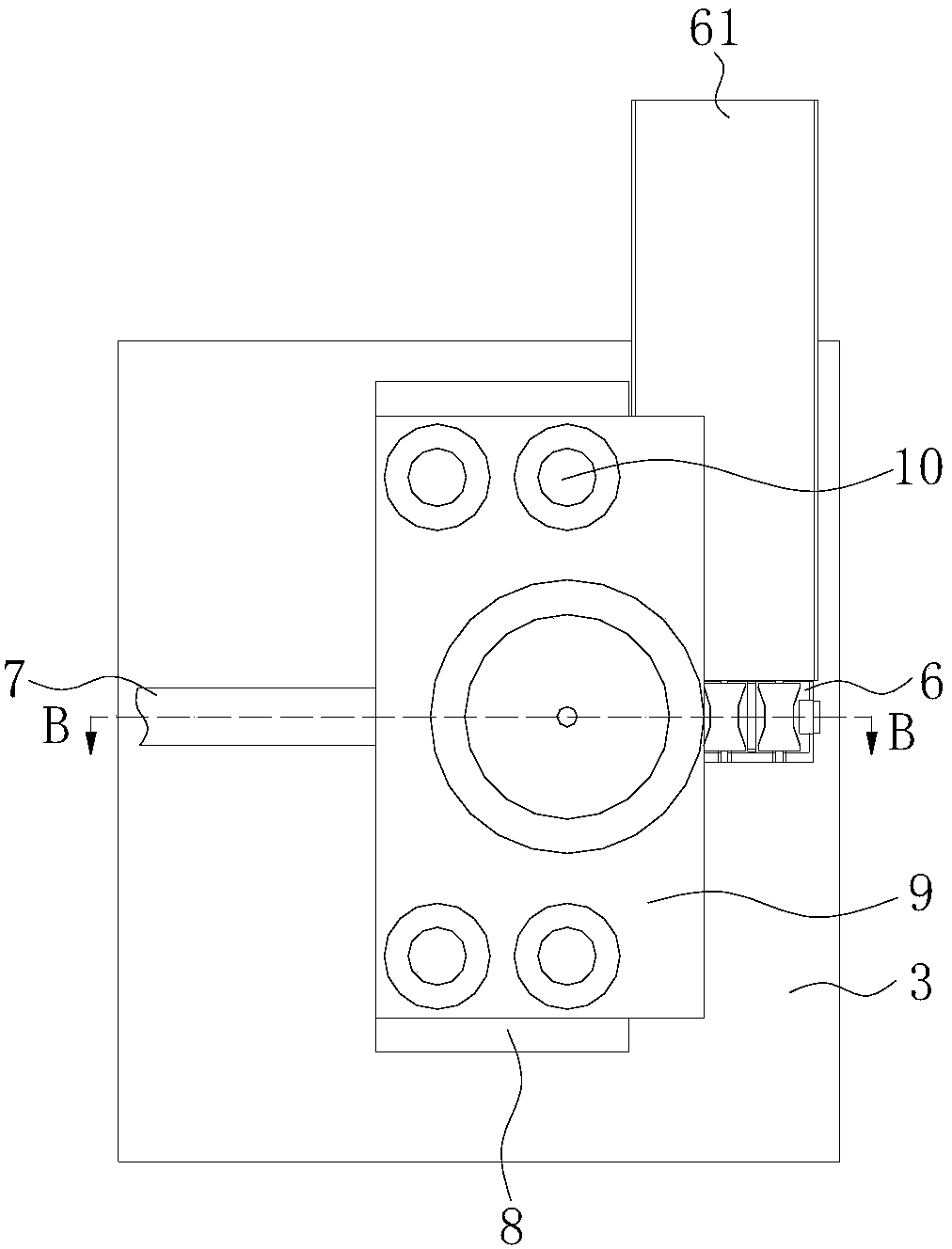

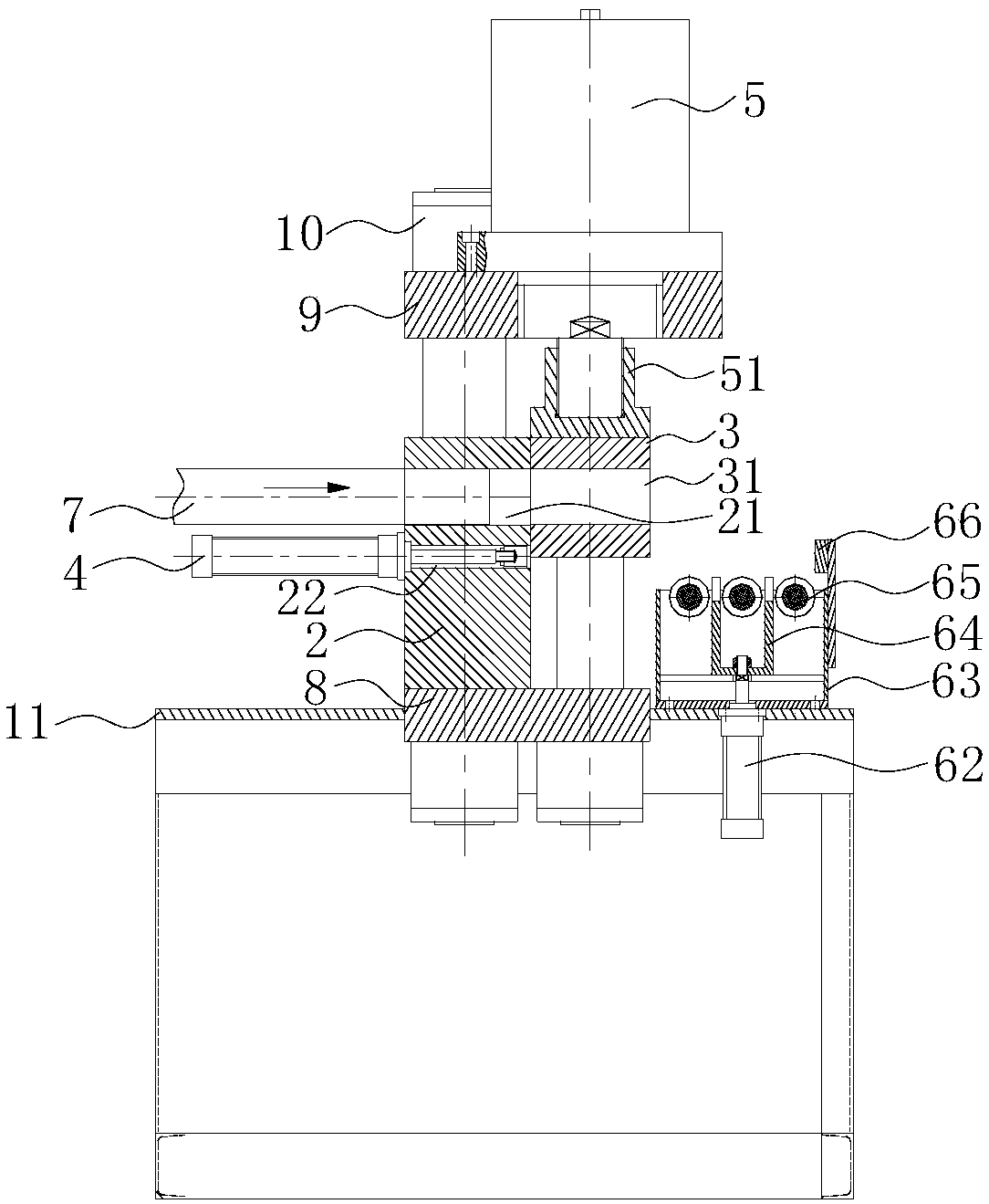

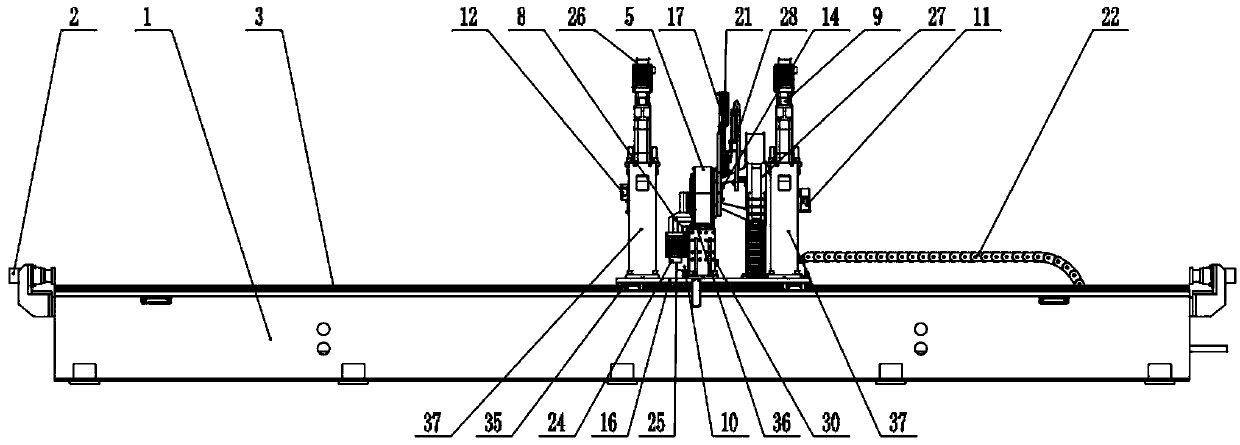

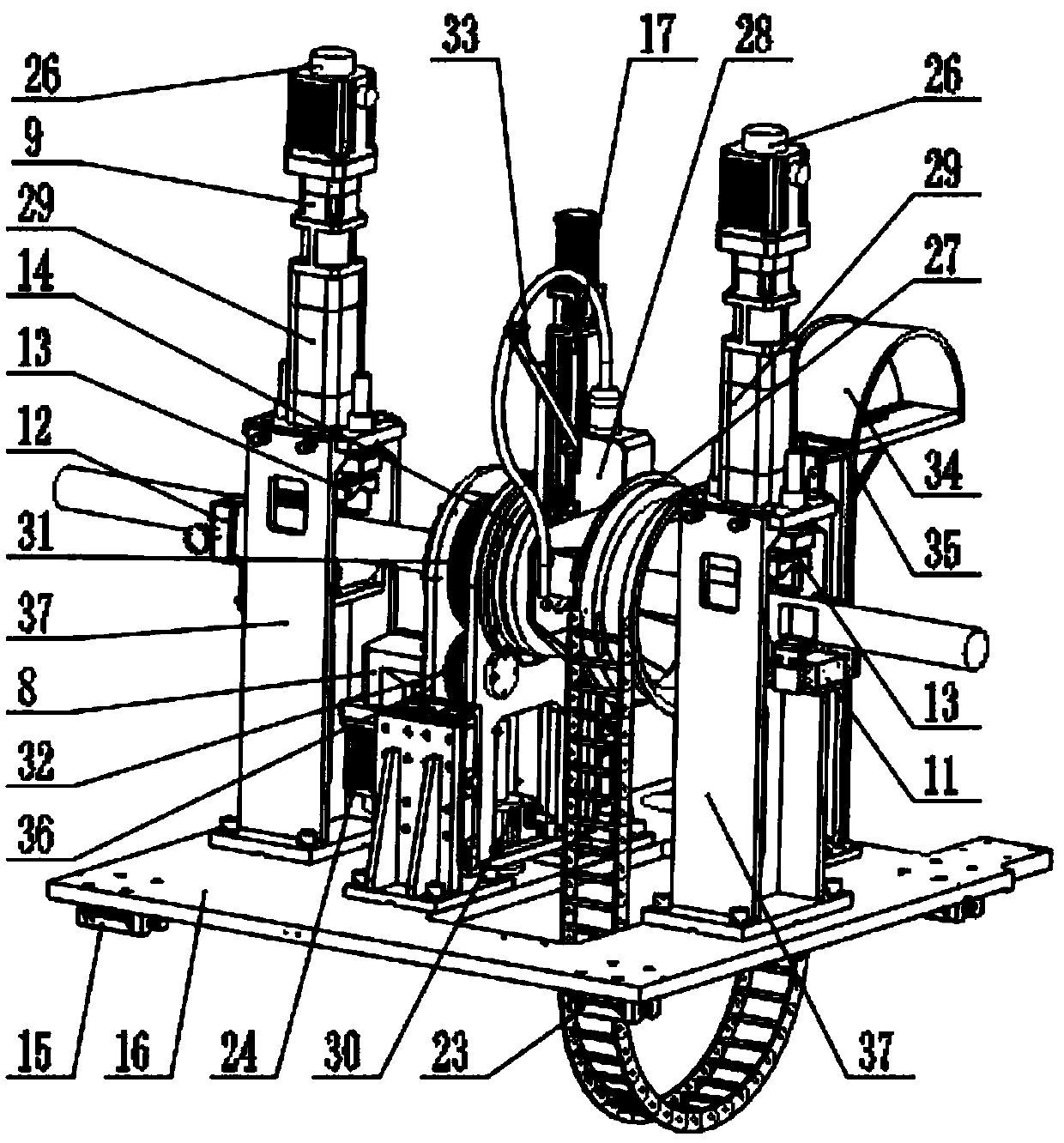

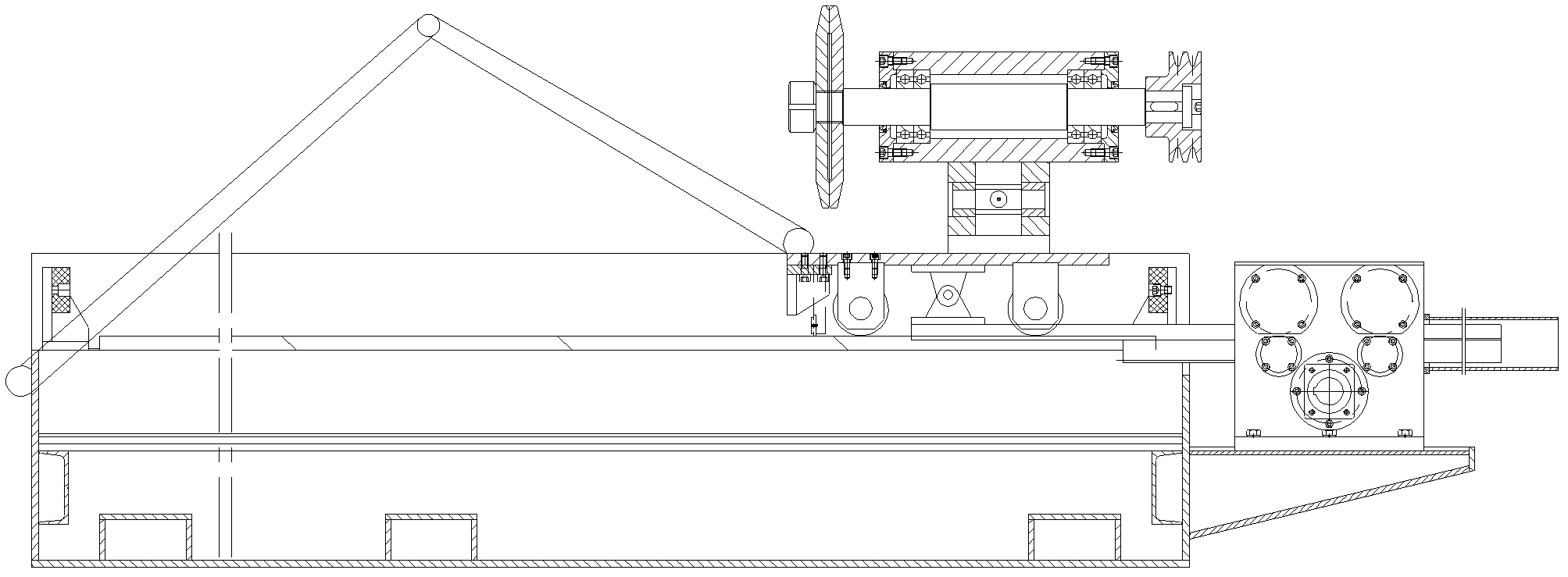

Welded pipe optical fiber laser flying sawing machine

PendingCN110842376AReduce cutting lossReduce cutting noiseLaser beam welding apparatusPhysicsBuffer (optical fiber)

The invention discloses a welded pipe optical fiber laser flying sawing machine. The welded pipe optical fiber laser flying sawing machine comprises a flying sawing machine body, liquid gas buffers, ahorizontal linear guide rail, a rack, a protective cover, a drag motor, a drag speed reducer, a rotating speed reducer, a clamping speed reducer, a lifting speed reducer, a discharging guide cylinder, a feeding guide roller, a clamping mechanism, a rotating mechanism, a first sliding block, a trolley platform, a linear module, a first gear, a second sliding block, a lifting guide rail, a feedingmotor, a first drag chain, a second drag chain, a rotating motor, a lifting motor, a clamping motor, a drag chain disc, an optical fiber laser cutting head, an electric cylinder, an elevator, a secondgear, a third gear, an optical fiber support, an optical fiber guide groove, a drag chain support, a rotating support and a clamping support. The liquid gas buffers are correspondingly arranged on two sides of the flying sawing machine body. The horizontal linear guide rail is arranged at the top of the flying sawing machine body. The welded pipe optical fiber laser flying sawing machine has thecharacteristics of being small in cutting loss and cutting noise.

Owner:SHENYANG CONTOR MACHINE & ELECTRIC EQUIP

Low-noise metal cutting production line

InactiveCN106001766ANo costTo isolate soundMetal sawing accessoriesMaintainance and safety accessoriesProduction lineLow noise

A low-noise metal cutting production line, comprising a cutting machine body, a protective cover arranged on the cutting machine body, and a saw blade arranged in the protective cover, the lower part of the saw blade is arranged in the cutting machine body, and the cutting part of the saw blade is Set in the protective cover; the protective cover is a box structure, the protective cover is provided with a water injection port, and the protective cover is used to hold soap bubbles; the protective cover is laid with at least one layer on the side facing the saw blade soundproofing material. On the one hand, the invention has low cost, on the other hand, it can effectively block the noise transmission, thereby further improving the working environment of the workshop, improving the working environment of the adjacent office area, making employees in a comfortable environment, which is more conducive to the physical and mental health of employees , and greatly improve work efficiency.

Owner:湖南亘晟门窗幕墙有限公司

Milling mechanism of pipe cutting machine

InactiveCN102626804ASmooth cut without burrsReduce vibrationMetal sawing devicesSlide plateEngineering

The invention discloses a milling mechanism of a pipe cutting machine. The milling mechanism comprises a base which is arranged on a rack of the pipe cutting machine; the base is provided with a lead screw; a first variable-speed motor is arranged at the end part of the lead screw; a sliding seat is movably arranged on the lead screw and is provided with a sliding plate; the sliding plate is provided with a second variable-speed motor and a speed reducing device connected with the second variable-speed motor; and an output shaft of the speed reducing device is provided with a saw blade. The milling mechanism of the pipe cutting machine, provided by the invention, has the advantages that the cut is smooth without burrs, the cutting noise is low, the structure is compact and the use is safe.

Owner:江苏中港冶金设备科技有限公司

Simultaneous cutting system for pipe extrusion

ActiveCN108817542BReduce generationReasonable structureMetal sawing devicesEngineeringMechanical engineering

Owner:ZHEJIANG JINBO FLUID CONTROL

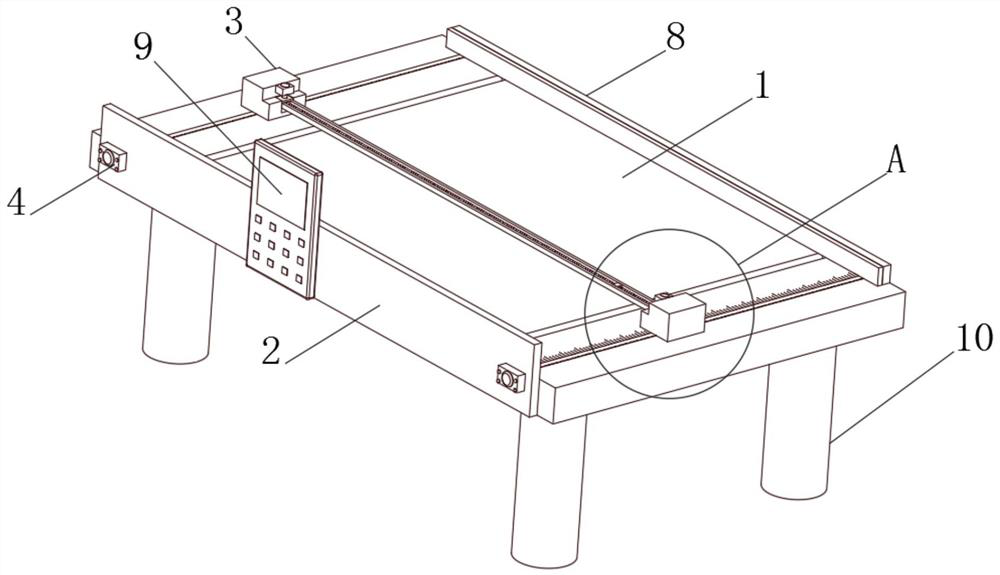

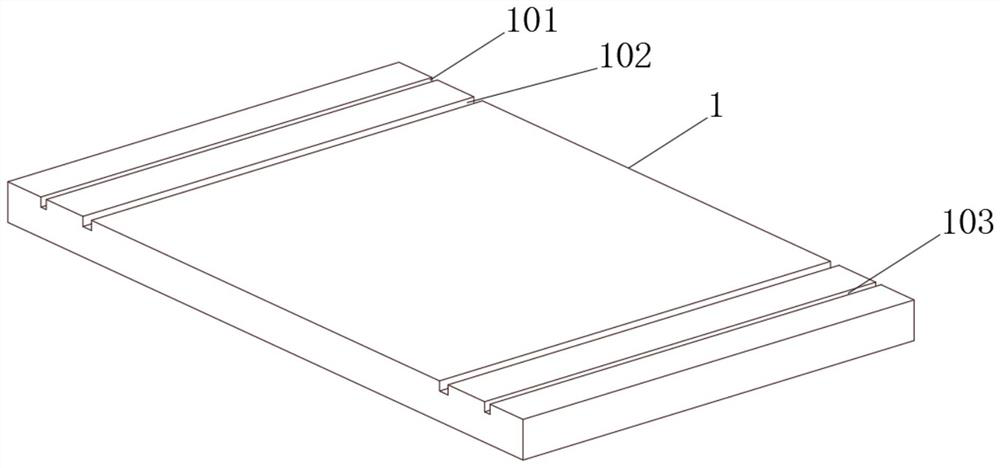

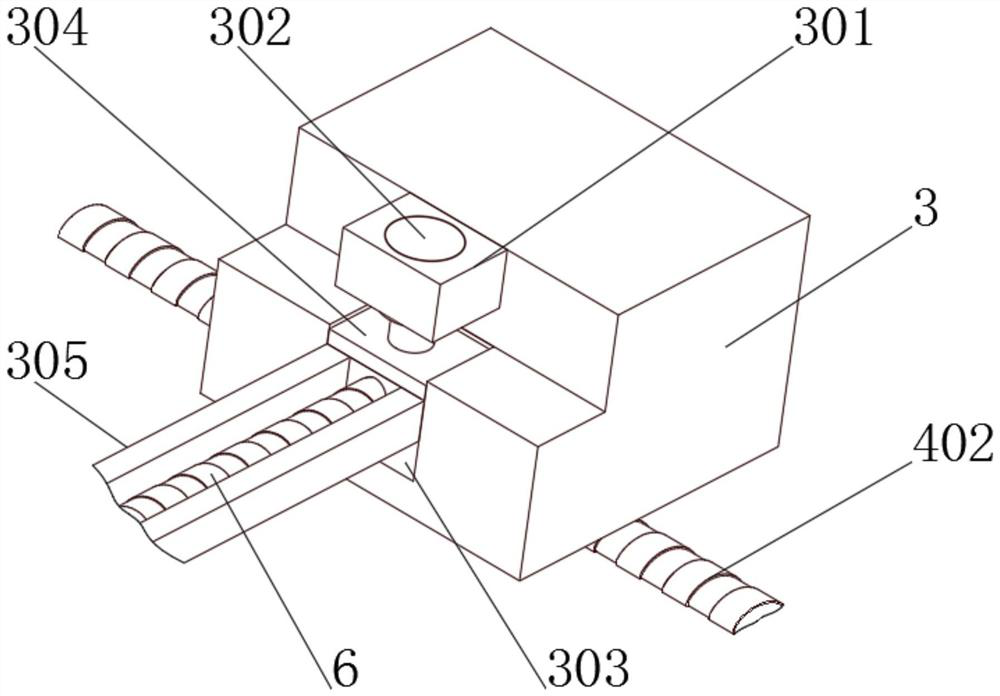

Anti-splashing ceramic tile cutting platform capable of achieving rapid positioning and cutting technology of anti-splashing ceramic tile cutting platform

PendingCN113320030ARealize automatic adjustment cuttingImprove cutting efficiencyWorking accessoriesStone-like material working toolsNumerical controlElectric machinery

The invention discloses an anti-splashing ceramic tile cutting platform capable of achieving rapid positioning and a cutting technology of the anti-splashing ceramic tile cutting platform. The anti-splashing ceramic tile cutting platform comprises a main body and a baffle, wherein a first sliding groove is formed in the outer wall of the top of the main body, a first sliding base is slidably connected to the inner wall of the first sliding groove, a first installing table is fixedly connected to the outer wall of the first sliding base, a first hydraulic rod is fixedly connected to the inner wall of the first installing table, a first sliding plate is fixedly connected to the end, away from the first installing table, of the first hydraulic rod, a first groove is formed in the outer wall of the first installing table, the inner wall of the first groove is slidably connected to the outer wall of the first sliding plate, a rail is fixedly connected to the outer wall of one side of the first sliding plate, and a machine base is arranged on the outer wall of the main body. The cutting length is adjusted by controlling the number of turns of rotation of a motor in a numerical control mode, compared with an existing cutting machine, the cutting machine is faster and more accurate, automatic cutting adjustment is achieved, the cutting efficiency is improved, and the position correction accuracy and the positioning efficiency are improved.

Owner:YANGXI BODE PRECISION IND BUILDING MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com