Chipless cutting machine for tubes

A cutting machine and pipe technology, applied in metal processing, etc., can solve the problems of waste of raw materials, heavy workload of employees, and insufficient smoothness of the cross section, etc., and achieve the effect of reducing workload, high cutting efficiency and good cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

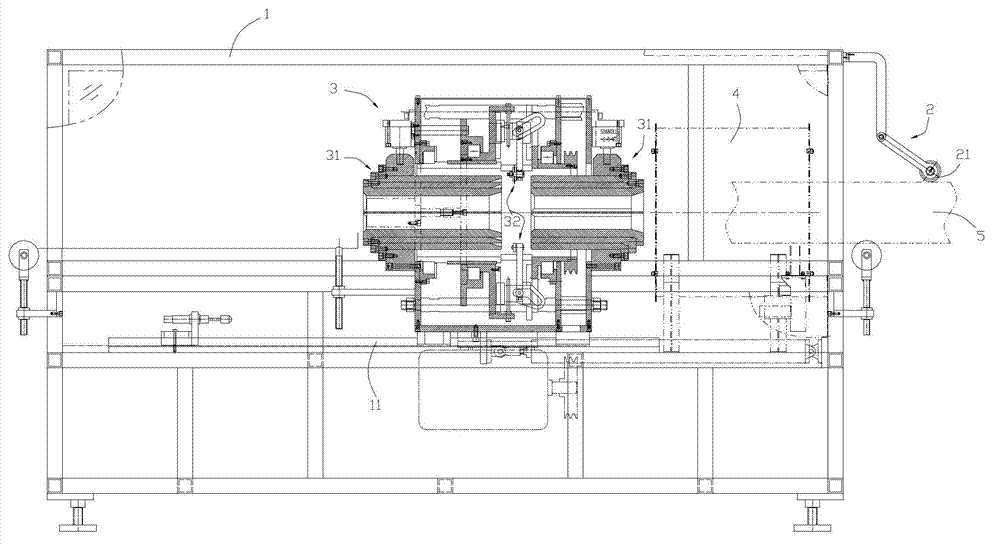

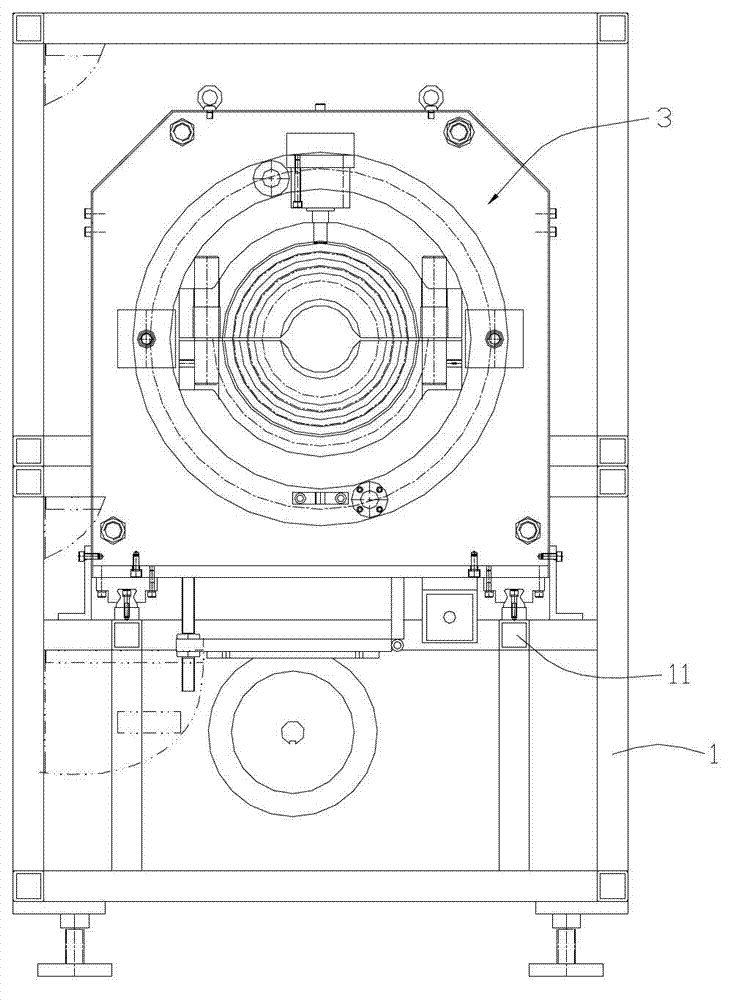

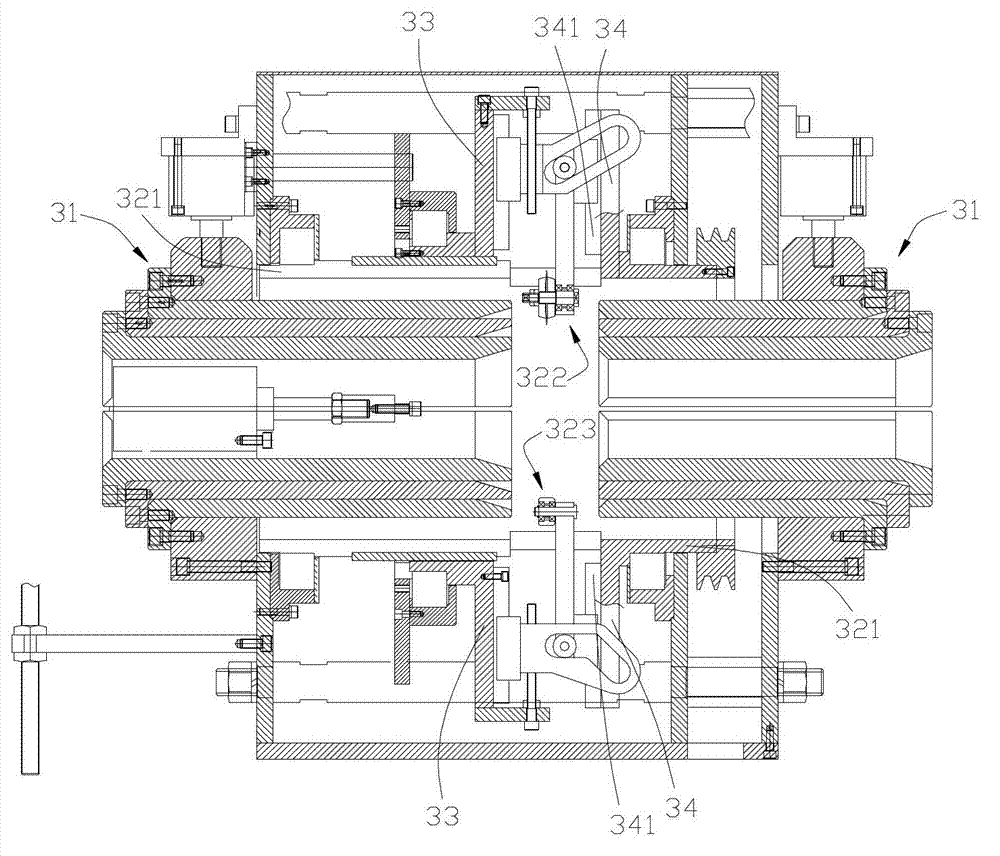

[0020] Combine below Figure 1 to Figure 7 The present invention is described in further detail:

[0021] The chipless pipe cutting machine of the present invention includes a frame 1, and also includes a pipe length measuring device 2 and a PLC control device (not shown in the figure). , the PLC control device controls the cutting device 3 to move along the frame according to the length counting signal, and enables the cutting device to cut the pipe to a fixed length. During implementation, the frame 1 is provided with a linear slide rail 11, and the PLC control device controls the cutting device to move along the slide rail. A heating device 4 for heating the pipe is installed between the cutting device and the length measuring device. The heating temperature of the heating device is controlled by the RKC temperature controller, so that the pipe is preheated and softened before cutting, which not only improves the cutting effect, And improve the cutting efficiency.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com