Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Short drive path" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

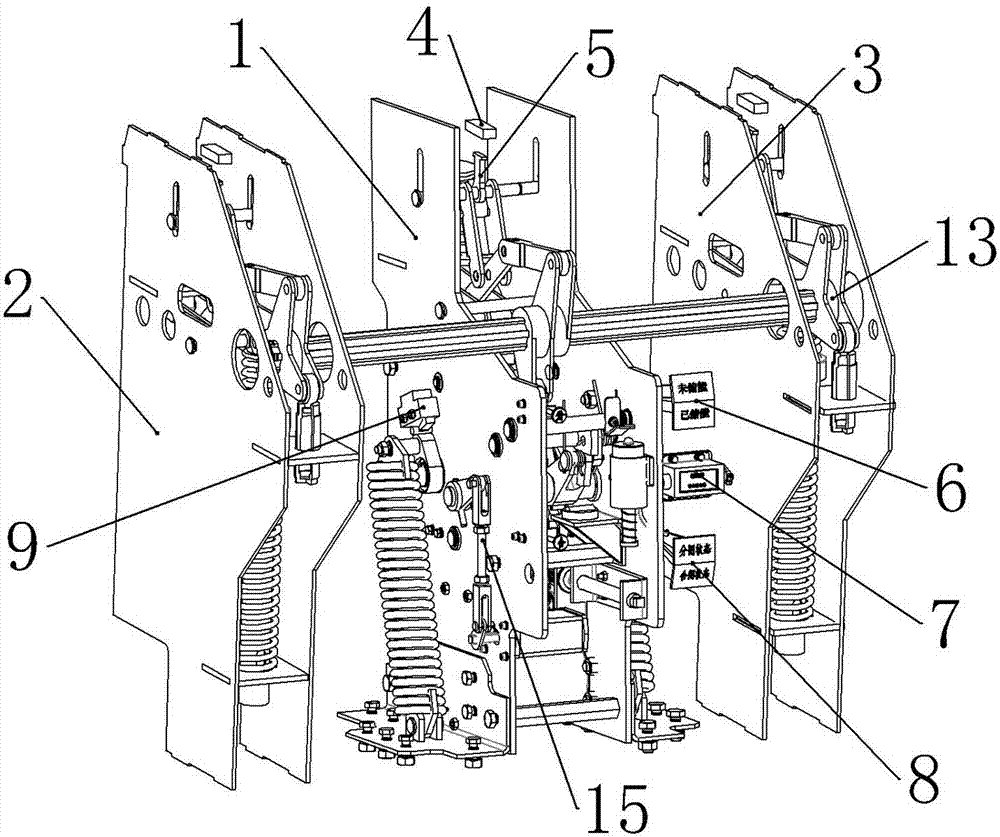

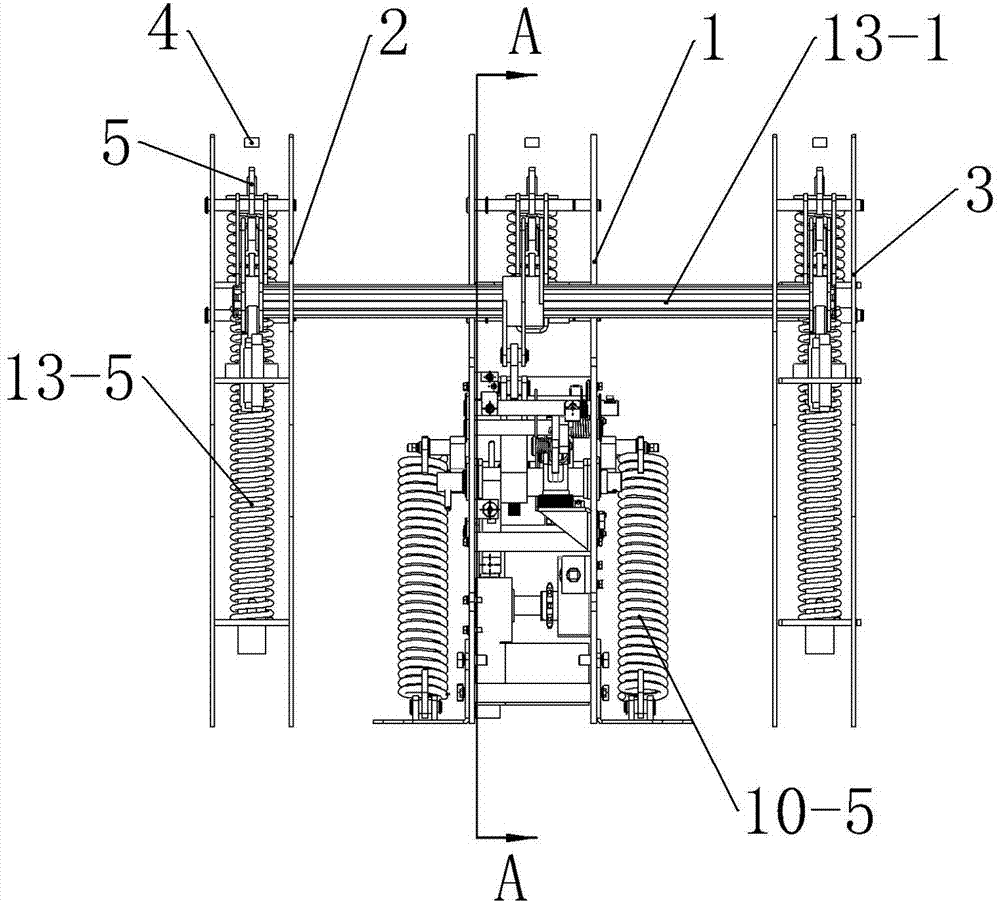

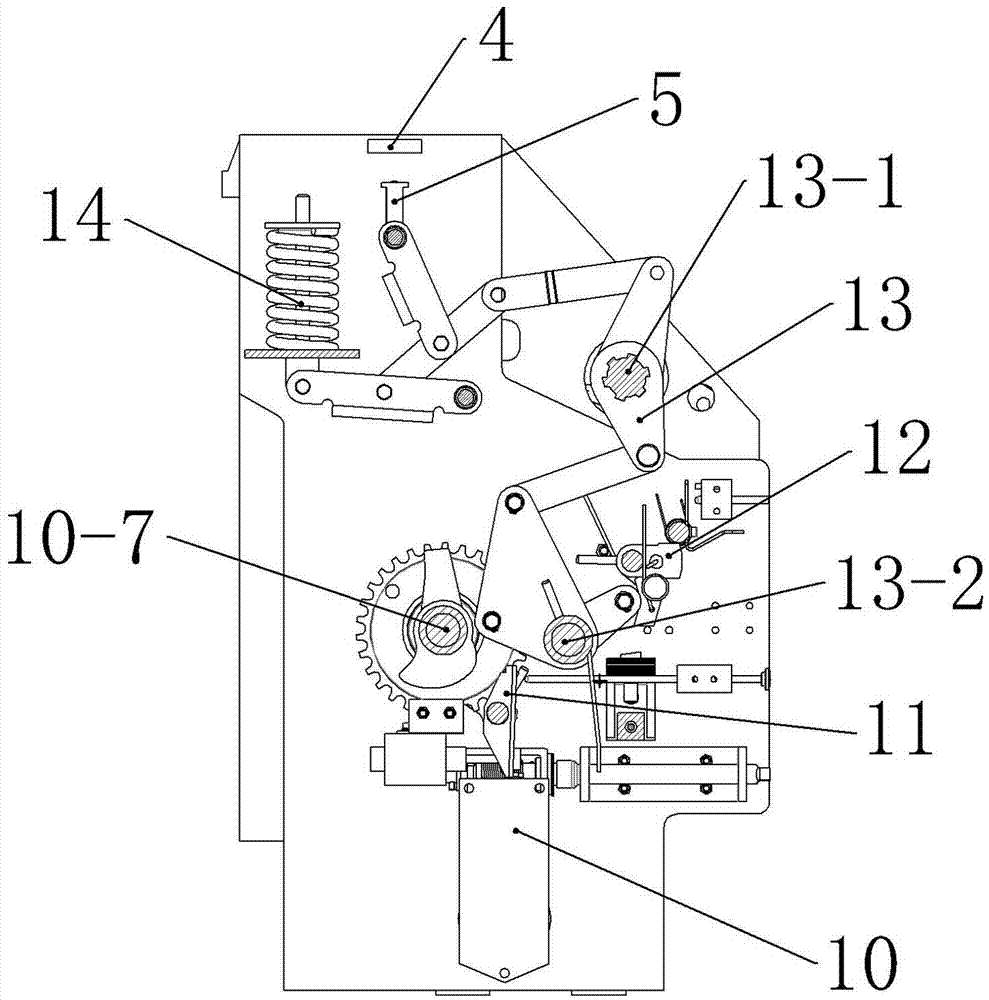

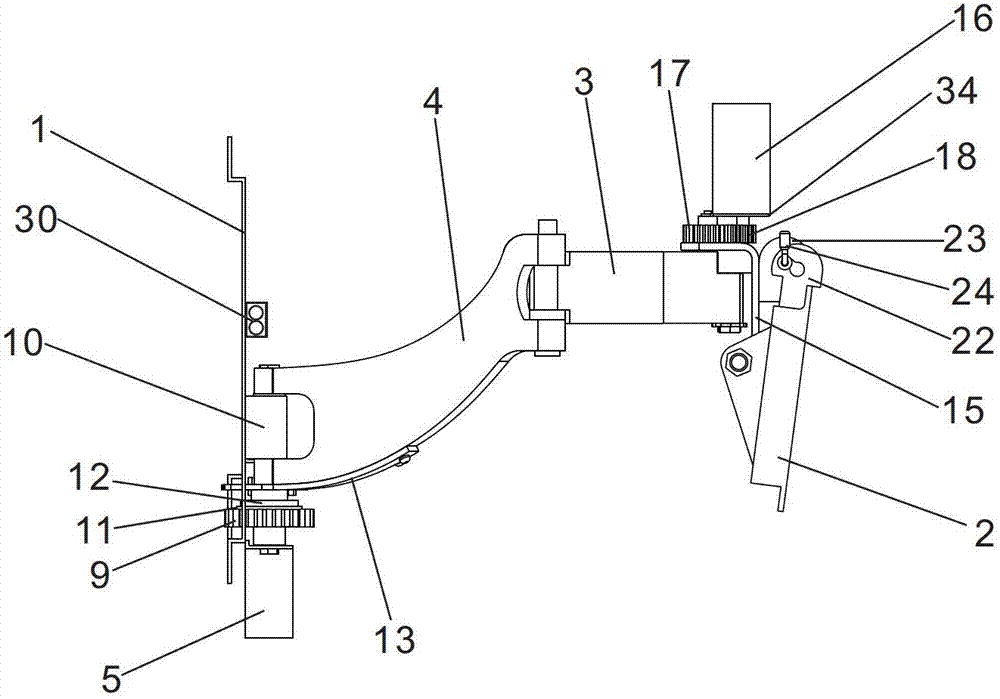

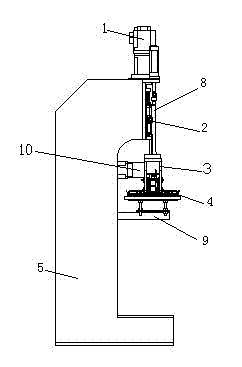

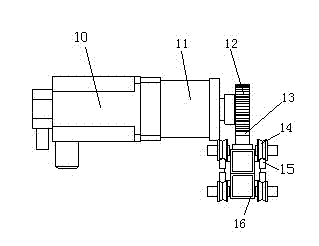

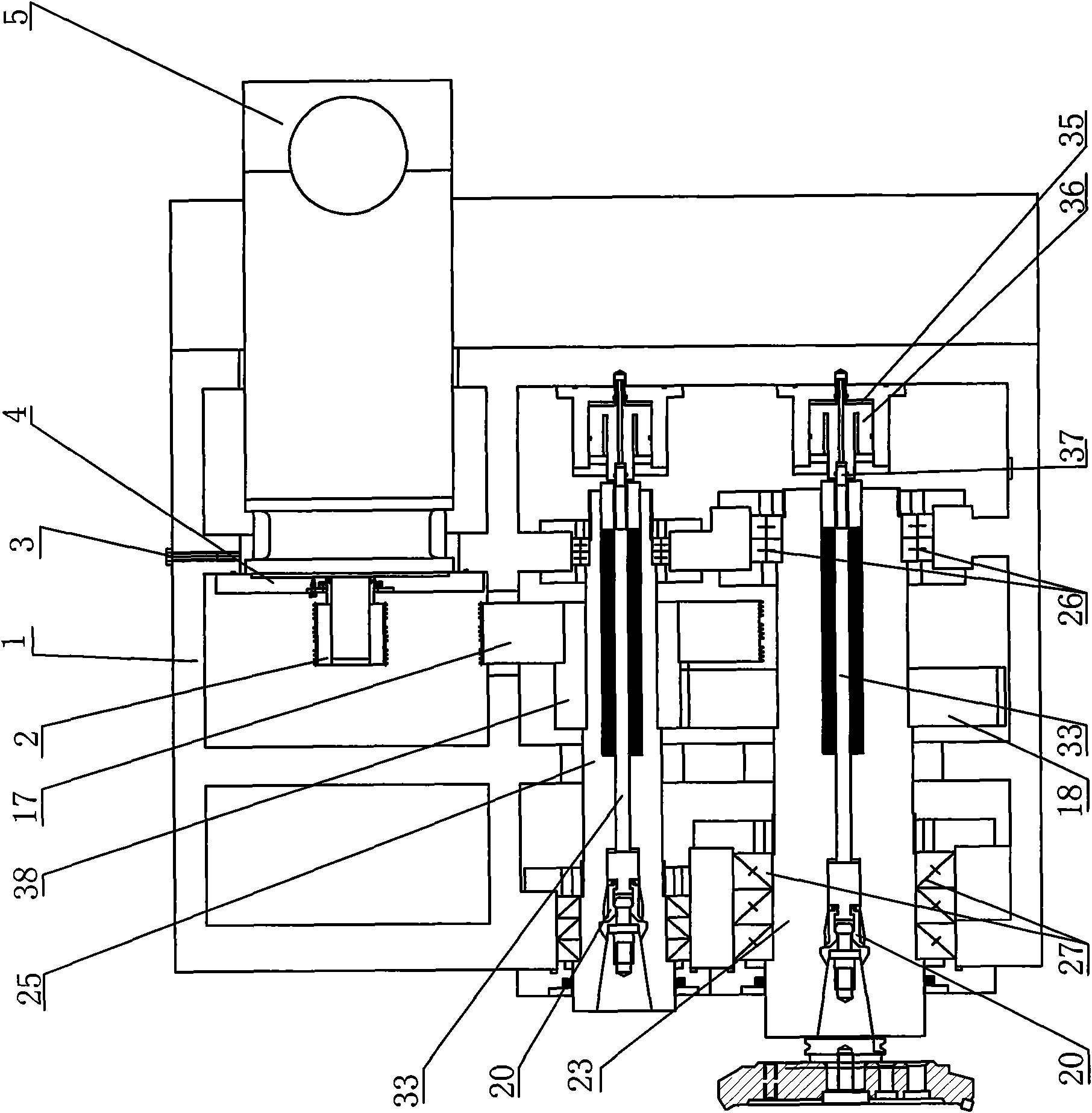

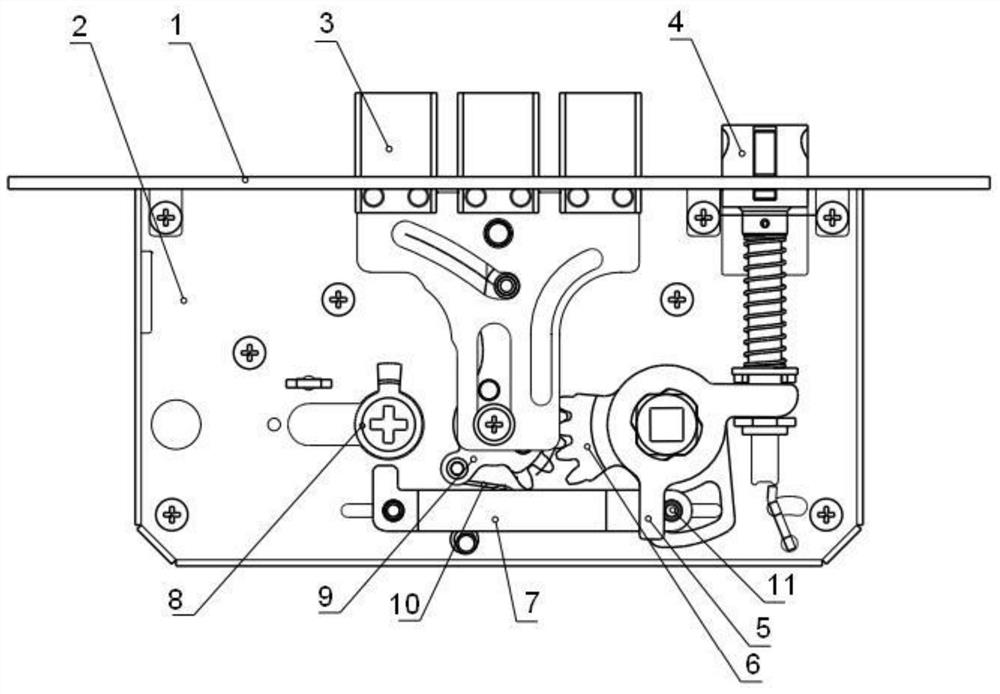

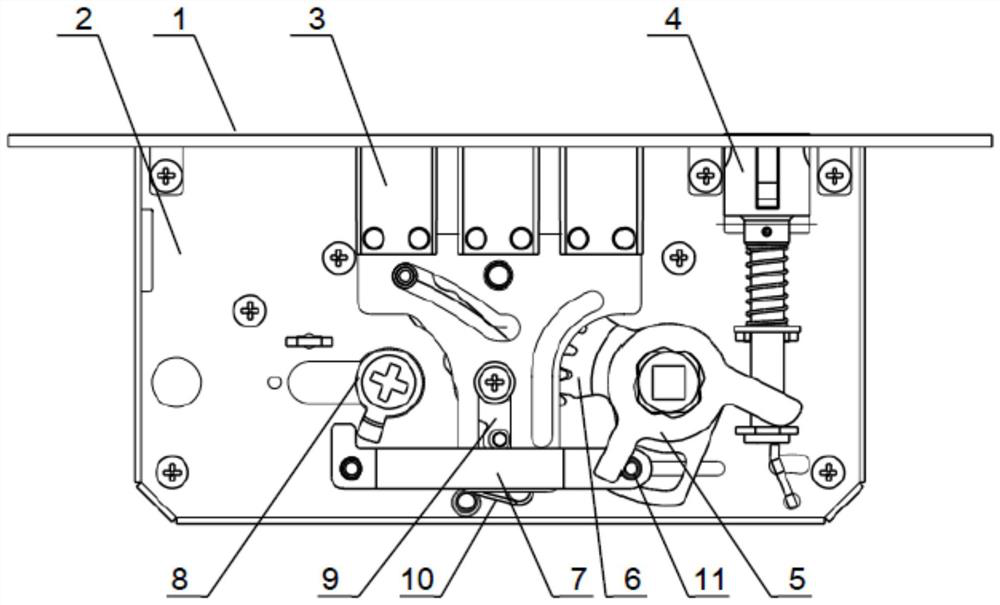

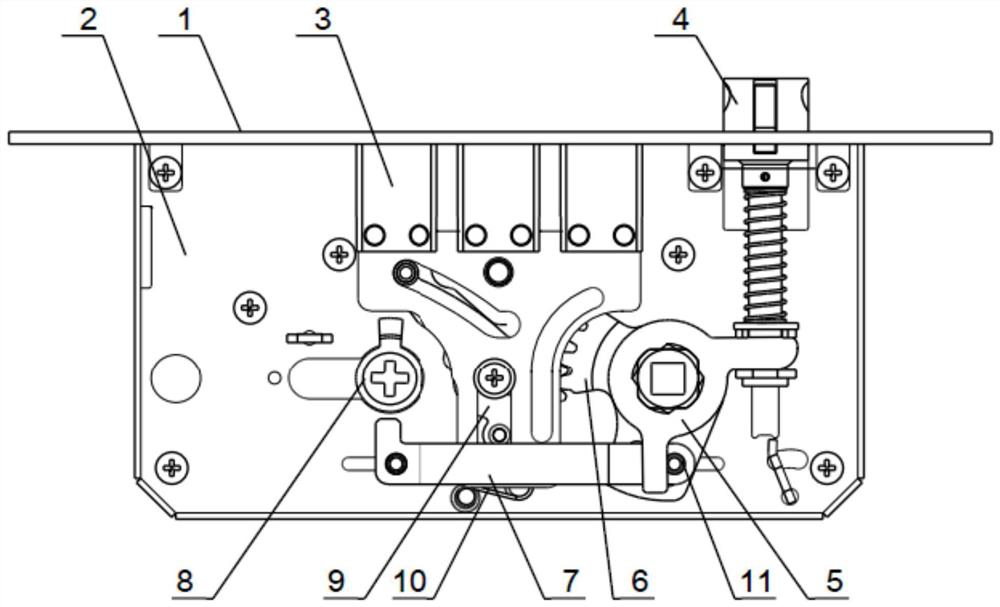

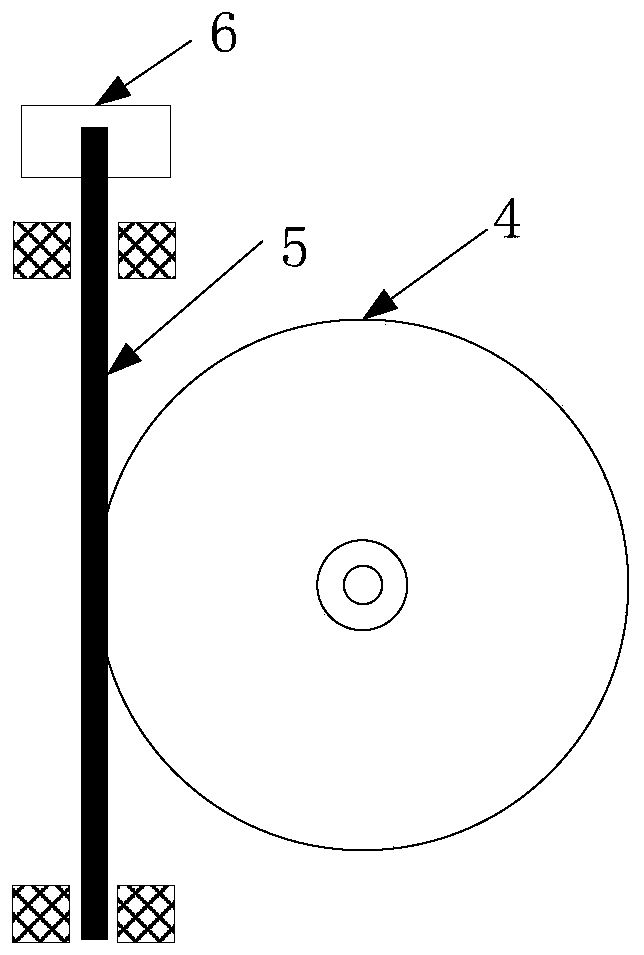

Spring operating mechanism and high-voltage vacuum breaker

ActiveCN104217890AShort drive pathSimple driveSwitch power arrangementsHigh-tension/heavy-dress switchesThree-phaseHigh pressure

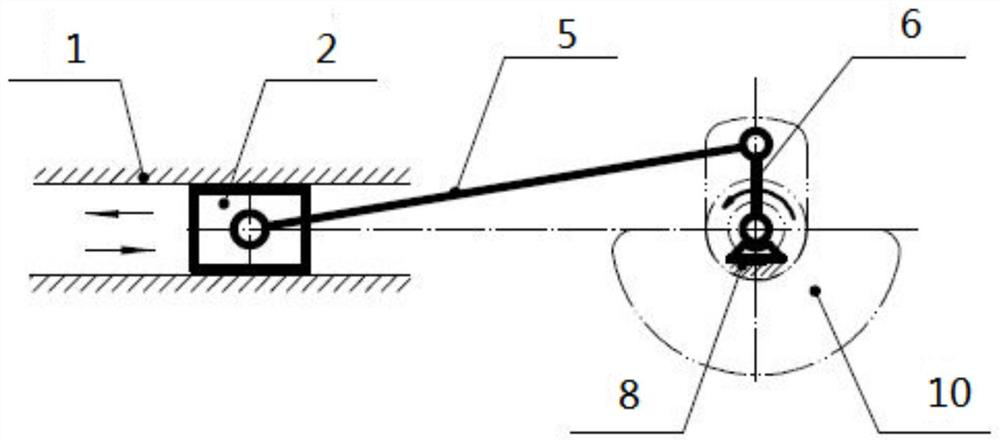

The invention discloses a spring operating mechanism and a high-voltage vacuum breaker. The spring operating mechanism comprises a frame. An energy accumulation shaft and a first drive unit for driving the energy accumulation shaft to rotate are disposed on the frame. A switch-on spring is disposed between the energy accumulation shaft and the frame. A transmission spindle in transmission connection with the energy accumulation shaft through a transmission mechanism is further disposed on the frame. The transmission spindle is located above the energy accumulation shaft, the first drive unit and the switch-on spring. The transmission spindle is provided with three transmission output ends which are respectively used for being in transmission connection with the movable contacts of a three-phase vacuum arc extinguishing chamber. The spring operating mechanism has the advantages the transmission spindle is disposed above the energy accumulation shaft, the first drive unit and the switch-on spring and is close to the three-phase vacuum arc extinguishing chamber of a breaker body, spring accumulated energy is transmitted to the transmission spindle from bottom to top, the transmission spindle directly drives the movable contacts of the arc extinguishing chamber through the three transmission output ends, transmission paths are shortened, transmission is simplified, and overall performance is increased.

Owner:STATE GRID CORP OF CHINA +2

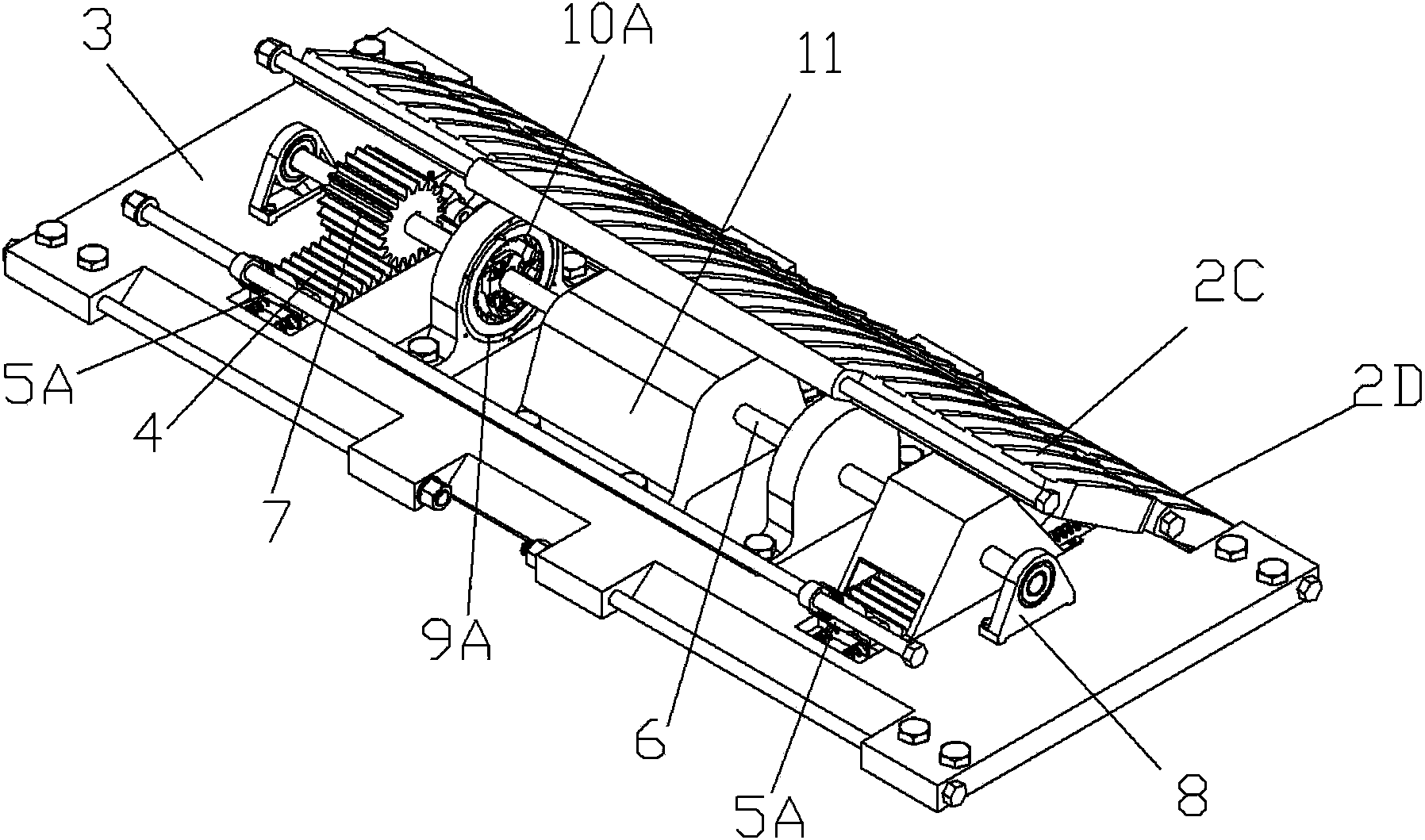

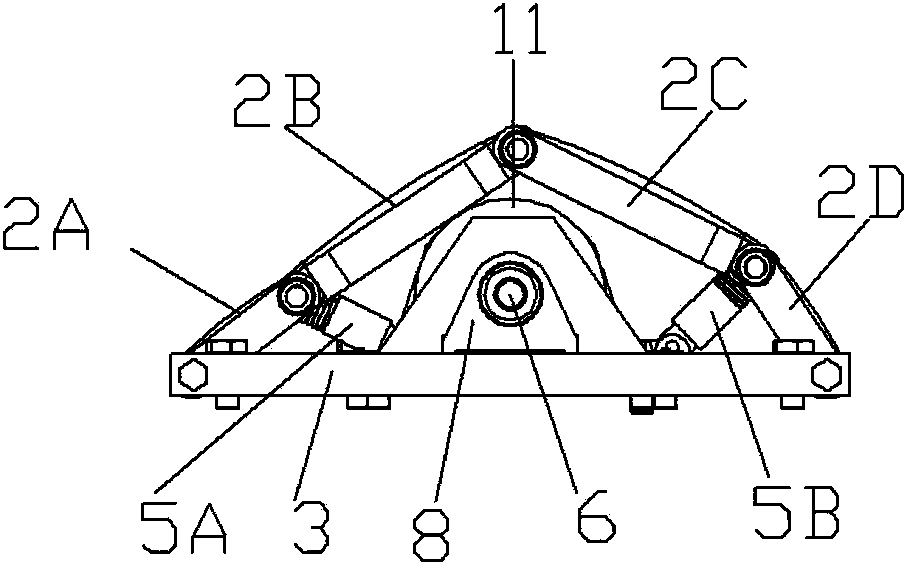

Double-mode adjusting television hanging bracket

InactiveCN102829309AAdjust viewing angleEasy and comfortable viewing angleToothed gearingsStands/trestlesGear driveRemote control

Owner:丁奇锴

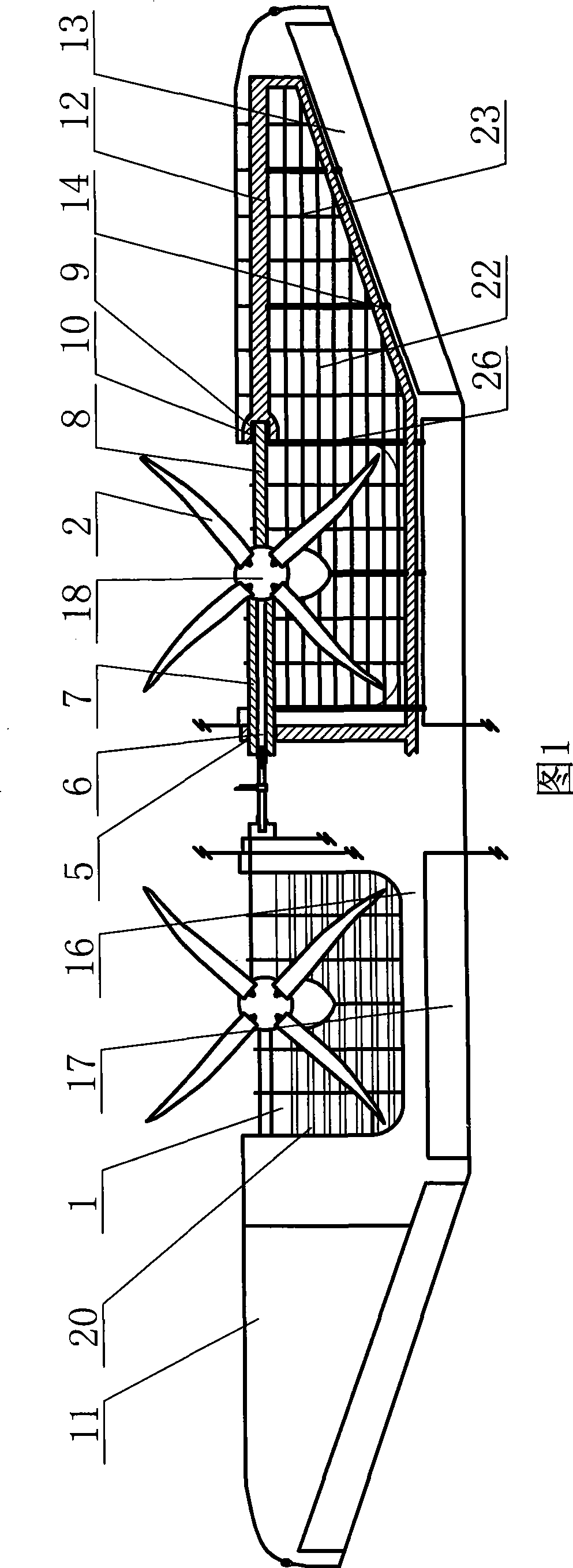

Split type wing

InactiveCN101274666AStrong bearing structureEnsure lateral stabilityVertical landing/take-off aircraftsRotocraftLevel flightAirframe

The invention discloses a cracking combined type wing which comprises a wing body which is connected with the main force-bearing frame of an airframe. The main force-bearing frame of the airframe is moveably provided with the rotatable section of a main wing beam and the two ends of the rotatable section of the main wing beam are connected with the unrotatable section of the main wing beam. The left and right sections of the rotatable section of the main wing beam are respectively provided with a cracking combined aerofoil which is provided with a set of rotating power devices at the front part. The cracking combined type aerofoil is positioned in a cracking communicating space of the wing body while the shape of the space is the same as that of the aerofoil. The left side and the right side of the wing body are fixedly connected with an external wing with a large span. The cracking combined type wing can minimize unbalanced moments caused during the vertical take-off and landing of an aircraft and resistance against the wind of the wing during the transition flight, meanwhile, the whole wing, more particularly the external wing with large span, remains stationary horizontally all the time, thus ensuring the stability of the aircraft during the vertical take-off and landing as well as smooth transition to the level flight so as to meet the user requirements.

Owner:穆骞

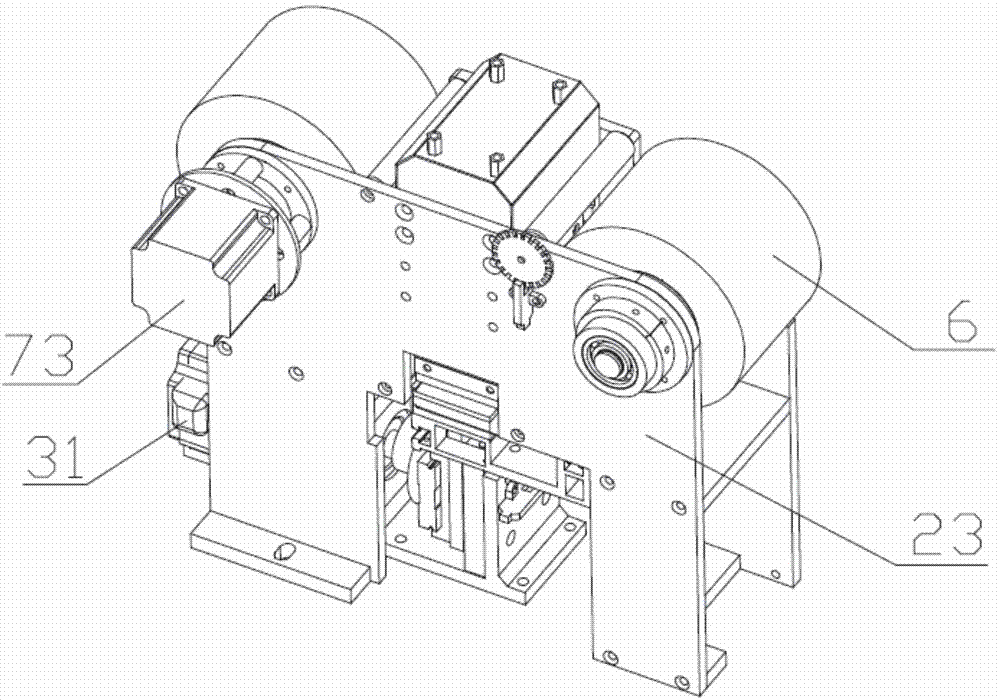

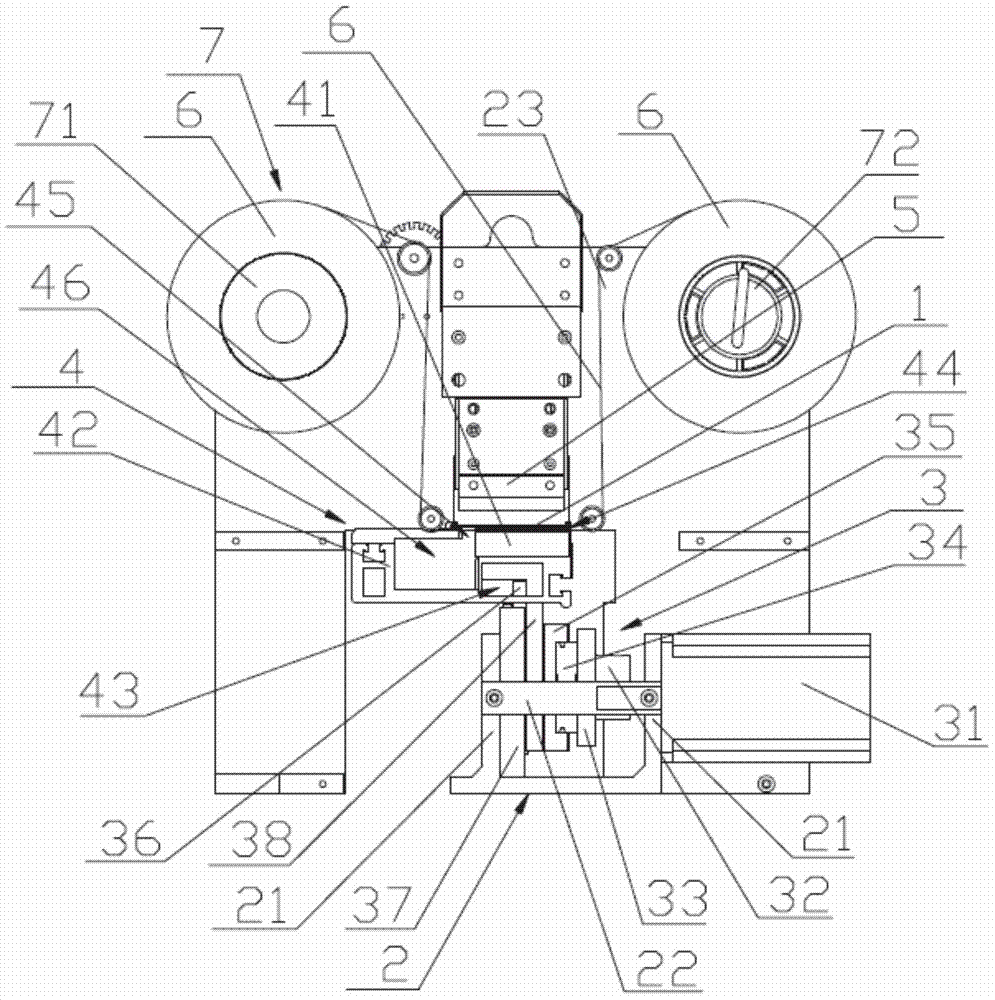

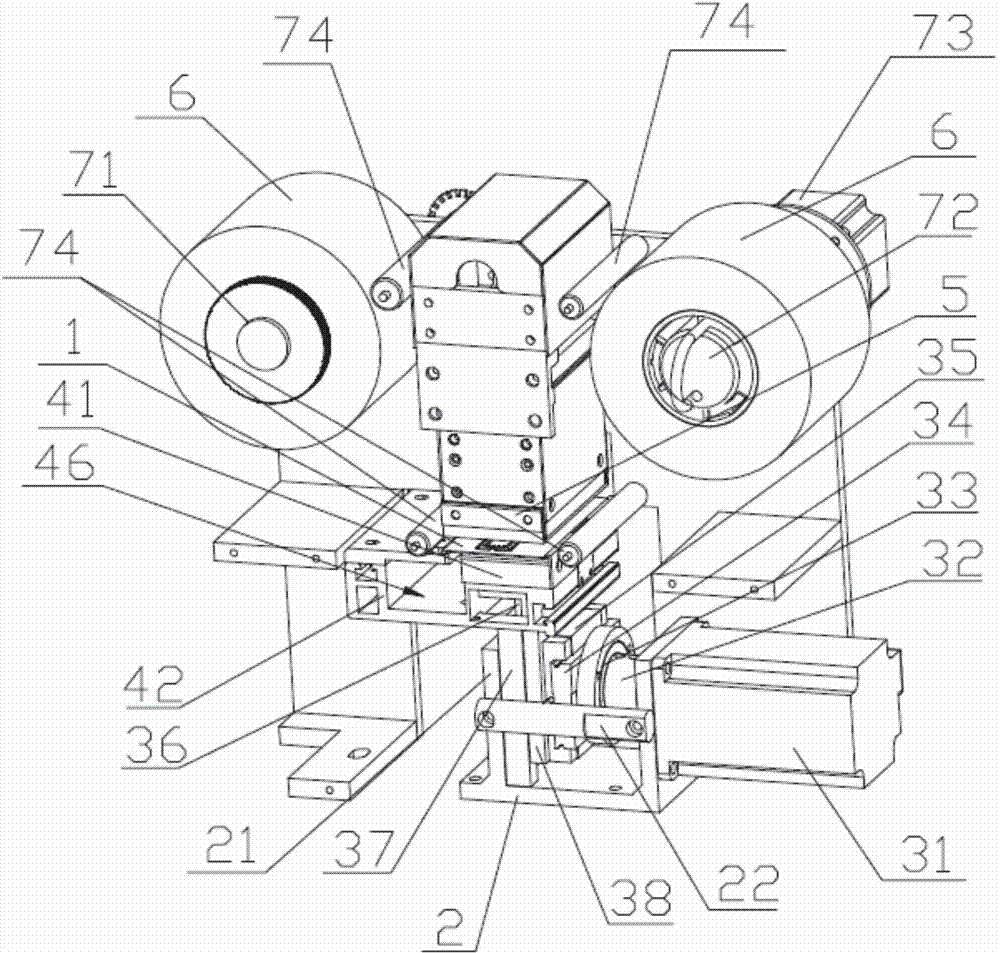

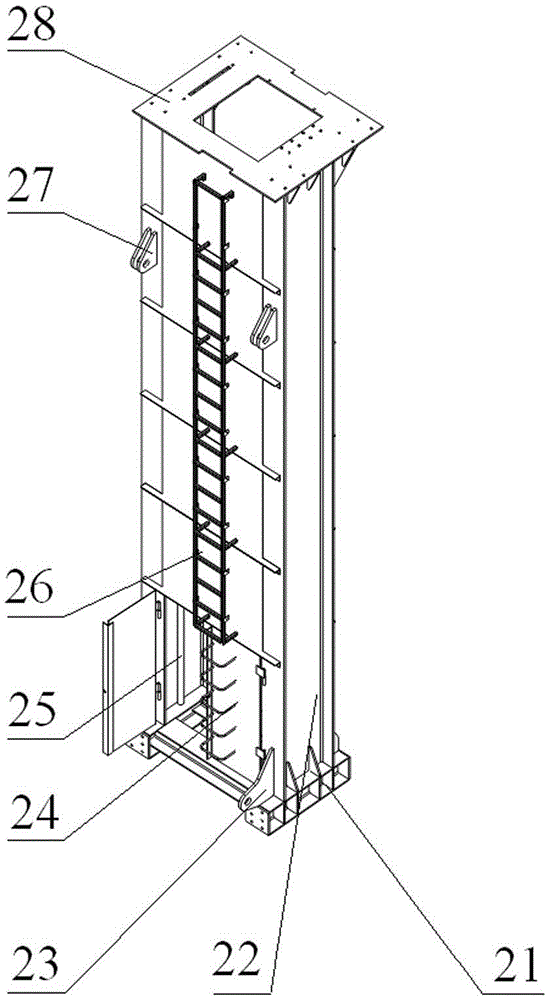

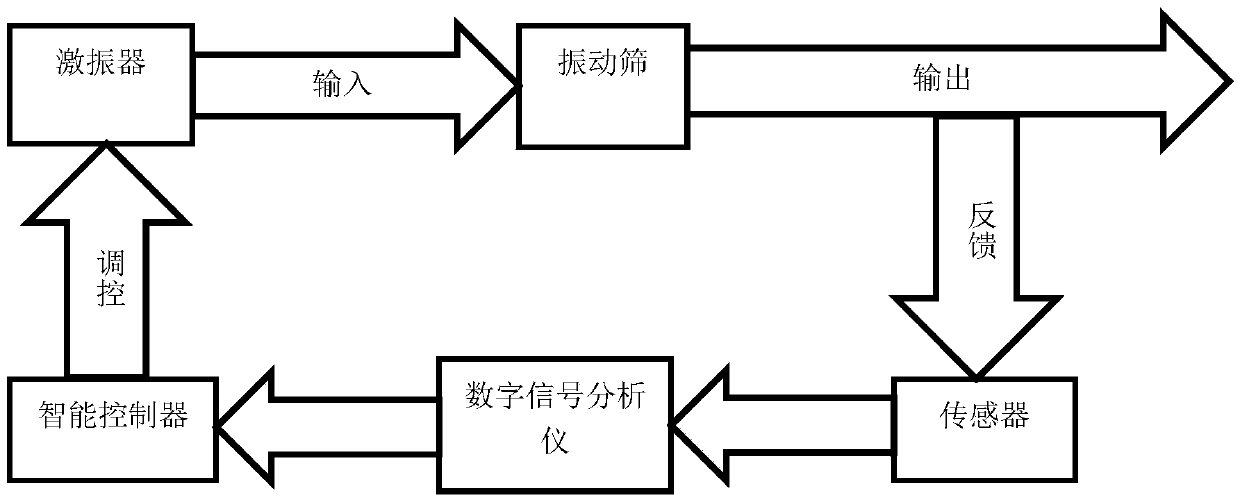

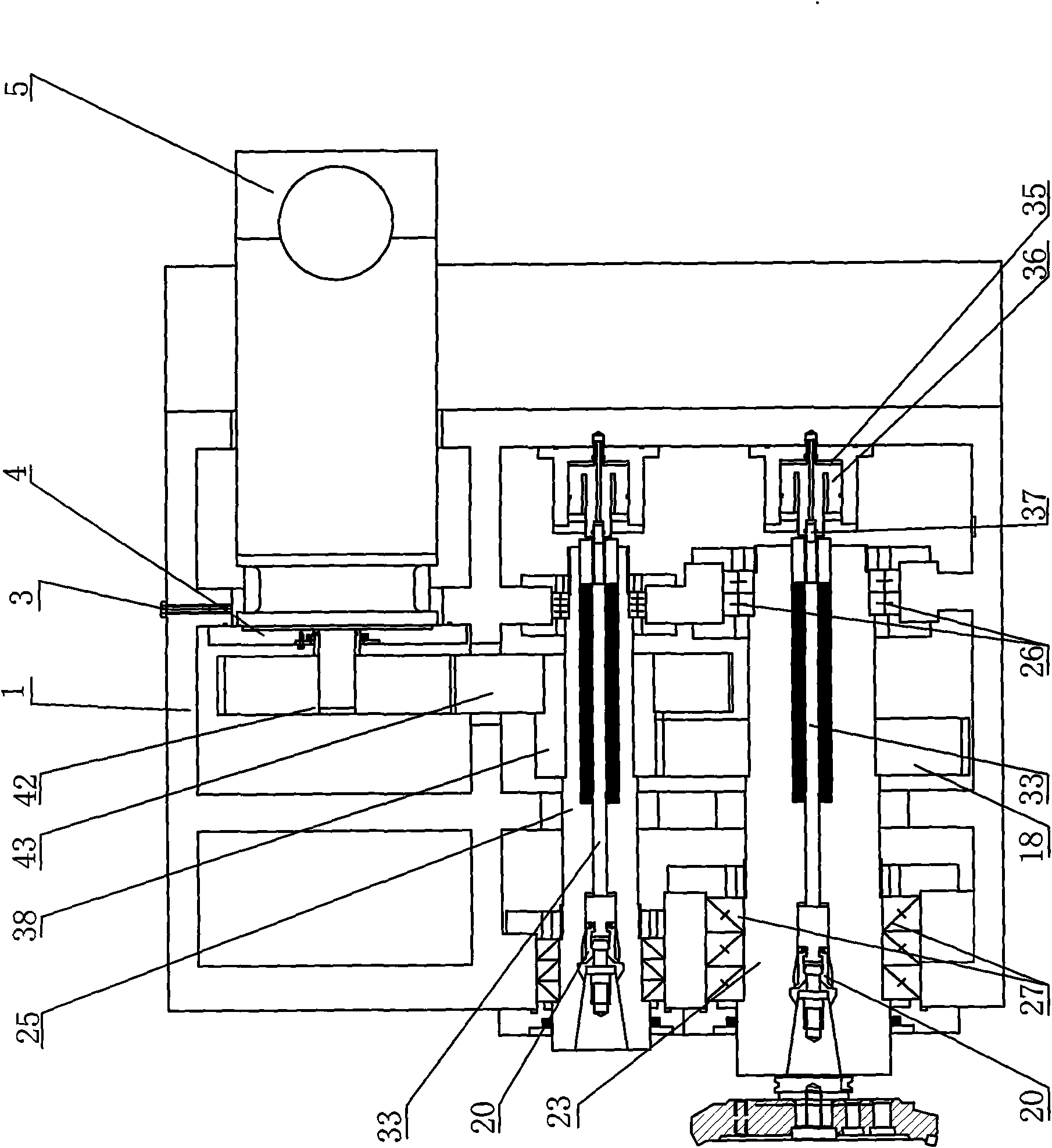

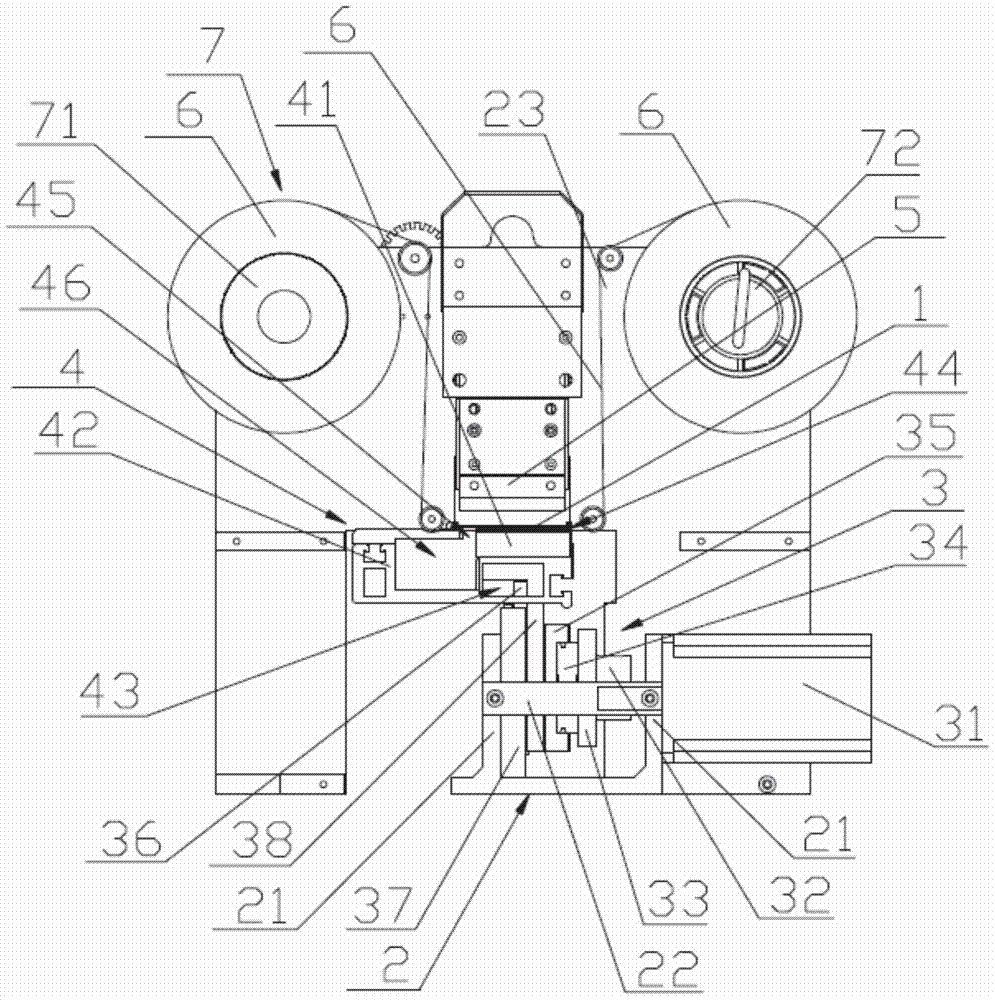

Intelligent card hot stamping device

The invention discloses an intelligent card hot stamping device. The intelligent card hot stamping device comprises a frame, as well as a hot stamping strip conveying mechanism, a hot stamping head, a card positioning seat and a hot stamping feeding mechanism which are arranged on the frame, wherein the hot stamping head is arranged below the card positioning seat, and a hot stamping strip in the hot stamping strip conveying mechanism passes through a position between the hot stamping head and the card positioning seat; the hot stamping feeding mechanism is connected to the card positioning seat and positioned below the card positioning seat, the hot stamping feeding mechanism comprises a card positioning seat driving mechanism for driving the card positioning seat to move up and down in a reciprocating manner, and the card positioning seat driving mechanism comprises a motor and a transmission mechanism for connecting the motor and the card positioning seat; the hot stamping strip conveying mechanism comprises a hot stamping strip, a wheel for winding the non-used hot stamping strip, the wheel for winding the used hot stamping strip and the motor, and the motor is connected to the wheel for winding the used hot stamping strip. The hot stamping device disclosed by the invention has the advantages of compact structure, simple transmission structure, high hot stamping precision, good stability in working and the like.

Owner:GUANGZHOU MINGSEN TECH CO LTD

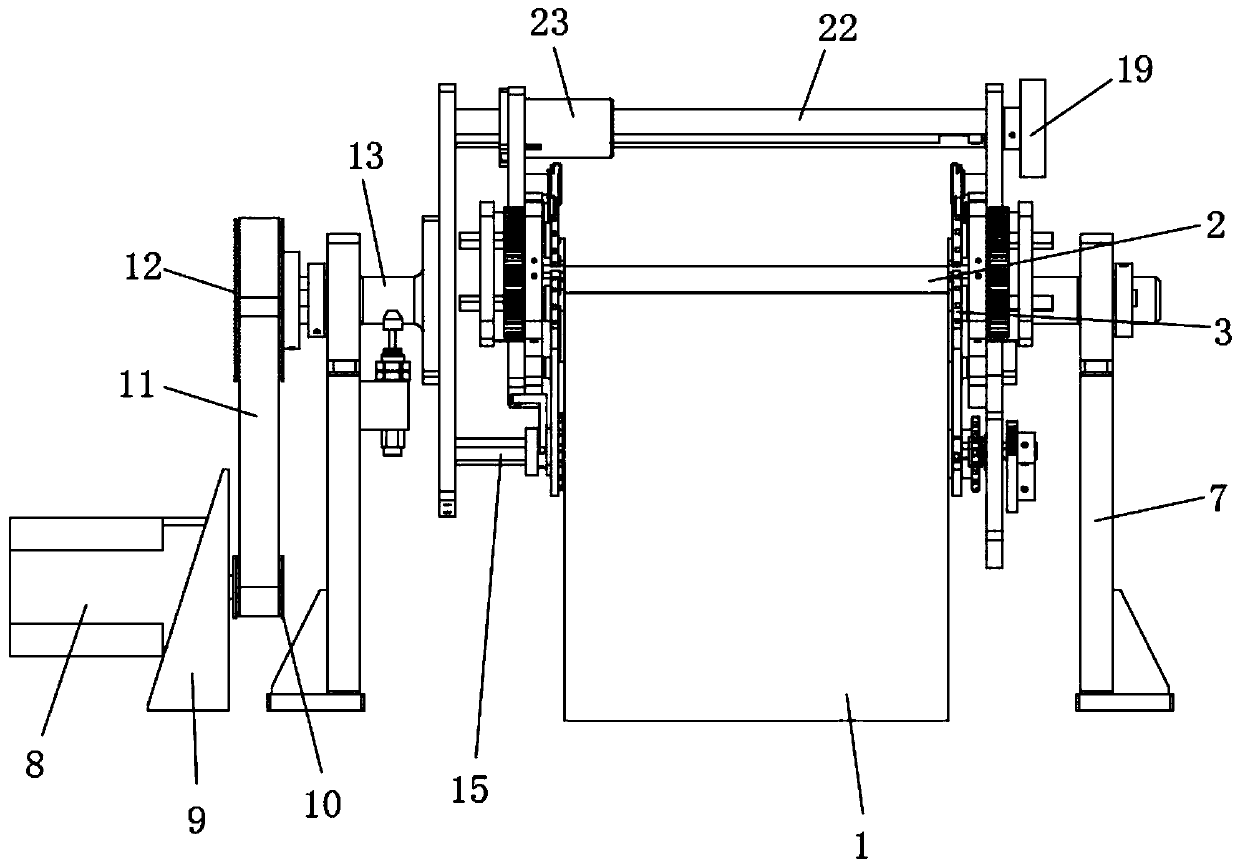

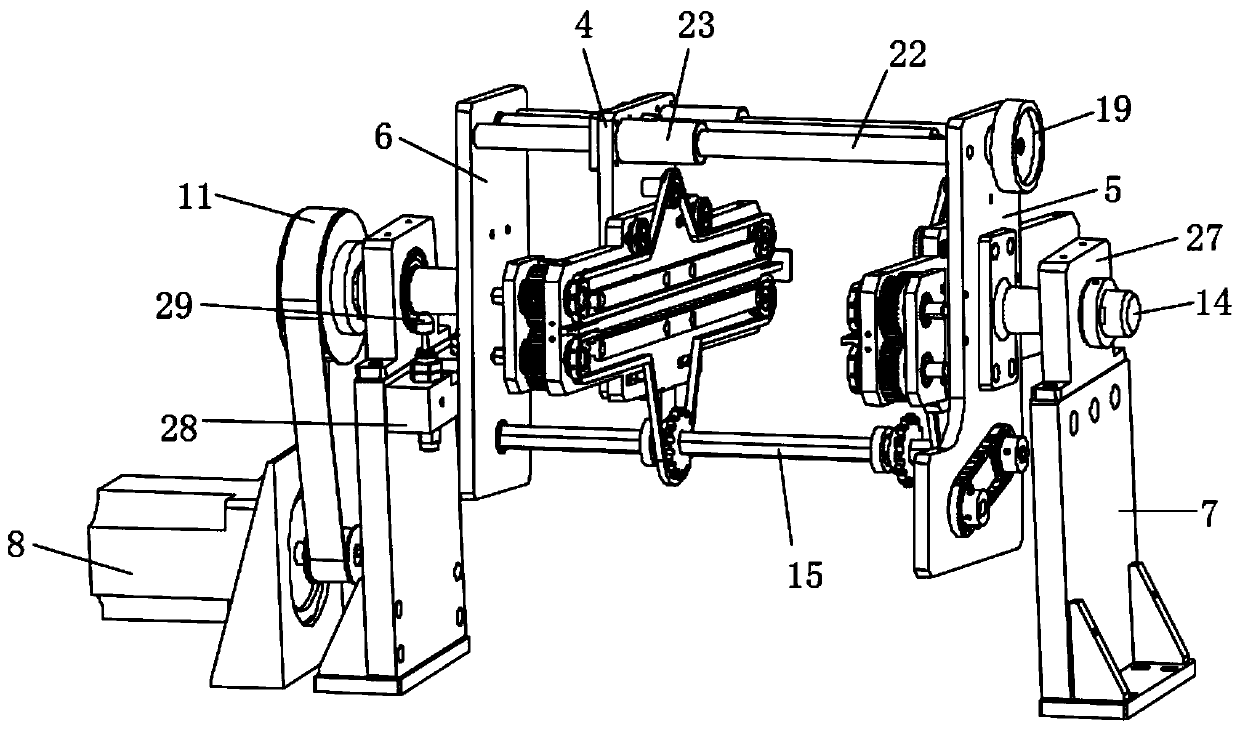

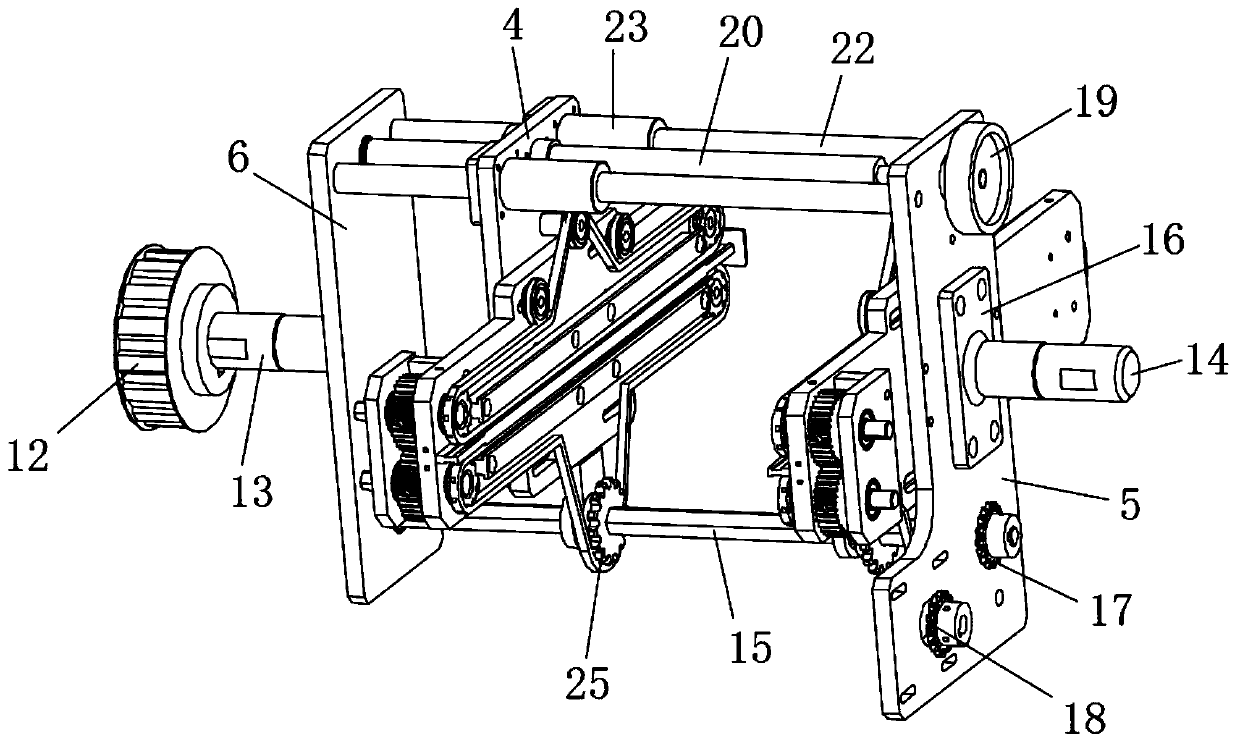

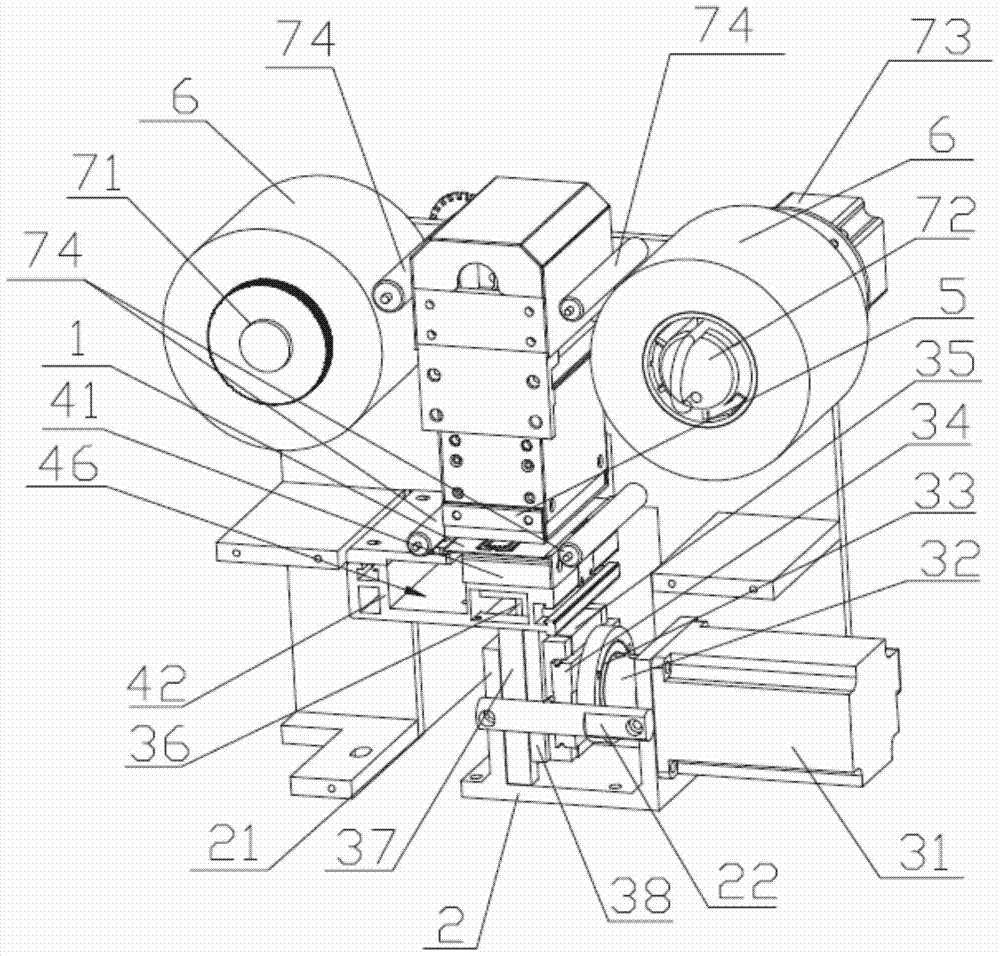

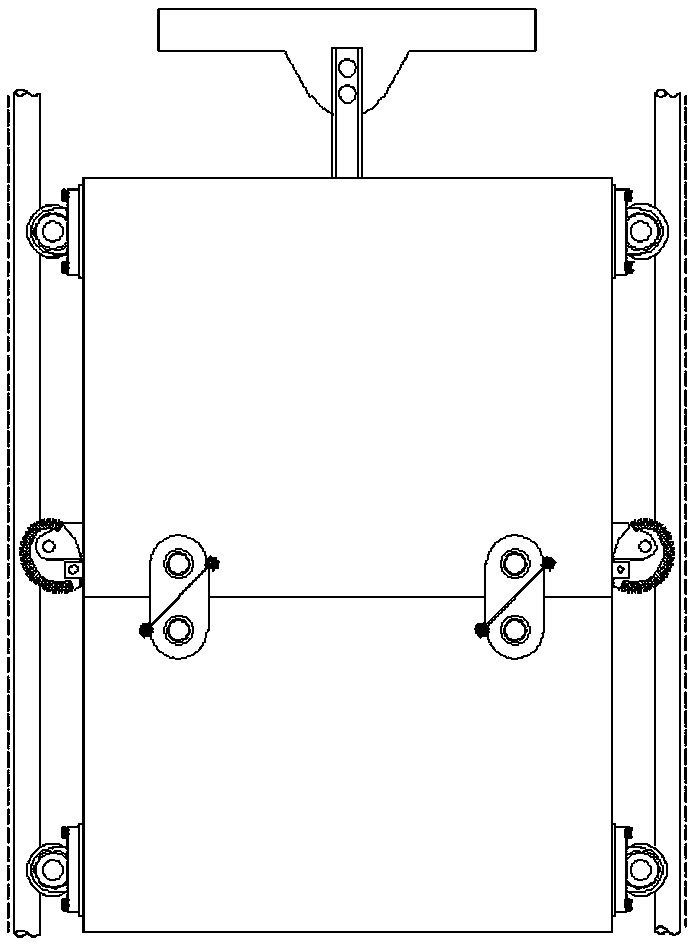

Two-axis manipulator for press line and working process of two-axis manipulator

InactiveCN102950590AIncrease stiffnessShort drive pathProgramme-controlled manipulatorMetal-working feeding devicesProduction lineControl system

The invention relates to a two-axis manipulator for a press line and a working process of the two-axis manipulator. The manipulator comprises a rack, a Y-axis transmission mechanism, an X-axis transmission mechanism, toolings and a control system, wherein a Y-axis servo motor is fixedly arranged above the rack and connected with a ball screw through a shaft coupling; a ball nut is fixedly arranged on a sliding platform; two sides of the sliding platform are respectively provided with a Y-axis guiding device; an X-axis servo motor is arranged in the middle part of a fixed bracket; two sides of the inner wall of the fixed bracket are respectively provided with a guiding device; cross rods can be horizontally and movably arranged in the guiding devices; and the toolings are respectively arranged below two ends of the cross rods. The manipulator is short in transmission path and high in transmission rigidity; the two cross rod structures are respectively suitable for different working conditions of high speed and low load as well as low speed and heavy load; and as a buffering stand structure is arranged, the two toolings can operate simultaneously, and the working efficiency is high.

Owner:江苏省(扬州)数控机床研究院 +1

Boring-milling machine

InactiveCN101658947AStable output powerReduce complexityTurning machine accessoriesMilling cuttersDrive shaftEngineering

The invention discloses a boring-milling machine, comprising a spindle box, a boring shaft, a milling shaft and a servo motor. The power of the servo motor is transmitted to the boring shaft and the milling shaft by a main transmission system. The boring shaft is a middle transmission shaft between the milling shaft and the servo motor. The boring-milling machine can lower the cost, simplify the transmission system, ensure low damage possibility of the transmission system, prolong the service life of the machine tool, simultaneously optimize the motor power and save the energy.

Owner:简东灿

Turnover positioning device for spraying heat preservation material for building and working method thereof

Owner:马鞍山市金韩防水保温工程股份有限公司

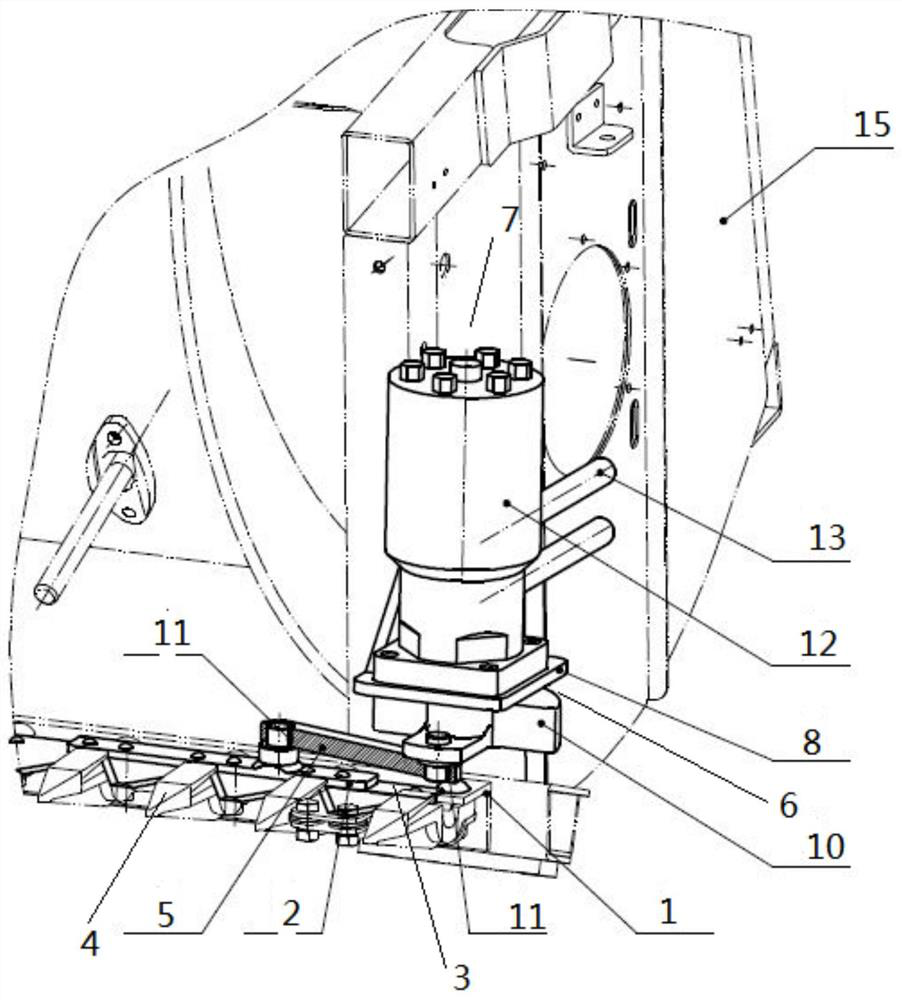

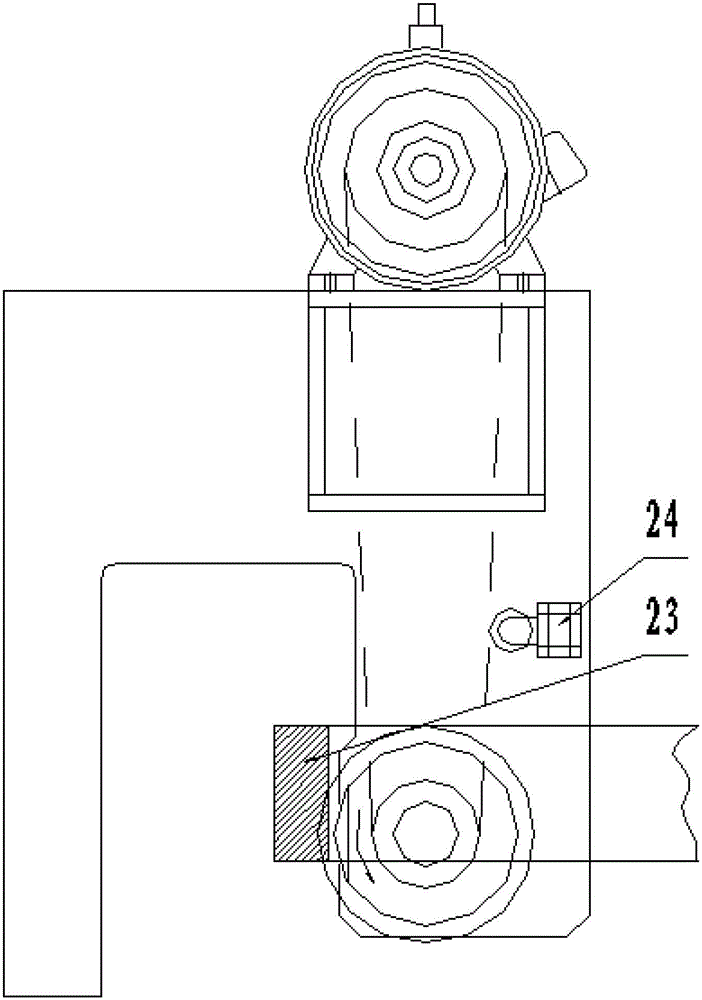

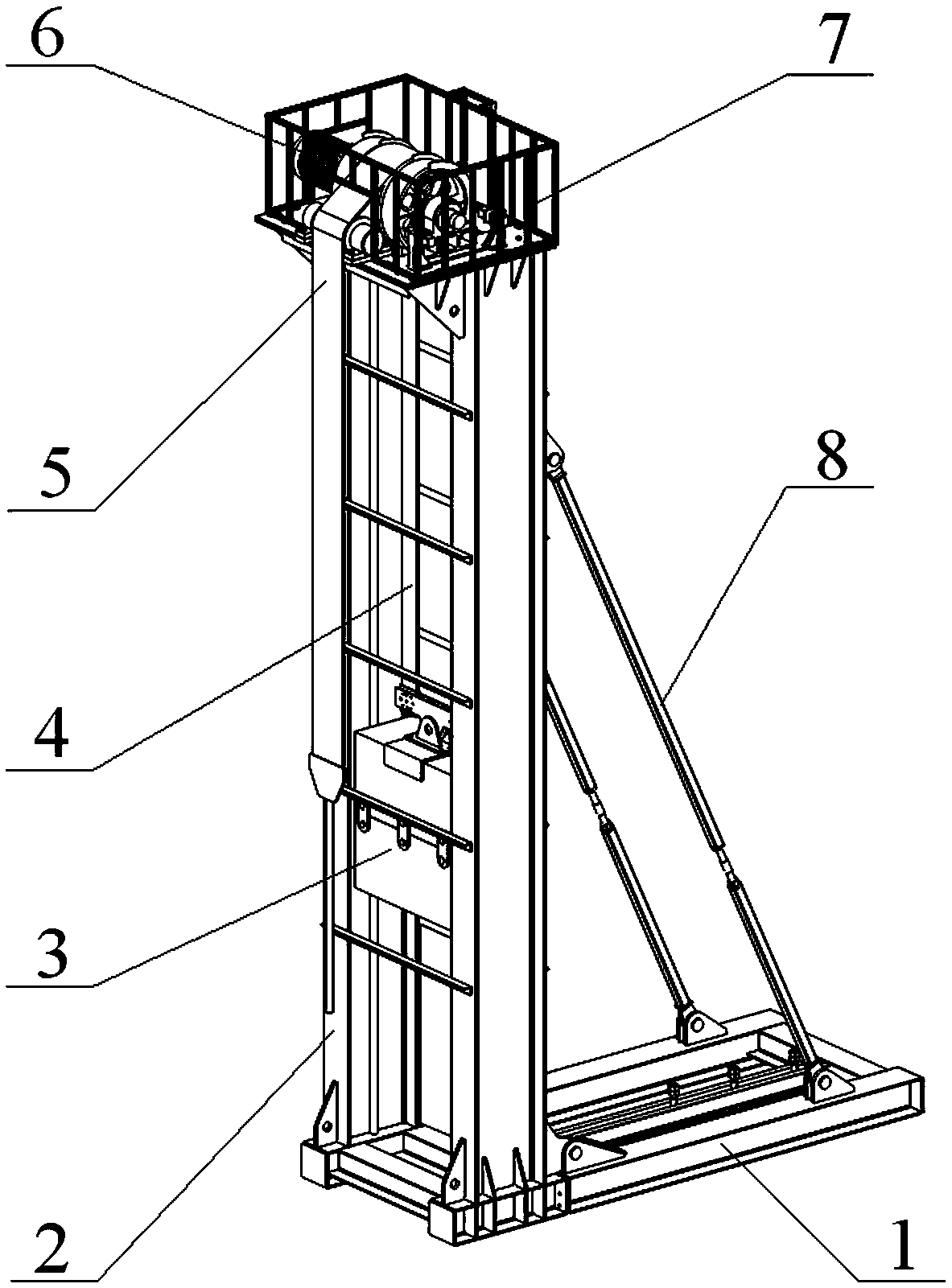

Long-stroke direct-drive pumping unit with dual-brake and balance weight fall prevention functions

ActiveCN105275434AImprove effectivenessImprove work efficiencyFluid removalReduction driveElectric machinery

The invention discloses a long-stroke direct-drive pumping unit with dual-brake and weight fall prevention functions. A motor of a power unit drives a built-in reducer installed in a drum to make the drum rotate forwardly and reversely. The pumping unit can be either braked by the motor or an electric hydraulic brake. A wellhead belt fixedly wound on the drum bypasses a guide drum capable of moving forward and backward to be connected with a wellhead polished rod. A weight belt fixedly wound on the drum in the opposite direction is connected with a fall prevention weight box in a rack. A wellhead polished rod load and a weight form scale balance. The pumping unit of the invention has the characteristics of being simple in form of transmission, safe and reliable, and the like.

Owner:山东高原油气装备有限公司

Coaxial type bending and twisting simultaneous transmission control surface transmission mechanism

InactiveCN111017196AImprove stealth performanceShort drive pathWith power amplificationNeedle roller bearingAirplane

The invention provides a design scheme of a coaxial type bending and twisting simultaneous transmission control surface transmission mechanism, and aims to solve inherent defects of a common pull rodrocker arm type control surface transmission mechanism for airplanes adopting airfoils with medium and above thicknesses. The mechanism is characterized by comprising a steering engine, a steering engine mounting rib, a needle bearing, a check ring, a coupler, a transmission spline, a control surface, a knuckle bearing, a rotating shaft pin, a control surface mounting rib and a machine body rear beam, wherein the steering engine is connected with the coupler, the needle bearing is arranged on the coupler, a check ring bearing is arranged on the outer side of the needle bearing, the check ringbearing is provided with the steering engine mounting rib, the steering engine mounting rib is connected with the transmission spline, one side of the transmission spline is the control surface, the control surface is provided with the rotating shaft pin, the rotating shaft pin is connected with the knuckle bearing, the knuckle bearing is connected with the control surface mounting rib, and the control surface mounting rib is connected with the machine body rear beam.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

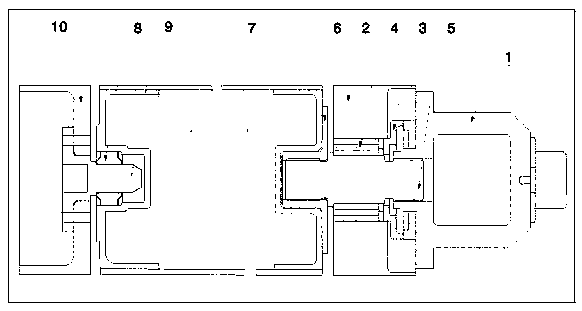

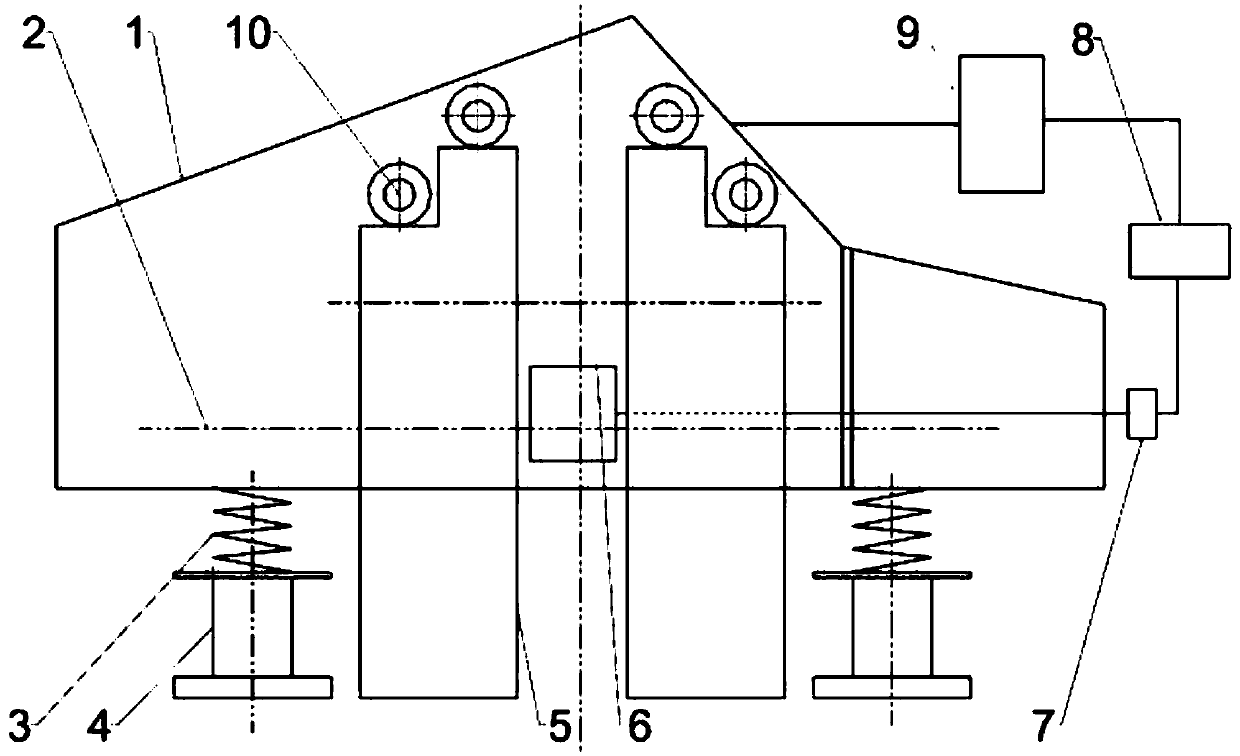

Intelligently controlled four-axis variable linear equal thickness vibrating screen and vibration method

InactiveCN109530216AAutomatically change the vibration situationAdjust the speed in timeSievingScreeningClosed loop feedbackFeedback control

The invention discloses an intelligently controlled four-axis variable linear equal thickness vibrating screen. The screen includes a screen box, a vibrating screen mesh, vibration damping springs, screen box supports, vibration exciters, a sensor, an integrated operational amplifier, a digital signal analyzer and an intelligent controller. The vibrating screen mesh is located at the bottom of thescreen box. The screen box is connected to the screen box supports through the vibration damping springs. Each vibration exciter consists of a variable frequency motor and a drive shaft with an eccentric block. Each driving shaft is connected to the corresponding variable frequency motor through a flexible coupling. The sensor is connected to the integrated operational amplifier through a data transmission line. The integrated operational amplifier is connected to the digital signal analyzer through a data transmission line. The digital signal analyzer is connected in series with the intelligent controller and the variable frequency motor to form a closed-loop feedback control system. A vibration exciting source of the four-axis variable linear equal thickness vibrating screen is directlyadjusted through the feedback control system, the vibration condition can be automatically adjusted without the adjustment of external vibration exciting force to make the four-axis variable linear equal thickness vibrating screen in an ideal working state to improve the screening efficiency.

Owner:CHINA UNIV OF MINING & TECH

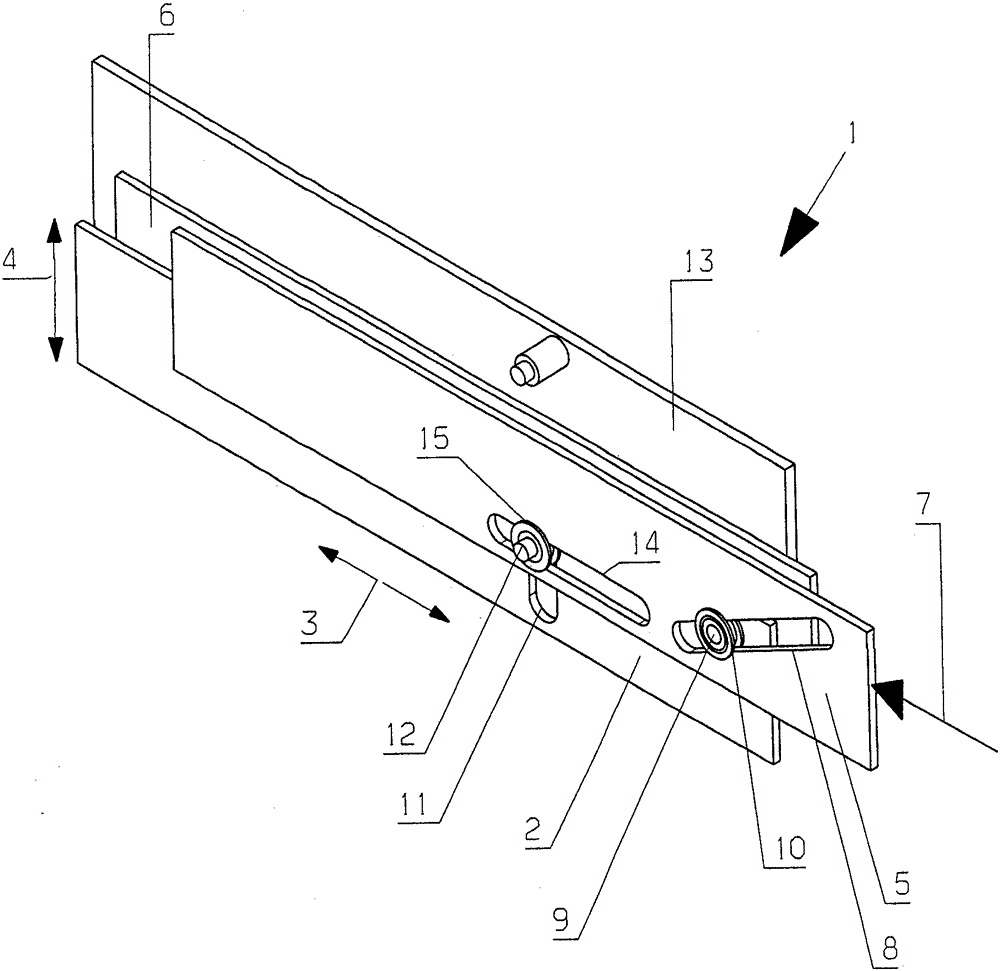

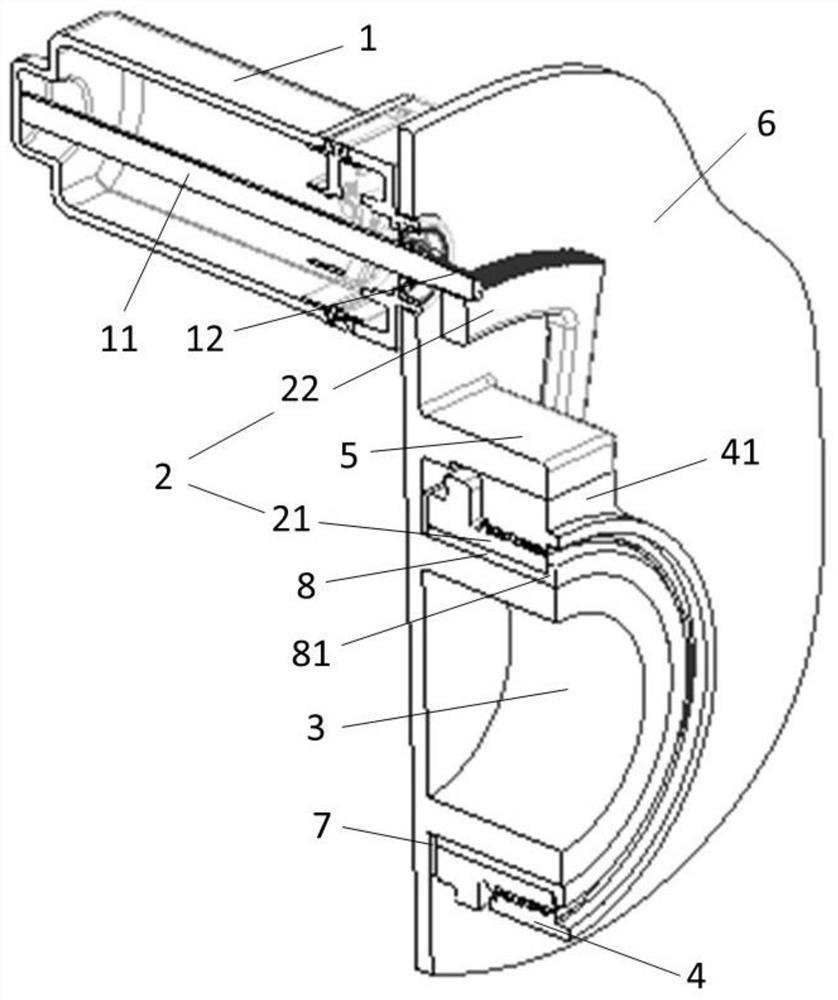

Fall plate assembly for warp knitting machine

ActiveCN103510271AExpanded Jacquard PossibilitiesWork fasterFlat warp knitting machinesEngineeringMechanical engineering

The invention relates to a fall plate assembly (1) for a warp knitting machine. The fall plate assembly (1) is provided with a fall plate (2) extending in parallel to a shifting direction (3); and a fall plate driver (7) driving the fall plate (2) in a moving direction (4) which is perpendicular to the shifting direction (3). The invention aims to make it possible that the fall plate can be driven without relatively large consumption and the working speed can be relatively high. Therefore, the fall plate driver (7) is configured to have a drive element (5) which can move in the shifting direction and act on the fall plate through steering assemblies (8-10).

Owner:KARL MAYER STOLL R&D GMBH

Cutting knife structure of harvester and harvester

InactiveCN112449841AShort drive pathThe overall structure is simple and reliableMowersReciprocating motionAgricultural engineering

The invention relates to a cutting knife structure of a harvester. The cutting knife structure comprises a cutting knife sliding groove frame provided with a sliding groove, a sliding block matched with the sliding groove, a cutting knife arranged on the sliding block, a connecting rod with one end connected with the sliding block, an eccentric counterweight assembly connected with the other end of the connecting rod and a driving device for driving the eccentric counterweight assembly to swing, so that the eccentric counterweight assembly drives the sliding block to do reciprocating motion inthe sliding groove, and the cutting knife cuts off crop stalks. The invention provides the harvester applying the cutting knife structure. According to cutting knife structure of the harvester and the harvester, stable cutting can be effectively achieved, the impact load of the cutting knife in the cutting process is reduced, meanwhile, the power transmission mode is changed, the transmission path is compressed, and the stability and reliability of power transmission are effectively guaranteed.

Owner:HUNAN NONGGUANG AGRI EQUIP CO LTD

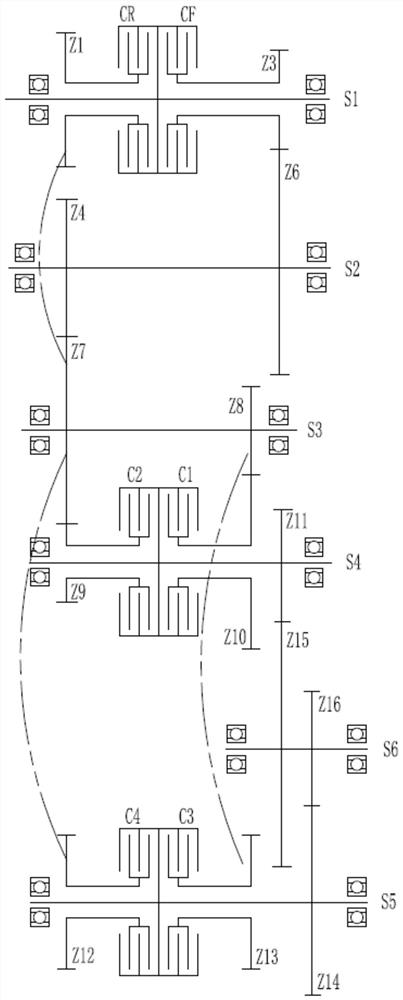

Modular design gearbox and gear implementation method

ActiveCN111609096AReduce manufacturing costReduce use costAgricultural vehiclesToothed gearingsDrive shaftGear wheel

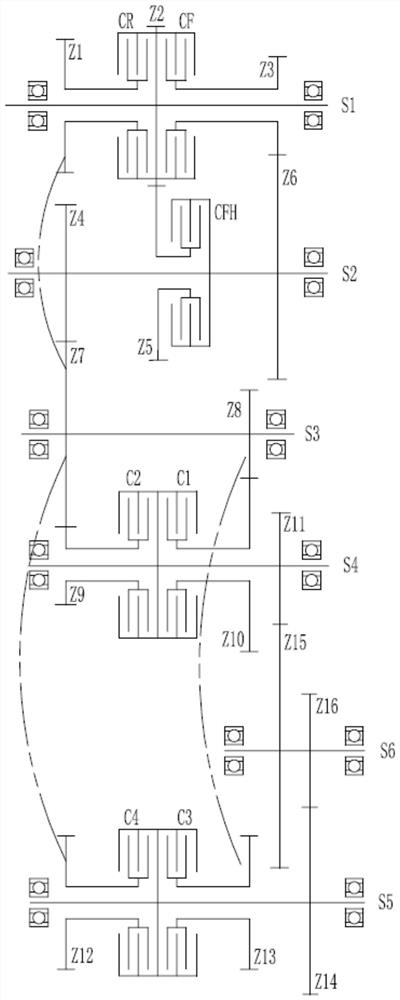

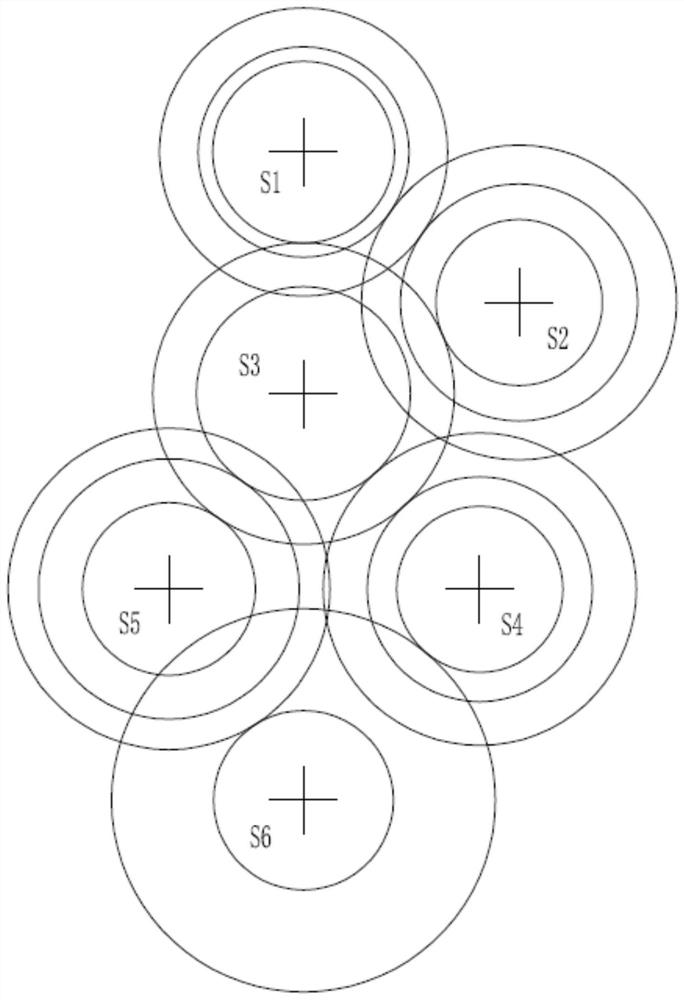

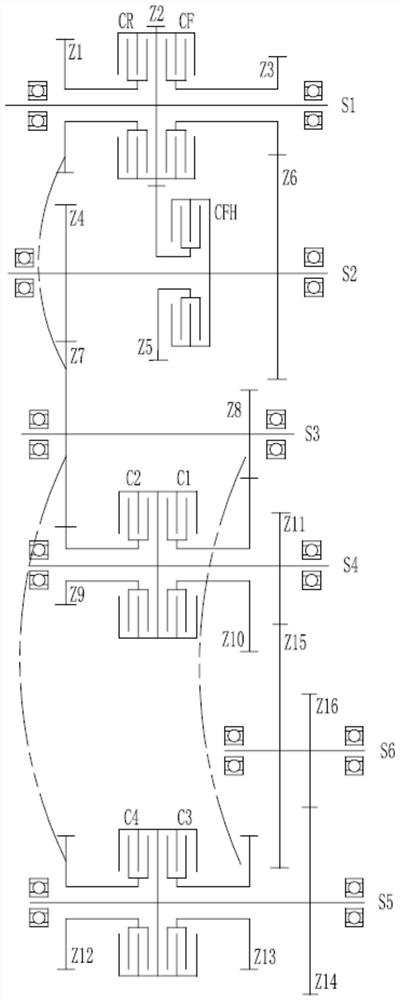

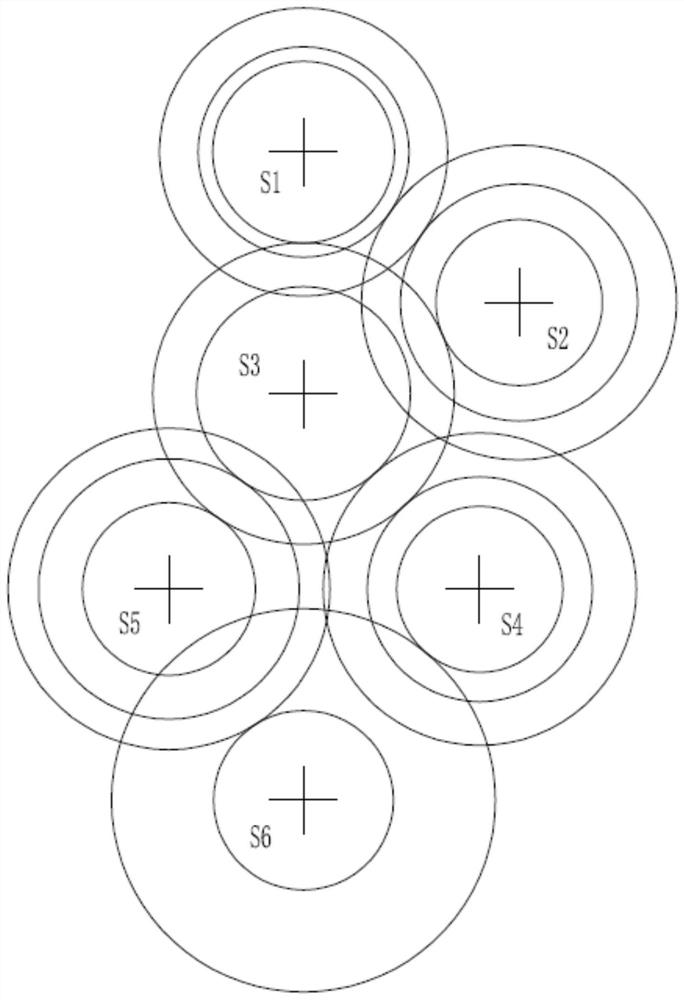

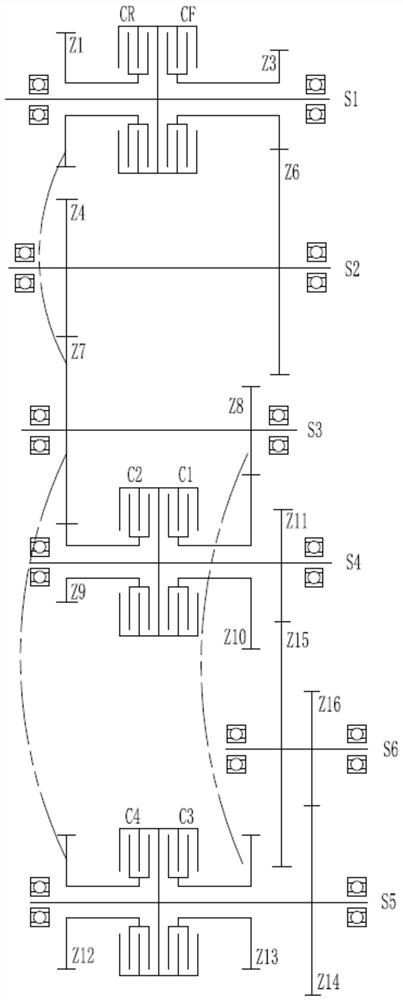

The invention relates to a modular design gearbox and a gear implementation method. The gearbox comprises a box body, a driving shaft, four middle shafts and an output shaft. The gearbox is of a six-shaft layout. The driving shaft S1, the middle shaft S4 and the middle shaft S5 are each provided with two clutch bags, and the middle shaft S2 is provided with one clutch bag. By means of the structure, the transmission path is short, and stability is better. By means of the six shafts and the seven clutches, the gearbox can achieve the mode of up to 8 forwarding gears and 4 backward gears, the speed ratio range is wide, and the gearbox can be adjusted flexibly, the less-gear mode can be achieved by reducing part of components, modularization is achieved, universality is improved, and the production cost and using cost of the gearbox are reduced. Meanwhile, the forwarding gear is achieved by combining two clutches and conducting gear engagement four times, the backward gear is achieved bycombining two clutches and conducting gear engagement three times, the transmission path is short, and reliability is high.

Owner:JIANGSU ADVANCED CONSTR MASCH INNOVATION CENT LTD +1

Milling machine

ActiveCN101658950AStable output powerReduce complexityMilling cuttersMilling machinesDrive shaftAgricultural engineering

The invention discloses a milling machine, comprising a spindle box, a first milling shaft, a second milling shaft and a servo motor. The power of the servo motor is transmitted to the first milling shaft and the second milling shaft by a main transmission system. The first milling shaft is a middle transmission shaft between the second milling shaft and the servo motor. The milling machine can lower the cost, simplify the transmission system, ensure low damage possibility of the transmission system, prolong the service life of the machine tool, simultaneously optimize the motor power and savethe energy.

Owner:东莞市鑫国丰机械有限公司

Louver type cracking composite wing

InactiveCN101380997AImprove lifting efficiencyStrong bending resistanceSpars/stringersLouverVertical take off and landing

The invention discloses a shutter-typed cracking composite wing, comprising a wing mainbody which is internally provided with a main wing beam and a rear wing beam; the main wing beam consists of an inclinable section and a non-inclinable section which are connected with each other; the wing mainbody is connected with an aircraft main bearing frame; the left side and the right side of the wing mainbody are respectively provided with two through spaces; the inclinable section of the main wing beam is provided with two groups of inclined power devices; each through space is respectively provided with a group of shutter-typed cracking composite envelope which consists of an upper shutter-typed cracking composite envelope and a lower shutter-typed cracking composite envelope; the upper shutter-typed cracking composite envelope and the lower shutter-typed cracking composite envelope are respectively connected with the wing mainbody. The wing leads the unbalanced moment during the vertical lifting of the aircraft and the wind-facing resistance during the transitional flying of the aircraft to be reduced to the minimum; meanwhile, the whole wing, especially for the external wing of the large wing keeps horizontal and still fixedly all the time, thus ensuring the stability during the vertical lifting of the aircraft and successful transition to the flat flying state.

Owner:穆骞

Yarn plate assembly of warp knitting machine

ActiveCN103510271BExpanded Jacquard PossibilitiesWork fasterFlat warp knitting machinesEngineeringDriven element

Owner:KARL MAYER STOLL R&D GMBH

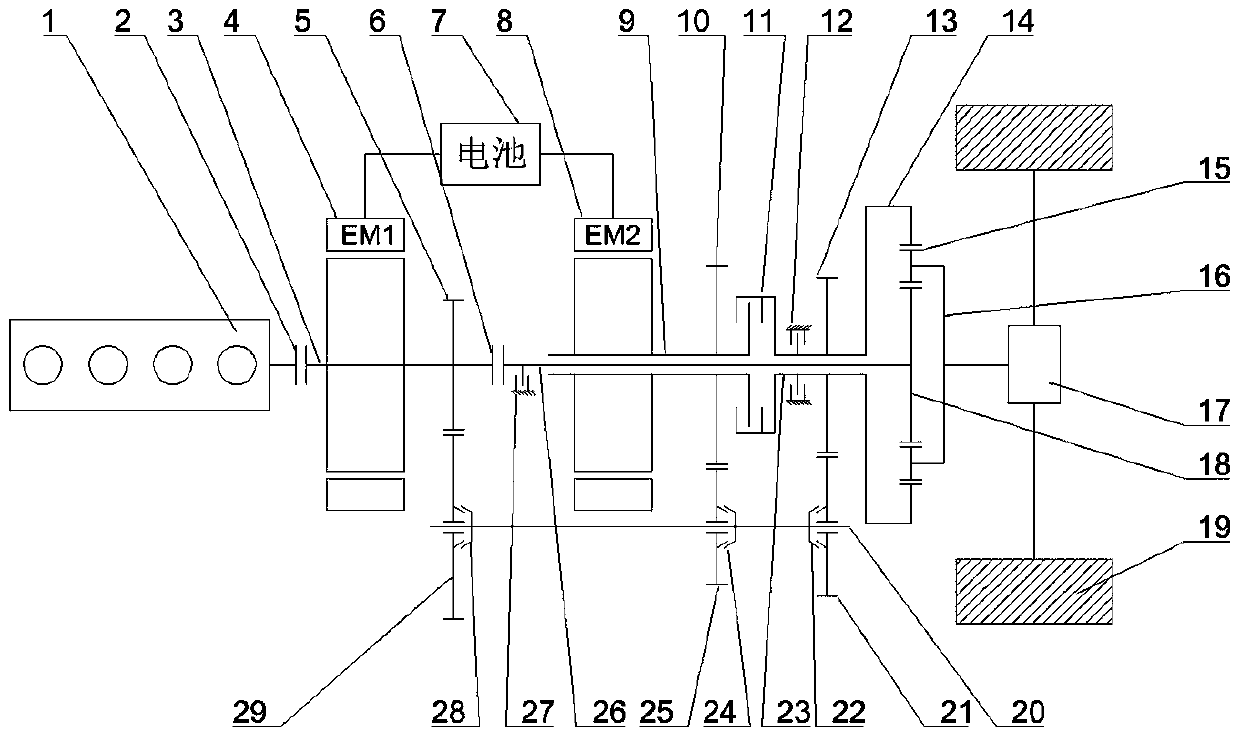

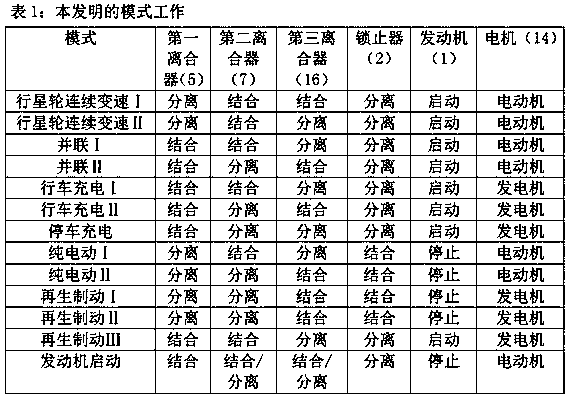

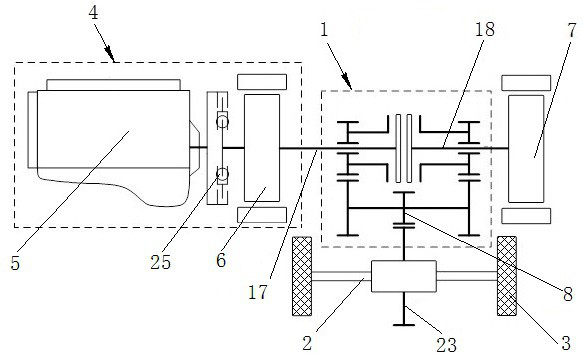

A Multi-mode Hybrid Coupling Drive System

ActiveCN109849642BOptimize layoutRealize functionGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingCouplingElectric machinery

The invention relates to a multi-mode hybrid power coupling driving system, comprising an engine, a first motor, a second motor, a differential and a transmission mechanism; the transmission mechanismcomprises a double clutch transmission mechanism and a single row planetary gear mechanism; the dual clutch transmission mechanism comprises an engine power input shaft, an input tube shaft, an engine power output shaft, an output tube shaft and an intermediate shaft; the input tube shaft and the output tube shaft are sequentially loosely sleeved on the engine power output shaft, and the output end of the input tube shaft and the input end of the output tube shaft are connected through a third clutch; the single row planetary gear mechanism comprises a sun gear, two or more planetary gears, aring gear and a planetary carrier. The multi-mode hybrid power coupling driving system realizes ten working modes, that is, seven modes of transmission output, one mode of braking, one mode of reverse gear and one mode of idle charging, and can realize three gear positions matched with the driving of the engine and the first motor, and three gear positions matched with the driving of the second motor separately. The multi-mode hybrid power coupling driving system has the advantages of simple and compact structure and low cost.

Owner:HEFEI UNIV OF TECH

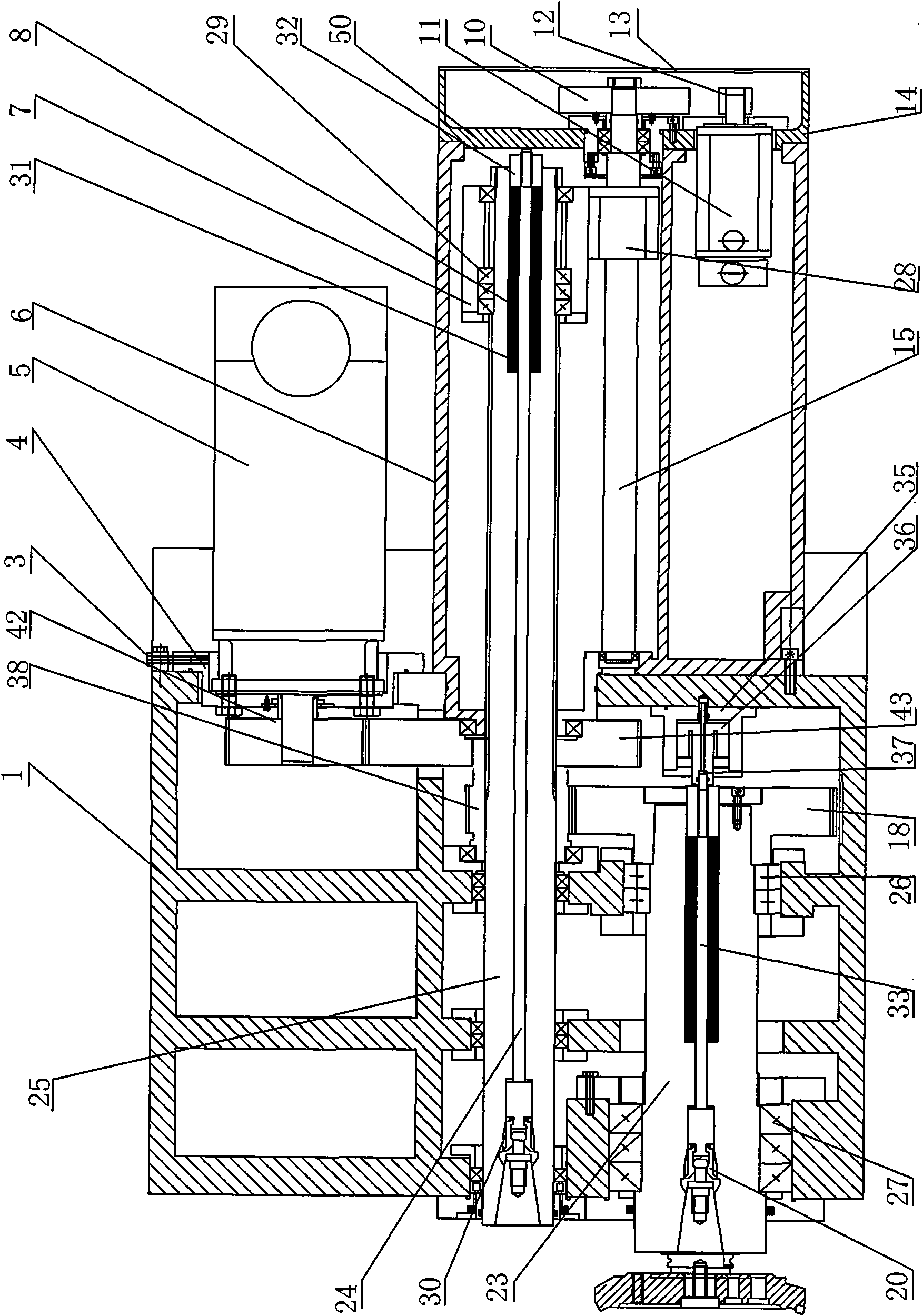

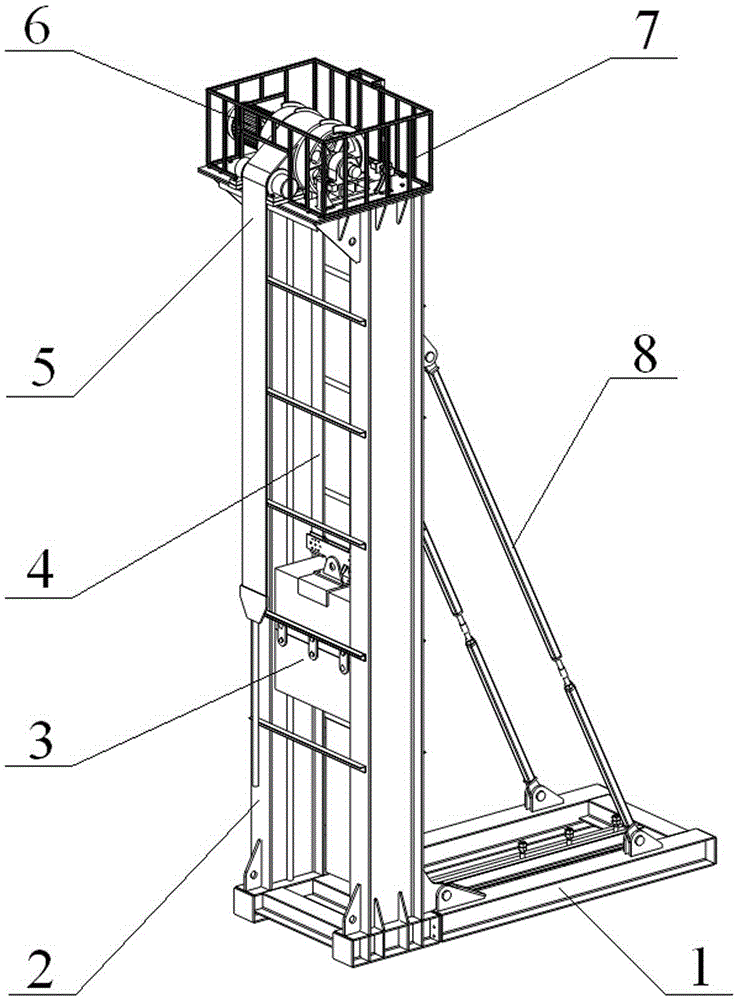

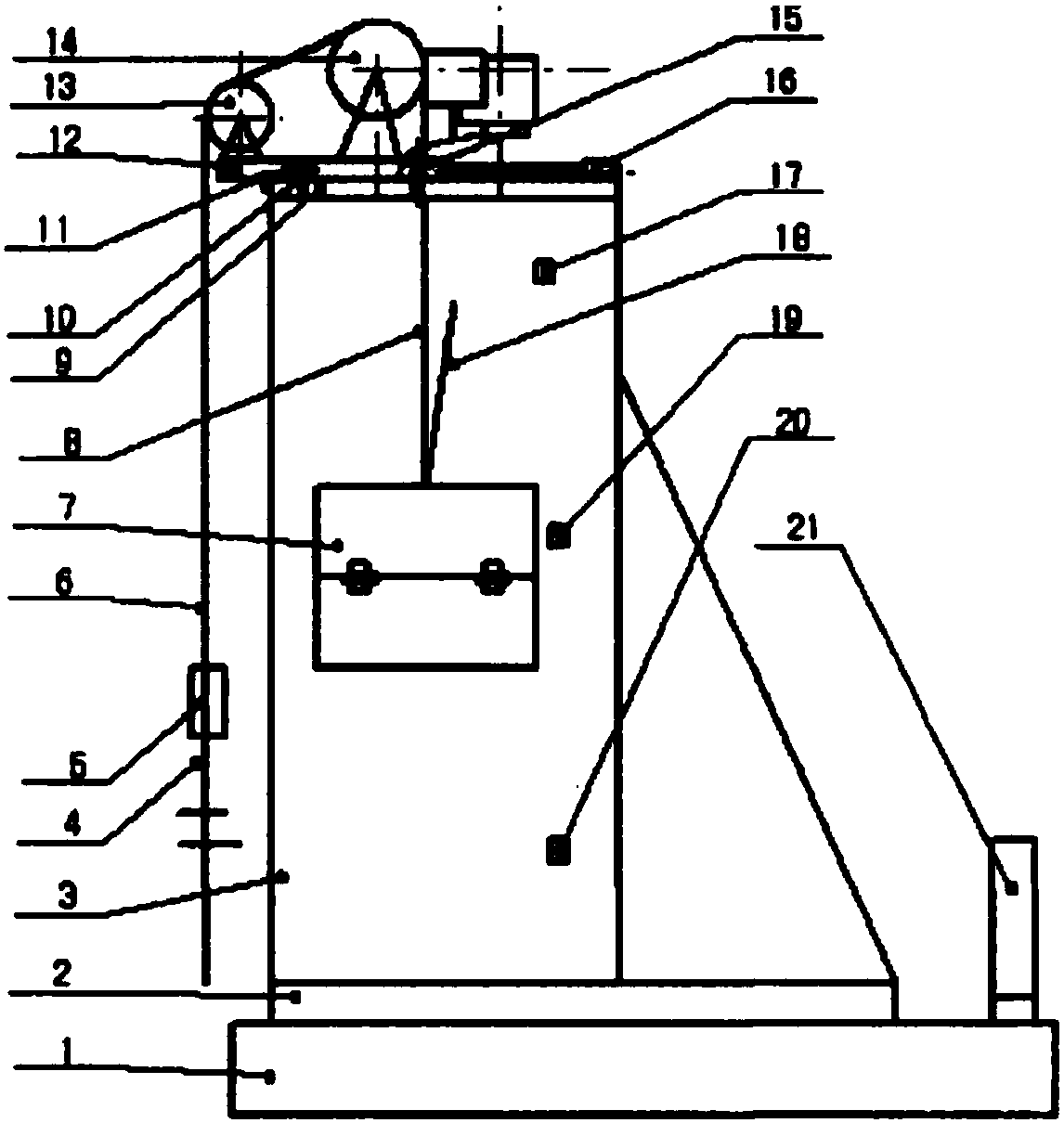

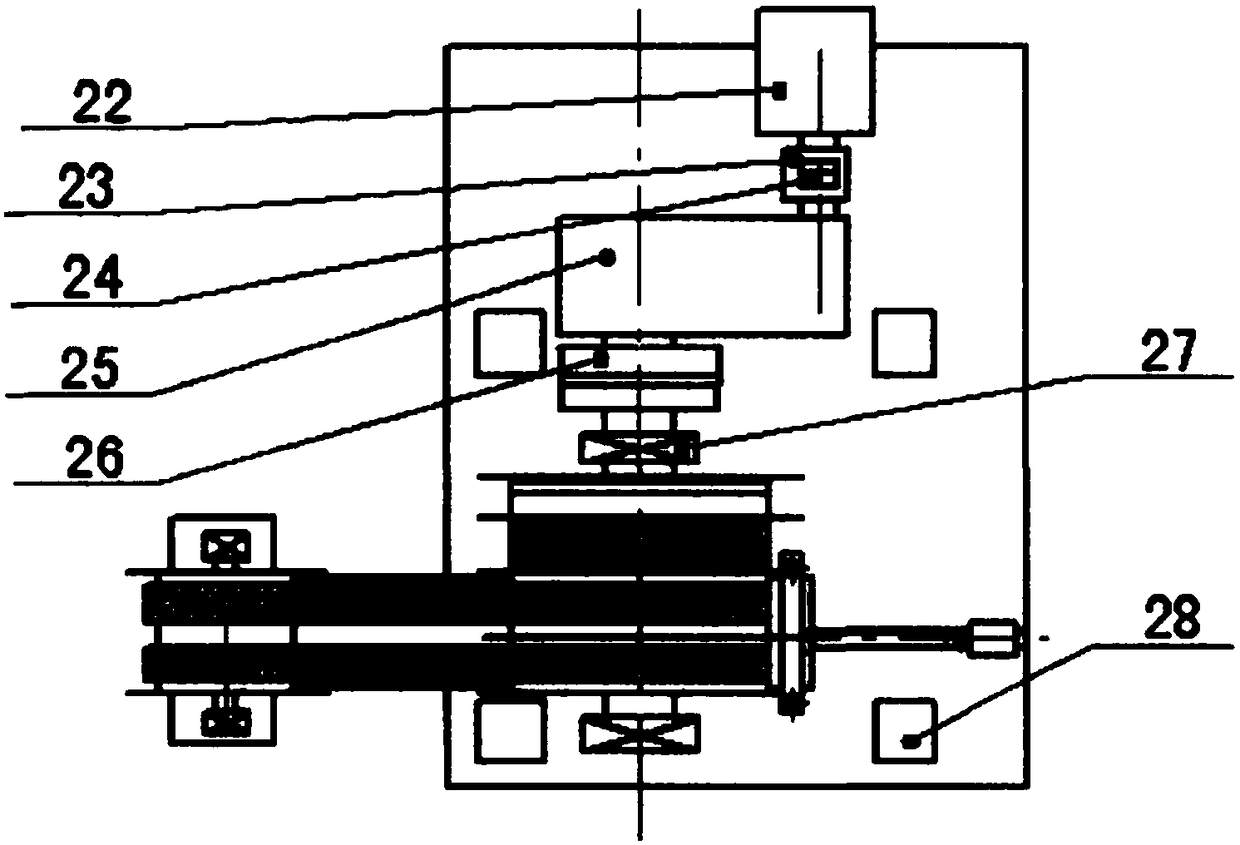

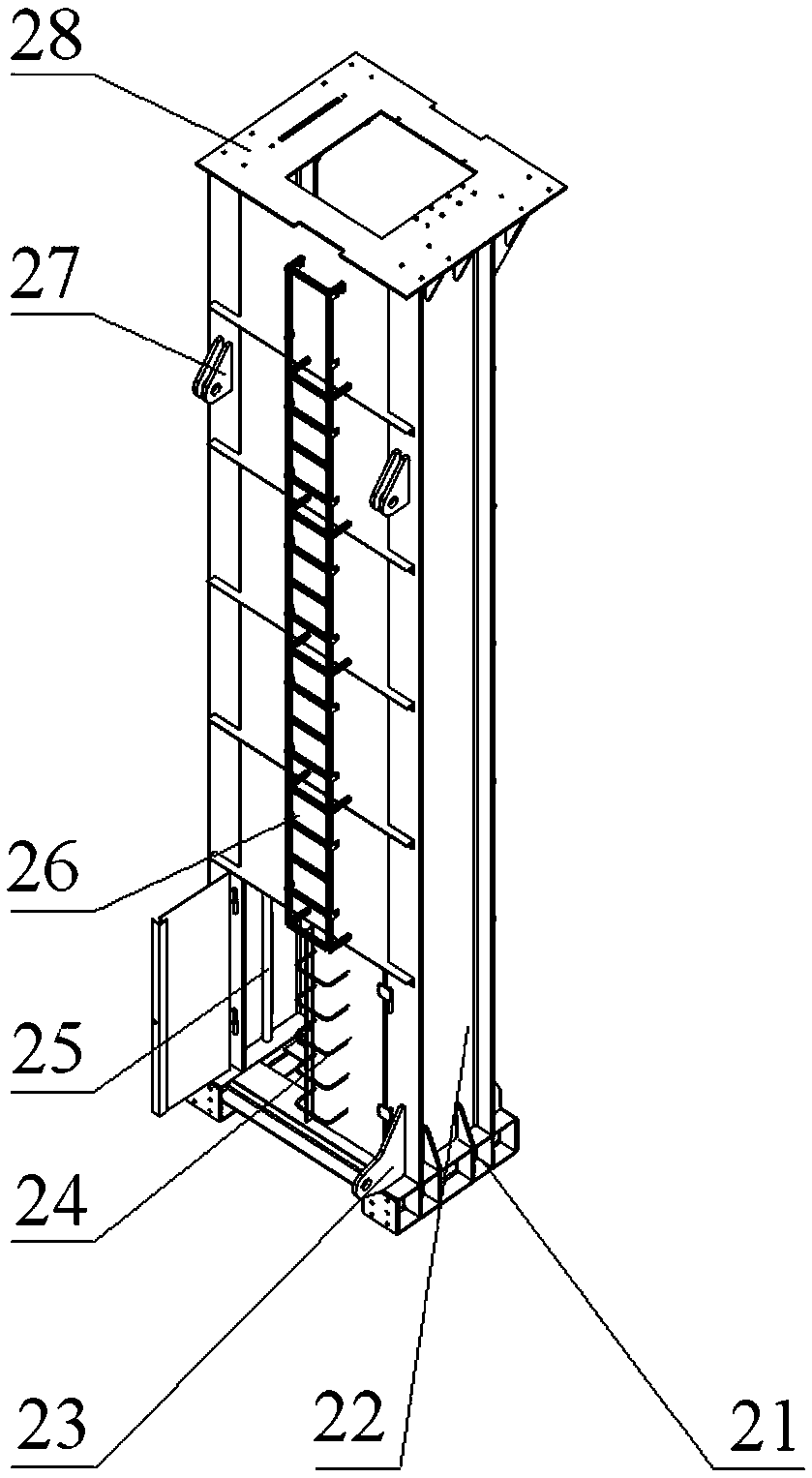

Intelligent adhesive tape pumping unit with long stroke

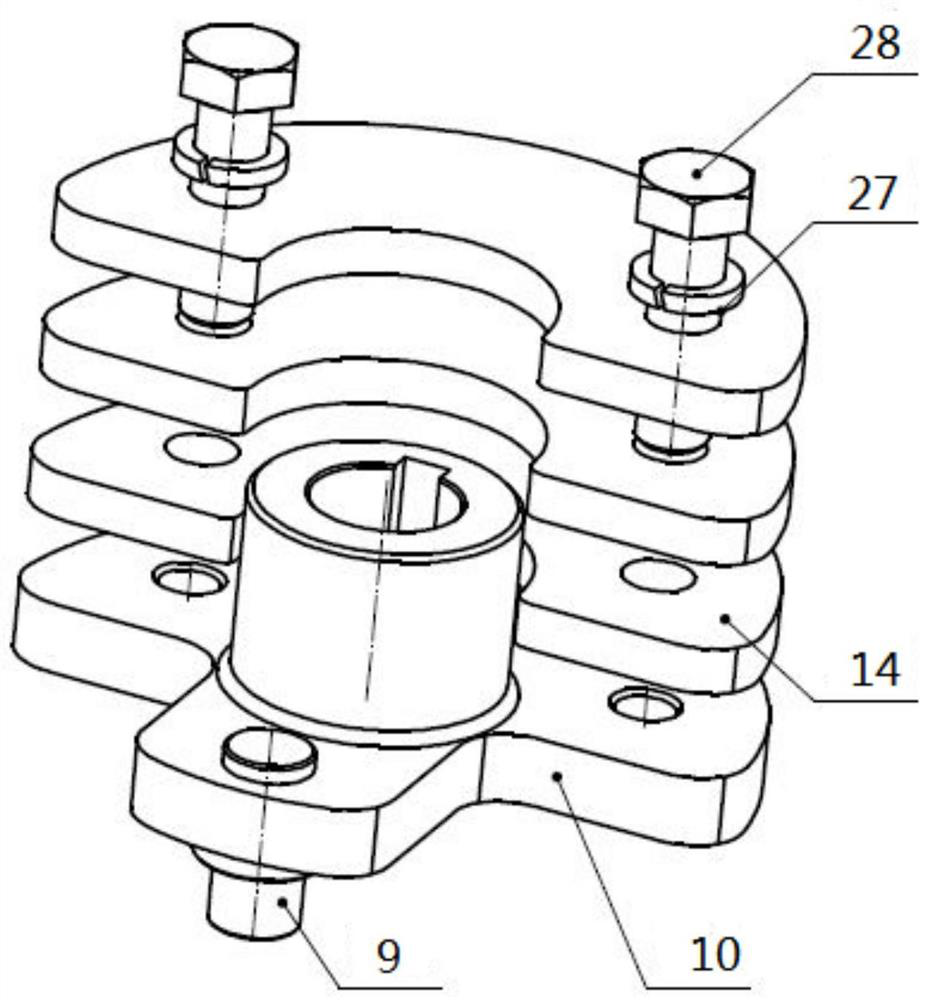

The invention discloses an intelligent adhesive tape pumping unit with a long stroke, and belongs to the field of oil recovery machines. The intelligent adhesive tape pumping unit with the long strokecomprises a movable foundation 1, a base 2, a machine frame 3, an oil pumping rod 4, a well opening adhesive tape / oil pumping rod connector 5, well opening adhesive tape 6, a counter weight box 7, counter weight adhesive tape 8, an upper platform 9, a thrust block seat 10, a cantilever beam telescopic front limiter 11, a cantilever beam 12, a guide wheel 13, a driving wheel 14, a cantilever beampressing bar and cantilever beam telescopic rear limiter 15, a lead screw 16, a counter weight box upper limiter 17, a protective rope 18, a middle switch 19, a counter weight box lower limiter 20, acontrol cabinet 21, a motor 22, a small coupler 23, a brake 24, a decelerator 25, a big coupler 26, a bearing seat 27 and an upper platform lateral moving mechanism 28. According to the intelligent adhesive tape pumping unit with the long stroke, a four-rod linkage structure of a conventional pumping unit is omitted, the transmission path is shortened, the size of the main machine frame is decreased, and energy consumption is reduced. Through the electromechanical integration technology, the operation of the whole pumping unit is safe and reliable, the working parameter can be intelligently adjusted, and the operation is simple. The pumping unit is thenovel pumping unit with the long stroke.

Owner:刘明选

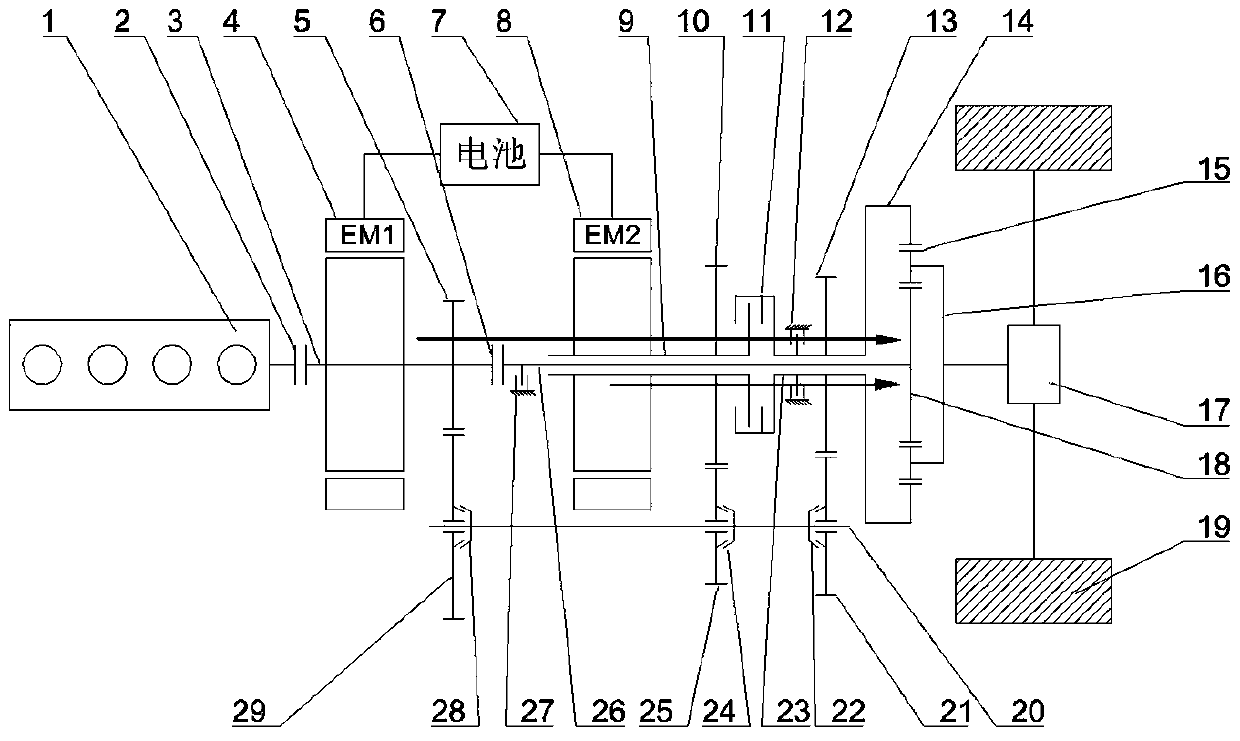

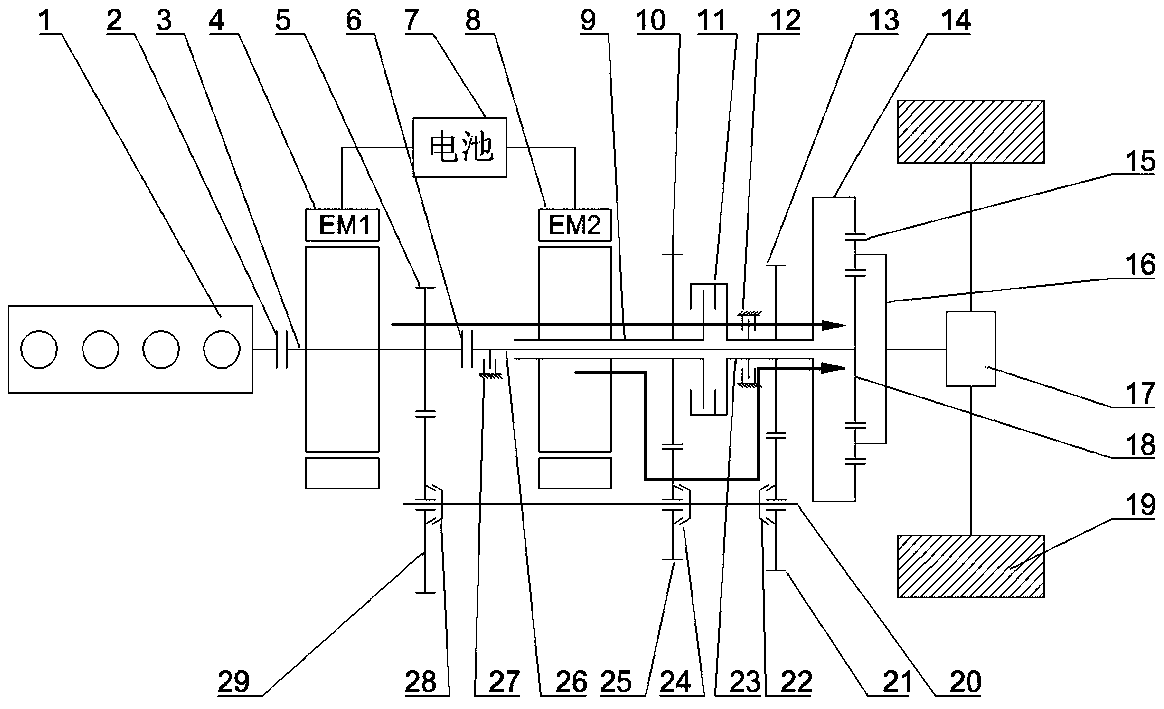

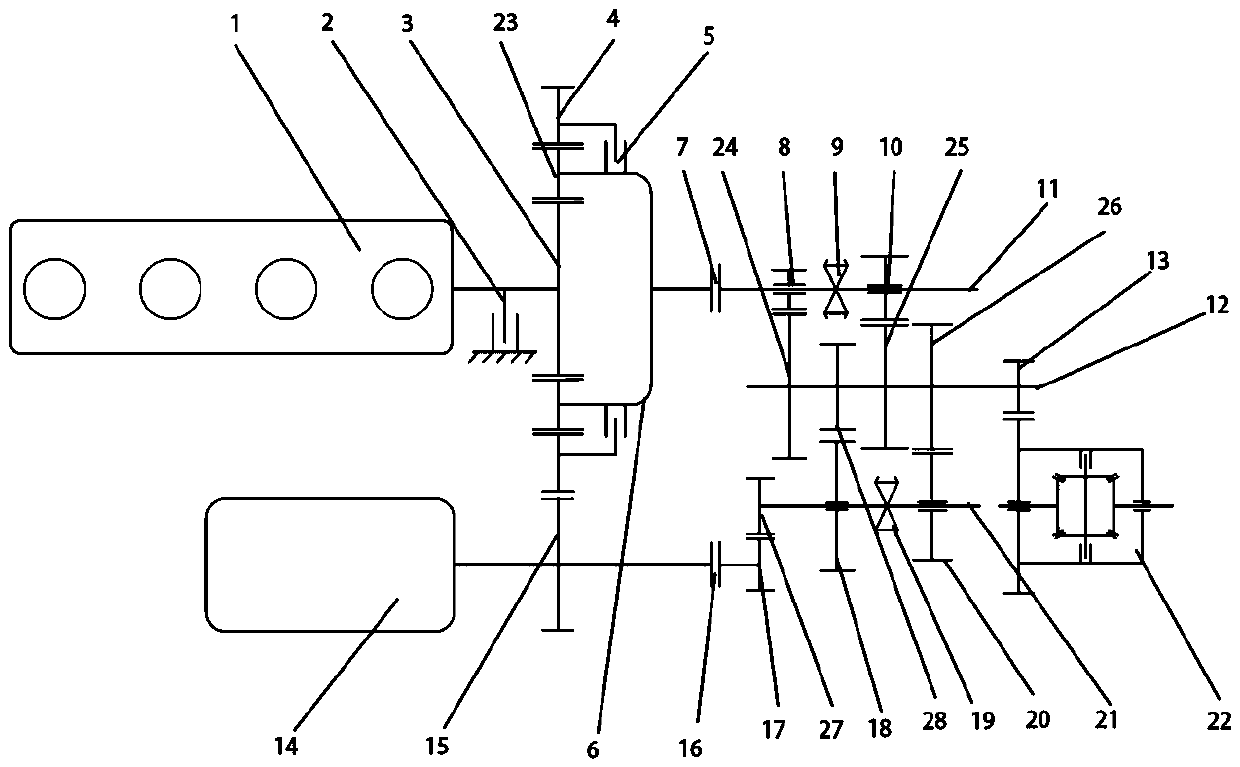

A multi-mode hybrid power transmission

ActiveCN108327514BAchieve decouplingImprove system efficiencyHybrid vehiclesGas pressure propulsion mountingElectric machineryControl theory

The invention relates to a multi-mode hybrid power transmission device comprising a single-line planetary wheel mechanism, a double-clutch speed change mechanism, a differential, an engine and a motor. According to the multi-mode hybrid power transmission device, 13 working modes are achieved, wherein six modes of transmission output and three modes of braking are achieved, and four or more modesof transmission ratio output are achieved; decoupling of the engine and the wheel edge rotational speed is achieved, the engine is easier to control in the high efficiency interval; more modes can beachieved through more transmission paths; and by coordinating the torque of the engine and the motor, the engine and the motor can always work in the high efficiency interval, and thus the higher system efficiency is achieved.

Owner:HEFEI UNIV OF TECH

Power-generation-type deceleration strip

InactiveCN102677608BSimple structureCompact structureMachines/enginesTraffic signalsGear wheelEngineering

The invention provides a power-generation-type deceleration strip which is characterized in that a grounding plate, a front cover plate I, a front cover plate II, a rear cover plate II and a rear cover plate I are sequentially hinged to form an arched hollow cavity, wherein the grounding plate is provided with a vertical rack; the front end of the rack is hinged with a hinging shaft between the front cover plate I and the front cover plate II through an elastic connecting piece I; the back end of the rack is hinged with a hinging shaft between the rear cover plate I and the rear cover plate II through an elastic connecting piece II; the rack is engaged with a gear at the upper side; the gear shaft of the gear is mounted on the grounding plate through a bearing seat; the gear shaft is further provided with an inner engaging ratchet wheel pawl mechanism I and an inner engaging ratchet wheel pawl mechanism II, and the pawl directions of the inner engaging ratchet wheel pawl mechanisms I and II are opposite; the inner engaging ratchet wheel pawl mechanism I is sleeved in the inner cavity of a stator I wound by a coil so as to form a generation device I; and the inner engaging ratchet wheel pawl mechanism II is sleeved in the inner cavity of a stator II wound by a coil so as to form a generation device II. The deceleration strip disclosed by the invention can convert kinetic energy lost by an automobile into electric energy and has the advantages of simple structure, low cost, safety and reliability in use and no pollution.

Owner:SOUTHWEST JIAOTONG UNIV

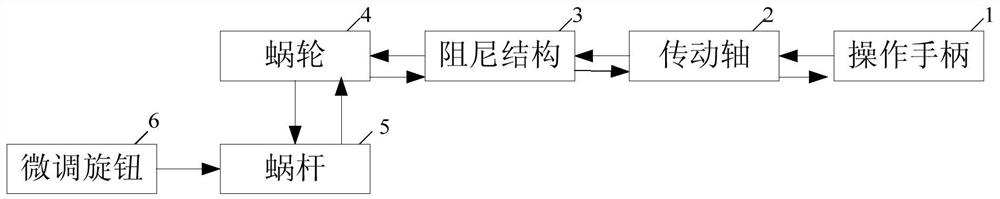

A fine-tuning mechanism and throttle control system

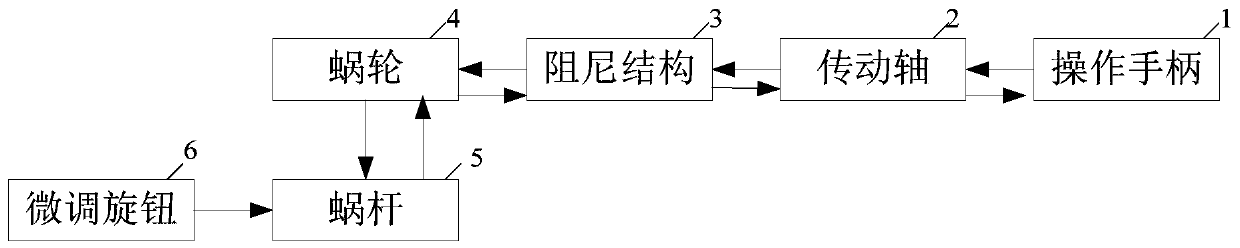

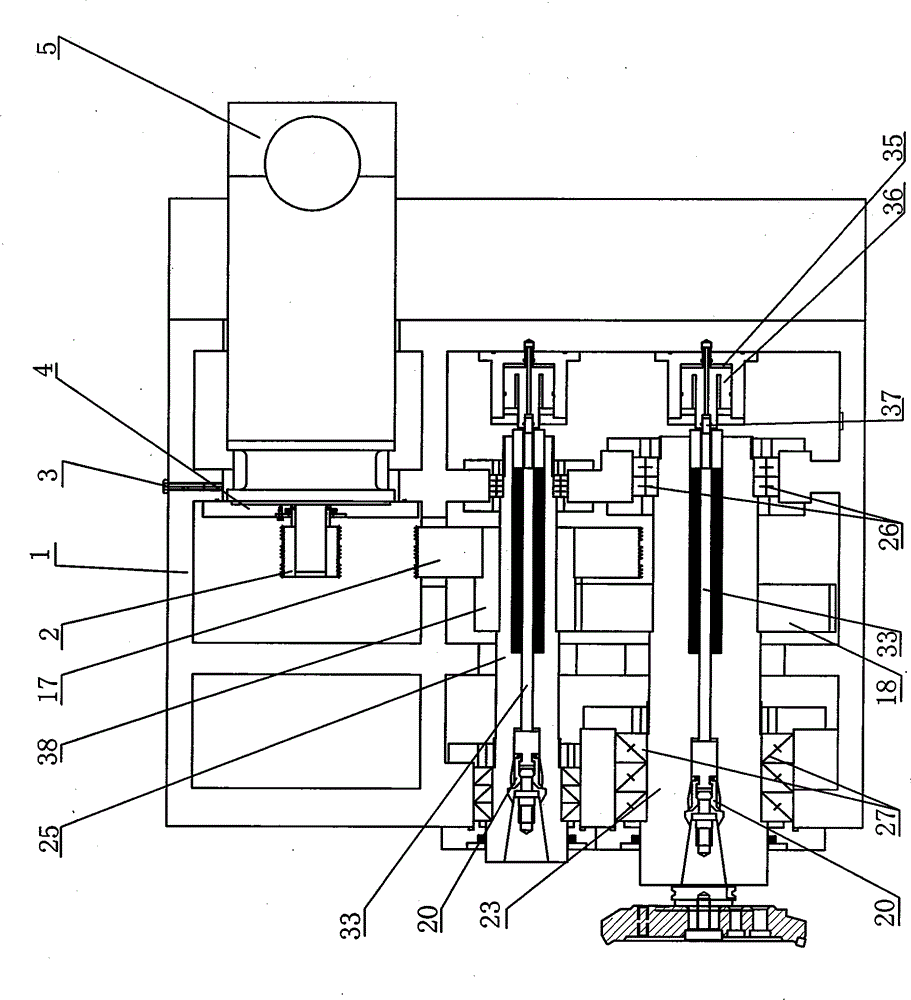

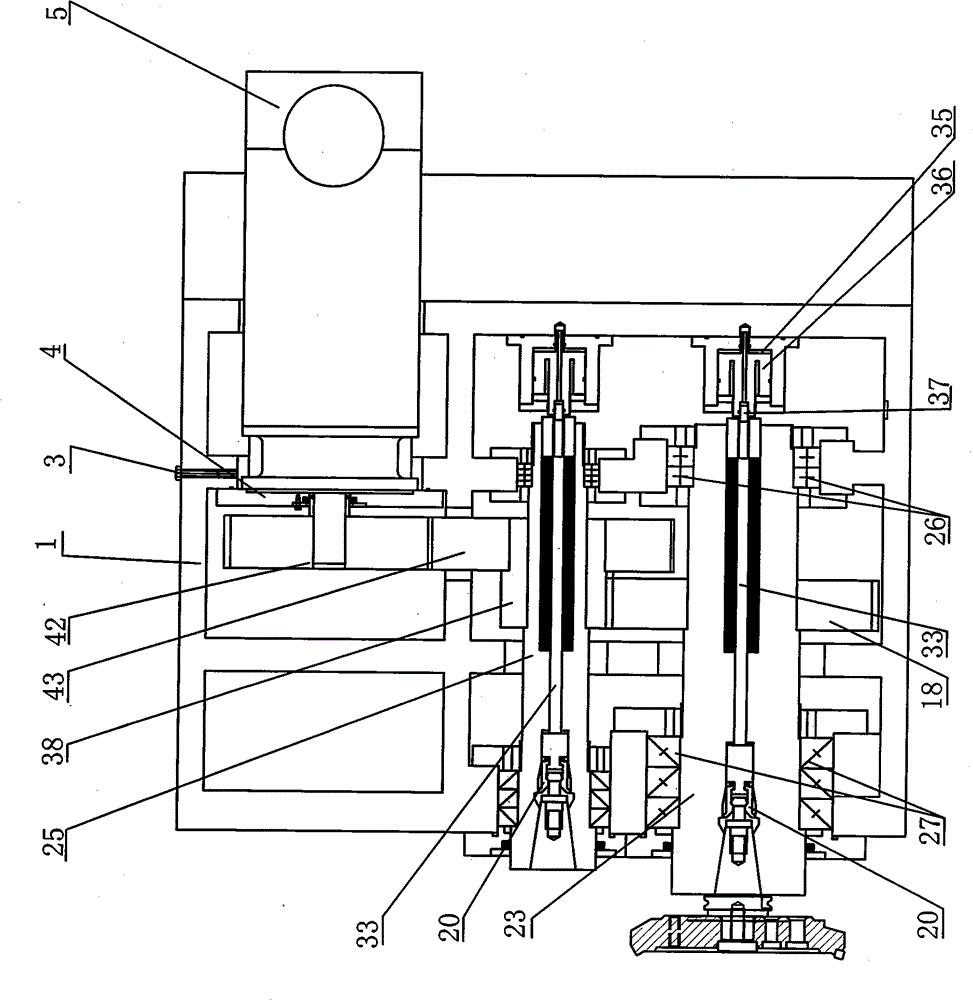

ActiveCN109779763BImprove stabilityShort drive pathTurbine/propulsion fuel controlThrottle controlDrive shaft

The invention relates to the technical field of mechanical structure transmission, and specifically discloses a fine-tuning mechanism, which includes: an operating handle, a transmission shaft, a damping structure, a one-way transmission mechanism, a fine-tuning knob and a rotation angle acquisition module, and one end of the operating handle and the transmission shaft connection, the damping structure is set on the transmission shaft, the one-way transmission mechanism is connected with the damping structure, the fine-tuning knob is set on the one-way transmission mechanism, the rotation angle acquisition module is set on the transmission shaft, and the fine-tuning knob can drive the one-way transmission mechanism when rotating Rotation, the rotation of the one-way transmission mechanism can drive the rotation of the transmission shaft through the rotation of the damping structure, the rotation of the transmission shaft can drive the rotation of the operating handle, and the rotation angle acquisition module is used for communication connection with the controller. The invention also discloses an accelerator control system. The fine-tuning mechanism provided by the invention has the advantages of higher stability and short transmission path.

Owner:中国航发控制系统研究所

A modular design gearbox and gear realization method

ActiveCN111609096BReduce manufacturing costReduce use costAgricultural vehiclesToothed gearingsGear wheelDrive shaft

The invention relates to a modular design gearbox and a gear realization method. The gearbox includes a box body, a drive shaft, four intermediate shafts and an output shaft. The gearbox has a layout of six shafts, wherein the drive shaft S1, the intermediate shaft S4, 2 clutch bags are installed on the intermediate shaft S5, and 1 clutch bag is installed on the intermediate shaft S2, such a structure has a short transmission path and better stability. The gearbox uses 6 shafts and 7 clutches to achieve a maximum forward speed of 8 speeds and a reverse speed of 4 speeds. The speed ratio range is wide and can be adjusted flexibly. By reducing some parts, it can realize a mode with fewer gears, realize modularization, and improve Versatility, reducing the production cost and use cost of the gearbox. At the same time, the forward gear is realized by the combination of two clutches and four gear meshes, and the reverse gear is realized by the combination of two clutches and three gear meshes. The transmission path is short and reliable. high.

Owner:JIANGSU ADVANCED CONSTR MASCH INNOVATION CENT LTD +1

A smart card stamping device

InactiveCN104494295BShort drive pathHigh transmission precisionRotary pressesHot stampingElectric machinery

Owner:GUANGZHOU MINGSEN TECH CO LTD

Dynamic coupling control device

The invention relates to a dynamic coupling control device. The dynamic coupling control device comprises is used for selectively putting through or breaking the transmission connection of a driving mechanism and a transmission system of a vehicle and comprises an actuating motor, an actuating gear, a supporting seat, an actuating piece and a stop piece; the actuating gear comprises a barrel-shaped shaft part and a gear part in transmission connection with the actuating motor; the shaft part is rotationally supported on the supporting seat, is fixed relative to the supporting seat in the axialdirection and can rotate relative to the supporting seat; the shaft part is sleeved with the actuating piece and is in screw-thread fitting with the actuating piece; the actuating piece and the supporting seat are located on the two opposite sides in the radial direction of the shaft part; and the stop piece is connected fixedly with the supporting seat and is connected with the actuating piece,so that the rotation movement of the actuating piece relative to the supporting seat is stopped. The dynamic coupling control device is simple in structure, high in control precision and high in reliability.

Owner:SCHAEFFLER TECH AG & CO KG

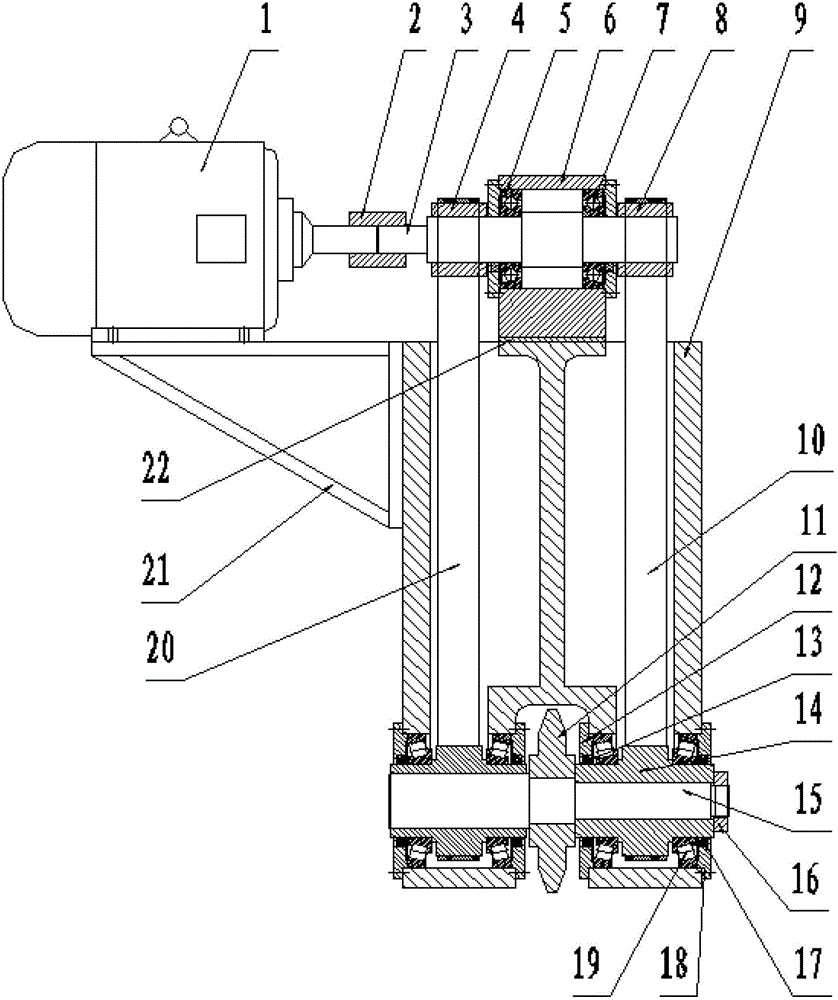

Gear milling spindle box directly driven by torque motor

ActiveCN102717100BImprove surface roughnessShort drive pathDriving apparatusGear teethLow speedGear wheel

A gear milling spindle box directly driven by a torque motor is characterized by comprising the low-speed high-torsion torque motor (1), a driving synchronous belt pulley axle (3), a first driving synchronous belt pulley (4), a second driving synchronous belt pulley (8), a spindle box body (9), a motor support (21), a first synchronous belt (10), a second synchronous belt (20), a disc milling cutter (11), a driven synchronous belt pulley axle (14) and a cutter bar (15). The low-speed high-torsion torque motor is directly connected with the disc milling cutter by the tensioned synchronous belts with arc teeth, a transmission path is short, and transmission efficiency is high. In addition, the tensioned synchronous belts can realize stable transmission without backlashes, nonlinear vibration of a transmission system due to fluctuating cutting load is avoided, cutting noise is lowered, surface roughness of a cut tooth surface is improved, and the risks of impact pitting corrosion of the tooth surface during gear transmission are avoided.

Owner:NANJING GONGDA CNC TECH

Quick-unlocking lock body

ActiveCN113202346AShorten the timeTo achieve the purpose of quick opening and quick lockingBuilding locksVehicular energy storageGear wheelLocked plate

The invention discloses a quick-unlocking lock body, and relates to the technical field of locksets. The quick-unlocking lock body comprises a main spring bolt and an inclined spring bolt, the main spring bolt is connected with a lock plate, the main spring bolt is connected with a main lock shifting piece through the lock plate, the main lock shifting piece is movably connected with a gear shifting piece, and the inclined spring bolt is connected with an inclined tongue shifting piece. The gear shifting piece and an inclined spring bolt shifting piece are both driven by a lock head shifting block, the lock head shifting block is driven by a lock head shifting wheel, the lock plate is provided with a first sliding groove and a second sliding groove, the forming direction of the first sliding groove is consistent with the stretching and retracting direction of the main spring bolt, and the lock plate is connected with the main lock shifting piece through the second sliding groove. The lock head shifting block is located between the gear shifting piece and the inclined spring bolt shifting piece. According to the quick-unlocking lock body, the problems of long unlocking waiting time and high power consumption can be solved.

Owner:DESSMANN CHINA MACHINERY & ELECTRONICS

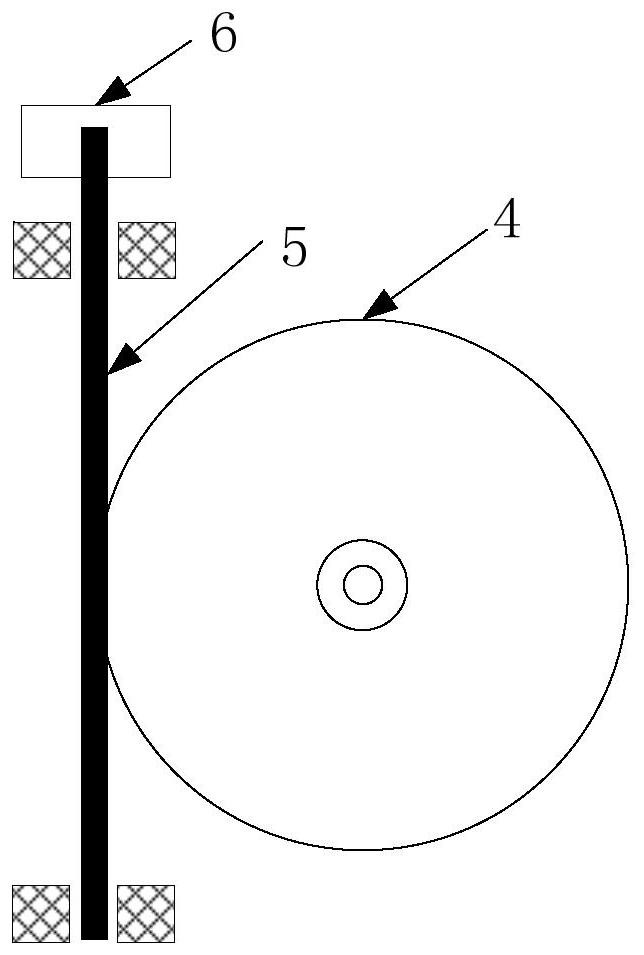

Fine adjustment mechanism and accelerator control system

ActiveCN109779763AImprove stabilityShort drive pathTurbine/propulsion fuel controlControl systemDrive shaft

The invention relates to the technical field of mechanical structure transmission, and particularly discloses a fine adjustment mechanism. The fine adjustment mechanism comprises an operating handle,a transmission shaft, a damping structure, a unidirectional transmission mechanism, a fine adjustment knob and a rotation angle acquisition module; the operating handle is connected with one end of the transmission shaft; the damping structure is arranged on the transmission shaft; the unidirectional transmission mechanism is connected with the damping structure; the fine adjustment knob is arranged on the unidirectional transmission mechanism; the rotation angle acquisition module is arranged on the transmission shaft; when the fine adjustment knob rotates, the fine adjustment knob can drivethe one-way transmission mechanism to rotate, the rotation of the one-way transmission mechanism can drive the transmission shaft to rotate through the rotation of the damping structure, and the rotation of the transmission shaft can drive the operation handle to rotate; and the rotation angle acquisition module is in communication connection with the controller. The invention also discloses an accelerator control system. The fine adjustment mechanism has the advantages of higher stability and a short transmission path.

Owner:中国航发控制系统研究所

Milling machine

ActiveCN101658950BExpand the scope of processingStable output powerDriving apparatusDrive shaftAgricultural engineering

The invention discloses a milling machine, comprising a spindle box, a first milling shaft, a second milling shaft and a servo motor. The power of the servo motor is transmitted to the first milling shaft and the second milling shaft by a main transmission system. The first milling shaft is a middle transmission shaft between the second milling shaft and the servo motor. The milling machine can lower the cost, simplify the transmission system, ensure low damage possibility of the transmission system, prolong the service life of the machine tool, simultaneously optimize the motor power and savethe energy.

Owner:东莞市鑫国丰机械有限公司

Two-gear gear shifting mechanism, two-gear power system and gear shifting control method of two-gear power system

ActiveCN113442713AShort transmission distanceImprove reliabilityHybrid vehiclesGas pressure propulsion mountingGear wheelControl theory

The invention relates to a two-gear shifting mechanism, a two-gear power system and a gear shifting control method of the two-gear shifting mechanism. The two-gear shifting mechanism comprises a first clutch and a second clutch; the driving end of the first clutch and the driving end of the second clutch are arranged oppositely; a first reduction gear set and a second reduction gear set; the first reduction gear set is in transmission connection with the driven end of the first clutch, and the second reduction gear set is in transmission connection with the driven end of the second clutch. The driving end of each clutch is provided with three control positions on the motion stroke of the clutch motion, and the three control positions are a first combination position combined with the corresponding driven end, a second combination position combined with the driving end of the other clutch and a separation position located between the first combination position and the second combination position. When the gear shifting mechanism with the structure shifts gears, power interruption is avoided, and stable running of a vehicle is guaranteed.

Owner:ZHENGZHOU YUTONG BUS CO LTD

A long-stroke direct-drive pumping unit with dual braking and counterweight anti-falling functions

ActiveCN105275434BImprove effectivenessImprove work efficiencyFluid removalMotor driveReduction drive

The invention discloses a long-stroke direct-drive pumping unit with double braking and counterweight anti-falling functions. The motor of the power device drives the built-in reducer installed in the reel to drive the reel to rotate in the forward and reverse directions. Dual braking functions of motor braking and electro-hydraulic braking. The reel is fixed and wrapped with the wellhead belt, bypassing the guide reel that can move back and forth to connect the wellhead polished rod; the reel is fixed in the opposite direction and wound with the counterweight belt to connect with the anti-falling counterweight box in the frame; the load of the wellhead polished rod and the counterweight form a balance balance . The pumping unit of the invention has the characteristics of simple transmission form, safety and reliability.

Owner:山东高原油气装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com