Intelligent card hot stamping device

A technology for smart cards and cards, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of high center of gravity of the coding device, complex transmission mechanism, easy to produce shaking, etc., to reduce the cost and difficulty of equipment manufacturing, flexible movement, Shake reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below with reference to the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

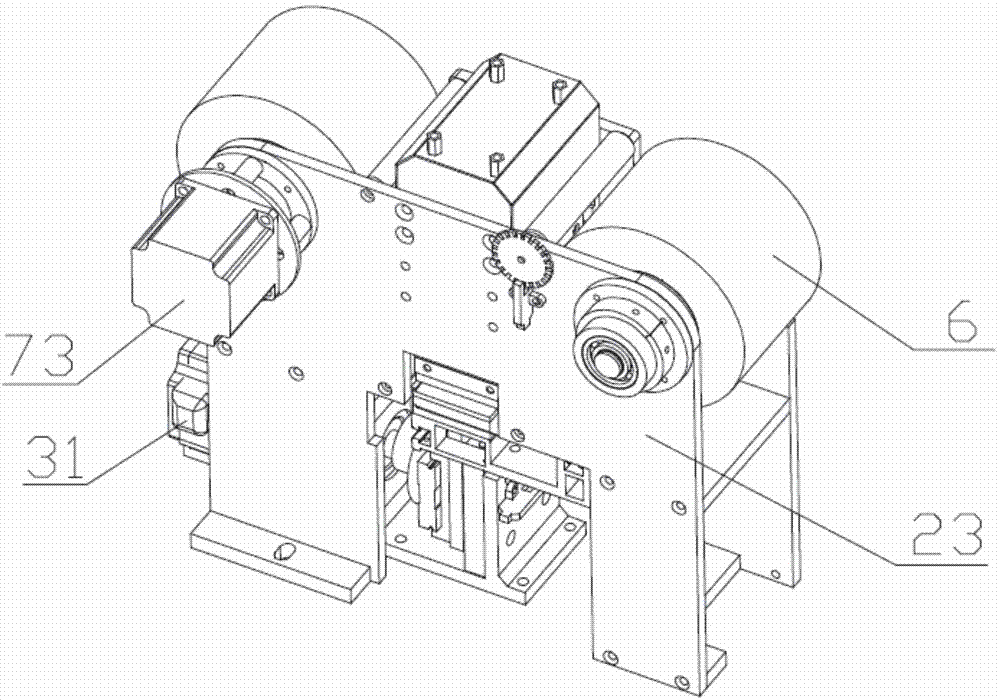

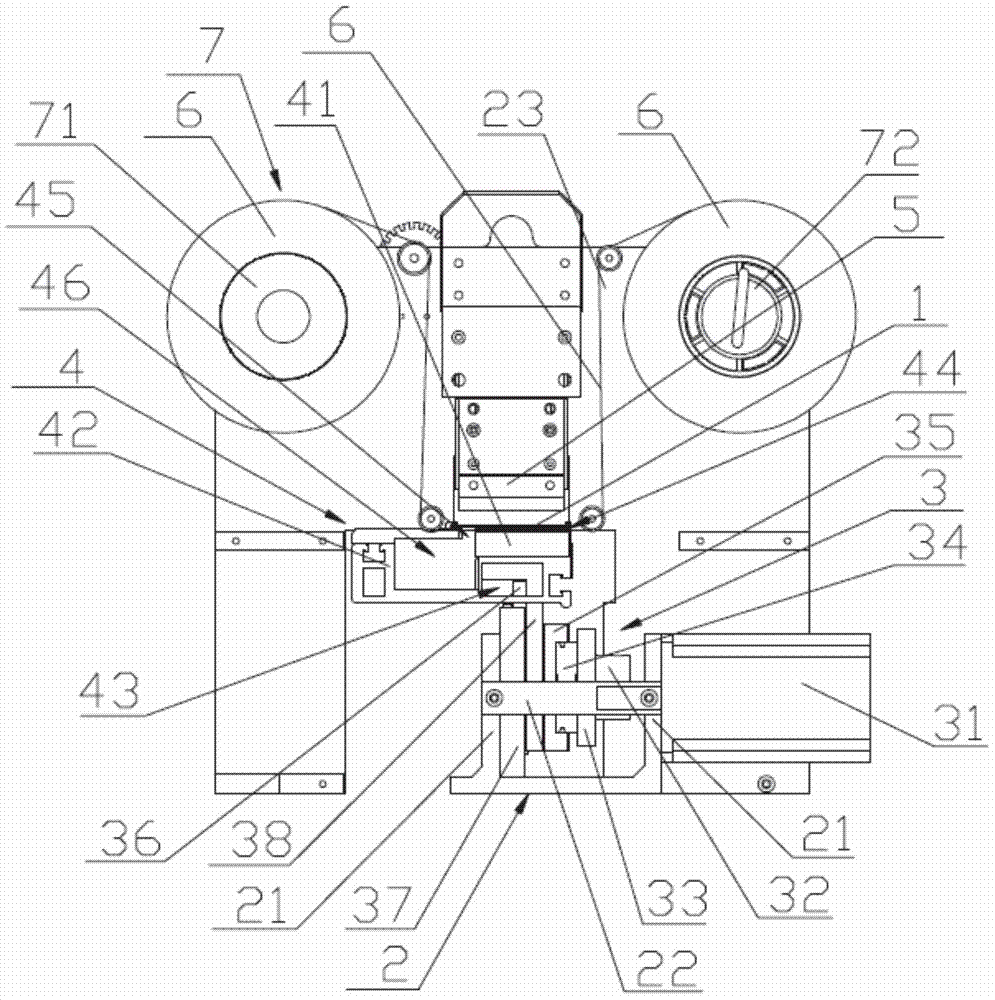

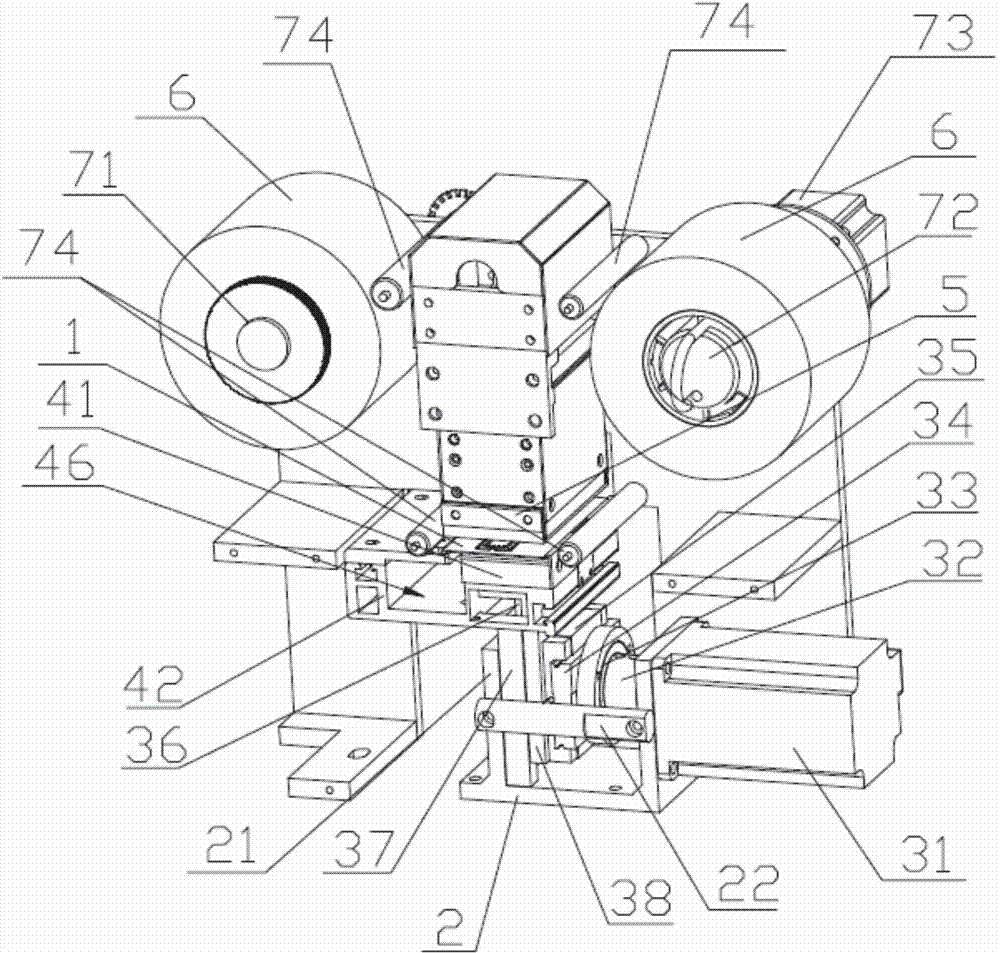

[0043] see Figure 1 to Figure 8 , the smart card hot stamping device of the present invention comprises a frame 2 and a hot belt conveying mechanism 7, a hot head 5, a card positioning seat 4 and a hot stamping feeding mechanism arranged on the frame 2, wherein, the hot head 5 is arranged on the Below the card positioning seat 4 , the ironing belt 6 in the ironing belt conveying mechanism 7 passes between the ironing head 5 and the card positioning seat 4 . The hot stamping feeding mechanism is connected to the card positioning seat 4 and is located below the card positioning seat 4. The hot stamping feeding mechanism includes a card positioning seat driving mechanism 3 that drives the card positioning seat 4 to reciprocate up and down. The seat driving mechanism 3 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com