Cutting knife structure of harvester and harvester

A harvester and chute technology, which is applied to harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of complex movement trajectories and routes of moving parts, many wearing parts, and long transmission paths.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0039] These two implementation methods, in order to meet the harvesting requirements, the transmission is stable, the trajectory of each moving part is long, and the route is complicated. However, in order to overcome this technical bias in this technical solution, this application creatively reduces a number of parts. Specific examples are as follows:

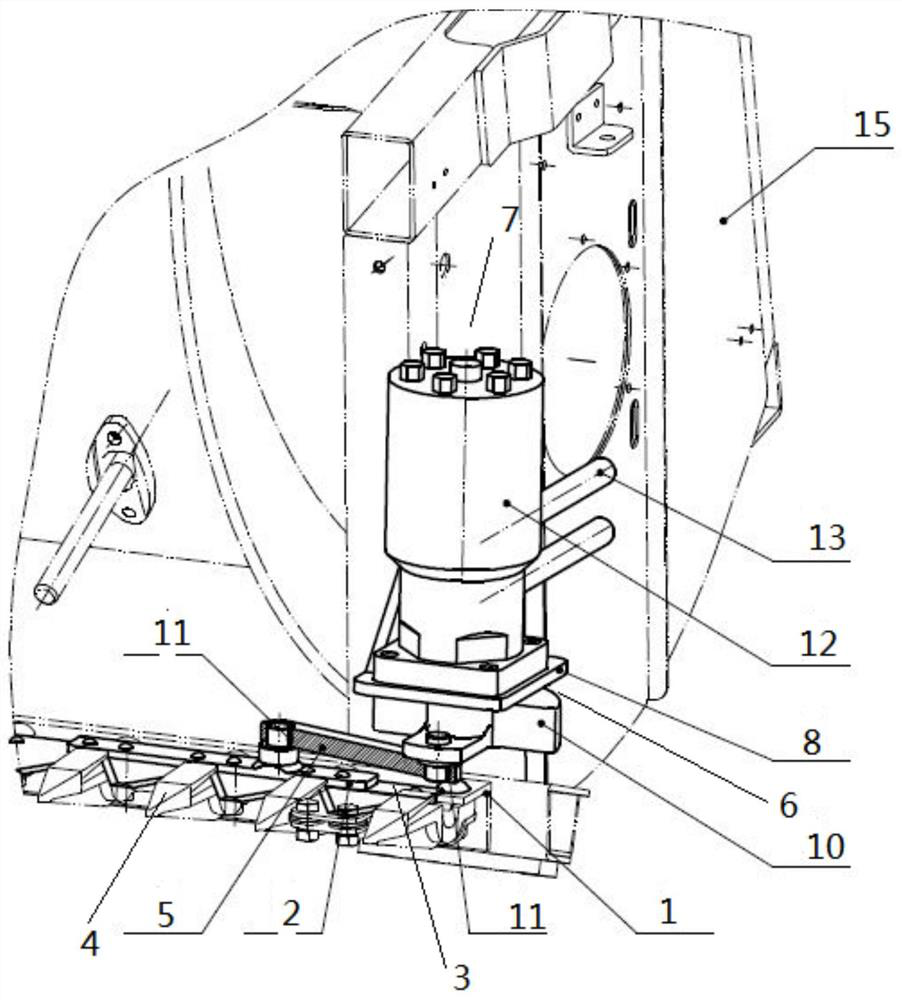

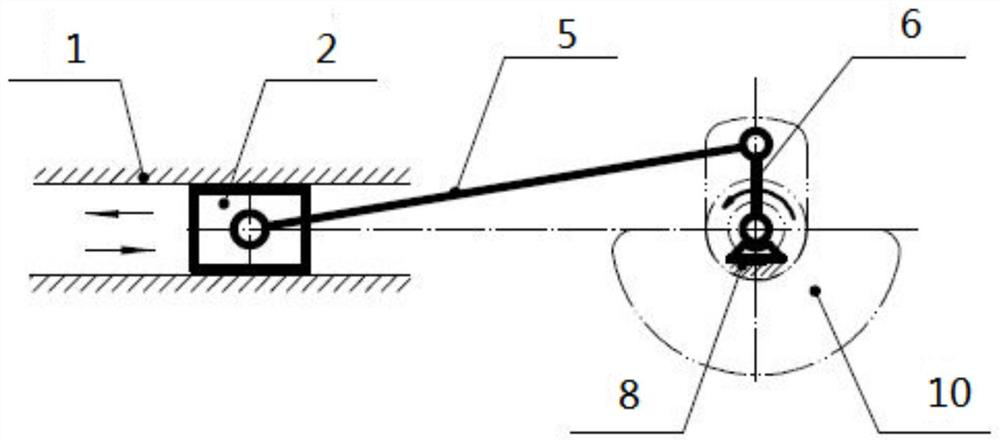

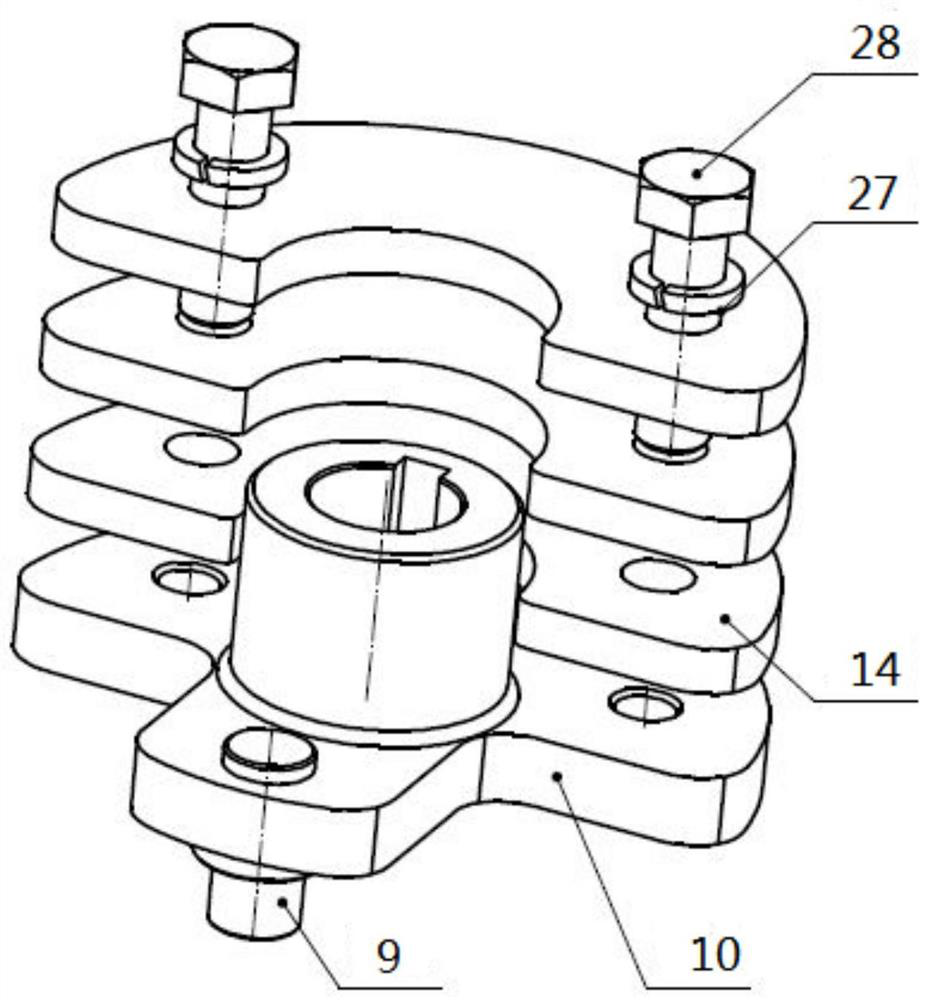

[0040] please if Figure 1 to Figure 3 As shown, the present invention provides a harvester cutter structure, comprising a cutter chute frame provided with a chute, a slide block matched with the chute, a cutter set on the slide block, one end connected with the slide block The connecting rod, the eccentric weight assembly connected with the other end of the connecting rod, drives the driving device for swinging the eccentric weight assembly, so that the eccentric weight assembly drives the slider to reciprocate in the chute, and the cutter cuts the crop stalks. Compared with the prior art, when the cutting knife structure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com