Milling machine

A technology for milling machines and milling shafts, which is applied in the field of milling machines, can solve problems such as affecting output power, prone to equipment failures, and limited adjustment range, and achieve stable output power, improved reliability, and simple transmission and reduction mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

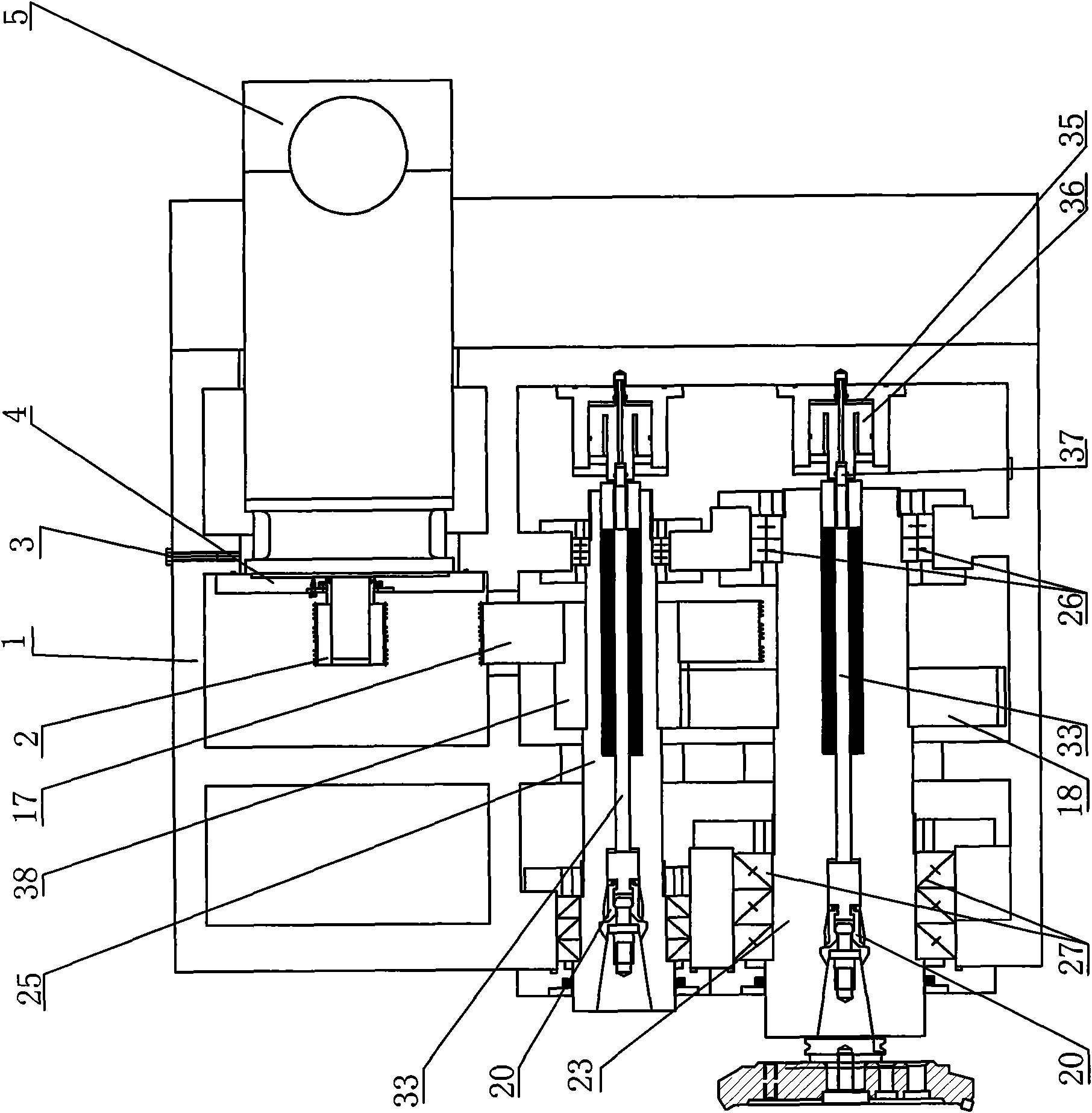

[0020] Such as figure 1 The shown milling machine comprises a spindle box 1, a servo motor 5, a first milling shaft 25, and a second milling shaft 23; A pre-tightening adjustment screw 3 is provided between the box 1 and the servo motor seat 4 for adjusting the position of the servo motor 5; the first milling shaft 25 is installed in the headstock 1 through a non-axial positioning bearing and a positioning bearing, The second milling shaft 23 is installed in the headstock 1 through a non-axial locating bearing and a locating bearing. In this embodiment, the non-axial locating bearing is a double row cylindrical roller bearing 26, and the axial locating bearing is an angular The contact bearing 27, the double row cylindrical roller bearing 26 is installed on the first milling shaft 25 and the second milling shaft 23 away from the end of the milling cutter, and the angular contact bearing 27 is installed on the first milling shaft 25 and the second milling shaft 23 close to the ...

no. 2 approach

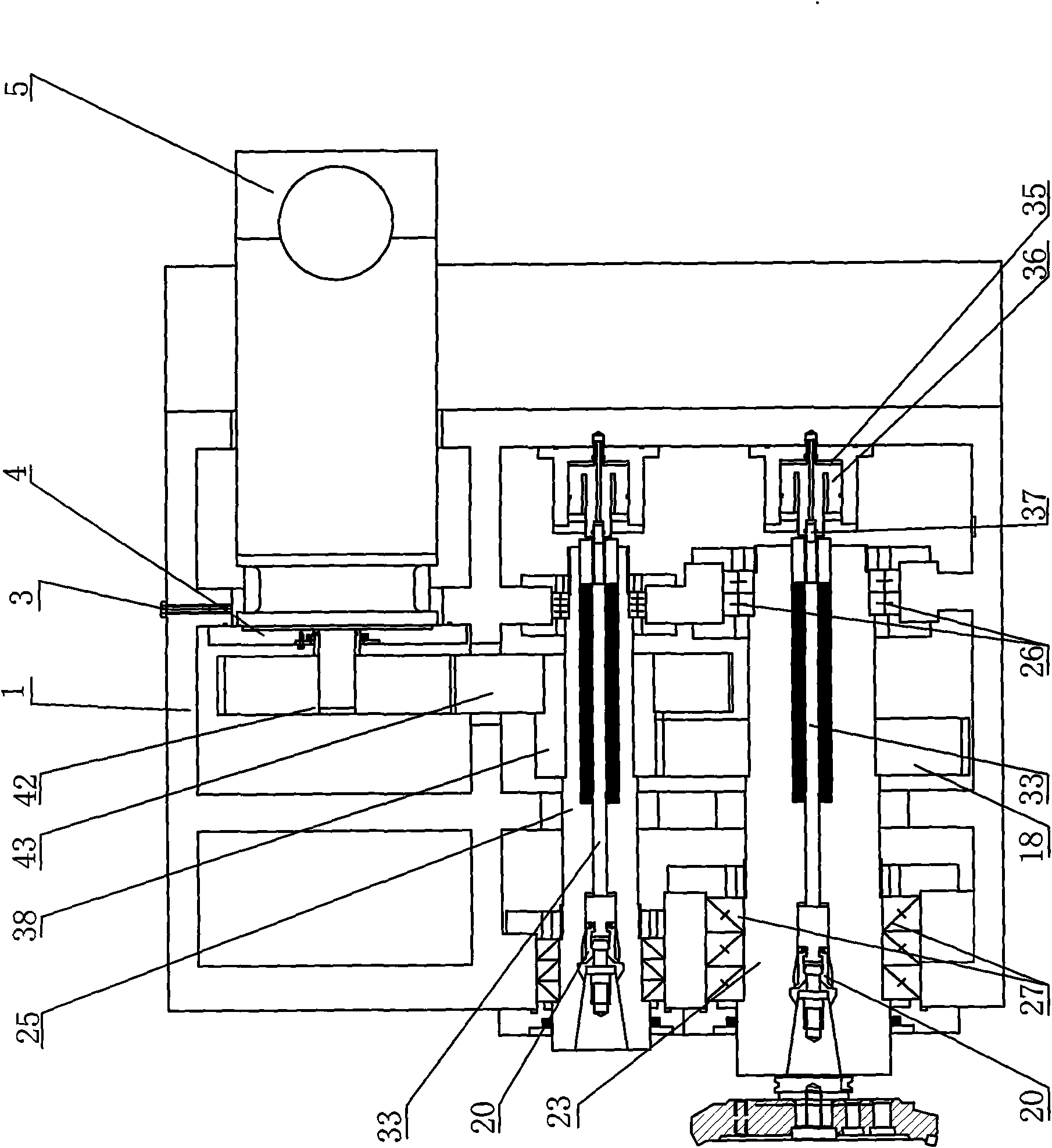

[0028] like figure 2 The shown milling machine comprises a spindle box 1, a servo motor 5, a first milling shaft 25, and a second milling shaft 23; A pre-tightening adjustment screw 3 is provided between the box 1 and the servo motor seat 4 for adjusting the position of the servo motor 5; the first milling shaft 25 is installed in the headstock 1 through a non-axial positioning bearing and a positioning bearing, The second milling shaft 23 is installed in the headstock 1 through a non-axial locating bearing and a locating bearing. In this embodiment, the non-axial locating bearing is a double row cylindrical roller bearing 26, and the axial locating bearing is an angular The contact bearing 27, the double row cylindrical roller bearing 26 is installed on the first milling shaft 25 and the second milling shaft 23 away from the end of the milling cutter, and the angular contact bearing 27 is installed on the first milling shaft 25 and the second milling shaft 23 close to the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com