Riser flexible wire cutting method and cutting equipment for steel castings

A cutting method and steel casting technology, which is applied in the direction of metal sawing equipment, metal processing equipment, sawing machine equipment, etc., can solve the problems of affecting the product quality of mechanical equipment, reducing the yield of castings, casting defects, etc., and achieve the elimination of labor intensity and production organization problems, low cutting noise, and less post-processing man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, technical scheme of the present invention will be further described:

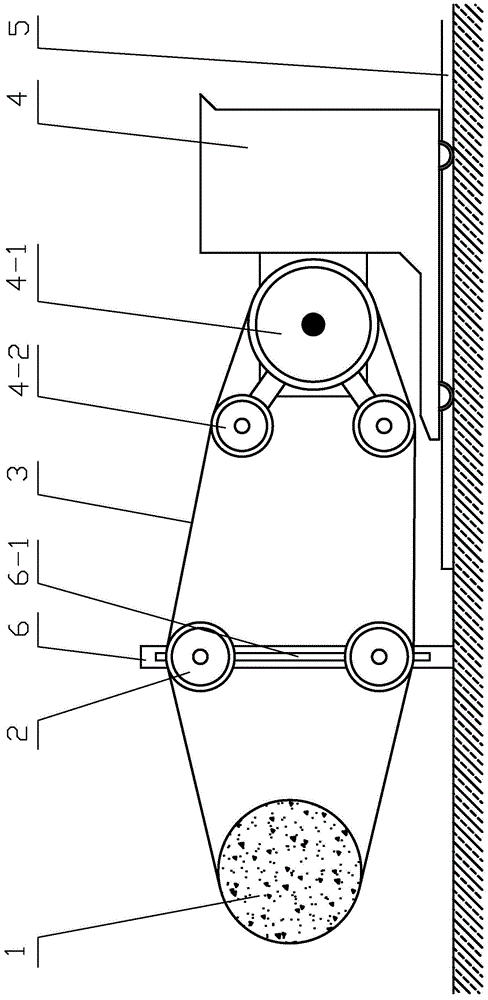

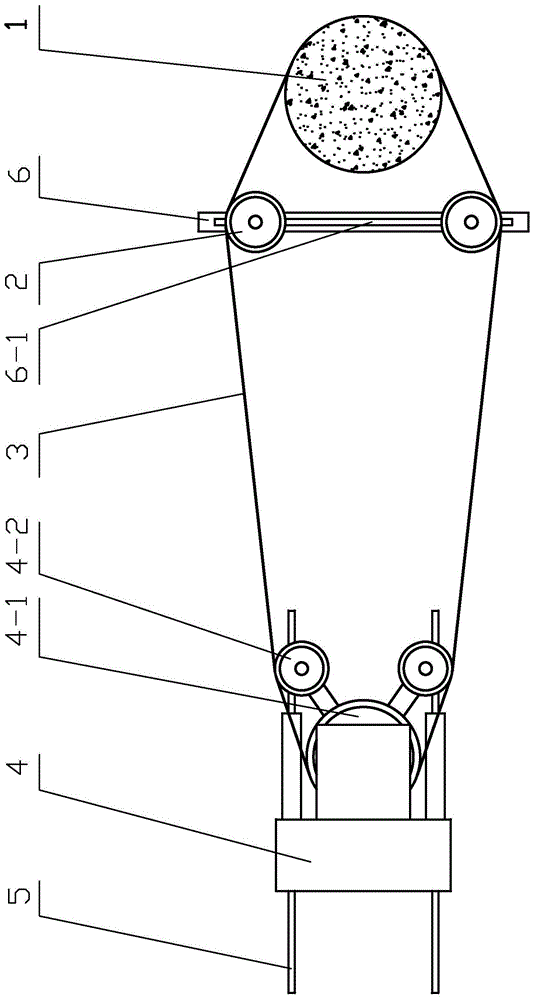

[0026] The steel casting riser flexible wire cutting equipment of the present invention includes a wire saw driving device 4, a beaded rope 3, a guide wheel 2 and a track 5, and the wire saw driving device 4 is placed next to the steel casting riser 1 placed horizontally or vertically Set on the track 5, adjust the rotating surface of the driving wheel 4-1 of the wire saw driving device 4 to be consistent with the cutting surface of the steel casting riser 1 (horizontal cutting surface or vertical cutting surface), and the driving wheel 4-1 is consistent with the steel casting A frame 6 is set between the risers 1 (the horizontal cutting surface corresponds to the vertical frame 6, and the vertical cutting surface corresponds to the horizontal frame 6), and two guide wheels 2 are placed on the frame 6 on the steel casting riser 1 are arranged on both si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com