Circular saw web and damping noise reduction structure thereof

A circular saw blade and damping technology, which is applied in the field of circular saw blades and their damping and noise reduction structures, can solve problems such as large noise, achieve noise reduction, significant noise reduction and noise reduction effects, and improve cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

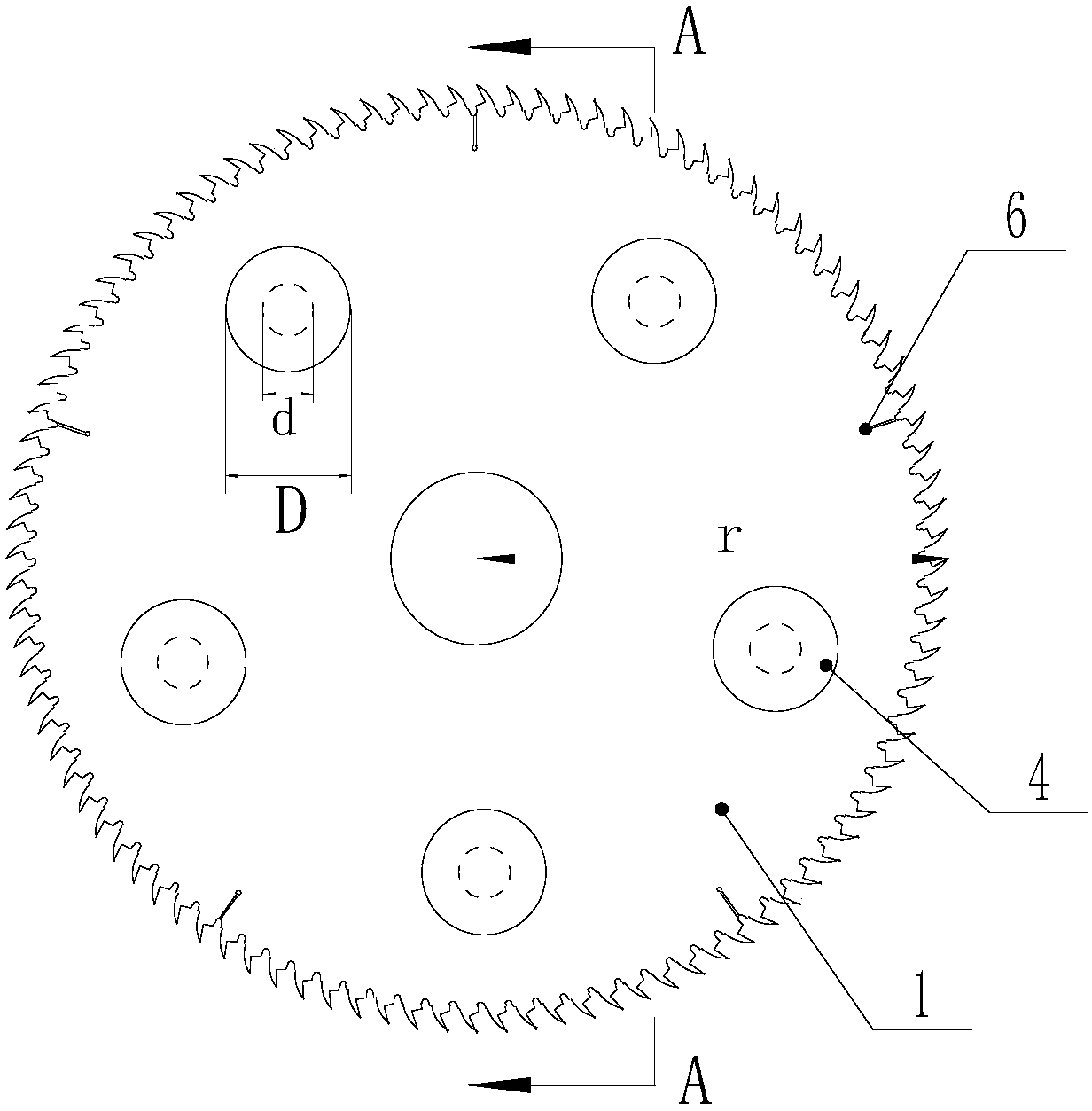

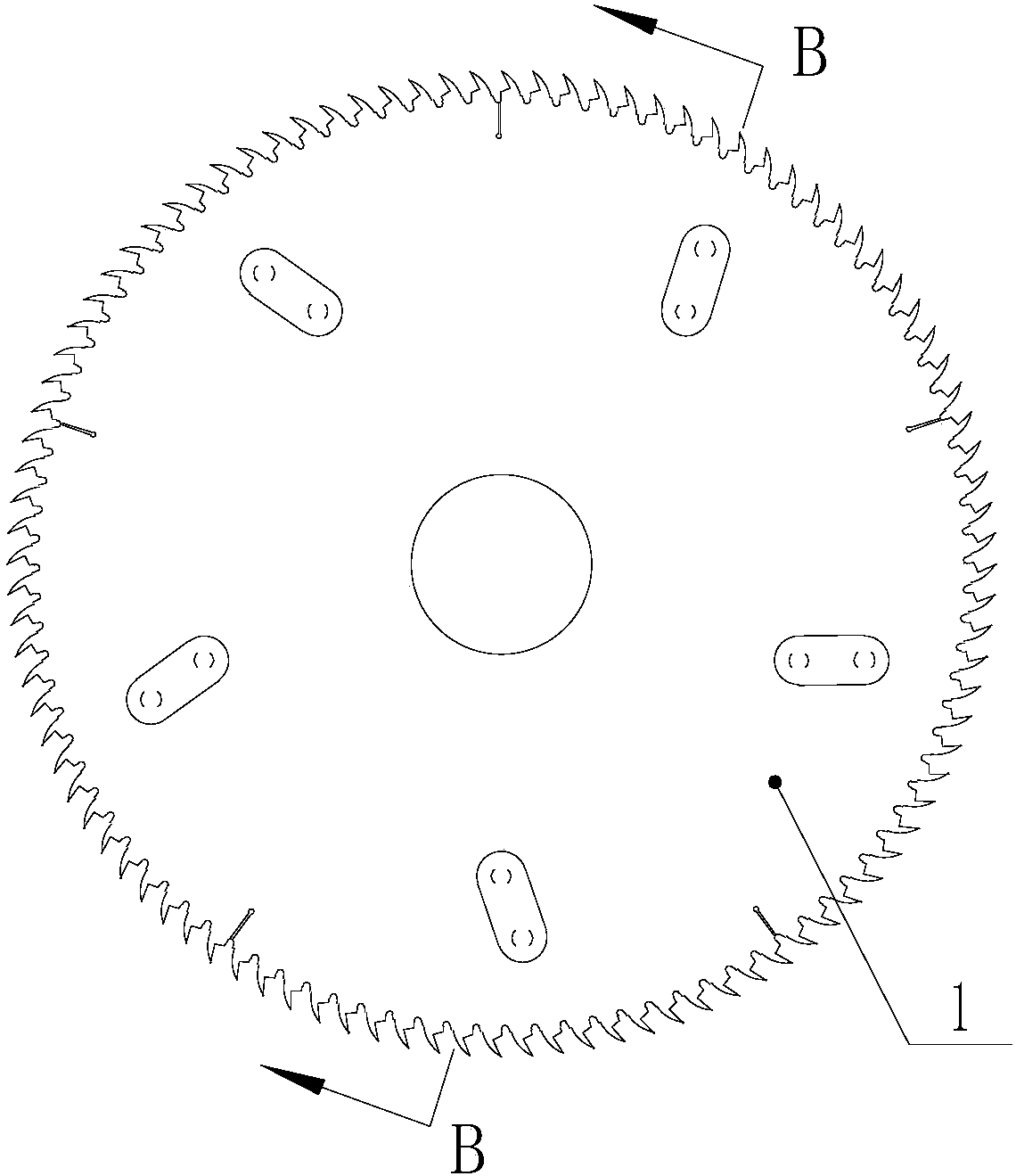

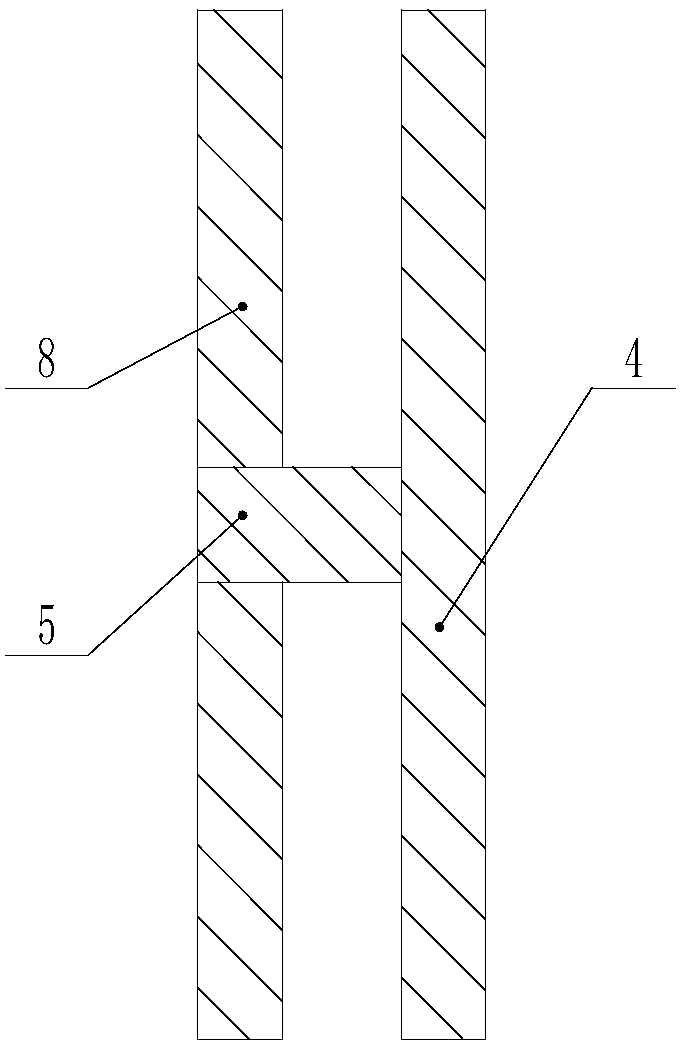

[0032] Such as image 3 As shown, a damping and sound-absorbing structure includes a first damping sheet 4 and a first cylinder 5 , and the first damping sheet 4 is fixedly connected to the first cylinder 5 .

Embodiment 2

[0034] Such as image 3 As shown, a damping and sound-absorbing structure includes a second damping sheet 8 fixedly connected to the first cylinder 5 . Other parts are identical with embodiment 1.

Embodiment 3

[0036] Such as Figure 4 As shown, a sound damping structure includes a second cylinder 10 fixedly connected to the first damping sheet 4 . Other parts are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com