Shear-extrusion type gear-ring-free fine blanking device and method

A gearless, fine blanking technology, applied in the field of mechanical processing, can solve the problems of increasing the difficulty and cycle of mold processing, reducing the life of the ring gear platen, increasing mold maintenance costs, etc., to reduce processing and maintenance costs, and improve hydrostatic pressure Stress, the effect of increasing compressive stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

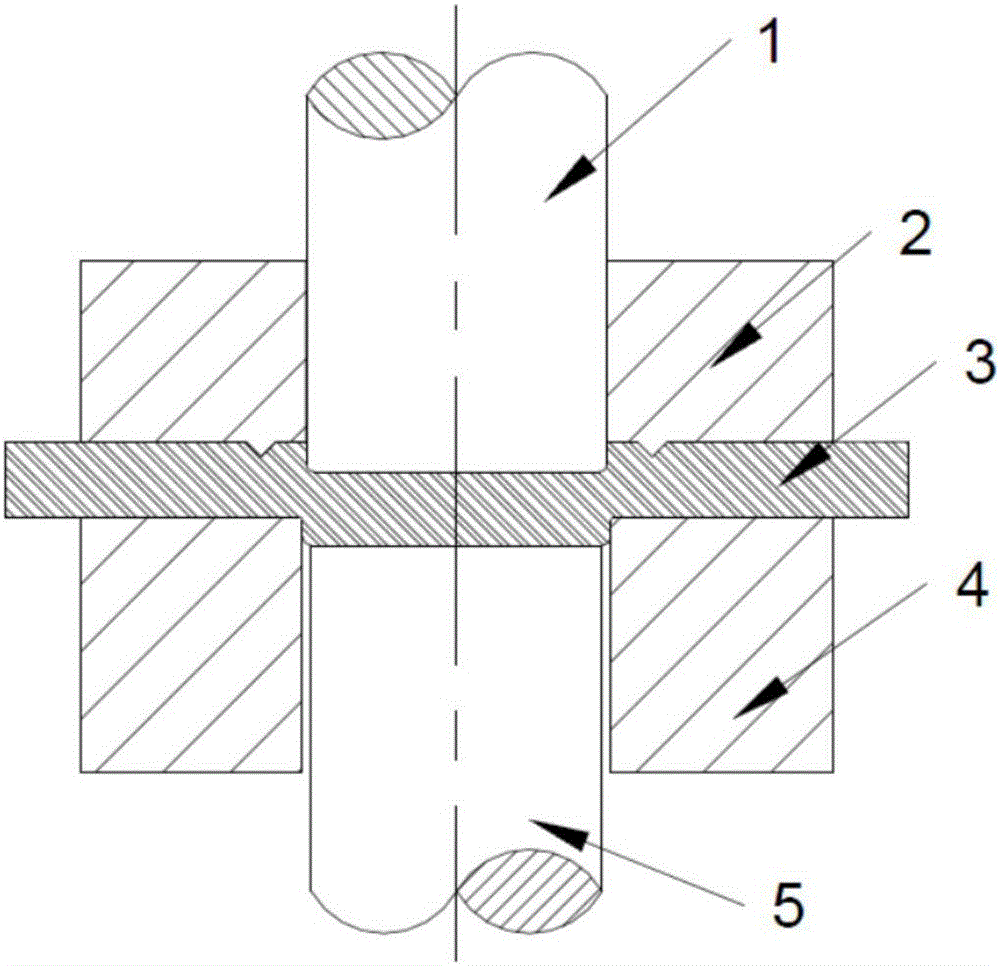

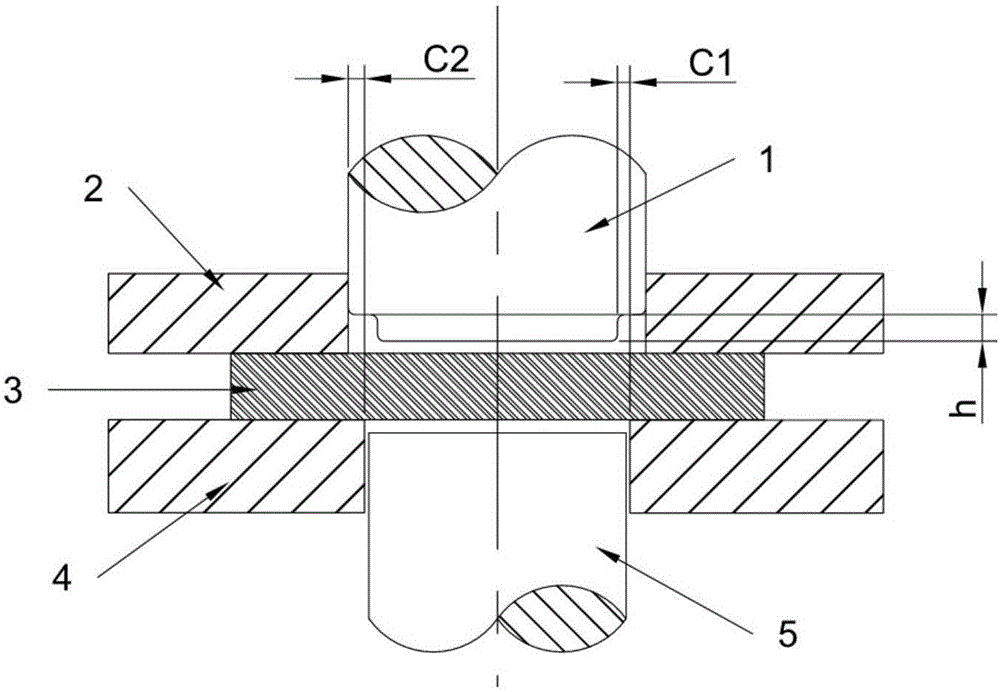

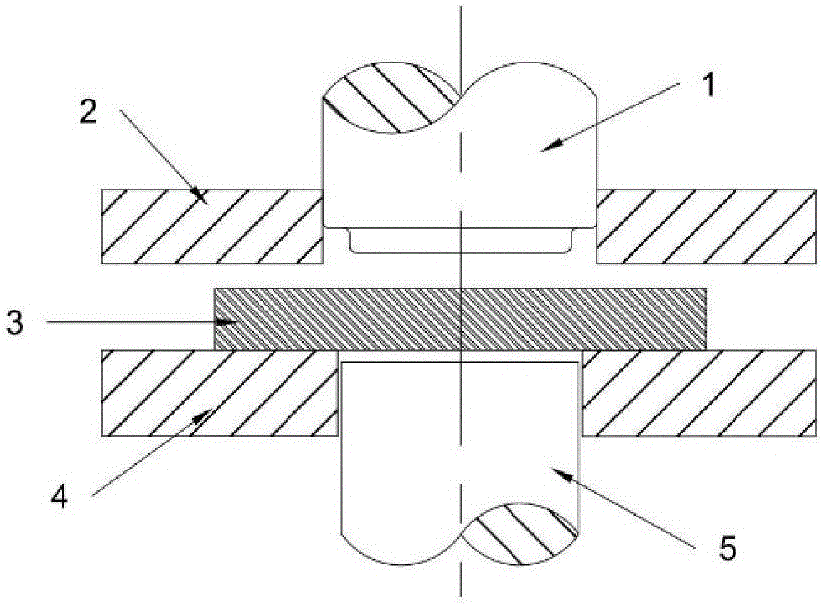

[0022] Such as figure 2 As shown, the fine blanking die in this embodiment is a positive die, that is, the punch 1 and the flat platen 2 are set on the upper side, the lower end of the punch is set in the punch hole of the platen, the die 4 and the reverse ejector pin 5 are set on the On the lower side, the reverse ejector rod 5 is located in the die; the punch 1, the flat platen 2, and the reverse ejector rod 5 are respectively connected with the dowel bar and the slider of the fine blanking machine. The pressure and action can be adjusted separately, and the die 4 is fixed on the Workbench under the press.

[0023] The sheet material 3 in this embodiment adopts C20E-EN steel which has been fully annealed and has a thickness of 6 mm. During implementation, the fine blanking die is set on a three-moving fine blanking machine to form parts.

[0024] The size of the two-stage punch 1 is related to the shape of the fine blanking part, the type and thickness of the processed ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com