Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Suction speed is fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of composite ceramic filter core containing diatomite and charcoal

ActiveCN101920140AImprove filtration efficiencyImprove uniformityCeramic shaping apparatusClay processing apparatusKeatiteComposite ceramic

The invention discloses a preparation method of a composite ceramic filter core containing diatomite and charcoal. In the preparation method, raw materials with high melting points are not used, and a mode of first dispersion and then partial flocculation is used for preparing a slurry for slip casting to enable raw materials and pores in a green body to be highly and uniformly dispersed, thus the sintering temperature is not higher than 950 DEG C, and natural micropores in the diatomite can not collapse because of high-temperature sintering.

Owner:SANDA FILM SCI & TECH XIAMEN

Production method of moisture-absorbing and sweat-discharging fabric

InactiveCN101962850AGood moisture absorption and quick drying effectSkinnyFibre cleaning/opening machinesWoven fabricsBreaking strengthPolyester

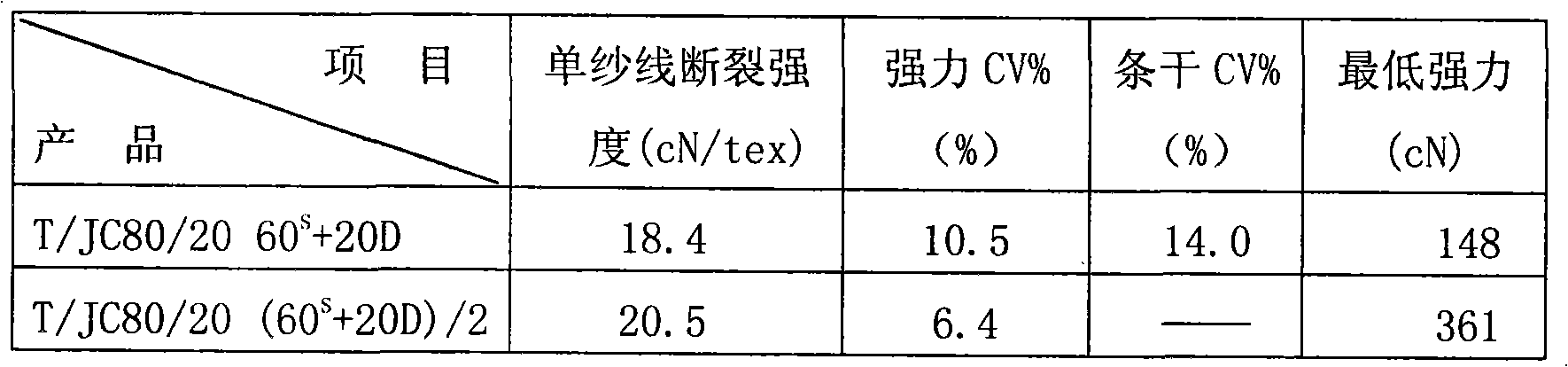

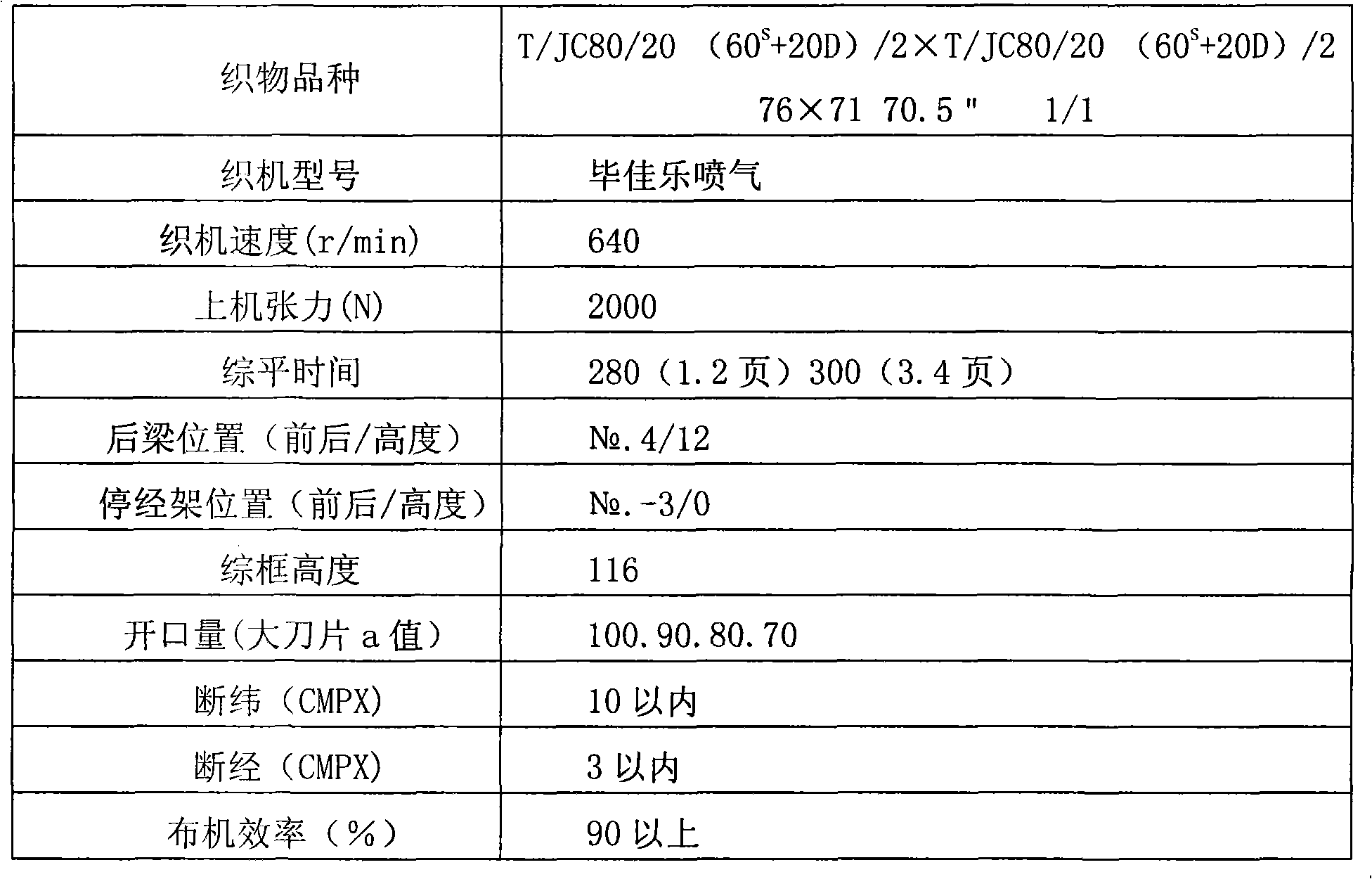

The invention relates to a production method of a moisture-absorbing and sweat-discharging fabric. In the method, the moisture-absorbing and sweat-discharging fabric is produced by using 80 percent of honeycomb moisture-absorbing and quick-drying fibers and 20 percent of cotton fibers as coating fibers and 20D common polyester filaments as core yarns. The method comprises the following steps: subjecting moisture-absorbing and sweat-discharging fibers to cotton opening and cleaning, cotton carding and primary combination, subjecting cotton fibers to cotton opening and cleaning, cotton carding and fine carding, and combining the moisture-absorbing and sweat-discharging fibers and cotton fibers primarily; combining secondarily; spinning a coarse yarn; spinning a fine yarn; winding single yarn; twisting; yarn strand winding; and producing T / JC80 / 20(60s+20D) single yarnbs and T / JC80 / 20(60S+20D) / 2 yarn stands, wherein the breaking strengths of the single yarn and the yarn strand are 18.4cN / tex and 20.5cN / tex respectively, the strength CV values of the single yarn and the yarn strand are 10.5 percent and 6.4 percent respectively, the lowest strength of the single yarn and the yarn strand are 148cN and 361cN respectively, and the yarn levelness of the T / JC80 / 20(60S+20D) single yarn is 14.0 percent; and weaving the yarn and yarn stand by warping, sizing, denting, weaving, finishing and producing a T / JC80 / 20(60s+20D) / 2*T / JC80 / 20(60s+20D) / 2 76*71 70.5''1 / 1. In the invention, the fabric produced by reasonable cotton cleaning and carding processes and proper sizing and weaving processes and by combining two combined yarns has high moisture-absorbing and rapid-drying effects and offers an excellent skinny effect.

Owner:JIHUA 3509 TEXTILE

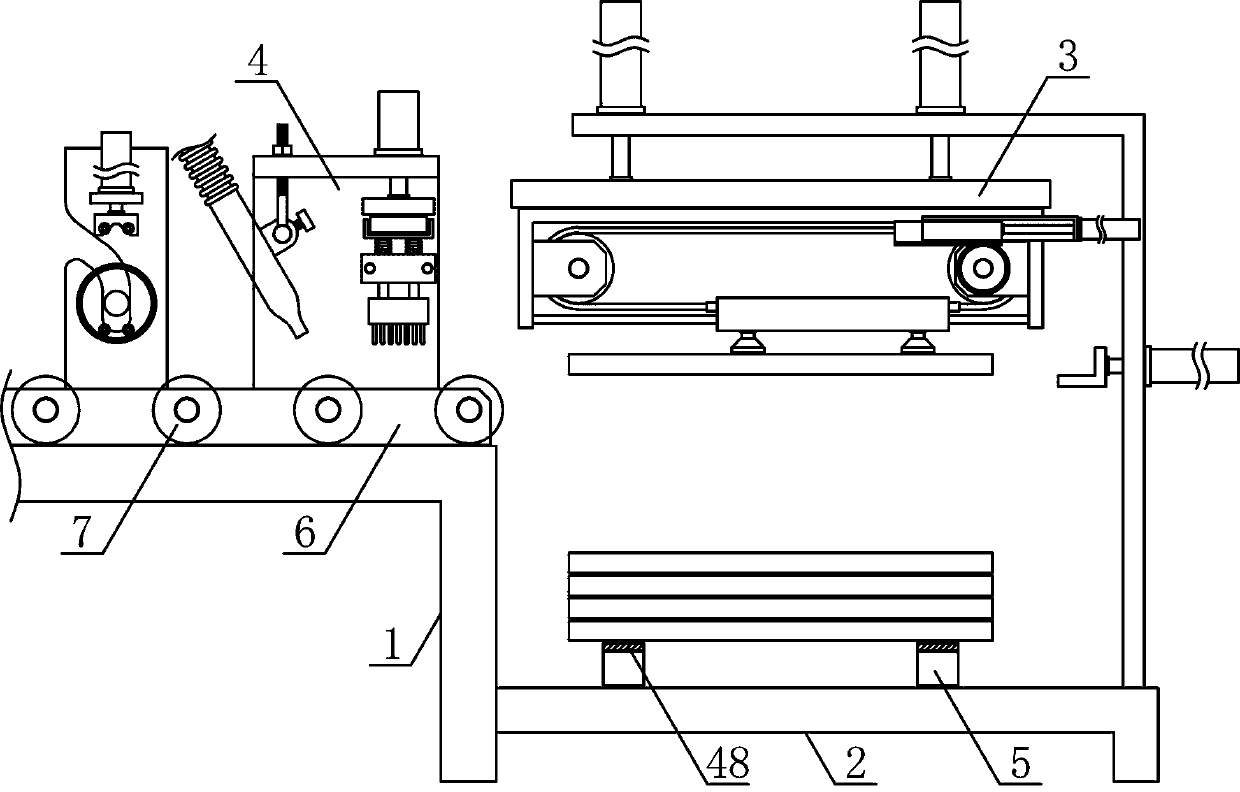

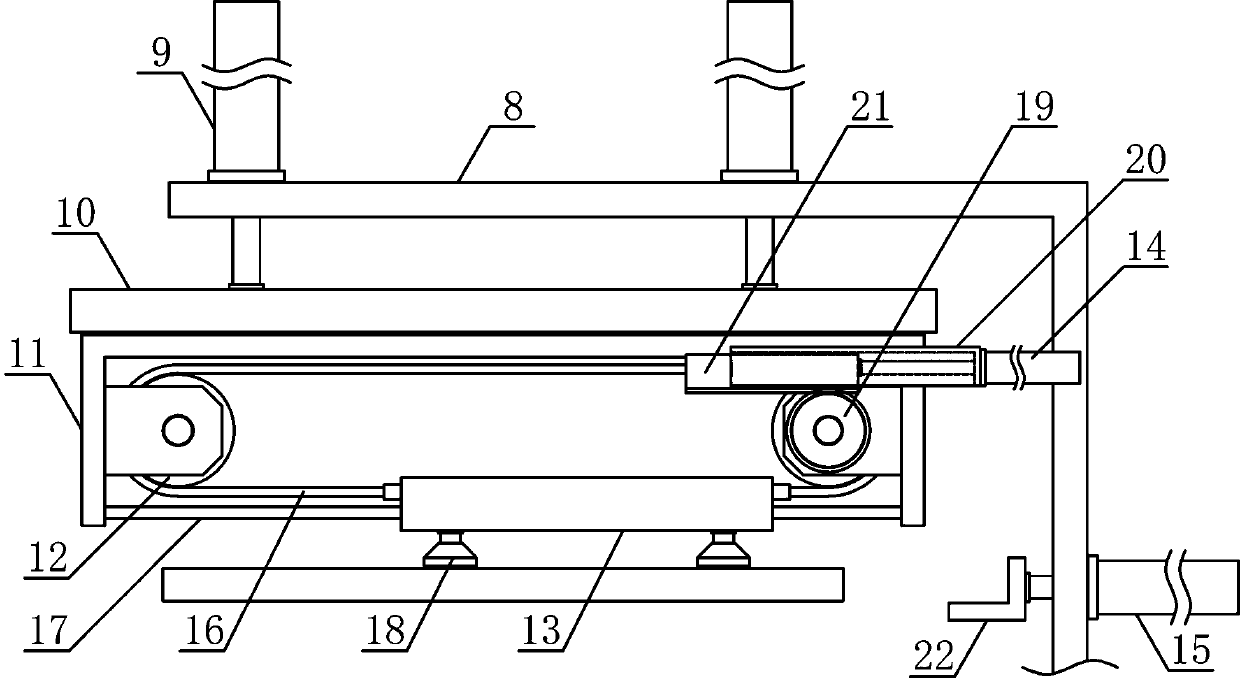

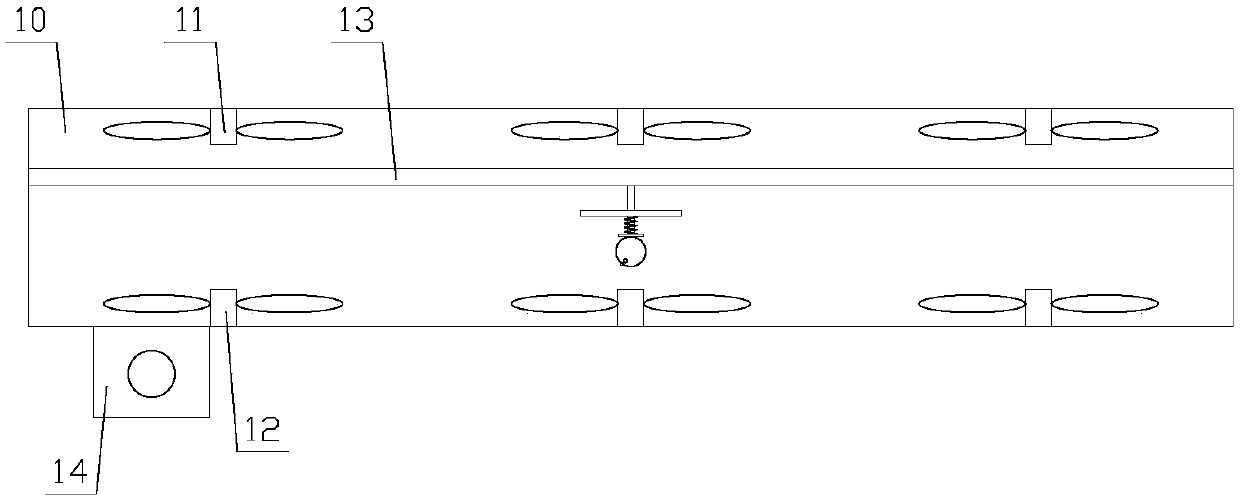

Prop plate dust removal device

InactiveCN110404832AImprove handling efficiencyImprove efficiencyCleaning using toolsCleaning using gasesMechanical equipmentEngineering

The invention discloses a prop plate dust removal device, and belongs to the field of display prop machining mechanical equipment. A plate moving mechanism of the device is fixedly arranged on the upper side of a plate placing support, a dust removal mechanism is fixedly arranged on the upper side of the guide plate support, a plurality of guide plate rotating rollers are arranged on the upper side of the guide plate support, a lifting support is horizontally and fixedly arranged on the lower side of a lifting connecting plate, a translation guide plate is arranged on a moving plate guide rodin a sliding mode in the horizontal direction, a plurality of moving plate suckers are uniformly and fixedly arranged on the lower side of the translation guide plate, a dust removal support is horizontally and fixedly arranged on the upper side of a rotary roller support, a dust brushing mechanism and a dust collection material pipe are sequentially arranged on the dust removal support in the horizontal direction, and a dust pastingmechanism is horizontally arranged on the upper side of the rotary roller support on one side of the dust collection material pipe. The device has the advantages that the structural design is reasonable, and prop plates can be rapidly and stably lifted and transferred one by one, so that the prop plates are subjected to efficient and smooth continuous dust removal processing, the automation degree of dust removal and machining of the prop plates is high, and the requirements of machining and use are met.

Owner:浙江高人道具有限公司

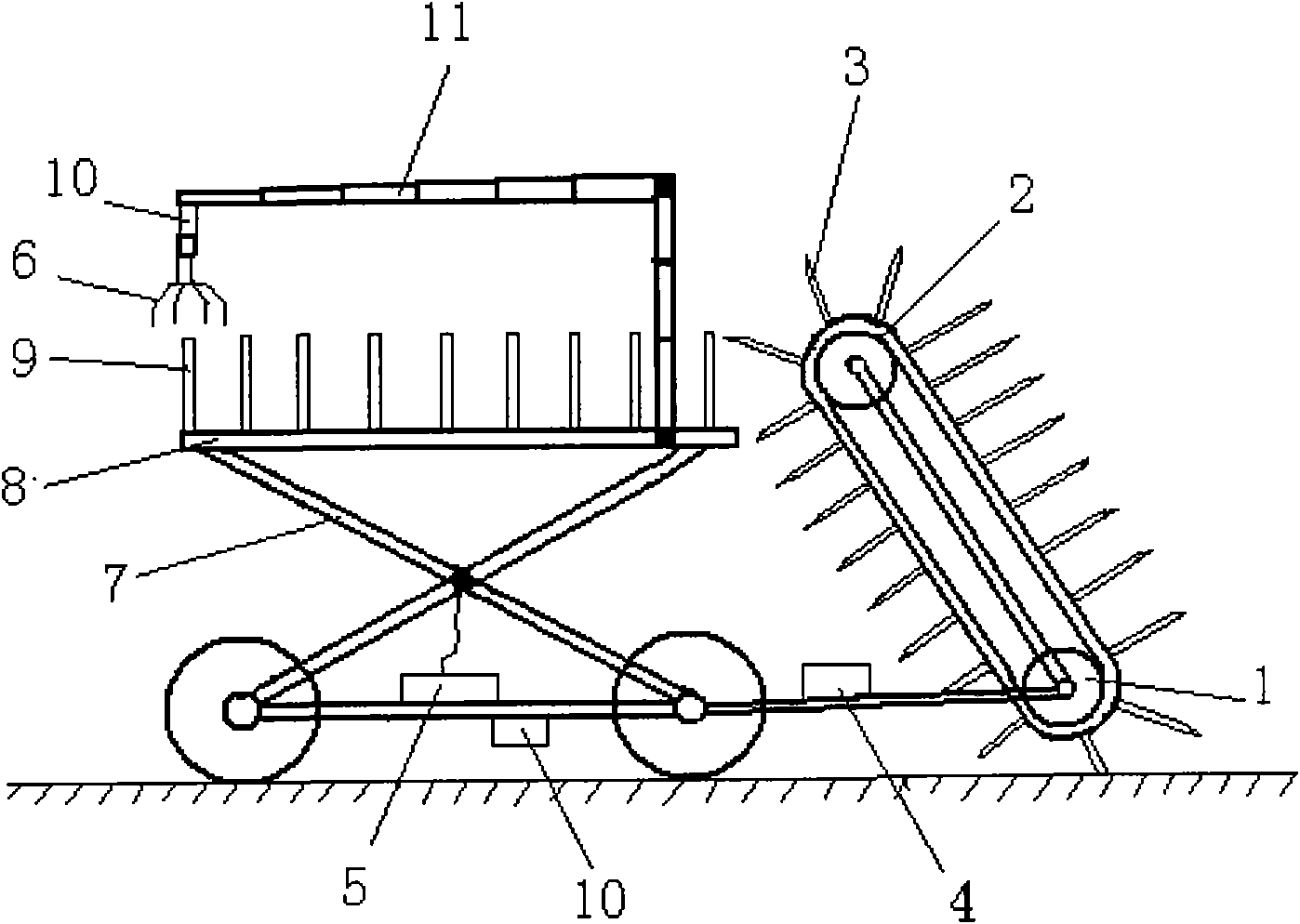

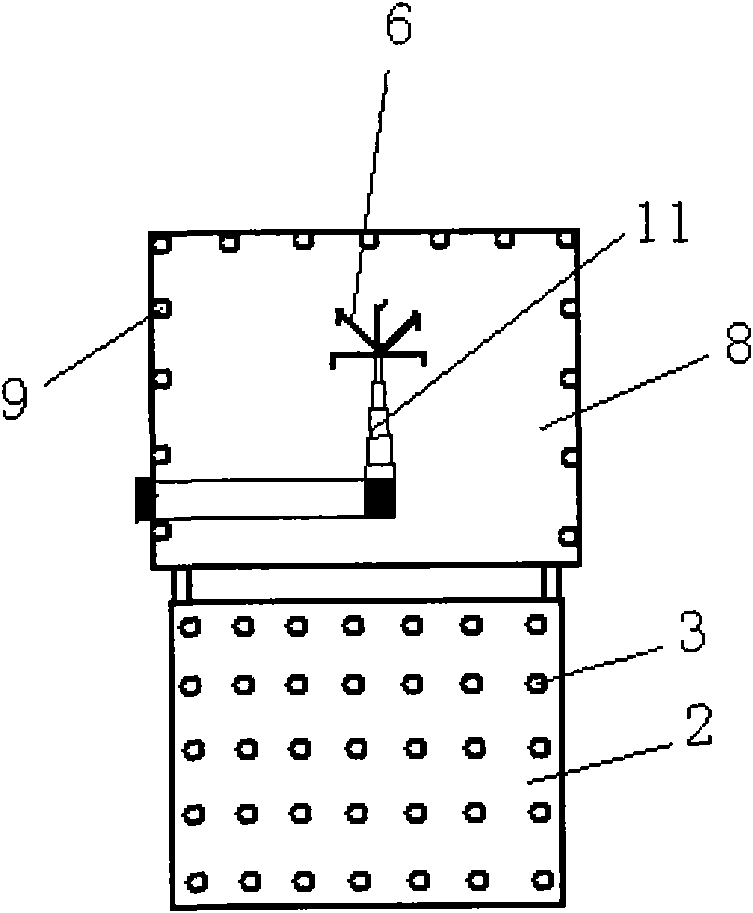

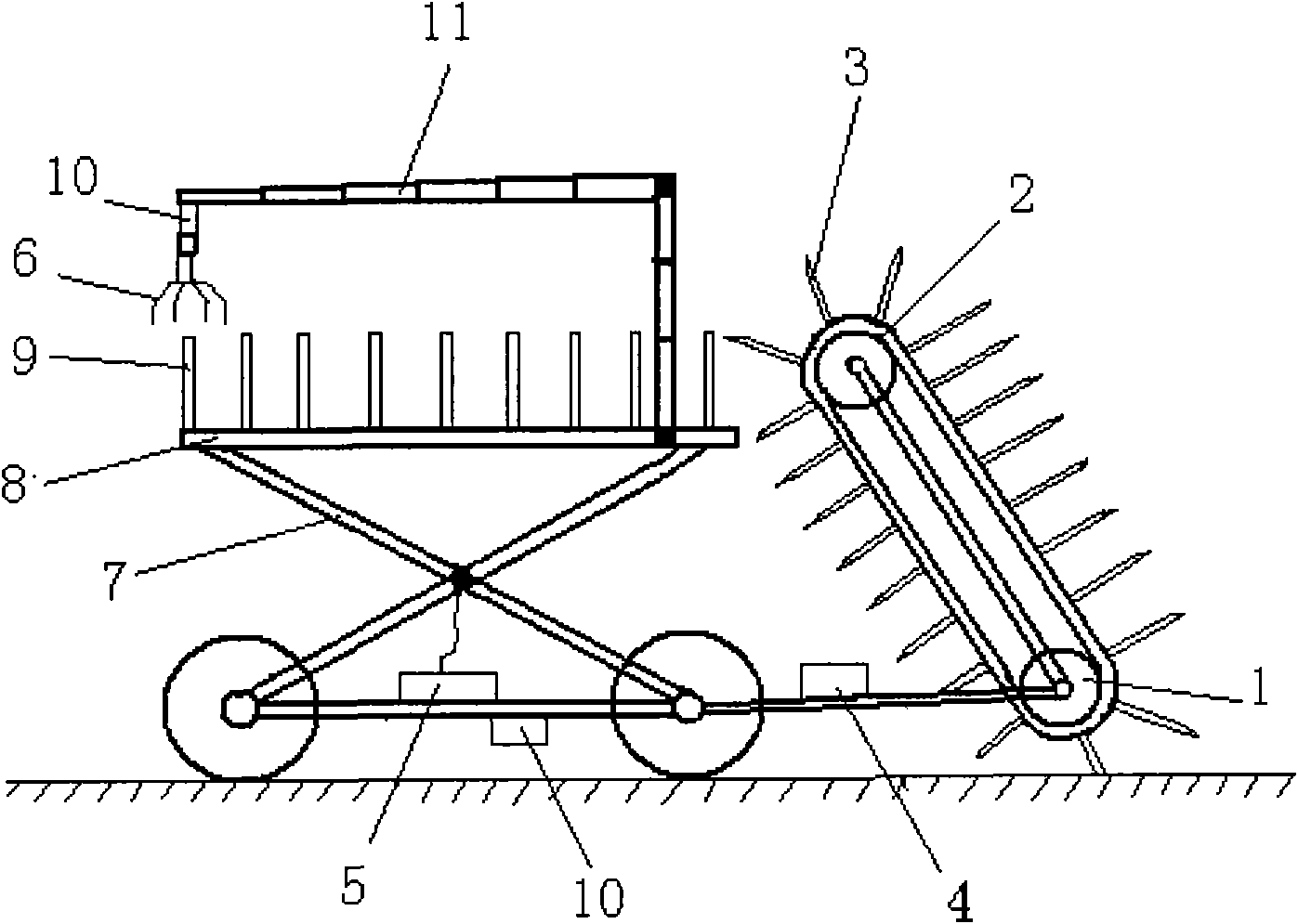

Intelligent ball collecting robot

InactiveCN101837588ASimple structureSimple and efficient operationProgramme-controlled manipulatorSortingWireless signalControl engineering

The invention discloses an intelligent ball collecting robot, which comprises a ball suction device, a ball lifting and storing device, a mechanical arm device and a remote controller, wherein the remote controller sends a wireless signal and controls the ball suction device, the ball lifting and storing device and the mechanical arm device by wireless signals. The device of the invention has the advantages of simple structure, simple and convenient operation, quick ball suction, high efficiency, easy promotion and labor conservation, and can be directly used for cleaning race courses, teaching, entertainment, robot demonstration and the like.

Owner:XIANGMING MIDDLE SCHOOL SHANGHAI

High efficiency ceramic blank casting slip and processing method thereof

The invention relates to a high efficiency ceramic blank casting slip. The ceramic blank casting slip comprises the following raw materials, by weight, 8-9 parts of Zhangcun soil, 6-7 parts of Zhangwu clay, 8-9 parts of Tangshan knag, 9-10 parts of Shanxi knag, 13-14 parts of Qinyang soil, 2-3.5 parts of Guangdong ball clay, 0.7-1.3 parts of Guangdong black mud, 1.4-1.7 parts of dolomite, 5-6 parts of Weichang clay, 9-10 parts of Fengrun sandstone, 14-15 parts of Luanxian feldspar, 3-4 parts of porcelain powder, 1-2.5 parts of Zhanjiang porcelain clay B, 7-8.5 parts of Xuanhua porcelain stone, 3-4 parts of northeast black mud, and 1.5-3 parts of Zhanjiang porcelain clay A, wherein dolomite in the raw materials is ground into a dolomite slurry, and the dolomite slurry and other raw materials, which are mixed, are ground in a ball mill according to a raw materials: balls: water ratio of 1:1.8:0.4. The raw materials of the casting slip are easy to obtain, a large ceramic product is subjected to slip casting twice each day, the slip suction speed is fast, the ceramic product production efficiency is improved, and the output is increased, so the ceramic blank casting slip is suitable for the large scale production.

Owner:TANGSHAN HUALI CERAMICS CO LTD

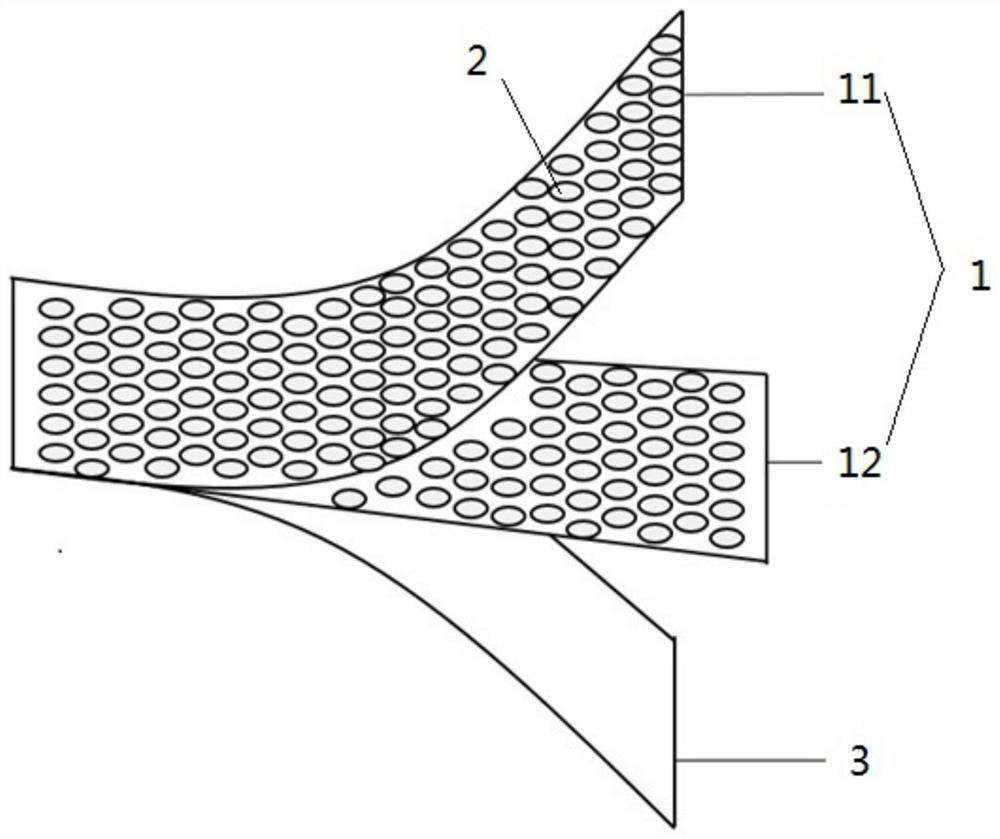

Spun-bonded non-woven fabric for diaper diversion layer and production technology of fabric

InactiveCN107904787AFluffy goodExcellent suction speedNon-woven fabricsBandagesReverse osmosisEngineering

The invention discloses a spun-bonded non-woven fabric for a diaper diversion layer and a production technology of the fabric. The non-woven fabric comprises an absorption core which is formed by coarse denier fiber, the direction of the coarse denier fiber is the longitudinal direction, the pattern of the coarse denier fiber is the strip pattern, the pattern of the absorption core is the patternof the character 'yi', and the pattern direction of the absorption core is consistent with the fiber direction. Compared with the prior art, the fabric has the advantages that a hot wind non-woven fabric can be replaced, the production speed of the spun-bonded non-woven fabric is higher than that of the hot wind short fiber, the cost is low, and the effect is good; the coarse denier product is good in diversion effect, diffusion is accelerated, the diffusion length is increased, and the amount of reverse osmosis is lowered; compared with ordinary hot wind non-woven fabrics and other products,the fluffiness is better, and the liquid absorbing speed is higher.

Owner:山东恒鹏卫生用品有限公司

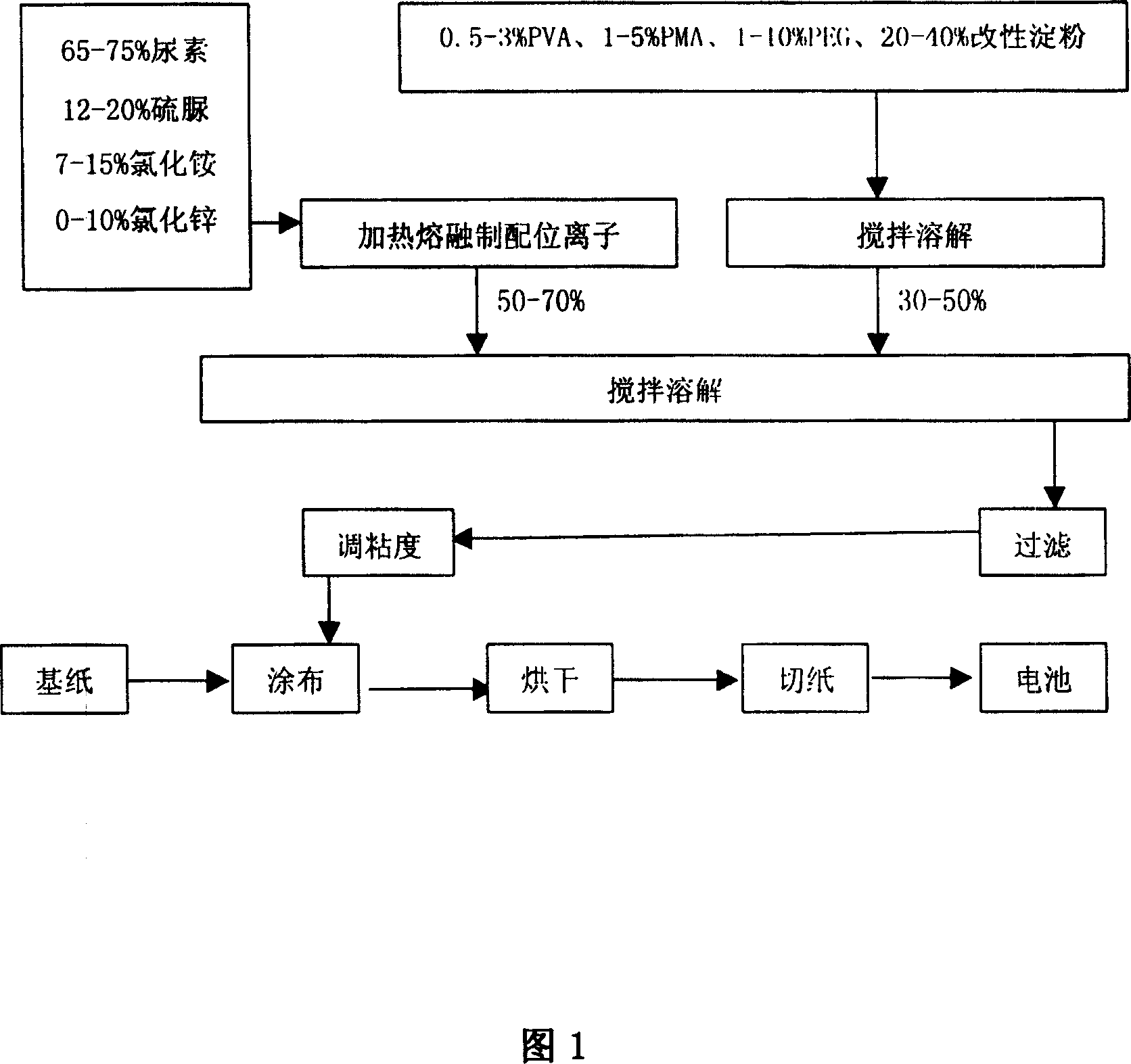

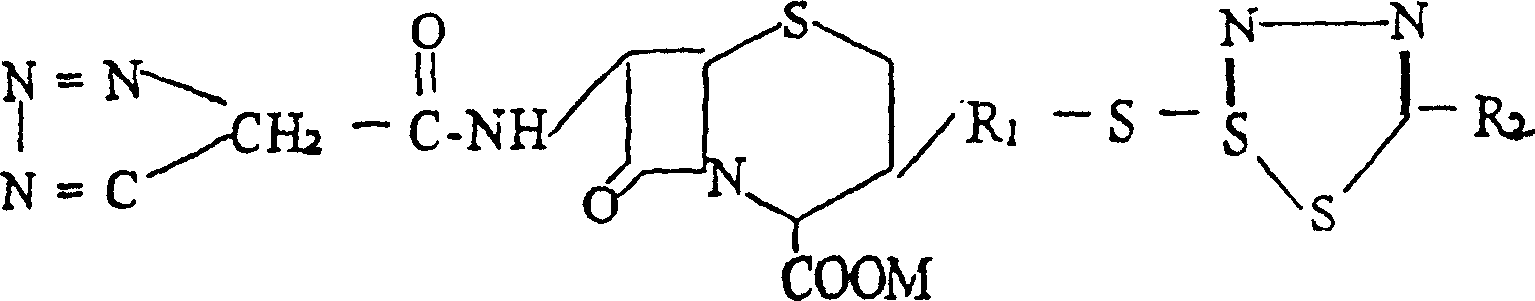

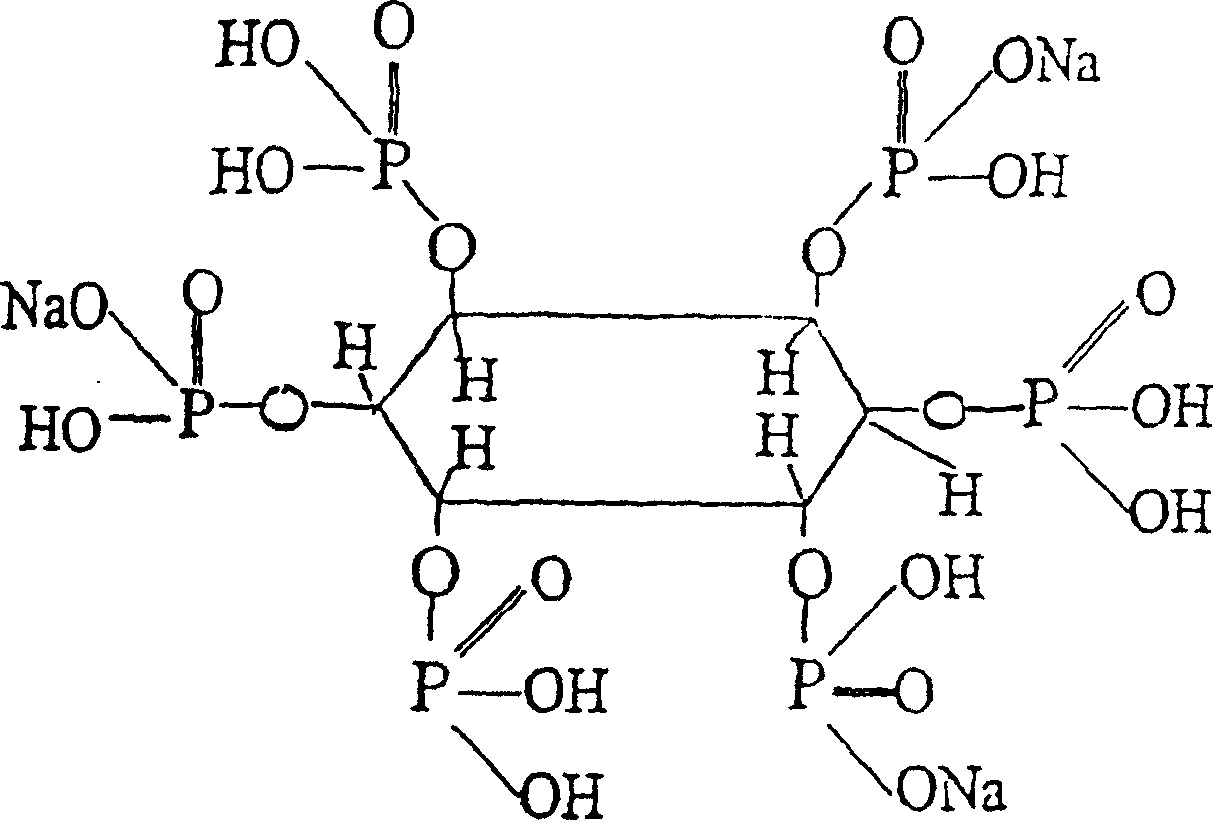

Non-mercury pulp layered paper of zinc-manganese battery containing high-polymer solid electrolyte

InactiveCN1673455ALower internal resistanceIncrease short circuit currentNon-fibrous pulp additionCell seperators/membranes/diaphragms/spacersInternal resistanceThiourea

The present invention relates to one kind of slurry paper for no-mercury Zn-Mn cell with polymer electrolyte. The slurry paper includes base paper and slurry, and the slurry consists of one kind of polymer gel prepared with coordination ion liquid and organic mercury-replacing buffer liquid. The coordination ion liquid is prepared with urea, thiourea, zinc chloride and ammonium chloride; and the polymer gel is prepared with coordination ion liquid, PVA, PAM, PEG and crosslinking starch in certain proportion. The no-mercury Zn-Mn cell with polymer electrolyte can decrease the internal resistance of cell, improve dynamic discharge performance of cell, prolong the maintenance time and avoid environmental pollution caused by mercury.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

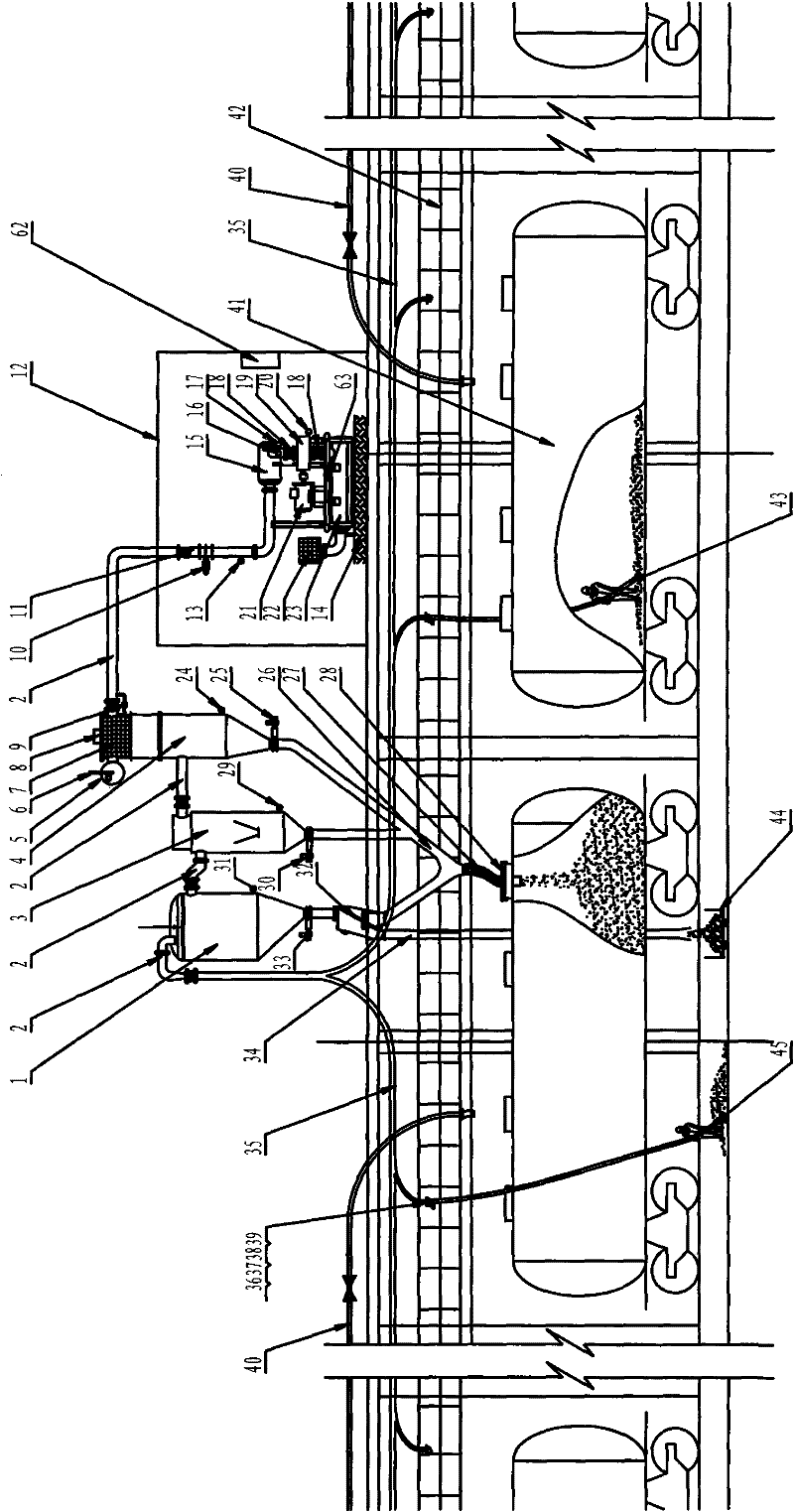

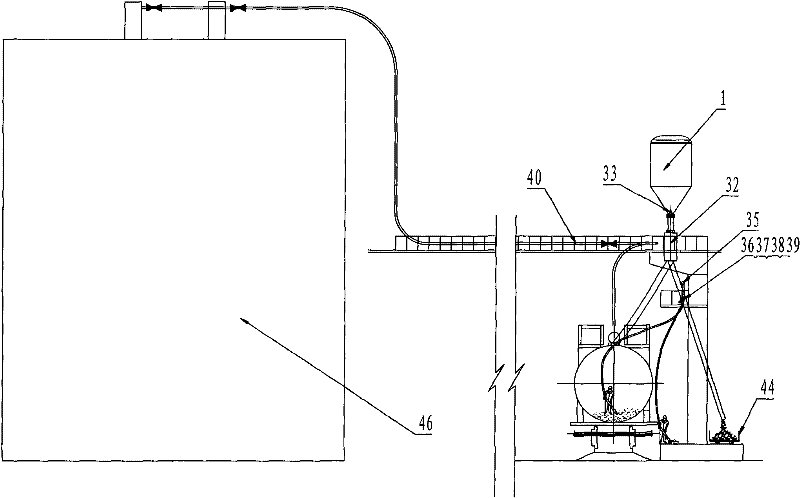

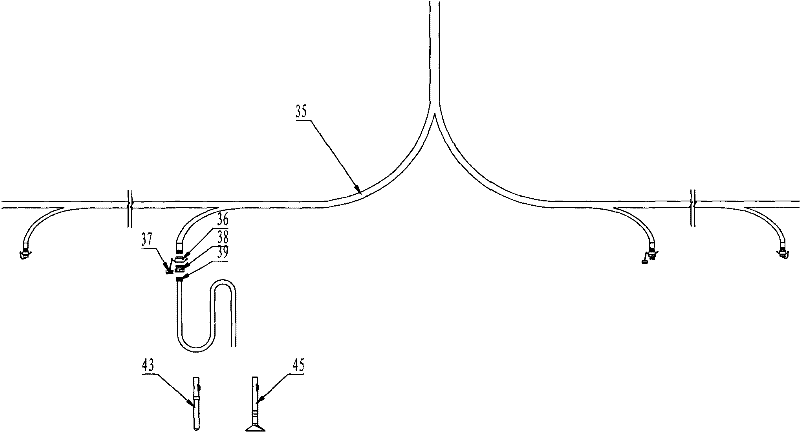

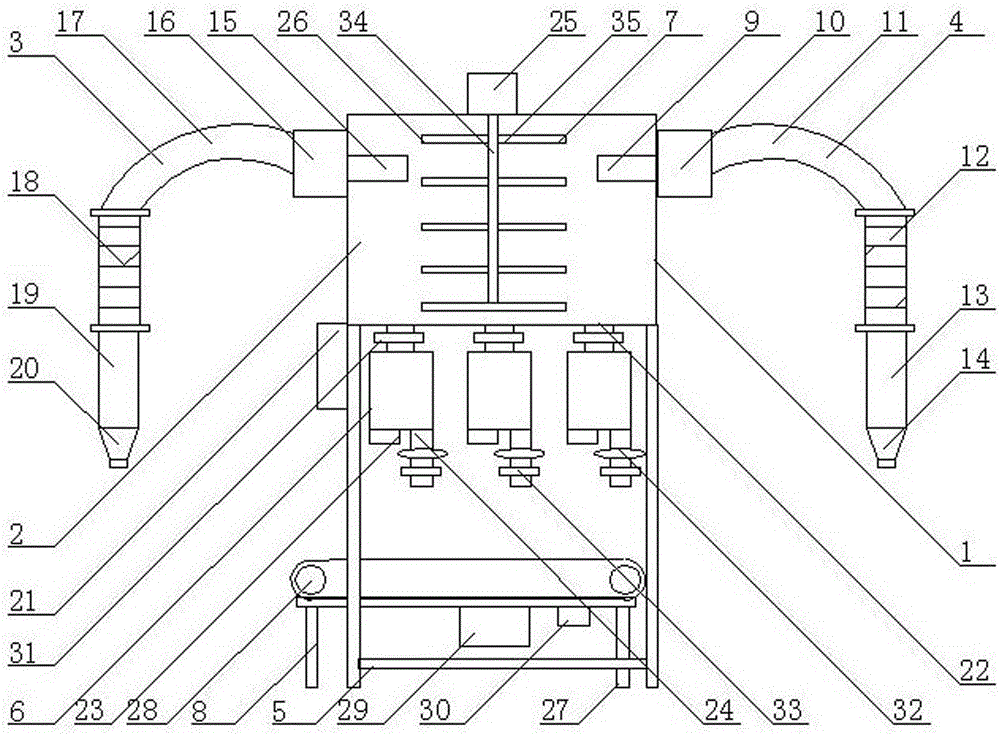

Method and device for recovering residual material and collecting dust at alumina unloading station

ActiveCN102268696AShort processEnable in-place recyclingCombination devicesWear resistantThree stage

The invention relates to a method and an apparatus for recovery of remaining alumina and dust collection in alumina discharge stations. According to the invention, a negative pressure dust collection system and a fixed type design are employed; main equipment is installed in a central material knockout platform of a discharge station; power for negative pressure is generated by a Roots pump; a gathered material obtained through a material gathering nozzle is conveyed by a wear resistant flexible pipe and a wear resistant pipe network and subjected to three-stage separation of interception by a material storing bunker, separation by a cyclone dust collector and separation by a bag filler; recovered alumina is screened by a flap sieve and returned to a railway alumina tank car which is empty or half-empty after material knockout; and an alumina discharge station dilute phase system is used to convey the recovered alumina to an alumina storing bunker. The advantages of the invention are as follows: the problems of multi-time turning of vehicles, multi-time rising of alumina and incapability of removing impurities in stained alumina on the floor existing in manual digging and manual sweeping of alumina are overcome; valuable resources are recovered; waste is reduced; labor intensity of workers are mitigated; working environment is improved; working efficiency is enhanced; clean production is realized. Therefore, the apparatus provided is applicable to electrolytic aluminum factories, alumina factories, alumina loading and unloading stations and harbors.

Owner:傅文渊

Filling device capable of quantifying liquid-state fertilizer

InactiveCN105966654APumping speed can be adjustedEasy to operateRotary stirring mixersLiquid materialAgricultural scienceLiquid manure

The invention discloses a filling device capable of quantifying a liquid-state fertilizer. The filling device capable of quantifying the liquid-state fertilizer comprises a machine body, wherein a liquid storage box is installed at the upper end of the machine body; a first material absorption device and a second material absorption device are installed at the upper ends of the left side and the right side of the liquid storage box respectively; a first support is installed at the left side and the right side of the bottom end of the liquid storage box; three parallel sub-packaging barrels are installed at the middle of the bottom end of the liquid storage box; a mixing device is installed at the middle end in the liquid storage box; and a conveying device is installed at the lower ends of the sub-packaging barrels. According to the filling device capable of quantifying the liquid-state fertilizer, which is disclosed by the invention, with the adoption of a quantitative filling manner, the filling device is convenient to fill, controllable in filling amount, low in sub-packaging error, simple and convenient to adjust, high in filling efficiency, and good in filling effect; due to a design of double material absorption devices, the filling device is fast in material absorption speed, and capable of absorbing two different materials simultaneously and mixing the materials, thus meeting a mixed filling need for many materials; and moreover, the filling device is simple to operate, and convenient to use.

Owner:哈尔滨尼亚农业有限公司

Method for preparing ultra-thin rapid-absorbing absorbency article

Owner:CHIAUS FUJIAN IND DEV

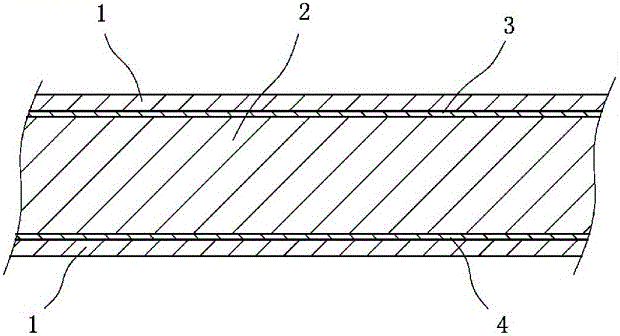

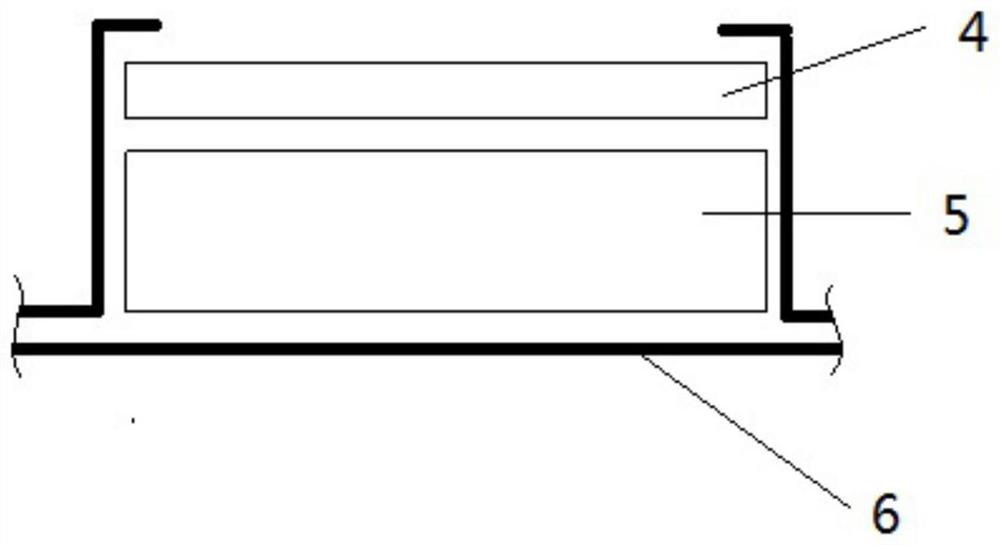

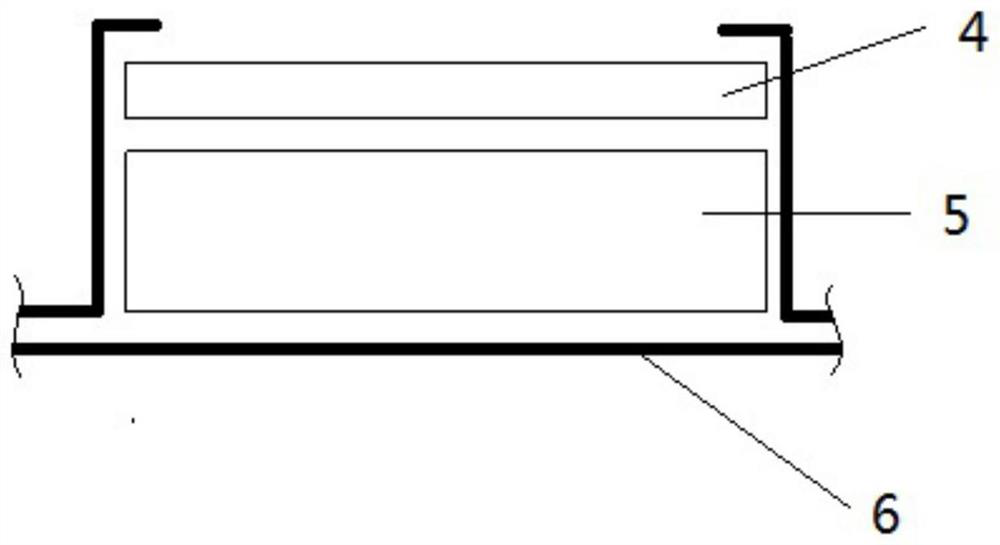

Storage battery partition plate and pregnant solution type storage battery

PendingCN106340606AIncrease liquid absorptionFast liquid absorptionFinal product manufactureCell component detailsFiber structureOxygen compound

The invention discloses a storage battery partition plate and a pregnant solution type storage battery. The partition plate is of a multi-component fiber structure and is formed by processing glass fibers and hydrophobic PE fibers of various diameters and lengths. The PE fiber content of an upper layer and a lower layer of the vertical section structure of the partition plate is the same and is lower than that of an intermediate interlayer. A bag type structure partition plate is adopted for the pregnant solution type storage battery. The storage battery partition plate can have the advantages that a PE partition plate and an AGM partition plate are small in pore diameter and low in resistance and easily made into a bag type, and it can be guaranteed that the pregnant solution type storage battery has good low temperature discharge performance, oxygen compound efficiency and cost performance.

Owner:SHANDONG SACRED SUN POWER SOURCES

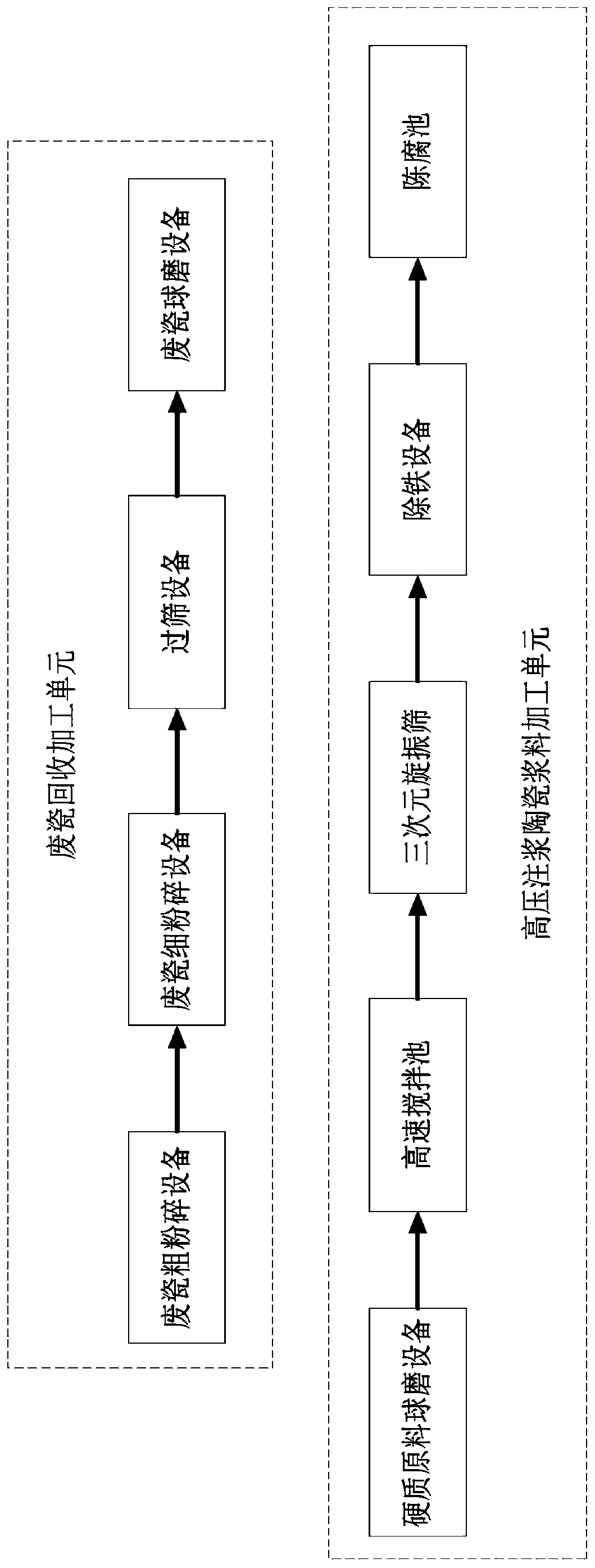

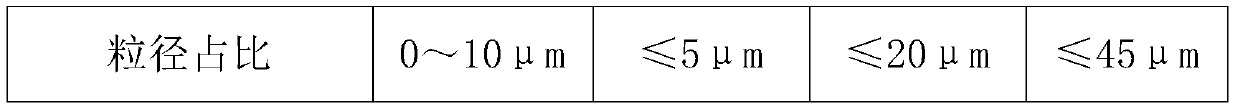

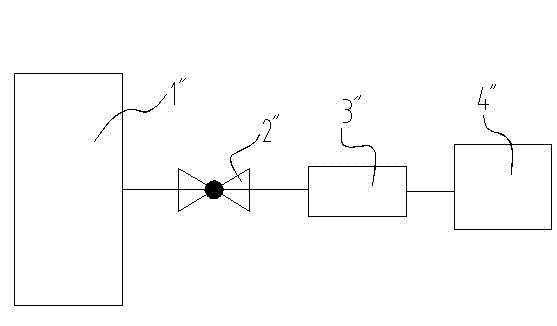

High-pressure grouting ceramic slurry based on waste ceramic recycling as well as preparation method and system

ActiveCN110078471AReduce manufacturing costImprove efficiencyClay mixing apparatusCeramic materials productionHigh sodiumPyrophyllite

The invention discloses high-pressure grouting ceramic slurry based on waste ceramic recycling as well as a preparation method and a system. The ceramic slurry comprises the following raw materials: 1-5 parts of quartz sand, 5-10 parts of high-sodium mountain flour, 5-10 parts of potassium albite, 8-13 parts of ball clay, 15-20 parts of kaolin, 15-20 parts of illite clay, 10-15 parts of pyrophyllite, 1-5 parts of dolomite, 10-15 parts of sericite and 5-10 parts of waste ceramic slurry, wherein the grain composition of the waste ceramic slurry is D55 of 0-10 mu m, D35 less than or equal to 5 mum, S70 less than or equal to 20 mu m and D95 less than or equal to 45 mu m. The use amounts of quartz and feldspar in the raw materials are greatly reduced, the production cost of the high-pressure grouting ceramic slurry is lowered, the waste ceramic recycling and utilization rate is up to 5-10 wt%, and environmental pollution can be reduced. Waste ceramic slurry granule distribution is centralized in a position of 10 mu m, defects that a high-pressure grouting ceramic blank is liable to layer, low in blank yield, easy in sintering layer swelling, and the like when being molded since waste ceramic slurry granules are distributed in positions of large particle sizes can be avoided, and high-ratio utilization of waste ceramics can be achieved.

Owner:江门市东鹏智能家居有限公司 +1

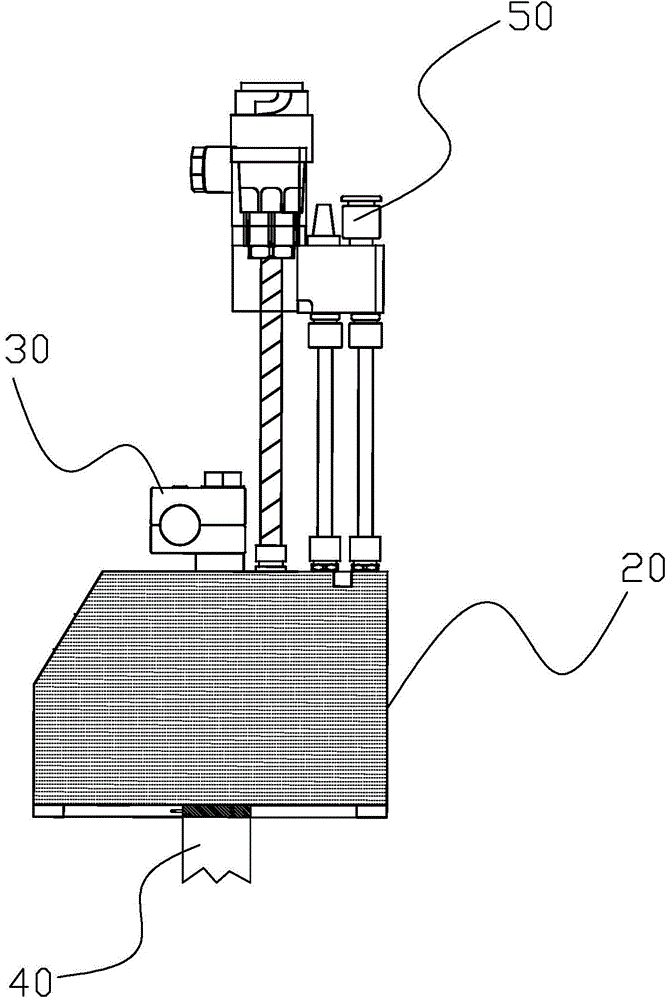

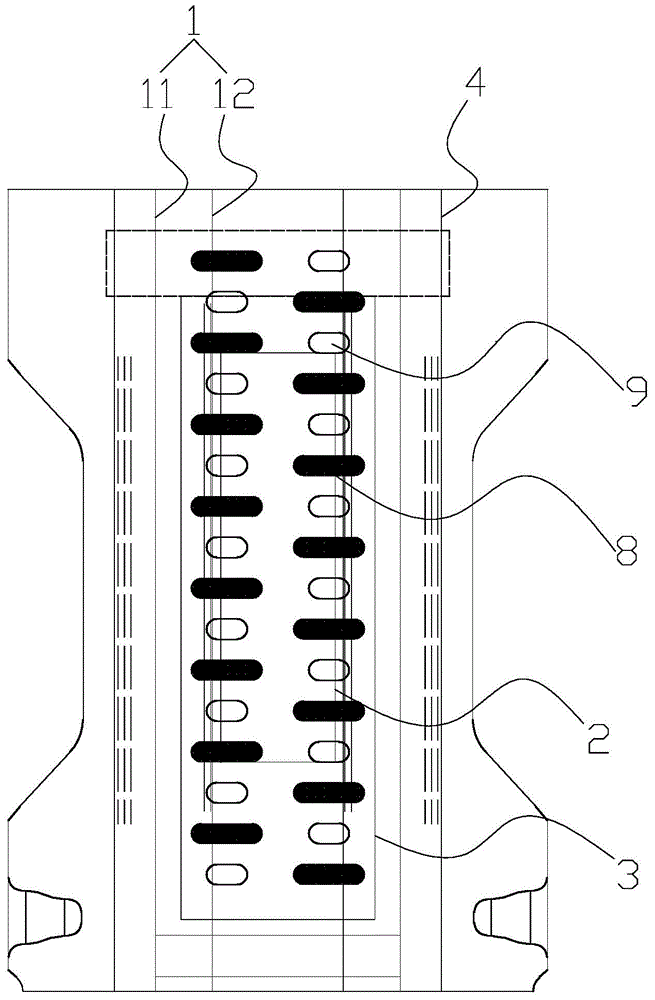

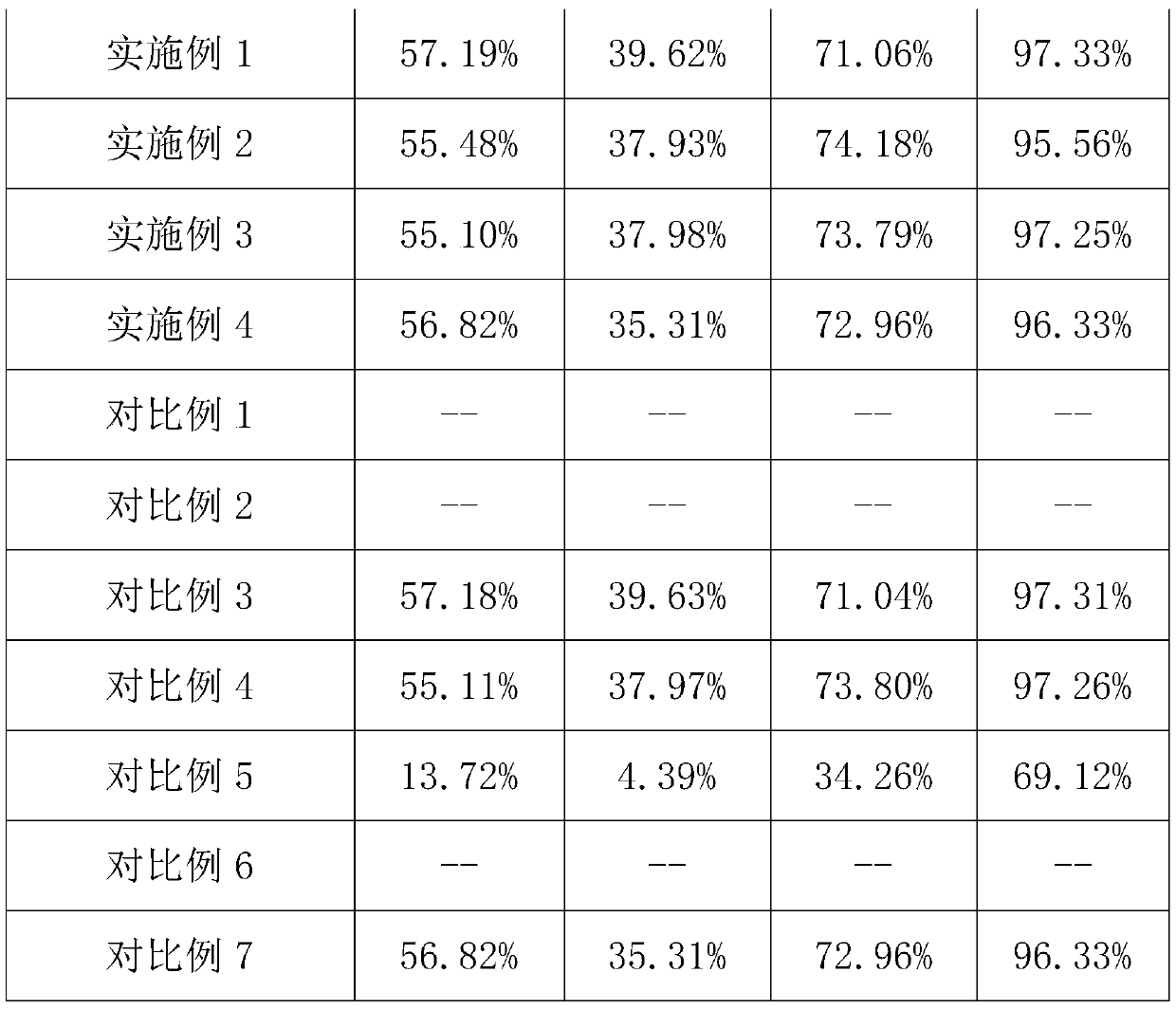

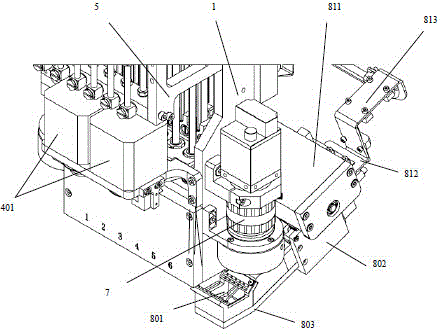

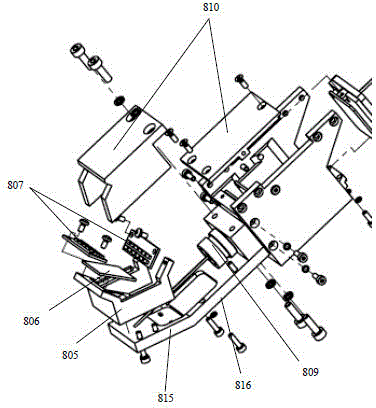

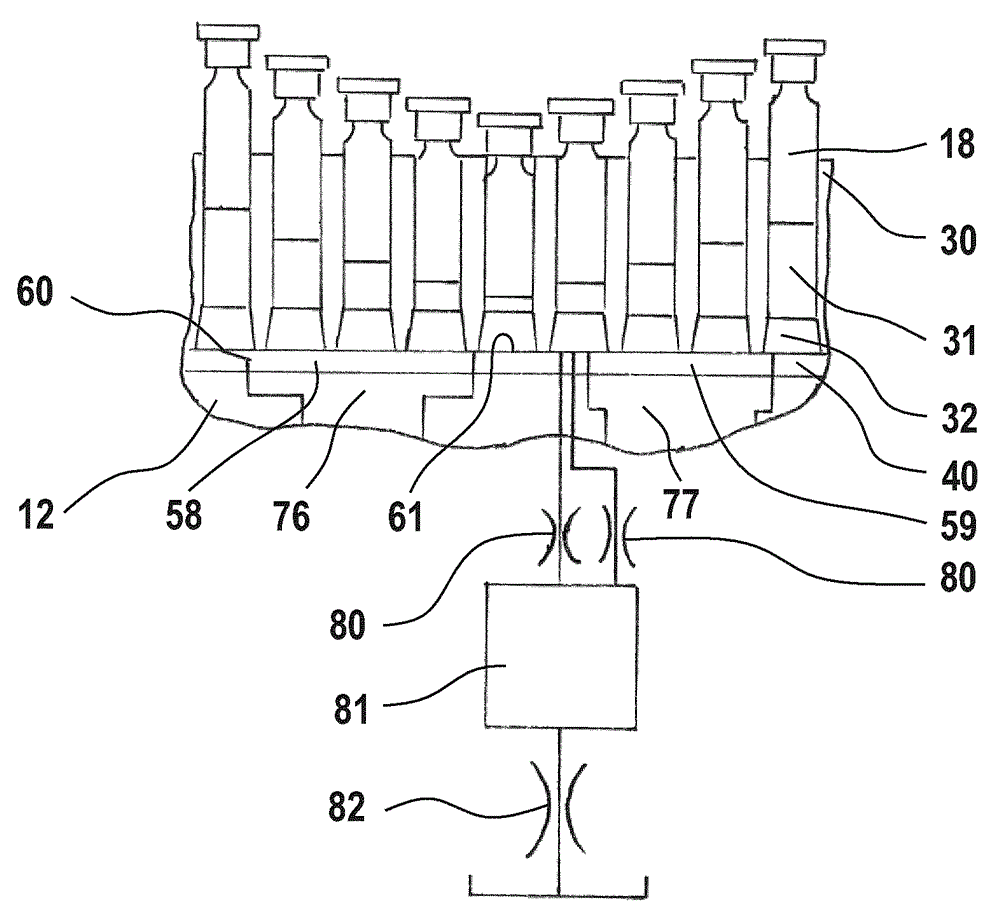

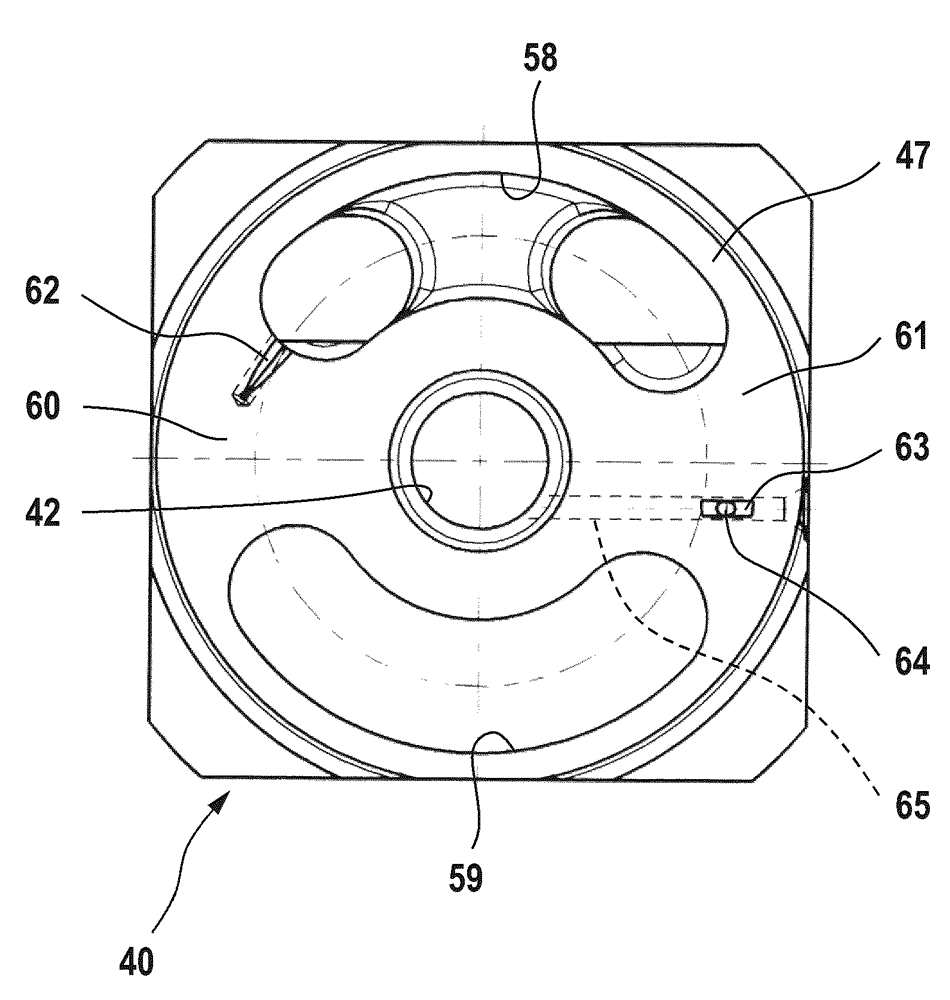

High-precision chip mounting head capable of flight identification

ActiveCN106304673AReduce deflectionGuaranteed uptimePrinted circuit assemblingAcute angleMiniaturization

The invention provides a high-precision chip mounting head capable of flight identification. The chip mounting head comprises a chip mounting head support, chip mounting shafts mounted in the chip mounting head support, a direction-Z elevation mechanism, a direction-R turning mechanism and a vacuum module group; the chip mounting head is characterized in that an integrated control assembly is mounted in the back side of the upper portion of the chip mounting head support, the vacuum module group is mounted in the front side of the upper portion of the support, a direction-R stepping motor which drives the direction-R turning mechanism and a CCD camera collecting images are mounted in the middle of the front side of the support, direction-Z driving motors are mounted in the back side of the support, and the directions of output shafts of the direction-Z driving motors are vertical to the axis-Z; and a flight camera device is mounted in the lower portion of the back side of the chip mounting head support, and comprises a light source assembly below a nozzle, a camera assembly, a camera support provided with the light source assembly and the camera assembly and a driving mechanism which enables the camera support to move along the axis-X, and an acute angle is formed between the direction of a lens of the camera assembly and the vertical direction in the XY plane. The chip mounting head is minimized and low-cost, and stable, accurate, rapid and high-precision chip mounting is realized.

Owner:江苏华志珹智能科技有限公司

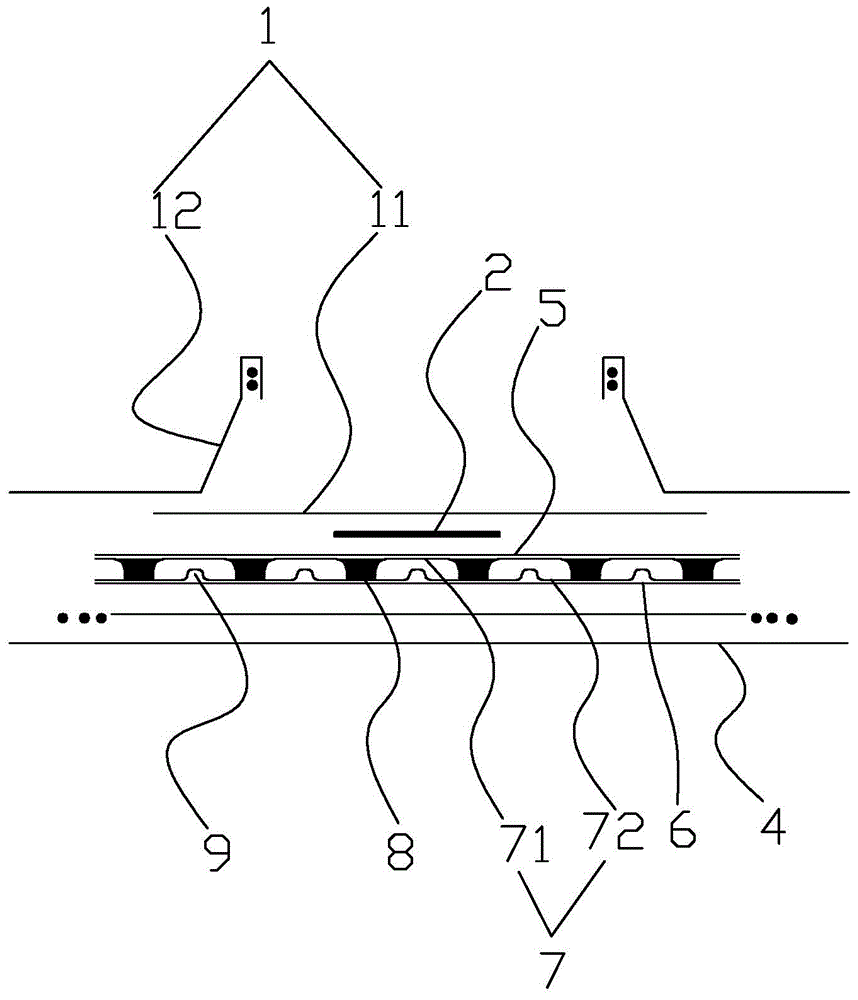

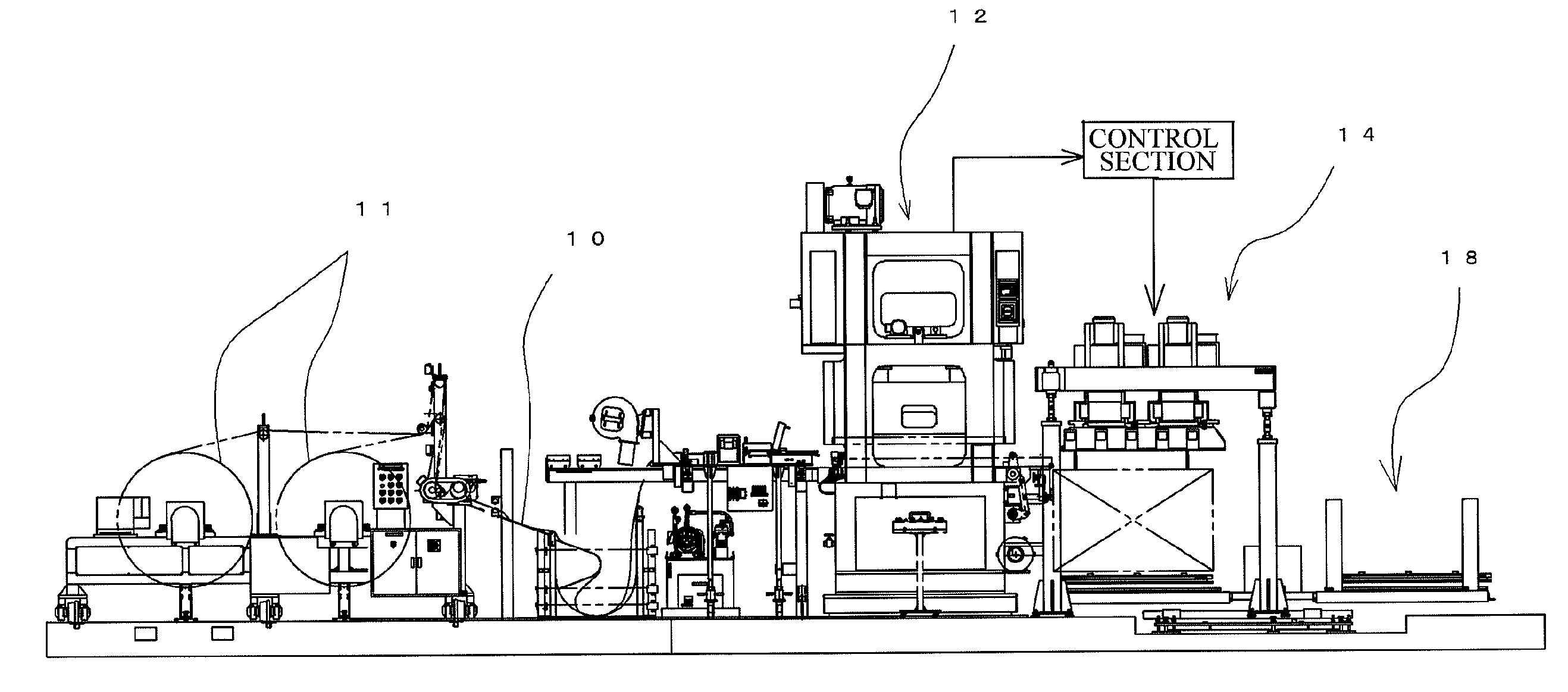

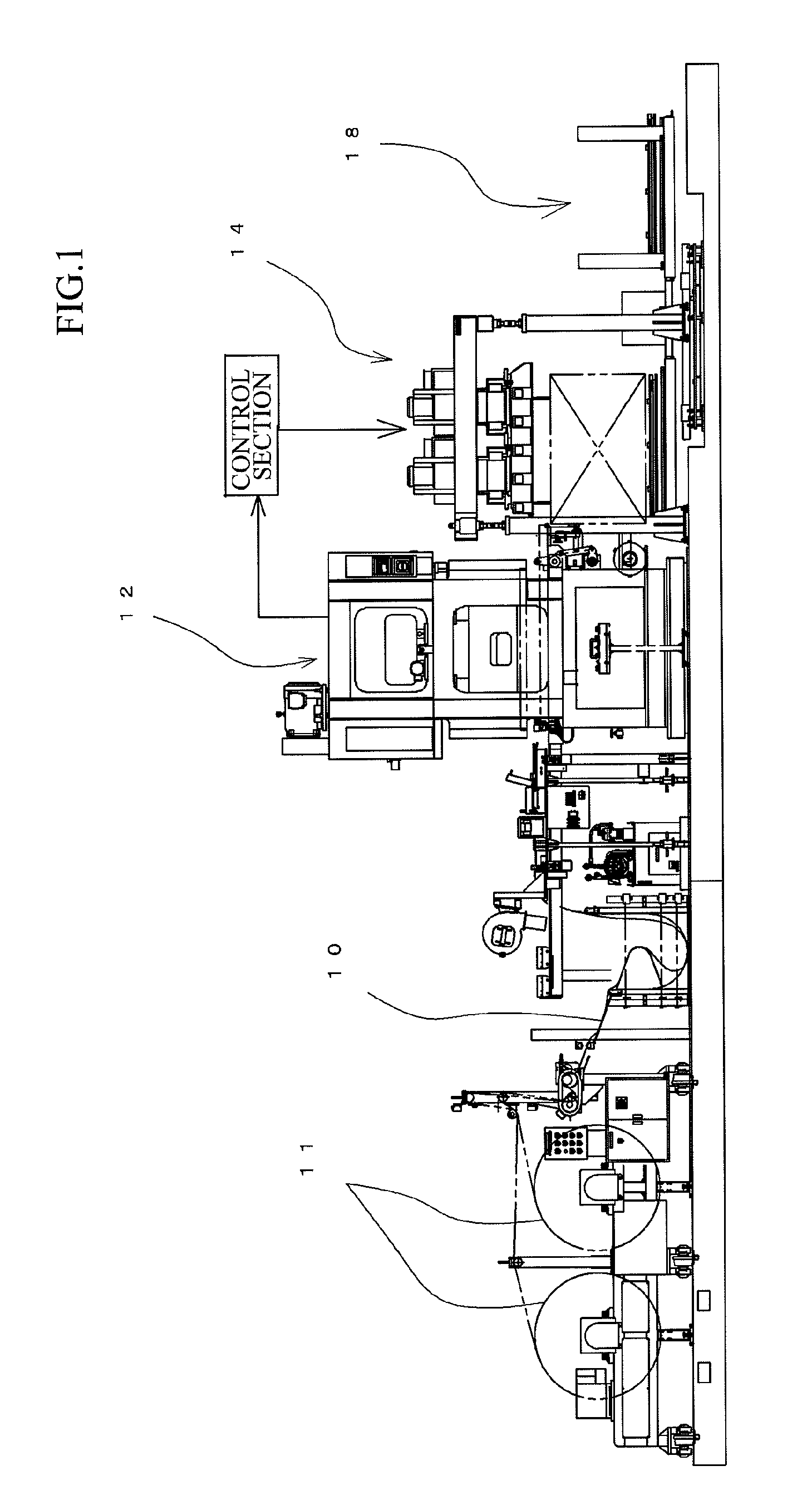

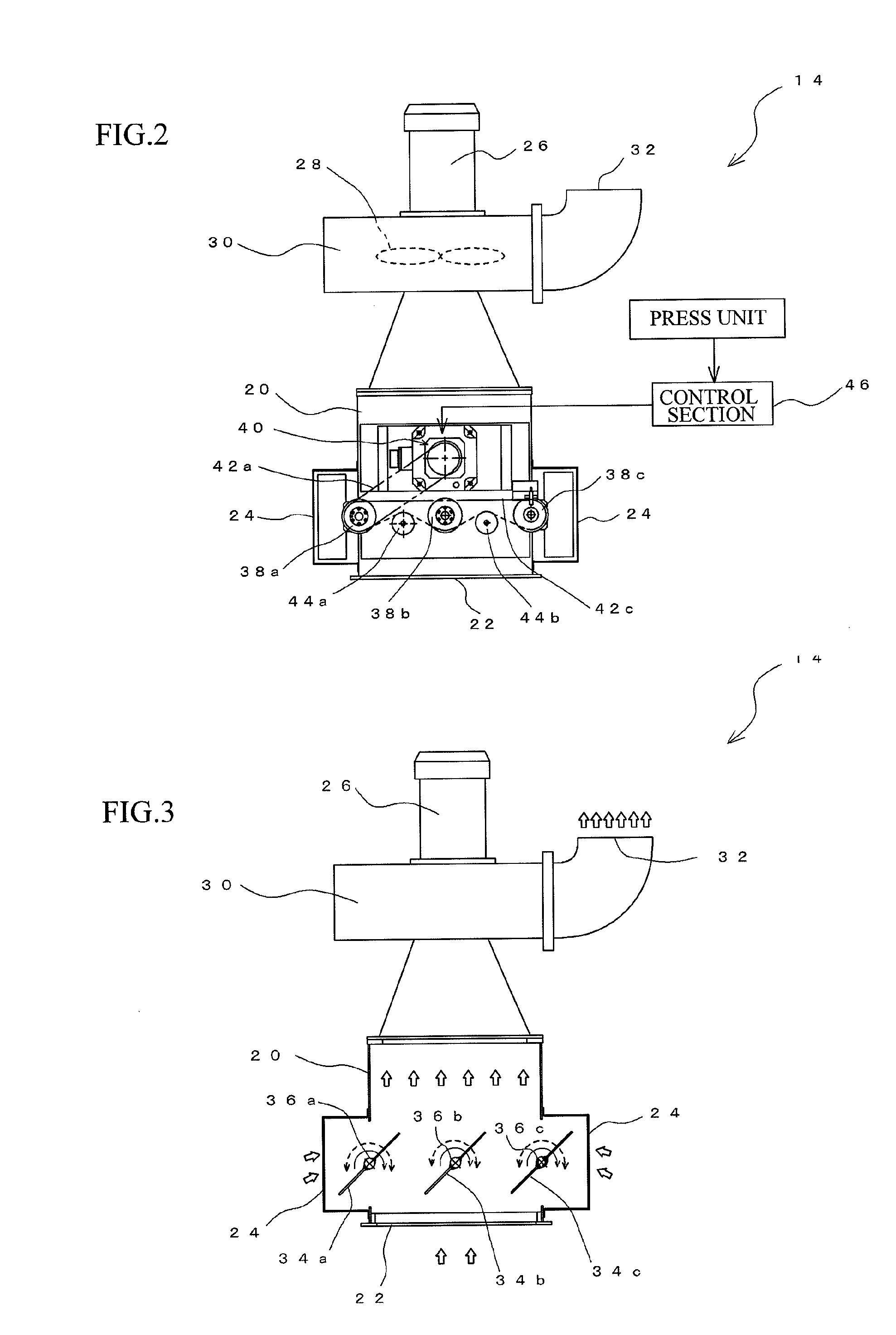

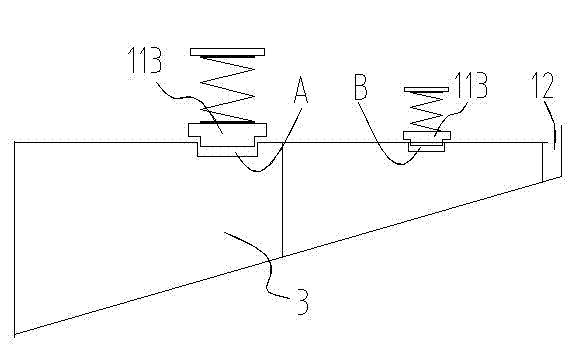

Suction unit and heat exchange fin manufacturing machine

InactiveUS20090235791A1Processing speedFast processingMetal-working feeding devicesHeat exchange apparatusEngineeringElectric motor

The suction unit of the present invention comprises: a cylindrical member having a sucking section capable of sucking an elongated piece having faced the sucking section, an opening section being opened at a prescribed position at which the elongated piece is prohibited to face the opening section, and a suction unit for sucking air from the sucking section and the opening section; a blocking plate being moved without contacting the cylindrical member, the blocking plate prohibiting the air suction from the opening section when the elongated piece faces the sucking section, the blocking plate allowing the air suction from the opening section when the elongated piece sucked by the sucking section is cut and formed into the heat exchange fin; and a control section controlling the electric motor so as to place the blocking plate at a sucking position when the elongated piece faces the sucking section and at a releasing position when the elongated piece is cut and formed into the heat exchange fin.

Owner:HIDAKA SEIKI KK

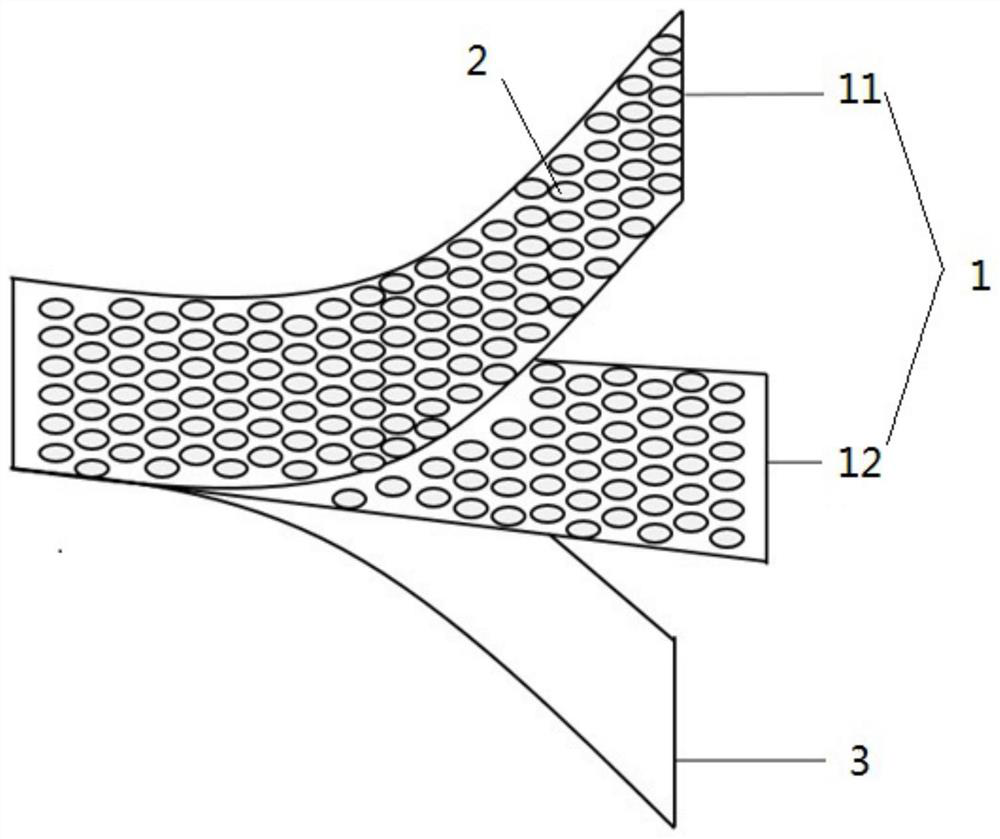

Pure cotton spunlace composite fabric as well as preparation method and application thereof

PendingCN112779666ASuction speed hindranceSuction speed is fastAbsorbent padsNon-woven fabricsPolymer scienceCotton fibre

The invention discloses a preparation method of a pure cotton spunlace composite fabric. The method comprises the following steps of preparing a surface layer from water-repellent cotton fibers, performing spunlace compounding on the pre-wetted surface layer and a structural layer to obtain a water-repellent all-cotton composite surface layer, preparing meshes in the water-repellent all-cotton composite surface layer by adopting a punching process, compounding the structural layer and a flow guide layer, and enabling the flow guide layer to cover the meshes in the water-repellent all-cotton composite surface layer, so that the pure cotton spunlace composite fabric is obtained. The water-repellent cotton fibers are creatively adopted to manufacture the water-repellent pure cotton surface layer, and after the water-repellent pure cotton surface layer and the structural layer are subjected to spunlace compounding, the water-repellent all-cotton composite surface layer with higher strength can be obtained, and the meshes with clearer edges are formed, so that it is guaranteed that the liquid absorption speed of the surface layer is not hindered by edge fibers of the meshes; and in addition, after the water-repellent all-cotton composite surface layer and the flow guide layer are compounded, the liquid absorption speed of the surface layer can be increased through the flow guide layer, and meanwhile the situation of glue leakage of the meshes of the surface layer can be effectively prevented.

Owner:WINNER MEDICAL CO LTD +1

A high-efficiency oil-free scroll compressor for both gas and liquid media

InactiveCN102269165ASolve the structural defects that cannot absorb pressure liquid mediumImprove work efficiencyRotary piston pumpsRotary piston liquid enginesSpacing toothLiquid medium

The invention discloses a high-efficiency oil-free scroll compressor for both gas and liquid media, which comprises a scroll stationary disk and a scroll movable disk; wherein the scroll static disk is provided with teeth to form a cogged structure, and the center of the cogged structure is There is a main outlet; the teeth of the vortex movable disk perform circular translation in the tooth groove of the vortex static disk, and the inner tooth surface of the vortex movable disk is close to the outer tooth surface of the vortex static disk teeth Sliding displacement, the alveolar structure formed by the vortex static disk teeth is provided with several bypass outlets connected with the main outlet at intervals, and each bypass outlet is equipped with a valve that automatically opens to discharge when the pressure exceeds a predetermined value. pressure balance regulator valve. The invention overcomes the defect that the existing oil-free scroll compressor cannot compress the liquid medium, and designs a high-efficiency oil-free scroll compressor for both gas and liquid media, which has the advantages of fast suction speed, good cleaning effect and long service life. Long life and low maintenance cost.

Owner:蒋友荣

Non-mercury pulp layered paper of zinc-manganese battery containing high-polymer solid electrolyte

InactiveCN1321244CLower internal resistanceIncrease short circuit currentNon-fibrous pulp additionCell seperators/membranes/diaphragms/spacersInternal resistanceThiourea

The present invention relates to one kind of slurry paper for no-mercury Zn-Mn cell with polymer electrolyte. The slurry paper includes base paper and slurry, and the slurry consists of one kind of polymer gel prepared with coordination ion liquid and organic mercury-replacing buffer liquid. The coordination ion liquid is prepared with urea, thiourea, zinc chloride and ammonium chloride; and the polymer gel is prepared with coordination ion liquid, PVA, PAM, PEG and crosslinking starch in certain proportion. The no-mercury Zn-Mn cell with polymer electrolyte can decrease the internal resistance of cell, improve dynamic discharge performance of cell, prolong the maintenance time and avoid environmental pollution caused by mercury.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

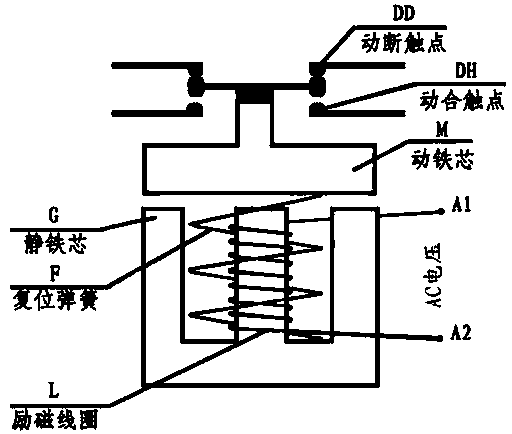

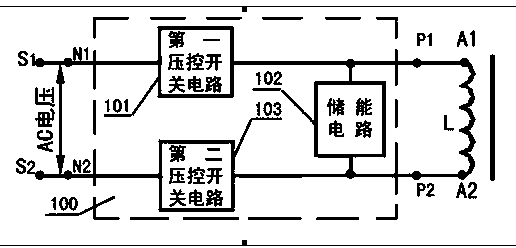

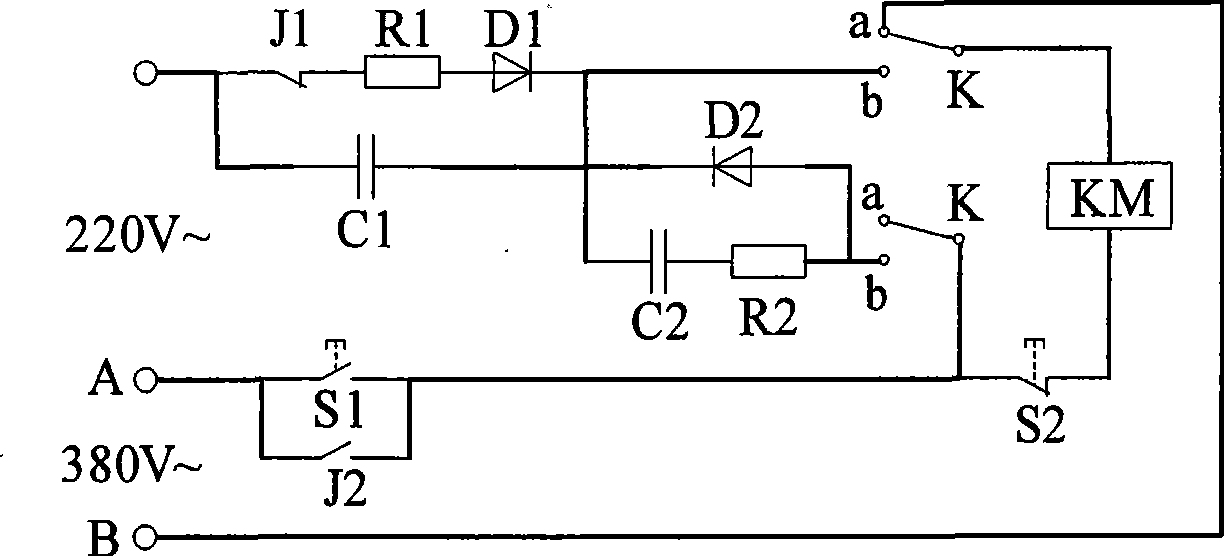

Power-saving type alternating current contactor with power-saving unit

The invention discloses a power-saving type alternating current contactor with a power-saving unit. The power-saving alternating current contactor with the power-saving unit is composed of a first voltage-controlled switching circuit, an energy-storing circuit and a second voltage-controlled switching circuit, and is characterized in that the power-saving type alternating current contactor with the power-saving unit is a network provided with four ports, the port N1 and the port N2 are input ports of the network, and the port P1 and the port P2 are output ports of the network; the input port N1 and the input port N2 are connected with the S1 end and the S2 end of the AC voltage respectively, and the output port P1 and the output port P2 are connected with the A1 end and the A2 end of the magnet exciting coil L of a traditional alternating current contactor respectively; the N1 end, the first voltage-controlled switching circuit, the energy-storing circuit, the second voltage-controlled switching circuit and the N2 end are sequentially connected in series, the P1 end is led from the connecting position of the first voltage-controlled switching circuit and the energy-storing circuit, and the P2 end is led from the connecting position of the energy-storing circuit and the second voltage-controlled switching circuit.

Owner:STATE GRID CORP OF CHINA +2

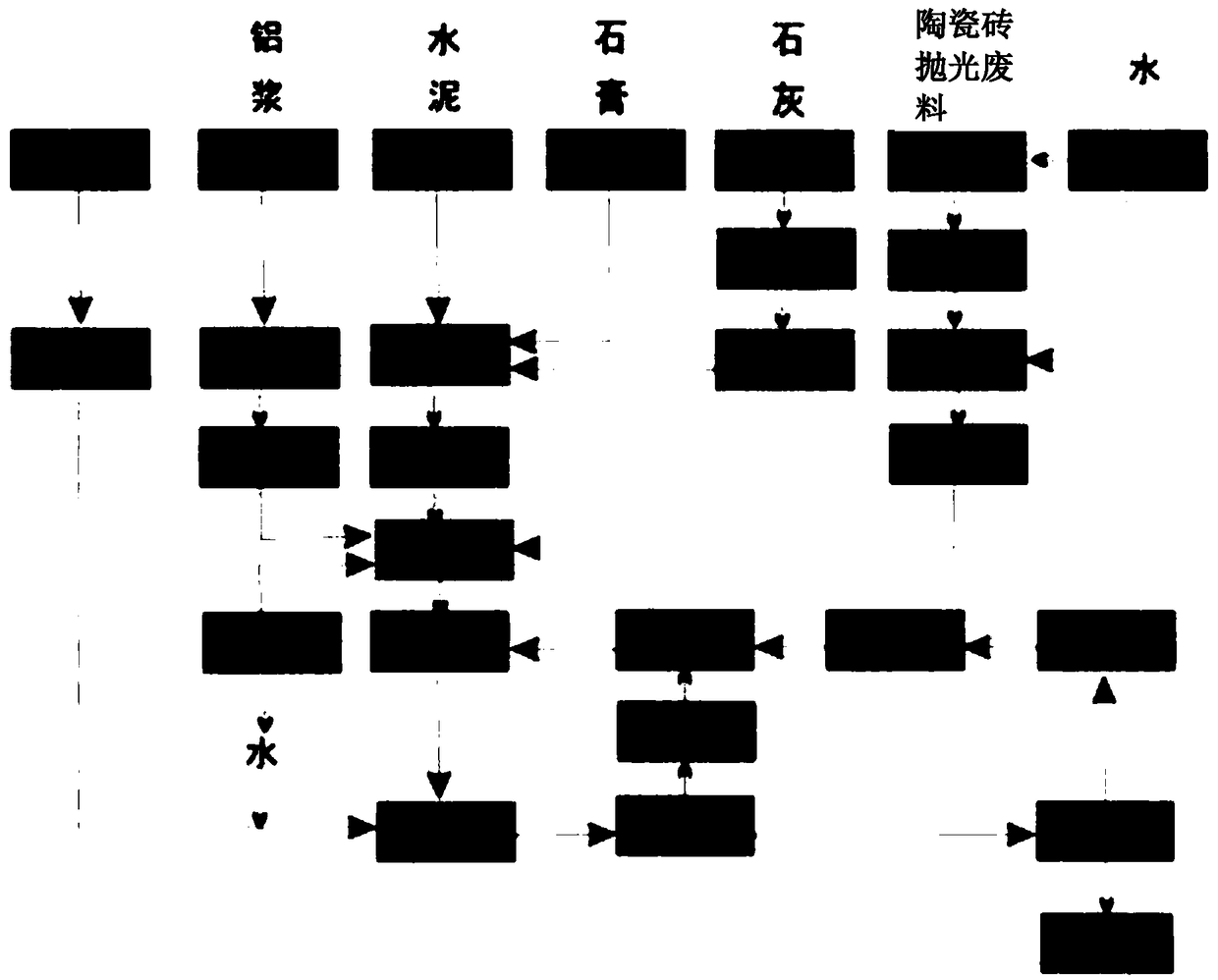

Aerated concrete block and preparation method thereof

InactiveCN108726942AReduce and inhibit compactionReduce and contain the spread of contaminationBrickSuperplasticizer

The invention discloses an aerated concrete block and a preparation method thereof. The aerated concrete block is prepared from slurry with a material-to-liquid ratio of 1: (70 to 83). The slurry is prepared from the following raw materials in parts by weight: 8 to 12 parts of cement, 16 to 24 parts of lime, 53.6 to 80.4 parts of ceramic slurry, 2.4 to 3.6 parts of gypsum, and 7.2 to 10.8 parts ofaluminum paste, wherein the ceramic slurry is prepared by mixing and stirring ceramic tile polished waste, NaOH, lignosulfonates high-performance water reduction agent and water. The preparation method comprises the following steps: storing and preparing raw materials, stirring the materials, pouring molding, pre-maintaining, maintaining at high pressure and the like. The aerated concrete block provided by the invention is fireproof, and capable of lowering the noise, preserving the heat and insulating the heat, has a breathing humidity regulation function, and is light in weight and high incompressive strength; and by directly utilizing the ceramic tile polished waste, the soil hardening and spreading of environment pollution caused by the industrial waste residues can be reduced and inhibited, and the aerated concrete block has certain social and economic benefit for controlling the environment pollution and improving the building function.

Owner:山东铭城环保新材料科技有限公司

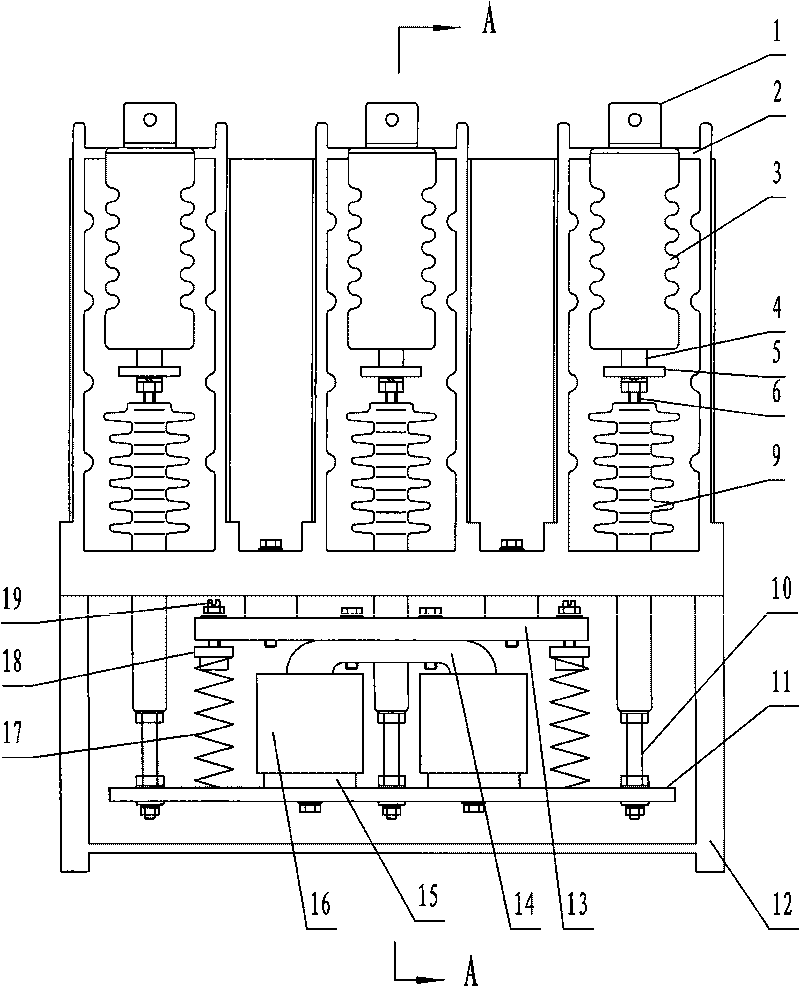

High-voltage three-pole AC vacuum contactor

InactiveCN101710546ASimple structureCompact designHigh-tension/heavy-dress switchesAir-break switchesDistribution systemEngineering

The invention relates to a high-voltage three-pole AC vacuum contactor which can be frequently operated by closing and separating and is suitable for a power supply and a distribution system with a rated voltage of 24KV. The high-voltage three-pole AC vacuum contactor adopts the technical scheme that a static guide rod and an electrokinetic guide rod are arranged in a vacuum arc extinguish chamber; the upper end of the static guide rod is connected with a fixed conducting bar fixed on the upper part of an insulation frame; a moving contact welded at the upper end of the electrokinetic guide rod is vertically opposite to a fixed contact welded at the lower end of the static guide rod, and the two contacts can be contacted and separated; the lower end of the electrokinetic guide rod extends out of the vacuum arc extinguish chamber and is connected with a moving conducting bar; and the extending end of the electrokinetic guide rod is connected with an insulator. The high-voltage three-pole AC vacuum contactor is characterized in that the lower end of the insulator is connected with a moving iron plate; the moving iron plate is connected with one end of a tripping spring, while the other end of the tripping spring is connected with a fixed iron plate; the fixed iron plate is fixed on the insulation frame, and the lower part of the fixed iron plate is connected with a fixed iron core; the upper part of the moving iron plate is connected with a moving iron core, and the moving iron core and the fixed iron core are vertically opposite to each other and a certain distance is reserved between the moving iron core and the fixed iron core; and a coil is sleeved outside the moving iron core and the fixed iron core. The invention has the advantages of skillful structure, reliable working, high response speed and wide application range.

Owner:无锡市蓝虹电子有限公司

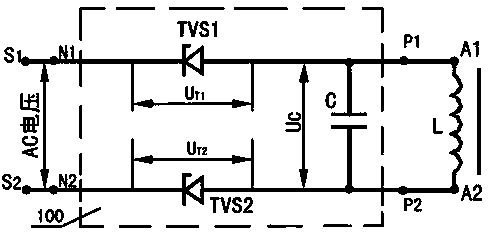

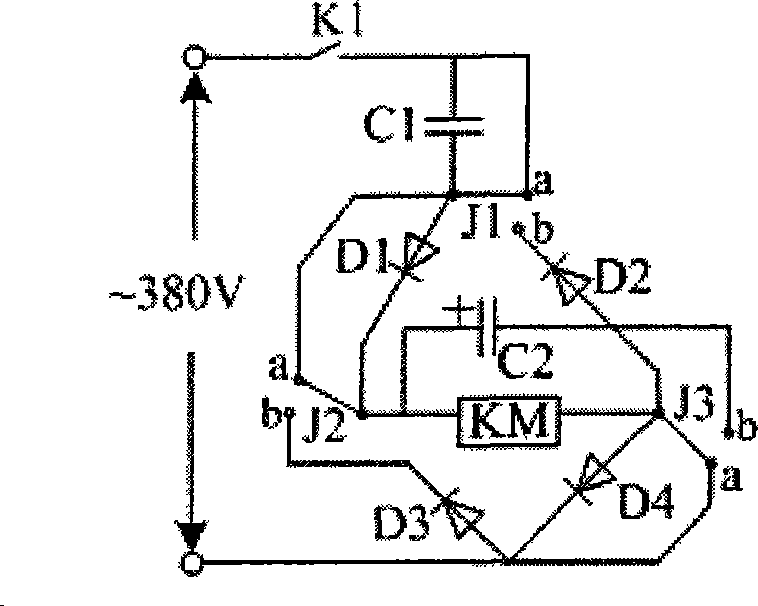

Energy accumulation type DC suction and DC keeping circuit for AC contactor

The invention relates to a circuit used for energy storage type direct current attracting and direct current keeping of an alternating current contactor. The circuit is formed as follows: a first capacitor is connected with the positive pole of a first diode and the negative pole of a third diode, the negative pole of the first diode is connected with the negative pole of a second diode, the positive pole of the second diode is connected with the negative pole of a fourth diode, and the positive pole of the fourth diode is connected with the positive pole of the third diode; the positive pole of a second capacitor is connected with the negative pole of the first diode, the negative pole of the second diode, and one end of a relay; the other end of the relay is connected with a contactor and the negative pole of a fifth diode, and at the same time the contactor is connected with the positive pole of the third diode, the positive pole of the fourth diode, the negative pole of the second capacitor, and one end of a resistance; and the other end of the resistance is connected with the positive pole of the fifth diode. The circuit has a simple structure, the regulation is convenience, no auxiliary contact is needed, the voltage for attracting and keeping is stable, the circuit is suitable for various alternating current contactors, and the reliability of the action of the built-in alternating current contactor of a soft starter can be efficiently improved.

Owner:天津诺尔电气股份有限公司

Spunlace compound fabric and preparation method and application thereof

PendingCN112760808ASuction speed is fastFast liquid absorptionNon-woven fabricsBandagesFiberWater repellent

The invention discloses a preparation method of a spunlace compound fabric. The preparation method comprises the following steps that spunlace compounding is carried out on a pre-wetted surface layer and a pre-wetted structural layer to obtain a compound surface layer; water repellent treatment is carried out on the compound surface layer to obtain a water-repellent compound surface layer; meshes are manufactured in the water-repellent compound surface layer by adopting a punching process; and the structural layer and a flow guide layer are compounded to obtain the spunlace compound fabric, so that the flow guide layer covers the meshes in the water-repellent compound surface layer, and the spunlace compound fabric is obtained. According to the preparation method of the spunlace compound fabric, after the surface layer and the structural layer are creatively subjected to spunlace compounding, the compound surface layer with higher strength can be obtained, so that the meshes with clearer edges are obtained, and the liquid absorption speed of the surface layer is ensured not to be hindered by fibers at the edges of the meshes; and besides, after the compound surface layer and the flow guide layer are compounded and the meshes of the compound surface layer are covered, the liquid absorption speed of the surface layer can be increased through the flow guide layer, and meanwhile, the situation of glue leakage of the meshes of the surface layer can be effectively prevented, so that the spunlace compound fabric which is high in liquid absorption speed and free of glue leakage is obtained.

Owner:WINNER MEDICAL CO LTD +1

Intelligent frying pan with air purification function

InactiveCN107669161AAvoid diffuse situationsImprove adsorption capacityFrying pansAir cleaningRespiratory health

The invention relates to an intelligent frying pan with air purifying function, comprising a pot body and a handle, as well as an air purifying mechanism, a disassembly mechanism and a fixing mechanism. The intelligent frying pan with air purifying function is provided with two There are two air purification mechanisms. In the working state, the two air purification mechanisms are deployed to both sides of the handle to quickly absorb the oil fume generated during cooking, and purify the air containing the oil fume and discharge it. In the non-working state, the air purification mechanism can It is folded and stored on the handle, and fixed on the handle by the fixing mechanism. When the air purification mechanism needs to be cleaned, the air purification mechanism can be removed by starting the disassembly mechanism, which improves the convenience and practicability. It is used to absorb oil fume with a range hood. This method has fast removal speed and better effect, avoids the occurrence of diffuse oil fume, and can purify the air with oil fume, which is more environmentally friendly and avoids impact on the health of human respiratory tract.

Owner:晋江市意翔环保科技有限公司

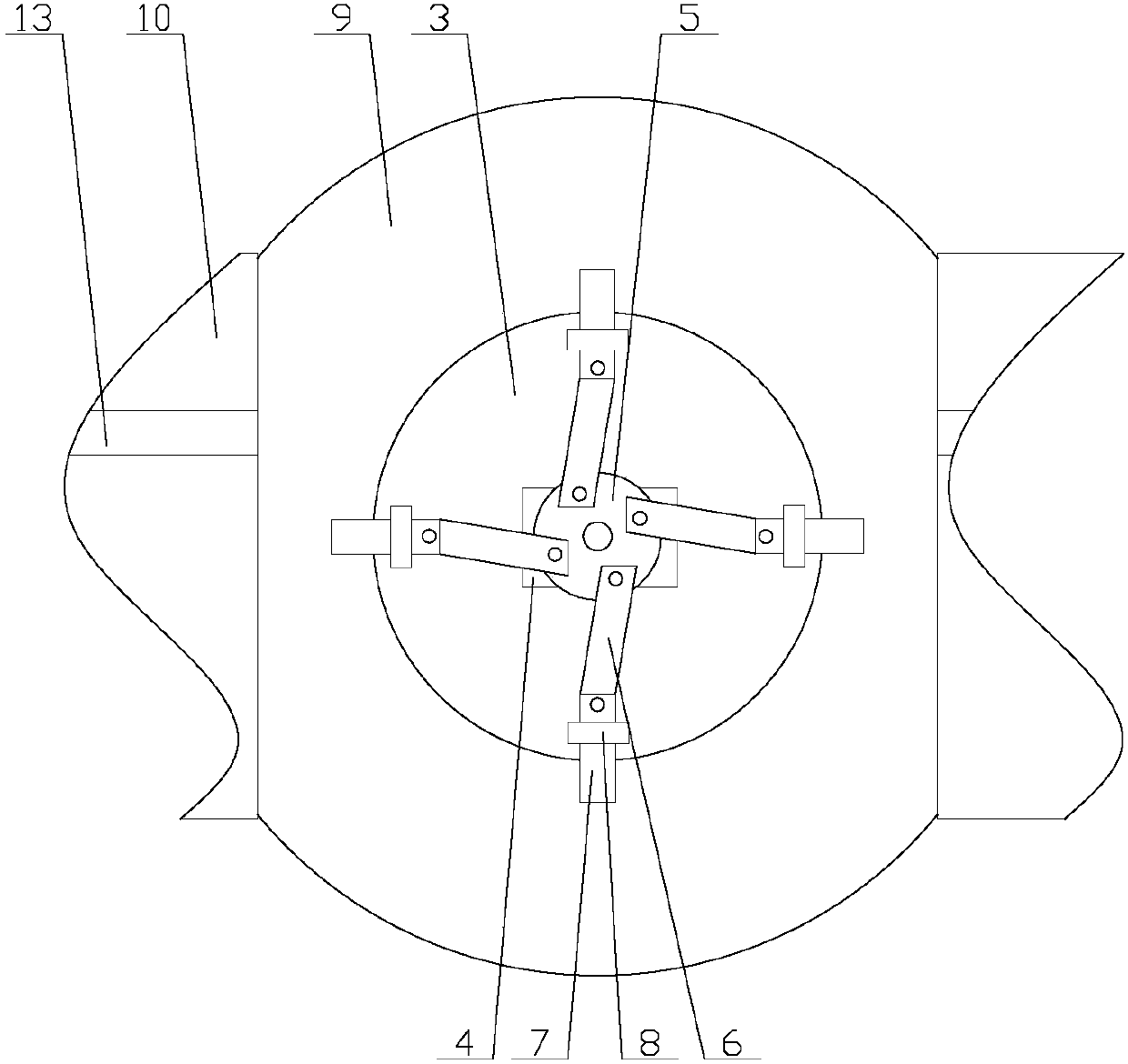

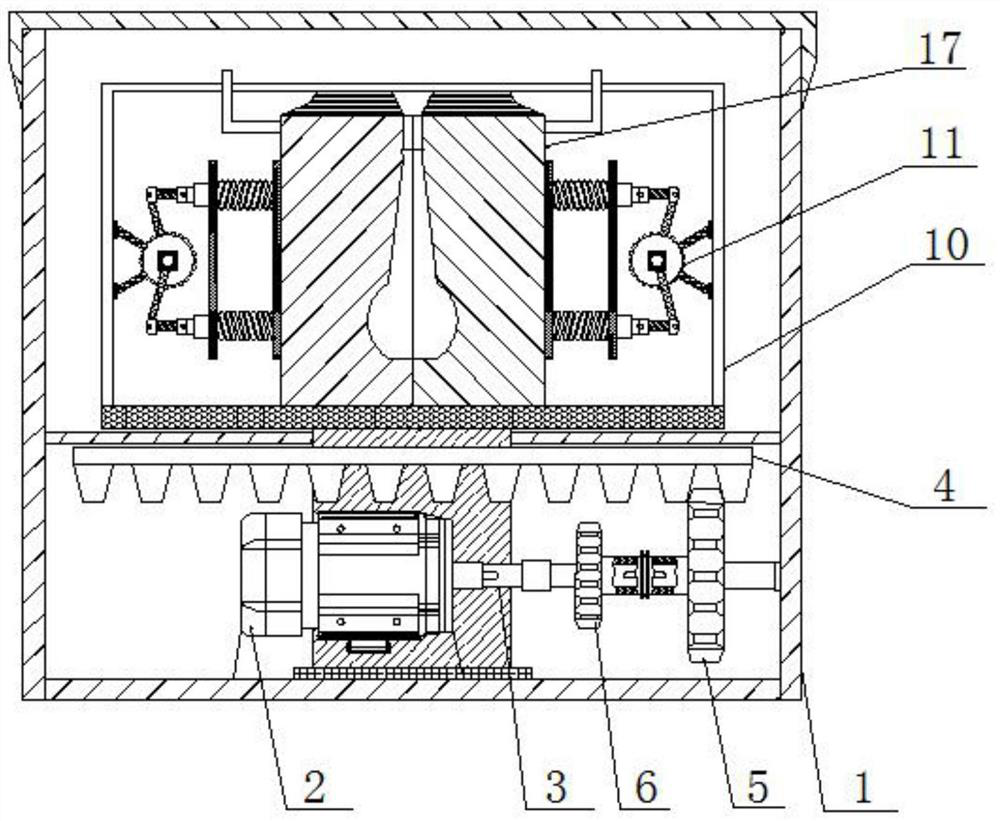

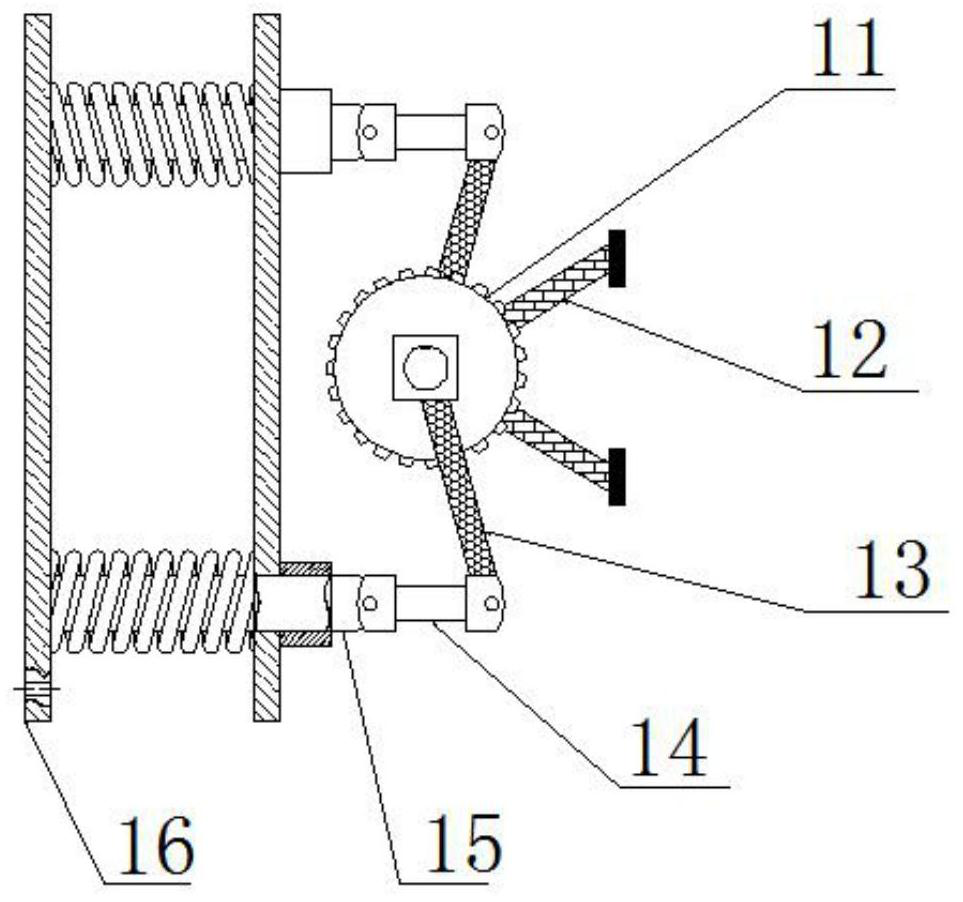

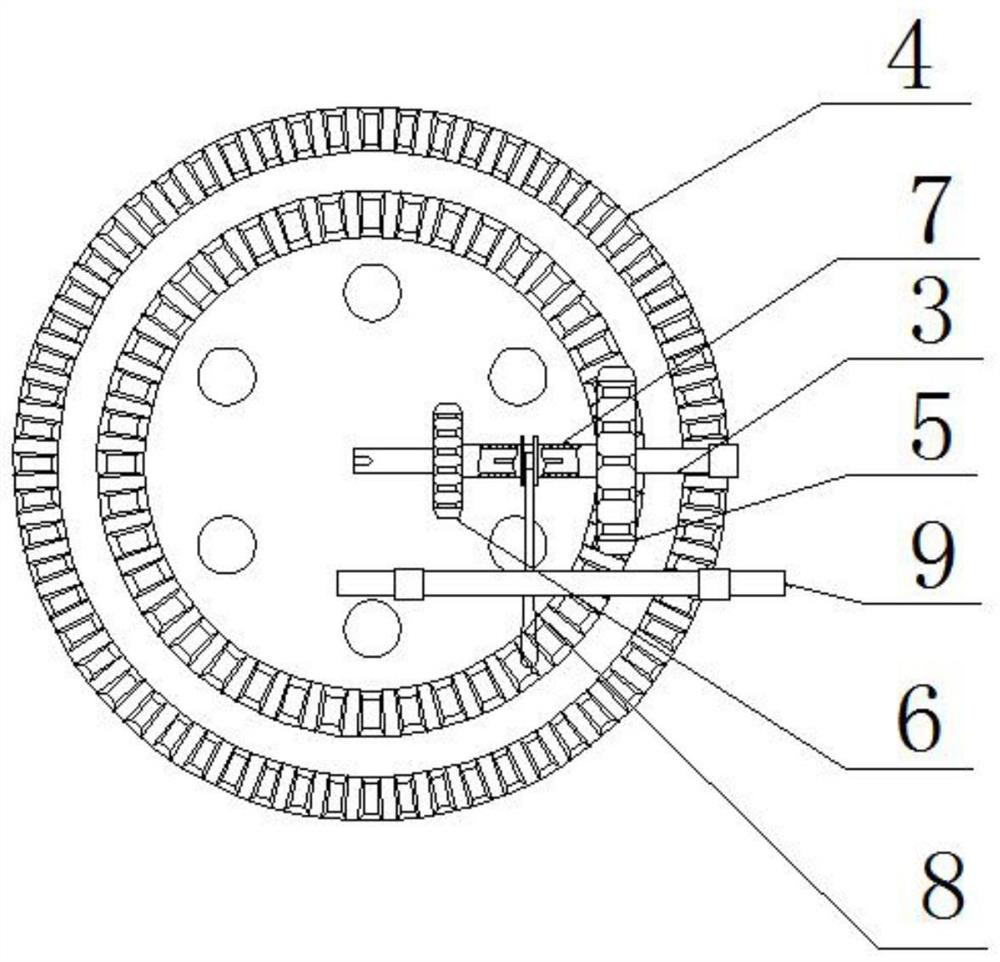

Differential centrifugal ceramic forming machine

The invention relates to the technical field of ceramic forming, and discloses a differential centrifugal ceramic forming machine. The machine comprises a rack, a motor is movably connected to the inner bottom of the rack, and a driving shaft is movably connected to the right side of the motor. A shaft sleeve is movably connected to the upper surface of the driving shaft, and a high-speed gear ismovably connected to the right side of the shaft sleeve. The left side of the shaft sleeve is movably connected with a low-speed gear, and the middle of the shaft sleeve is movably connected with a paddle shift. Slurry is made to abut against the mold wall to form a compact blank through centrifugal force generated by rotation driven by a gear disc, bubbles are concentrated in the middle and finally broken out, and generation of bubbles and pinholes in a product is avoided. The slurry suction speed and the product quality are improved, few large particles can be concentrated on the surface ofthe blank due to differential centrifugation, and inconsistent shrinkage caused by uneven tissue is avoided. During mold opening, a clamping gear rotates reversely, clamping plates move outwards to pull a mold open, and the product can be taken out conveniently through mold opening under the displacement and extrusion effect of compressed air.

Owner:李慧

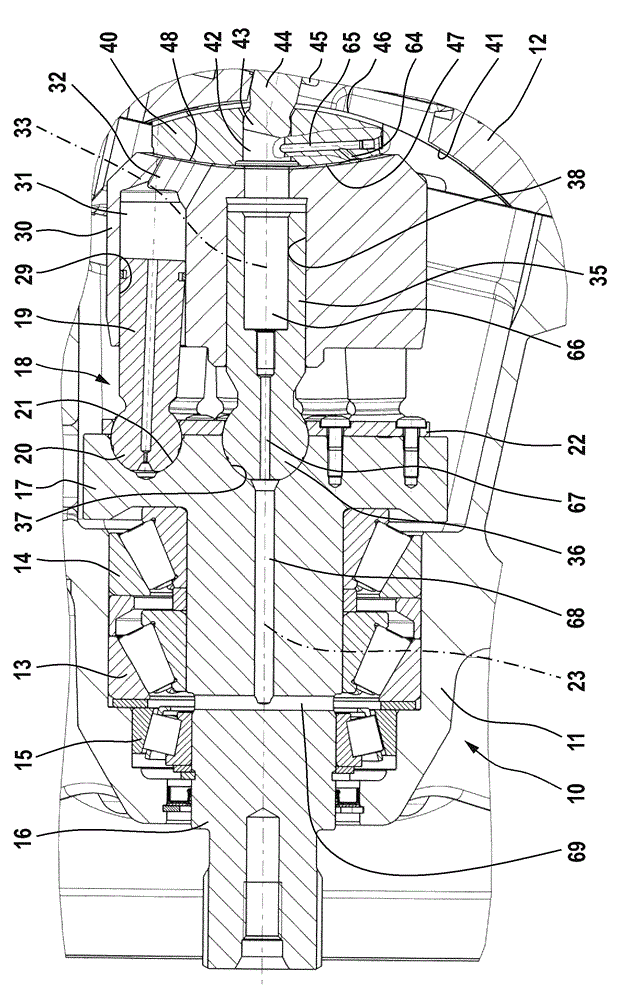

Hydrostatic piston machine

ActiveCN105089961AIncrease pressureLong durabilityReciprocating piston enginesPositive-displacement liquid enginesEngineeringHigh pressure

The invention relates to a hydrostatic piston machine having a housing for accommodating return oil, a rotary cylinder body leaning against a control member and having a plurality of cylinder chambers. A piston in the piston machine passes a cylinder chamber afflux part and is alternately connected to a low pressure channel through a low pressure control opening of the control member and connected to a high pressure channel through a high pressure control opening. Two switching regions exist between the low and high pressure control openings on the control member. The piston reverses a motion direction in a dead point, and the corresponding cylinder chamber afflux part sweeps the switching regions of the control member. A pre-control opening exists in the switching regions. The cylinder chamber afflux part switches from the high pressure control opening towards the low pressure control opening of the control member. Before the cylinder chamber afflux part is opened to the low pressure control opening, the cylinder chamber afflux part is connected a low pressure region through a pressure reduction flow path with a first throttling device. The pressure reduction flow path is configured to be pressure reduction cascade. Besides the first throttling device, the pressure reduction flow path has at least a second throttling device in serial connection with the device and has a flow container between the two serial devices.

Owner:ROBERT BOSCH GMBH

Industrial circulating water dirt purifying device and dirt removal method thereof

PendingCN109231600ANo secondary pollutionAvoid mutual interferenceScale removal and water softeningTreatment involving filtrationControl powerEngineering

The invention discloses an industrial circulating water dirt purifying device which comprises a shell, a first electrode, a second electrode, a control power supply, a first conductor, a second conductor, a water inlet branch pipe, a drain branch pipe, a main water inlet pipe, a main drain pipe, an alkaline drain pipe, an acid drain pipe, a seed crystal grinder, a seed crystal coalescer and a filter, wherein the two poles of the control power supply are connected with the first electrode and the second electrode respectively. The invention further provides a dirt treatment method of the industrial circulating water dirt purifying device. By controlling the dirt removal and absorption process of the first electrode and the second electrode connected with the power supply, the seed crystal grinder and the seed crystal coalescer gather a great amount of dirt, and the filter filters the dirt to achieve an aim of purifying the circulating water. The device and method provided by the invention have the advantages of high efficiency of dirt removal and prevention, low cost and little pollution.

Owner:SHANGHAI BIANJIE ENVIRONMENTAL PROTECTION TECH CO LTD

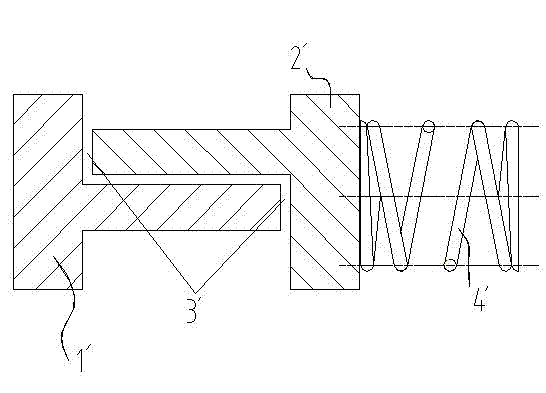

Material capsule with dynamic combined material pipe

The invention discloses a material capsule with a dynamic combined material pipe. The material capsule comprises a capsule body, a material opening is formed in the top end of the capsule body, a fixing frame is further arranged at the position of the material opening, a mounting hole is formed in the center of the fixing frame, a main material pipe is arranged at the position of the mounting hole, at least two connecting holes are further formed in the fixing frame, and sleeves are further fixedly installed in the connecting holes. The sleeves are similar to the main material pipe in structure, each sleeve comprises a lining pipe and an external pipe and is connected and provided with a material pipe through a rubber hose, the material pipe comprises an inner pipe and an outer pipe, the top of the inner pipe is higher than the top of the outer pipe, the bottom of the inner pipe is higher than the bottom of the outer pipe, and an auxiliary moving device used for dynamic self-moving quick discharging of the combined material pipe is further arranged on the material pipe. Through cooperation of the combined distribution material pipe and the auxiliary moving device which are arranged in the capsule body, the effect that sucked materials automatically move to be close to the middle is achieved under rubber elastic recovery and external force action, and the use value of the material capsule and the cleanliness degree of the sucked materials are improved.

Owner:郭银平

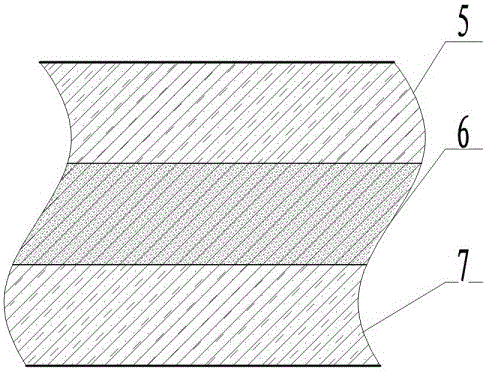

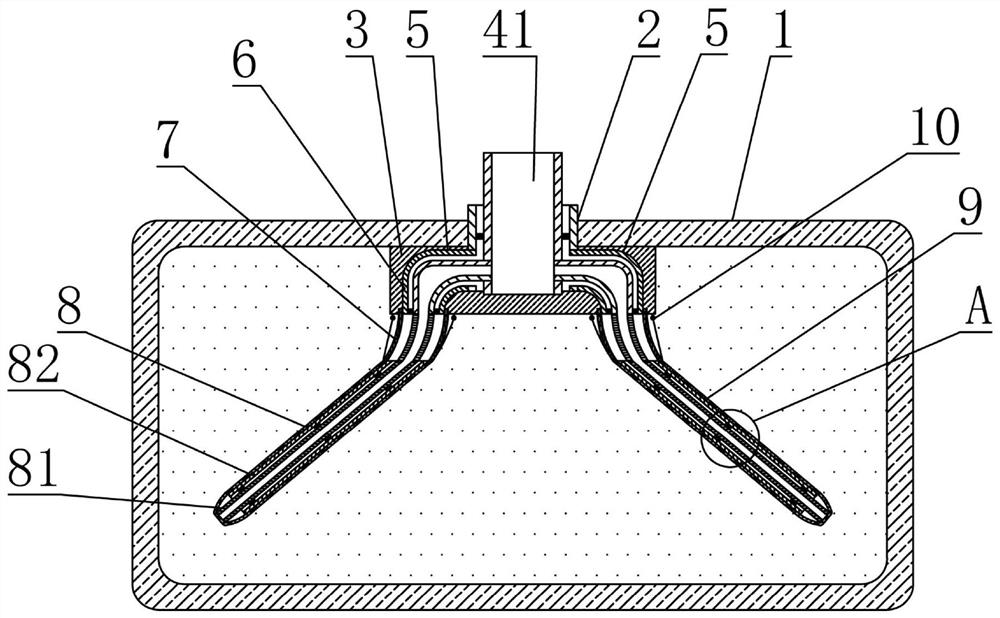

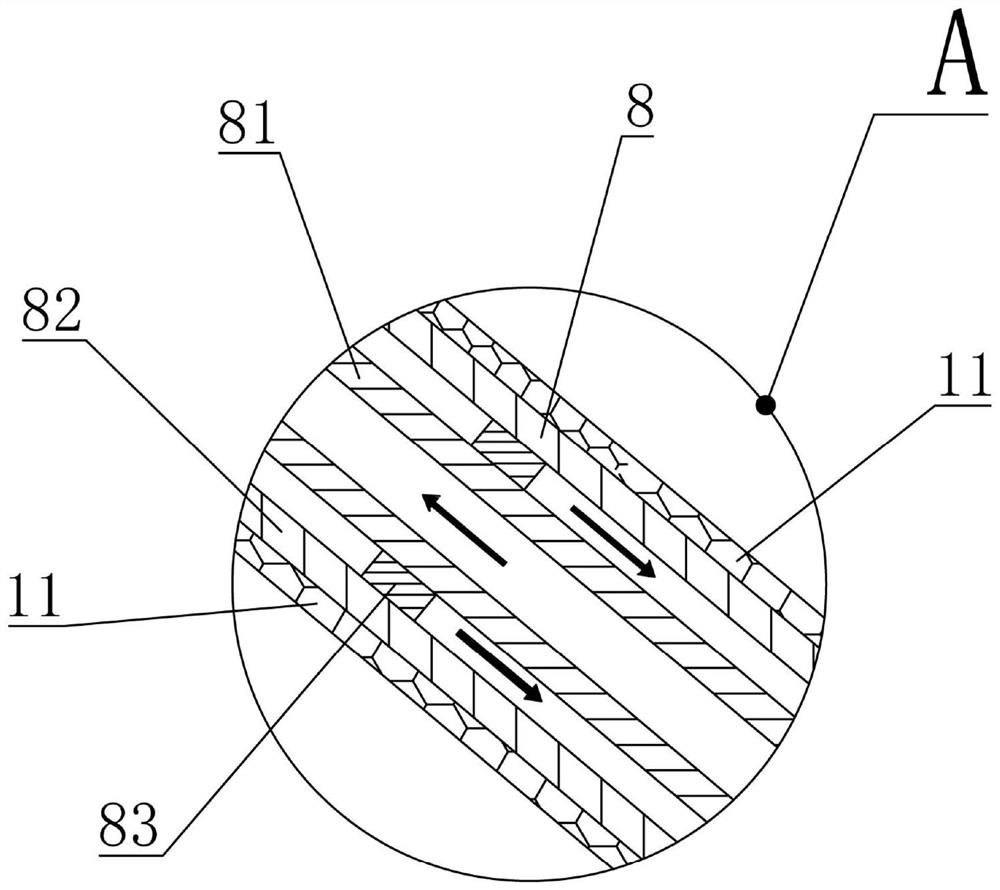

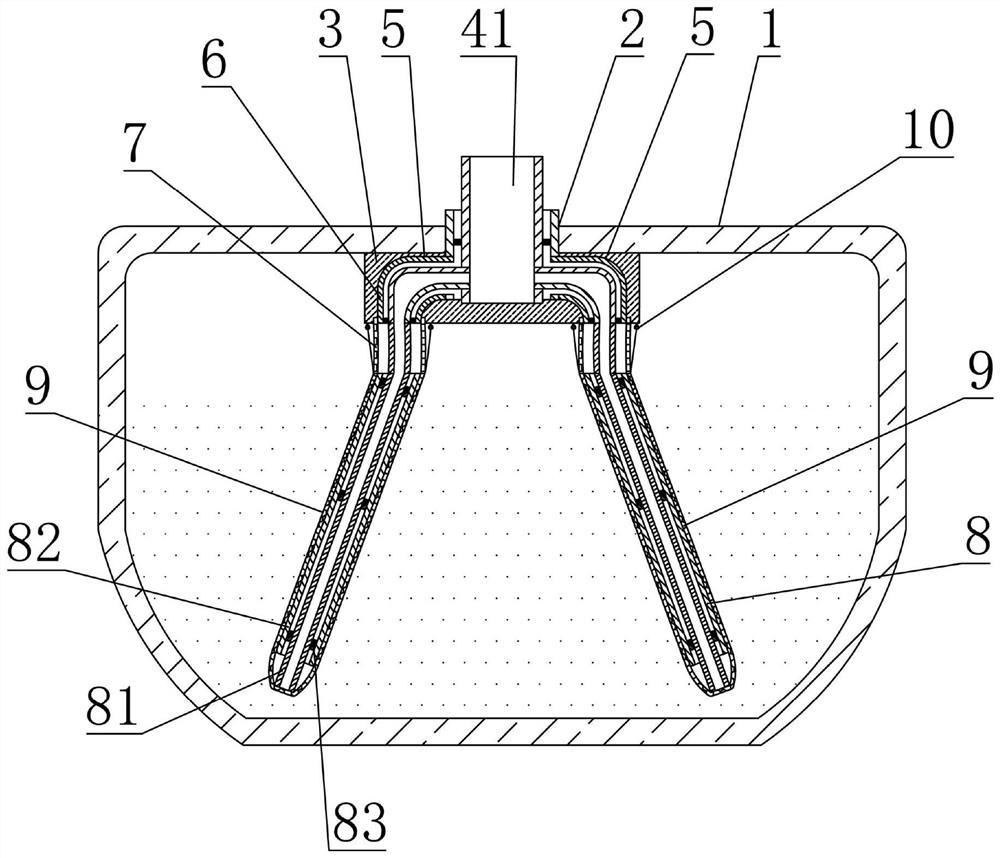

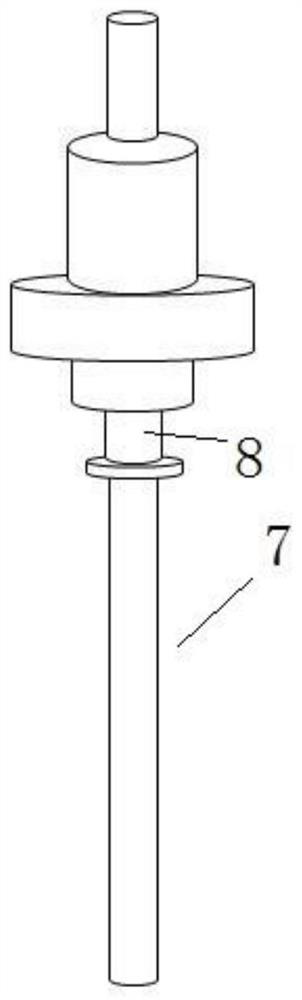

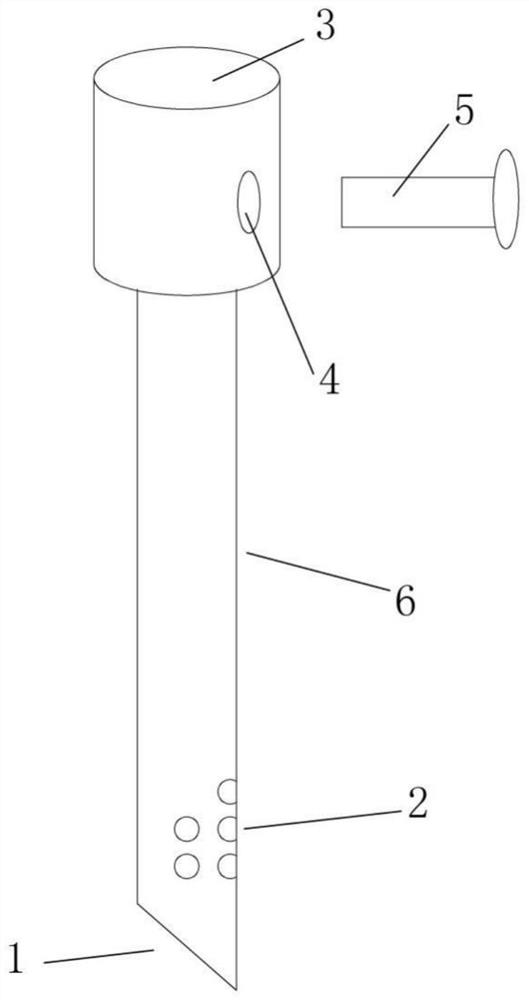

Antigen harvesting device for infectious bronchitis

PendingCN111763611AReduce cloggingQuick drawBiological material testing proceduresSpecific use bioreactors/fermentersYolkAntigen

The invention relates to the technical field of antigen harvesting, and especially relates to an antigen harvesting device for infectious bronchitis. The harvesting device includes a harvesting head;the harvesting head includes a liquid suction rod (7) and a coat; the coat is formed by a liquid suction rod inserting head (3) and a liquid suction rod coat (6) in successive arrangement from top tobottom through connection; the lower end of the liquid suction rod coat (6) is a beveled sharp head (1), and the included angle between the inclined plane of the beveled sharp head (1) and a horizontal plane is 30-45 degrees; and the sidewall, on the same side with the tip of the beveled sharp head (1), of the liquid suction rod coat (6) is provided with multiple liquid suction holes (2). The beveled sharp head of the device is only in contact with the eggshell edge of chicken embryo during harvesting, and the incline plane can effectively avoid the yolk when going down; and the harvesting head has more liquid suction holes at the top part and less liquid suction holes at the bottom part, so that liquid suction rod can be further shortened, therefore, blocking can be effectively avoided, allantoic fluid can be quickly sucked, and thorough suction can be achieved.

Owner:兆丰华生物科技(南京)有限公司

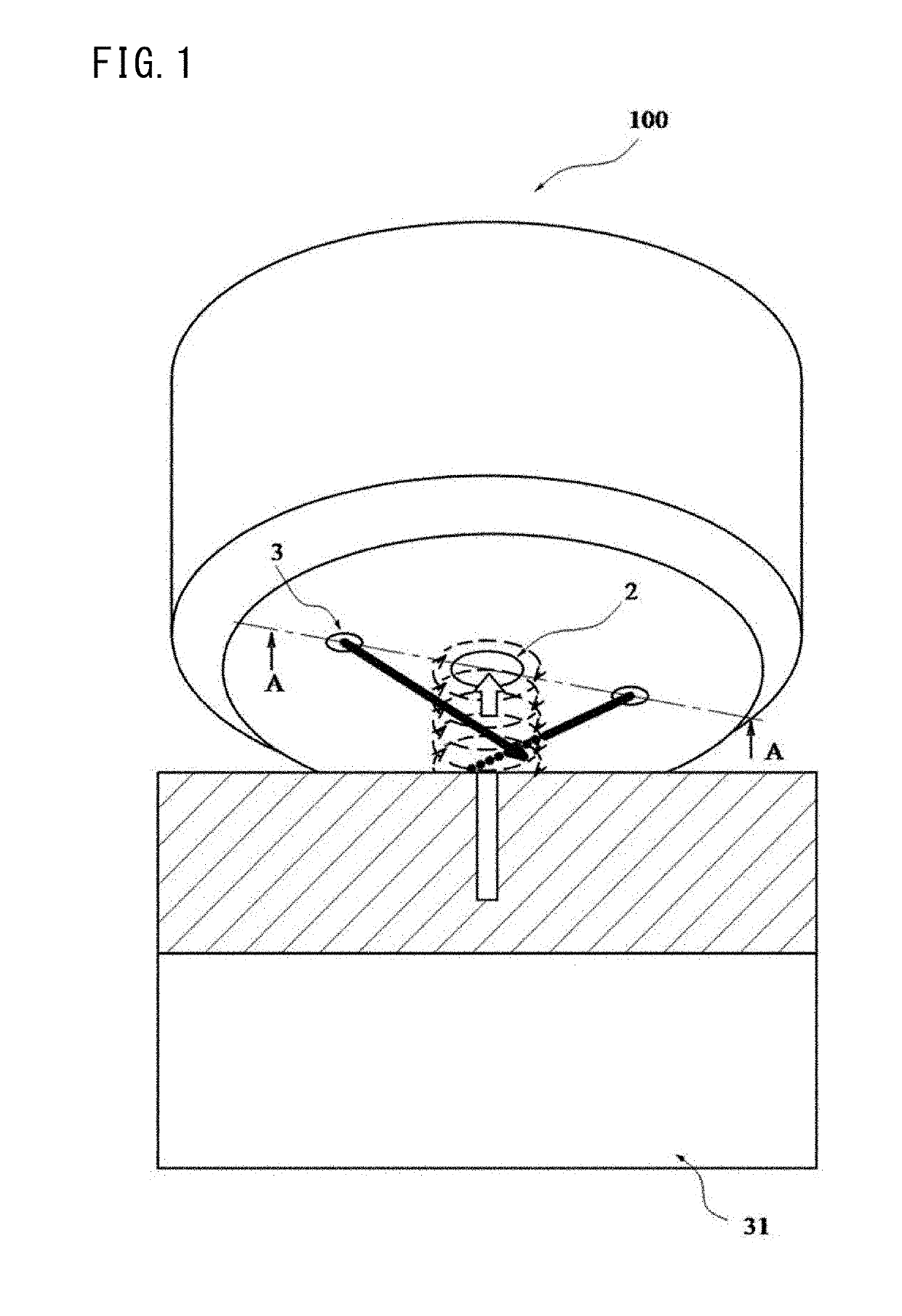

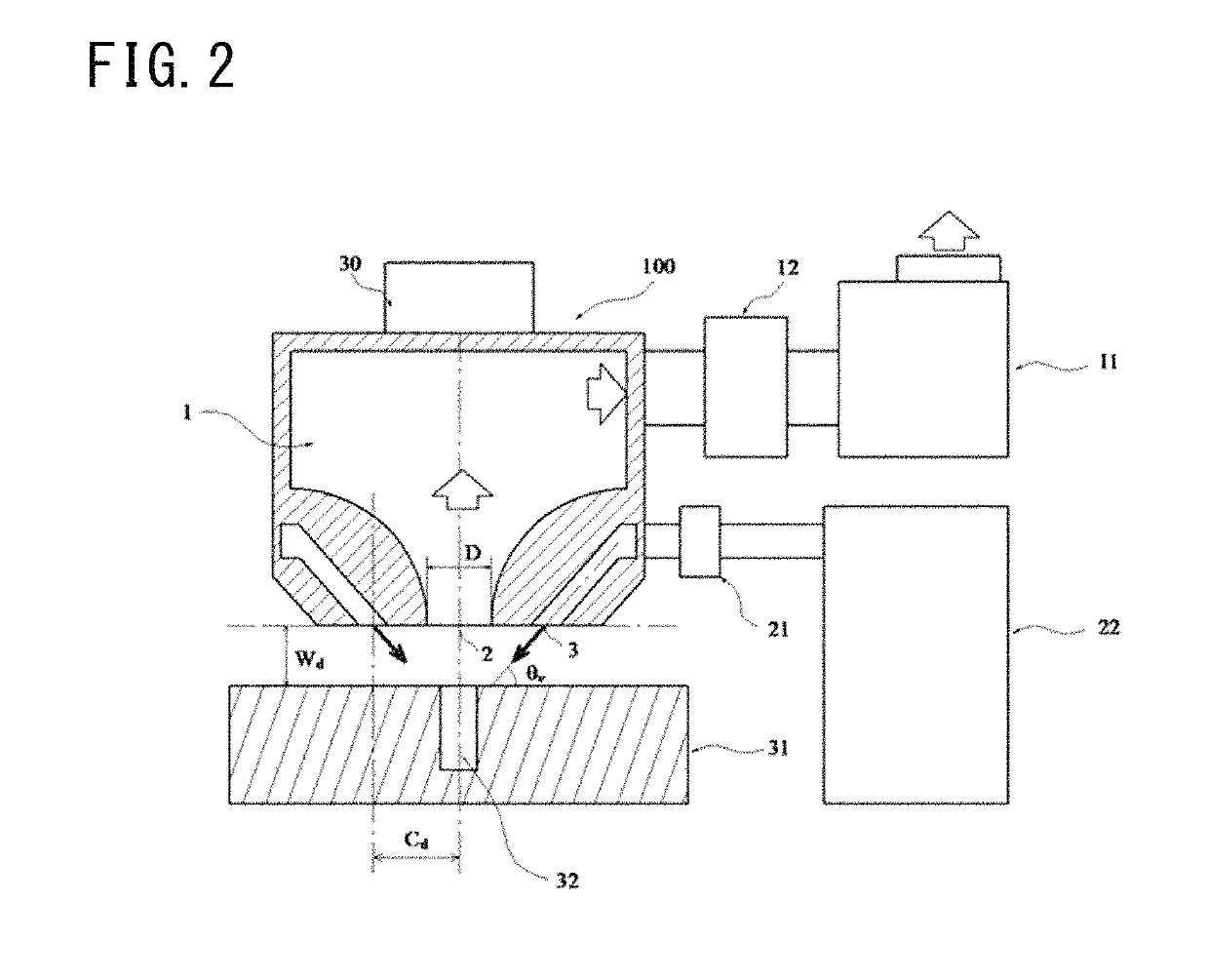

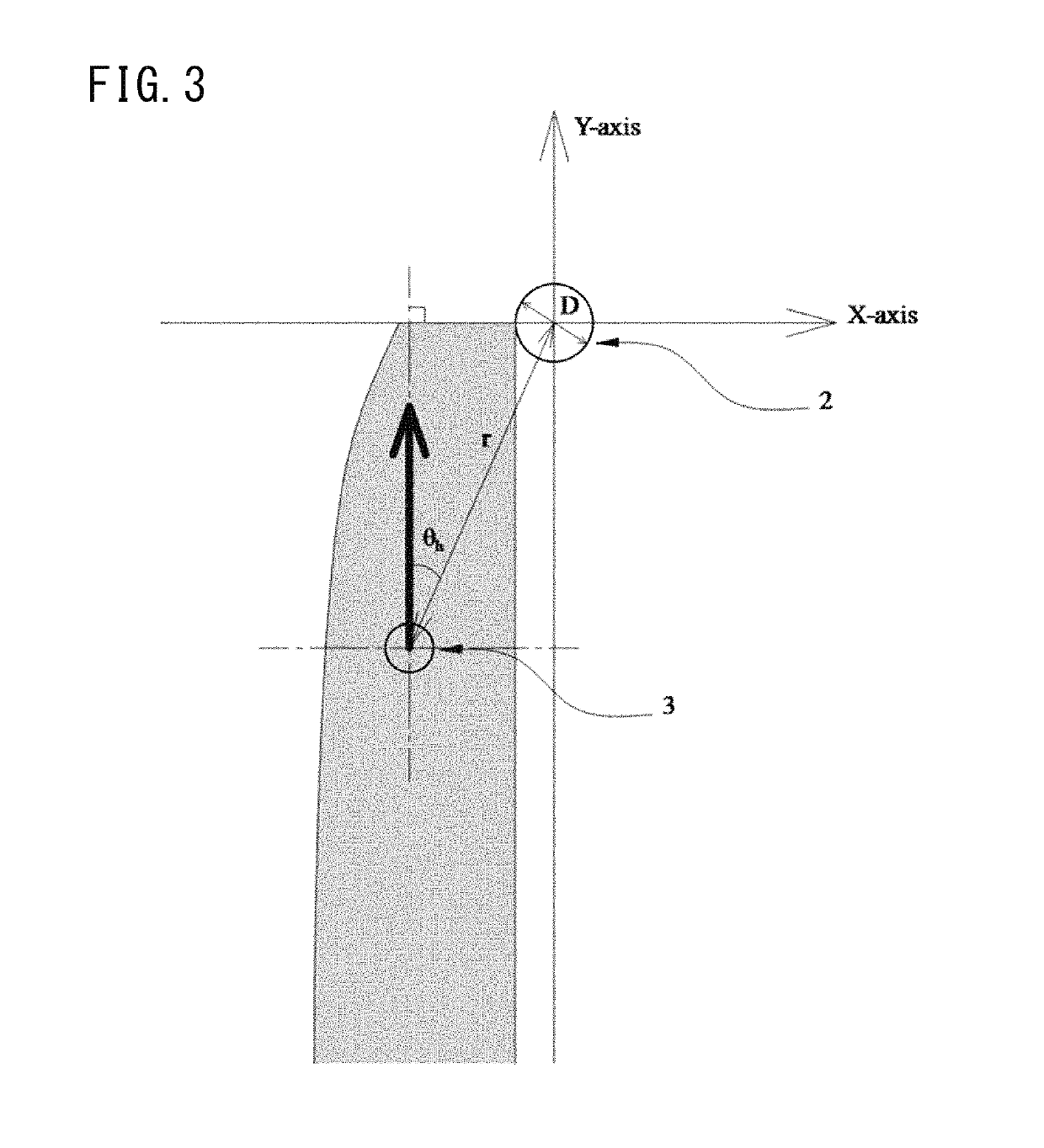

Suction method, suction device, laser processing method, and laser processing device

ActiveUS10456863B2Suction speed is fastHigh recovery rateDirt cleaningCleaning using gasesLaser processingEngineering

An object is to provide a suction method and a suction device which depressurize the pressure of the surface of a target installed in an open system to a critical pressure or less and which thereby can suck it and a laser processing device and a laser processing method using these. In a state where a predetermined operating distance is apart from a target installed in an open system and a suction port, the pressure of an inside of a pressure reduction chamber communicating with the suction port is set equal to or less than a critical pressure at which the speed of a gas sucked from the suction port is brought into a critical state; the jet speed of the gas in a jetting port from which the gas is jetted toward the target is set more than a Mach number of 0.2, the Mach number being obtained by dividing a jet speed of the gas by the sound speed of the gas jetted from the jetting port, the gas is jetted from the jetting port and is sucked by the suction port; a swirl flow is formed so as to surround the suction port between the surface of the target and the suction port; and thus the pressure of a central region of the swirl flow from the suction port to the surface of the target is reduced to the critical pressure or less and suction is performed.

Owner:FUKUI PREFECTURE

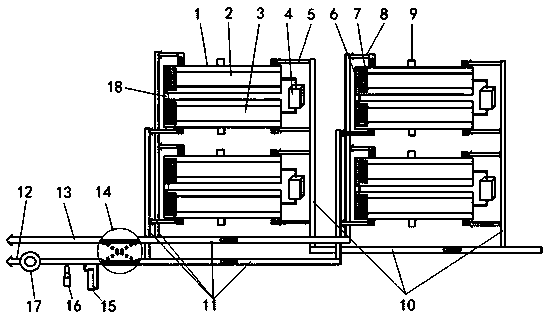

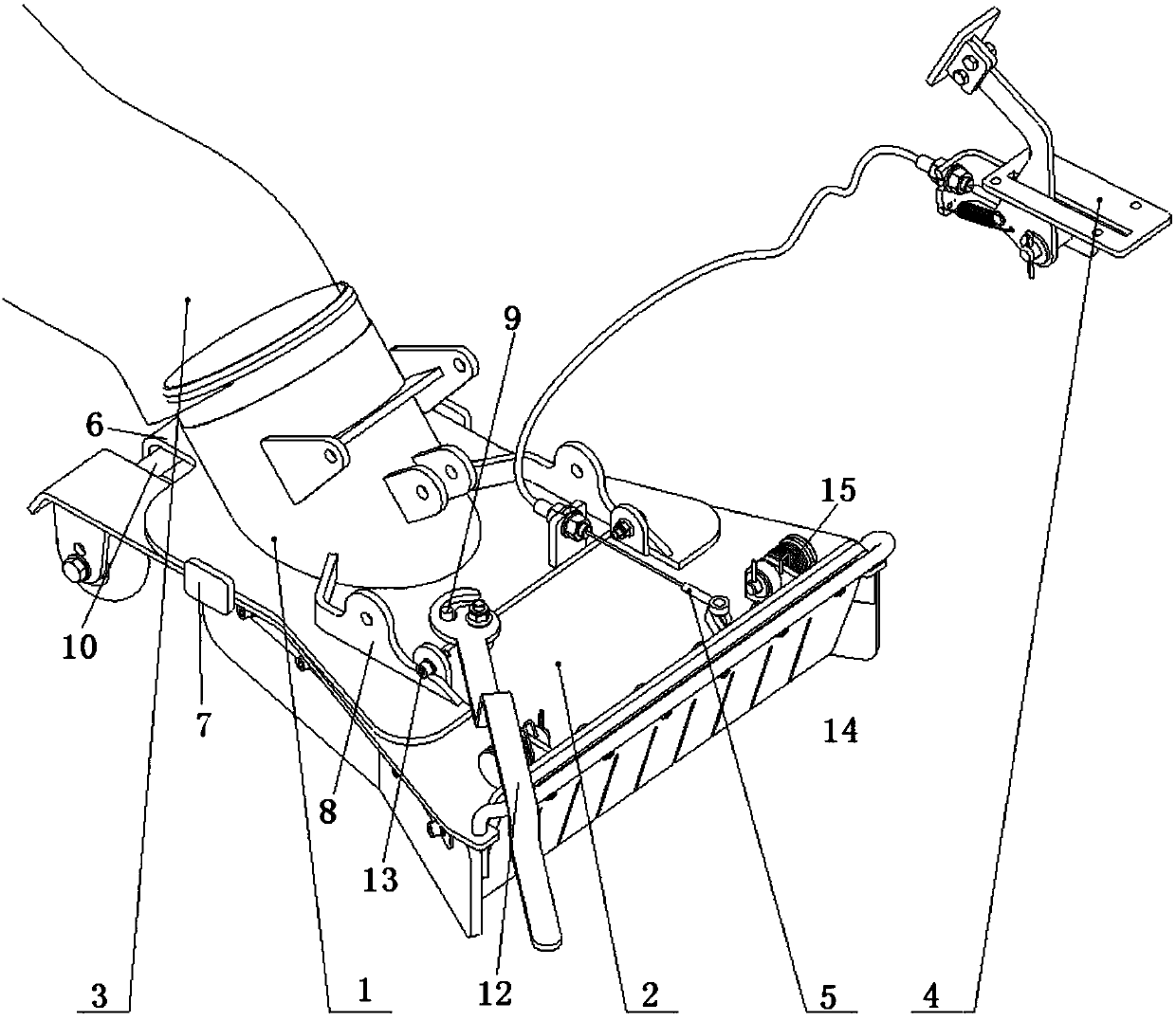

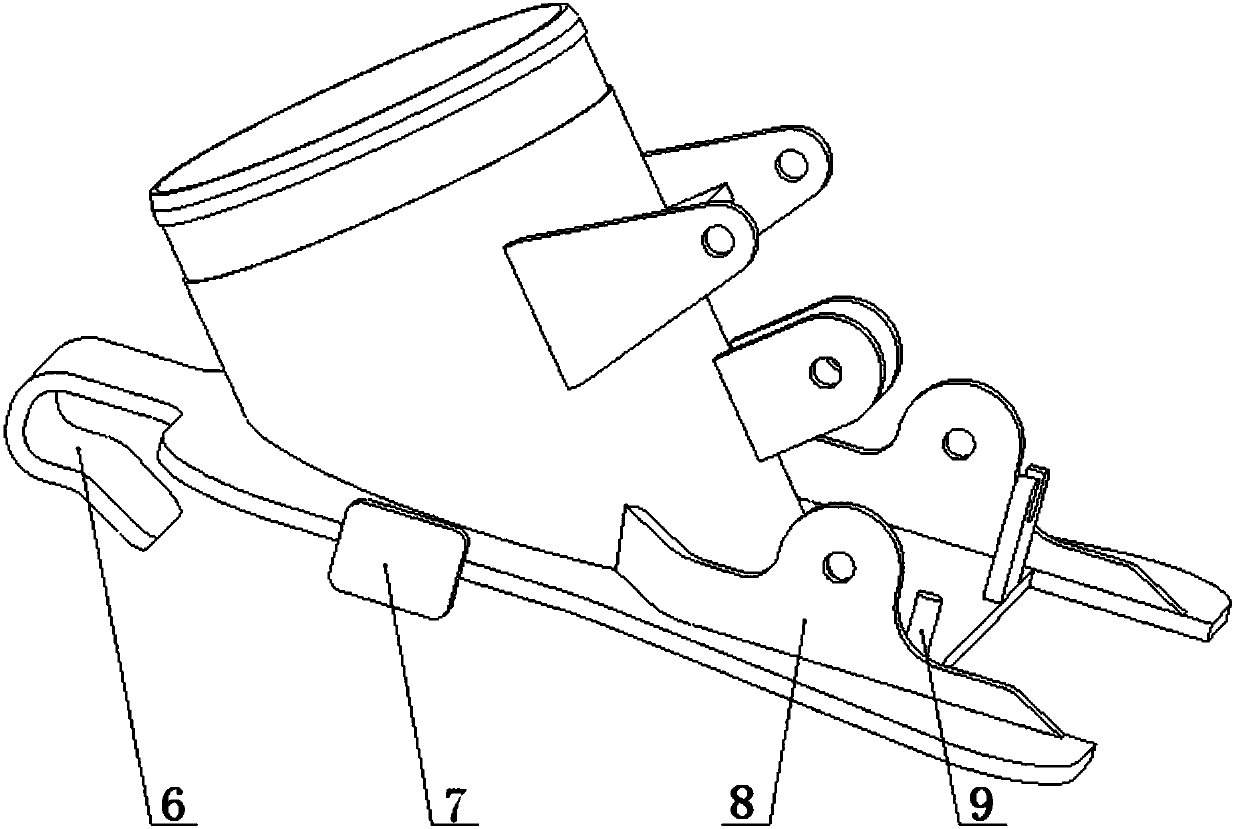

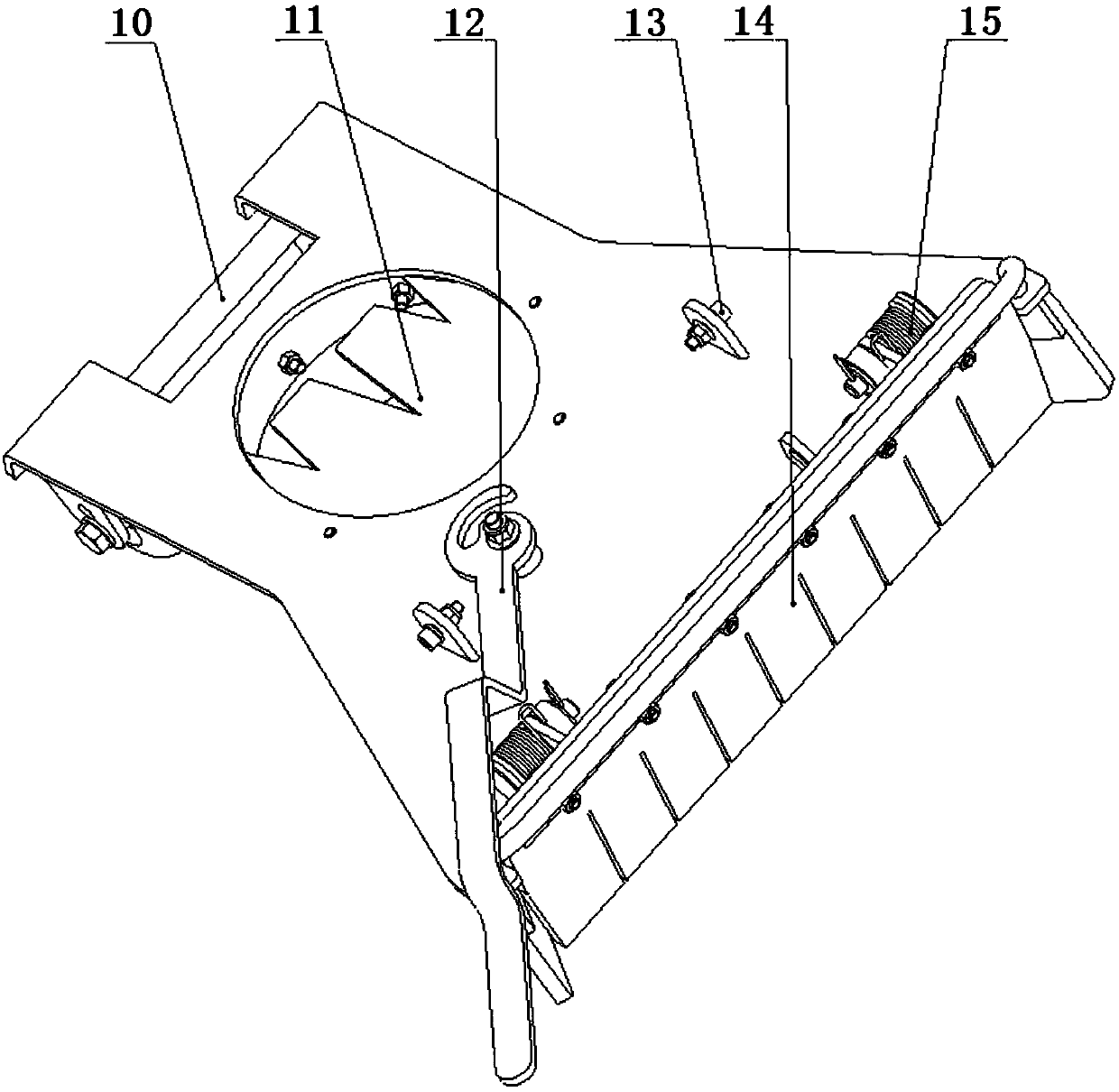

Layered sucker device of street sweeper

PendingCN107893398AEasy to assemble and disassembleEasy to cleanRoad cleaningDriver/operatorStructural engineering

The invention discloses a layered sucker device of a street sweeper. The layered sucker device includes a sucker support, a sucker body, a pedal, and a pull rope; the sucker support and the sucker body are separated from each other; the sucker support is arranged on a frame of the street sweeper; in working, an upper surface of a main board of the sucker body and a lower surface of a main board ofthe sucker support attach onto each other and are fixed together; quick cleaning and maintenance of the sucker device can be achieved by quick demounting of the sucker body; the pedal is fixed on a floor of a cab, and the pedal is connected to an overturning plate of the sucker body through the pull rope; a driver can step the pedal to pull the pull rope so as to allow the overturning plate to overturn, and then materials and gathered rubbish are sucked into the inner cavity of the sucker. The problem that the sucker sucks large rubbish and rubbish is accumulated on the front end of the sucker can be solved.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com