High-pressure grouting ceramic slurry based on waste ceramic recycling as well as preparation method and system

A technology of high-pressure grouting and ceramic slurry, which is applied in the field of architectural ceramics, can solve the problems of waste porcelain incorporation, stratification of high-pressure grouting ceramic slurry, and damage to soil structure, so as to reduce usage, increase slurry suction speed, The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

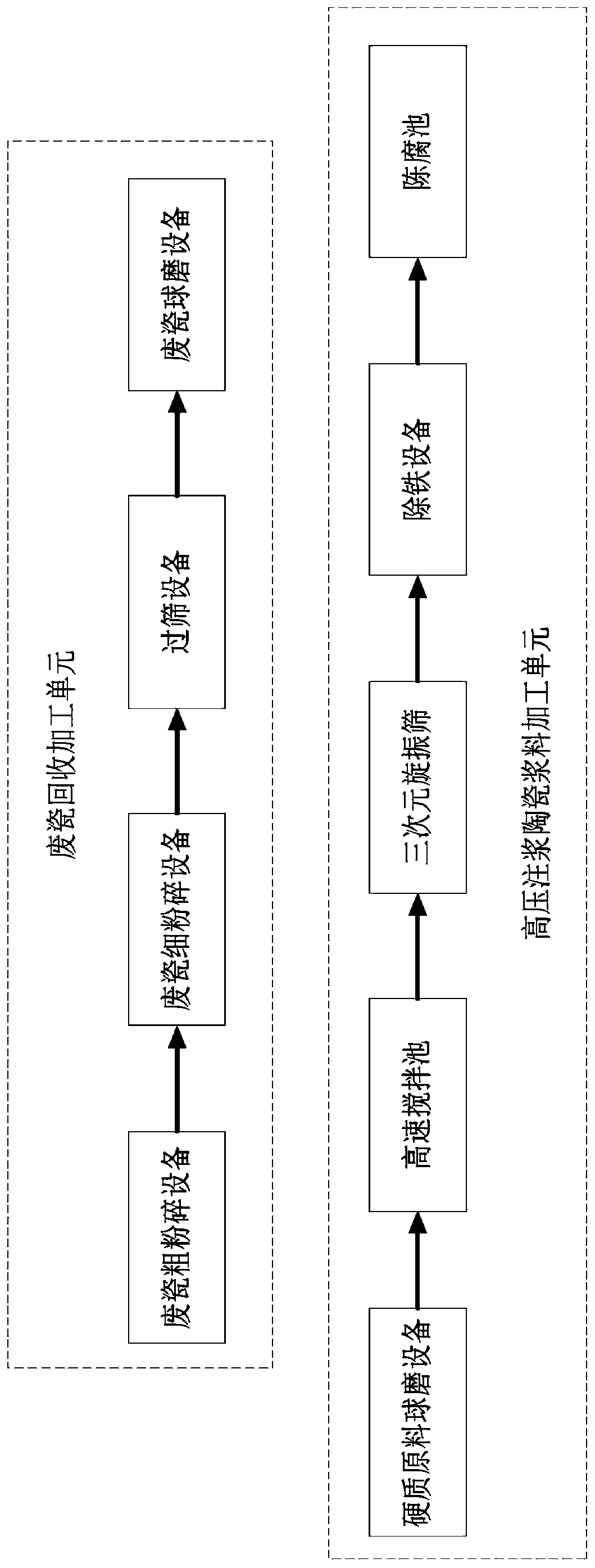

[0043] The preparation method of the high-pressure grouting ceramic slurry based on the recycling of waste porcelain comprises the following steps:

[0044] A. Preparation of waste porcelain slurry

[0045] Step A1, crushing the waste porcelain material to a particle size of 5-10 mm to obtain waste porcelain powder;

[0046] Step A2, according to weight percentage, weigh 1-10% raw ore black mud and 90-99% of the waste porcelain powder in step A1, add water ball mill until the fineness of the ball is 325 mesh sieve and the remaining 3-8%, and the waste ceramic powder is prepared. Porcelain pulp;

[0047] B. Preparation of High Pressure Grouting Ceramic Slurry

[0048] Step B1, according to parts by weight, weigh 1 to 5 parts of quartz sand, 5 to 10 parts of soda stone powder, 5 to 10 parts of potassium albite feldspar, 10 to 15 parts of pyrophyllite, 1 to 5 parts of dolomite and 10 to 15 parts of Sericite, adding water and ball milling until the fineness of the ball is 325 m...

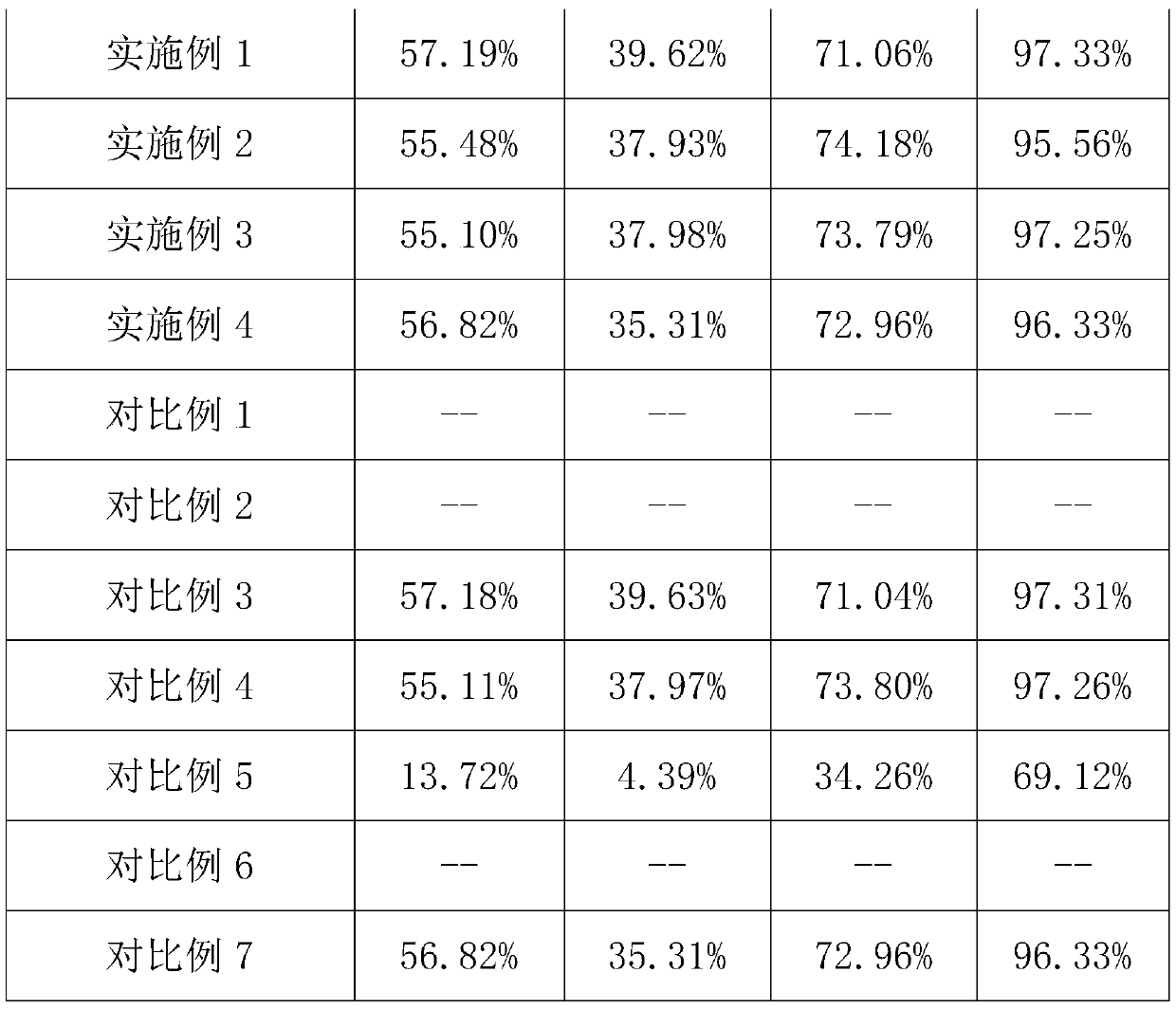

Embodiment 1~4

[0074] Embodiments 1 to 4 weighed each raw material according to Table 1 according to parts by weight; the percentage by weight of each raw material of the waste porcelain slurry is shown in Table 2, and the high-pressure grouting ceramic slurry was prepared according to the following steps:

[0075] A. Preparation of waste porcelain slurry

[0076] Step A1.1, using a jaw crusher to coarsely crush the ceramic waste until the particle size of the ceramic waste is 10-20mm;

[0077] Step A1.2, using a hammer mill to finely crush the ceramic waste that has passed step A1.1 until the particle size of the ceramic waste is 5-10 mm;

[0078] Step A1.3, using a drum sieve to sieve the waste porcelain material in step A1.2 to obtain waste porcelain powder with a particle size of ≤10 mm;

[0079] Step A2, adding water to ball mill the raw ore black mud and the waste porcelain powder in the step A1.3 until the fineness of the ball is 8% of the 325 mesh sieve to obtain a waste porcelain s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com