Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

197 results about "Differential centrifugation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Differential centrifugation (also differential velocity centrifugation) is a common procedure in biochemistry and cell biology used to separate organelles and other sub-cellular particles on the basis of sedimentation rate. Although often applied in biological analysis, differential centrifugation is a general technique also suitable for crude purification of non-living suspended particles (e.g. nanoparticles, colloidal particles, viruses). In a typical case where differential centrifugation is used to analyze cell-biological phenomena (e.g. organelle distribution), a tissue sample is first lysed to break the cell membranes and release the organelles and cytosol. The lysate is then subjected to repeated centrifugations, where particles that sediment sufficiently quickly at a given centrifugation force for a given time form a compact "pellet" at the bottom of the centrifugation tube. After each centrifugation, the supernatant (non-pelleted solution) is removed from the tube and re-centrifuged at an increased centrifugal force and/or time. Differential centrifugation is suitable for crude separations on the basis of sedimintation rate, but more fine grained purifications may be done on the basis of density through equilibrium density-gradient centrifugation.

Cultivation method of Cyp gene knocked-out rats, and preparation method of liver microsome of the rats

ActiveCN106148416ADiverse in vitro modelsImprove transfer abilityMicroinjection basedFermentationHepaticaMicro injection

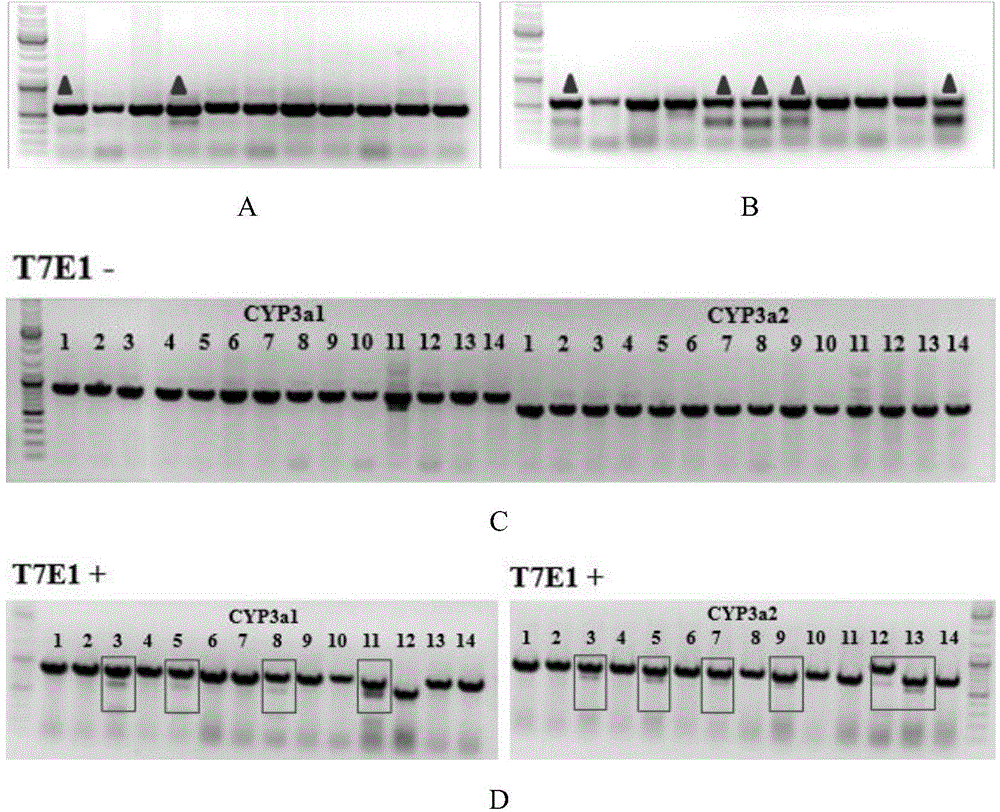

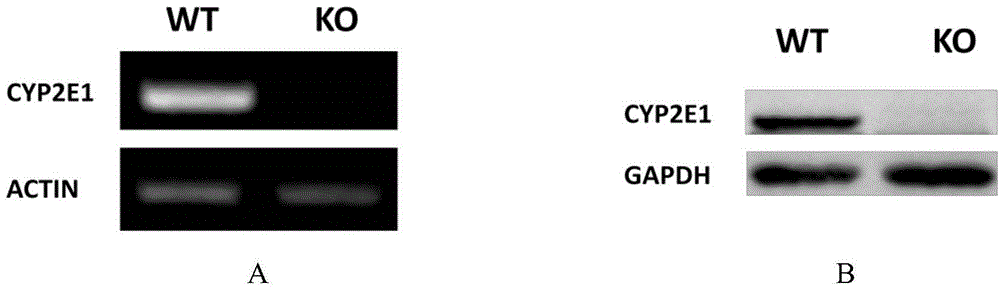

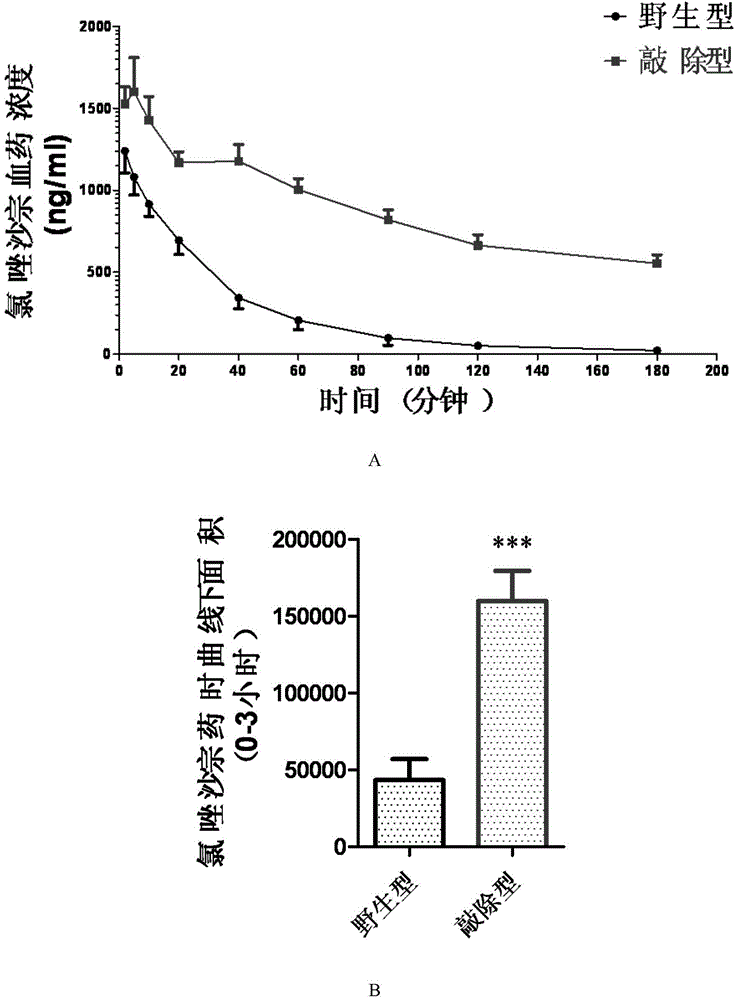

The invention provides a cultivation method of Cyp gene knocked-out rats, and a preparation method of liver microsome of the rats. The Cyp gene knock-out herein includes Cyp single gene knock-out and Cyp multiple gene knock-out. In the method, firstly a Cyp gene knocked-out rat is constructed by means of a CRISPR / Cas system, which includes selection of a knocked-out target site, in-vitro synthesis and transcription of sg RNA and Cas9m RNA, preparation of a pseudopregnant female rat, in-vitro micro-injection and transplanting of a single-cell embryo, and cultivation of the rat, and finally, a homozygote Cyp gene knocked-out rat can be cultured. Furthermore, the liver of the Cyp gene knocked-out rat is extracted and is subjected to homogenization and differential centrifugation to prepare the liver microsome of the rat in Cyp gene deletion. The invention also provides an application of the Cyp gene knocked-out rats and the liver microsome thereof in study on drug metabolism.

Owner:EAST CHINA NORMAL UNIV

Method for obtaining an extract from ginkgo biloba leaves

A novel and environmentally friendly method is disclosed for producing a purified extract from Ginkgo biloba leaves comprising the novel steps of differential centrifugation and extraction with supercritical CO2.

Owner:PHARMLINE

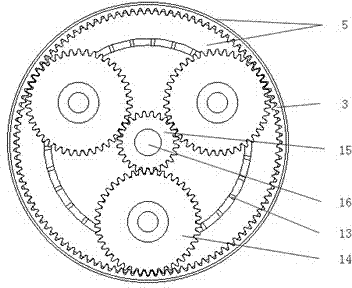

Three-screw planetary transmission vertical medium stirring mill

ActiveCN104841525ACompact structureHigh transmission efficiencyGrain treatmentsReliable transmissionCentrifugation

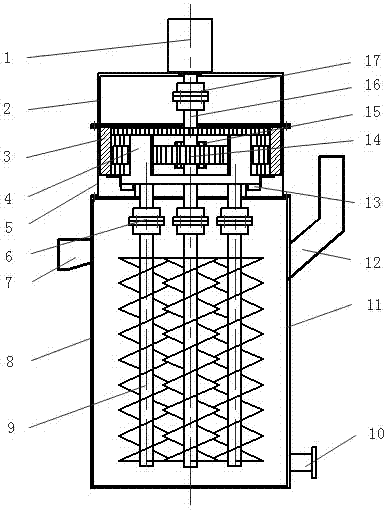

The invention relates to a three-screw planetary transmission vertical medium stirring mill, and belongs to the field of ore dressing and grinding fragmentation. The three-screw planetary transmission vertical medium stirring mill comprises a motor, a motor support, an outer tooth ring, a plant rack, a gear box, a shaft coupling I, a material outlet, a cylindrical shell, stirrers, a material return tube, a cylindrical shell liner plate, a material inlet tube, a roller needle, a planetary gear, a sun gear, a short shaft and a shaft coupling II. The three helical stirrers are ingeniously combined with planetary transmission, and the advantages of the planetary transmission are fully used to make a transmission structure compact, greatly improve the transmission efficiency and the power density and realize a direct deceleration effect; and the revolution and rotation motion of the three helical stirs increases the motion complexity of materials in the cylindrical shell and effectively reduces the central dead zone phenomenon induced by material centrifugation, so the effective grinding area in the mill is increased. The three-screw planetary transmission vertical medium stirring mill has the advantages of superior grinding mechanism, reliable transmission, compact structure, low energy consumption, high efficiency, small occupied area, wide application range, and simple and convenient use and maintenance.

Owner:KUNMING UNIV OF SCI & TECH

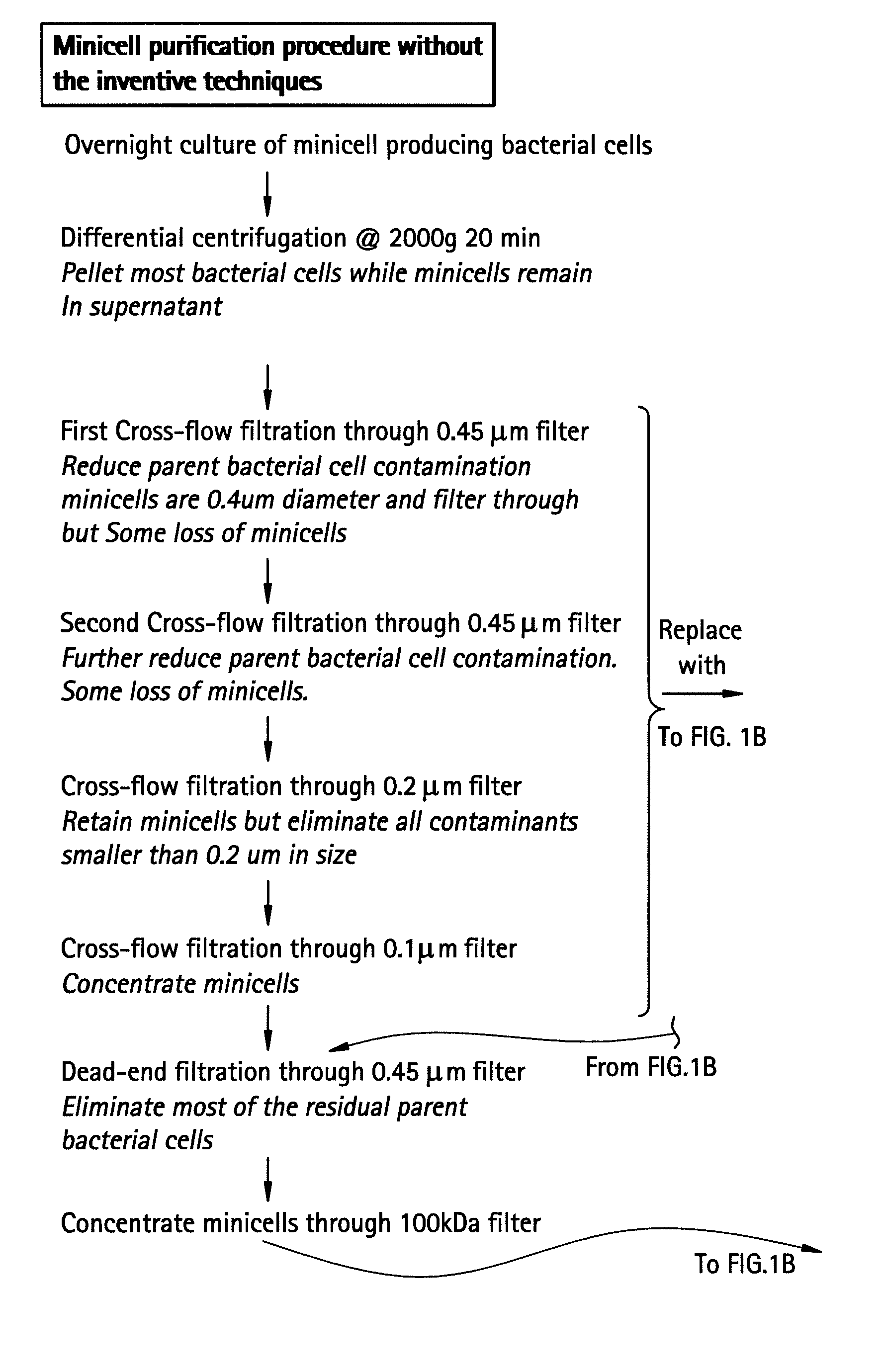

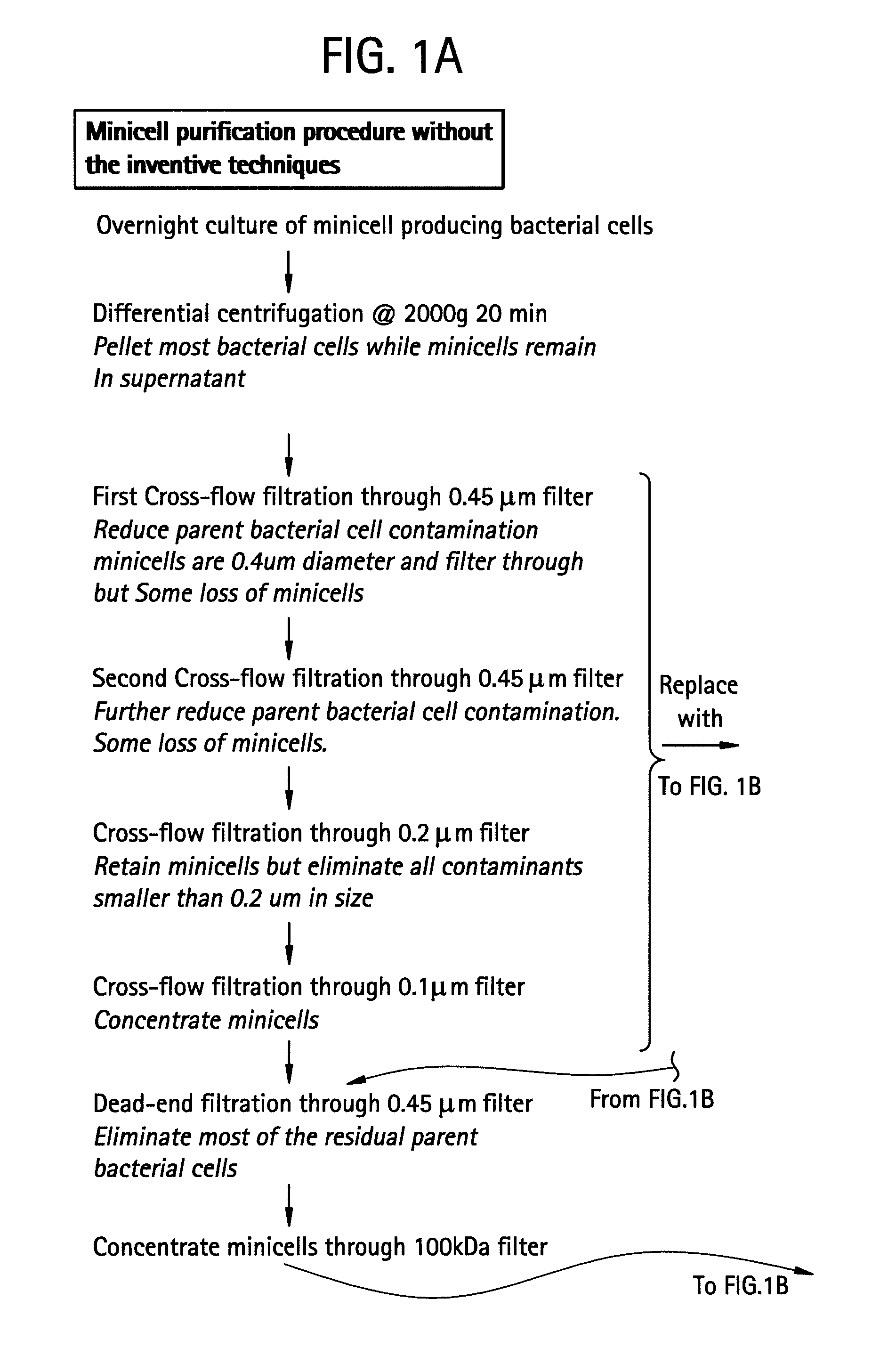

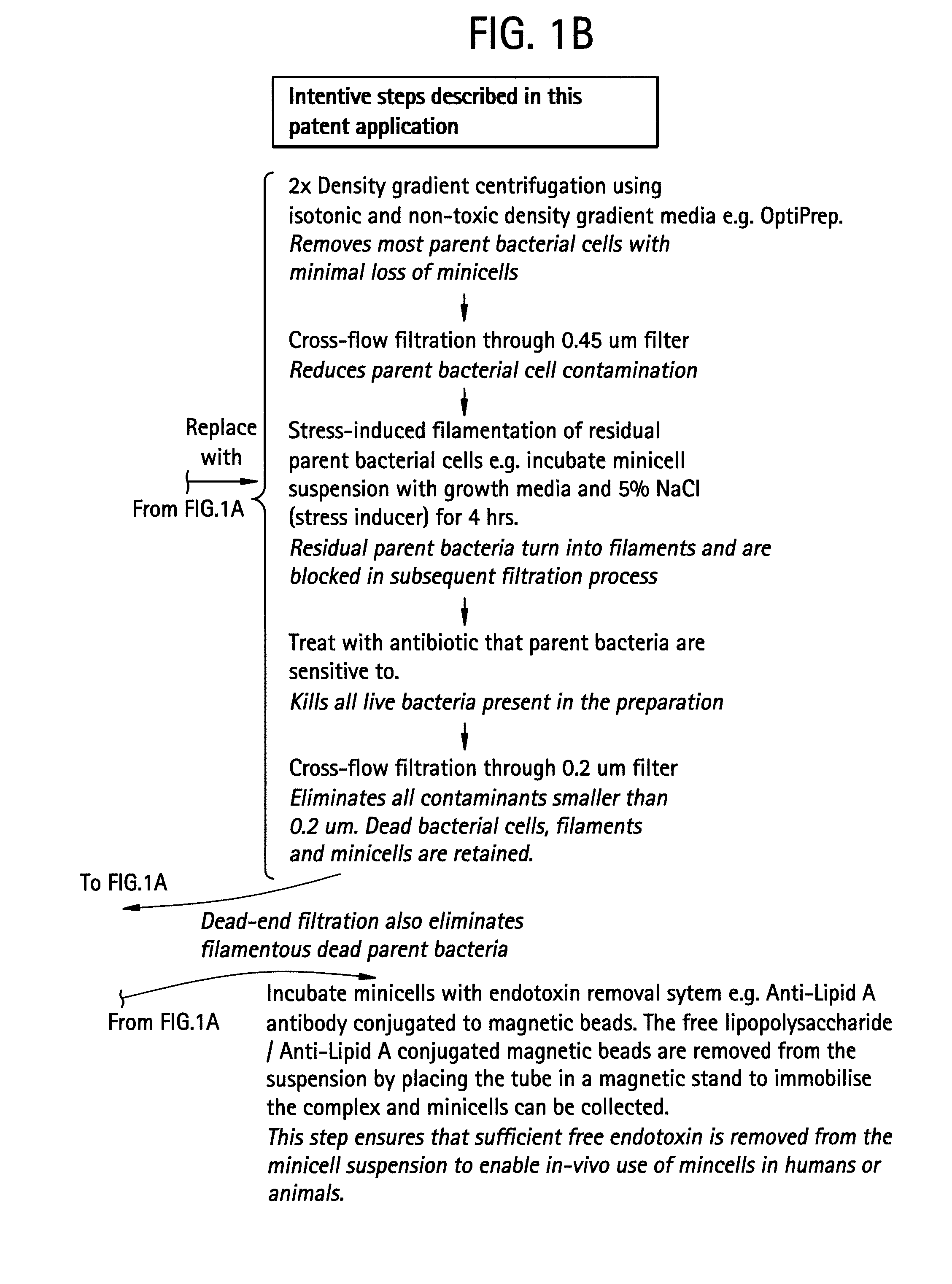

Pharmaceutically compatible method for purifying intact bacterial minicells

InactiveUS20070241067A1BiocideWater/sewage treatment by centrifugal separationFiltrationCentrifugation

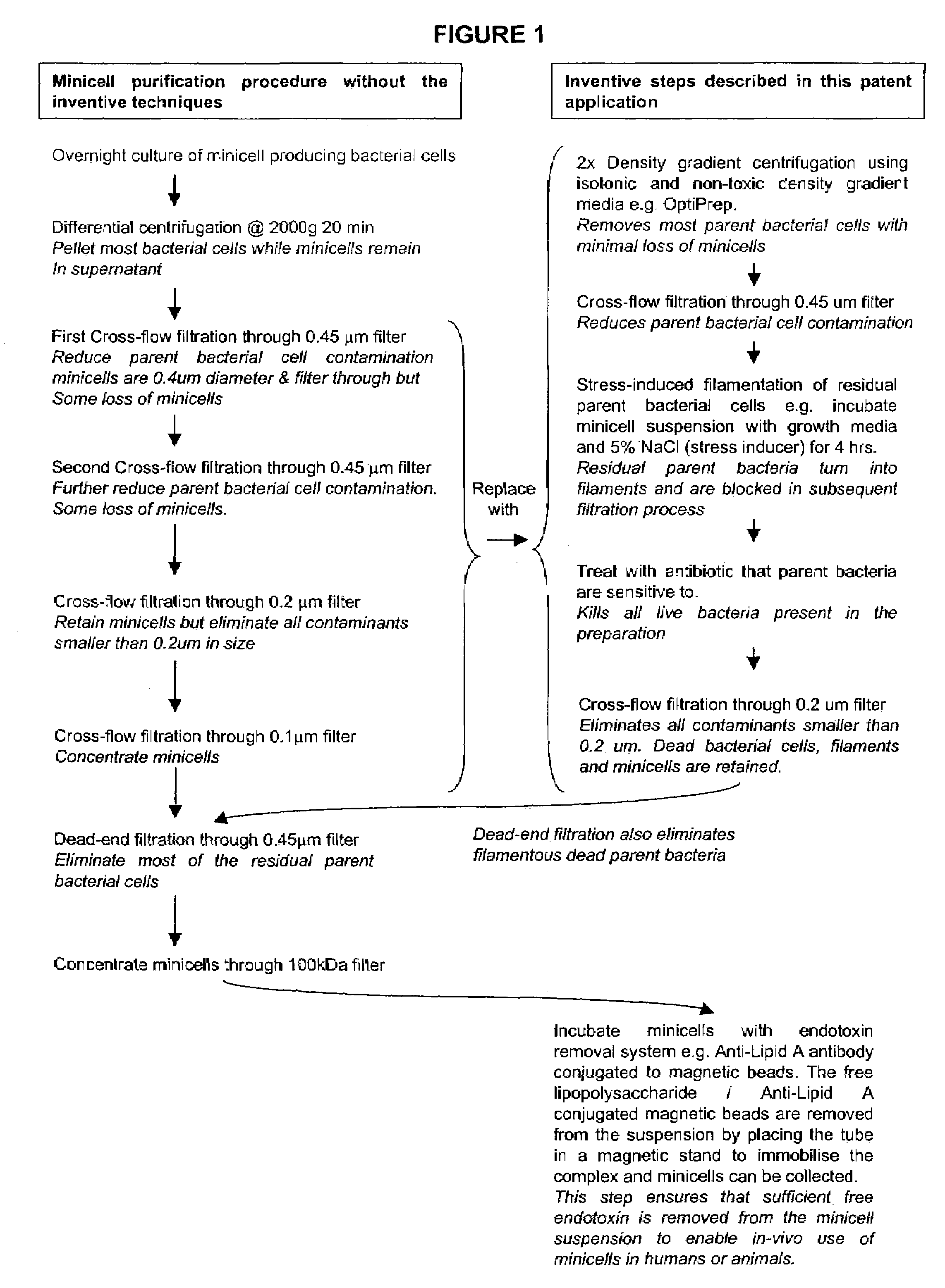

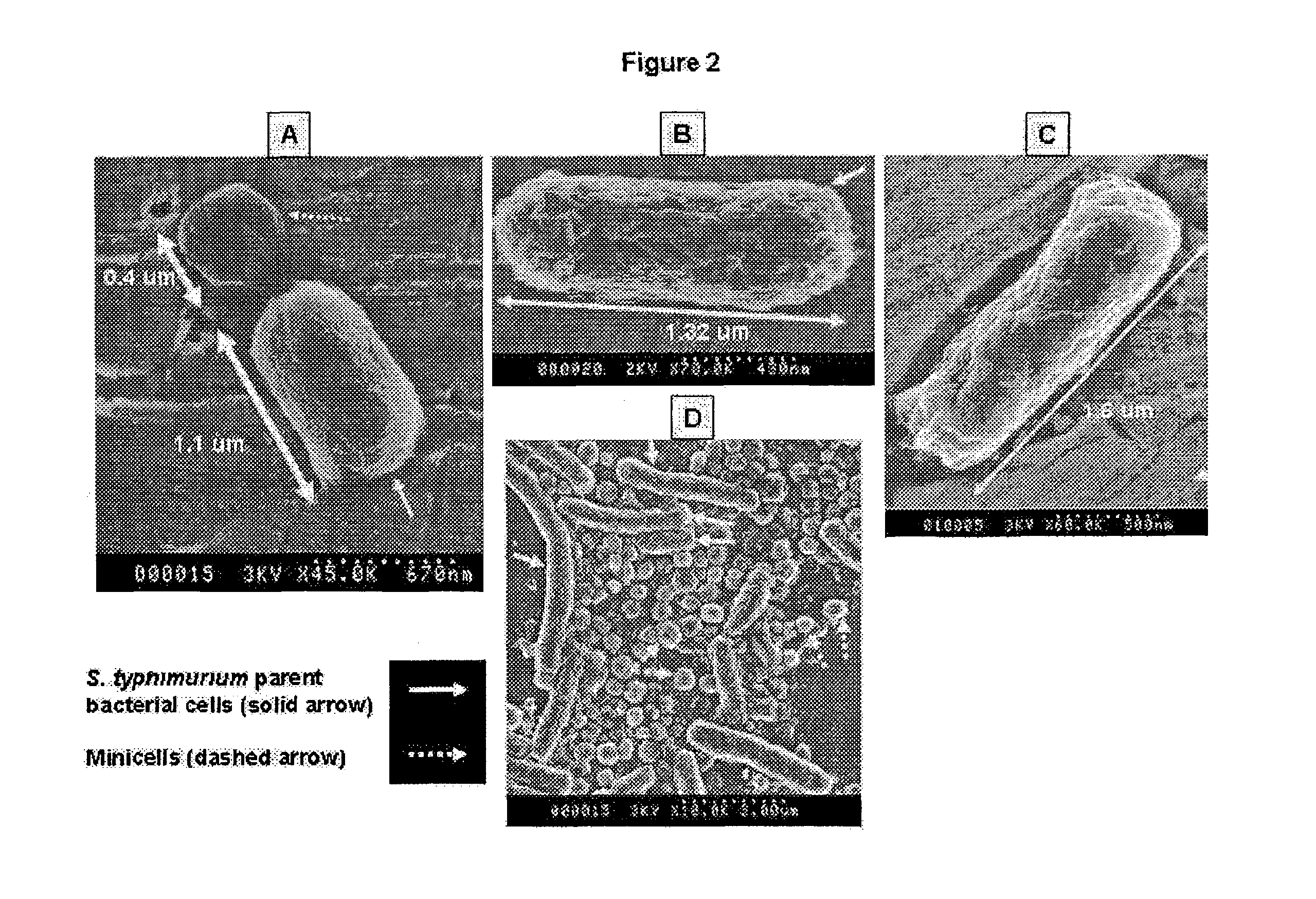

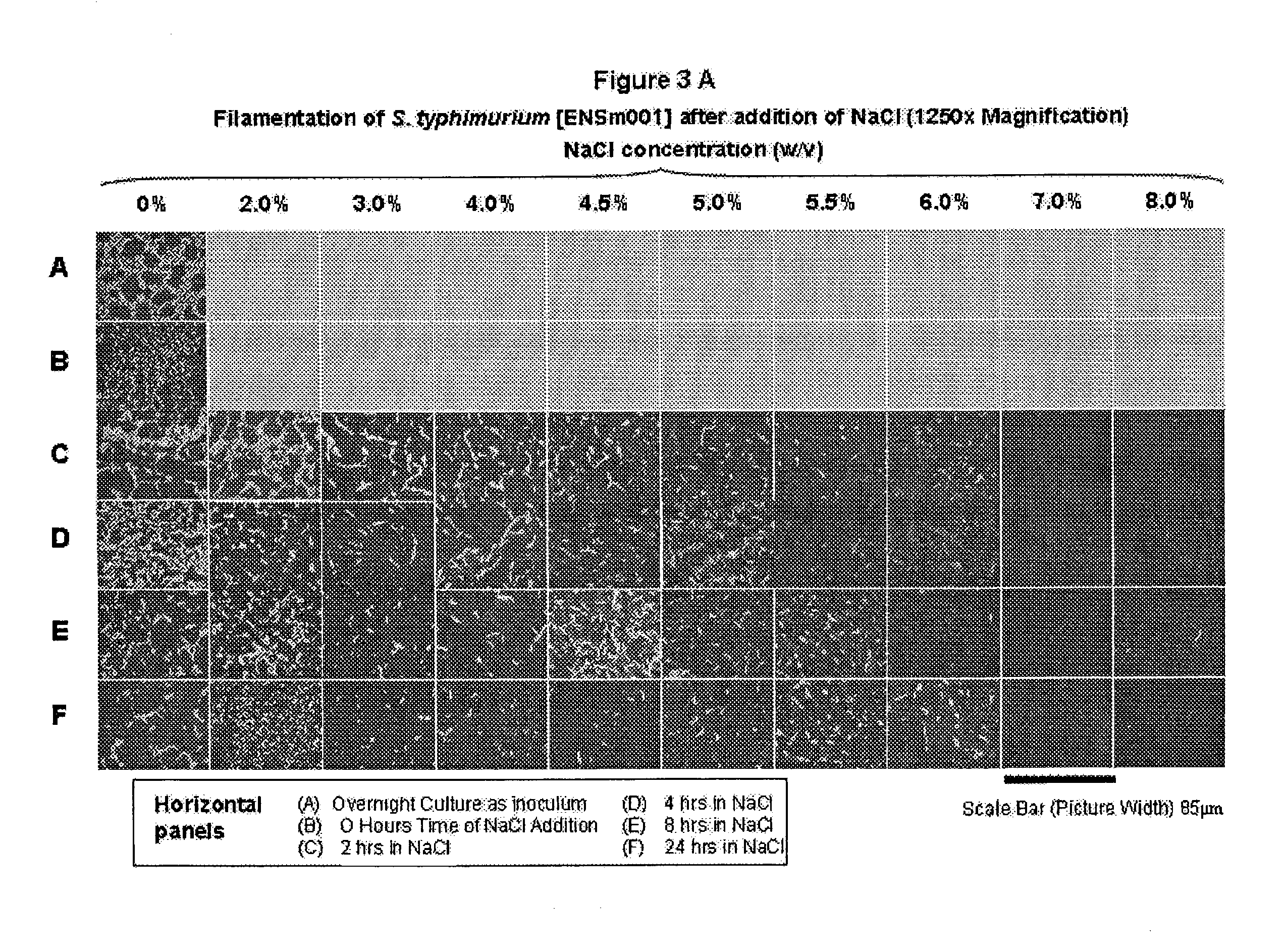

The present invention provides a method for purifying bacterial minicells that involves subjecting a sample containing minicells to density gradient centrifugation in a biologically compatible medium. The method optionally includes a preliminary differential centrifugation step and one or more filtration steps. The invention also provides a method for purifying bacterial minicells in which a sample containing minicells is subjected to a condition that induces parent bacterial cells to adopt a filamentous form, followed by filtration of the sample to separate minicells from parent bacterial cells. The inventive methods optionally include one or more steps to remove endotoxin from purified minicell preparations, and / or treatment of purified minicell preparations with an antibiotic. Additionally, the invention provides purified minicell preparations, prepared according to the foregoing methods, and containing fewer than about 1 contaminating parent bacterial cell per 107, 108, 109, 1010, or 1011 minicells.

Owner:ENGENEIC MOLECULAR DELIVERY PTY LTD

Scaffolds of umbilical cord decellularized Wharton jelly for tissue engineering and preparation method thereof

InactiveCN102198292AControllable fine structureModerate degradation rateProsthesisFine structureEnzymatic digestion

The invention discloses scaffolds of umbilical cord decellularized Wharton jelly for tissue engineering and a preparation method thereof. Umbilical cords are employed as the raw material and their outer membranes and vascular tissues are peeled off. And the rest part of the umbilical cords is subjected to hypotonic freeze-thaw, mechanical pulverization, differential centrifugation, enzymatic digestion for decellularization. Then the umbilical cord Wharton jelly is collected and injected into a mold. After freeze drying and crosslinking, multiple three dimensional porous sponge scaffolds and composite scaffolds can be obtained. The method of the invention has the advantages of wide material source, low cost, simple technology. And the prepared scaffolds are characterized by controllable fine structure, appropriate degradation rate, good biocompatibility, and biomechanical strength, which are in favor of cell adhesion and the uniform distribution of seed cells within the scaffolds, as well as seed cell multiplication, migration and growth. Thus, the scaffolds of umbilical cord decellularized Wharton jelly in the invention can be widely applied in the tissue engineering field such ascartilage, bone, skin and nerve, with a favorable clinical application prospect.

Owner:卢世璧

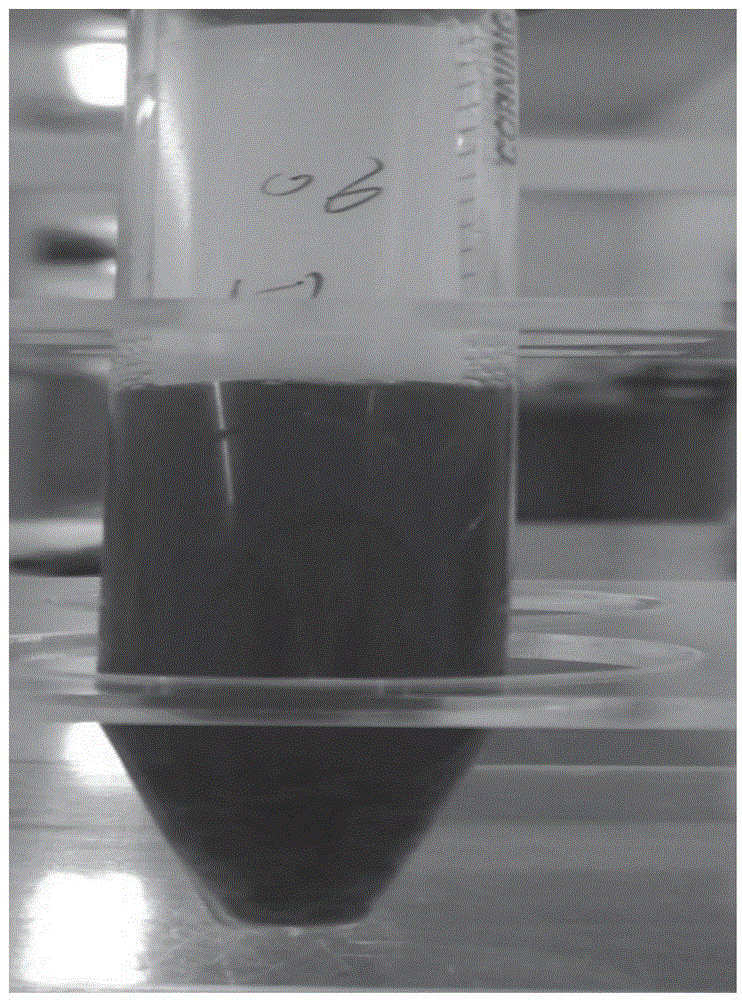

Method for preparing human umbilical cord mesenchymal stem cell exosomes

PendingCN109880797AHigh purityClear sourceSkeletal/connective tissue cellsMesenchymal stem cellMycoplasma contamination

The invention discloses a method for preparing human umbilical cord mesenchymal stem cell exosomes. The method uses a newborn umbilical cord as a source of umbilical cord mesenchymal stem cells, usesa medium prepared by a fetal calf serum or a serum substitute in which exosome carried by itself is removedfor culturing, collects a supernatant, and further separates and extracts the exosomesby differential centrifugation, the purity is high, and the source of the umbilical cord mesenchymal stem cell exosomes is ensured; the exosomes is prepared by the differential centrifugation, the operationis simple, and the method is suitable for large-scale production; during the whole process, sterility is guaranteed, the contamination ofmycoplasma is prevented, and the product safety is higher.

Owner:JINAN PANSHENG BIOTECH

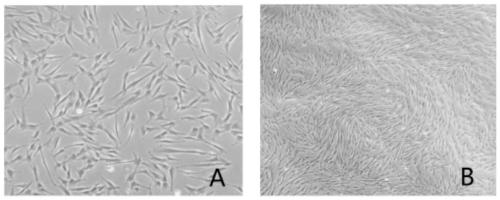

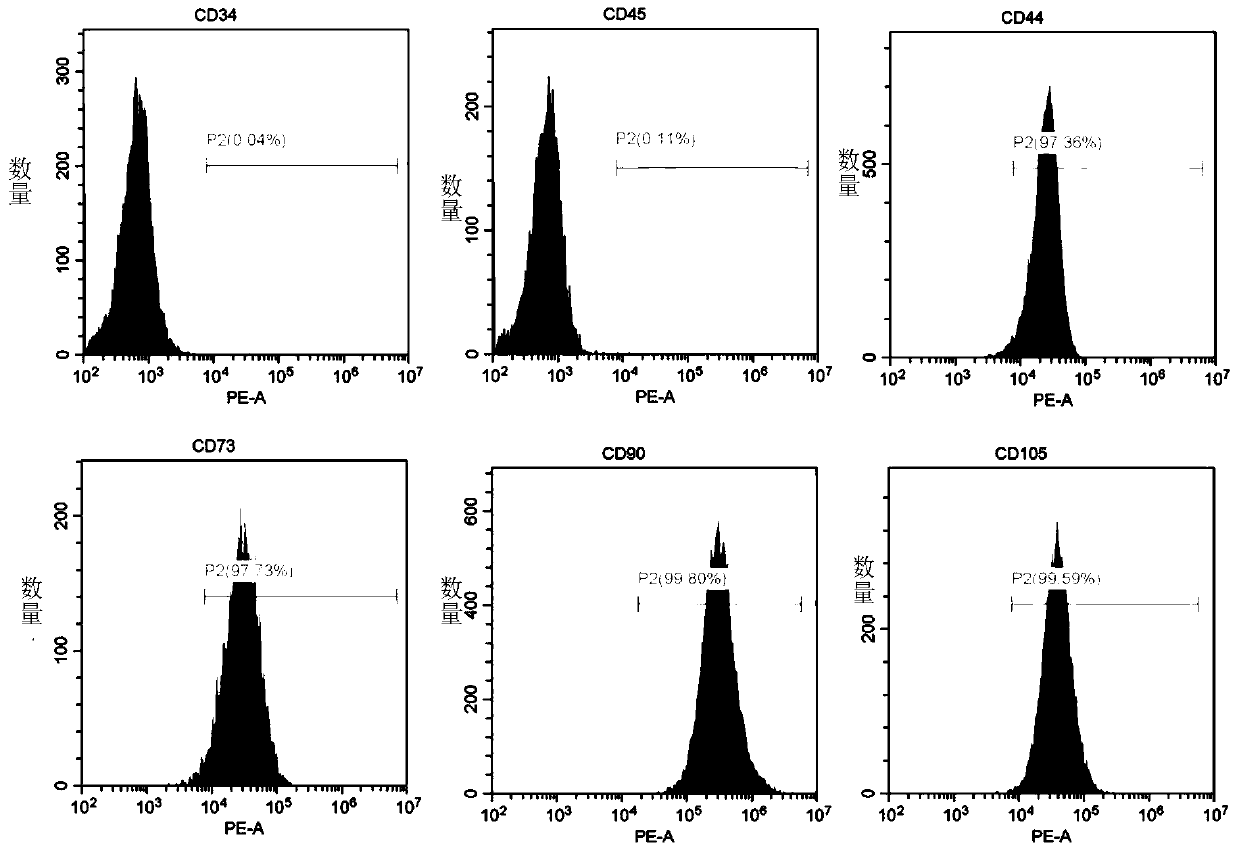

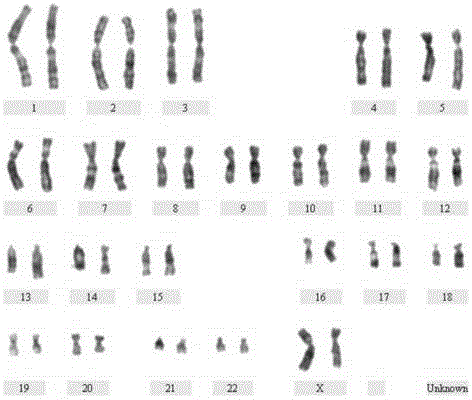

Culturing method of mesenchymal stem cells of menstrual blood

ActiveCN104560871APollution prevention methodsReduced Chances of ContaminationSkeletal/connective tissue cellsHydroxyethyl starchSurface marker

The invention provides a method for preparing mesenchymal stem cells of menstrual blood. The method comprises steps as follows: female menstrual blood is collected and taken as a raw material and is subjected to sterile processing; stem cells in the menstrual blood are separated; the mesenchymal stem cells of the menstrual blood are cultured; the mesenchymal stem cells of the menstrual blood are cryopreserved; and the mesenchymal stem cells of the menstrual blood are recovered. The method has the technical characteristics as follows: the female menstrual blood is collected and stored in a preservative fluid; by means of a bacterial pollution prevention method, the pollution probability is reduced from a collection source, a collecting cup is repeatedly washed by sterile water, and the pollution probability is effectively reduced; with the adoption of a differential centrifugation method, bacteria in the menstrual blood are removed as far as possible; a sample is repeatedly separated by HES (hydroxyethyl starch), and the maximum quantity of mesenchymal stem cells of the menstrual blood can be obtained; a serum-free medium is utilized for culturing, components of animal origin are reduced, the cell performance is stable, the in-vitro long-term culturing process of the mesenchymal stem cells of the menstrual blood can be kept, and cellular morphology, multiplication capacity, MSC (mesenchymal stem cell) surface marker expression, differentiation capacity and the like are maintained. The method is simple, practical and convenient to operate, the maximum quantity of required stem cells can be obtained, and the stem cells are successfully cultured.

Owner:SHENZHEN BEIKE BIOTECH

Piezoelectric composite dressing for promoting peripheral nerve repair and wound healing and loading exosome of traditional Chinese medicine and preparation method

ActiveCN110464867AReduce manufacturing costImprove conductivityPharmaceutical delivery mechanismAbsorbent padsInjury mouthNerve repair

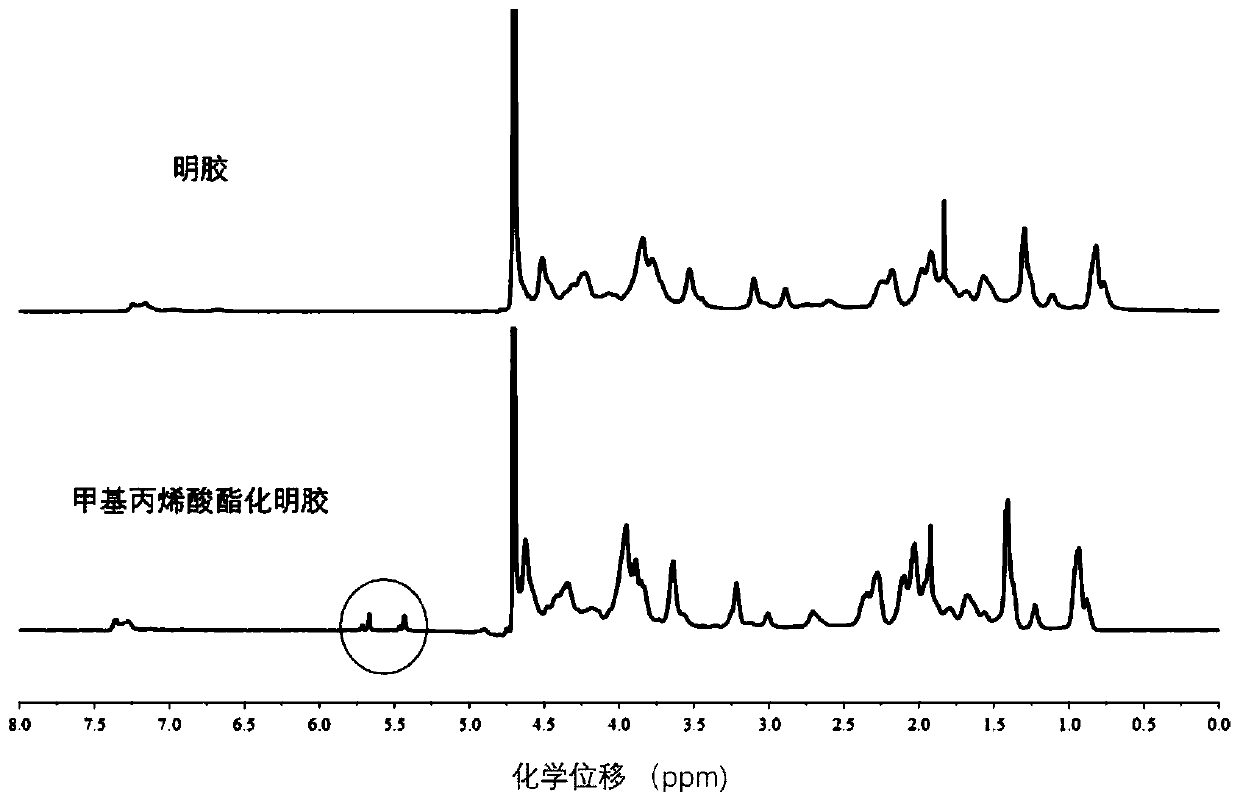

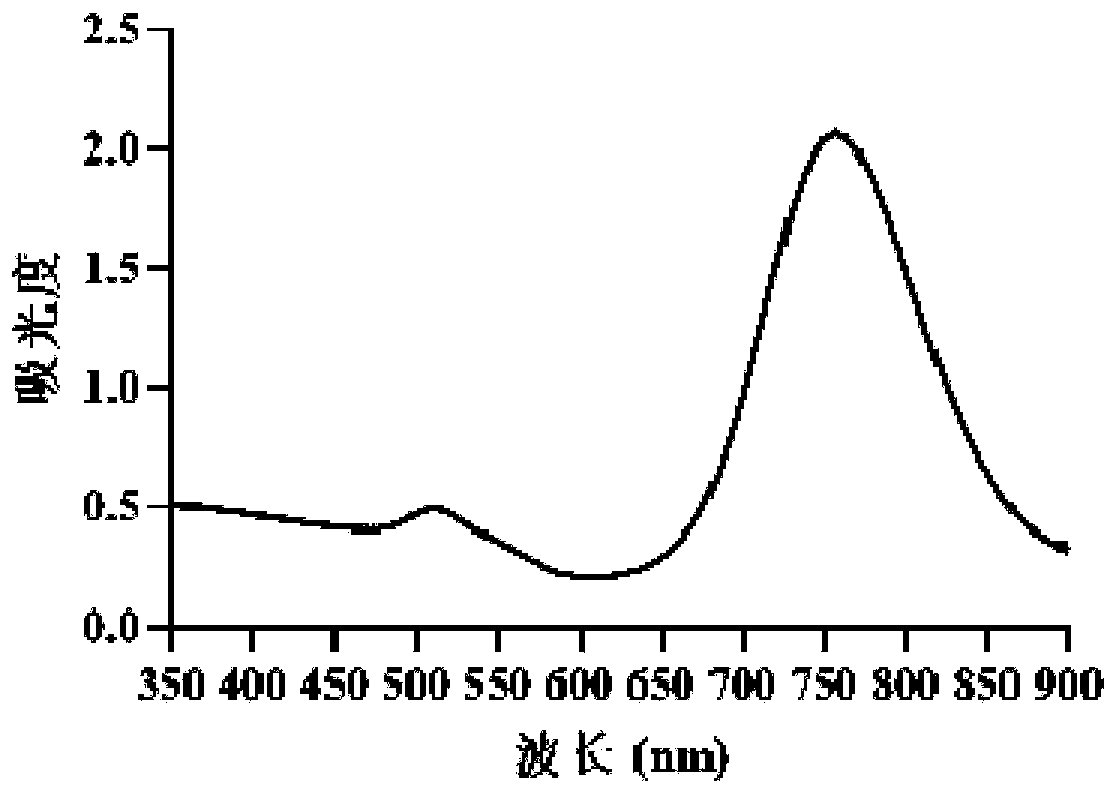

The invention provides a piezoelectric composite dressing for promoting peripheral nerve repair and wound healing and loading exosome of traditional Chinese medicine and a preparation method. The preparation method comprises the following steps that gelatin and methacrylic anhydride react to prepare methacrylate gelatin; the exosome of the Chinese medicine is prepared through differential centrifugation;a conductive pregel system is prepared through the recombination of gold nanorods, the exosome and the methacrylate gelatin; and the conductive pregel and a polyvinylidene fluoride ethylene piezoelectric thin film arerecombined, and the piezoelectric composite dressing is prepared. The dressing prepared by the preparation method is a novel dressing for piezoelectric stimulation composite medicine action, polyvinylidene fluoride ethylene produces electricity potential to stimulate a wound area through the conductive gel, wound healing and nerve regeneration are promoted with the exosomeof the traditional Chinese medicine, and the problems in the current wound repair and nerve repair process can be effectively solved. Therefore, the composite dressing has a wide application value inthe treatment of trauma and nerve repair.

Owner:ZHEJIANG UNIV

Pharmaceutically compatible method for purifying intact bacterial minicells

The present invention provides a method for purifying bacterial minicells that involves subjecting a sample containing minicells to density gradient centrifugation in a biologically compatible medium. The method optionally includes a preliminary differential centrifugation step and one or more filtration steps. The invention also provides a method for purifying bacterial minicells in which a sample containing minicells is subjected to a condition that induces parent bacterial cells to adopt a filamentous form, followed by filtration of the sample to separate minicells from parent bacterial cells. The inventive methods optionally include one or more steps to remove endotoxin from purified minicell preparations, and / or treatment of purified minicell preparations with an antibiotic. Additionally, the invention provides purified minicell preparations, prepared according to the foregoing methods, and containing fewer than about 1 contaminating parent bacterial cell per 107, 108, 109, 1010, or 1011 minicells.

Owner:ENGENEIC MOLECULAR DELIVERY PTY LTD

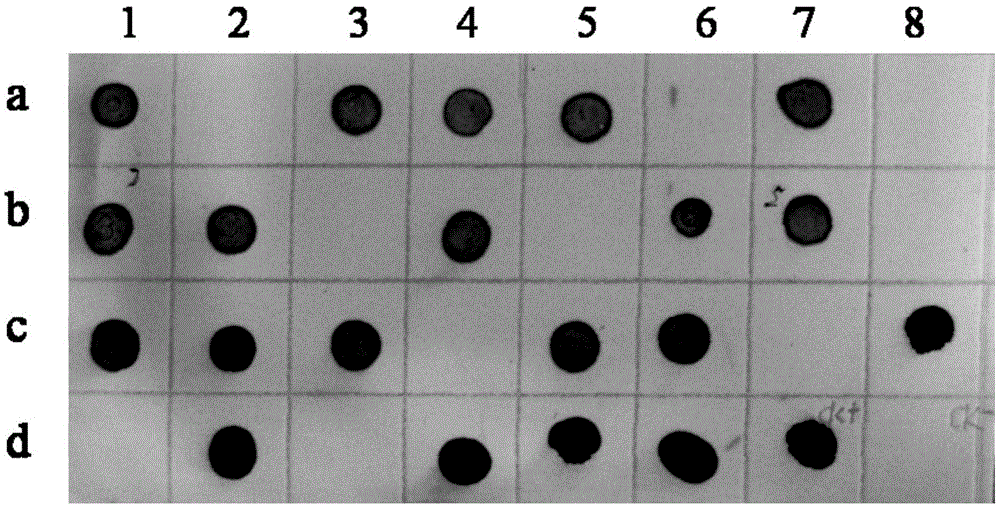

Hybridoma cell strain secreting monoclonal antibody against barley yellow dwarf virus GAV strain and application of monoclonal antibody thereof

ActiveCN103911349AAccurate detectionSensitive detectionImmunoglobulins against virusesTissue cultureAntibody typesBALB/c

The invention discloses a hybridoma cell strain secreting a monoclonal antibody against a barley yellow dwarf virus GAV strain, and an application of the monoclonal antibody thereof. A BALB / c mouse is immunized with barley yellow dwarf virus (BYDV) GAV strain virions which is used as antigens and is purified by a differential centrifugation method, and a hybridoma cell strain 27E1 which can be subcultured stably and secretes a monoclonal antibody against BYDV GAV is obtained through cell fusion, screening, and cloning, and the accession number is CGMCC No. 8781. The monoclonal antibody secreted by the hybridoma cell has an ascetic ELISA titer of more than 10<-6>, and the antibody type and subtype are IgG1, kappa chain. A specific reaction can be carried out between the monoclonal antibody secreted by the hybridoma cell strain 27E1 and the barley yellow dwarf virus GAV strain, but the monoclonal antibody does not react with rice stripe virus, rice ragged stunt virus, Chinese wheat mosaic virus, wheat yellow mosaic virus, barley yellow mosaic virus, barley yellow dwarf virus GPV strains and PAV strains. The hybridoma cell strain 27E1 and the secreted monoclonal antibody provide technical and material support for the diagnosis, detection and scientific prevention and control of wheat viral diseases.

Owner:ZHEJIANG UNIV

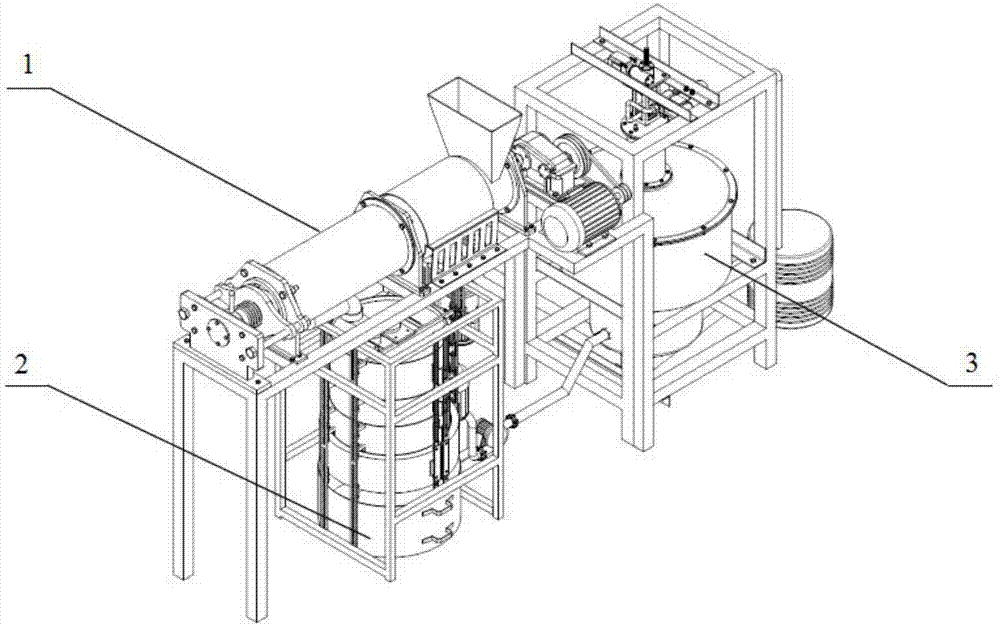

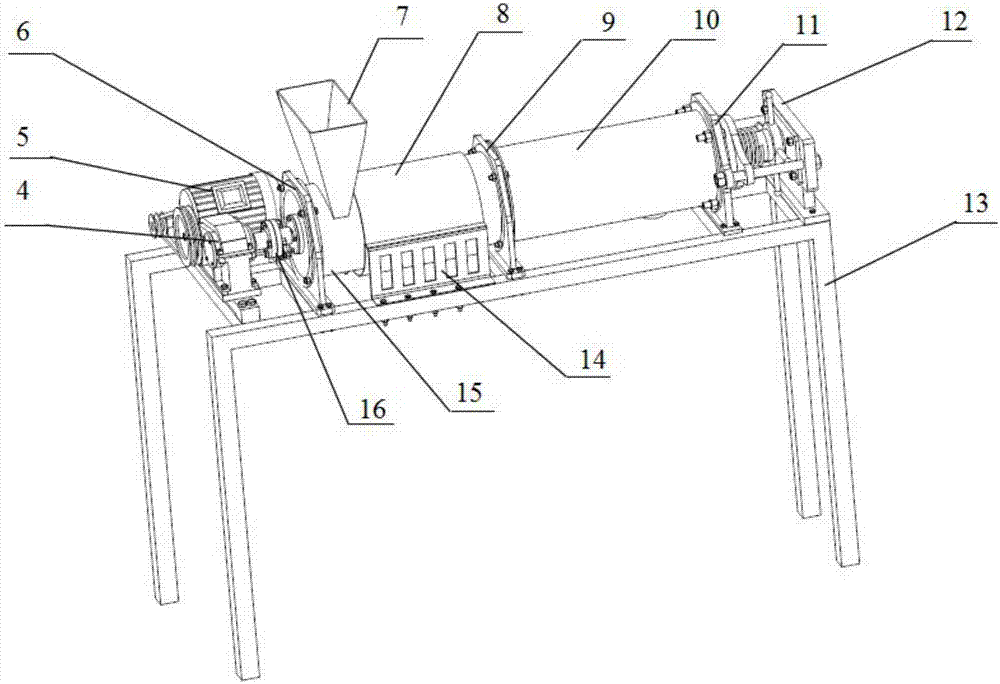

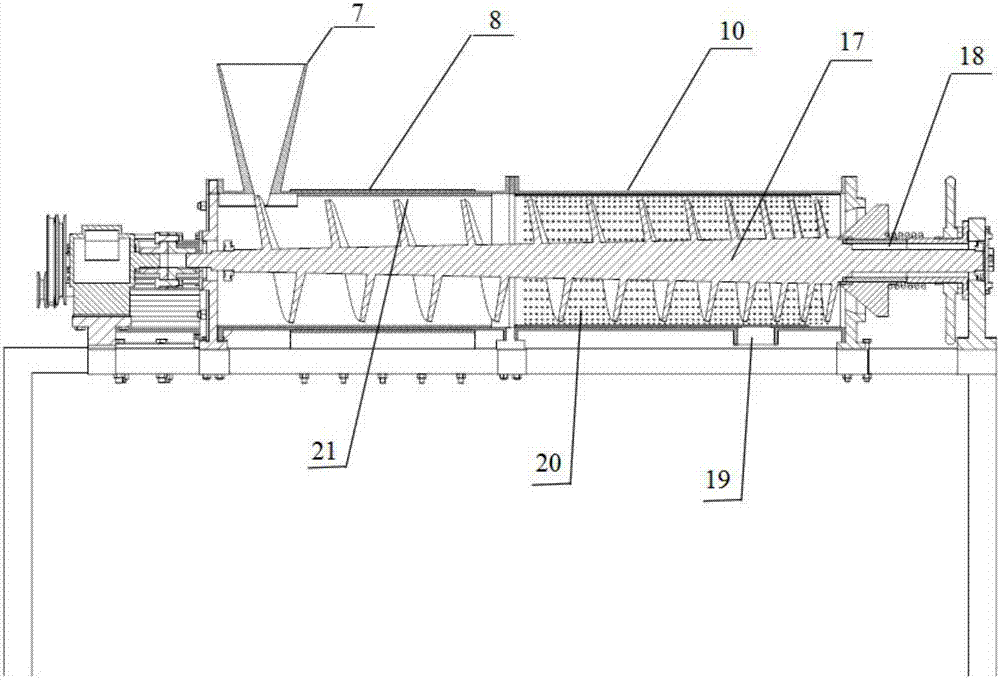

Restaurant swill processing device

ActiveCN107265760AAchieve separationEfficient separationWater/sewage treatment by centrifugal separationSpecific water treatment objectivesAxial-flow pumpSlag

The invention discloses a restaurant swill processing device. The restaurant swill processing device is formed by combining three independent parts which are a first-level solid-liquid separation device, a second-level slag removing device and a third-level oil-liquid separation device, wherein the first-level solid-liquid separation device is self-provided with a temperature detection and constant temperature heating system, the second-level slag removing device is provided with a differential centrifugation mechanism, and the third-level oil-liquid separation device is provided with a biochemical filter screen and an automatic oil liquid extracting mechanism; the first-level device and the second-level device are connected by a connecting pipe, and the second-level device and the third-level device are connected by an axial flow pump. According to the restaurant swill processing device disclosed by the invention, dehydration is carried out on swill through gradually varied screw blades so as to obtain solid residues, which have different water contents, and a separating medium, wherein the solid residues can be processed into feed or fertilizer after being collected, afterwards, the separating medium enters the second-level slag removing device, secondary filtration is carried out on the separating medium by utilizing centrifugal force, finally, the third-level oil-liquid separation device is used for processing, the obtained liquid meets the requirement of environmental protection, the degree of automation is high, and the continuous and large-batch swill processing can be realized.

Owner:ANHUI UNIV OF SCI & TECH

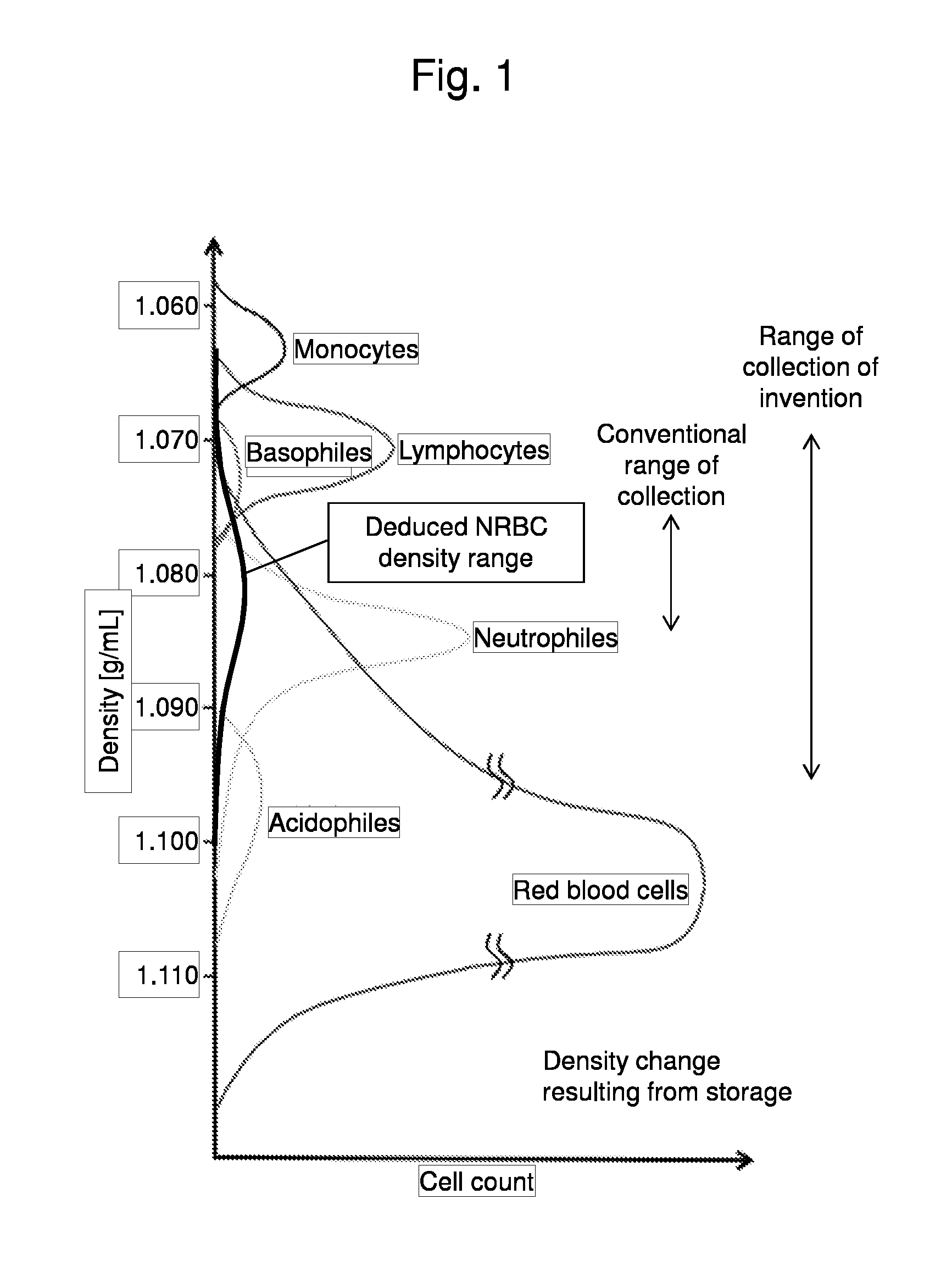

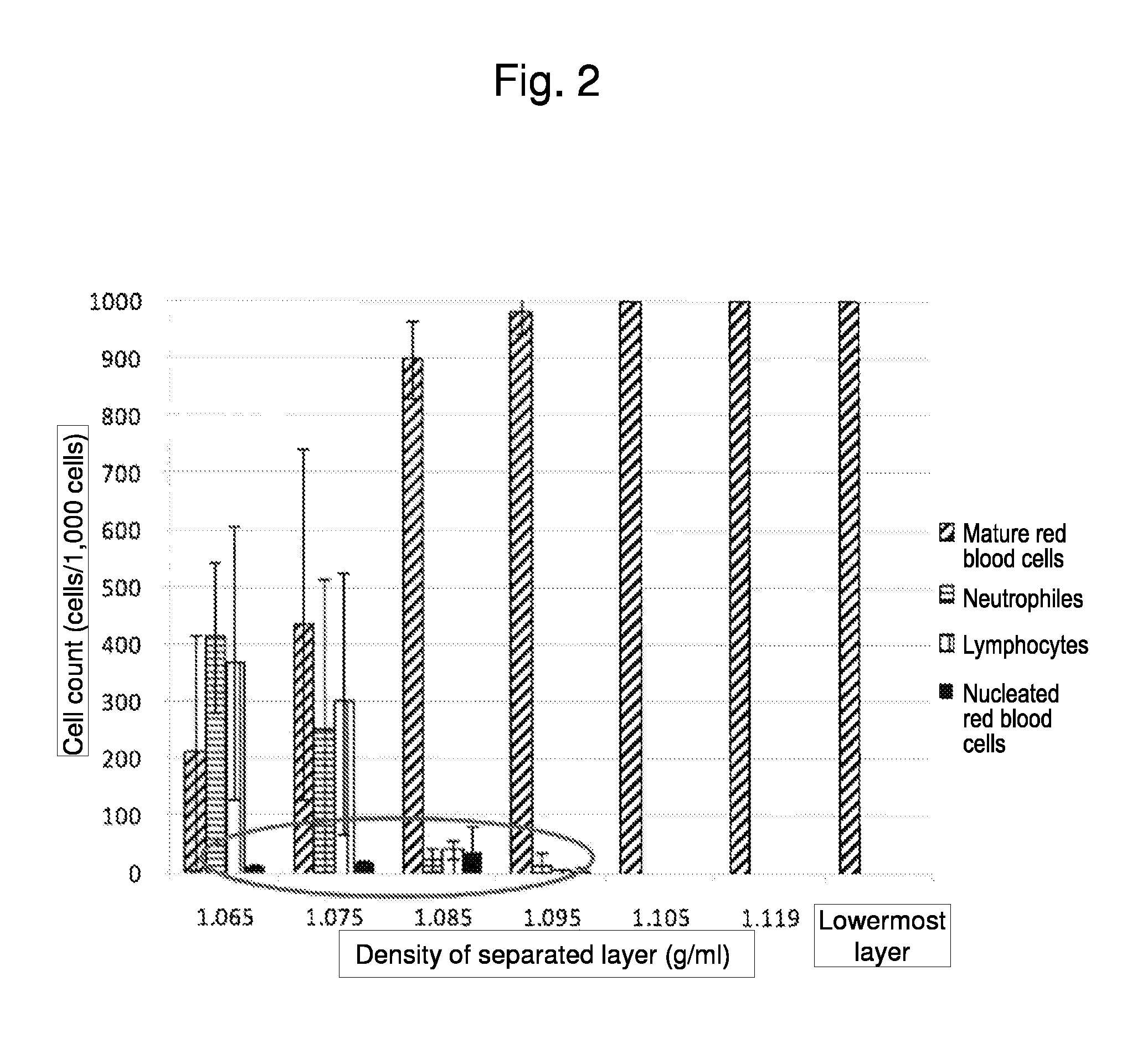

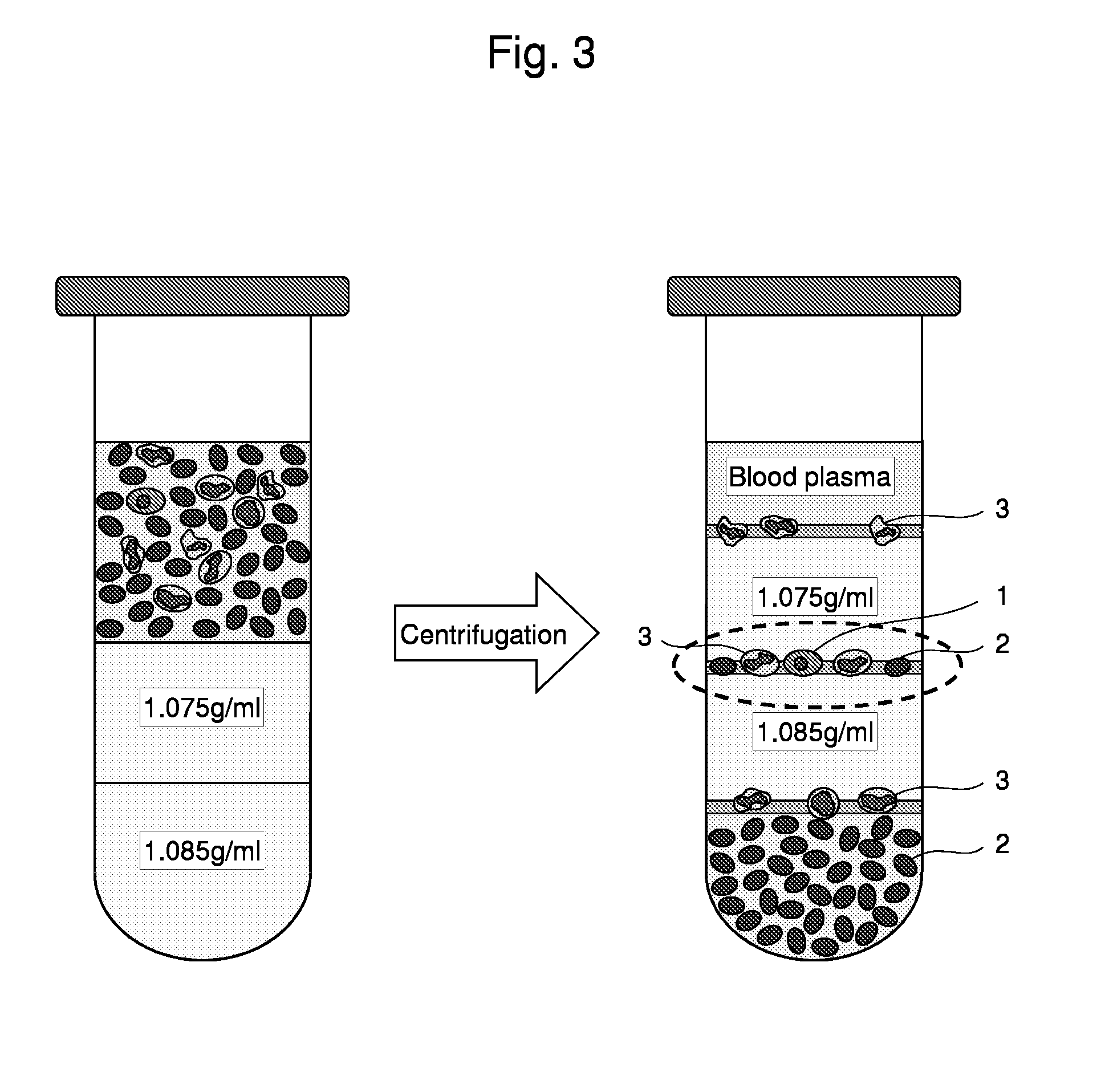

Method for collecting nucleated red blood cells via density-gradient centrifugation utilizing changes in blood cell density

ActiveUS20130072402A1Cell count is reducedIncreased riskMicrobiological testing/measurementLibrary screeningCell FractionRed blood cell

This invention provides a method for concentrating and collecting small quantities of fetal nucleated red blood cells contained in the maternal blood. The method for concentrating and collecting nucleated red blood cells from the maternal blood comprises: (i) subjecting the maternal blood to a first density-gradient centrifugation and collecting a cell fraction containing nucleated red blood cells; (ii) treating the cell fraction containing nucleated red blood cells so as to selectively changes the density of the nucleated red blood cells from that of the white blood cells; and (iii) subjecting the treated cell fraction containing the nucleated red blood cells to a second density-gradient centrifugation so as to collect a fraction containing nucleated red blood cells.

Owner:JAPAN ADVANCED INST OF SCI & TECH +2

Preparation method of exosomes of deer placenta and application

ActiveCN108143750AHigh purityGood market prospectCosmetic preparationsToilet preparationsClinical valueFreeze-drying

The invention discloses a preparation method of exosomes of deer placentas and application thereof and belongs to the technical field of biology. The preparation method and the application have the advantages that the high-purity exosomes are obtained by preparing living bodies of healthy-deer placentas into uniform slurry and carrying out differential centrifugal separation and low-temperature overspeed purification; good treating effect is obtained in the experimental treatment of the animal skin injury; the exosomes can be prepared into freeze-dried powder which can be stored for long term;the freeze-dried powder can be matched with different auxiliary materials to form different preparation products so as to have an excellent market prospect and clinical value.

Owner:HUBEI WEILAIJIAYUAN HIGH TECH AGRI CO LTD

Method for extracting Cryptococcus humicola mitochondrion

InactiveCN104178431AHigh yieldQuality improvementFungiMicroorganism based processesBiotechnologyCellulase

The invention discloses a method for extracting a Cryptococcus humicola mitochondrion. According to the method, the operation steps of the existing differential centrifugation method, the extraction of the components of a buffer and the preparation method are improved, the pretreatment time of a thallus is prolonged, and the shaking is continuously carried out; in the enzymatic and wall-breaking steps, the components of the enzymatic buffer are improved, the amount of the snailase is increased and meanwhile the cellulose is added, the enzymolysis and wall-breaking time and the incubation temperature are prolonged, the wall of the thallus is completely broken, and the yield of a protoplast is increased; in order to mildly lyse the protoplast so as not to break the mitochondrion, the protoplast lysate and a mitochondrion washing buffer solution are both prepared from PBS. Due to adoption of the method, the high-quality mitochondrion can be extracted, the mitochondrion has a complete structure and activity and the cytochrome oxidase system is not destroyed. The mitochondrion extracted by the method can be used for physiology and biochemistry studies with the mitochondrion as an object of the study. The method is simple, economical, easy in operation and the like and is suitable for being operated and popularized in an ordinary biological laboratory.

Owner:KUNMING UNIV OF SCI & TECH

High-purity and high-quality extraction method of chloroplast DNA of strip-leaf plants

The invention discloses a method for extracting chloroplast DNA of strip-leaf plants. The method comprises the following steps that A, the protoplasts of leaves are acquired by means of making mechanical injuries on the leaves and enzymolysis treatment in combination, wherein the acquired protoplasts contain chloroplasts, mitochondria and nuclei; B, impurities in the acquired products from step A are removed by differential centrifugation treatment to conduct crude extraction of the chloroplasts; C, the impurities in the acquired products from step B are removed by density gradient centrifugation to conduct purification of the chloroplasts; D, extraction is conducted on the acquired products from step C by means of a Tiangen rapid biochemical plant genome DNA extraction system to obtain high-purity chloroplast DNA. With the method for extracting the chloroplast DNA of the strip-leaf plants, high-purity and high-quality extraction can be conducted on the chloroplast DNA of the strip-leaf plants.

Owner:唐山润泽粮油食品有限公司

Three-dimensional porous sponge scaffold with meniscus matrix source and preparation method and application

InactiveCN105903079AControllable fine structureModerate degradation rateTissue regenerationProsthesisEnzyme digestionFreeze-drying

The invention discloses a three-dimensional porous sponge scaffold with a meniscus matrix source and a preparation method and an application. The method comprises the following steps: with meniscus as a raw material, removing cells through mechanical crushing treatment, acetic acid enzyme digestion and a differential centrifugation method to obtain meniscus extracellular matrix slurry; building a three-dimensional porous scaffold through freeze-drying; and carrying out crosslinked reinforcement on the scaffold through ultraviolet and chemical methods. The prepared three-dimensional porous sponge scaffold with the meniscus matrix source has a controllable microstructure, appropriate degradation rate, good biocompatibility and certain biomechanical strength, is beneficial to cell adhesion, uniform distribution of seed cells to enter into the scaffold and proliferation migration growth, is free of immunological rejection when implanted in vivo, can be widely applied to the field of meniscus and cartilage tissue engineering, and has a good clinical application prospect.

Owner:GENERAL HOSPITAL OF PLA

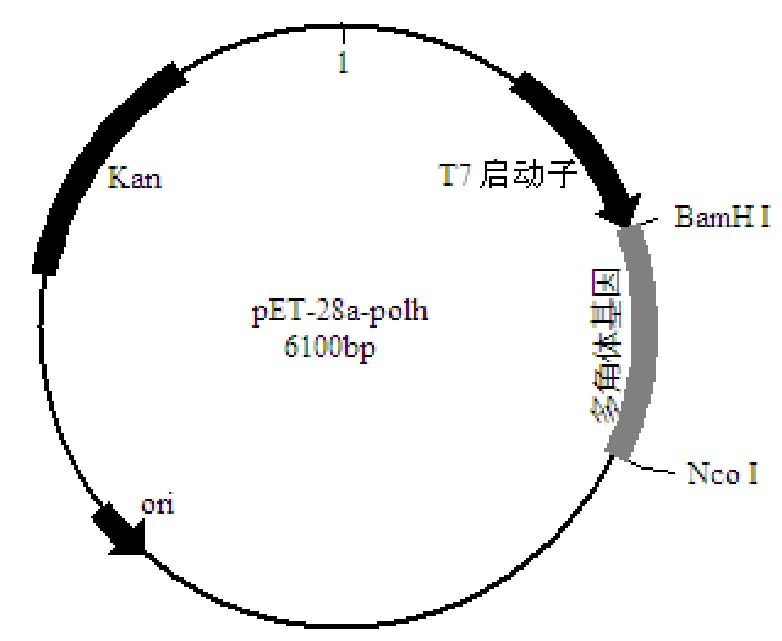

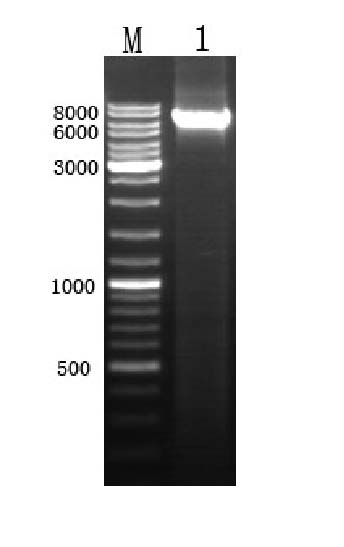

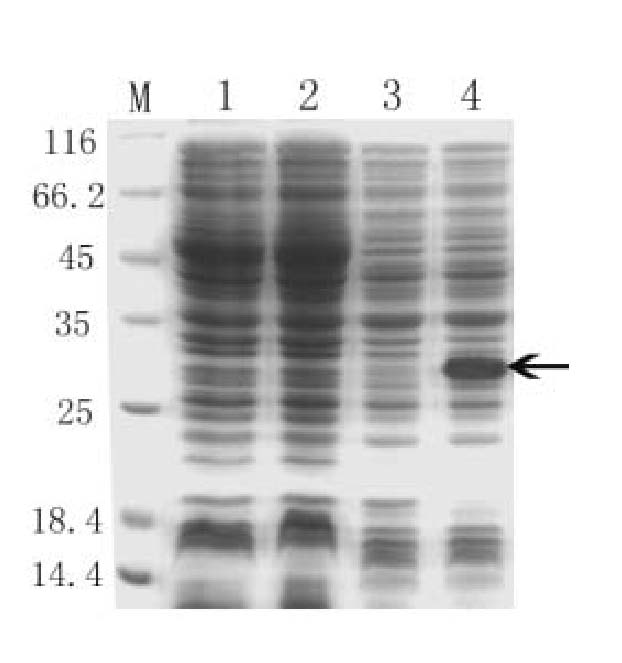

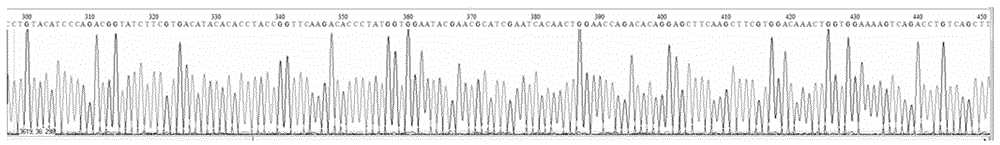

Mutant polyhedron and preparation method thereof

The invention relates to a mutant polyhedron with which a target protein yield can be improved. The invention related to the field of biology. According to the invention, a recombinant expression vector pET-28a-polh is constructed; the recombinant expression vector is mutated by using a commercialized kit, such that a complete recombinant expression vector containing mutant sites is obtained; the complete recombinant expression vector is subject to induction expression, such that the mutant polyhedron which can reduce a dissolving pH is obtained. When the mutant polyhedron provided by the invention is connected to a target protein gene, an obtained fusion protein can be purified through pH regulation and differential centrifugation methods with the property of the polyhedron, such that the purification steps are simplified. The obtained fusion protein can also be digested under an optimal protease active pH condition, such that target protein with a maximal amount can be obtained. Therefore, the yield of target protein is greatly improved.

Owner:TIANJIN YAOYU BIOLOGICAL TECH

Method for preparing cyprini herpesvirus II antigen coated polyhedrosis based on baculovirus expression system

ActiveCN106834352AImprove biological activityReduce manufacturing costAntibody mimetics/scaffoldsVirus peptidesAntigenStructural protein

The invention relates to the technology of antigen protein expression, and particularly relates to a method for preparing a cyprini herpesvirus II antigen coated polyhedrosis based on a baculovirus expression system. According to the method, by designing and recombining bombyx mori nuclear polyhydrosis virus BmNPV-VP3-cyHV-polh, 1-186, 993-1197, 603-783 and 85-186 regional sequences of ORF72, ORF66, ORF81 and ORF82 and the coding sequence of the 1-279 region of a VP3 gene of bombyx mori cytoplasmic polyhedrosis virus structural protein are connected in series to form a fused sequence which is controlled by baculovirus P10 promoter; and the bombyx mori cytoplasmic polyhedrosis protein gene is controlled by a polyhedrin gene promoter of baculovirus. The virus is used for inoculating bombyx mori or bombyx mori culture cells, the recombinant virus expressed cyprini herpesvirus II antigen protein can be coated in bombyx mori cytoplasmic polyhedrosis; the formed polyhedrosis can be purified by simple differential centrifugation; the purified polyhedrosis is cracked under a basic condition, the polyhedrosis protein can be precipitated by centrifuging, and the cyprini herpesvirus II antigen is reserved in supernatant, so that the cyprini herpesvirus II antigen can be quickly and conveniently obtained.

Owner:苏州培恩特生物科技有限公司

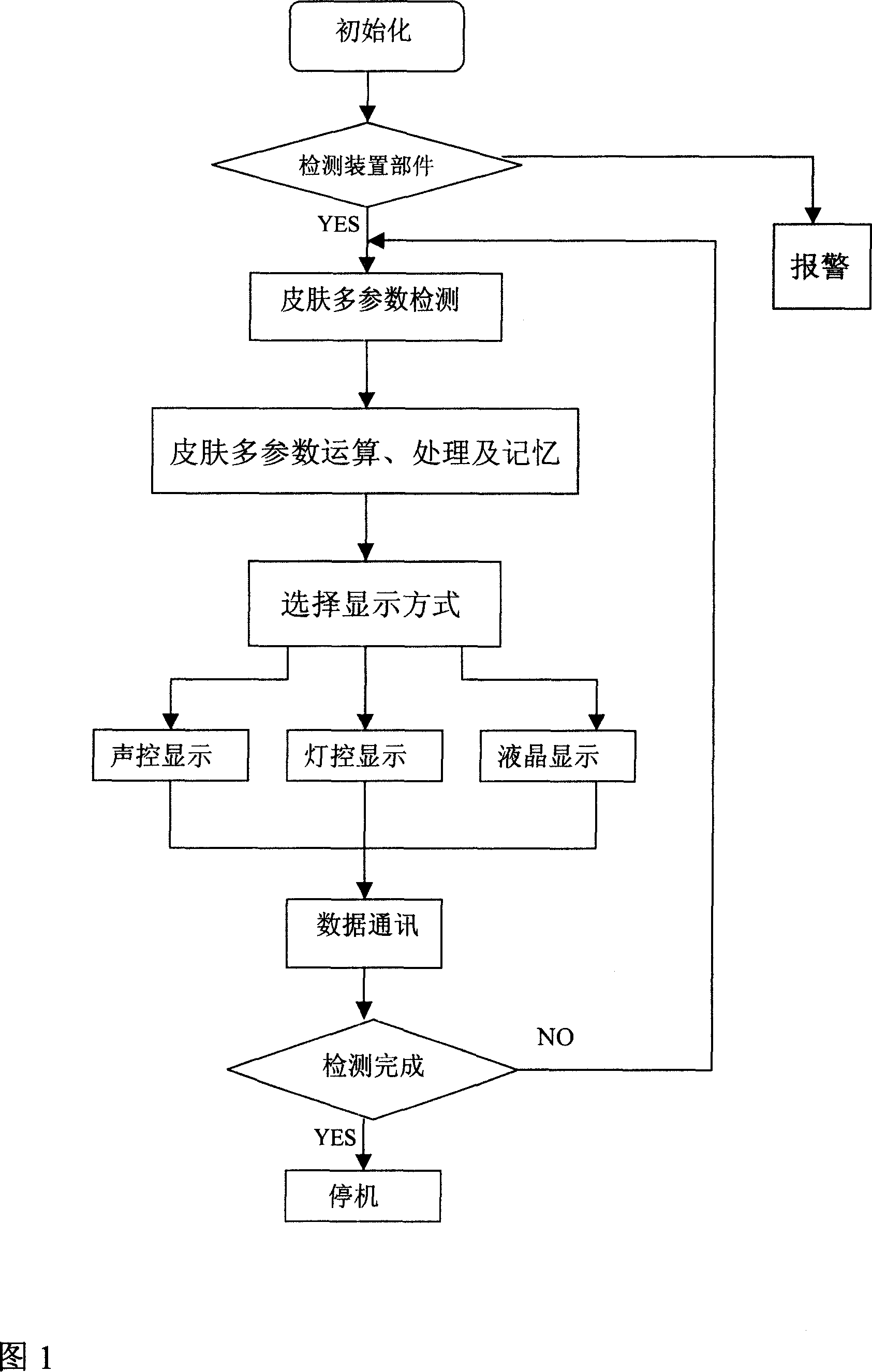

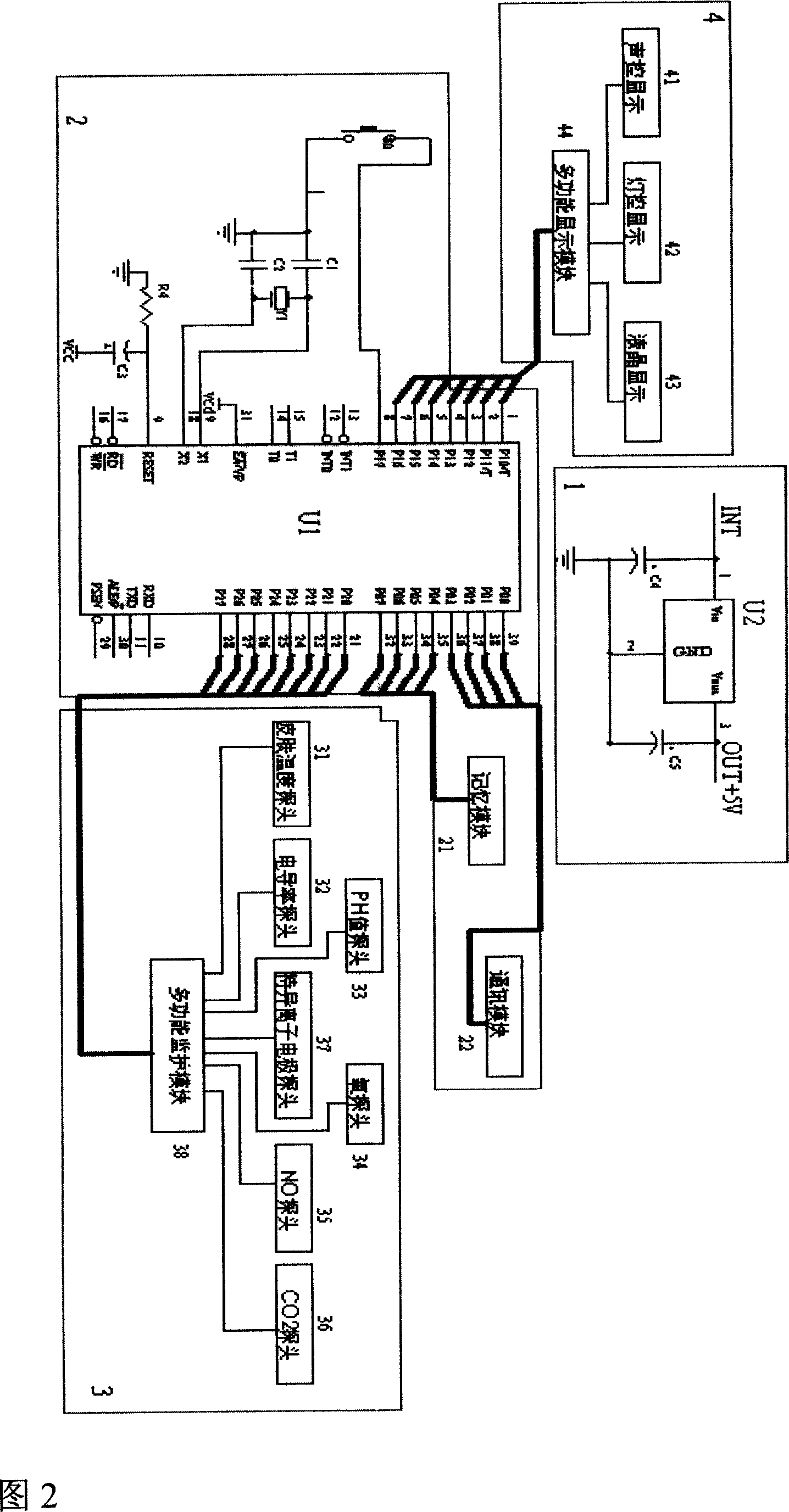

Method for detecting the skin irritation intensity caused by skin care products and arrangement thereof

InactiveCN101112304ASimple and fast operationRealize the purpose of individualized use of skin care productsDiagnostic recording/measuringSensorsLiquid-crystal displayStimulus strength

The invention relates to a method and a device which adopts multiple parameter to detect the stimulus strength of the skin care product to the skin. A plurality of physical or chemical parameters are collected after the skin being stimulated by the skin care product, including the temperature, the electric conductivity, the pH value of the stimulus position of the skin and the information of the active change of O2, NO, CO2 and the differential centrifugation ion, the effective outcome of the parameter is achieved through the comprehensive analysis and calculation of the solidified software procedure which is arranged inside a computer microprocessing unit, and the degree of the stimulus strength is displayed by the alternative audio control, the lamp control and the liquid crystal display device. The invention has the advantages of acute, rapid, exact and easy operation and so on, which supplies the remote service for the individual through network and achieves the purpose that the individual uses the skin care product optimally.

Owner:许越

Separation and culture method for different cellular components of human mammary tissue

InactiveCN104480062AThe method of isolation and culture is simple and easyGood cell modelArtificial cell constructsSkeletal/connective tissue cellsCellular componentLow speed

The invention relates to a separation and culture method for different cellular components of a human mammary tissue, and belongs to the technical field of cell culture. The method comprises the following steps: (1) sampling a fresh human mammary tissue specimen; (2) carrying out mechanical shearing and collagenase and hyaluronidase combined digestion to prepare a mammary tissue cell suspension; (3) carrying out low-speed and differential centrifugation to layer and separate the different cellular components; (4) carrying out centrifugation, washing and adherent culture for multiple times to purify the cell components, so as to obtain the different cellular components of the mammary tissue, which comprise epithelial cells, matrix cells and preadipocytes. The separation and culture method disclosed by the invention can be used for quickly, simply and effectively separating and purifying the different cellular components from the same mammary tissue; the cultured mammary gland cells are sufficient in quantity, good in cell viability and purity which is up to 95% above; the separation and culture method can provide very useful materials for molecular biology study associated with mammary glands and breast cancer, and establishes a foundation for construction of a mammary gland microenvironment multi-cell culture model.

Owner:GUANGDONG OCEAN UNIVERSITY

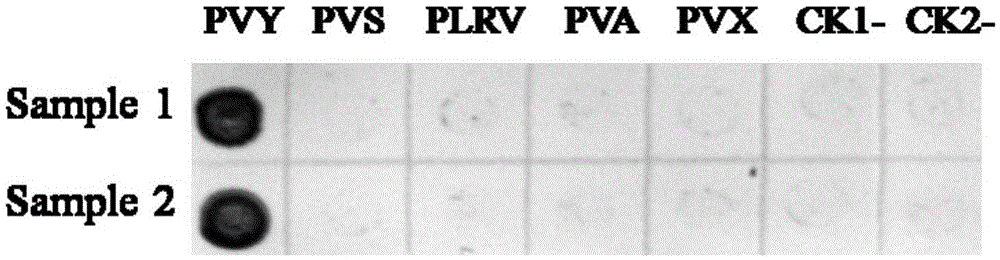

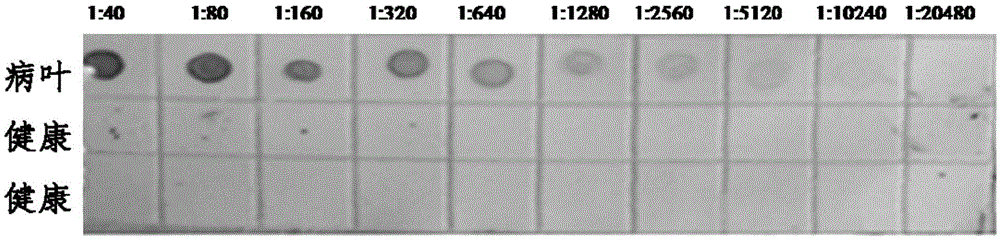

Hybridoma cell strain secreting potato-virus-Y-resistant monoclonal antibodies and monoclonal antibody application thereof

ActiveCN105543176ASensitive detectionAccurate detectionImmunoglobulins against virusesTissue cultureBALB/cAntibody types

Owner:ZHEJIANG UNIV

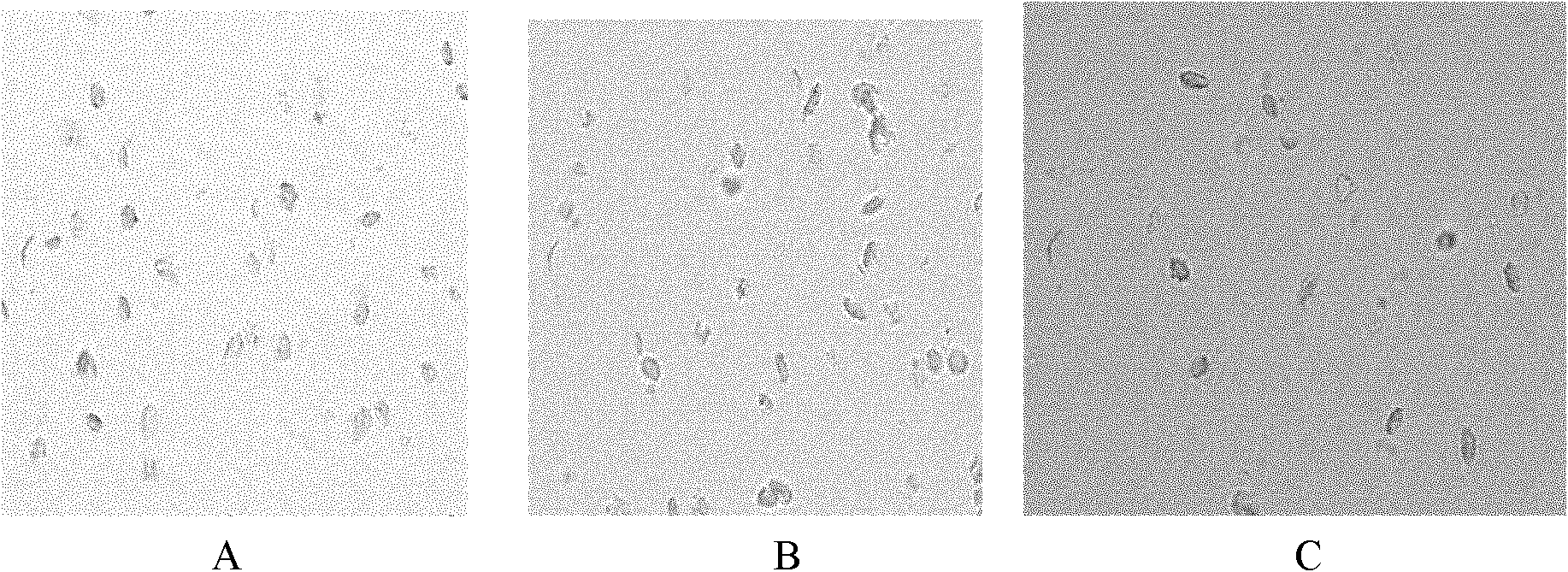

Complete chloroplast long-time isolated culture method

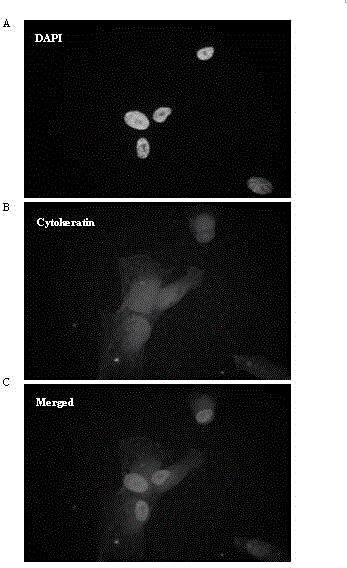

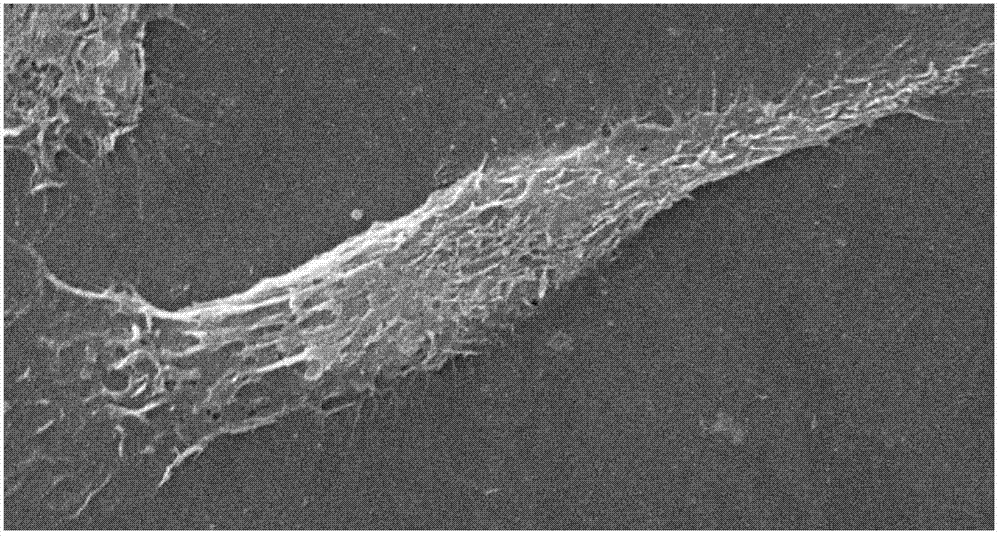

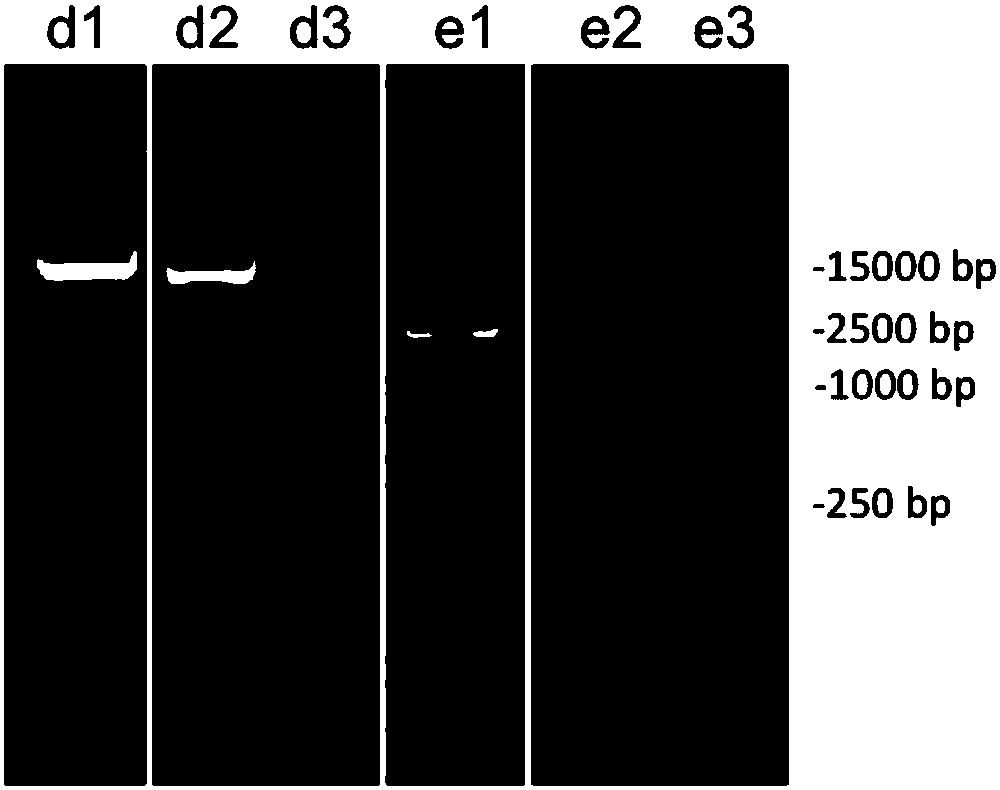

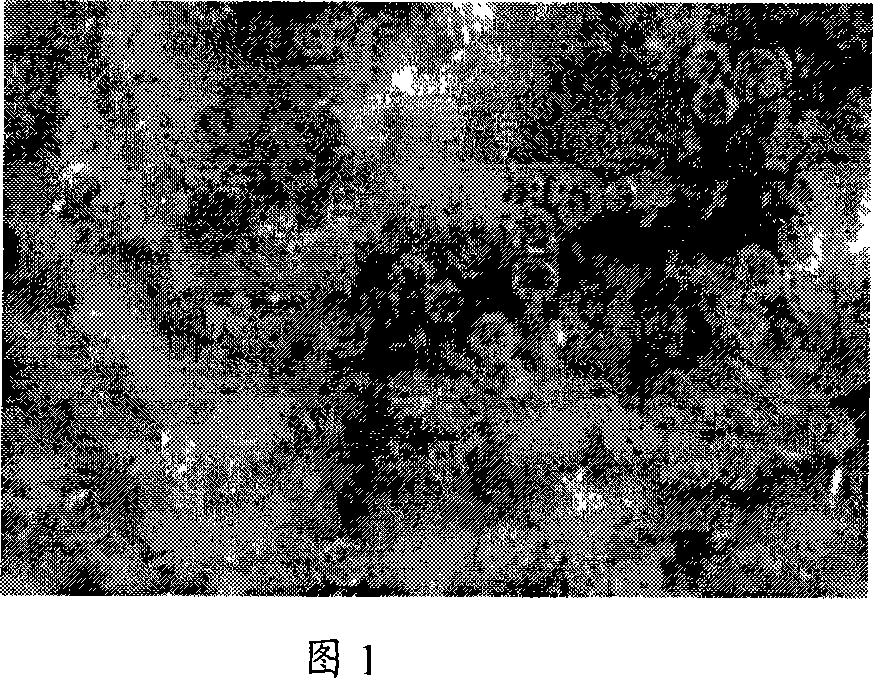

The invention discloses a complete chloroplast long-time isolated culture method. Sterile seedling cotyledons of cucumber, tobacco and spinach are used as materials respectively; citric acid, NaCl, Tris and ethylene diamine tetraacetic acid (EDTA) are used as chloroplast extraction reagents of main components; complete chloroplast (figure 1) is separated by the operations of grinding, gauze filtration, differential centrifugation and the like of the plant materials; and MnCl2, MgSO4, NaCl, sorbitol and the like are used as culture reagents of the main components, and the isolated chloroplast is subjected to liquid culture. After being cultured in vitro for about 20 days, the chloroplast still keeps green and is microscopically normal (figure 2), and the membrane structure is complete (figure 3). In two weeks of isolated culture, the chloroplast is split and propagated to reach relatively stable number (figure 4). Proved by isolated transformation and exogenous gene detection of the chloroplast, the DNA in the chloroplast cultured for long time is not degraded (figure 5). The method can provide convenience and a new path for basic theories and application research of chloroplast function, genetic transformation, cell engineering and the like.

Owner:NANKAI UNIV

Extraction method of mouse liver sinusoidal endothelial cells

InactiveCN102787096AComplete window structureKeep aliveArtificial cell constructsVertebrate cellsTwo stepImmunologic function

The invention discloses an extraction method of mouse liver sinusoidal endothelial cells. According to the method, the separation of the liver sinusoidal endothelial cells is realized through removing kupffer cells through gadolinium chloride injection, in combination with two-step perfusion, differential centrifugation, percoll centrifugation and differential attachment. The method has the advantages of simplicity, easiness, feasibility, high cellular purity and high pick-up rate, can keep complete structure and function activity in vitro culture, and can be used for biochemistry and immunology. In addition, the method, which can use general instruments in a laboratory, is low in cost and can be popularized to most laboratories.

Owner:王慧 +2

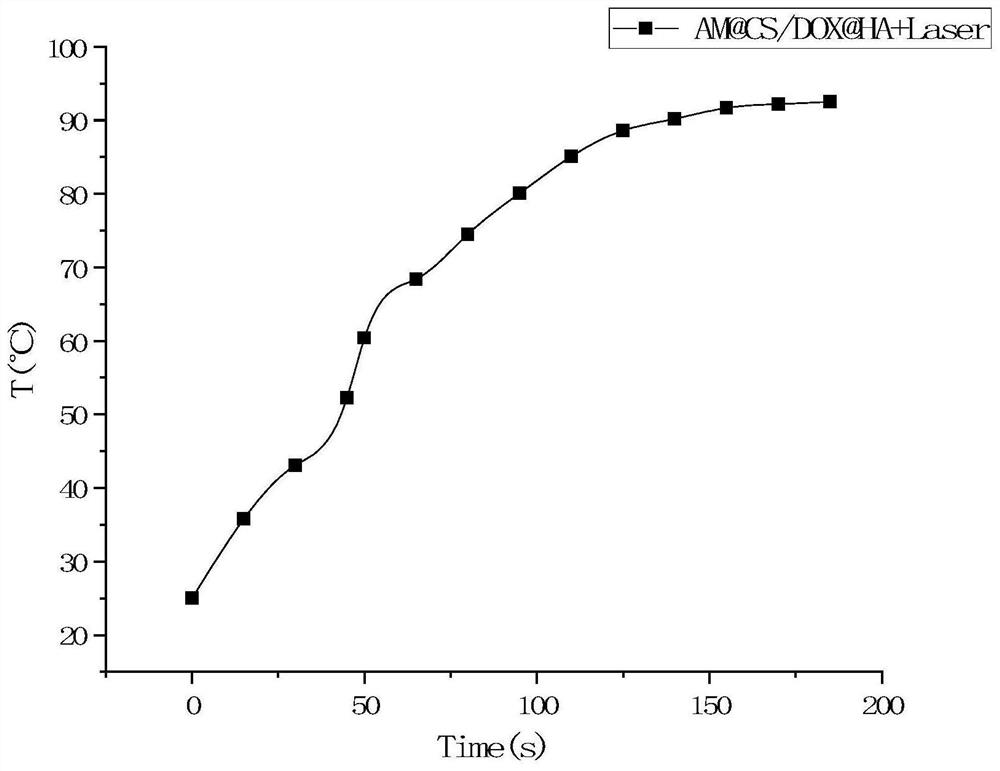

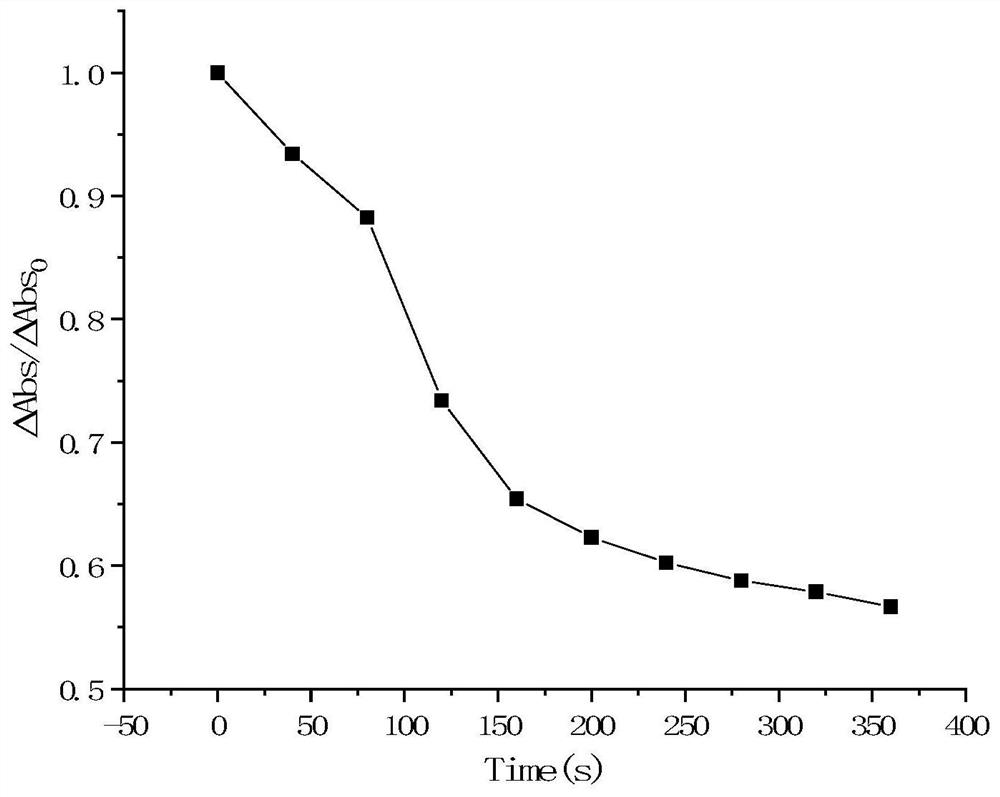

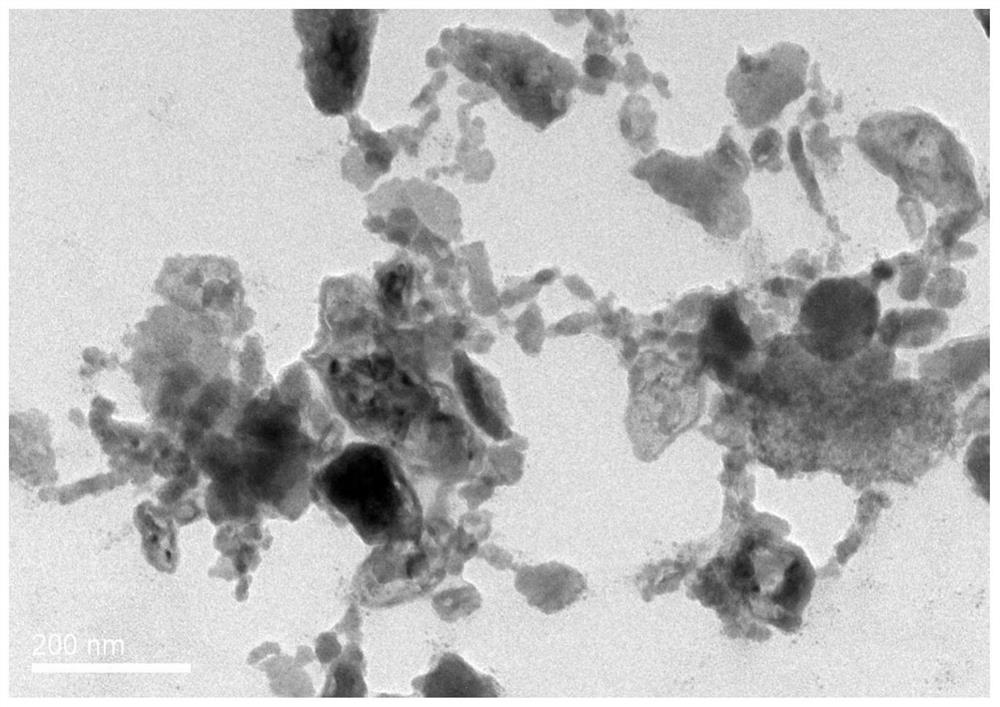

Preparation method of antimonene-based tumor targeted drug-loaded nanoparticles

ActiveCN112675150AGood biocompatibilityImprove structural stabilityMaterial nanotechnologyOrganic active ingredientsTumor targetNanoparti cles

The invention relates to the field of medicines, and discloses a preparation method of antimonene-based tumor targeted drug-loaded nanoparticles. Firstly, antimonene nanoparticles are obtained through a liquid phase mechanical stripping method and differential centrifugation, then the surface of AMNPs with negative charges is coated with chitosan and adriamycin with positive charges through the electrostatic adsorption effect, and finally the surface of chitosan is coated with hyaluronic acid with negative charges; and the photo-thermal / chemotherapy drug-loaded nanoparticles capable of realizing tumor targeting, drug sustained release and multi-modal imaging are obtained. The drug-loaded nanoparticles have important development prospects in the aspects of anti-tumor photo-thermal photodynamic therapy, drug nano-carriers and the like.

Owner:ZHEJIANG SCI-TECH UNIV

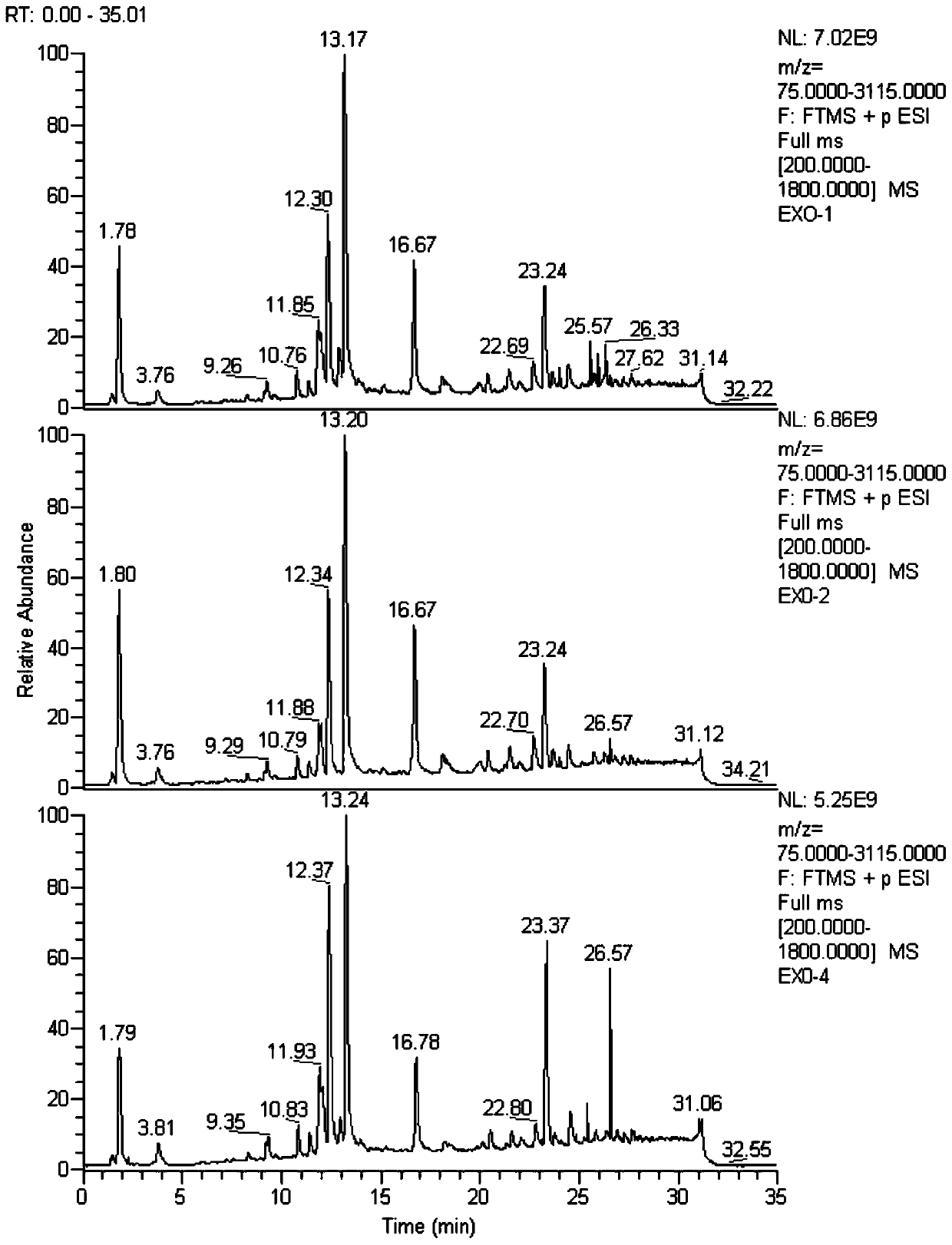

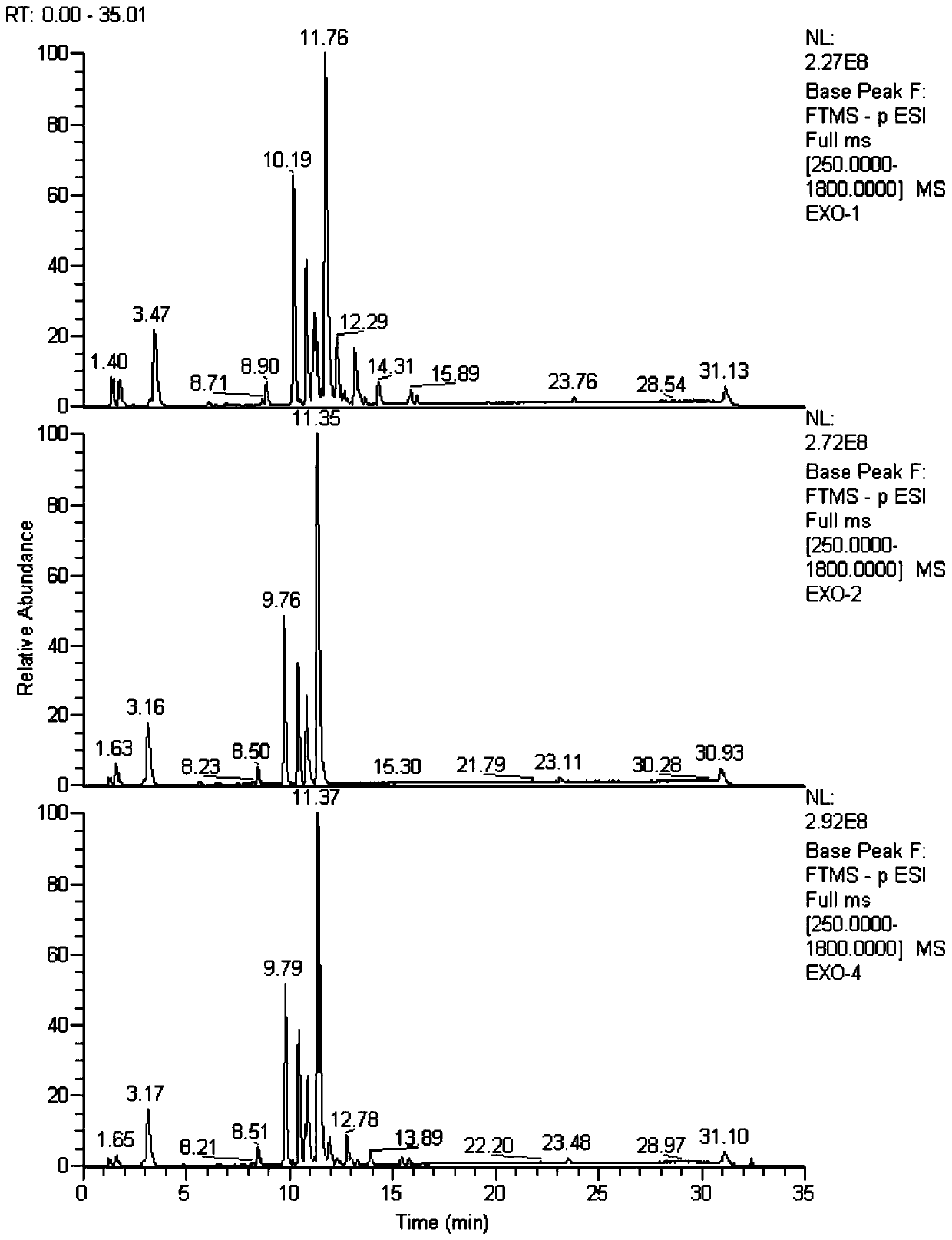

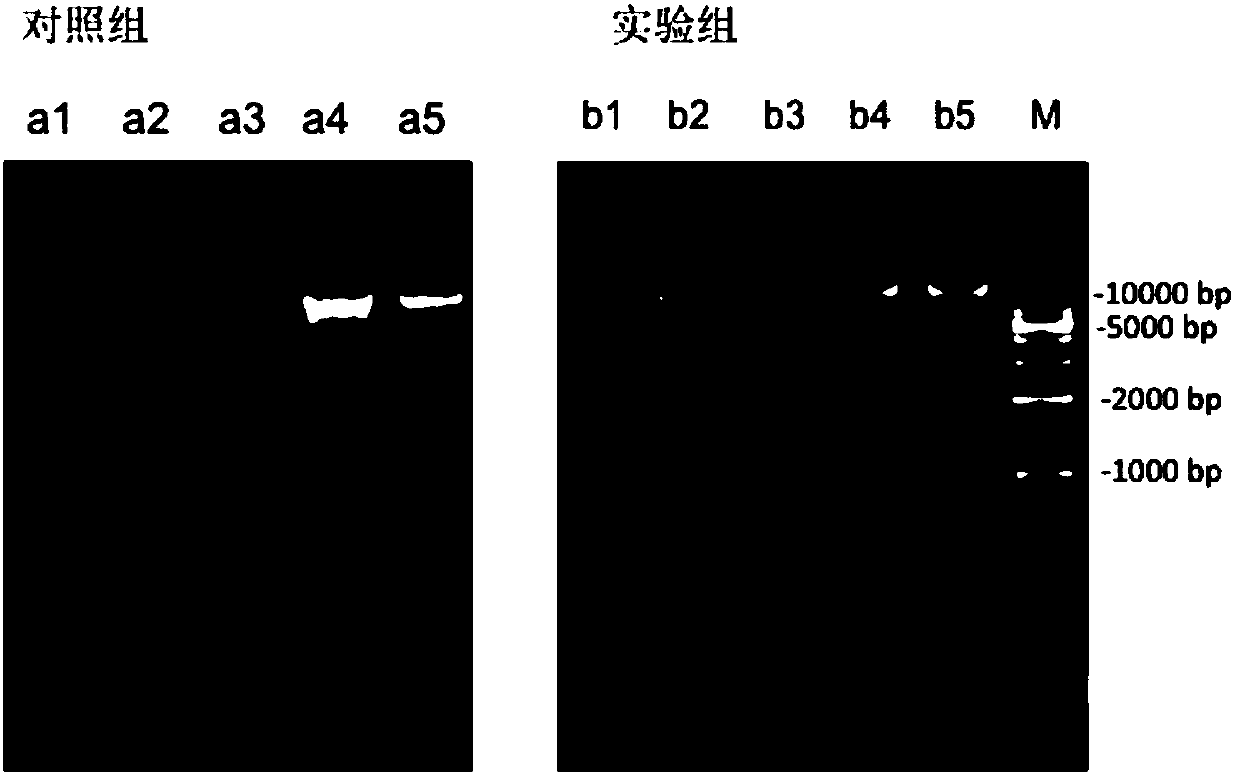

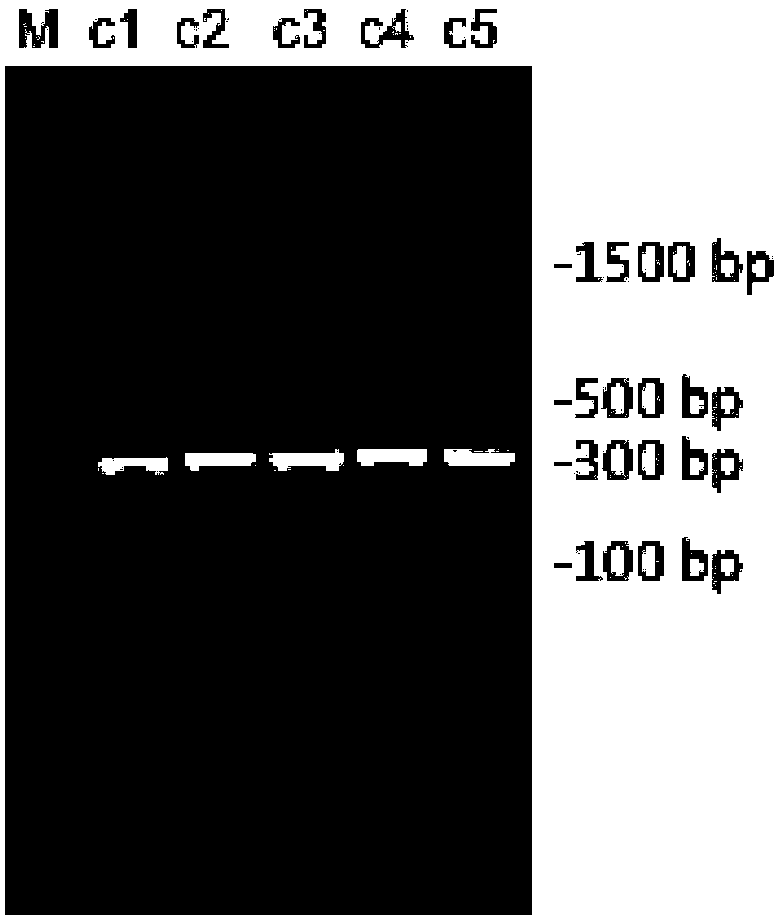

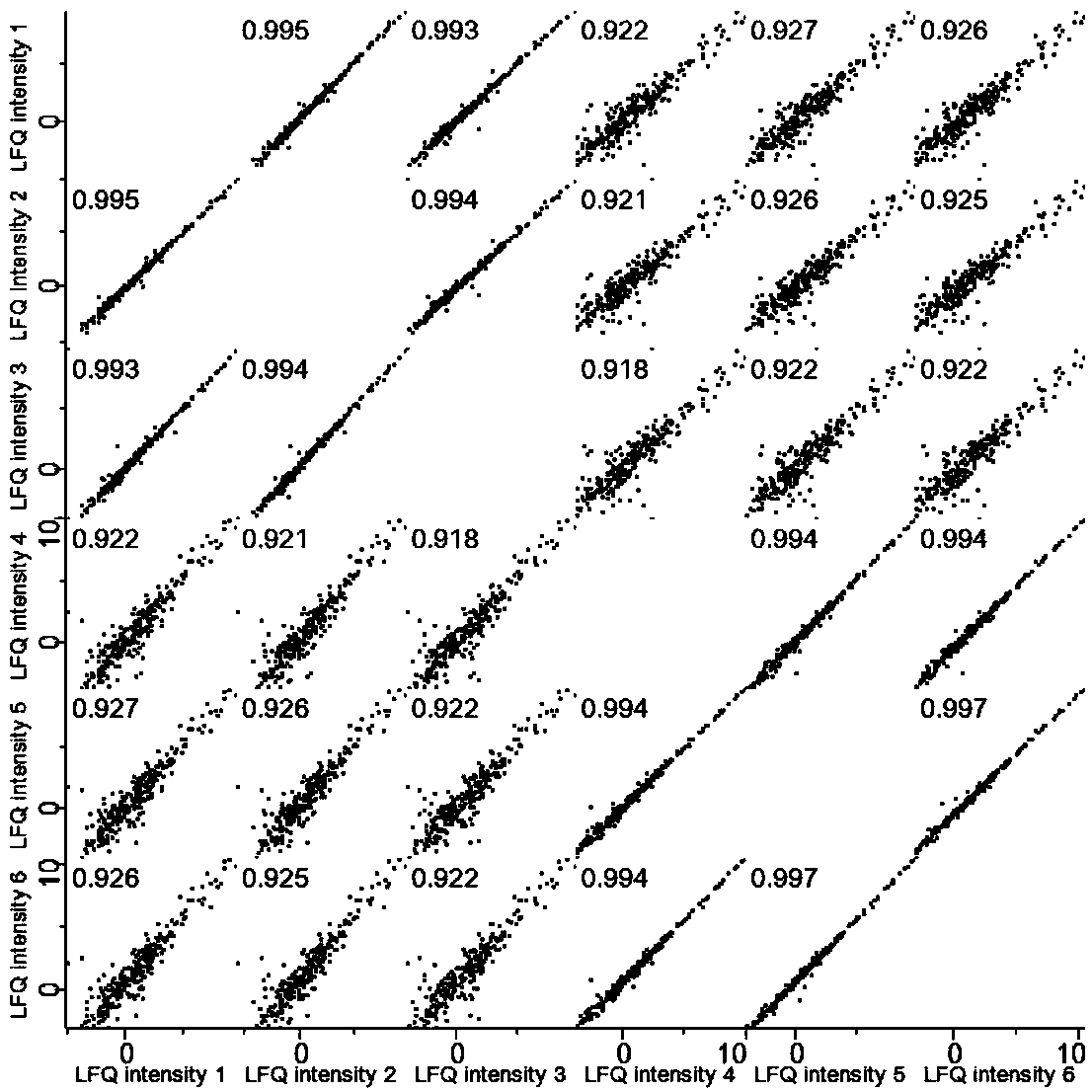

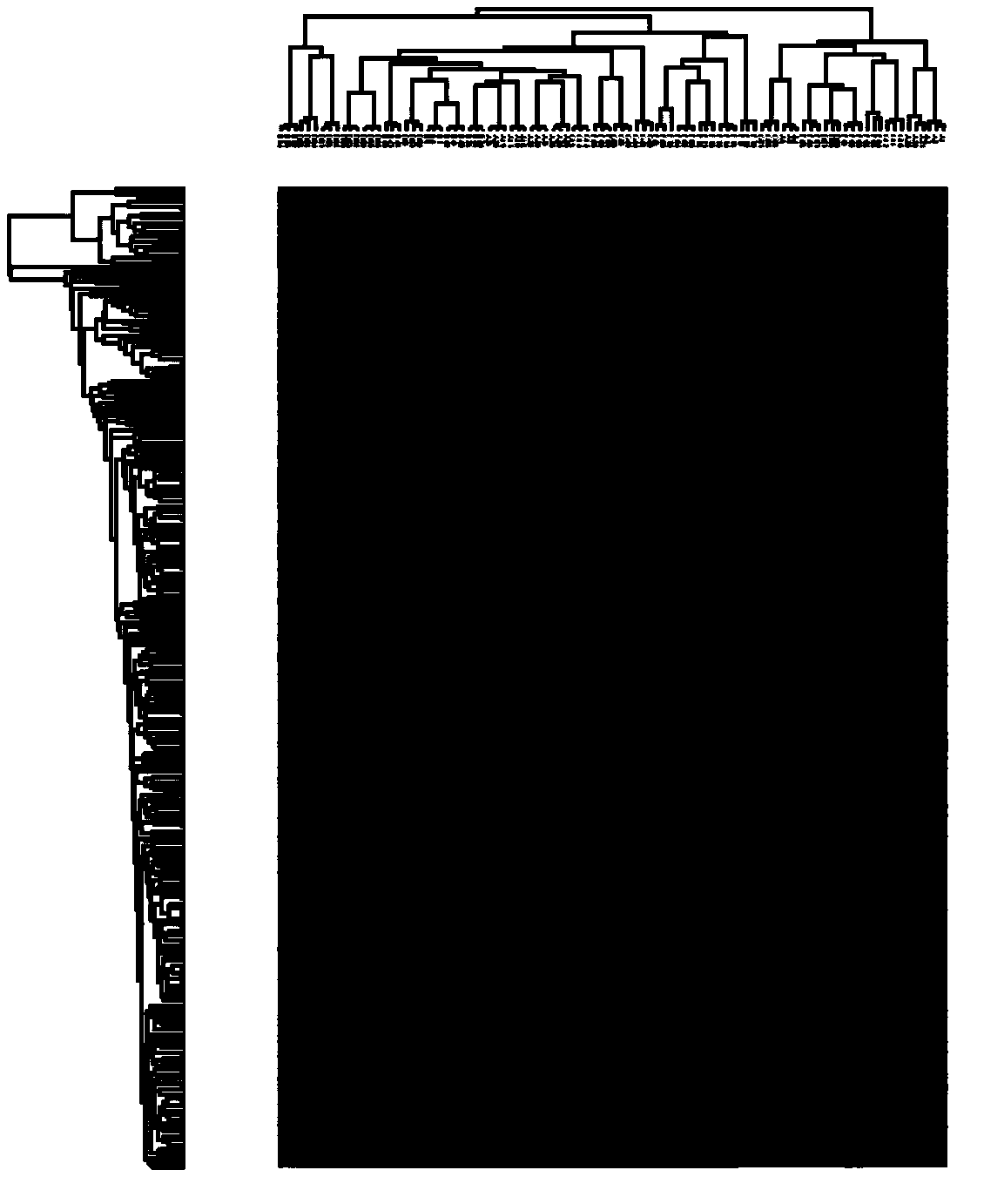

Cell exosome lipidomics analysis method based on LC-MS

The invention provides a cell exosome lipidomics analysis method based on LC-MS. A differential centrifugation enrichment exosome is matched with an internal standard method for quantitative measurement; optimized analysis parameters of liquid chromatography and mass spectrometry are combined; various stable isotope internal standard substances are added into a to-be-detected substance, so that the quantitative influence caused by an ion inhibition effect can be effectively reduced, high-coverage lipidomics is carried out on a cell exosome sample to obtain absolute quantitative analysis, the stability is better, and the quantitative accuracy can be greatly improved.

Owner:上海中科新生命生物科技有限公司

Method for extracting microbial metagenome DNA from intestinal tract content

ActiveCN107653243AEasy extractionReduce species preferenceMicrobiological testing/measurementDNA preparationMicroorganismFeces

The invention discloses a method for extracting a microbial metagenome DNA from intestinal tract content. Themethod for extracting the microbial metagenome DNA from the intestinal tract content comprises the following steps that 1, the intestinal tract content or excrement of an animal is subjected to differential centrifugation; 2, microbial cells are combined and are broken by using a liquid nitrogen repeated freezing and thawing cracking method, a glass bead grinding method and a lysate high-temperature cracking method to obtain broken cells; 3, genomes DNA of the broken cells are firstly extracted and then are purified. By adding the steps of washing and enriching microbial cells, the pollution of host and food DNA is reduced. By combining the multiple microbial cell cracking and breaking methods, and the speciespreference of the metagenome DNA is reduced. By adding a purifying step, the purity of the DNA is ensured, and the DNA requirements for establishing second generation of high-throughput sequencing libraries can be met.

Owner:AGRI GENOMICS INST CHINESE ACADEMY OF AGRI SCI

Exosome enrichment method

ActiveCN110411816AEasy to handleReduce processing timePreparing sample for investigationEnrichment methodsUltrafiltration

The invention relates to an exosome enrichment method and an application of the exosome enrichment method in exosome fast enrichment concentration in a biological sample. The method comprises the following steps of carrying out differential centrifugation treatment or ultrafiltration treatment on a biological sample to remove cell interference in the sample; adding a PEG solution into a supernate,and standing for a period of time at a low temperature; and putting the sample at a proper temperature to form a uniform solution, carrying out centrifuging at a low speed, and obtaining precipitatewhich is the exosome.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparation of novel subunit vaccine for treating porcine pseudorabies

InactiveCN101081298ANo latent infectionOptimized Extraction TechnologyViral antigen ingredientsAntiviralsRabiesCyst

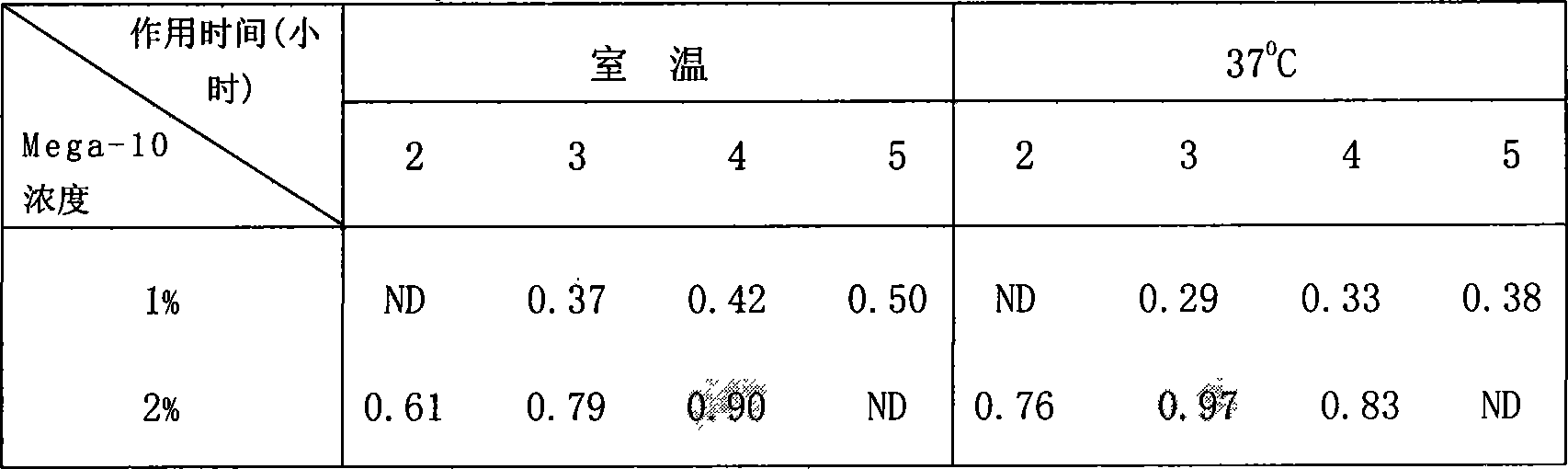

The present invention discloses preparation process of new subunit vaccine of pig's pseudo rabies. The preparation process includes: differentially centrifuging pseudo rabies low virulent strain (PRV-FB strain), suspending the virus in PBS, regulating the protein concentration of the viral antigen, adding Mega-10 lytic virus cyst membrane protein, centrifugally extracting cyst membrane protein, adding proper amount of ISCOM matrix, bagging and dialyzing to obtain PRV type subunit vaccine. The PRV type subunit vaccine is safe and effective, and may be used in preventing and controlling pig's pseudo rabies.

Owner:陈少莺

Method for separating and purifying citrus pulp mitochondria

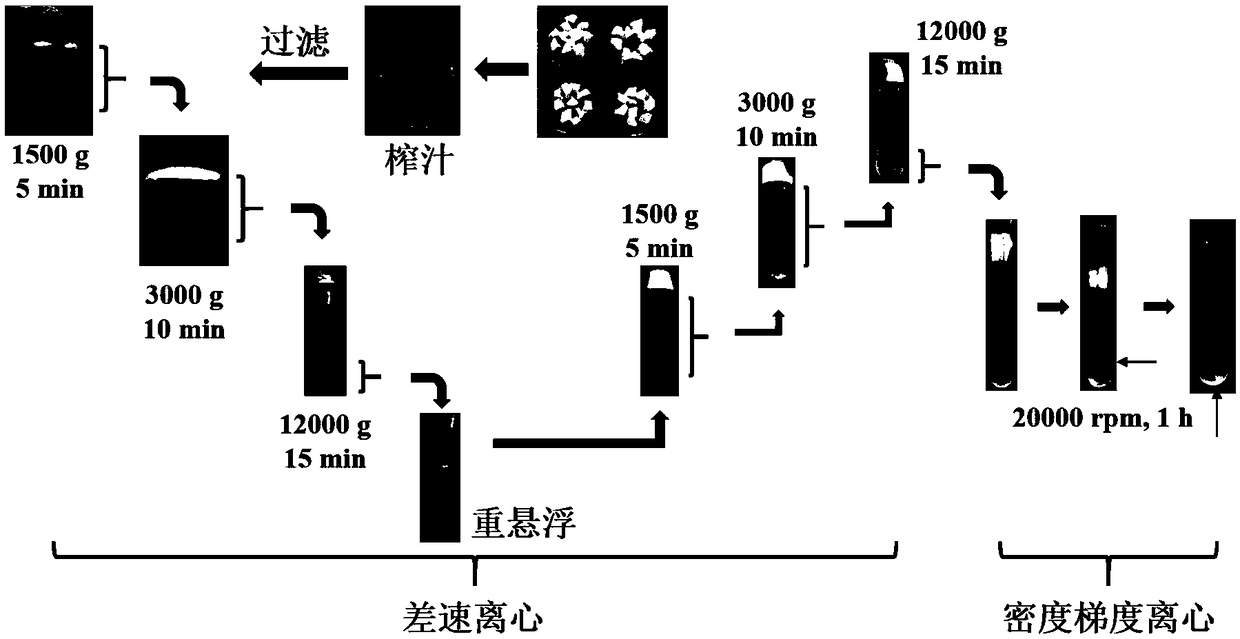

The invention provides a method for separating and purifying citrus pulp mitochondria, and relates to the technical field of plant biochemistry. Percoll is used as a gradient medium, and the citrus pulp mitochondria are separated and purified by means of differential centrifugation and density gradient differentiation by the aid of the method. The method includes steps of 1), mixing citrus pulp and buffer solution A with each other, then squeezing juice and filtering the juice to obtain filtered fluid; 2), carrying out differential centrifugation on the obtained filtered fluid, and suspendingobtained precipitates by buffer solution B to obtain samples I; 3), carrying out density gradient centrifugation on the obtained samples I to obtain samples II; 4), mixing the obtained samples II andbuffer solution B with one another and centrifugally collecting precipitates to obtain samples III; 5), mixing the obtained samples III and buffer solution B with one another and centrifugally collecting precipitates to obtain the citrus pulp mitochondria. The method has the advantages that the citrus pulp mitochondria obtained by the aid of the method are in the typical shapes of ellipsoids, double-layer membrane structures are complete, and cristae are clearly visible; the citrus pulp mitochondria purified by the aid of the method are high in purity, and good purification effects can be realized by the aid of the method.

Owner:HUAZHONG AGRI UNIV

Saliva test for early diagnosis of cancers

InactiveUS20050106642A1Reduce concentrationReduce amountDisease diagnosisFermentationCancer antigenOvary cell

Proteonic cancer markers (PCMs) for breast, colon, liver and ovary were isolated, from the respective lysate of transformed cells, by differential centrifugation. Polyclonal antibodies were generated in mice against the (PCMs) for breast, colon, liver and ovary individually and combination thereof. Saliva from normal people was assayed by ELISA for antimixture of PCMs; breast, colon, liver and ovary cells individually. It was revealed that cancer antigen was detectable in saliva from normal people and the ELISA titer / 100 μl ranged from 1:200 to 1:1600. Out of 32 normal salivas tested, ELISA titer was higher than 1:1000 in seven specimens. Those specimens were assayed by ELISA tests for individual PCM using anti-breast, anti-colon, anti-liver and anti-ovary. Each saliva specimen showed highest titer for one type of cancer antigen. Four saliva specimens showed high titers for breast PCM, two for colon one for liver. Only one saliva specimen showed high titer for ovary and colon PCMs. Thus, the invention further relates to the quantitative assessment of specific PCMs for breast, colon, liver and ovary in human saliva, by using antibodies against these markers individually.

Owner:LIPPS BINIE V +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com