Three-screw planetary transmission vertical medium stirring mill

A planetary transmission and three-screw technology, which is applied in the field of grinding, crushing, and mineral processing, can solve the problems of small effective grinding area, central empty area, low transmission efficiency and energy density, and achieve high transmission efficiency and power density, saving deceleration device, increase the effect of the effective grinding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

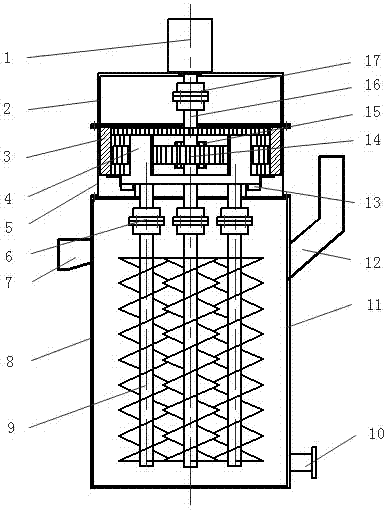

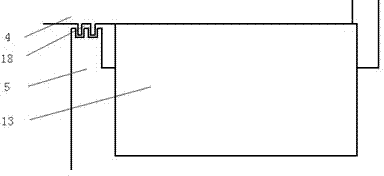

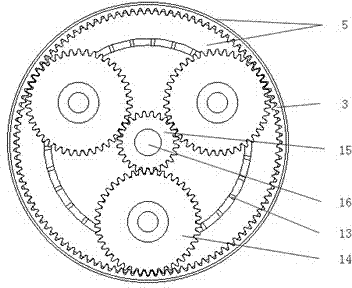

[0031] Embodiment 1: as Figure 1-4 As shown, a three-screw planetary drive vertical medium-stirred mill, including a motor 1, a motor bracket 2, an outer ring gear 3, a planet carrier 4, a gearbox 5, a coupling I6, a discharge port 7, and a cylinder 8 , agitator 9, return pipe 10, cylinder liner 11, feed pipe 12, needle roller 13, planetary gear 14, sun gear 15, short shaft 16, coupling II 17; the output shaft of the motor 1 passes through Coupling II17 is connected with the short shaft 16, the short shaft 16 is connected with the sun gear 15 through a key, the sun gear 15 drives three evenly distributed planetary gears 14 to move on the outer ring gear 3, and the outer ring gear 3 is installed in the gearbox 5 , the three planetary wheels 14 are installed on the planetary carrier 4 through uniformly distributed bearings 19, the planetary carrier 4 is installed in the gearbox 5, the planetary carrier 4 and the planetary wheels 14 do revolution together, and the planetary whee...

Embodiment 2

[0032] Embodiment 2: as Figure 1-4 As shown, a three-screw planetary drive vertical medium-stirred mill, including a motor 1, a motor bracket 2, an outer ring gear 3, a planet carrier 4, a gearbox 5, a coupling I6, a discharge port 7, and a cylinder 8 , agitator 9, return pipe 10, cylinder liner 11, feed pipe 12, needle roller 13, planetary gear 14, sun gear 15, short shaft 16, coupling II 17; the output shaft of the motor 1 passes through Coupling II17 is connected with the short shaft 16, the short shaft 16 is connected with the sun gear 15 through a key, the sun gear 15 drives three evenly distributed planetary gears 14 to move on the outer ring gear 3, and the outer ring gear 3 is installed in the gearbox 5 , the three planetary wheels 14 are installed on the planetary carrier 4 through uniformly distributed bearings 19, the planetary carrier 4 is installed in the gearbox 5, the planetary carrier 4 and the planetary wheels 14 do revolution together, and the planetary whee...

Embodiment 3

[0036] Embodiment 3: as Figure 1-4 As shown, a three-screw planetary drive vertical medium-stirred mill, including a motor 1, a motor bracket 2, an outer ring gear 3, a planet carrier 4, a gearbox 5, a coupling I6, a discharge port 7, and a cylinder 8 , agitator 9, return pipe 10, cylinder liner 11, feed pipe 12, needle roller 13, planetary gear 14, sun gear 15, short shaft 16, coupling II 17; the output shaft of the motor 1 passes through Coupling II17 is connected with the short shaft 16, the short shaft 16 is connected with the sun gear 15 through a key, the sun gear 15 drives three evenly distributed planetary gears 14 to move on the outer ring gear 3, and the outer ring gear 3 is installed in the gearbox 5 , the three planetary wheels 14 are installed on the planetary carrier 4 through uniformly distributed bearings 19, the planetary carrier 4 is installed in the gearbox 5, the planetary carrier 4 and the planetary wheels 14 do revolution together, and the planetary whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com