Aerated concrete block and preparation method thereof

A technology for aerated concrete blocks and ceramics, applied in the field of building materials, can solve the problems of inability to achieve energy saving and heat preservation, and high cost of aerated concrete, and achieve the effects of suppressing hardening and the spread of environmental pollution, improving building functions, and improving stable dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

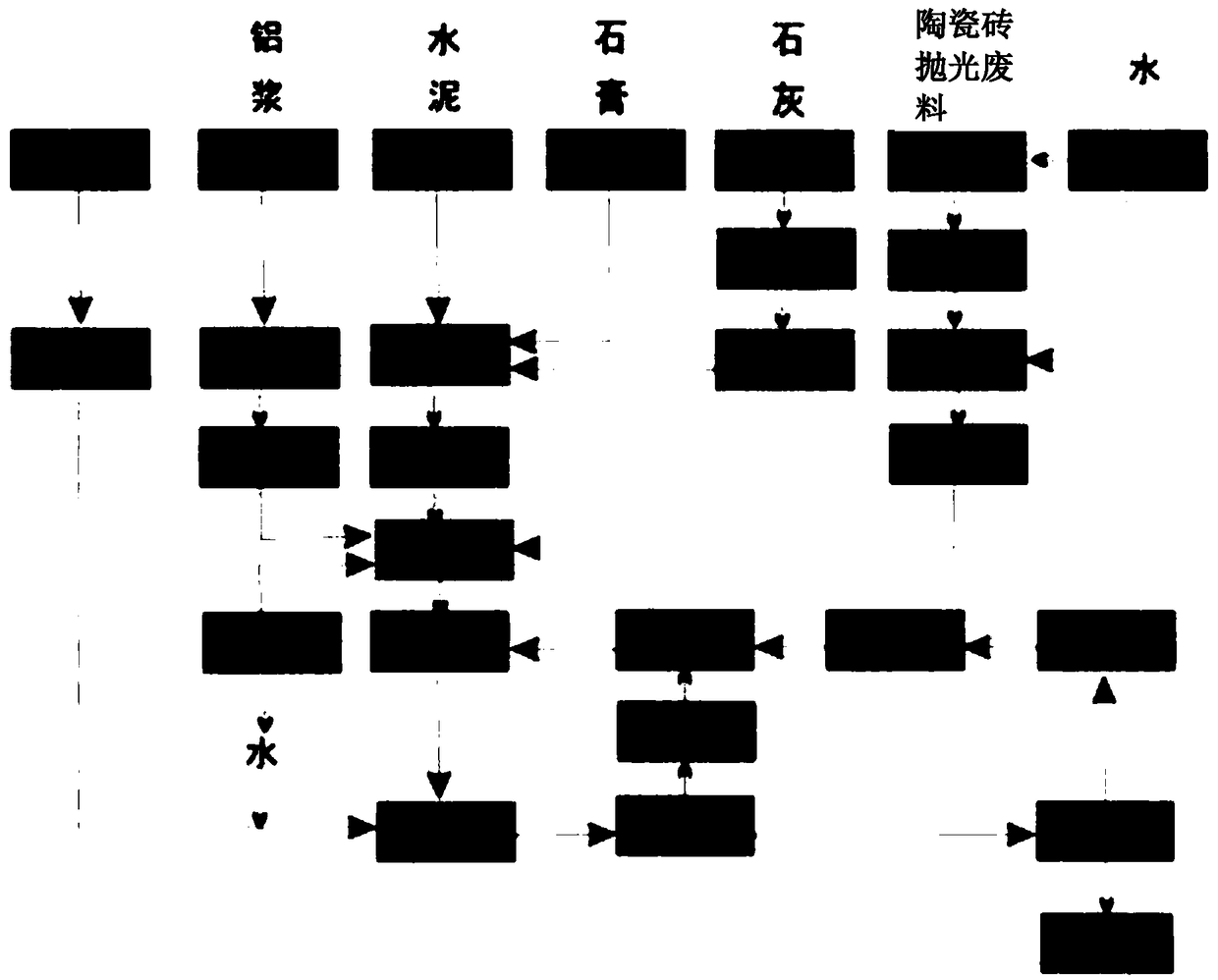

[0036] like figure 1 As shown, the present invention provides an aerated concrete block, which is made of a slurry with a material-to-liquid ratio of 1:70, and the slurry includes the following materials in parts by weight: 8 parts of cement, 16 parts of lime, and 53.6 parts of ceramic slurry 2.4 parts of gypsum, 7.2 parts of aluminum powder paste; wherein the ceramic slurry is mixed and stirred by water and ceramic tile polishing waste, NaOH, and lignosulfonic acid superplasticizer with a mass ratio of 1:0.013:0.27, The material-to-liquid ratio of the ceramic slurry is 1:1.6;

[0037] A method for preparing an air-entrained concrete block, comprising the following steps:

[0038] (1) Ceramic tile polishing waste and lime are ball milled at a speed of 300r / min for 0.4h respectively to obtain lime powder and powder with particle size of 150 meshes. The lime powder of the gained is stand-by. Sulfonic acid high-efficiency water reducer and water are mixed and stirred continuously...

Embodiment 2

[0043] like figure 1 As shown, the present invention provides an aerated concrete block, which is made of a slurry with a material-to-liquid ratio of 1:75, and the slurry includes the following materials in parts by weight: 10 parts of cement, 20 parts of lime, and 67 parts of ceramic slurry parts, 3 parts of gypsum, and 9 parts of aluminum powder paste; wherein the ceramic slurry is mixed and stirred by water and ceramic tile polishing waste, NaOH, and lignosulfonic acid superplasticizer with a mass ratio of 1:0.013:0.31, The material-to-liquid ratio of the ceramic slurry is 1:1.62;

[0044] A method for preparing an air-entrained concrete block, comprising the following steps:

[0045] (1) Ceramic tile polishing waste and lime are ball milled at a speed of 350r / min for 0.5h respectively to obtain lime powder and powder with particle size of 180 meshes. The lime powder of the gained is stand-by, and the powder of the gained is mixed with NaOH, wood Sulfonic acid high-effici...

Embodiment 3

[0051] like figure 1 As shown, the present invention provides an aerated concrete block, which is made of a slurry with a material-to-liquid ratio of 1:83, and the slurry includes the following materials in parts by weight: 12 parts of cement, 24 parts of lime, and 80.4 parts of ceramic slurry parts, 3.6 parts of gypsum, and 10.8 parts of aluminum powder paste; wherein the ceramic slurry is formed by mixing and stirring ceramic tile polishing waste, NaOH, and lignosulfonic acid superplasticizers with a mass ratio of 1:0.013:0.43, The material-to-liquid ratio of the ceramic slurry is 1:1.65;

[0052] A method for preparing an air-entrained concrete block, comprising the following steps:

[0053] (1) Ceramic tile polishing waste and lime are ball milled at a speed of 400r / min for 0.6h respectively to obtain lime powder and powder with particle size of 200 meshes. The lime powder of the gained is stand-by, and the powder of the gained is mixed with NaOH, wood Sulfonic acid high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com