Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

313results about How to "Uniform height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

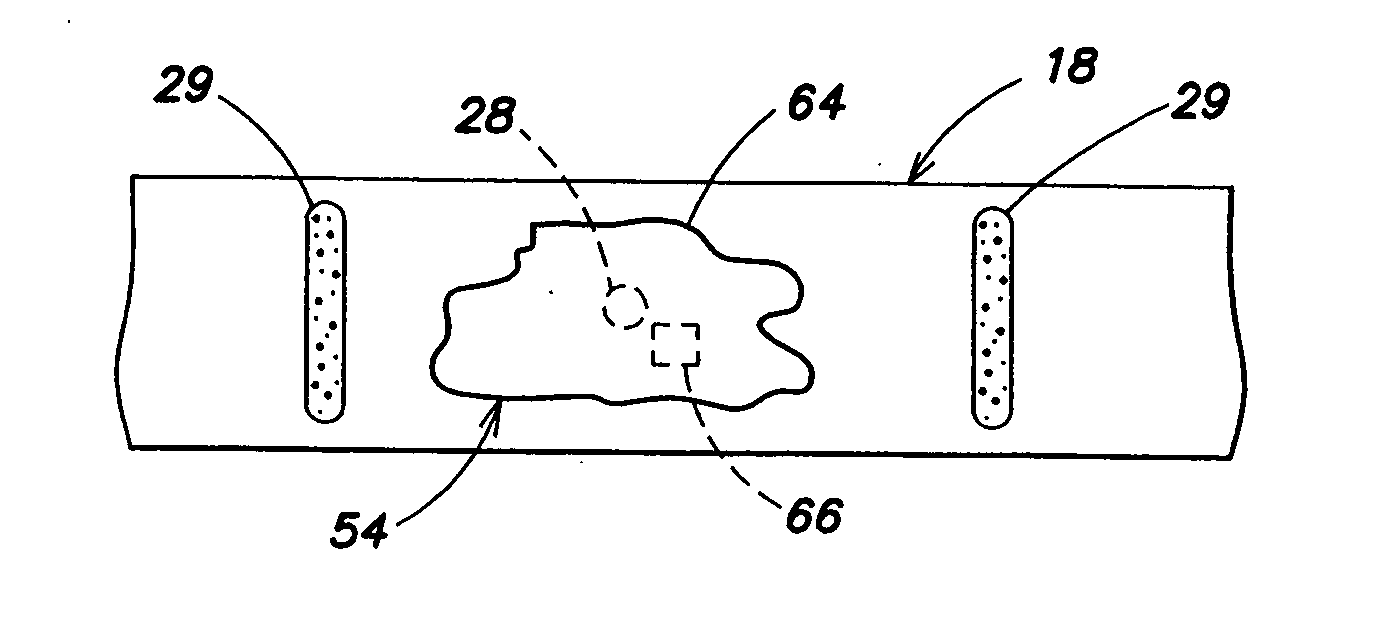

Disposable Chamber for Analyzing Biologic Fluids

ActiveUS20070243117A1Accurately determinableUniform heightBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringBiological fluids

Owner:WARDLAW PARTNERS +2

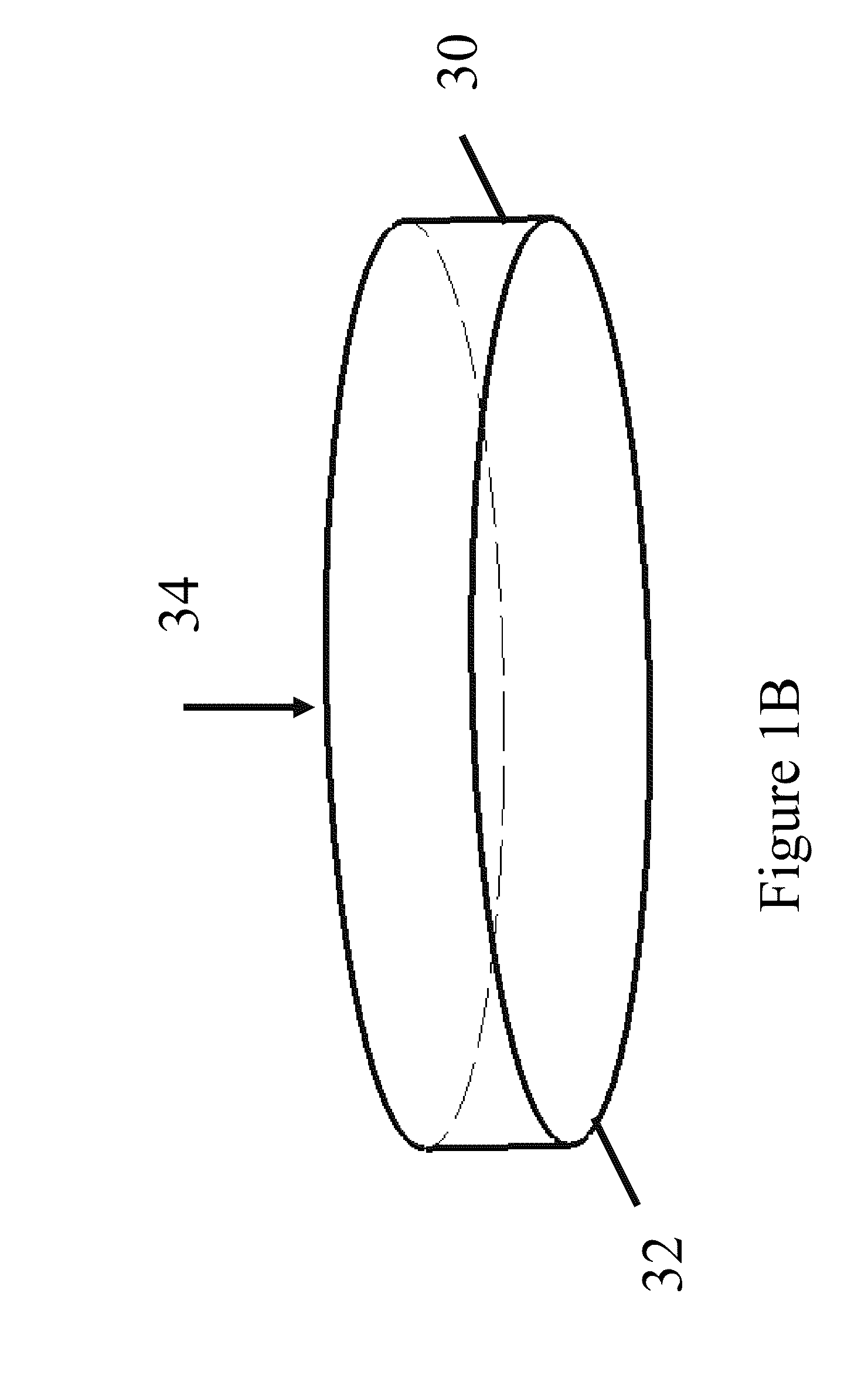

Implant having arcuate upper and lower bearing surfaces along a longitudinal axis

The present application is directed to interbody spinal fusion implants having a structural configuration that provides for the maintaining and creating of the normal anatomic angular relationship of two adjacent vertebrae of the spine to maintain and create spinal lordosis. The spinal fusion implants are sized to fit within the disc space created by the removal of disc material between two adjacent vertebrae and conform wholly or in part to the disc space created. The spinal fusion implants of the present invention have upper and lower surfaces that form a support structure for bearing against the end plates of the adjacent vertebrae. The upper and lower surfaces are disposed in a converging angular relationship to each other such that the implants have an overall “wedged-shape” in an elevational side view. The angular relationship of the upper and lower surfaces places and maintains the vertebrae adjacent to those surfaces in an angular relationship to each other, creating and maintaining the desired lordosis.

Owner:WARSAW ORTHOPEDIC INC

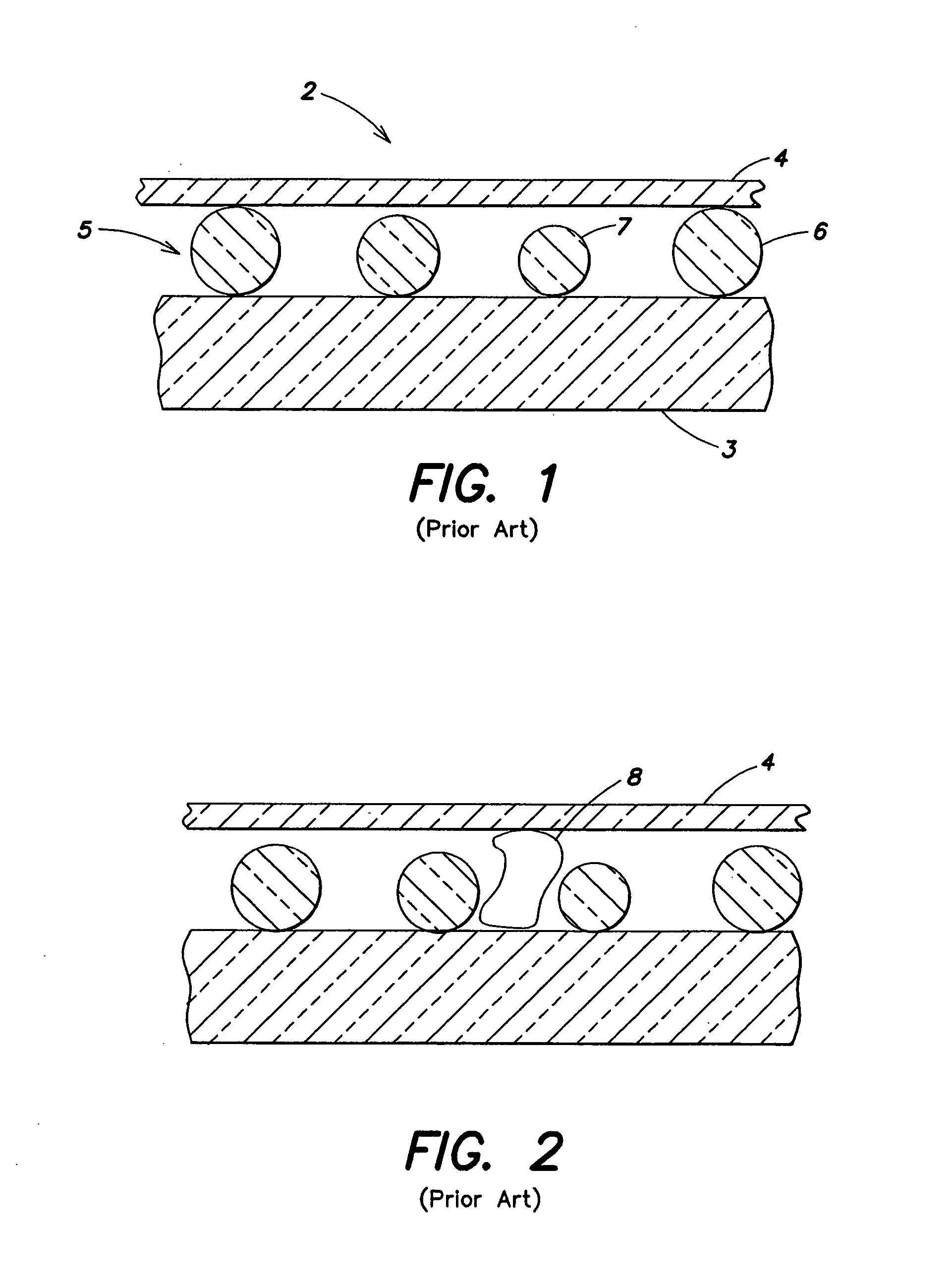

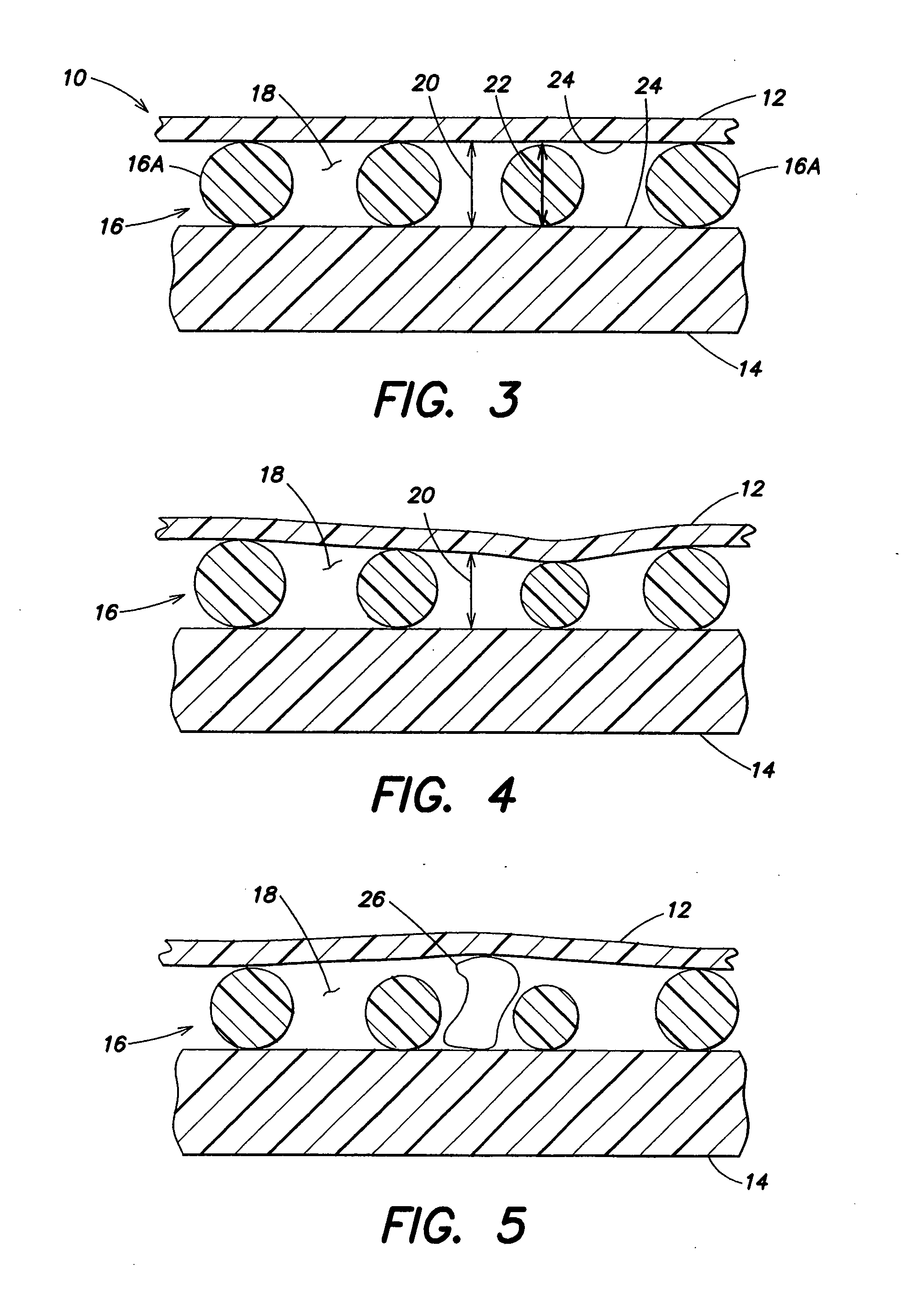

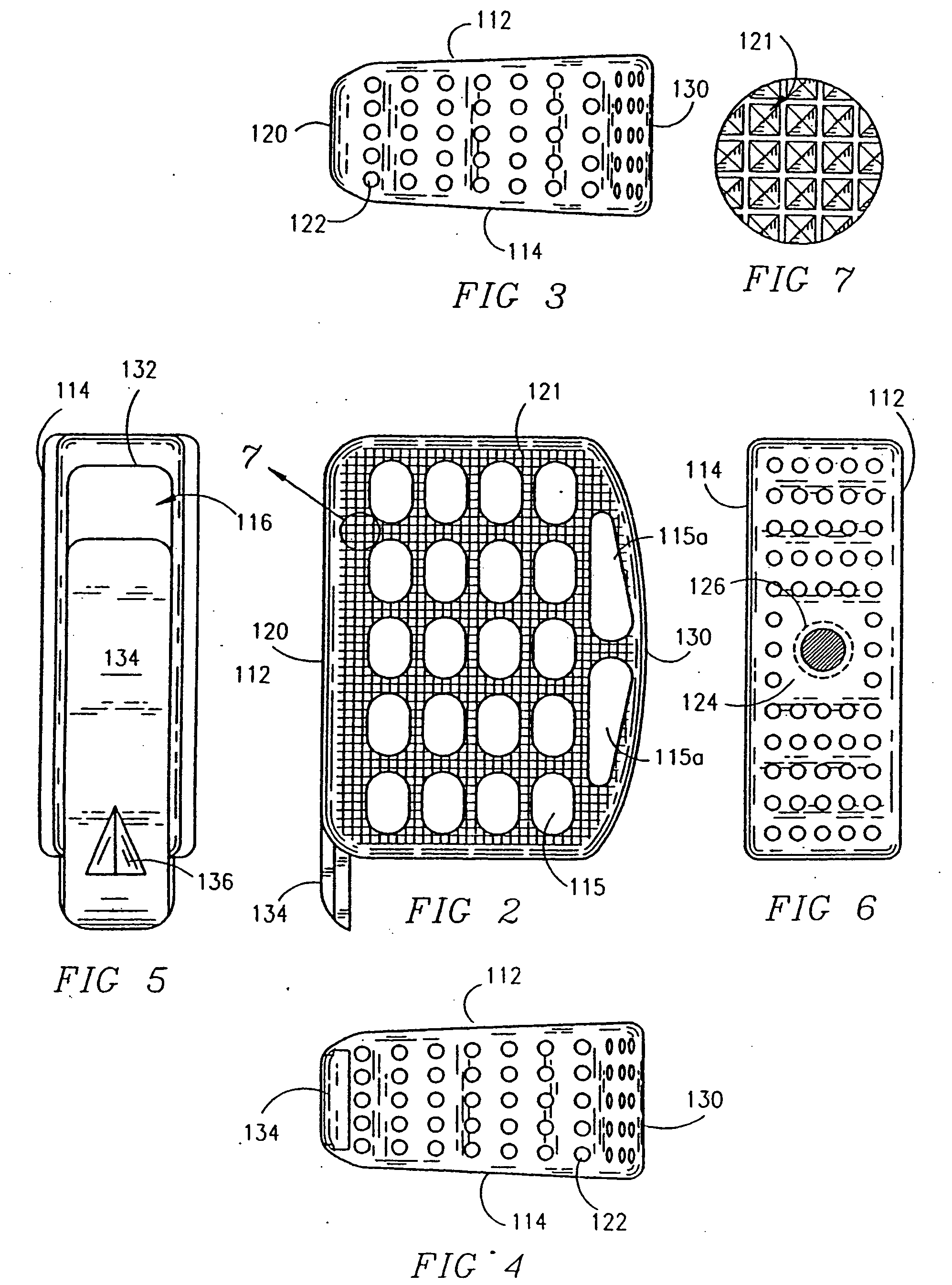

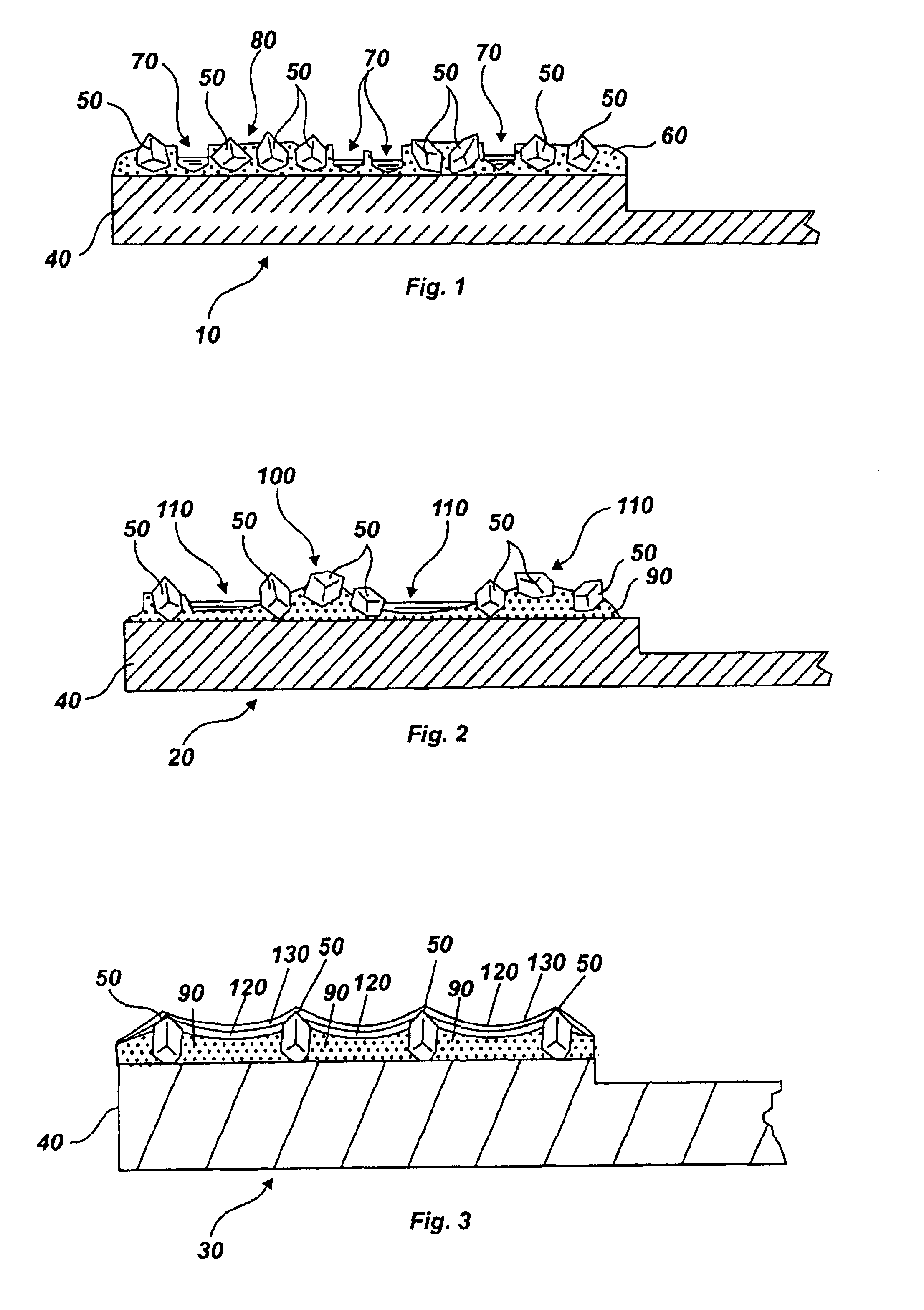

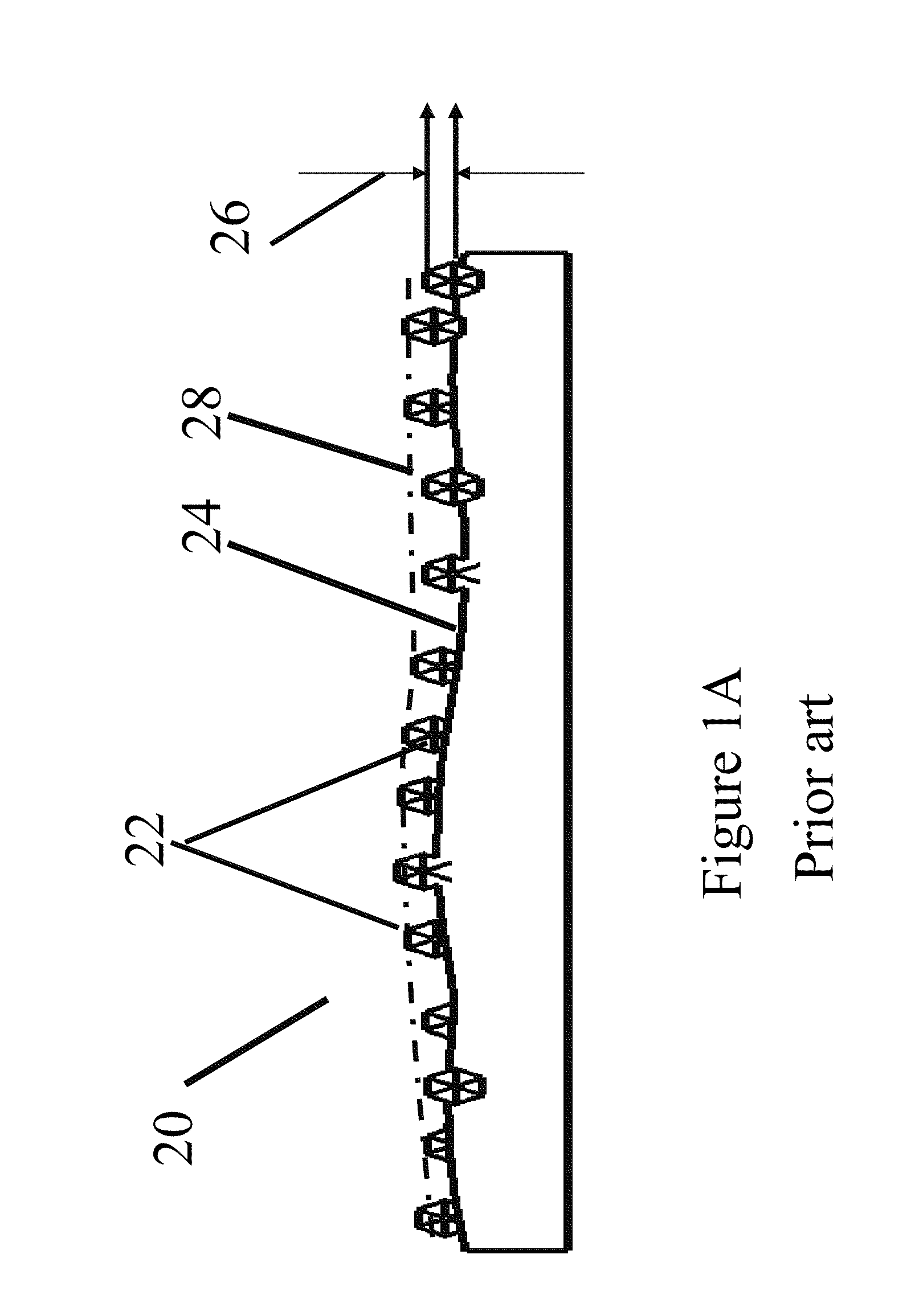

Brazed diamond tools and methods for making the same

Owner:SUNG CHIEN MIN

Brazed diamond tools and methods for making the same

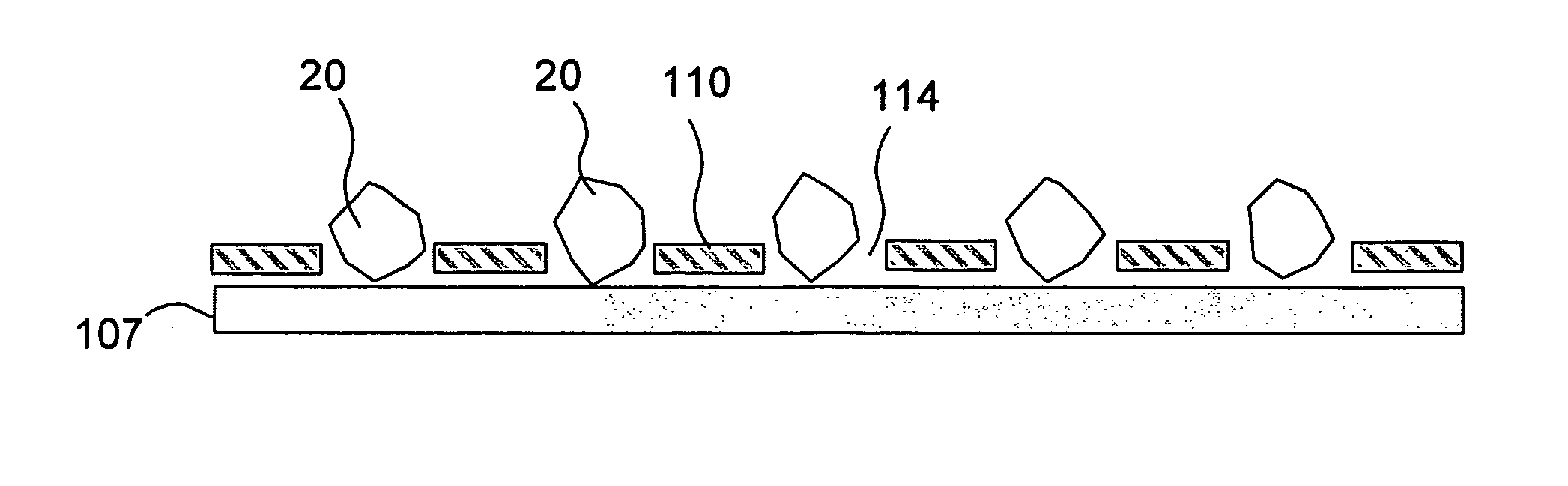

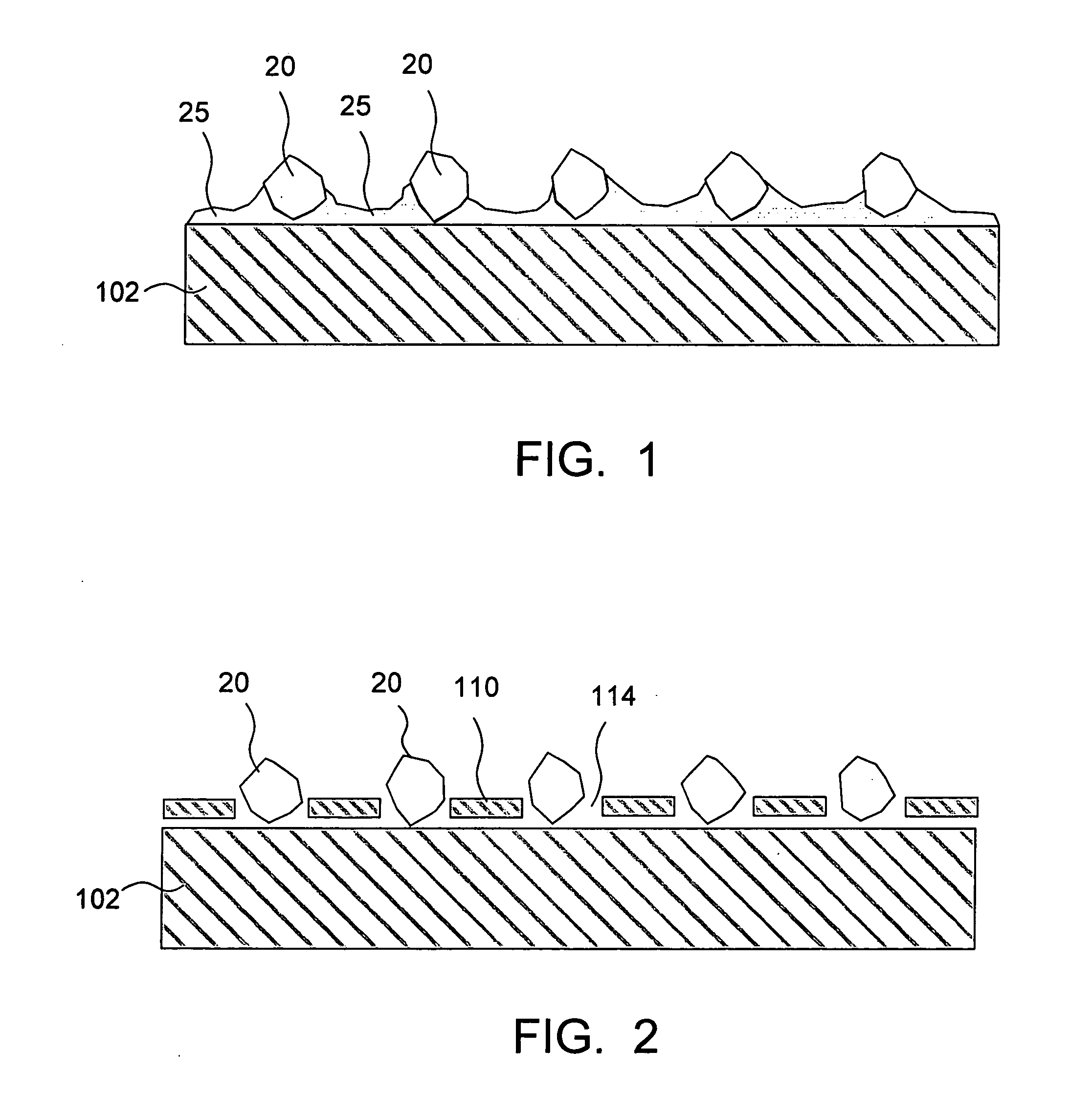

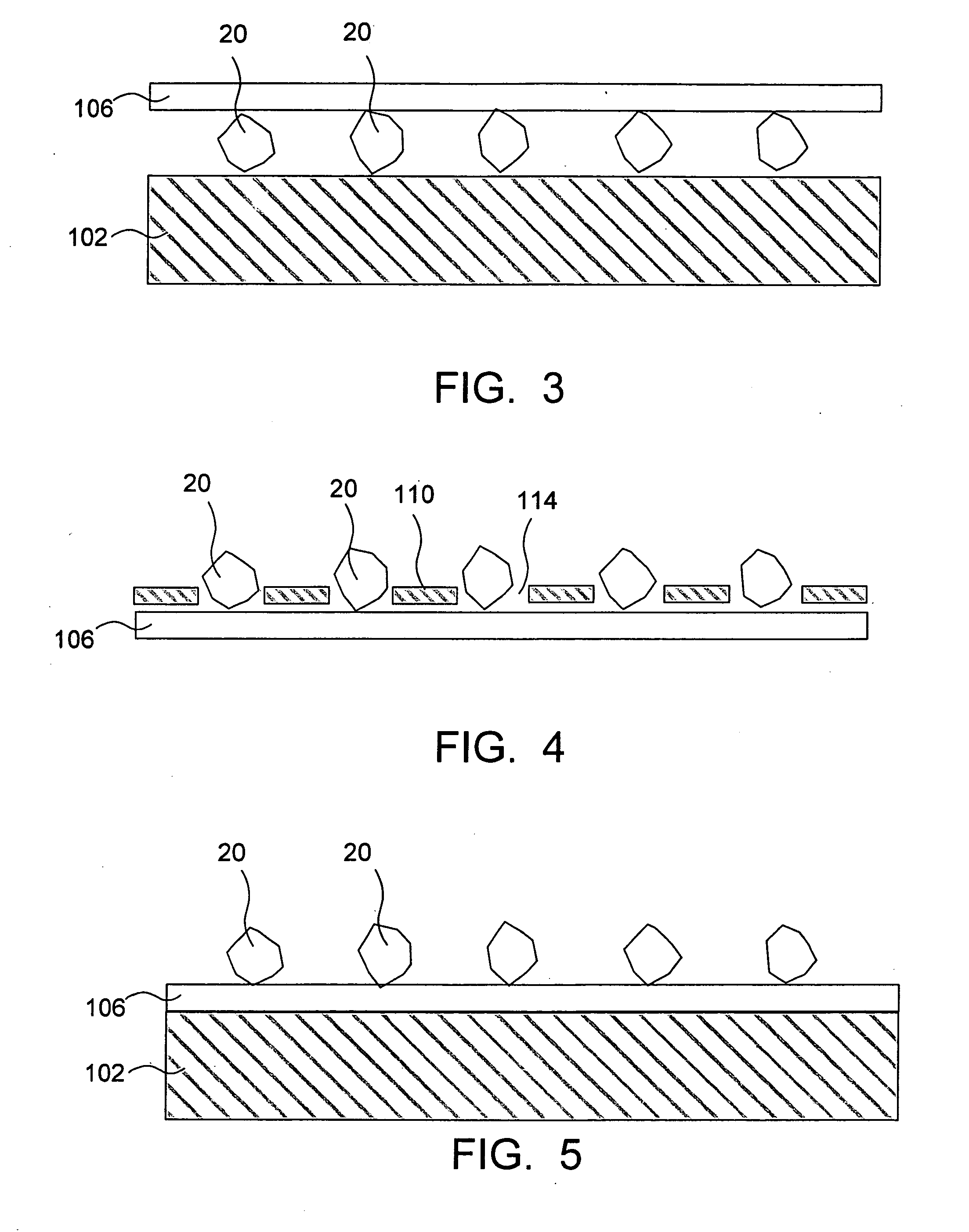

Superabrasive tools and methods for the making thereof are disclosed and described. In one aspect, superabrasive particles are chemically bonded to a matrix support material according to a predetermined pattern by a braze alloy. The brazing alloy may be provided as a powder, thin sheet, or sheet of amorphous alloy. A template having a plurality of apertures arranged in a predetermined pattern may be used to place the superabrasive particles on a given substrate or matrix support material.

Owner:SUNG CHIEN MIN +1

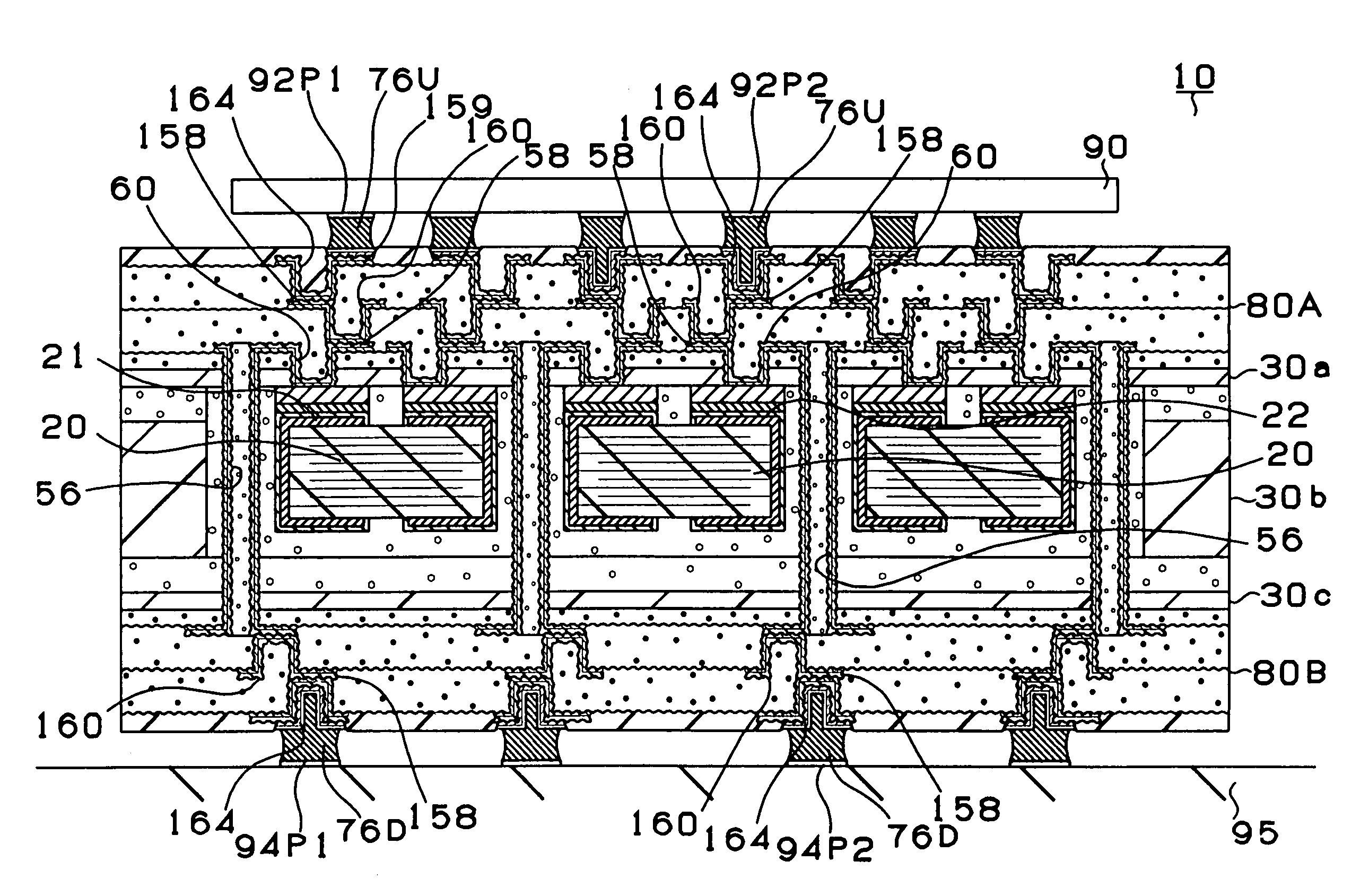

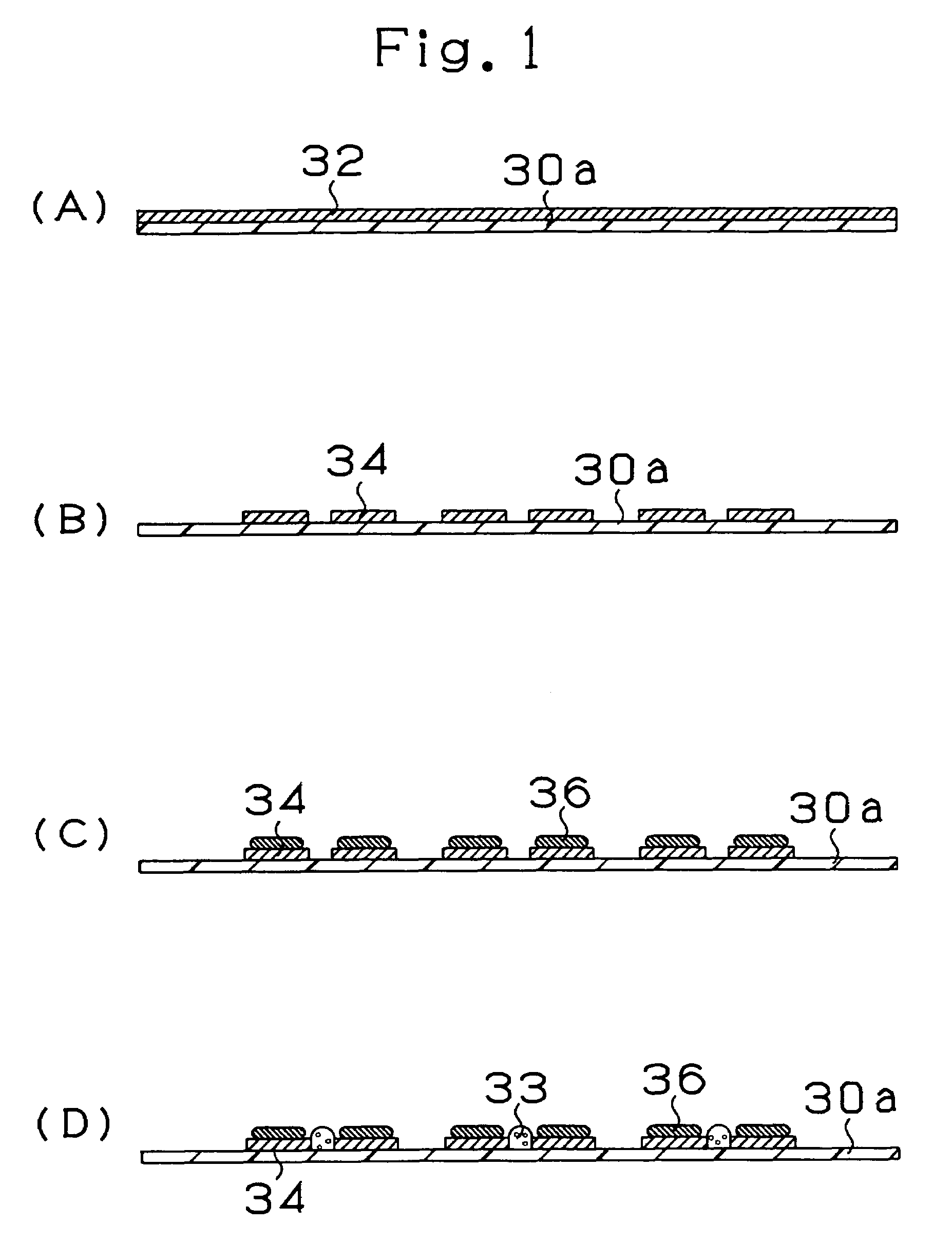

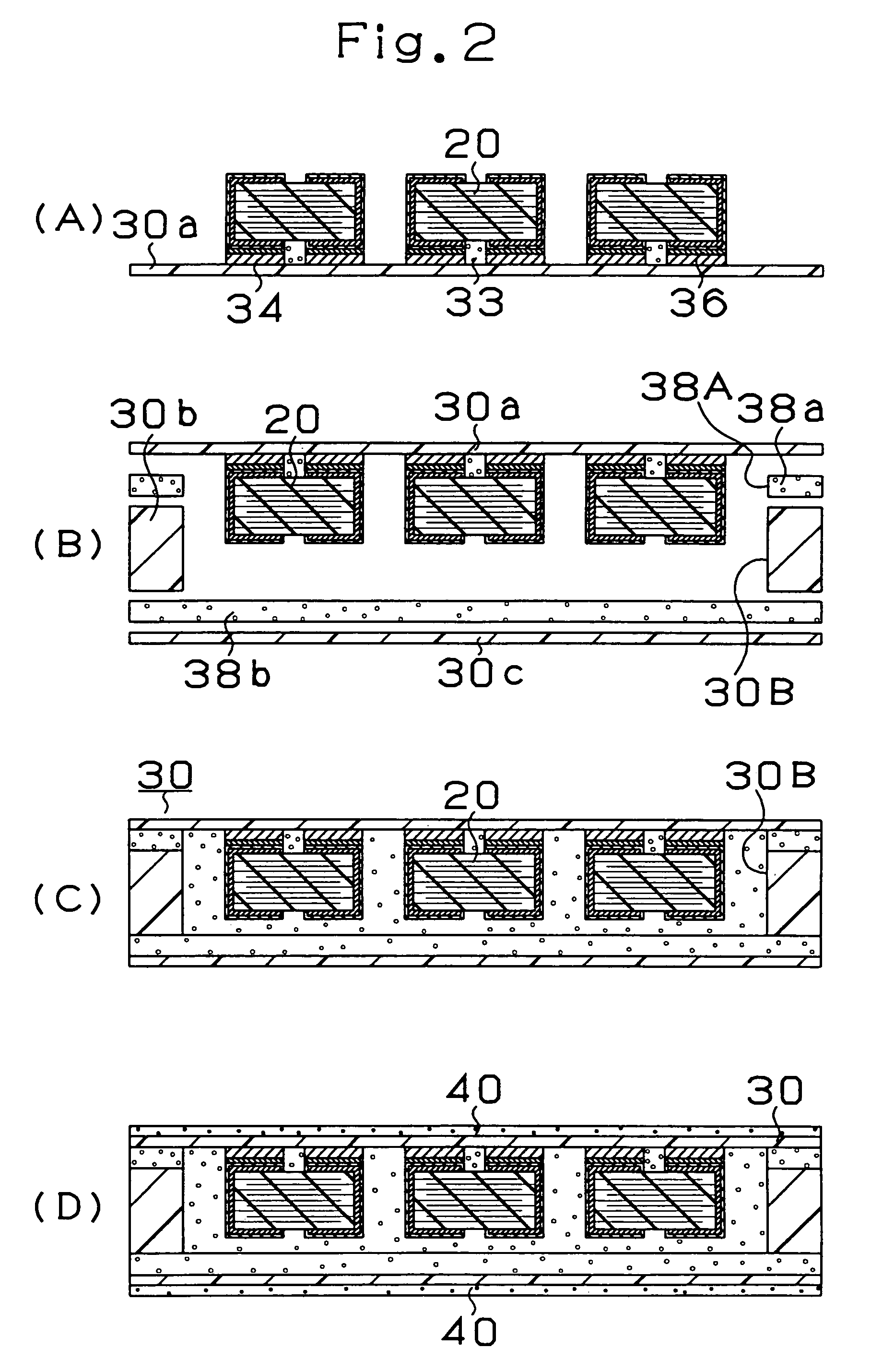

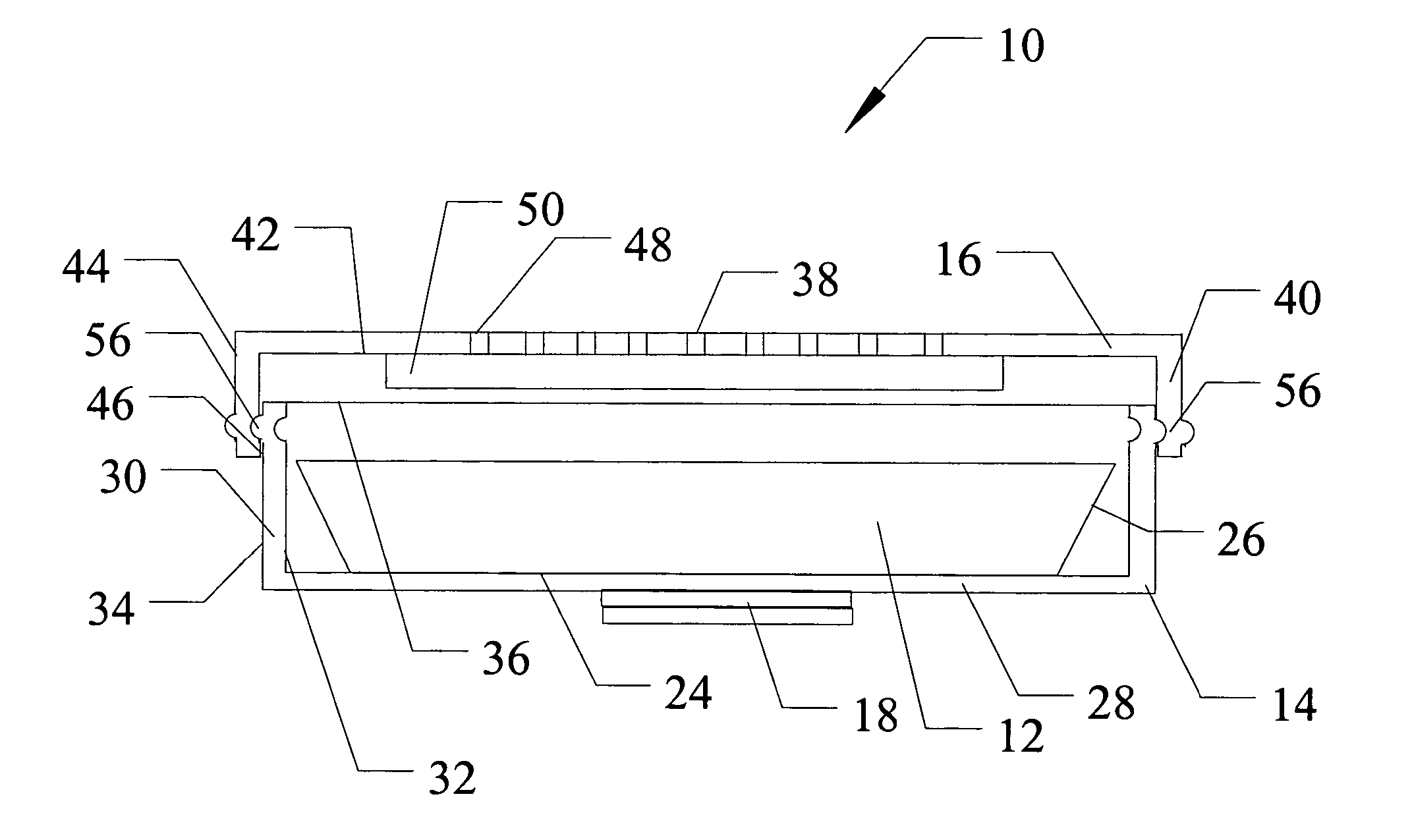

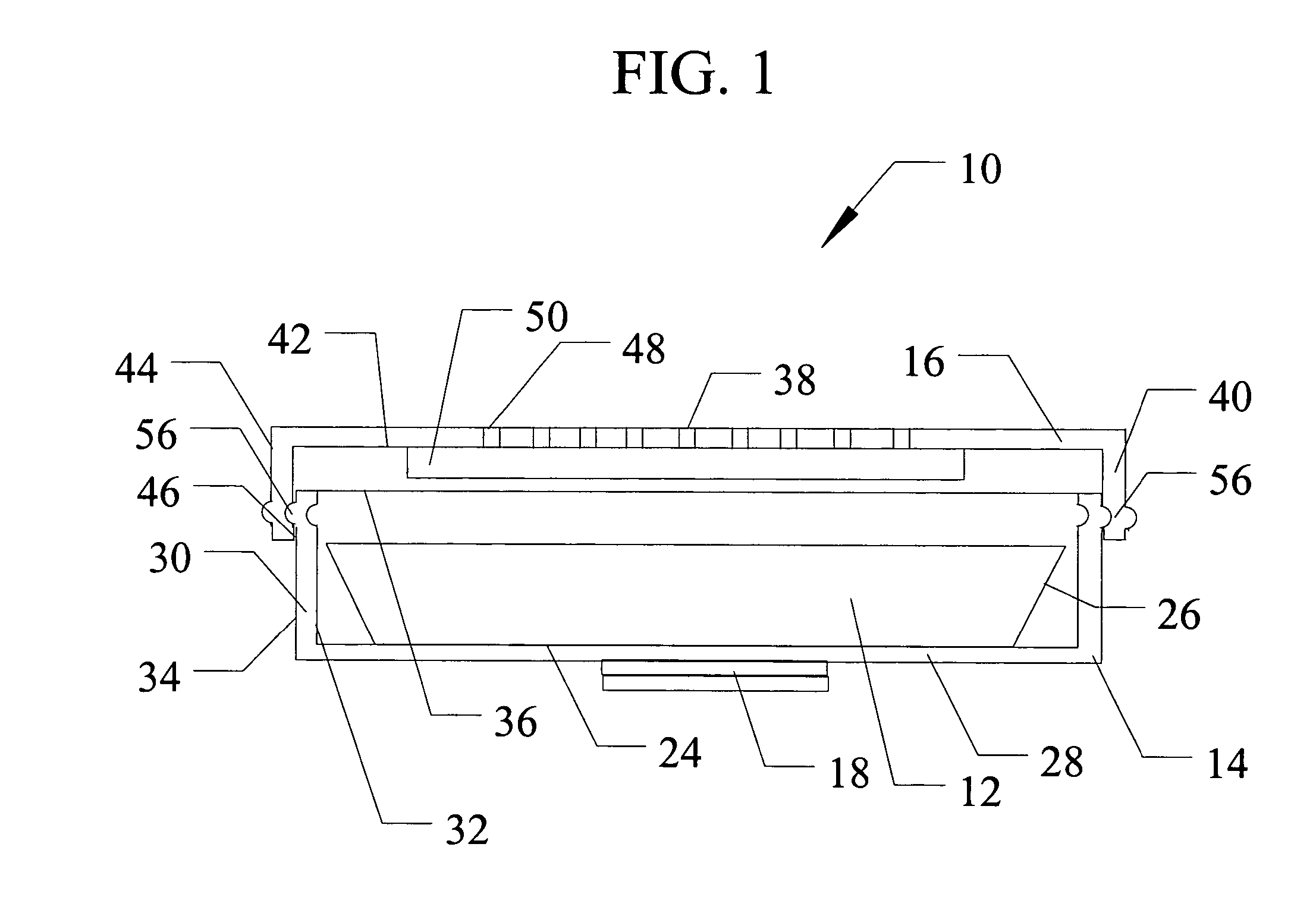

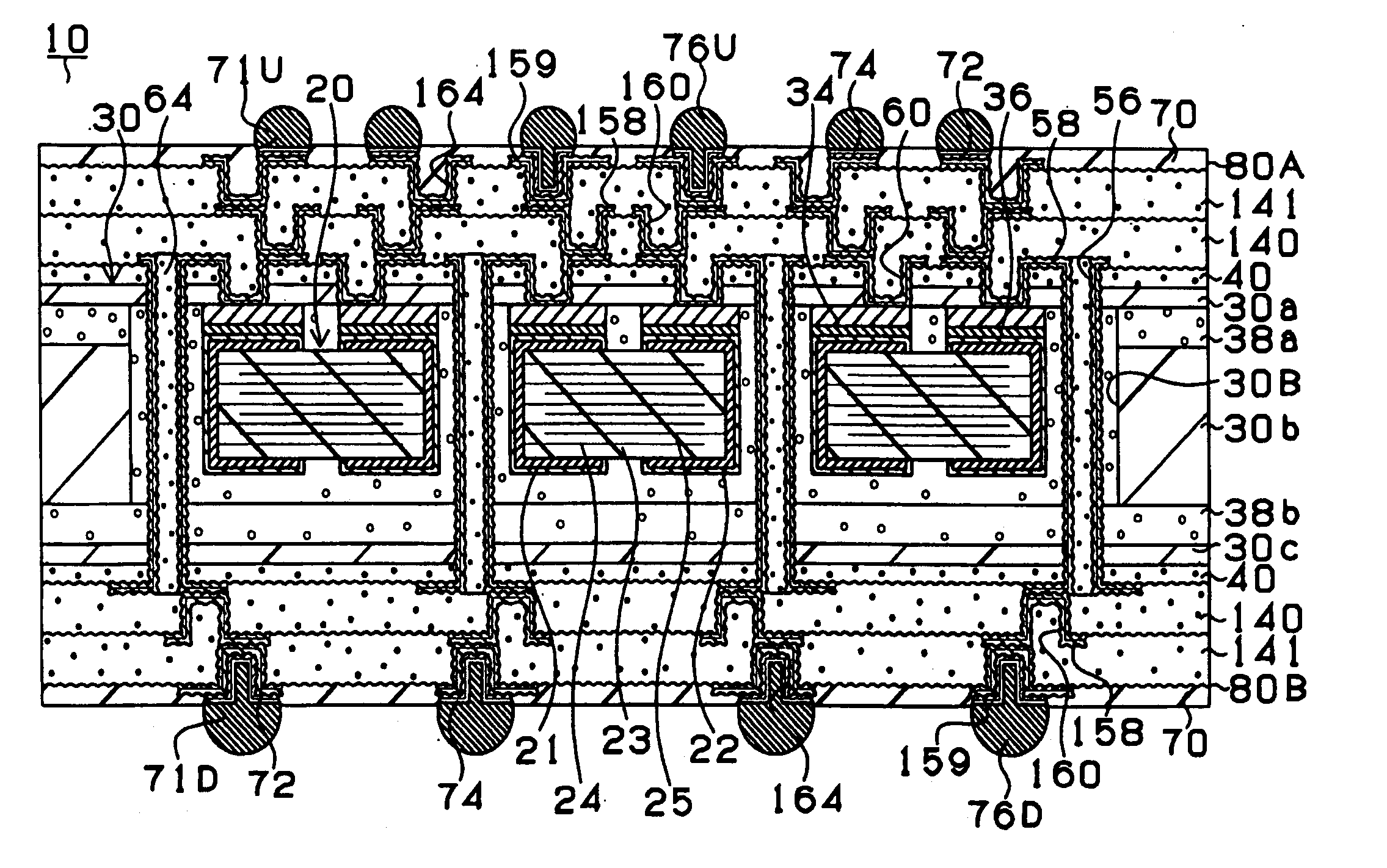

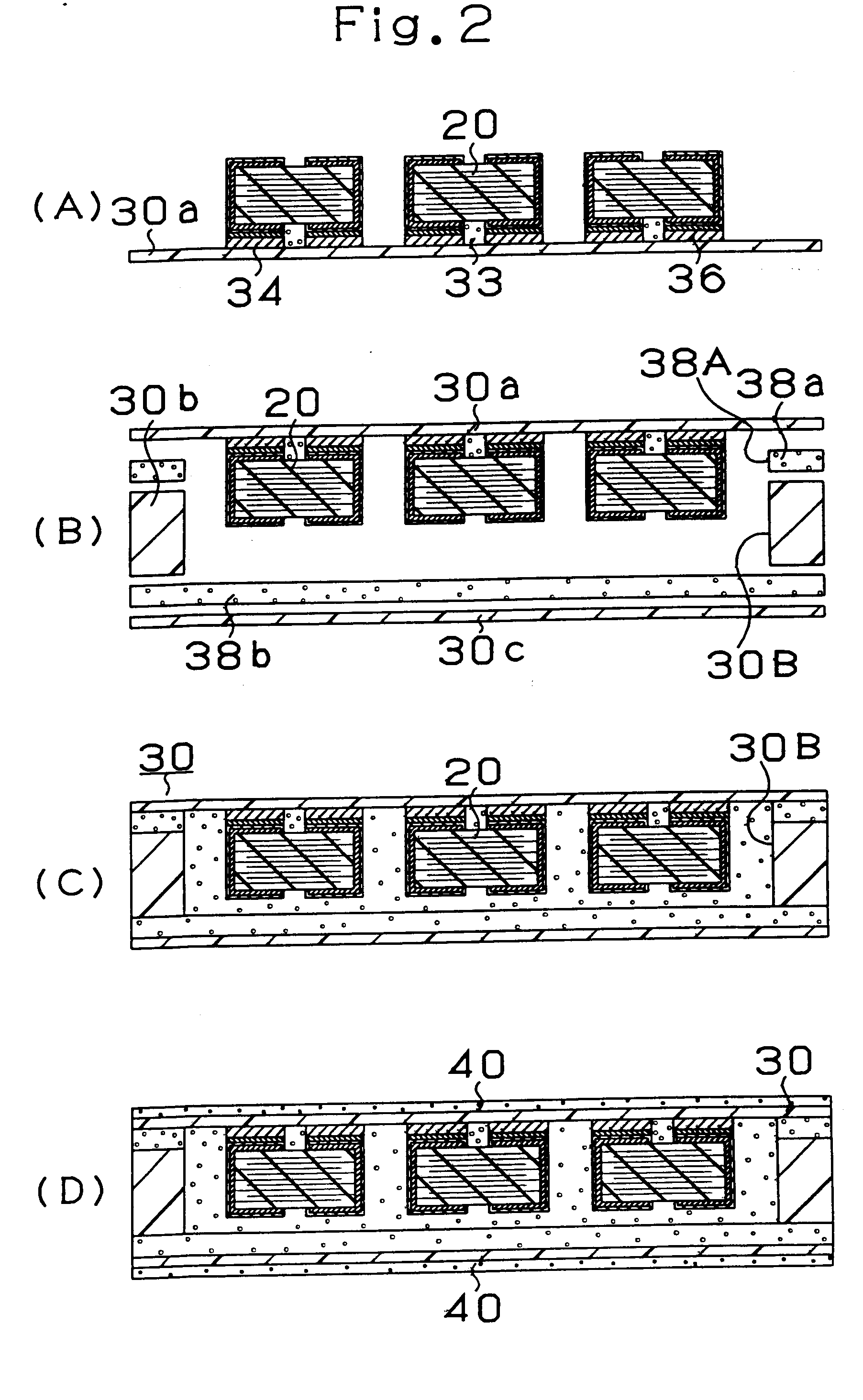

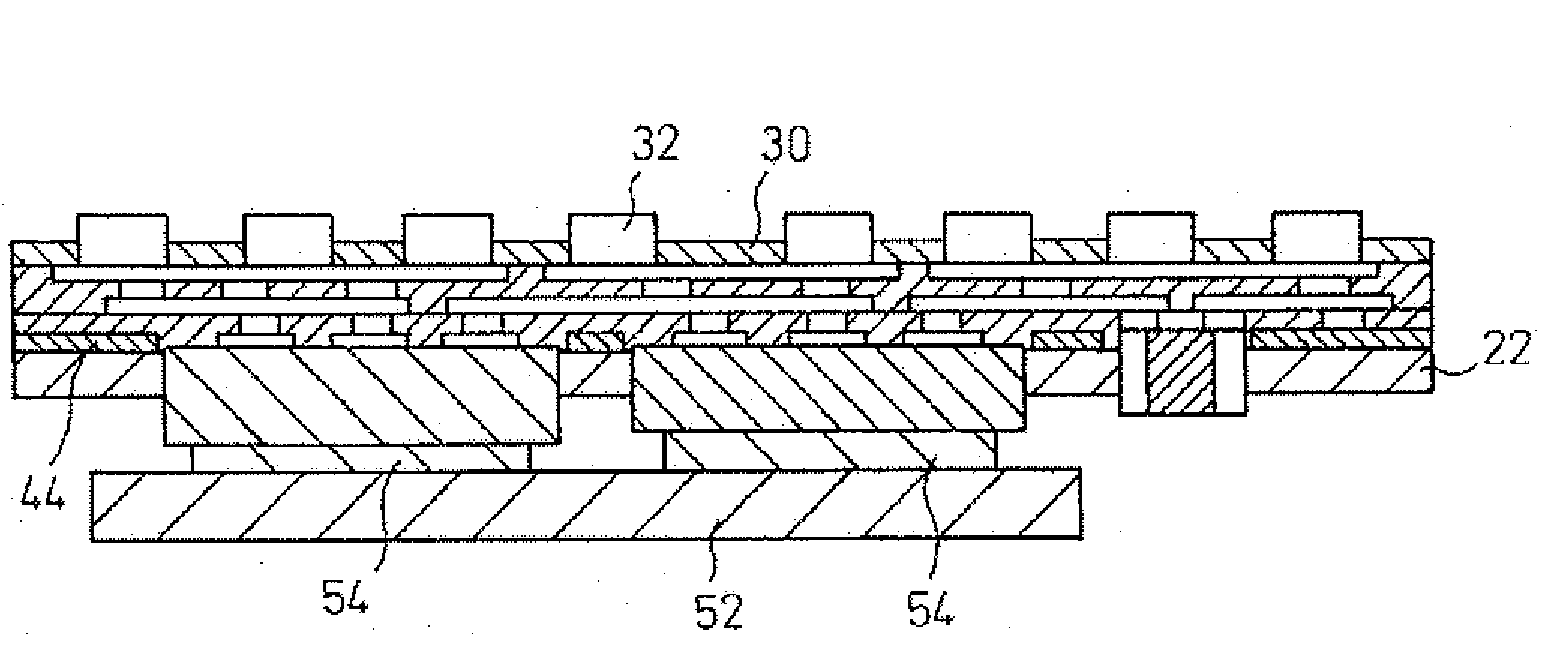

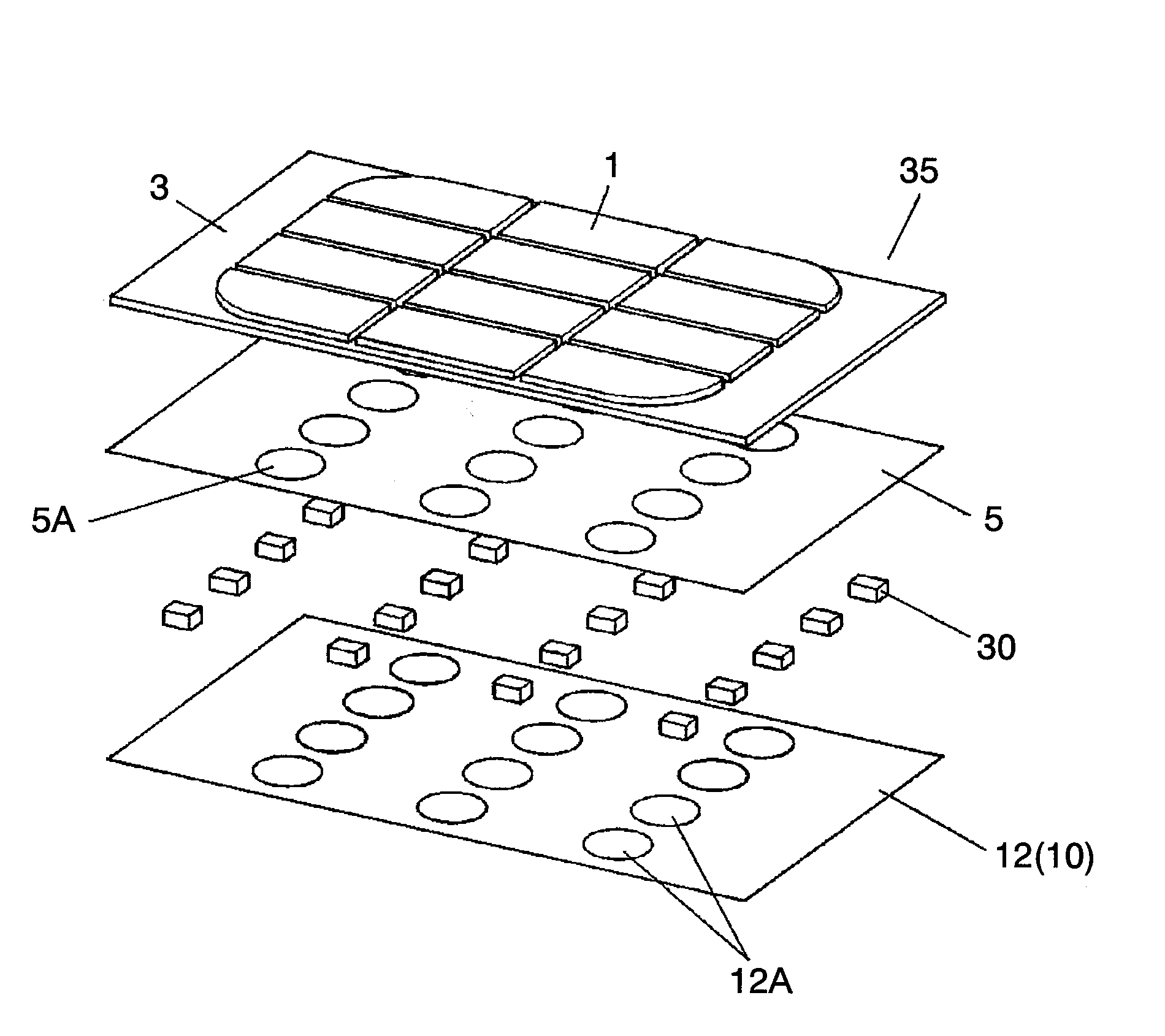

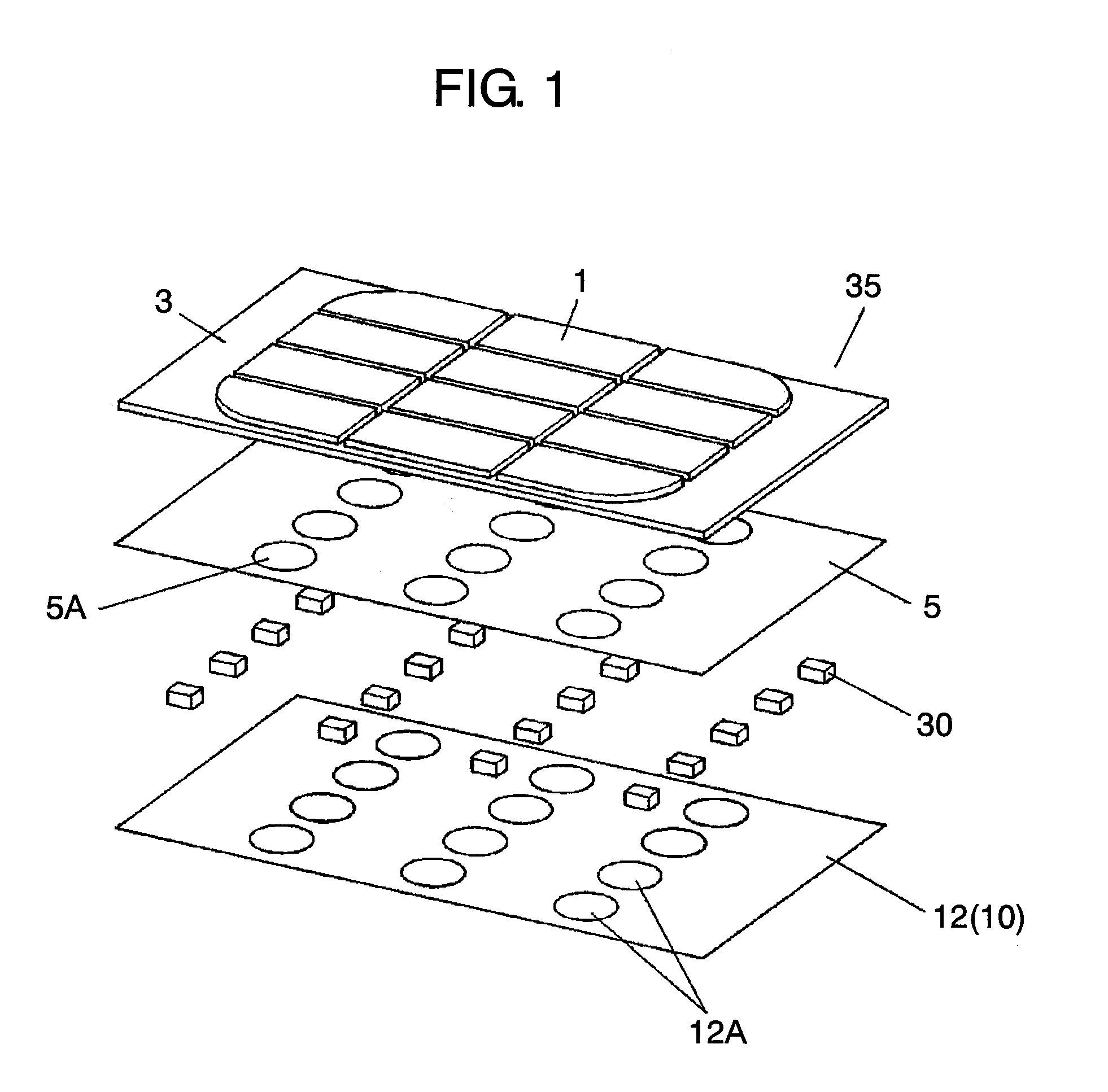

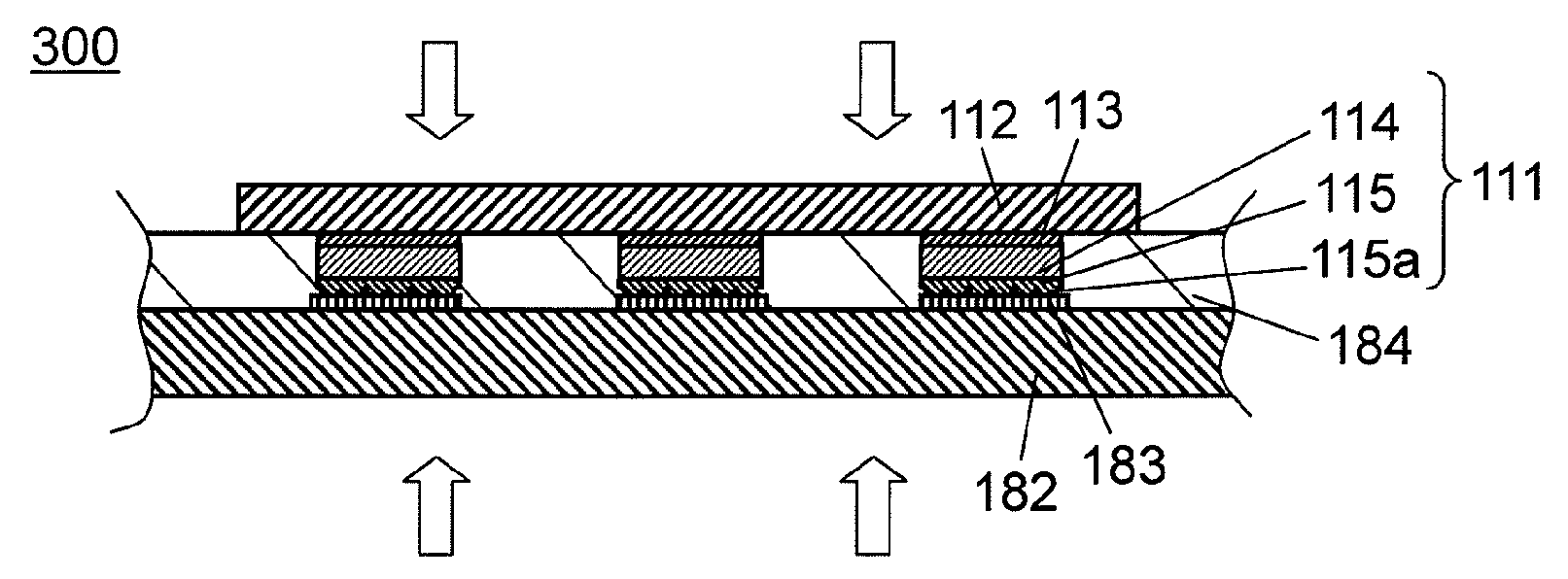

Printed circuit board and method of manufacturing printed circuit board

InactiveUS7342803B2Reduce loop inductanceReduce incidenceFinal product manufactureSemiconductor/solid-state device detailsEngineeringPrinted circuit board

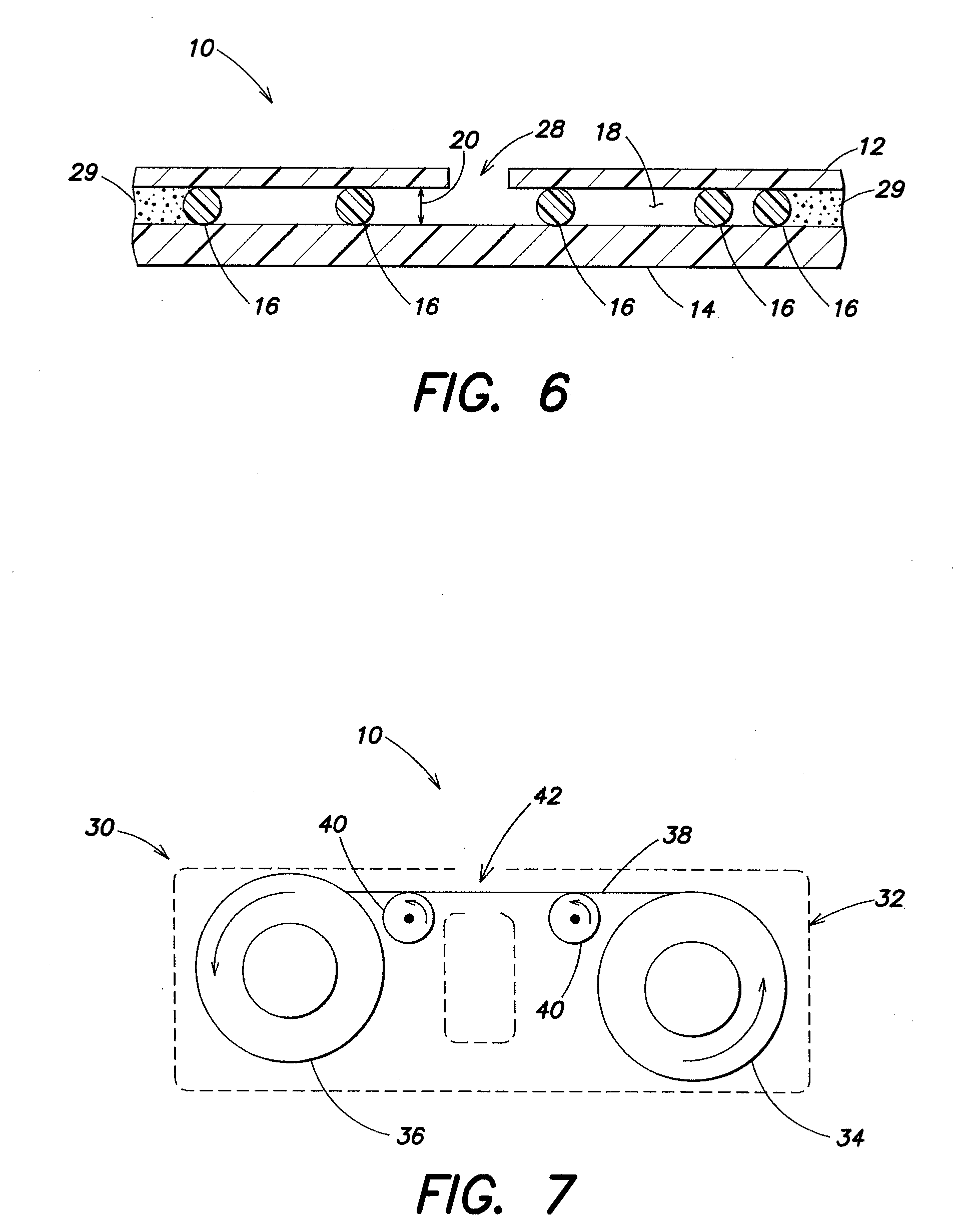

A chip capacitor 20 is provided in a core substrate 30 of a printed circuit board 10. This makes it possible to shorten a distance between an IC chip 90 and the chip capacitor 20 and to reduce loop inductance. Since the core substrate 30 is constituted by providing a first resin substrate 30a, a second resin substrate 30b and a third resin substrate 30c in a multilayer manner, the core substrate 30 can obtain sufficient strength.

Owner:IBIDEN CO LTD

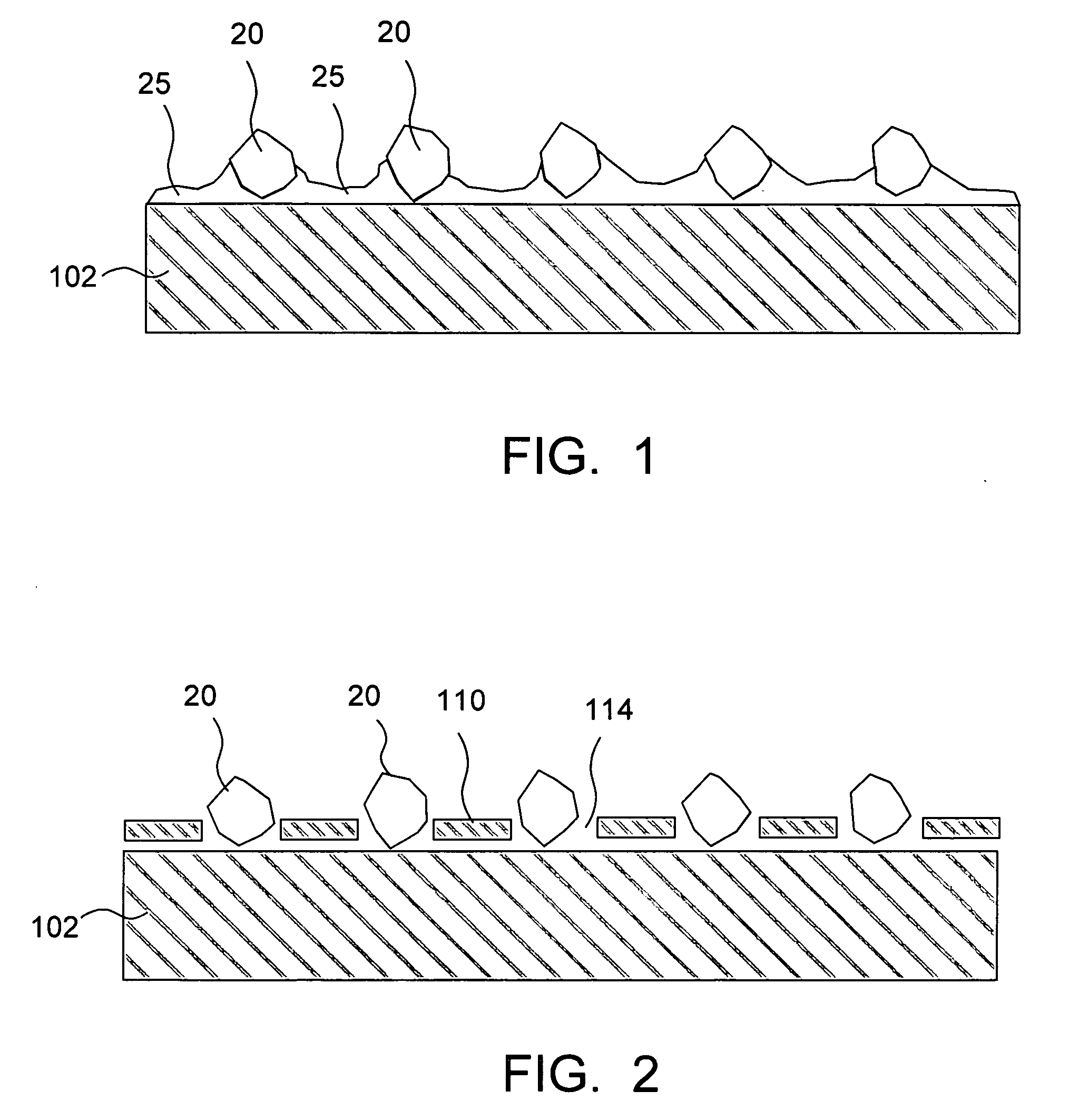

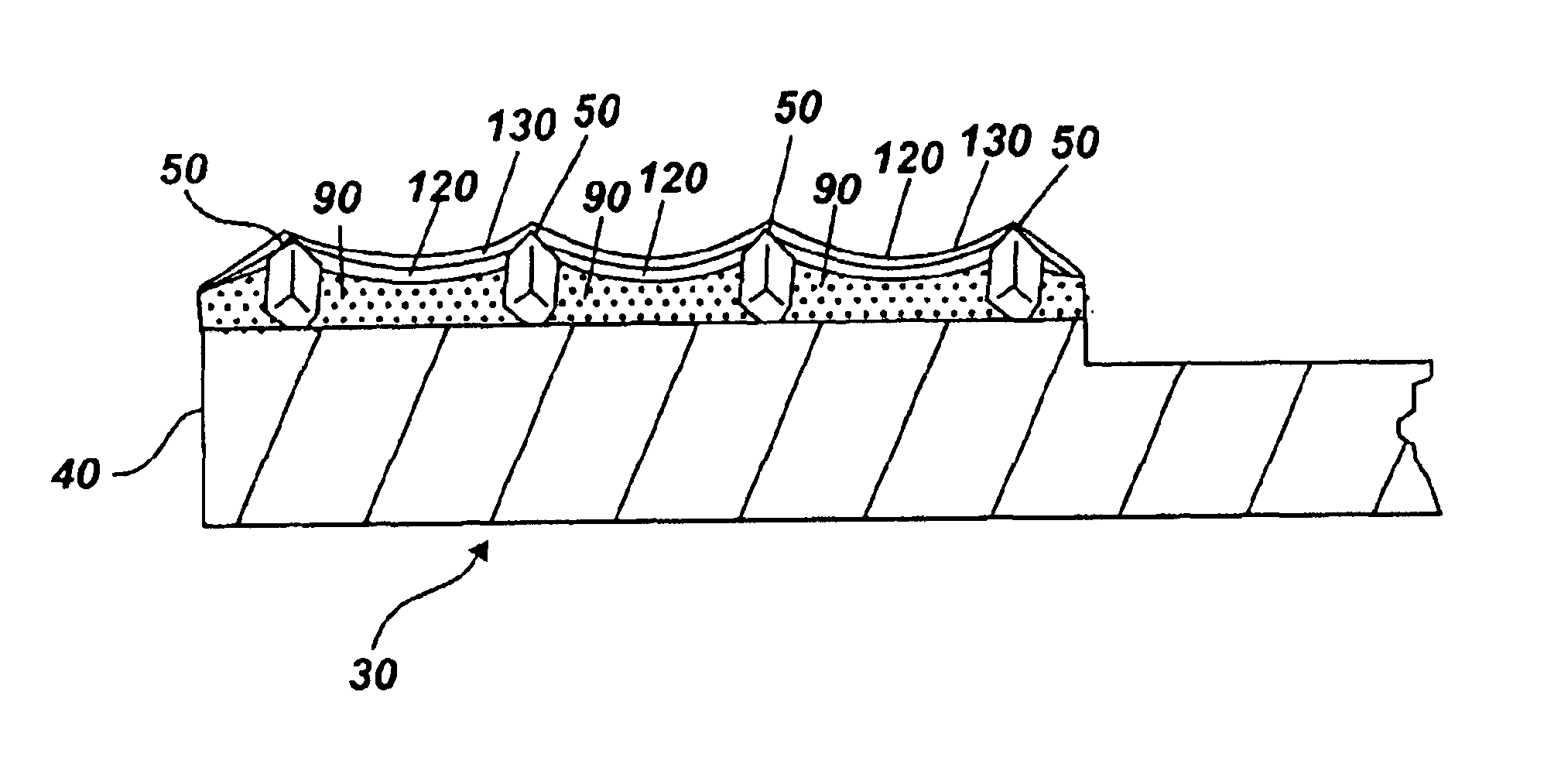

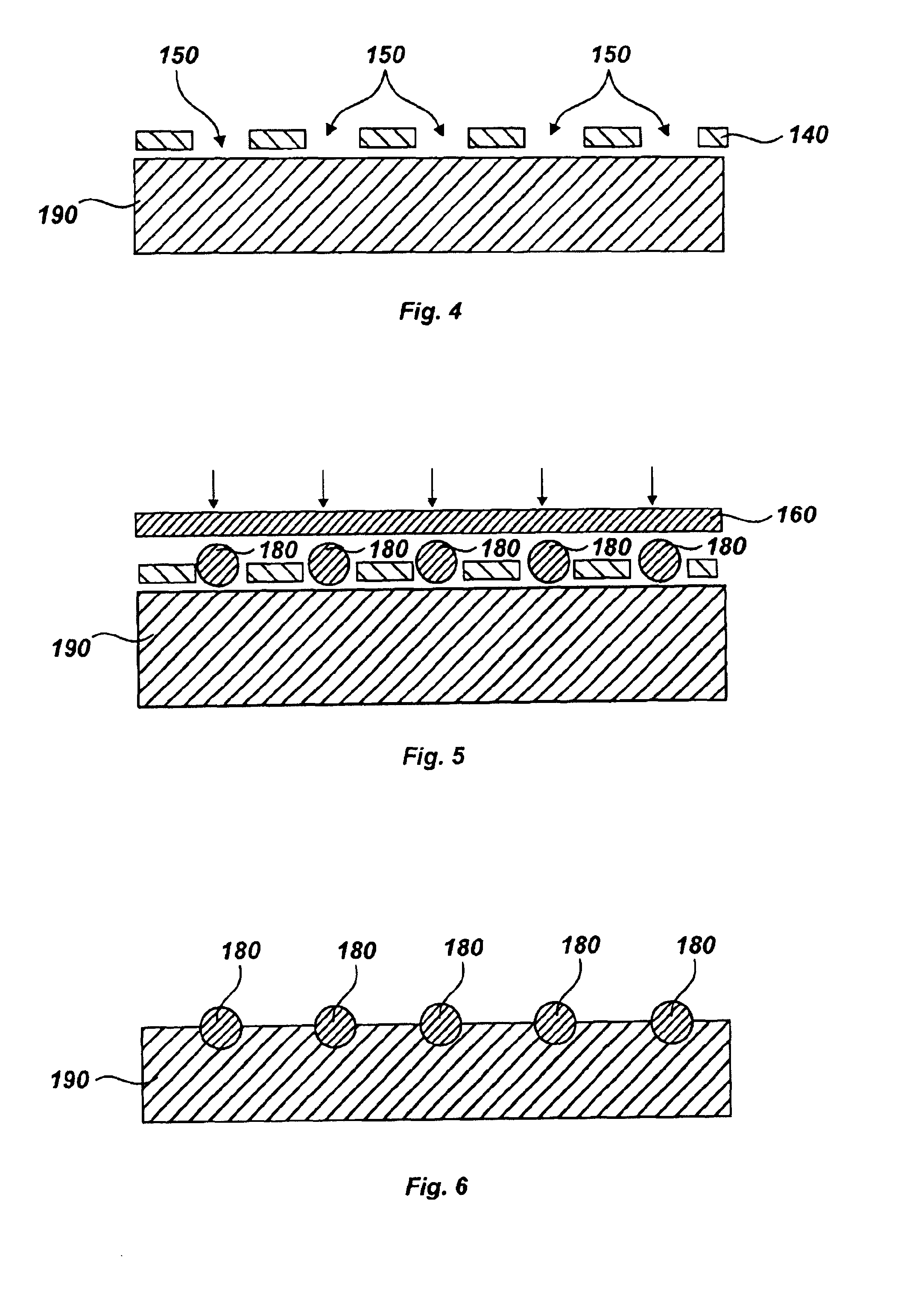

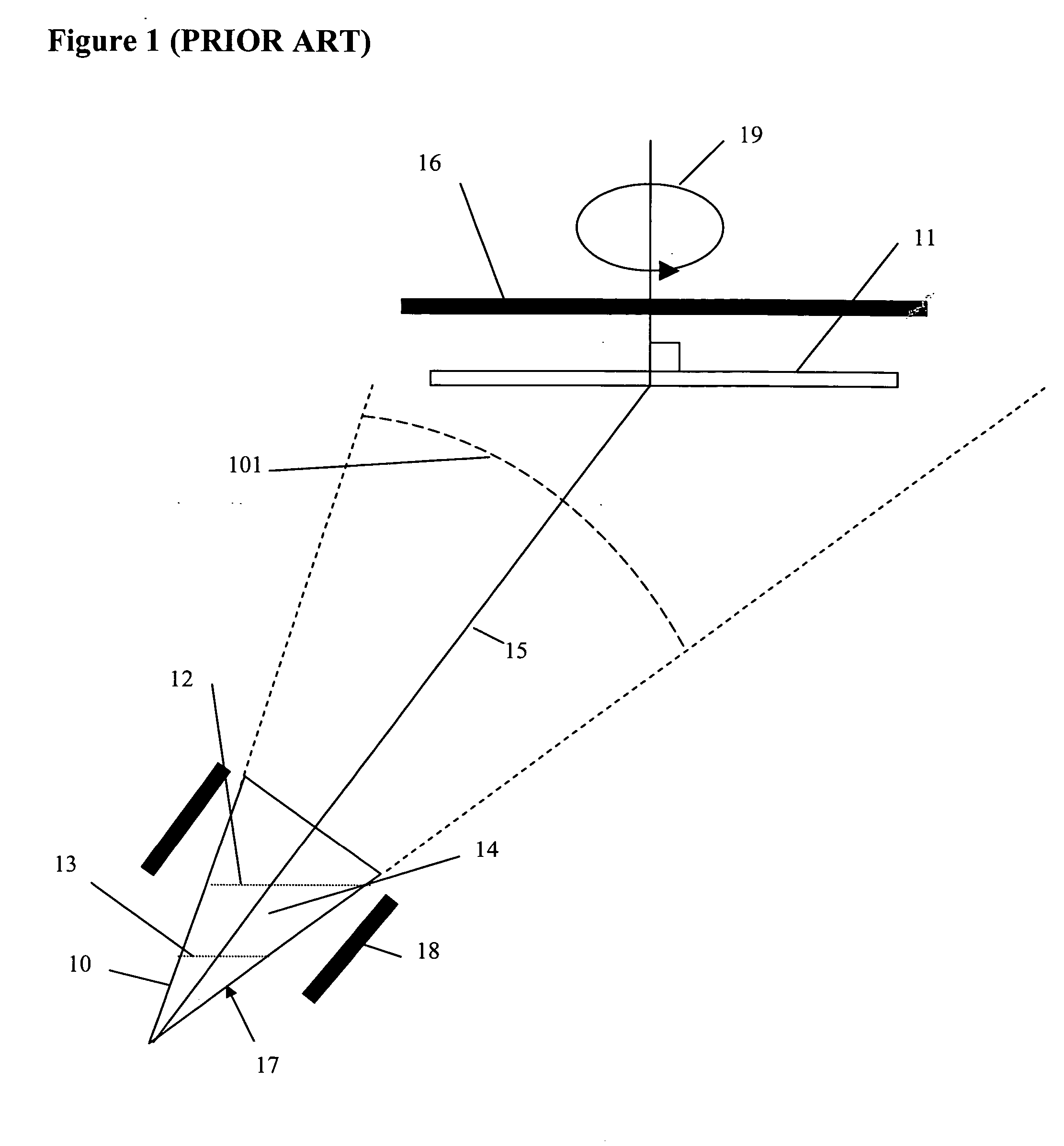

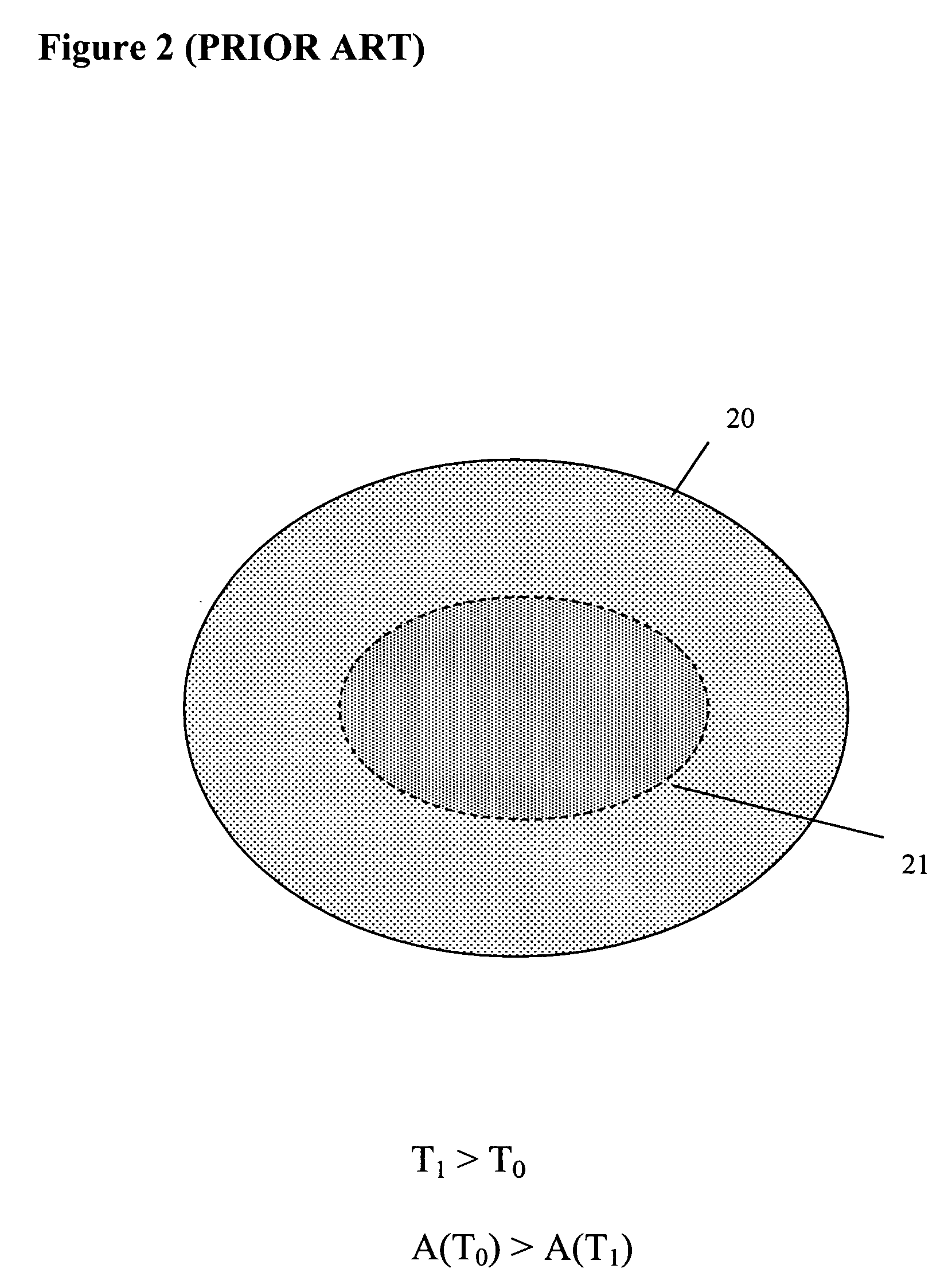

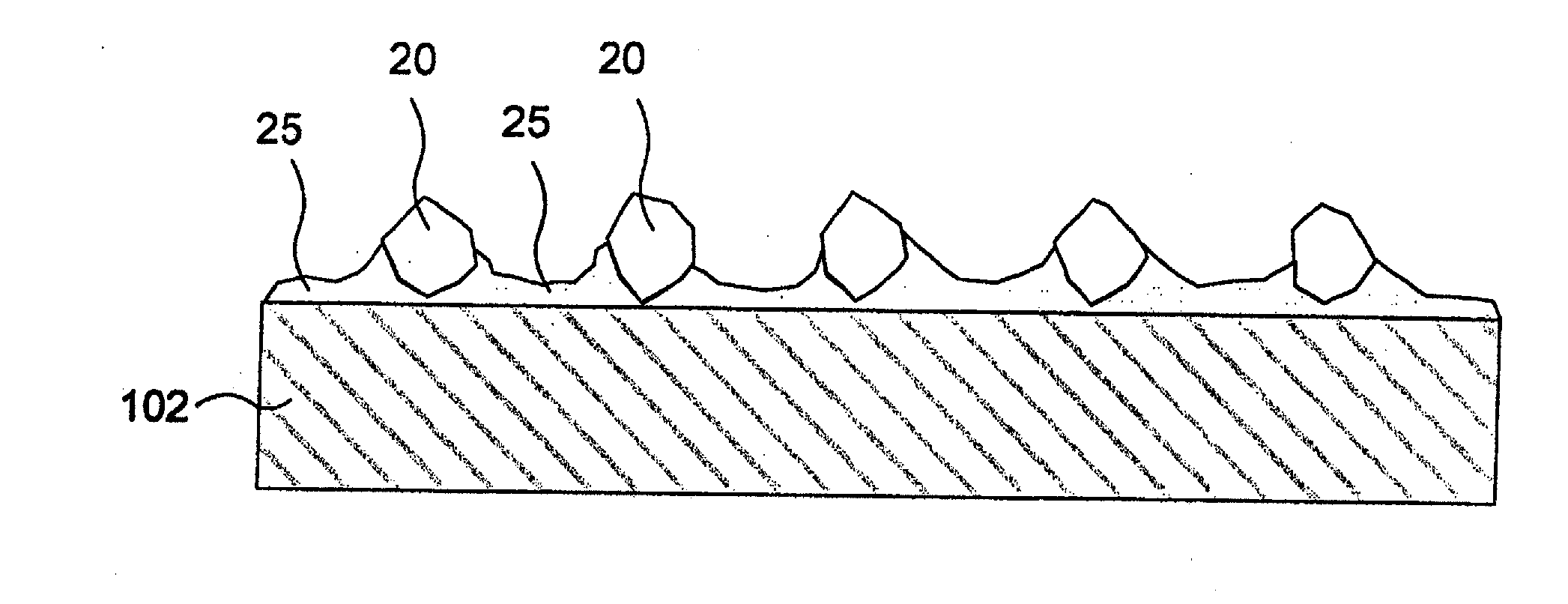

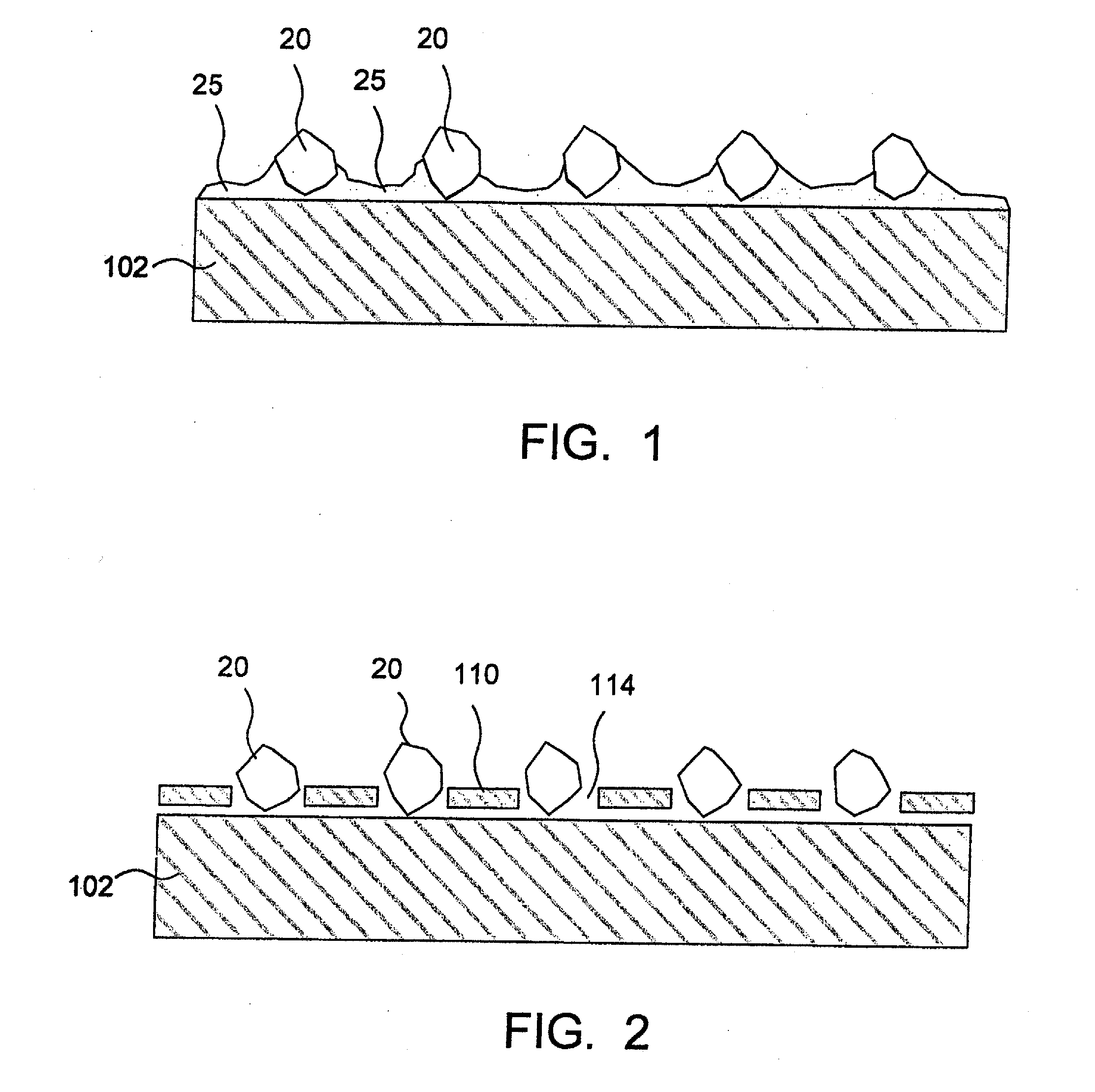

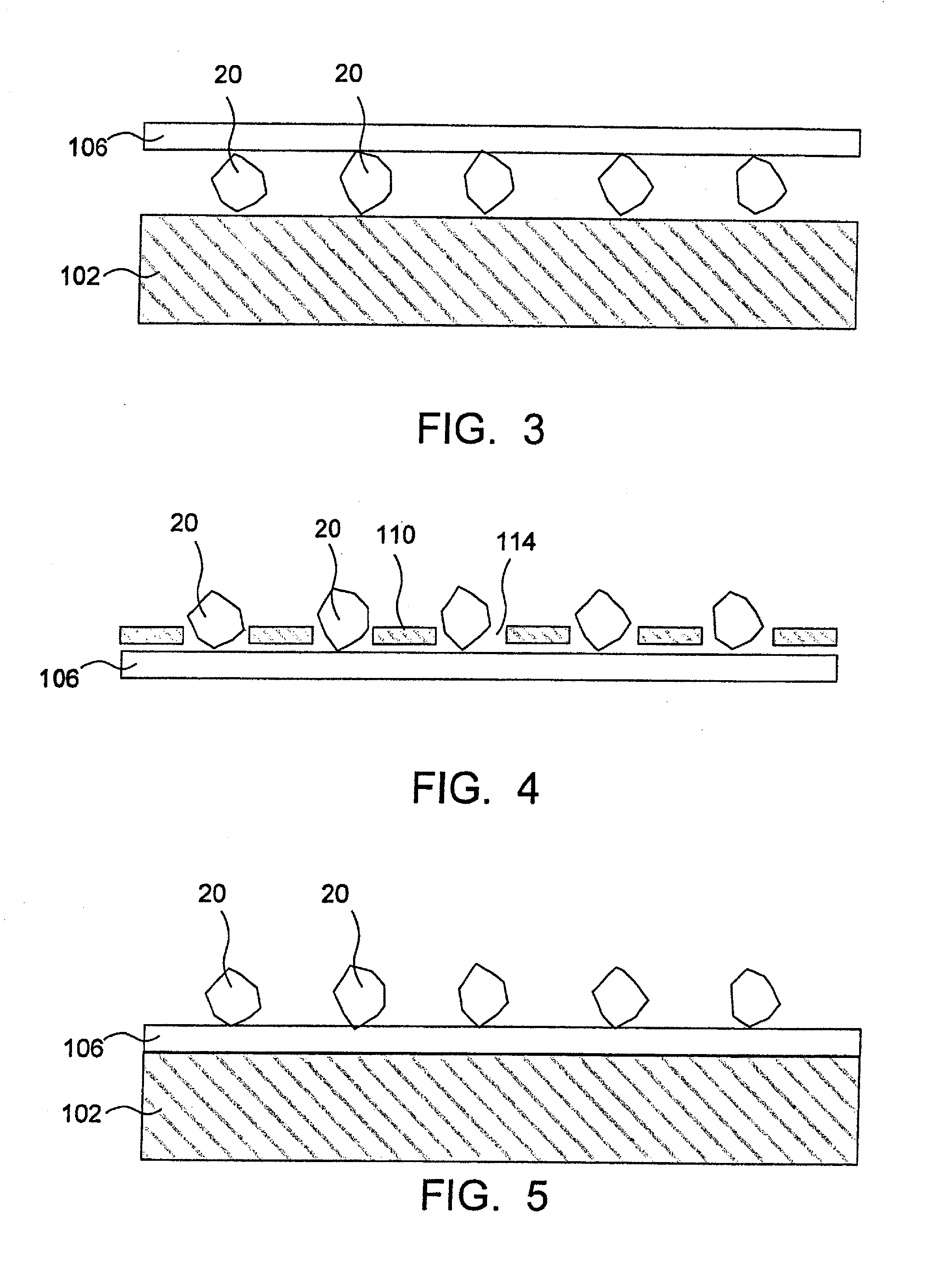

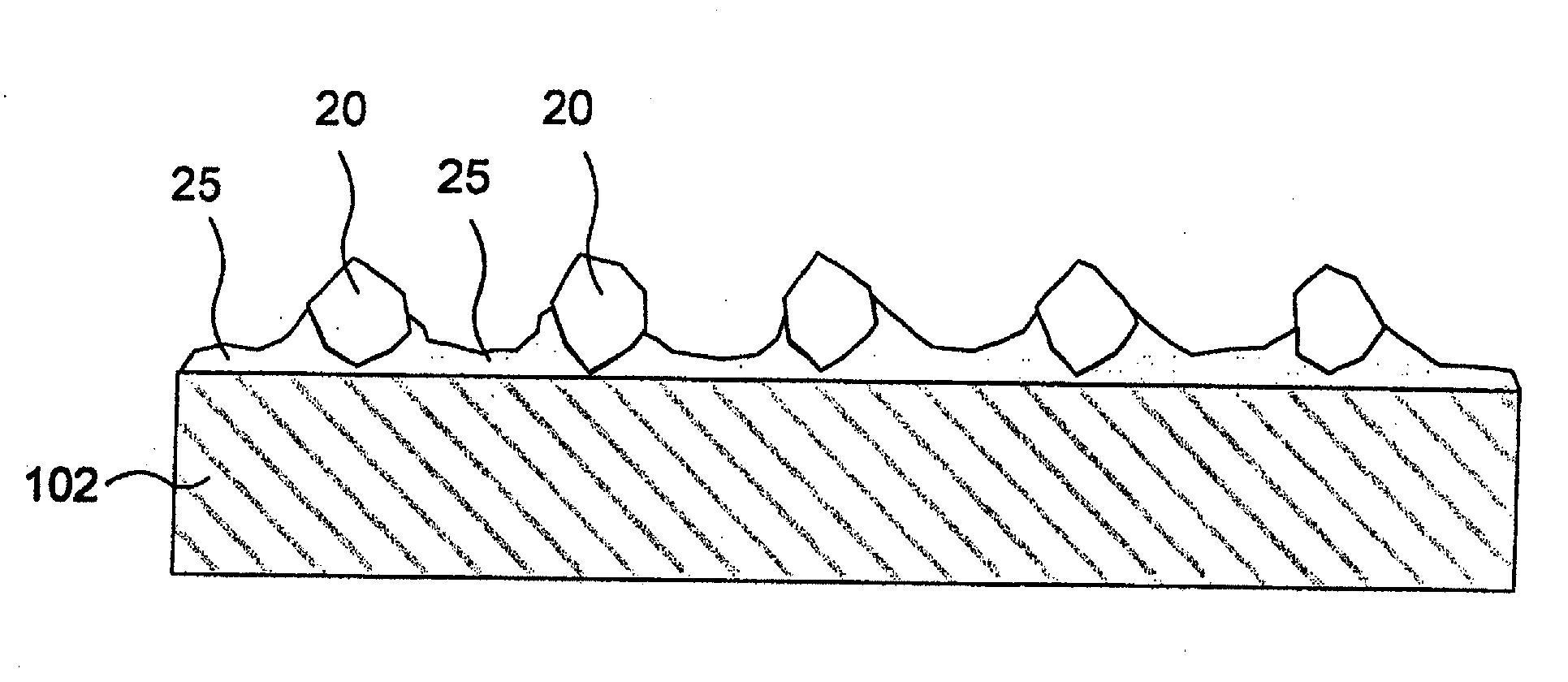

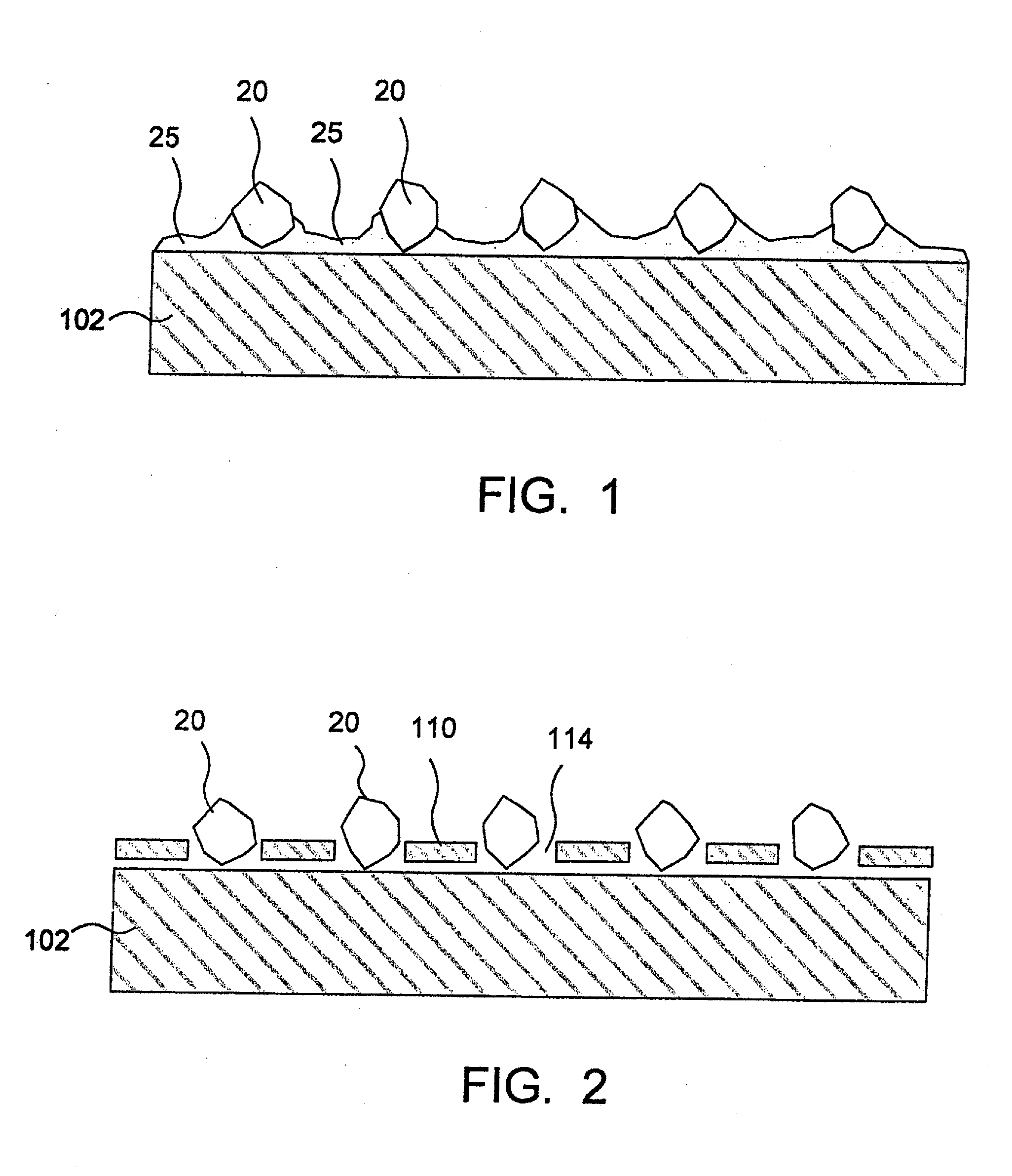

Diamond grid CMP pad dresser

InactiveUS6884155B2Easy to monitorUniform sizePolishing machinesRevolution surface grinding machinesSuperhard materialDiamond-like carbon

The present invention discloses a CMP pad dresser which has a plurality of uniformly spaced abrasive particles protruding therefrom. The abrasive particles are super hard materials, and are typically diamond, polycrystalline diamond (PCD), cubic boron nitride (cBN), or polycrystalline cubic boron nitride(PcBN). The abrasive particles are brazed to a substrate which may be then coated with an additional anti-corrosive layer. The anti-corrosive layer is usually a diamond or diamond-like carbon which is coated over the surface of the disk to prevent erosion of the brazing alloy by the chemical slurry used in conjunction with the CMP pad. This immunity to chemical attack allows the CMP pad dresser to dress the pad while it is polishing a workpiece. In addition to even spacing on the substrate, the abrasive particles extend for a uniform distance away from the substrate, allowing for even grooming or dressing of a CMP pad both in vertical and horizontal directions. A method of producing such a CMP pad dresser is also disclosed.

Owner:KINIK

Disposable chamber for analyzing biologic fluids

InactiveUS20100216248A1Accurately determinableUniform heightBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringBiological fluids

Owner:ABBOTT LAB INC

Brazed diamond tools and methods for making the same

Superabrasive tools and methods for the making thereof are disclosed and described. In one aspect, superabrasive particles are chemically bonded to a matrix support material according to a predetermined pattern by a braze alloy. The brazing alloy may be provided as a powder, thin sheet, or sheet of amorphous alloy. A template having a plurality of apertures arranged in a predetermined pattern may be used to place the superabrasive particles on a given substrate or matrix support material.

Owner:SUNG CHIEN MIN

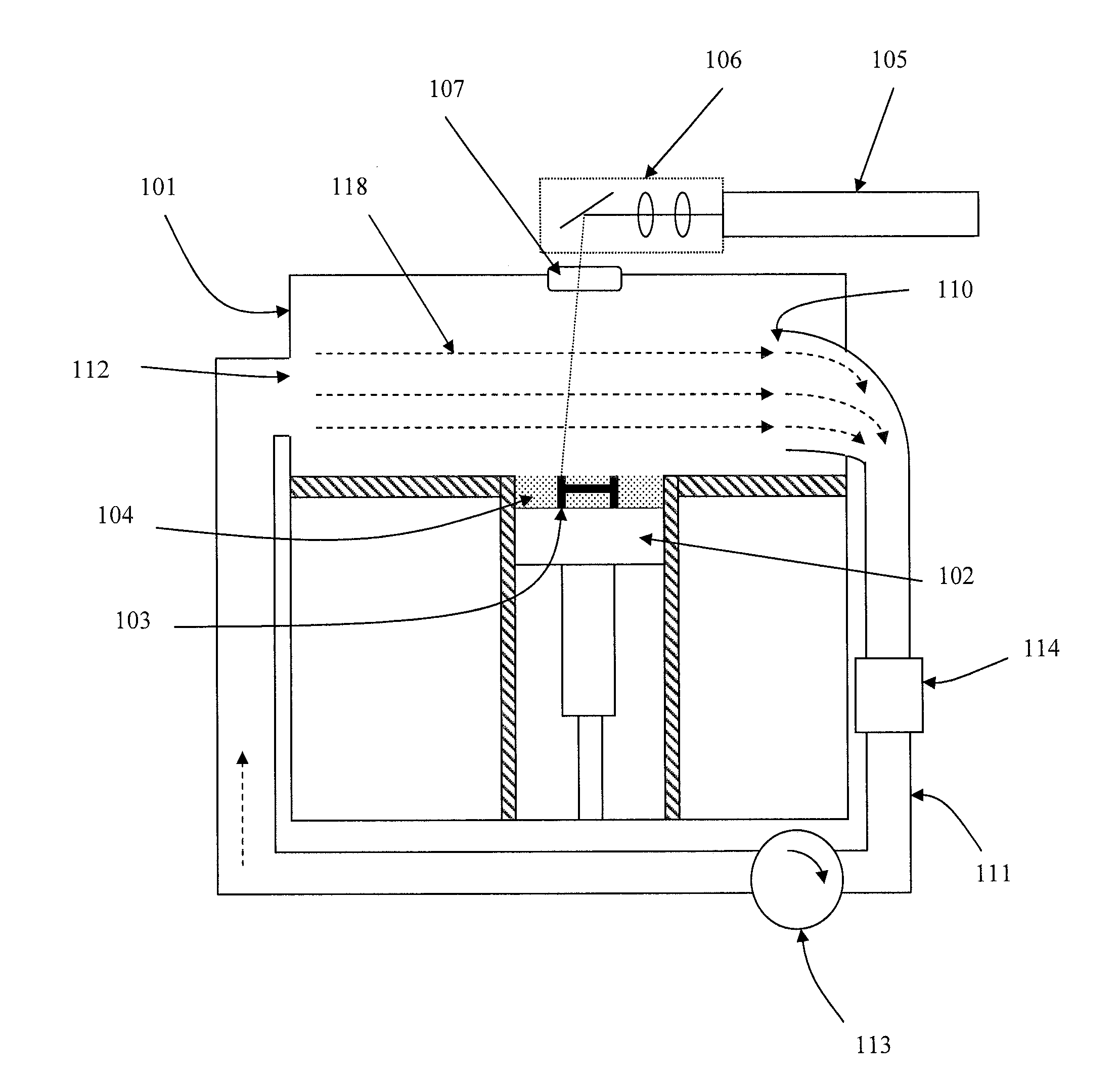

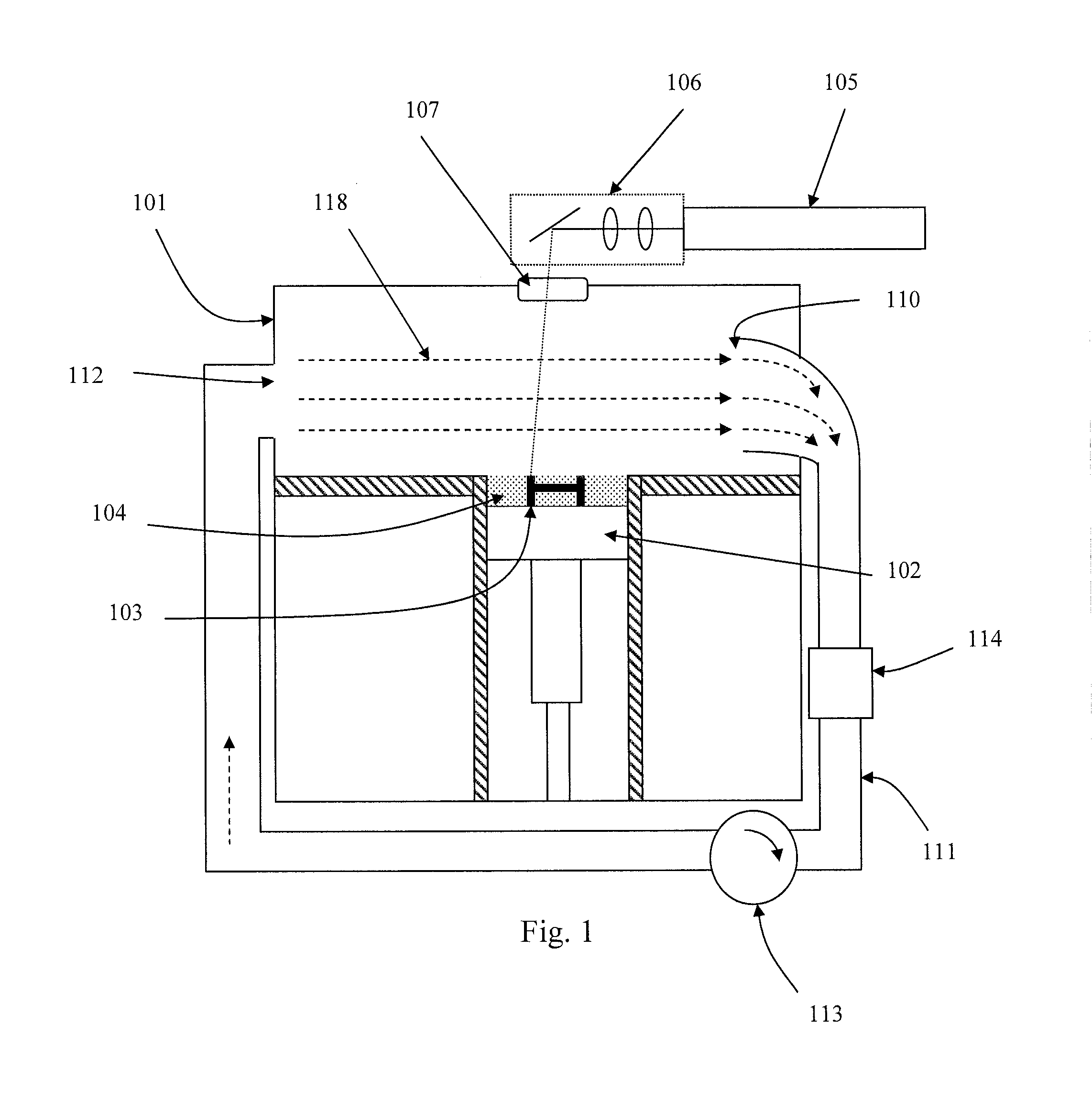

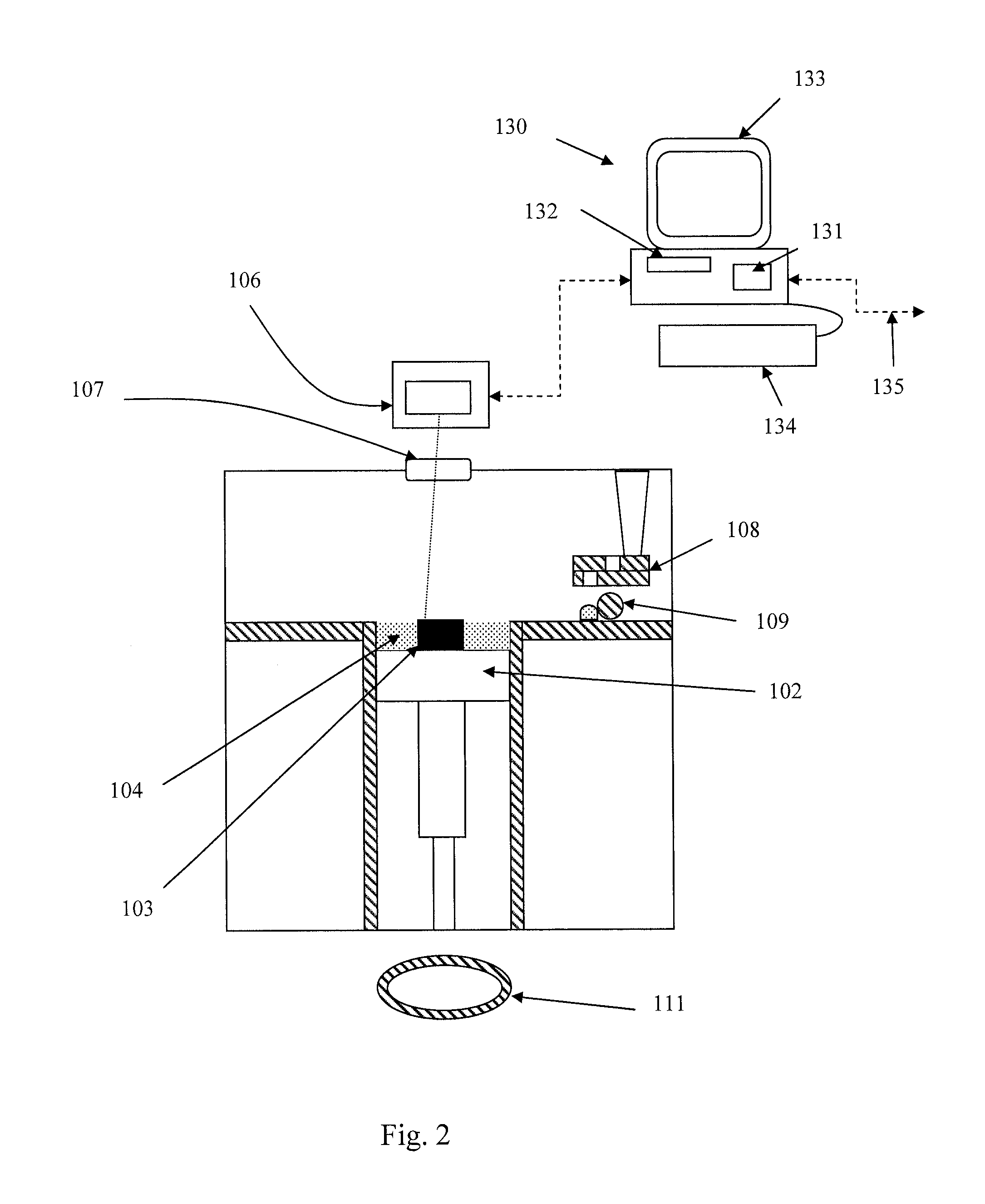

Selective laser solidification apparatus and method

ActiveUS20140271965A1Uniform heightAdditive manufacturing apparatusAuxillary shaping apparatusLaser scanningLaser beams

A selective laser solidification apparatus including: a powder bed onto which a powder layer can be deposited, a gas flow unit for passing a flow of gas over the powder bed along a gas flow direction, a laser scanning unit for scanning a laser beam over the powder layer to selectively solidify at least part of the powder layer to form at least one object and a processing unit for selecting a scanning sequence of the laser beam based on the gas flow direction.

Owner:RENISHAW PLC

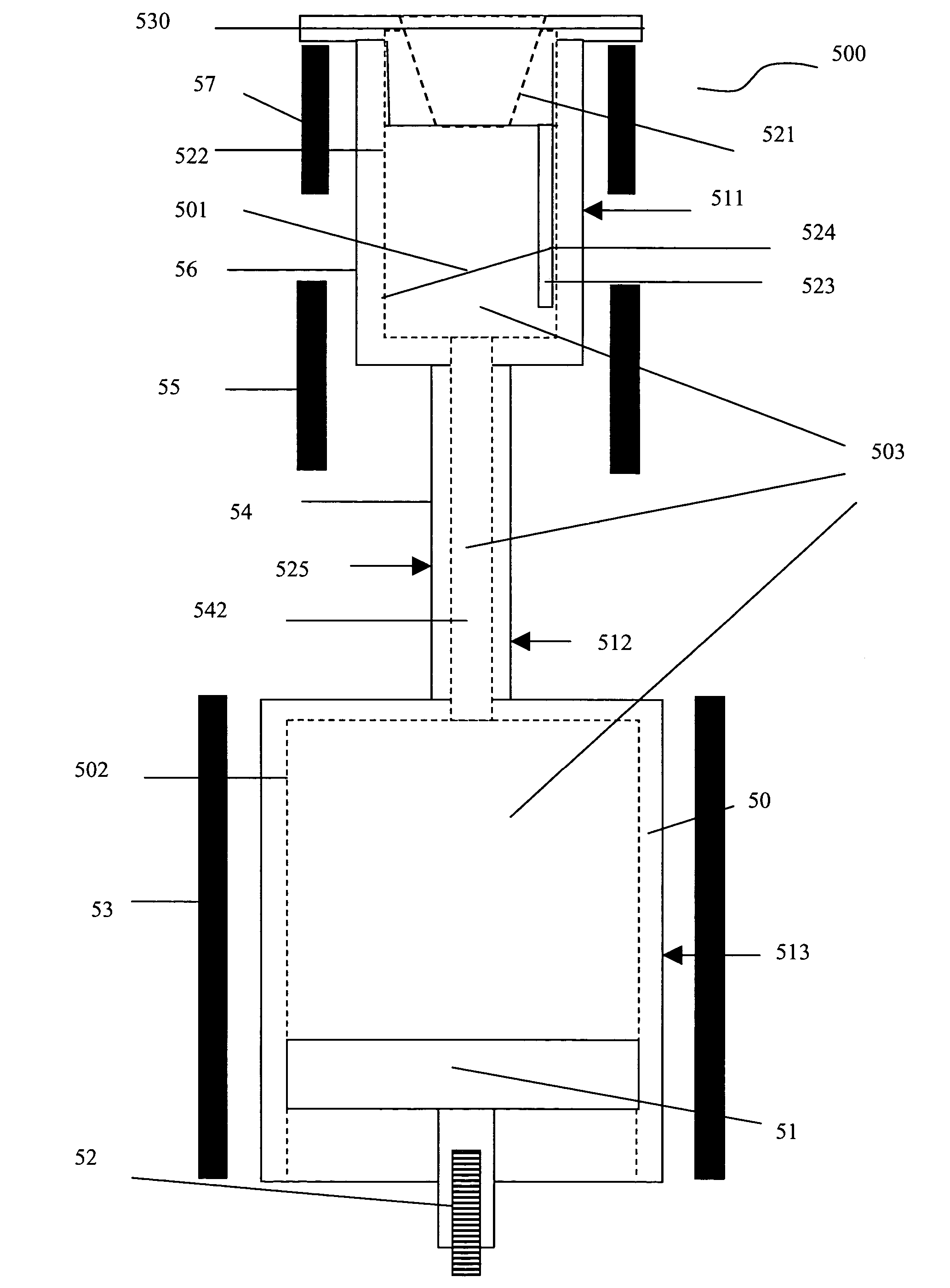

Means and method for a liquid metal evaporation source with integral level sensor and external reservoir

InactiveUS20050229856A1Long operating timeReduce hydrostatic pressureVacuum evaporation coatingSputtering coatingEvaporation (deposition)Engineering

A liquid metal evaporation source for use in Molecular Beam Epitaxy and related metal vacuum deposition techniques. An evaporator is maintained at a high temperature to evaporate a liquid metal, a reservoir for holding the liquid metal source is maintained at a temperature above the melting point of the metal but below the temperature in the evaporator, and a hollow transport tube connecting the evaporator and reservoir is maintained at a temperature between these temperatures. The reservoir is in the shape of a hollow cylinder with a close-fitting cylindrical piston which is used to force the liquid metal through the hollow transport tube into the evaporator. The liquid metal will not flow past the piston seal if a suitably small gap is formed between the piston and the reservoir walls wherein the surface tension of the liquid metal will exceed its hydrostatic pressure against the piston thus forming a leak-tight seal.

Owner:RJM SEMICON

Air freshener and combination container and lid

InactiveUS20070051826A1Not pronePrevent spillageTobacco devicesGaseous substancesConductive materialsAir purifier

An air freshener and combination container and lid for forming an air freshener. The air freshener includes a scented wax solid, a container, a lid, and an attachment for attaching the container to a surface. The container is manufactured of a thermally conductive material and has a bottom and at least one sidewall defining an interior, an exterior, and an open top. The interior of the container is dimensioned such that scented wax solid fits within the interior. The lid is removably attached to the open top of the container and includes a seal and a plurality of vent openings disposed therethrough. The air freshener prevents liquid wax from escaping through the vent openings when the container is moved in a direction parallel to the bottom of the container.

Owner:SCHOFIELD JOSHUA

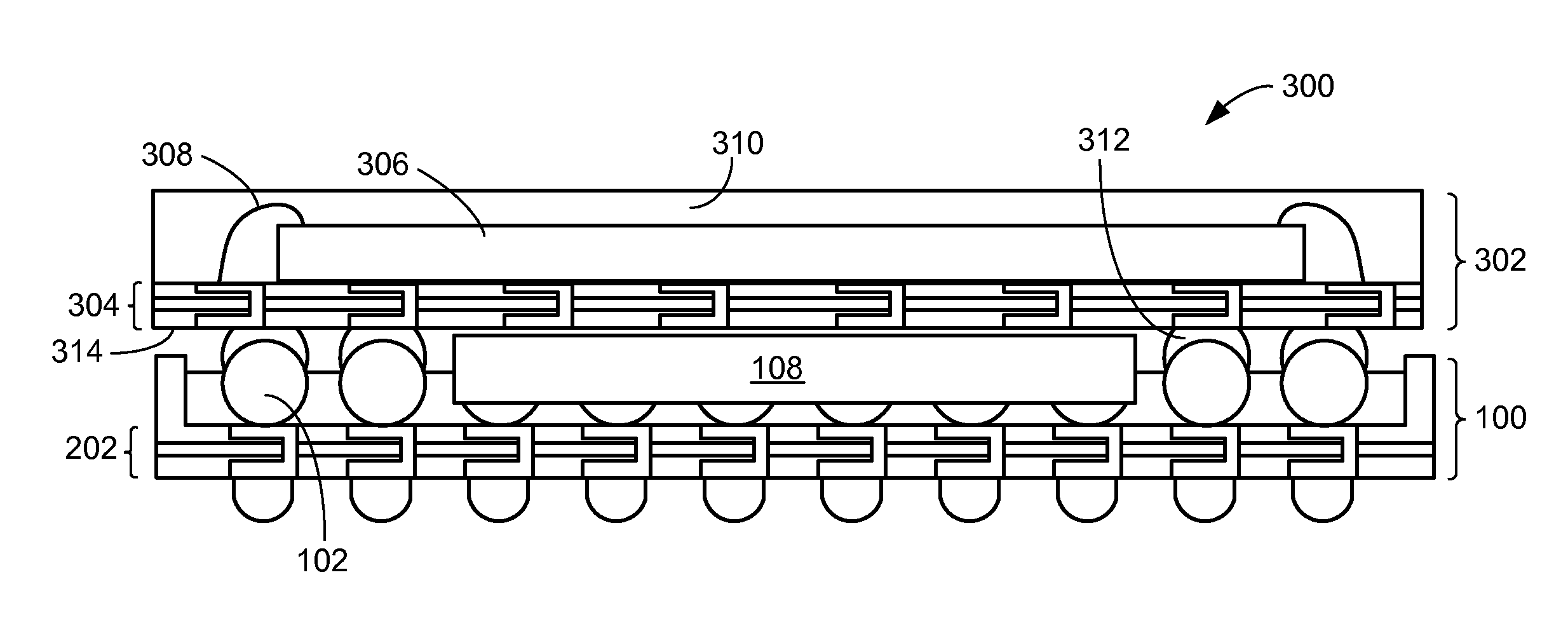

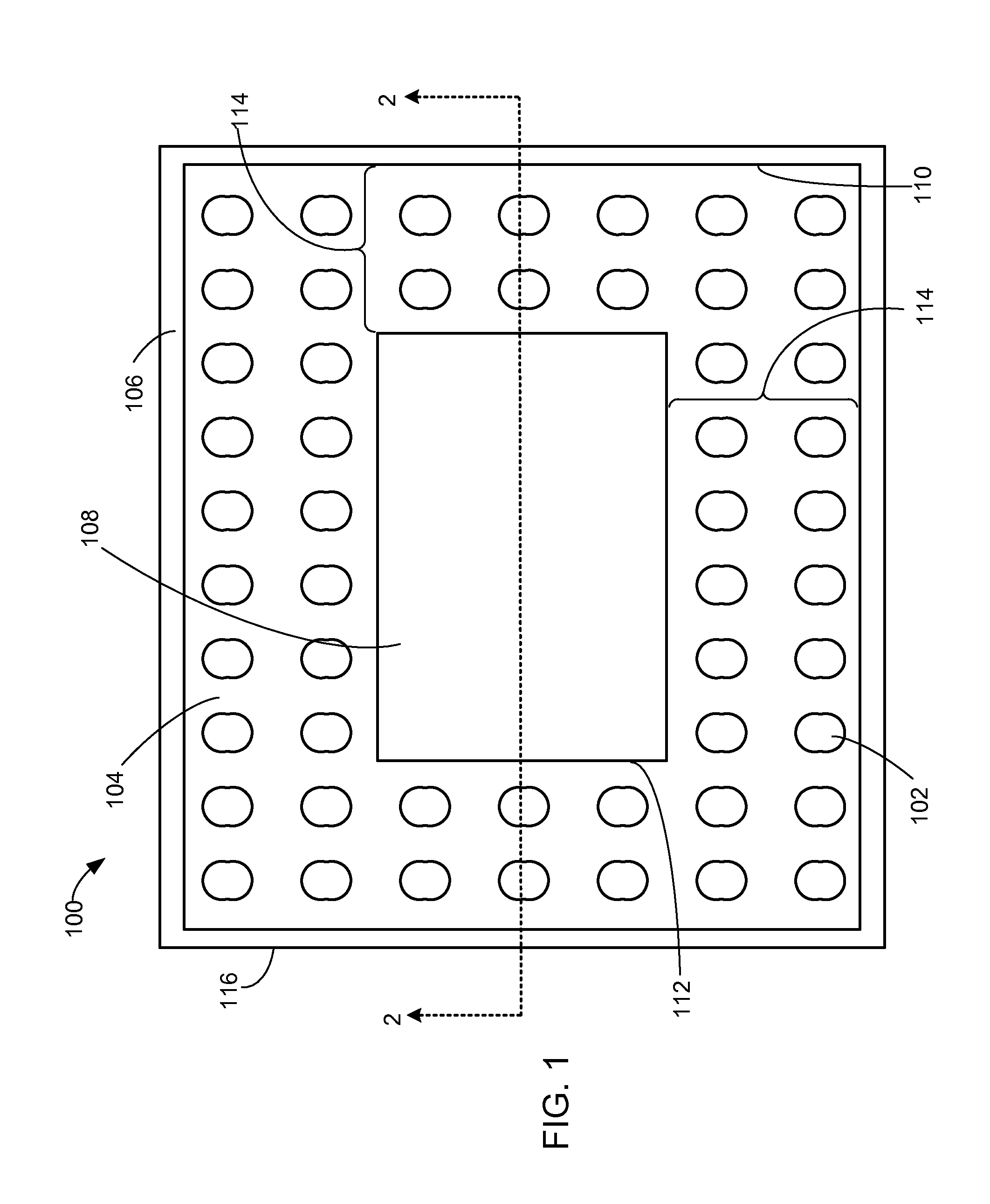

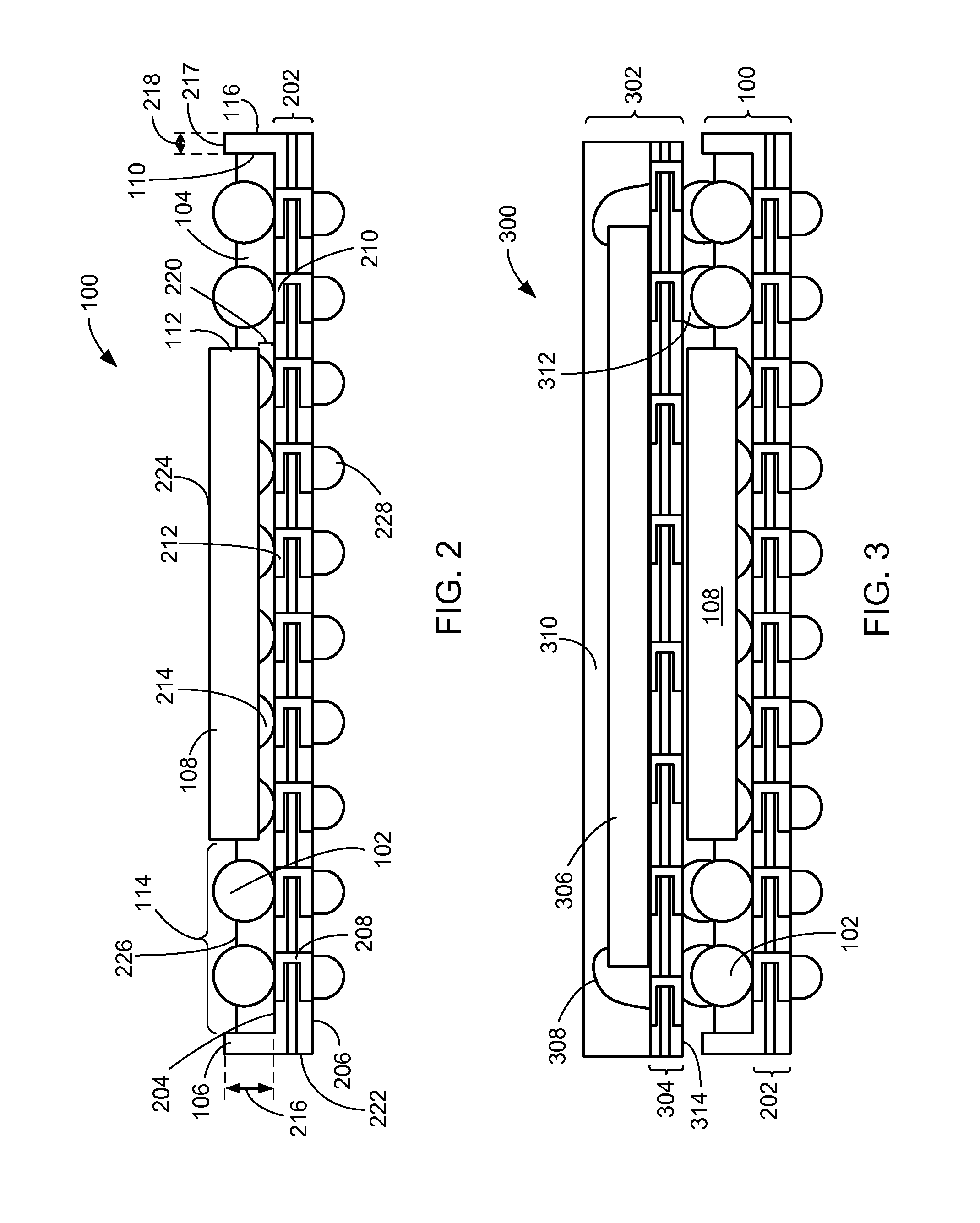

Integrated circuit packaging system with underfill and method of manufacture thereof

ActiveUS20120319300A1Uniform heightSemiconductor/solid-state device detailsSolid-state devicesEngineeringIntegrated circuit packaging

A method of manufacture of an integrated circuit packaging system includes: providing a substrate with a projection formed along a perimeter of a first surface of the substrate; mounting an integrated circuit over the first surface; forming a protruding interconnect over the first surface between the projection and the integrated circuit; and forming an underfill between the integrated circuit and the projection with a uniform height, the uniform height of the underfill less than a height of the projection.

Owner:STATS CHIPPAC LTD

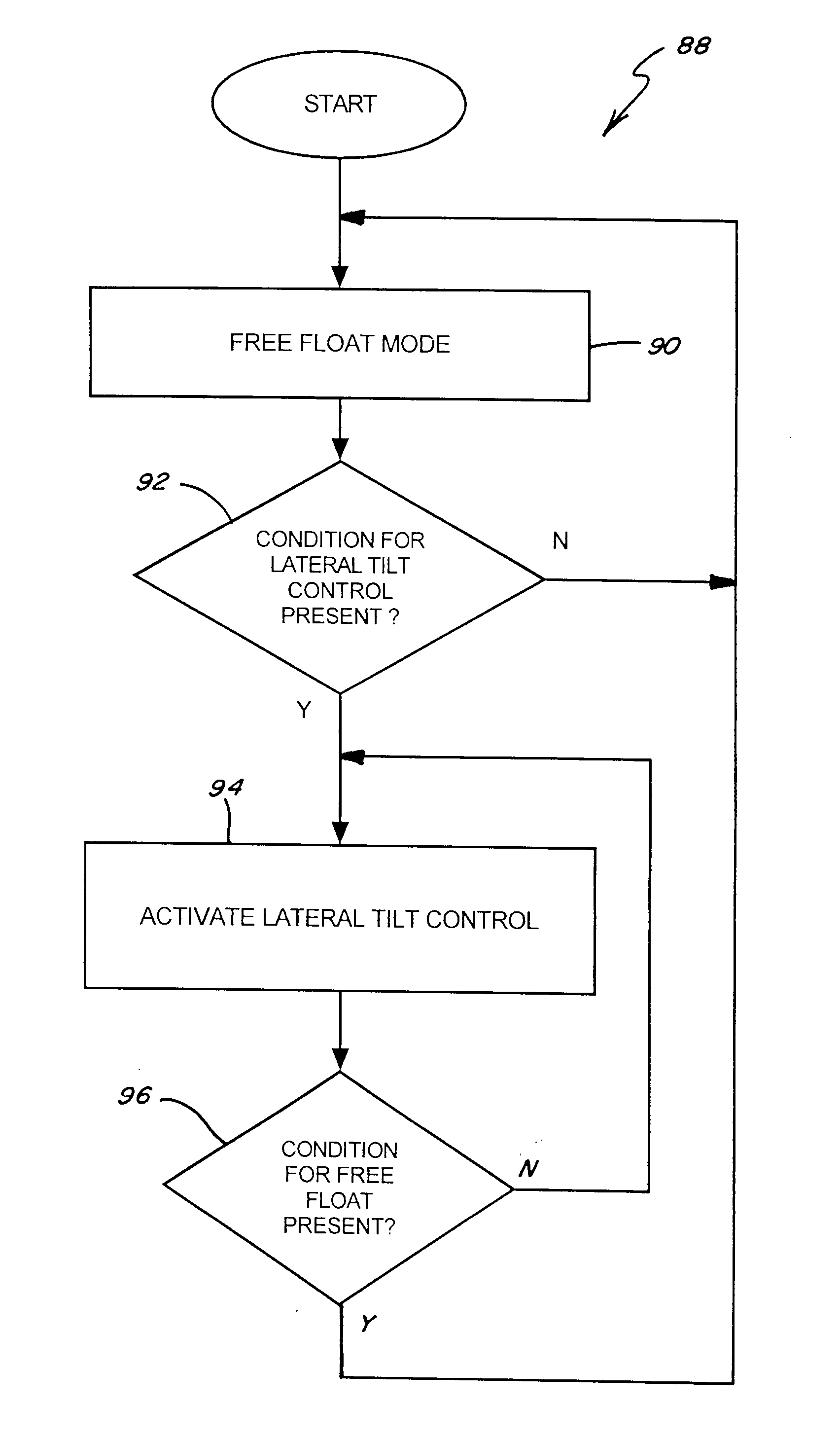

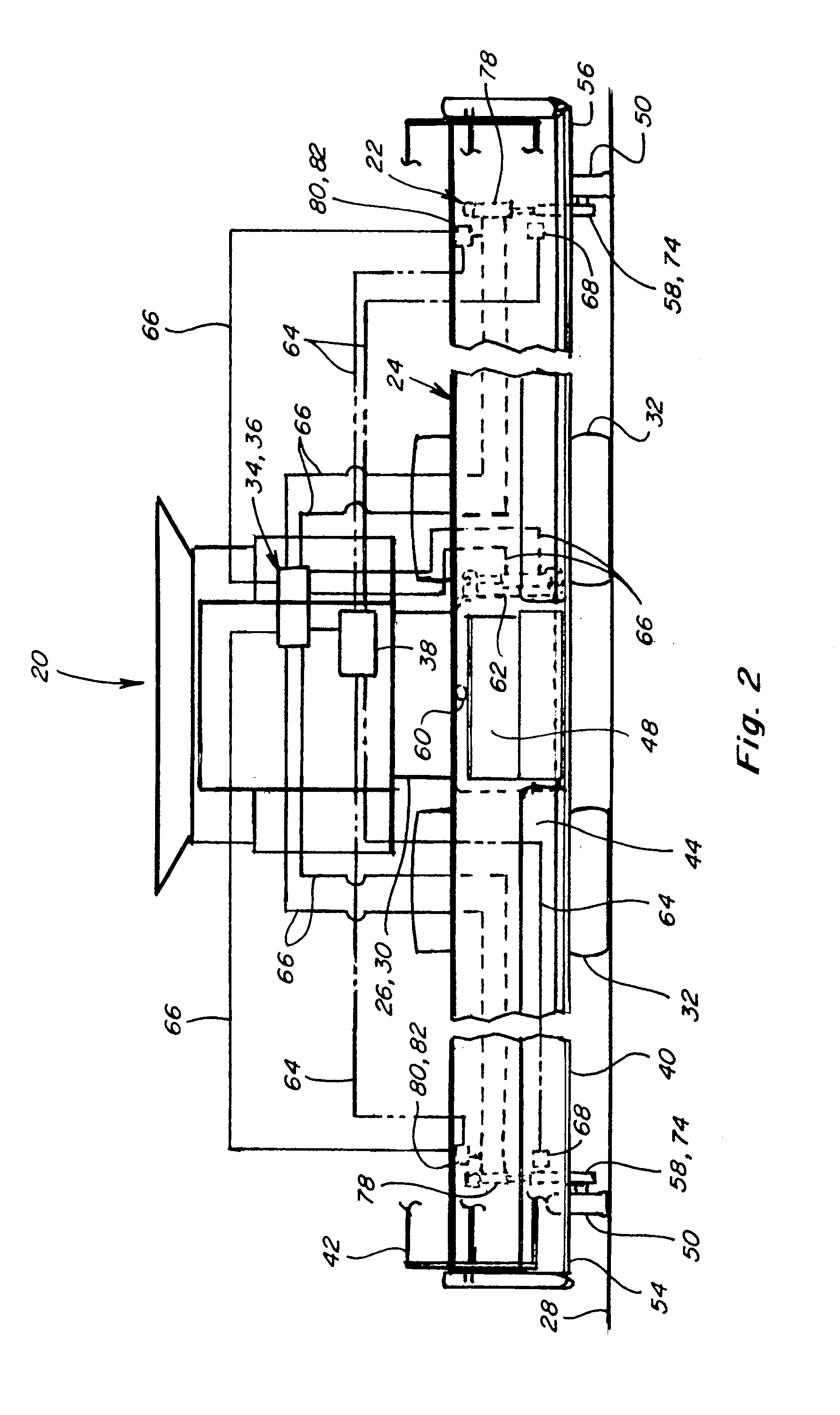

Header lateral tilt control with automatic operation in free float and controlled tilt modes

ActiveUS20150033692A1Improve uniformityReduce signal noiseMowersPicking devicesEngineeringSlide plate

A method and system for controlling lateral tilt of a header of an agricultural machine, uses gauge wheels or skids on lateral ends of the header in combination with operation in a free float mode for maintaining uniform cut height across the header, and automatically changes to a controlled tilt mode when one or more conditions for that mode is present. During operation in the controlled tilt mode, if a condition or conditions for free float is present, the system will operate in that mode. The system can also optionally damp relative up and down movements of the gauge wheels or skids and the header on each end, and can limit the tilt in the free float mode.

Owner:BLUE LEAF I P

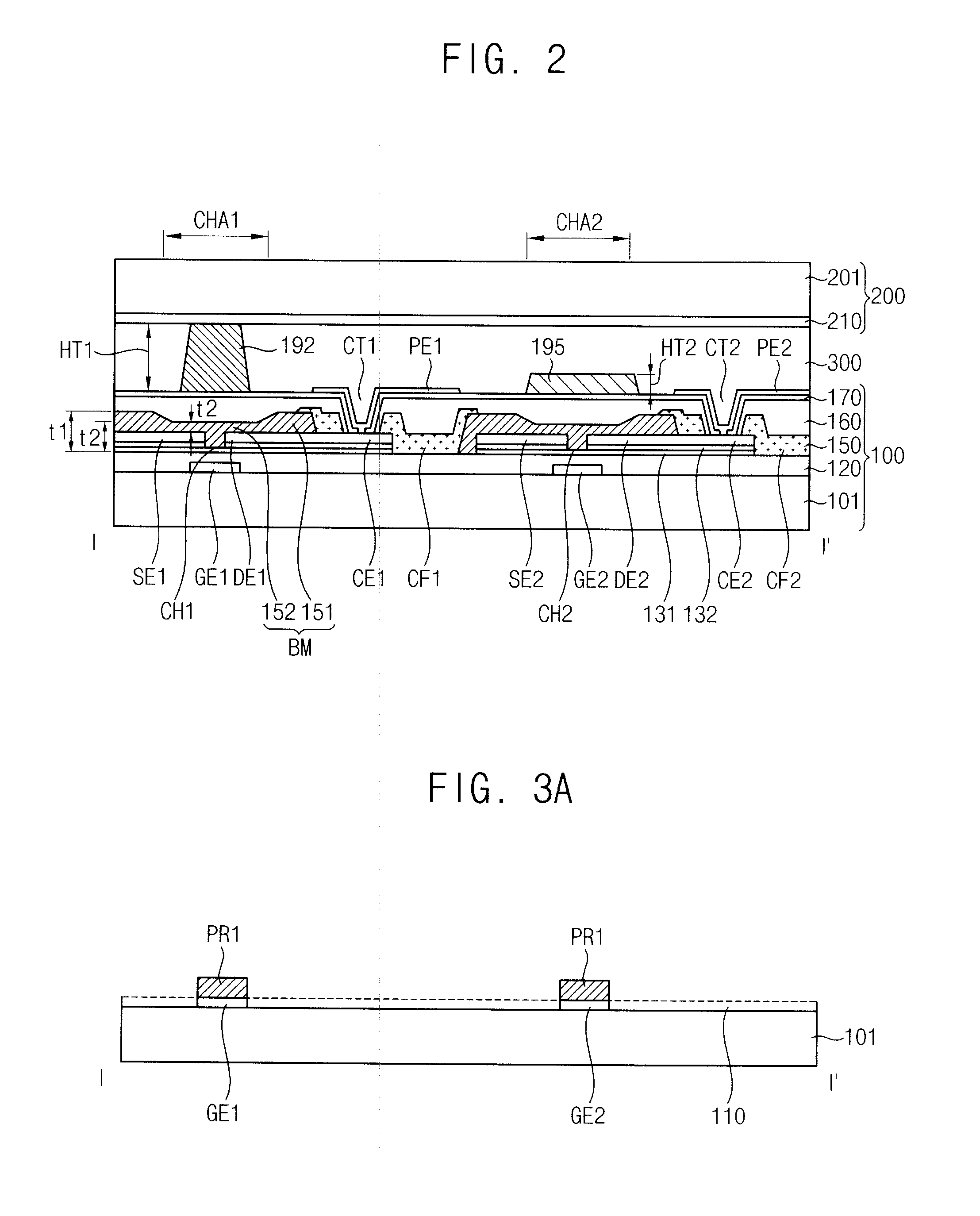

Display substrate and method of manufacturing the same

ActiveUS20110180798A1Enhancing structure characteristicIncrease process marginSemiconductor/solid-state device testing/measurementCarpet cleanersEngineeringBlack matrix

A display substrate includes a transistor, a black matrix and a color spacer. The transistor is connected to a gate line, and a data line crossing the gate line. The black matrix includes a first light-blocking portion covering the gate line and the data line, and a second light-blocking portion covering a channel of the transistor. The second light-blocking portion has a thickness which is smaller than a thickness of the first light-blocking portion. The color spacer is disposed on the second light-blocking portion.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

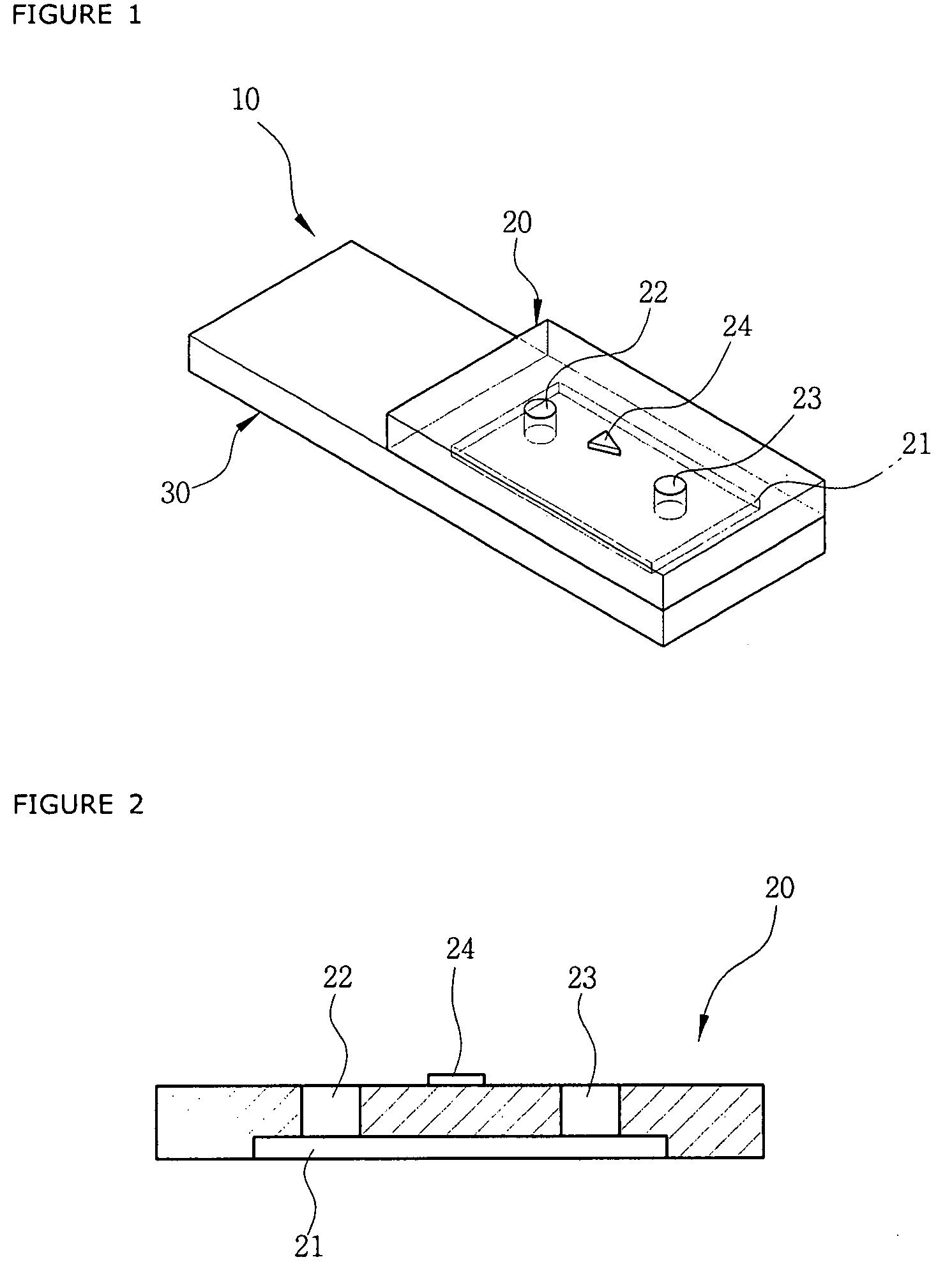

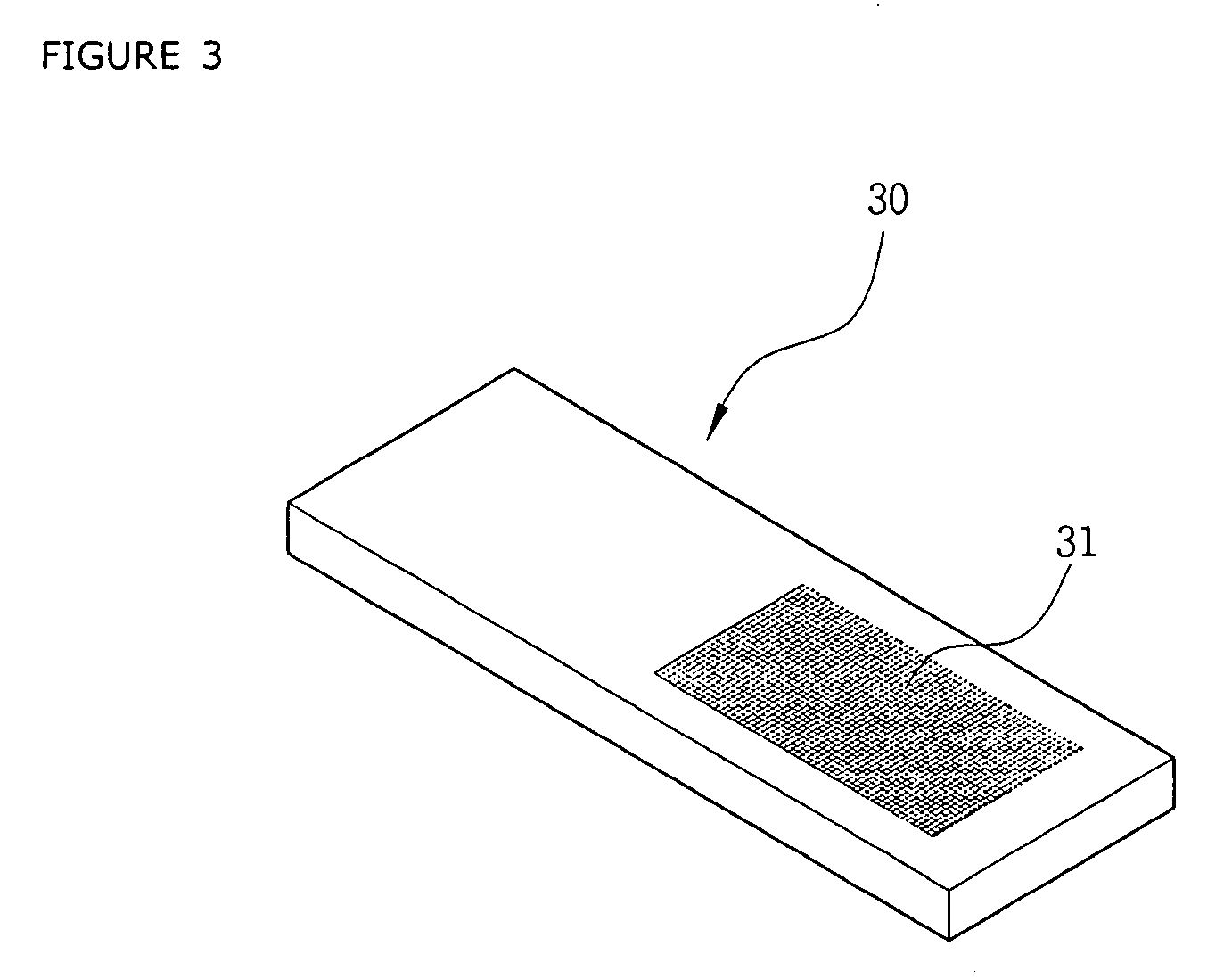

Plastic microchip for microparticle analysis and method for manufacturing the same

InactiveUS20070238164A1Easy to observeUniform heightBioreactor/fermenter combinationsBiological substance pretreatmentsMicroparticleEngineering

Disclosed herein is a plastic microchip used in counting the number of microparticles and a method for manufacturing the same and, more particularly, to a plastic microchip including a negative microgrid pattern formed on a lower substrate, a solvent channel and solvent inlets for a solvent welding process, and a method for manufacturing the plastic microchip by injection molding the lower substrate on which a negative microgrid pattern is formed and by injecting a solvent through the solvent inlets so as to fix an upper substrate to the lower substrate.According to the present invention, it is possible to form a microgrid pattern of a relatively narrow width deeply and uniformly as a negative microgrid pattern is formed on the lower substrate and thereby to provide a clear microgrid pattern, thus facilitating accurate observation of microparticles. Moreover, it is also possible to provide a uniform height of an injection chamber by welding an upper substrate and a lower substrate to each other by a solvent welding process, thus ensuring a more accurate analysis result.

Owner:INCYTO

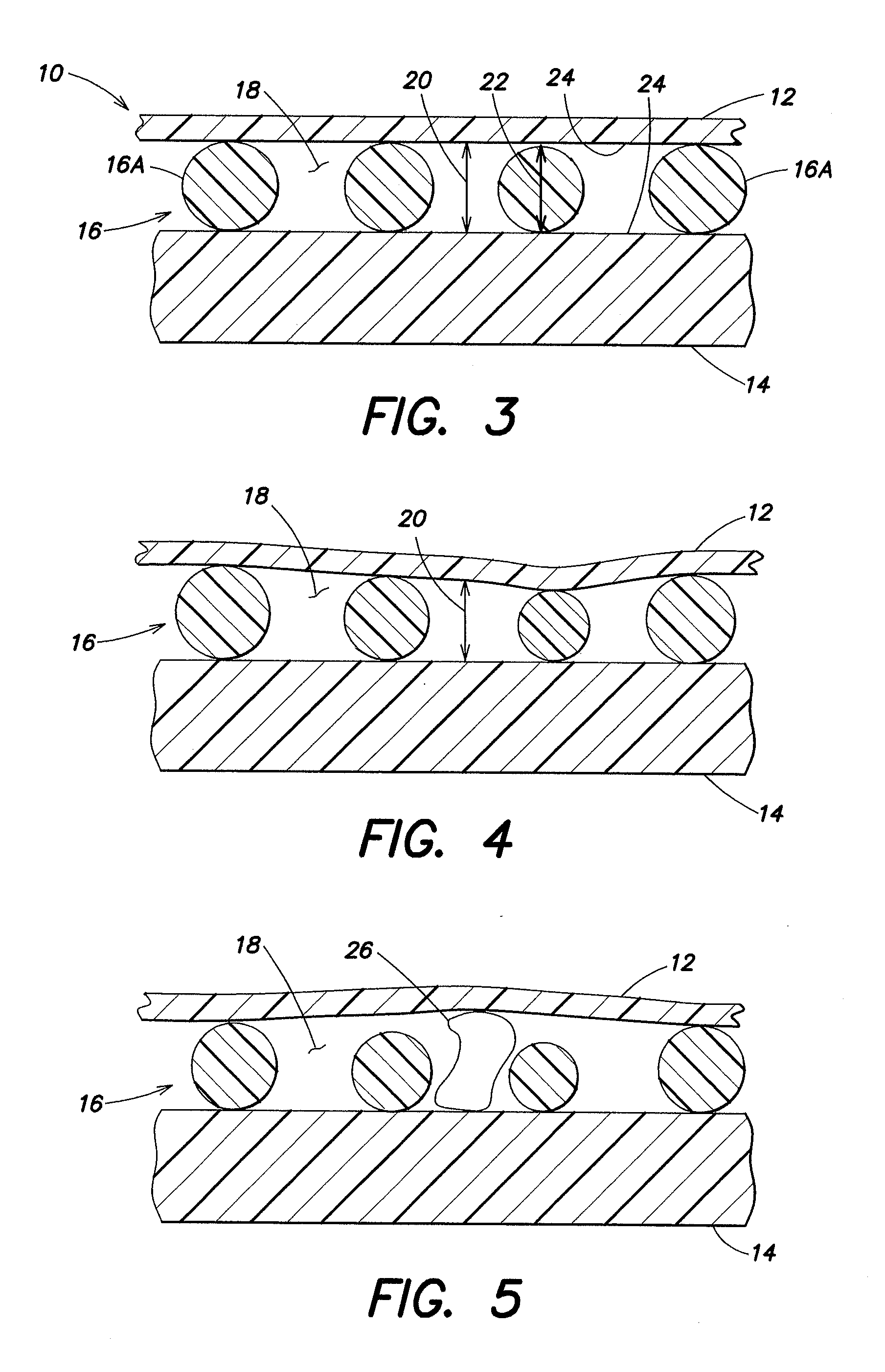

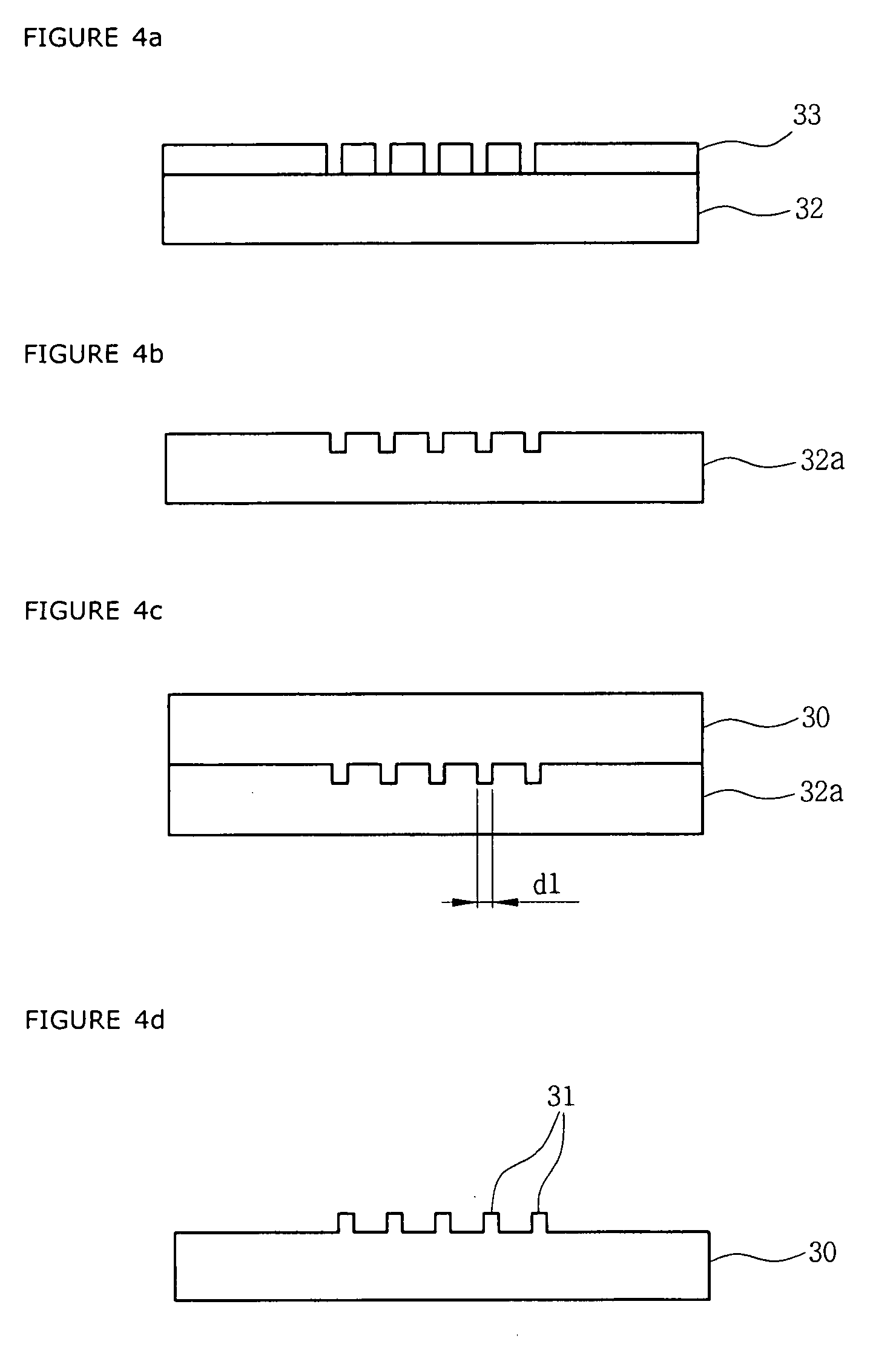

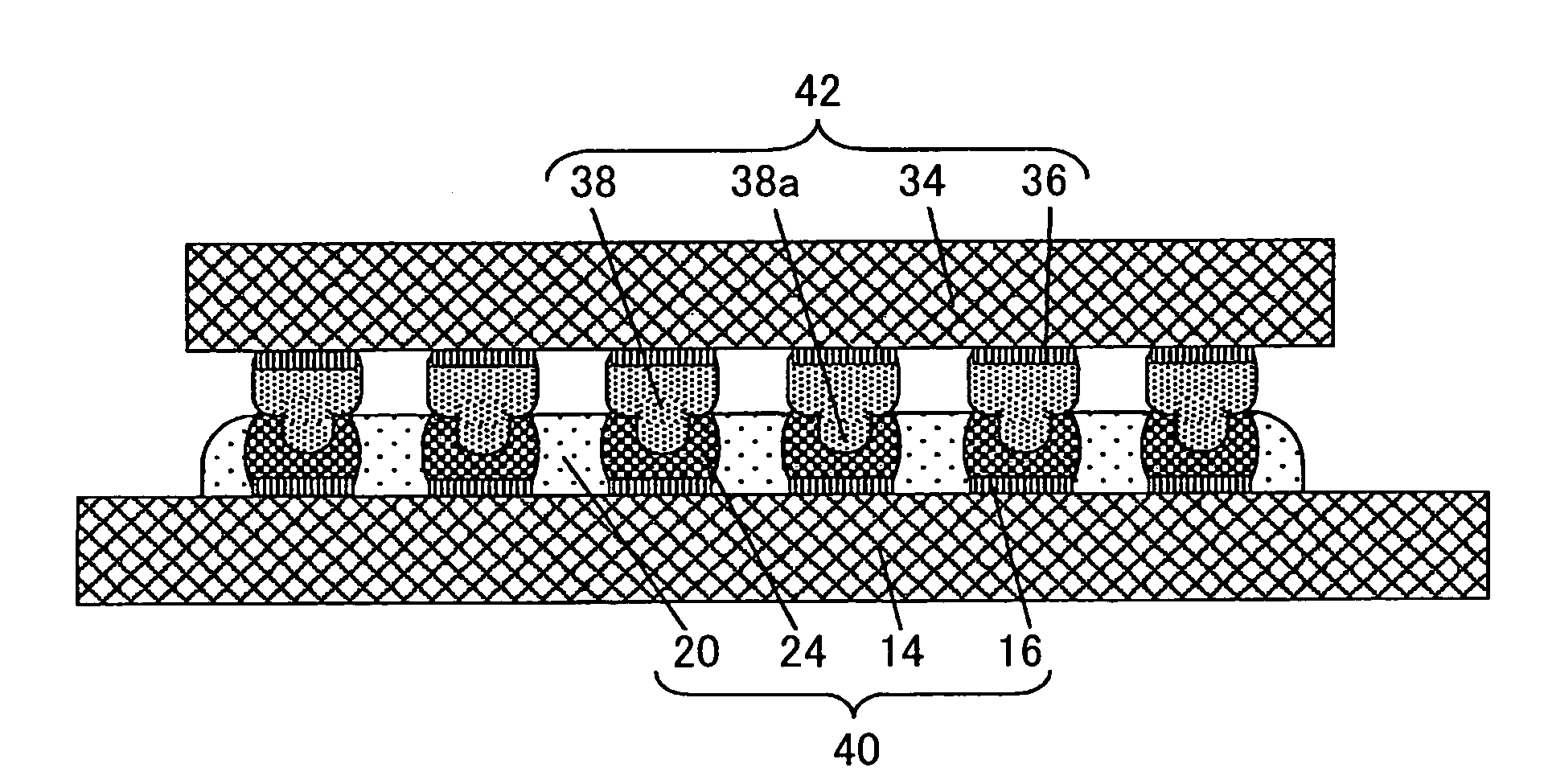

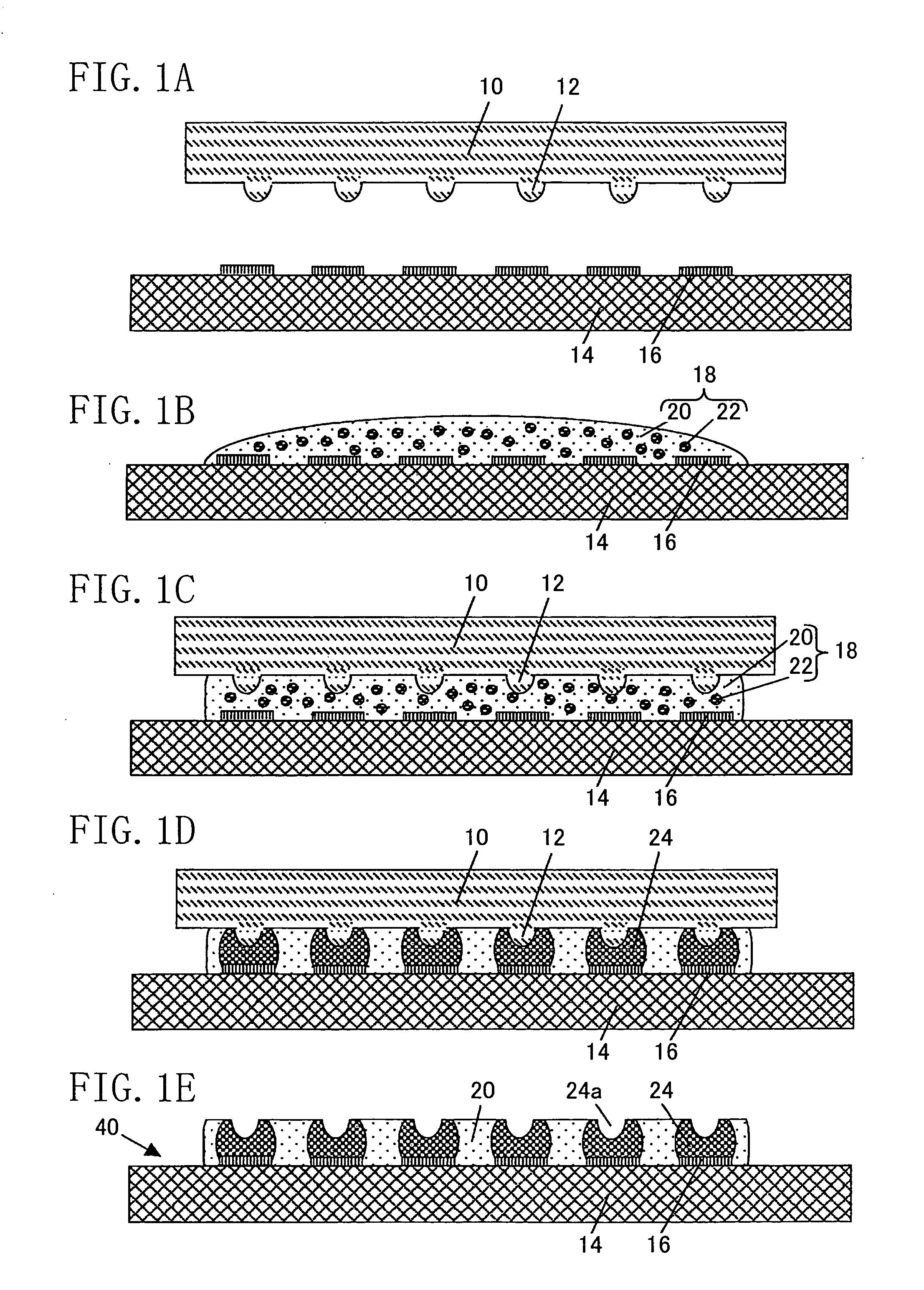

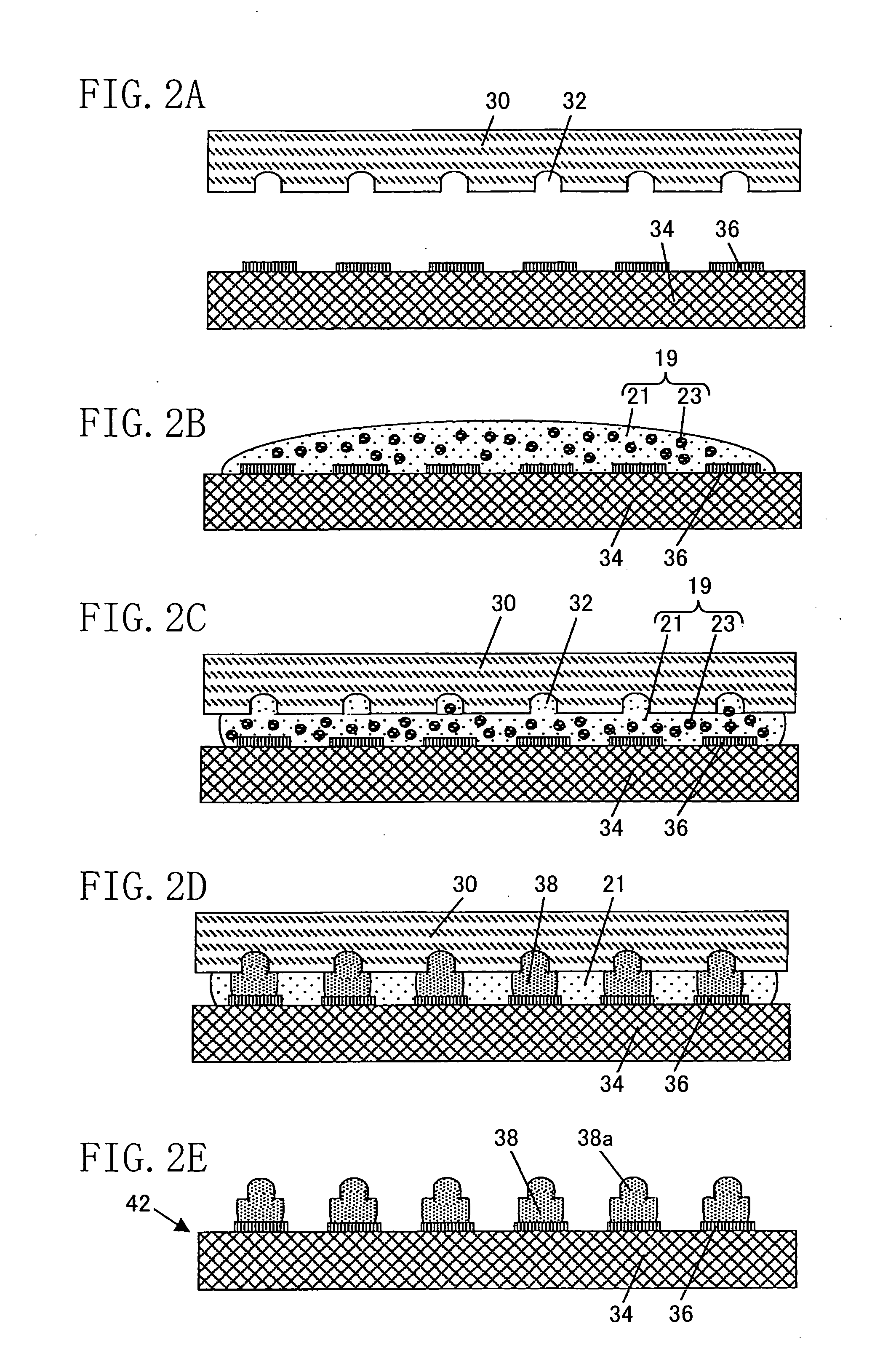

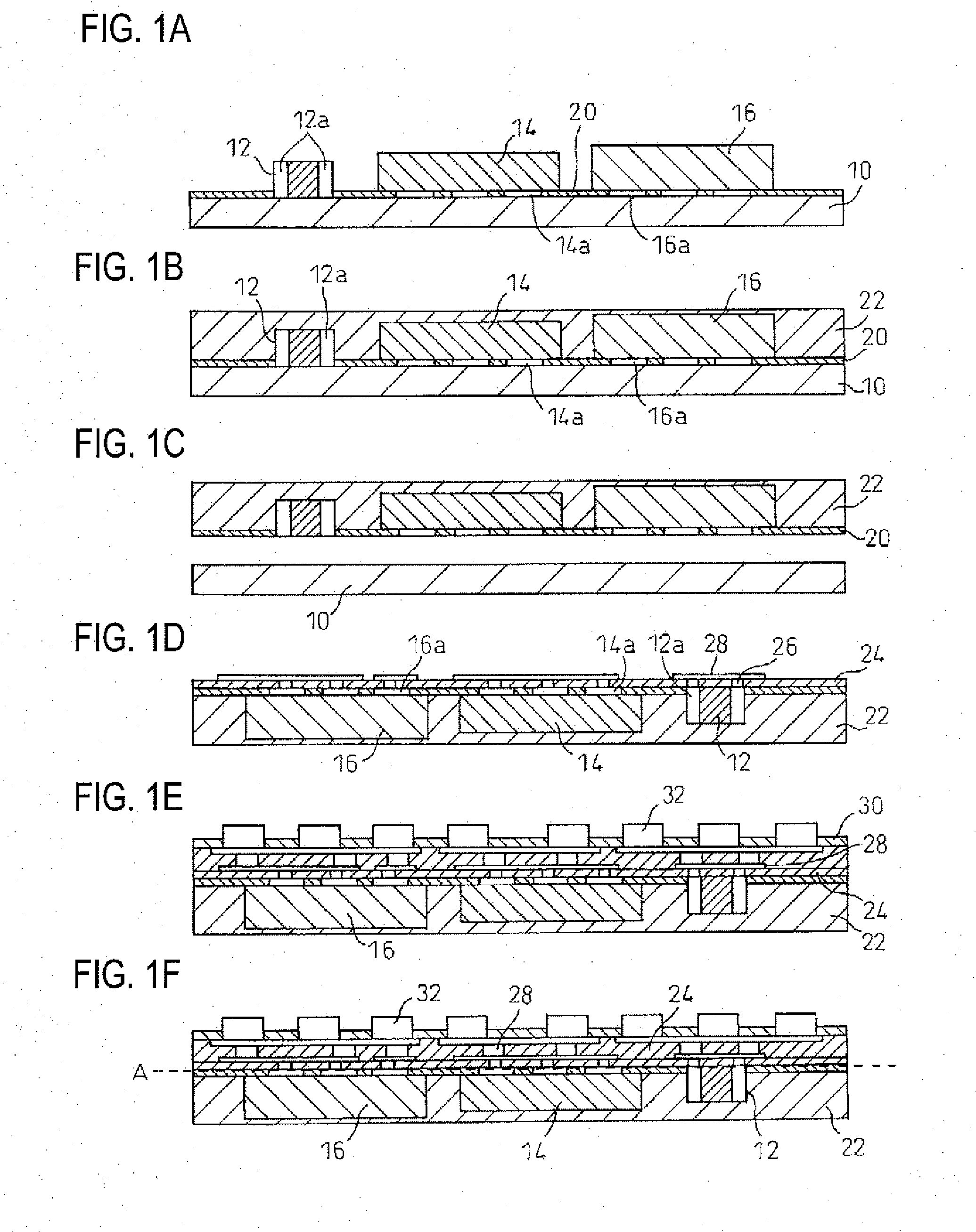

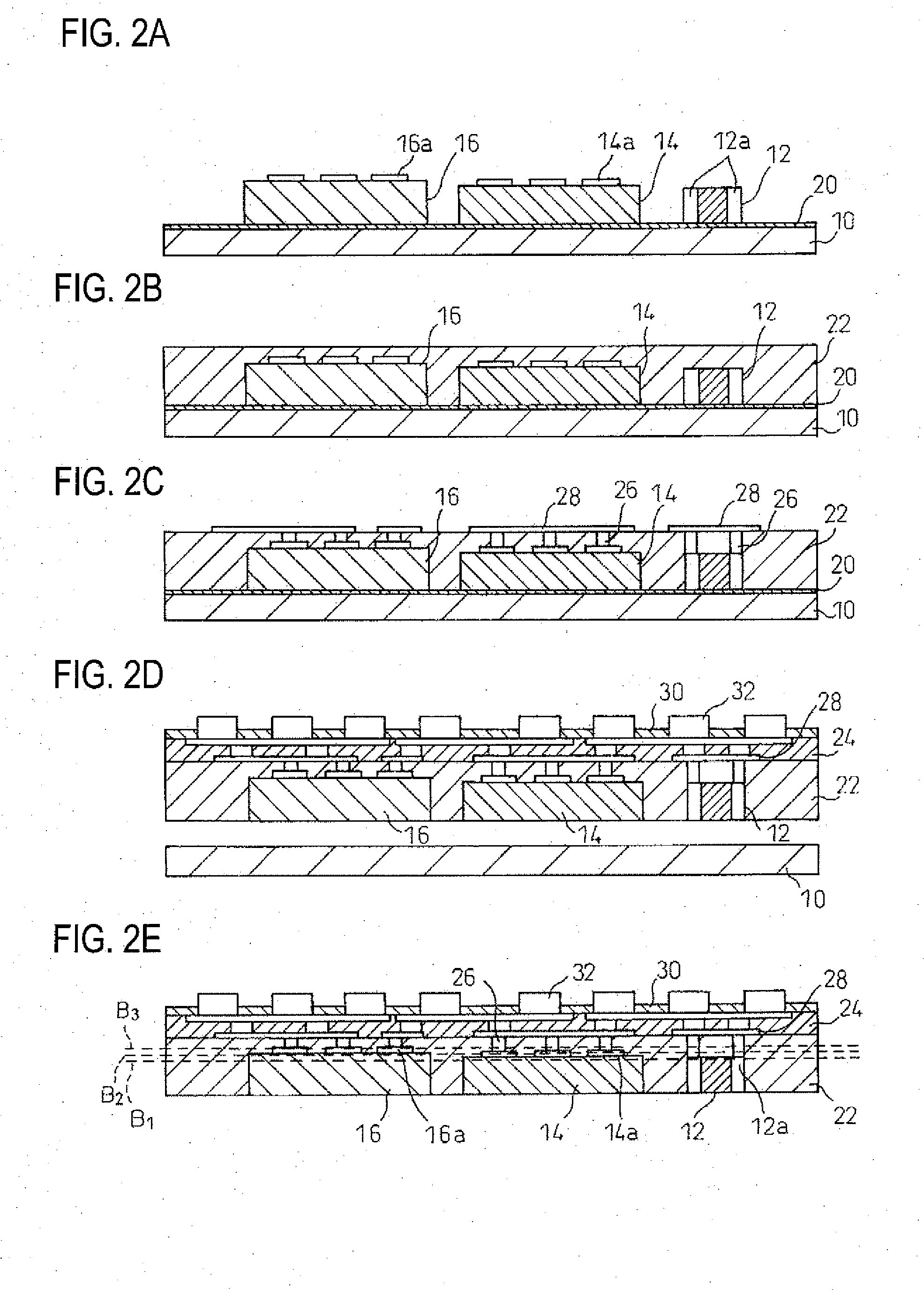

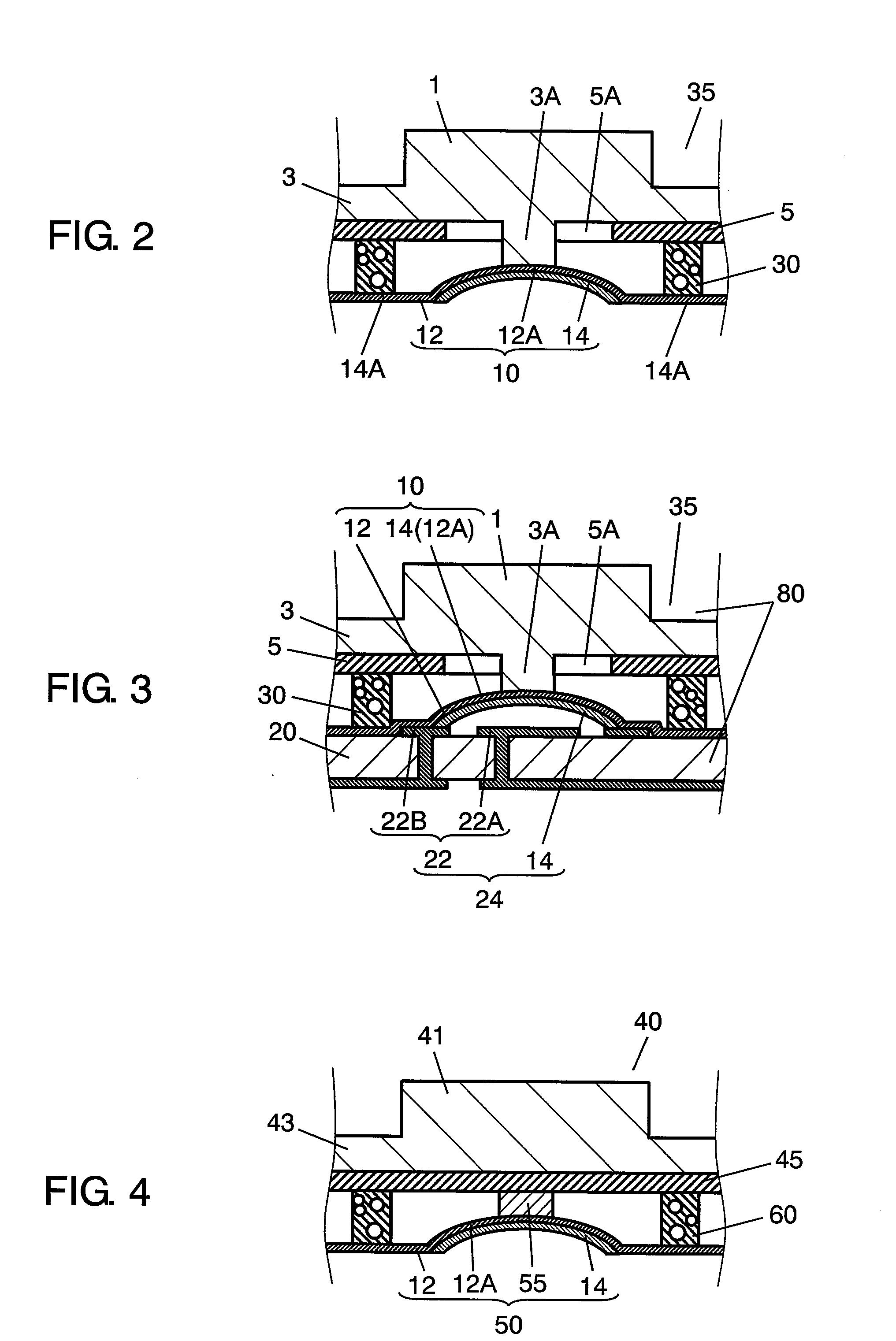

Method for Forming Solder Bump and Method for Mounting Semiconductor Device

ActiveUS20080197173A1Well formedHigh densityFinal product manufactureSemiconductor/solid-state device detailsHigh densityMetallurgy

[Problem] To provide a method for forming solder bumps for realizing high density mounting and a highly reliable method for mounting a semiconductor device.[Means for Solving Problem] A flat plate 10 or 30 having a plurality of projections 12 or recesses 32 thereon is prepared; the flat plate is aligned to oppose an electronic component 14 or 34 and a resin composition 18 or 19 including a solder powder 22 or 23 is supplied to a gap between the flat plate and the electronic component; the resin composition is annealed to melt the solder powder included in the resin composition for growing the solder powder up to the level of the surface of the flat plate by allowing the melted solder powder to self-assemble on terminals 16 or 36, so as to form solder bumps 24 or 38 on the terminals; and the flat plate is removed after cooling and solidifying the solder bumps. Thus, the solder bumps 24 or 38 having pits 24a corresponding to the projections 12 or having projections 38a corresponding to the recesses 32 are formed.

Owner:PANASONIC CORP

Printed circuit board and method of manufacturing printed ciruit board

InactiveUS20070258225A1Improve connection characteristicsPrevent smoothnessFinal product manufactureCross-talk/noise/interference reductionCapacitanceEngineering

A chip capacitor 20 is provided in a core substrate 30 of a printed circuit board 10. This makes it possible to shorten a distance between an IC chip 90 and the chip capacitor 20 and to reduce loop inductance. Since the core substrate 30 id constituted by provided a first resin substrate 30a, a second resin substrate 30b and a third resin substrate 30c in a multilayer manner, the core substrate 30 can obtain sufficient strength.

Owner:IBIDEN CO LTD

Brazed Diamond Tools and Methods for Making the Same

InactiveUS20120260582A1Low costEvenly spacedPigmenting treatmentPressurized chemical processBraze alloyThin sheet

Superabrasive tools and methods for the making thereof are disclosed and described. In one aspect, superabrasive particles are chemically bonded to a matrix support material according to a predetermined pattern by a braze alloy. The brazing alloy may be provided as a powder, thin sheet, or sheet of amorphous alloy. A template having a plurality of apertures arranged in a predetermined pattern may be used to place the superabrasive particles on a given substrate or matrix support material.

Owner:KINIK

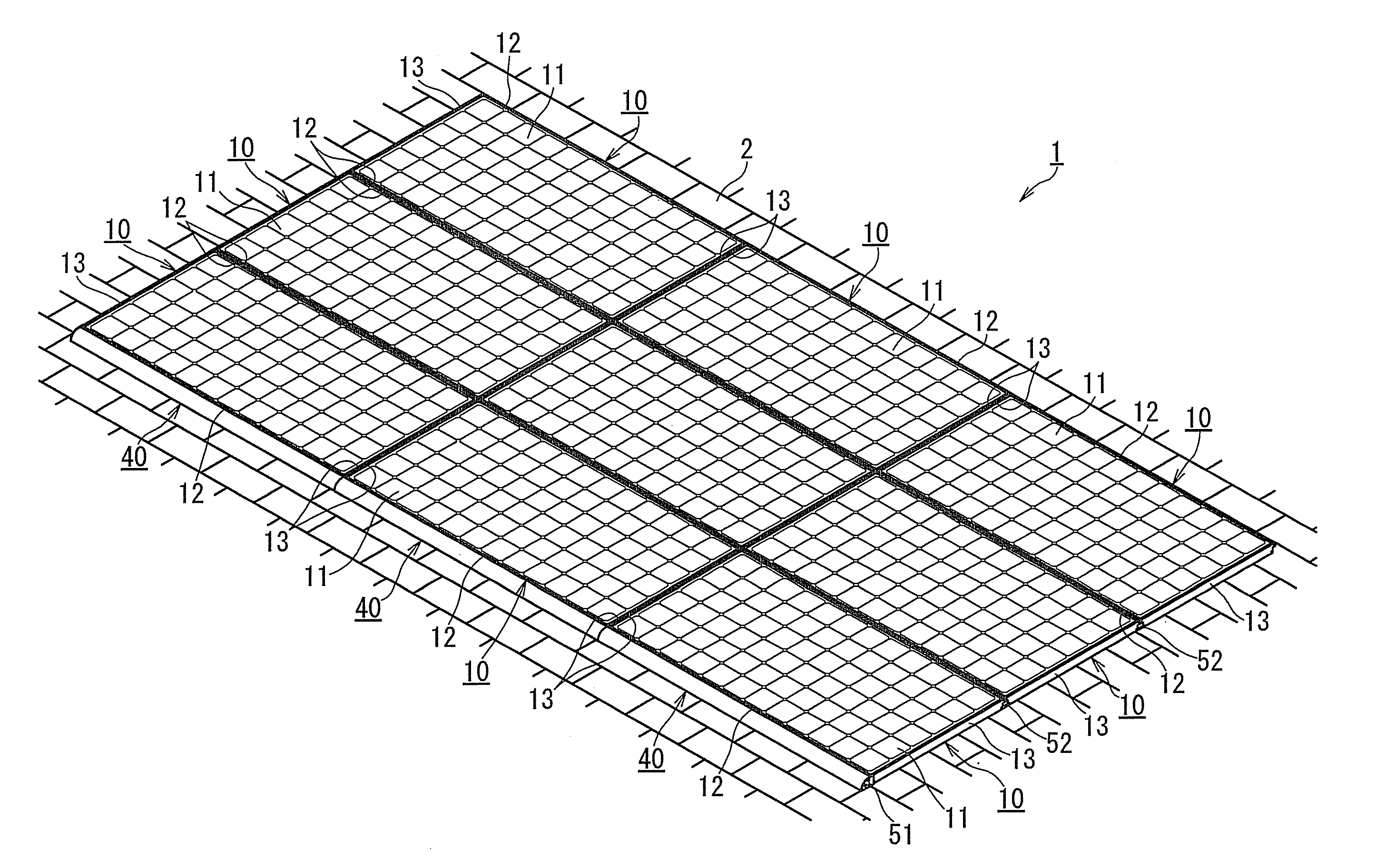

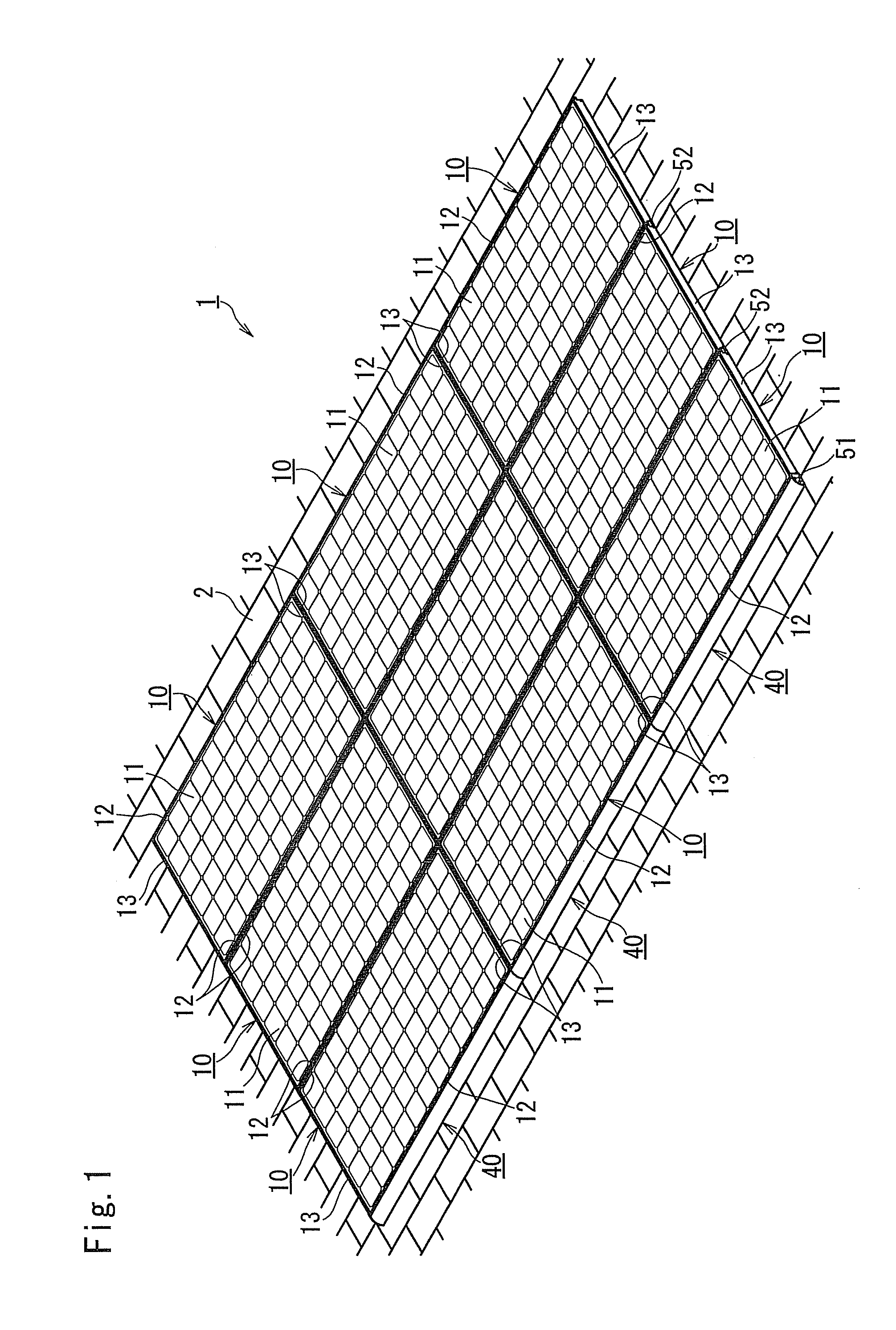

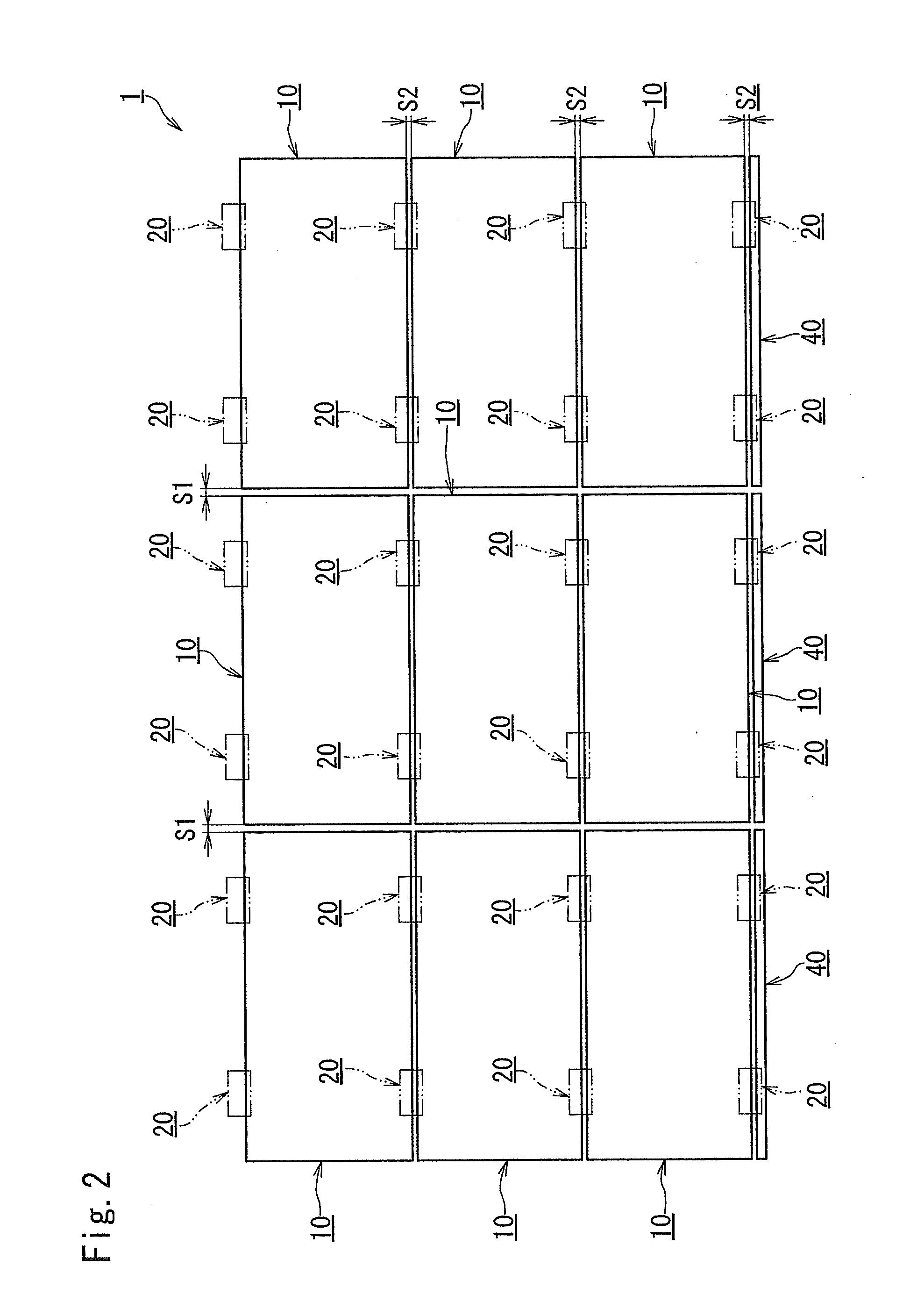

Auxiliary member

ActiveUS20120180406A1Accurate materialsUniform heightPhotovoltaic supportsSolar heating energyEngineeringMechanical engineering

Owner:YANEGIJUTSUKENKYUJO CO LTD

Brazed diamond tools and methods for making the same

InactiveUS20110296766A1Low costEvenly spacedPigmenting treatmentPressurized chemical processBraze alloyThin sheet

Superabrasive tools and methods for the making thereof are disclosed and described. In one aspect, superabrasive particles are chemically bonded to a matrix support material according to a predetermined pattern by a braze alloy. The brazing alloy may be provided as a powder, thin sheet, or sheet of amorphous alloy. A template having a plurality of apertures arranged in a predetermined pattern may be used to place the superabrasive particles on a given substrate or matrix support material.

Owner:CHIEN MIN SUNG +1

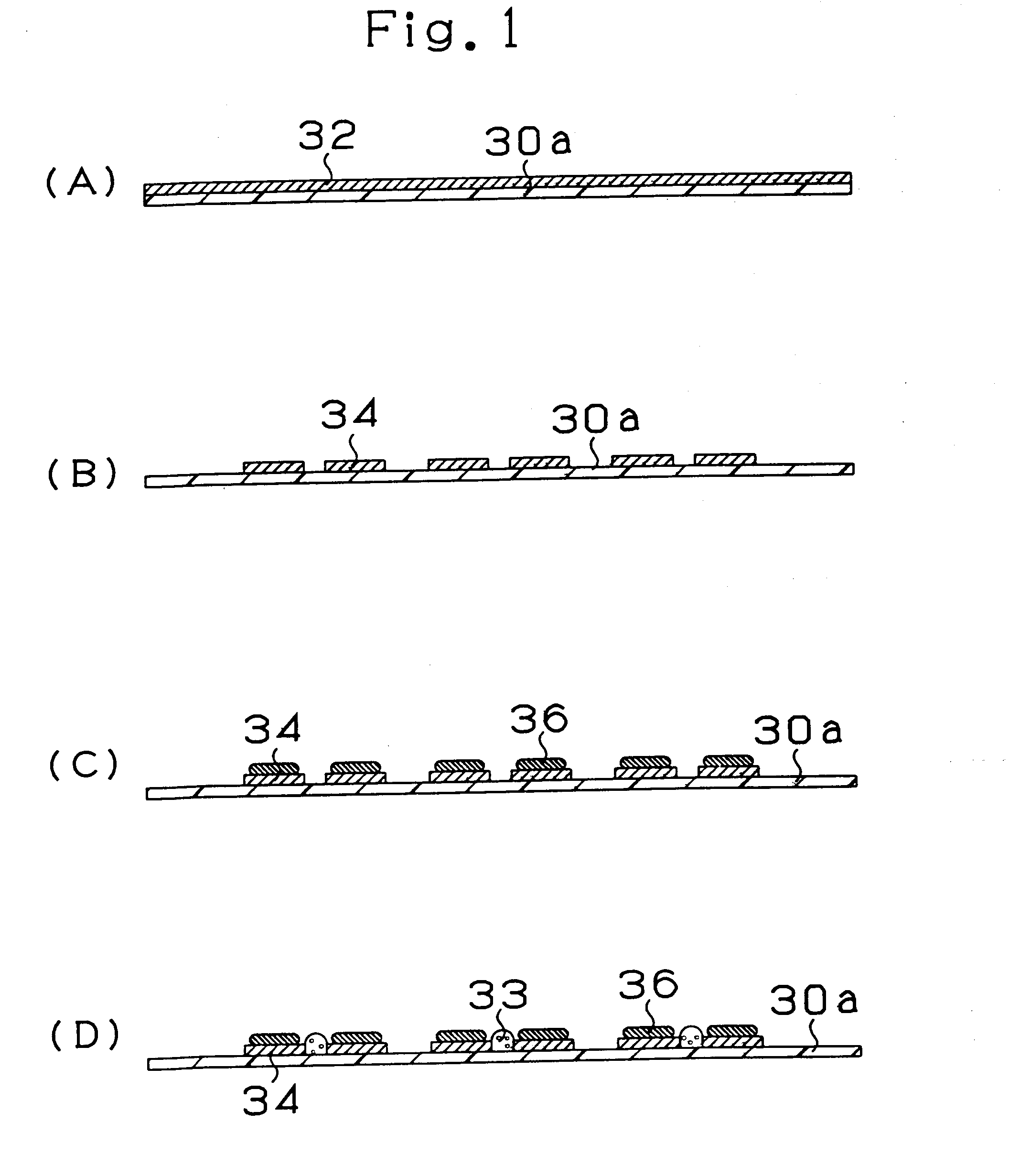

Fine wiring package and method of manufacturing the same

ActiveUS20100155126A1Easy to carryUniform heightPrinted circuit assemblingPrinted electric component incorporationEngineeringElectronic component

At least one electronic component having a plurality of terminals on one of surfaces is temporarily fixed to a surface of a first support with a first adhesive layer in such a manner that the terminal side of the electronic component faces the first support. A second support having a second adhesive layer is fixed to the electronic component in order to interpose the electronic component between the first support and the second support. The first support and the first adhesive layer are peeled. The electronic component on the second support is sealed with a sealing resin in such a manner that at least a part of the terminals of the electronic component is exposed. An insulating resin layer and a wiring layer to be electrically connected to the terminal of the electronic component are stacked on the electronic component and the sealing resin.

Owner:SHINKO ELECTRIC IND CO LTD

Stator for a synchronous machine

InactiveUS6858965B2High slot fill factorUniform heightMagnetic circuit stationary partsEngineeringConductor Coil

Stators for harmonic motors are disclosed. The stators are easy to assemble and include a laminated armature made of sheet metal plates. The laminated armature is formed of a substantially cylindrical laminated star armature with a plurality of radially outwardly oriented pole heads distributed along the circumference of the laminated star armature, and a substantially cylindrical laminated yoke armature having radially inwardly oriented pole teeth and arranged radially outside of and concentrically with the laminated star armature. Each of the pole heads is arranged radially adjacent to a corresponding one of the pole teeth. Windings are applied to the pole teeth before the tooth head sleeve or the laminated star armature are inserted in and joined with th laminated yoke armature.

Owner:SIEMENS AG

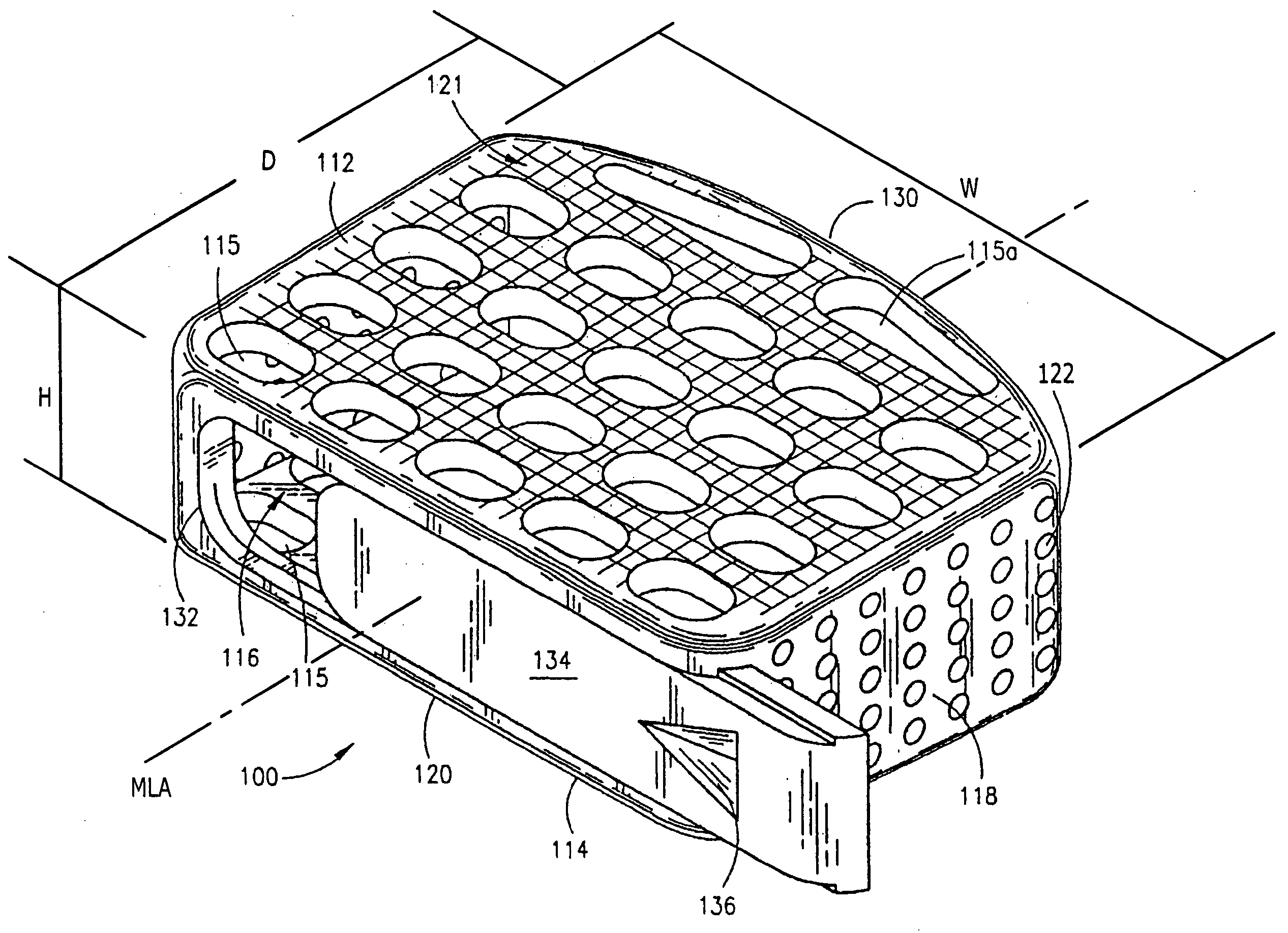

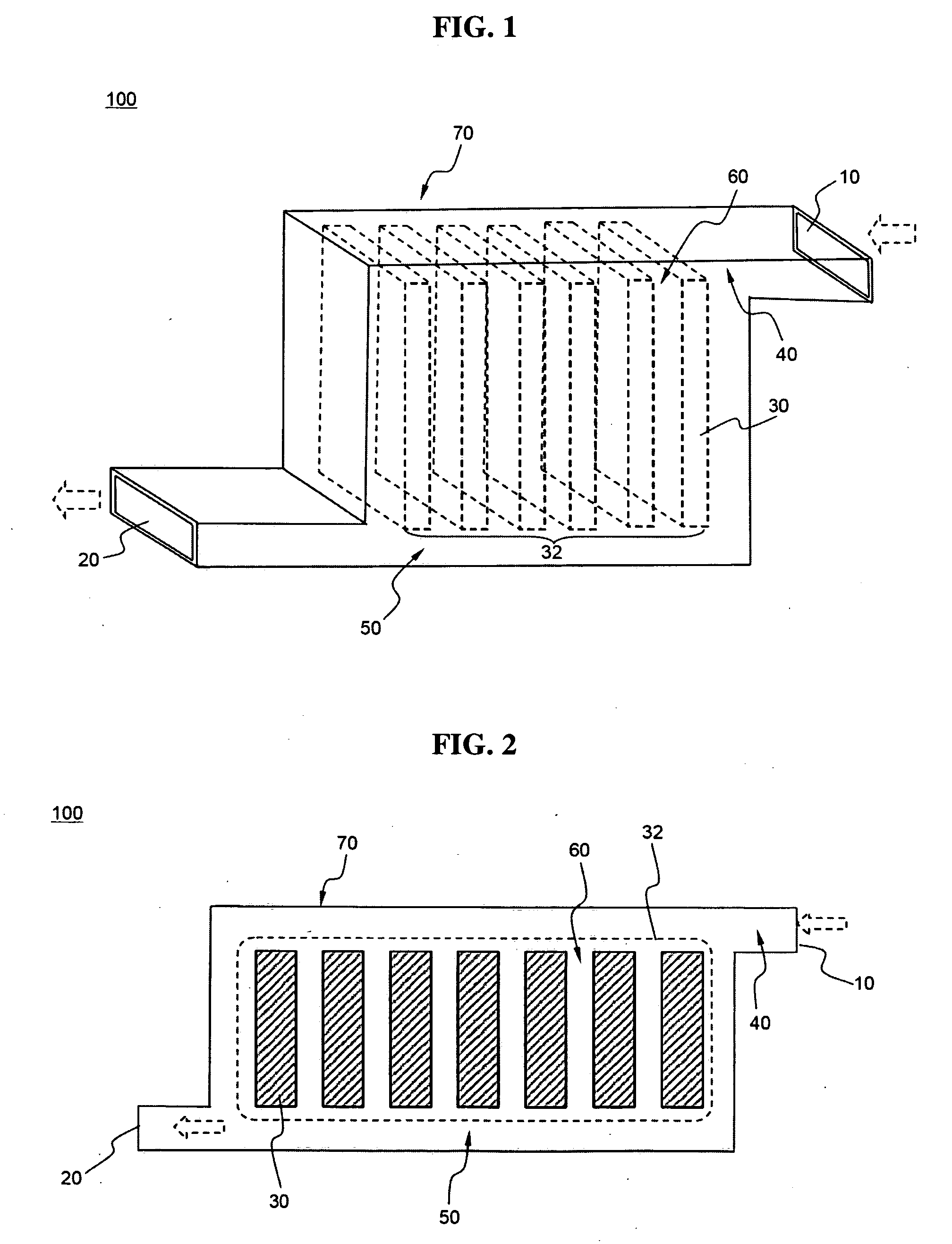

Middle- or large-sized battery pack case providing improved distribution uniformity in coolant flux

ActiveUS20090311586A1Uniform heightImprove coolant discharge efficiencyCell temperature controlCell component detailsEngineeringBattery pack

Disclosed herein is a battery pack case in which a battery module (32) having a plurality of stacked unit cells (30) is mounted. The battery pack case is provided at an upper part and a lower part thereof with a coolant inlet port (10′) and a coolant outlet port (20′), respectively. The coolant inlet port (10′) and the coolant outlet port (20′) are directed in opposite directions. The battery pack case is further provided with a coolant introduction part (40′) and a coolant discharge part. An upper end inside part of the coolant introduction part. (40′) is configured in a structure in which an incline plane starting from an end opposite to the coolant inlet port (10′) has an inclination increasing toward the coolant inlet port (10′) with respect to the top of the cell stack.

Owner:LG ENERGY SOLUTION LTD

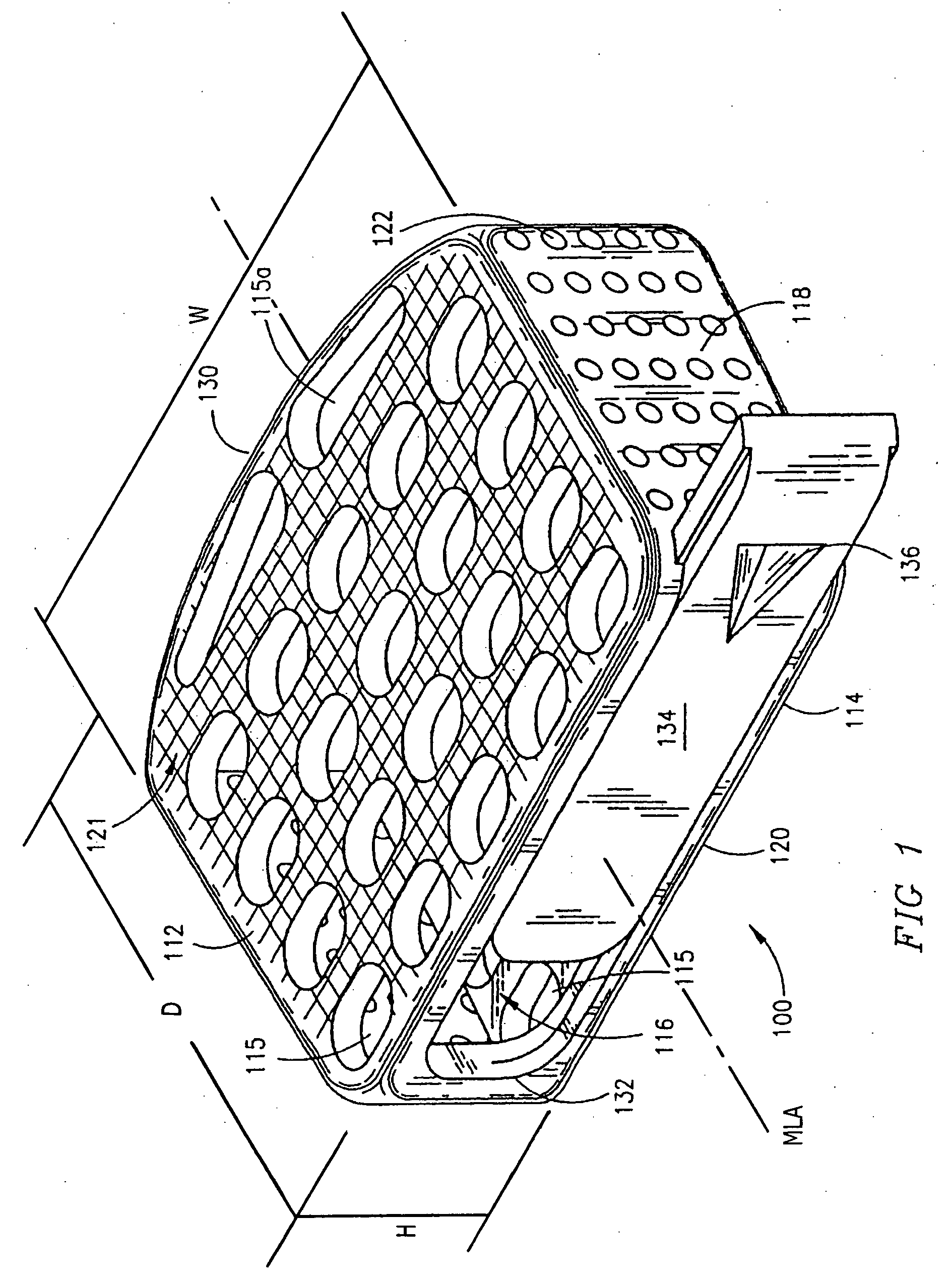

Input device and method of manufacturing module unit for input device

InactiveUS20080309638A1Uniform heightContact mechanismsContact with seperate bridge contactEngineeringElectrical and Electronics engineering

An input device comprises a wiring board having stationary contacts and a module unit placed on the wiring board. The module unit has a structure formed integrally with actuating key portions, movable contacts, cushioning members and protruding portions. The movable contacts are disposed under the actuating key portions, and actuated by a push-on operation of the actuating key portions. The cushioning members are disposed in a space between a lower surface of the actuating key portions and an upper surface of a movable contact retainer bearing the movable contacts to make the space shrinkable when subjected to the push-on operation whereas it maintains an uniform height when not subjected to the push-on operation. The protruding portions depress top center portions of the movable contacts. The input device includes switch elements, each comprising the movable contact and the stationary contact, and the switch element is actuated by the push-on operation on the actuating key portion.

Owner:PANASONIC CORP

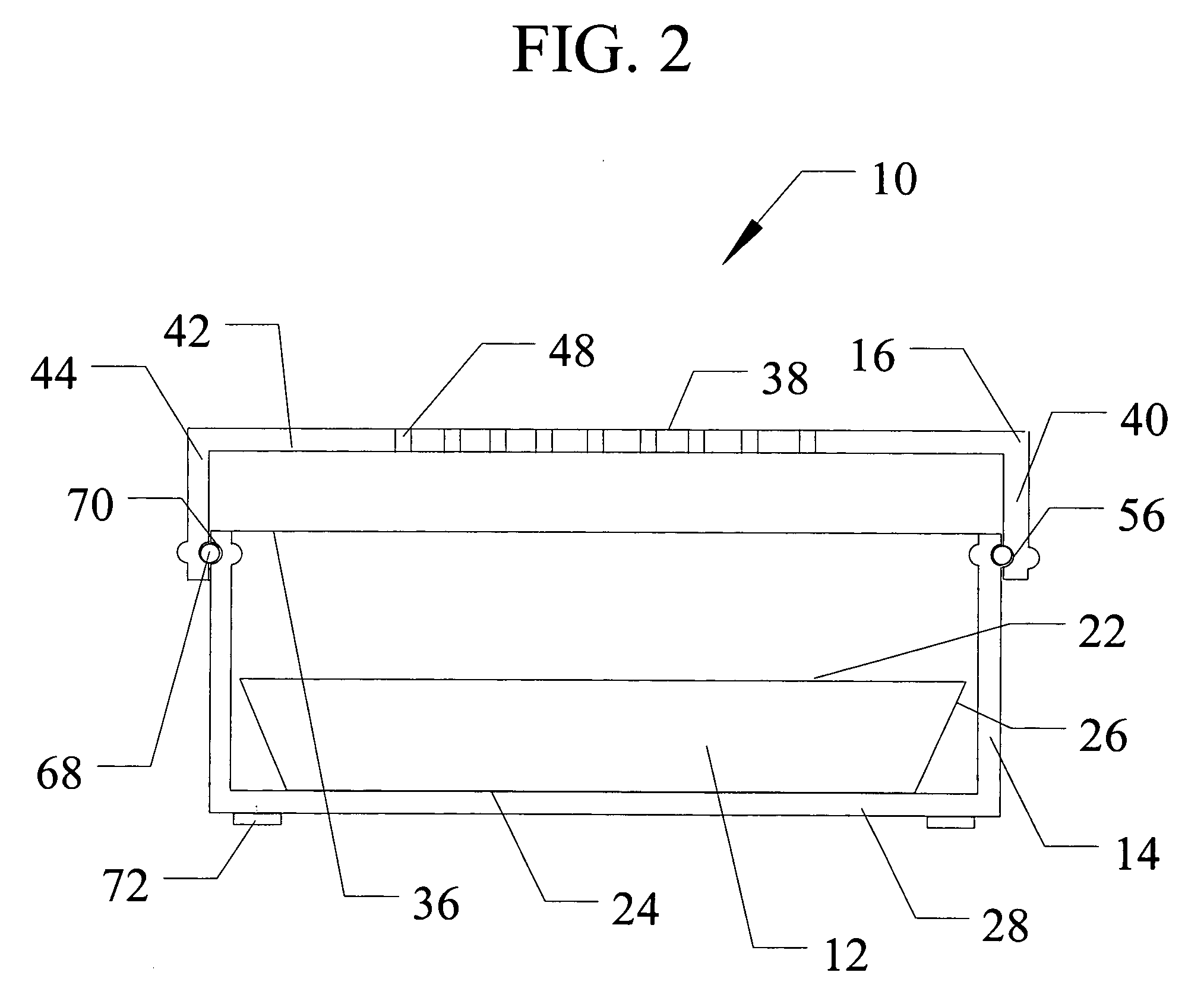

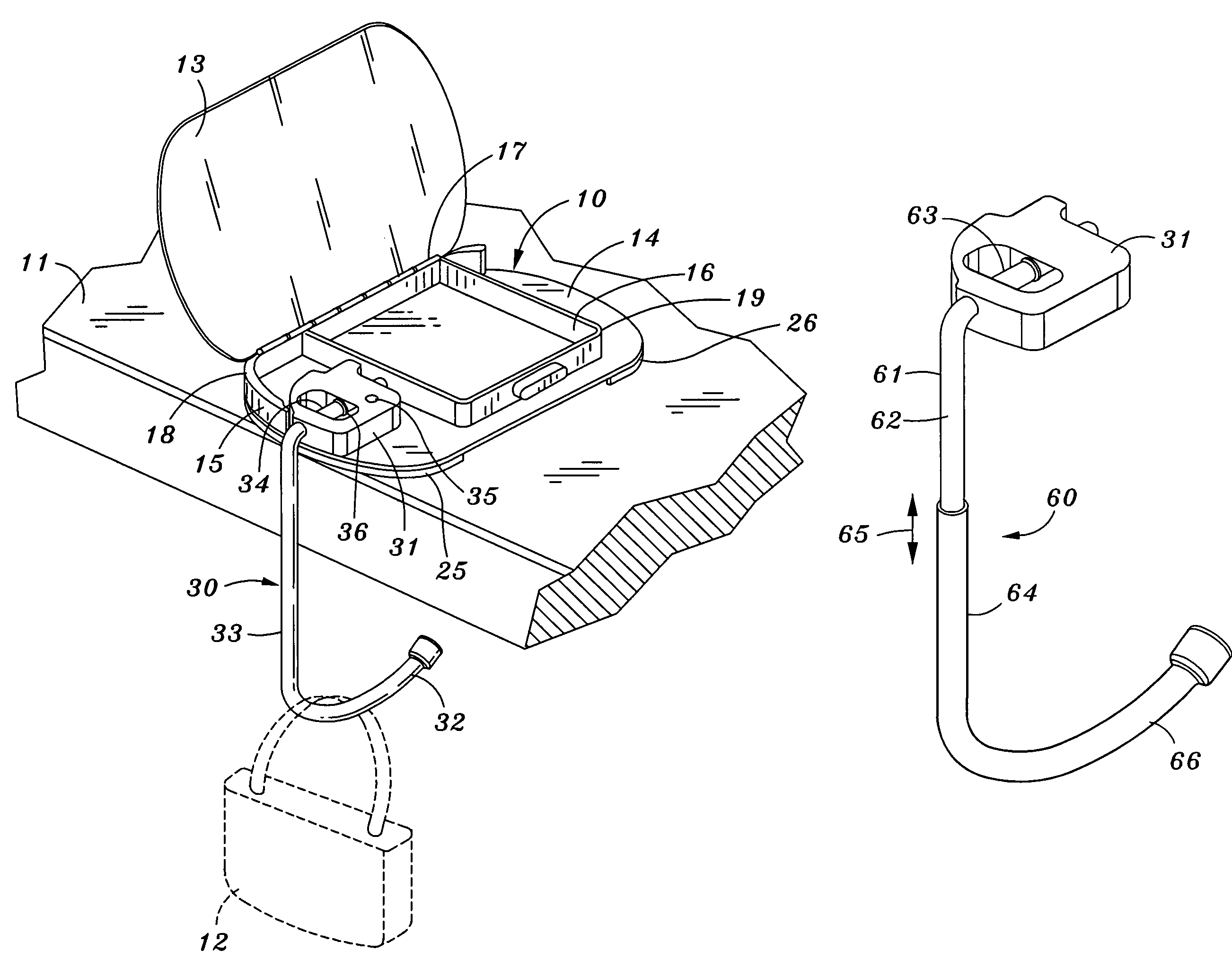

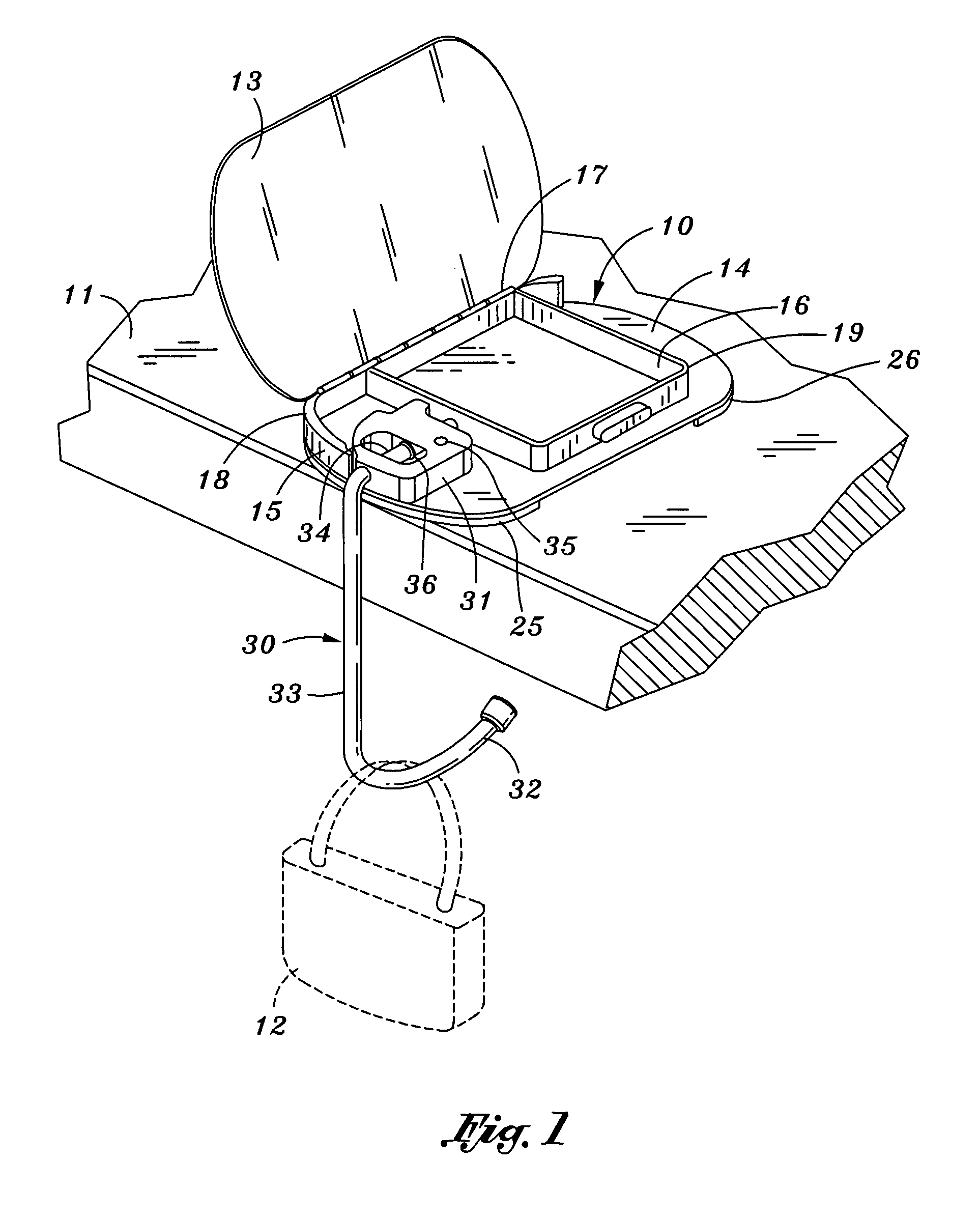

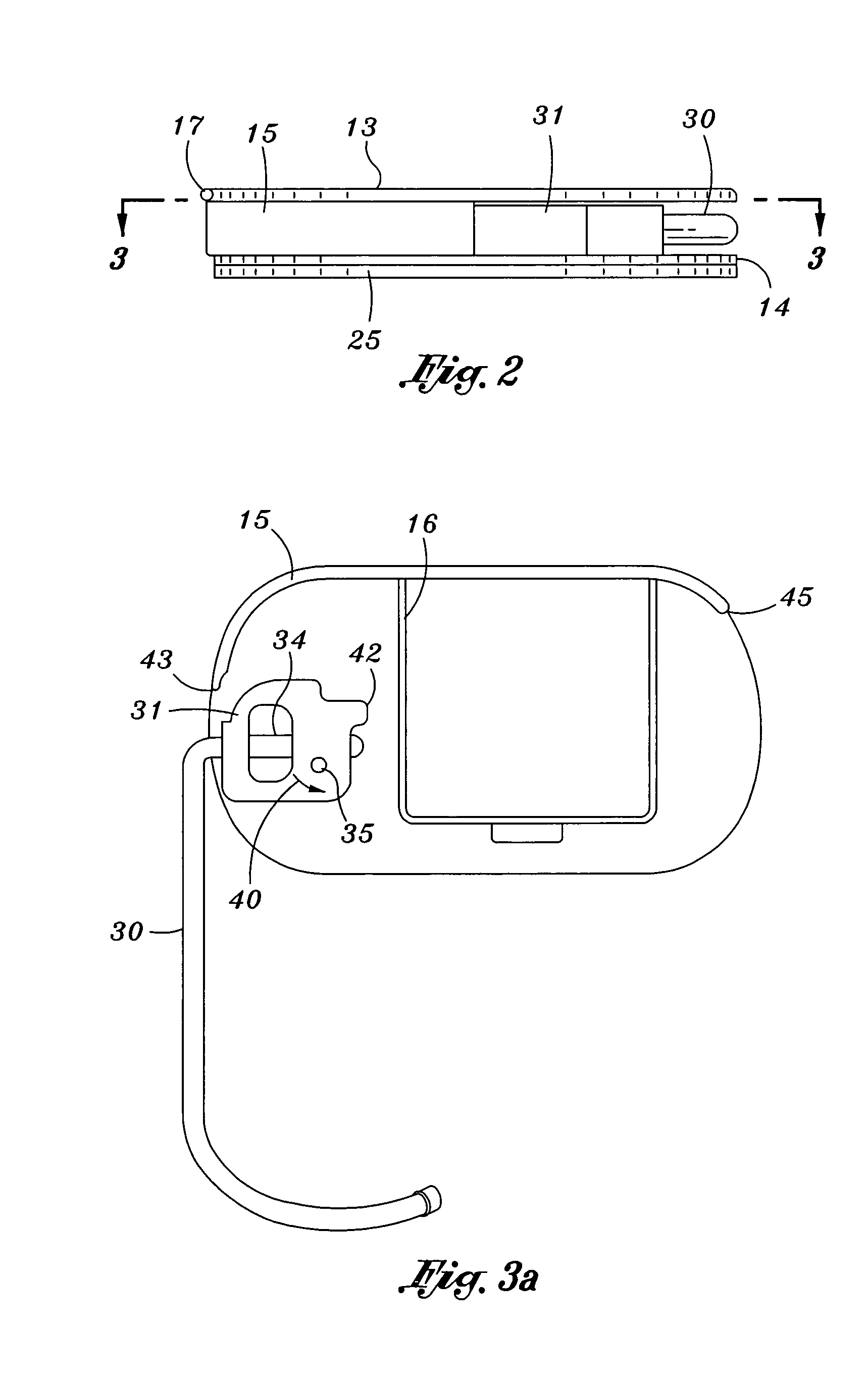

Table edge supporting apparatus

InactiveUS7516929B2Uniform heightPrecise positioningCurtain suspension devicesStands/trestlesEngineeringMechanical engineering

A handbag 12 is supported from a table surface 11. A hook 30 extends from the space between parallel panels 13 and 14 and includes a segment 34 rotatable with pivot block 31 between the panels. In one position (FIG. 1), hook 30 is perpendicular to panels 13 and 14 to support the handbag 12. Hook 30 is rotatable in directions 41 (FIG. 5) to a position between, and parallel to, the panels. Hook 30 is coupled to a pivot 35 to rotate with pivot block 31 in a horizontal plane to a storage position. In this position, hook 43 is fixedly positioned relative to magnet 35. To prevent the hook 30 from being dislodged from surface 11, non-skid members are secured to the bottom surface of panel 14.

Owner:COHEN LAURIE

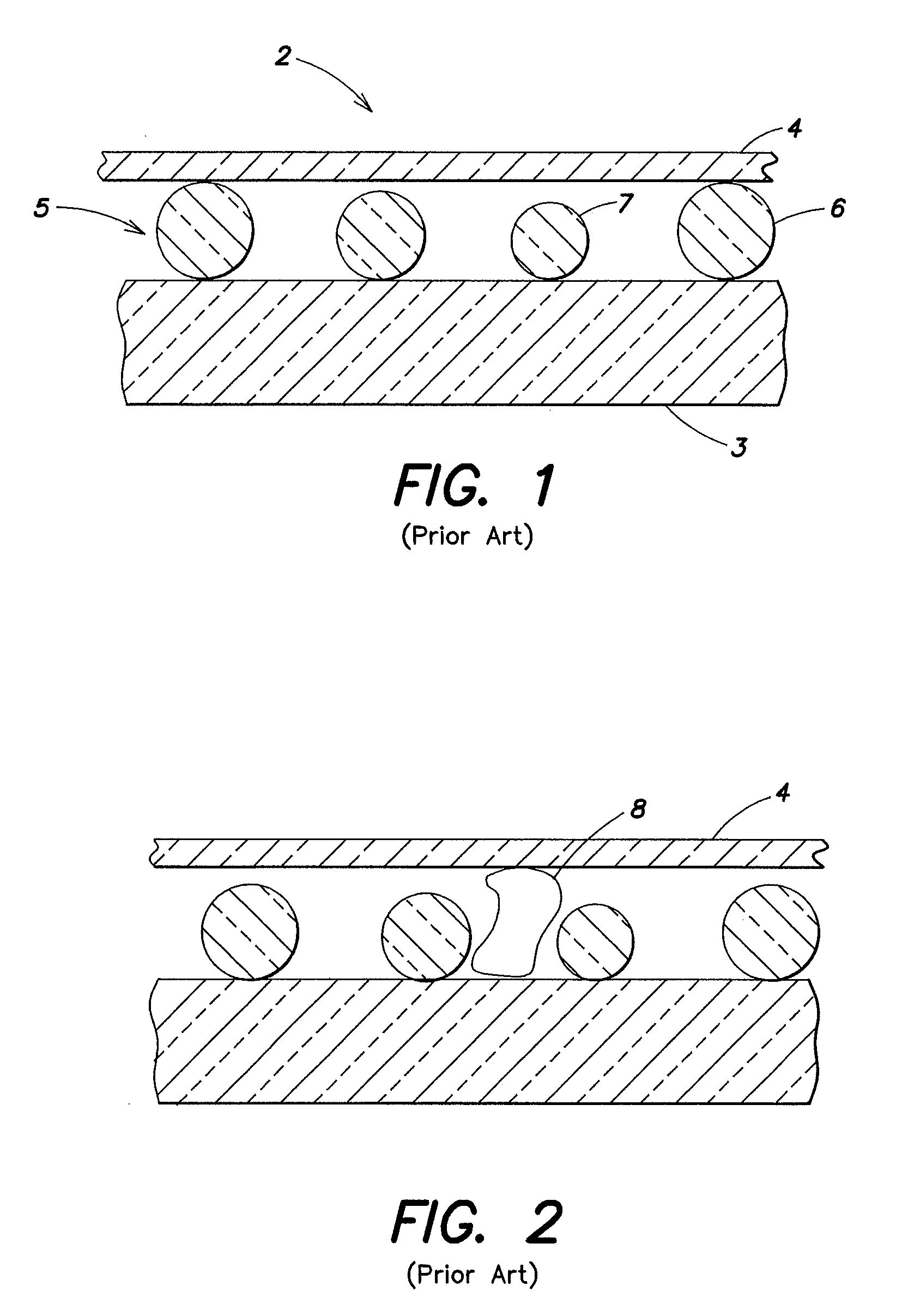

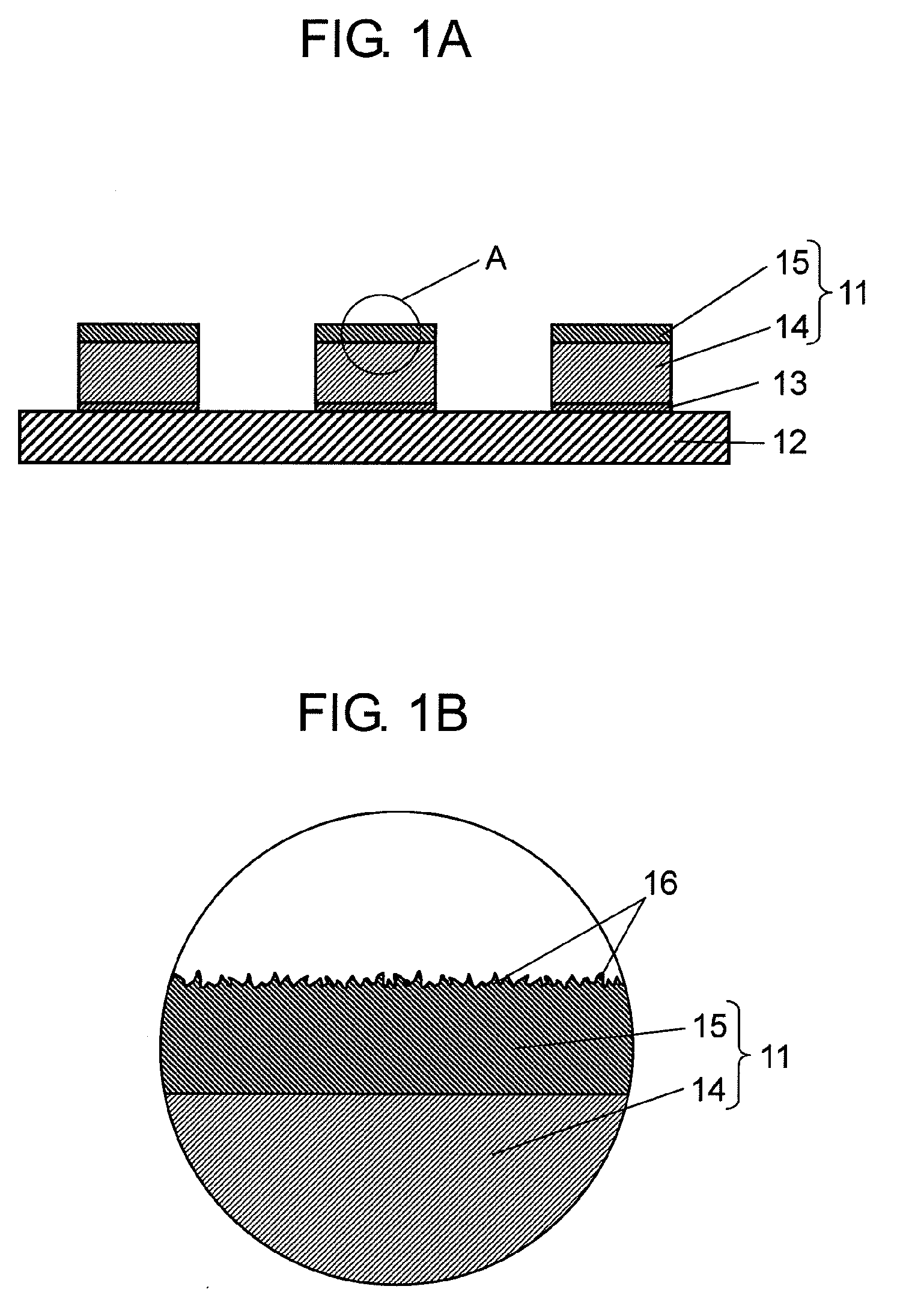

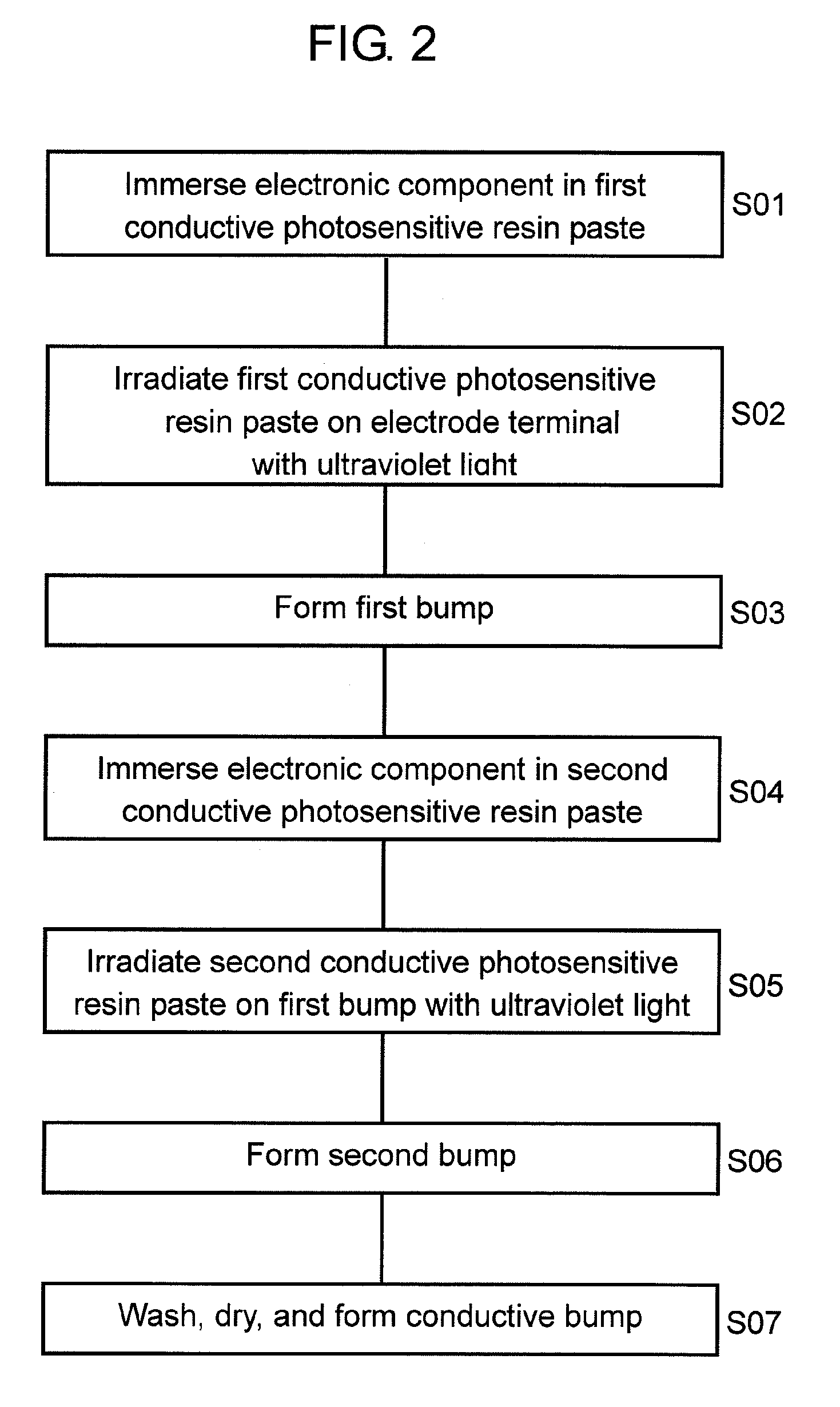

Conductive bump, method for forming the same, and electronic component mounting structure using the same

InactiveUS20090301771A1Improve connection strengthReduce connection resistanceLine/current collector detailsPrinted electric component incorporationEngineeringSpherical shaped

A conductive bump formed on an electrode of an electronic component. The conductive bump is composed of a first bump having one or more layers formed on the electrode and including resin containing at least a spherical-shaped conductive filler, and a second bump formed on an upper surface of the first bump and including photosensitive resin containing a scale-shaped conductive filler.

Owner:PANASONIC CORP

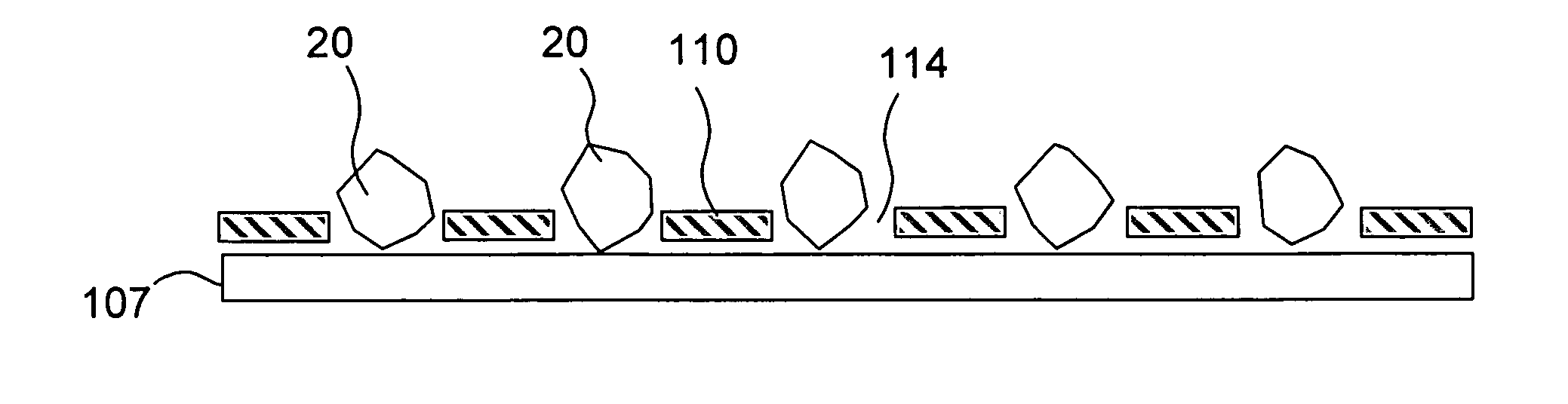

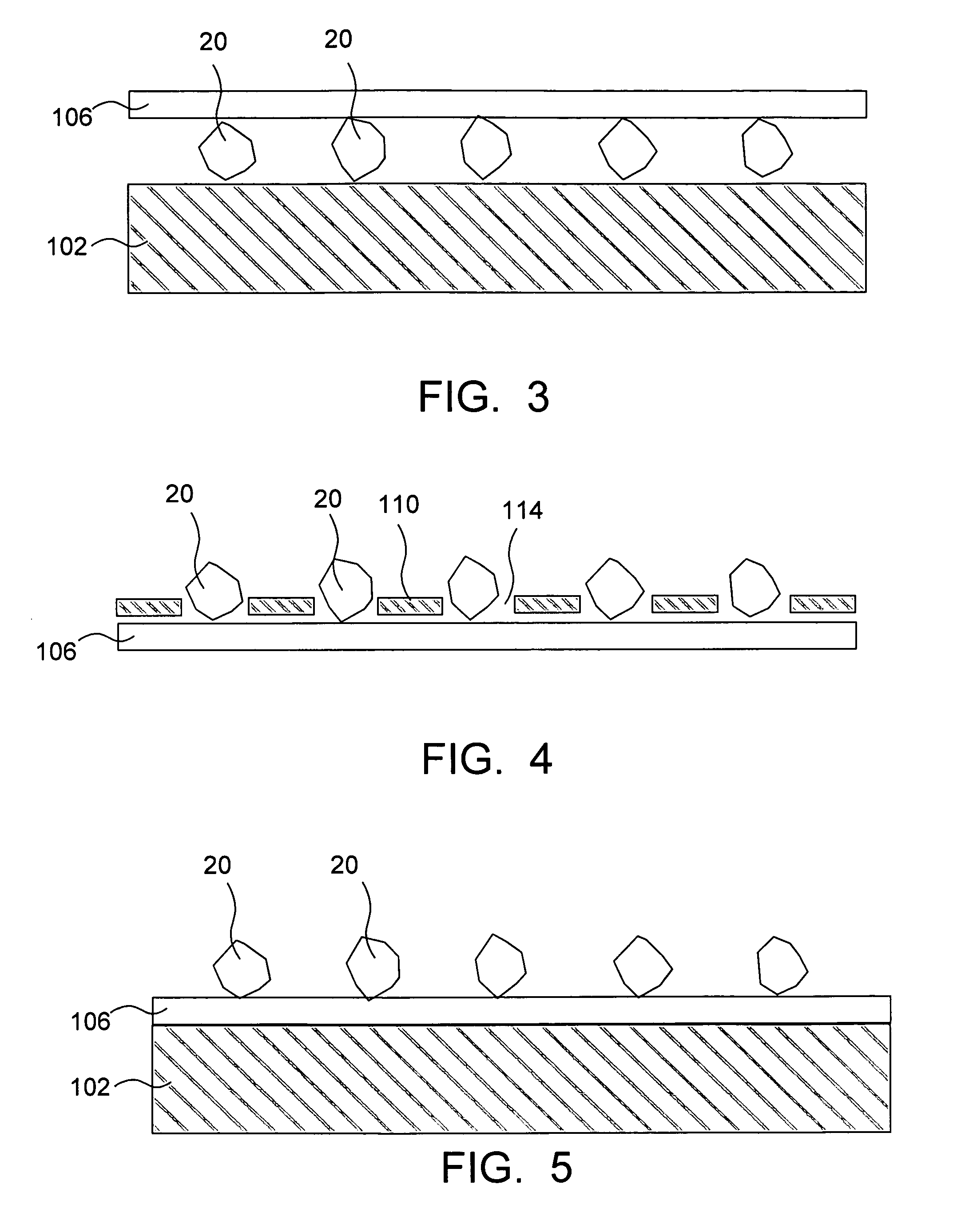

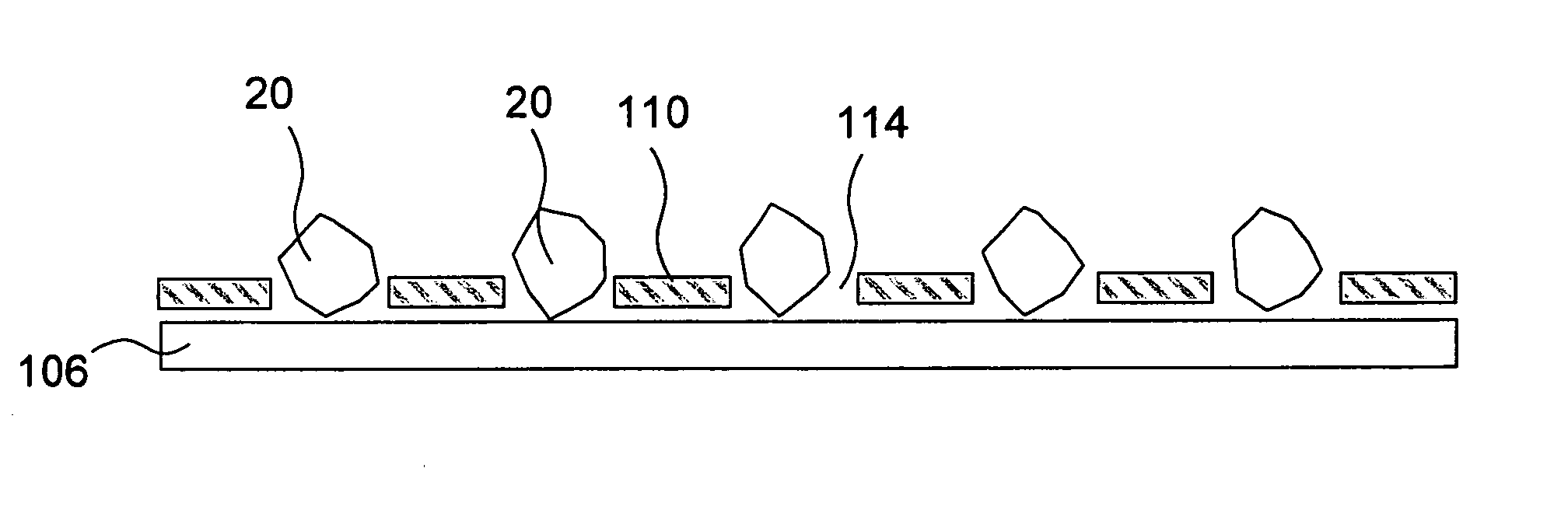

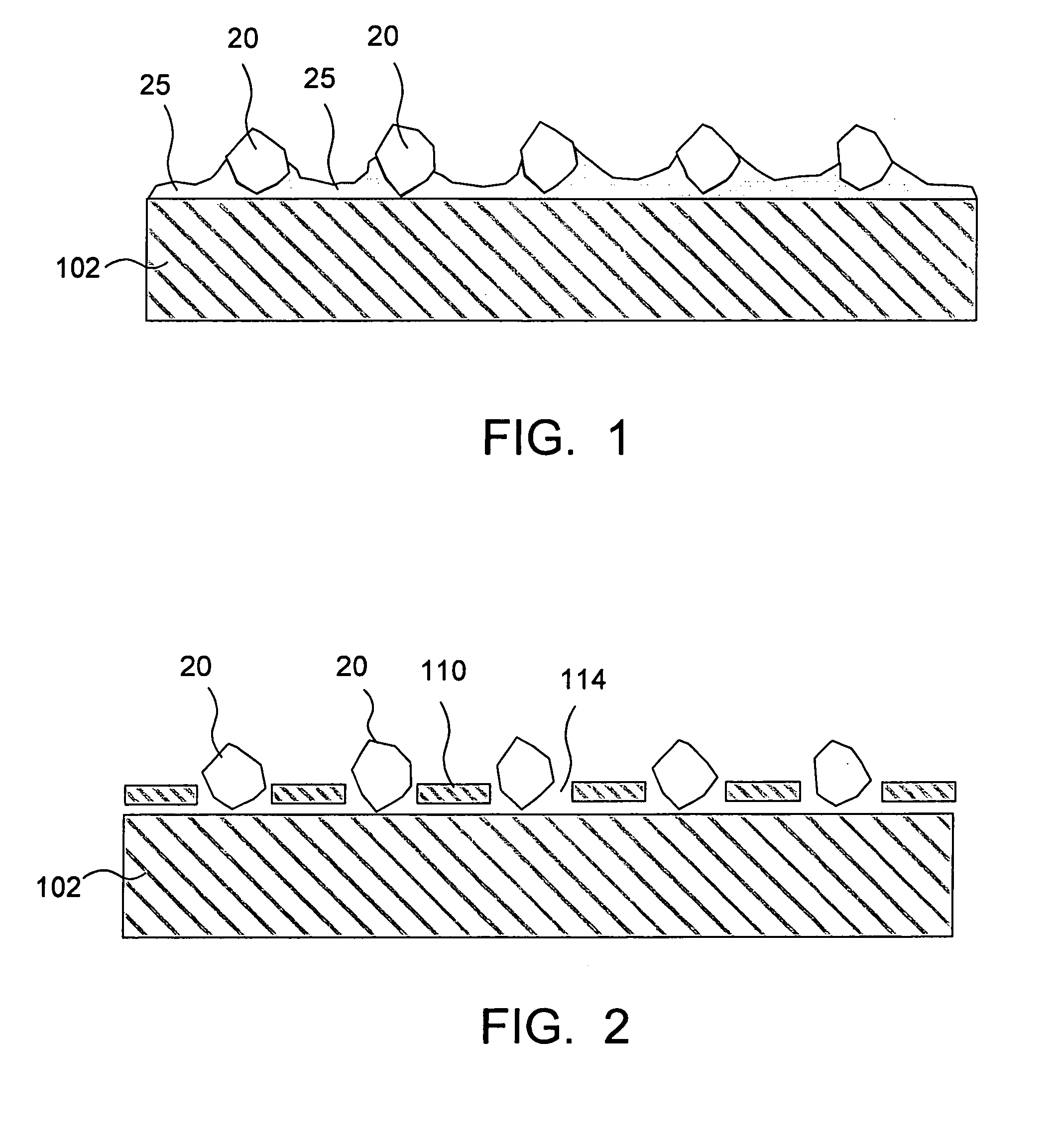

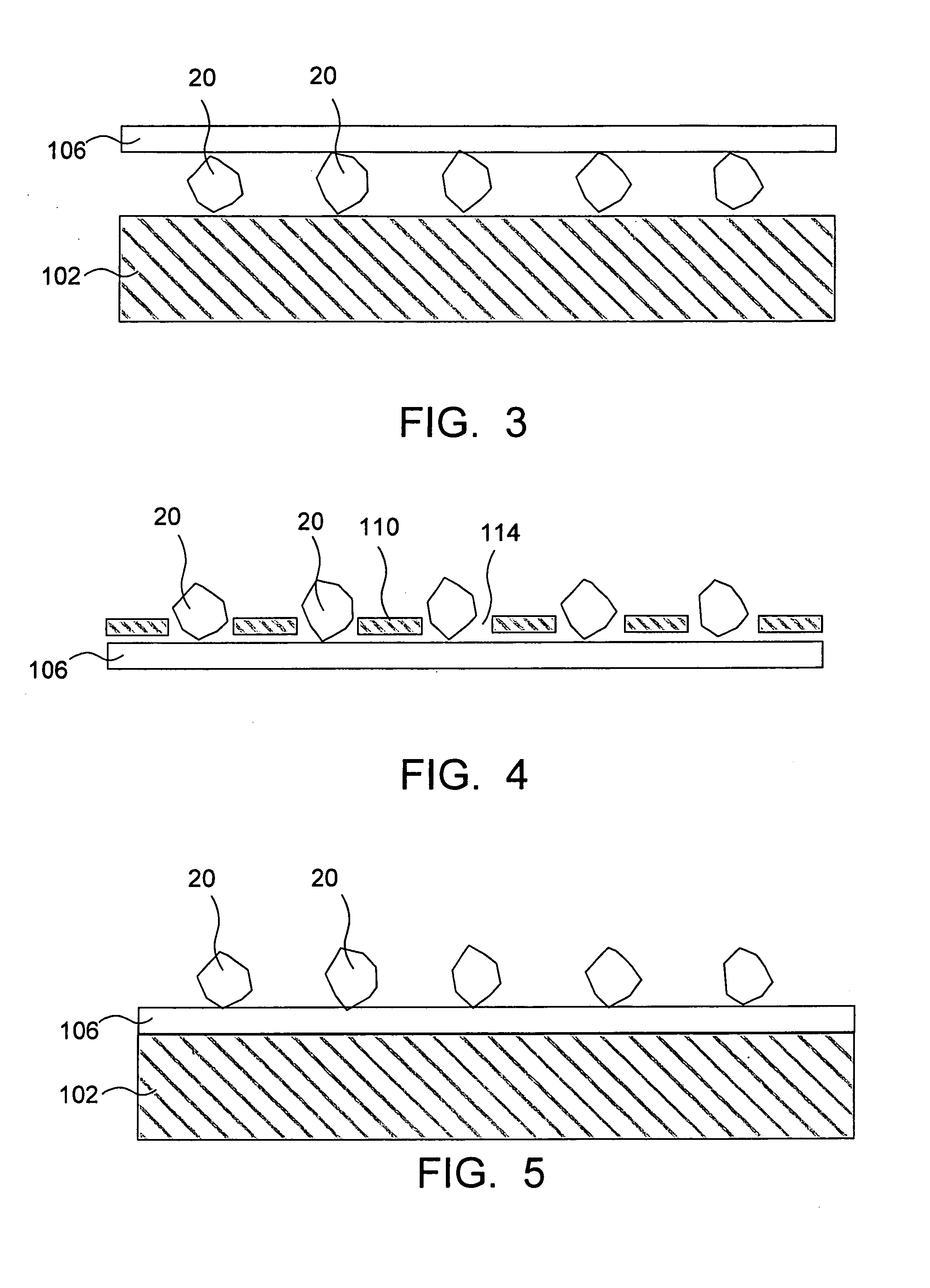

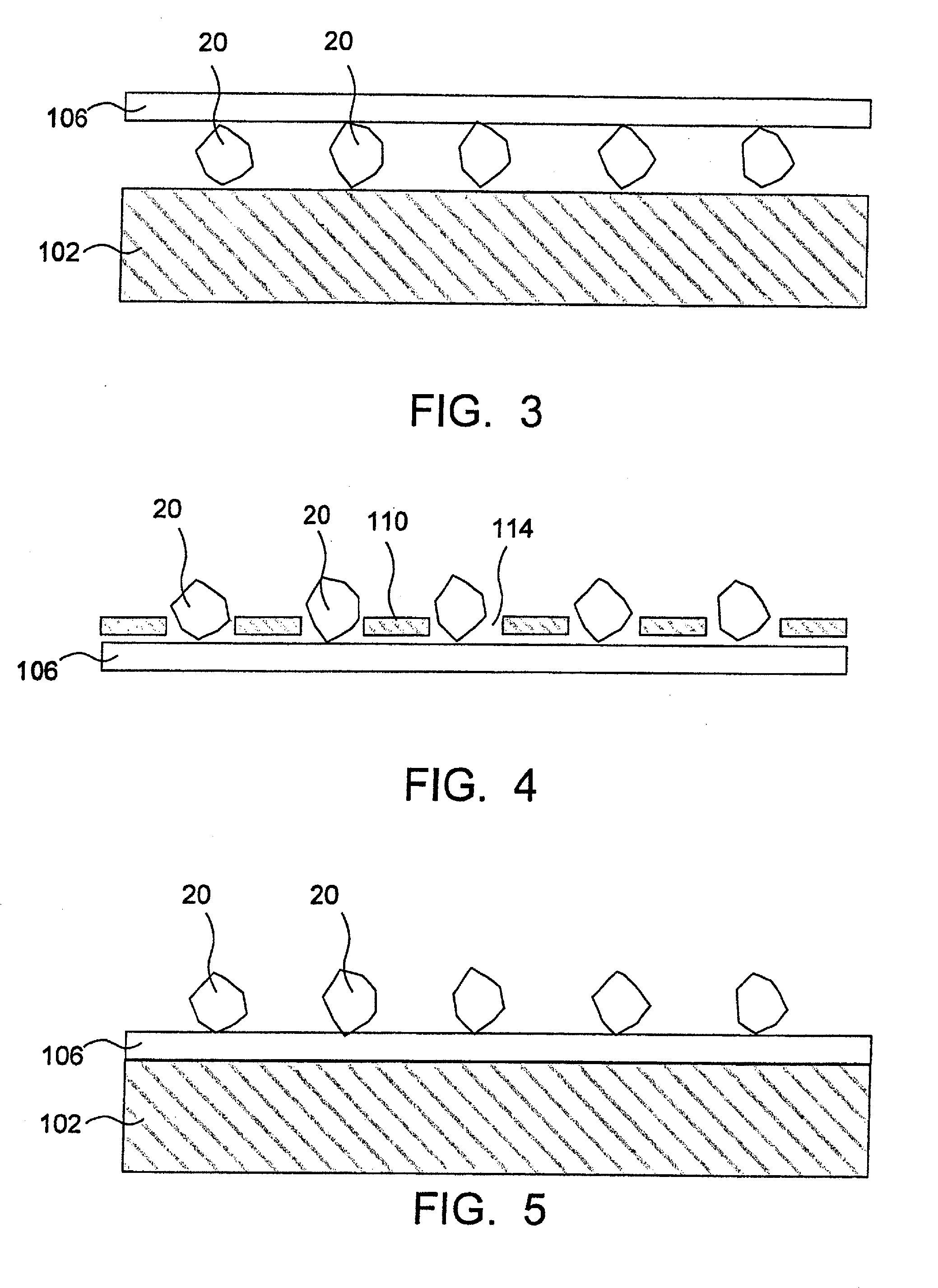

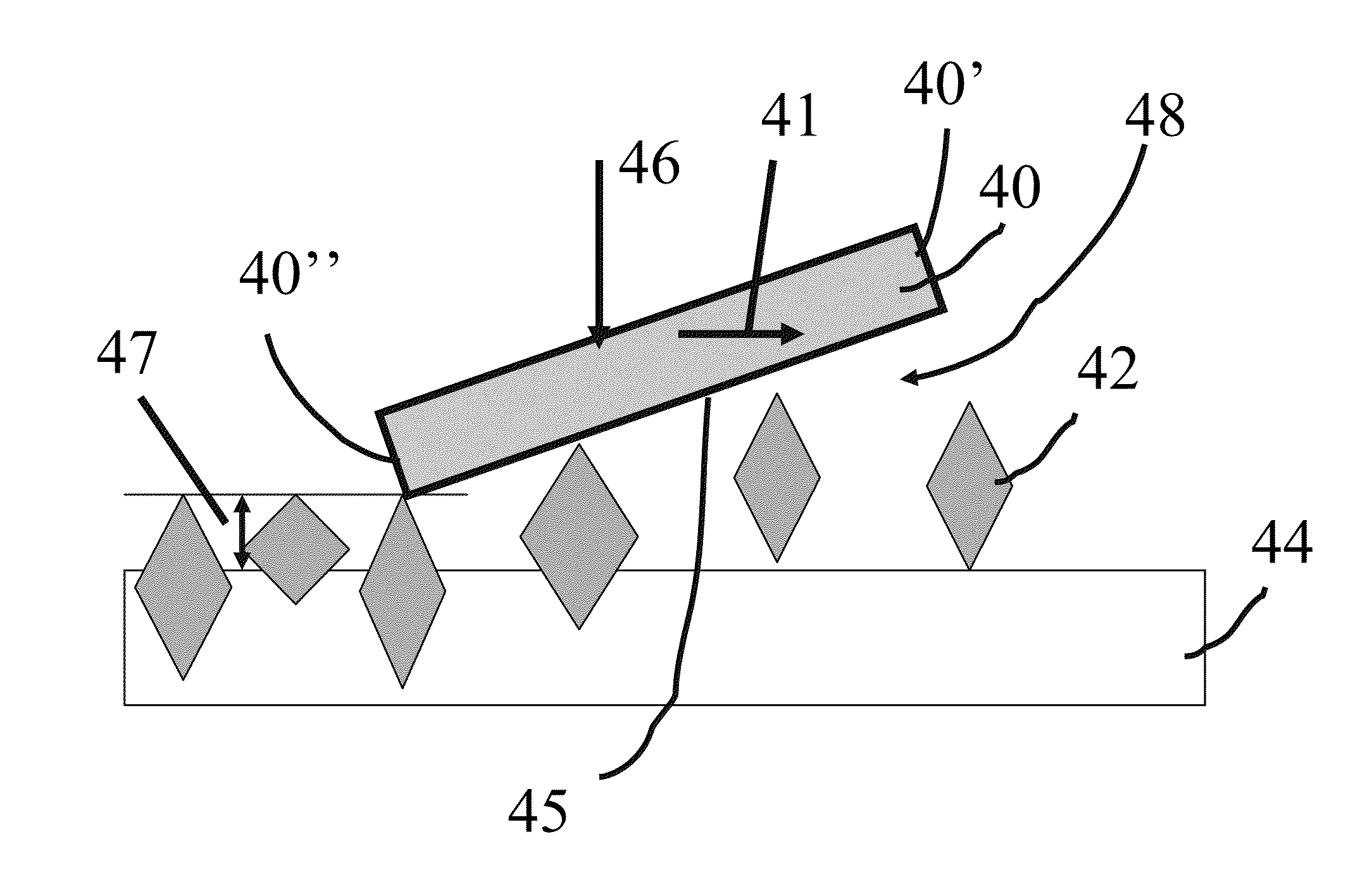

Method and apparatus for embedding abrasive particles into substrates

InactiveUS20110027549A1Reduce nanometer-scale height variationProduce stiffnessLayered productsAbrasion apparatusWear particleMicrometer scale

A dressing bars for embedding abrasive particles into a substrate at a substantially uniform height. Spacing pads, hydrostatic and / or hydrodynamic fluid bearing (air is the typical fluid) maintains a constant spacing and attitude between the dressing bar and the substrate. The fluid bearing permits the dressing bar to maintain a desirable stiffness between the lapping plate and the dressing bar. The bar geometry and fluid bearing design permits the bar to mitigate or compensate for the micrometer-scale and / or millimeter-scale wavelengths of waviness on the substrate, while maintaining a substantially constant clearance to uniformly embed the abrasive particle into the substrate.

Owner:SCHWAPPACH KARL

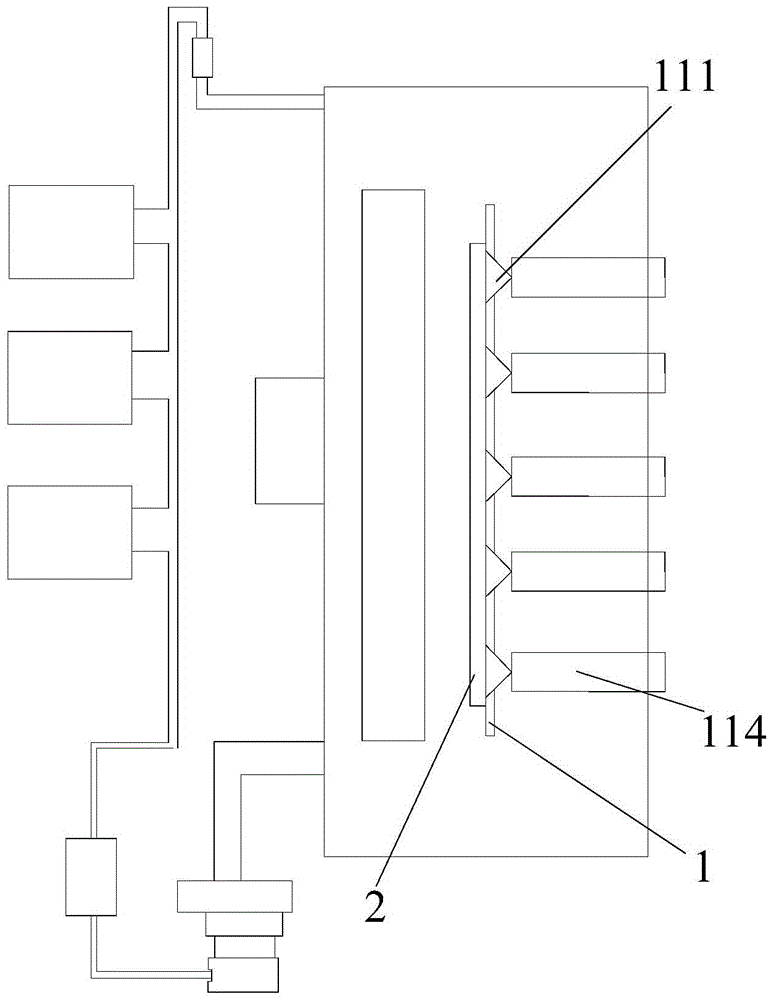

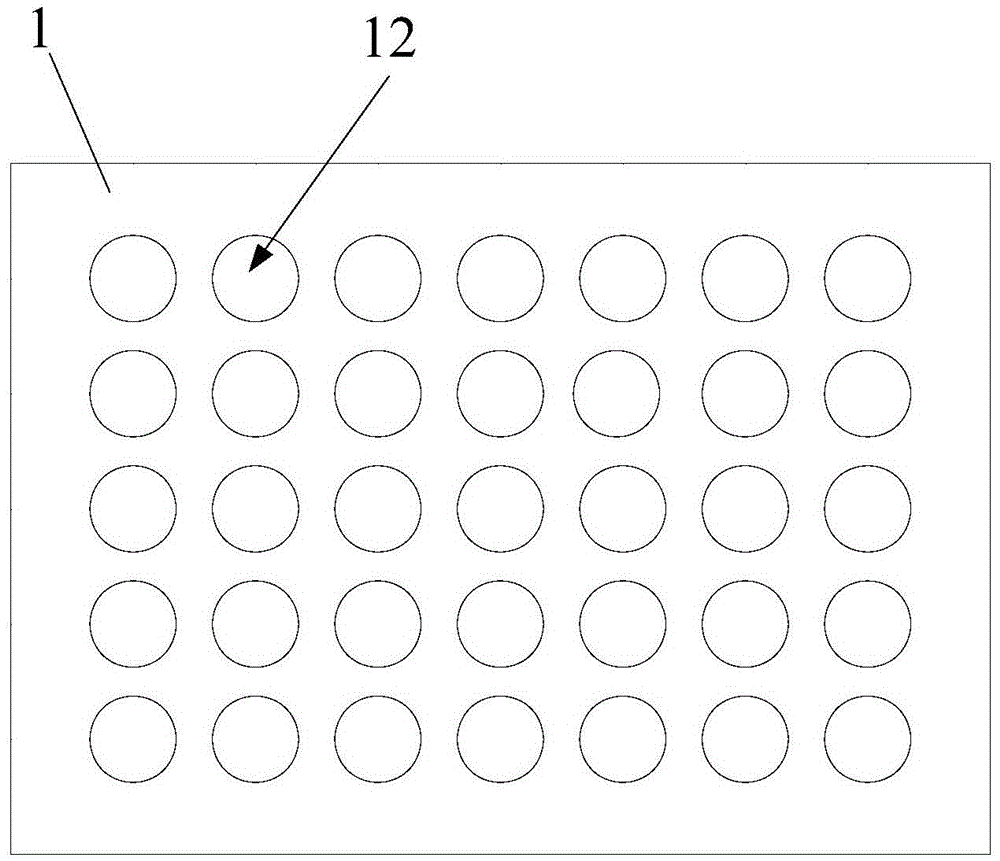

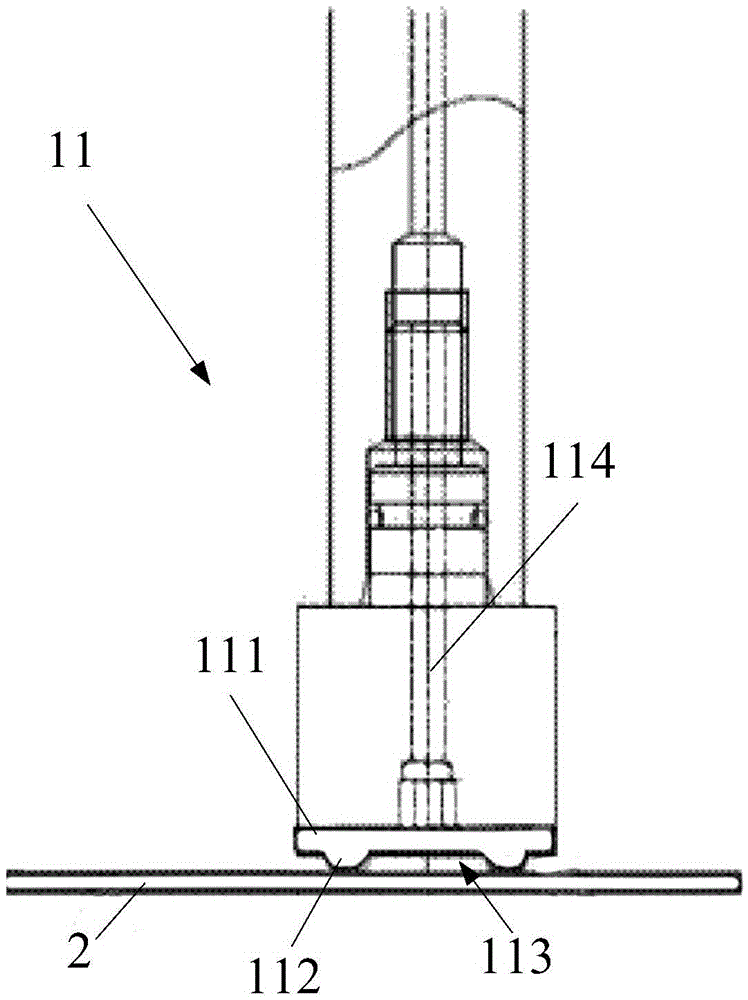

Base plate bearing device

ActiveCN105572925AEasy to fixReduce deformationNon-linear opticsManufacturing technologyLiquid-crystal display

The invention relates to the technical field of liquid crystal display design and manufacturing, in particular to a base plate bearing device which comprises a base platform, a press fit sucking mechanism and an adhesive sucking mechanism, wherein the press fit sucking mechanism and the adhesive sucking mechanism are arranged on the base platform; the adhesive sucking mechanism is made of an adhesive material; the press fit sucking mechanism is used for enabling the base plate to be tightly pressed to the adhesive sucking mechanism. When being placed on the base platform by using a manipulator, the base plate can be sucked by the adhesive sucking mechanism made of the adhesive material through action force of molecules, and can be fixed on the base platform, so that the problems that the base plate can be deformed and is relatively poor in coating uniformity when being fixed by using a clamp are solved; compared with a conventional fixation mode of a triangular clamp, the base plate bearing device is relatively stable and solid, the deformation quantity of the base plate is relatively low, the coating uniformity is greatly improved, and meanwhile the defects that the base plate is deformed and dropped are also solved.

Owner:BOE TECH GRP CO LTD +1

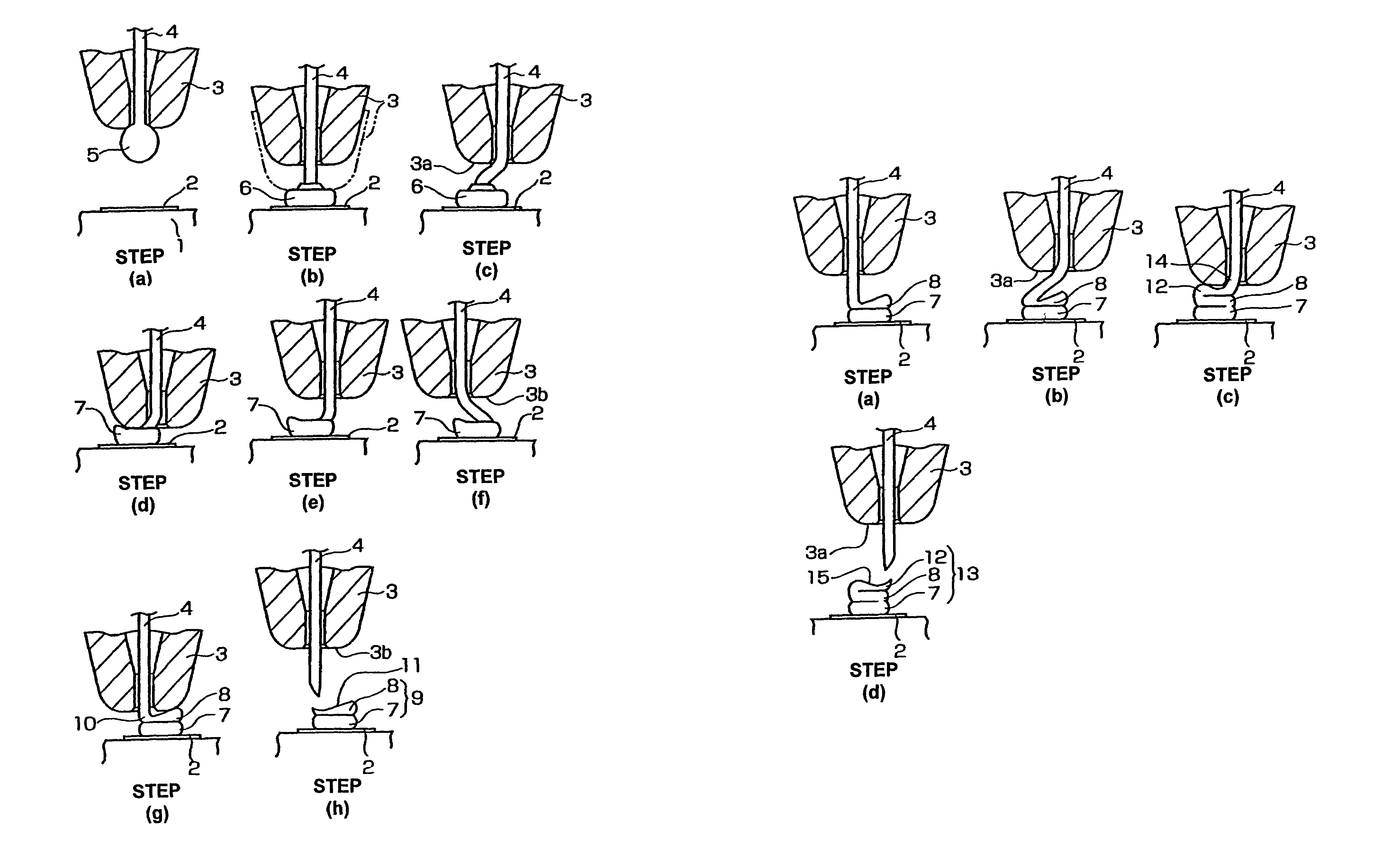

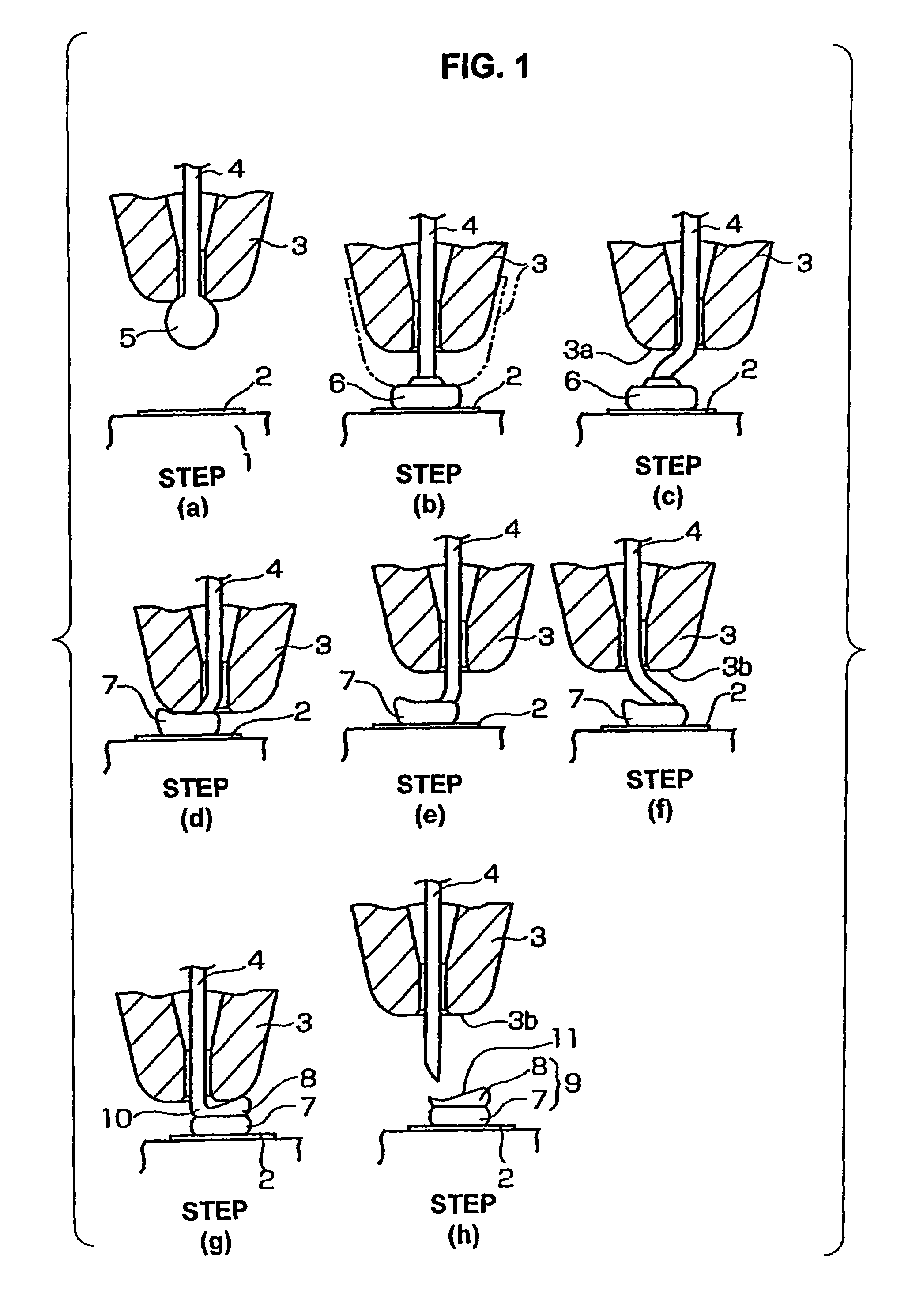

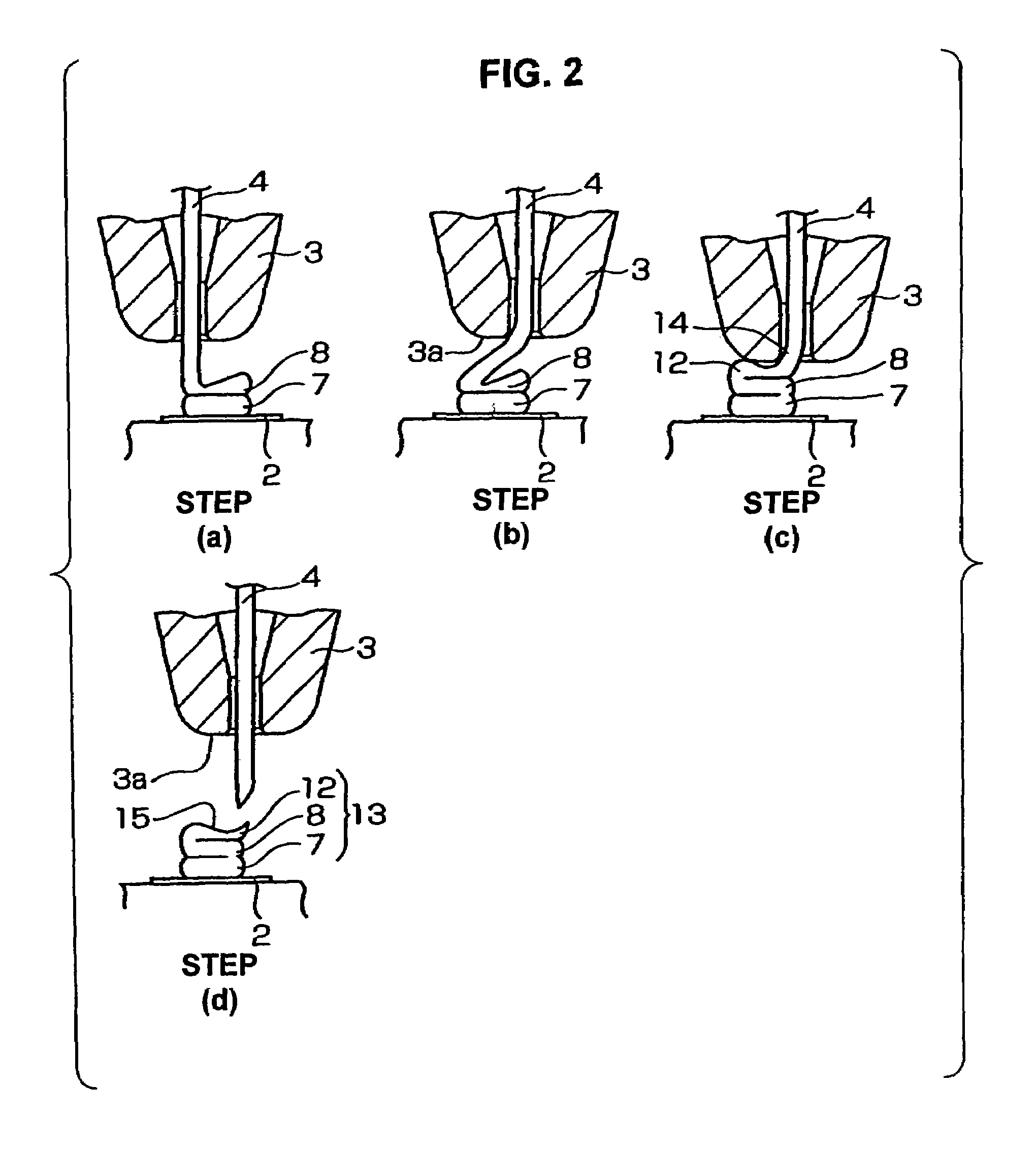

Bump formation method and wire bonding method

InactiveUS7044357B2Uniform heightUniform shapeDental implantsSolid-state devicesEngineeringMechanical engineering

Bump formation method and wire bonding method including a step of forming a ball on the tip end of a wire that passes through a capillary and joining this ball to an electrode pad so as to make a press-bonded ball. In the next step, the capillary is raised and moved horizontally so that the bottom flat portion of the capillary faces the press-bonded ball. Then, the capillary is lowered and the press-bonded ball is pressed, thus forming a first bump. Next, the capillary is raised and moved horizontally in a direction that is opposite from the previous horizontal-direction, thus positioning the flat portion of the capillary to face the first bump. Then, the capillary is lowered, and the wire is bent and pressed against the surface of the first bump so as to form a second bump. The wire is then cut from the second bump.

Owner:SHINKAWA CO LTD

Laminated core and method for manufacturing the same

InactiveUS20100090560A1Avoid clearingReduce vibrationMagnetic circuit stationary partsManufacturing stator/rotor bodiesElectrical and Electronics engineering

A laminated core 10 including a plurality of segment core sheets 13 spirally wound and laminated in layers while connecting portions 12 connecting the adjacent segment core sheets 13 are bent, ends of the segment core sheets 13 are aligned with each other and the connecting portions 12 in the adjacent layers are circumferentially displaced relative to each other, the connecting portions 12 located in outer peripheral areas 11 of the segment core sheets 13, the laminated core 10 comprising:a concave cutout 22 formed on a radially outward side of the connecting portion 12, the concave cutout 22 accommodating a radially expanded part 21 within an outer circle of the laminated core 10, the radially expanded part 21 formed in the connecting portion 12 radially outward at the bending of the connecting portion 12; an interior cutout 23 formed on a radially inward side of the connecting portion 12, the interior cutout 23 defining a bent position of the connecting portion 12; anddepressed receptacles 16, 17 respectively formed on a top side and a bottom side of a radially outward area of the segment core sheet 13 except for the connecting portions 12, the depressed receptacles 16, 17 each receiving a thickness-direction expanded part 15 formed in the connecting portion 12 in a thickness direction thereof at the bending of the connecting portion 12.

Owner:MITSUI HIGH TEC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com