Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

276results about How to "Reduce connection resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

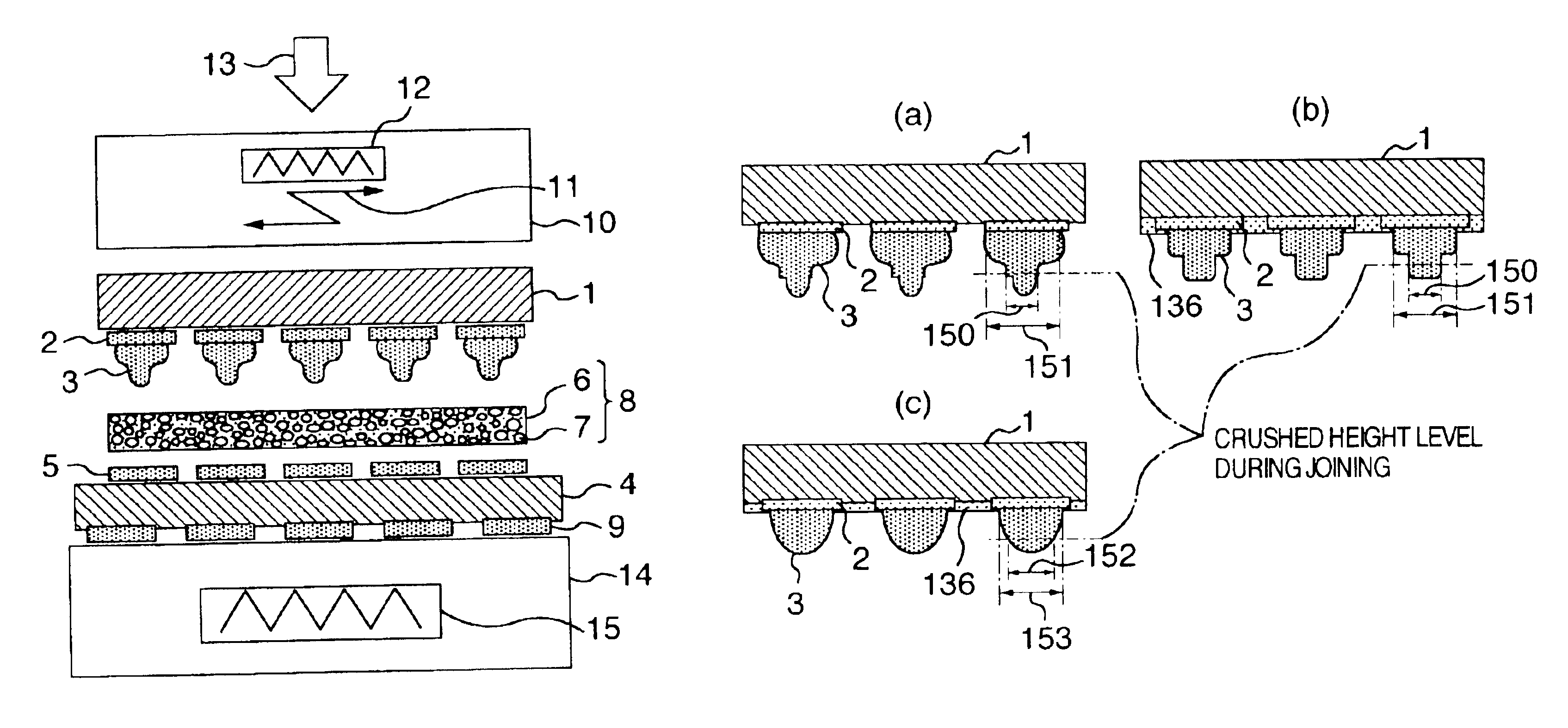

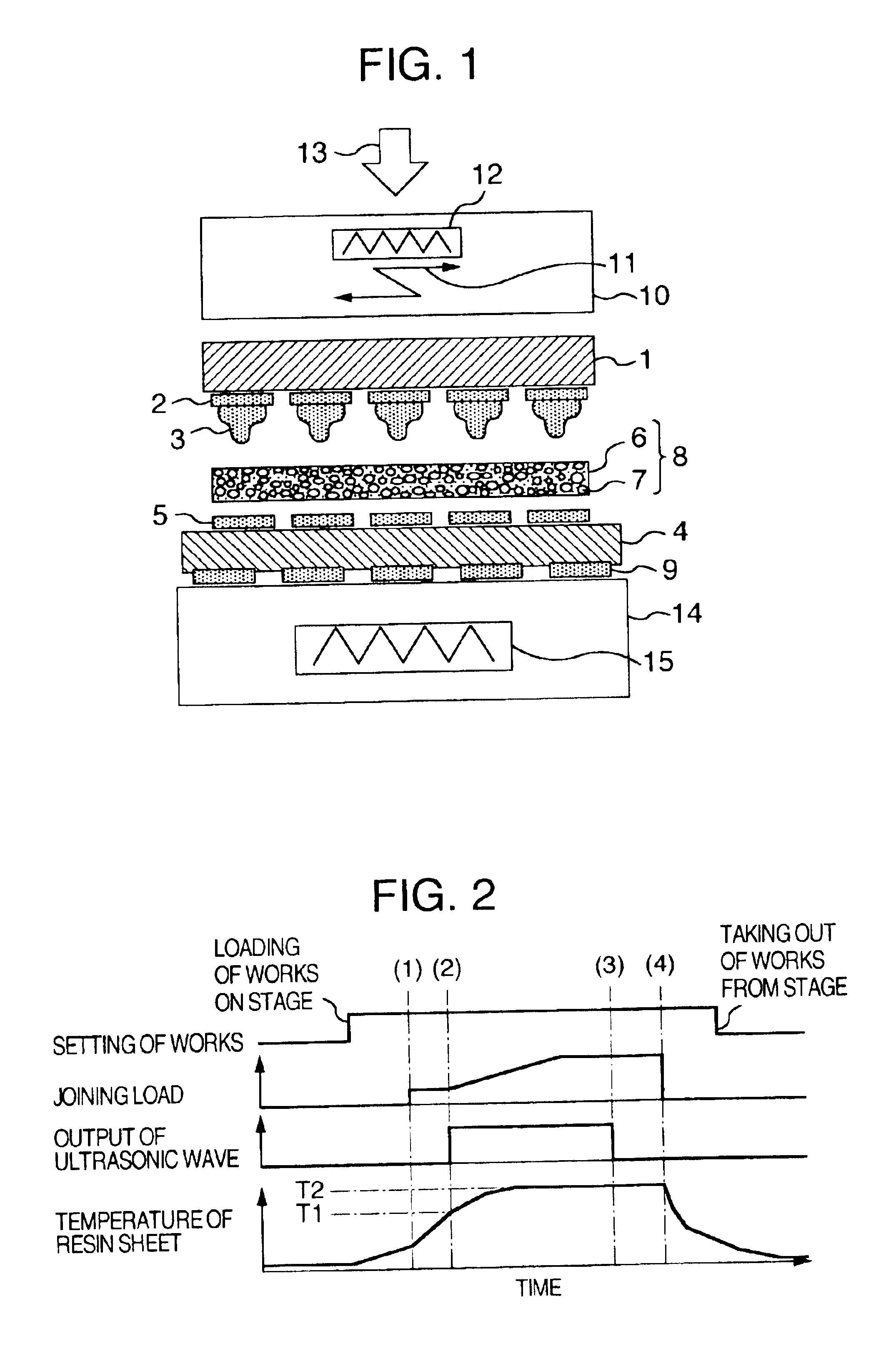

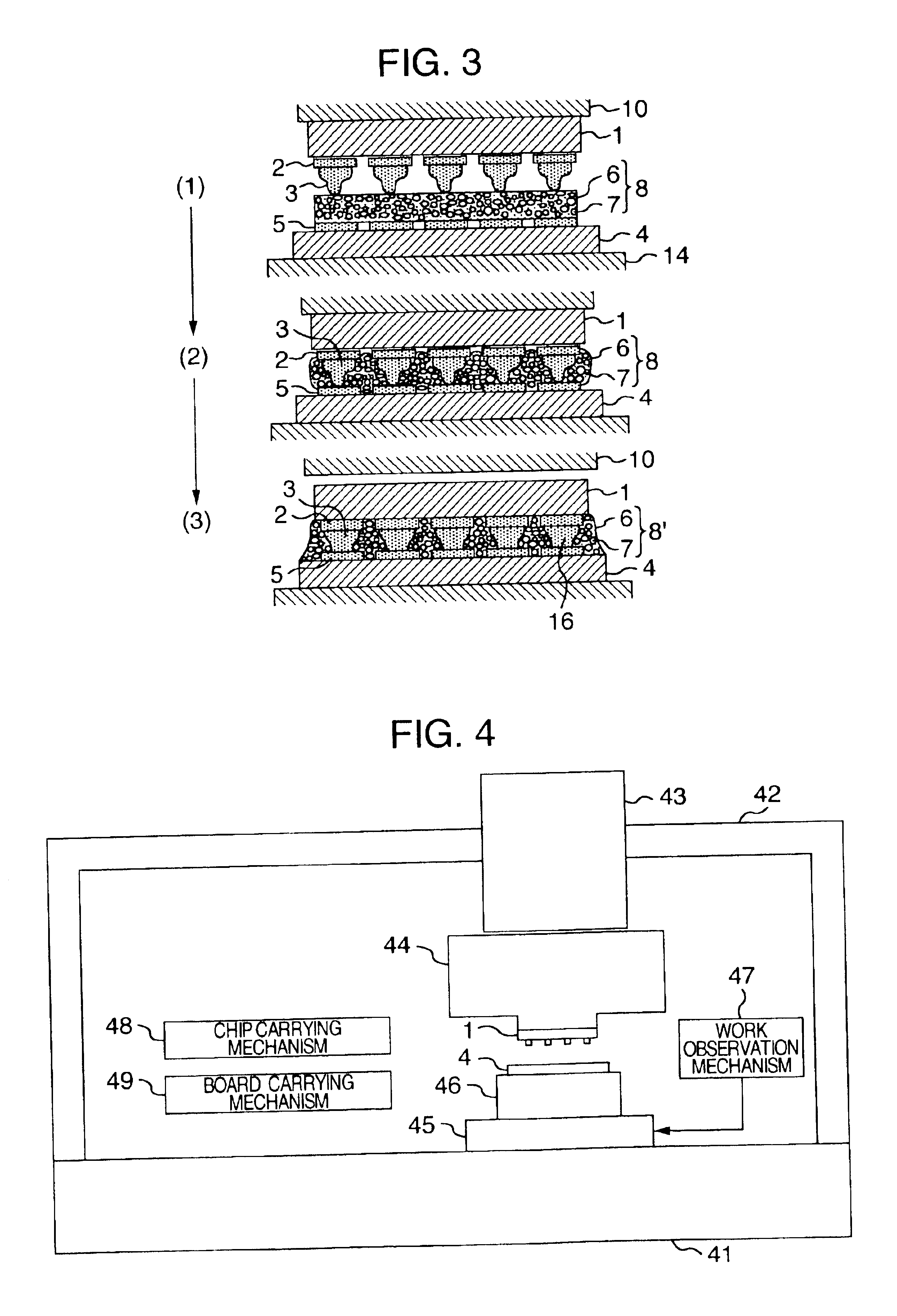

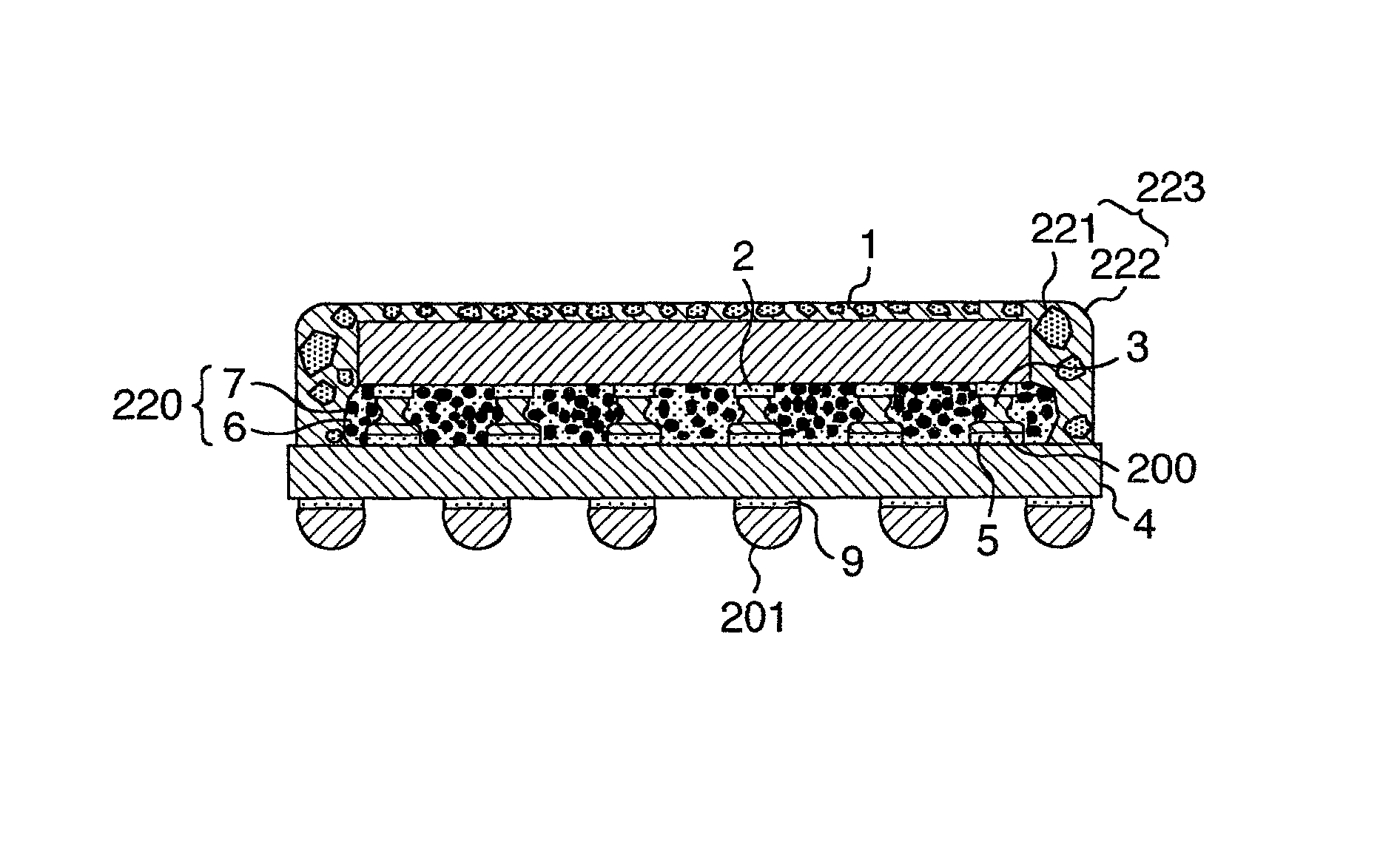

Flip chip assembly structure for semiconductor device and method of assembling therefor

InactiveUS6798072B2Improve productivityImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesDevice materialMetallic materials

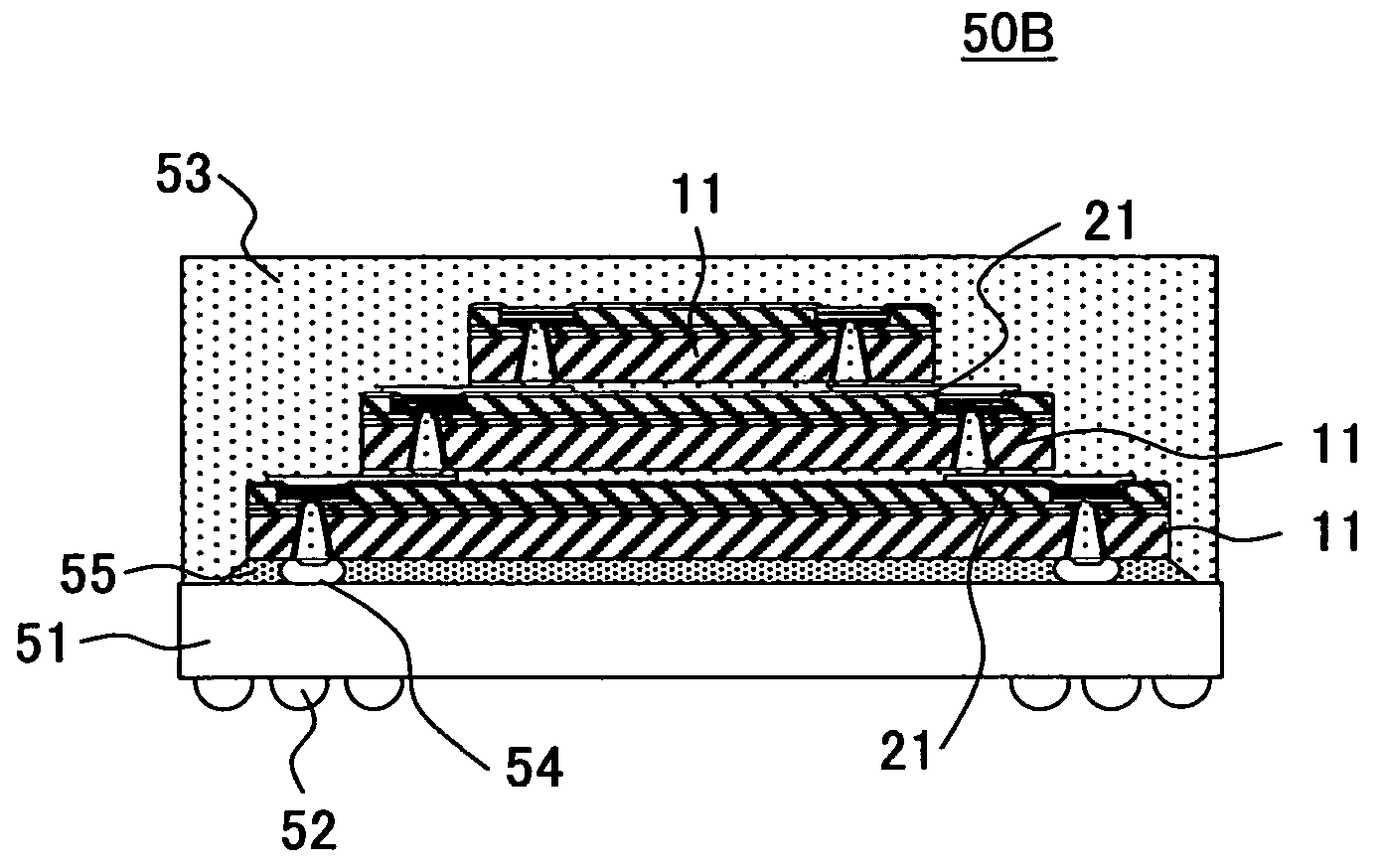

A semiconductor device includes a semiconductor chip and a printed circuit board. Metal electrodes of the semiconductor chip and the internal connection terminals of the printed circuit board are electrically connected through the metallic joining via precious metal bumps. A melting point of a metal material constituting each of the metallic joining parts is equal to or higher than 275 degrees, and a space defined between the chip and the board is filled with resin (under fill) containing 50 vol % or more inorganic fillers.

Owner:HITACHI LTD

Flip chip assembly structure for semiconductor device and method of assembling therefor

InactiveUS20020056906A1Improve productivityImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesPrinted circuit boardMetallic materials

A semiconductor device includes a semiconductor chip and a printed circuit board. Metal electrodes of the semiconductor chip and the internal connection terminals of the printed circuit board are electrically connected through the metallic joining via precious metal bumps. A melting point of a metal material constituting each of the metallic joining parts is equal to or higher than 275 degrees, and a space defined between the chip and the board is filled with resin (under fill) containing 50 vol % or more inorganic fillers.

Owner:HITACHI LTD

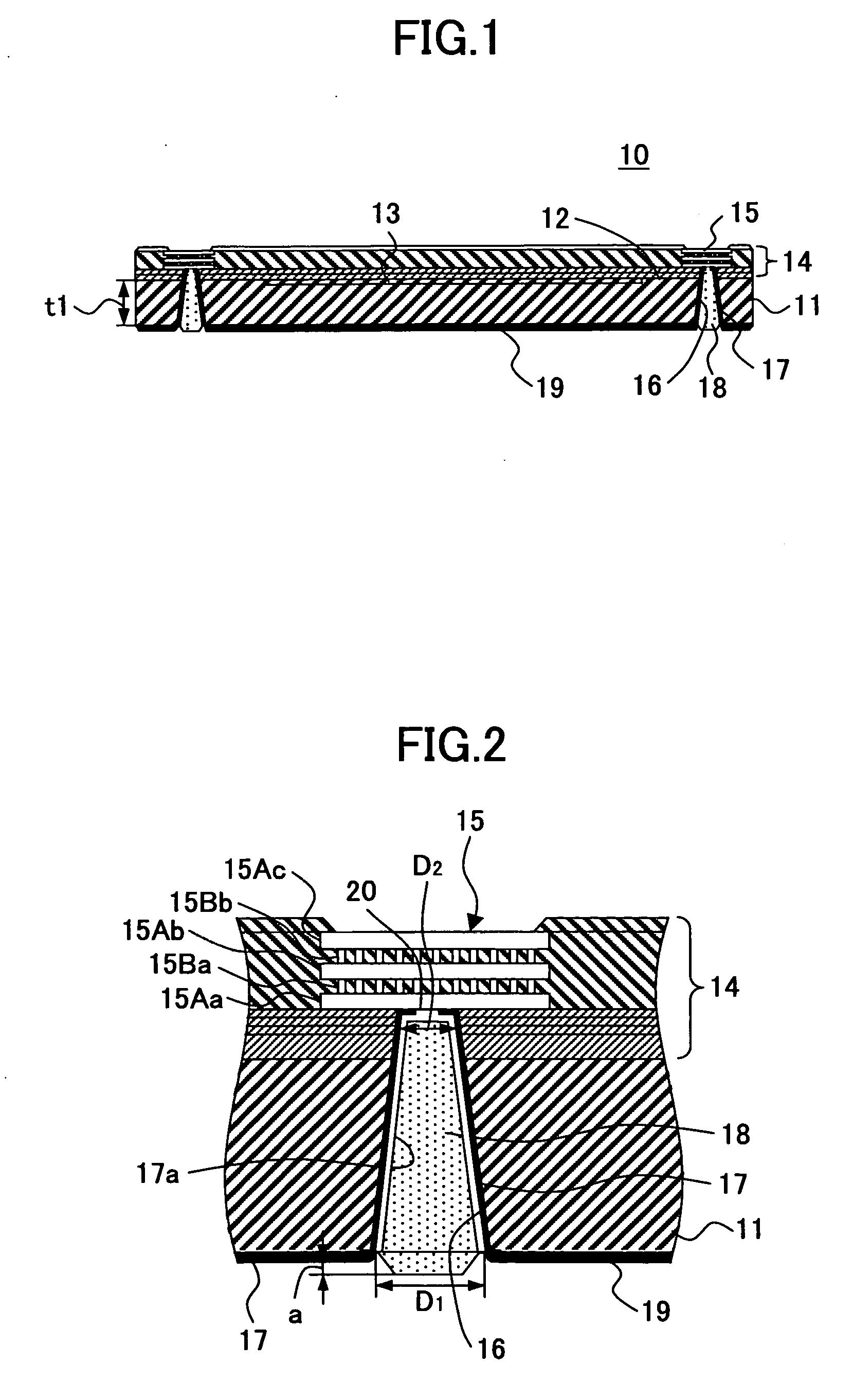

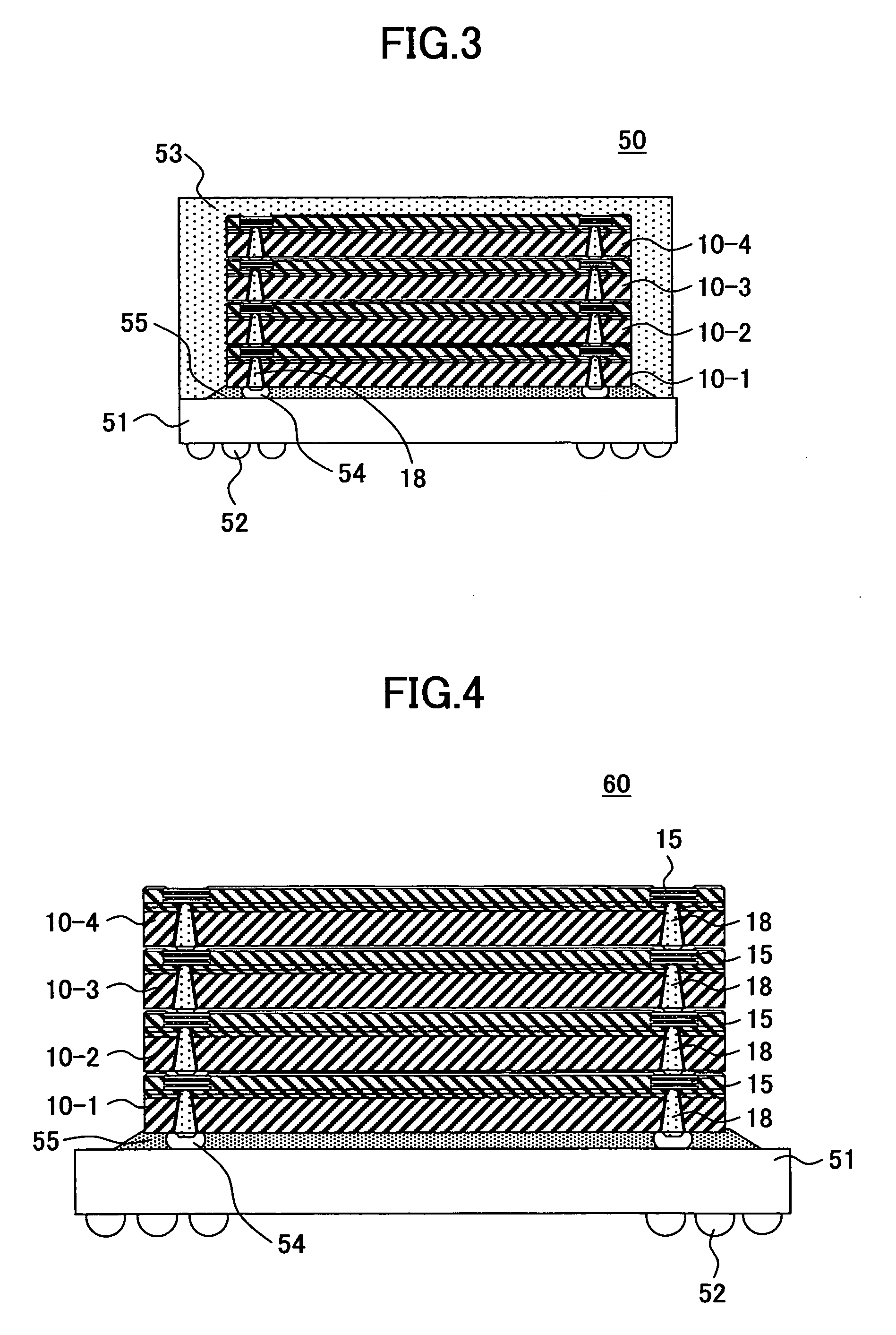

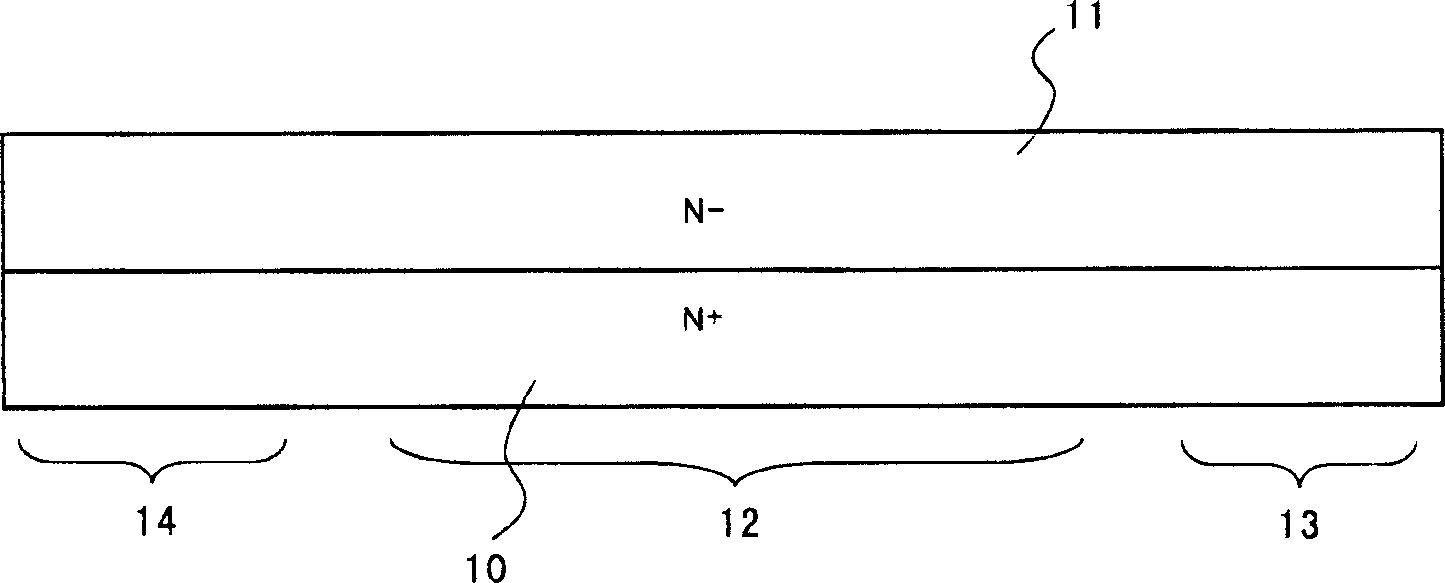

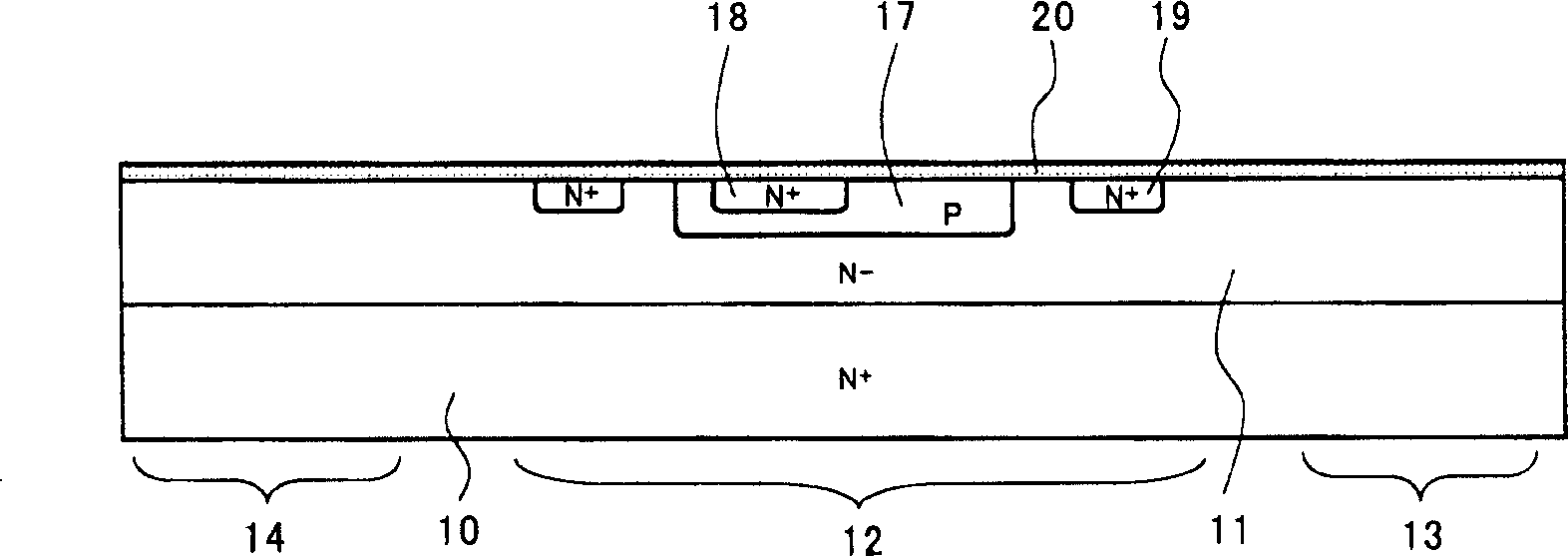

Semiconductor device, three-dimensional semiconductor device, and method of manufacturing semiconductor device

InactiveUS20050167812A1Reduce connection resistanceHigh densitySemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

A semiconductor device is provided that forms a three-dimensional semiconductor device having semiconductor devices stacked on one another. In this semiconductor device, a hole is formed in a silicon semiconductor substrate that has an integrated circuit unit and an electrode pad formed on a principal surface on the outer side. The hole is formed by etching, with the electrode pad serving as an etching stopper layer. An embedded electrode is formed in the hole. This embedded electrode serves to electrically lead the electrode pad to the principal surface on the bottom side of the silicon semiconductor substrate.

Owner:FUJITSU LTD

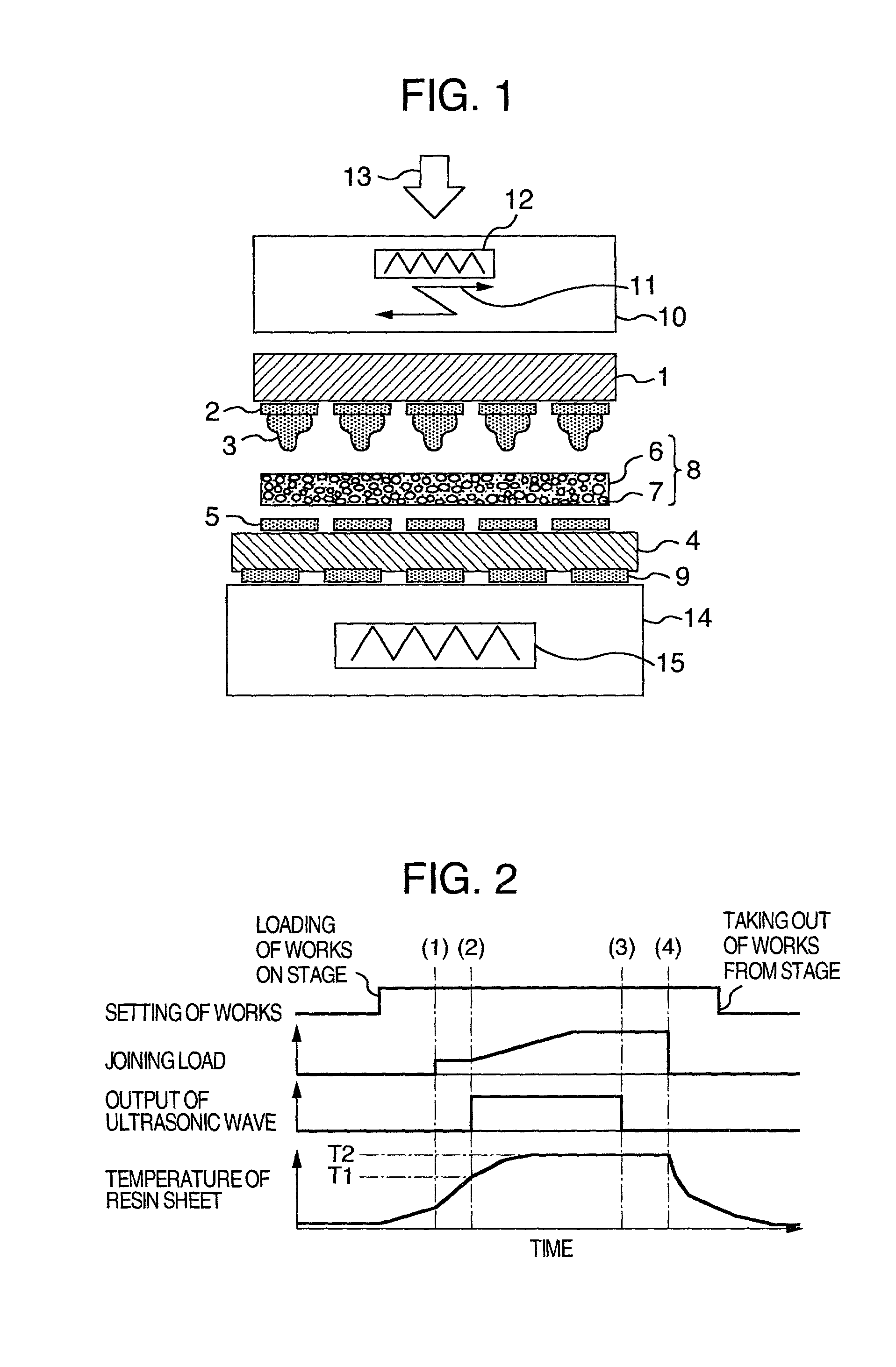

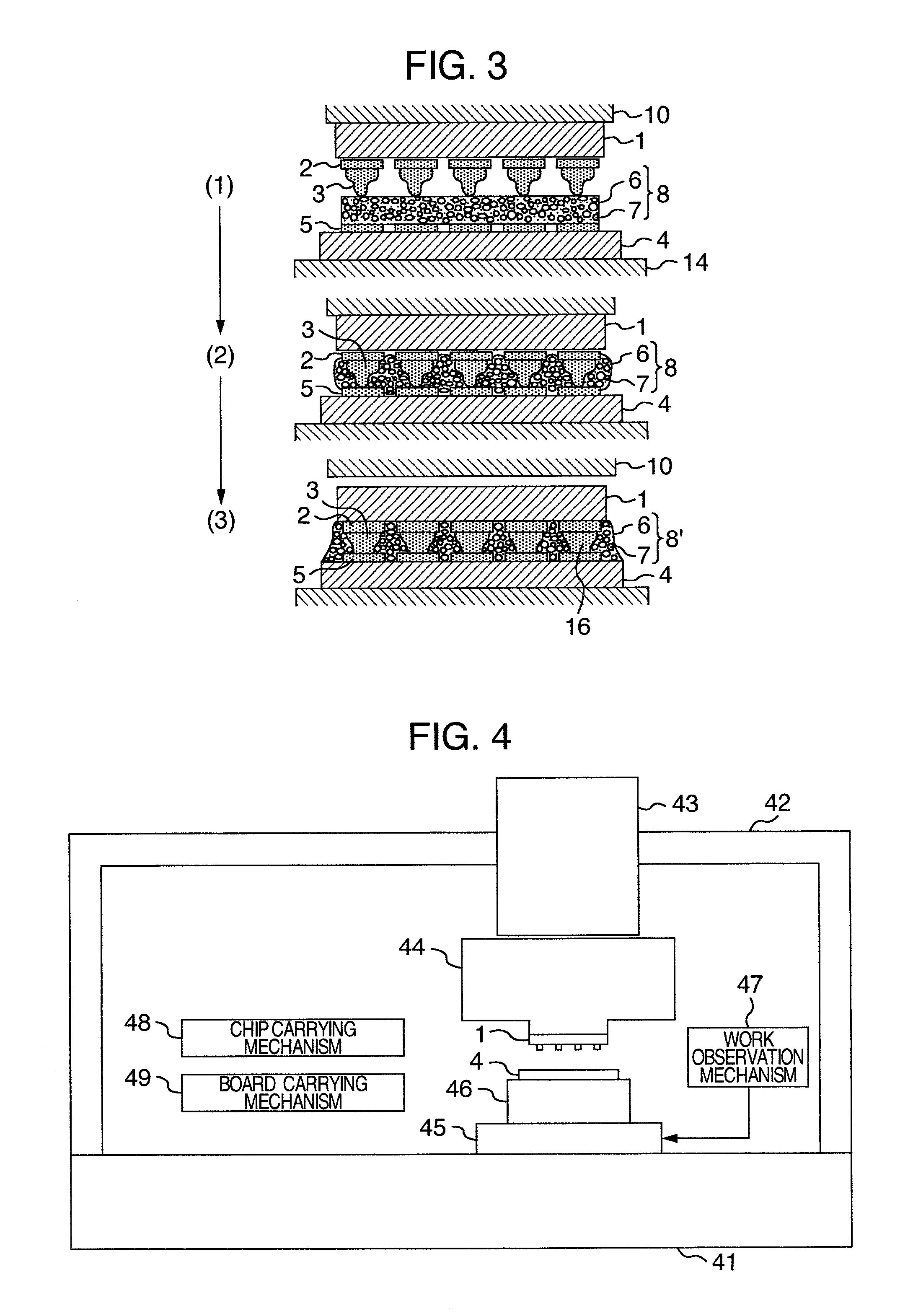

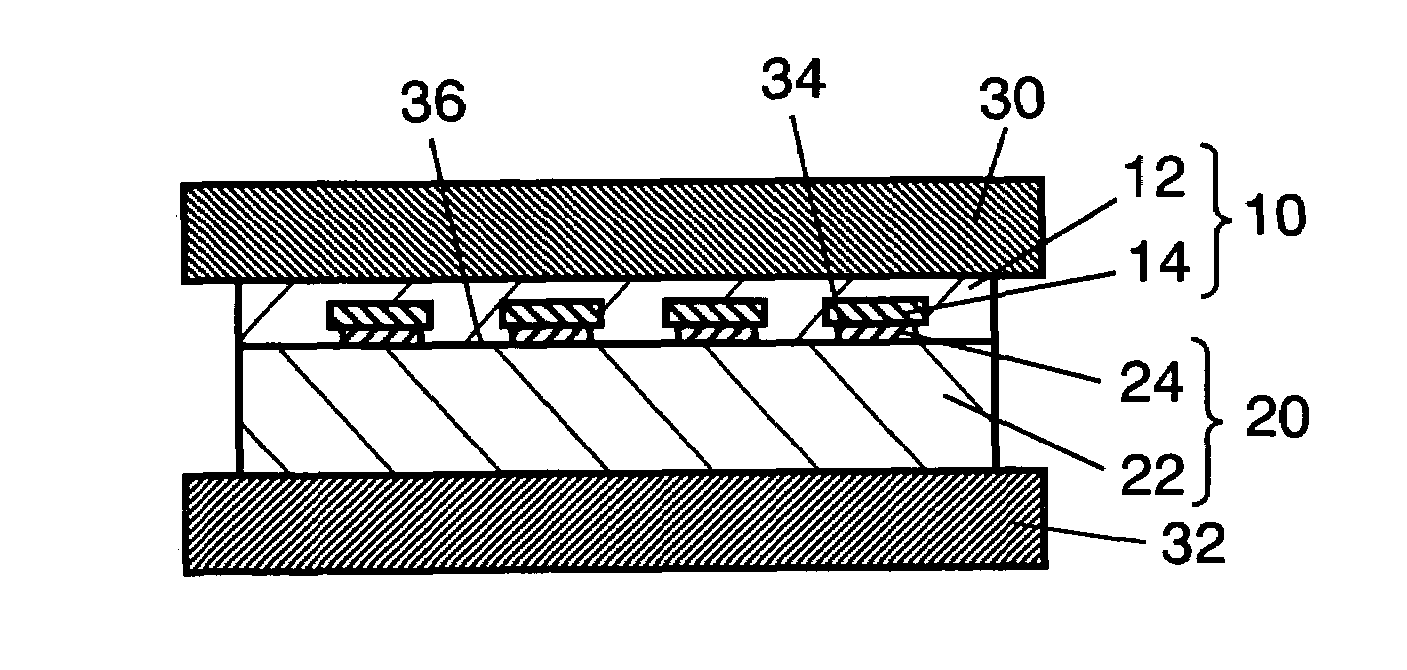

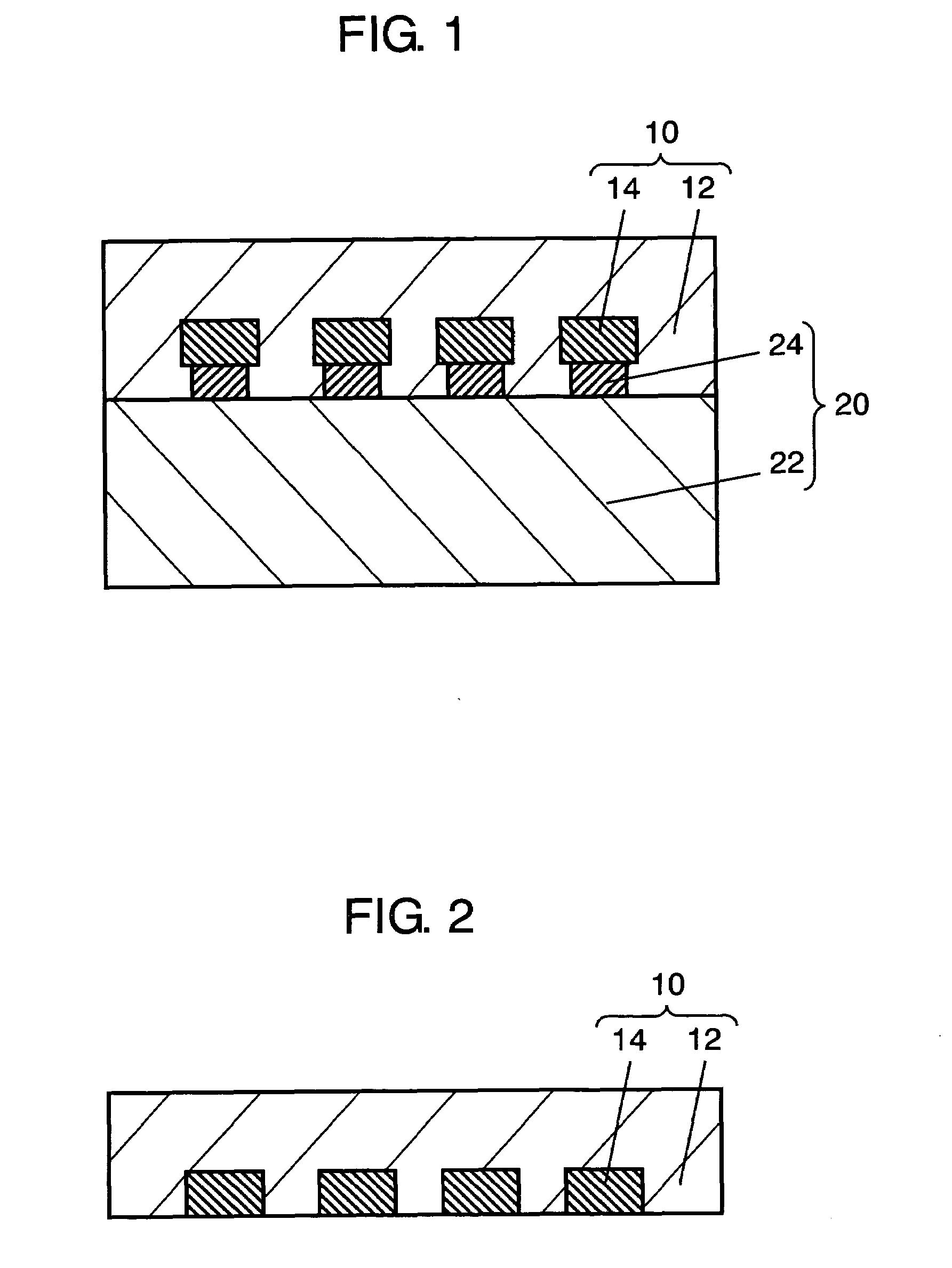

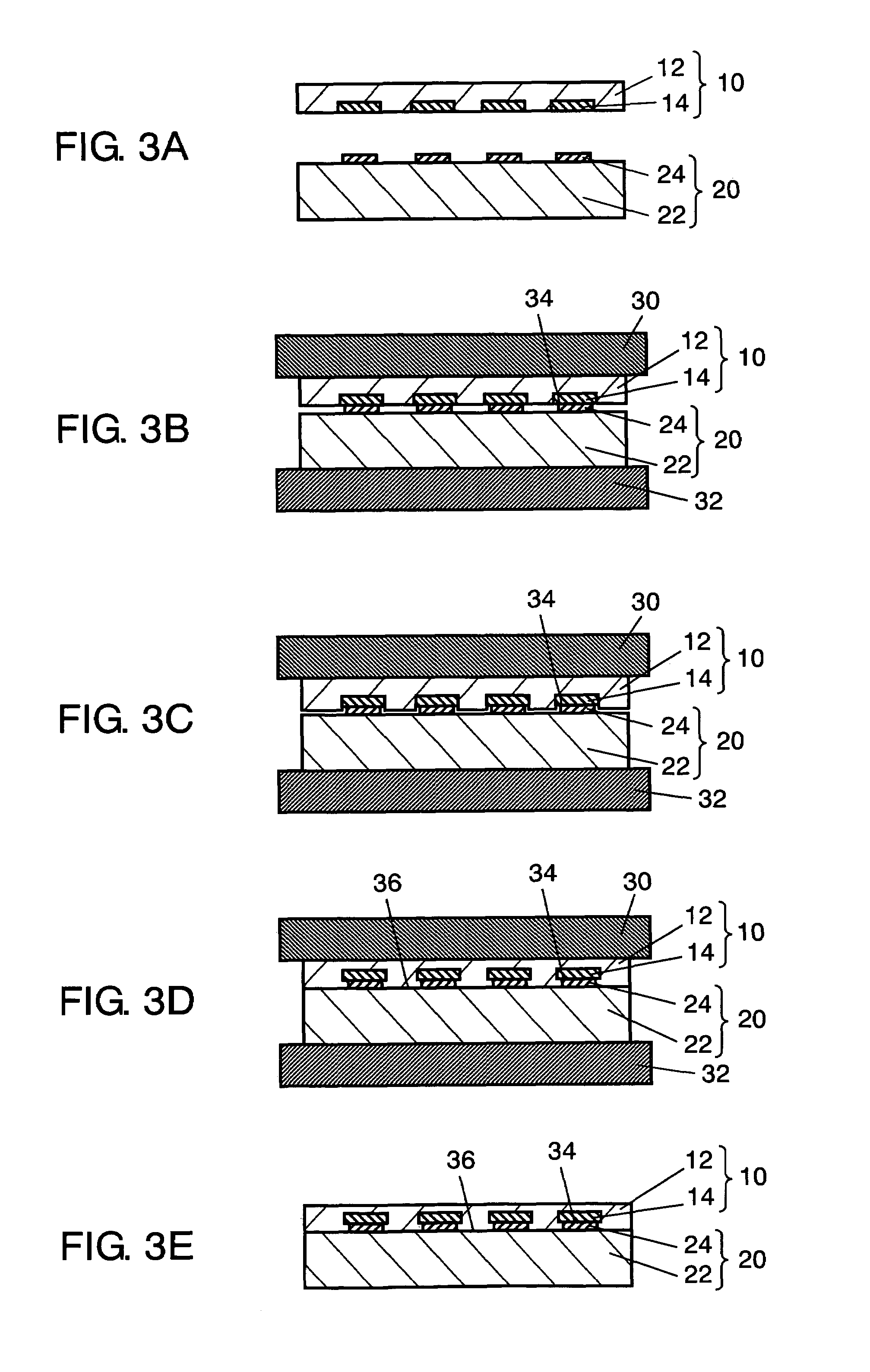

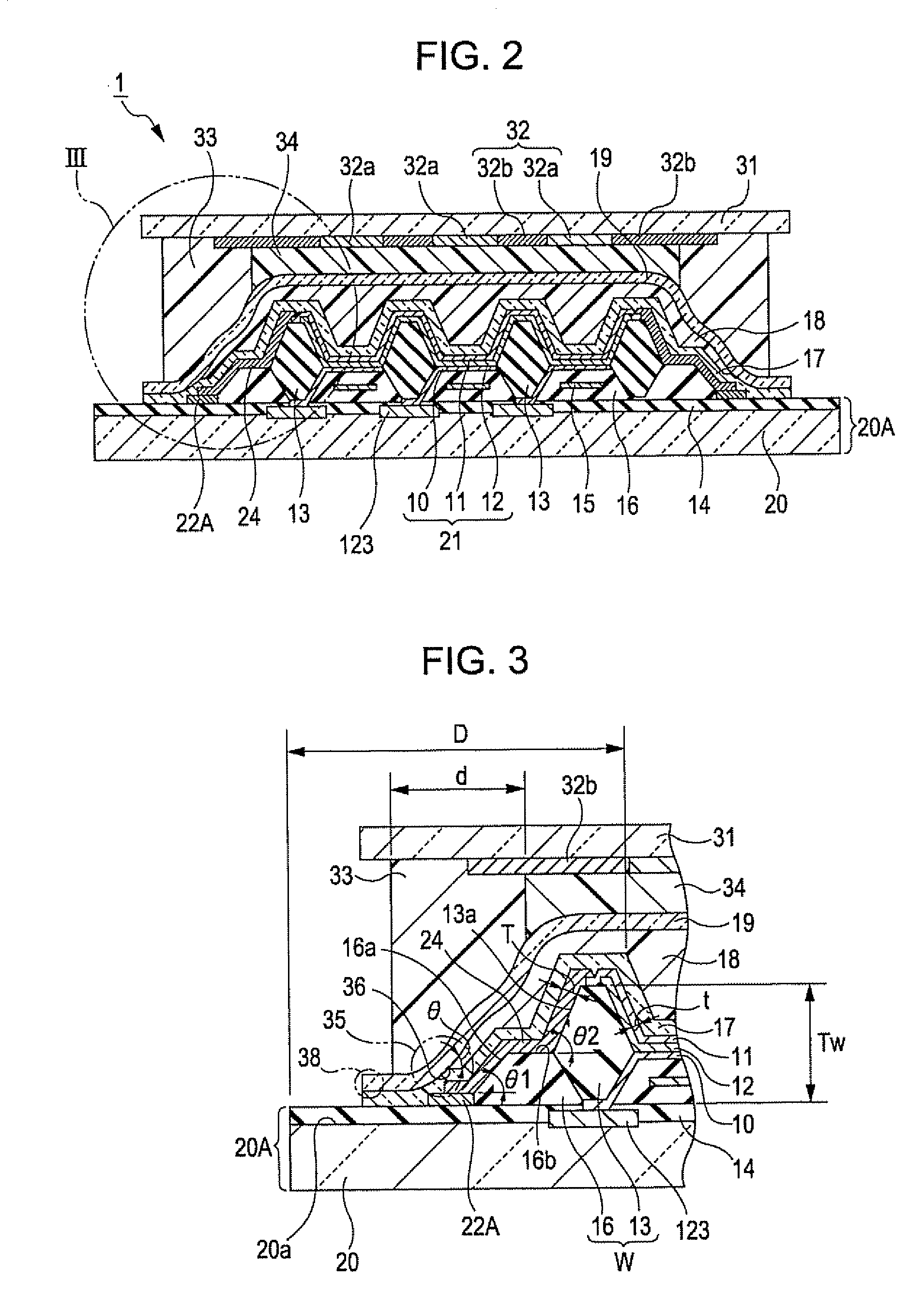

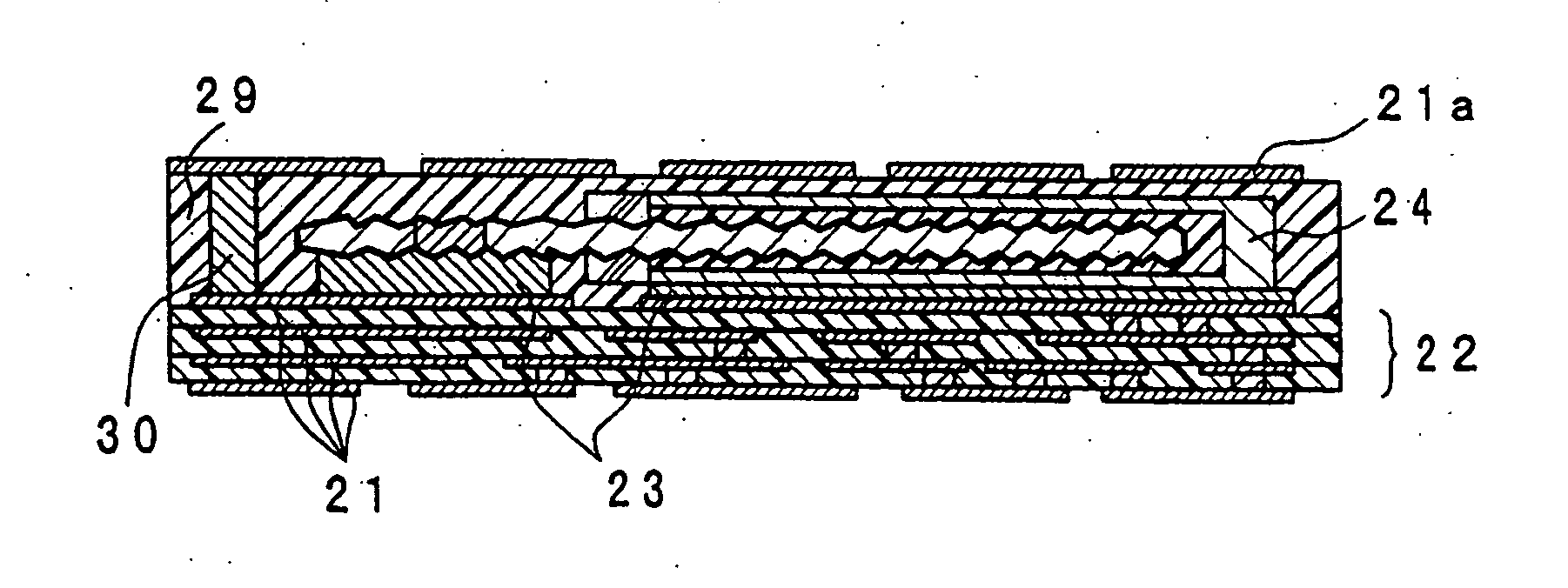

Connecting structure of circuit board and method for manufacturing the same

InactiveUS7229293B2Increase productionReduce connection resistanceSoldered/welded connectionsPrinted circuit manufactureElectrical conductorEngineering

First circuit board 10 including first resin base material 12 which is softened by heating and has a fusing property, and a plurality of first conductor patterns 14 formed on a surface of first resin base material 12, and second circuit board 20 on which a plurality of second conductor patterns 24 are formed with the same pitch as that of first conductor patterns 14 are provided. In the configuration, first conductor patterns 14 and second conductor patterns 24 are brought into mechanical contact with each other to provide electrical conduction; first resin base material 12 covers first conductor patterns 14 and second conductor patterns 24 and is bonded to second resin base material 22 of second circuit board 20, thereby connecting first circuit board 10 and second circuit board 20 to each other.

Owner:PANASONIC CORP

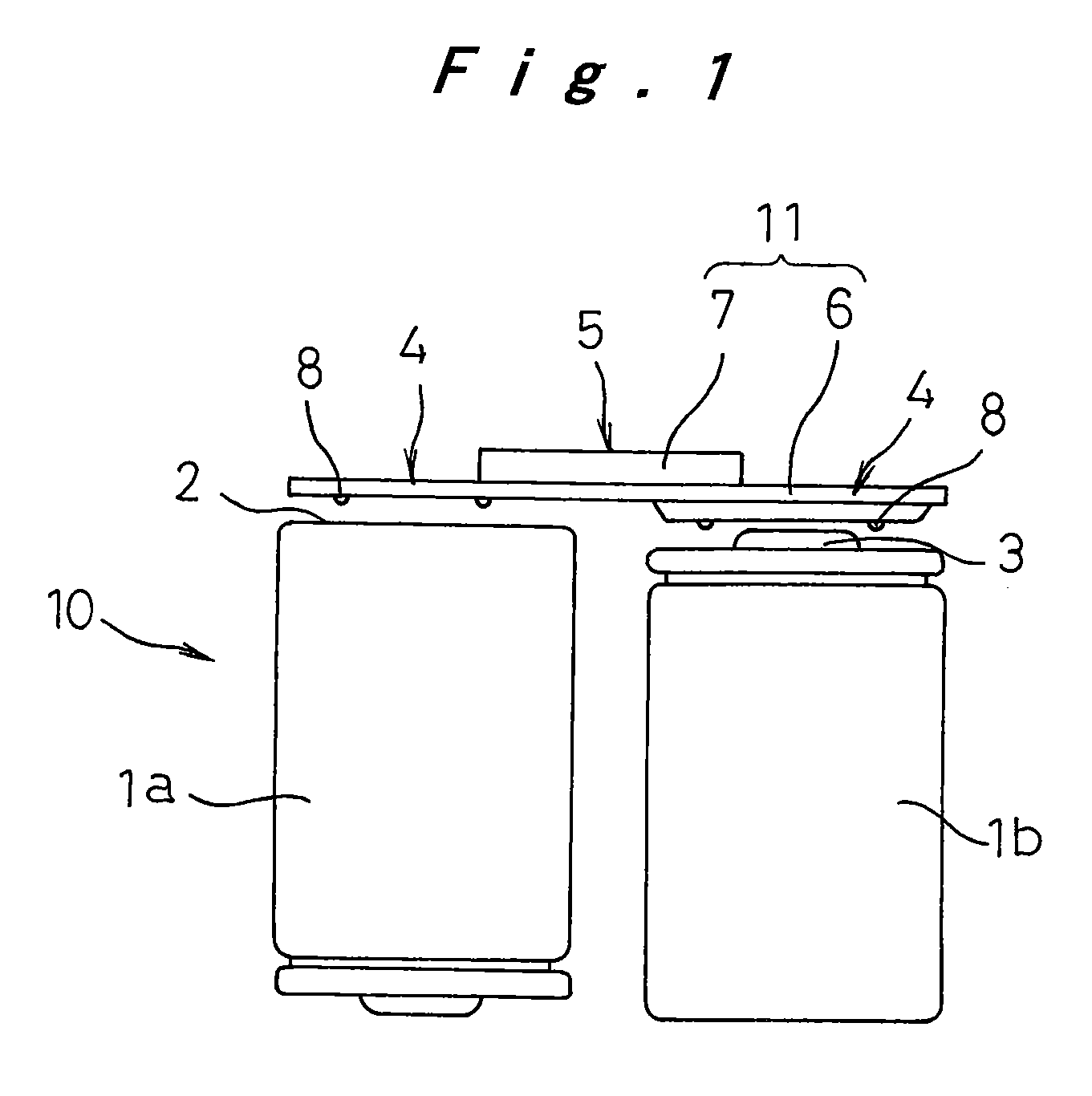

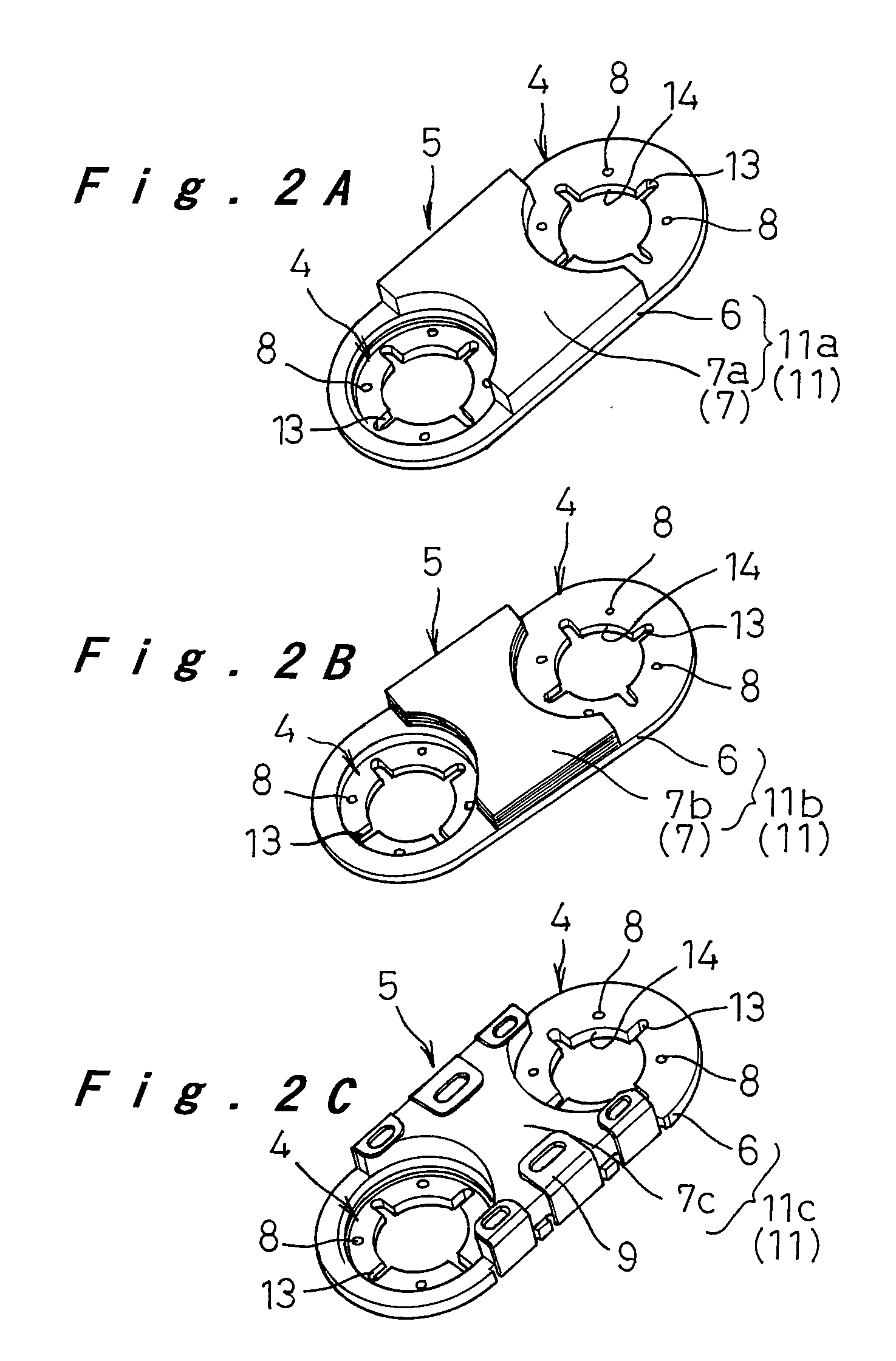

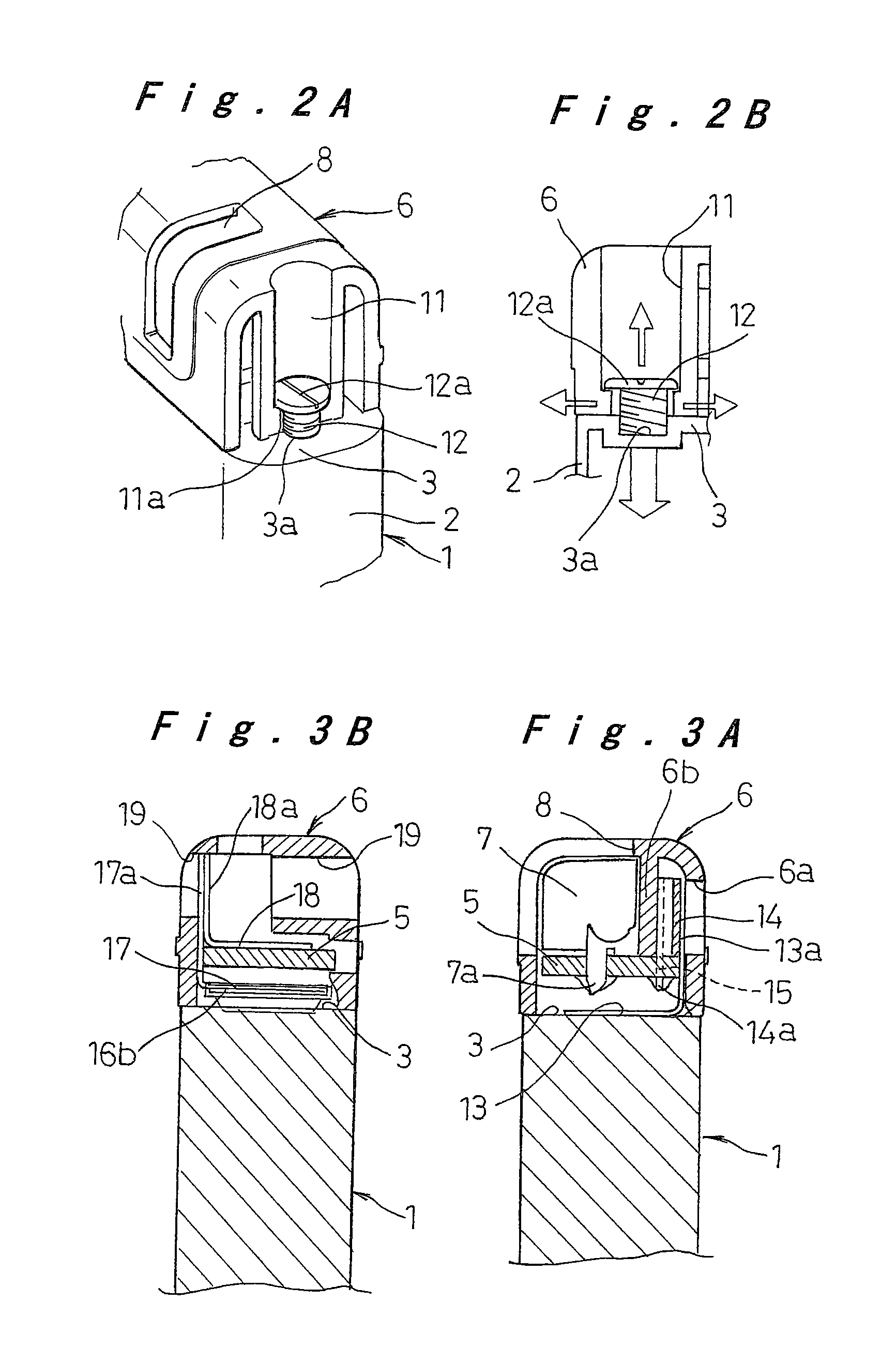

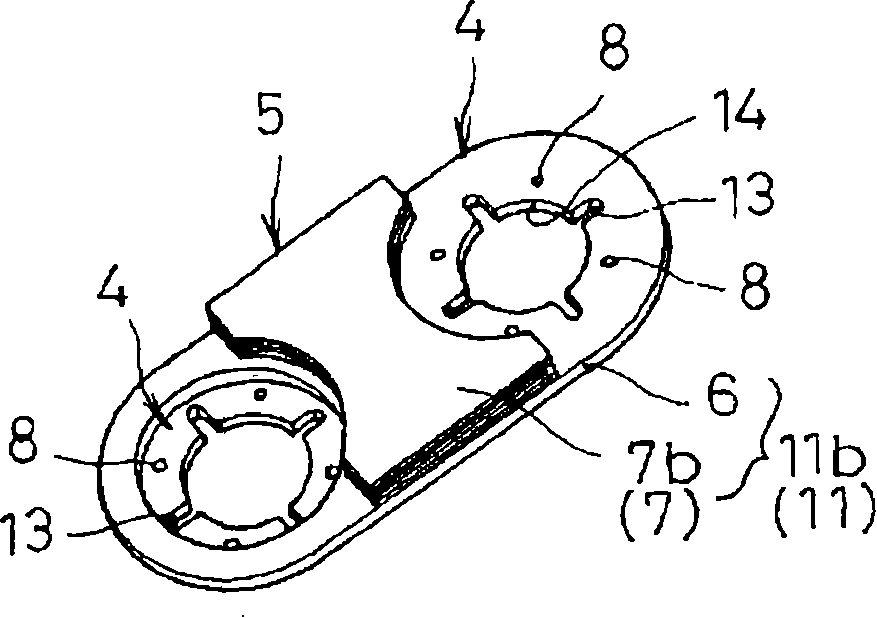

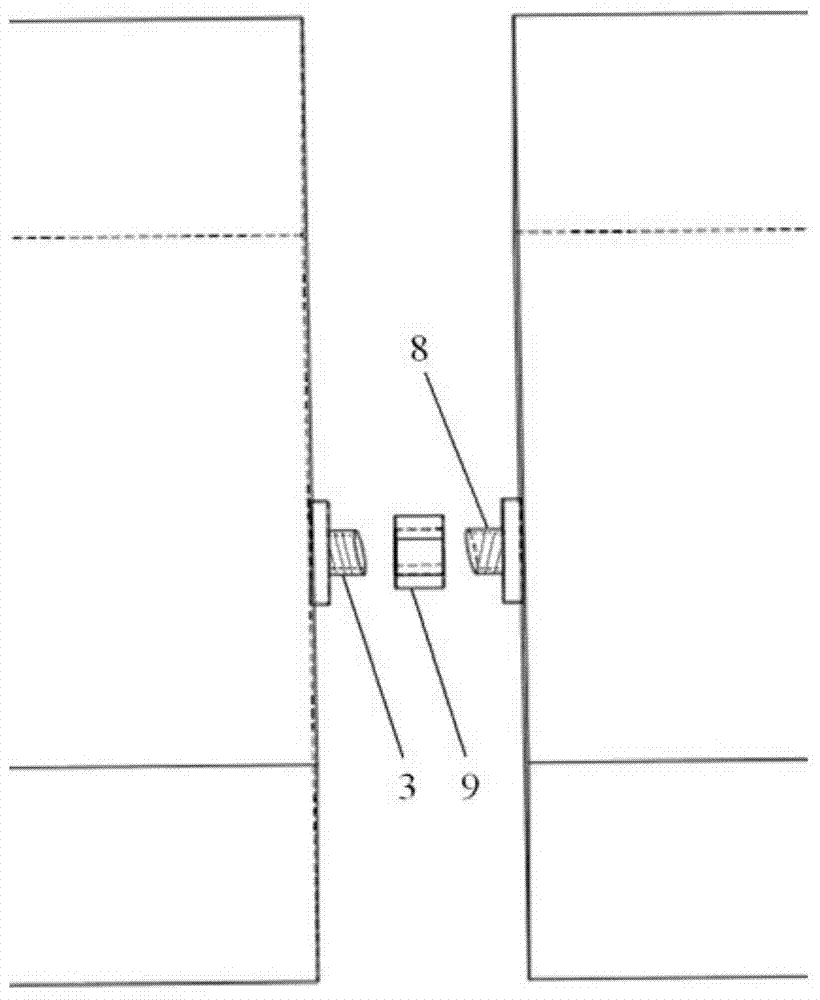

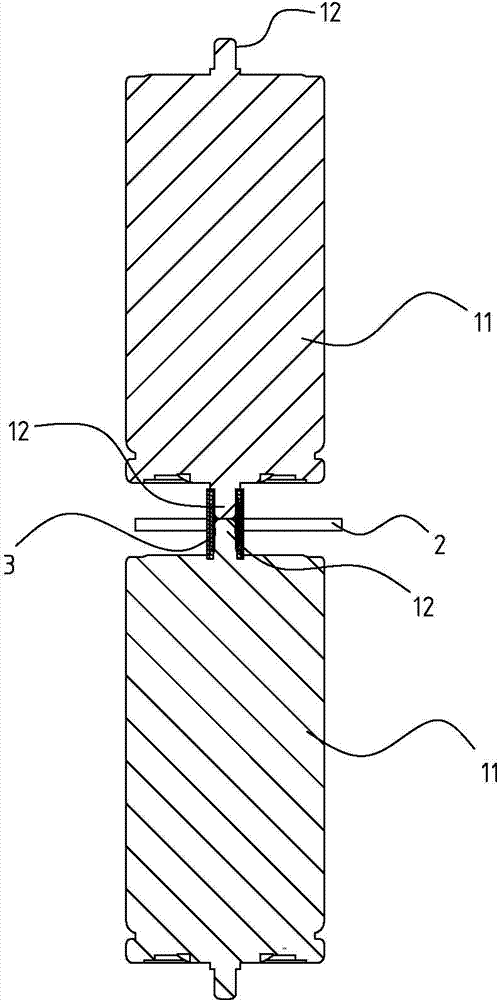

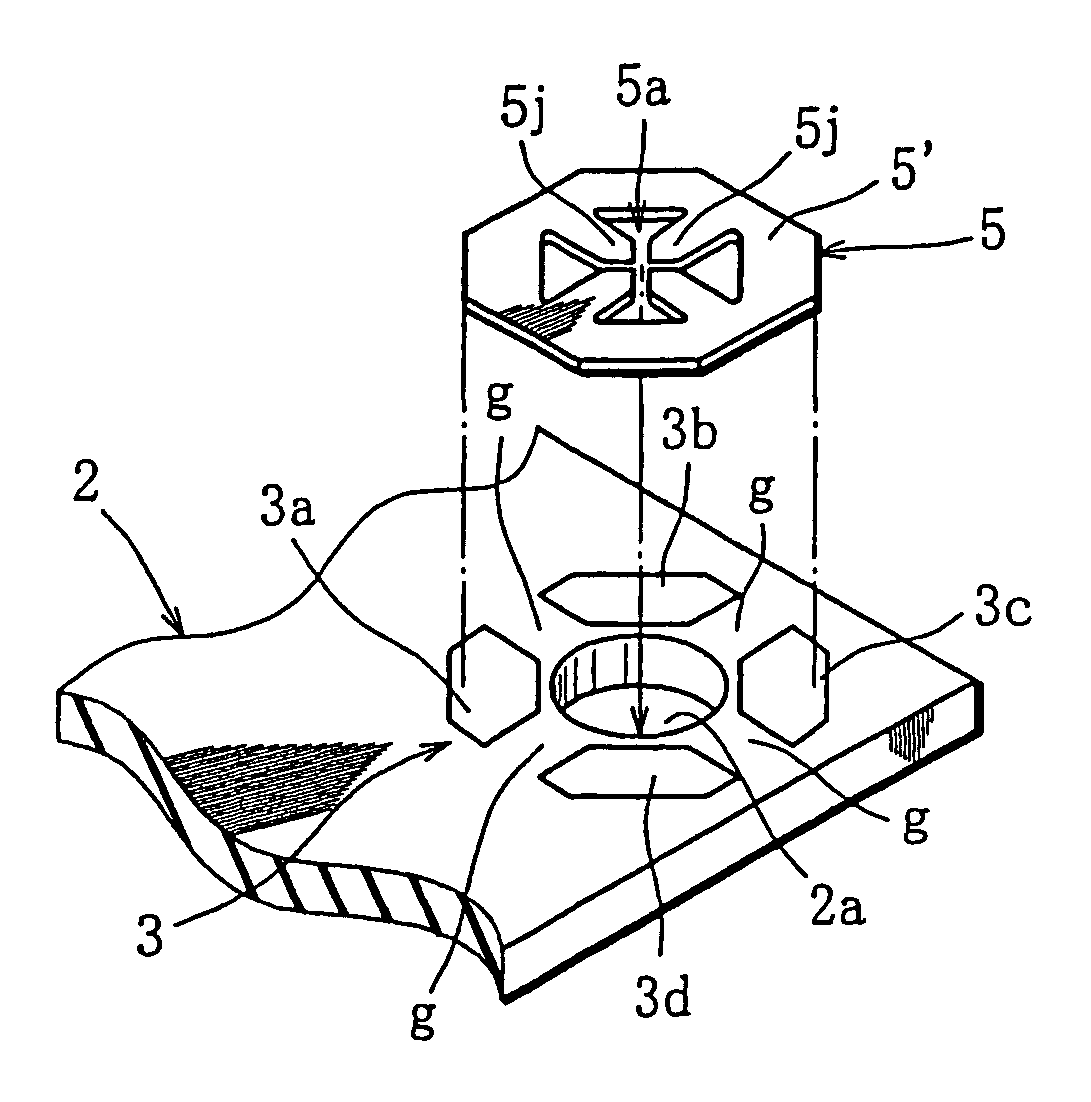

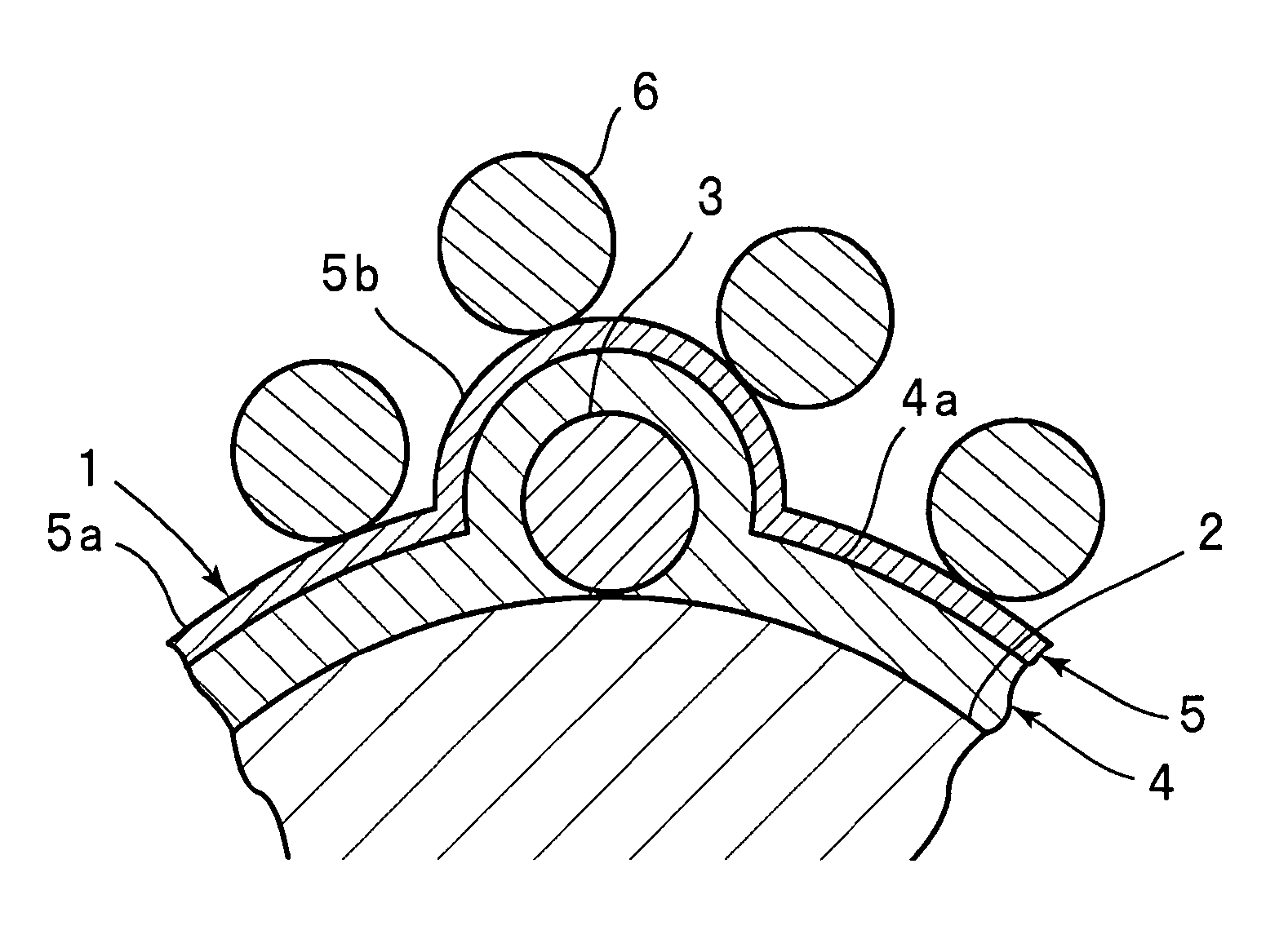

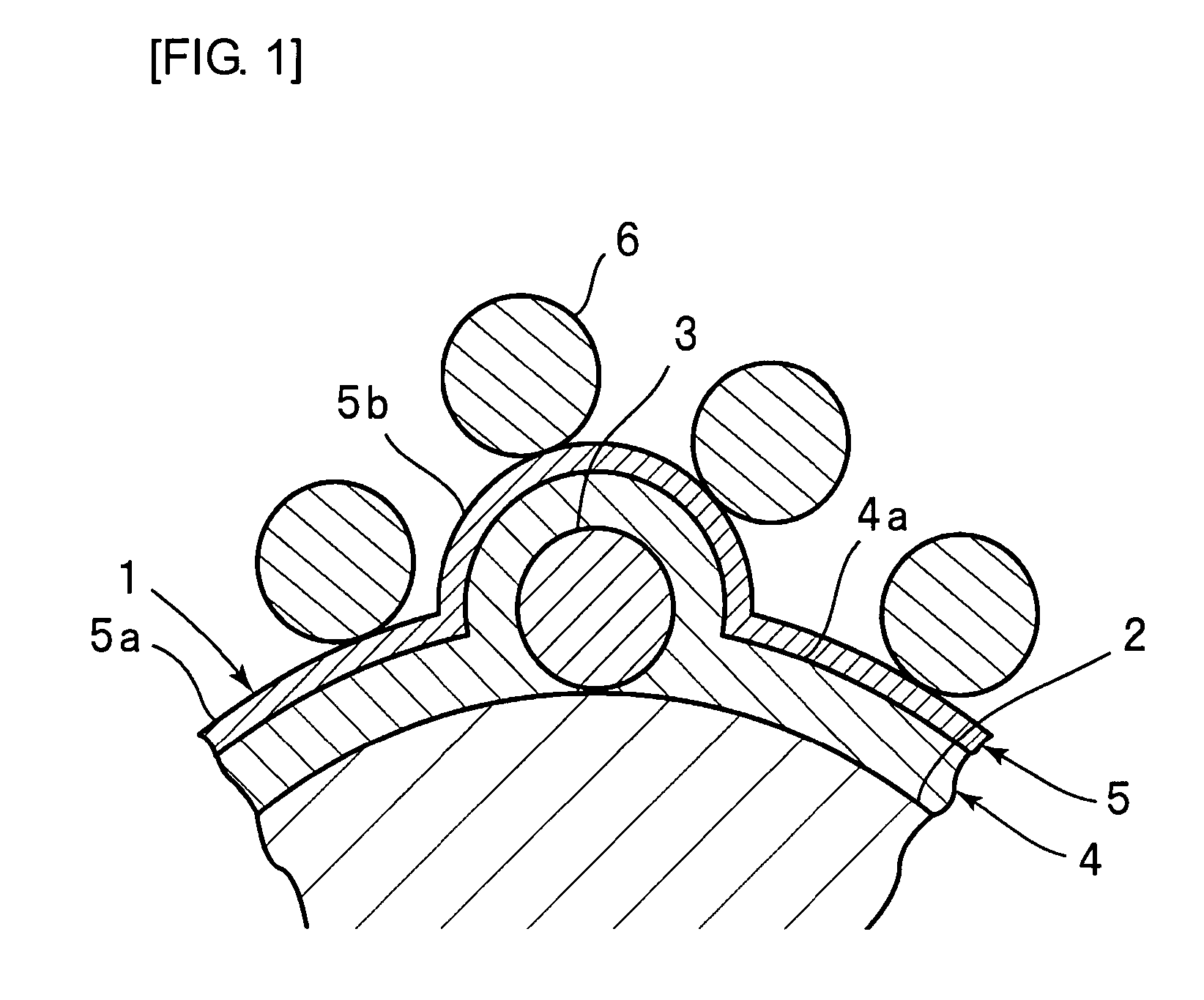

Inter-battery connection device

InactiveUS20090123830A1Avoid problemsReliable weldingPrimary cell to battery groupingNon-aqueous electrolyte accumulatorsElectrical batteryEngineering

An inter-battery connection device for connecting terminals of two batteries (1a, 1b) arranged with their axes parallel to each other. The inter-battery connection device includes an inter-battery connection plate (11) that connects the battery case bottom (2) and the sealing plate (3) of the two batteries. The inter-battery connection plate (11) includes welding portions (4) at the ends of its base plate (6) for welding to the case bottom (2) and the sealing plate (3), respectively. An intermediate metal plate (7) is joined to the middle part of the base plate (6) between the welding portions (4, 4) to form an intermediate portion (5) having a greater thickness than each welding portion (4). The inter-battery connection device has reduced electric resistance while achieving improved weldability.

Owner:PANASONIC CORP

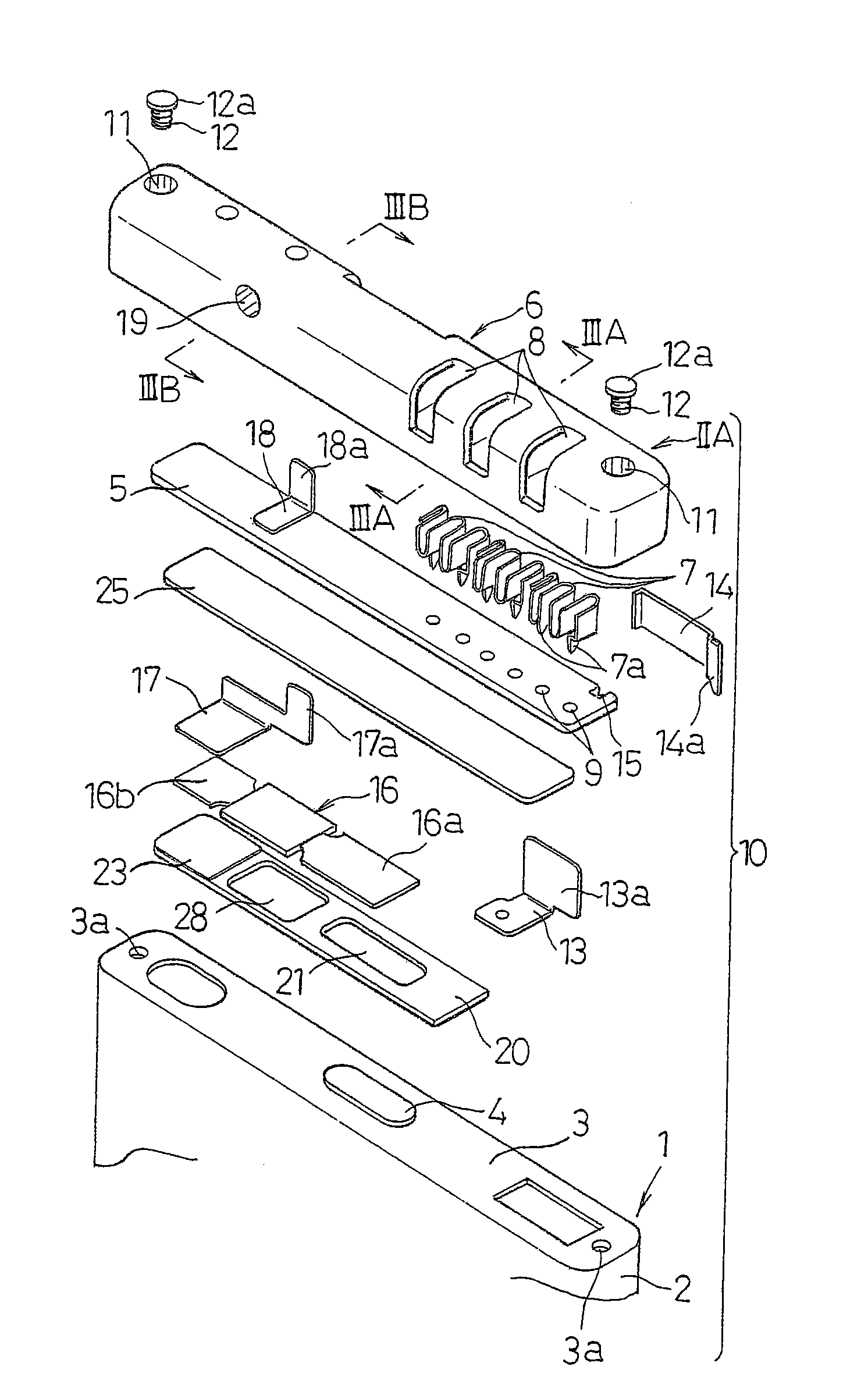

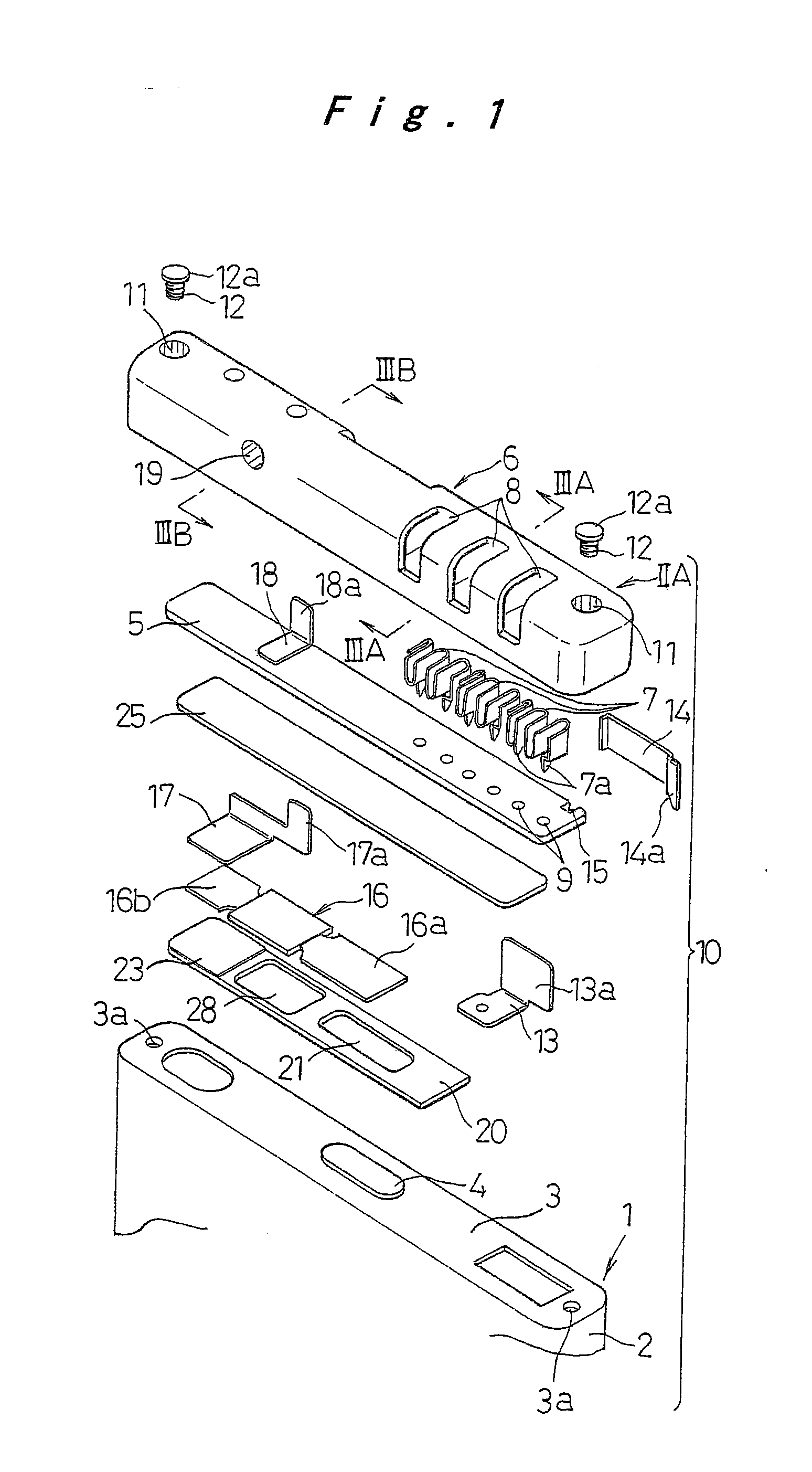

Battery Pack

InactiveUS20080233472A1Strengthen the strength of attachmentReduce connection resistanceBatteries circuit arrangementsPrimary cellsScrew headElectrical and Electronics engineering

A battery pack (10) includes: a battery (1); a circuit substrate (5) having a charge / discharge safety circuit and arranged on one end face (3) of the battery; and an end case (6) in which an external connection terminal (7) is set. In this battery pack, the circuit substrate (5) is arranged inside the end case (6), and the end case (6) is secured to the battery by screws (12) with a screw head (12a) extending through and engaging with the end case (6) at both ends and tips of the screw (12) being engaged into the end face (3) at both ends of the battery (1). This achieves a compact battery pack with a reduced connection resistance, while achieving both high reliability and productivity.

Owner:PANASONIC CORP

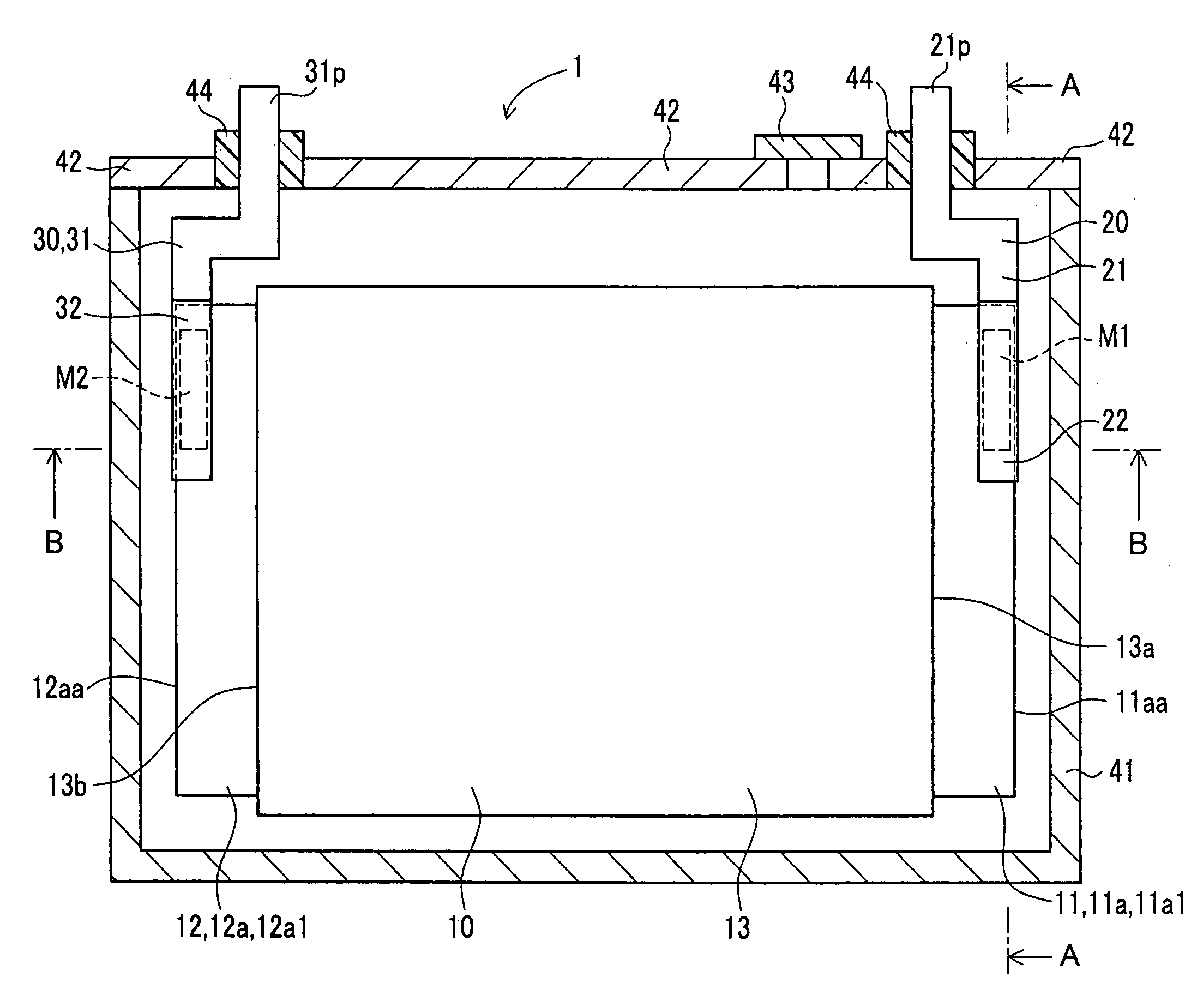

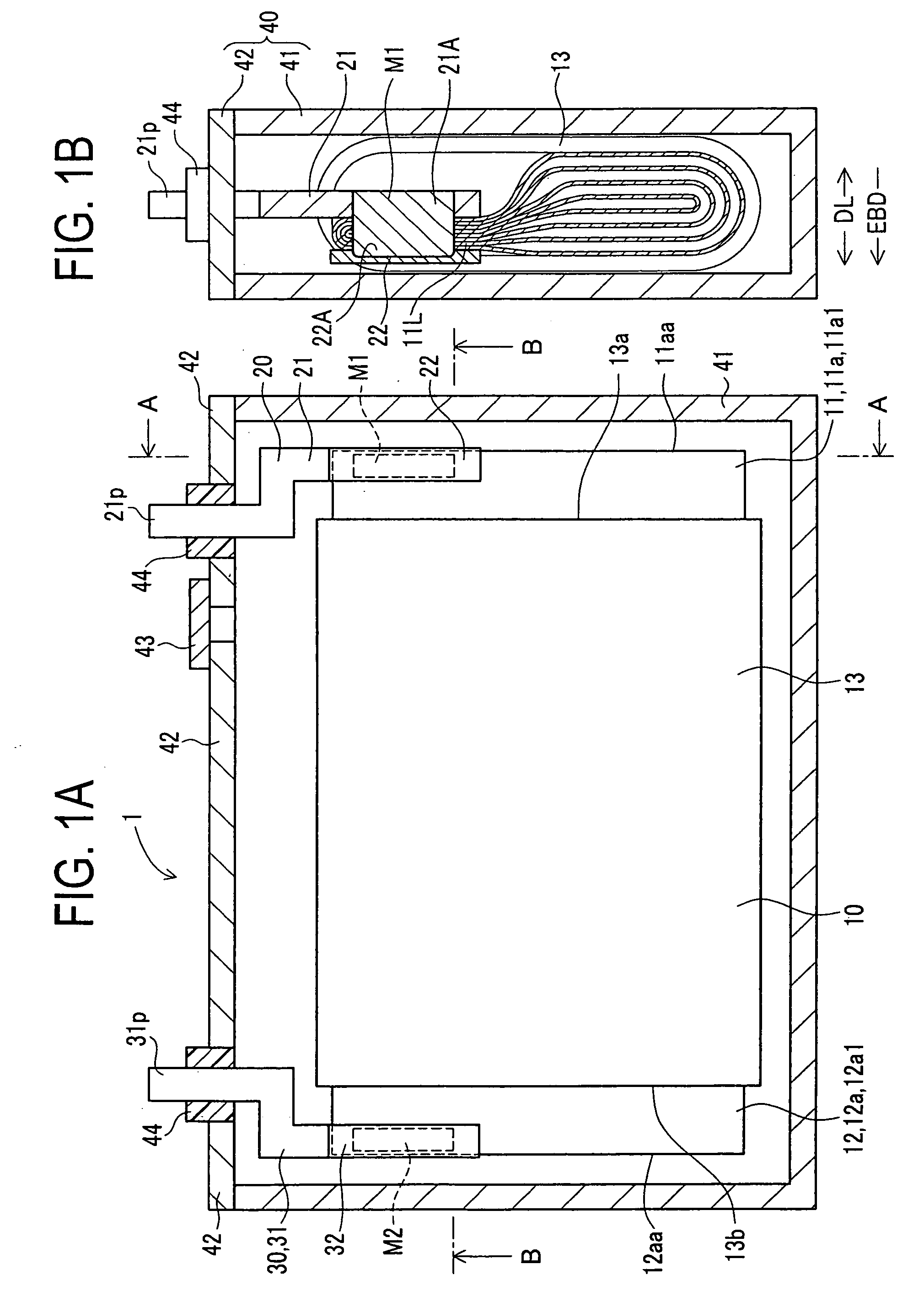

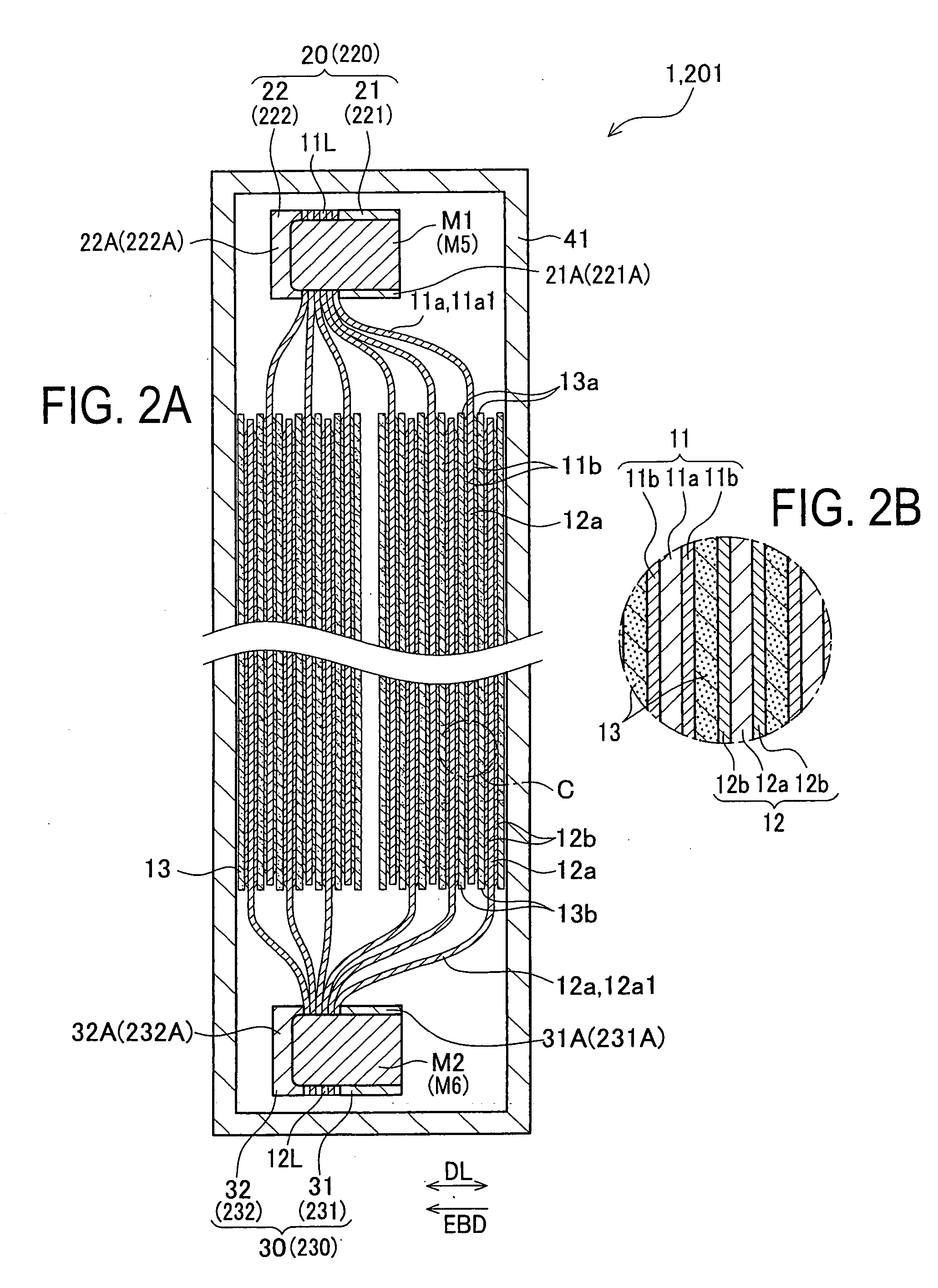

Secondary battery and manufacturing method thereof

InactiveUS20090104525A1Easy to manufactureEasy to handleLarge-sized flat cells/batteriesPrimary cellsMetal foilEngineering

In a secondary battery, a positive metal foil having a laminated portion in which parts of the metal foil are laminated in close contact with each other, and a positive electrode current collector terminal member has a contact portion placed in close contact with at least one side of the positive foil laminated portion in a lamination direction thereof The secondary battery is manufactured by welding the parts of the positive metal foil to each other and the positive foil laminated portion and the contact portion to each other by irradiation of an energy beam emitted to travel in the lamination direction while an irradiation site is moved.

Owner:PANASONIC EV ENERGY CO LTD

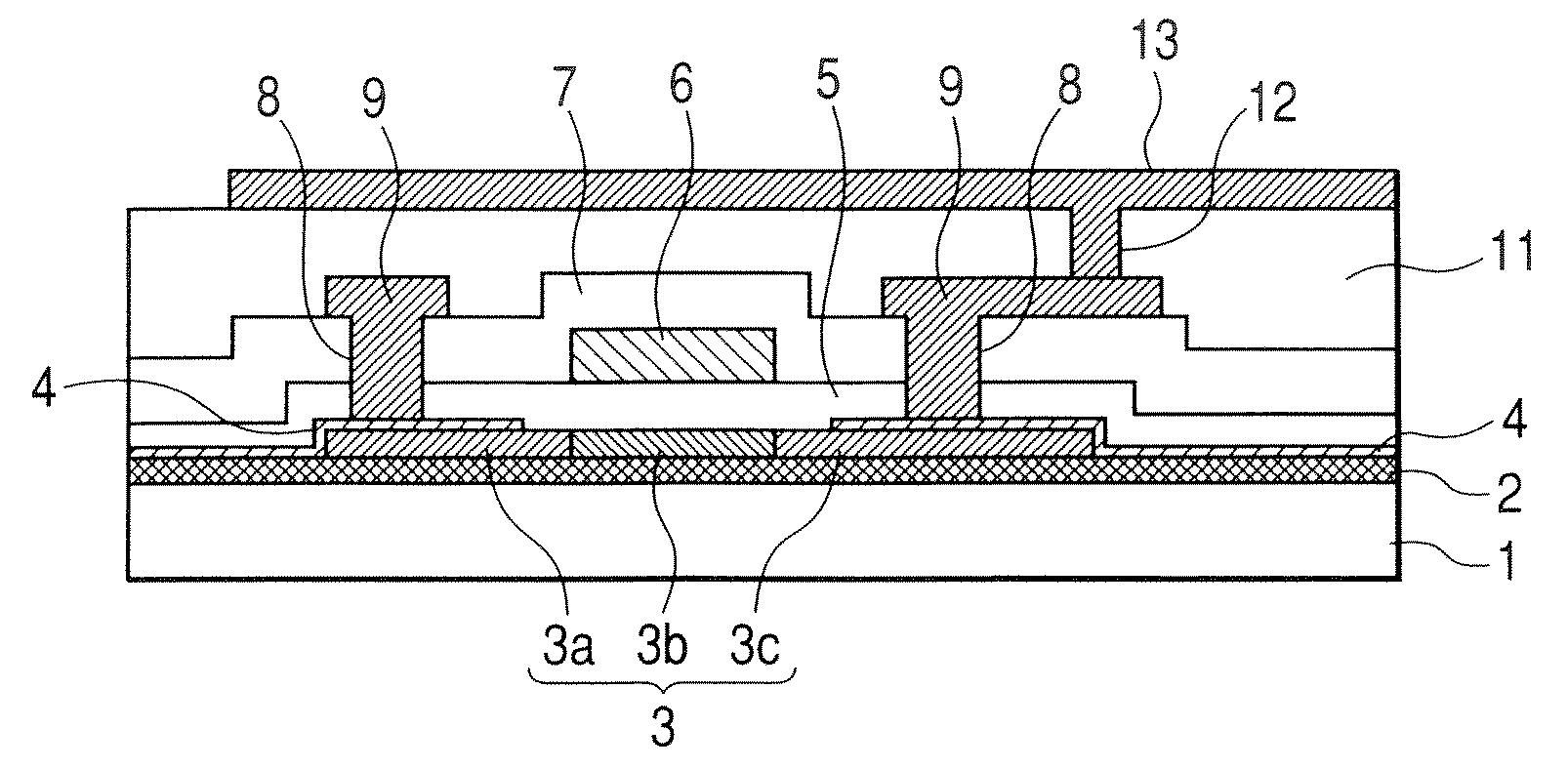

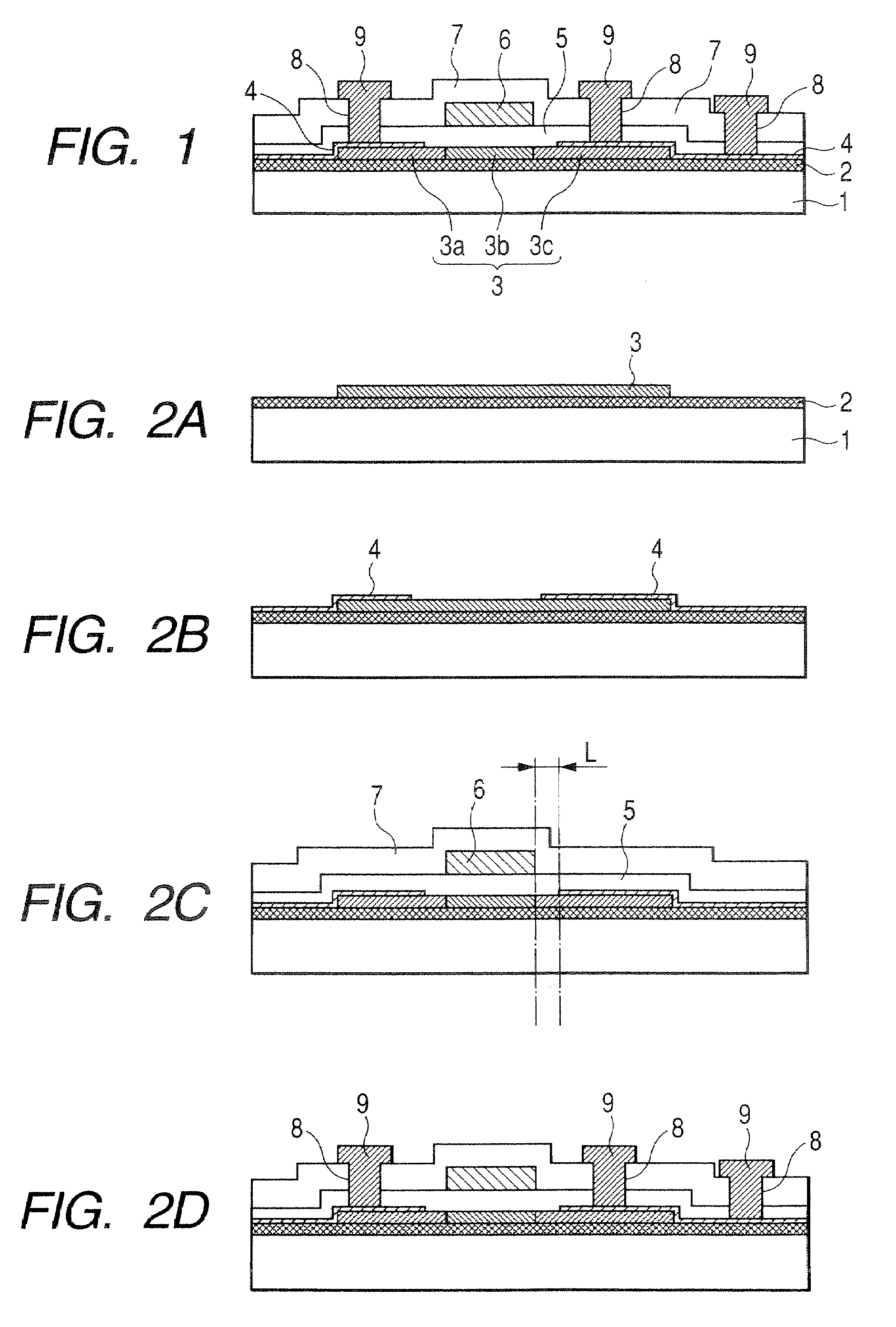

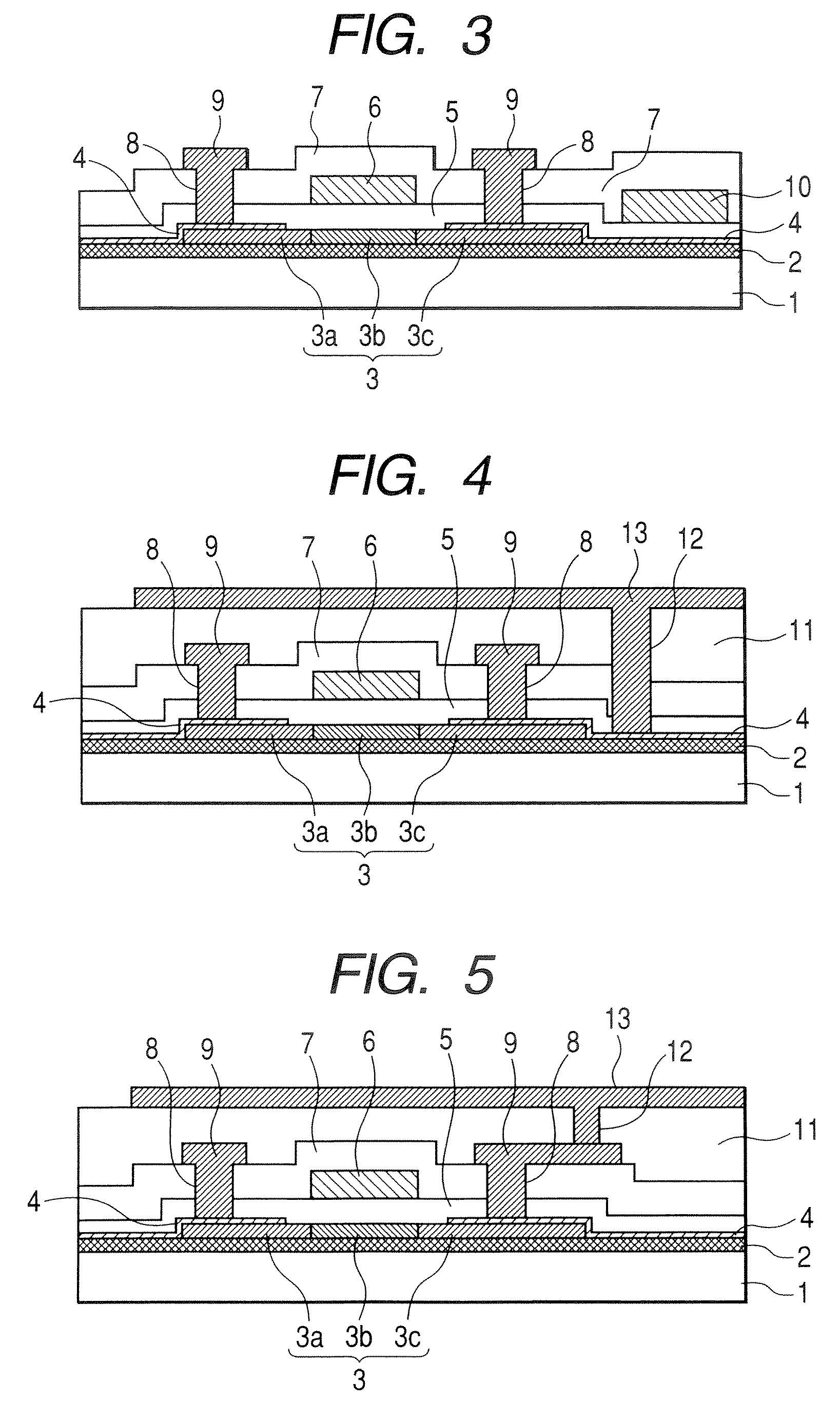

Thin film transistor device, method for manufacturing the same and display apparatus having the same

InactiveUS20070148831A1Easy resistanceImprove batch productivitySolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorMetal

A thin film transistor device includes: an island shaped semiconductor layer; a metal film that covers at least a part of a source region and a drain region of the semiconductor layer; a gate insulating film that covers the semiconductor layer and the metal film; an interlayer insulating film that covers the gate insulating film; and a signal wire that lies on the interlayer insulating film. The gate insulating film and the interlayer insulating film are formed with contact hole that reaches the metal film. The signal wire is connected to the metal film through the contact hole.

Owner:MITSUBISHI ELECTRIC CORP

Semiconductor device manufacturing method

InactiveCN1841651AGood adhesionIncrease bonding areaWalking sticksUmbrellasBiomedical engineeringSemiconductor

Owner:SANYO ELECTRIC CO LTD

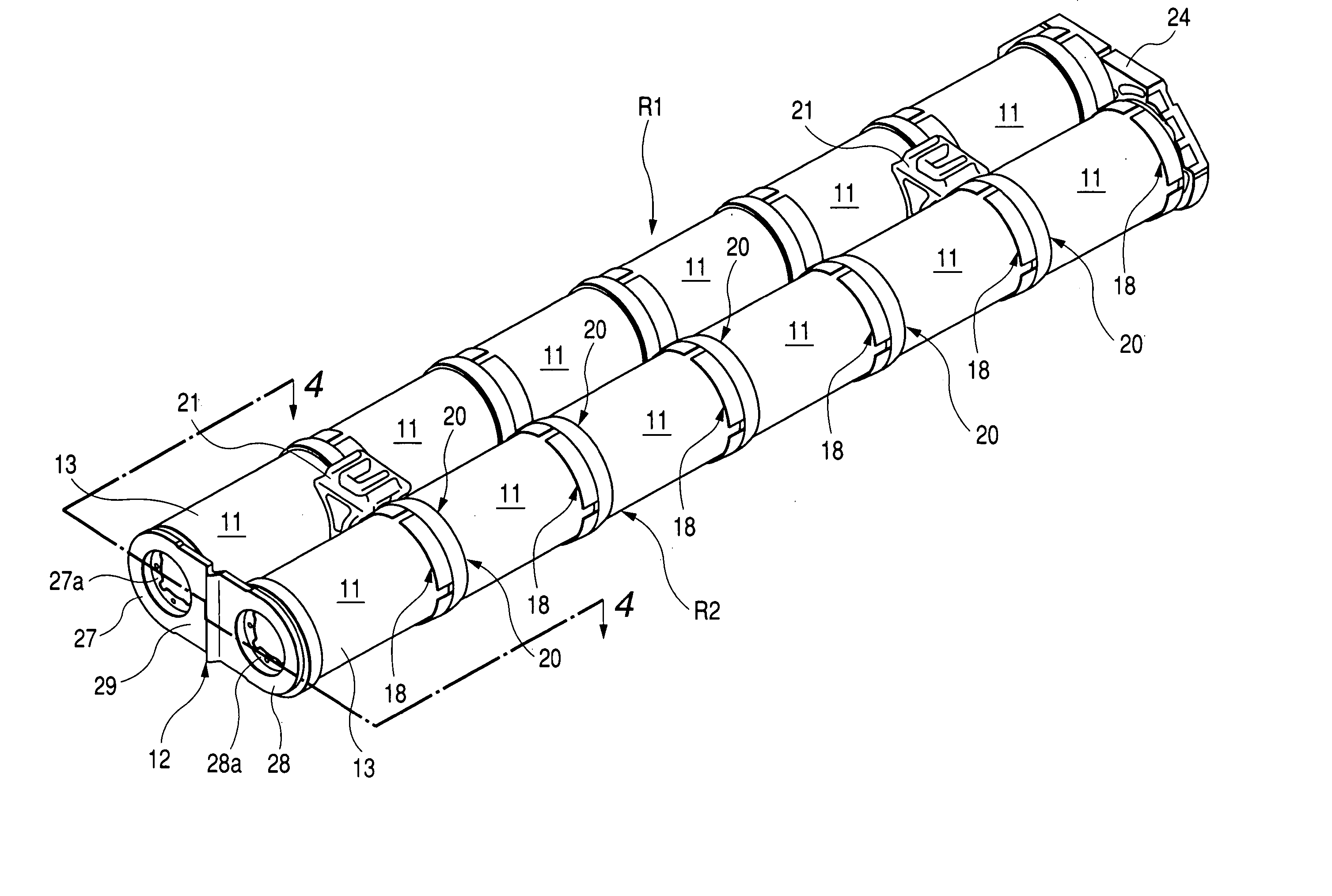

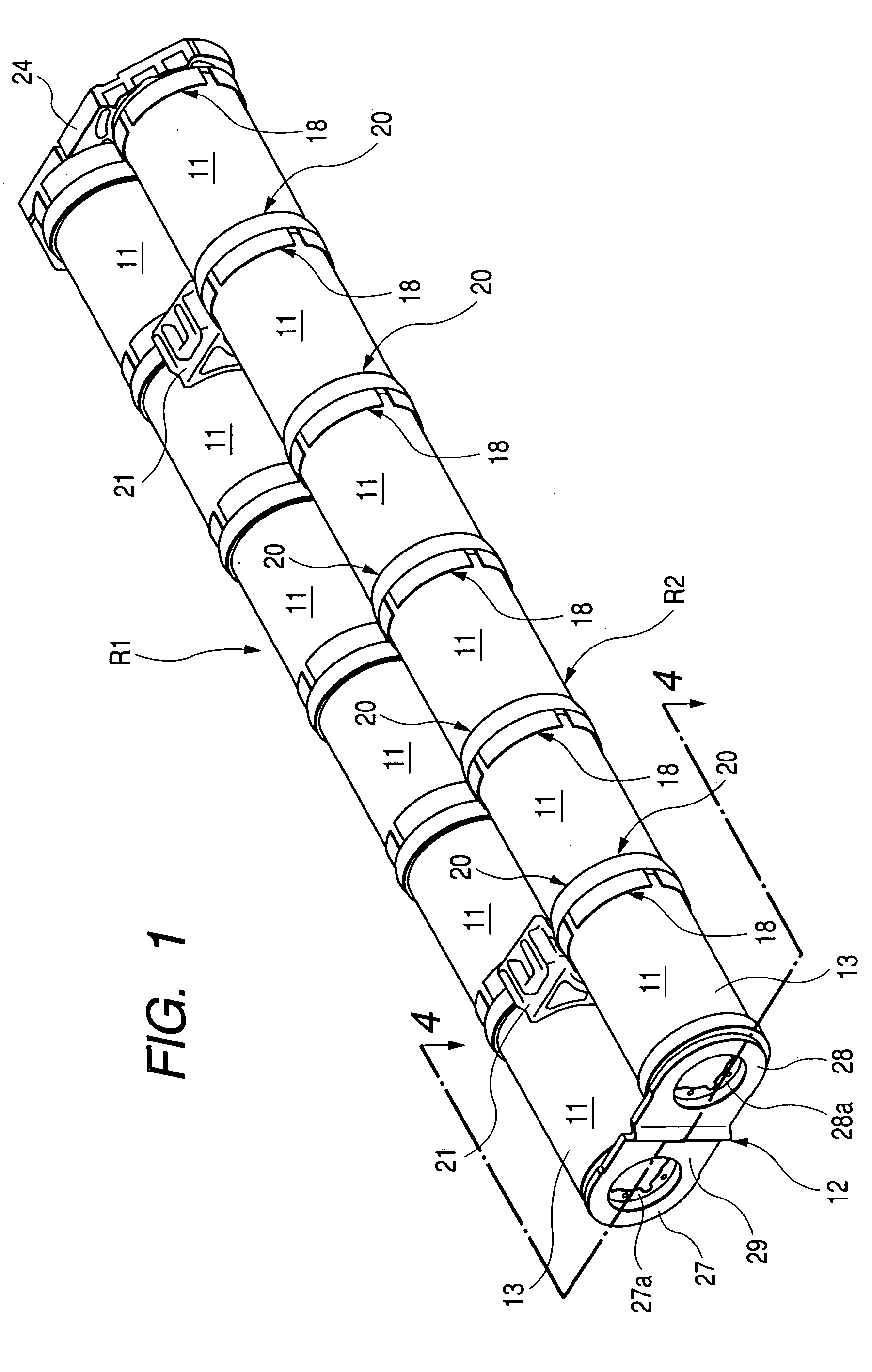

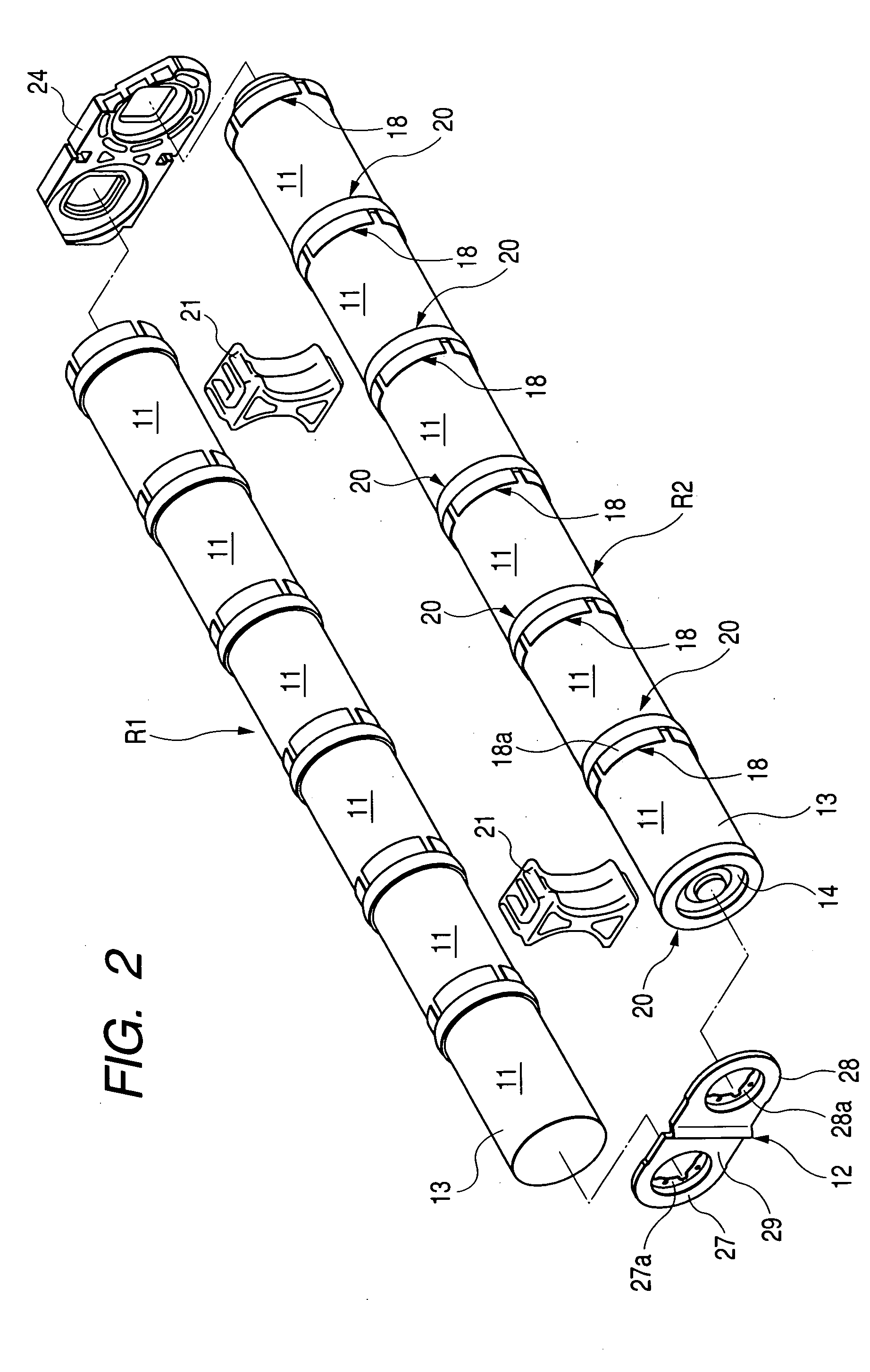

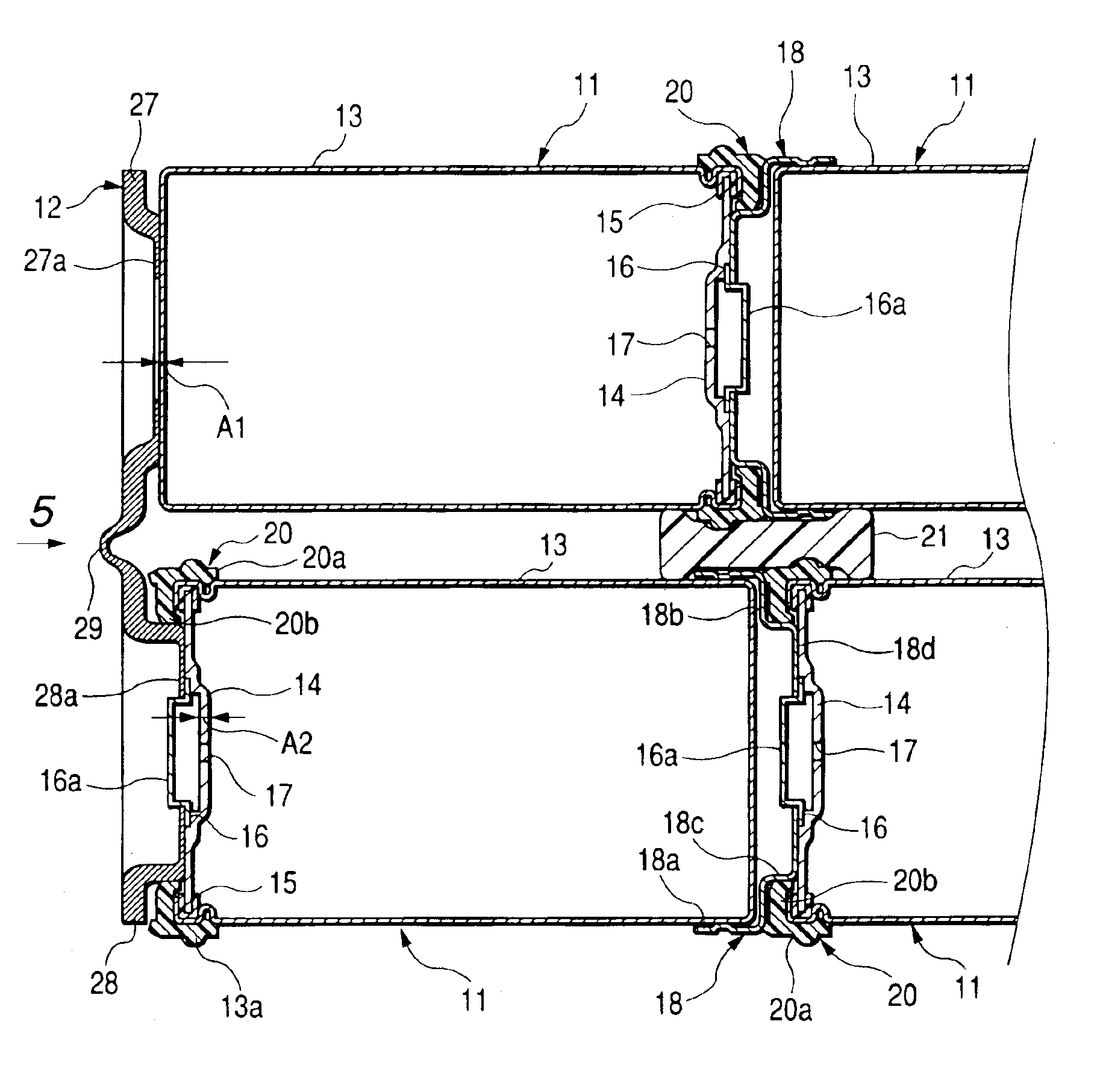

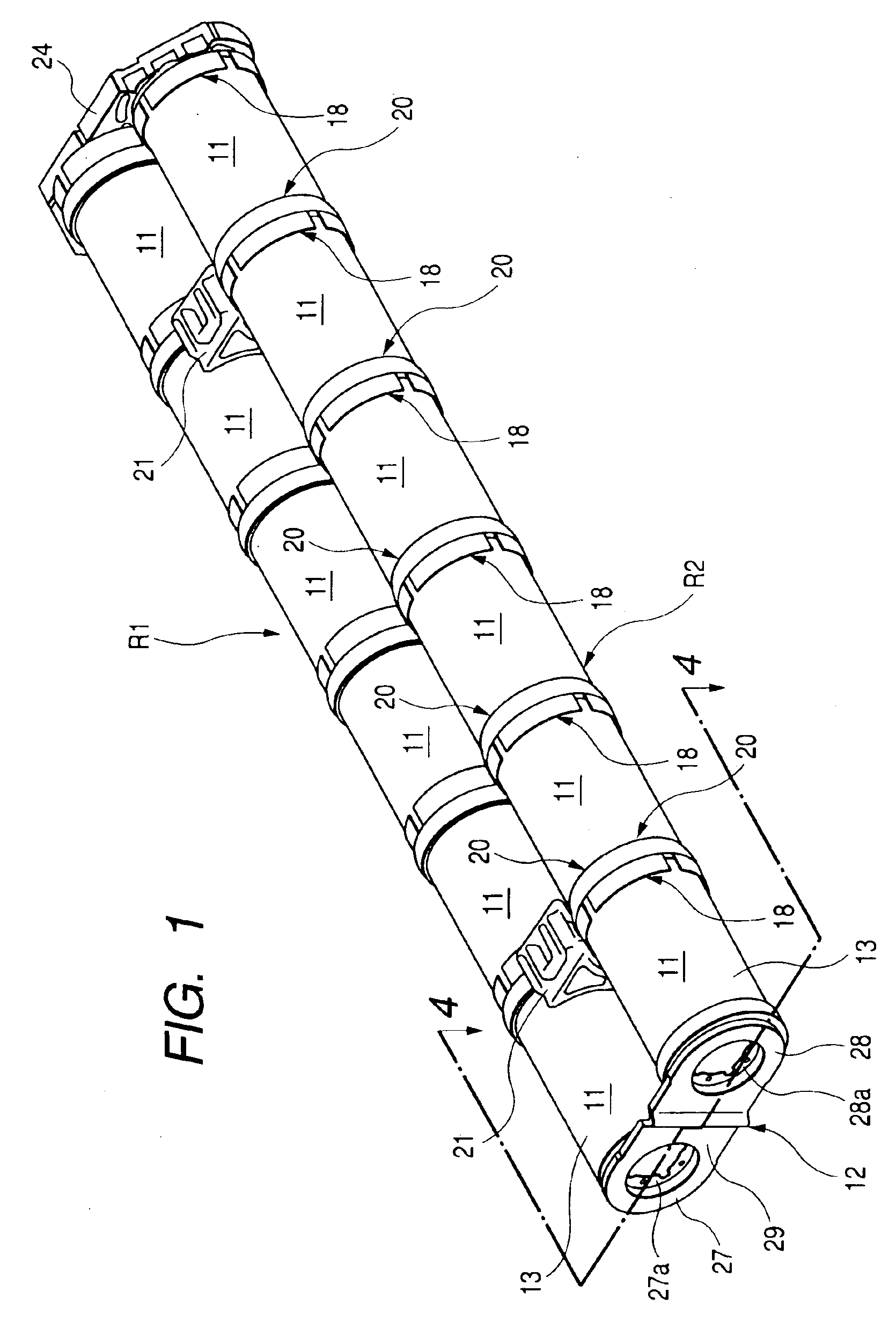

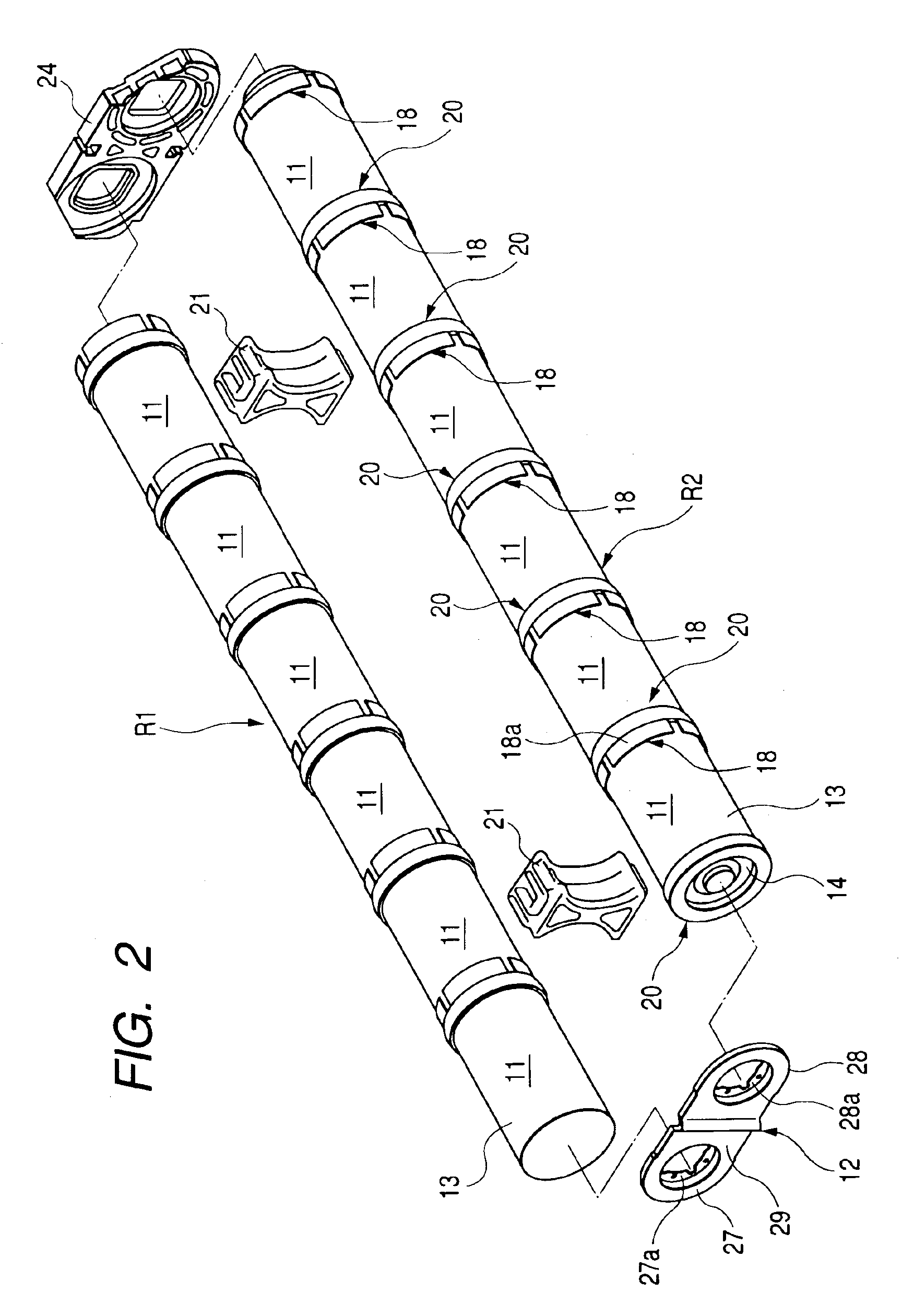

Connecting structure for electric cells

InactiveUS20050070164A1Avoid harmElectric resistance can be suppressed to lowElectric discharge tubesTwo-part coupling devicesCouplingEngineering

A connecting bus bar 12 is formed from a negative opposing section 27 which is smaller in thickness than a closed end of a bottomed cylinder 13, partially has a negative weld plate section 27a to be welded to the closed end of a bottomed cylinder 13, and opposes the closed end of the bottomed cylinder 13; a positive opposing section 28 which is smaller in thickness than a seal plate 14, partially has a positive weld plate section 28a to be welded to the seal plate 14, and opposes the seal plates 14; and the coupling section 29 for connecting together the negative opposing section 27 and the positive opposing section 28. The connecting bus bar 12 is formed such that the connecting bus bar 12, which excludes the negative weld plate section 27a and the positive weld plate section 28a, becomes lower in thickness than a thinner one of the closed end of the bottomed cylinder 13 and the seal plate 14.

Owner:HONDA MOTOR CO LTD

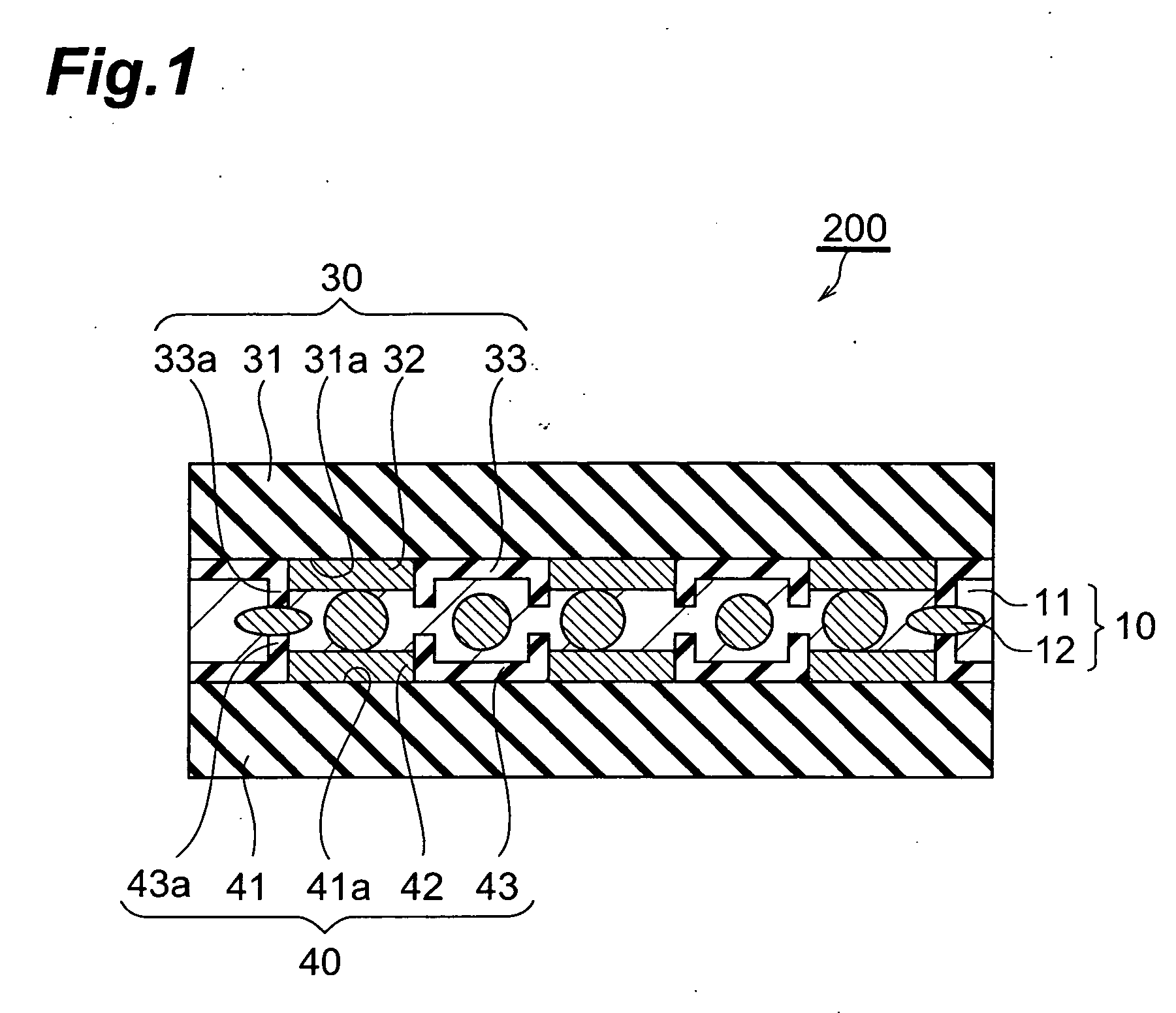

Circuit connecting material, film-like circuit connecting material using the same, circuit member connecting structure, and method of producing the same

InactiveUS20060100314A1Reduce connection resistanceSuperior long-term reliabilitySemiconductor/solid-state device detailsSolid-state devicesElastic modulusEngineering

The present invention is a circuit connecting material used for the mutual connection of a circuit member in which electrodes and insulating layers are formed adjacent to each other on the surface of a board, and a circuit member in which electrodes and insulating layers are formed adjacent to each other on the surface of a board, with the edge parts and of the insulating layers being formed with a greater thickness than the electrodes on the basis of the main surfaces, wherein this circuit connecting material contains a bonding agent composition and conductive particles that have a mean particle size of 1 μm or greater but less than 10 μm and a hardness of 1.961 to 6.865 GPa, and this circuit connecting material exhibits a storage elastic modulus of 0.5 to 3 GPa at 40° C. and a mean coefficient of thermal expansion of 30 to 200 ppm / ° C. at from 25° C. to 100° C. when subjected to the curing treatment.

Owner:HITACHI CHEM CO LTD

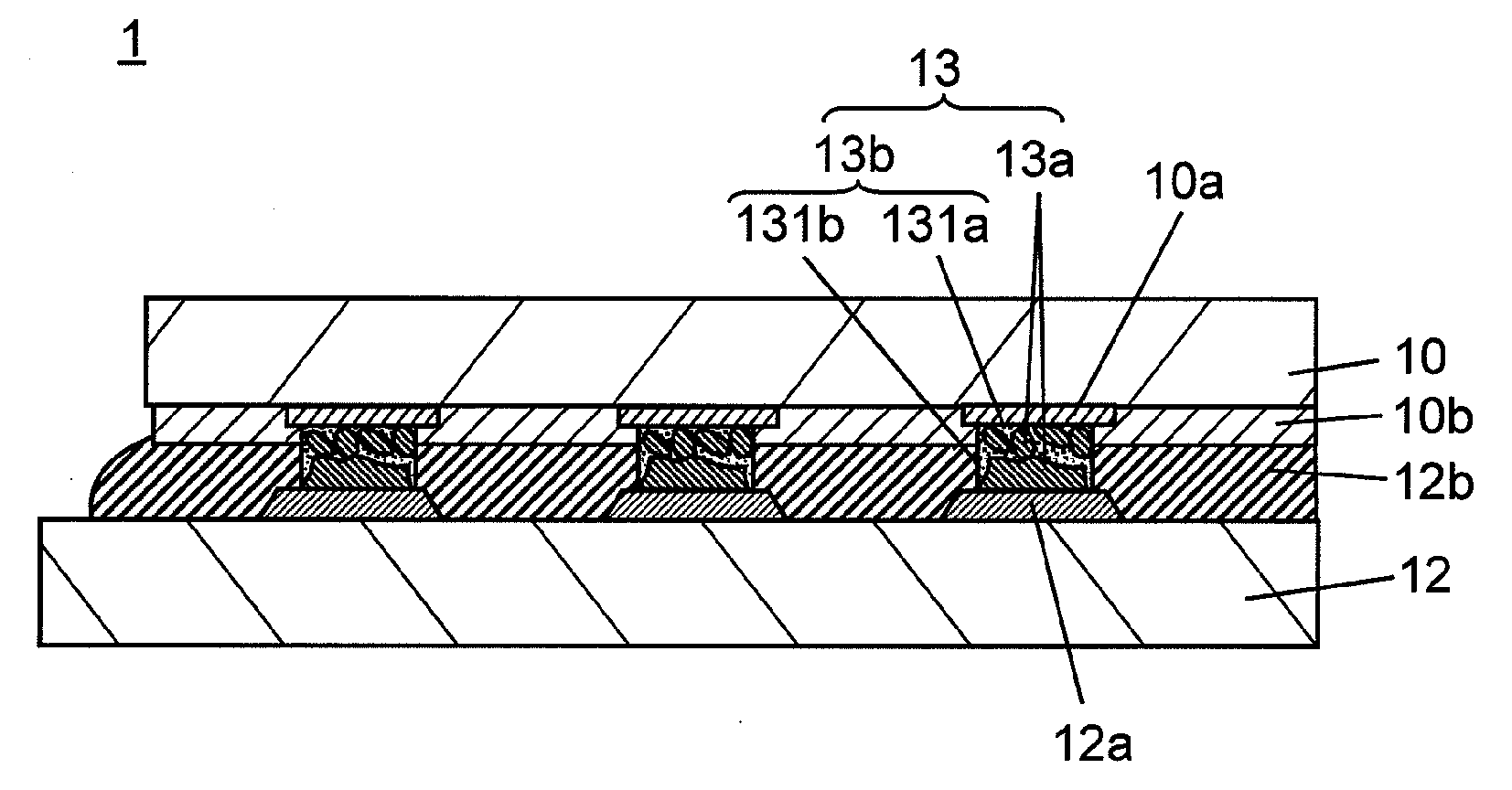

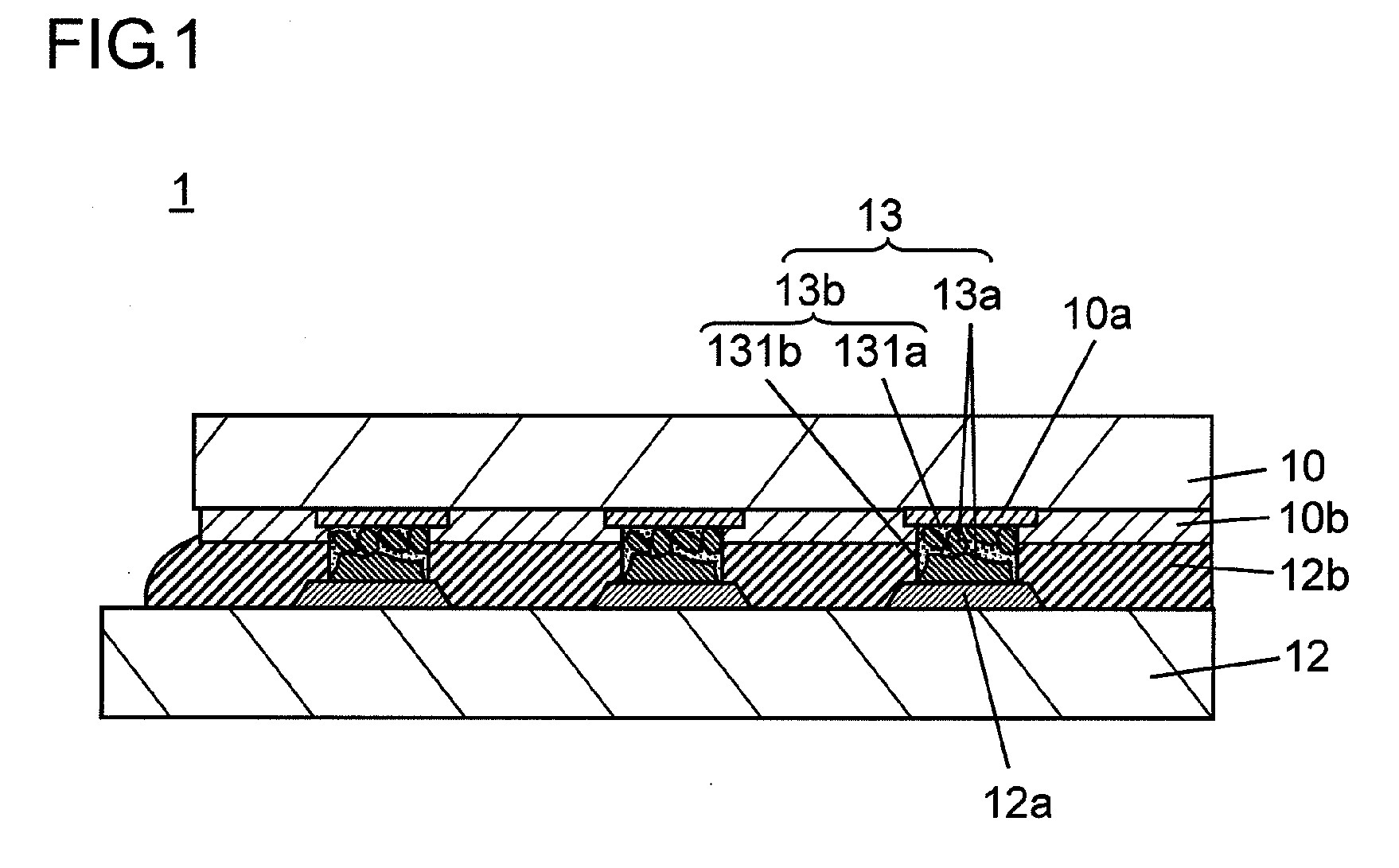

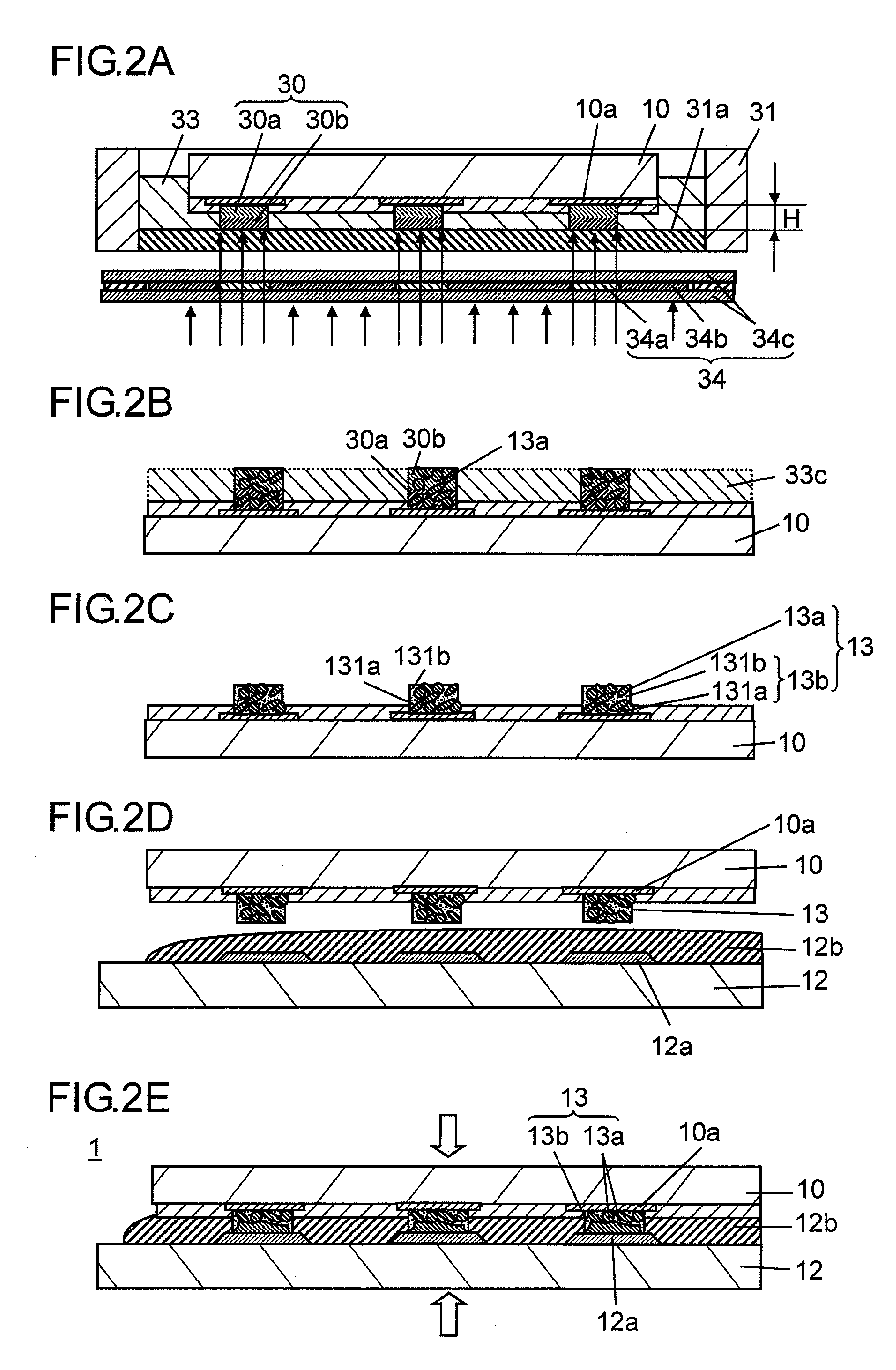

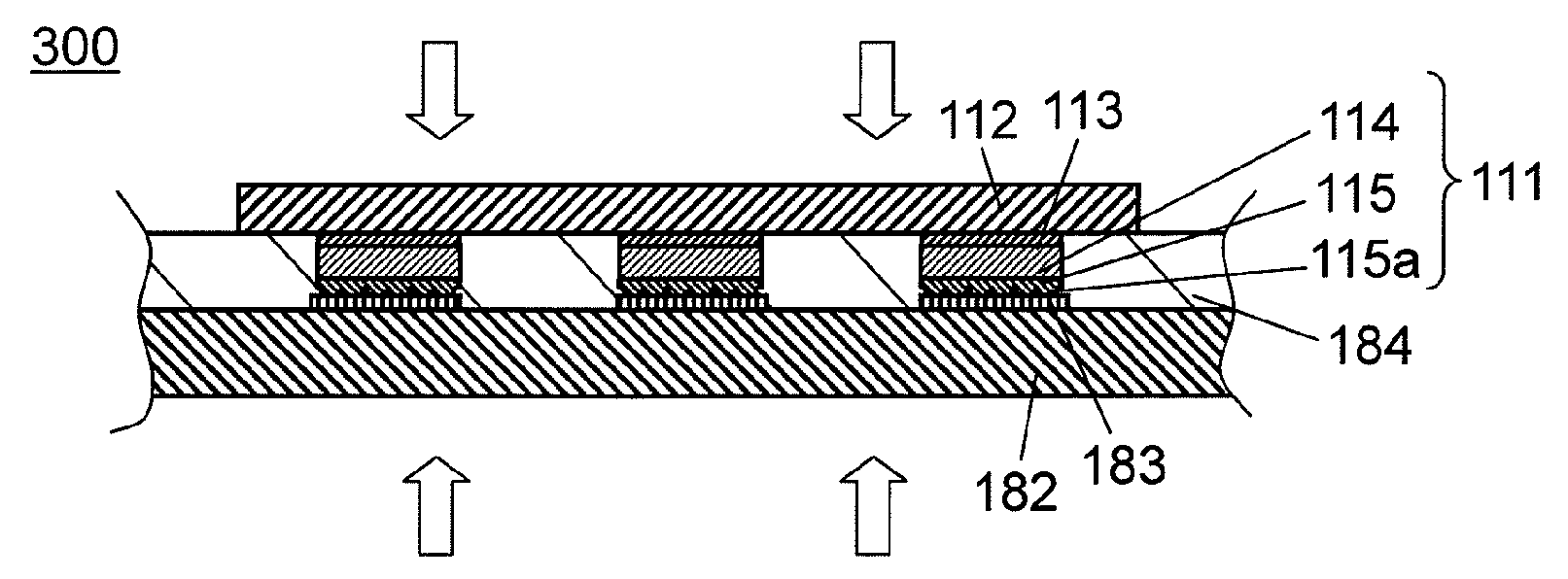

Electronic component mounting structure and method for manufacturing the same

InactiveUS20100052189A1Low costEfficiently prevent breakdownAdditive manufacturing apparatusSemiconductor/solid-state device detailsEngineeringElectronic component

Electronic component mounting structure (1) comprising electronic component (10) provided with a plurality of electrode terminals (10a), mounting substrate (12) provided with connector terminals (12a) in positions corresponding to electrode terminals (10a), wherein electrode terminal (10a) is connected to connector terminal (12a) via protrusion electrode (13) disposed on electrode terminal (10a) or connector terminal (12a), and protrusion electrode (13) includes at least conductive filler (13a) and photosensitive resin (13b), and varies in resin component crosslink density of photosensitive resin (13b) in the height direction of protrusion electrode (13).

Owner:PANASONIC CORP

Organic el device

ActiveUS20090200930A1Reduce connection resistanceIncrease the sectionDischarge tube luminescnet screensLamp detailsElectrical and Electronics engineeringElectrode

An organic EL device includes an element region having a plurality of light-emitting elements, each including a first electrode disposed on a substrate body, a functional layer disposed above the first electrode, and a second electrode disposed above the functional layer; an enclosing member which surrounds the element region, covers the peripheral sides of the functional layers contained at least in the light-emitting elements located closest to the outer periphery of the substrate body among the plurality of light-emitting elements, and is disposed on the substrate body; a conductive member placed outside the enclosing member; and a connecting conductive member which is connected to the conductive member, extends from outside of the enclosing member over the enclosing member, and is connected to the second electrode. The connecting conductive member has a thickness larger than the thickness of the second electrode.

Owner:ELEMENT CAPITAL COMMERCIAL CO PTE LTD

Capacitor and method for producing the same, and circuit board with a built-in capacitor and method for producing the same

InactiveUS20070022590A1Improve connection reliabilityReduce connection resistancePrinted circuit assemblingLiquid electrolytic capacitorsDielectricElectrically conductive adhesive

Owner:PANASONIC CORP

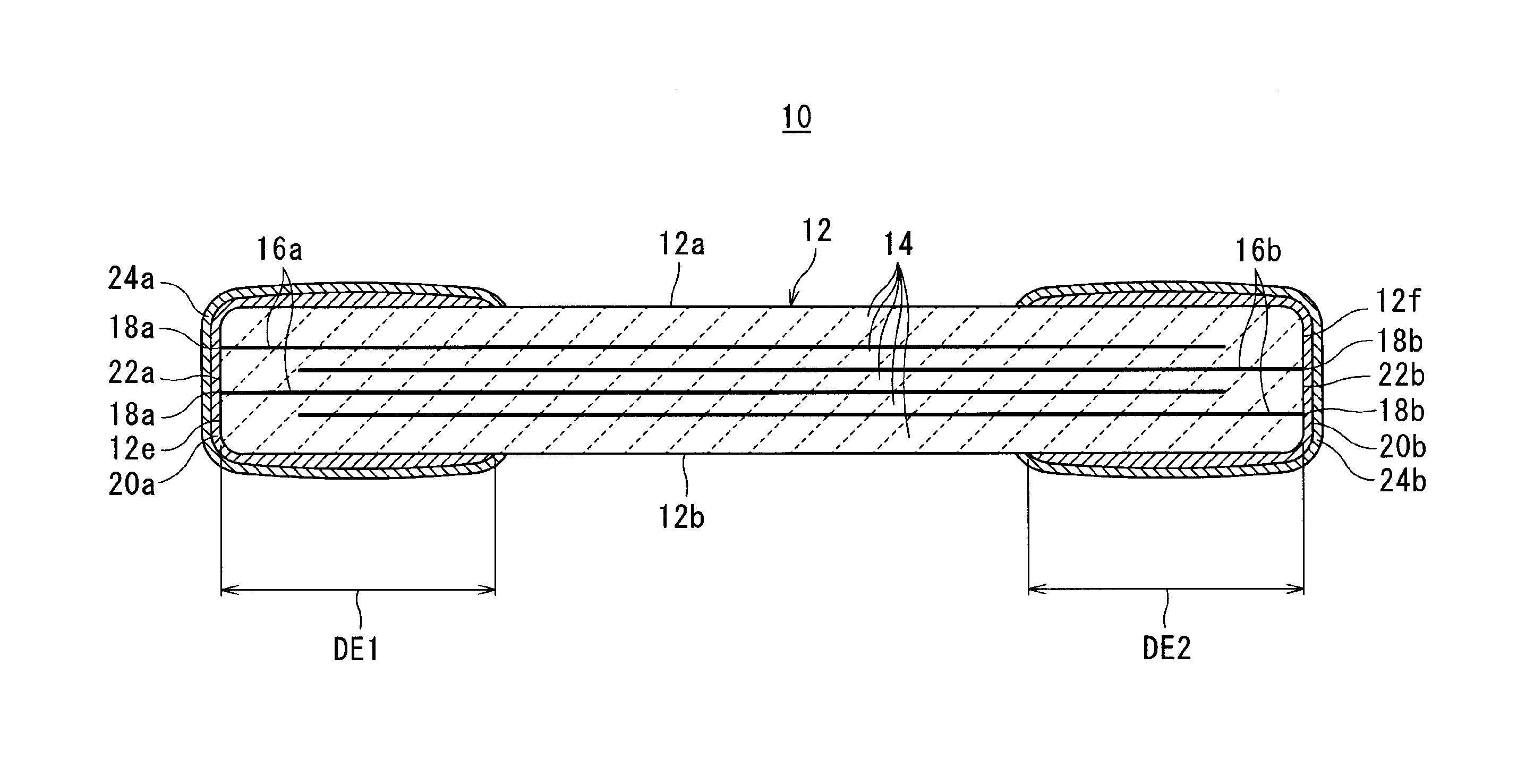

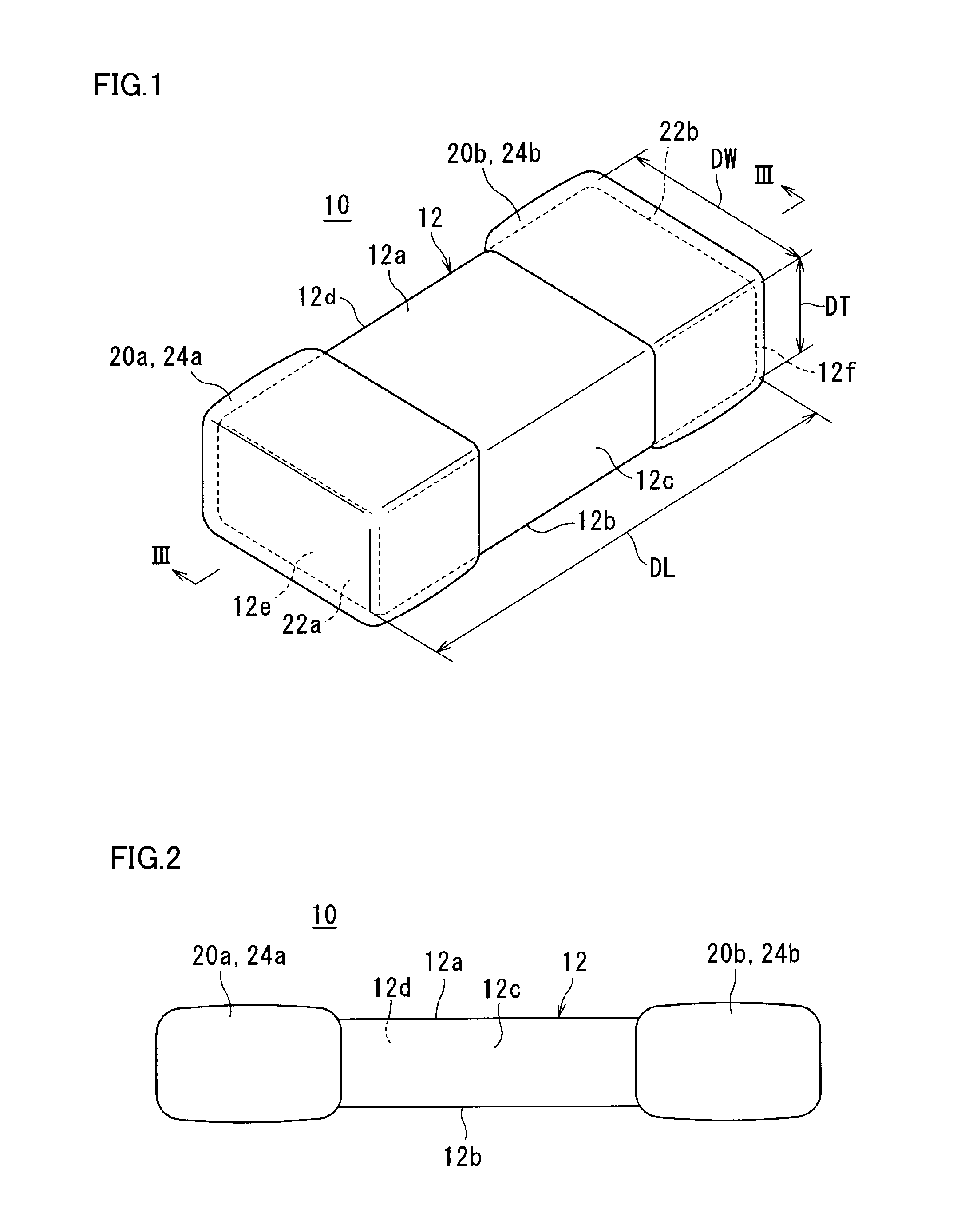

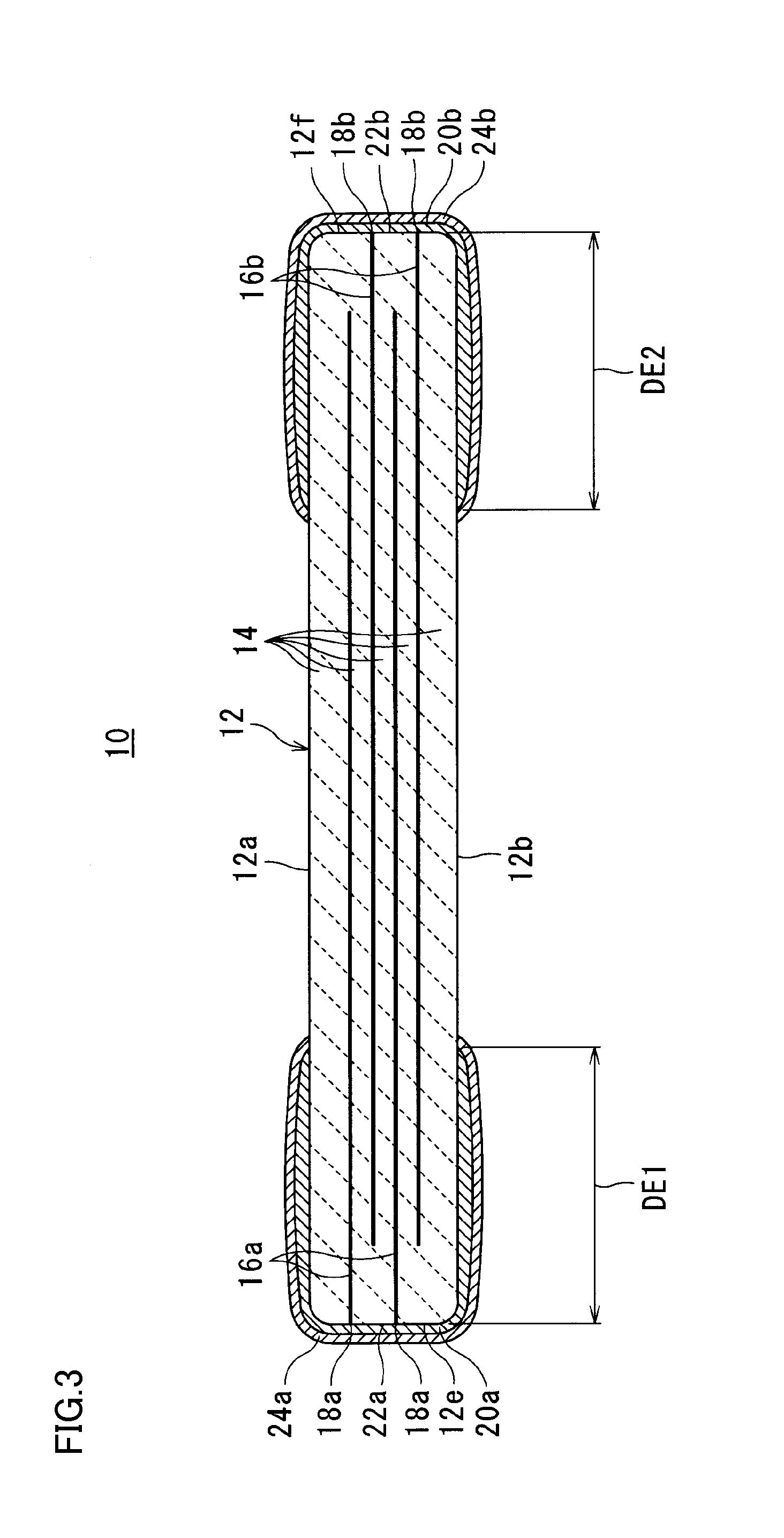

Ceramic electronic component and method for manufacturing the same

ActiveUS20150016018A1Increase bonding areaReduce connection resistancePiezoelectric/electrostriction/magnetostriction machinesFixed capacitor electrodesComposite materialElectrical connection

External electrodes, electrically connected to exposed portions of internal electrodes, are arranged on end surfaces of a ceramic main body of a laminated ceramic capacitor. Alloy layers of a metal contained in internal electrodes, and a metal contained in external electrodes, are arranged at the boundaries between external electrodes, and the ceramic main body and internal electrodes. Plating layers are provided on surfaces of external electrodes. A ceramic electronic component having a reduced ESR is thus provided.

Owner:MURATA MFG CO LTD

Connecting device between batteries

ActiveCN101218697AIncrease the welding areaImprove welding strengthNon-aqueous electrolyte accumulatorsCurrent conducting connectionsMechanical engineeringMetal

An inter-battery connection device for connecting terminals of two batteries (1a, 1b) arranged with their axes parallel to each other. The inter-battery connection device includes an inter-battery connection plate (11) that connects the battery case bottom (2) and the sealing plate (3) of the two batteries. The inter-battery connection plate (11) includes welding portions (4) at the ends of its base plate (6) for welding to the case bottom (2) and the sealing plate (3), respectively. An intermediate metal plate (7) is joined to the middle part of the base plate (6) between the welding portions (4, 4) to form an intermediate portion (5) having a greater thickness than each welding portion (4). The inter-battery connection device has reduced electric resistance while achieving improved weldability.

Owner:PANASONIC CORP

Connecting structure for electric cells

InactiveUS6932651B2Low costLight weightElectrically conductive connectionsElectric discharge tubesCouplingEngineering

A connecting bus bar 12 is formed from a negative opposing section 27 which is smaller in thickness than a closed end of a bottomed cylinder 13, partially has a negative weld plate section 27a to be welded to the closed end of a bottomed cylinder 13, and opposes the closed end of the bottomed cylinder 13; a positive opposing section 28 which is smaller in thickness than a seal plate 14, partially has a positive weld plate section 28a to be welded to the seal plate 14, and opposes the seal plates 14; and the coupling section 29 for connecting together the negative opposing section 27 and the positive opposing section 28. The connecting bus bar 12 is formed such that the connecting bus bar 12, which excludes the negative weld plate section 27a and the positive weld plate section 28a, becomes lower in thickness than a thinner one of the closed end of the bottomed cylinder 13 and the seal plate 14.

Owner:HONDA MOTOR CO LTD

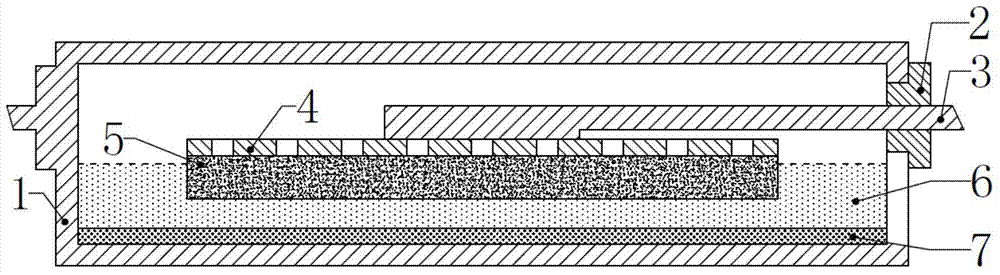

Liquid metal battery and KW-scale module of liquid metal battery

ActiveCN104505526AEasy single-layer connectionImprove energy conversion efficiencyCell component detailsFuel cell detailsElectrical batteryPhysical chemistry

The invention provides a liquid metal battery and a KW-scale module of the liquid metal battery. The positive electrode and the negative electrode of the liquid metal battery are led out from the side wall of a battery shell; the KW-scale module is formed by a plurality of battery modules through serial connection, the battery module is composed of an inner core of the battery module and a heat preservation layer wrapping the outside of the inner core of the battery module, the inner core of the battery module is composed of a heating partition plate and a plurality of liquid metal batteries used as repeating units and stacked on the heating partition plate, and all the liquid metal batteries in the inner core of the battery module are serially connected sequentially. The battery structure facilitates single-layer battery connection, the connecting distance among the batteries can be shortened to the maximum extent, the space is saved, the connecting resistance among the batteries can be reduced to be minimum, the energy loss inside the battery module can be reduced to the maximum extent, and the energy conversion efficiency of the battery module is improved. The design blank of the KW-scale module of the liquid metal battery is filled, and the commercialized process of the liquid metal battery can be promoted greatly.

Owner:XI AN JIAOTONG UNIV

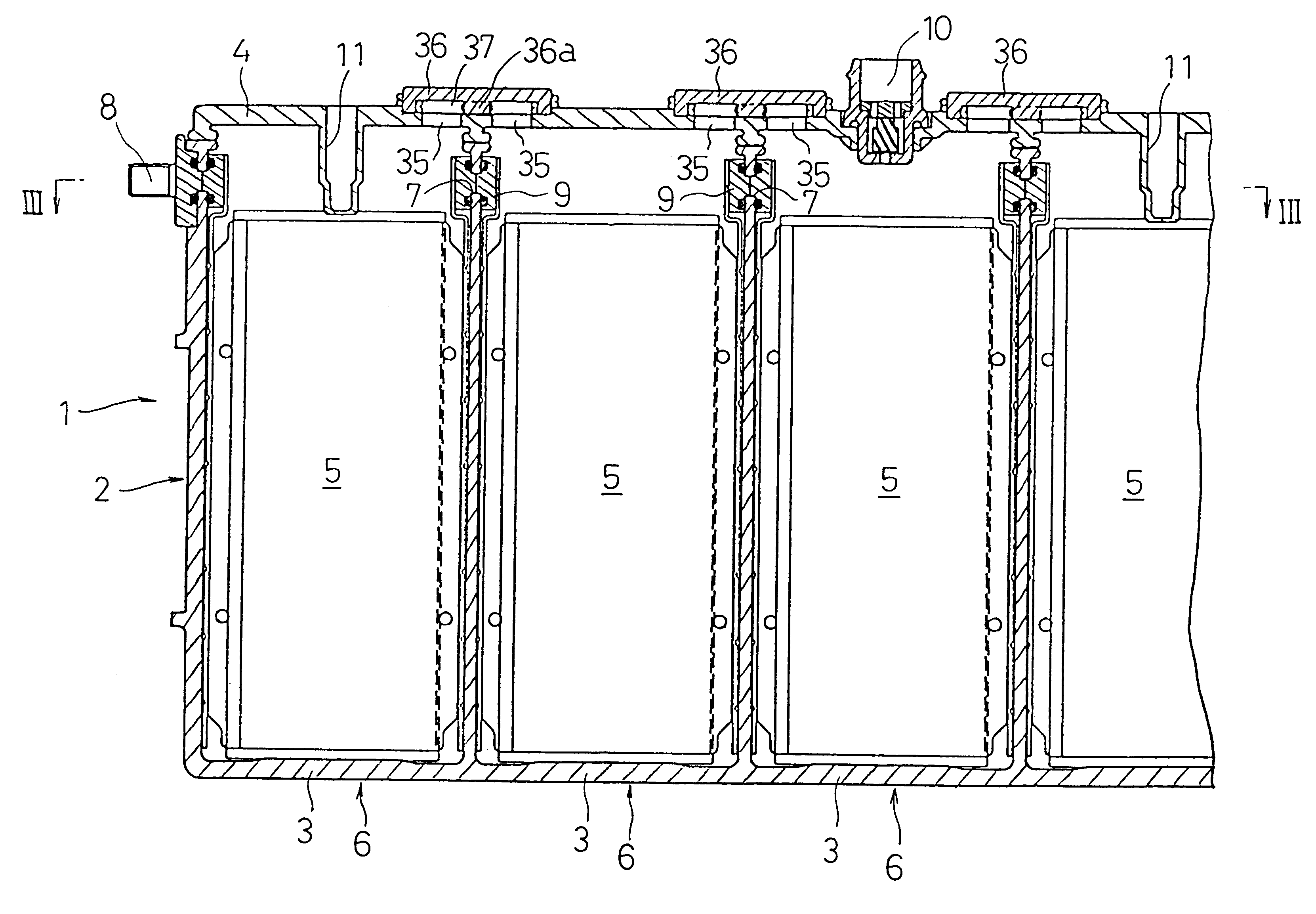

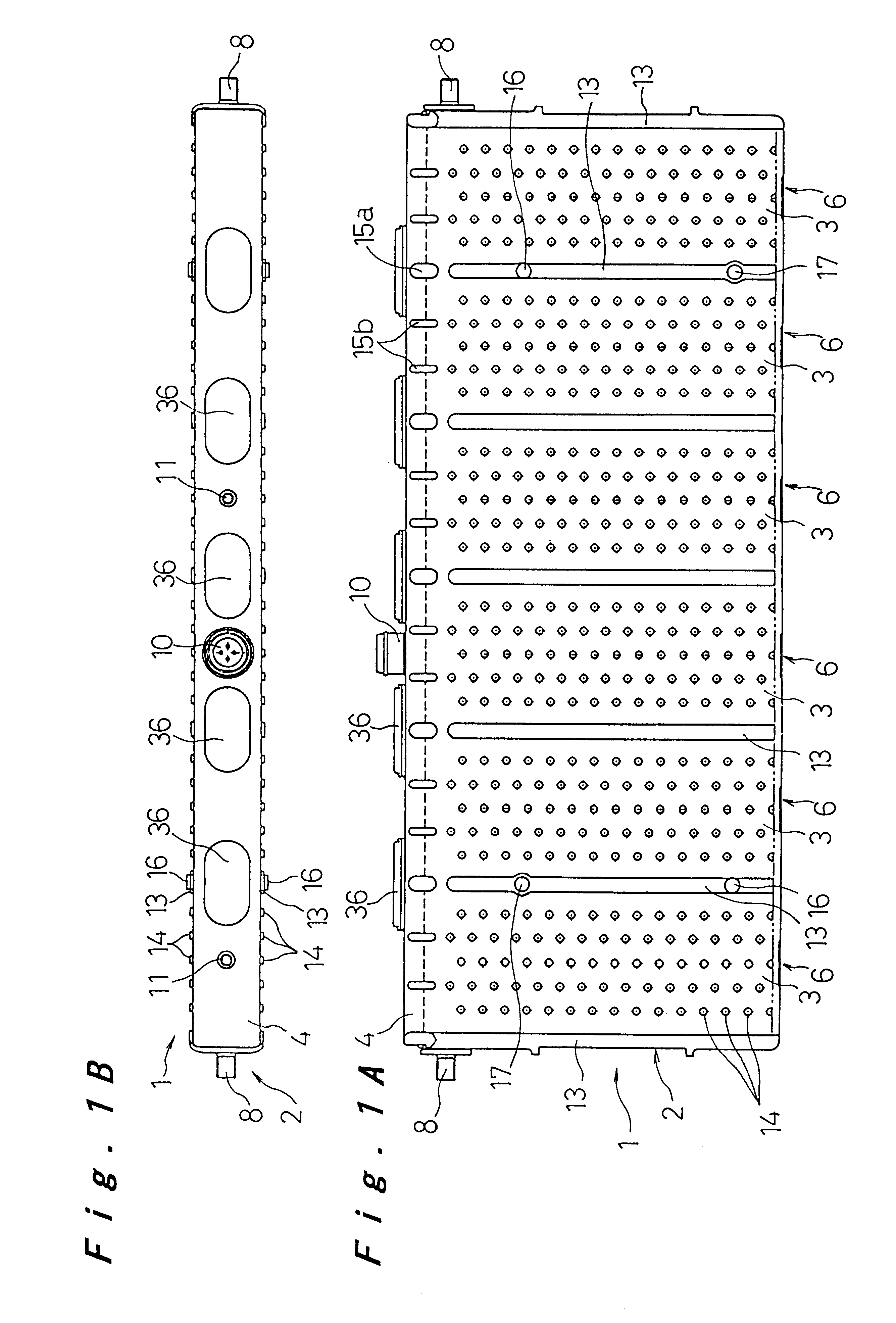

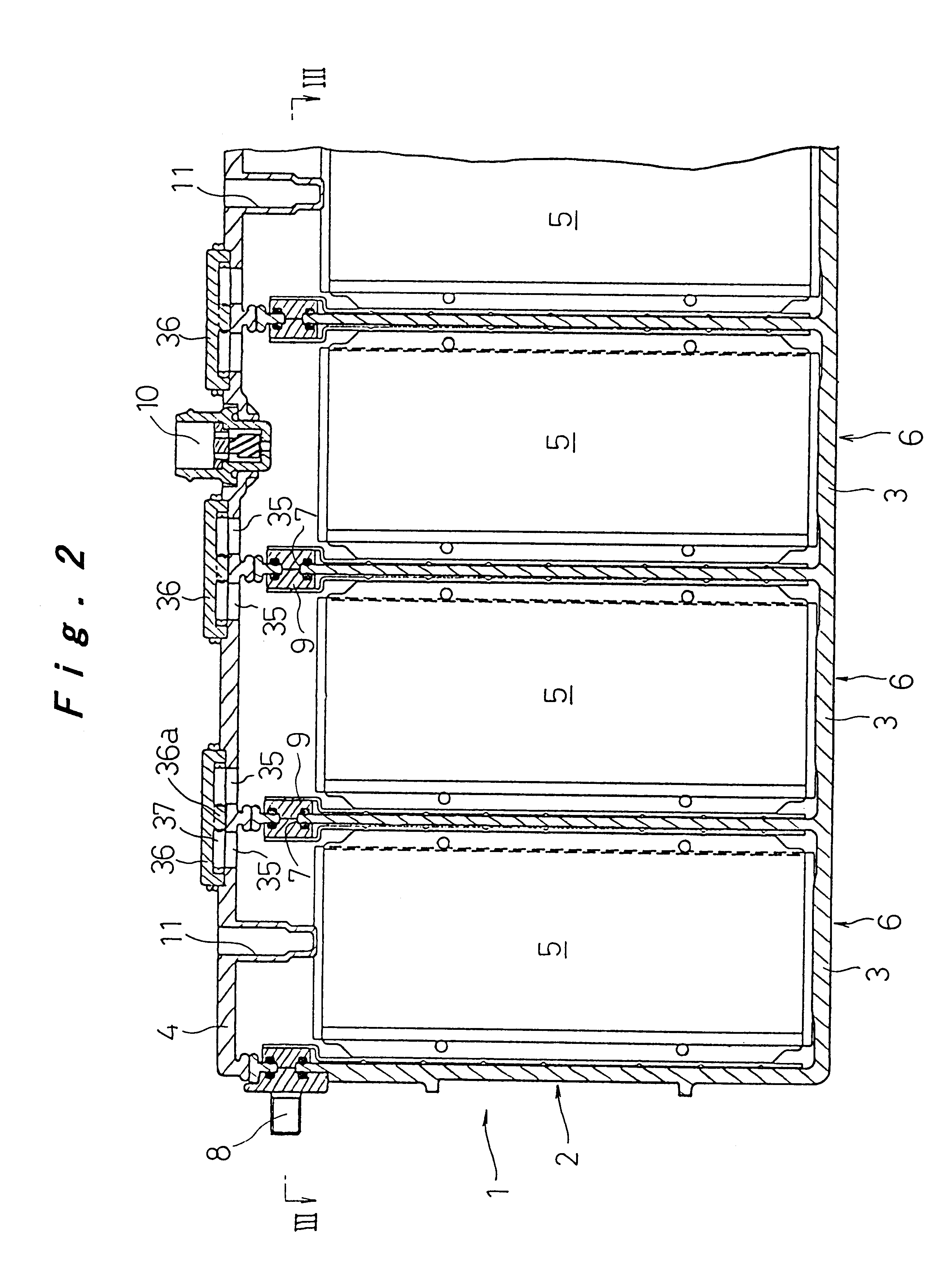

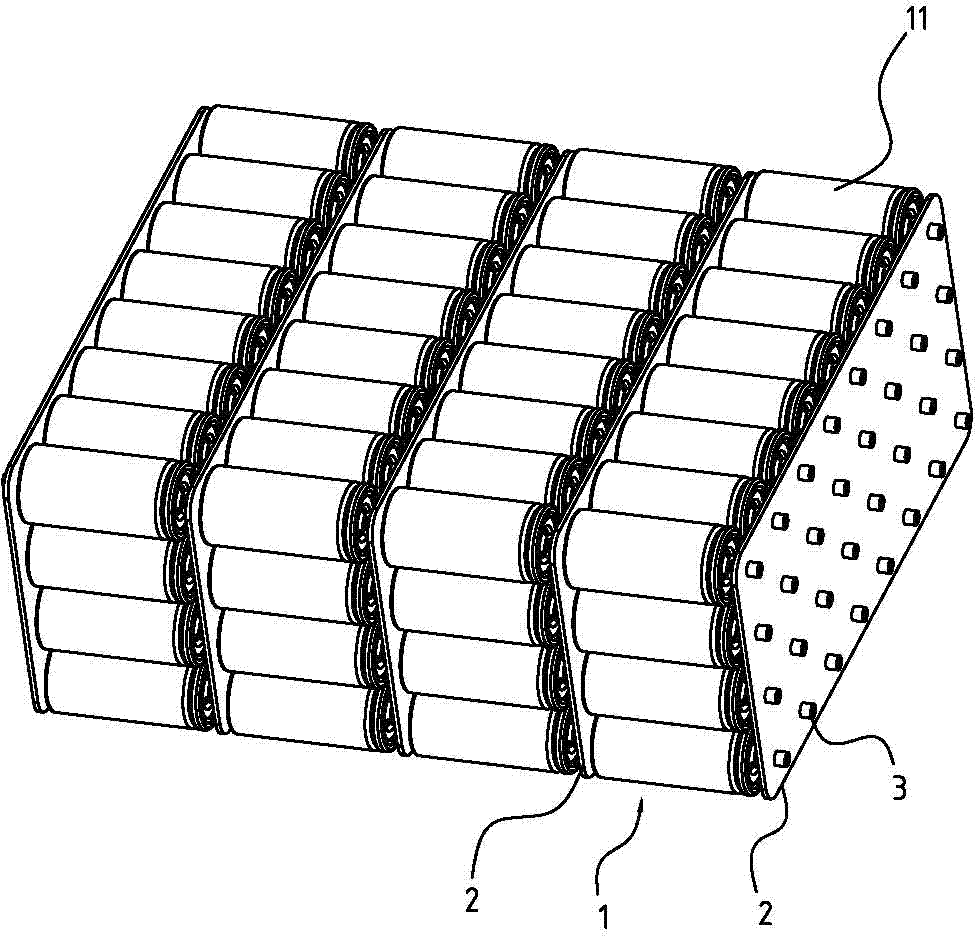

Battery module

InactiveUS6551741B1Suppressing progressImprove balanceFinal product manufactureCell temperature controlInternal pressureEngineering

An integrated battery case 2 is made by coupling together a plurality of cell cases 3 into an integral body, open ends of the cell cases 3 being closed integrally with a lid member 4. Communicating paths 37 for communicating a suitable number of neighboring cell cases 3 with one another are provided in the lid member 4, whereby the cell cases 3 have a uniform internal pressure.

Owner:PANASONIC CORP +1

Power cell module connecting structure and connecting method thereof

ActiveCN103035870AAvoid quality problemsStrong vibration resistanceCell component detailsEngineeringPrinted circuit board

The invention relates to a power cell module connecting structure method. A power cell module is composed of a plurality of single cell groups, the adjacent power cell modules are connected through a connecting structure, the connecting structure comprises a PCB (printed circuit board), and the PCB plate is provided with more than one connector; the connector comprises a metal shell the two ends of which are communicated, the shell is internally provided with a spring piece, and a support ring is arranged between the spring piece and the inner wall of the shell and is used for fixing the spring piece and the shell; the PCB plate is provided with through holes, the shell of the connector is electrically connected with the PCB plate, and connecting holes are formed in the connector; and the contact pins of each single cell in a power cell module on the two sides of the PCB are inserted into the connecting holes of the corresponding connector, the contact pins are kept to be electrically connected with a spring piece in the connector, and the monomer cells in the adjacent power cell modules are electrically connected through the connector. According to the invention, the connector is used for replacing a bolted connection, the contact pins and the connector are elastically connected, and the structure can not generate a loose phenomenon because of vibration.

Owner:SHENZHEN BUSBAR SCI TECH DEV

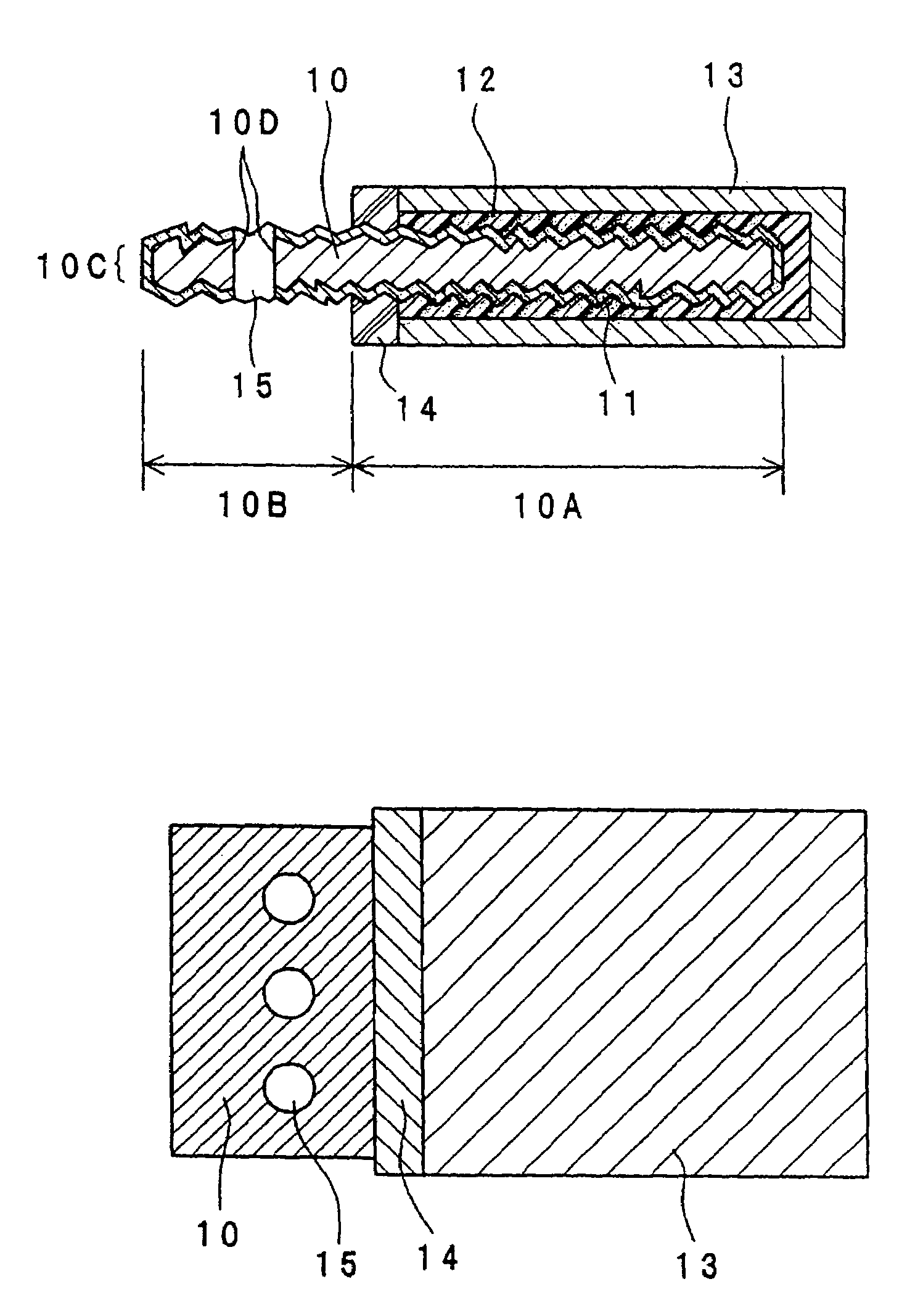

Ground terminal and method for mounting a printed board mounted with a ground terminal to a chassis

InactiveUS7044755B2Easy constructionDownsizeVehicle connectorsContact member assembly/disassemblyMiniaturizationEngineering

A ground terminal capable of being downsized and having good electrical connectability with a chassis. The ground terminal includes a ground terminal body formed into an annular shape as viewed in plan, and at least one connection portion formed integrally with the ground terminal body, the connection portion being bendable and extending from an inner circumference of the ground terminal body toward the center of the ground terminal. When a mounting screw used to mount a printed board mounted with the ground terminal to a chassis is inserted into the annular ground terminal body and a mounting hole of the printed board, the connection portion of the ground terminal is bent in the mounting hole to be brought in contact with the chassis.

Owner:KYOSHIN KOGYO CO LTD

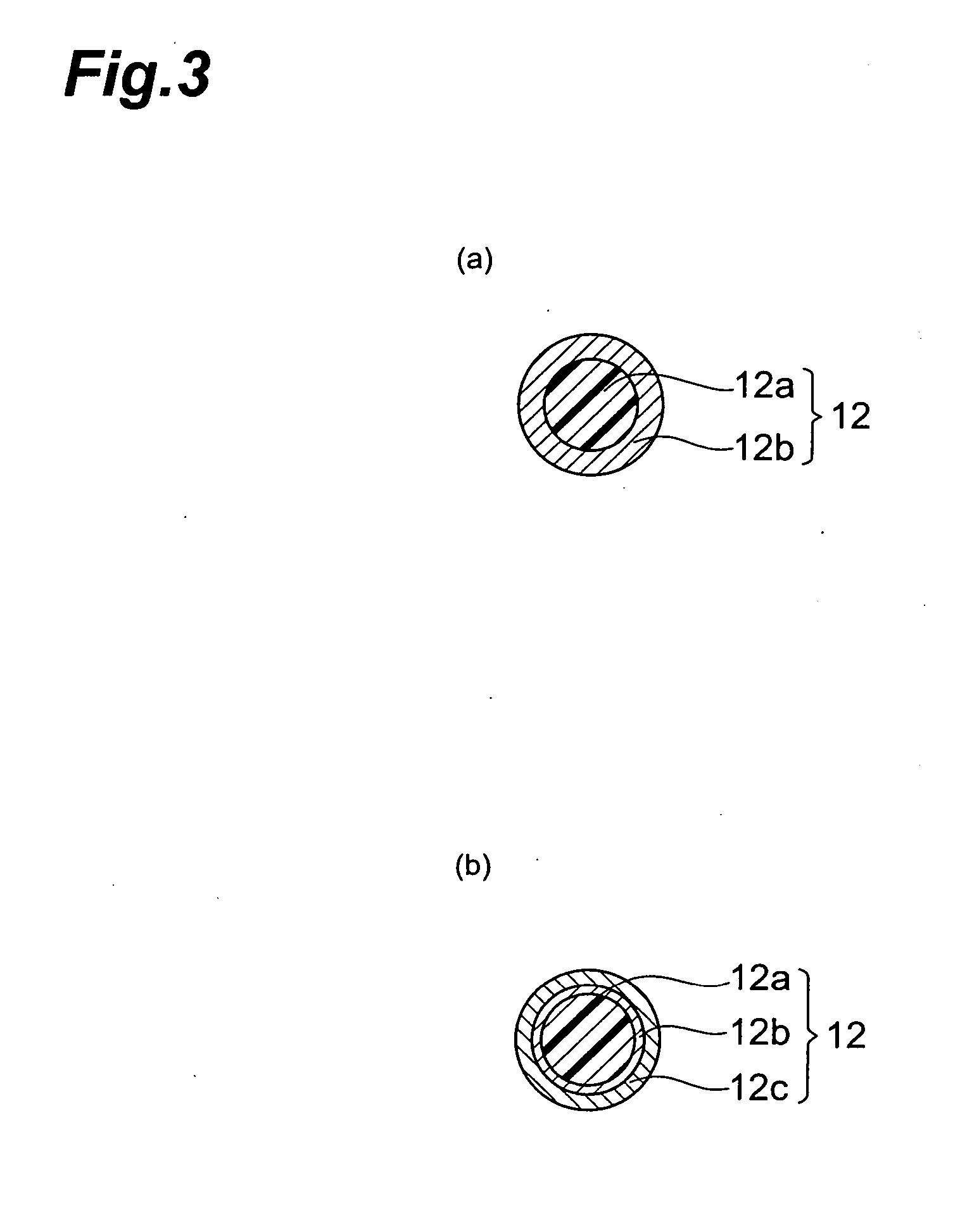

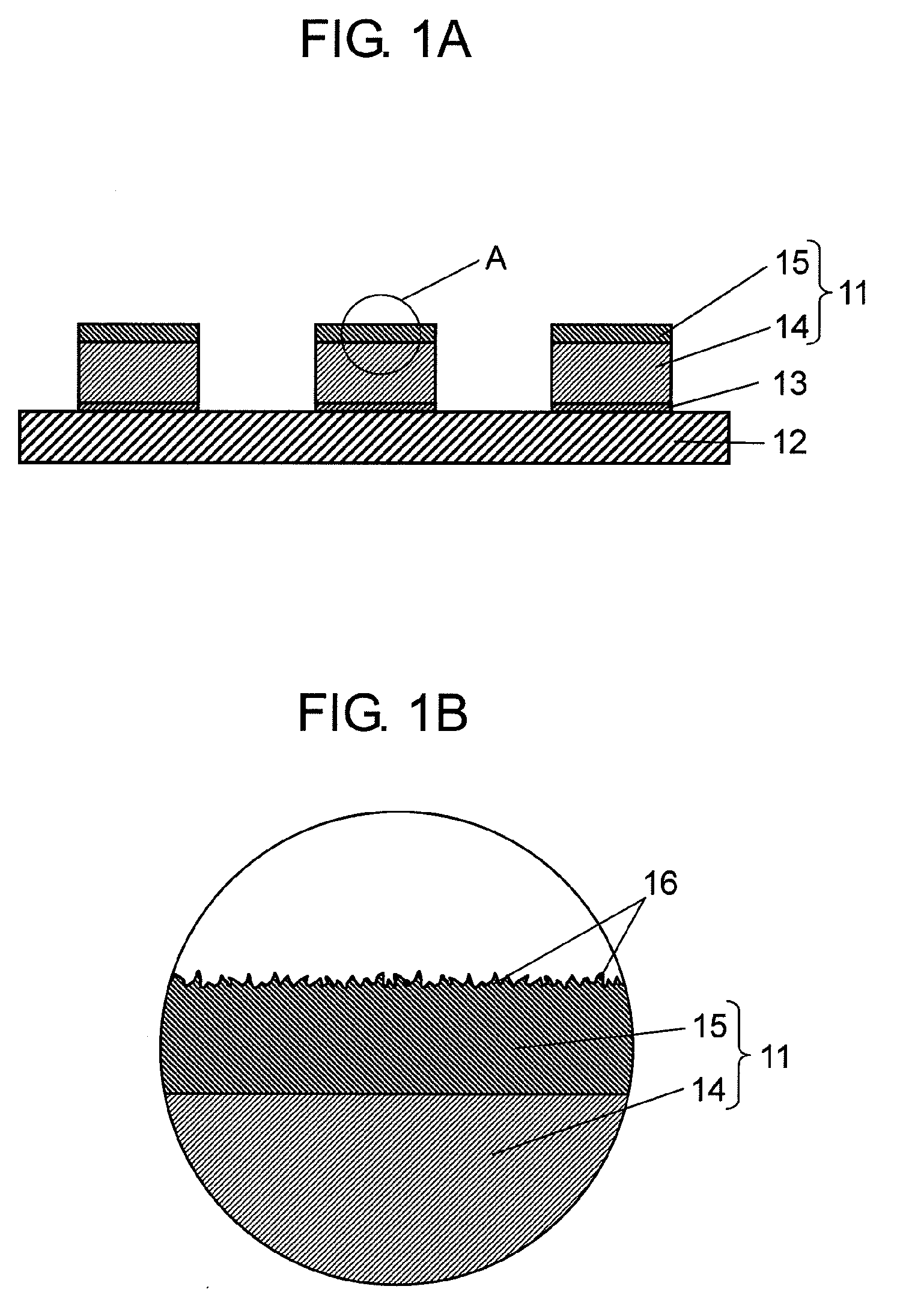

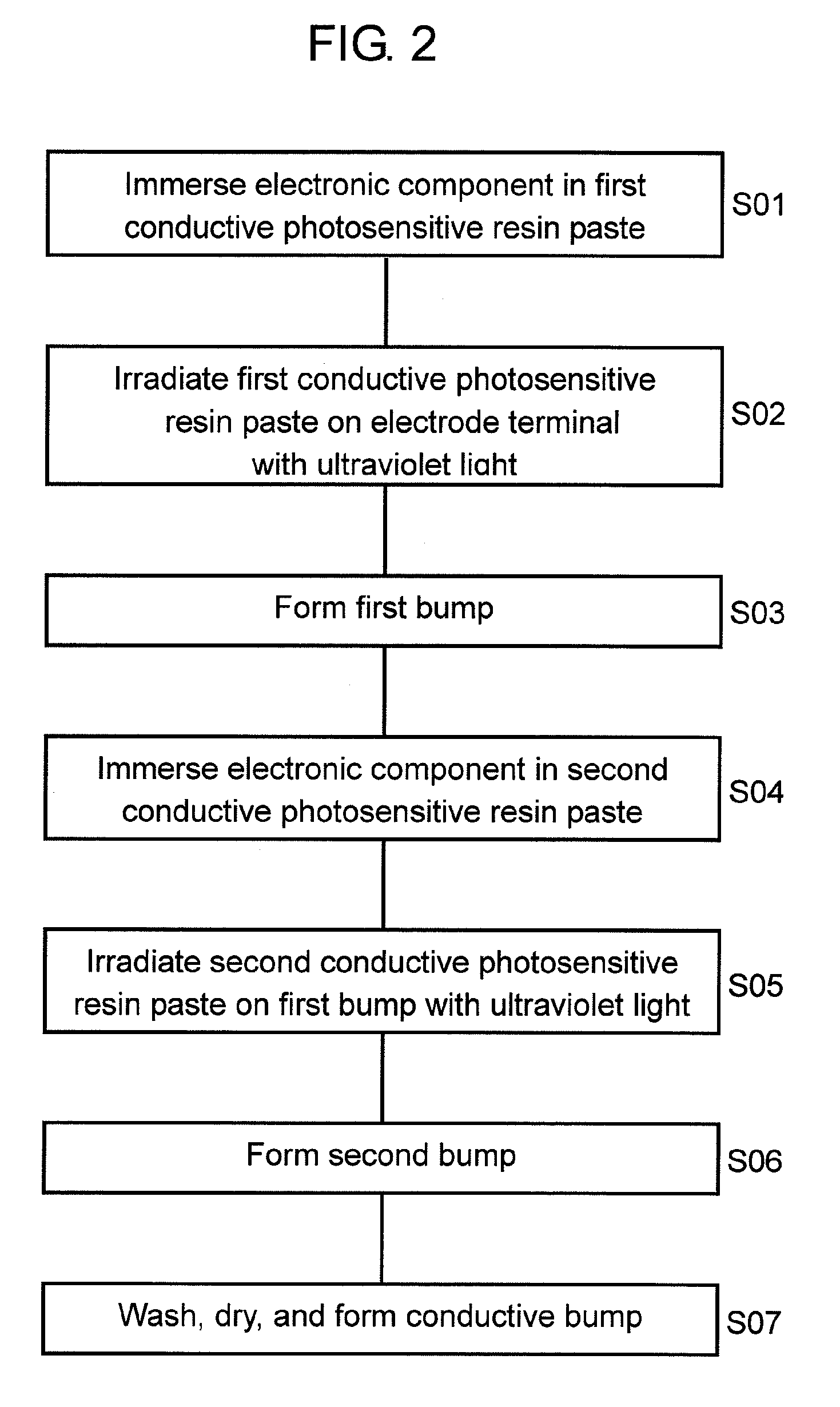

Conductive bump, method for forming the same, and electronic component mounting structure using the same

InactiveUS20090301771A1Improve connection strengthReduce connection resistanceLine/current collector detailsPrinted electric component incorporationEngineeringSpherical shaped

A conductive bump formed on an electrode of an electronic component. The conductive bump is composed of a first bump having one or more layers formed on the electrode and including resin containing at least a spherical-shaped conductive filler, and a second bump formed on an upper surface of the first bump and including photosensitive resin containing a scale-shaped conductive filler.

Owner:PANASONIC CORP

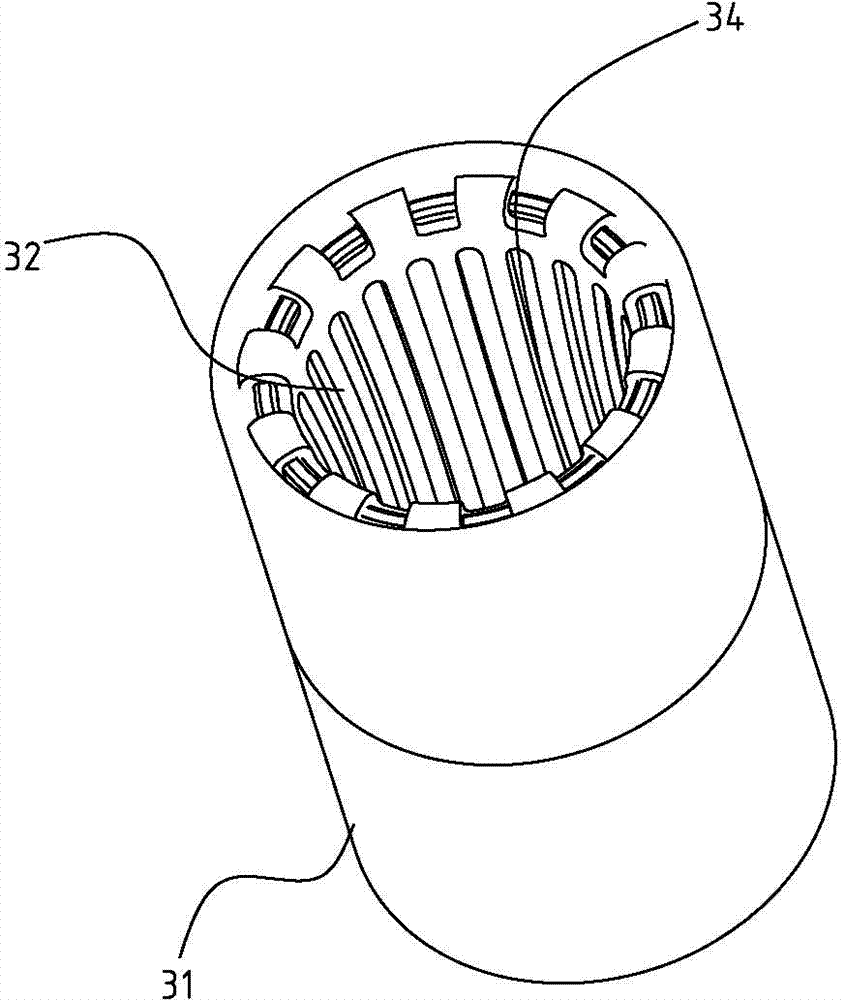

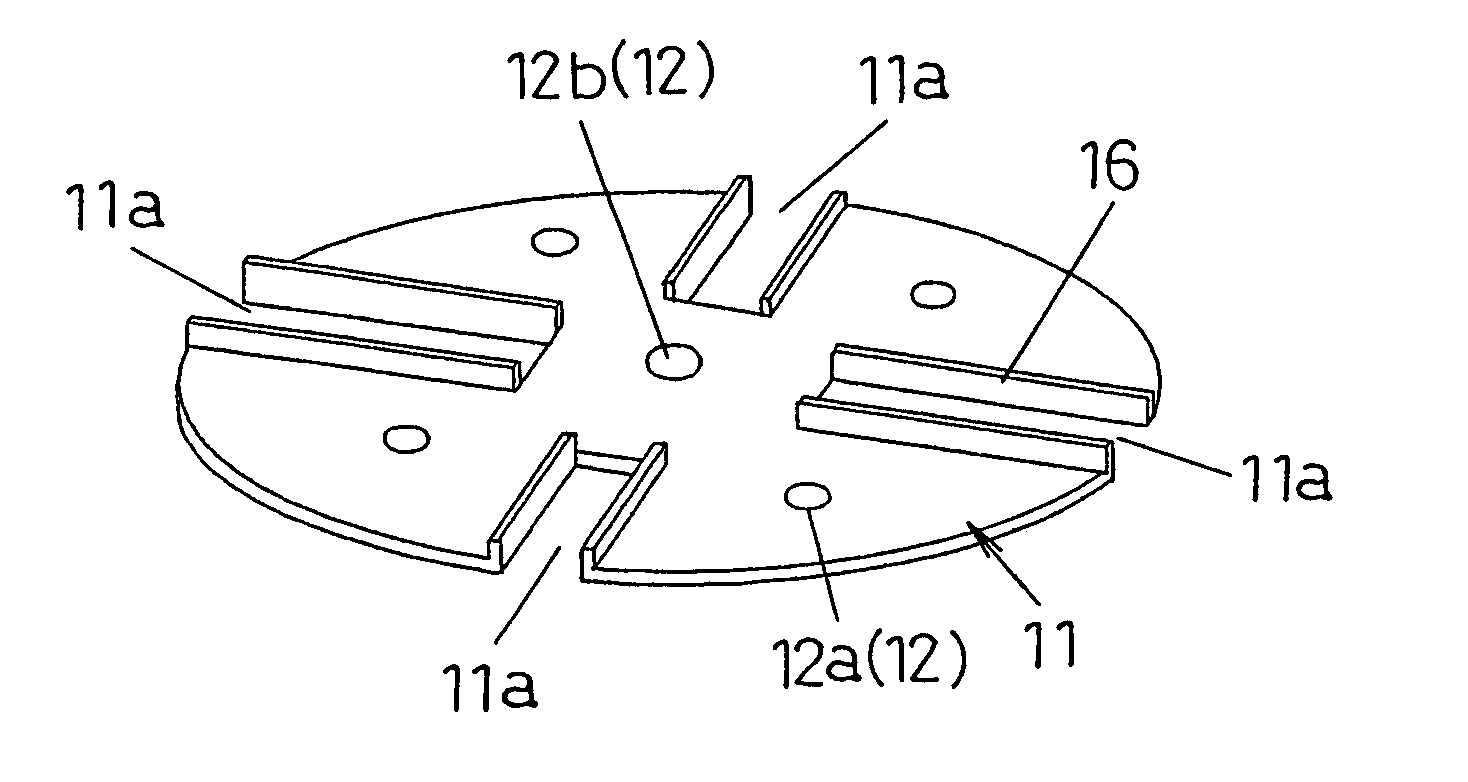

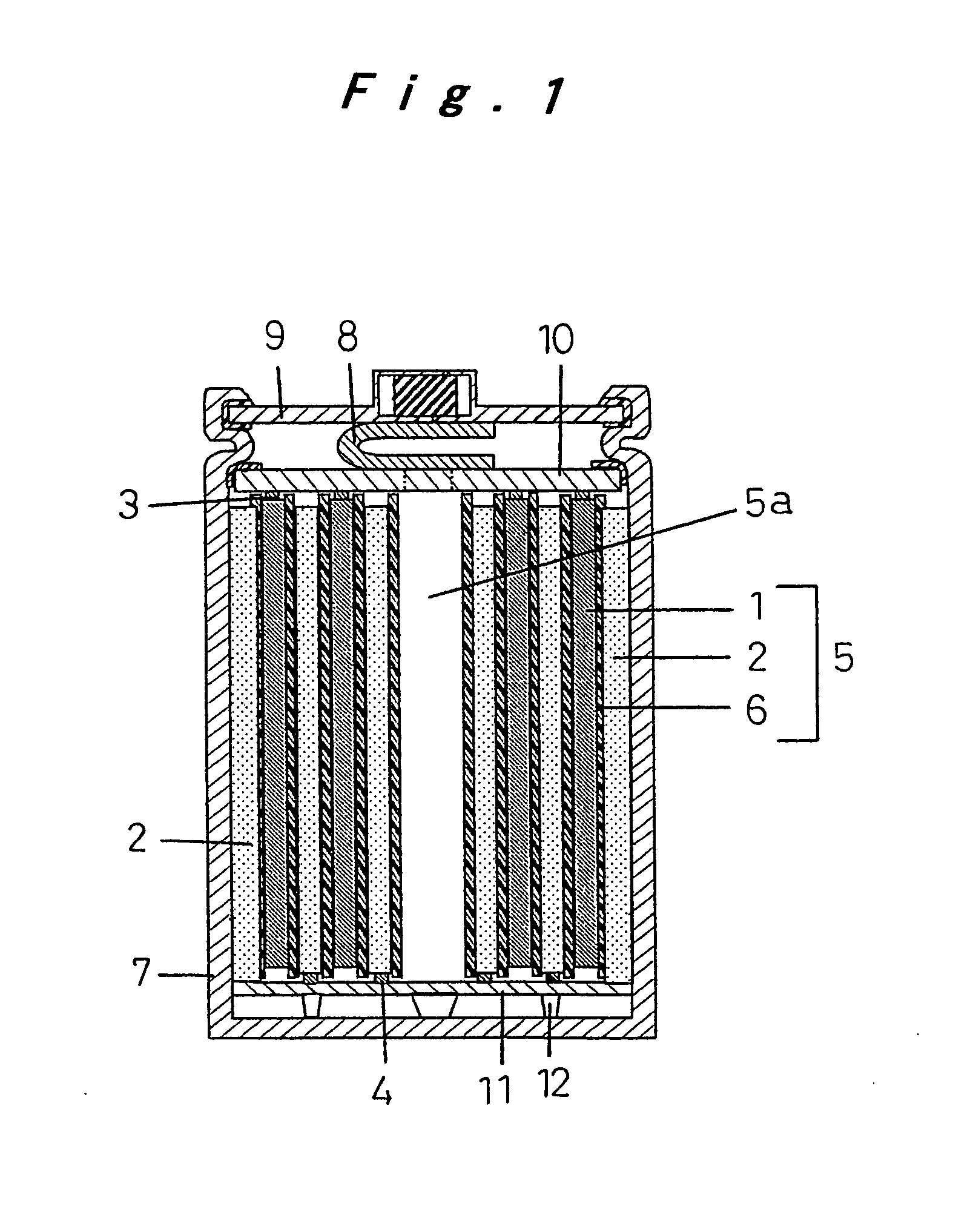

Cylindrical cell and manufacturing method thereof

ActiveUS20070020518A1Stably keeps battery performanceReduce connection resistanceFinal product manufactureSmall-sized cells cases/jacketsEngineeringHigh pressure

A cylindrical battery includes: an electrode plate assembly (5); a positive electrode collector (10) welded to a projecting portion of a core material for a positive electrode of the electrode plate assembly (5); a negative electrode collector (11) that includes a plurality of projections (12) at its lower surface and is welded to a projecting portion of a core material for a negative electrode of the electrode plate assembly (5) at its upper surface; a metal case (7) for accommodating the electrode plate assembly (5) to which the positive and negative electrode collectors (10, 11) are jointed, so as to arrange the negative electrode collector (11) down, the projections (12) of the negative electrode collector (11) being welded to an inner bottom surface of the metal case (7); an electrolyte poured into the metal case (7); and a sealing member (9), electrically insulated from the metal case (7), for sealing a top of the metal case (7), wherein the projections (12) of the negative electrode collector (11) are arranged at a plurality of locations in a region between a portion opposed to a hollow cylindrical portion (5a) of the electrode plate assembly (5) and a peripheral portion. Thus, it is possible to provide the cylindrical battery that is favorable when large current discharge is performed and that has high pressure resistance of the metal case.

Owner:PANASONIC CORP

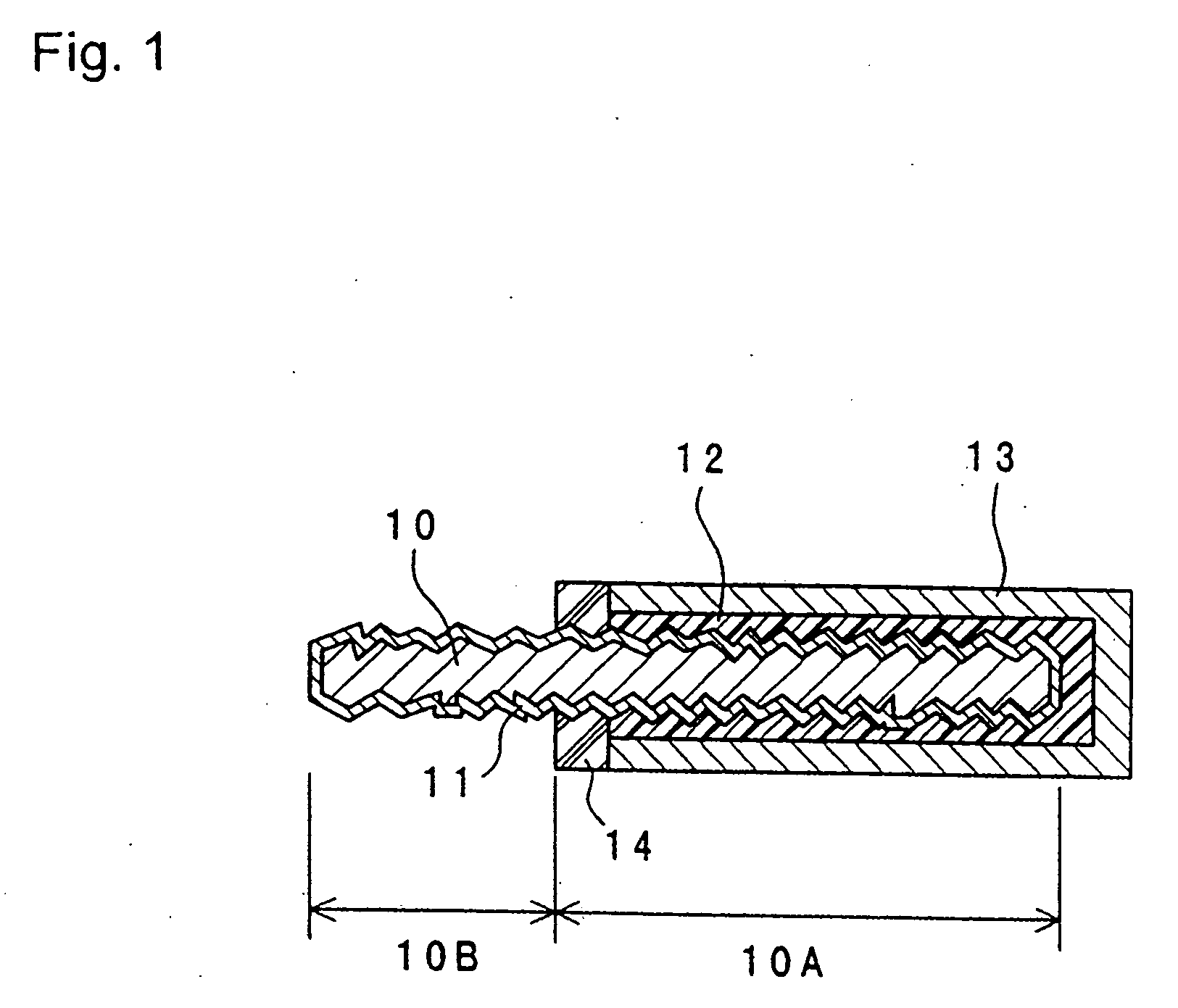

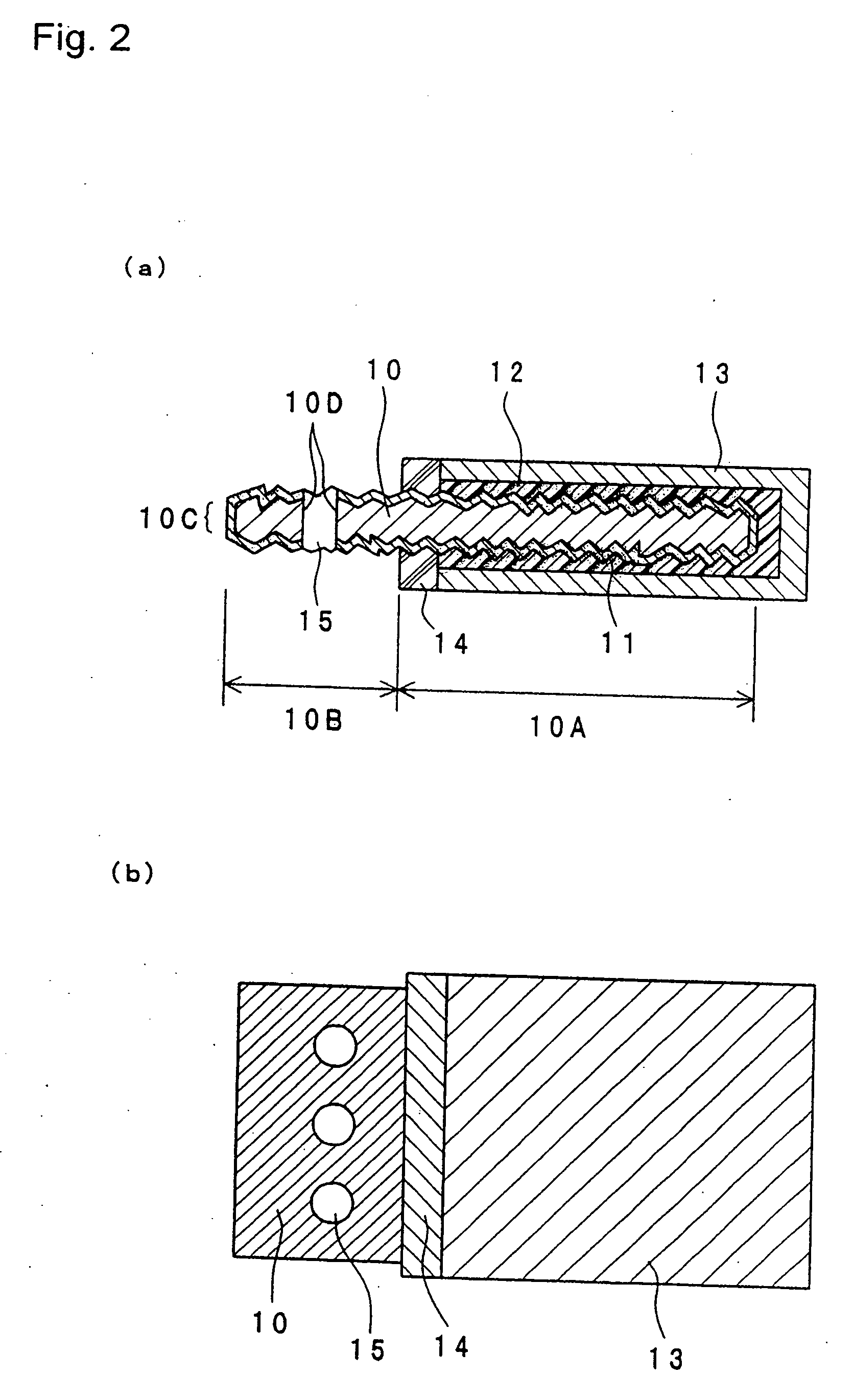

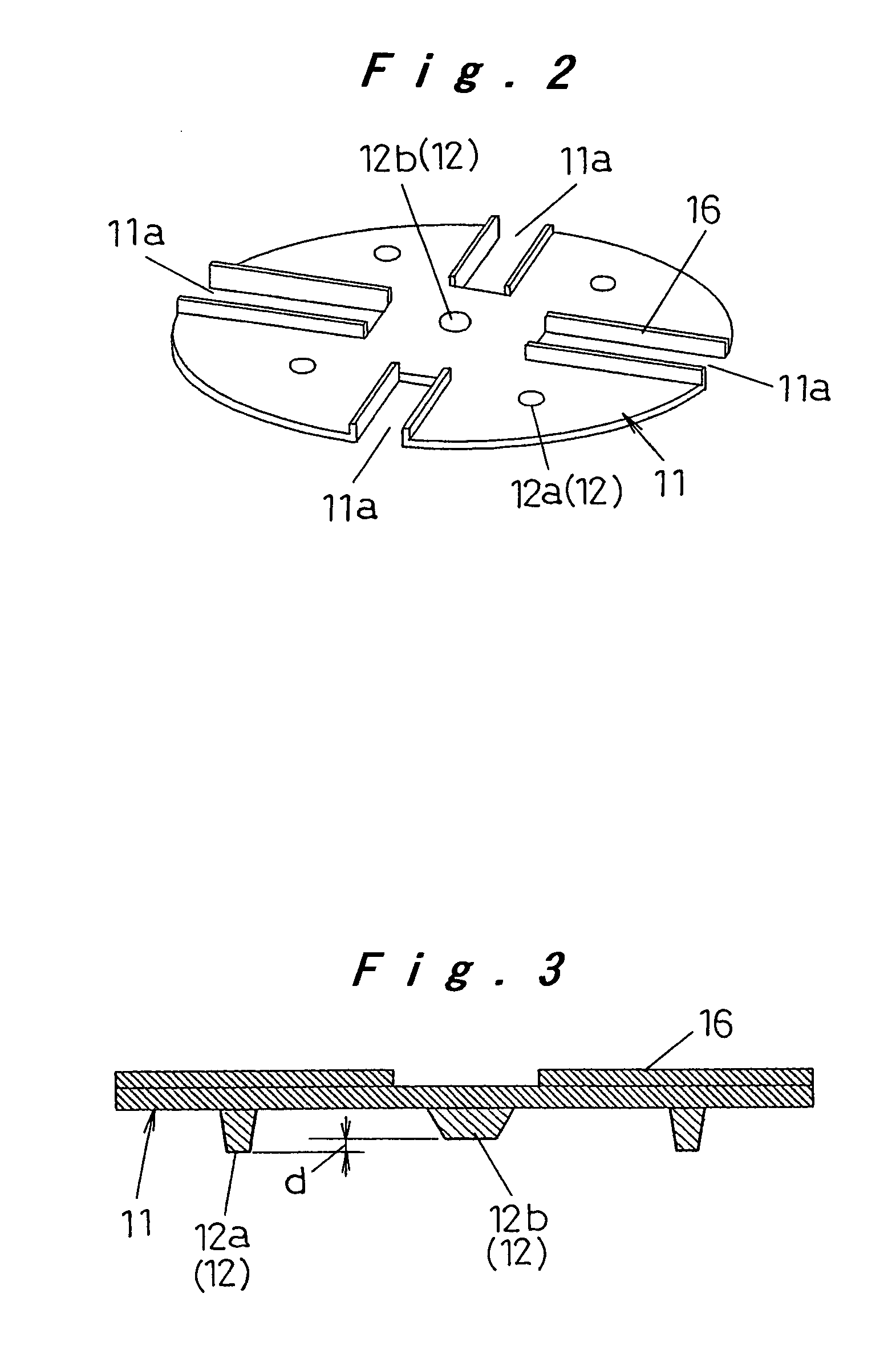

Capacitor and method for producing the same, and circuit board with a built-in capacitor and method for producing the same

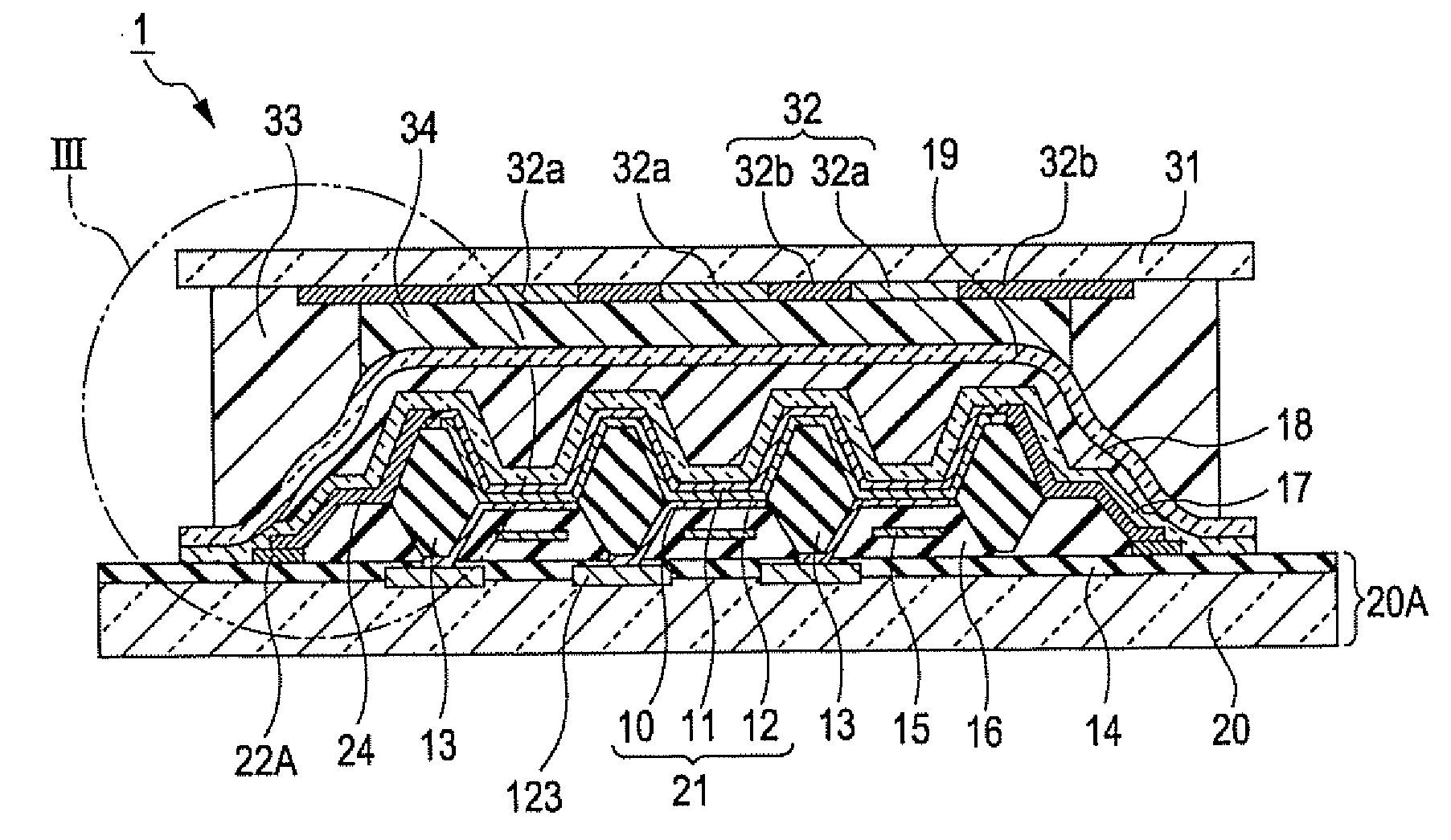

InactiveUS7247178B2Improve connection reliabilityReduce connection resistancePrinted circuit assemblingLiquid electrolytic capacitorsDielectricEngineering

A miniature solid electrolytic capacitor is provided, which is suitable for being disposed within an electrically insulating layer, and is connected to other component using an electrically conductive adhesive with a connection resistance at an anode low and with connection reliability improved. Specifically, the electrolytic capacitor includes a valve metal element for an anode 10 having a capacitor forming part 10A and an electrode lead part 10B, a dielectric oxide film 11 formed on the valve element, a solid electrolyte layer 12 formed on the dielectric oxide film 11 and a charge collecting element for a cathode 13 formed on the solid electrolyte layer 12, wherein at least one through hole 15 is formed in the electrode lead part 10B so as to expose a core 10C of the valve metal element, and an exposed portion 10D of the core is used for connecting portion.

Owner:PANASONIC CORP

Touch panel and method for manufacturing the same

InactiveUS20130181944A1Improve electrical stabilityImprove touch sensitivityLiquid/solution decomposition chemical coatingPrinted circuit manufactureConductive materialsTouch panel

A touch panel according to the embodiment includes a substrate; a first electrode formed on the substrate in a first direction and including a plurality of sensor parts and connection parts connecting the sensor parts with each other; and a second electrode formed in a second direction crossing the first direction while being insulated from the first electrode and including a plurality of sensor parts and connection parts connecting the sensor parts with each other. The sensor parts and the connection parts include transparent conductive materials, and the connection parts have resistance lower than resistance of the sensor parts in at least one of the first and second electrodes.

Owner:LG INNOTEK CO LTD

Conductive fine particle and anisotropic conductive material

ActiveCN1906705ALittle variation in conductivityReduce connection resistancePrinted circuit assemblingNon-insulated conductorsElectrical resistance and conductanceElectronic instrument

The present invention relates to conductive fine particles having low connection resistance, small variation in particle conductive performance, and excellent conduction reliability, and an anisotropic conductive material using the conductive fine particles. Anisotropic conductive materials using conductive fine particles are sandwiched between opposing substrates or electrode terminals in electronic devices such as mobile phones. However, with the development of electronic devices in recent years, the use of anisotropic conductive materials is sought Improvement of conductivity reliability of conductive fine particles, etc. The present invention seeks to improve the reliability of conduction by using, as the conductive fine particles used in the anisotropic conductive material, etc., the conductive fine particles in which the surface (2) of the base material fine particles is covered with a conductive film (4 ), (5) coating, and having a plurality of protrusions (5b) protruding from the surface of the conductive film (1), is characterized in that the surface of the matrix particle has a surface that makes the surface of the conductive film protrude The core material (3) is composed of a conductive material different from the conductive material constituting the conductive film.

Owner:SEKISUI CHEM CO LTD

Conductive fine particles and anisotropic conductive material

InactiveUS7470416B2Reduce connection resistanceFacilitate conductionNon-insulated conductorsLayered productsElectrical resistance and conductanceOptoelectronics

Conductive fine particles which prevent a leak current from being caused by conductive fine particles as a result of fine-pitched electrodes and are low in connection resistance and excellent in conduction reliability, and an anisotropic conductive material using the conductive fine particles. The conductive fine particles have the surfaces of base material fine particles covered with conductive films, with the conductive films provided on the surfaces thereof with swelling protrusions, wherein the swelling protrusions have an average height of at least 50 nm, the portions of swelling protrusions consist of, as a core material, conductive materials different from those of the conductive films, and the outer peripheries of the conductive fine particles are provided with insulating coating layers or insulating fine particles, preferably the thickness of the insulating coating layers being at least 0.2 nm, preferably an average particle size of the insulating fine particles being at least 30 nm and up to an average height of the protrusions; and the anisotropic conductive material having the conductive fine particles dispersed in its resin binder.

Owner:SEKISUI CHEM CO LTD

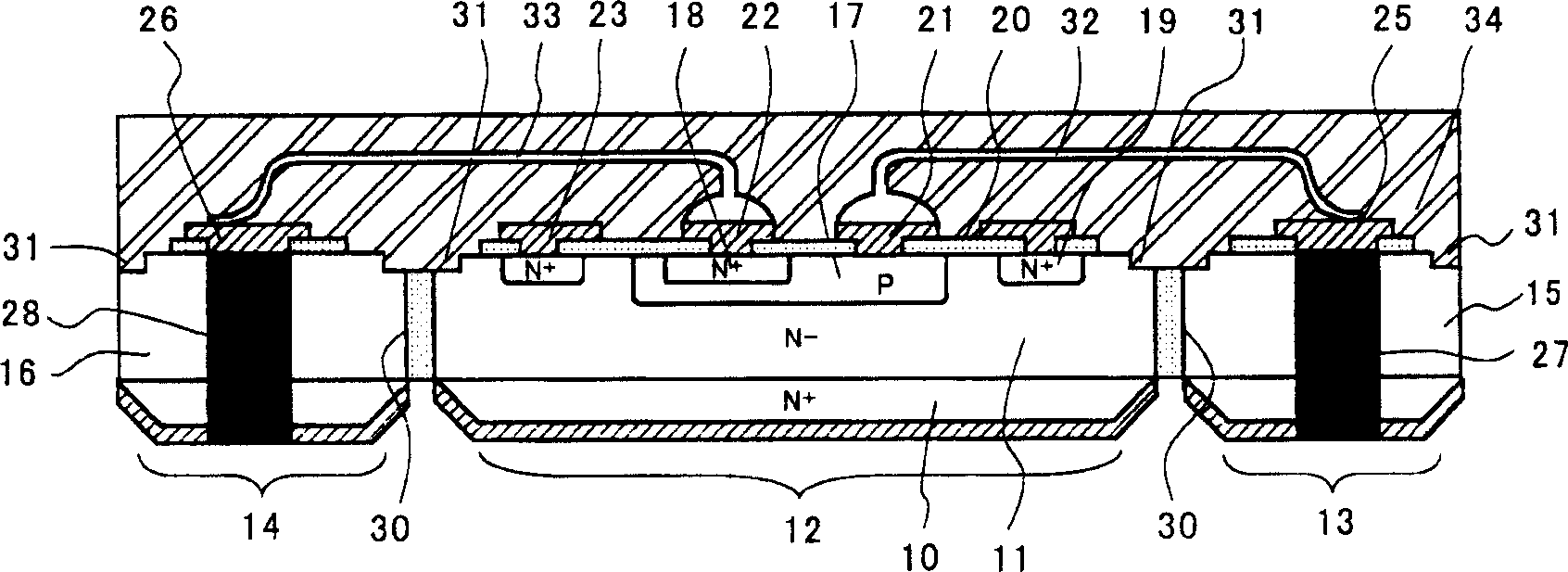

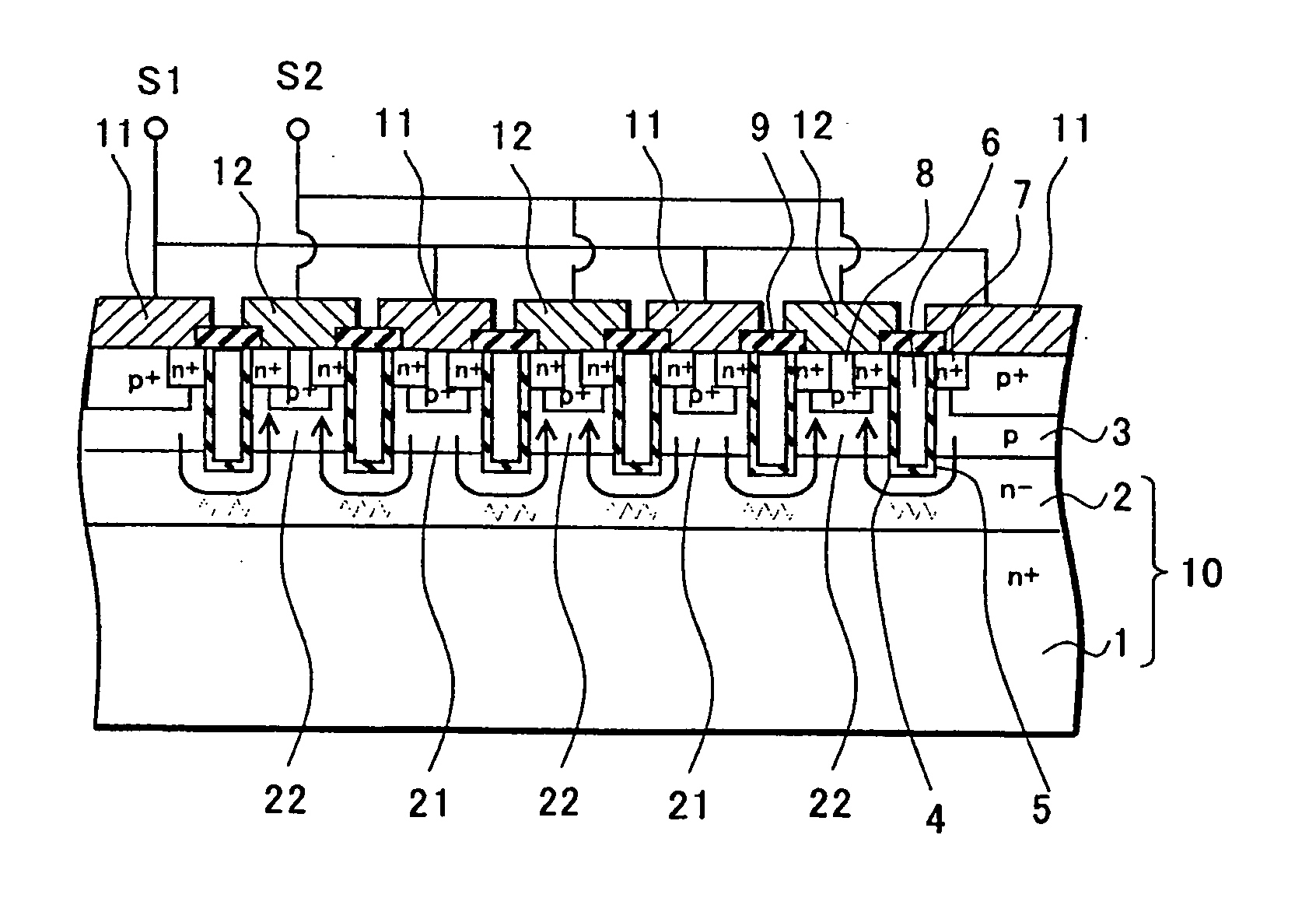

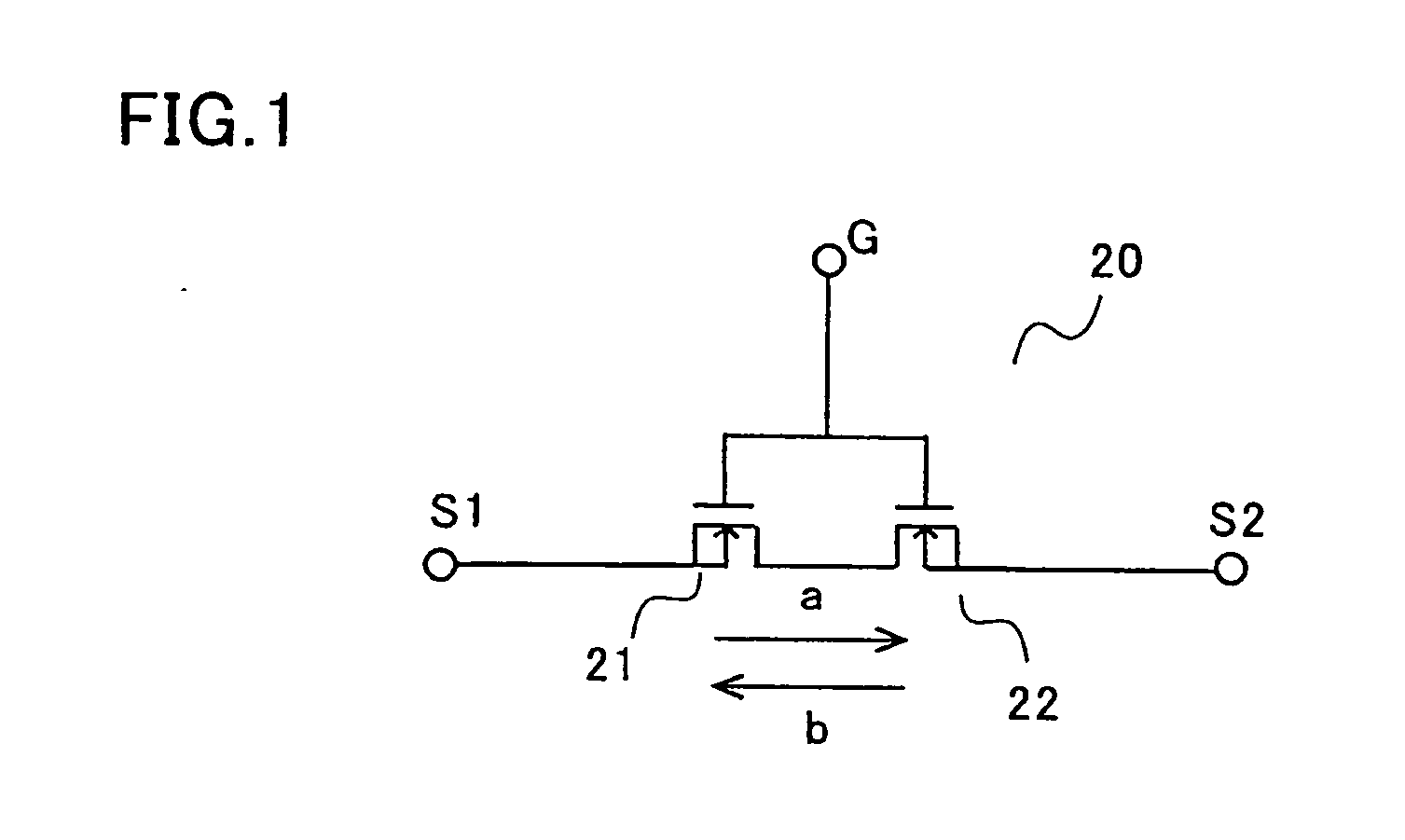

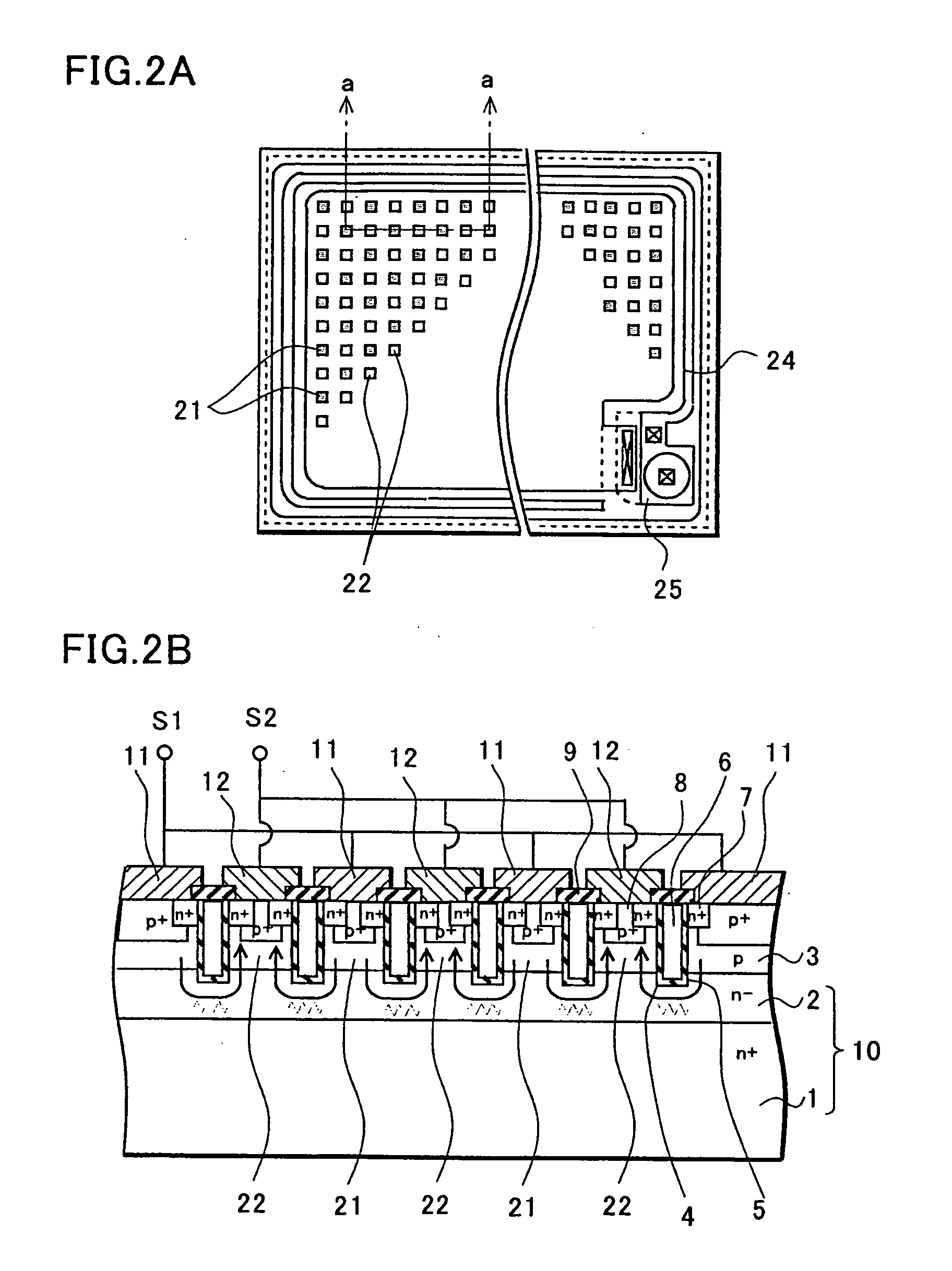

Semiconductor device

InactiveUS20060118866A1Reduce connection resistanceIncrease resistanceTransistorSolid-state devicesDevice materialEngineering

In a preferred embodiment of the present invention, first MOS transistors connected to first source electrodes and second MOS transistors connected to second source electrodes are arranged alternately next to each other on one chip. Different potentials are applied respectively to the first source electrodes and to the second source electrodes, and both of the MOS transistors are controlled with respect to an ON or OFF state by one gate terminal. Currents flow along surroundings of trenches, whereby on-resistance is reduced.

Owner:SANYO ELECTRIC CO LTD

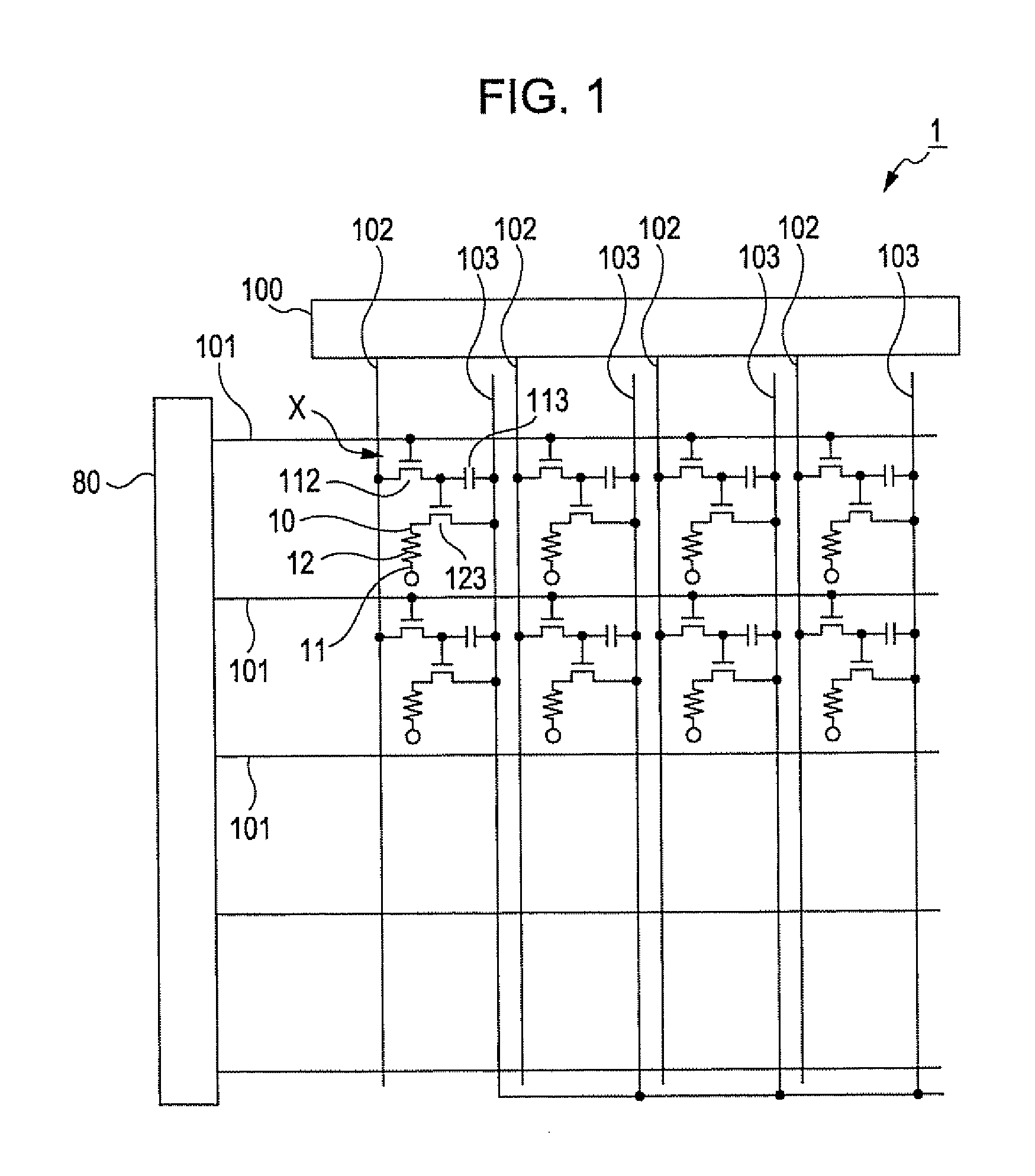

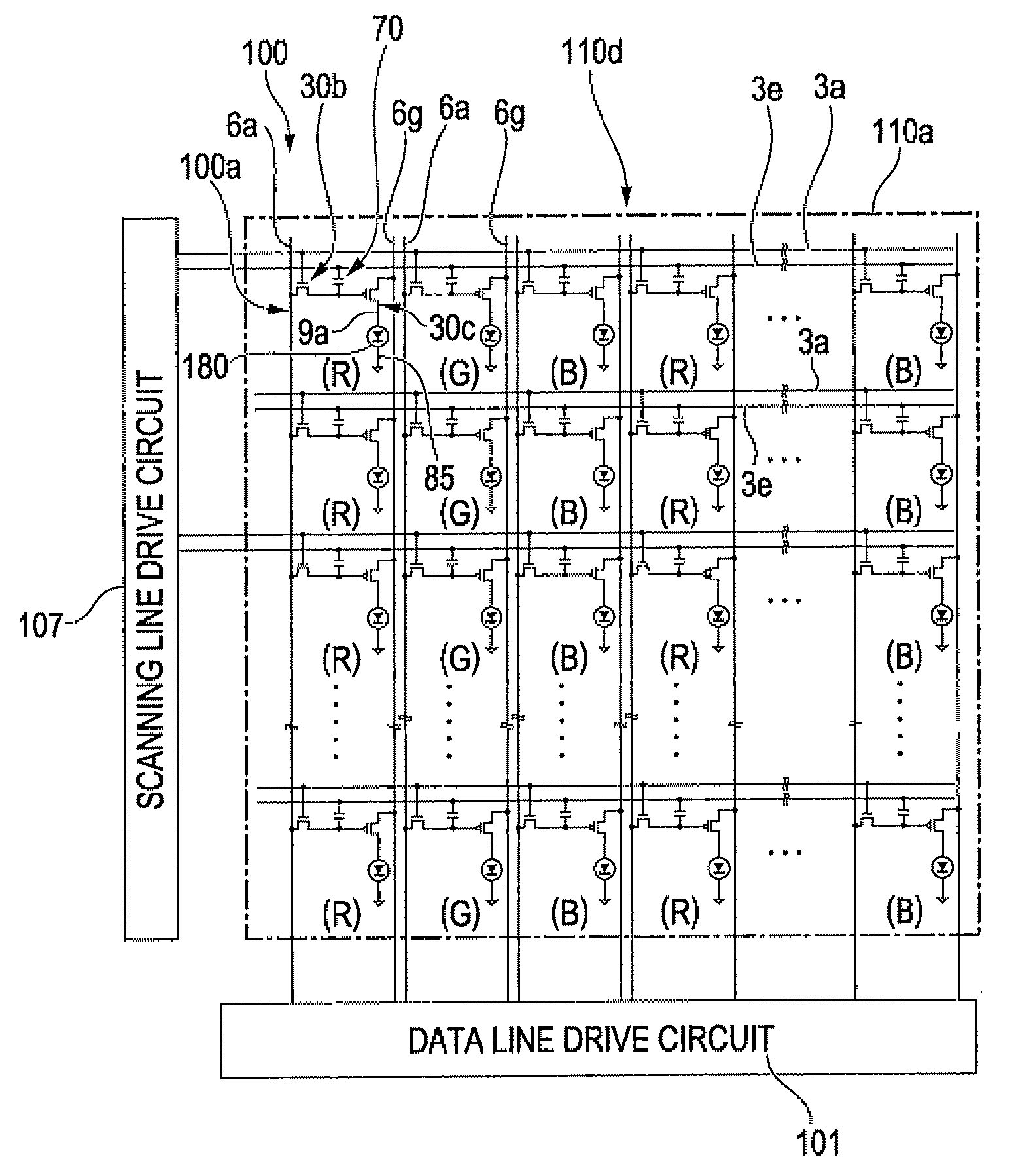

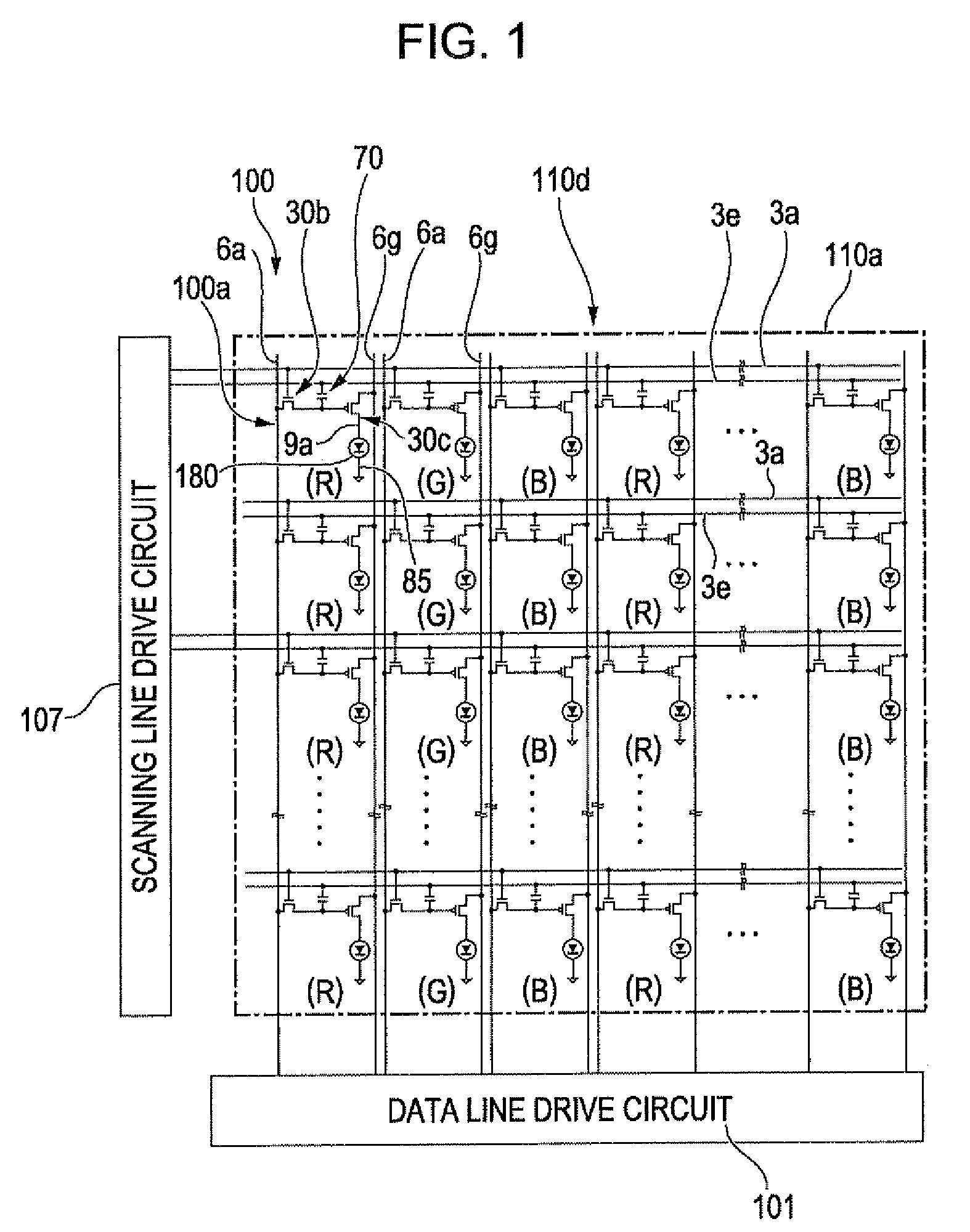

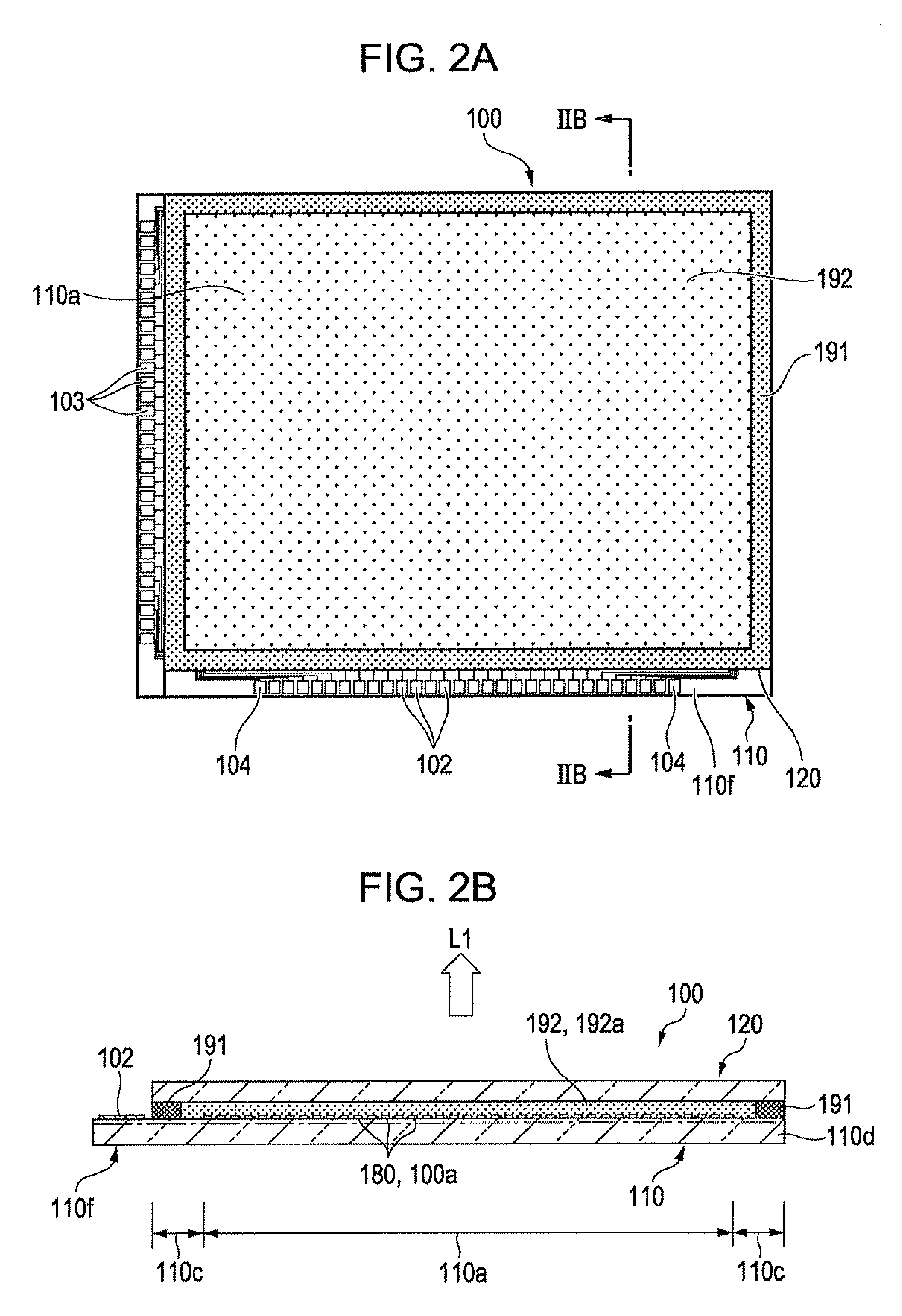

Organic electroluminescent device and electronic apparatus

ActiveUS20090261720A1Increase resistanceWide range of fieldsDischarge tube luminescnet screensLamp detailsEngineeringOrganic electroluminescence

An organic electroluminescent device includes a pixel region in which a plurality of pixels is disposed on a support substrate, each pixel having an electroluminescent element in which at least a first electrode layer, a light-emitting layer, and a second electrode layer are laminated in that order at an upper layer side of an insulating film; a first conductive pattern portion provided at a lower layer side of the insulating film for applying a potential to the second electrode layer; and a second conductive pattern portion which is composed of a conductive film having a sheet resistance lower than that of the second electrode layer and which is provided at the upper layer side of the insulating film to connect the second electrode layer to the first conductive pattern portion. In this organic EL device, the second conductive pattern portion has a third conductive pattern portion which is provided on an upper surface of the first conductive pattern portion at a contact portion composed of a non-forming region of the insulating film and which is in contact with the first pattern portion.

Owner:SEIKO EPSON CORP

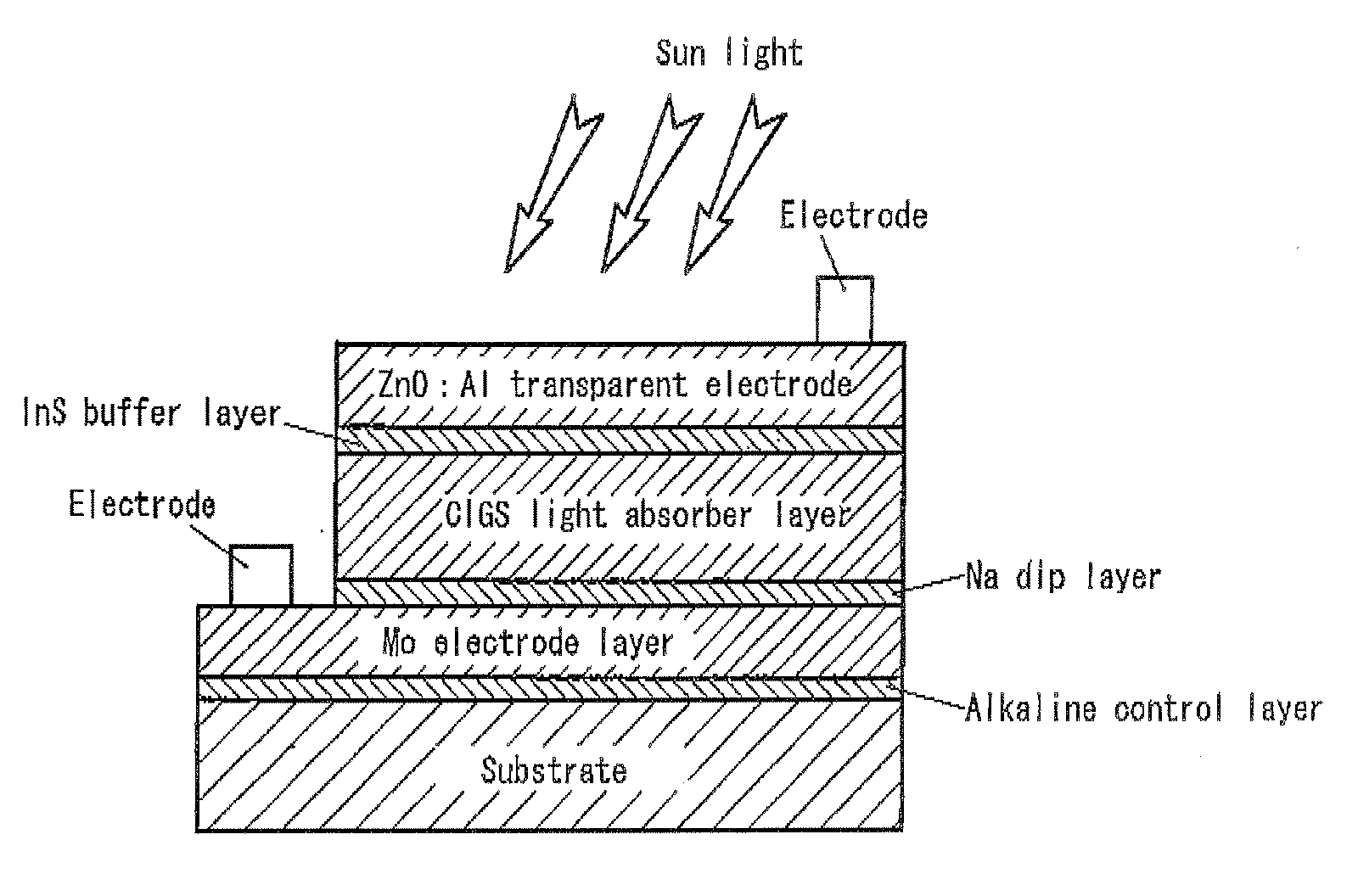

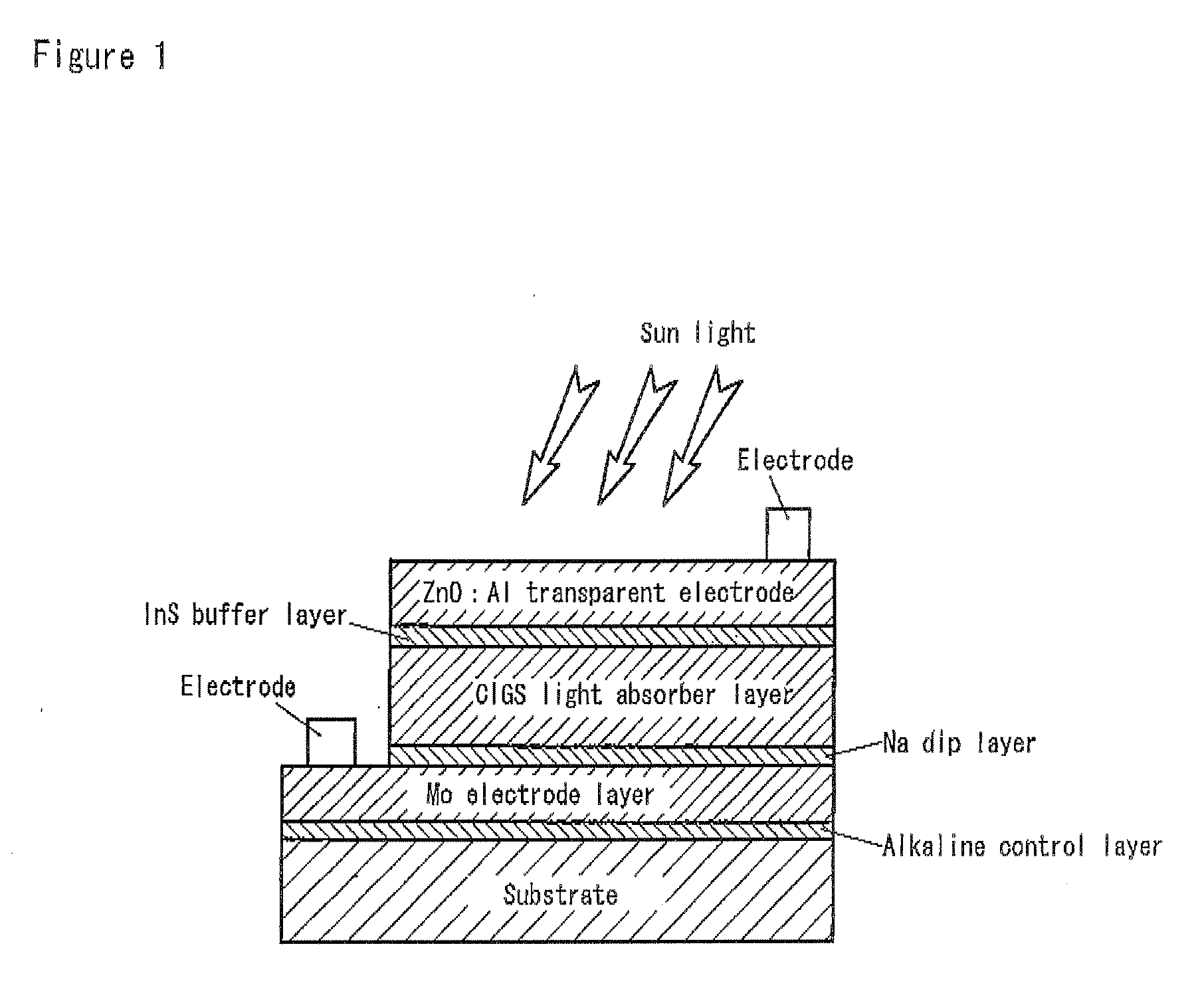

Solar Cell

InactiveUS20090242022A1Improve reliabilityBreakage of substrate can be preventedFinal product manufactureSolid-state devicesElectrical conductorCopper indium gallium selenide

A flexible solar cell is achieved which has a high photoelectric conversion efficiency and no aged deterioration. A cell 10 (unit cell) is formed as a unit, comprising: a lower electrode layer 2 (Mo electrode layer) formed on a flexible mica sheet substrate 1 (substrate); a light absorber layer 3 (CIGS light absorber layer) which contains copper indium gallium selenide; a highly resistant buffer layer thin film 4 formed of InS, ZnS, CdS, or the like on the light absorber layer 3; and an upper electrode layer 5 (TCO) formed of ZuOAl or the like, and furthermore, a contact electrode section 6 for connecting between the upper electrode layer 5 and the lower electrode layer 2 is formed in order to connect a plurality of unit cells 10 in series. The contact electrode section 6 has a Cu / In ratio higher than that of the light absorber layer 3, and in other words, has less In contained therein to have a property of p+ (plus) type or a conductor relative to the light absorber layer 3 which is a p-type semiconductor.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com