Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

491results about How to "Increase the welding area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

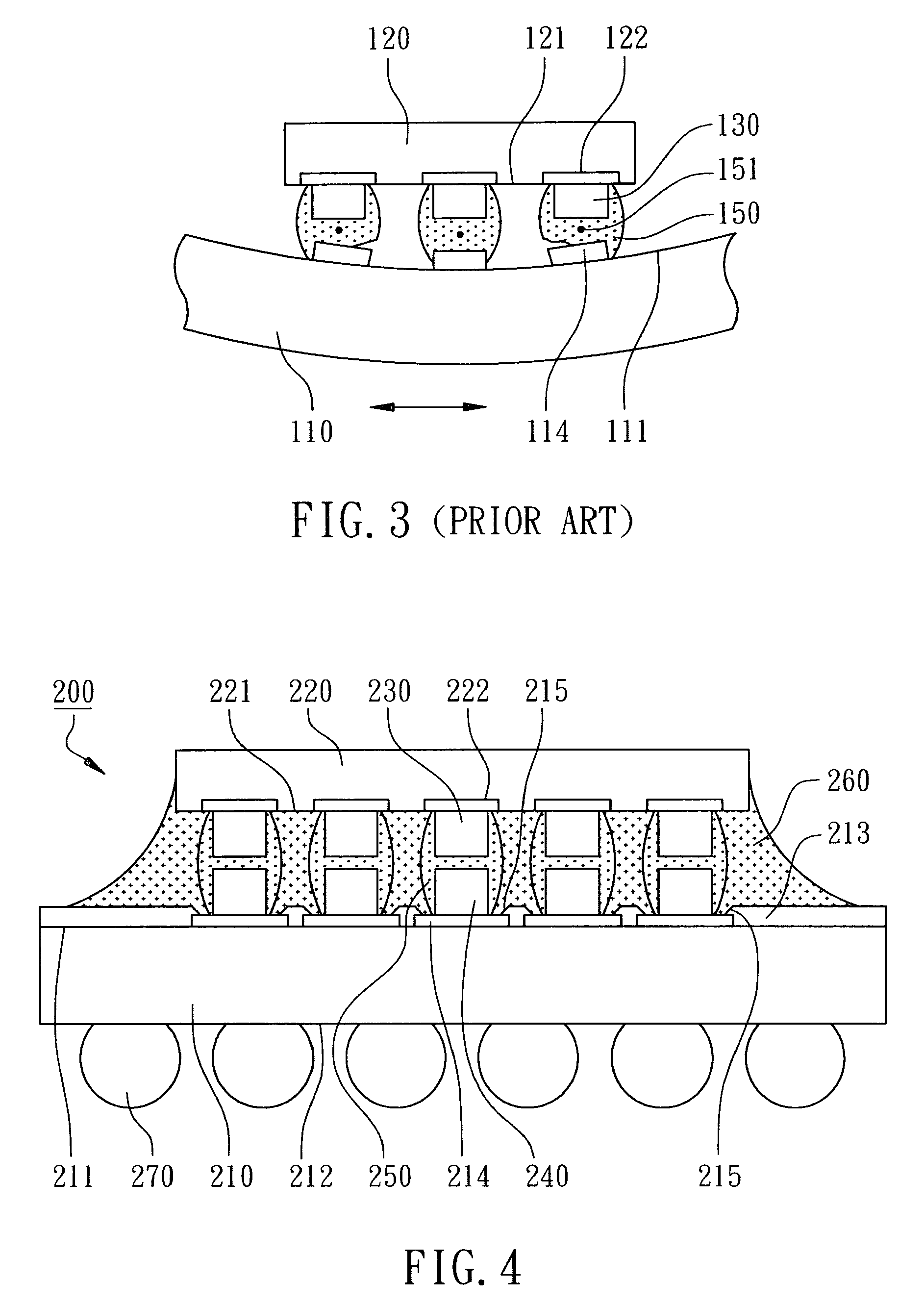

Pillar-to-pillar flip-chip assembly

ActiveUS7569935B1Reduce thermal stressPrevent peelingFinal product manufactureSemiconductor/solid-state device detailsSolder maskSolder ball

A pillar-to-pillar flip-chip assembly primarily comprises a substrate, a chip disposed on the substrate, a plurality of first copper pillars on the bonding pads of the chip, a plurality of second copper pillars on the bump pads of the substrate, and a soldering material. A first height of the first copper pillars protruding from the active surface of the chip is the same as a second height of the second copper pillars from the solder mask on the substrate. When the soldering material electrically and mechanically connects the first copper pillars to the second copper pillars, a plurality of central points of the soldering material are formed on an equal-dividing plane between the chip and the substrate to reduce the direct stresses exerted at the soldering material to avoid peeling or breaks from the bump pads. Moreover, each of conventional solder balls is replaced with two soldered copper pillars to meet the lead-free requirements with higher reliability and lower costs.

Owner:POWERTECH TECHNOLOGY

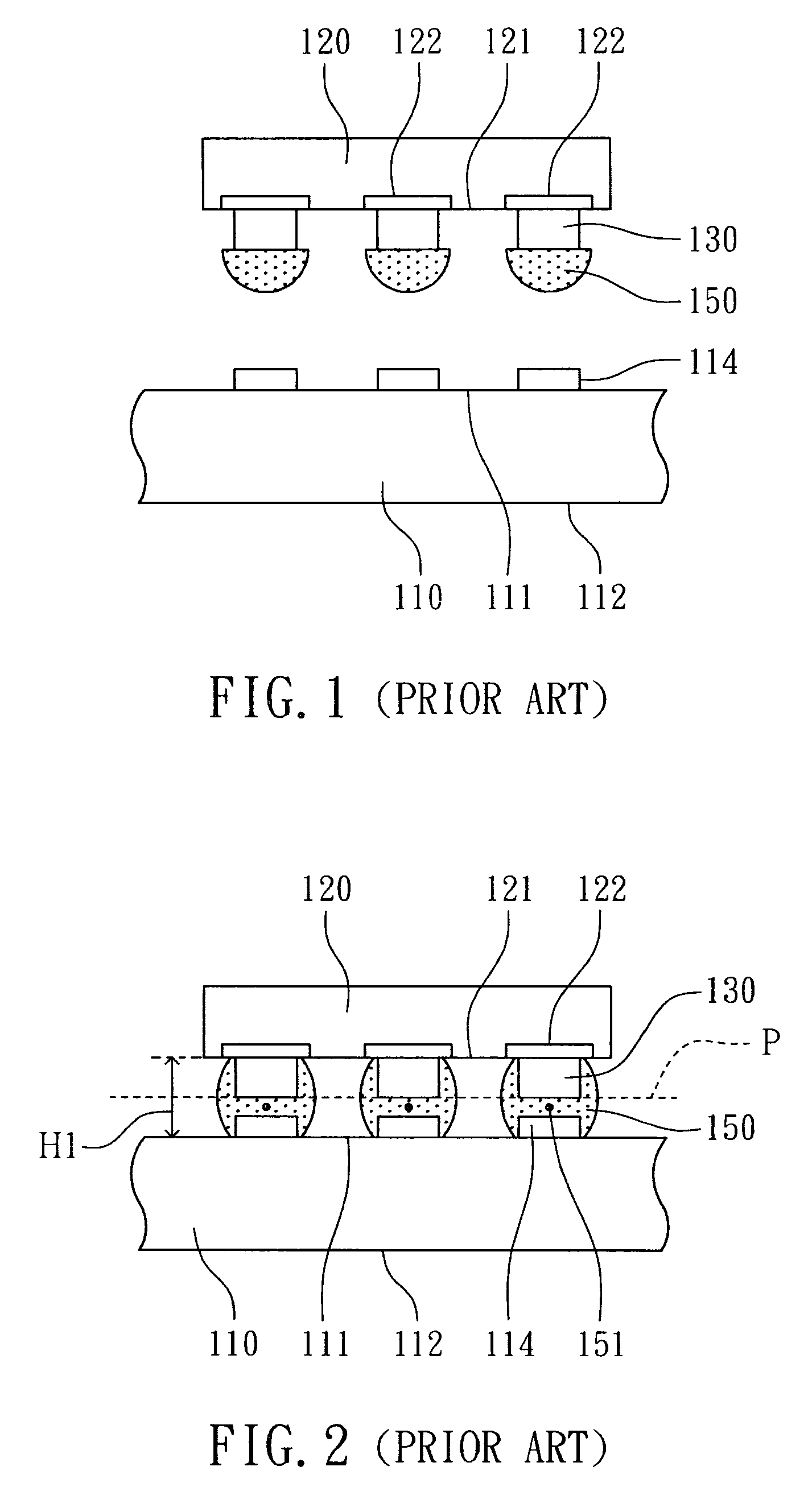

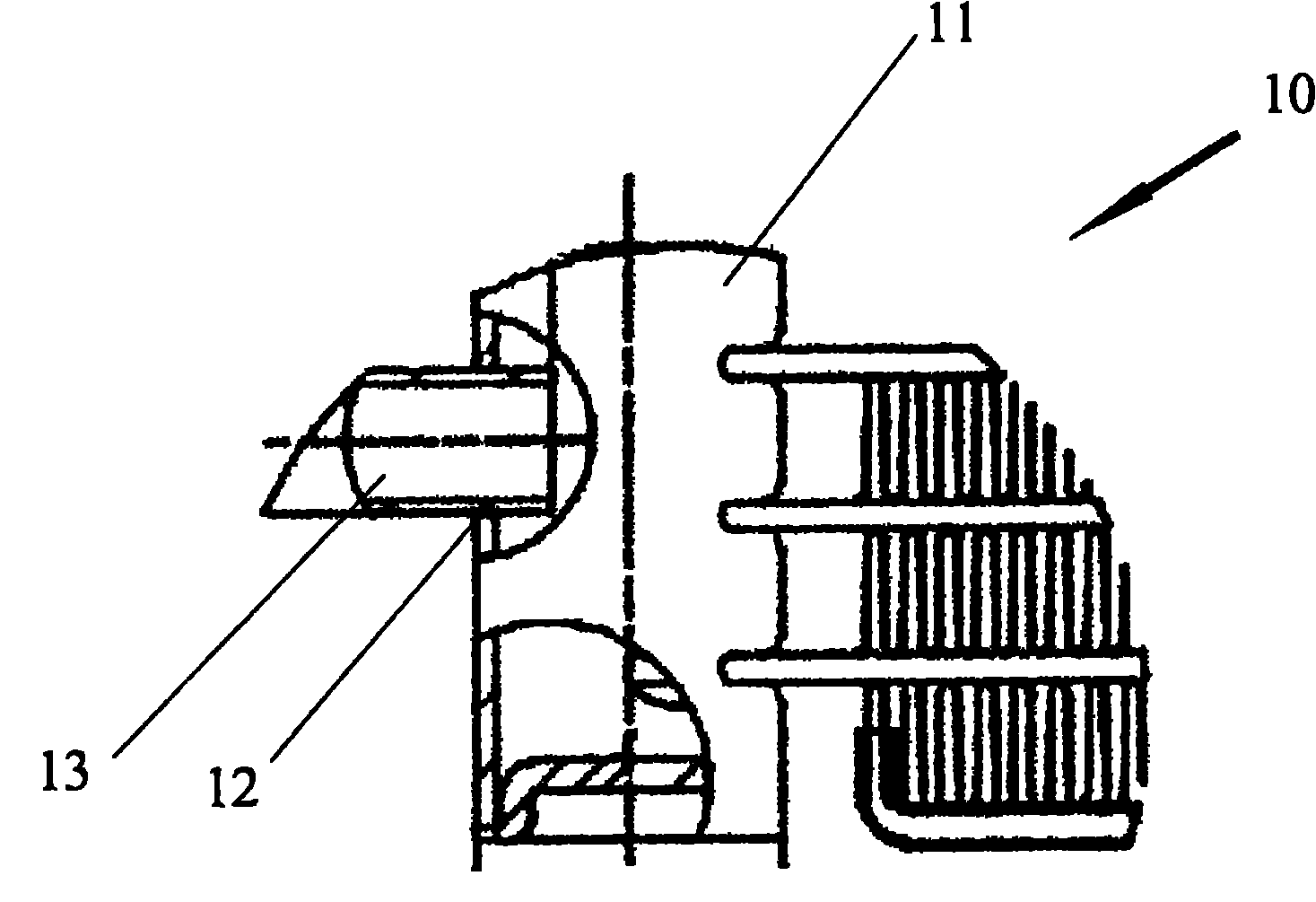

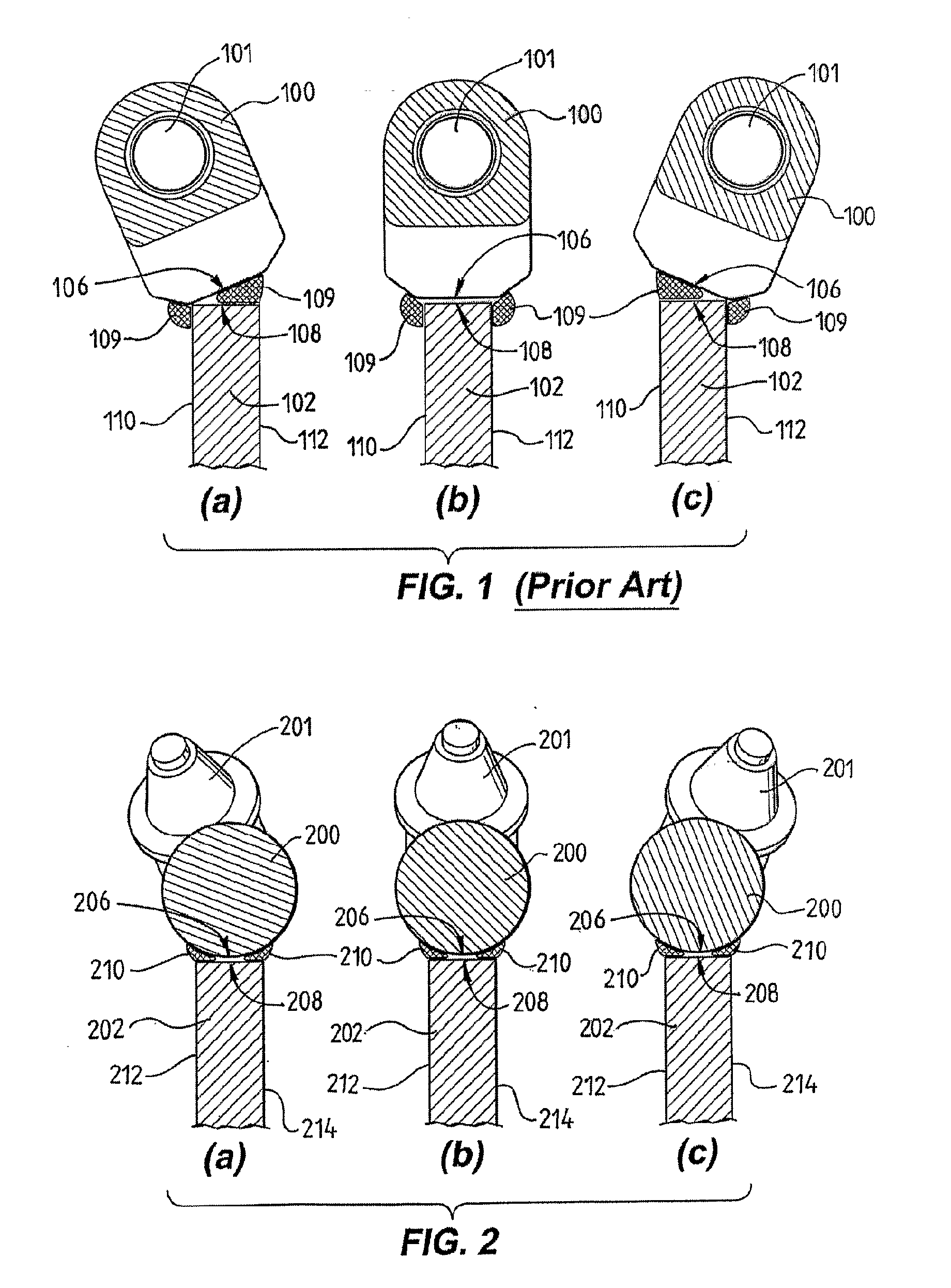

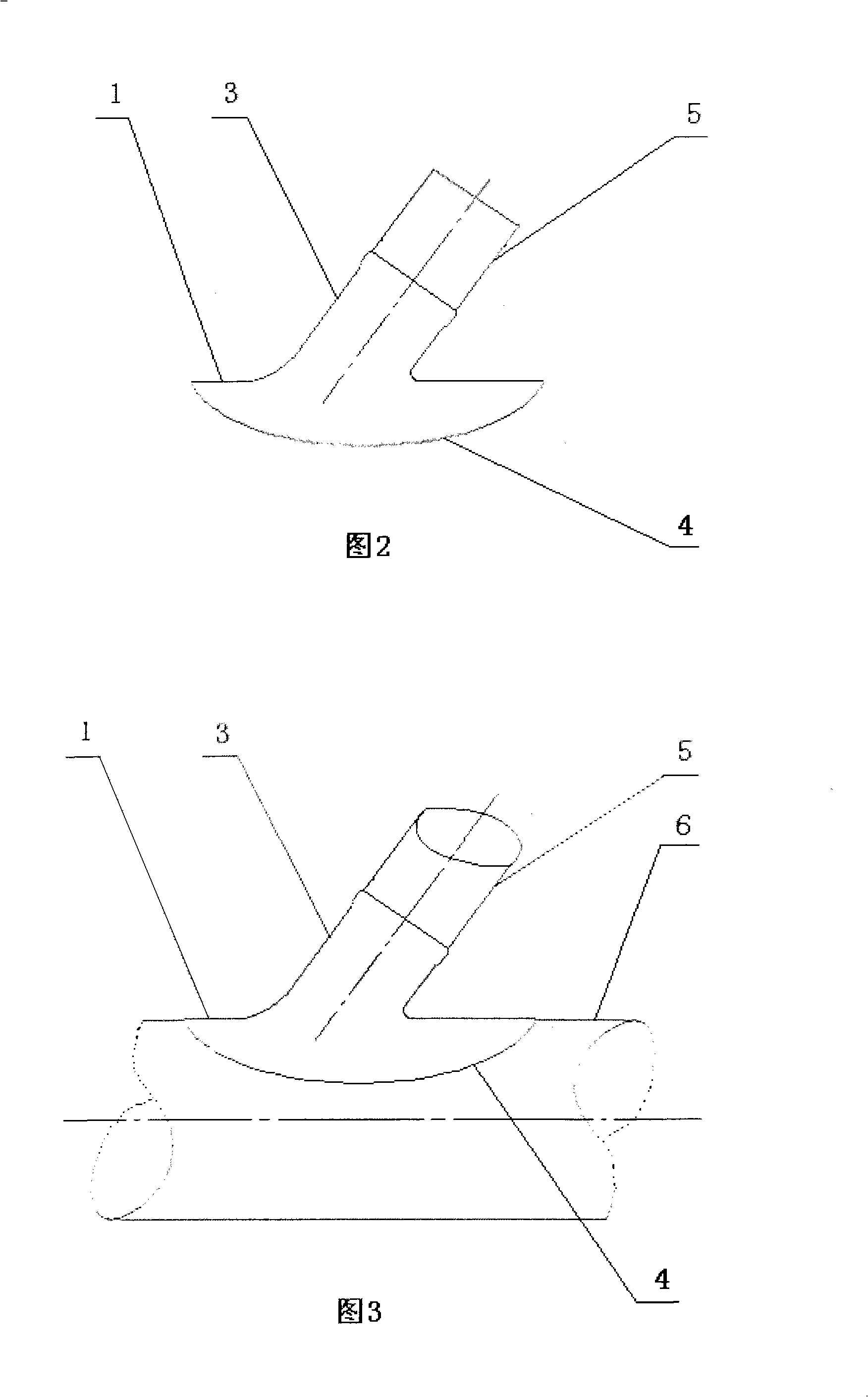

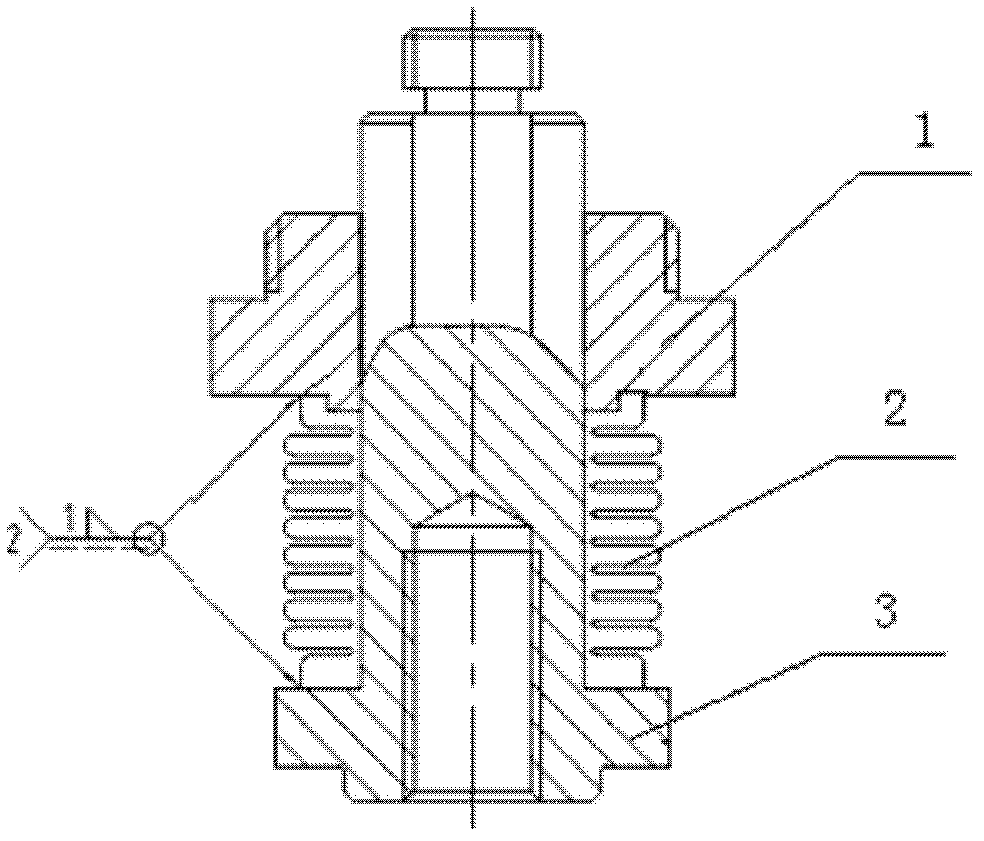

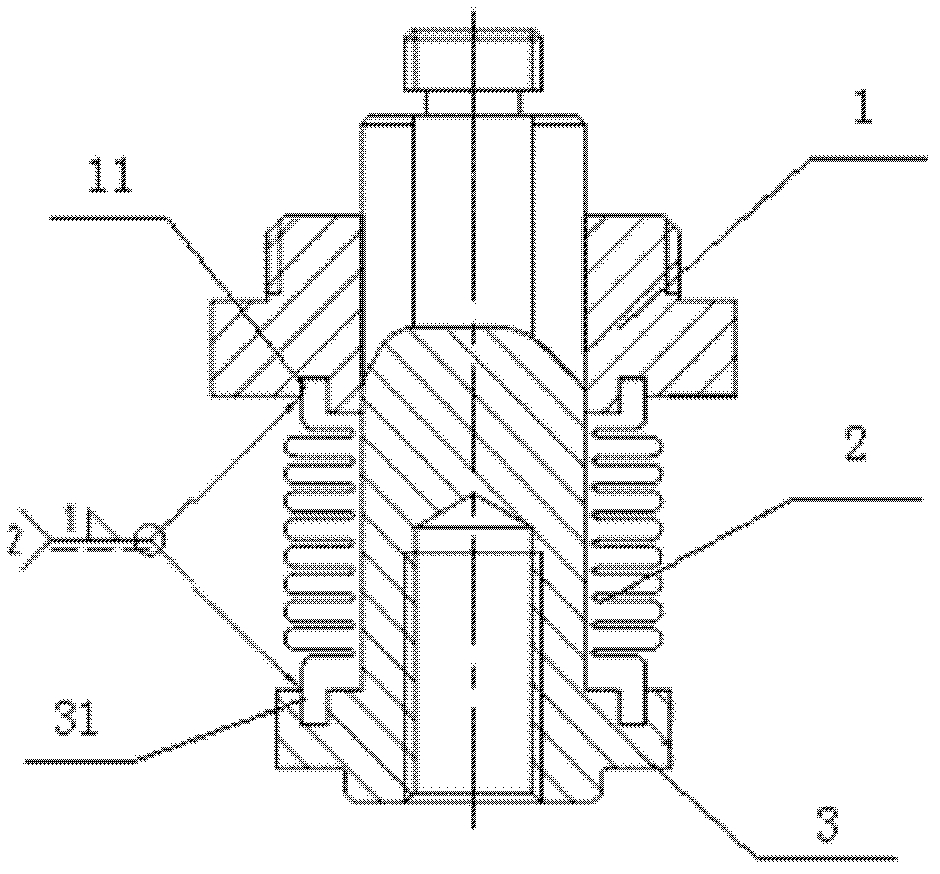

Friction stirring-welding method

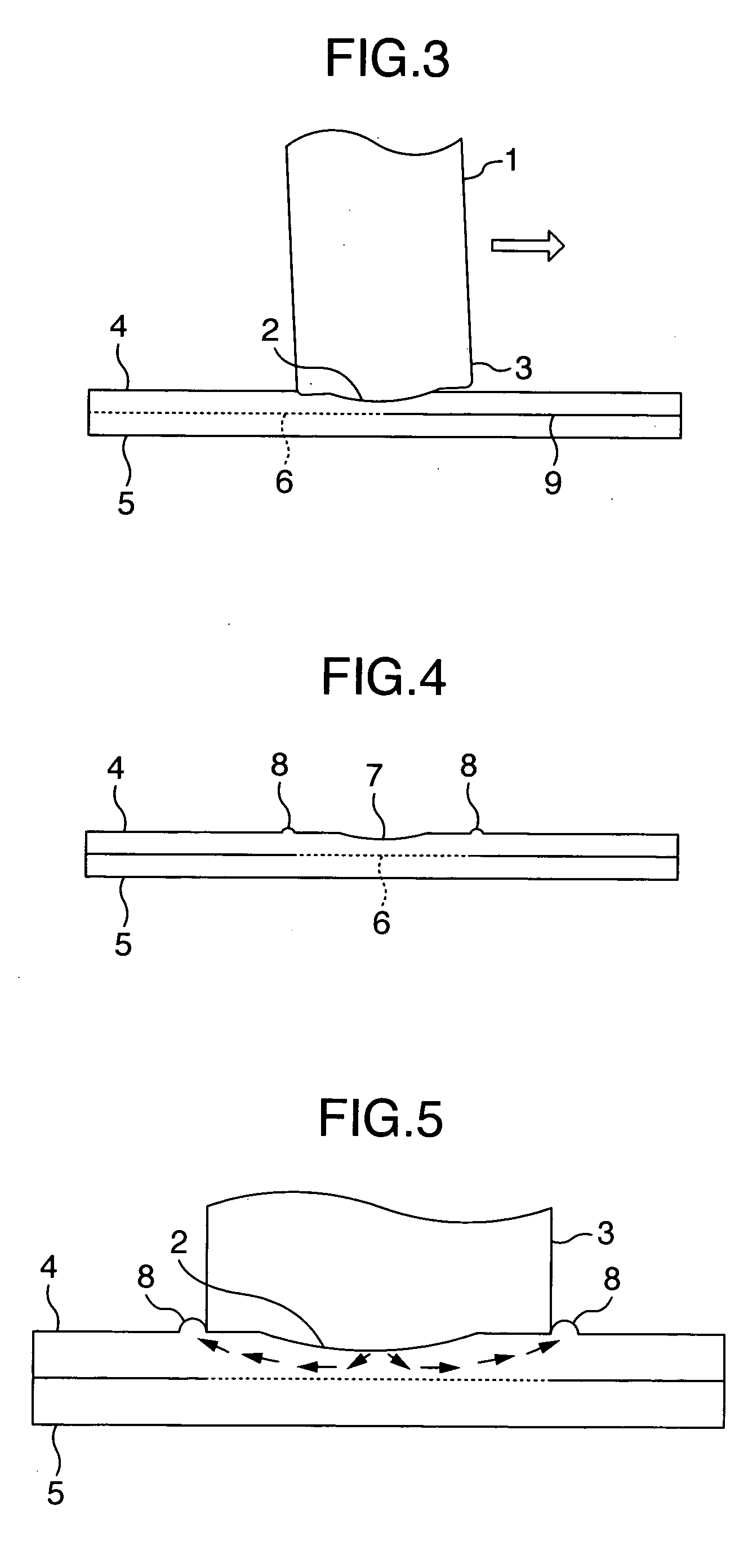

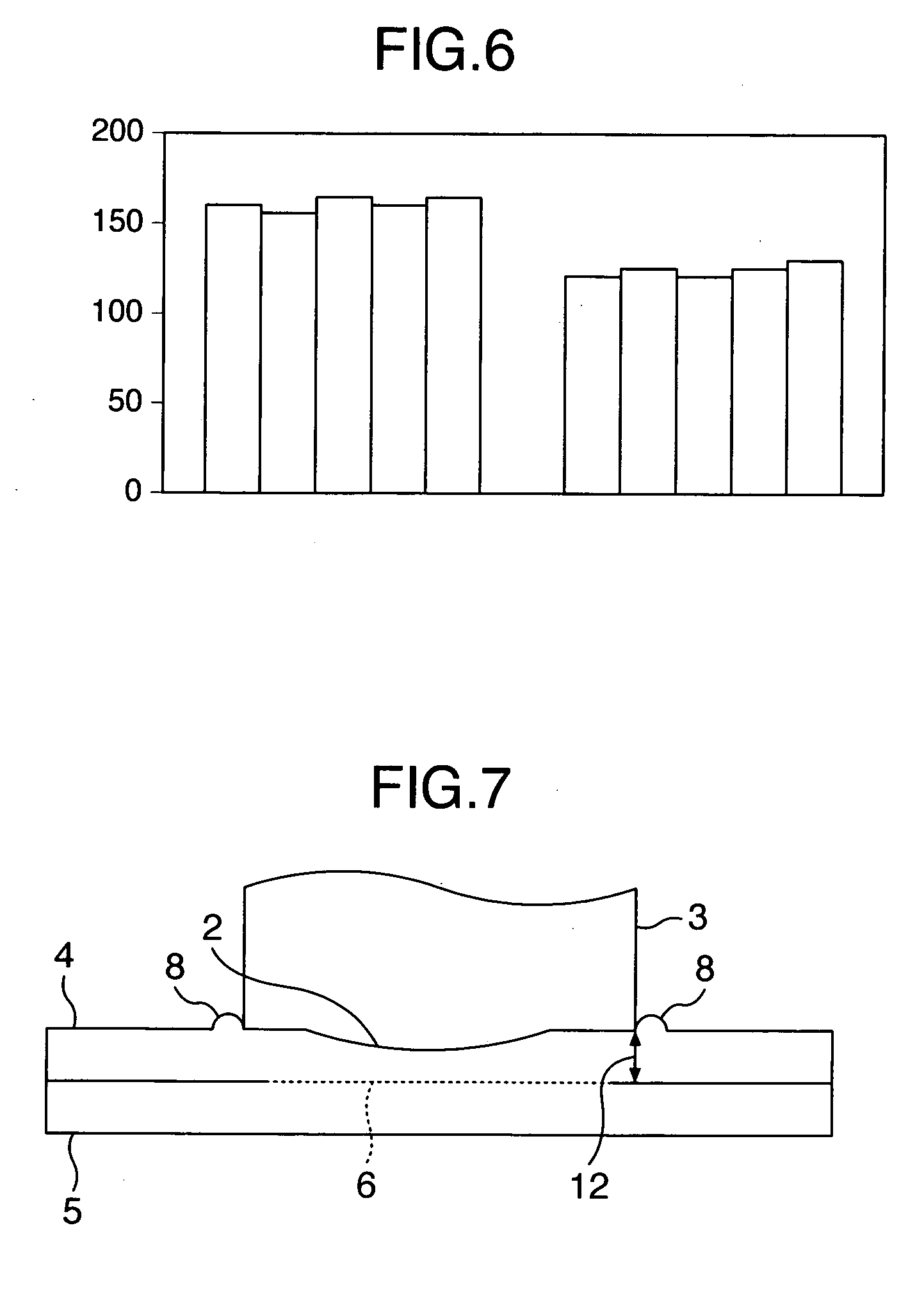

InactiveUS20060138197A1Easy to disassembleEfficient methodNon-electric welding apparatusLap jointSurface oxidation

A friction stirring-welding method capable of increasing the welding strength of a lap joint. A welding tool (1) comprises a small diameter projected part (2) at the tip of a shoulder (3). The welding tool is press-fitted to the upper plate (4) of the lap joint while being rotated. By a friction stirring action, an upper plate side welding boundary surface (6) plastically flows, a surface oxidation film on a lapped surface is peeled off, and the boundary surface is activated to provide an excellent welding part. Also, since the welding tool is formed in a shape having the small diameter semispherical projected part (2) at the tip thereof, the thickness (12) of an upper plate welding part is increased, and a lap joint part with high welding strength can be provided.

Owner:HITACHI LTD

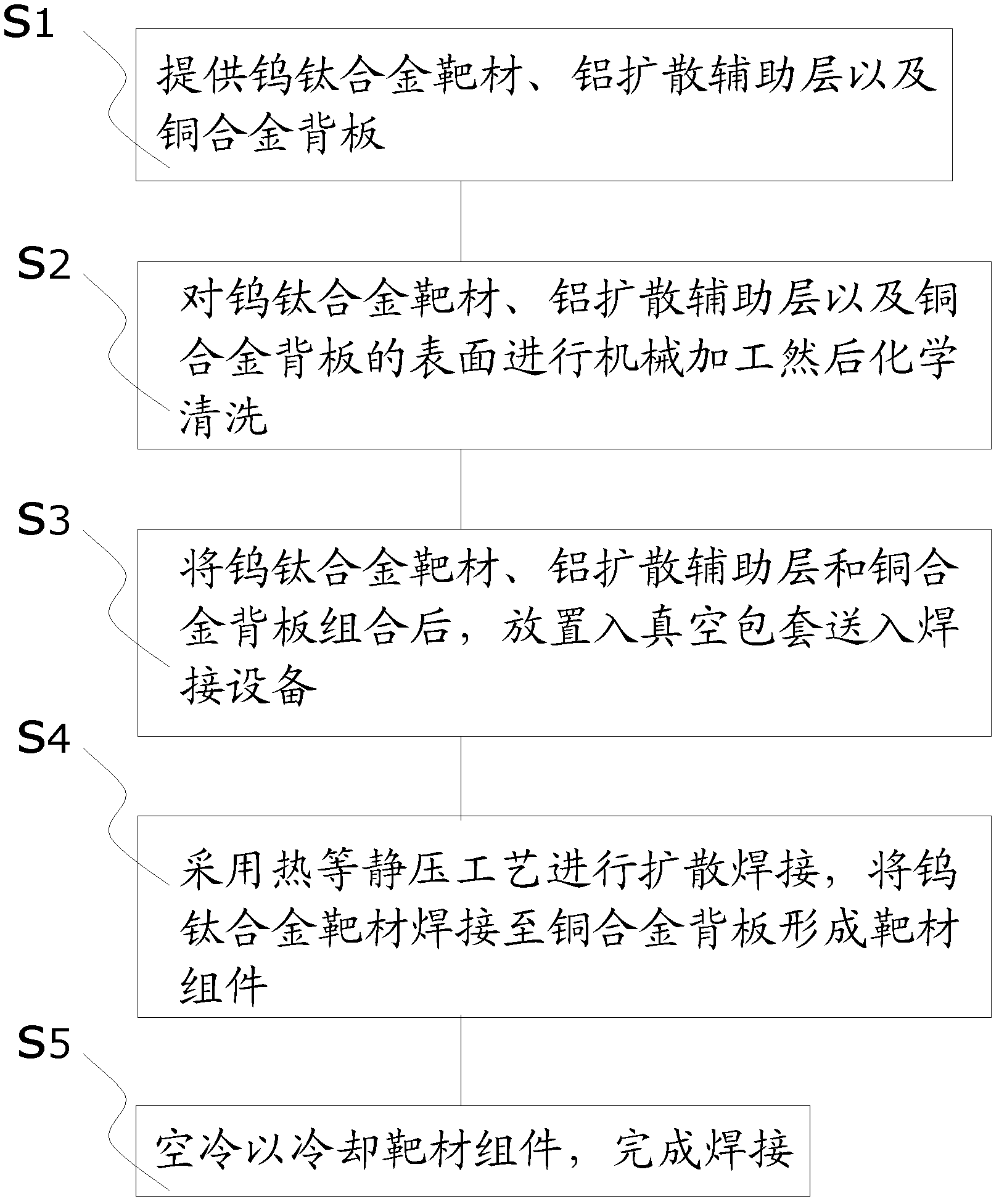

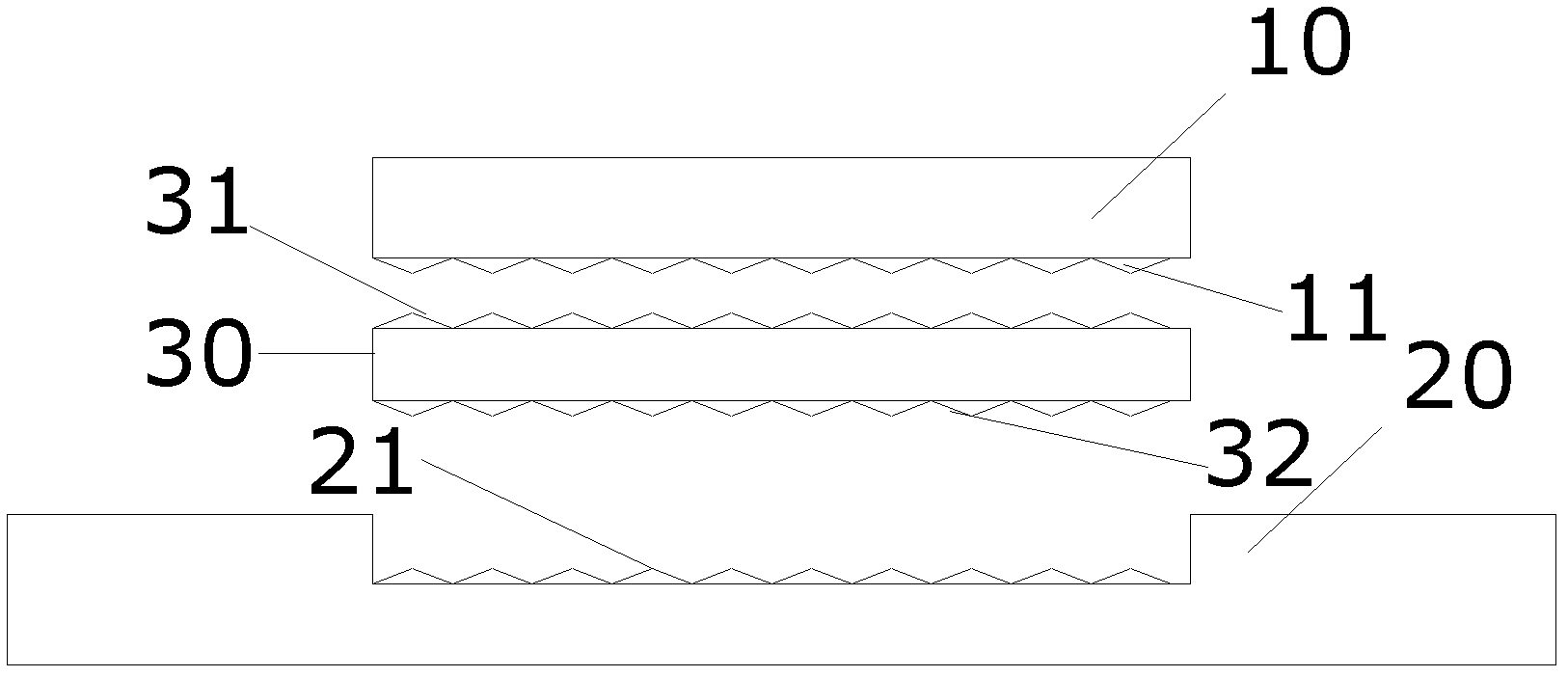

Diffusion welding method for tungsten-titanium alloy target and copper alloy back plate

ActiveCN102554455APrevent oxidationLow costNon-electric welding apparatusThermal deformationTitanium alloy

Disclosed is a diffusion welding method for a tungsten-titanium alloy target and a copper alloy back plate. An aluminum diffusion auxiliary layer is arranged between the tungsten-titanium alloy target and the copper alloy back plate, diffusion welding of the tungsten-titanium alloy target, the aluminum diffusion auxiliary layer and the copper alloy back plate is realized by the aid of high-strength atomic diffusivity between the tungsten-titanium alloy target and the aluminum diffusion auxiliary layer and between the aluminum diffusion auxiliary layer and the copper alloy back plate, and finally, welding quality of the tungsten-titanium alloy target and the copper alloy back plate is improved. Diffusion welding of the tungsten-titanium alloy target and the copper alloy back plate is implemented by a hot isostatic pressing process. As diffusion welding is performed in a vacuum sheath and air is isolated, the contact surface of welded metal can be effectively prevented from being oxidized, the bonding strength of the tungsten-titanium alloy target, the aluminum diffusion auxiliary layer and the copper alloy back plate is enhanced, the target is prevented from being separated from the back plate during sputtering, and sputtering coating is normally performed. A target assembly formed by the diffusion welding method has the advantages of high bonding compactness, high thermal deformation resistance and the like.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

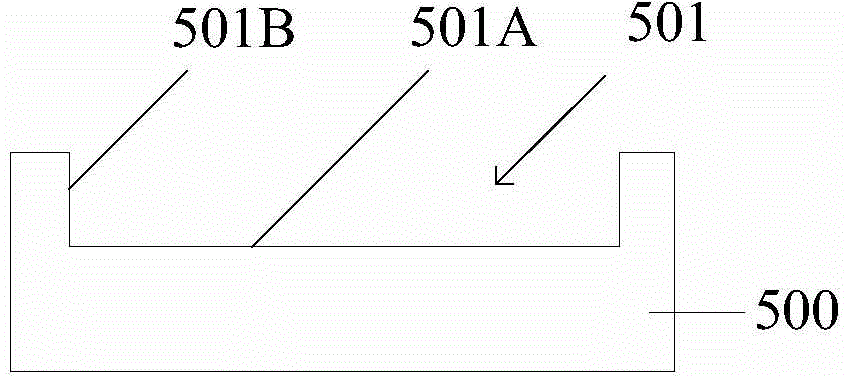

Welding method of tungsten target material component

ActiveCN104551381AReduce deformationUnbreakableWelding/soldering/cutting articlesMetal working apparatusHot isostatic pressingWeld strength

The invention discloses a welding method of a tungsten target material component. The welding method comprises the following steps: providing a tungsten target material and a copper back plate; turning threads in the welding surface of the tungsten target material; forming a groove in the copper back plate; mounting the tungsten target material in the groove; welding the tungsten target material and the copper back plate by a hot isostatic pressure method. Through the use of the welding method, the threads are turned in the welding surface of the tungsten target material, the groove is formed in the copper back plate, and the tungsten target material and the copper back plate are mounted together, so that the tungsten target material is positioned in the groove; then welding by the hot isostatic pressure method is performed, in the welding process, the deformation quantity of the tungsten target material is small, and a fragmentation phenomenon not easily occurs; in addition, because of the threads, the area of the welding surface of the tungsten target material is enlarged, and the welding strength of the tungsten target material component is improved; after welding, the threads are embedded in the copper back plate from the welding surface of the tungsten target material, so that the welding strength of the tungsten target material component is further improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

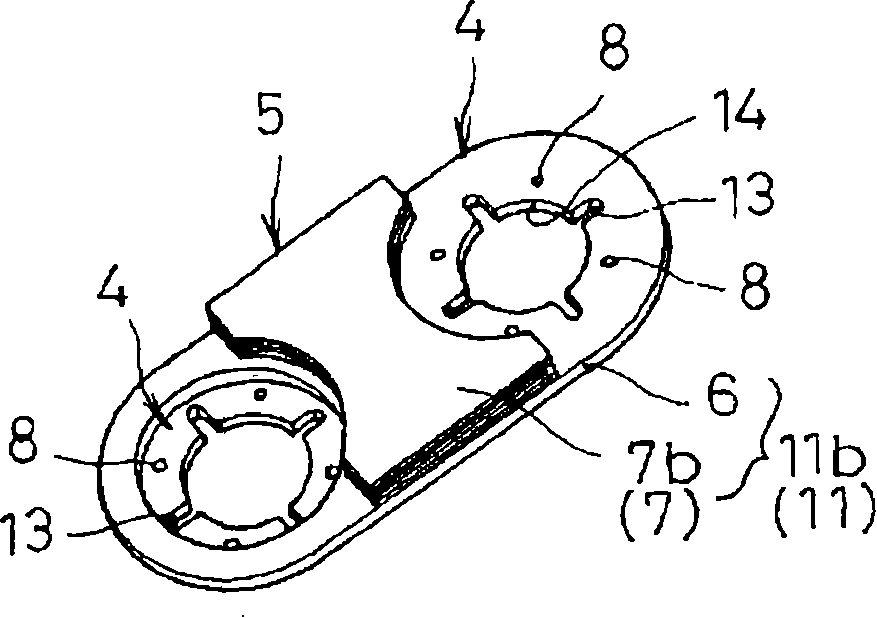

Connecting device between batteries

ActiveCN101218697AIncrease the welding areaImprove welding strengthNon-aqueous electrolyte accumulatorsCurrent conducting connectionsMechanical engineeringMetal

An inter-battery connection device for connecting terminals of two batteries (1a, 1b) arranged with their axes parallel to each other. The inter-battery connection device includes an inter-battery connection plate (11) that connects the battery case bottom (2) and the sealing plate (3) of the two batteries. The inter-battery connection plate (11) includes welding portions (4) at the ends of its base plate (6) for welding to the case bottom (2) and the sealing plate (3), respectively. An intermediate metal plate (7) is joined to the middle part of the base plate (6) between the welding portions (4, 4) to form an intermediate portion (5) having a greater thickness than each welding portion (4). The inter-battery connection device has reduced electric resistance while achieving improved weldability.

Owner:PANASONIC CORP

Metal snow guard

InactiveUS6922948B2Prevent overheating and underheatingRuining appearanceRoof covering using slabs/sheetsRoof covering using tiles/slatesRough surfaceWire mesh

A metal snow guard is provided with a solid layer of soldering material on its base to be heated and melted with application of heat to the upper side of the snow guard to solder the base to an underlying metal roof. The preferred soldering material comprises an interior layer of solder and an outer layer of flux. In one form, the soldering material is in the form of spaced spots or projections providing a rough surface on the underside of the snow guard with the projections melting and spreading laterally into uneven surfaces where the roof or the base of the snow guard is not flat. The amount of solder and / or flux in the solid layer is limited so that the solder and / or flux does not flow outwardly from the snow guard and run down the metal roof thereby damaging or marring the metal roof surface. The preferred snow guards are formed of sheet metal of relatively few pieces and which are folded and joined together in an inexpensive manner. Preferably, the projections of soldering material are formed by forcing a paste of solder and flux through spaced holes in a plate or screen onto the base and then applying heat to melt the past and form a crust of flux on the outside of the projections which are mainly then comprised of solder. The outer crust layer of flux should protect the inner solder from oxidizing.

Owner:SNO GEM

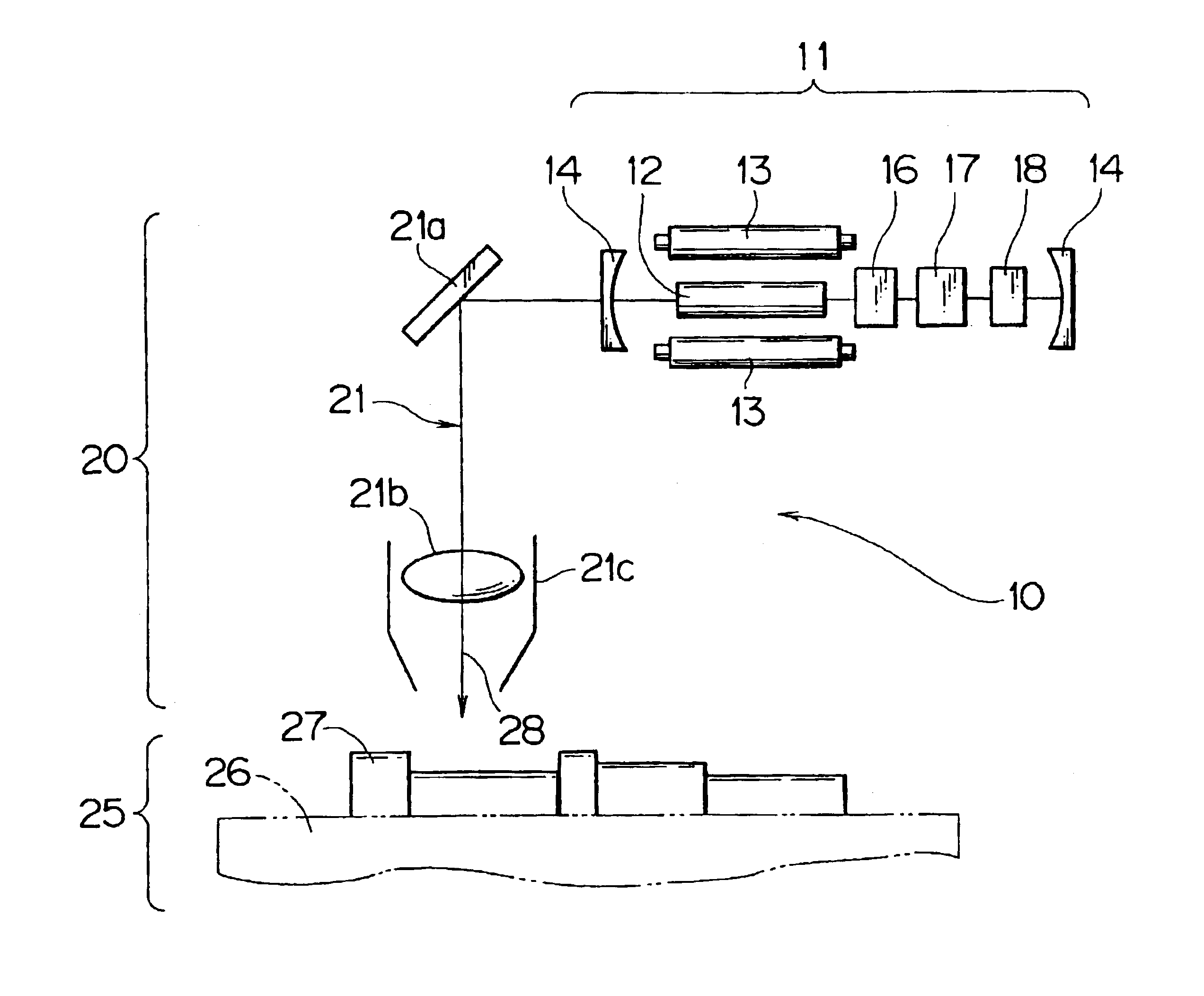

Optical fiber fixing method

InactiveUS6886991B2Less influenceShorten the timeOptical articlesCoupling light guidesPulsed modeSynthetic resin

While a ferrule or a laser beam is being shifted in an axial direction, the laser beam is applied, thereby forming a plurality of welded portions at the boundary between a coating of an optical fiber and the ferrule. A YAG laser in a Q switch pulse mode is used to provide a laser beam. The beam. The YAG laser in the Q switch pulse mode is preferably oscillated in a pulse exciting system. The ferrule is made of transparent or semi-transparent synthetic resin. The coating of the optical fiber is made of translucent synthetic resin. In this way, an optical fiber fixing method can be provided which can surely fix an optical fiber and a ferrule in a shortened time, and minimize the thermal influence on the vicinity of the portion to be processed.

Owner:YAZAKI CORP

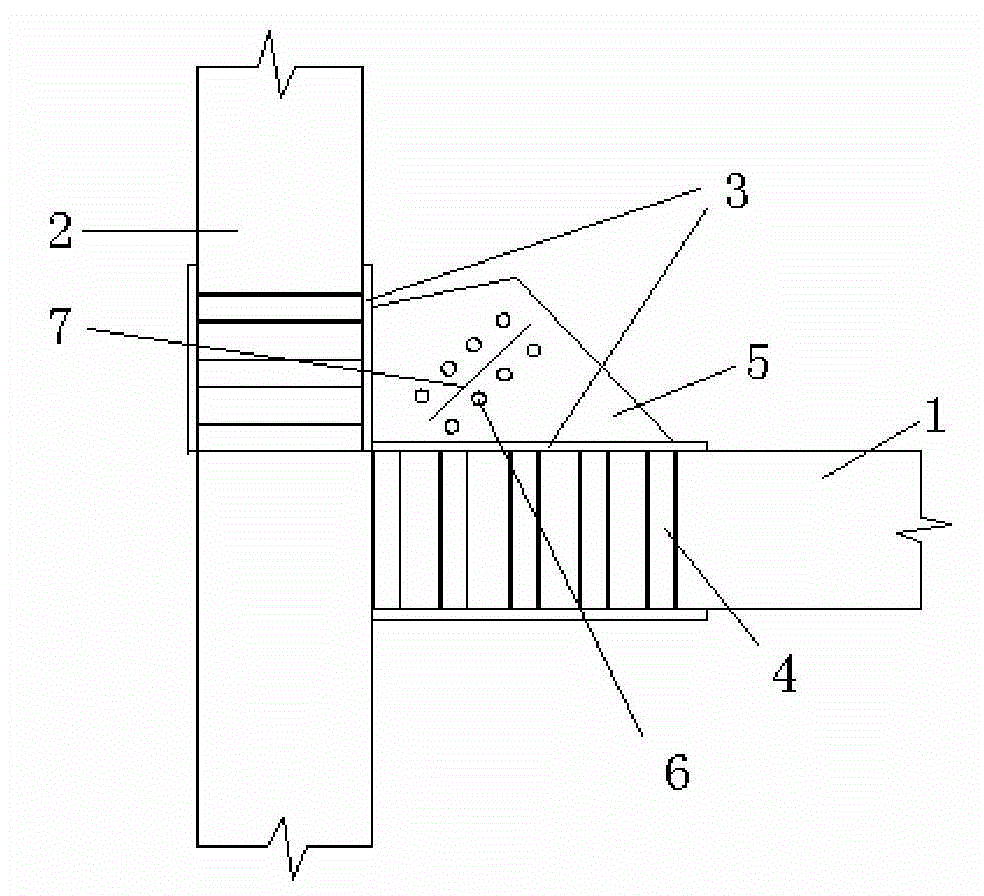

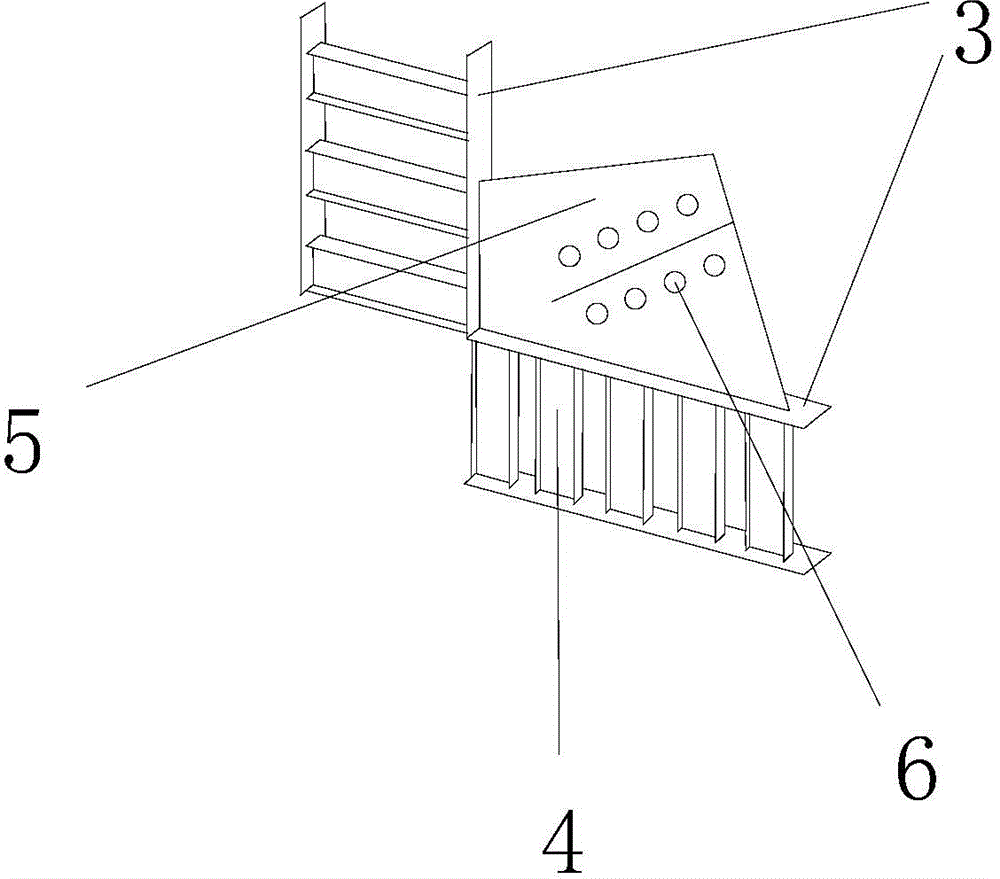

Novel sleeve-type fabricated joint of square steel tube column and H-shaped steel girder and construction method of novel sleeve-type fabricated joint

PendingCN107761957AEasy constructionShorten the construction periodBuilding constructionsSteel platesSteel tube

The invention provides a novel sleeve-type fabricated joint of a square steel tube column and an H-shaped steel girder and a construction method of the novel sleeve-type fabricated joint. The novel sleeve-type fabricated joint comprises a joint area square steel tube column section, a joint area H-shaped steel girder section and a connecting piece. The connecting piece comprises a square sleeve, an H-shaped sleeve and a supporting steel plate, the square sleeve and the square steel tube column are connected through high-strength bolts, the situation that the column wall is too thin, and thus local protrusion occurs to the positions, where the bolts are located, of the square steel tube column is effectively prevented, and thus the bearing force of bolted connecting positions of the columnand the girder is increased; the H-shaped sleeve and the square sleeve are connected in a welded mode, the welding area is increased compared with a conventional mode, and thus the joint is firmer andsafer; the supporting steel plate is connected with the square sleeve, the joint area H-shaped steel girder section and the joint area square steel tube column section simultaneously through high-strength bolts, the bearing force of the girder and column joint is increased, thus stress is more reasonable, and the joint is firmer; and the welding section can be completed in a factory, on-site zero-welding is achieved, and thus the novel sleeve-type fabricated joint is suitable for fabricated connecting of the square steel tube column structure and the H-shaped steel girder structure.

Owner:JIANGSU UNIV

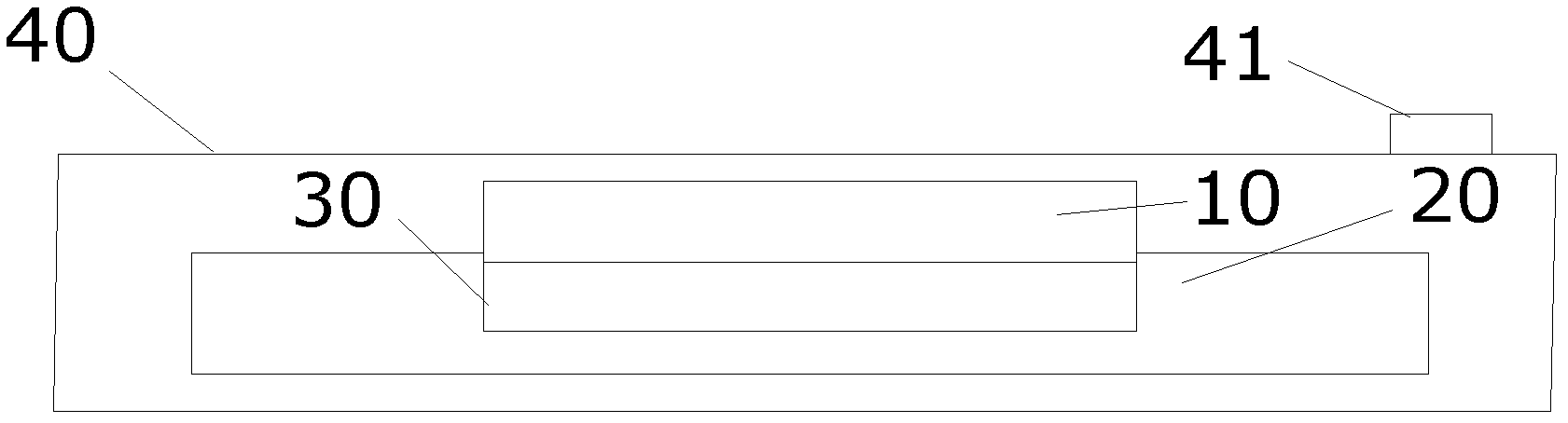

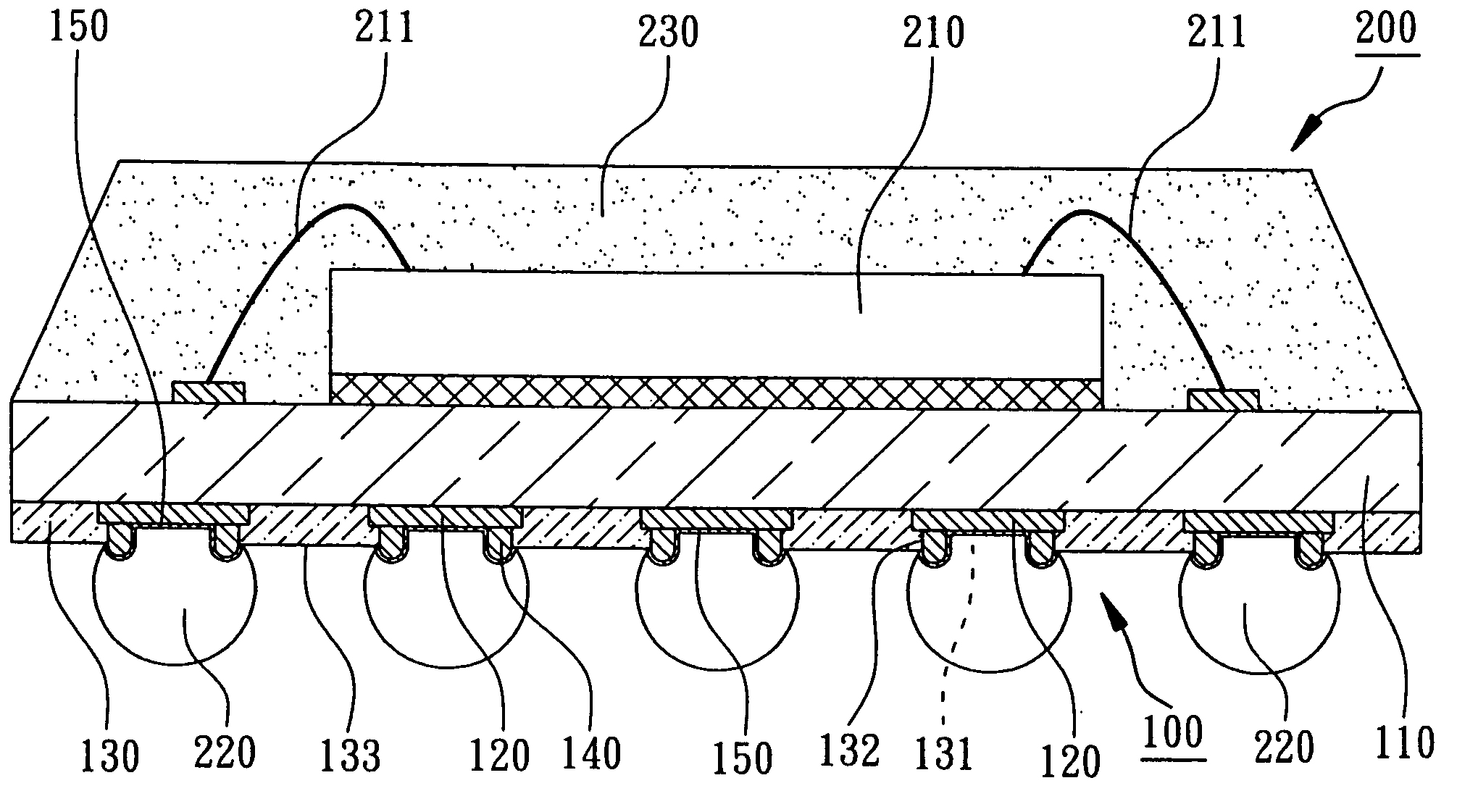

Ball grid array package substrate and method for manufacturing the same

InactiveUS20050017375A1Improve welding strengthGood solder wettabilityPrinted circuit assemblingFinal product manufactureSolder maskSolder ball

A ball grid array package substrate includes a substrate body having a surface. A least a ball pad and a solder mask are formed on the surface of the substrate body. The solder mask has an opening corresponding to the ball pads to enable the ball pad to have an exposed surface out of the opening of the solder mask. A patterned reinforcing metal layer is formed on the exposed surface of ball pads along a sidewall of the opening of the solder mask so that the sidewall of the opening will not directly contact the solder balls. Solder balls can be reflowed on the ball pads and the patterned reinforcing metal layers to increase jointing area and improve the shear strength of the solder balls.

Owner:ADVANCED SEMICON ENG INC

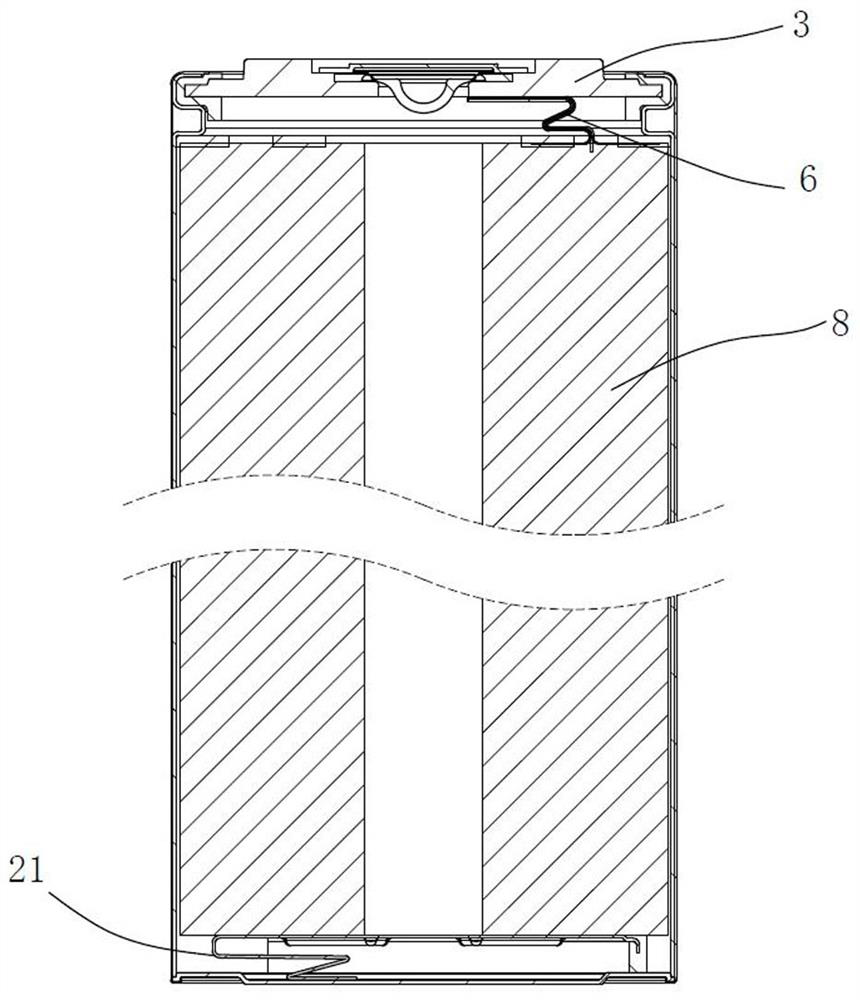

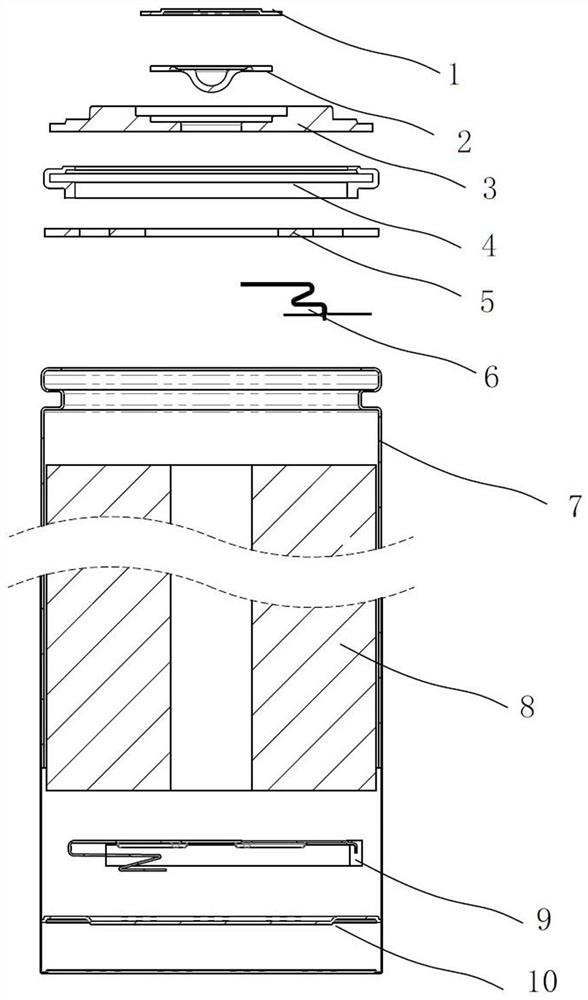

Circular lithium battery and production method thereof

PendingCN112151732AGuaranteed overcurrent capabilityEasy injectionFinal product manufactureSmall-sized cells cases/jacketsMechanical engineeringBattery cell

The invention discloses a circular lithium battery and a production method thereof. The lithium battery comprises a shell, a battery cell, a positive electrode battery cover plate assembly and a negative electrode battery cover plate assembly. A positive electrode foil and a negative electrode foil are separated by a diaphragm and then wound into a cylindrical battery cell. A positive electrode isa multi-tab structure, and a negative electrode is a full-tab structure. A sealing body is fixed on the anode battery cover plate in surrounding manner, and a safety valve is arranged in the middle.The negative electrode battery cover plate assembly comprises a current collector, a negative electrode battery cover plate and a current collector bracket; and the current collector body is fixedly connected to the upper part of the current collector bracket and is electrically connected with the negative electrode battery cover plate through a current collector connecting part. According to theinvention, an over-current capability of the battery is ensured, liquid injection and formation of the battery are facilitated, and installation is convenient and reliable.

Owner:星恒电源(滁州)有限公司

Pipe joint structure

InactiveCN101788244AIncrease the welding areaImprove welding strengthHeat exchanger casingsBursting strengthCivil engineering

The invention relates to a pipe joint structure, comprising a collecting pipe for delivering fluid along a first direction, an inlet / outlet pipe for delivering fluid along a second direction which is perpendicular to the first direction and a hollow pipe joint hermetically jointed to the collecting pipe and the inlet / outlet pipe. The first joint part of the pipe joint is jointed to one end part of the inlet / outlet pipe and maintains the fluid communication, the second joint part of the pipe joint is jointed to the collecting pipe and maintains the fluid communication with the collecting pie via a hole on the side wall of the collecting pipe, thereby enabling the fluid communication between the inlet / outlet pipe and the collecting pipe is maintained. The second joint part forms a pipe-like wall or partially pipe-like wall configuration jointed to the collecting pipe. The pipe joint structure has advantages of small pressure drop in the inlet / outlet pipe, high burst strength in the joint part and low cost.

Owner:SANHUA HLDG GRP +1

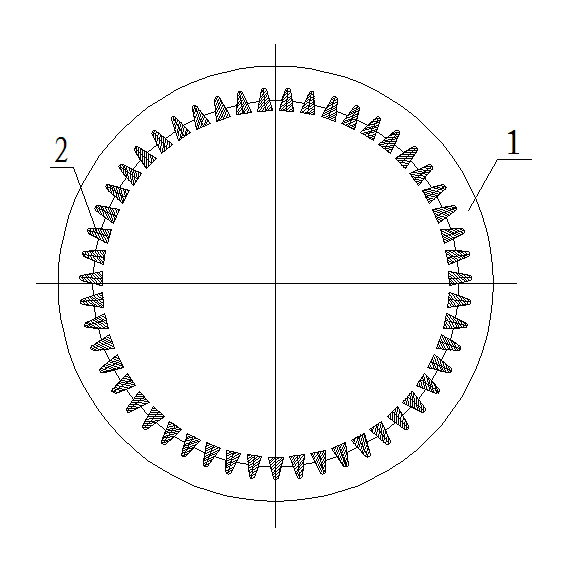

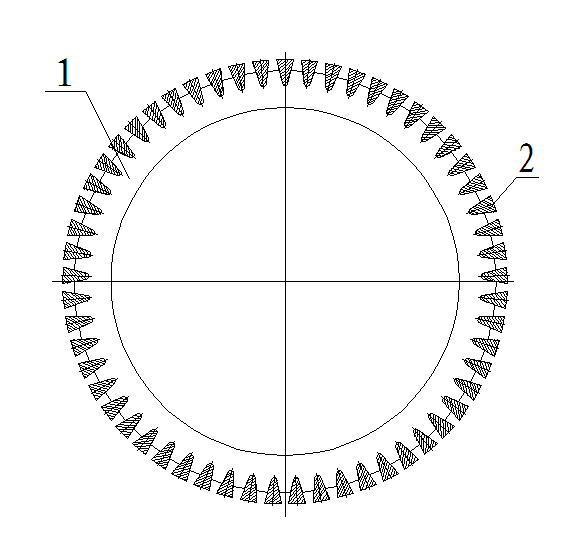

Industrial filter screen with V-shaped wires and laser processing process thereof

ActiveCN102049161AQuality improvementImprove welding strengthFiltration separationLaser beam welding apparatusLaser processingEngineering

The invention provides an industrial filter screen with V-shaped wires. The filter screen comprises a supporting frame and filter wires of which the cross sections are triangles, wherein the supporting frame is vertical to the axial direction of the filter wires to form a stagger net structure; the supporting frame is a tooth-shaped structure with V-shaped tooth troughs; and a corner of each filter wire is inserted into the tooth troughs to engage with the tooth troughs to form a whole. The laser processing process can realize higher welding quality stability and guarantee uniform gap intervals and better surface evenness.

Owner:LIAONING YUTONG PETROCHEM MACHINE & INSTR

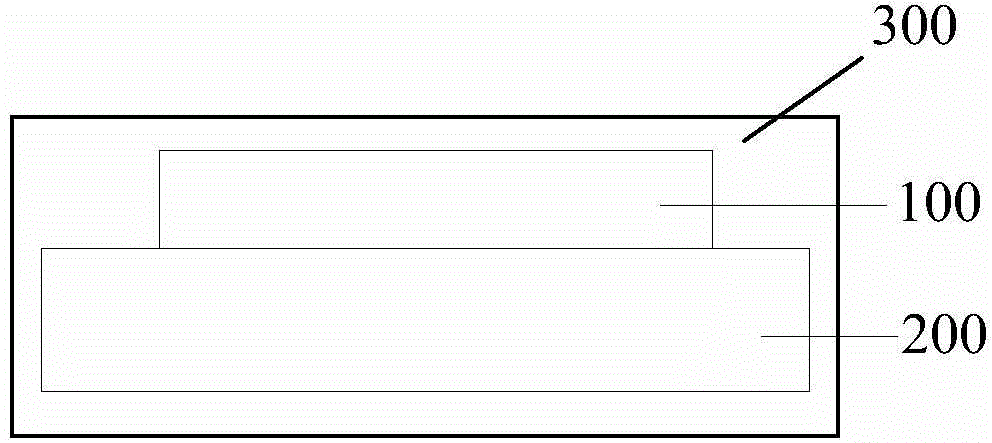

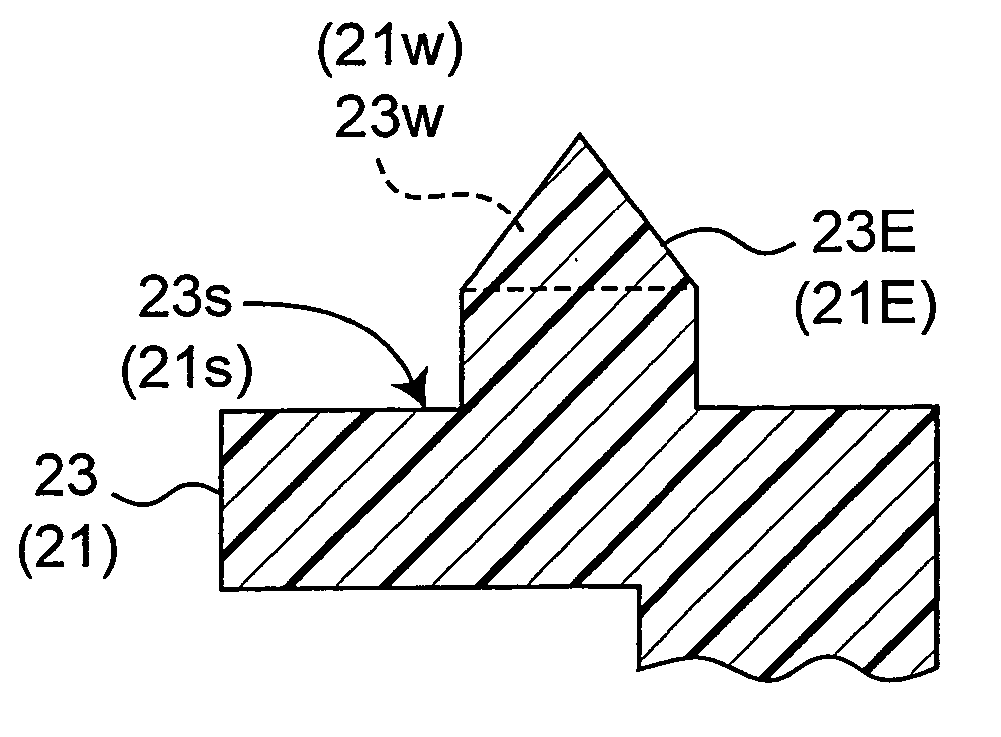

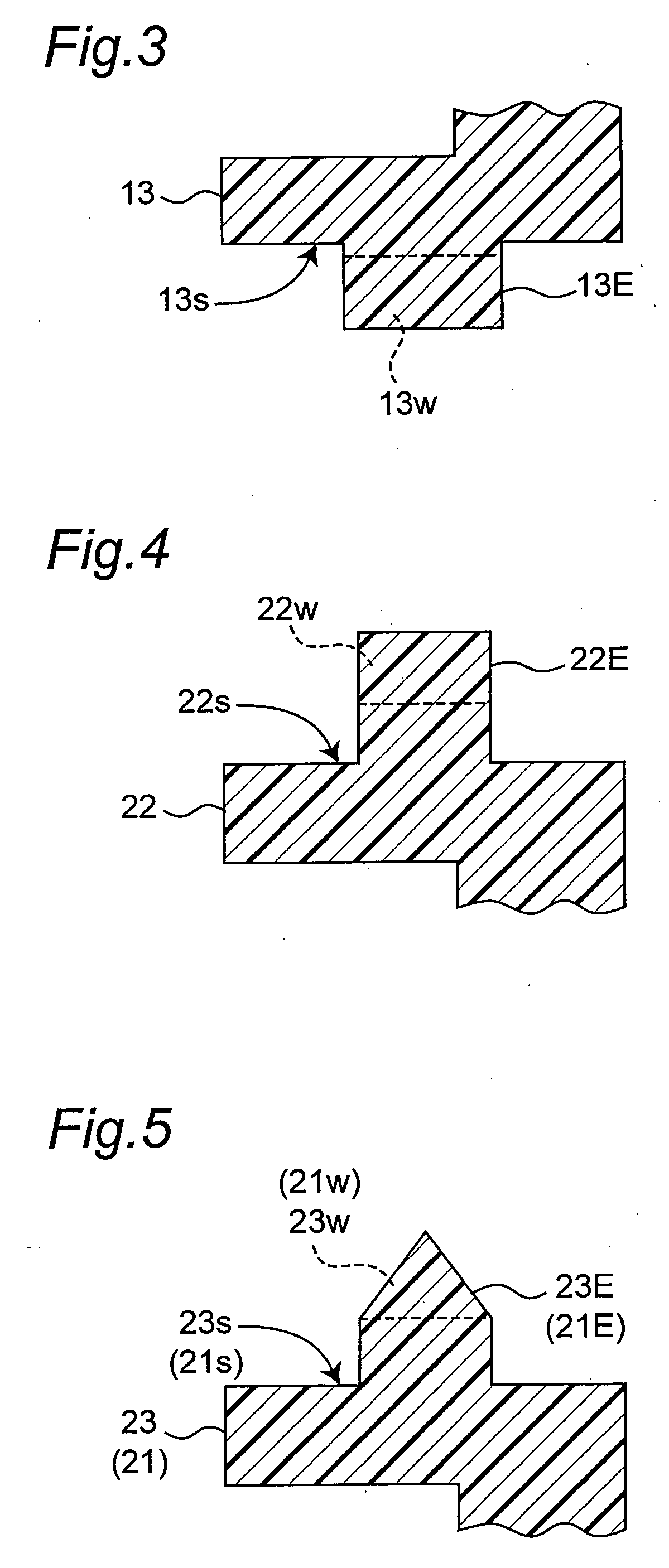

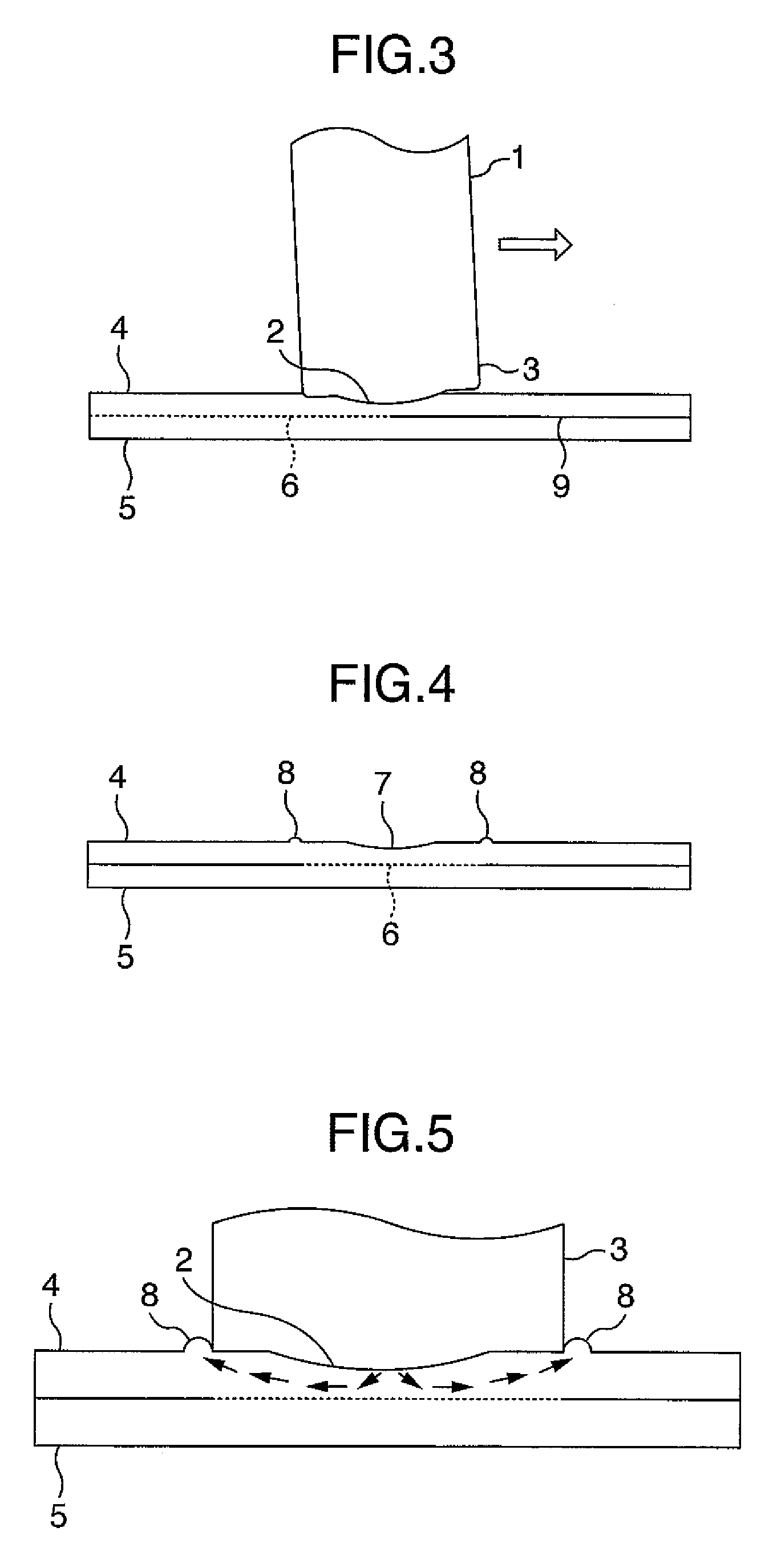

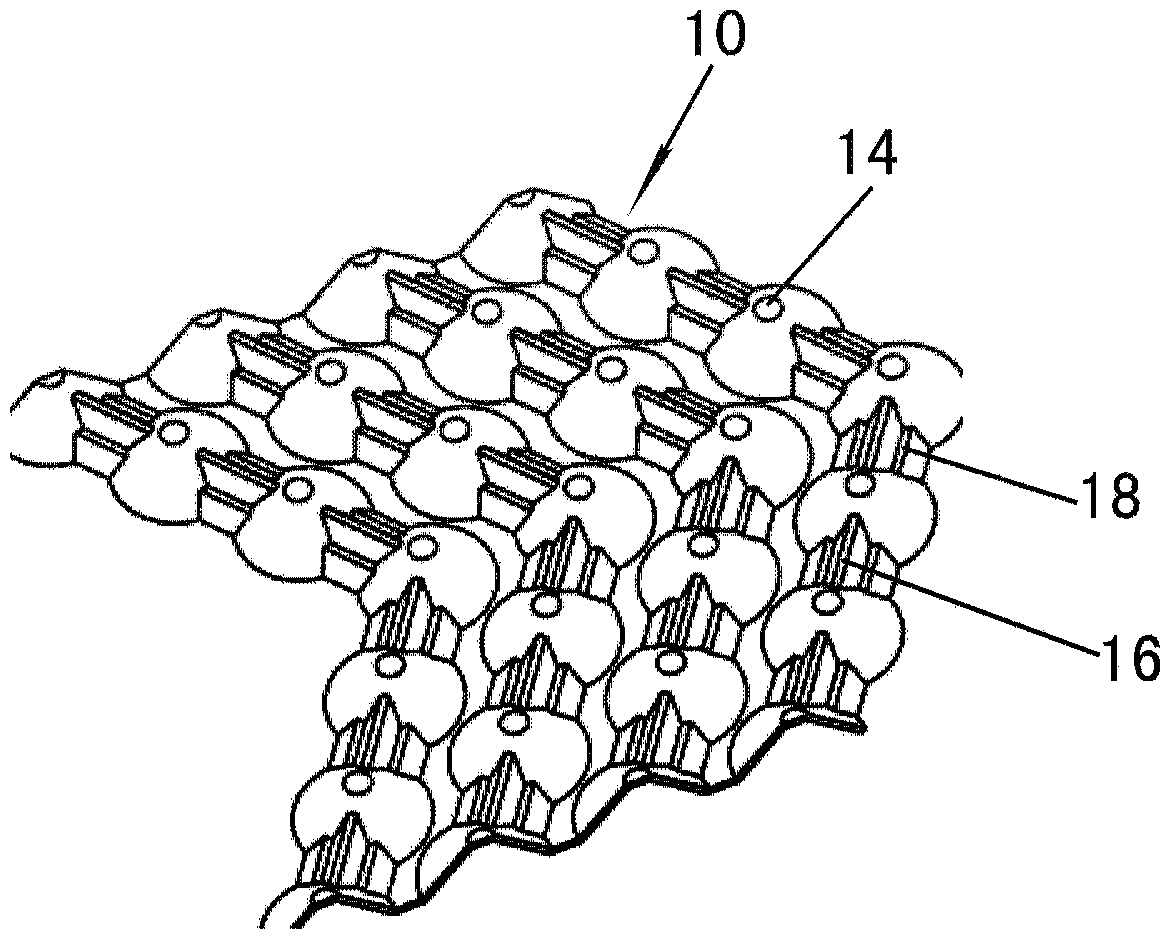

Structure of joining resin molded bodies

InactiveUS20060068161A1Reliable and superior joining strengthJoining strengthLayered productsThin material handlingEngineeringWelding

A reliable and superior joining strength in entire joining parts of resin molded bodies including tilting portions is obtained by devising a shape and a size of each protrusion for welding provided in the joining parts of the resin molded bodies. In a structure of joining resin molded bodies according to the present invention, upper and lower half bodies 10 and 20 are joined with each other by means of a vibration welding method while the upper and lower half bodies 10 and 20 are being pressurized in a state in which joining parts thereof are butted into each other in a substantially entire area of the joining parts. The joining parts of the respective half bodies have vertical portions 11 and 13 and vertical portions 21 and 23 respectively vertical to a pressurizing direction and tilting portions 12 and 22 tilting relative to the pressurizing direction, and protrusions for welding 11E to 13E or 21E to 23E are provided in at least the joining part of one of the half bodies. Further, referring to a butting area of the protrusions in a butted state, the butting area in the vertical portions is set to be narrower than the butting area in the tilting portions.

Owner:DAIKYONISHIKAWA CORP

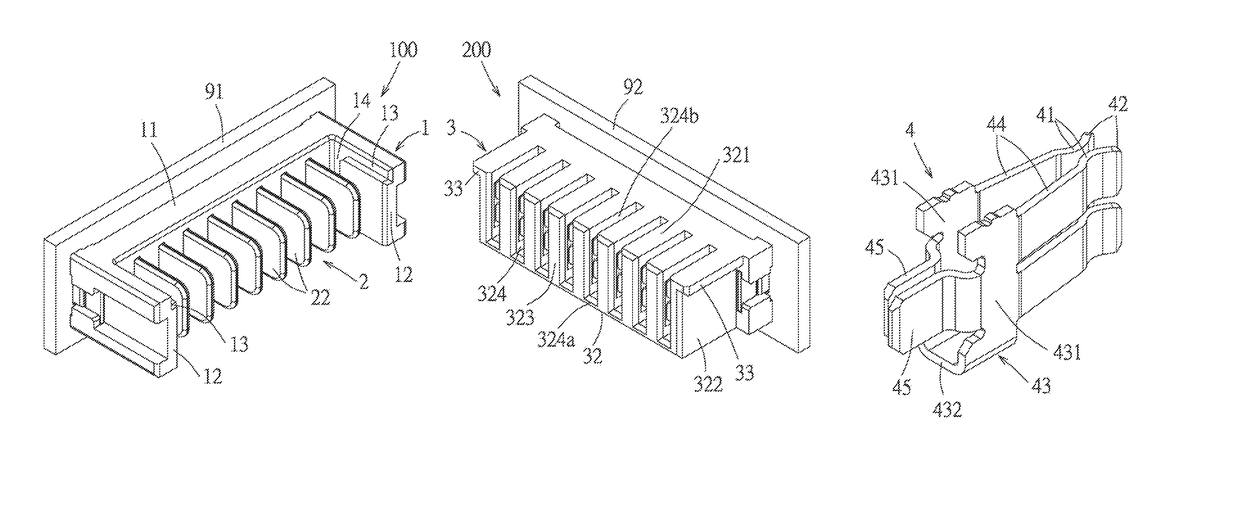

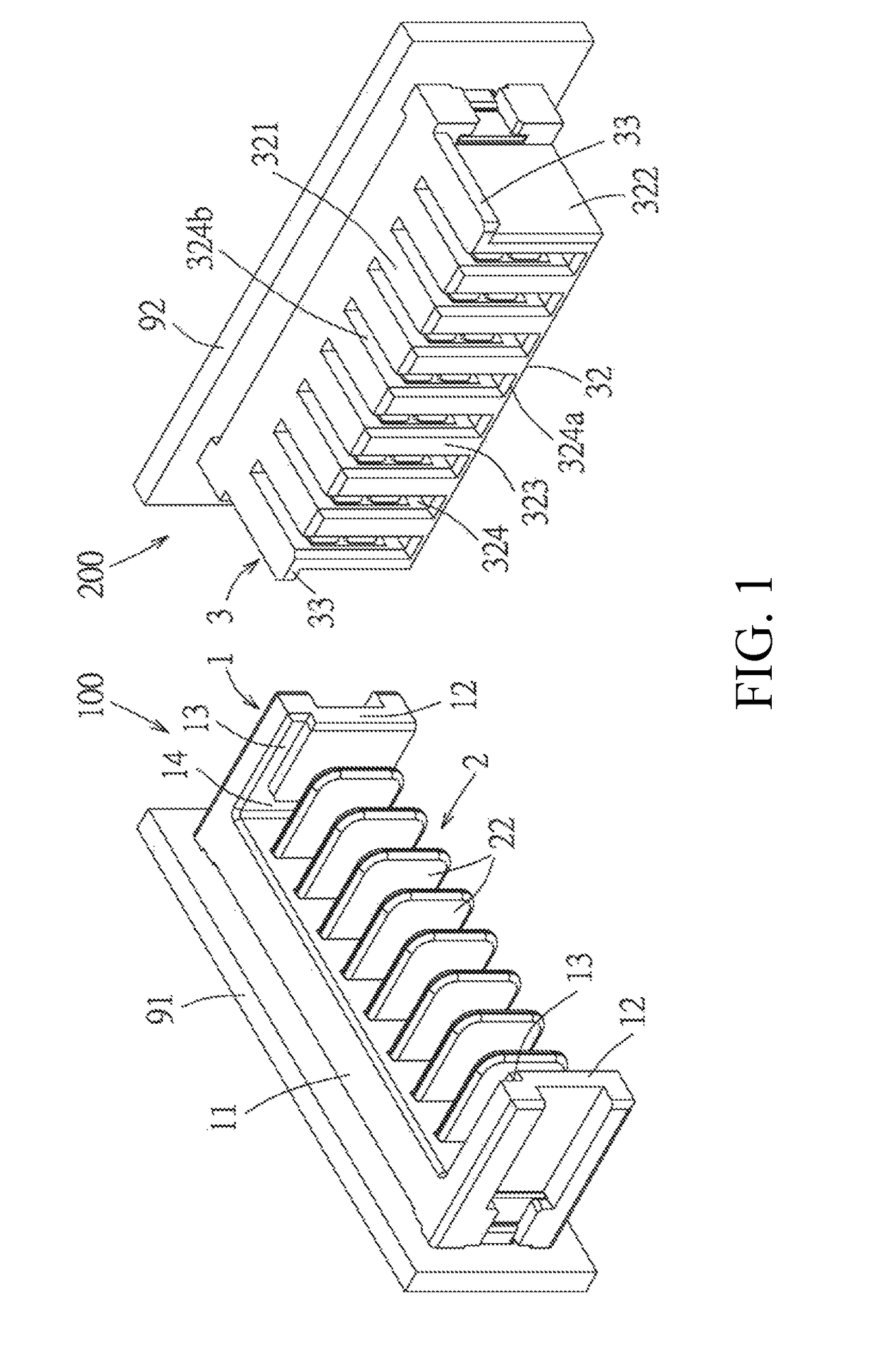

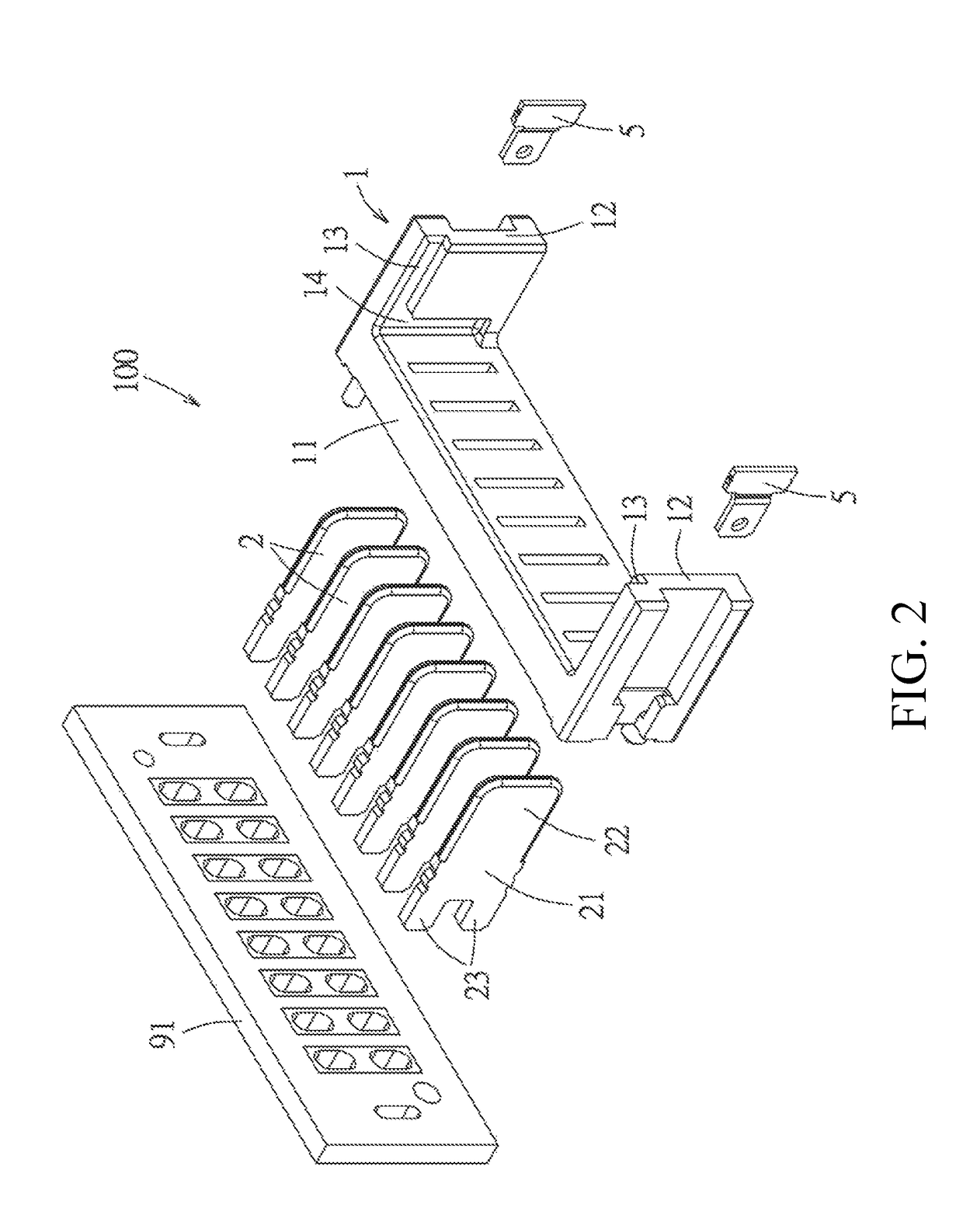

UVA battery connector

ActiveUS9711897B2Increase the welding areaPlurality of obstructionCoupling contact membersElectrical connectionEngineering

An electrical connection device and a terminal are provided. The electrical connection device includes first and second connectors. The first connector includes an insulating body and a plurality of blade-type terminals. The insulating body has a base portion and two ear portions, an inner wall surface of the ear portion has a first guide groove which is perpendicular to the base portion and a second guide groove which is parallel to the base portion. The second connector includes an insulating housing and a plurality of elastic terminals. The insulating housing has a mating portion and a protruding rail, the mating portion has a plurality of terminal grooves respectively provided with the elastic terminals. When the connectors are mated, each contact portion can contact the guide portion of the corresponding elastic terminal and then contact the contact portion of the corresponding elastic terminal to prevent the elastic terminal from being damaged.

Owner:MOLEX INC

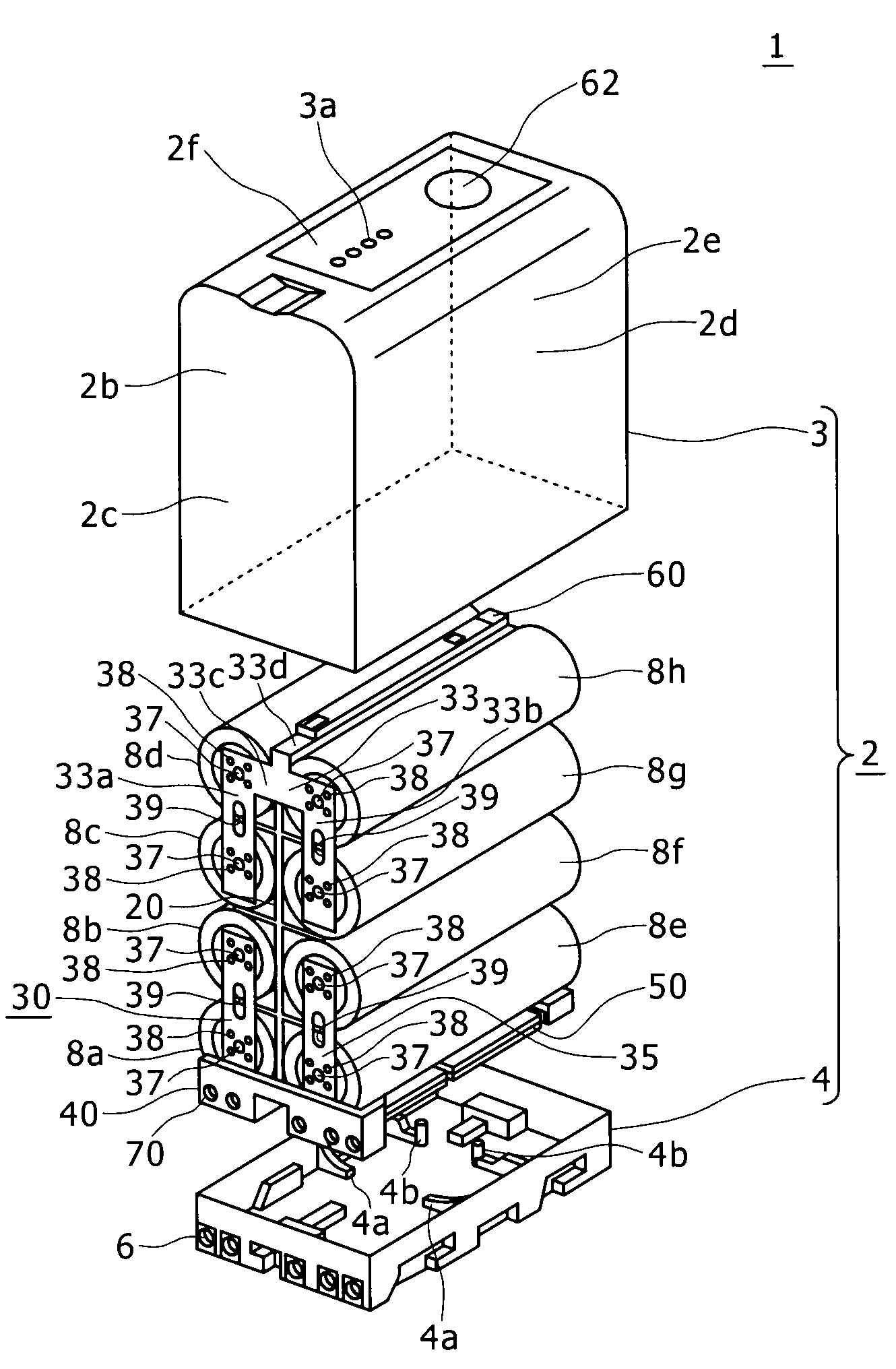

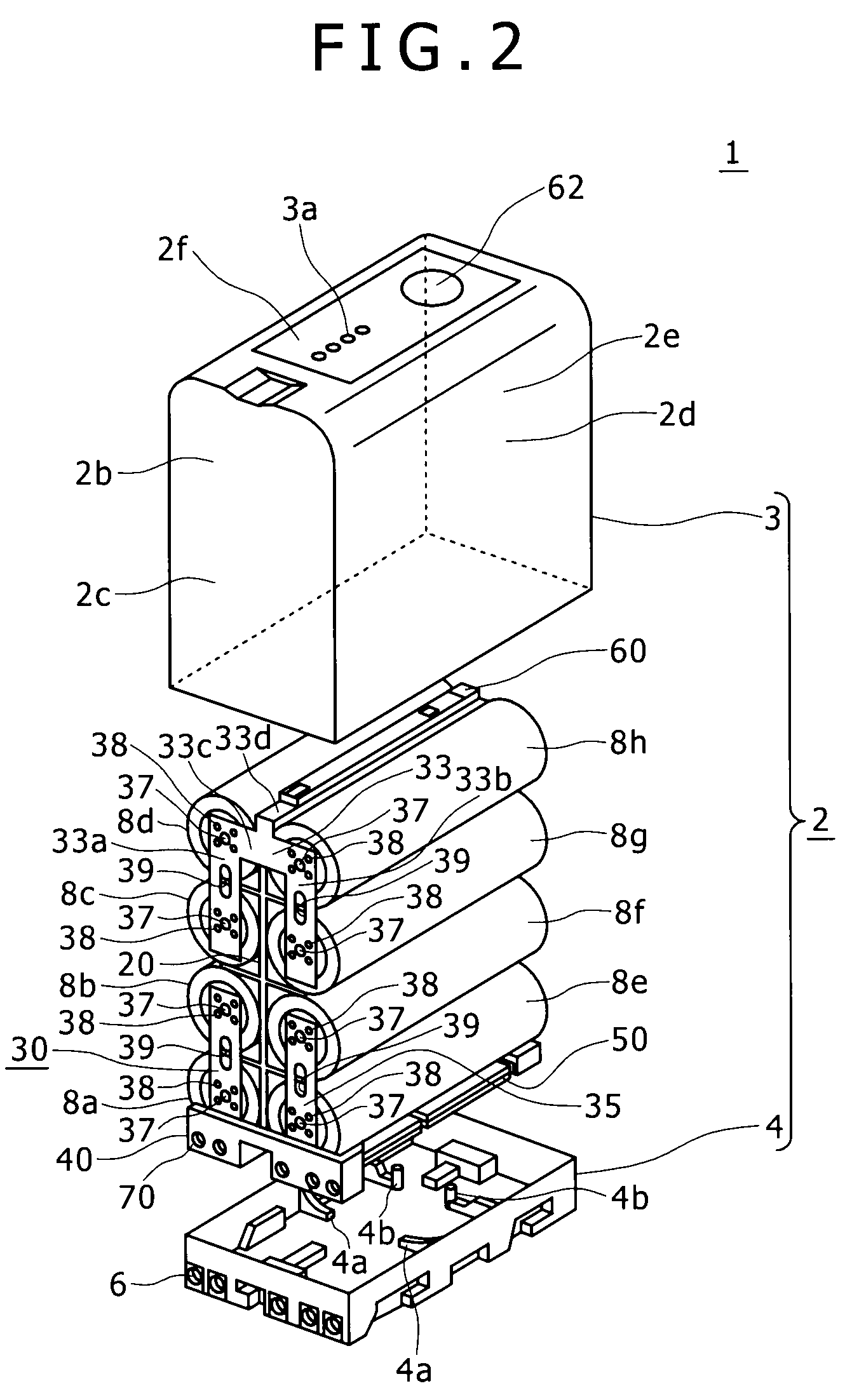

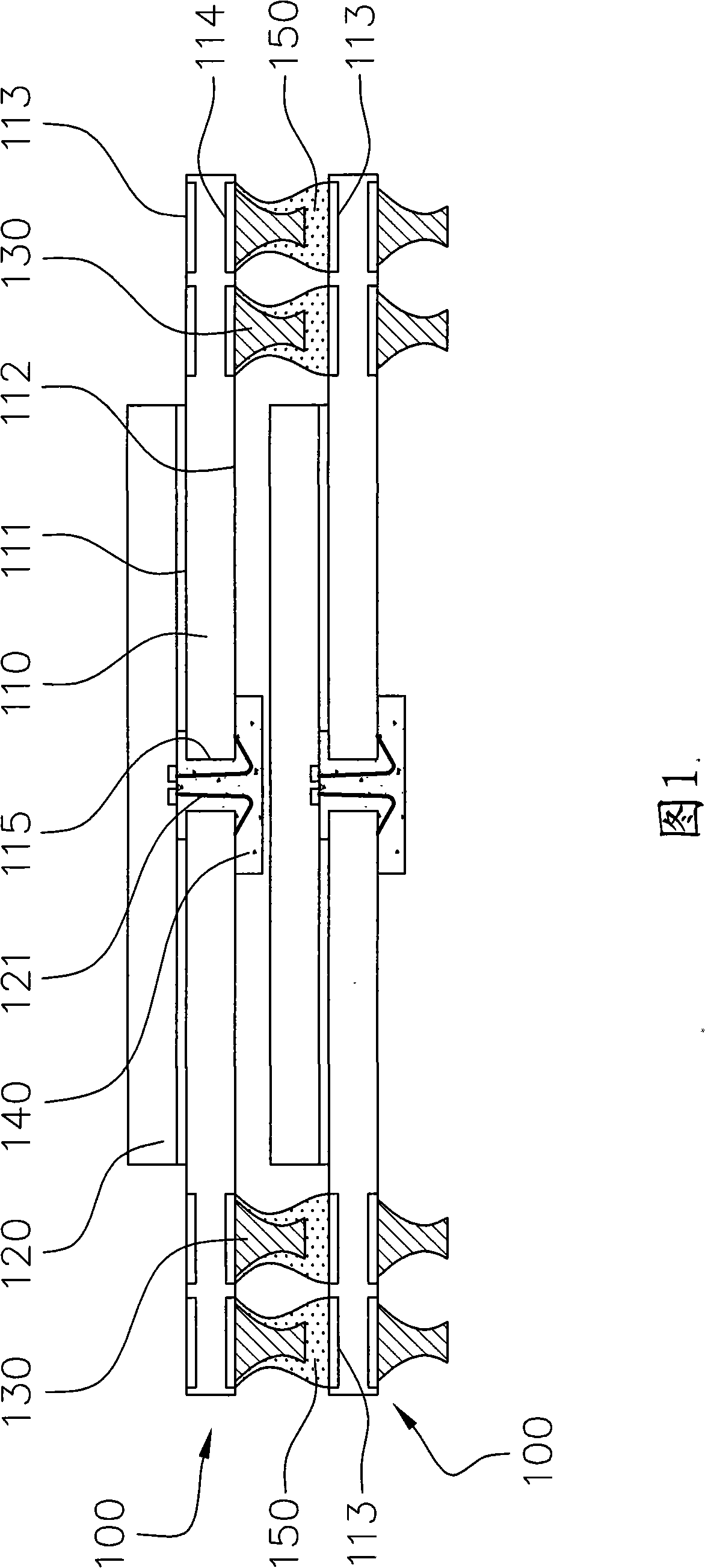

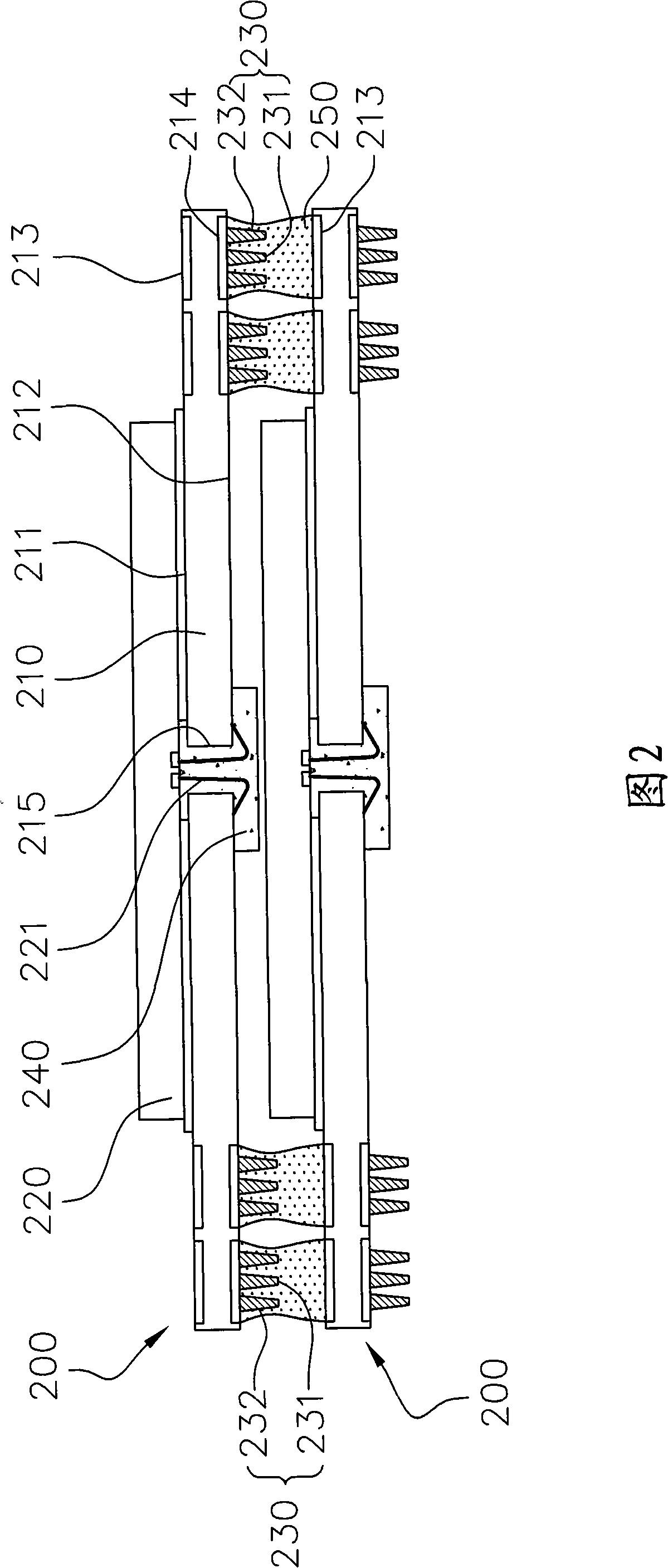

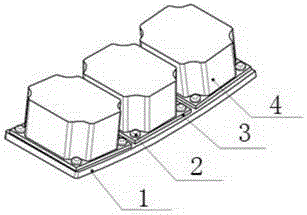

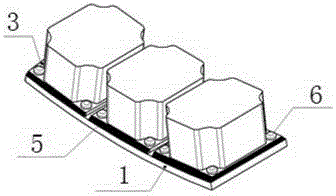

Battery pack including ultrasonic welding surfaces

InactiveUS7638234B2Welding strengthIncrease the welding areaSecondary cellsCell component detailsUltrasonic weldingEngineering

Disclosed herein is a battery pack including: a plurality of cylindrical battery cells arranged in a plurality of rows and a plurality of layers; a lower case for supporting the battery cells; and an upper cover welded to the lower case in the state of covering the battery cells supported by the lower case; wherein the end parts of the upper cover and the lower case are opposed to and abutted on each other, and are welded to each other by ultrasonic welding.

Owner:SONY CORP

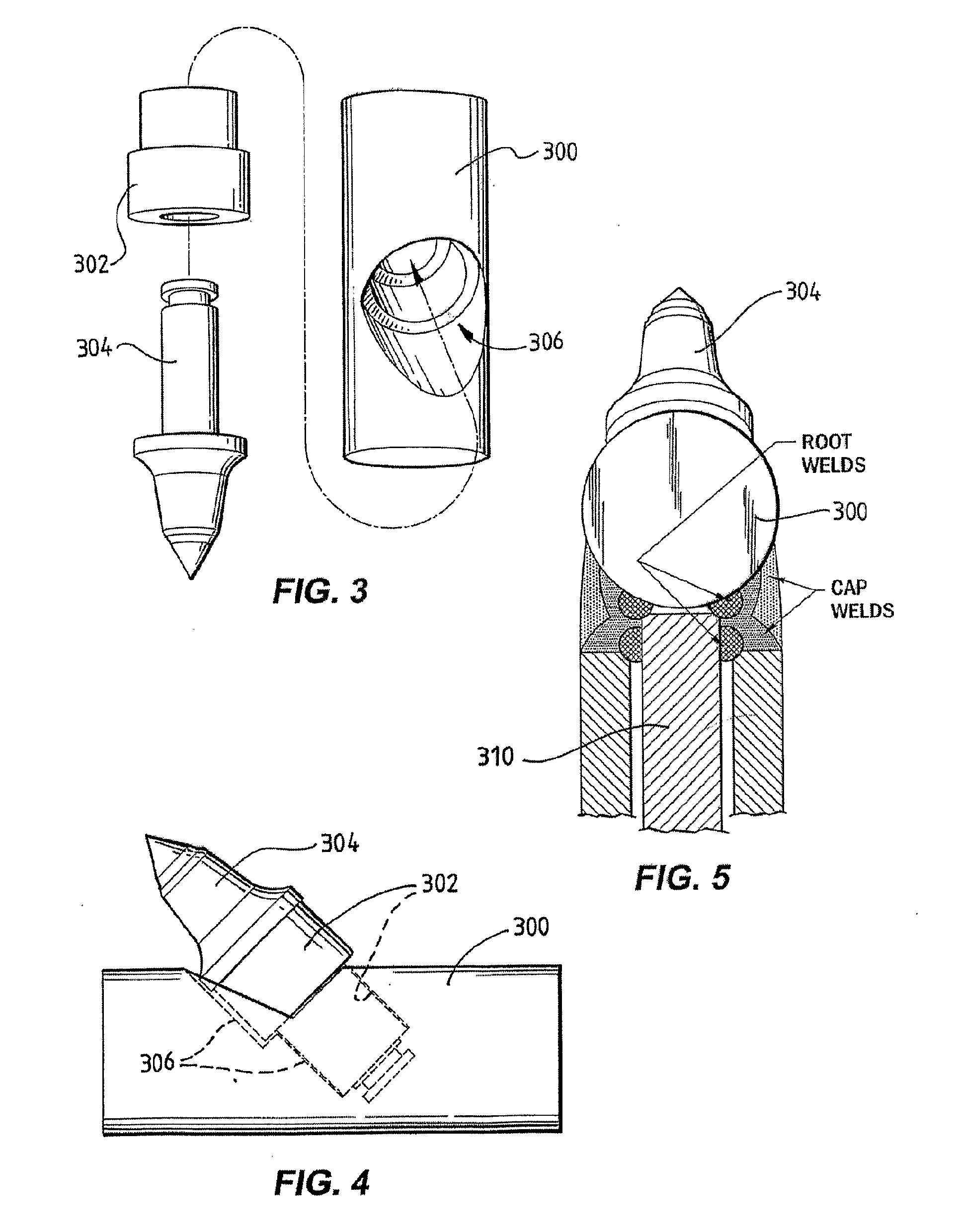

Holder for holding a tooth on a body of a cutting blade or grinding drum for cutting or grinding rock or hard earth formations

InactiveUS20090302668A1Significant practical advantageReduce maintenanceDrill bitsSlitting machinesEngineeringMechanical engineering

The present invention provides a holder for holding a tooth on a body of a cutting blade or grinding drum for cutting or grinding rock or hard earth formations. The body has an attachment surface for attaching the holder. The holder comprises a portion for holding the tooth in a manner such that a portion of the tooth projects from the holder. The holder also comprises a base surface for attaching the holder to the attachment surface of the body. The holder is positionable in a plurality of different orientations in which the base surface is attachable to the attachment surface and in which the received tooth projects from the body in a predetermined direction. When the holder is positioned in one of the plurality of orientations, the base surface has, within an area over the attachment surface, a shape which is profiled so that a region defined between the base surface and the attachment surface is, for at least one of the plurality of different orientations, smaller than a region that would be defined if the base surface would have a flat shape.

Owner:ROCK SAW HLDG

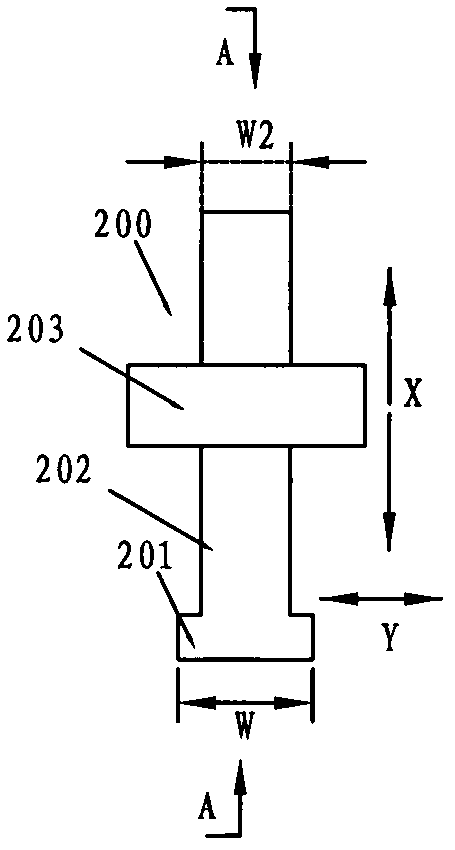

Lithium ion electrical core and lug

InactiveCN102306735AAvoid bloatingIncrease the welding areaSecondary cellsCell component detailsEngineeringPole piece

The invention relates to the field of lithium ion batteries, and discloses a lithium ion electrical core and a lug. The lug comprises a metal band and lug glue, wherein the lug glue is bonded in the middle positions of the front surface and the back surface of the metal band; a protrusion part is arranged at one tail end of the metal band along the longitudinal direction; the protrusion part protrudes along the horizontal direction of the metal band; and the width of the protrusion part along the horizontal direction of the metal band is greater than that of the middle part of the metal band. The impedance at the welding part of the lug and a pole piece can be reduced by applying the lug in the lithium ion battery, the heat productivity at the welding part of the lug and the pole piece is reduced, and the bulge phenomenon of the lithium ion battery is avoided.

Owner:SHENZHEN GREPOW BATTERY CO LTD

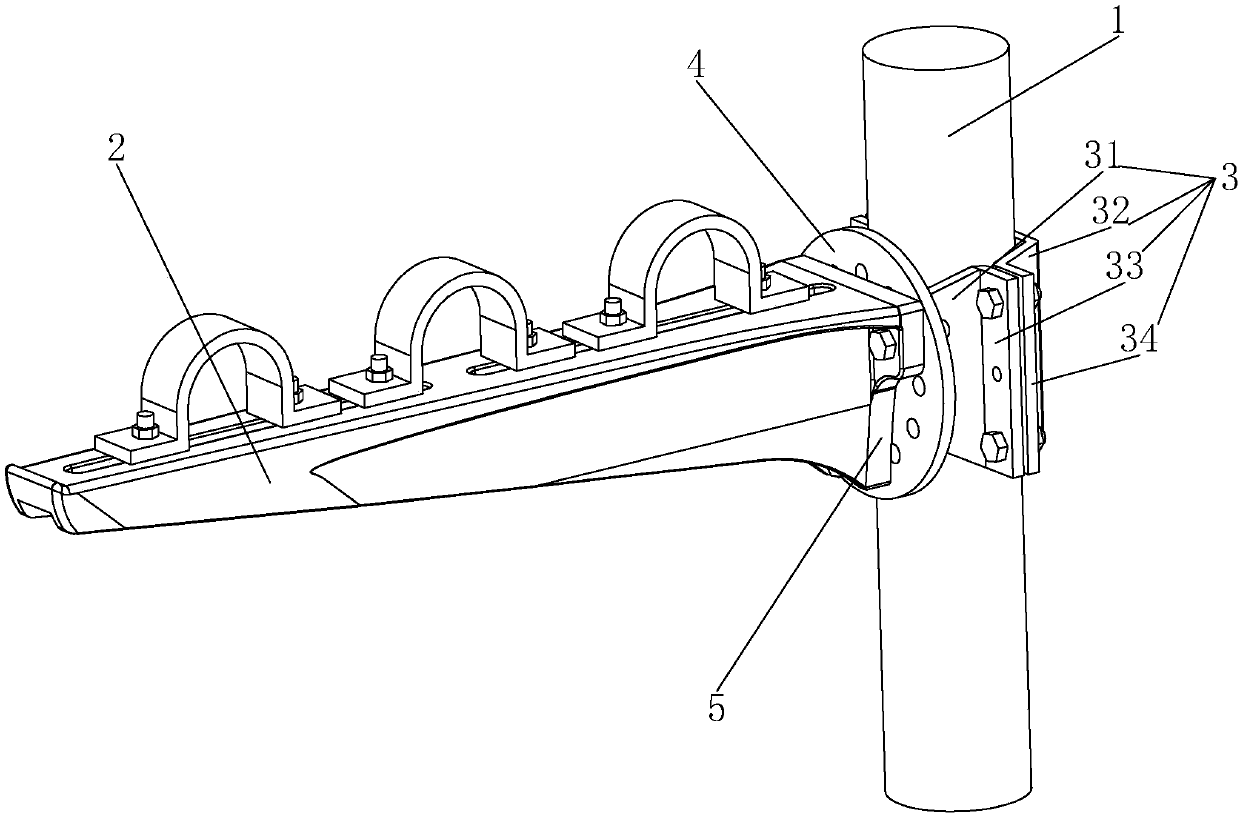

Cable holder with adjustable horizontal and vertical directions and axial direction of support arm

The invention, which relates to the technical field of cable laying, discloses a cable holder with adjustable horizontal and vertical directions and an adjustable axial direction of a support arm. Thecable holder comprises a standing post, a support arm, and a hoop. A mounting plate is fixed on the hoop; a connecting plate is fixed at one end of the support arm; and an adjusting element that enabling the connecting plate to be fixed at the mounting plate after autoroatation of the connecting plate at different angles on the mounting plate is arranged between the support arm and the mounting plate. When the support arm rotates in an inclination direction of the upper surface of the support arm and the inclination direction is in tangency with an arc track for turning of a cable, the support arm is fixed by the adjusting element and then the cable is installed on the upper surface of the support arm by an omega-shaped cable clamp. Compared with the horizontal upper surface of the support arm, the support arm upper surface with the inclination direction in tangency with the arc track for turning of tube cable enables the arc of bending needed by the cable to be reduced, so that the possibility of any damage of the cable is reduced; and the omega-shaped cable clamp can be installed conveniently and the local stress between the omega-shaped cable clamp and the cable is reduced.

Owner:绍兴市卓元电气科技有限公司

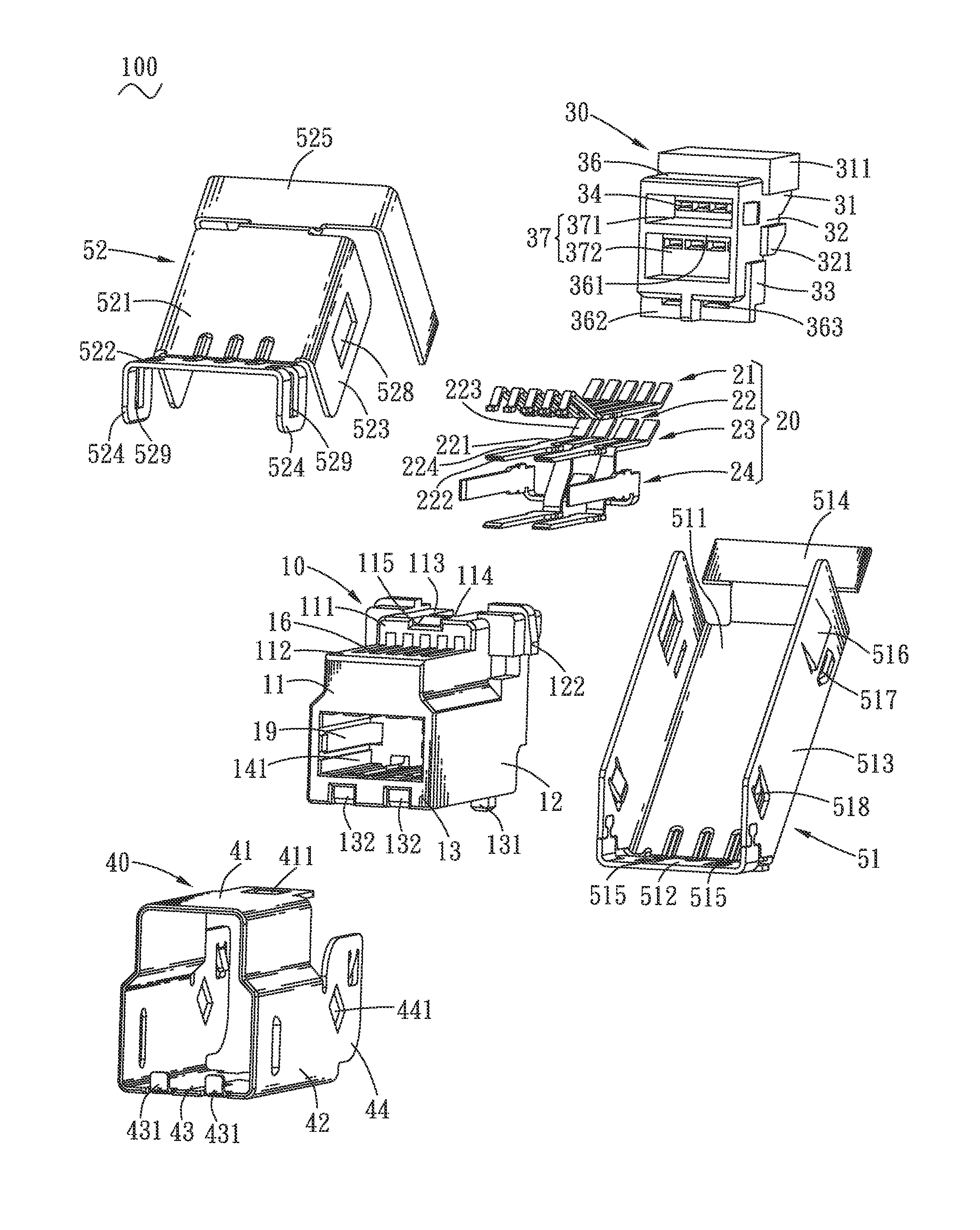

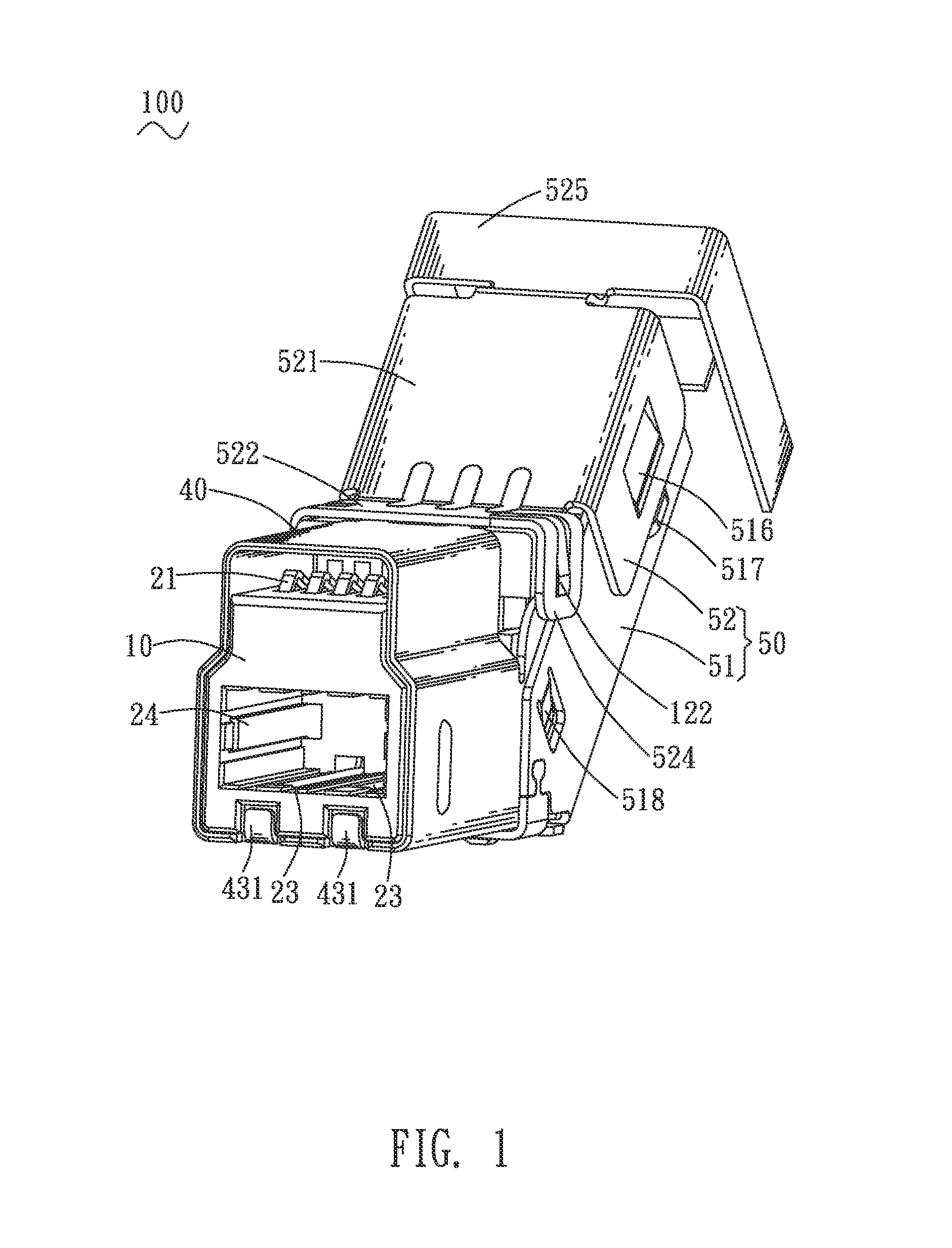

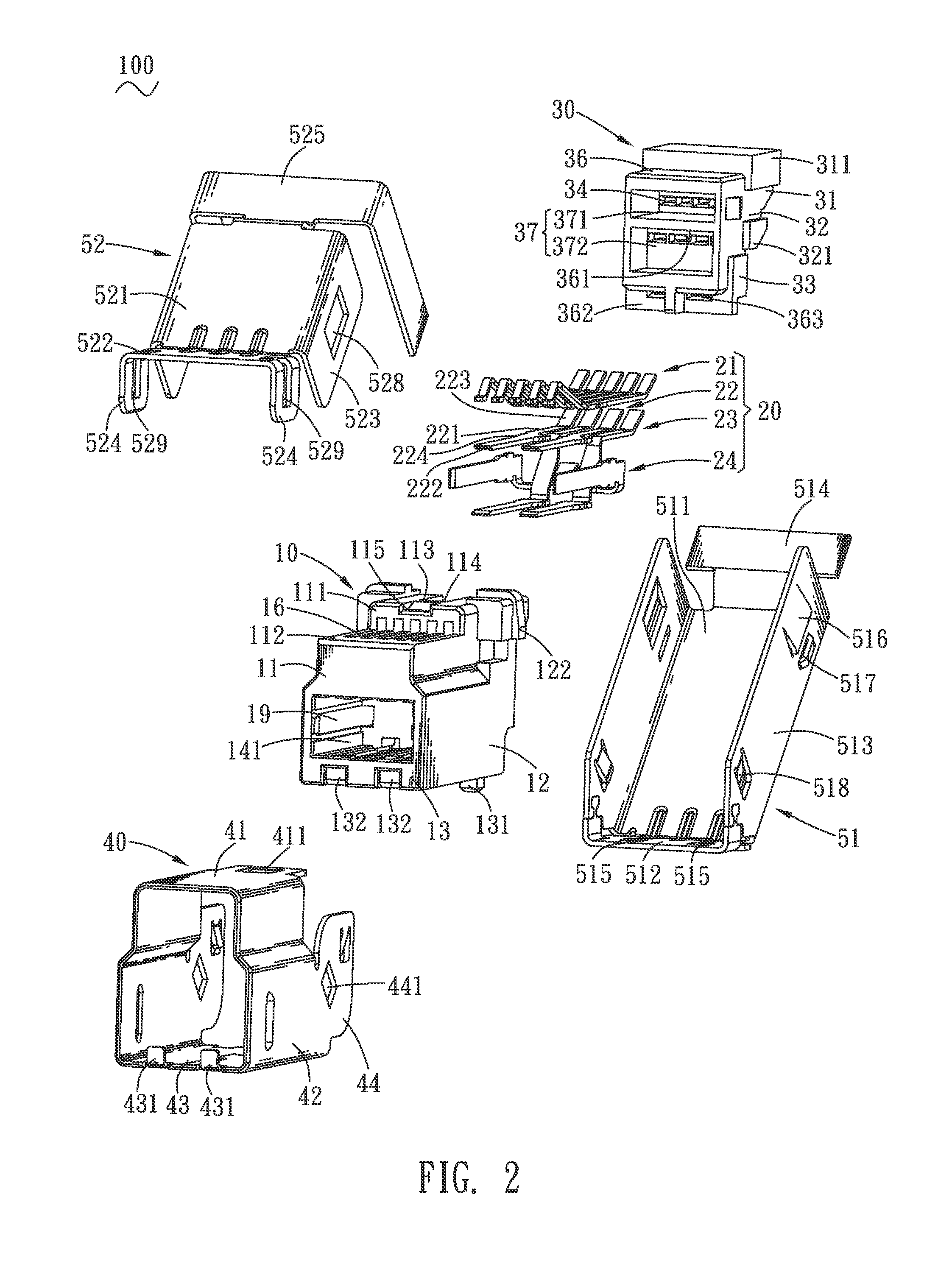

Universal serial bus connector

InactiveUS8821186B2Increase the welding areaTwo-part coupling devicesCoupling protective earth/shielding arrangementsEngineeringSoldering

A universal serial bus connector includes an insulating housing, a plurality of terminals disposed to the insulating housing, a dielectric base, a first shielding shell surrounding the insulating housing, and a second shielding shell. Each of the terminals has a fastening portion, and a soldering portion slantwise extending upward and rearward from a rear end of the fastening portion to be exposed behind the insulating housing. The dielectric base disposed to a rear end of the insulating housing defines a plurality of rows of insertion slots and resisting surfaces exposed behind the insulating housing. The soldering portions are inserted into the insertion slots and abut against the resisting surfaces. The second shielding shell disposed to rear ends of the insulating housing and the first shielding shell includes a first main board and a second main board parallel with the soldering portions abutting against the resisting surfaces.

Owner:CHENG UEI PRECISION IND CO LTD

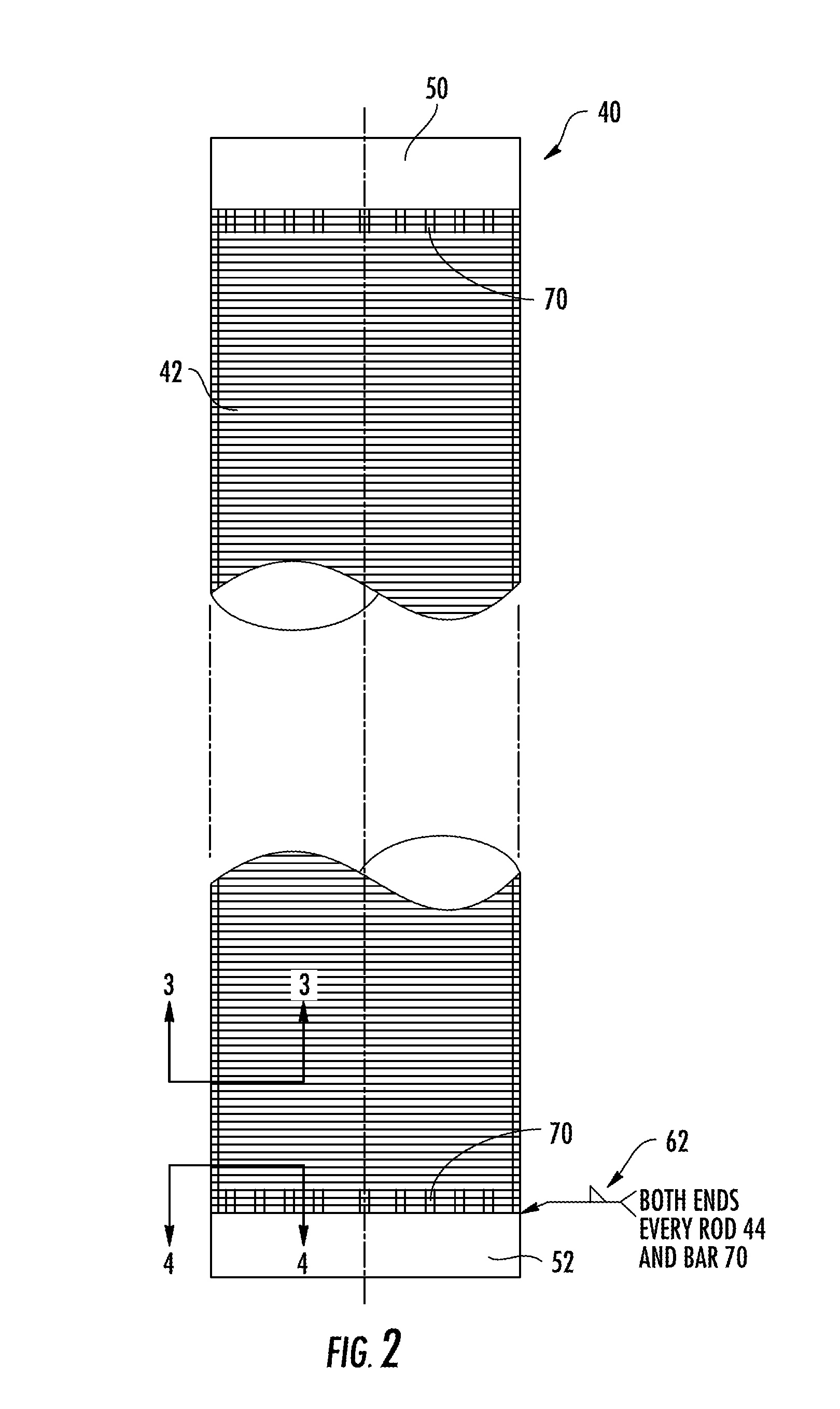

Fluid intake screen

ActiveUS20150014242A1Increase welding areaIncrease the welding areaWelding apparatusStationary filtering element filtersPhysicsStructural element

A screen for intake of fluid. The screen includes parallel and spaced rods, filtration material, a fitting, and structural members. The rods may be distributed in a cylindrical configuration. The filtration material, in some embodiments spirally wrapped wire, is disposed around the rods to define an interior volume. The fitting is disposed at an end of the rods and adjacent to the filtration material. Each structural member, which in some embodiments are elongated bars, is interposed between adjacent rods. The structural members are welded to the adjacent rods, and the adjacent rods and the structural members are welded to the fitting to increase the effective weld area, the tensile strength of the connection, and potentially the overall strength of the screen. The screen may be used for a variety of fluids and installations, and is particularly suited to use in water wells.

Owner:AQSEPTENCE GRP INC

Technique for molding inclined connector saddle between main pipe and branch pipe as well as welding method

InactiveCN101352747AIncrease the welding areaAvoid cloggingBranching pipesWorkpiece edge portionsEllipseEngineering

The invention discloses a saddle forming process for an interface between main pipe and branch pipe with an inclination angle and a welding method thereof. The saddle forming process comprises the following steps: a metal block consistent with outside dimension of the main pipe and the branch pipe is punched, an elliptical hole is punched on the metal block according to the inner diameter of the branch pipe, the elliptical hole is stretched to be a boss according to the inclination angle between the main pipe and the branch pipe, the metal block is punched according to the outer diameter of the main pipe to form a curved surface consistent with peripheral curvature of the main pipe, the surplus part of the metal block periphery is cut off according to the size of a welded surface, etc. The welding method comprises the following steps: a hole is drilled at the place where the main pipe needs a branch; one end of the branch pipe is welded with the boss of the saddle; and the curved surface on the saddle consistent with the peripheral curvature of the main pipe is jointed and welded with the borehole position on the main pipe, etc. The saddle forming process for the interface between the main pipe and the branch pipe with the inclination angle and the welding method thereof guarantee the welding flatness and the welding intensity, and avoid the obstruction resulting from inserting the branch pipe into the main pipe.

Owner:天津滨海新区大港顺力汽车零部件厂

Friction stirring-welding method

InactiveUS20090218033A1Increase pressurePromote resultsWelding/cutting auxillary devicesAuxillary welding devicesSurface oxidationLap joint

A friction stirring-welding method capable of increasing the welding strength of a lap joint. A welding tool (1) comprises a small diameter projected part (2) at the tip of a shoulder (3). The welding tool is press-fitted to the upper plate (4) of the lap joint while being rotated. By a friction stirring action, an upper plate side welding boundary surface (6) plastically flows, a surface oxidation film on a lapped surface is peeled off, and the boundary surface is activated to provide an excellent welding part. Also, since the welding tool is formed in a shape having the small diameter semispherical projected part (2) at the tip thereof, the thickness (12) of an upper plate welding part is increased, and a lap joint part with high welding strength can be provided.

Owner:HITACHI LTD

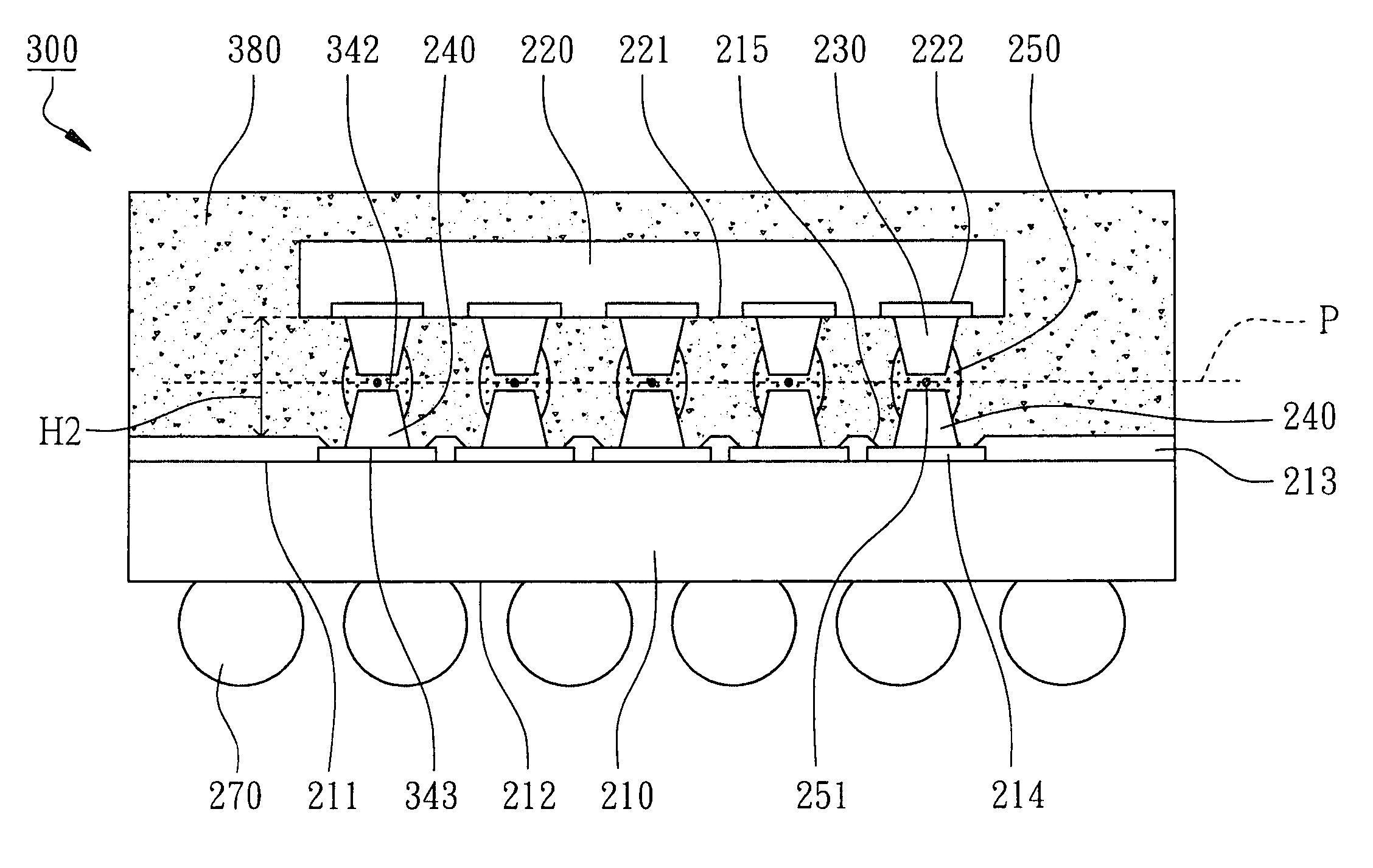

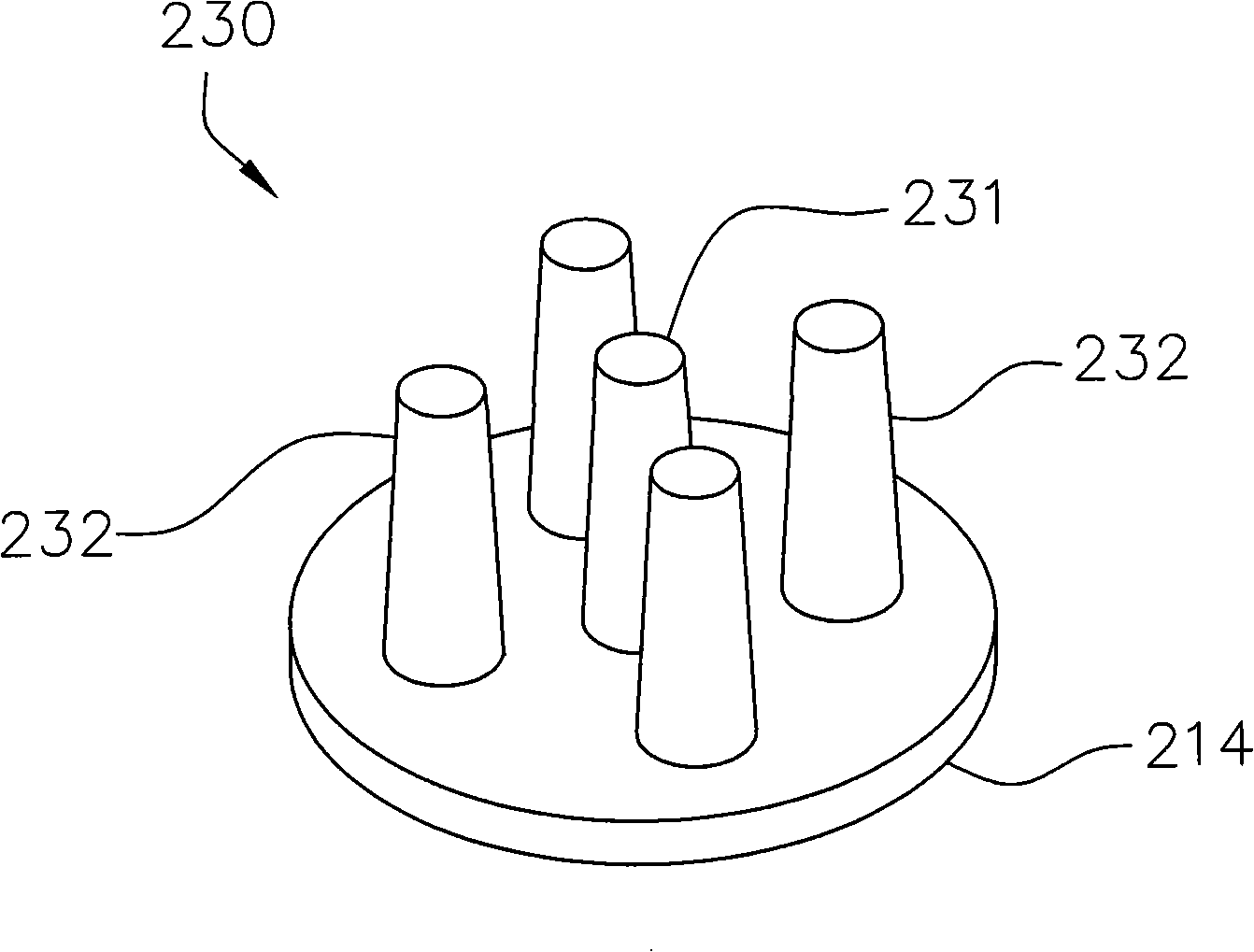

Stackable semiconductor encapsulation construct for multi-cylinder body

InactiveCN101355070AIncrease joint areaIncreased complexitySemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSemiconductor package

The invention relates to a polycylinder stackable semiconductor packaging structure. The structure mainly comprises a wafer carrier, a wafer and a plurality of downwards convex block groups, wherein the wafer carrier has a plurality of switchover pads on an upper surface and a plurality of external pads on a lower surface; the wafer is arranged on and is electrically connected with the wafer carrier; the downwards convex block groups are correspondingly arranged on the external pads, and each downwards convex block group connected with each external pad consists of a plurality of conducting cylinders; and a solder filling gap is arranged between adjacent conducting cylinders of the same downwards convex block group. The stackable semiconductor packaging structure is used to increase welding area and perplex the shape of a welding interface, thereby achieving high durability of welding spots and reducing the growing possibility of cracks. In addition, the convex block group arranged on each external pad has the solder filling gap, solder can be filled and stored in the convex block group, so that a plaque does not extrude the solder to cause bridging short circuit even when inclined or warped; therefore, the structure is particularly suitable for practical use.

Owner:POWERTECH TECHNOLOGY

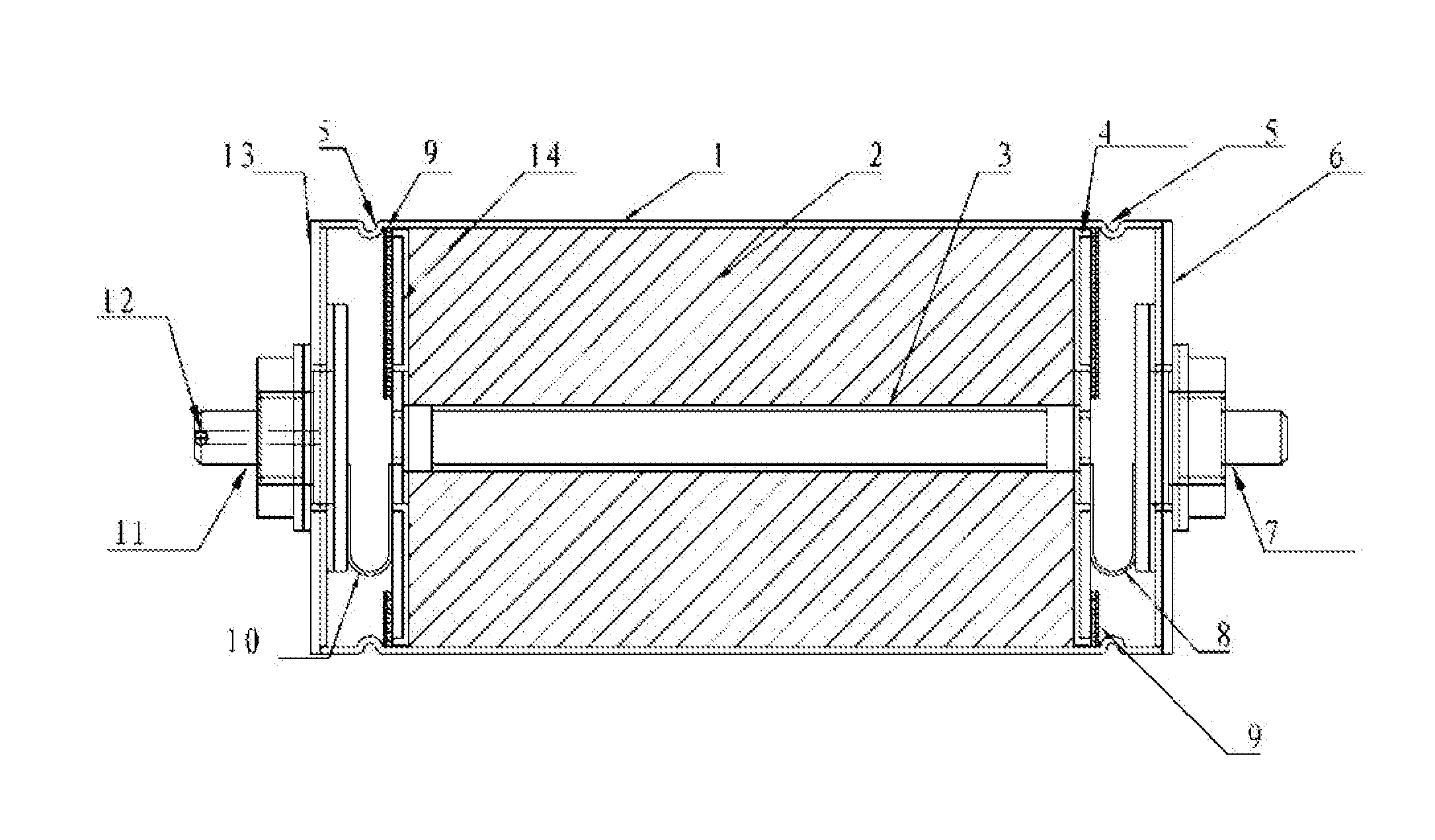

Bellows assembly of SF6 valve and manufacturing method thereof

InactiveCN102384310AIncrease the welding areaImprove sealingSpindle sealingsSoldering apparatusEngineeringAir tightness

The invention discloses a bellows assembly of an SF6 valve and a manufacturing method thereof. The bellows assembly comprises a valve rod, a support seat and a bellows, wherein the support seat is fixedly connected with the valve rod, and the valve rod is provided with a circular flange; the bellows is sleeved at the periphery of the valve rod between the circular flange and the support seat; and two ends of the bellows are respectively arranged in annular grooves formed on two oppositely arranged end faces of the circular flange and the support seat, and the bellows and the annular grooves are fixed by means of braze welding. Therefore, by using the bellows assembly of the SF6 valve disclosed by the invention, open welding between the mouth of the bellows and the valve rod as well as the support seat can be effectively avoided, thereby greatly improving the air tightness and service life of the bellows assembly.

Owner:JIANGSU CHENDONG MACHINERY MFG

High-capacity Cylindrical Lithium Ion Battery and Production Method Thereof

InactiveUS20140087225A1High densityWeight increaseCell electrodesFinal product manufactureEngineeringWeld strength

The invention discloses a high-capacity cylindrical lithium ion battery. Tab-position end face is shaped; a high frequency oscillation and pressure are applied on to make the foil bodies softened in the scope of 0.1-6.5 mm. At the instant of high-frequency oscillation, the rigidity of the foil body is greatly decreased; and the foil bodies are mutually wound and compressed together, so that the weight density of the foil body in unit volume is increased and meanwhile, the rigidity of the compressed foil body at the Tab-position end face is greatly increased, thereby laying a firm foundation for laser welding of the 1 Tab-position end face and a current collector, increasing a laser welding effective area of the Tab-position end face and the current collector, and improving the welding strength.

Owner:SHIHLIEN APEX HUAIAN TECH CO LTD

Joint for connecting buckling-restrained brace, concrete beam and concrete column

InactiveCN104563304AImprove stabilityIncrease stiffnessShock proofingStress concentrationBuckling-restrained brace

The invention discloses a joint for connecting a buckling-restrained brace, a concrete beam and a concrete column; an anchoring part anchored in the concrete beam and the concrete column is composed of two groups of spaced H-shaped profile steels; the H-shaped profile steels and an anchoring plate are welded into a whole one; the internal edge of the anchoring plate id arranged at the external sides of the concrete beam and the concrete column; a joint plate is integrally welded with the anchoring plate; the external end of the anchoring plate integrally welded with the joint plate is lengthened to be longer than the lateral side of the joint plate; and bolt holes for fixing the buckling-restrained brace are formed on the joint plate. The H-shaped profile steels in the joint plate have good stability in a plane and high rigidness and are not easy in instability; the profile steels have big welded areas with the anchoring plate and are not easy to produce pulling / pushing damage; the profile steels have big contact and load-transfer areas with the concrete and are capable of uniformly dispersing the load to the concrete beam; the lengthened parts at two ends of the anchoring plate are capable of effectively avoiding direct extrusion between the joint plate and the concrete, so that the stress concentration is relieved and the service life of the joint is prolonged; the integrality of the concrete beam and the concrete column is not influenced, so that hoops and longitudinal ribs in the concrete beam can be arranged easily; the steel ratio in the joint area of the beam and the column is increased and the strength and rigidness of the joint is improved by the plastic deformation of the beam restrained by the anchoring plate; the whole component can be manufactured in a factory and the construction time is saved.

Owner:SHENYANG JIANZHU UNIVERSITY

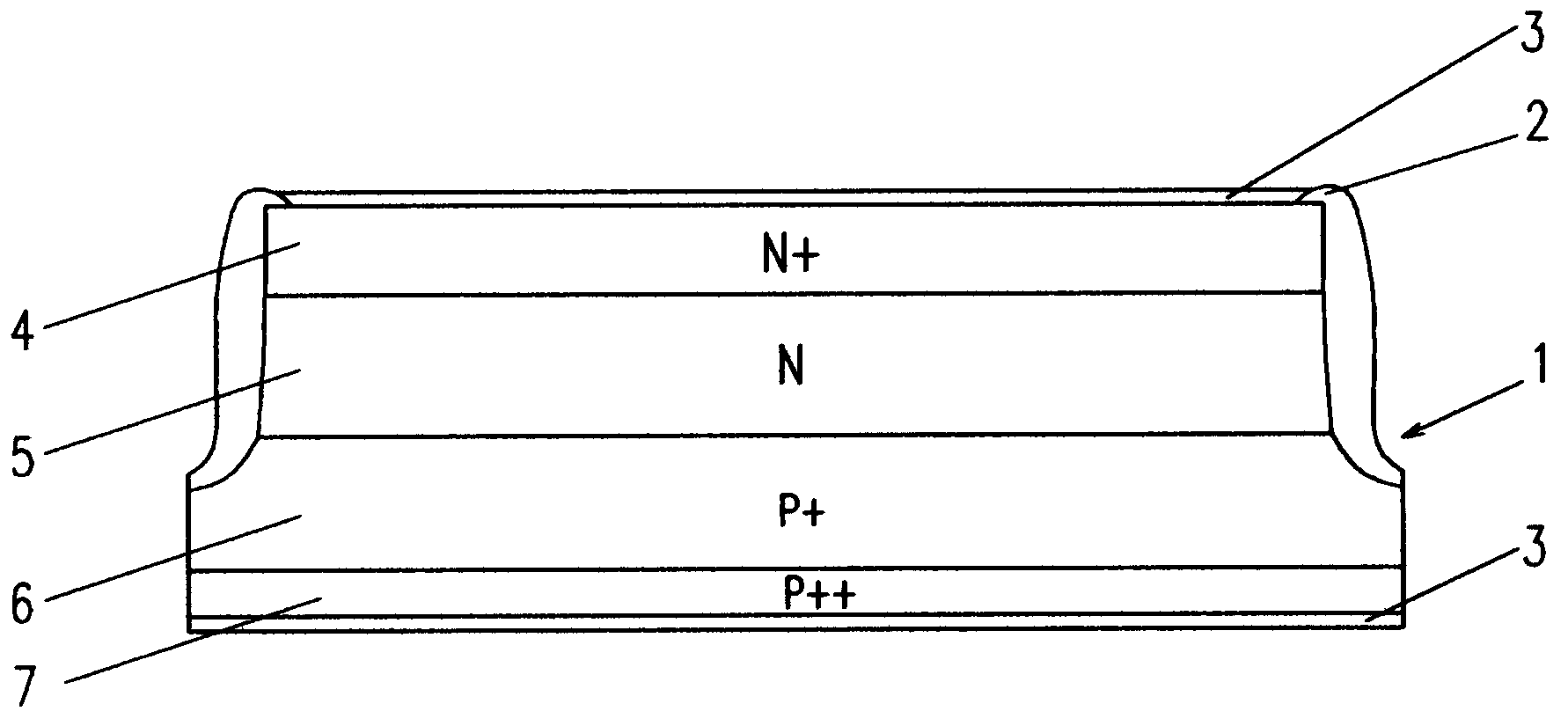

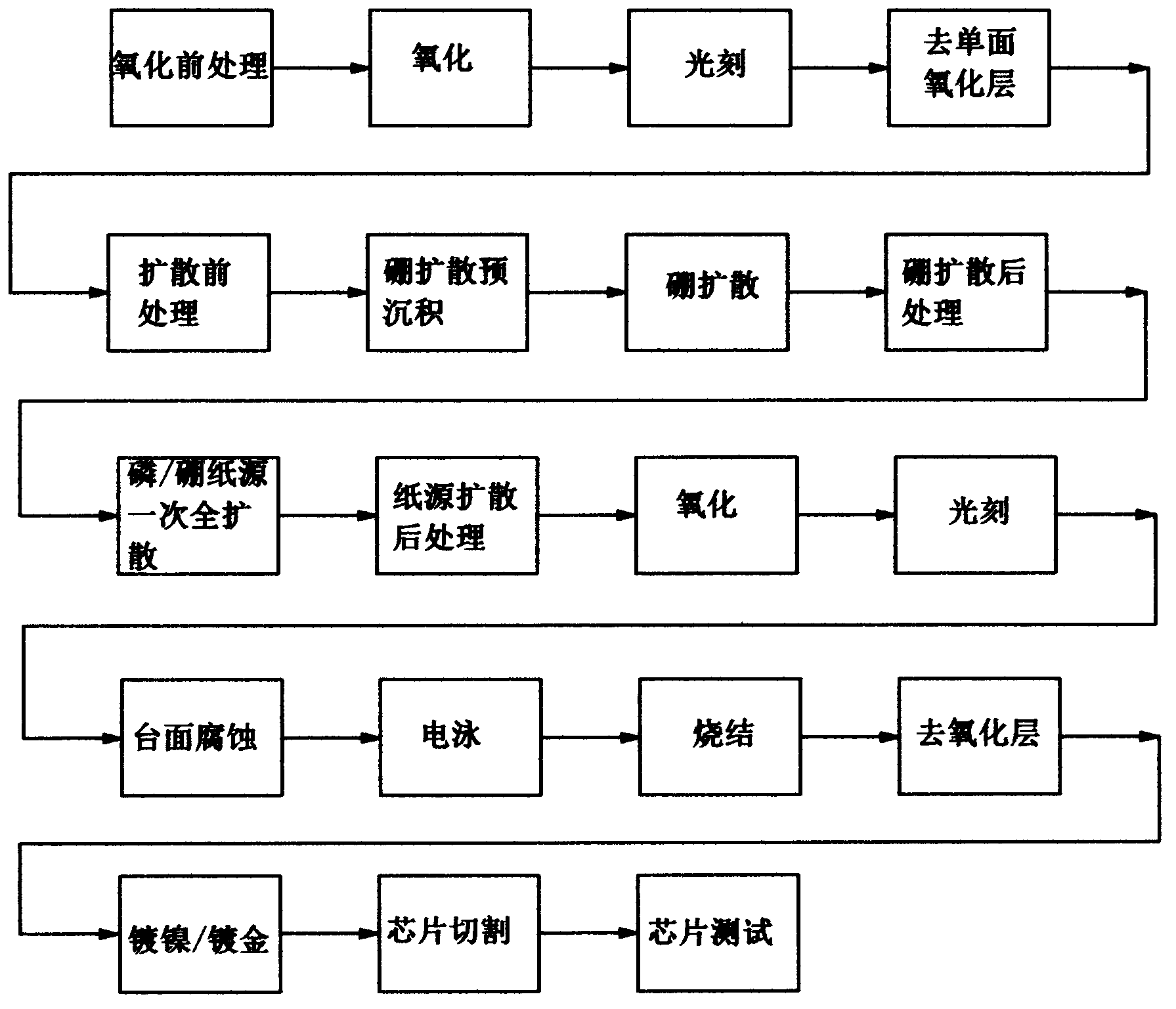

Backward GPP (Glass Passivation Pellet) high voltage diode chip in automobile module, and production technology

ActiveCN104078353AReduce widthLower body pressure dropSemiconductor/solid-state device manufacturingSemiconductor devicesEtchingLayer removal

The invention discloses a backward GPP (Glass Passivation Pellet) high voltage diode chip in an automobile module, and a production technology. The technology comprises the following steps of oxidation pretreatment, oxidation, photoetching, single-side oxidation layer removal, diffusion pretreatment, boron diffusion predeposition, boron diffusion, once phosphorus source / boron source diffusion, diffusion aftertreatment, N<+> surface mesa etching, electrophoresis, sintering, oxidation layer removal, nickel plating, gold plating and chip cutting. The obtained chip is in a P<++>-P<+>-N-N<+> type structure. According to the high voltage diode chip and the production technology, the defect of great electric leakage of a geminate axial diode is improved, damage to glass passivation protection during welding of a backward diode in a geminate GPP diode is avoided, an effective welding area is increased, and the whole heat dissipation function of the geminate diode is improved. An N-type substrate slice replaces a P-type substrate slice, and a backward GPP high voltage diode is manufactured in a deep N<+> surface corrosion groove, so that the backward GPP high voltage diode in the automobile module fills a gap in the technical field of domestic automobile modules.

Owner:上海瞬雷科技有限公司

Heat exchange plate for plate heat exchanger and plate heat exchanger with same

ActiveCN103791758AHigh strengthChange transitionLaminated elementsEngineeringUltimate tensile strength

The invention discloses a heat exchange plate for a plate heat exchanger. The heat exchange plate comprises a heat exchange part, a plurality of protrusions and transition parts. The protrusions protrude from a plate plane to at least one side of the plate plane on the heat exchange part, and are distributed along a plurality of lines. The transition parts are arranged between the adjacent protrusions distributed along one line and protrude towards the at least one side of the plate plane, and the dimension of the top of each protrusion in the direction perpendicular to the lines is larger than that of the tops of the transition parts. The dimension of a welding part or the dimension of a bearing part is increased, and therefore the strength of the heat exchange plate of the plate heat exchanger is improved.

Owner:DANFOSS MICRO CHANNEL HEAT EXCHANGER JIAXING

Powder metallurgy brake shoe with bent welded structure

The invention relates to a powder metallurgy brake shoe, in particular to a powder metallurgy brake shoe with a bent welded structure, which comprises a steel backing, a skeleton, a plurality of friction blocks, a brake shoe nose and a stopping block, wherein a brake block is formed on one skeleton by sintering friction blocks; the skeleton is welded onto the steel backing. According to the invention, a plurality of friction blocks are welded onto one whole skeleton at the same time, and then, the whole skeleton is welded onto the steel backing, the powder metallurgy brake shoe has the benefits of large friction area, simple structure, high convenience for processing, short processing periods, low cost, low possibility of looseness and flaking off for brake blocks, and high safety.

Owner:贵州新安航空机械有限责任公司

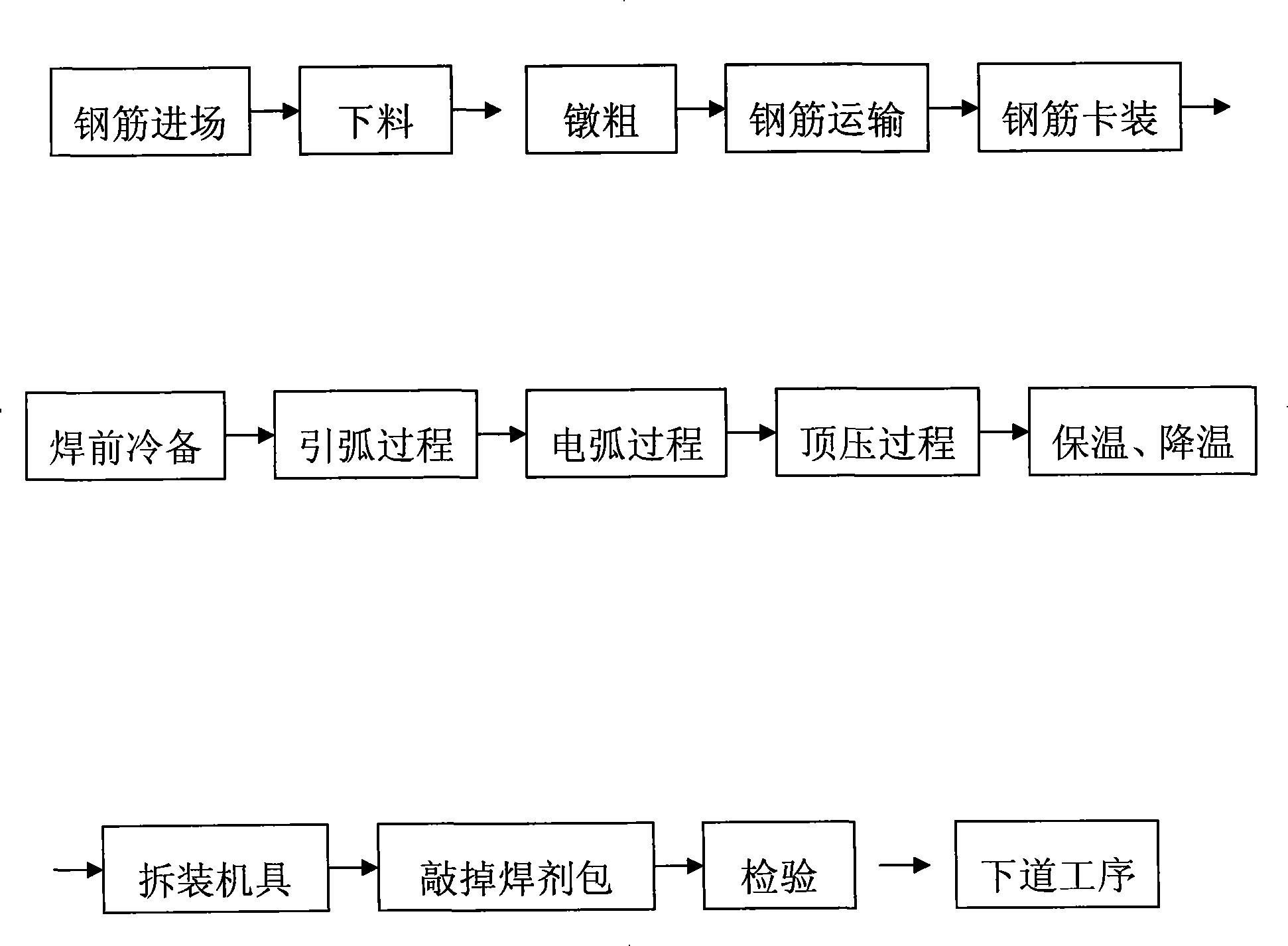

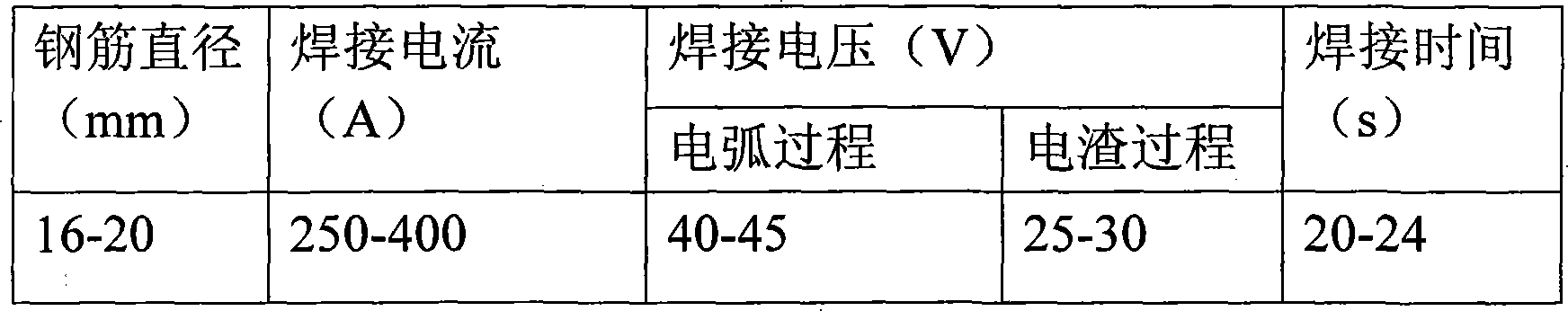

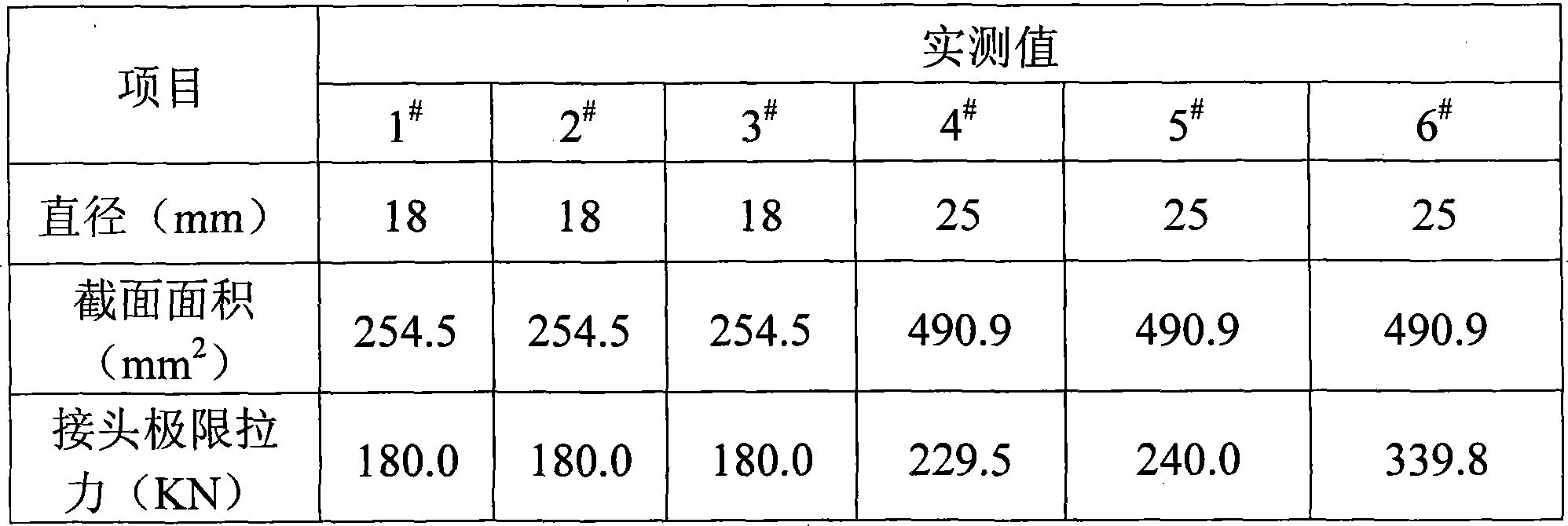

Construction method for steel bar work down electro-slag pressure welding

InactiveCN101244488AImprove efficiencyGood carbon equivalentArc welding apparatusElectricityElectrical resistance and conductance

The invention relates to a method of steel bar upsetting electroslag pressure welding. First, the steel bar head is upset thick to enlarge the welding area. Then two steel bars are positioned in a vertical docking form. The welding current passes through space between two steel bar upsetting ends by use of a welding machine to form an electric arc process and an electroslag process under the welding flux layer. The electric arc heat and the resistance heat are produced and the steel bars are melted. Then vertical pressure is reinforced on two steel bars so that two steel bars are combined together. After cooling, two steel bars are fixedly connected with each other through a welding package. The method of steel bar upsetting electroslag pressure welding has the advantages that the craft is advanced; the operation is easy; the welding quality is good; HRB500 steel bar has high strength, good ductility, low carbon equivalence, and good weldability; steels are save; the function of the steel bar section in the concrete means is reduced; the bearing capacity of the means is improved; the construction is convenient; and the environmental pollution is avoided. The method has also the advantages of solving problems of complicated welding, low efficiency, and poor quality, being a great invention in the technology of steel bar welding, and having huge economic and social benefits.

Owner:XINPU CONSTR GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com