Industrial filter screen with V-shaped wires and laser processing process thereof

A technology of laser processing and filter screen, used in laser welding equipment, metal processing equipment, filtering and separation, etc., can solve the problems of large mesh gap accuracy error, mesh gap accuracy error, unstable solder joint quality, etc. Surface flatness, high welding strength, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0038] detailed description: The present invention will be further described below in conjunction with accompanying drawing:

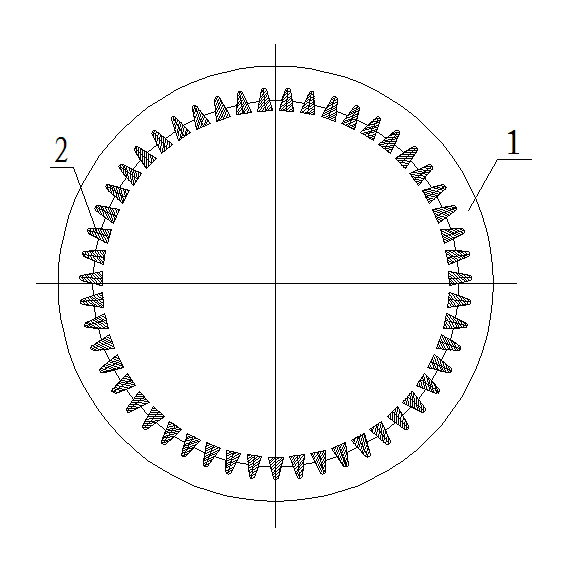

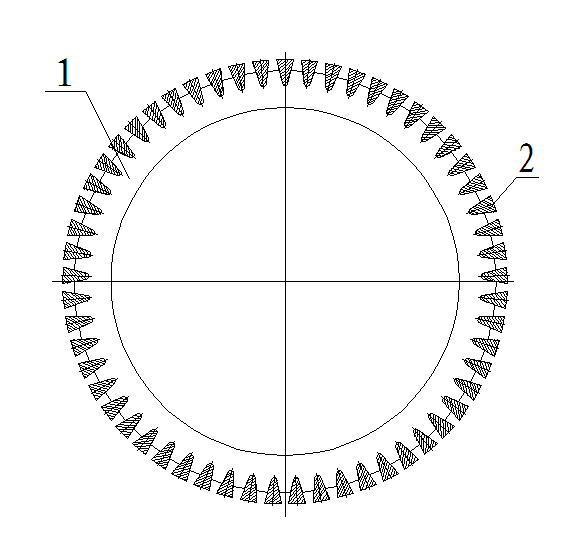

[0039] Such as figure 1 As shown, the present invention provides a V-shaped silk industrial filter screen, which includes a support frame 1 and a filter wire 2 with a triangular cross-section, and the axis directions of the support frame 1 and the filter wire 2 are formed perpendicular to each other. Figure 9 The staggered net structure shown; the support frame 1 is a toothed structure with a "V'-shaped tooth groove 3, and one corner of the filter wire 2 is inserted into the tooth groove 3 to mesh with the tooth groove 3 to form a whole.

[0040] The support frame 1 is figure 1 straight support frame as shown or as figure 2 and 3 The circular support frame shown.

[0041] The filter wire 2 meshes with the tooth slots 3 of the straight support frame to form a flat filter screen or the filter wire 2 meshes with the tooth slots 3 of the circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com