Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Joining strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

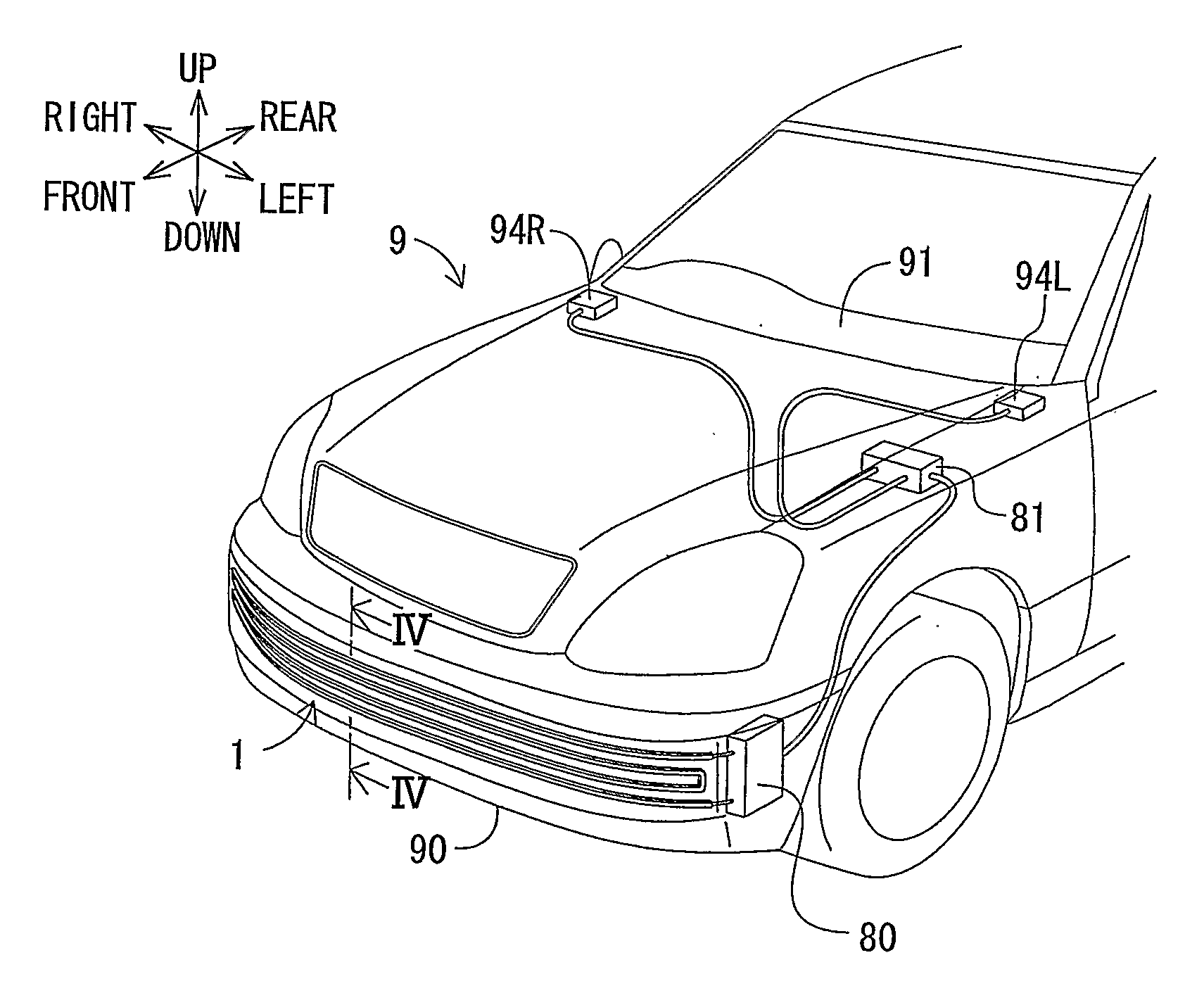

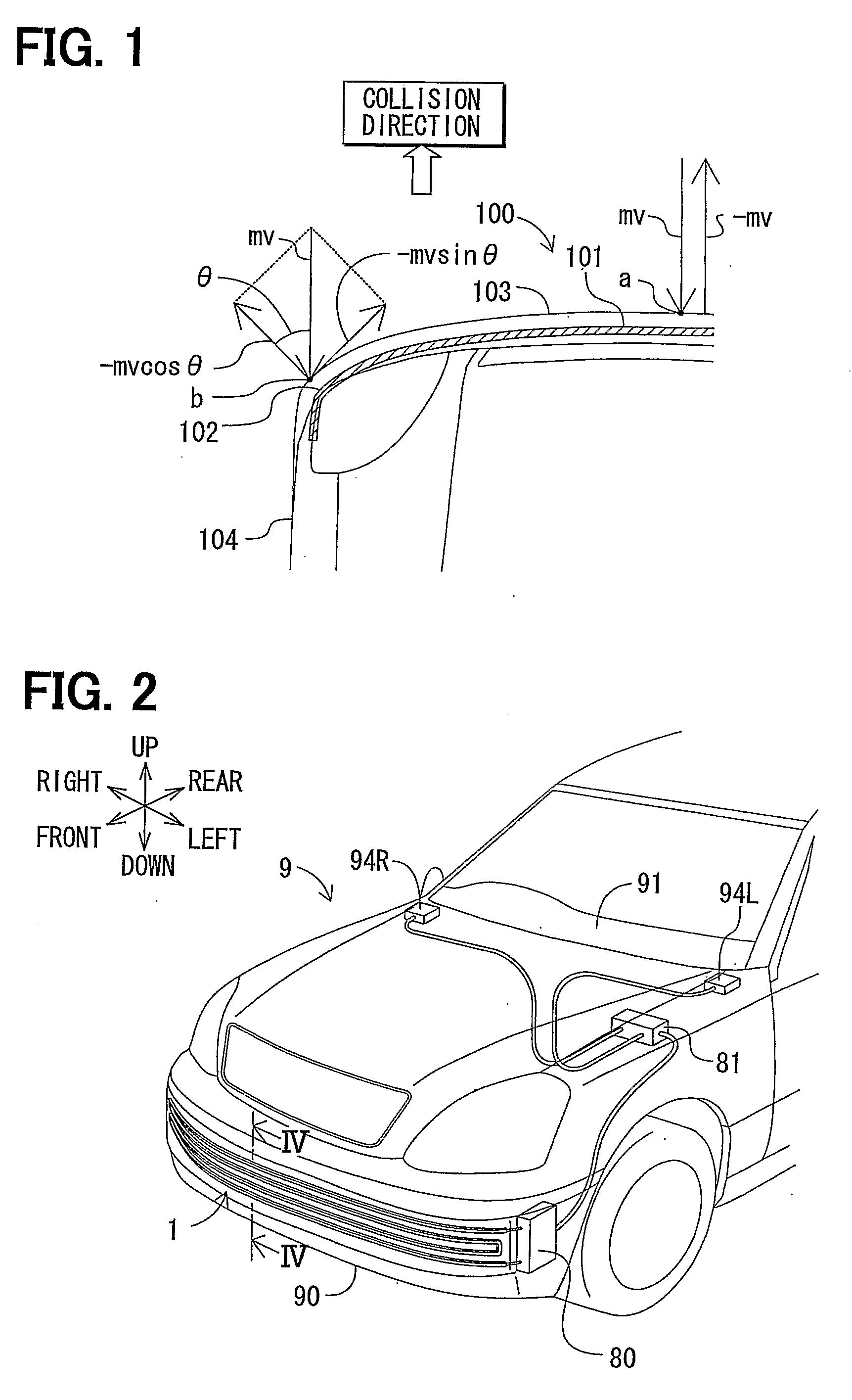

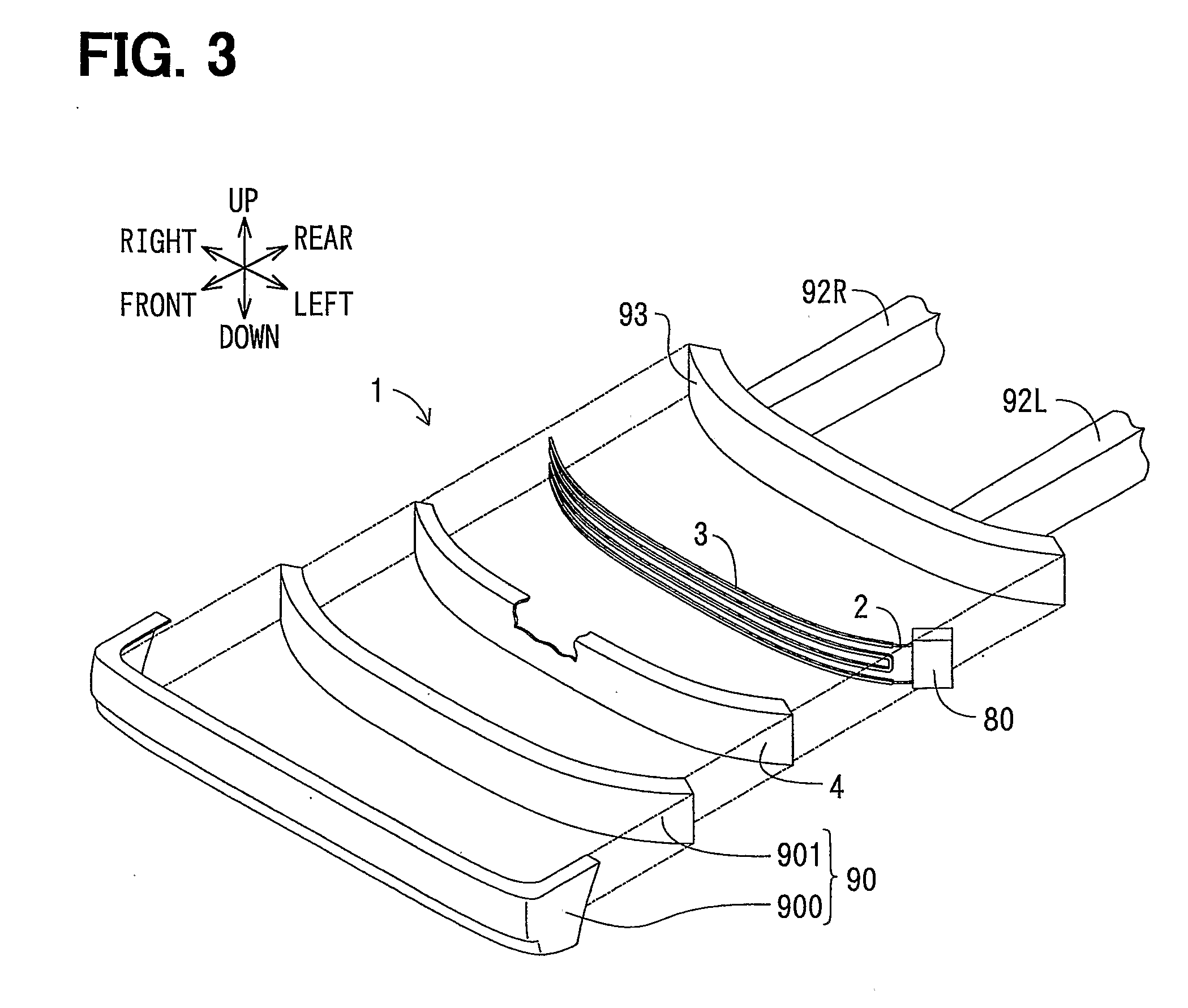

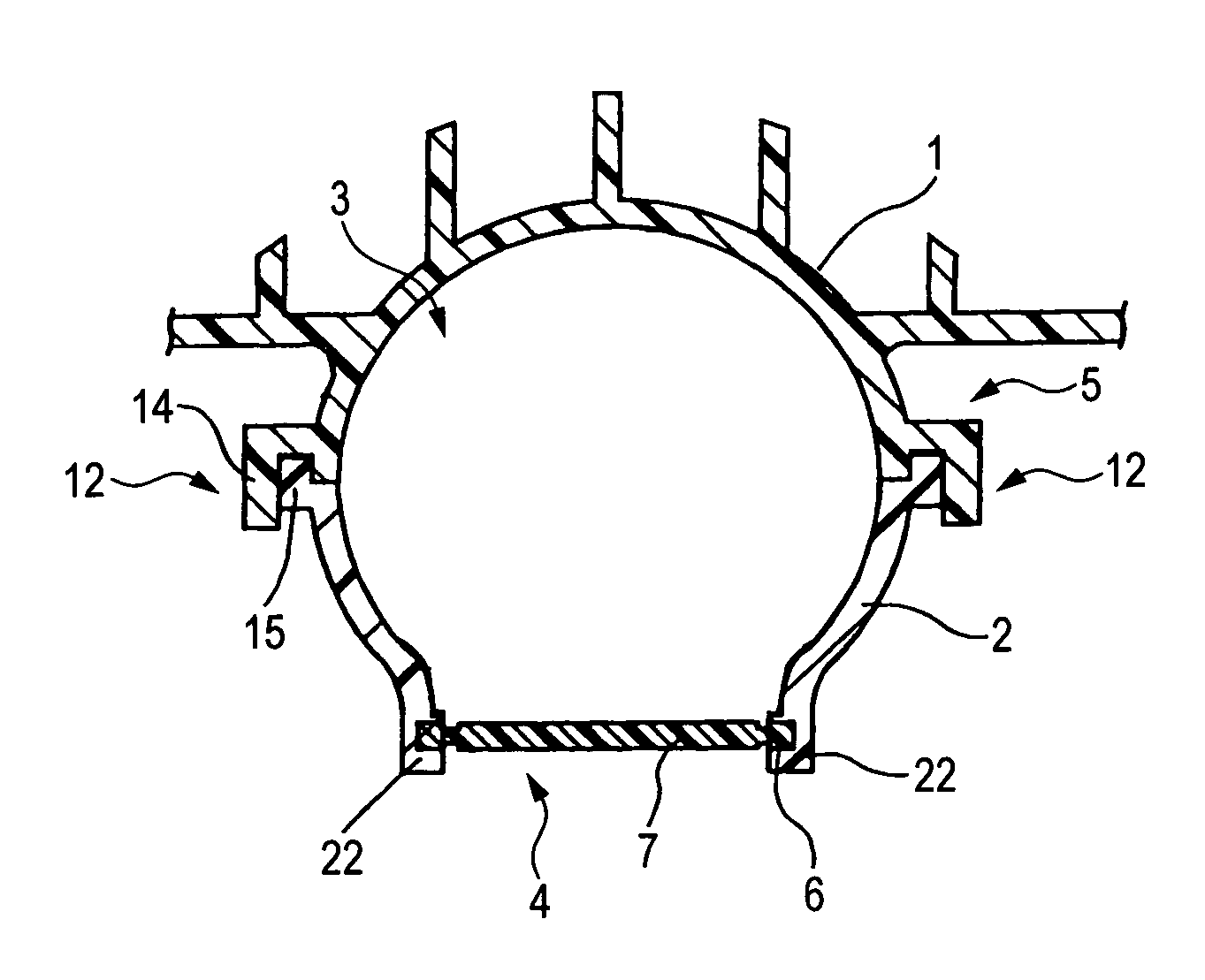

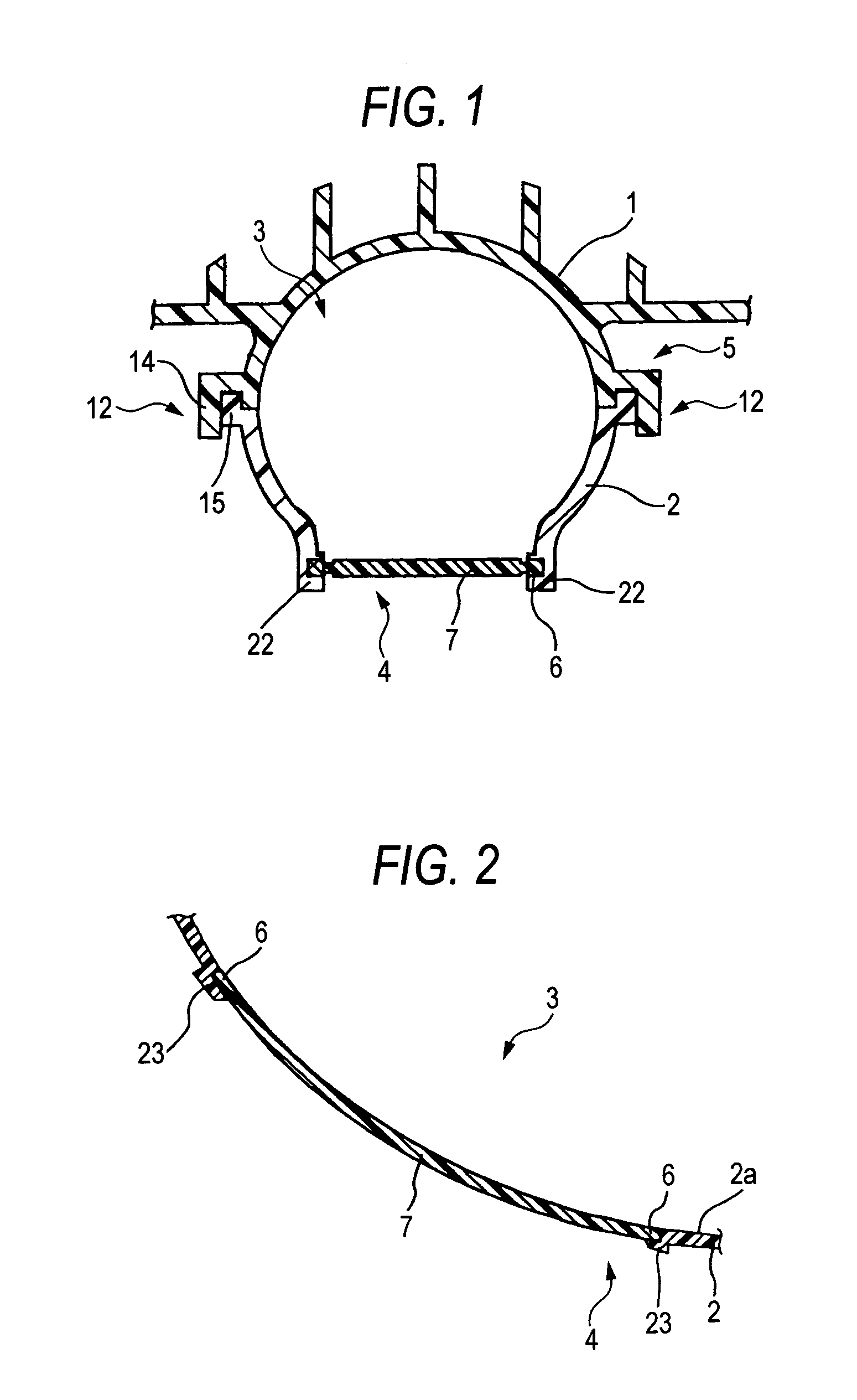

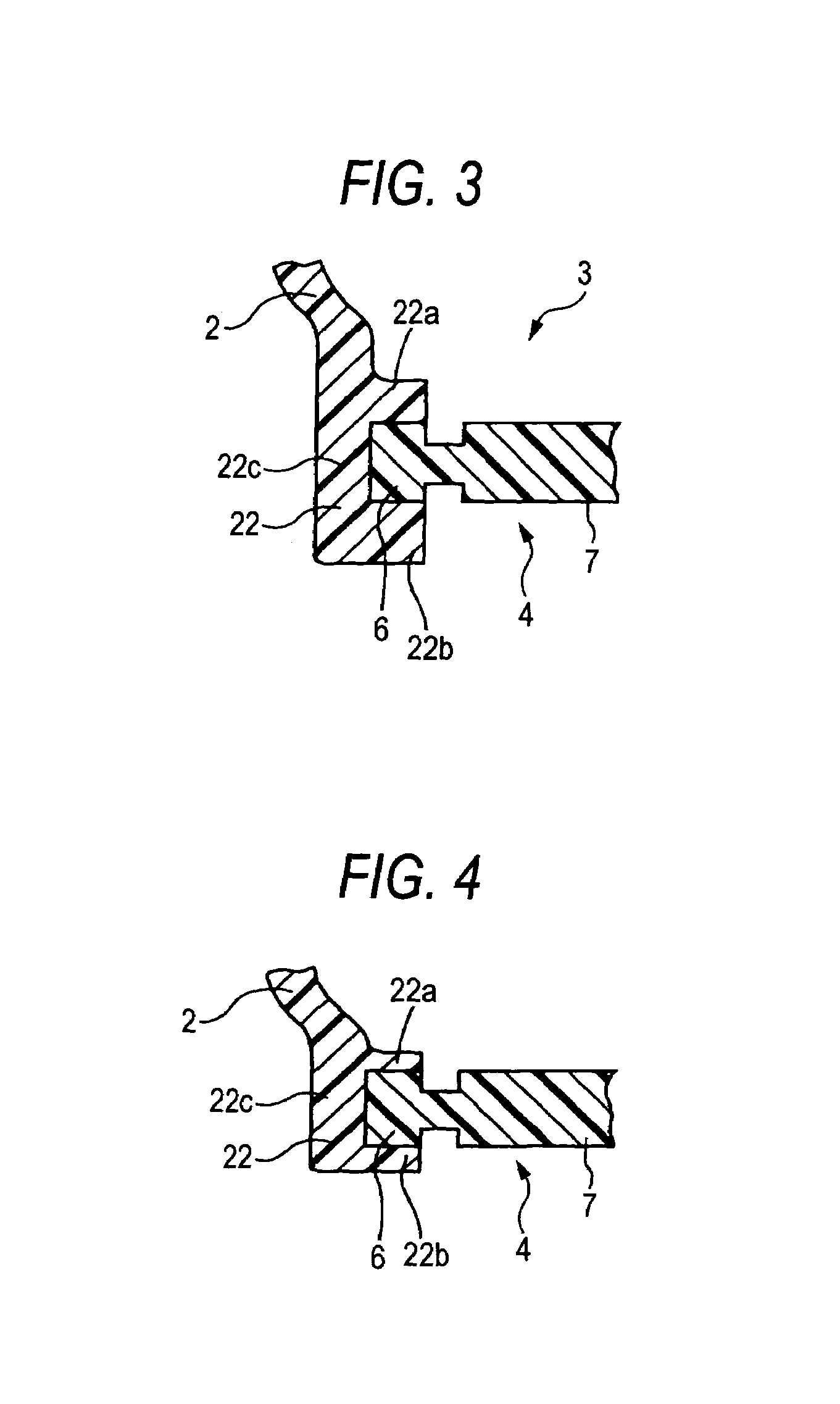

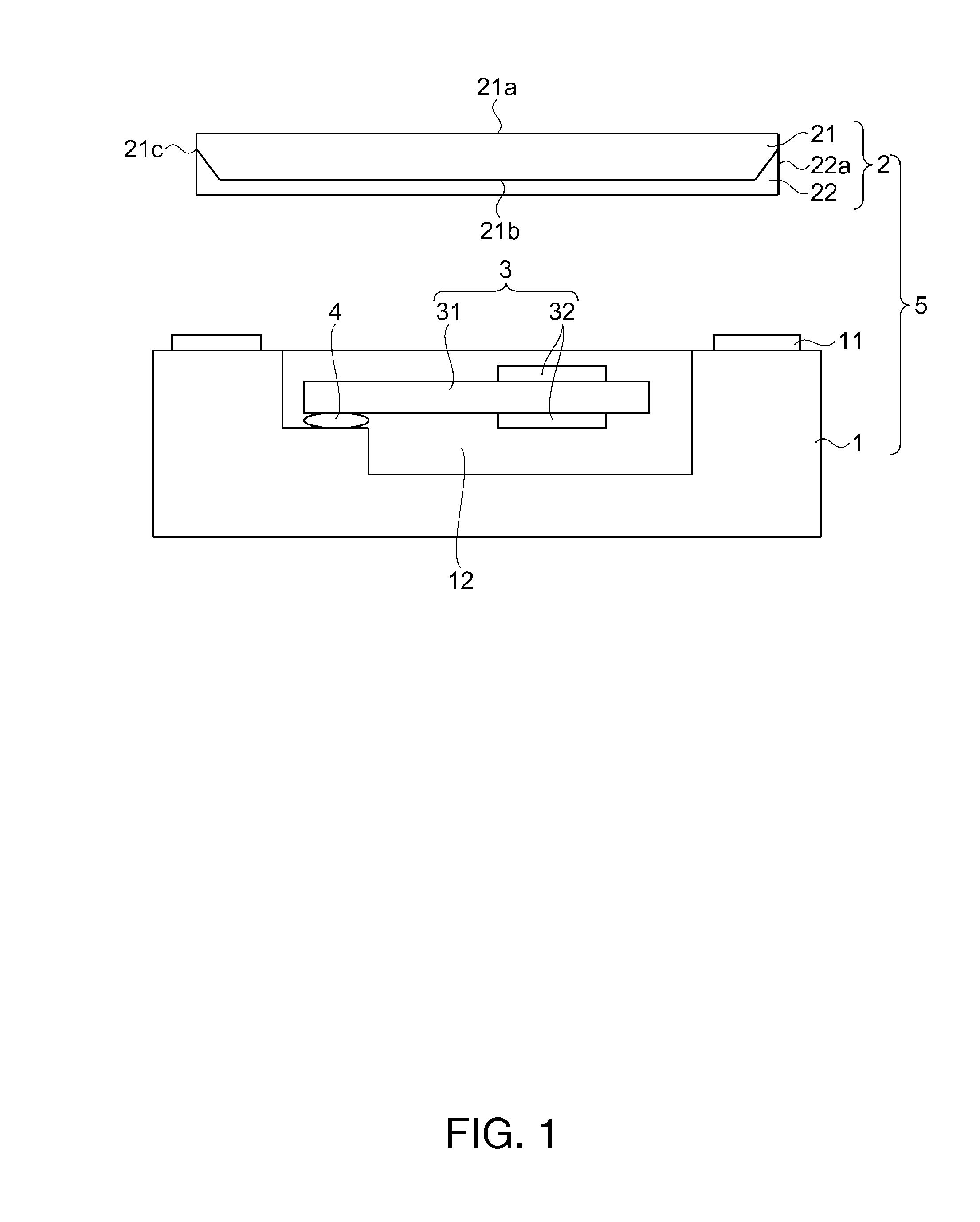

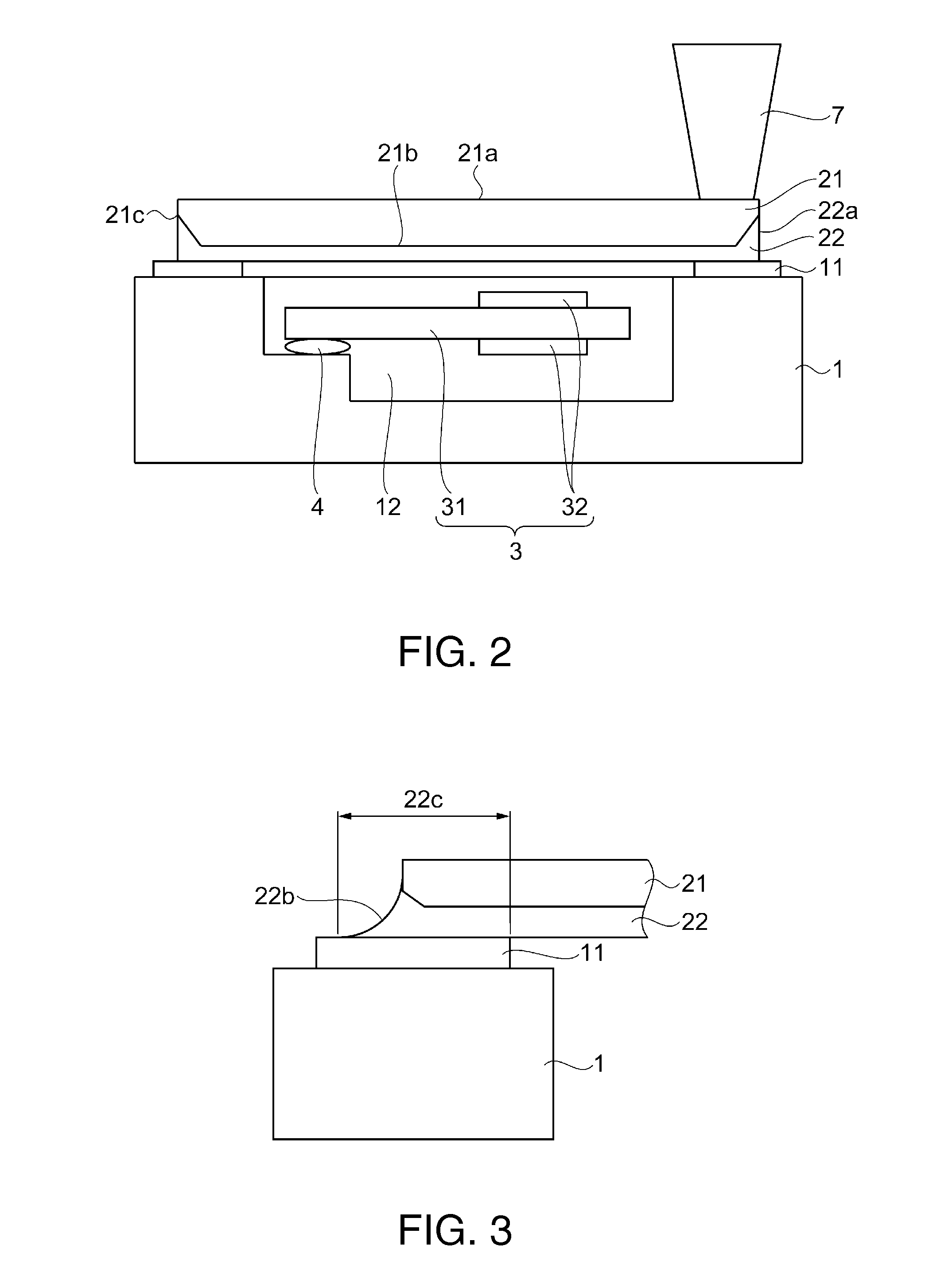

Collision Detection Device and Method of Manufacturing the Same

InactiveUS20080122599A1Joining strengthImprove joint strengthDigital data processing detailsPedestrian/occupant safety arrangementCollision detectionEngineering

A collision detection device is provided with a load detection member 2 for detecting a collision load in a collision, and a mold member 3 which is molded to be integral with the load detection member 2. The mold member 3 covers at least the surface of a collision side of the load detection member 2, to absorb at least a part of impact energy in the collision by a resilient deformation of the mold member 3. Thus, the collision detection device is substantially resistant to an impact in the collision, while being simply manufactured.

Owner:DENSO CORP +1

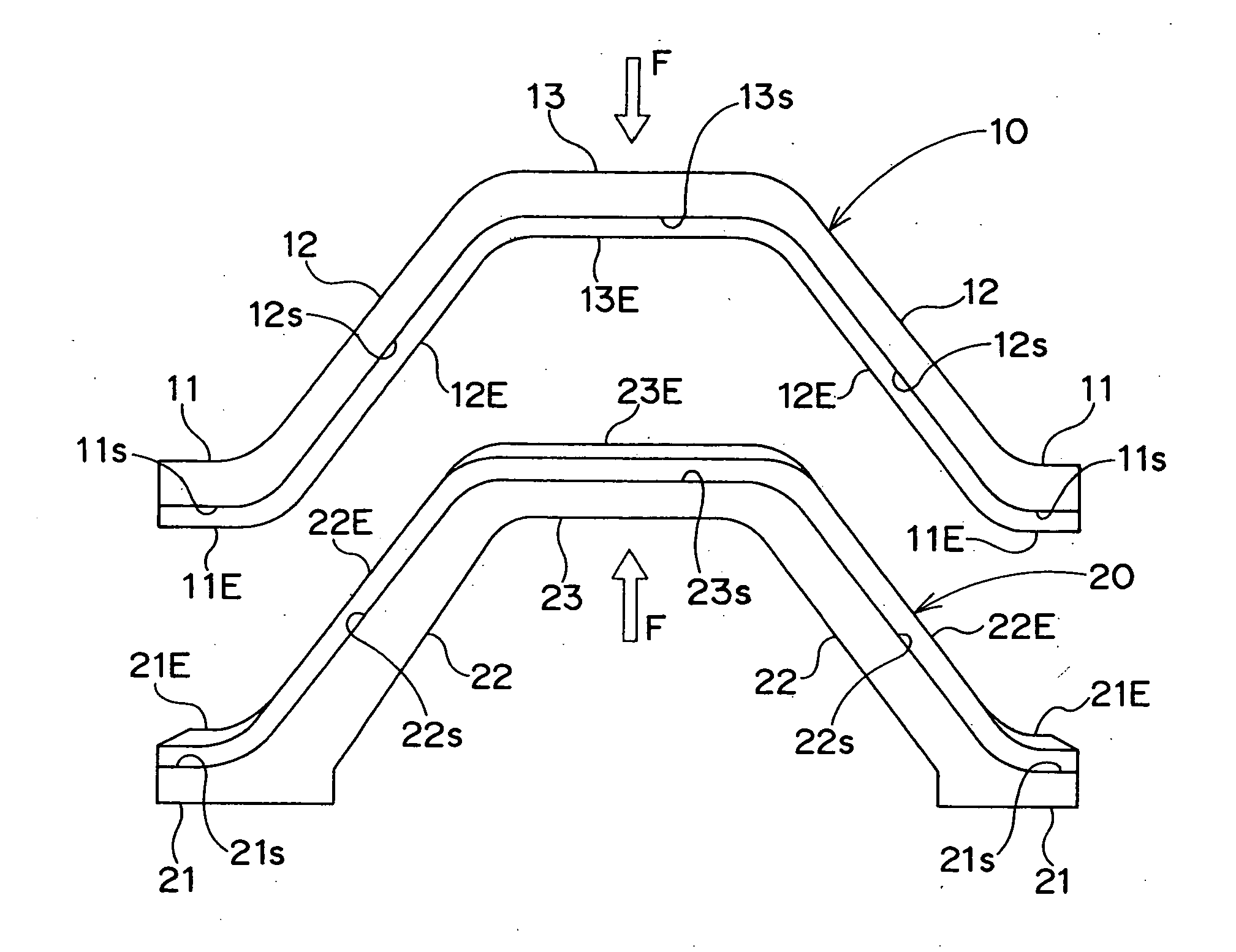

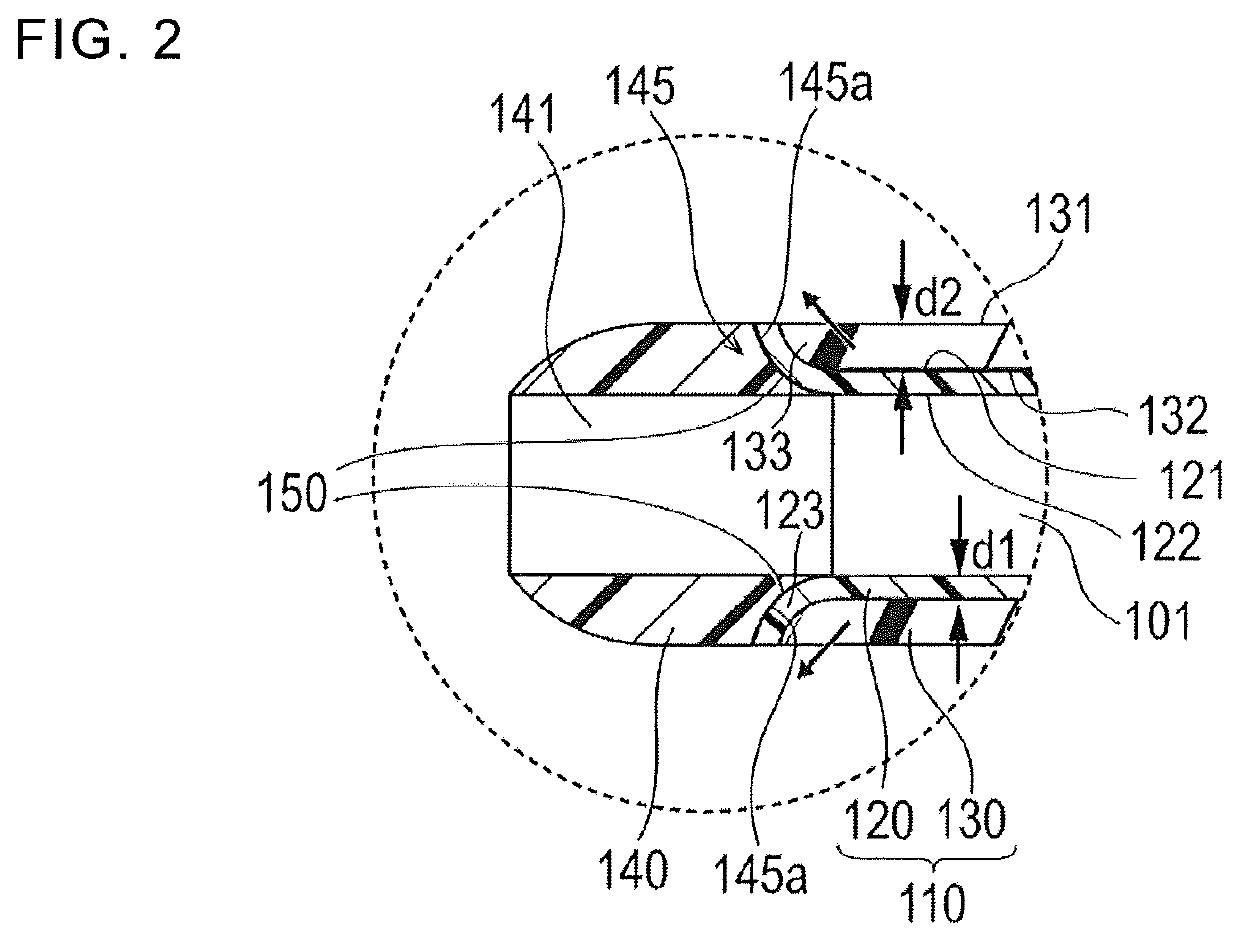

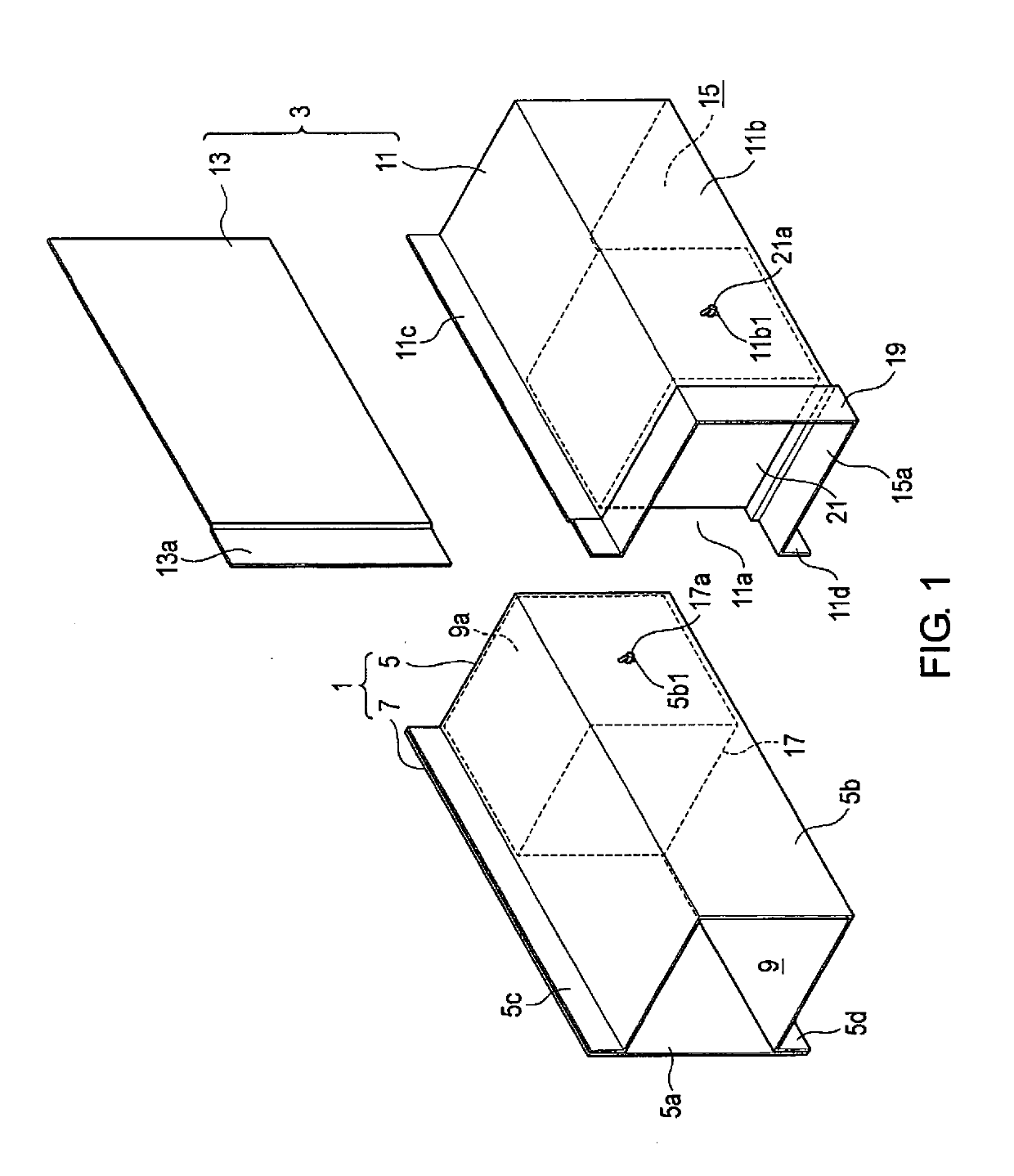

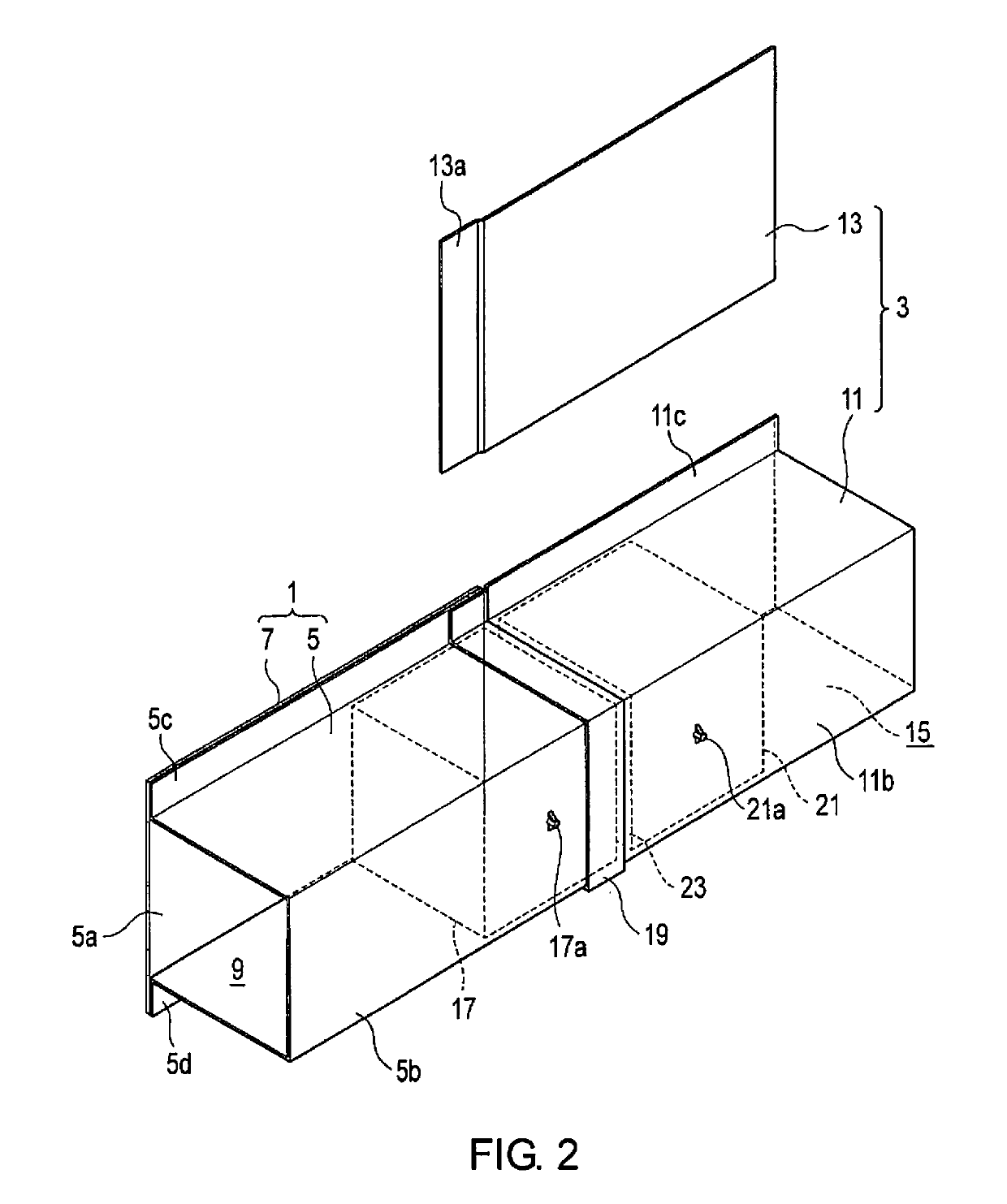

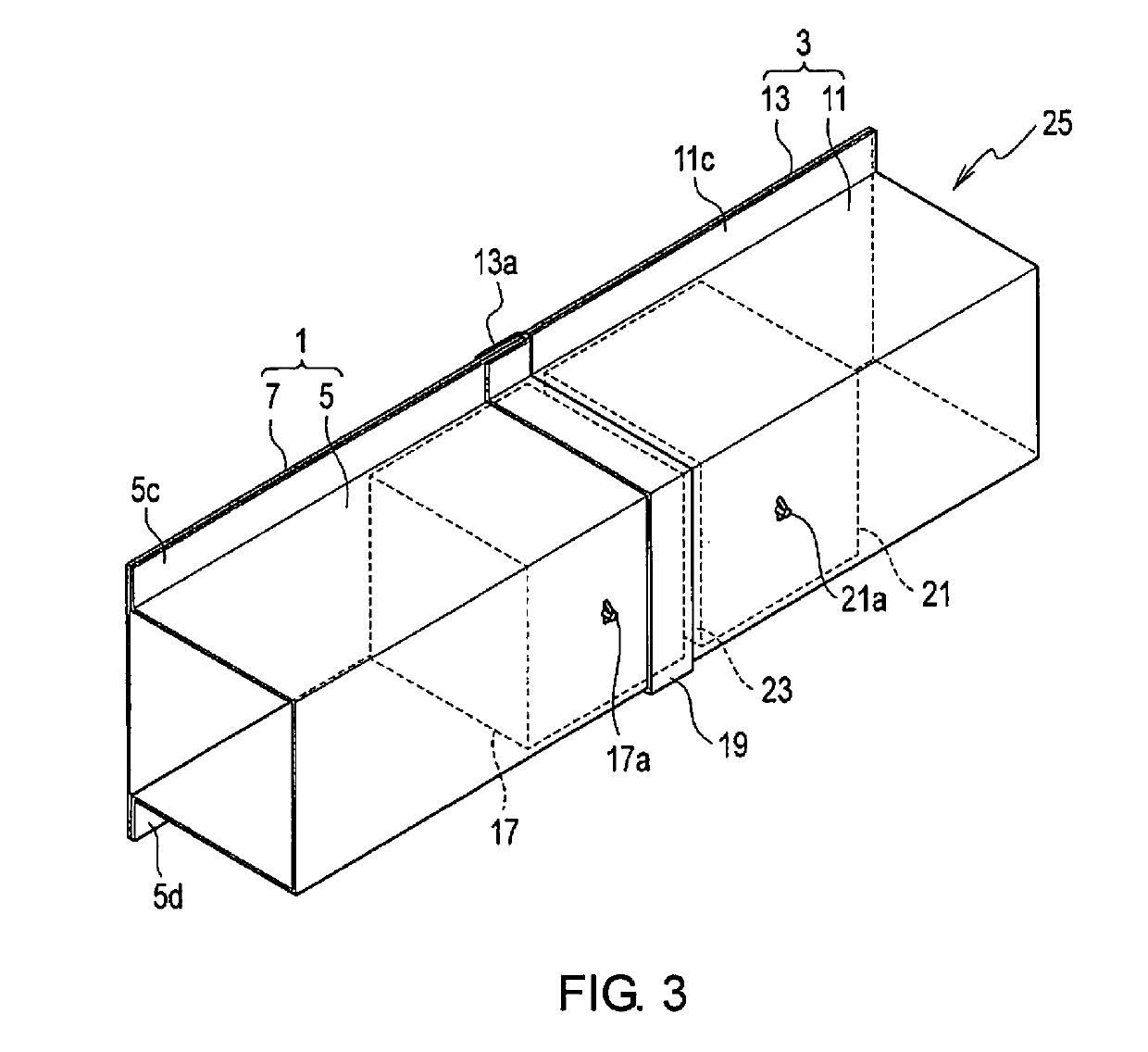

Structure of joining resin molded bodies

InactiveUS20060068161A1Reliable and superior joining strengthJoining strengthLayered productsThin material handlingEngineeringWelding

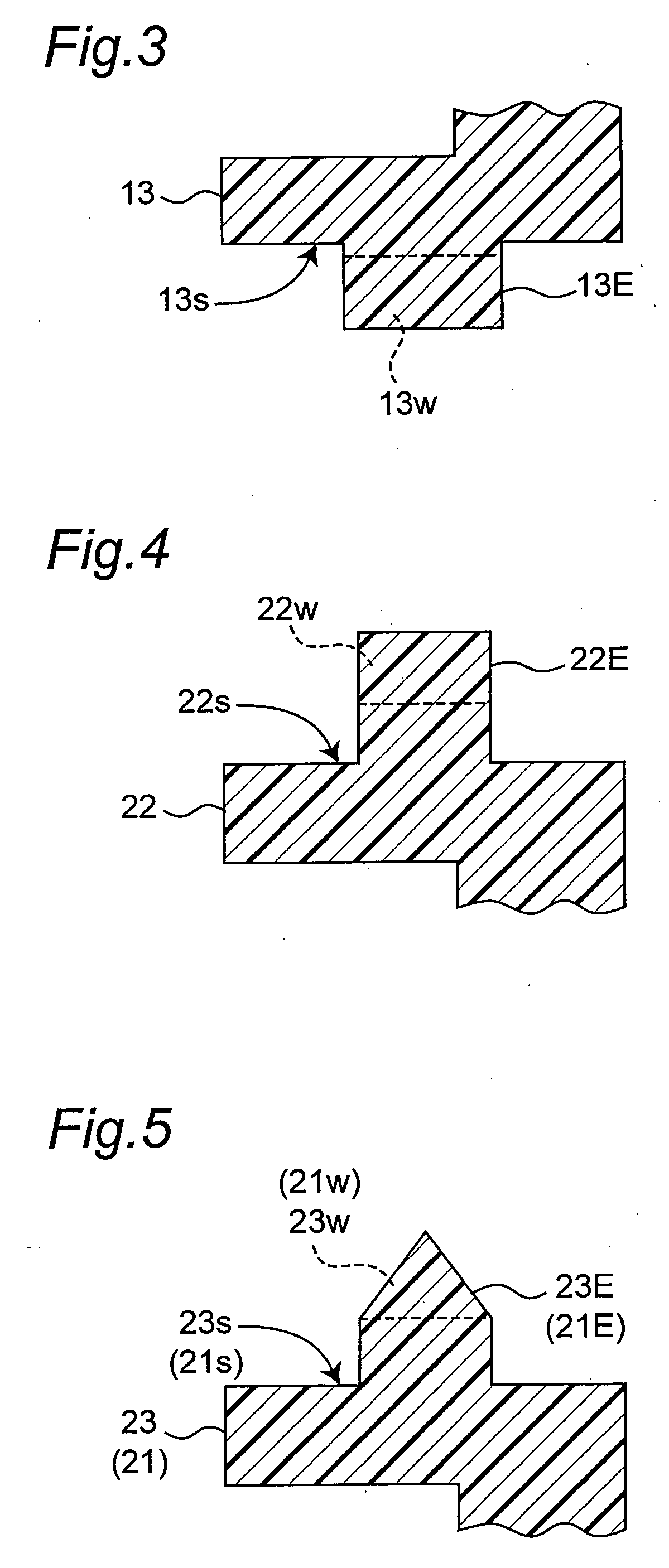

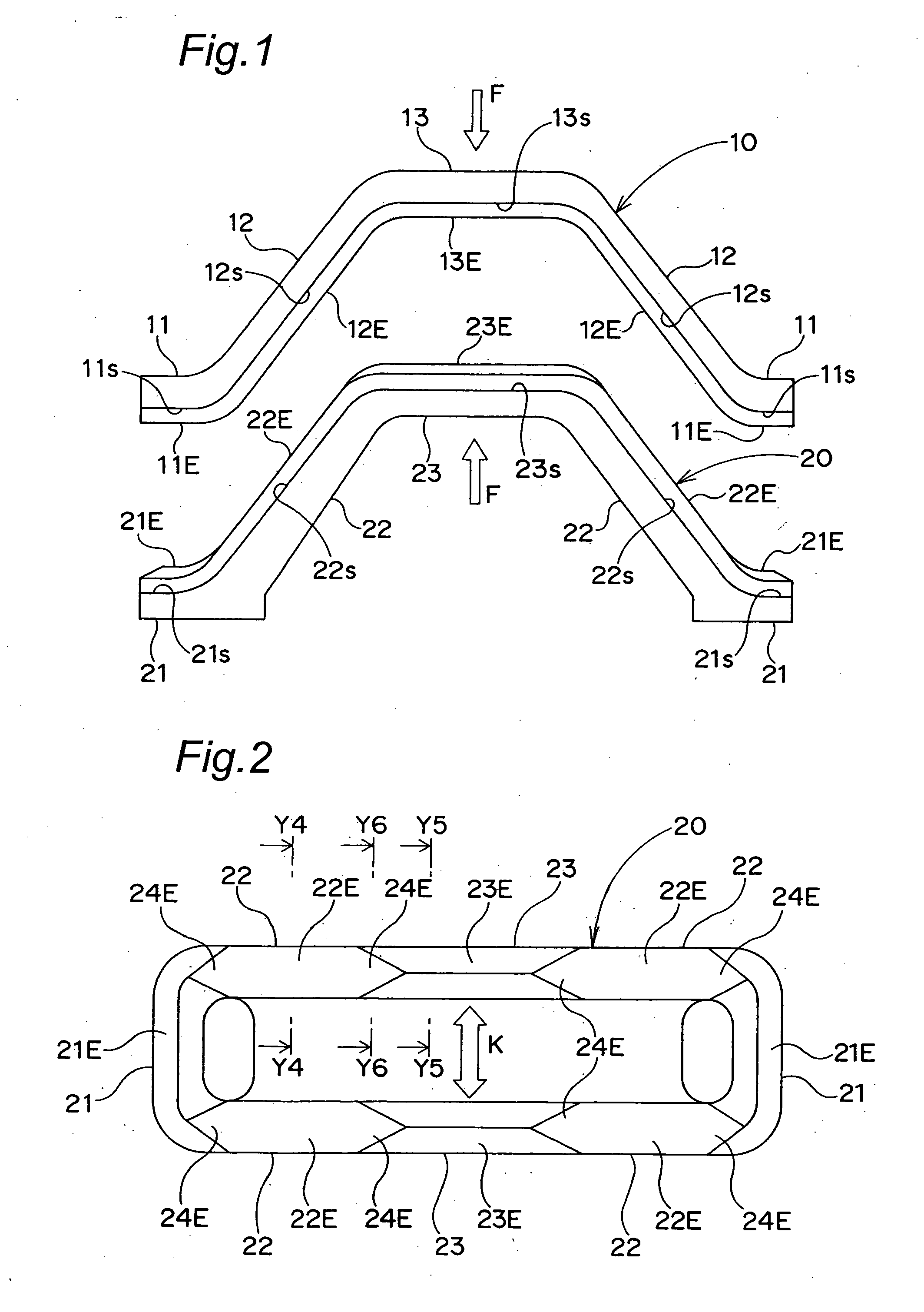

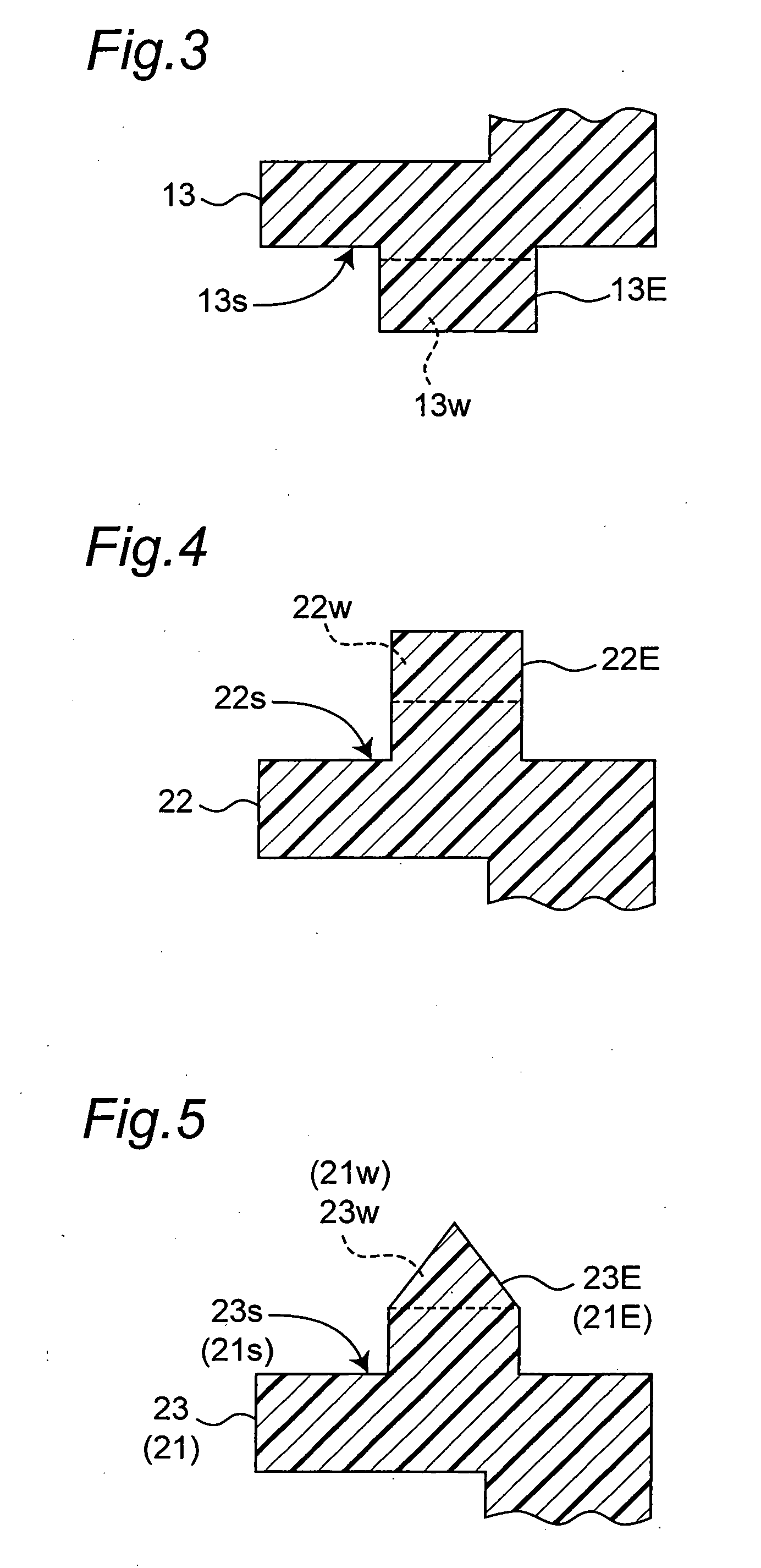

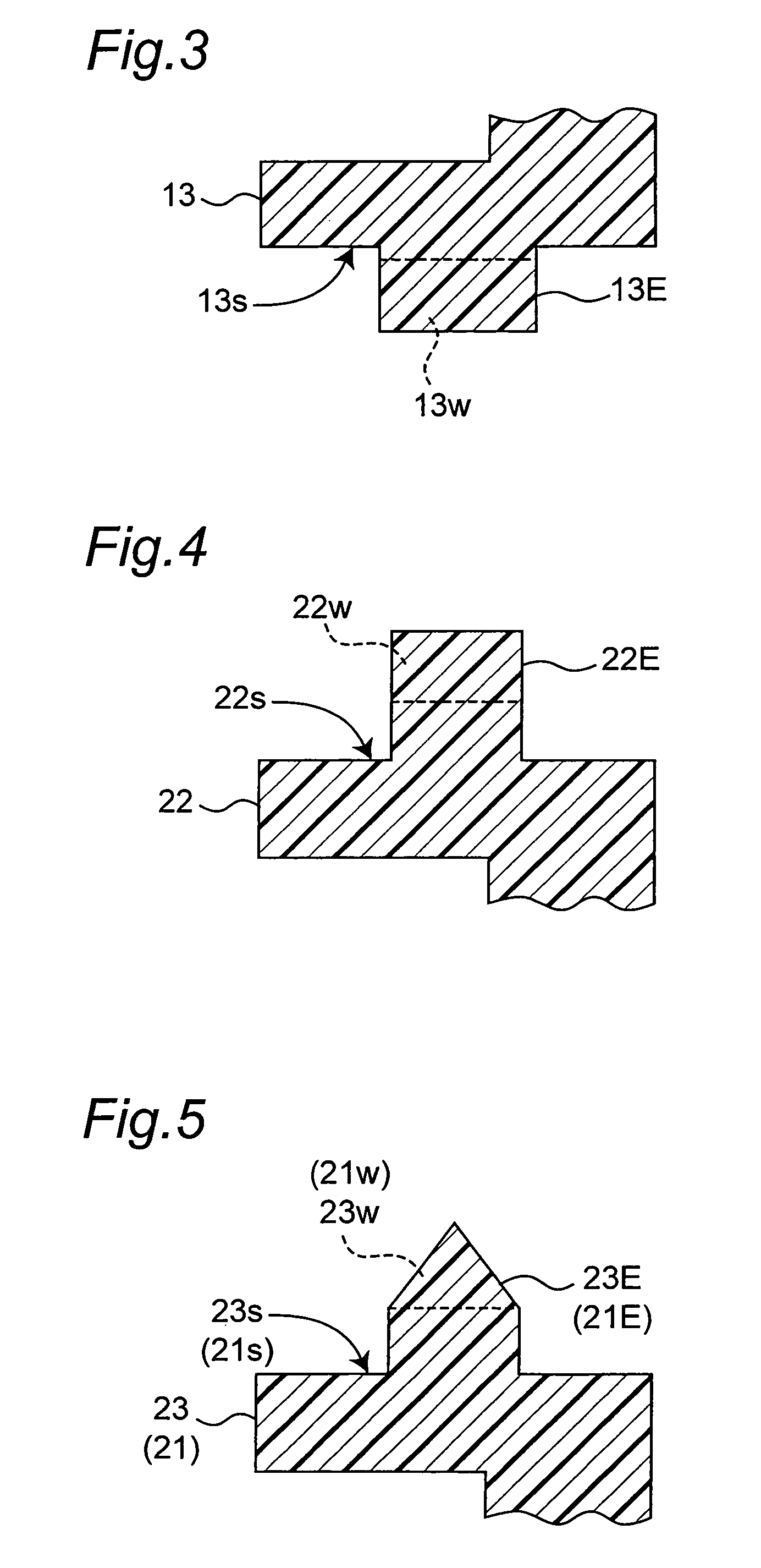

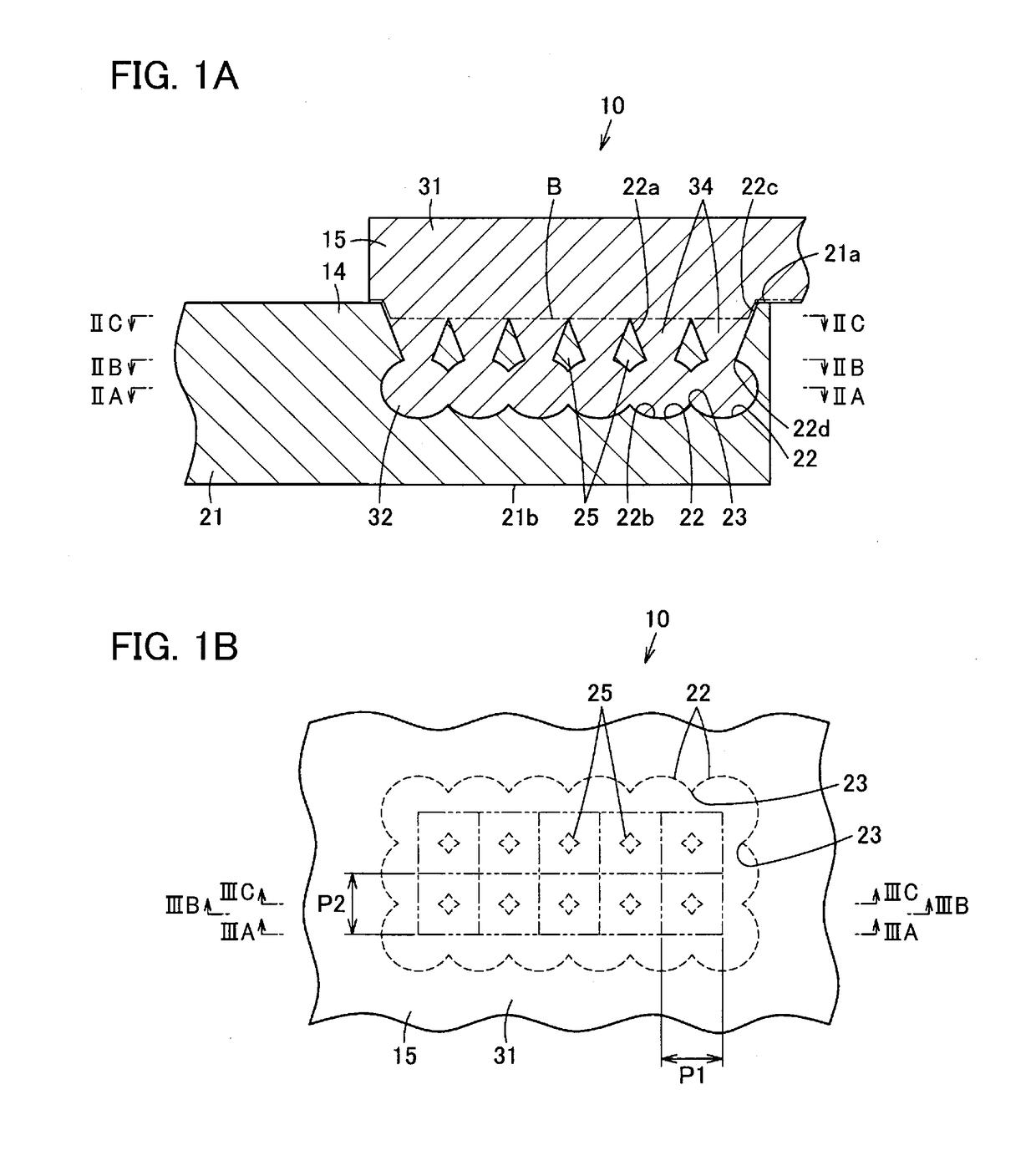

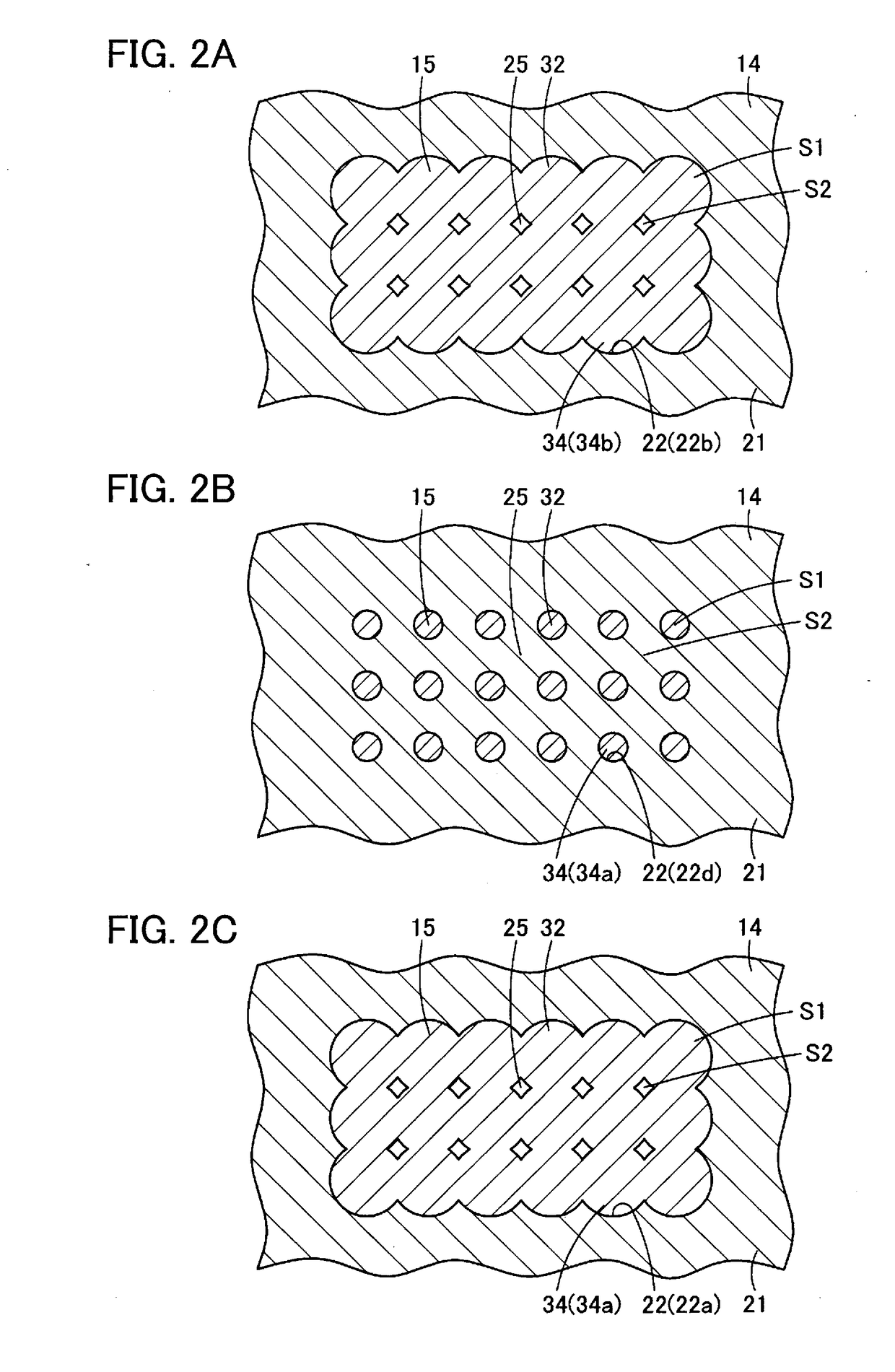

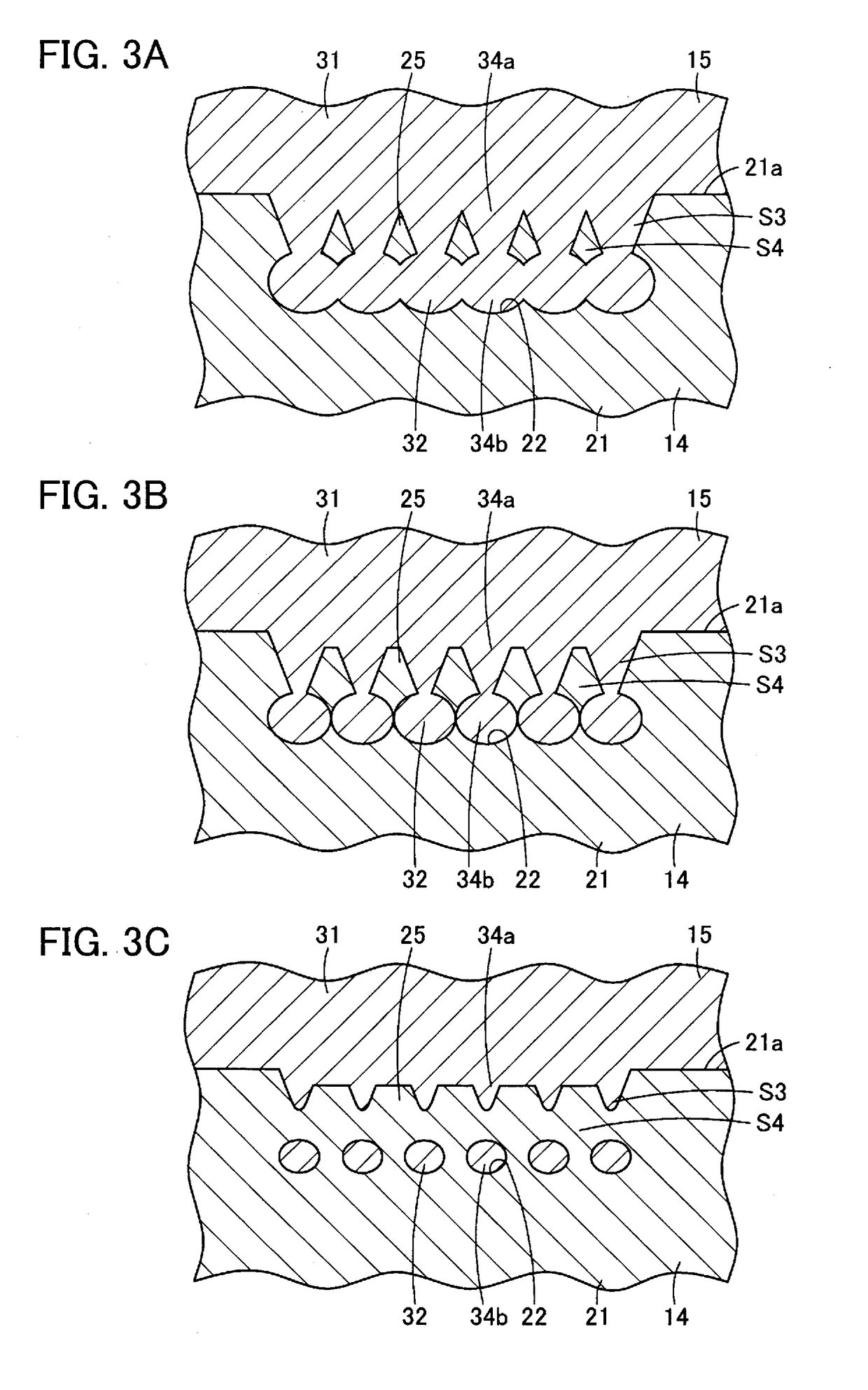

A reliable and superior joining strength in entire joining parts of resin molded bodies including tilting portions is obtained by devising a shape and a size of each protrusion for welding provided in the joining parts of the resin molded bodies. In a structure of joining resin molded bodies according to the present invention, upper and lower half bodies 10 and 20 are joined with each other by means of a vibration welding method while the upper and lower half bodies 10 and 20 are being pressurized in a state in which joining parts thereof are butted into each other in a substantially entire area of the joining parts. The joining parts of the respective half bodies have vertical portions 11 and 13 and vertical portions 21 and 23 respectively vertical to a pressurizing direction and tilting portions 12 and 22 tilting relative to the pressurizing direction, and protrusions for welding 11E to 13E or 21E to 23E are provided in at least the joining part of one of the half bodies. Further, referring to a butting area of the protrusions in a butted state, the butting area in the vertical portions is set to be narrower than the butting area in the tilting portions.

Owner:DAIKYONISHIKAWA CORP

Absorbent article

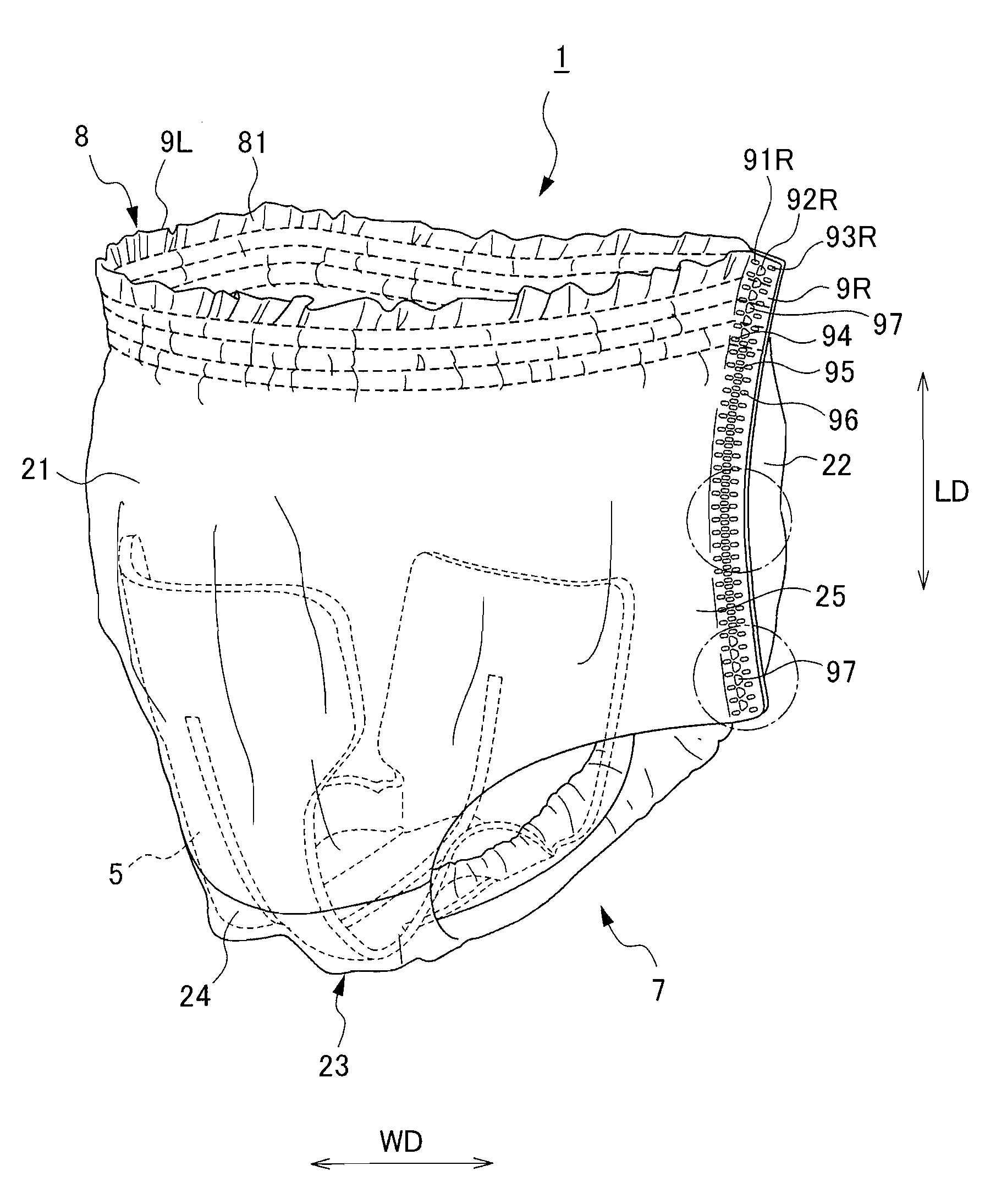

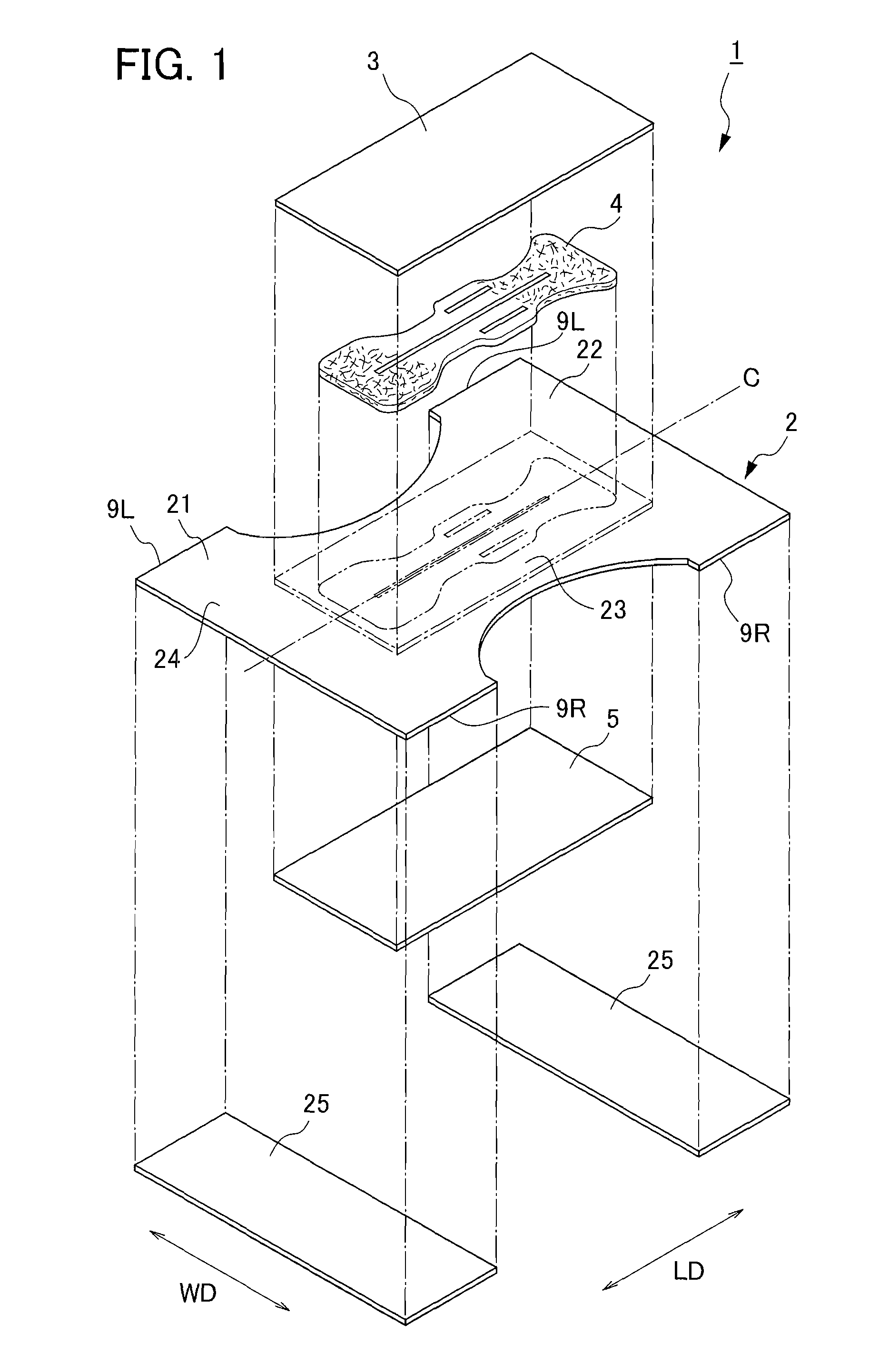

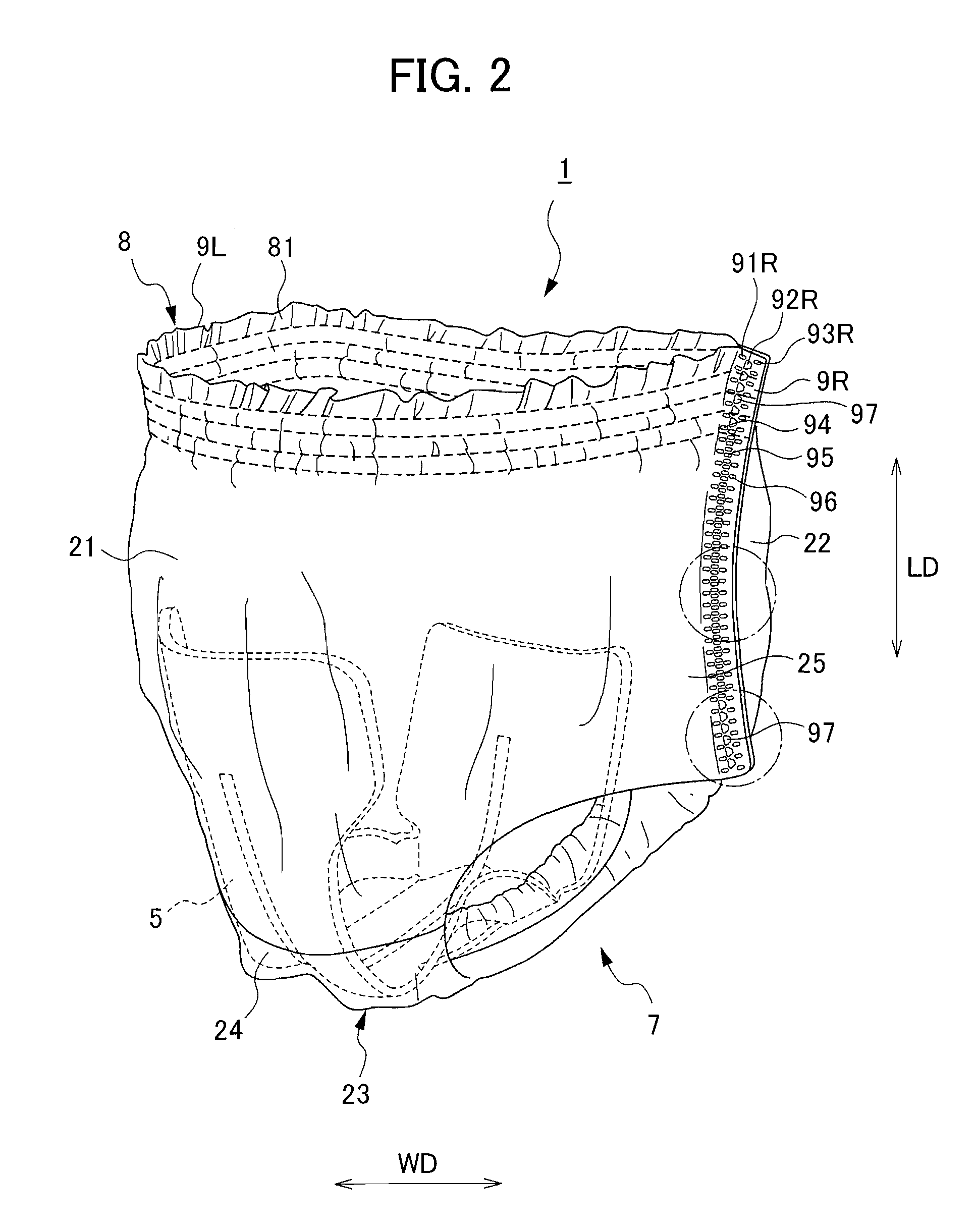

InactiveUS20080140038A1Joining strengthImprove joint strengthBaby linensDomestic articlesPerivulvar areaEngineering

The present invention provides an absorbent article in which a joining strength between sheet-shaped members is improved. A joint portion which joins a front trunk-surrounding region and a rear trunk-surrounding region of the absorbent article to each other has a first joint region arranged continuously along an outer edge and the second joint portion arranged continuously in a region closer to the outer edge than the first joint region, substantially parallel to the first joint region. The sum of the areas of the plurality of first joint portions in the first joint region is less than the sum of the areas of the second joint portions in the second joint region.

Owner:UNI CHARM CORP

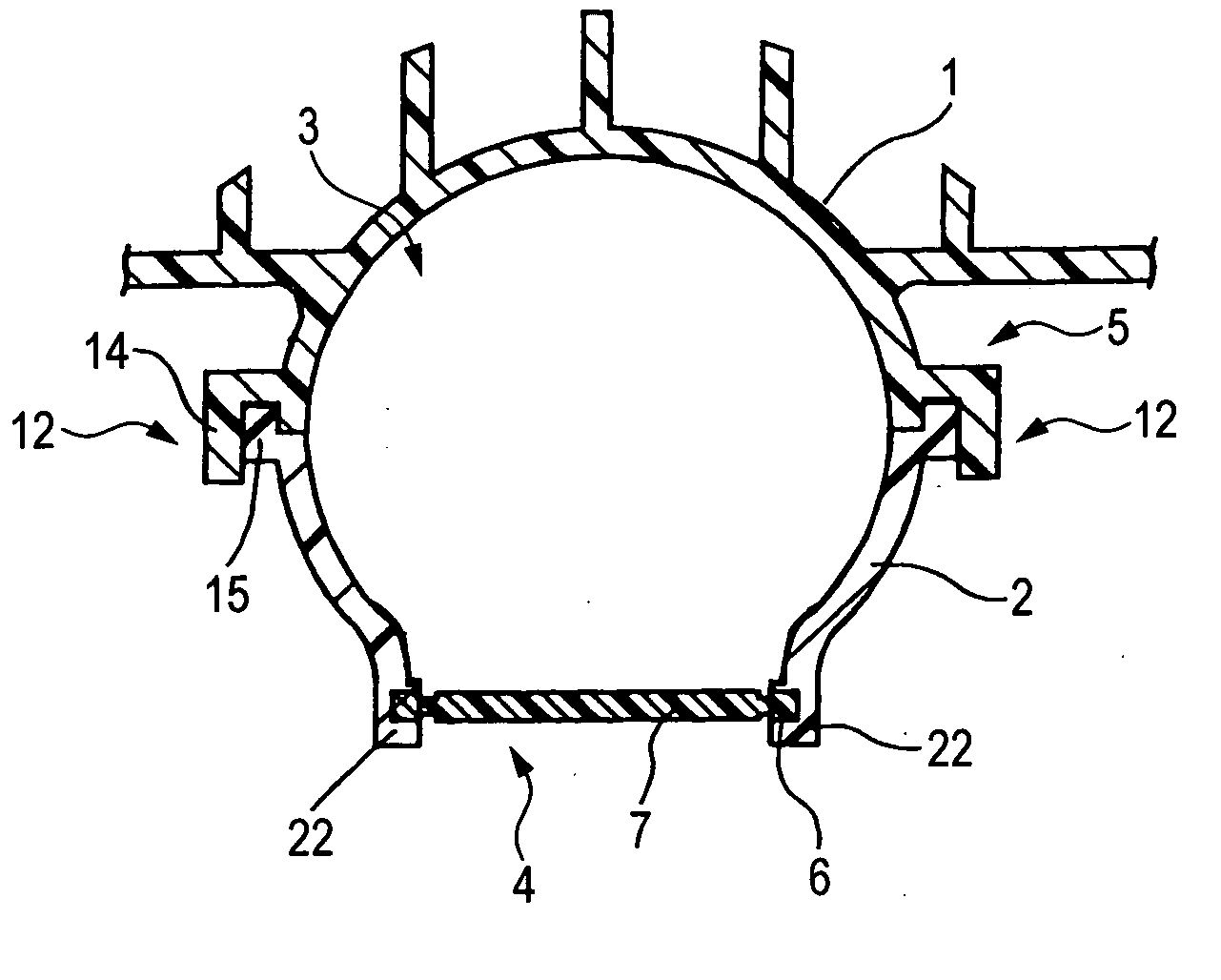

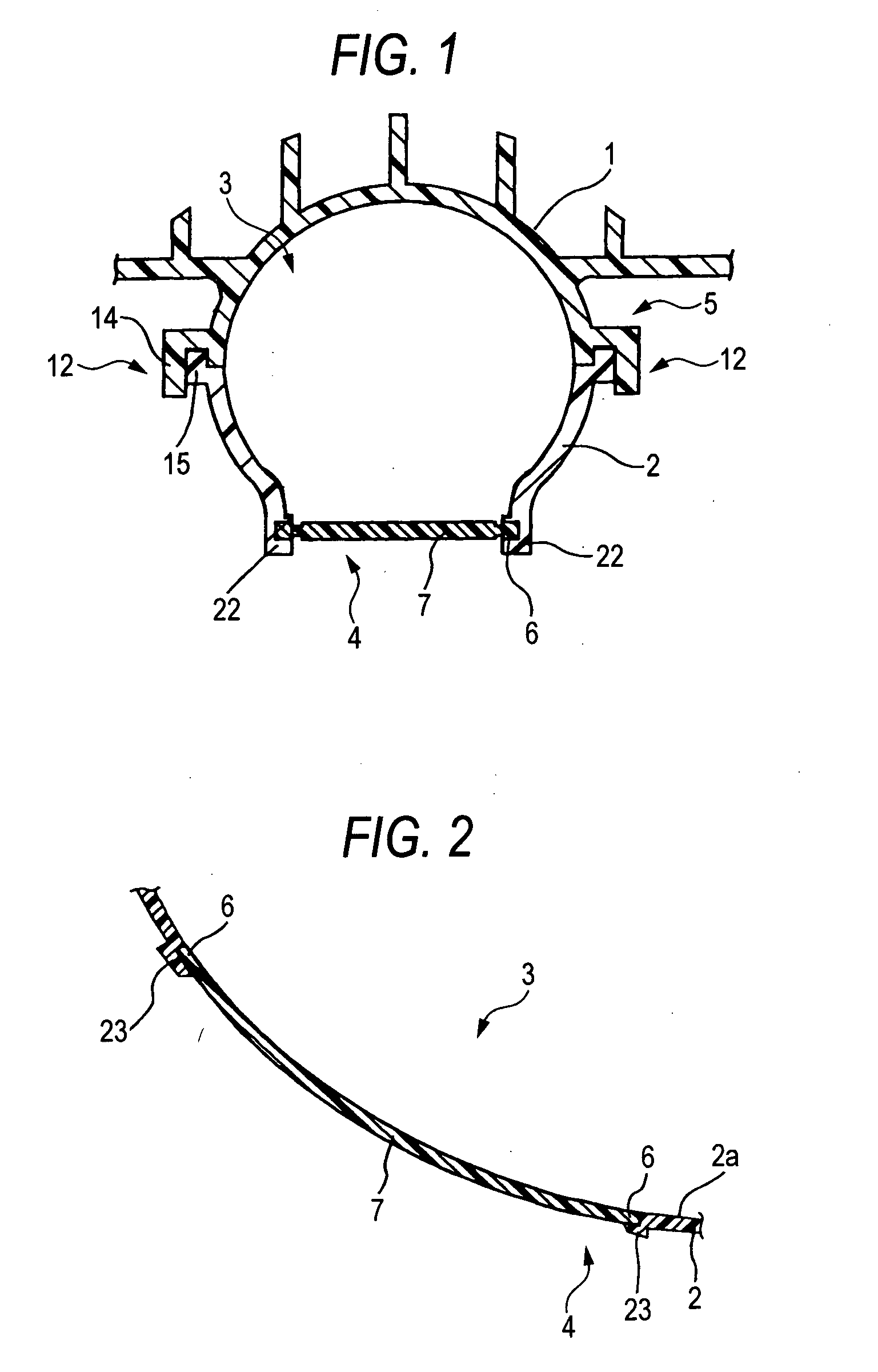

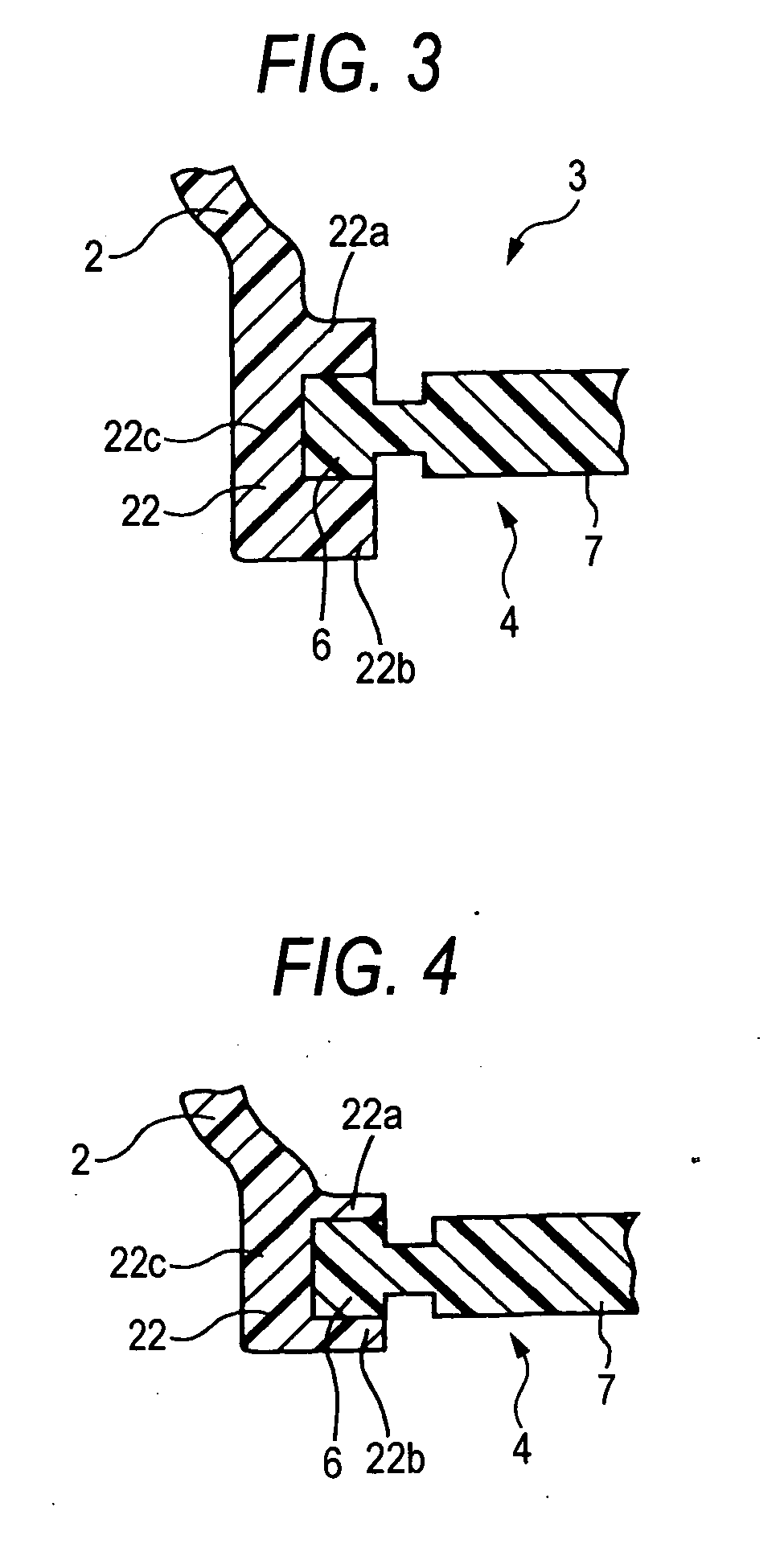

Intake duct

ActiveUS7322381B2Reduce the amount of solutionJoining strengthMachines/enginesRigid pipesEngineeringInternal combustion engine

A duct main body is formed into a hollow tubular shape having in an interior thereof an intake passageway for introducing outside air into an internal combustion engine by connecting integrally a plurality of divided bodies such as a first divided body and a second divided body which are formed of a thermoplastic resin and has in a duct wall of the second divided body an opening which establishes a communication between the inside and outside of the intake passageway. An air-permeable member is insert molded in the second divided body in such a manner as to cover the opening. The air-permeable member has on an outer edge thereof a joining portion which is impregnated with the thermoplastic resin. The second divided body has in at least part of an inner peripheral edge of the opening a vertical wall portion which protrudes outwards from the duct wall of the second divided body along an inner edge of the opening, and at least part of the joining portion of the air-permeable member is embedded in the vertical wall portion in such a manner as to be held therein in a thickness direction.

Owner:TOYODA GOSEI CO LTD

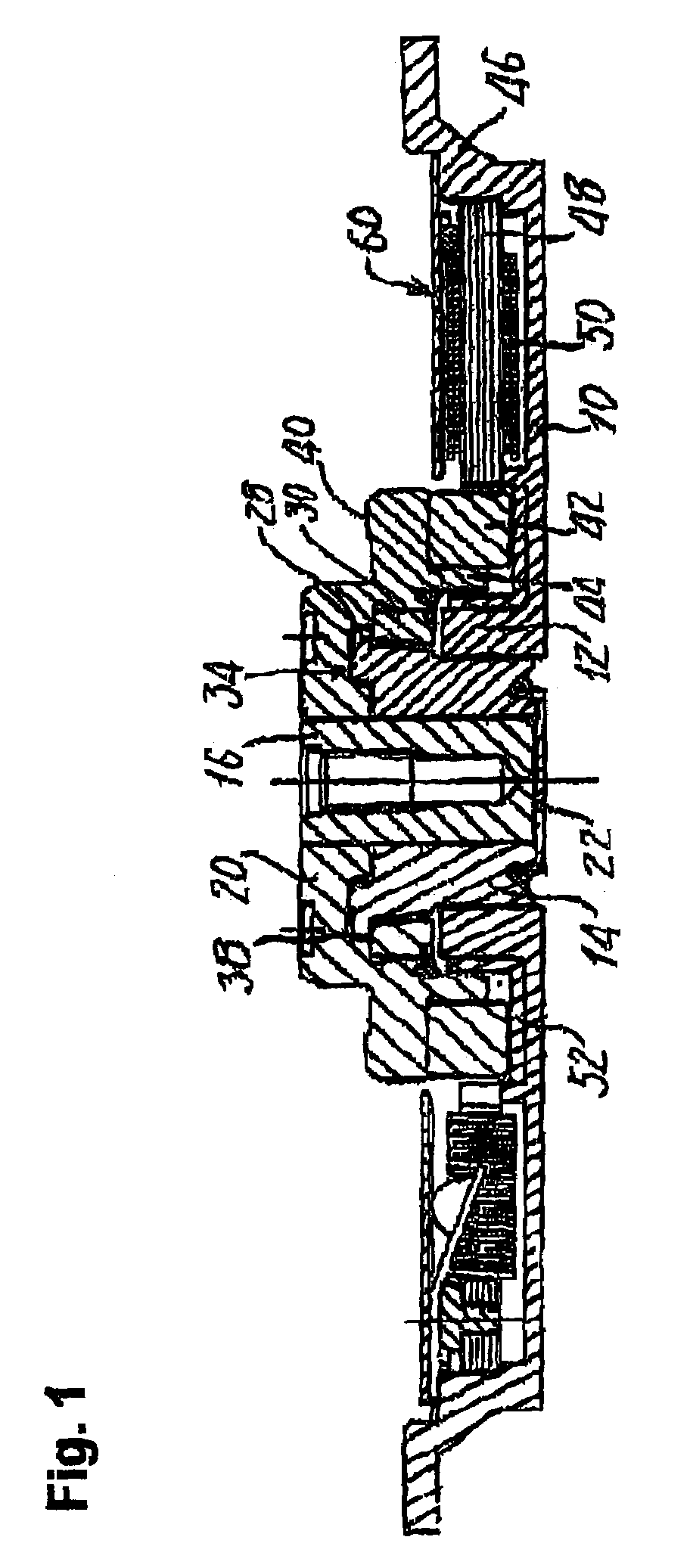

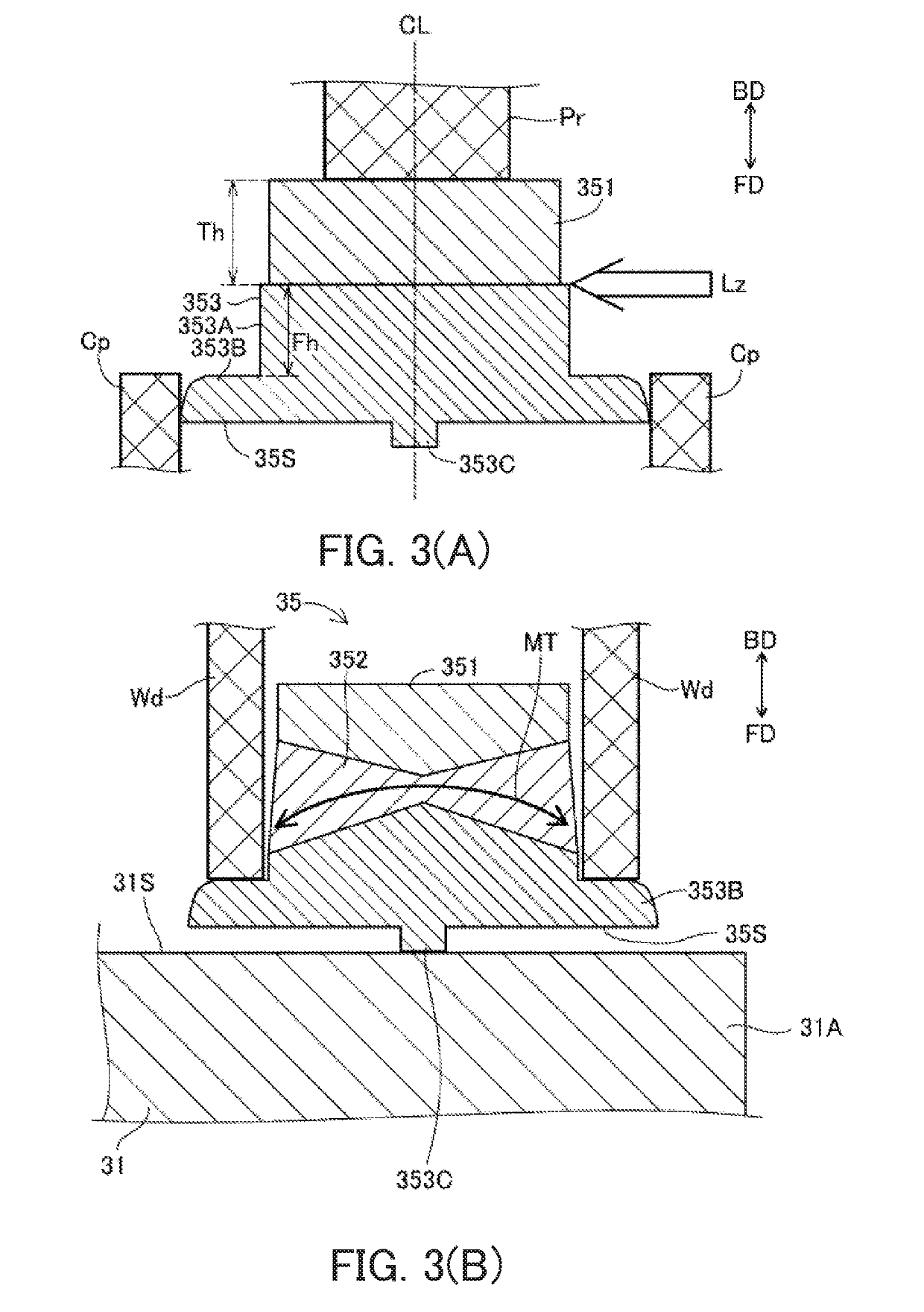

Motors with oil dynamic pressure bearing, oil dynamic pressure bearing devices and method for manufacturing the same

InactiveUS7059771B2Improve rigidityIncrease dynamic pressureShaftsBearing componentsEngineeringDynamic pressure

A motor with fluid dynamic pressure bearing is disclosed. The motor includes a dynamic pressure bearing member having a concave section that is concave in an axial direction, a rotary shaft that is rotatively supported by the dynamic pressure bearing, and a rotary member that is joined to the rotary shaft in one piece along a joint section between the rotary member and the rotary shaft, and rotatively driven by electromagnetic drive force, an expanded diameter section that is provided on the dynamic pressure bearing member. A fallout preventing member is provided on the rotary member, which overlaps the expanded diameter section of the dynamic pressure bearing member in the axial direction to prevent the rotary shaft from falling out of the dynamic pressure bearing member. The concave section of the rotary member opposes in the axial direction the expanded diameter section of the dynamic pressure bearing member, wherein the expanded diameter section is placed inside the concave section, and the joining section between the rotary member and the rotary shaft overlaps the expanded diameter section in the radial direction.

Owner:NIDEC CORP

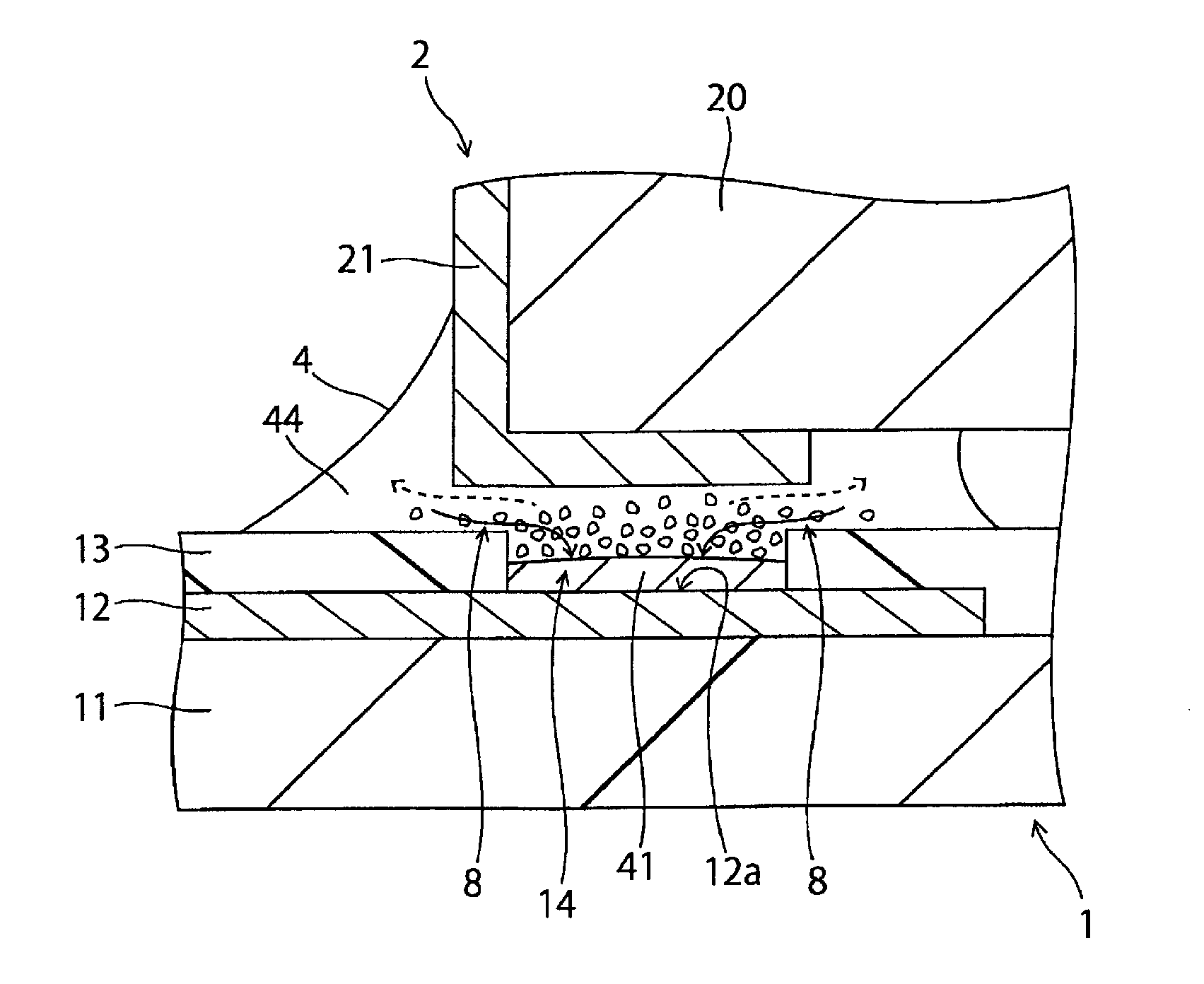

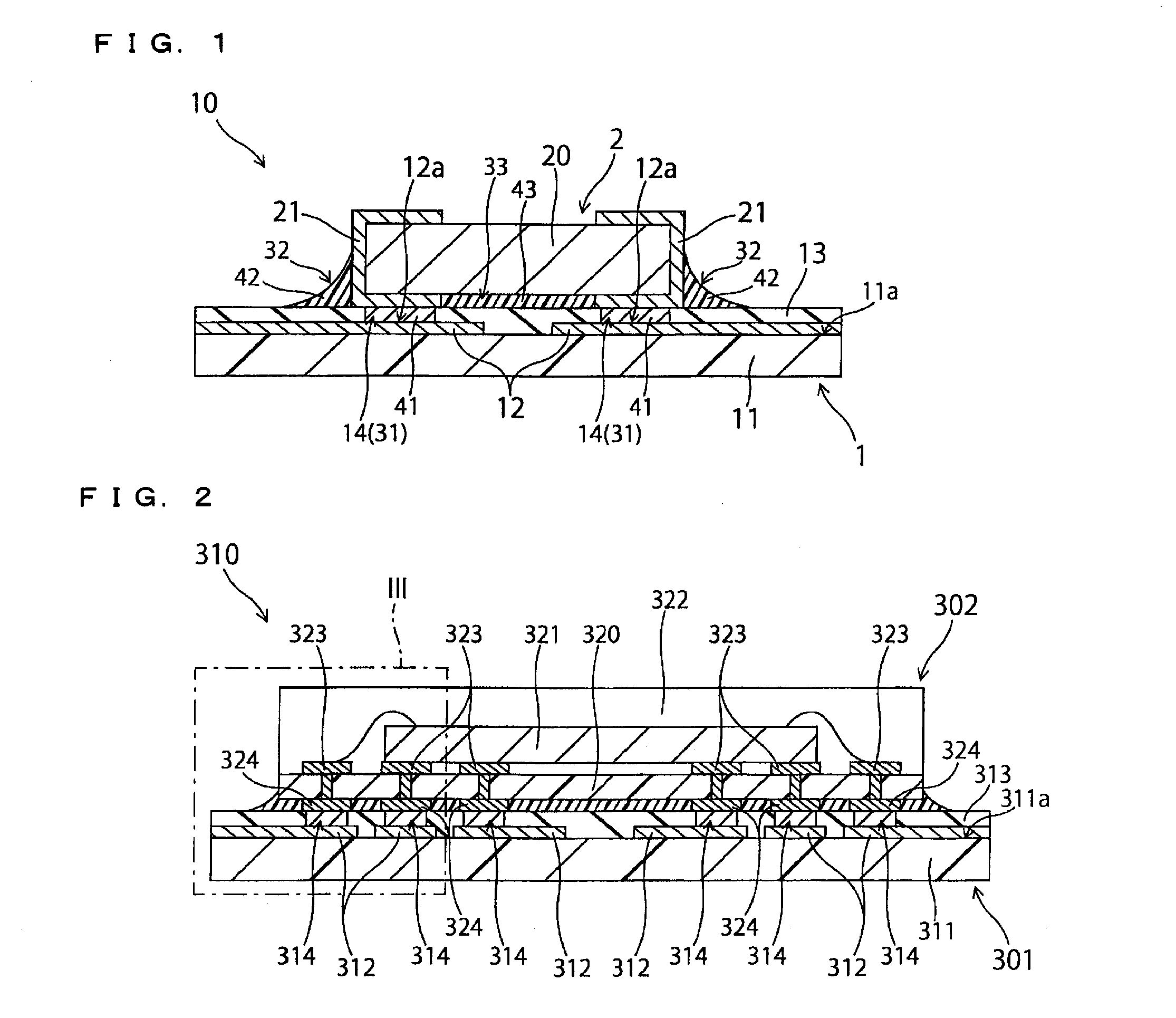

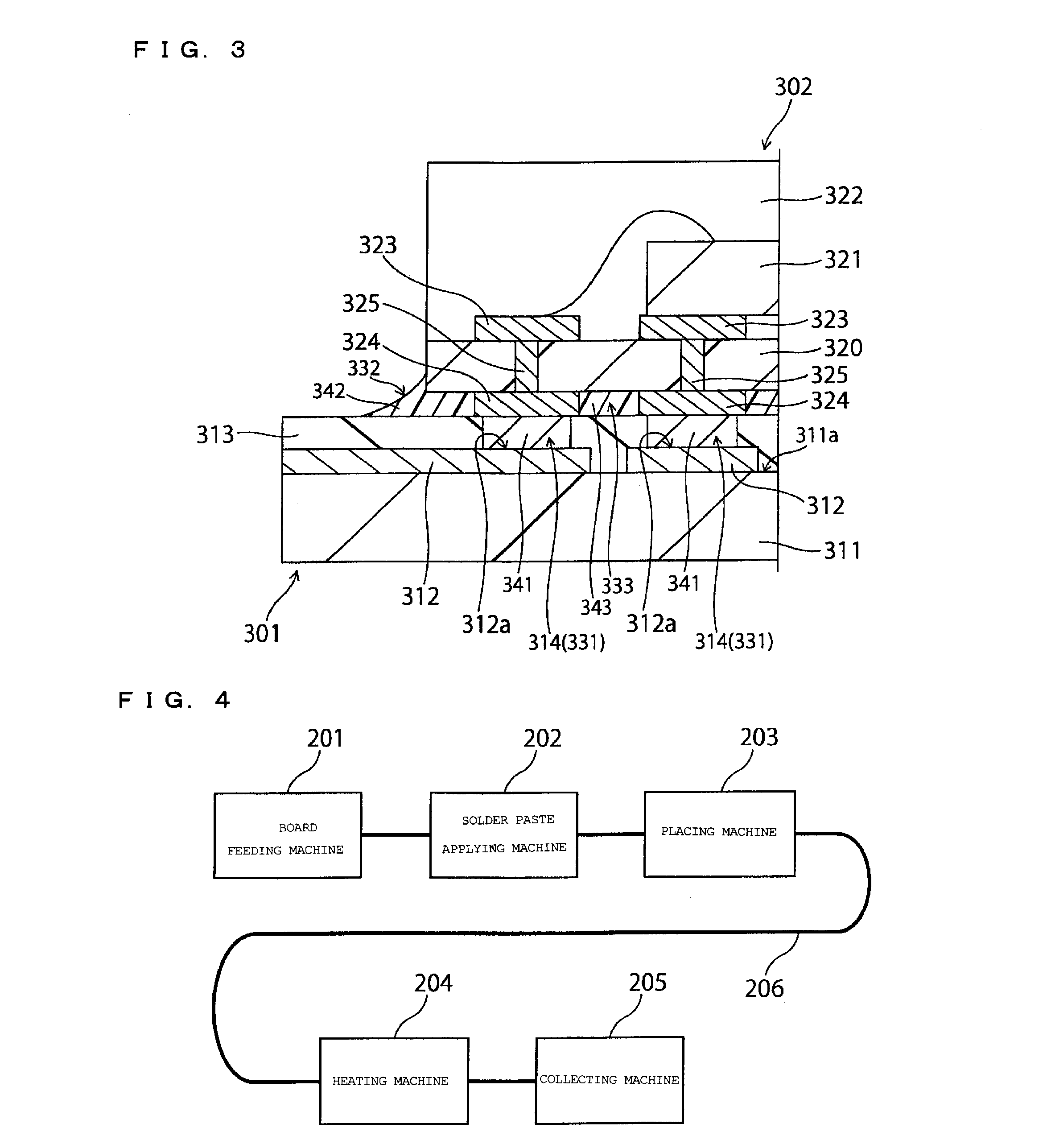

Method and system for producing component mounting board

ActiveUS20140158751A1Joining strengthHigh joining strengthFinal product manufacturePrinted circuit aspectsResistEngineering

A wiring board on which an electronic component is to be mounted includes a resist having an opening exposing a joint face which is part of the surface of a wiring layer and to which a terminal of the electronic component is to be joined. In the placing step, the electronic component is placed on the wiring board such that the terminal covers the opening entirely and contacts the solder paste applied onto the joint face. Next, the solder paste applied onto the joint face is heated to melt solder and soften thermosetting resin. This allows the solder to gather in a first space within the opening closed with the wiring layer and the electronic component, while allowing the thermosetting resin to gather in a second space formed between a top side of the resist and a lateral side of the electronic component.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

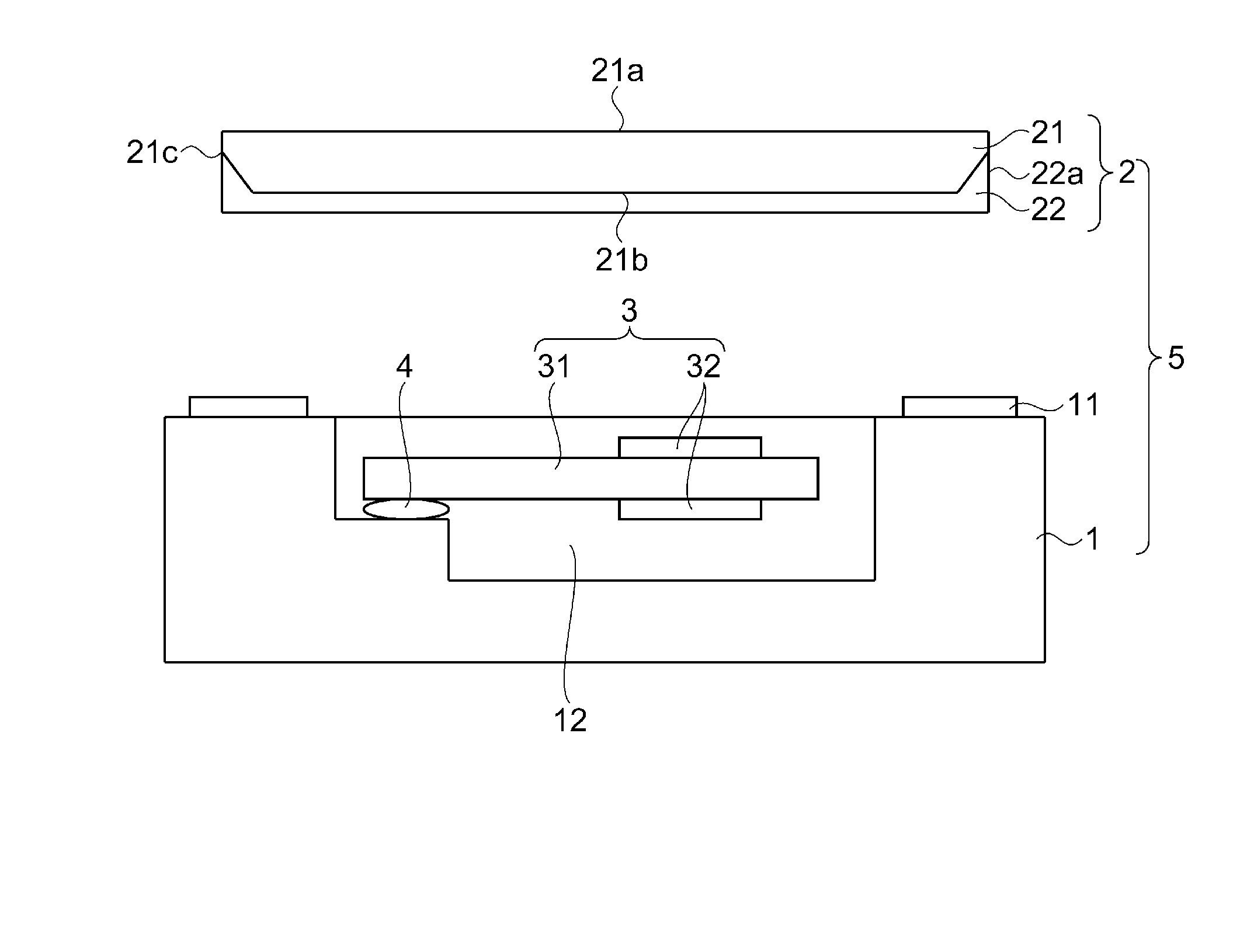

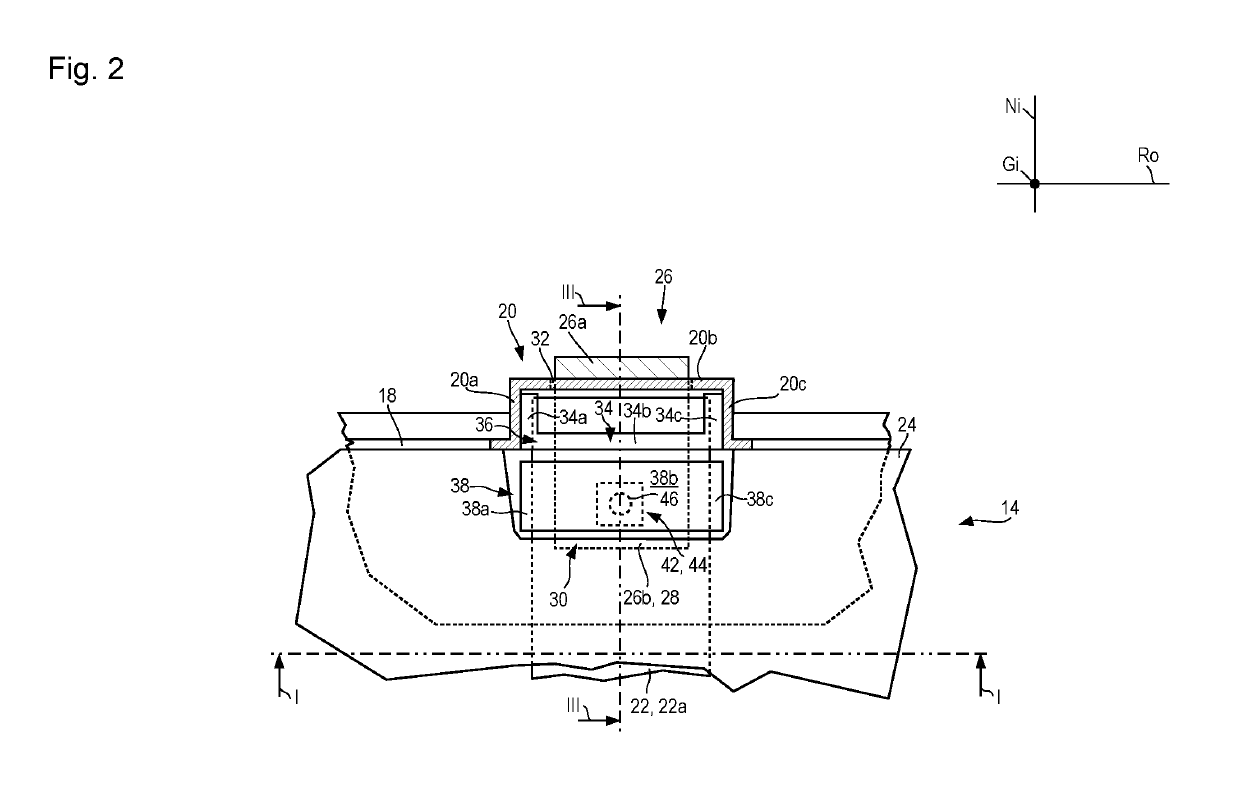

Package, electronic device, method of manufacturing electronic device, electronic apparatus, and moving object

ActiveUS20140291010A1Improve reliabilityJoining strengthCoupling device connectionsCapsElectronMaterials science

A package includes a base portion, and a lid which is placed on the base portion to define an inner space with the base portion and has a metal plate layer and a brazing material layer that is laminated on the metal plate layer, in which the base portion has a metalized layer which is joined with the brazing material layer around the inner space in a plane view, and the brazing material layer has a protrusion which protrudes in a opposite direction of the base portion on an outer peripheral side surface of the metal plate layer.

Owner:SEIKO EPSON CORP

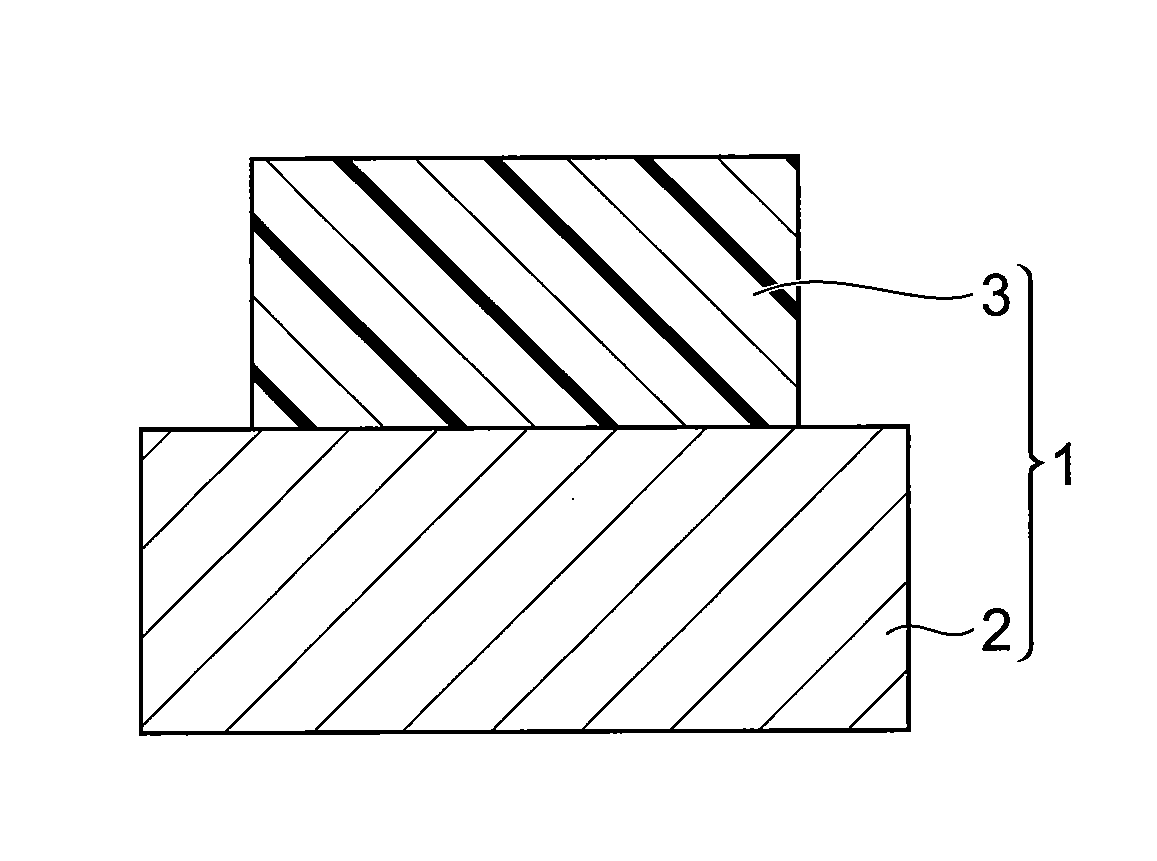

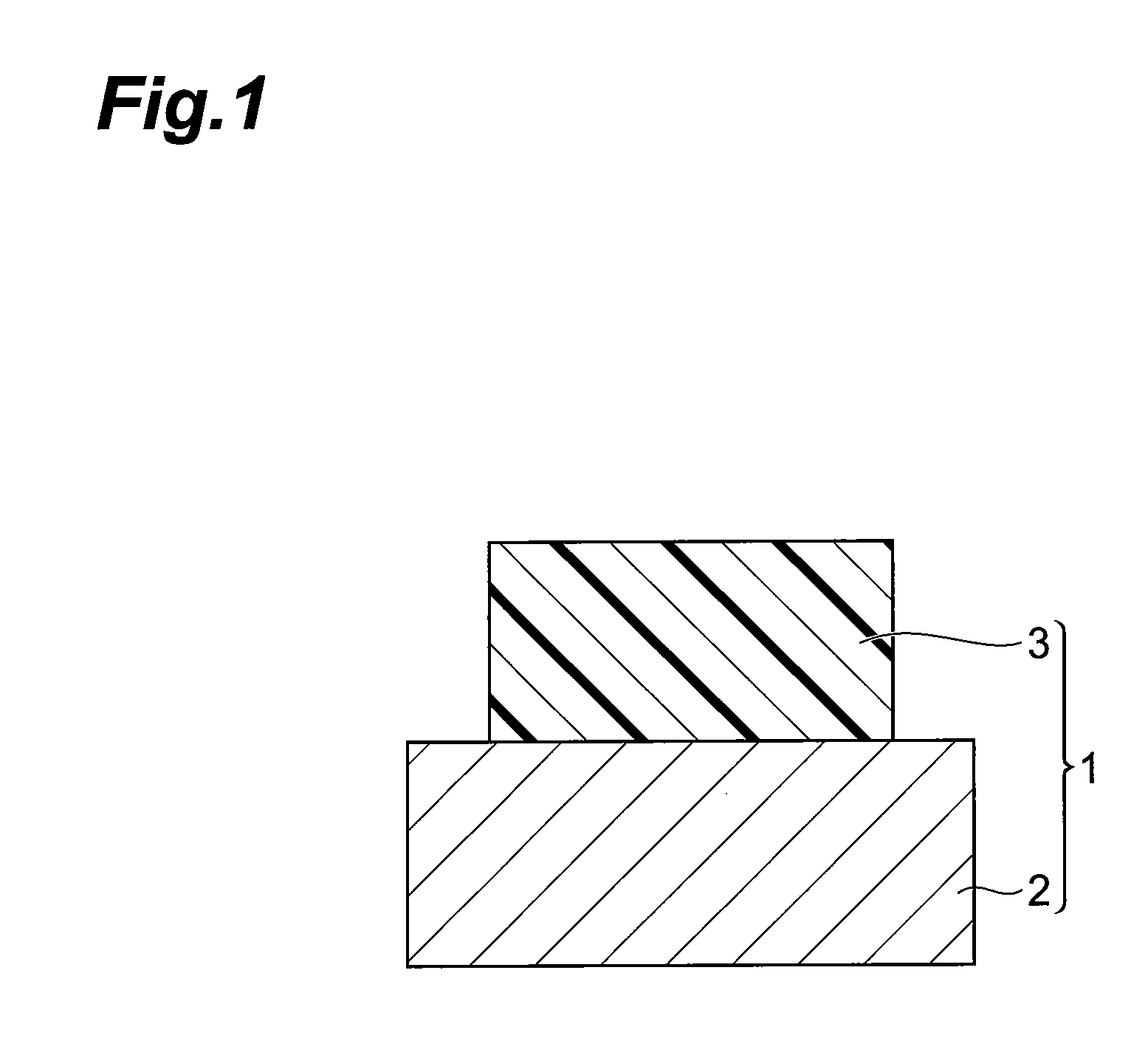

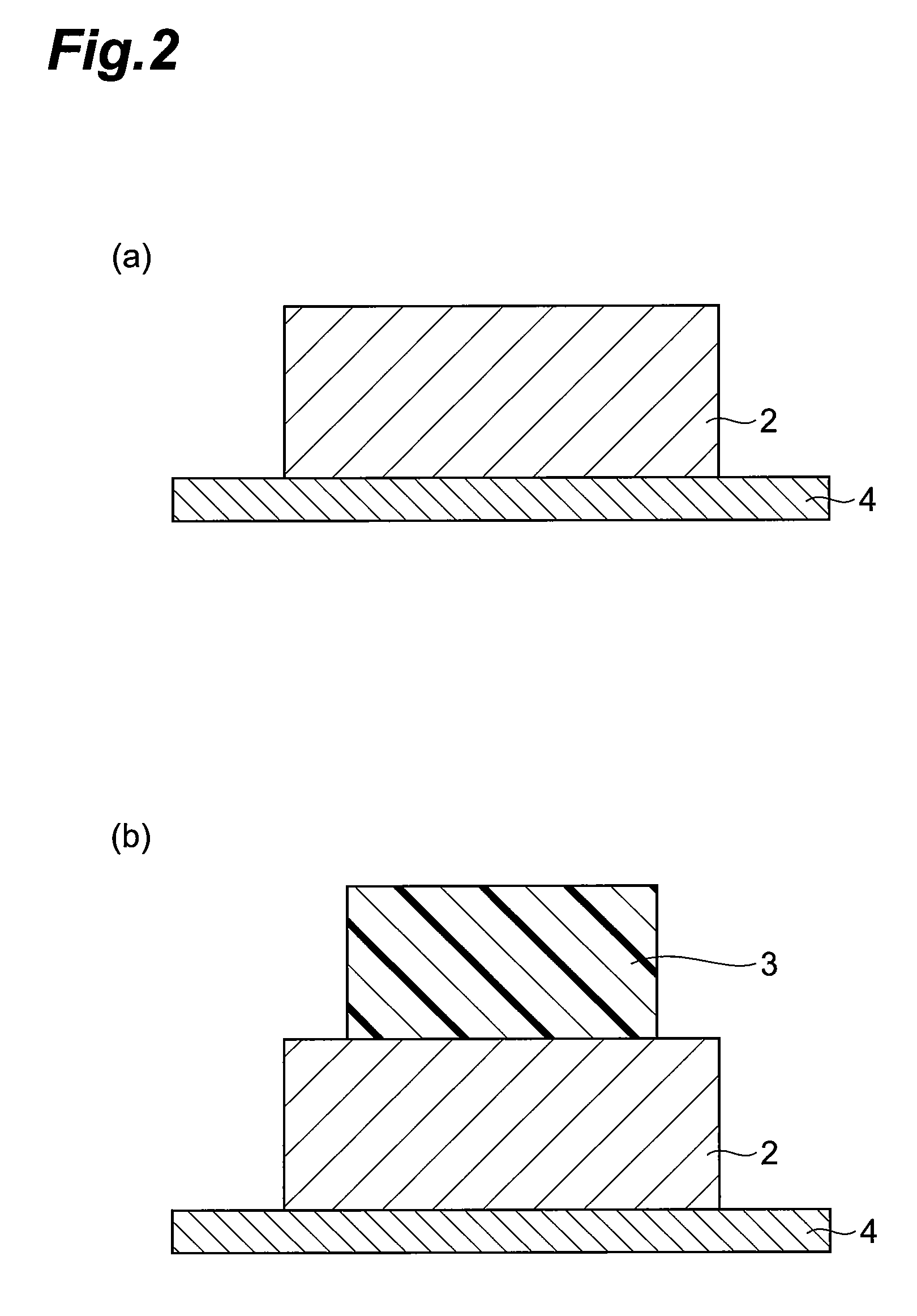

Production method for ceramic-resin composite

InactiveUS20110232826A1Improve joint strengthJoining strengthSynthetic resin layered productsLaminationResin compositeComposite material

A production method for a ceramic-resin composite, comprising a welding step of ultrasonically welding a ceramic component and a thermoplastic resin component, wherein at the welding step, at least one of the ceramic component and the thermoplastic resin component has been heated.

Owner:SUMITOMO CHEM CO LTD

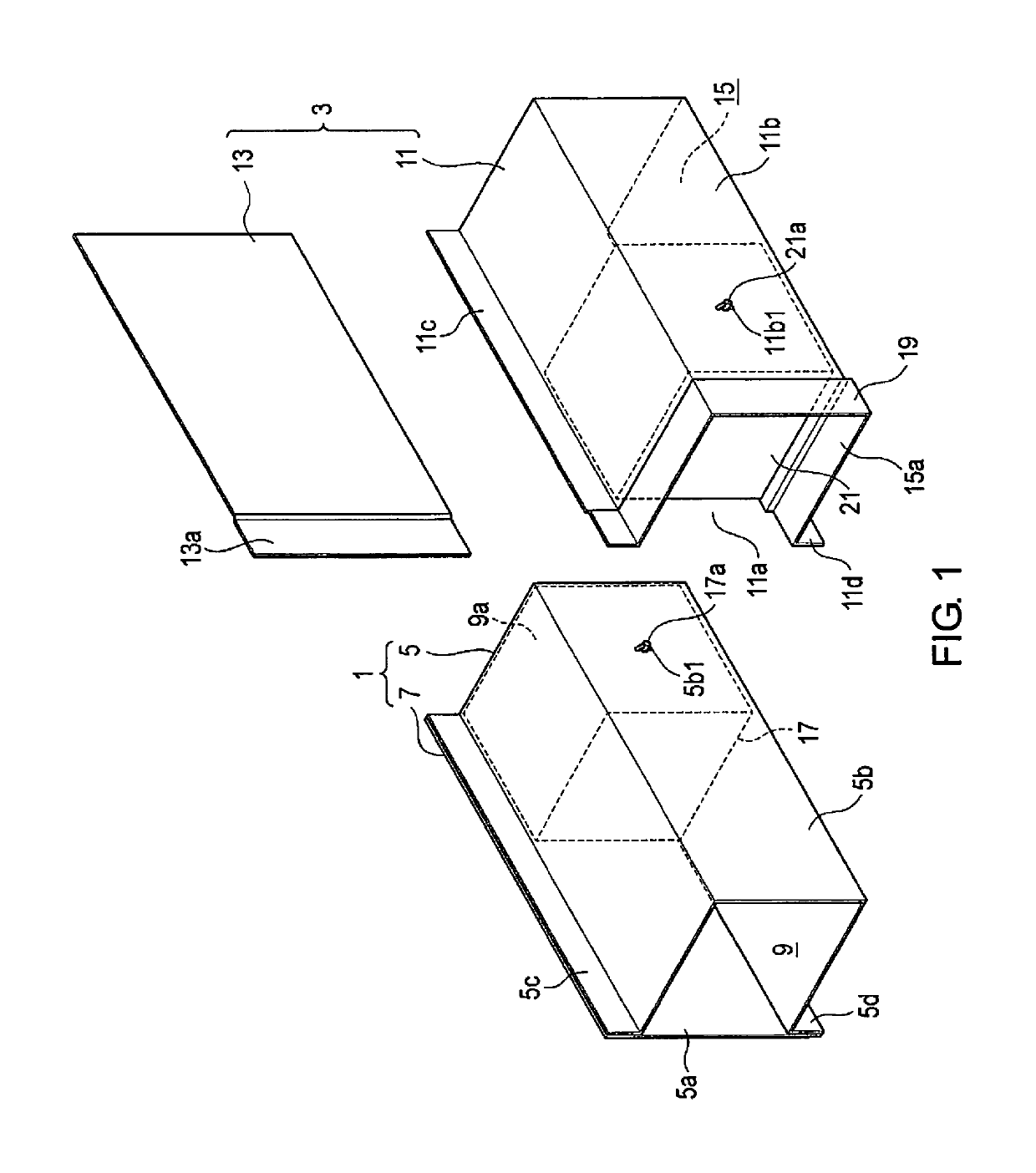

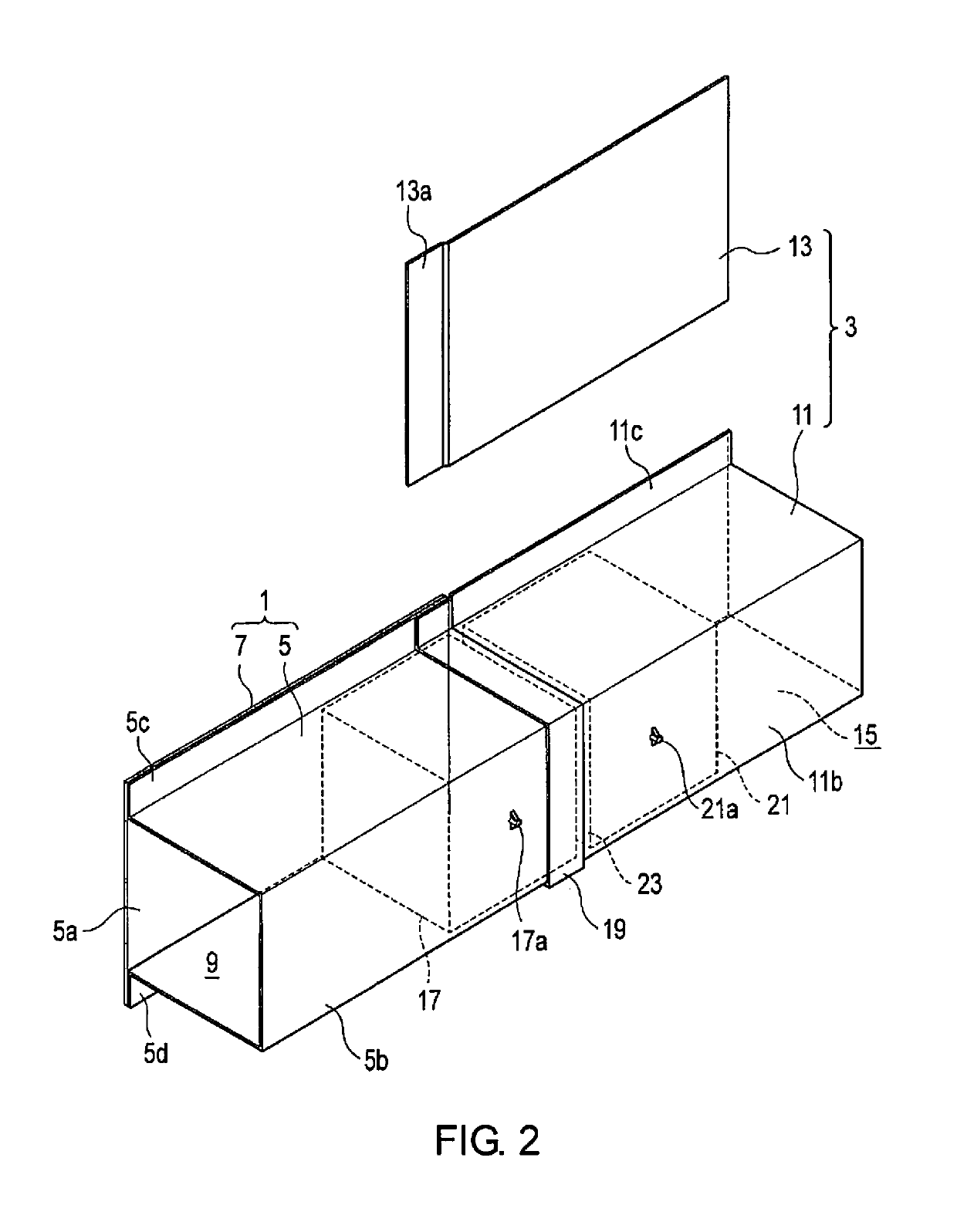

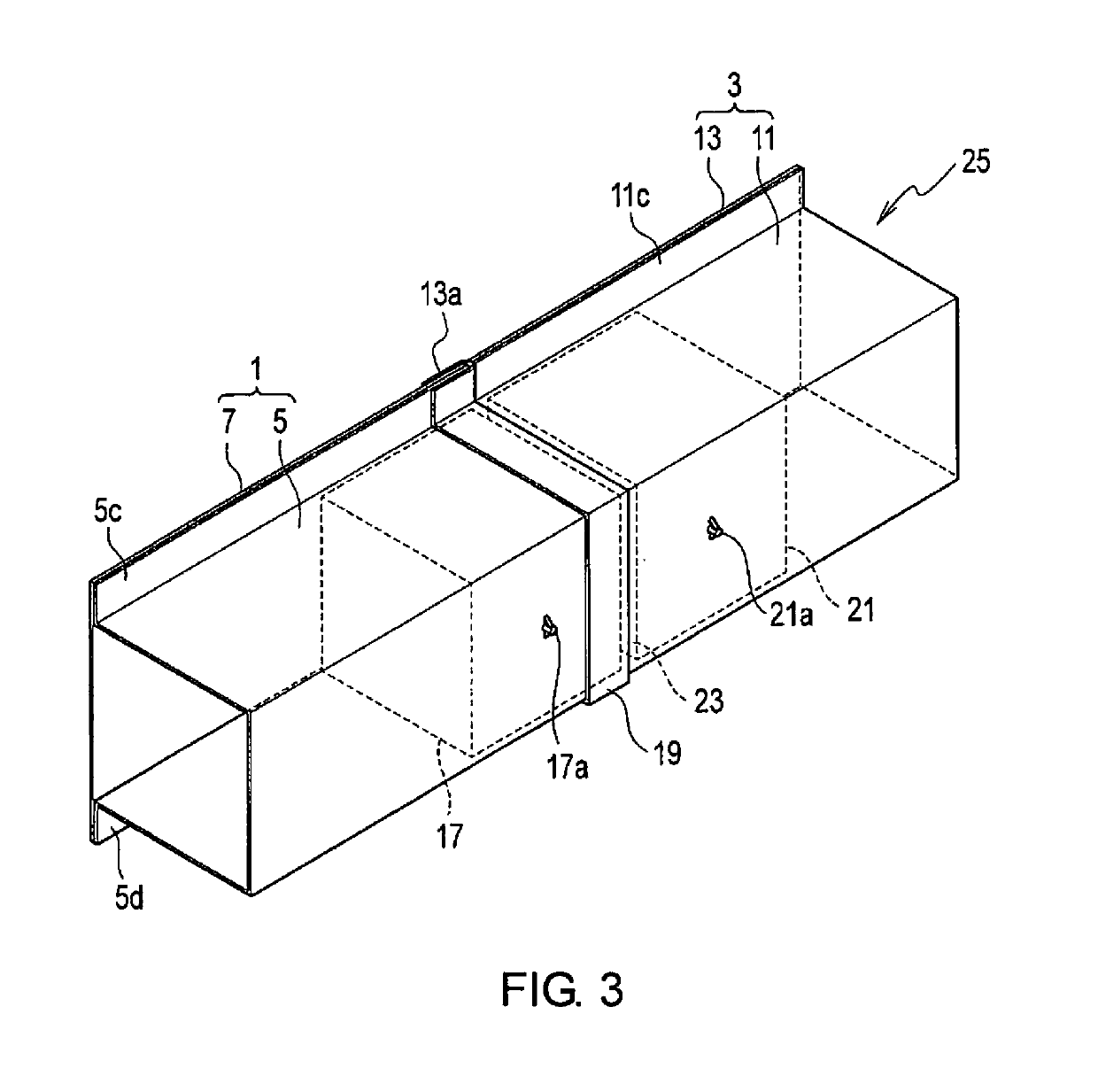

Intake duct

ActiveUS20070068589A1Increase joining strengthJoin property be improveMachines/enginesRigid pipesInternal combustion engineEngineering

A duct main body is formed into a hollow tubular shape having in an interior thereof an intake passageway for introducing outside air into an internal combustion engine by connecting integrally a plurality of divided bodies such as a first divided body and a second divided body which are formed of a thermoplastic resin and has in a duct wall of the second divided body an opening which establishes a communication between the inside and outside of the intake passageway. An air-permeable member is insert molded in the second divided body in such a manner as to cover the opening. The air-permeable member has on an outer edge thereof a joining portion which is impregnated with the thermoplastic resin. The second divided body has in at least part of an inner peripheral edge of the opening a vertical wall portion which protrudes outwards from the duct wall of the second divided body along an inner edge of the opening, and at least part of the joining portion of the air-permeable member is embedded in the vertical wall portion in such a manner as to be held therein in a thickness direction.

Owner:TOYODA GOSEI CO LTD

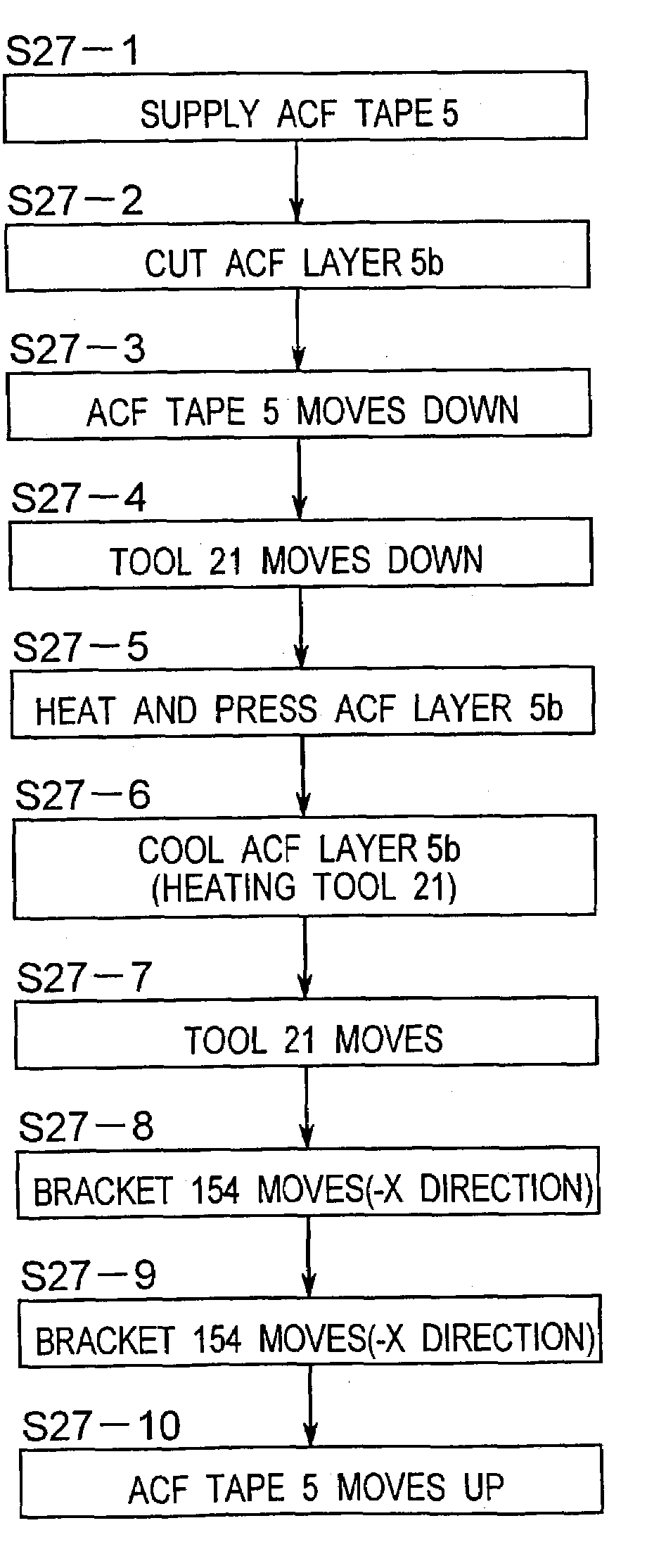

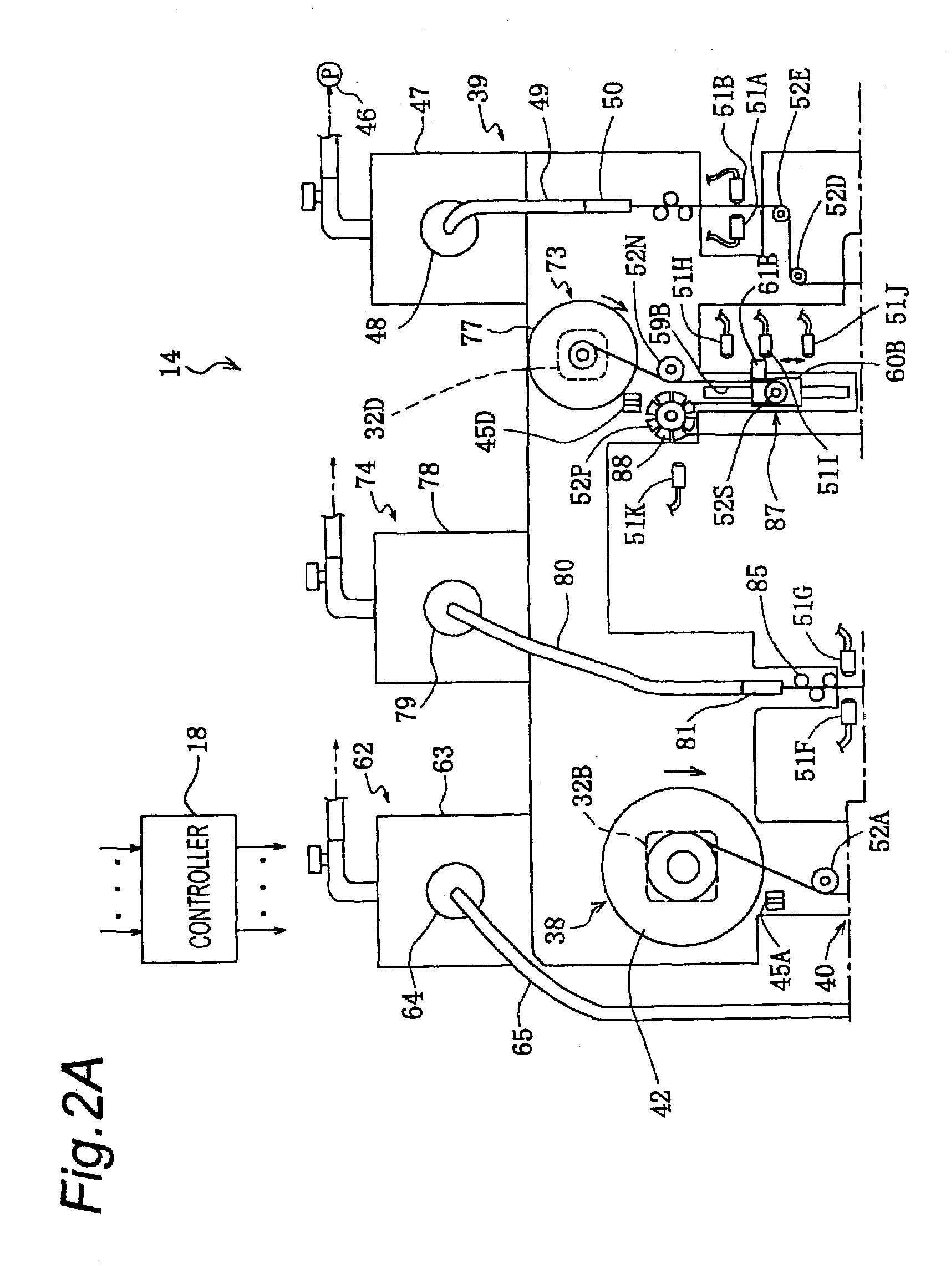

Pressurizing method

InactiveUS7076867B2Joining strengthImprove joint strengthPrinted circuit assemblingLine/current collector detailsEngineeringMechanical engineering

Owner:PANASONIC CORP

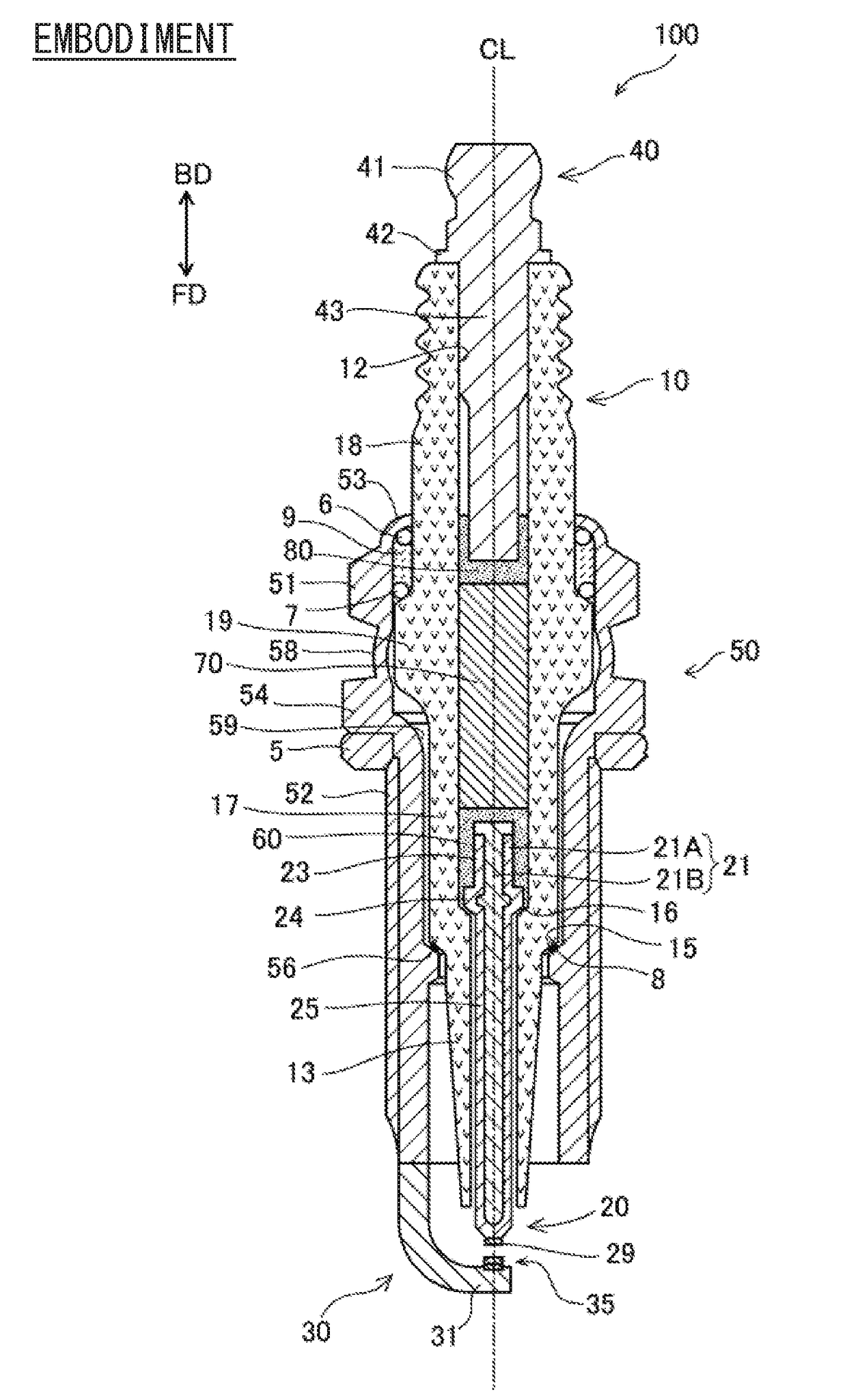

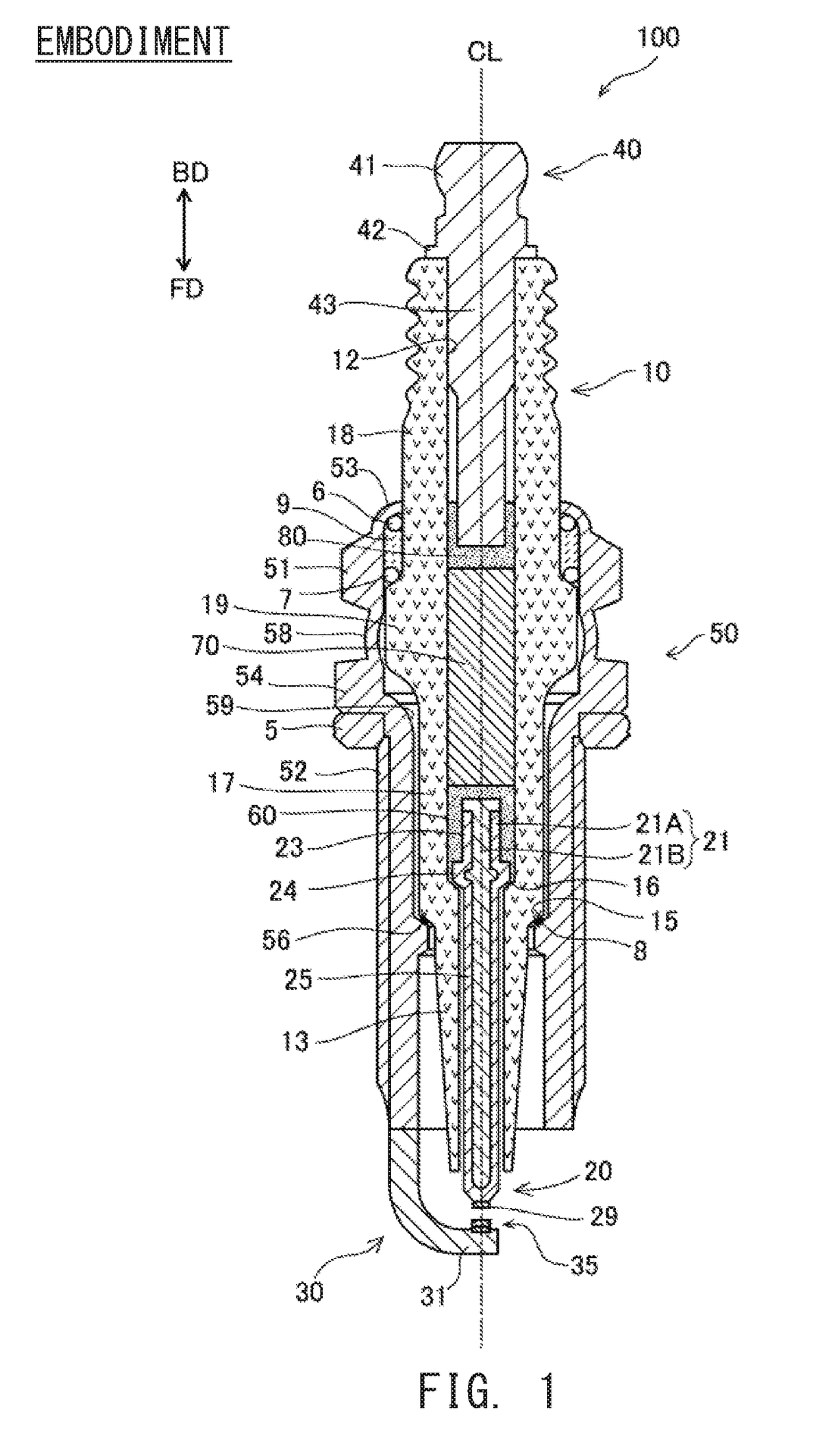

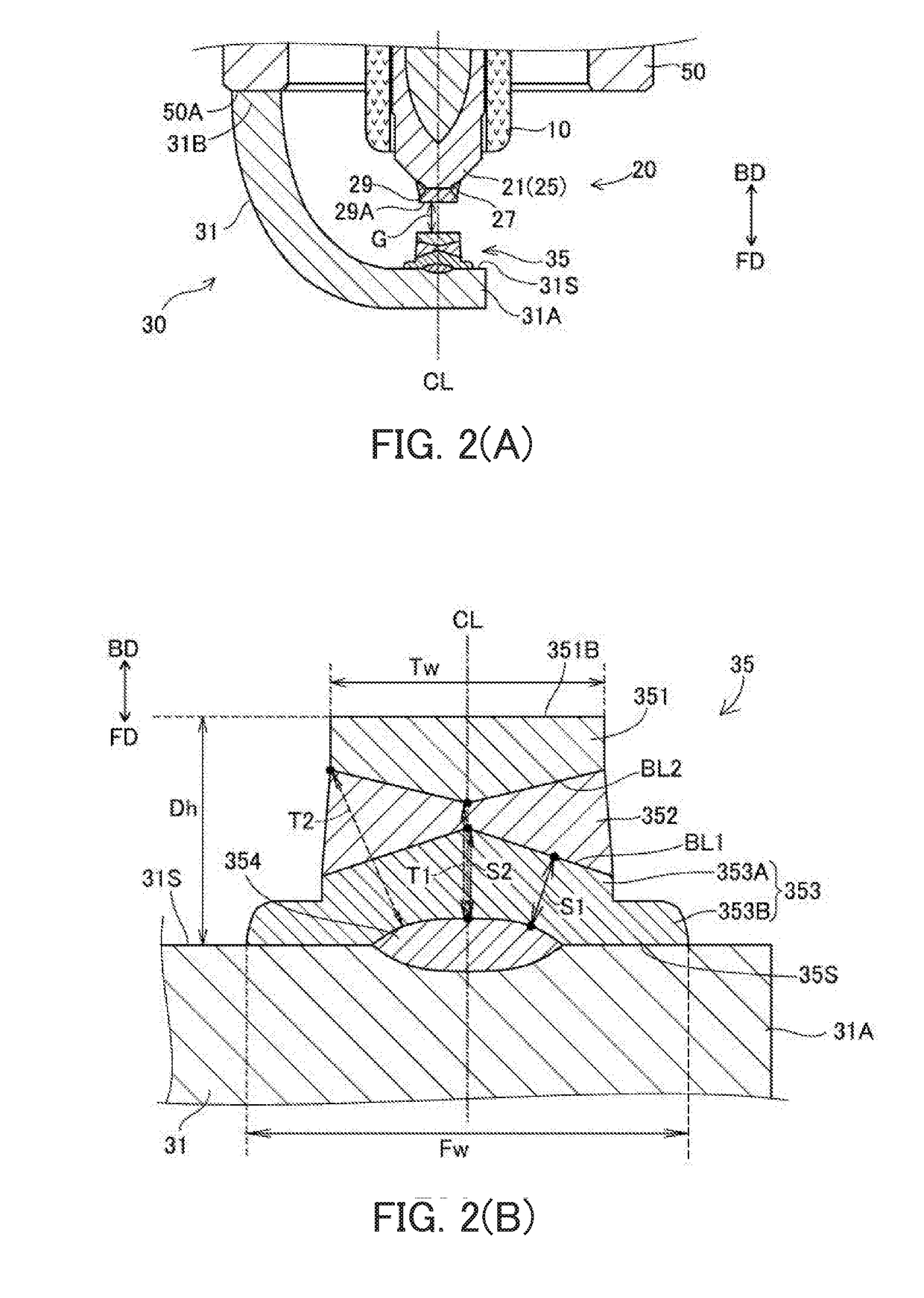

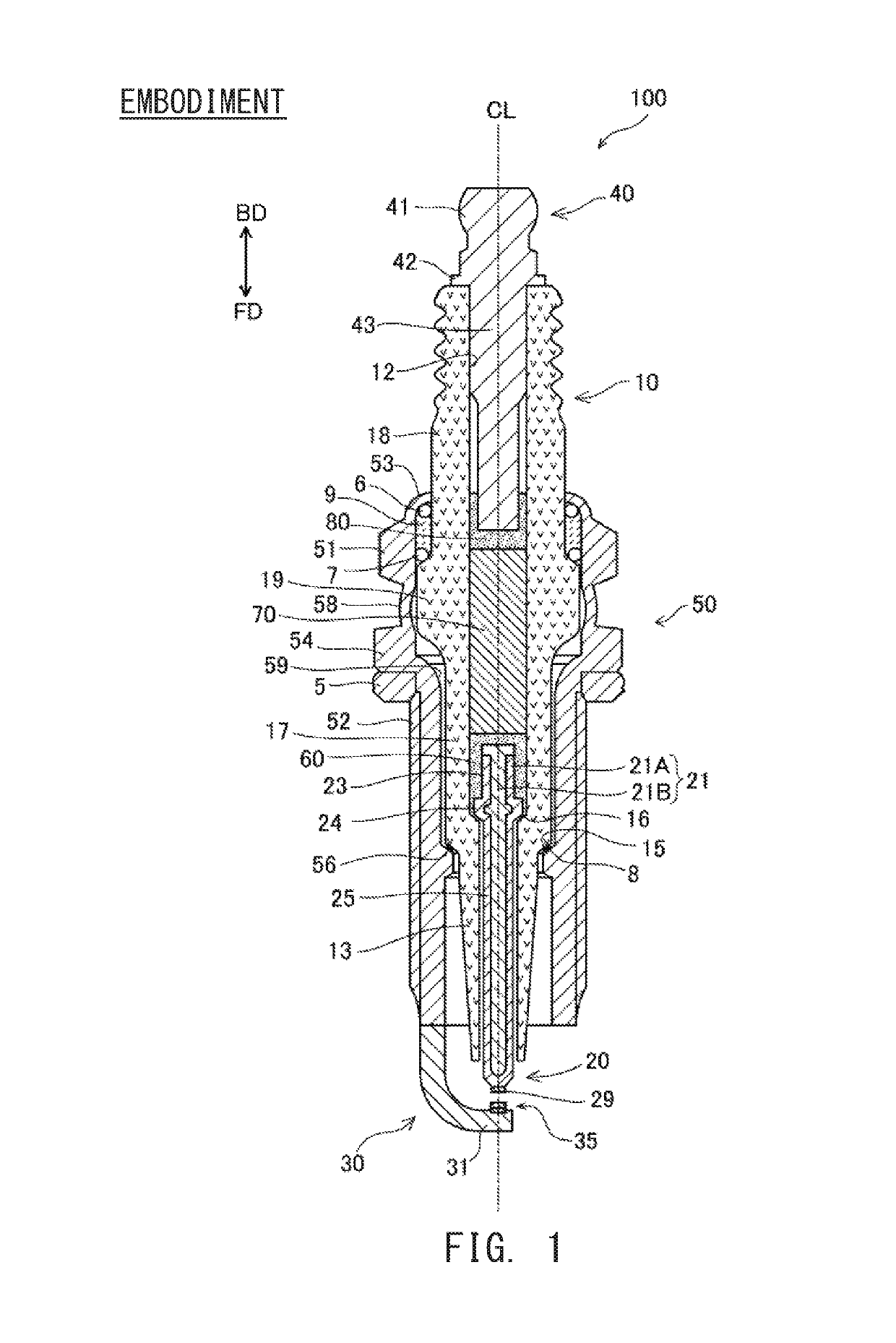

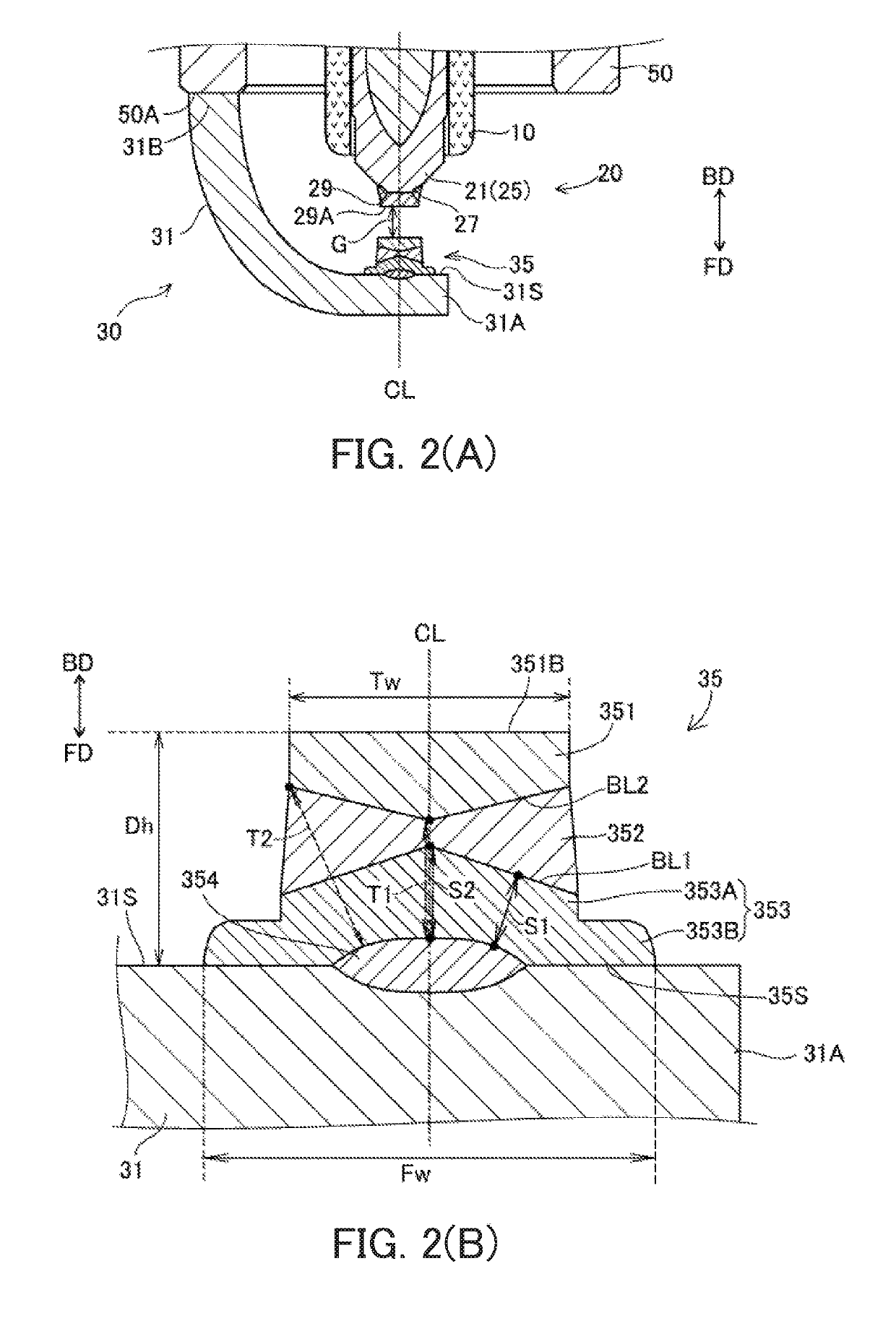

Spark plug

ActiveUS20180323584A1Suppress stressJoining strengthSpark gap detailsSparking plugs manufactureShortest distanceEngineering

An electrode of the spark plug includes a first melt portion formed between a body portion of an intermediate member and a noble metal tip; and a second melt portion that is formed, between a flange portion of the intermediate member and an electrode base material, at least at a position of intersection with an axial line of the noble metal tip. In a cross section including the axial line of the noble metal tip, when: a diameter of the noble metal tip is denoted by Tw; the shortest distance between the second melt portion and a boundary between the first melt portion and the intermediate member is denoted by S1; and the longest distance between the second melt portion and the boundary between the first melt portion and the intermediate member is denoted by S2, 1.0 mm≤Tw≤1.2 mm and (S2−S1)≤0.3 mm are met.

Owner:NGK SPARK PLUG CO LTD

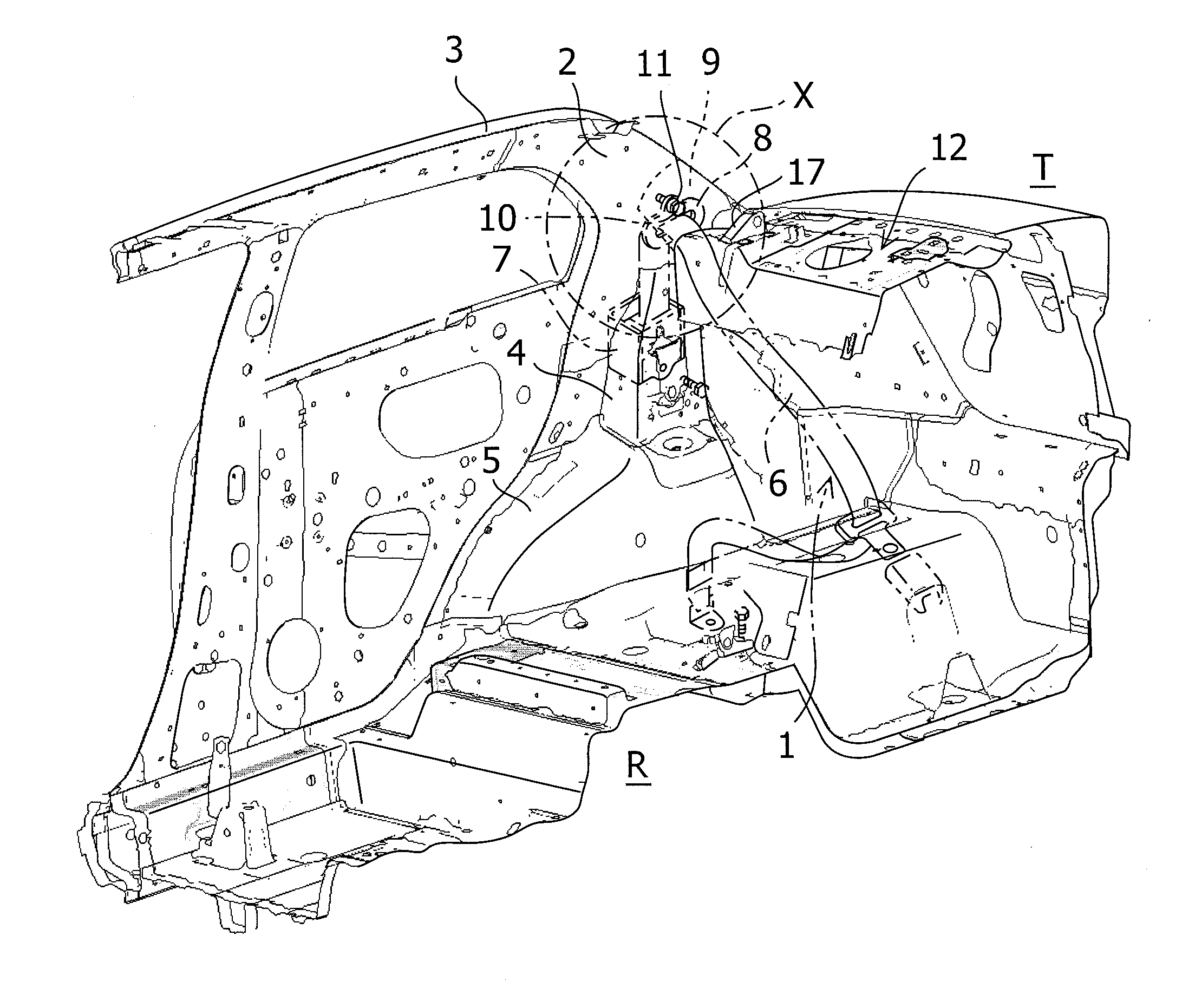

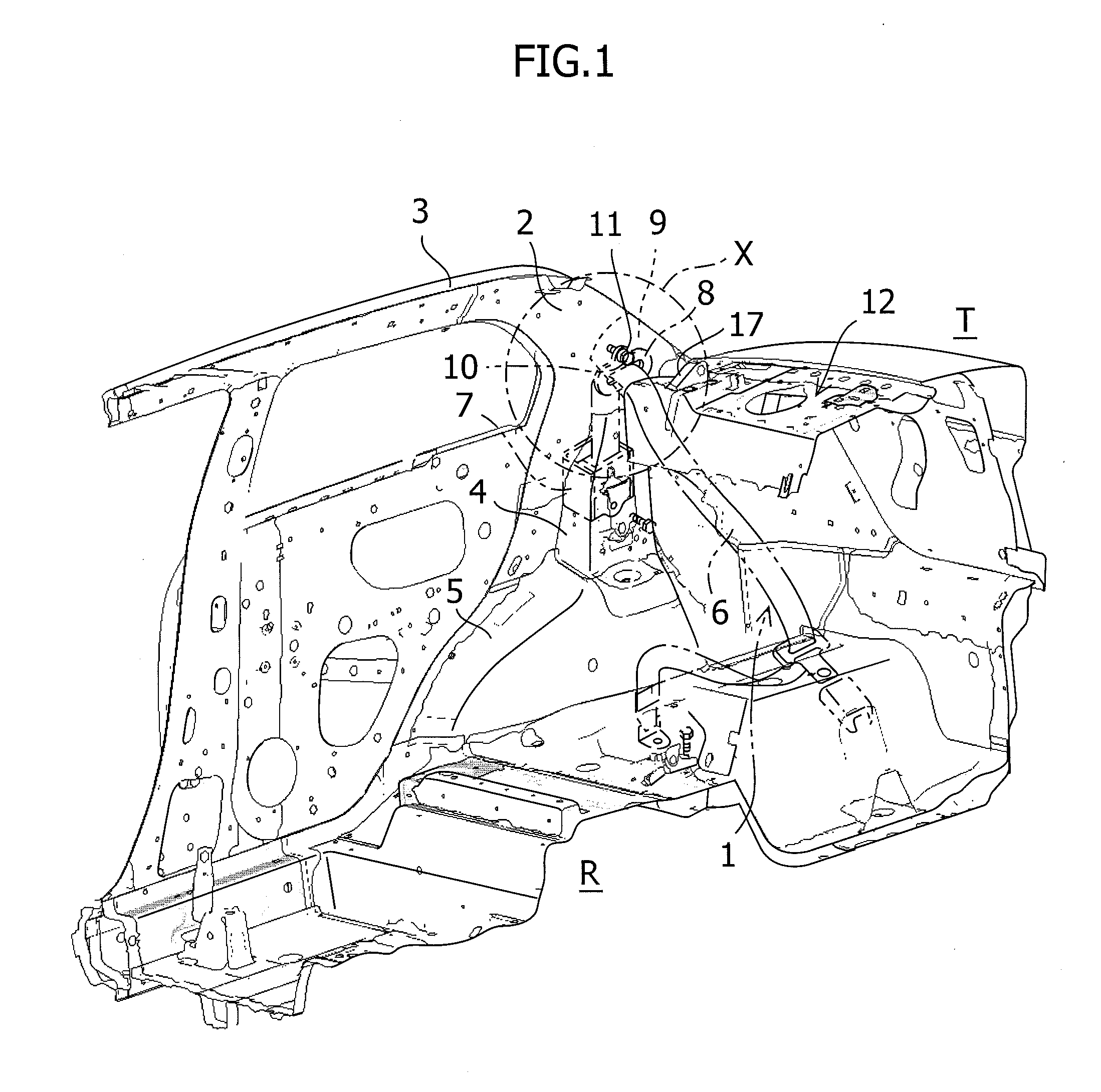

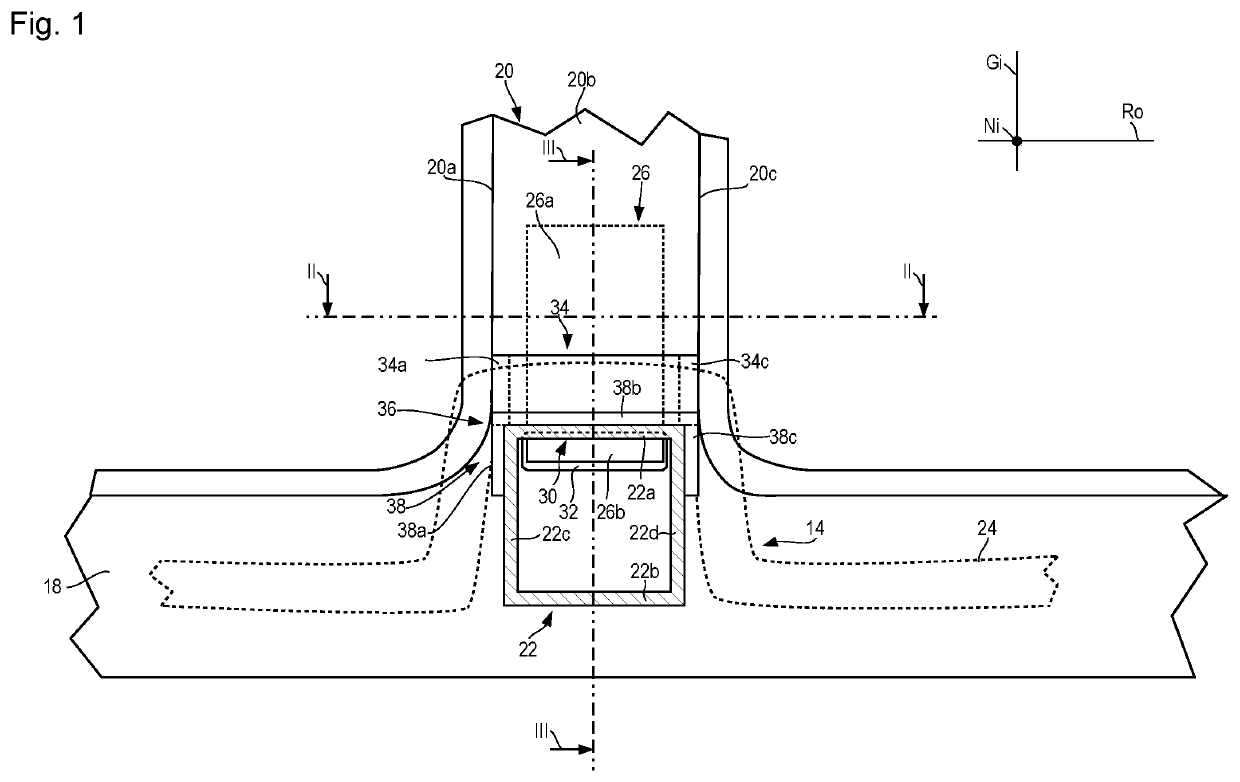

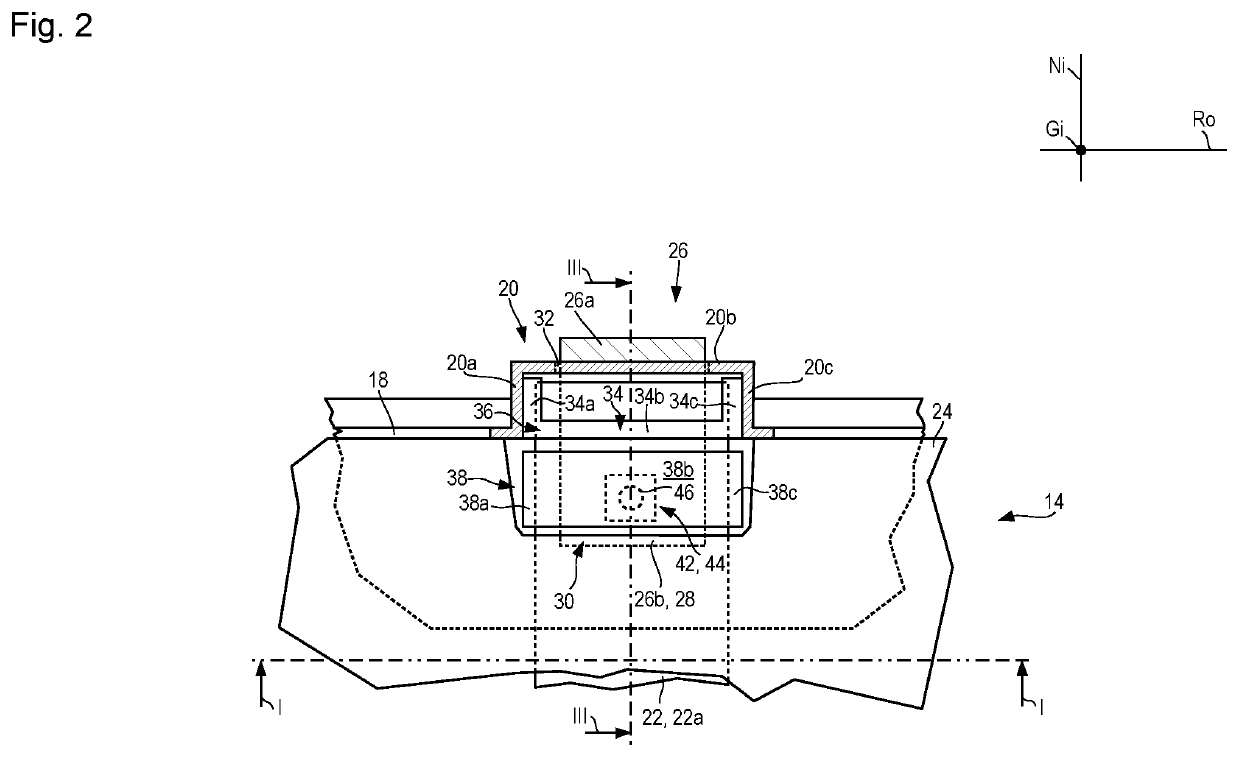

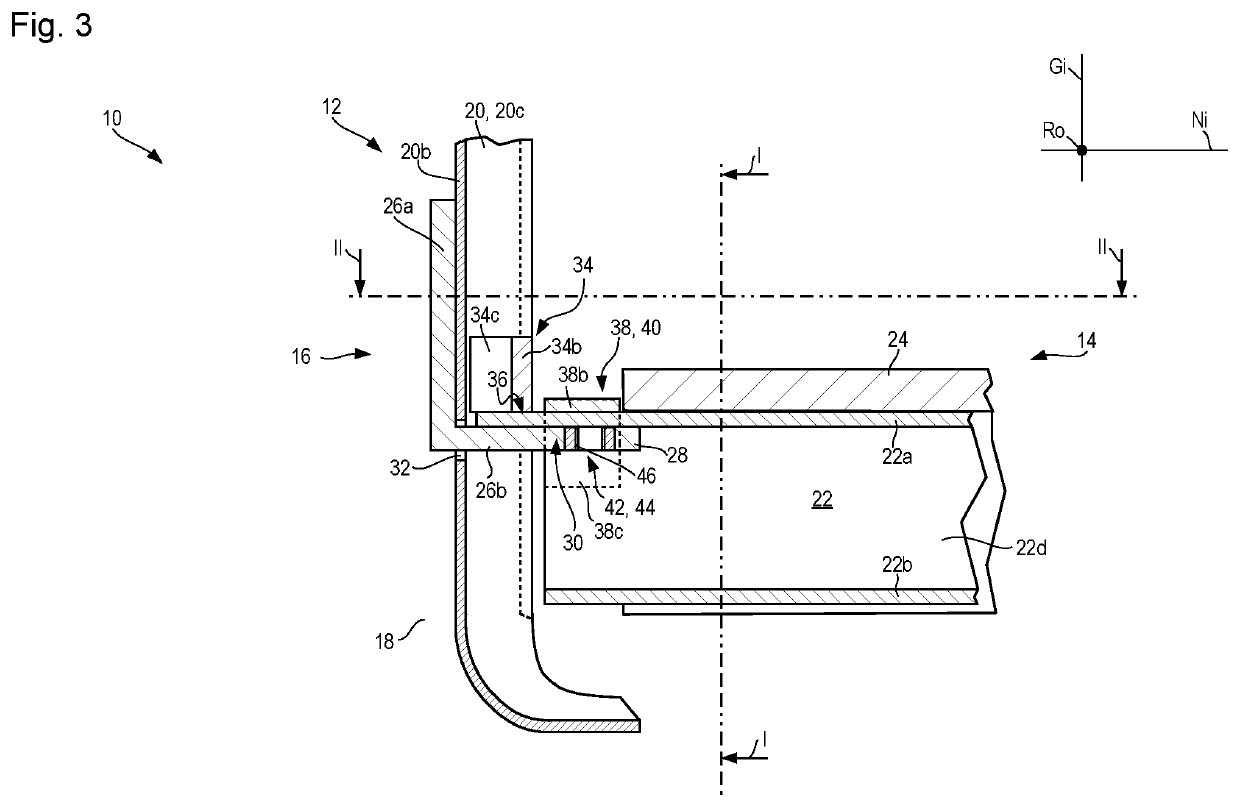

Vehicle partition side member structure

InactiveUS20120049557A1Increase flexibilityIncrease the sectionVehicle arrangementsSuperstructure subunitsMechanical engineering

Owner:SUZUKI MOTOR CORP

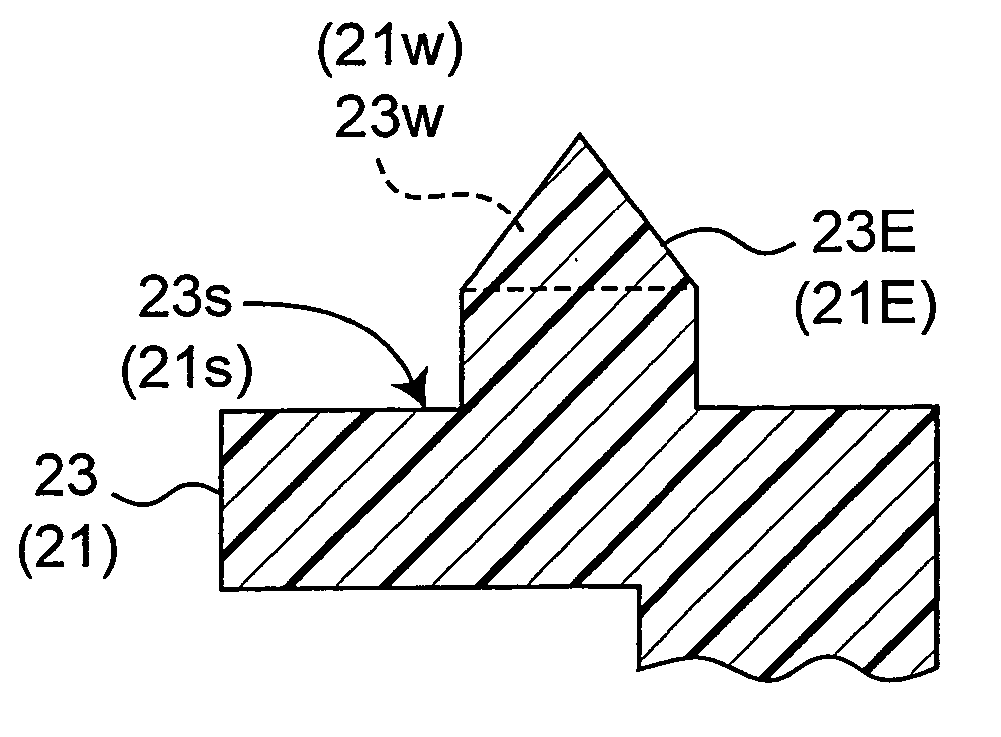

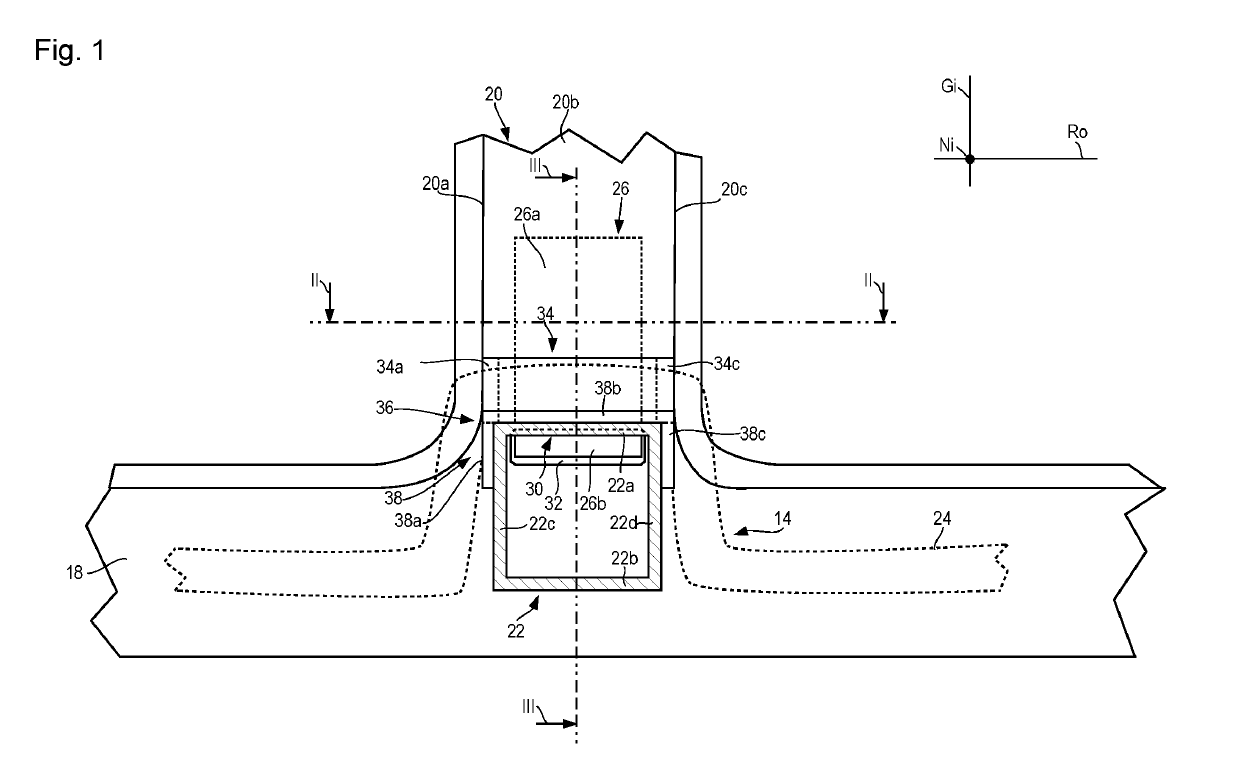

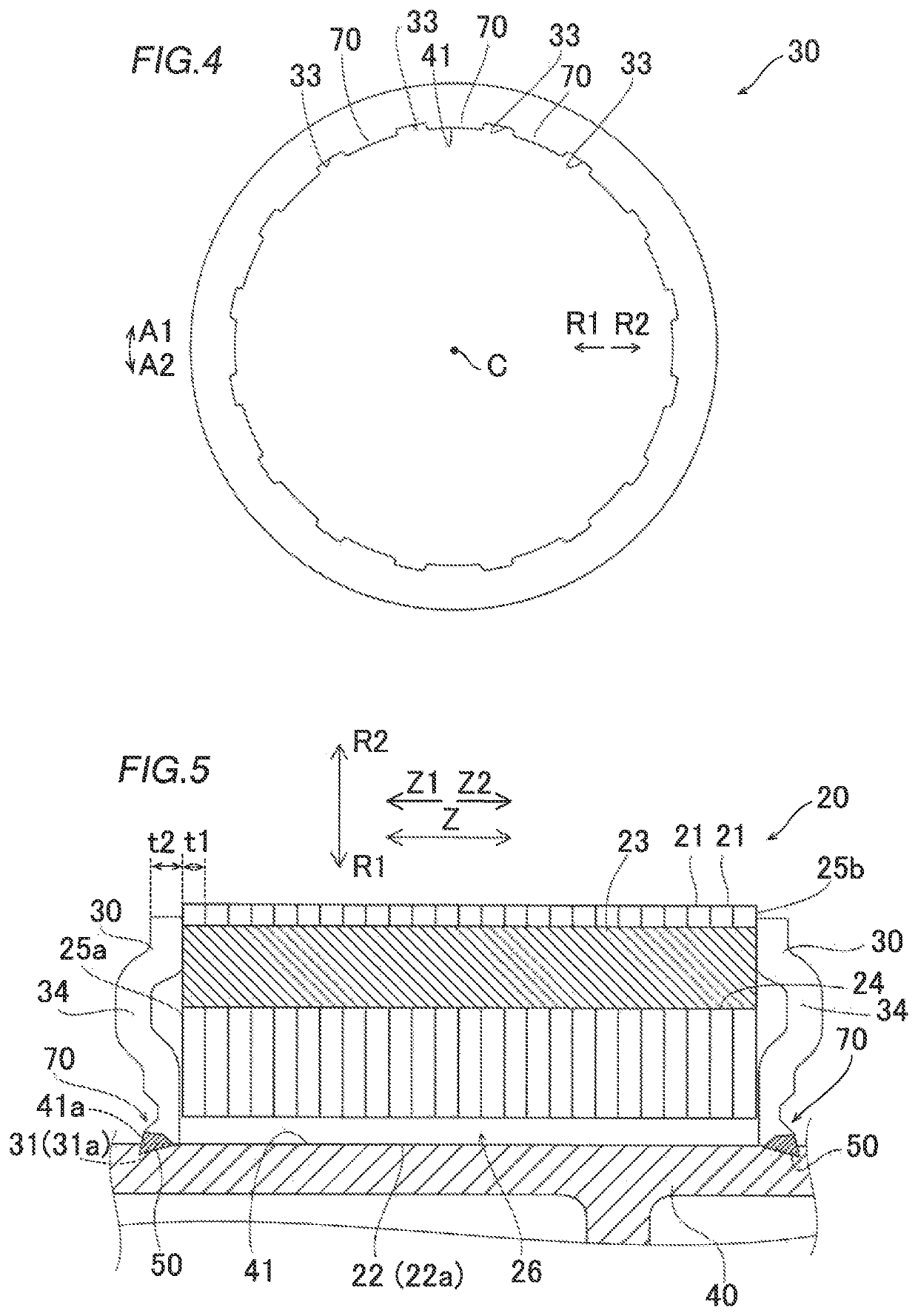

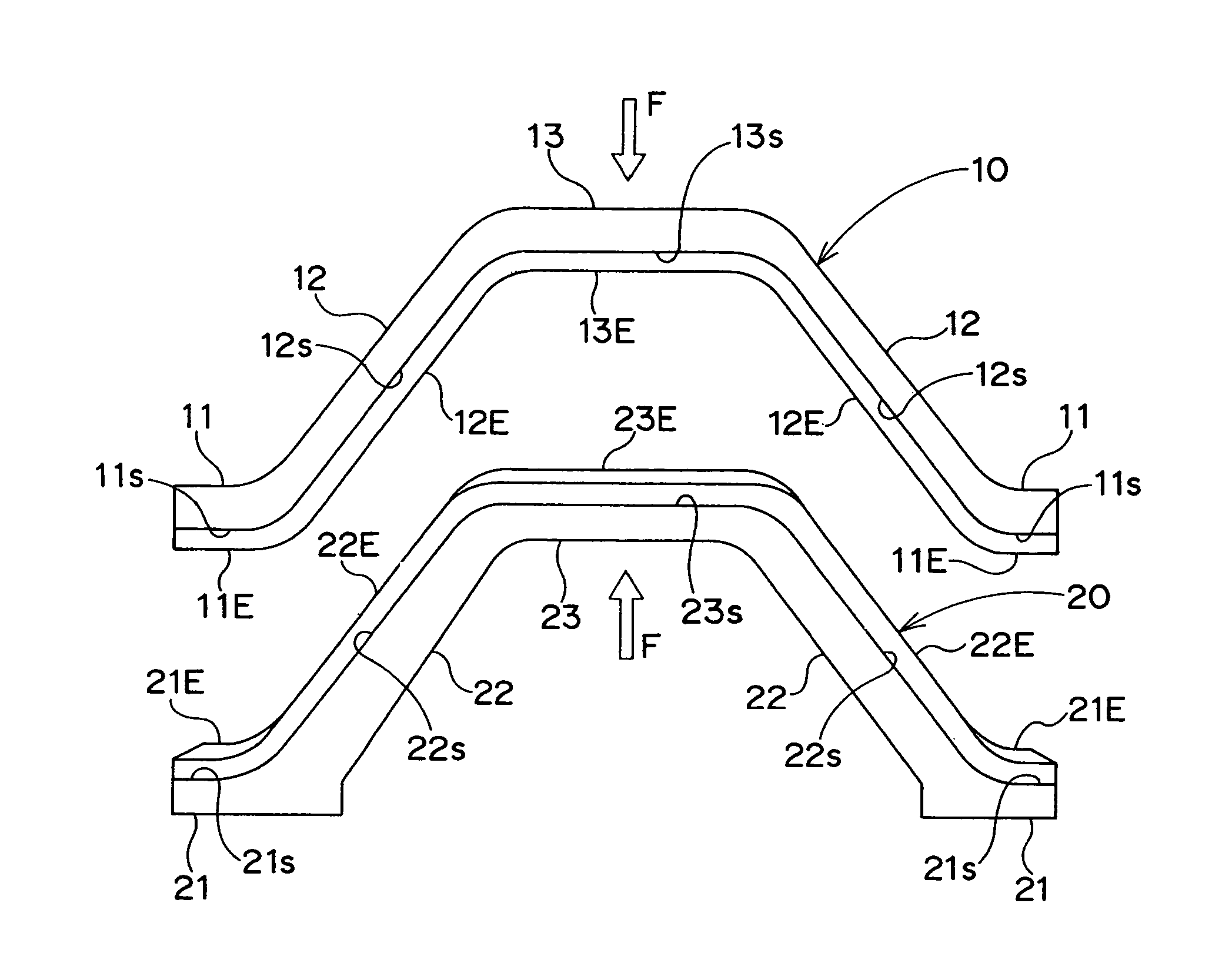

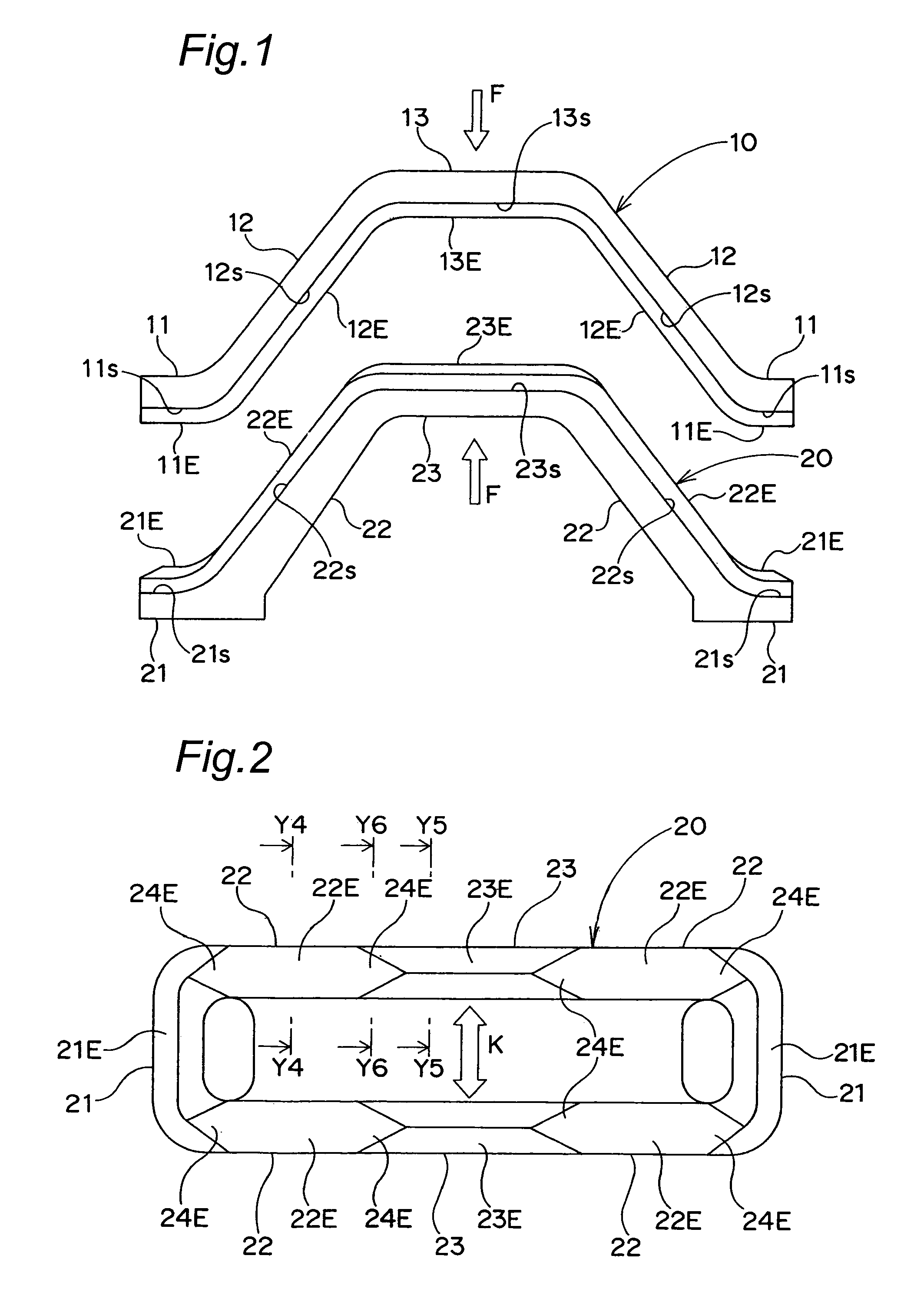

Structure of joining resin molded bodies

InactiveUS20080156412A1Reliable and superior strengthJoining strengthLaminationLamination apparatusEngineeringWelding

A reliable and superior joining strength in entire joining parts of resin molded bodies including tilting portions is obtained by devising a shape and a size of each protrusion for welding provided in the joining parts of the resin molded bodies. In a structure of joining resin molded bodies according to the present invention, upper and lower half bodies 10 and 20 are joined with each other by means of a vibration welding method while the upper and lower half bodies 10 and 20 are being pressurized in a state in which joining parts thereof are butted into each other in a substantially entire area of the joining parts. The joining parts of the respective half bodies have vertical portions 11 and 13 and vertical portions 21 and 23 respectively vertical to a pressurizing direction and tilting portions 12 and 22 tilting relative to the pressurizing direction, and protrusions for welding 11E to 13E or 21E to 23E are provided in at least the joining part of one of the half bodies. Further, referring to a butting area of the protrusions in a butted state, the butting area in the vertical portions is set to be narrower than the butting area in the tilting portions.

Owner:DAIKYONISHIKAWA CORP

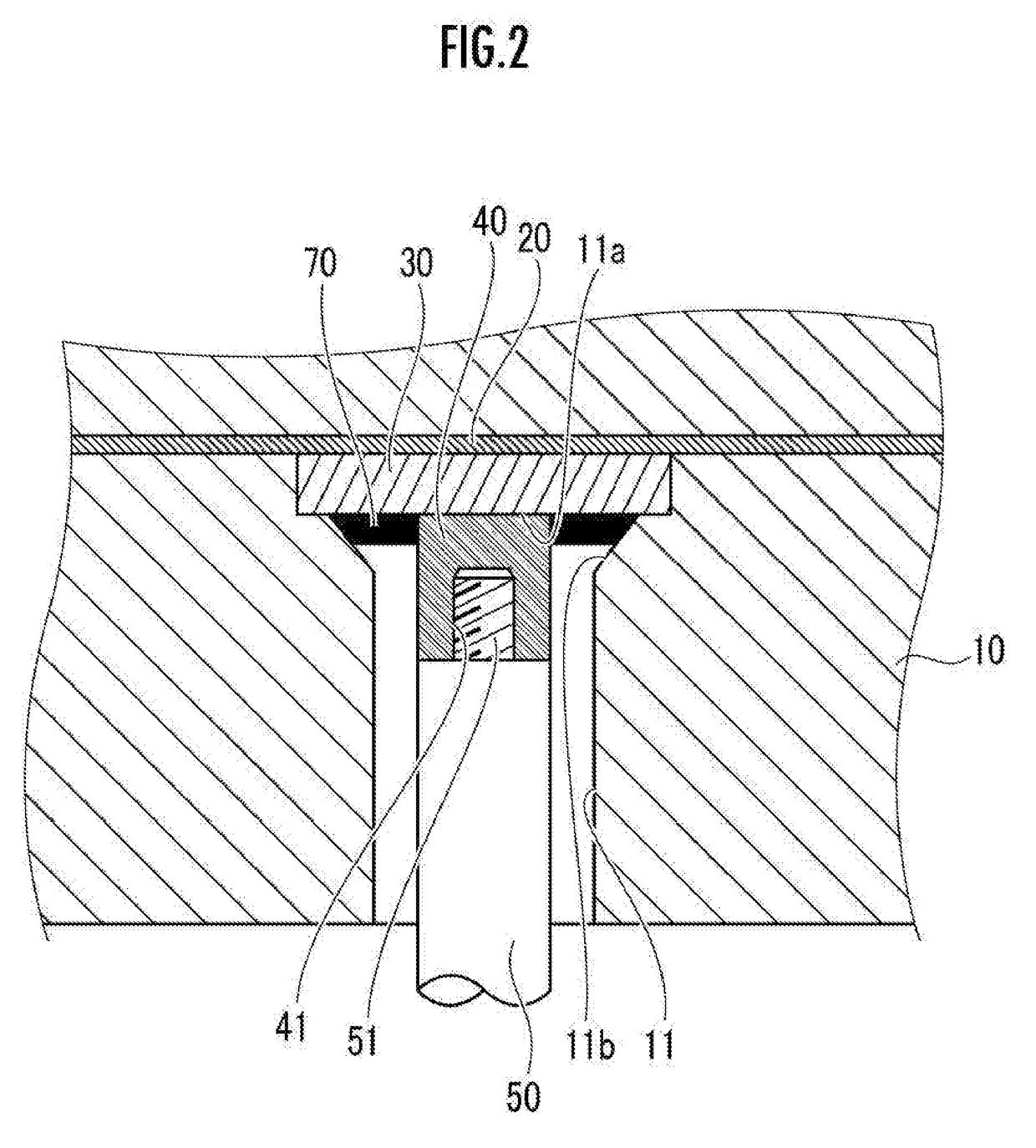

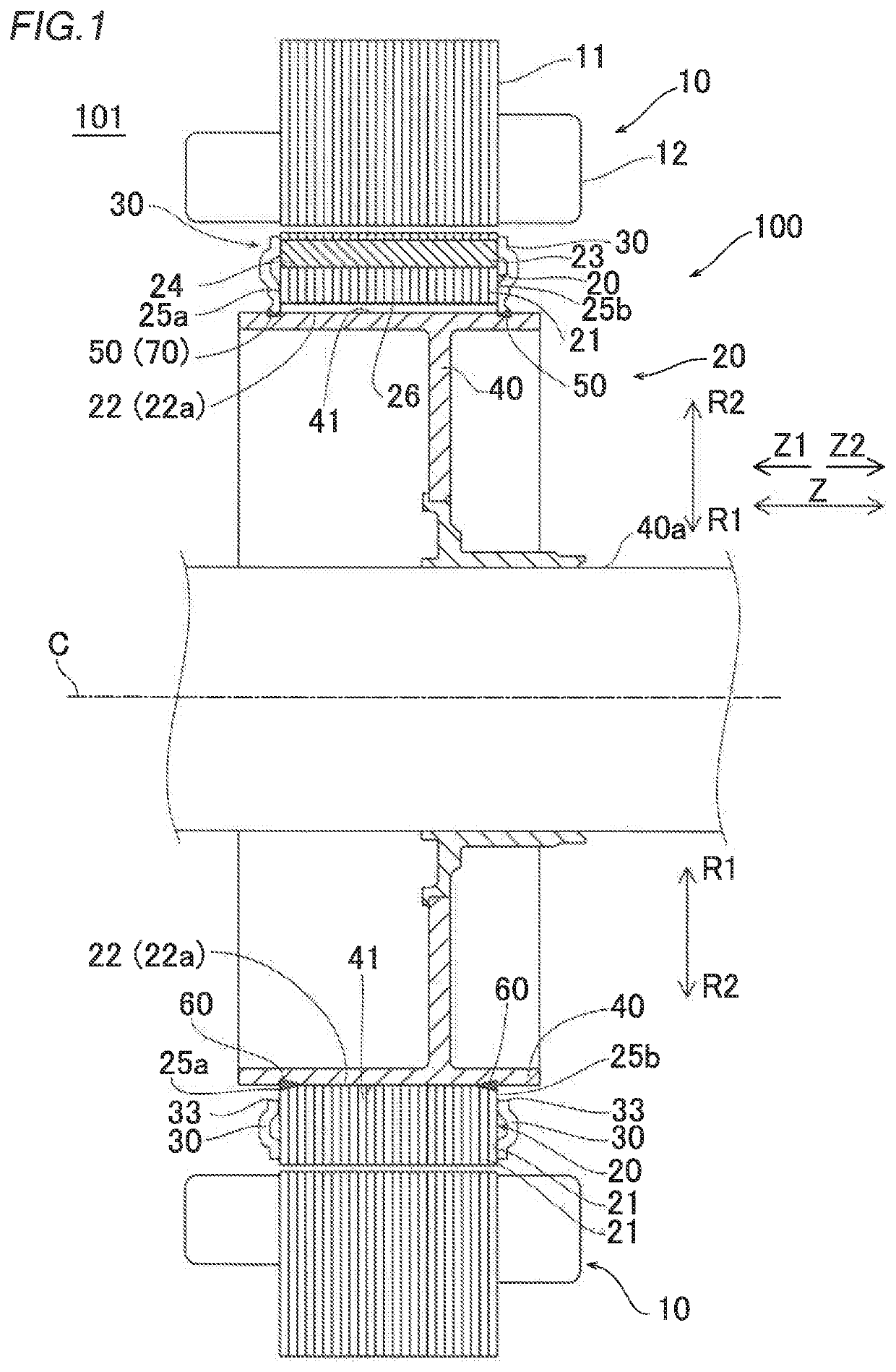

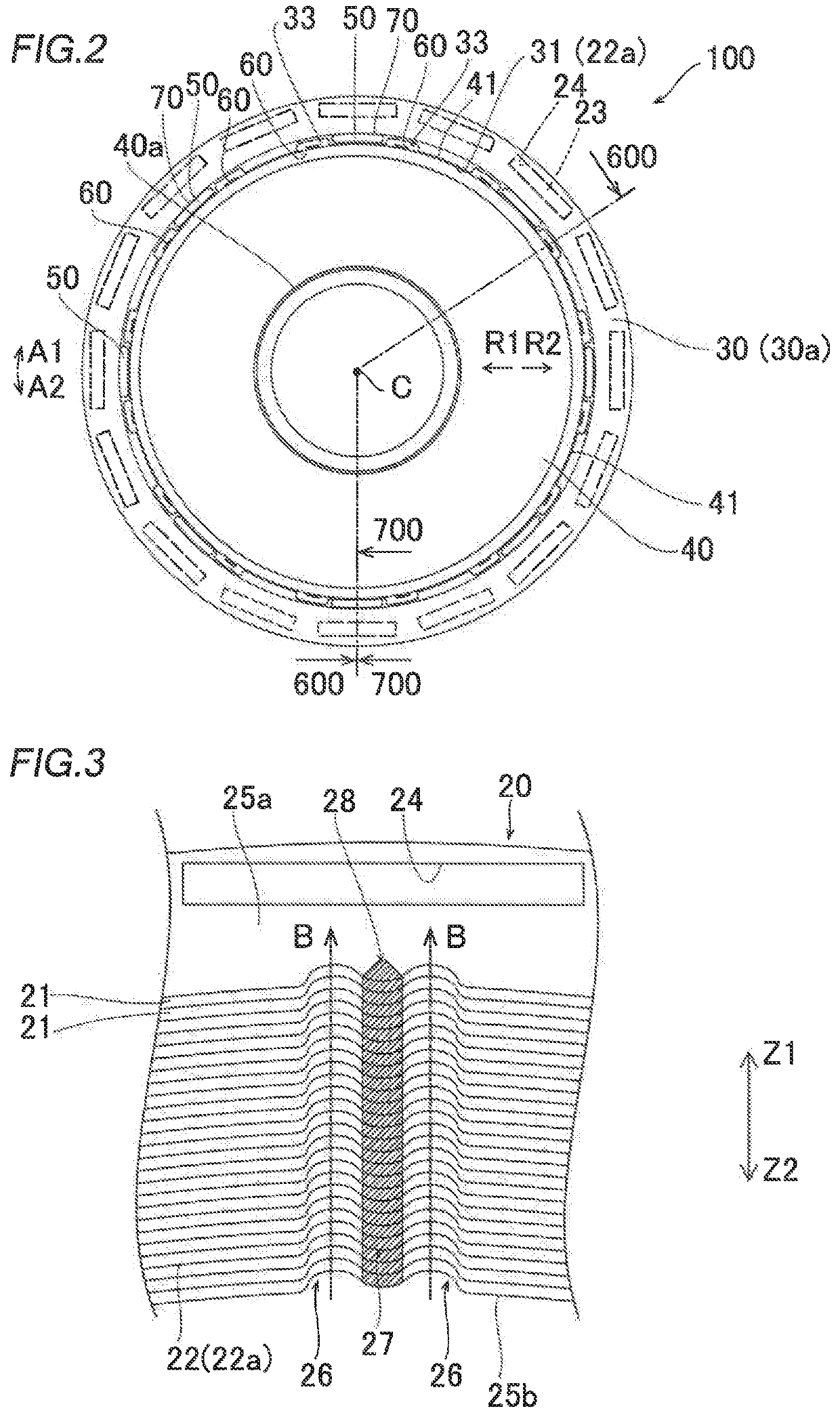

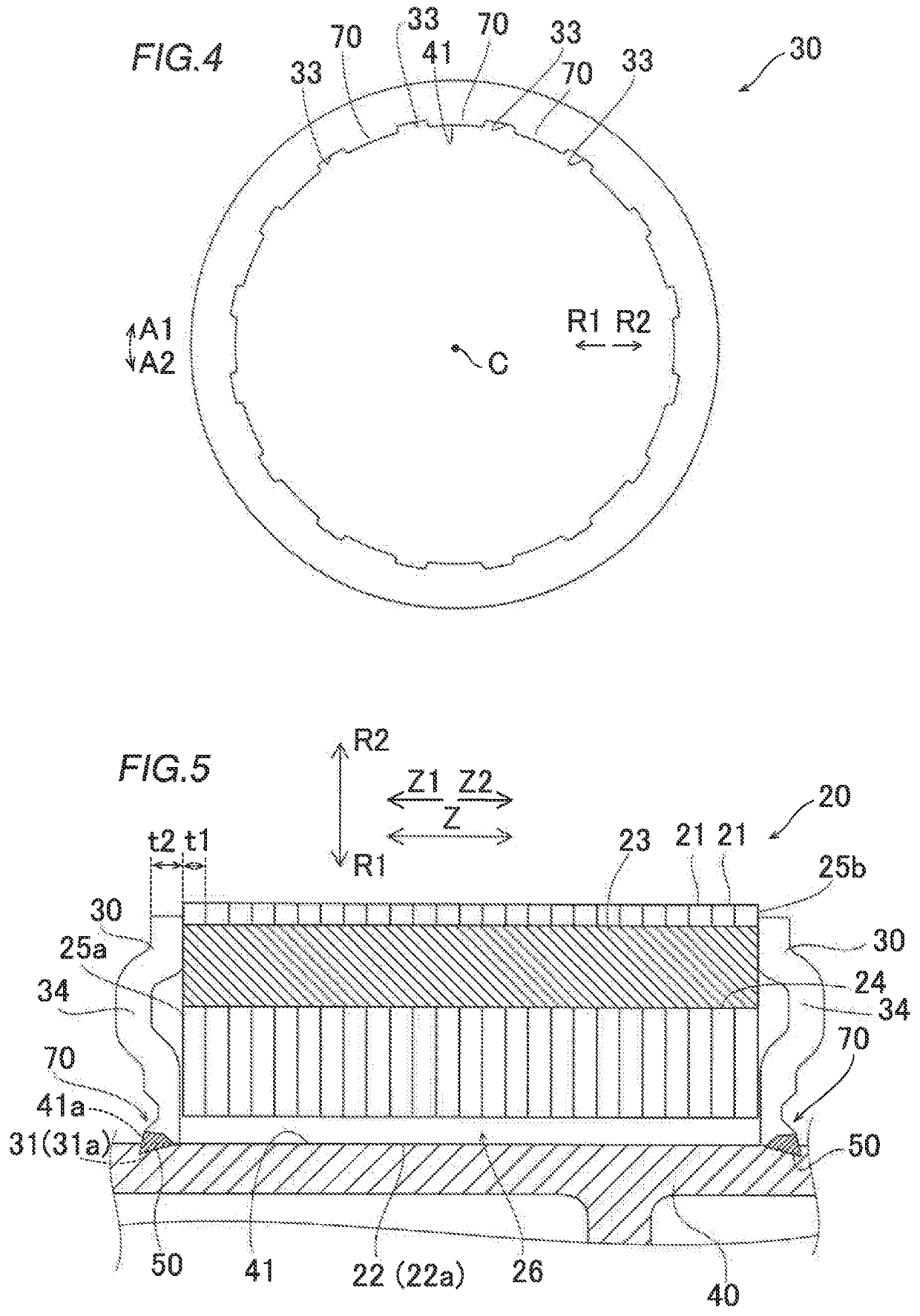

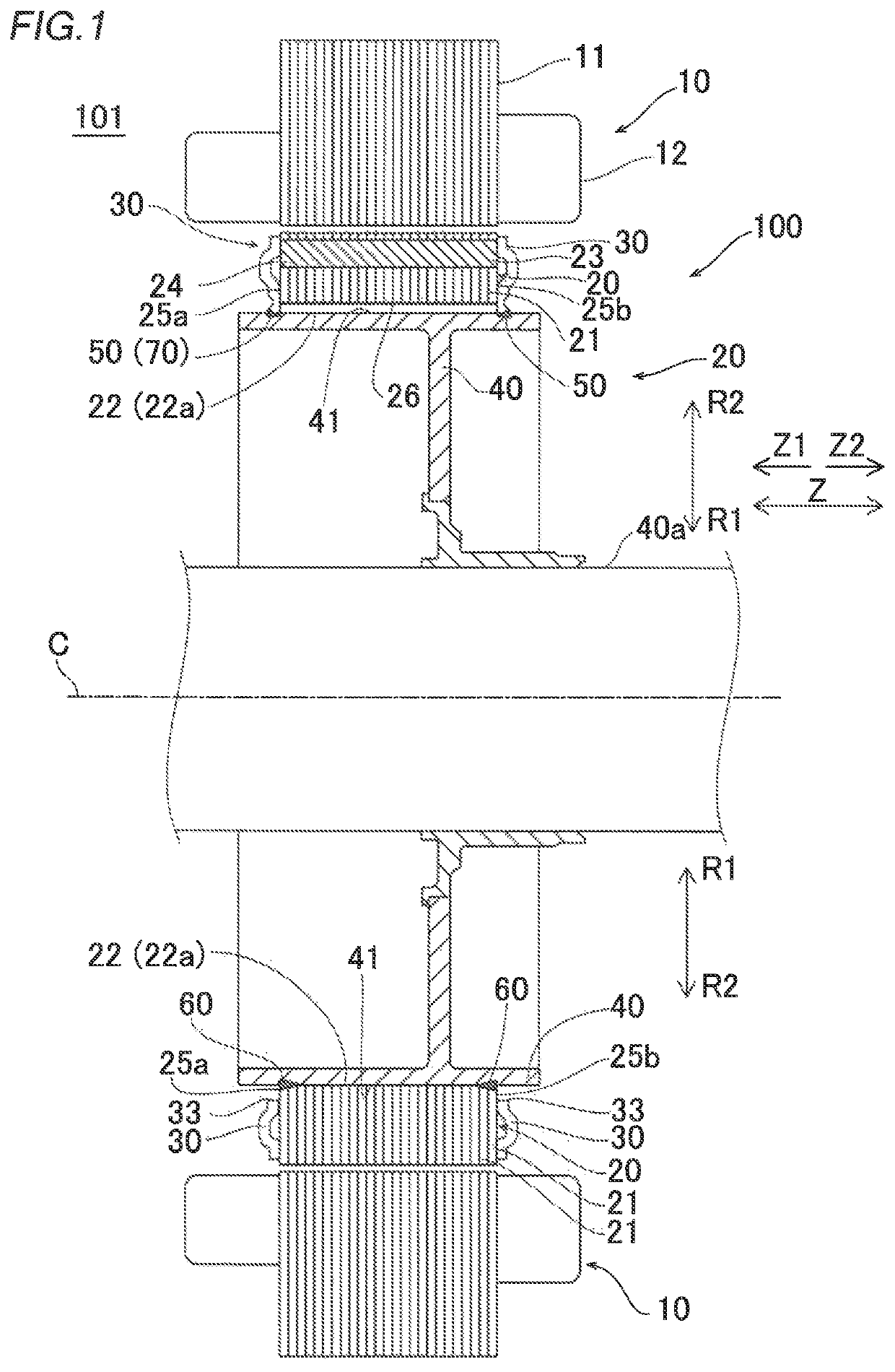

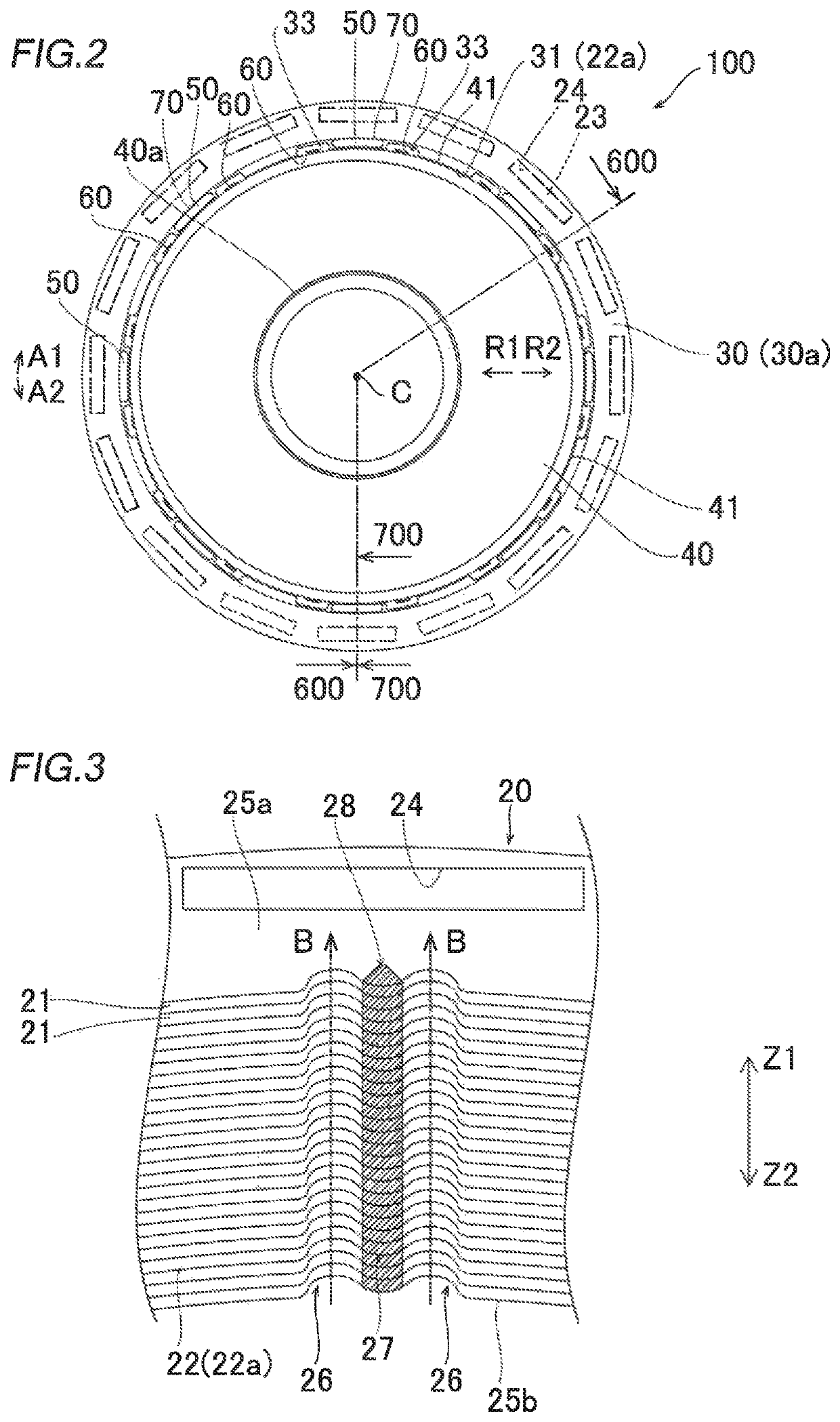

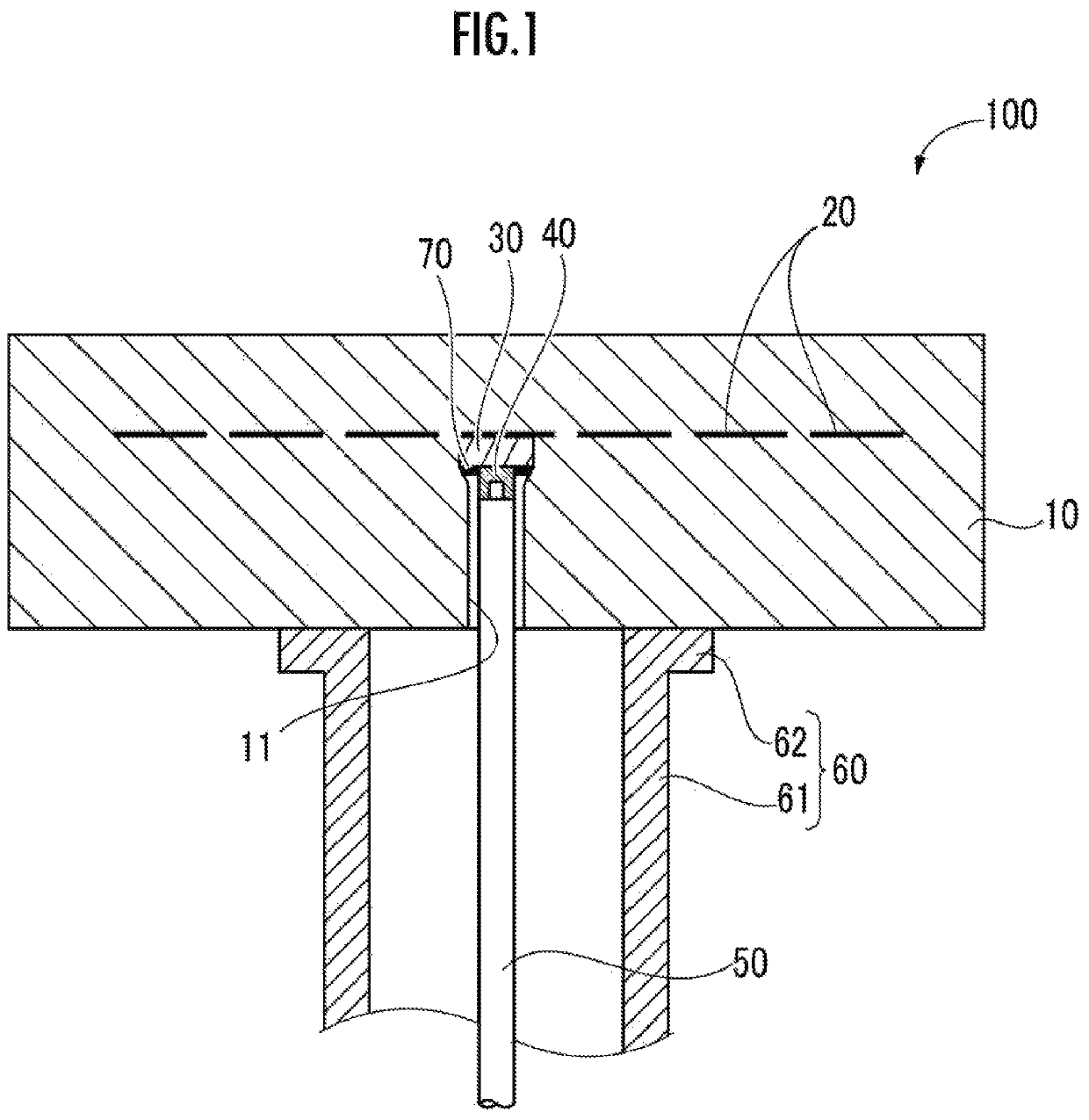

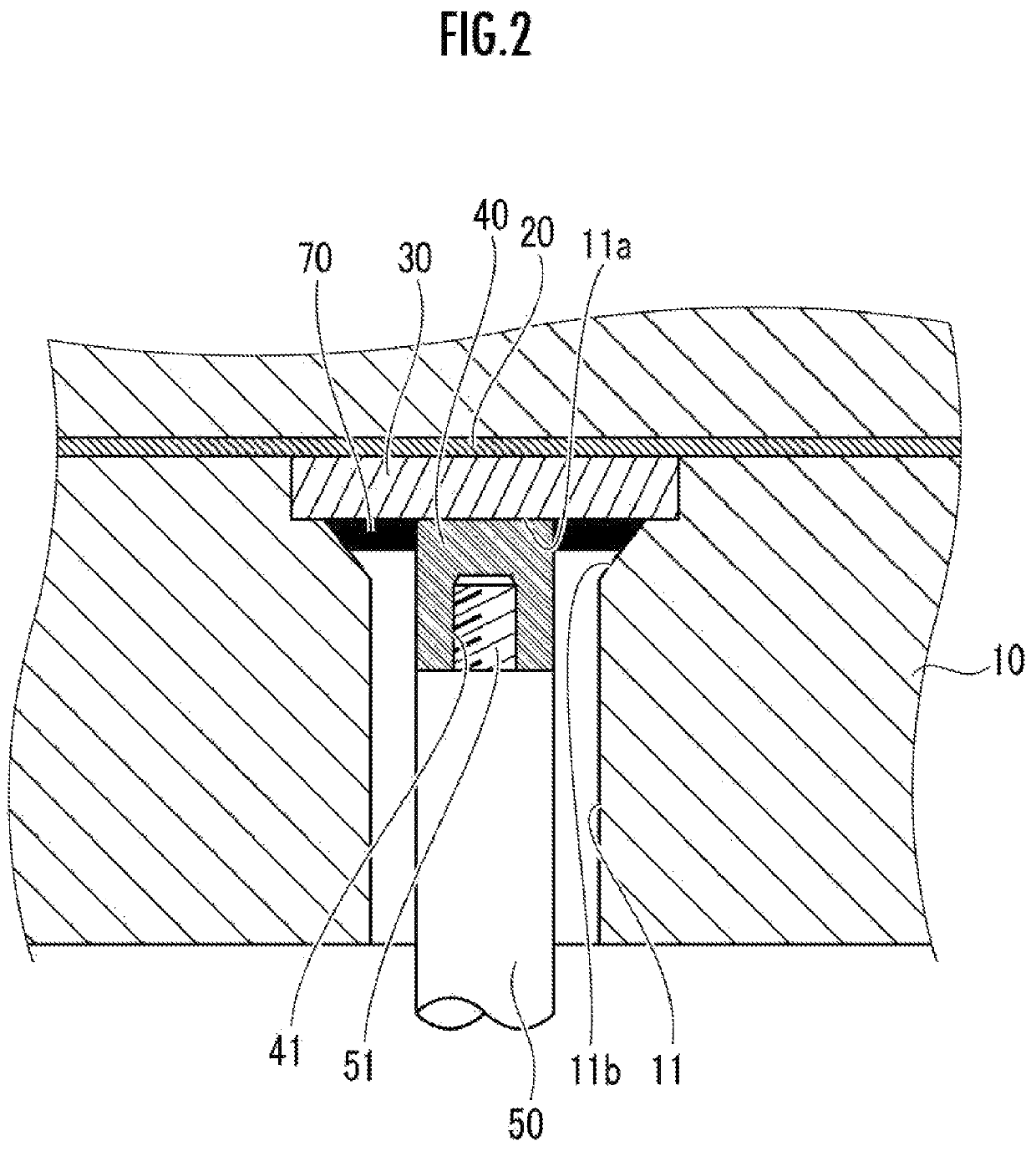

Ceramic member

ActiveUS20180033668A1Reduce liquidityImprove liquiditySemiconductor/solid-state device manufacturingCeramic layered productsMaterials science

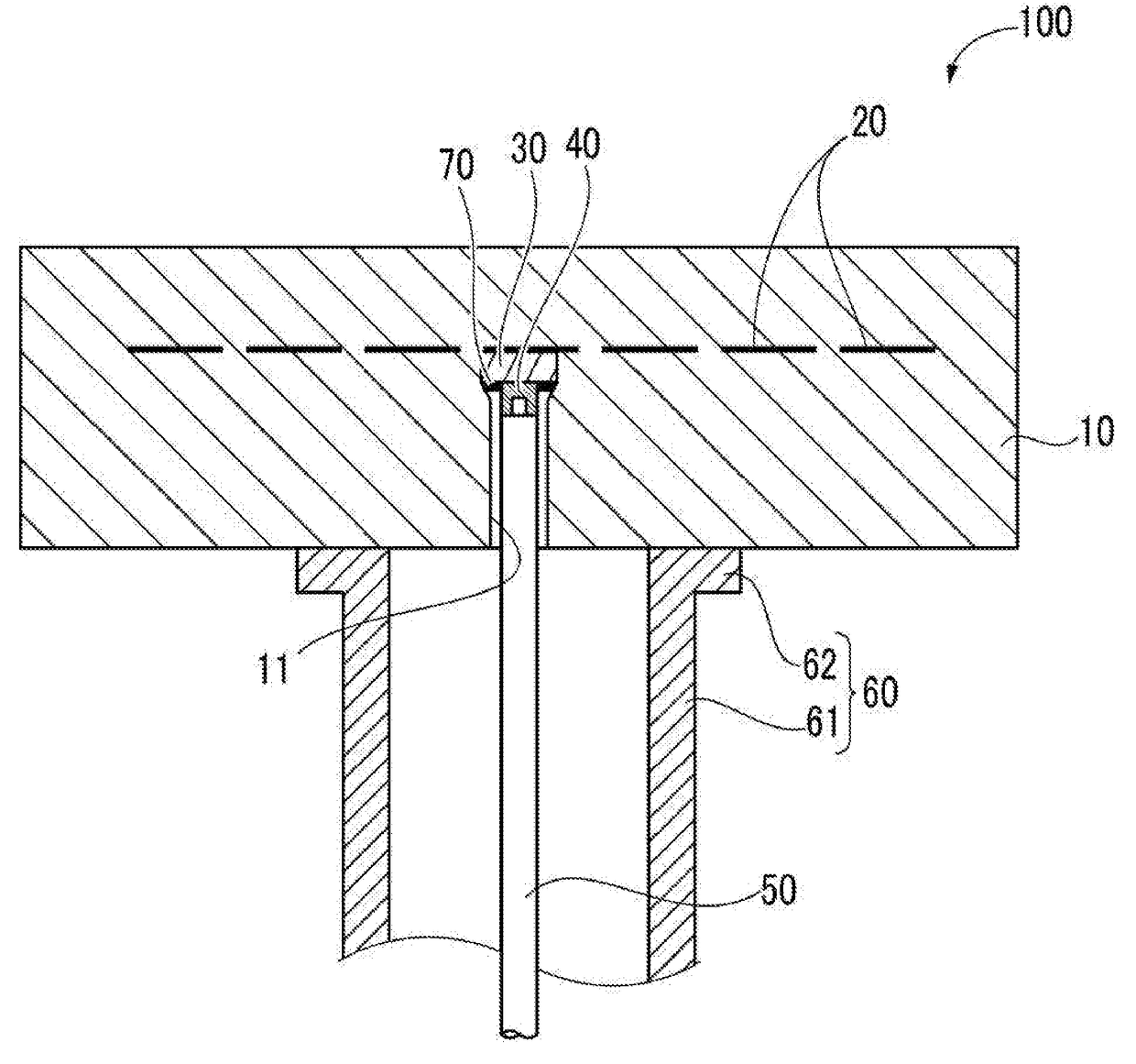

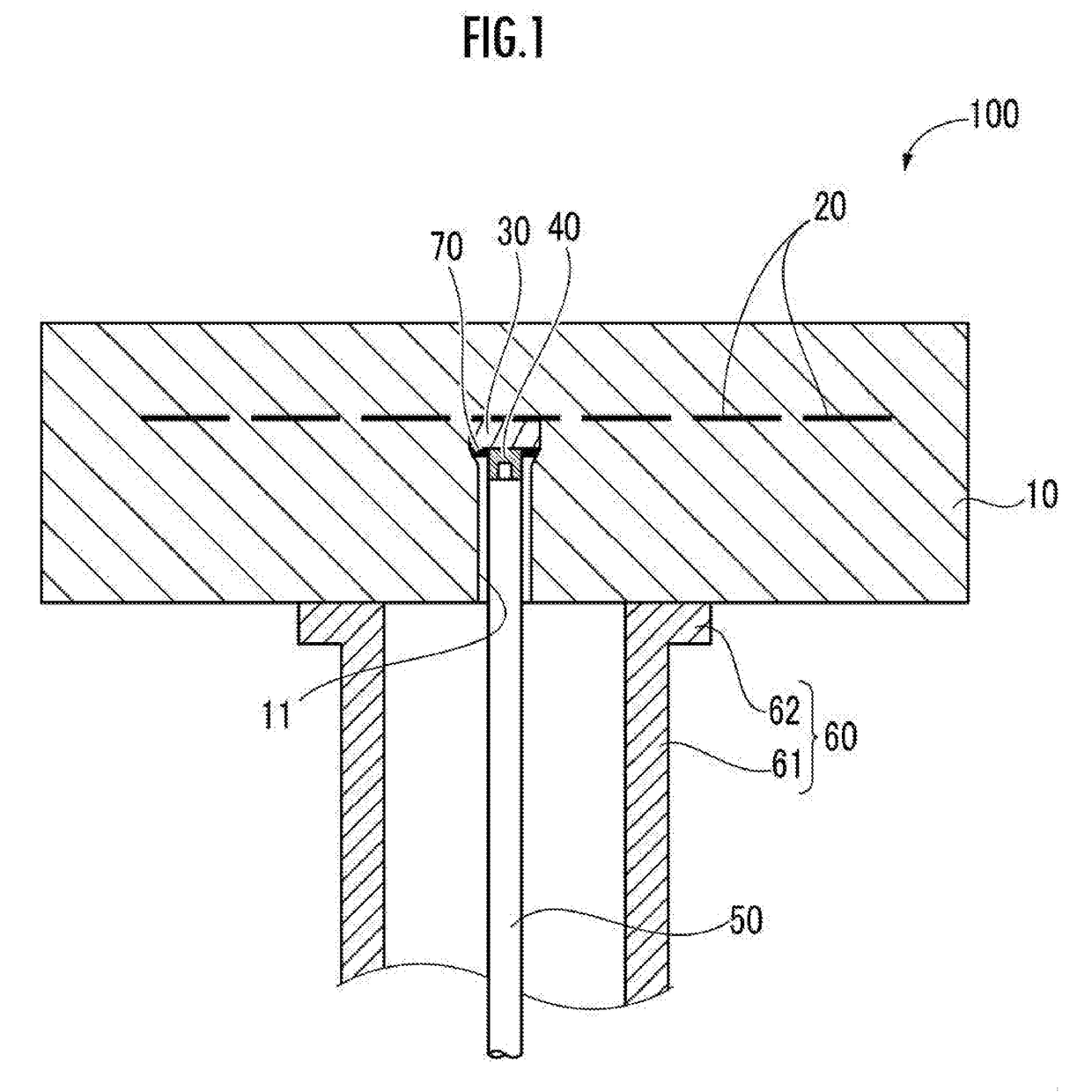

This ceramic member 100 includes: a ceramic base body 10 having a terminal 30 embedded therein; a blind hole 11 formed in the ceramic base body 10 and causing the lower surface of the ceramic base body 10 and the terminal 30 to communicate with each other; and a connection member 40 inserted in the blind hole 11, the connection member 40 connected to the terminal 30 by means of a brazing material solidified portion 70. In the blind hole 11, the space surrounded by the inner peripheral surface of the blind hole 11 has, at least at a bottom face 11a, an enlarged portion 11b that is enlarged toward the upper side at least partially with respect to the circumferential direction, and at least a part of the brazing material solidified portion 70 is present in the enlarged portion 11b.

Owner:NGK SPARK PLUG CO LTD

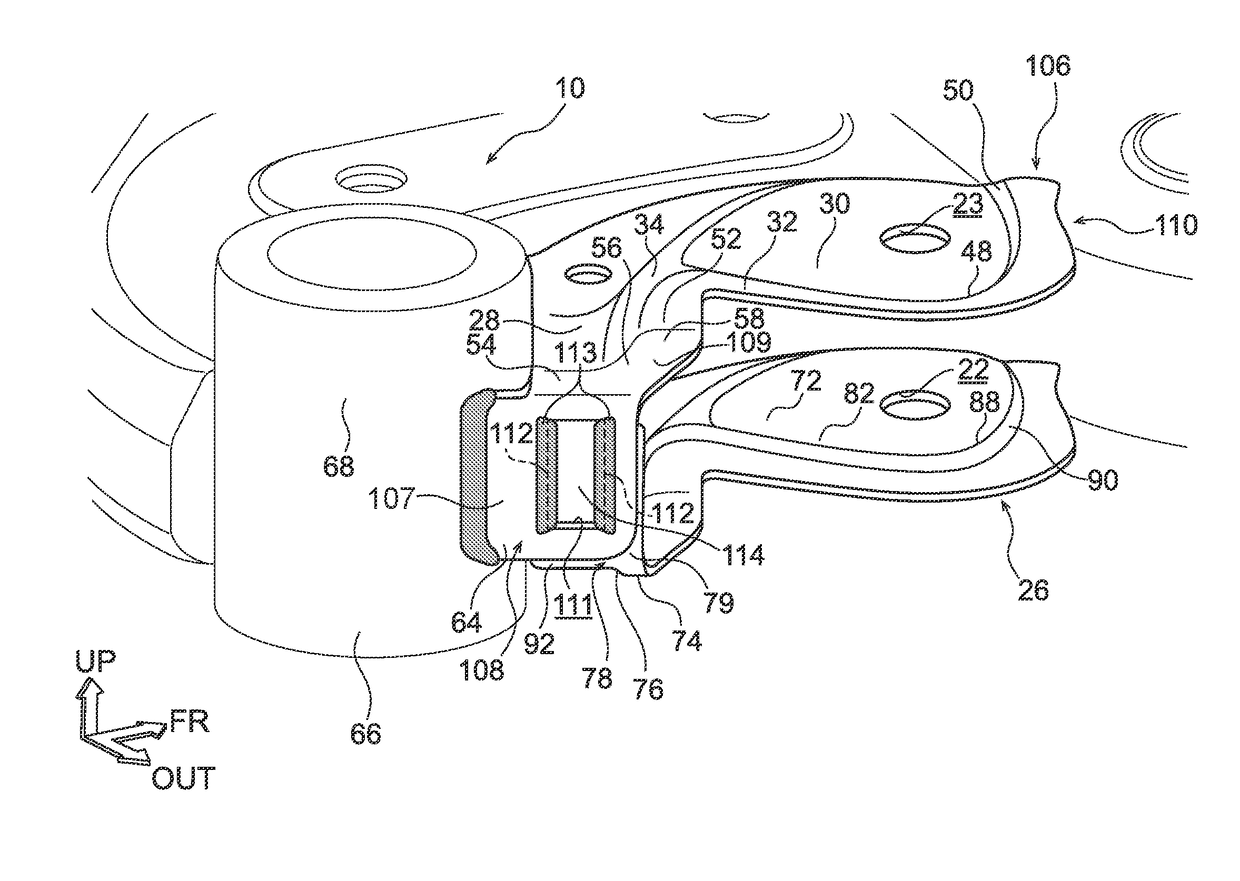

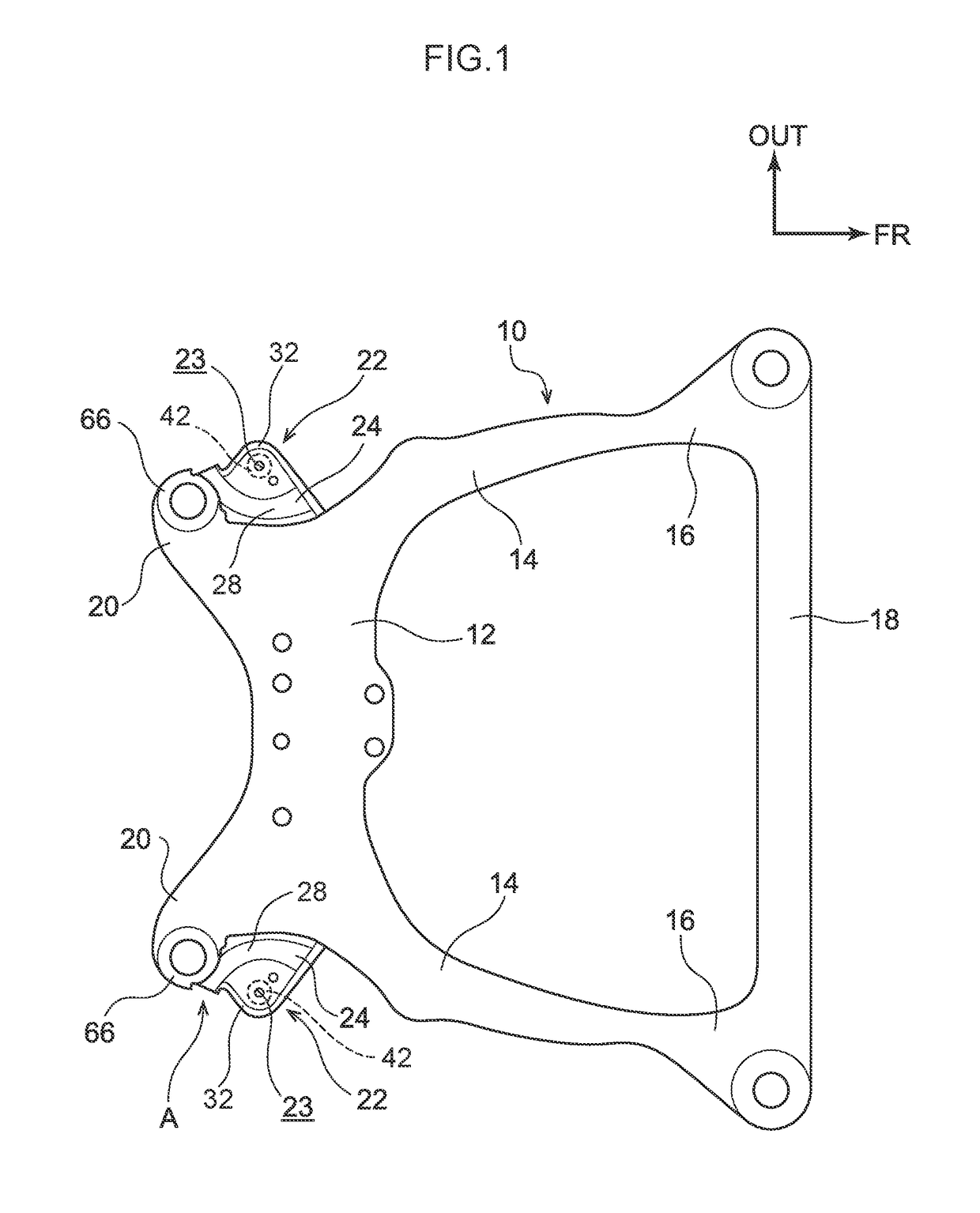

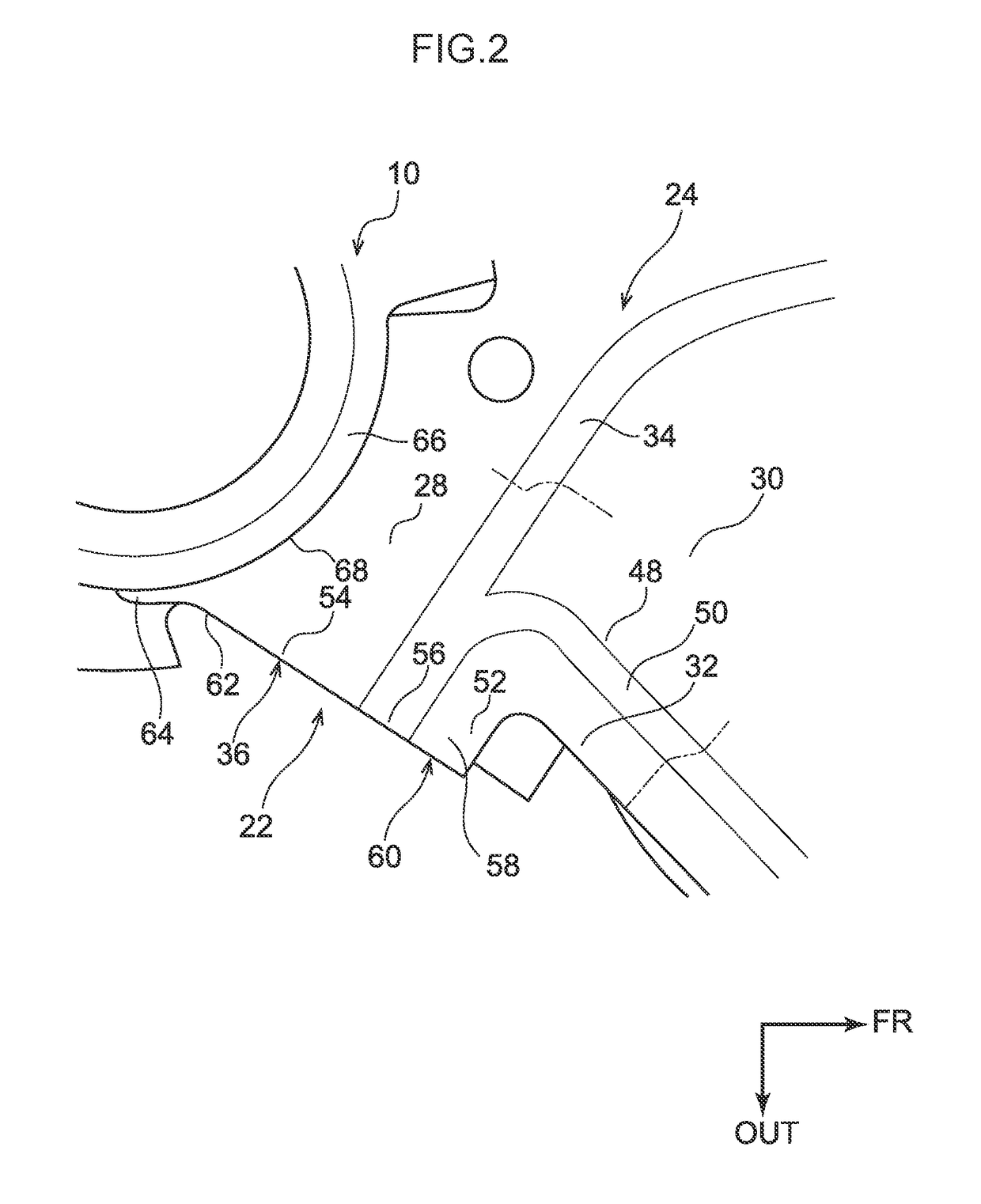

Suspension member lower arm bracket structure

ActiveUS20170087948A1Joining strengthHigh strengthUnderstructuresPivoted suspension armsCouplingEngineering

A lower arm bracket is provided. A portion of the lower arm bracket is an upper panel that includes a first surface wall, a second surface wall, a third surface wall, a first coupling surface wall connecting the first surface wall and the second surface wall together, and a first vertical wall extending toward the vehicle lower side from a position including an end portion in the length direction of the first coupling surface wall. A portion of the lower arm bracket is configured by a lower panel that includes a fourth surface wall, a fifth surface wall, a sixth surface wall, a third coupling surface wall connecting the fourth surface wall and the fifth surface wall together, and a second vertical wall extending toward the vehicle upper side from a position including an end portion in the length direction of the third coupling surface wall.

Owner:TOYOTA JIDOSHA KK

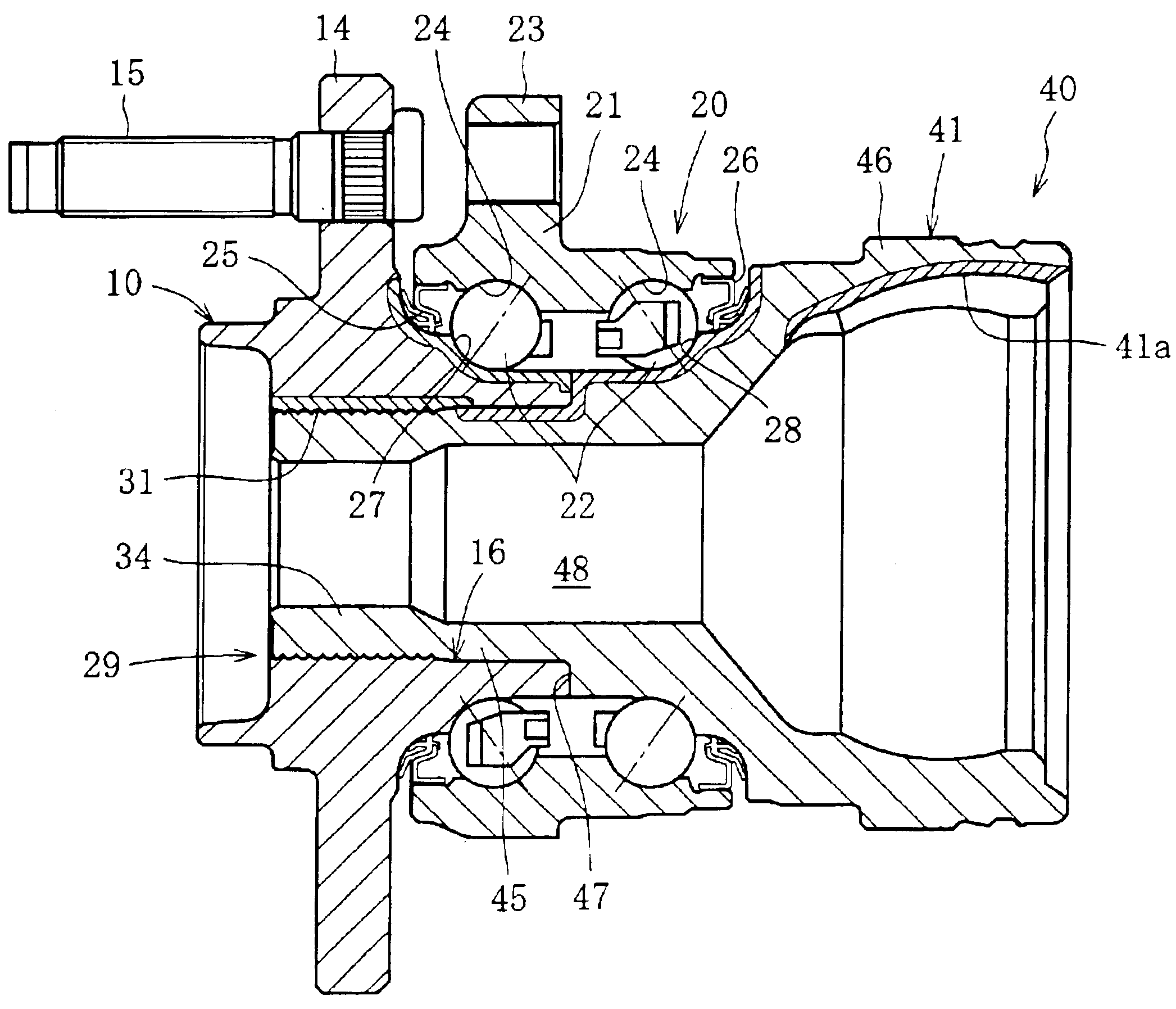

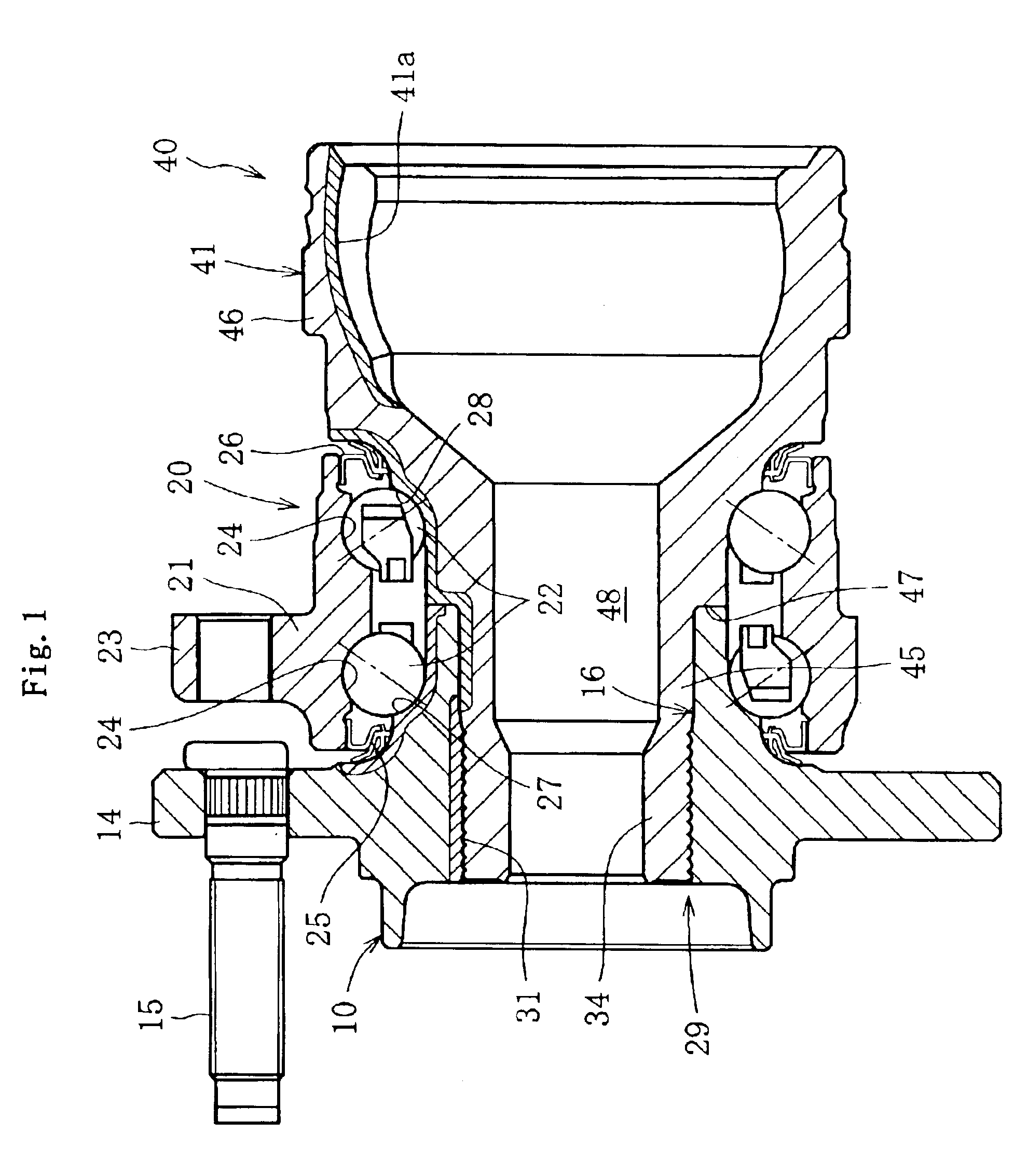

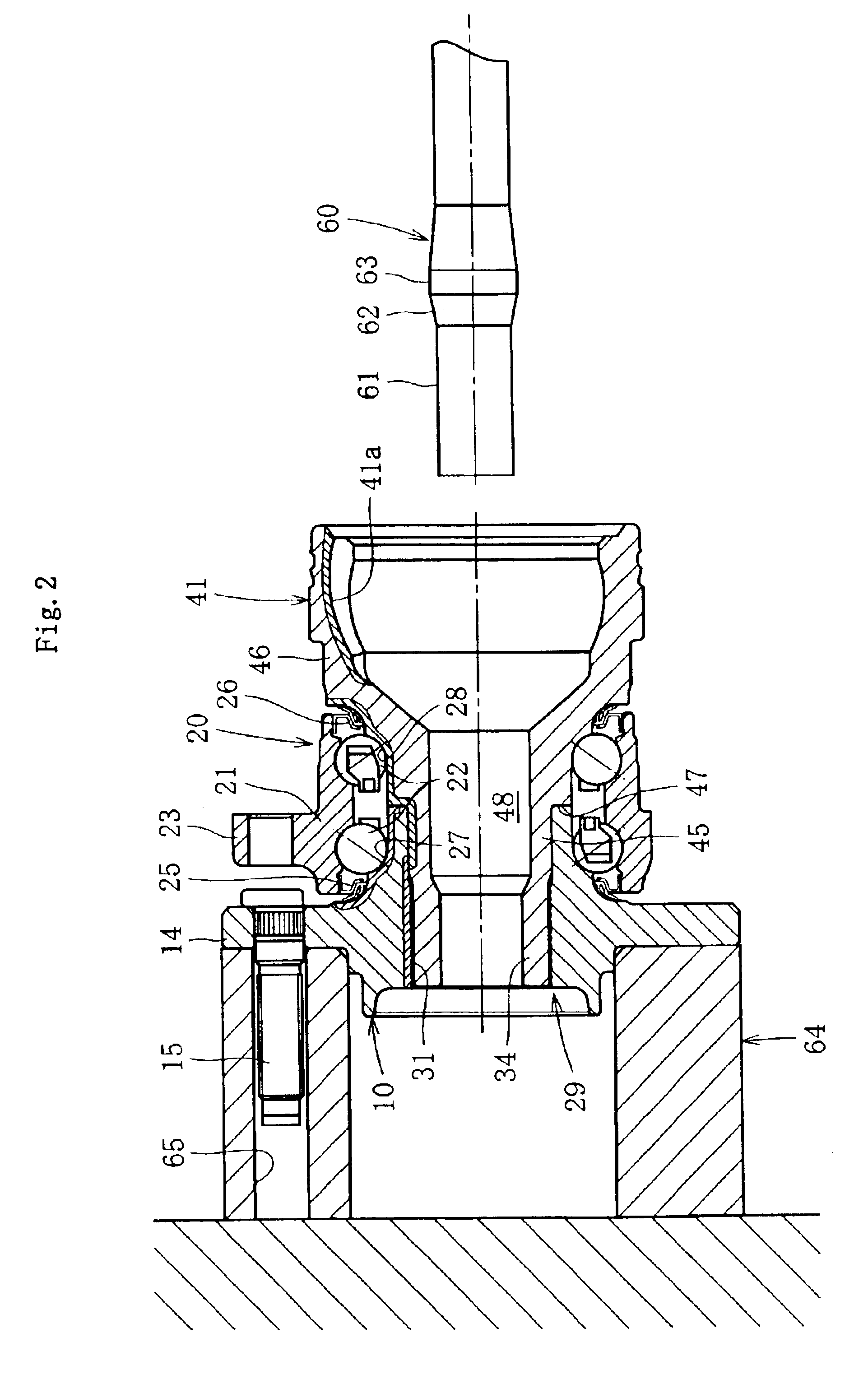

Wheel bearing device

InactiveUS6942393B2Increased durabilityImprove carrying capacityHubsBall bearingsJoint componentUltimate tensile strength

An outer joint member for a constant velocity joint is fitted to the inner periphery of a wheel hub, and the stem portion of the outer joint member that is located inside is plastically deformed in the radially outward direction in order to couple the wheel hub and the outer joint member. The ratio of the inner diameter ΦdA before plastic deformation in the plastic deformation portion of the outer joint member and the inner diameter ΦdB after the plastic deformation (Δ=ΦdB / ΦdA) is set in the range from 1.05 to 1.15 (1.05≦Δ≦1.15). In this way, high workability and joining strength can be achieved at a time in the swaging process in the radially outward direction.

Owner:NTN CORP

Motor vehicle body having a bodyshell and vehicle underbody, and having a securing structure component

ActiveUS20190315411A1Joining strengthImprove joint strengthVehicle body-frame connectionsUnderstructuresEngineeringMotorized vehicle

A motor vehicle body encompasses a surface-coated bodyshell having an underbody carrying portion and a underbody that is embodied separately from the bodyshell and is fixedly joined to the underbody carrying portion, the underbody having a planar, multiply curved underbody structure component encompassing fiber-reinforced plastic, as well as at least one underbody member, joined to the underbody structure component, having a member material different from the structural material of the underbody structure component; a support projection, on which the underbody member is braced and to which the underbody member is fixedly joined by adhesive bonding, protruding toward the vehicle interior from the underbody carrying portion; the vehicle body encompasses at least one securing structure component that is embodied separately both from the bodyshell and from the underbody and encompasses at least two limbs arranged at an angle to one another, which component is joined to the bodyshell and / or to the underbody member to secure the underbody on the bodyshell.

Owner:ROCHLING AUTOMOTIVE SE

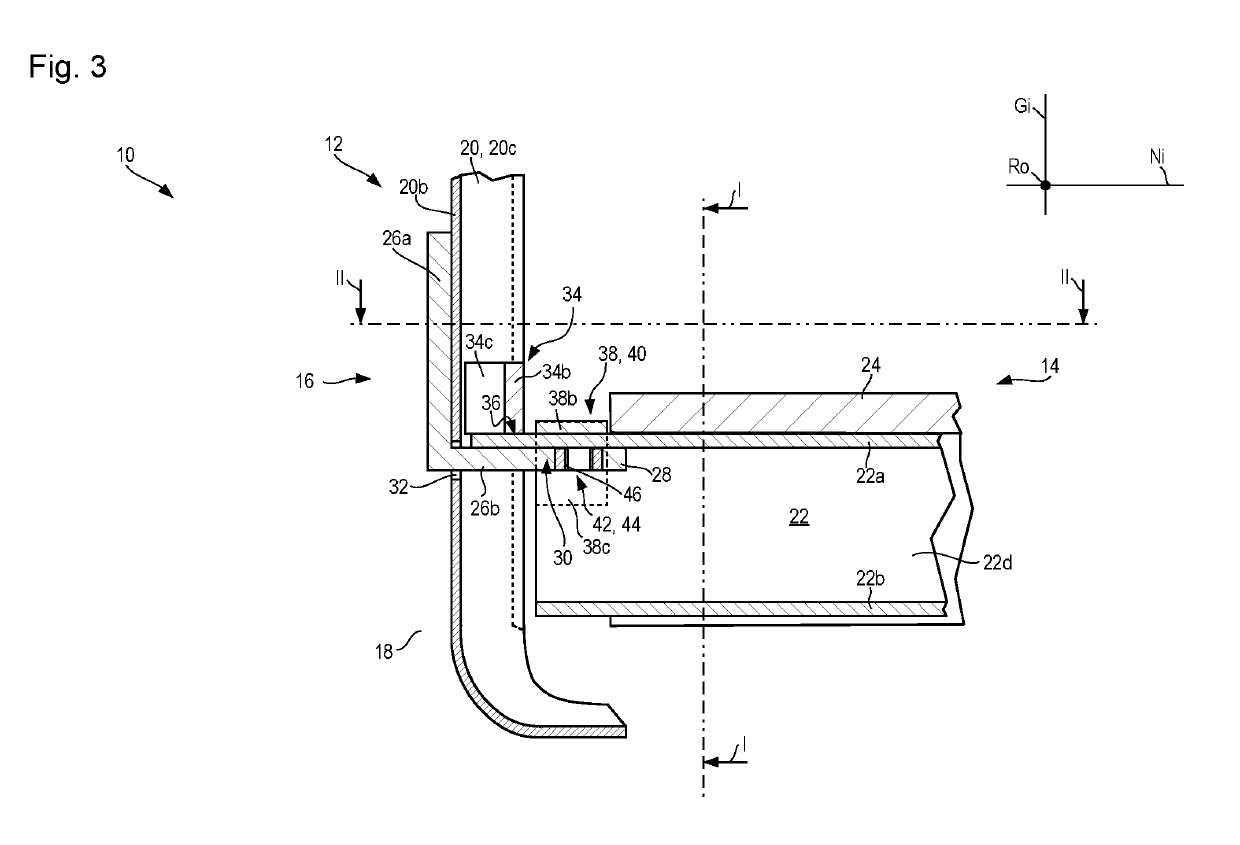

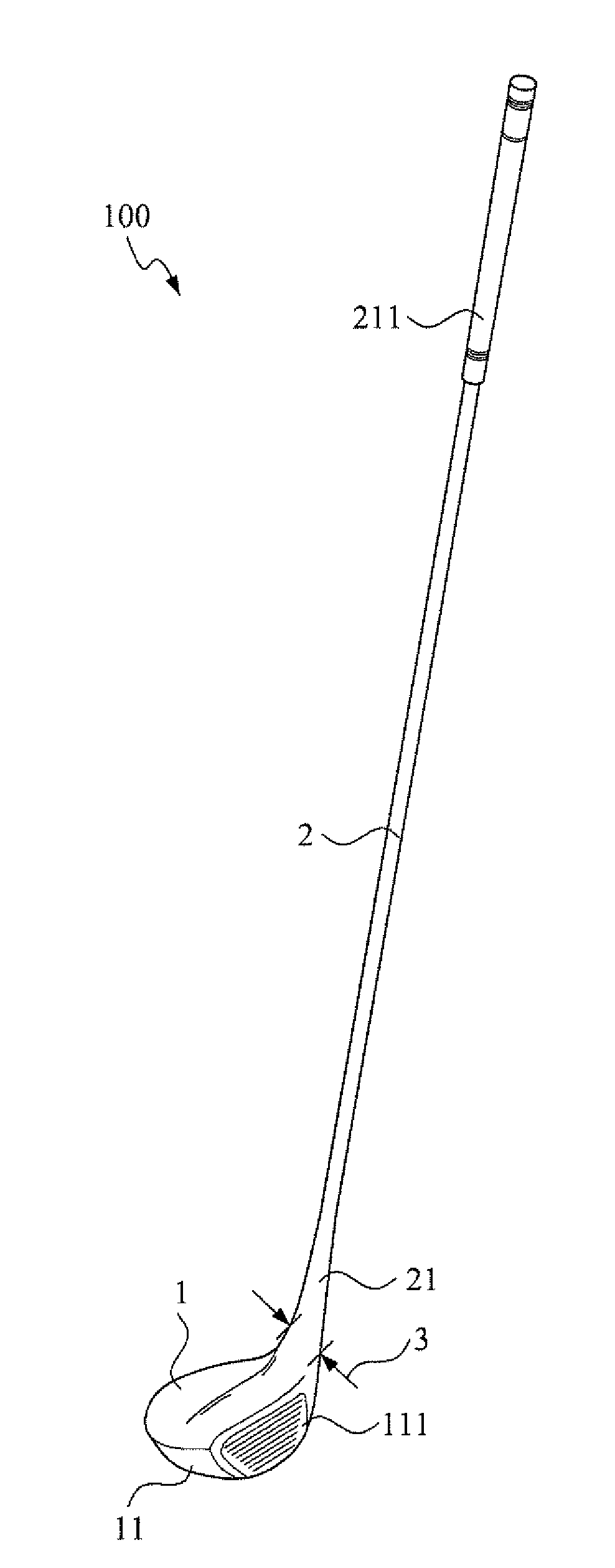

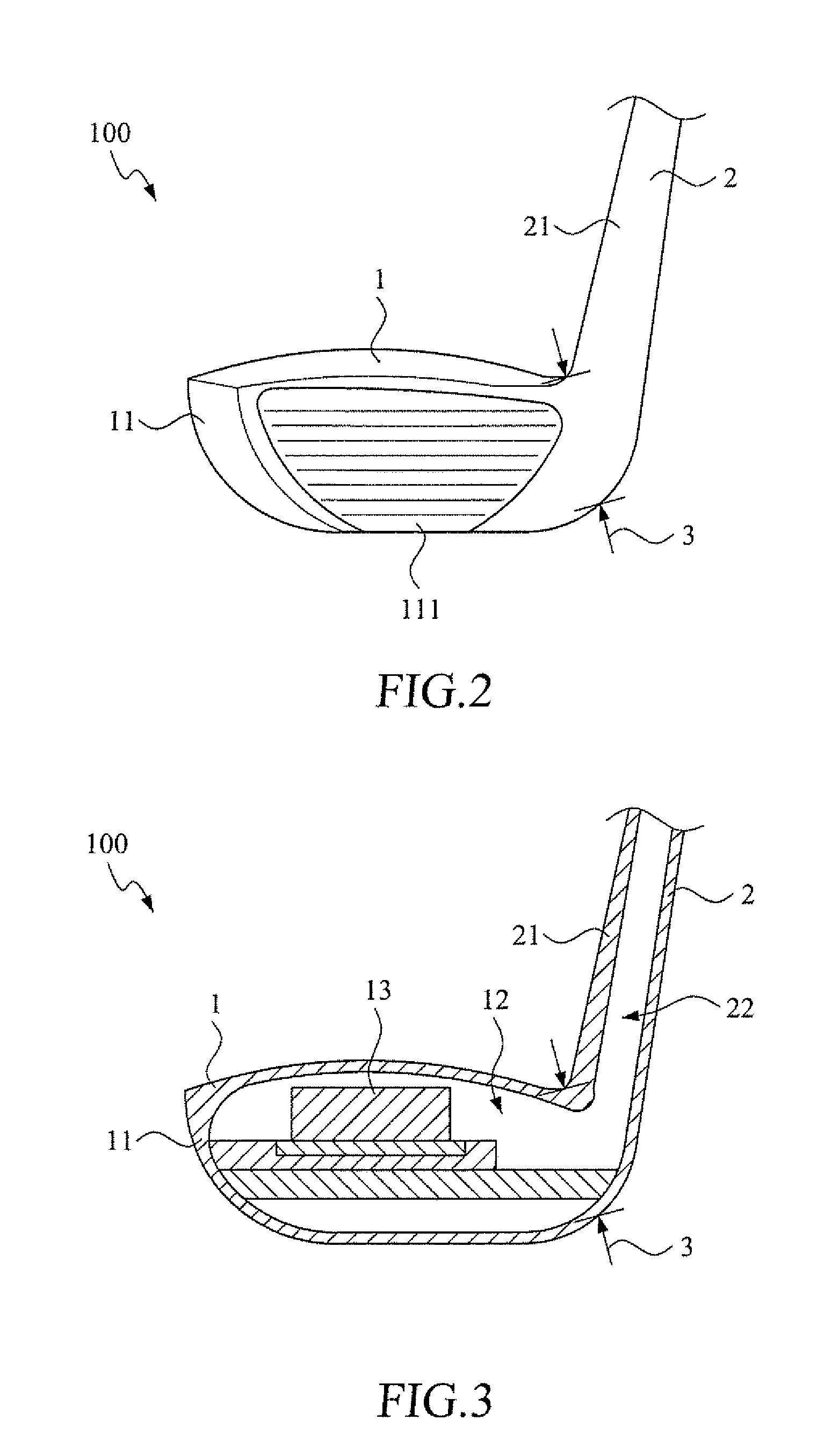

Integrally Formed Golf Club

InactiveUS20130281225A1Excellent distributed strengthJoining strengthGolf clubsRacket sportsEngineeringGolf club

An integrally formed golf club comprising: a golf club head and a golf shaft, wherein the golf club head including a club head component formed by casting, the casted club head component has a club head surface formed by forging, the golf shaft is formed by drawing the casted club head component, and is integrally formed with the casted club head component. It thus the integrally formed golf club has characteristics of excellent distributed strength and no partial concentration of applied force, it thus the accuracy of direction and the ability of control is improved.

Owner:HSU WELKIN +1

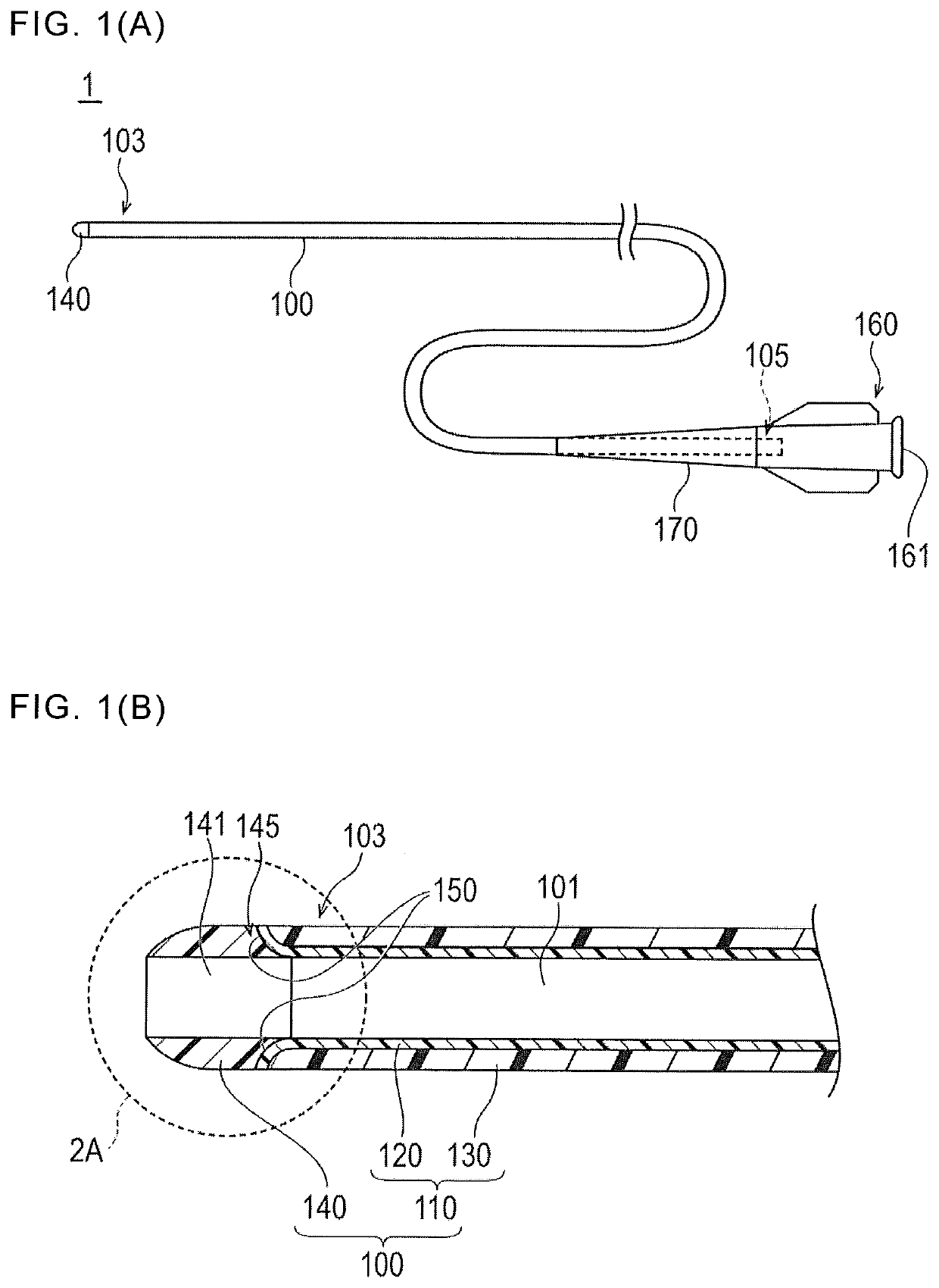

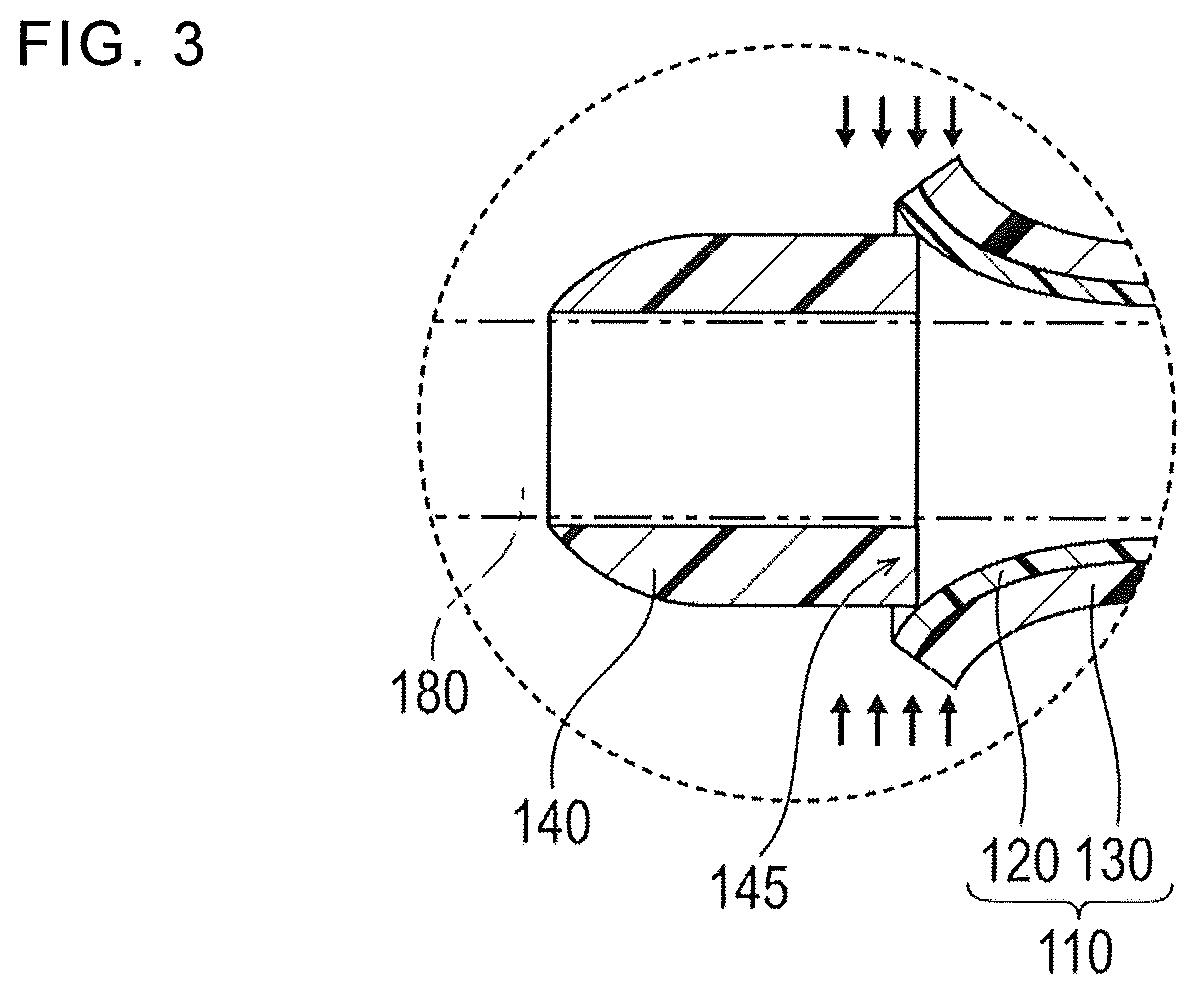

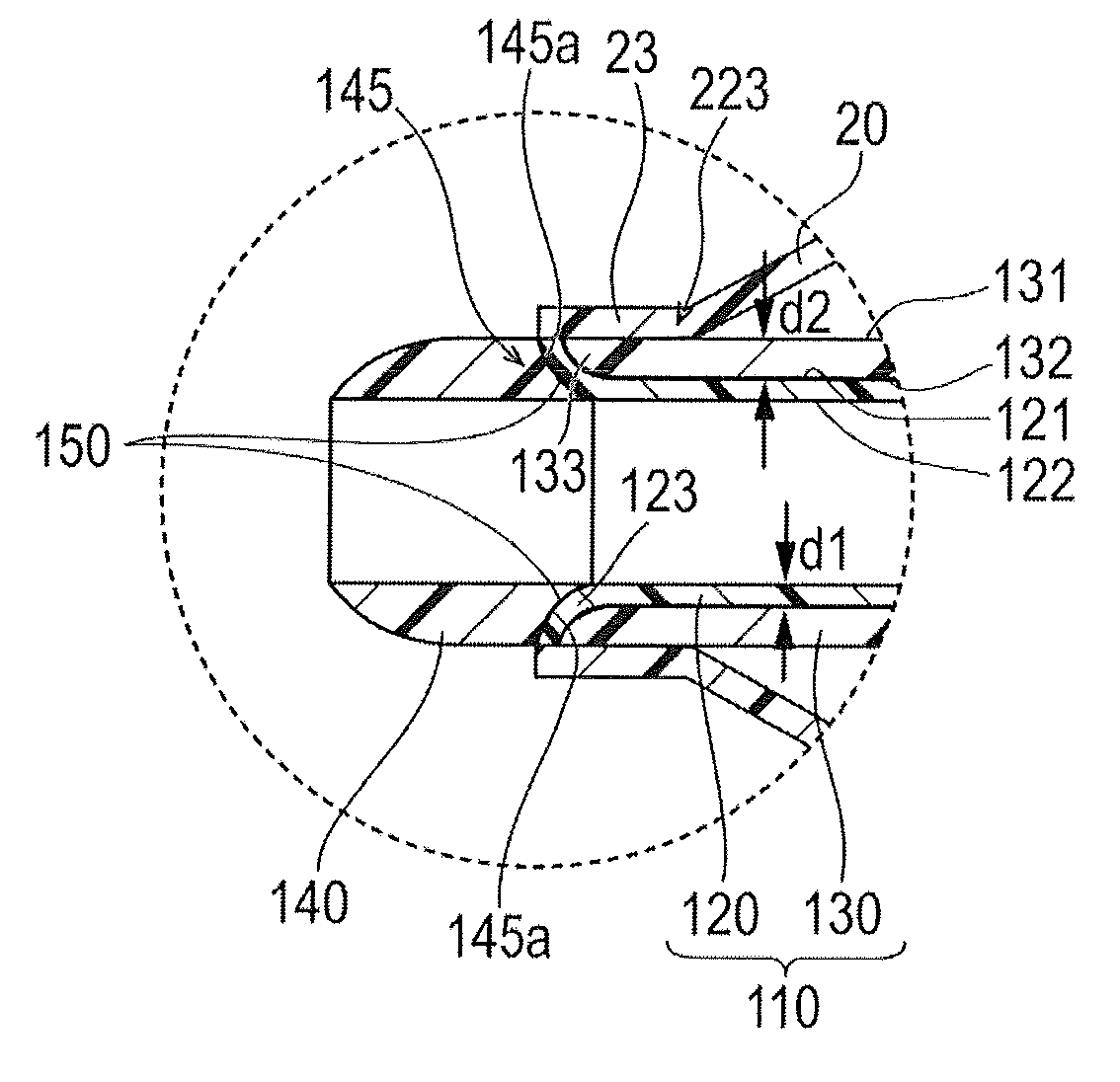

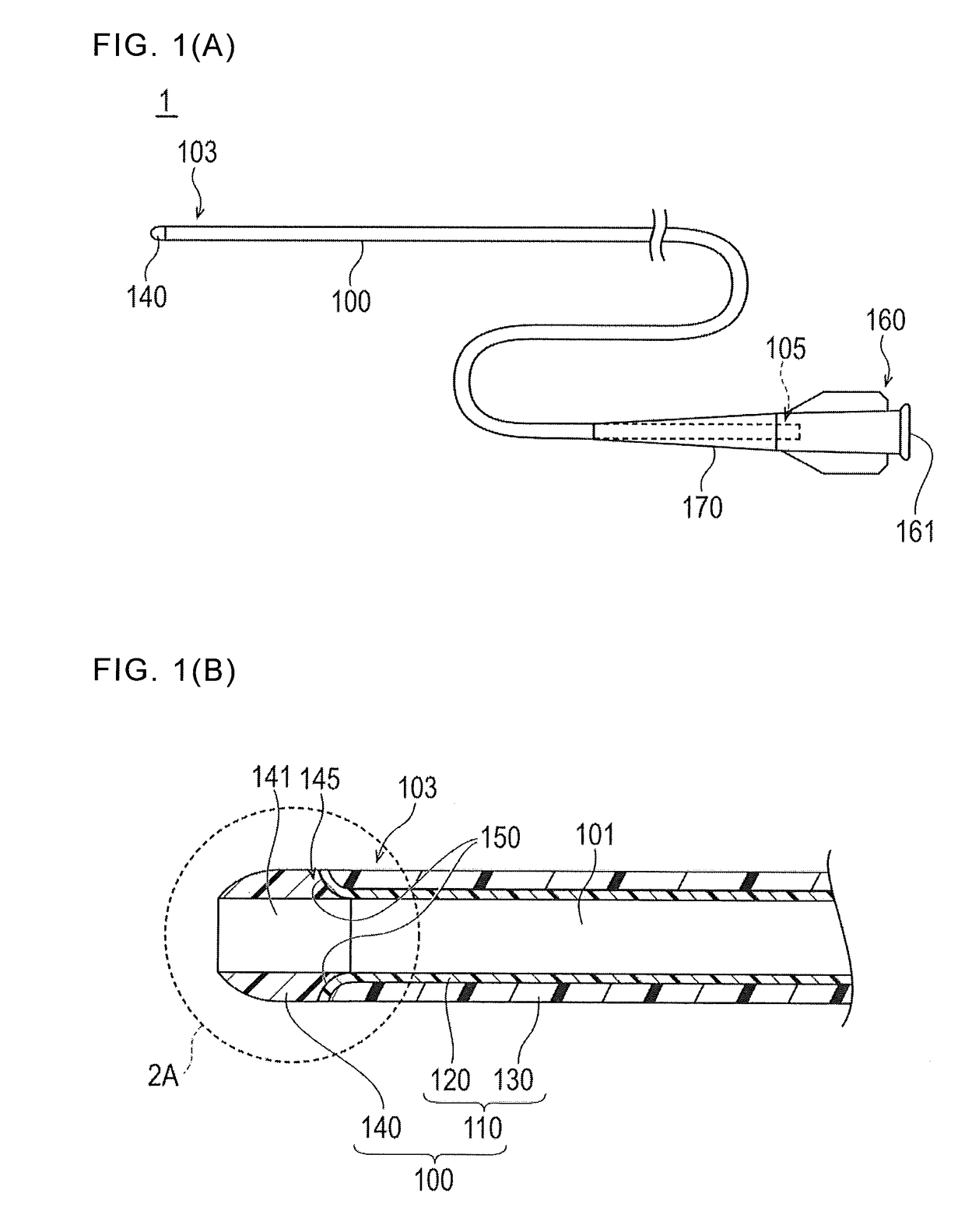

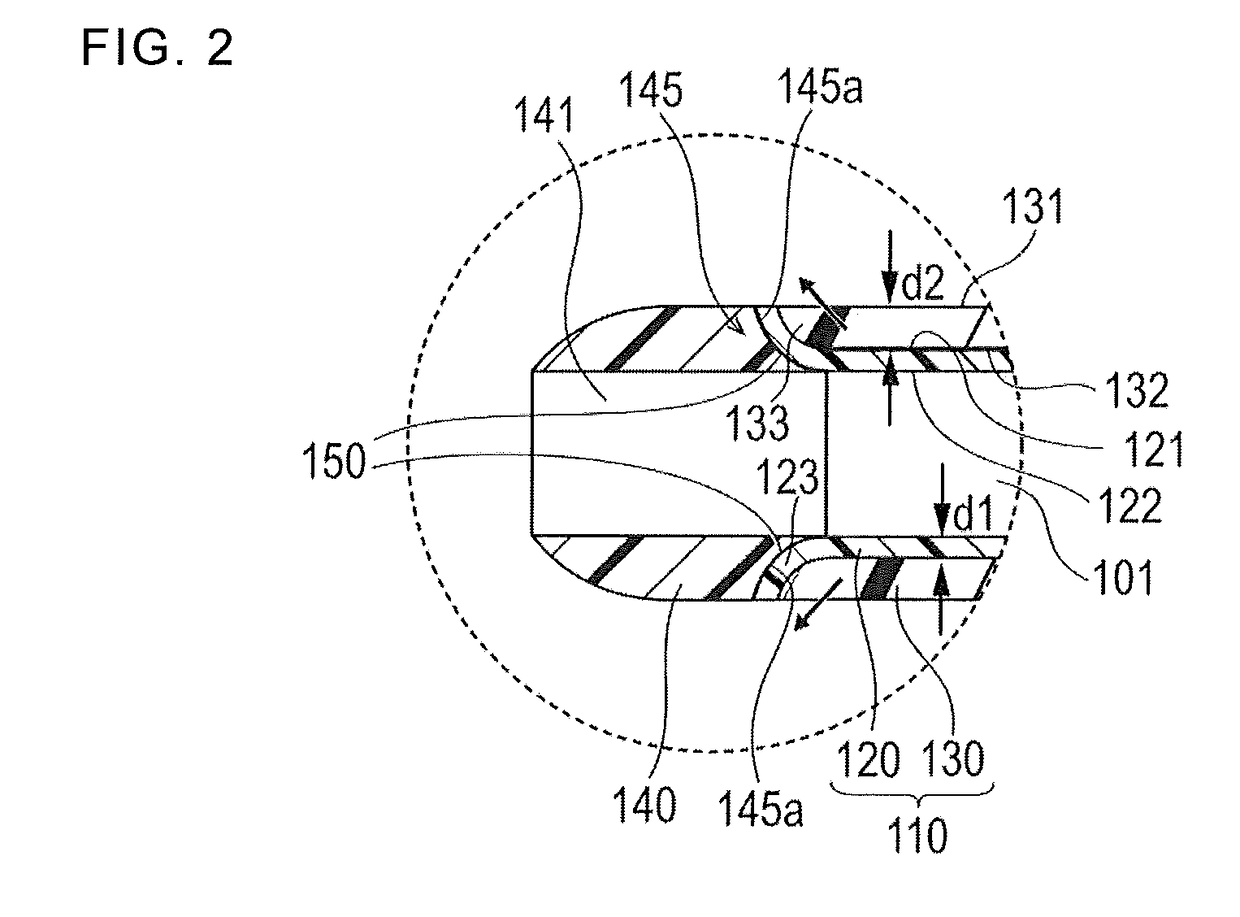

Medical elongated body and balloon catheter

ActiveUS10617852B2Improve joint strengthJoining strengthBalloon catheterGuide wiresBalloon catheterBiomedical engineering

A medical elongated body or a balloon catheter that include a catheter main body, a tubular body, and a distal member at a distal end of the tubular body. The distal member is more flexible than the tubular body. The distal end of the tubular body is joined to the distal member at a joint portion. The tubular body includes an outer layer and an inner layer disposed inside of the outer layer in the radial direction of the tubular body. The material of the inner layer possesses better fusing properties with respect to the distal member than the fusing properties of the outer layer material with respect to the distal member material. The inner layer is interposed between the distal member and the outer layer by extending between the distal member and the outer layer at the joint portion.

Owner:TERUMO KK

Medical elongated body and balloon catheter

ActiveUS20170224965A1Improve joint strengthJoining strengthBalloon catheterGuide wiresBalloon catheterBiomedical engineering

A medical elongated body or a balloon catheter that include a catheter main body, a tubular body, and a distal member at a distal end of the tubular body. The distal member is more flexible than the tubular body. The distal end of the tubular body is joined to the distal member at a joint portion. The tubular body includes an outer layer and an inner layer disposed inside of the outer layer in the radial direction of the tubular body. The material of the inner layer possesses better fusing properties with respect to the distal member than the fusing properties of the outer layer material with respect to the distal member material. The inner layer is interposed between the distal member and the outer layer by extending between the distal member and the outer layer at the joint portion.

Owner:TERUMO KK

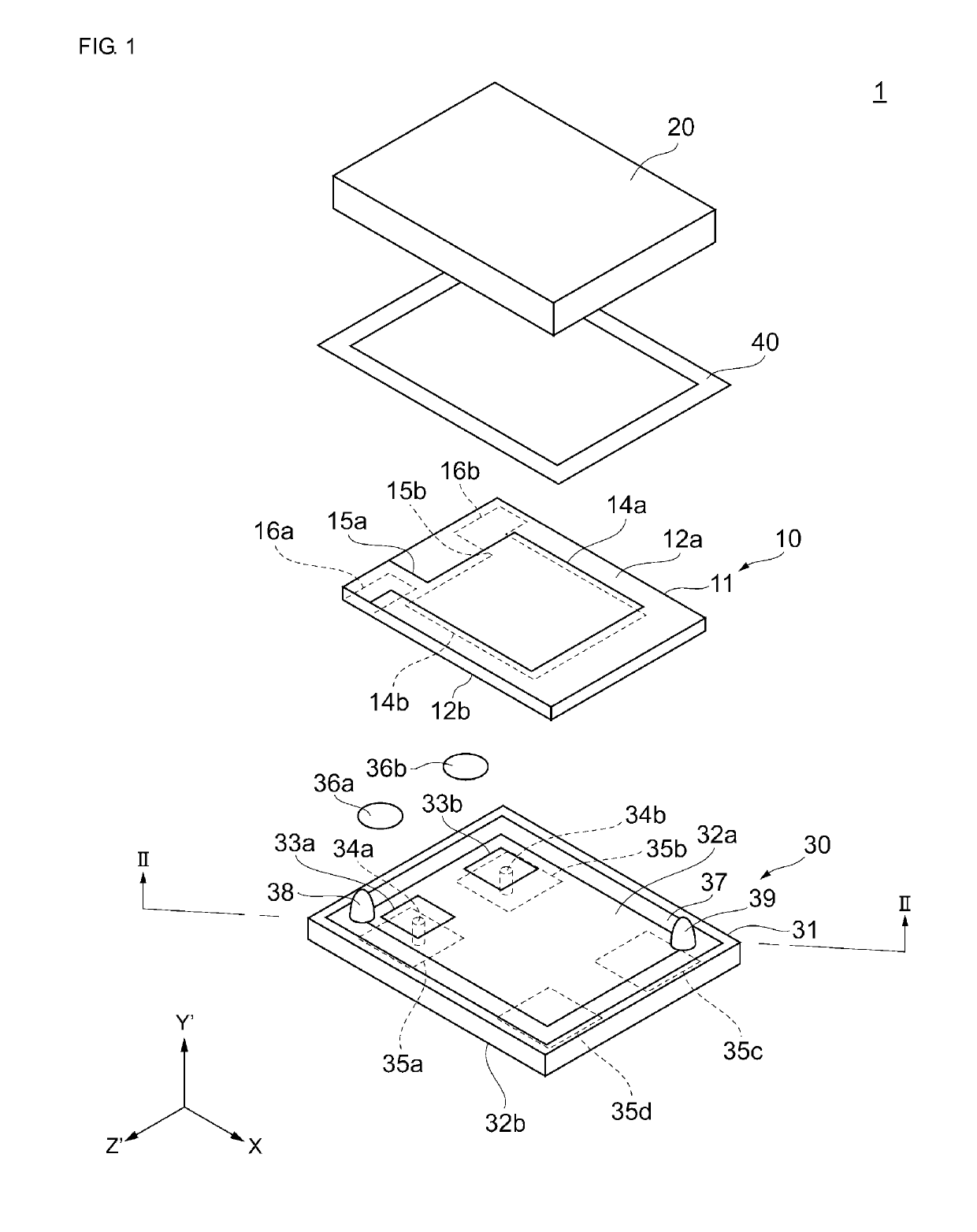

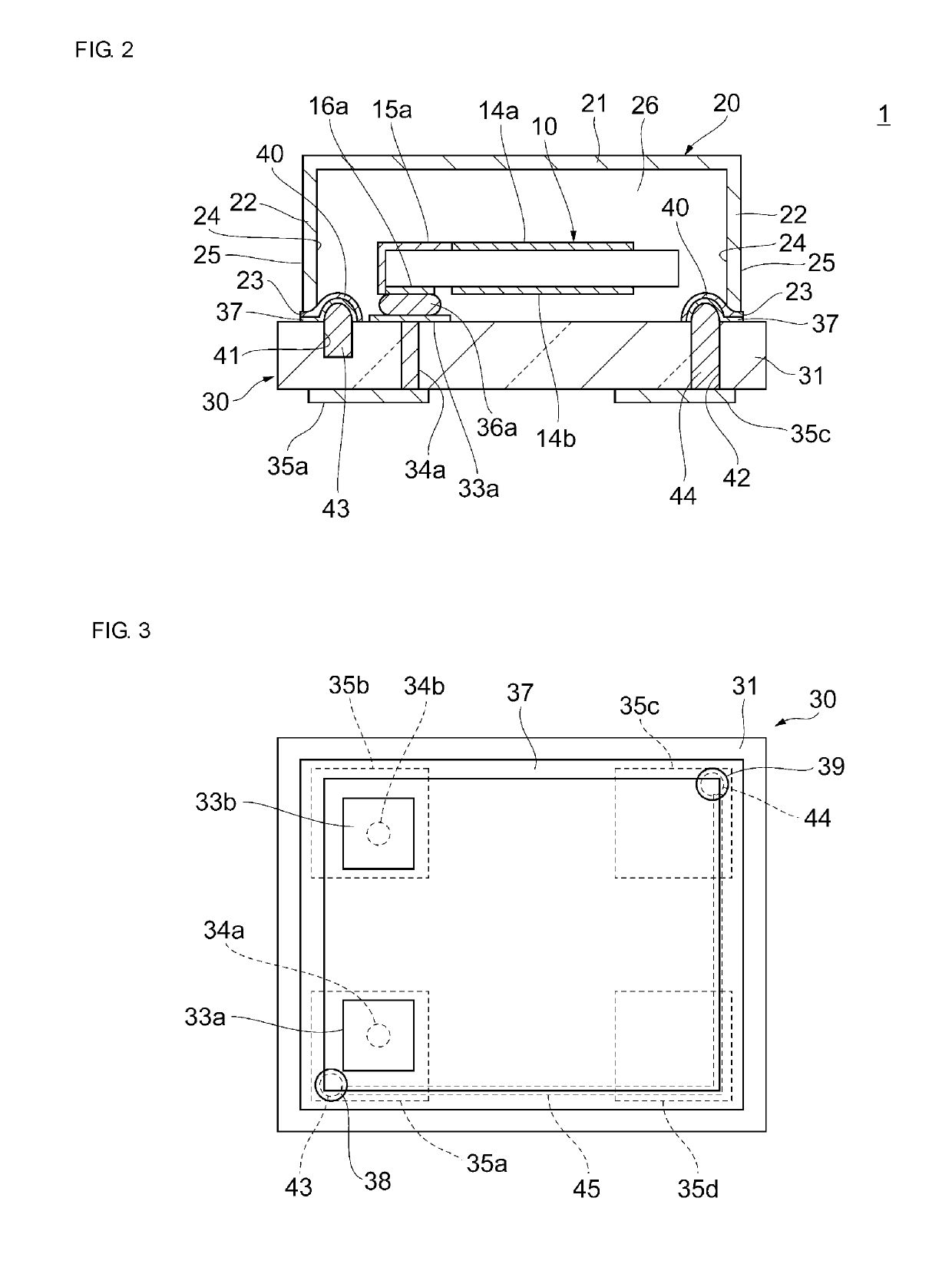

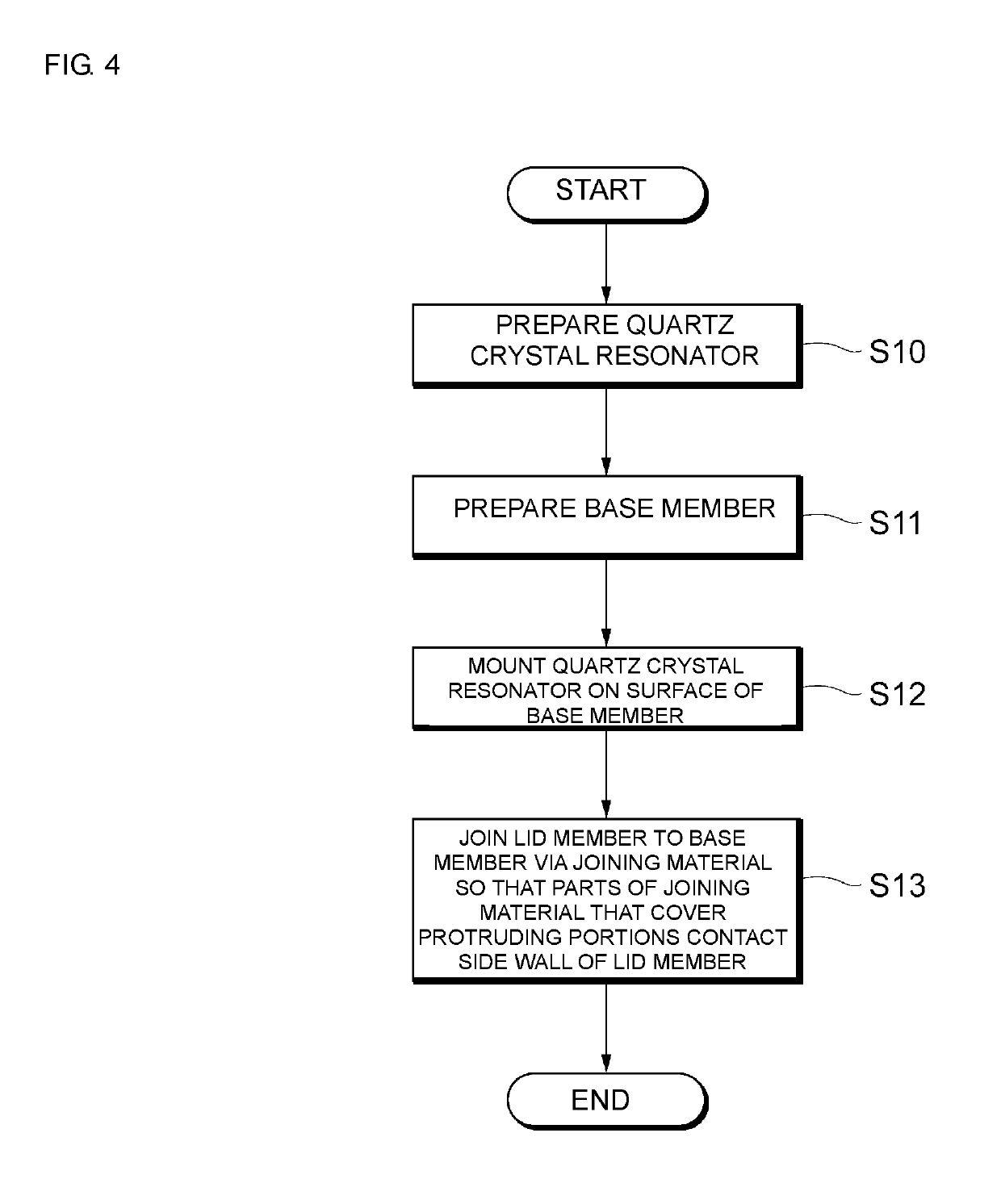

Quartz crystal resonator unit and method of manufacturing the same

PendingUS20190245512A1Joining strengthEnhance joining strengthImpedence networksQuartz crystal resonatorEngineering

A quartz crystal resonator unit includes a quartz crystal resonator that includes a quartz crystal blank. A pair of excitation electrodes are disposed on opposed main surfaces of the quartz crystal blank so as to face each other. A pair of connection electrodes are electrically connected to respective ones of the pair of excitation electrodes. A base member has a surface on which the quartz crystal resonator is mounted. A lid member is joined to the surface of the base member via a joining member. The quartz crystal resonator is accommodated in an inner space defined by the lid member and the base member on the surface of the base member. Parts of the joining member that cover protruding portions are in contact with a side wall of the lid member so as to restrain movement of the lid member when seen in a plan view in a direction normal to the surface of the base member.

Owner:MURATA MFG CO LTD

Spark plug

ActiveUS10283941B2Suppress stressJoining strengthSpark gap detailsSparking plugs manufactureShortest distanceEngineering

An electrode of the spark plug includes a first melt portion formed between a body portion of an intermediate member and a noble metal tip; and a second melt portion that is formed, between a flange portion of the intermediate member and an electrode base material, at least at a position of intersection with an axial line of the noble metal tip. In a cross section including the axial line of the noble metal tip, when: a diameter of the noble metal tip is denoted by Tw; the shortest distance between the second melt portion and a boundary between the first melt portion and the intermediate member is denoted by S1; and the longest distance between the second melt portion and the boundary between the first melt portion and the intermediate member is denoted by S2, 1.0 mm≤Tw≤1.2 mm and (S2−S1)≤0.3 mm are met.

Owner:NGK SPARK PLUG CO LTD

Member joining method

ActiveUS10480556B1Improve joint strengthJoining strengthMaterial gluingSuperstructure subunitsEngineeringMechanical engineering

A member joining method includes applying a first resin member to a first member and a second resin member to a second member and joining end portions of the first and second members together. The member joining method further includes integrally joining the first resin member of the first member and the second resin member of the second member by heat deformation to mix and cure areas adjacent the end portions at a time of coating.

Owner:NISSAN MOTOR CO LTD

Manufacturing method of rotor

ActiveUS20200295637A1Joining strength can be ensuredJoining strengthMagnetic circuit rotating partsManufacturing stator/rotor bodiesRotational axisEngineering

The manufacturing method of a rotor includes: a step of preparing a plate that is composed of an austenitic material and that has a projected portion and a part with a width in a rotational axis direction smaller than a width of the projected portion in the rotational axis direction; and a step of forming a welded portion across the projected portion of the plate and a rotation transmitting member by emitting an energy beam on at least a part of the projected portion to melt at least a part of the projected portion.

Owner:AISIN CORP

Manufacturing method of rotor

ActiveUS11336159B2Joining strengthMagnetic circuit rotating partsManufacturing stator/rotor bodiesRotational axisAustenite

The manufacturing method of a rotor includes: a step of preparing a plate that is composed of an austenitic material and that has a projected portion and a part with a width in a rotational axis direction smaller than a width of the projected portion in the rotational axis direction; and a step of forming a welded portion across the projected portion of the plate and a rotation transmitting member by emitting an energy beam on at least a part of the projected portion to melt at least a part of the projected portion.

Owner:AISIN CORP

Structure of joining resin molded bodies

InactiveUS7799155B2Reliable and superior strengthJoining strengthLaminationLamination apparatusEngineeringMechanical engineering

A reliable and superior joining strength in entire joining parts of resin molded bodies including tilting portions is obtained by devising a shape and a size of each protrusion for welding provided in the joining parts of the resin molded bodies. The joining parts of upper and lower half bodies 10 and 20 have vertical portions 11 and 13 and vertical portions 21 and 23 respectively vertical to a pressurizing direction and tilting portions 12 and 22 tilting relative to the pressurizing direction, and protrusions for welding 11E to 13E or 21E to 23E are provided in at least the joining part of one of the half bodies. Further, referring to a butting area of the protrusions in a butted state, the butting area in the vertical portions is set to be less than the butting area in the tilting portions.

Owner:DAIKYONISHIKAWA CORP

Composite component

InactiveUS20180339494A1Improve joint strengthJoining strengthDomestic articlesSuperstructuresEngineeringMechanical engineering

A composite component is a composite component including a metal portion formed of a metal and a resin portion formed of a resin. The metal portion includes: a main body portion, a plurality of hole portions provided along any one of directions separating from each other and directions parallel to each other in the main body portion from outside toward inside, and a connecting portion configured to connect the hole portions to each other inside the main body portion. The resin portion includes: a cover portion covering the main body portion in a position corresponding to at least the hole portions, and a joint portion provided in a protruding manner from the cover portion to be positioned inside the plurality of hole portions, the joint portion being continuous in a position of the connecting portion.

Owner:NIHON PLAST CO LTD

Member joining method

ActiveUS20190338795A1Improve joint strengthJoining strengthMaterial gluingSuperstructure subunitsEngineeringMechanical engineering

A member joining method includes applying a first resin member to a first member and a second resin member to a second member and joining end portions of the first and second members together. The member joining method further includes integrally joining the first resin member of the first member and the second resin member of the second member by heat deformation to mix arid cure areas adjacent the end portions at a time of coating.

Owner:NISSAN MOTOR CO LTD

Ceramic member

ActiveUS10515836B2Improve joint strengthJoining strengthSemiconductor/solid-state device manufacturingCeramic layered productsMaterials science

This ceramic member 100 includes: a ceramic base body 10 having a terminal 30 embedded therein; a blind hole 11 formed in the ceramic base body 10 and causing the lower surface of the ceramic base body 10 and the terminal 30 to communicate with each other; and a connection member 40 inserted in the blind hole 11, the connection member 40 connected to the terminal 30 by means of a brazing material solidified portion 70. In the blind hole 11, the space surrounded by the inner peripheral surface of the blind hole 11 has, at least at a bottom face 11a, an enlarged portion 11b that is enlarged toward the upper side at least partially with respect to the circumferential direction, and at least a part of the brazing material solidified portion 70 is present in the enlarged portion 11b.

Owner:NGK SPARK PLUG CO LTD

Motor vehicle body having a bodyshell and vehicle underbody, and having a securing structure component

ActiveUS10889335B2Joining strengthImprove joint strengthVehicle body-frame connectionsSuperstructure subunitsMotorized vehicleMechanical engineering

A motor vehicle body encompasses a surface-coated bodyshell having an underbody carrying portion and a underbody that is embodied separately from the bodyshell and is fixedly joined to the underbody carrying portion, the underbody having a planar, multiply curved underbody structure component encompassing fiber-reinforced plastic, as well as at least one underbody member, joined to the underbody structure component, having a member material different from the structural material of the underbody structure component; a support projection, on which the underbody member is braced and to which the underbody member is fixedly joined by adhesive bonding, protruding toward the vehicle interior from the underbody carrying portion; the vehicle body encompasses at least one securing structure component that is embodied separately both from the bodyshell and from the underbody and encompasses at least two limbs arranged at an angle to one another, which component is joined to the bodyshell and / or to the underbody member to secure the underbody on the bodyshell.

Owner:ROECHLING AUTOMOTIVE SE & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com