Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Increase dynamic pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

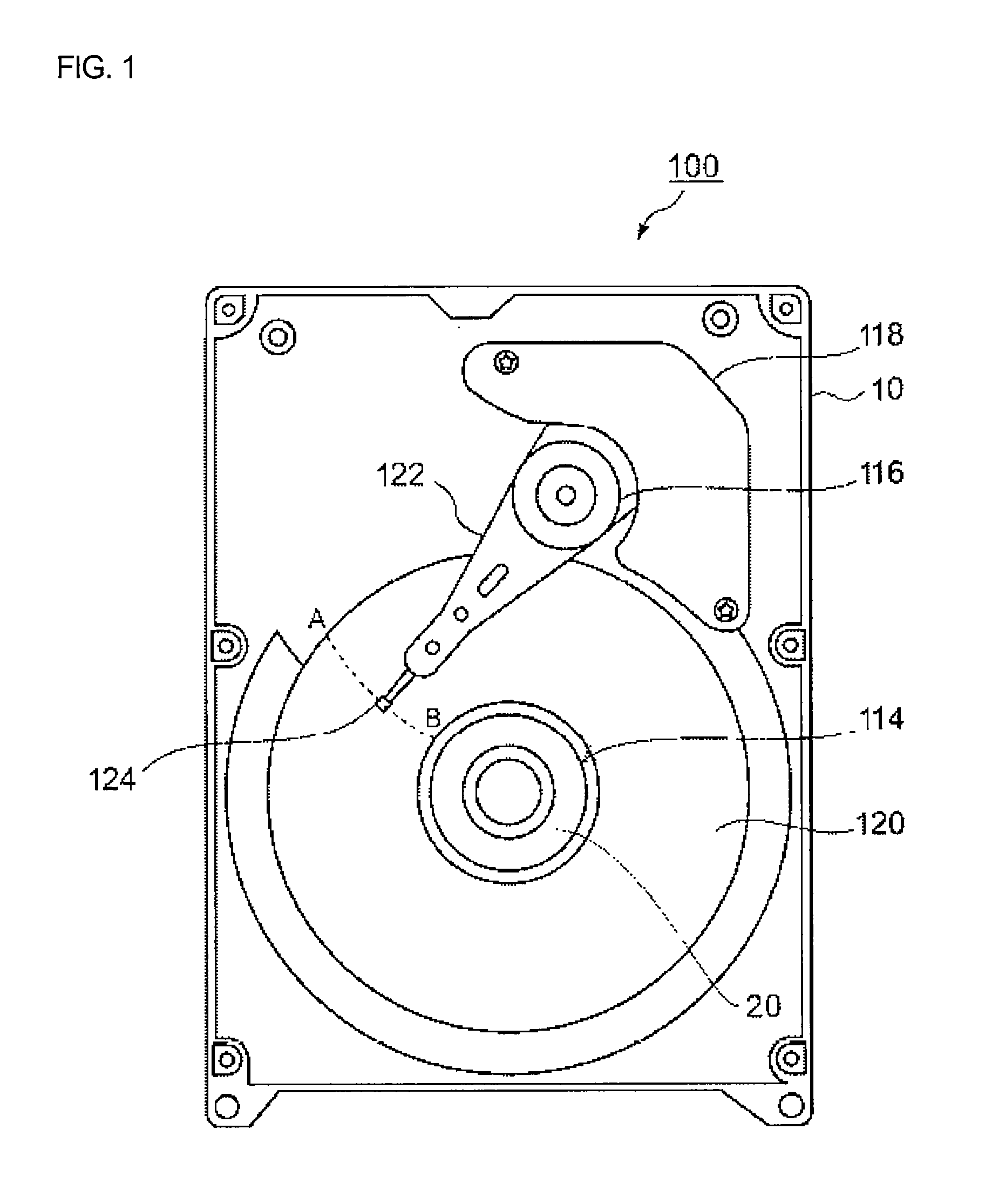

Fluid Dynamic Pressure Bearing and Recording Disk Drive Device Comprising the Same

InactiveUS20050244086A1Prevent negative pressureIncrease lifeRolling contact bearingsShaftsEngineeringAxial length

In a radial minute gap between a substantially columnar shaft and an inner peripheral face of a substantially cylindrical sleeve, oil is retained and a radial dynamic pressure bearing is formed. A plurality of recessed portions are arranged in a circumferential direction on at least one of an outer peripheral face of the shaft and the inner peripheral face of the sleeve and a first hill portion is provided to an axial end portion of each the recessed portion. Thus, it is possible to achieve a dynamic pressure bearing with which sufficient radial shaft support can be obtained in spite of a short axial length.

Owner:NIDEC CORP

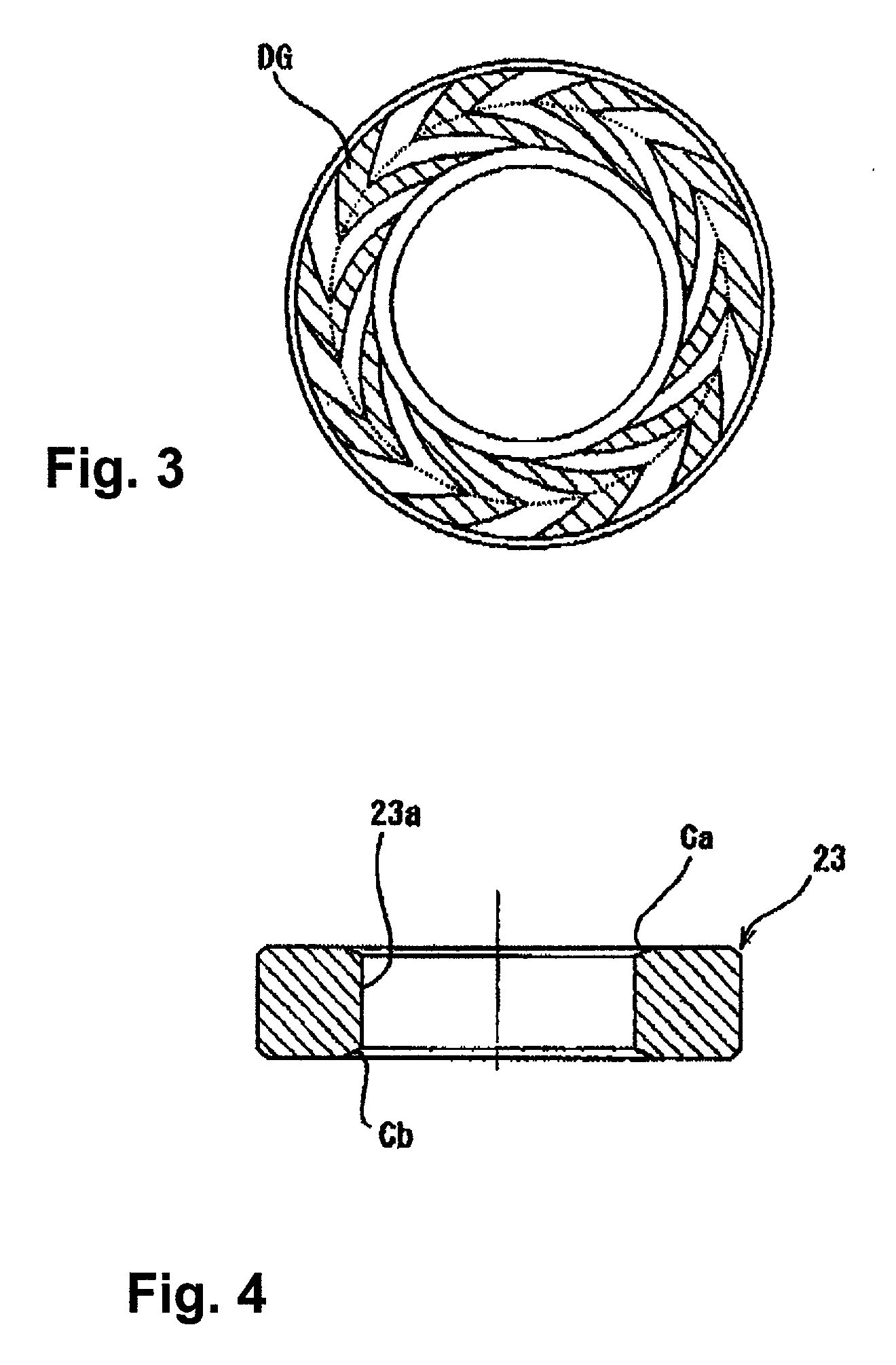

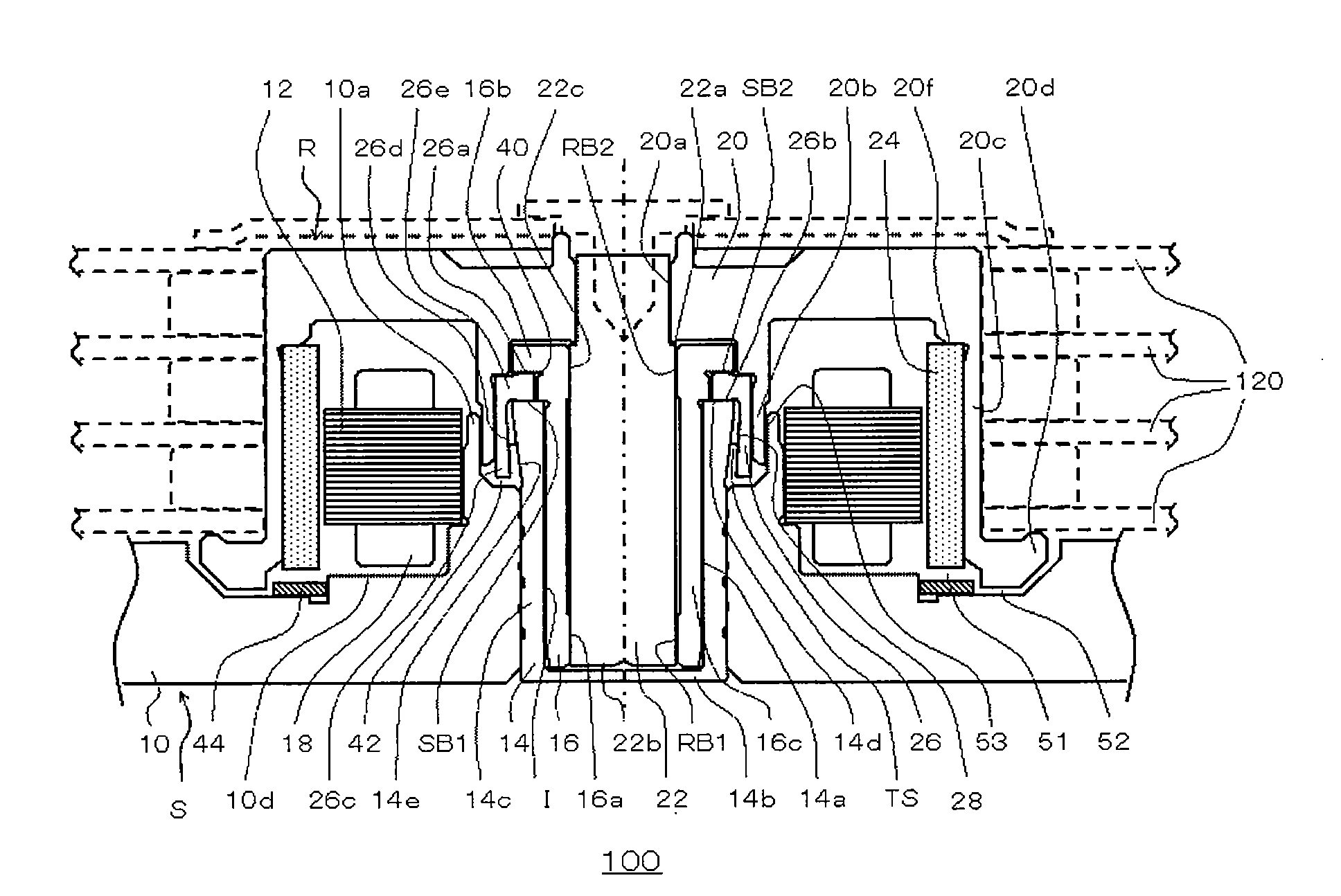

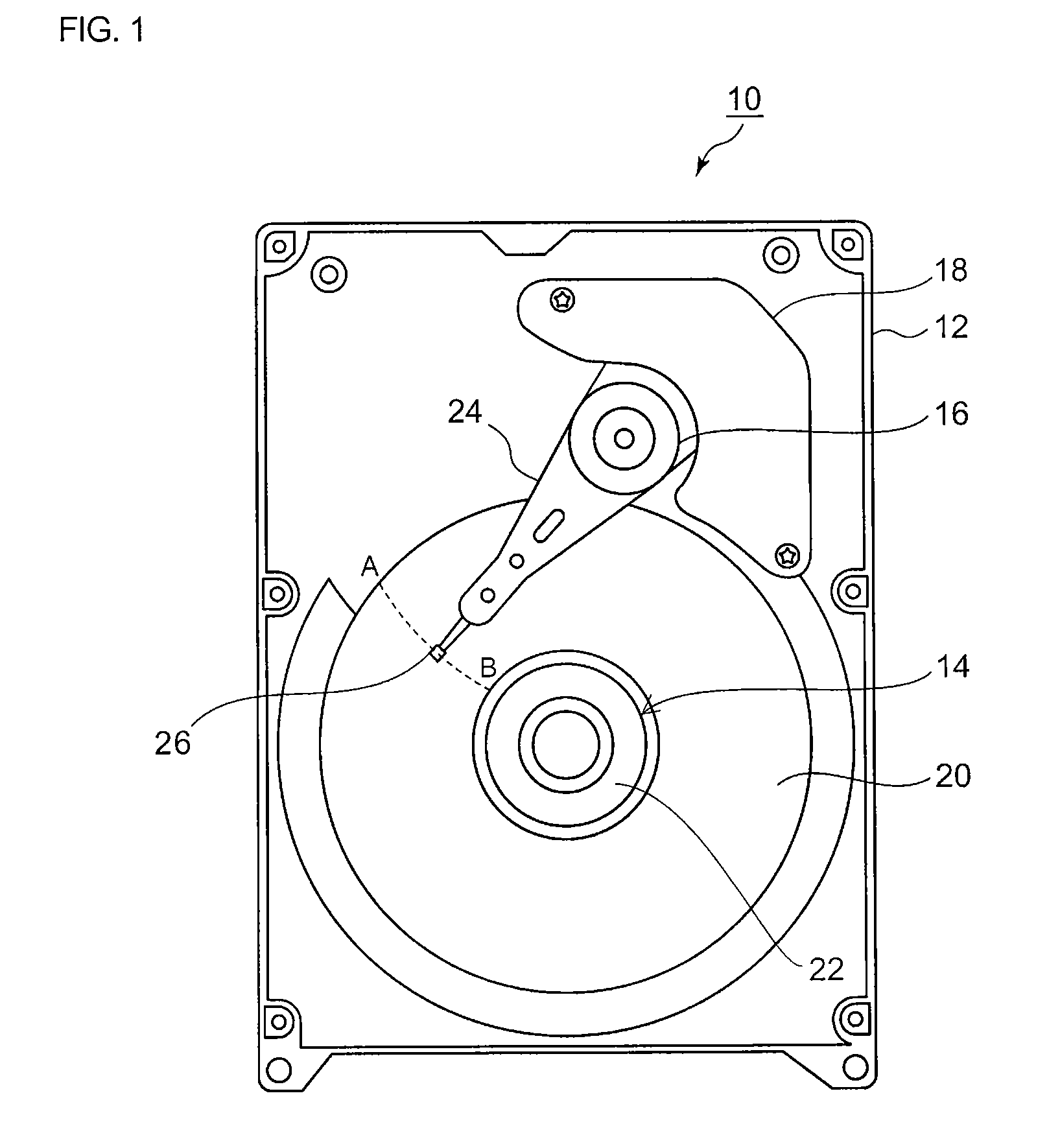

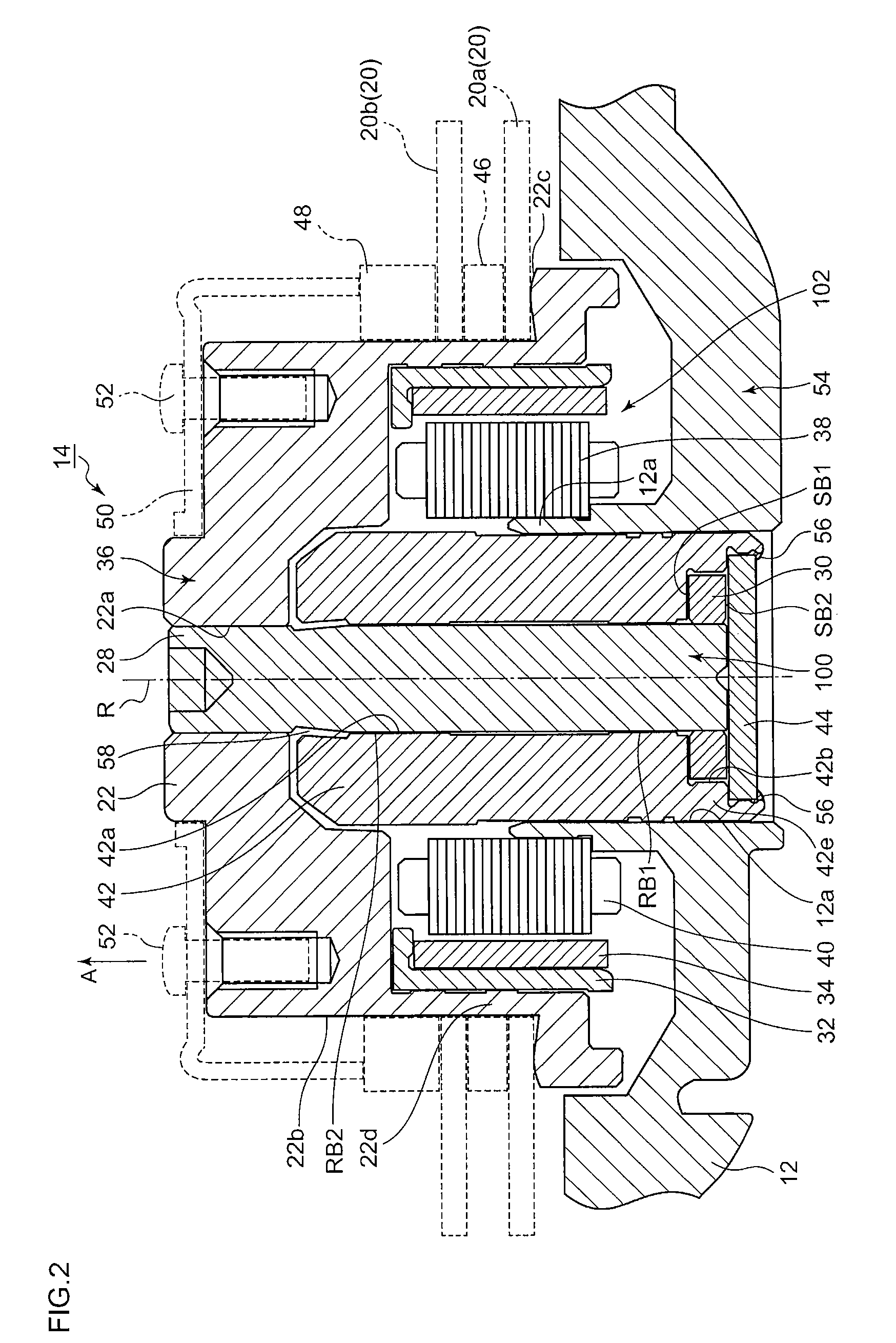

Disk drive device capable of being improved in Anti-vibration characteristic

InactiveUS20110064341A1Increase dynamic pressureStablyPiezoelectric/electrostrictive device manufacture/assemblyTurning machine accessoriesEngineeringDynamic pressure

A disk drive device includes: a hub on which a recording disk is to be mounted; a shaft; a sleeve configured to house the shaft and to be rotatable relatively with respect to the shaft; a radial space portion formed between the inner circumferential surface of the sleeve and the outer circumferential surface of the shaft; a radial dynamic pressure generating portion configured to generate radial dynamic pressure between at least part of the inner circumferential surface of the sleeve and the outer circumferential surface of the shaft in the radial space portion; and lubricant. The axial length of the radial dynamic pressure generating portion is formed to be longer than the diameter of the radial dynamic pressure generating portion such that radial dynamic pressure, which is defined with the axial length of the radial dynamic pressure generating portion and the diameter thereof being parameters, is greater than or equal to a predetermined minimum reference value.

Owner:SAMSUNG ELECTRO MECHANICS JAPAN ADVANCED TECHNOLOGY CO LTD

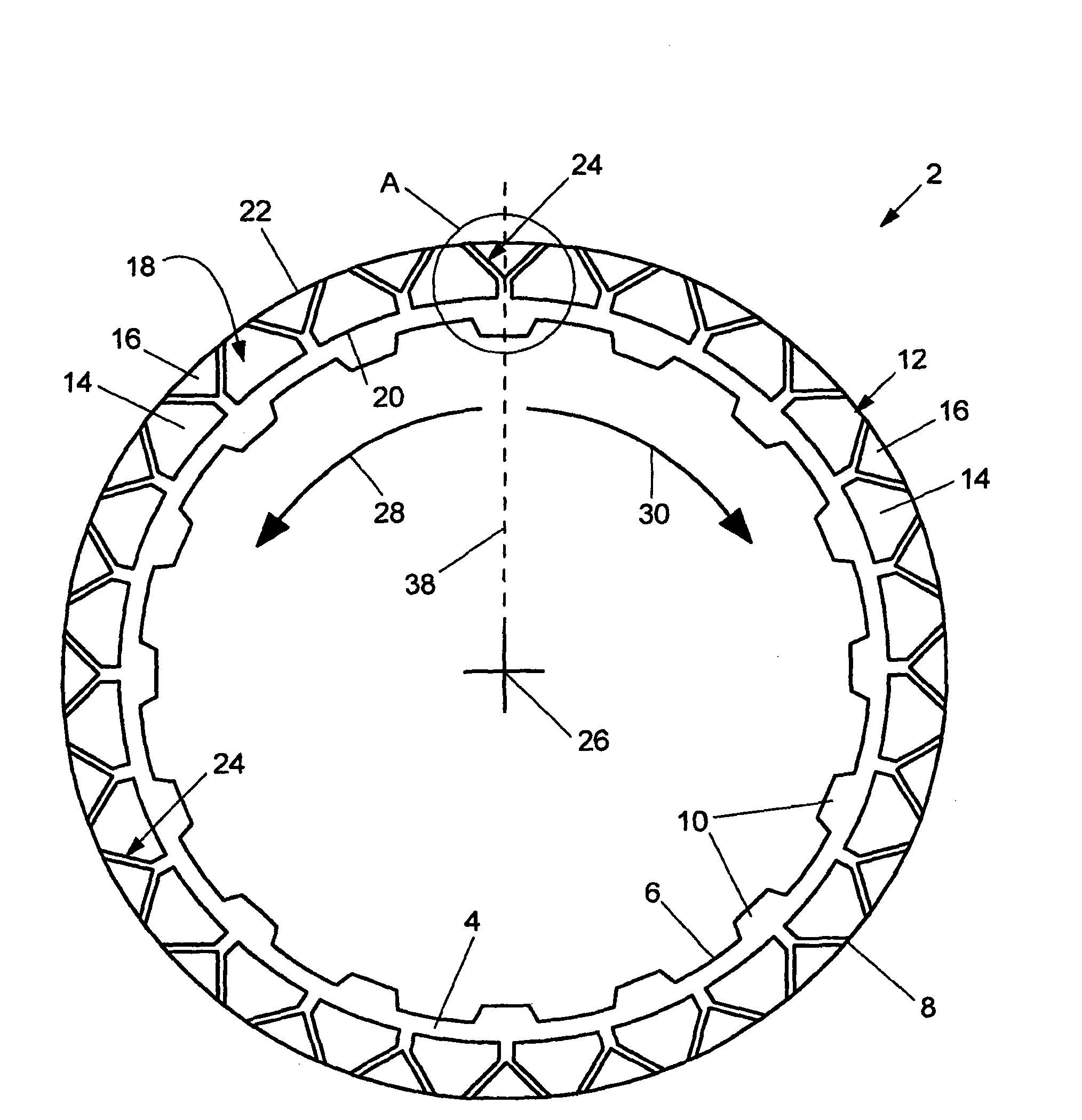

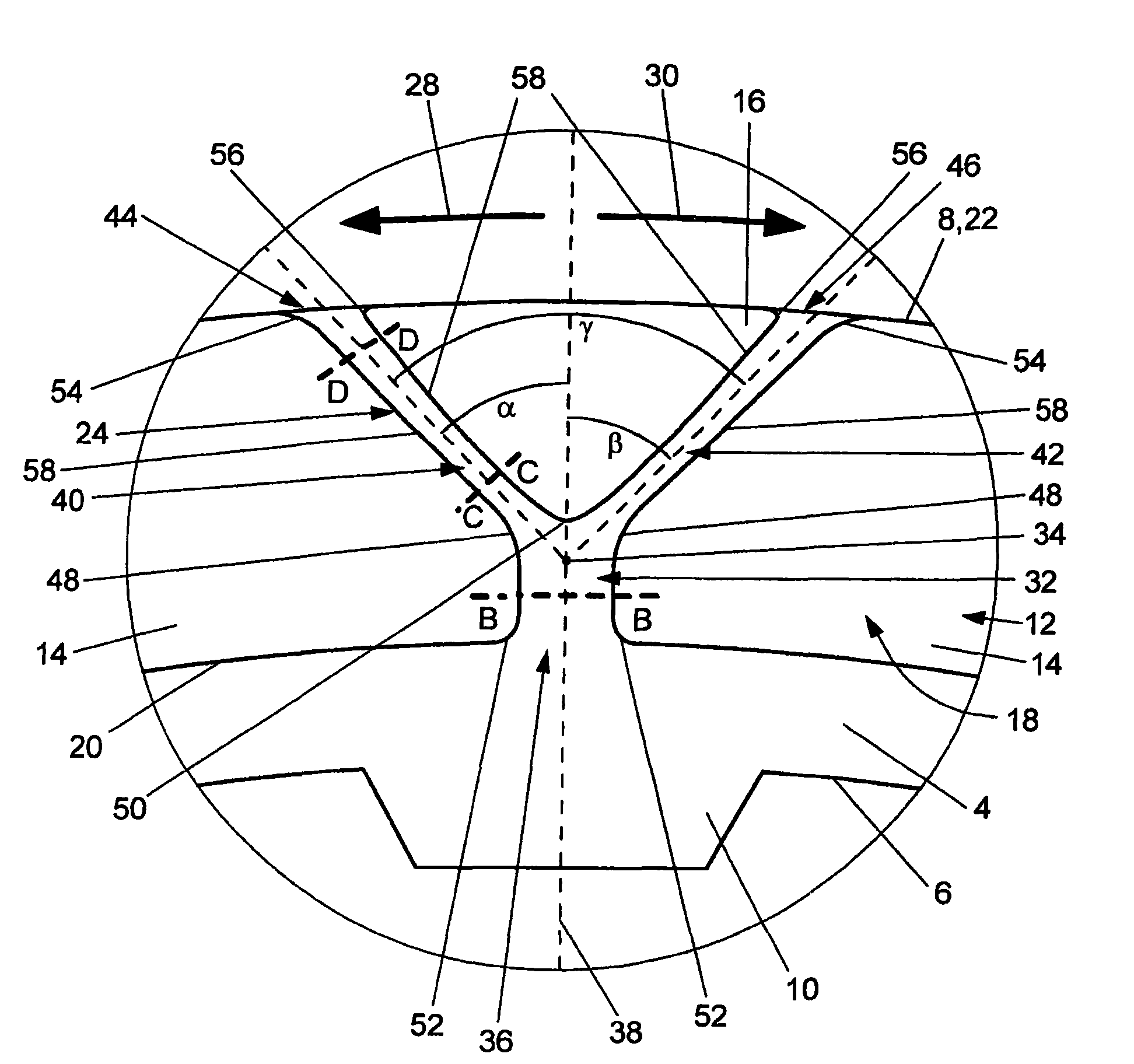

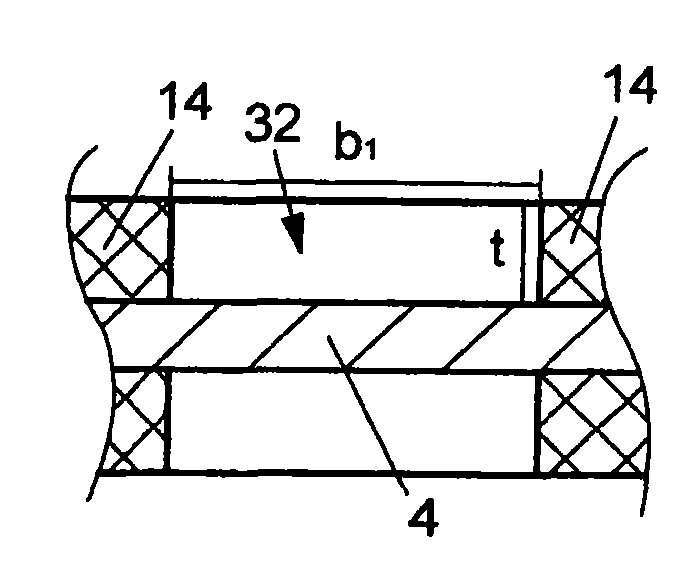

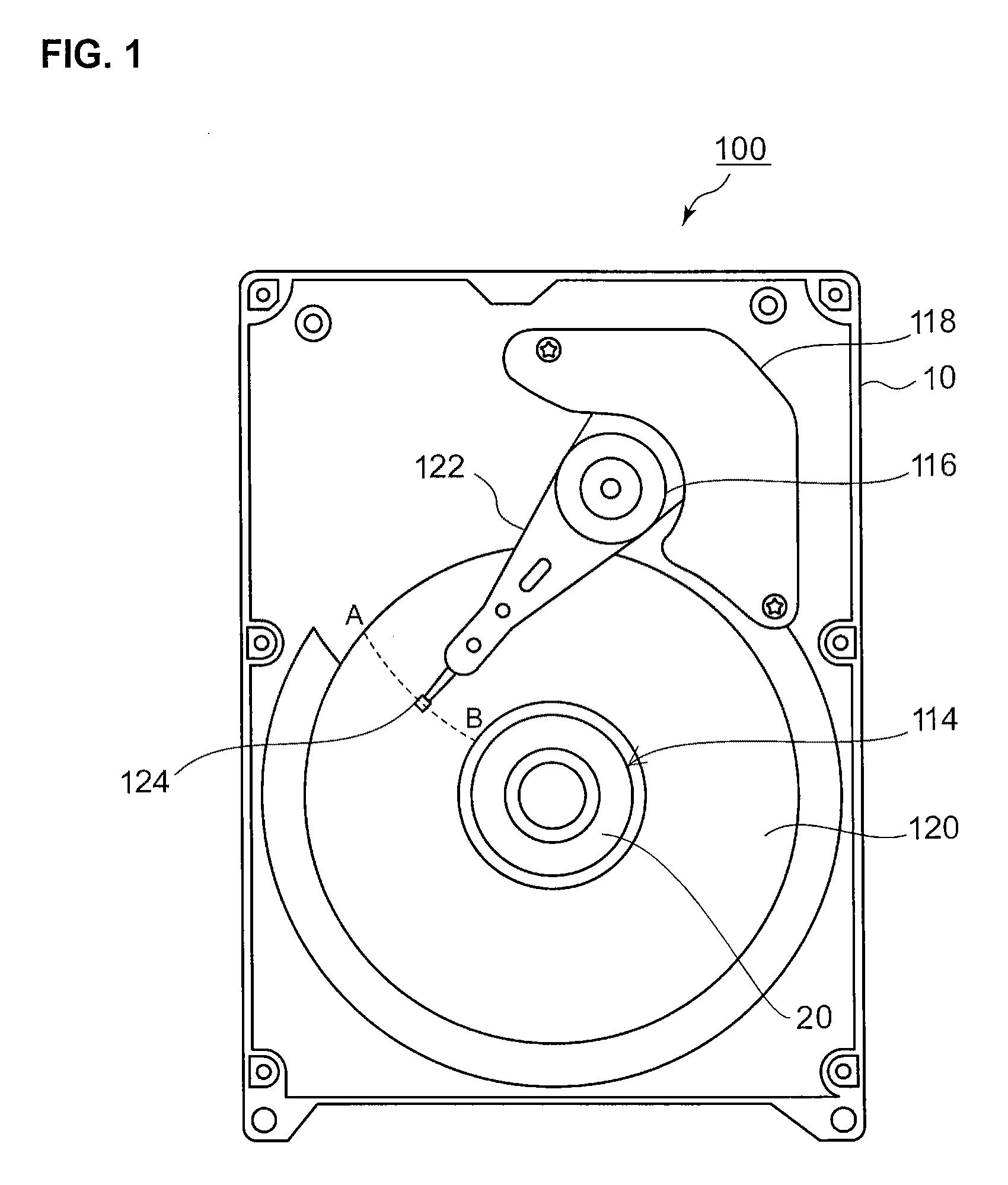

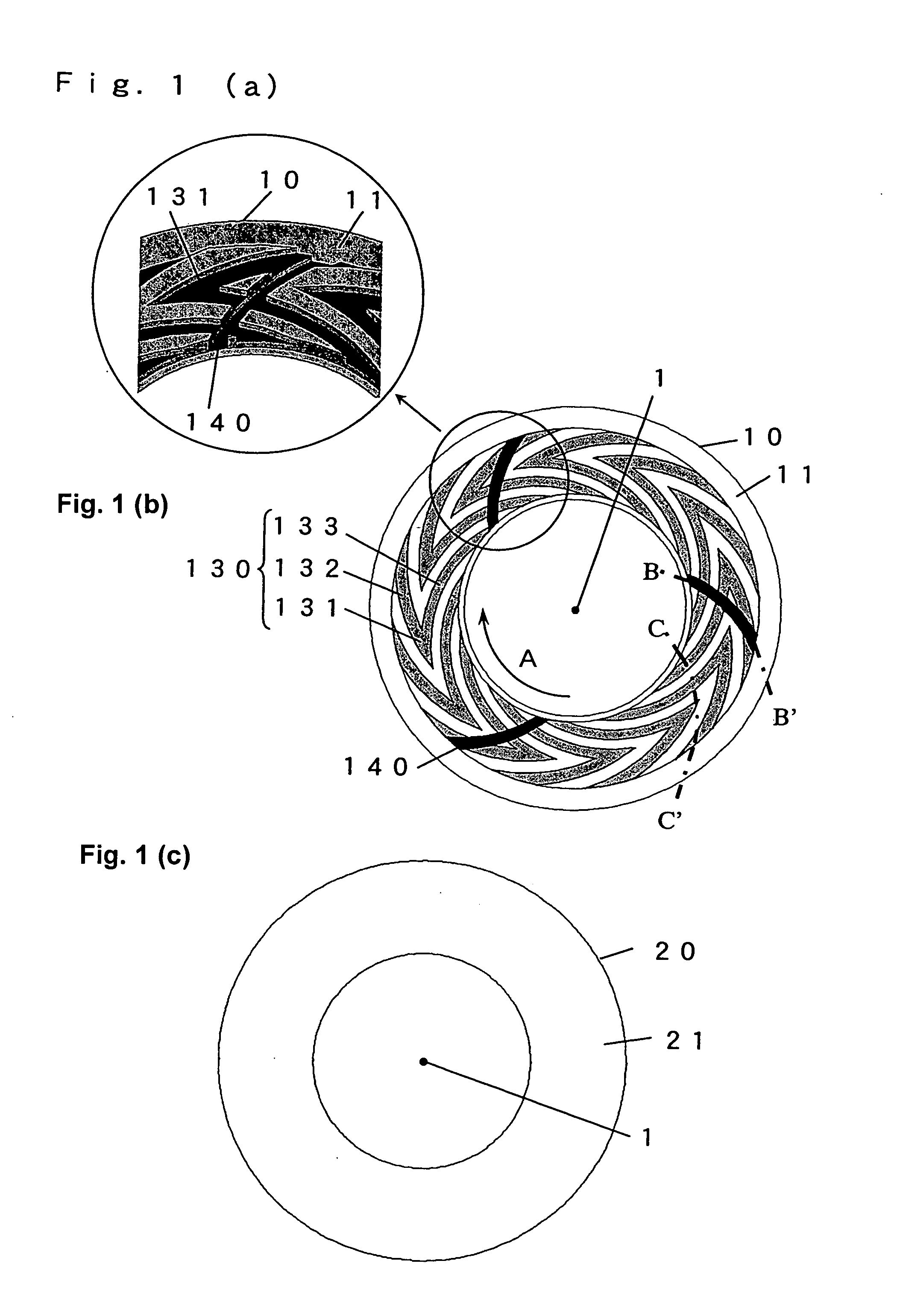

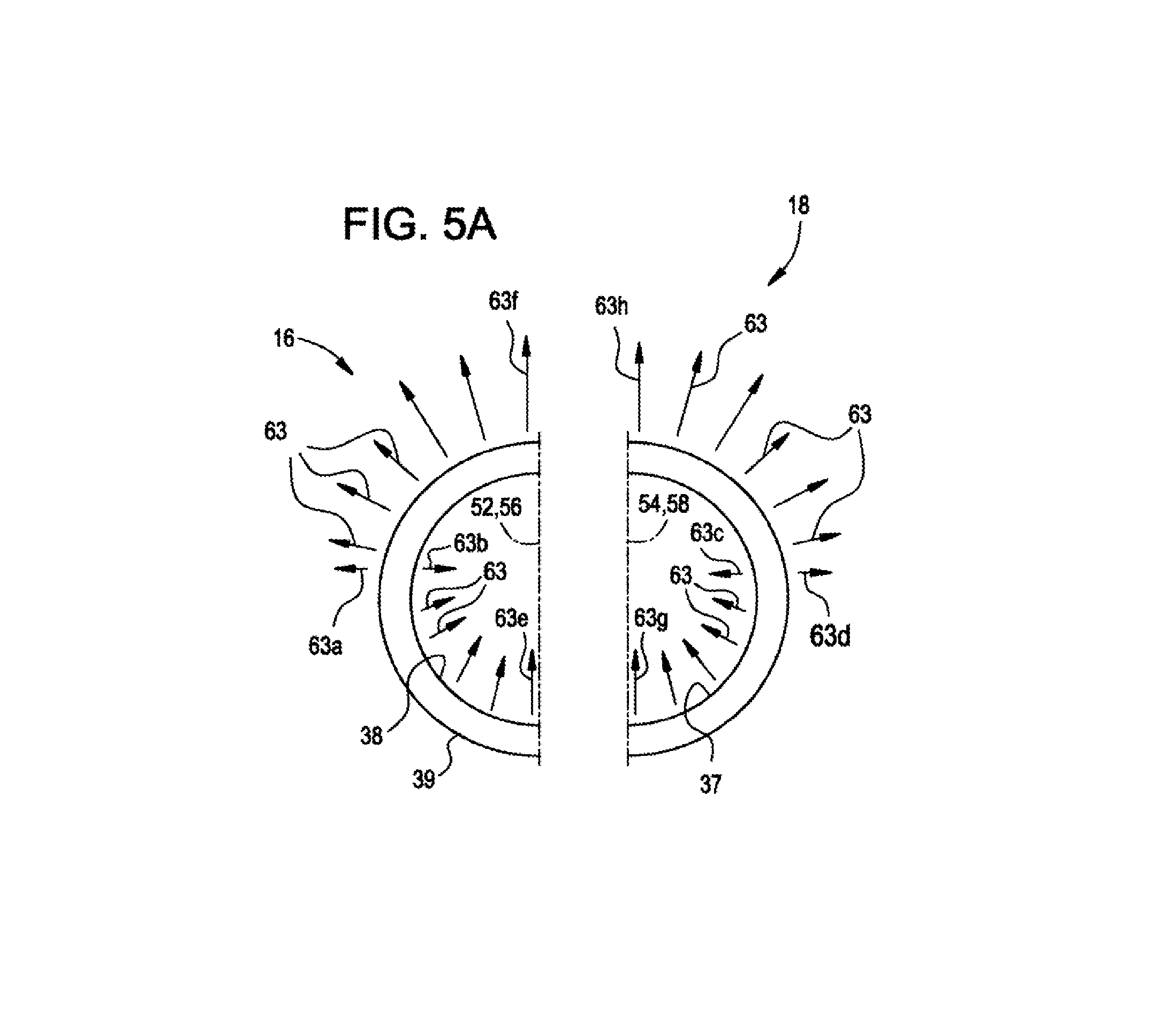

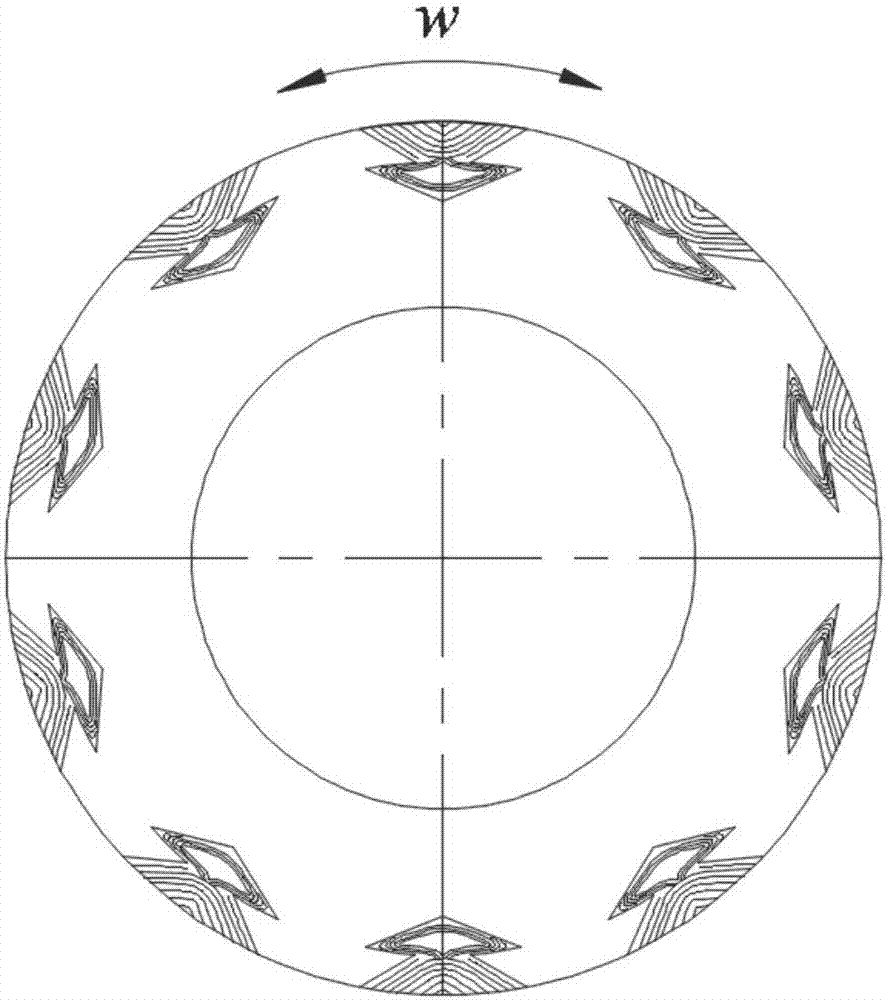

Friction part for a frictionally acting device, and frictionally acting device having a friction part of said type

InactiveCN101517256APromote absorptionAvoid vortexFriction clutchesFriction liningMechanical engineeringPhysics

The present invention relates to a friction part (2) for a frictionally acting device, having an annular friction face (18) which has an inner edge (20) and an outer edge (22), wherein at least one set of grooves (24) is provided in the friction face (18), which set of grooves (24) has a first groove (32) which extends from the inner edge (20) or the outer edge (22) to a branching point (34) between the inner edge (20) and the outer edge (22), and a second and third groove (40, 42) which extend in each case from the branching point (34) to the other edge (22, 20). According to the invention, the second groove (40) is inclined in the one peripheral direction (28) and the third groove (42) is inclined in the other peripheral direction (30) of the friction face (18) with respect to a radial line (38) through the branching point (34). The present invention also describes a frictionally acting device having a friction part (2) of said type.

Owner:BORGWARNER INC

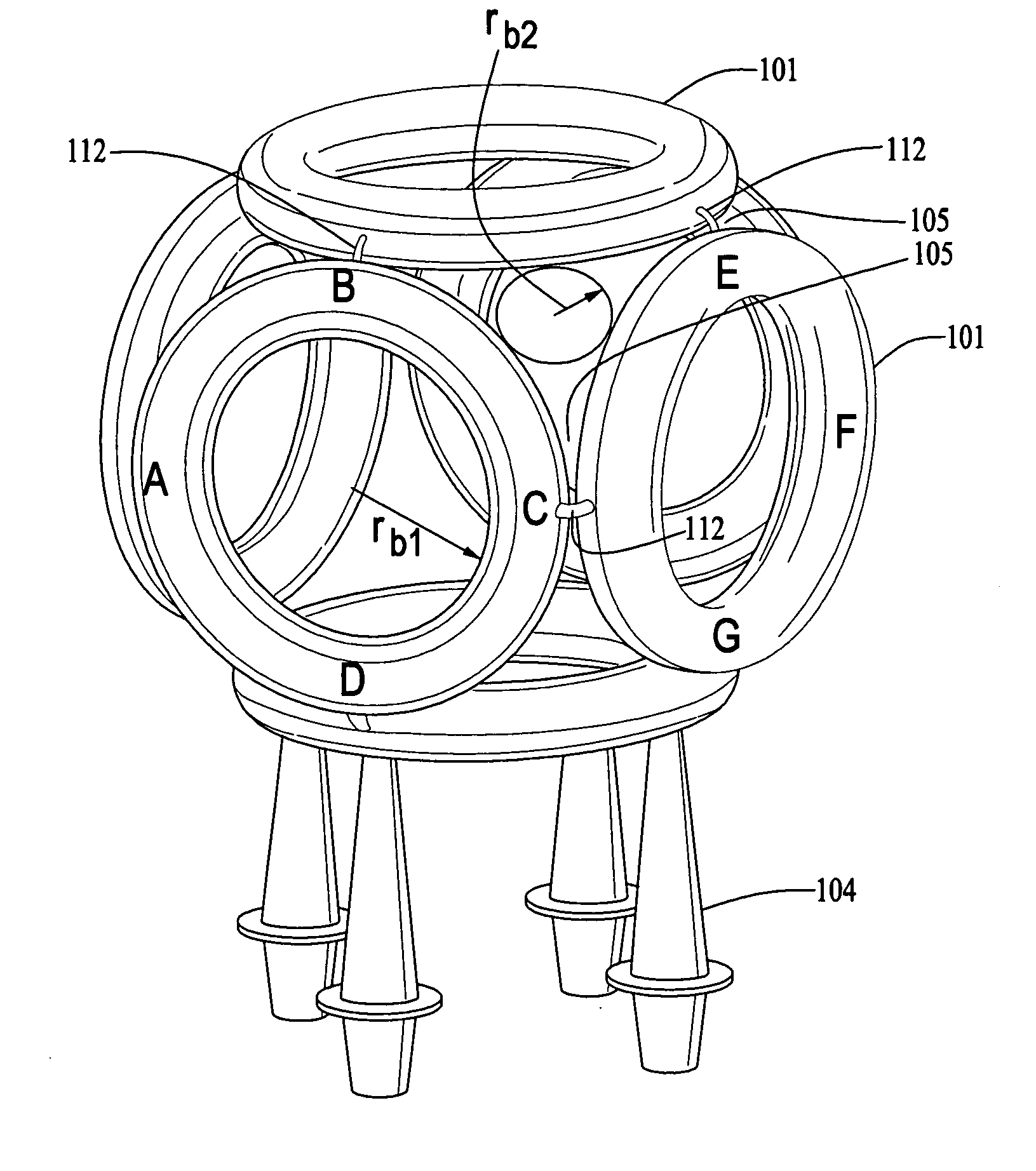

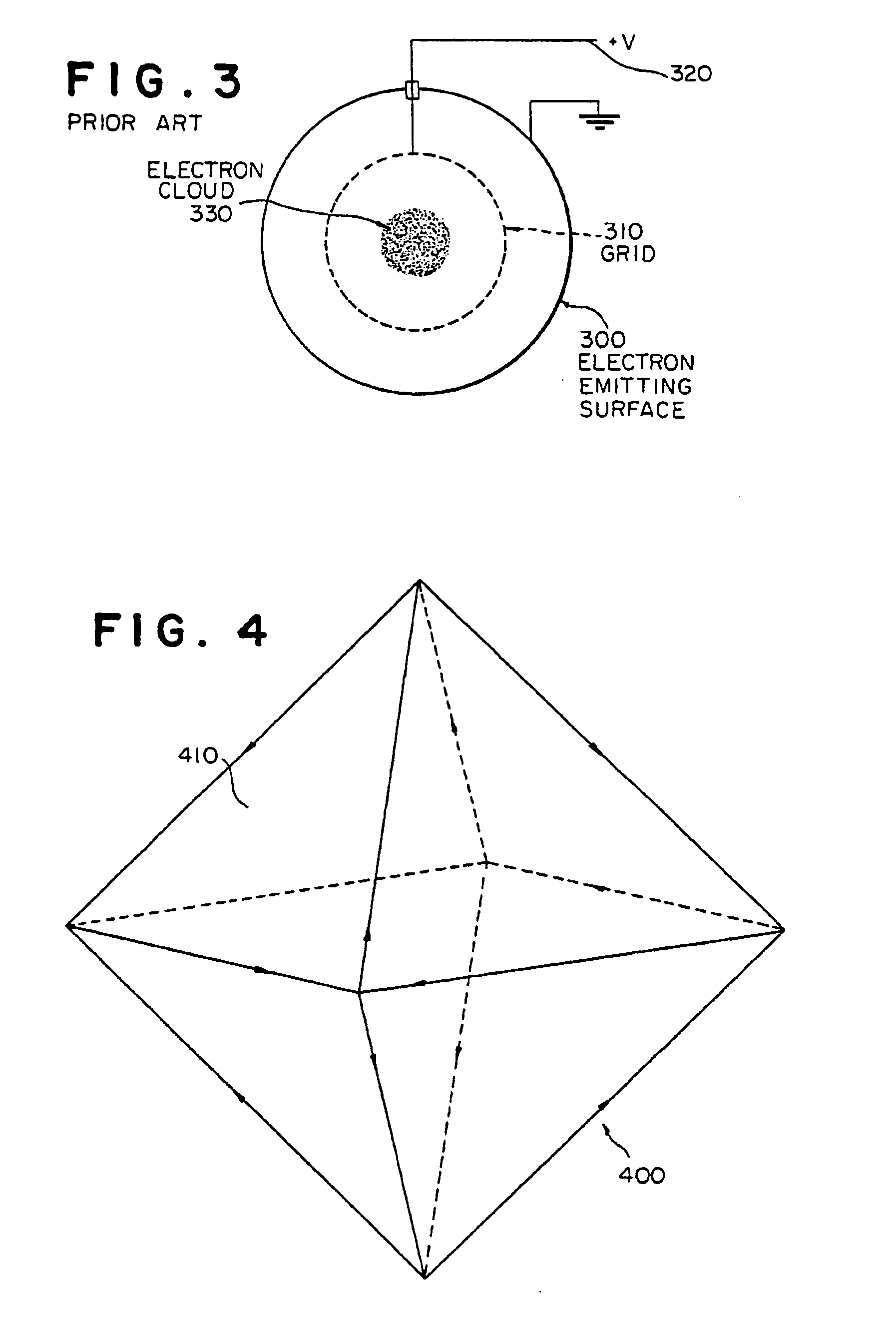

Method and apparatus for controlling charged particles

InactiveUS20110170647A1Increase dynamic pressureGood magnetic surface “ reflection ”Nuclear energy generationPlasma techniqueNegative potentialCharged particle

An apparatus and method for controlling charged particles. The charged particles comprise electrons and positive ions. A magnetic field having only point cusps is used to confine energetic injected electrons and so to generate a negative potential well. Positive ions injected into or created within the negative potential well are trapped therein. The magnetic field is generated by current-carrying elements arranged at positions spaced from but closely adjacent and parallel to edges of a polyhedron which has an even number of faces surrounding each vertex or corner. The current-carrying elements must be spaced apart at their corners (the vertices of the polyhedron) so as not to touch, and the containing structures for the current-carrying coils of the magnetic-field-providing system are conformal to the fields so produced.

Owner:EMC2

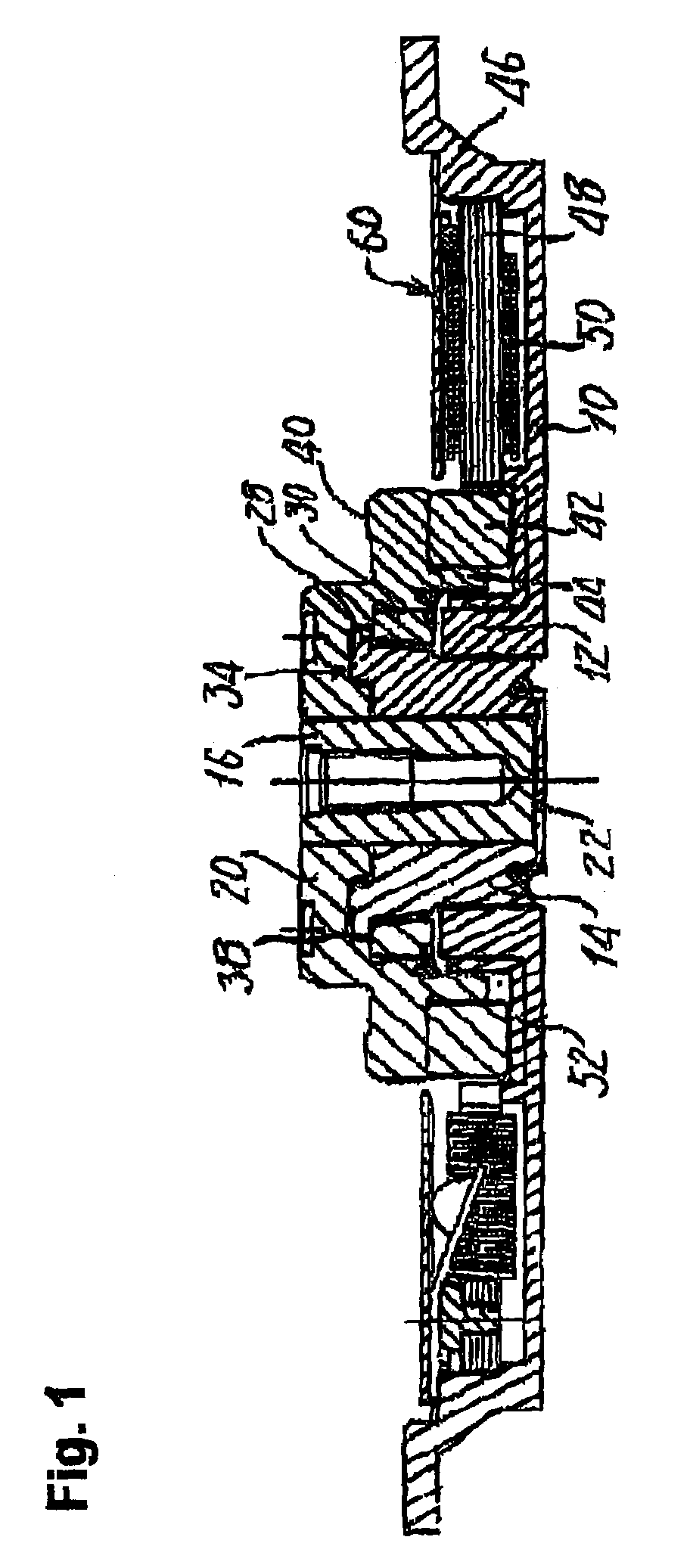

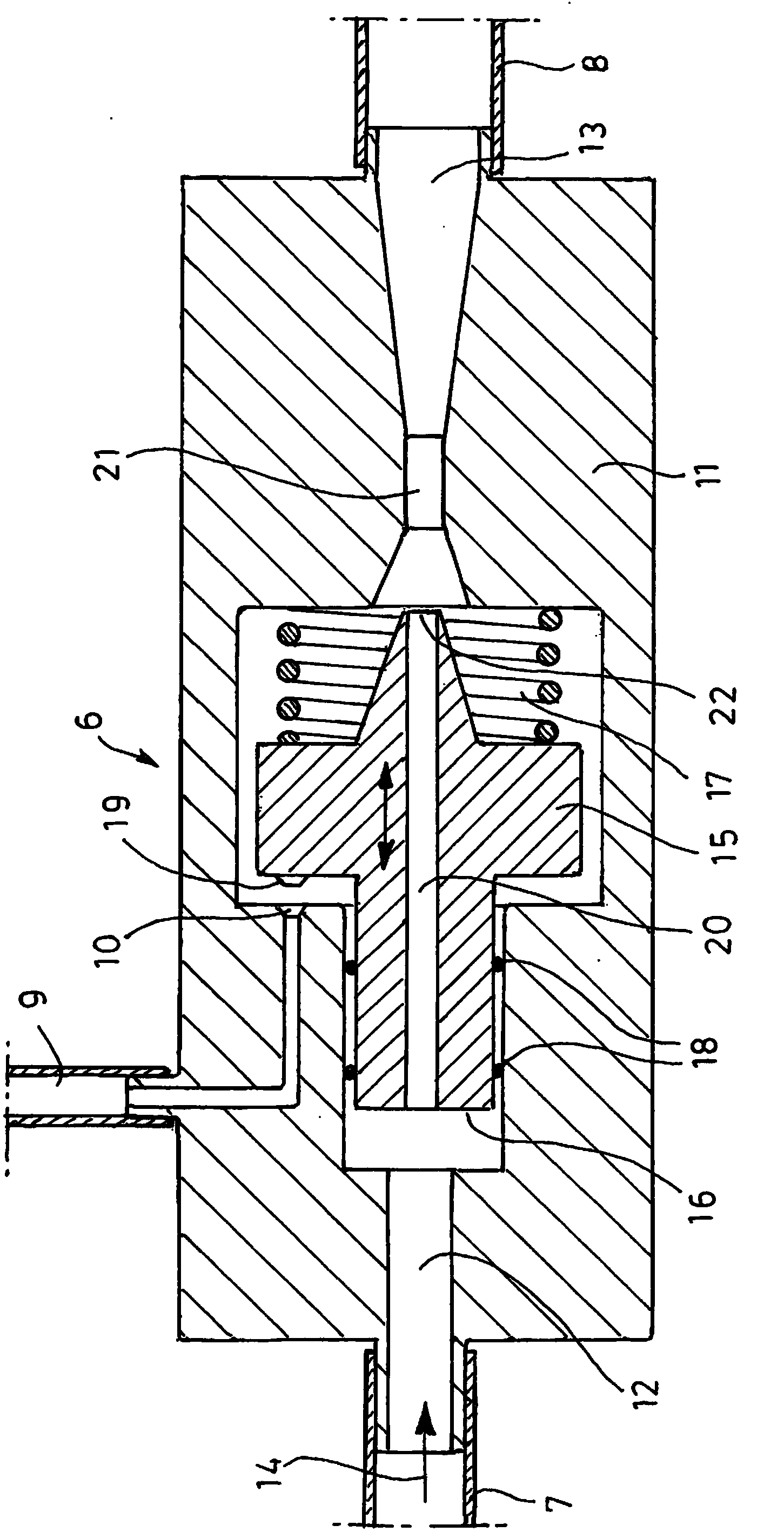

Motors with oil dynamic pressure bearing, oil dynamic pressure bearing devices and method for manufacturing the same

InactiveUS7059771B2Improve rigidityIncrease dynamic pressureShaftsBearing componentsEngineeringDynamic pressure

A motor with fluid dynamic pressure bearing is disclosed. The motor includes a dynamic pressure bearing member having a concave section that is concave in an axial direction, a rotary shaft that is rotatively supported by the dynamic pressure bearing, and a rotary member that is joined to the rotary shaft in one piece along a joint section between the rotary member and the rotary shaft, and rotatively driven by electromagnetic drive force, an expanded diameter section that is provided on the dynamic pressure bearing member. A fallout preventing member is provided on the rotary member, which overlaps the expanded diameter section of the dynamic pressure bearing member in the axial direction to prevent the rotary shaft from falling out of the dynamic pressure bearing member. The concave section of the rotary member opposes in the axial direction the expanded diameter section of the dynamic pressure bearing member, wherein the expanded diameter section is placed inside the concave section, and the joining section between the rotary member and the rotary shaft overlaps the expanded diameter section in the radial direction.

Owner:NIDEC CORP

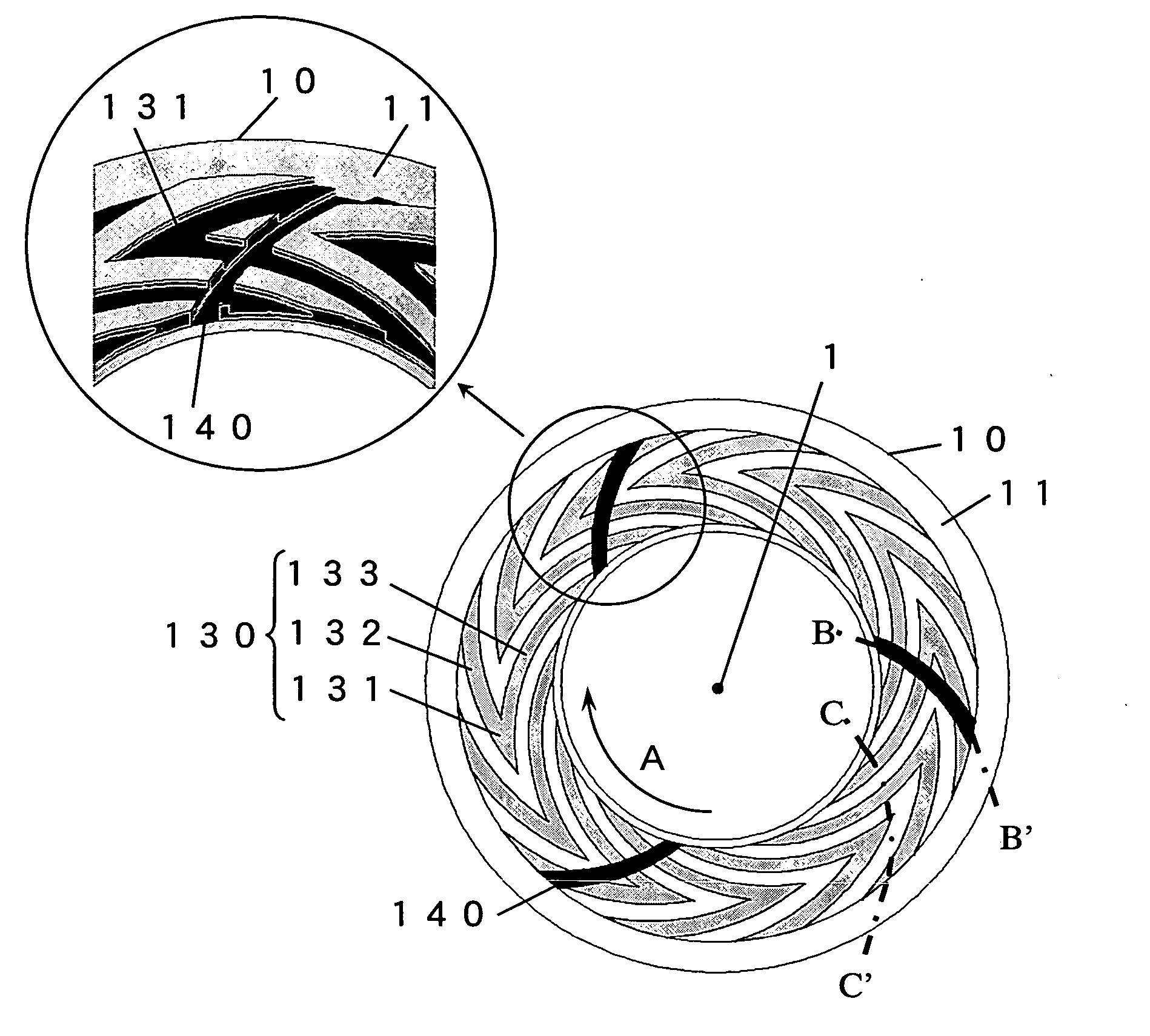

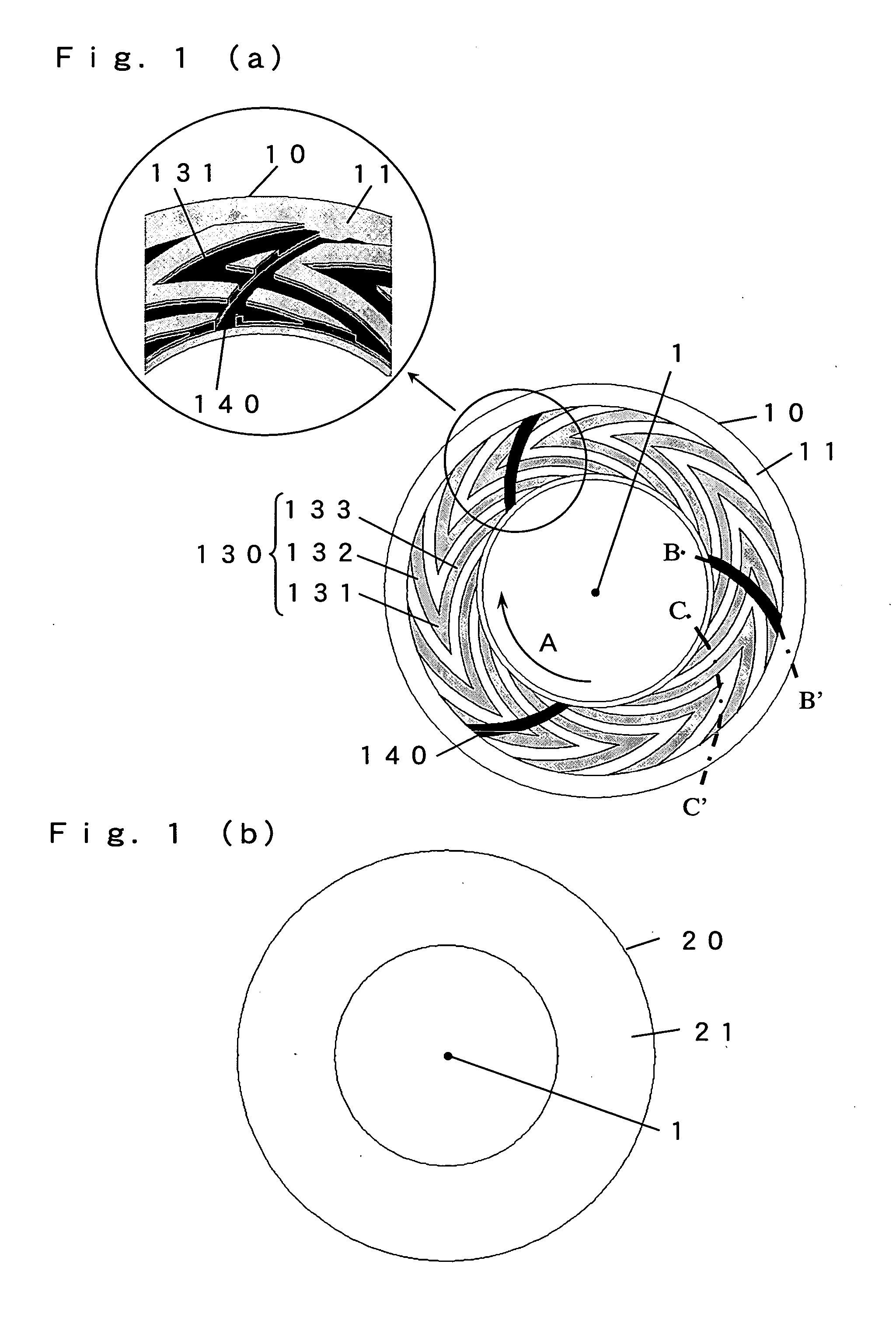

Thrust dynamic pressure bearing, spindle motor using the same, and information recording and reproducing apparatus using them

InactiveUS20050141789A1Improve reliabilityIncreased durabilityShaftsRecord information storageAir liquid interfaceDynamic pressure

In order to prevent lubricating oil leak due to bubbles in thrust dynamic pressure bearing of herringbone grooves, stabilize the bearing performance, and enhance the reliability and durability, auxiliary grooves deeper than pump-in type herringbone grooves for generating dynamic pressure are provided, and the bearing inner periphery and bearing outer periphery are linked by a pressure gradient descending slowly, and therefore bubbles present in bearing inner periphery can be guided into the bearing outer periphery through auxiliary grooves, and discharged to outside of the bearing from the air-liquid interface, so that lubricating oil leak due to bubbles can be prevented.

Owner:PANASONIC CORP

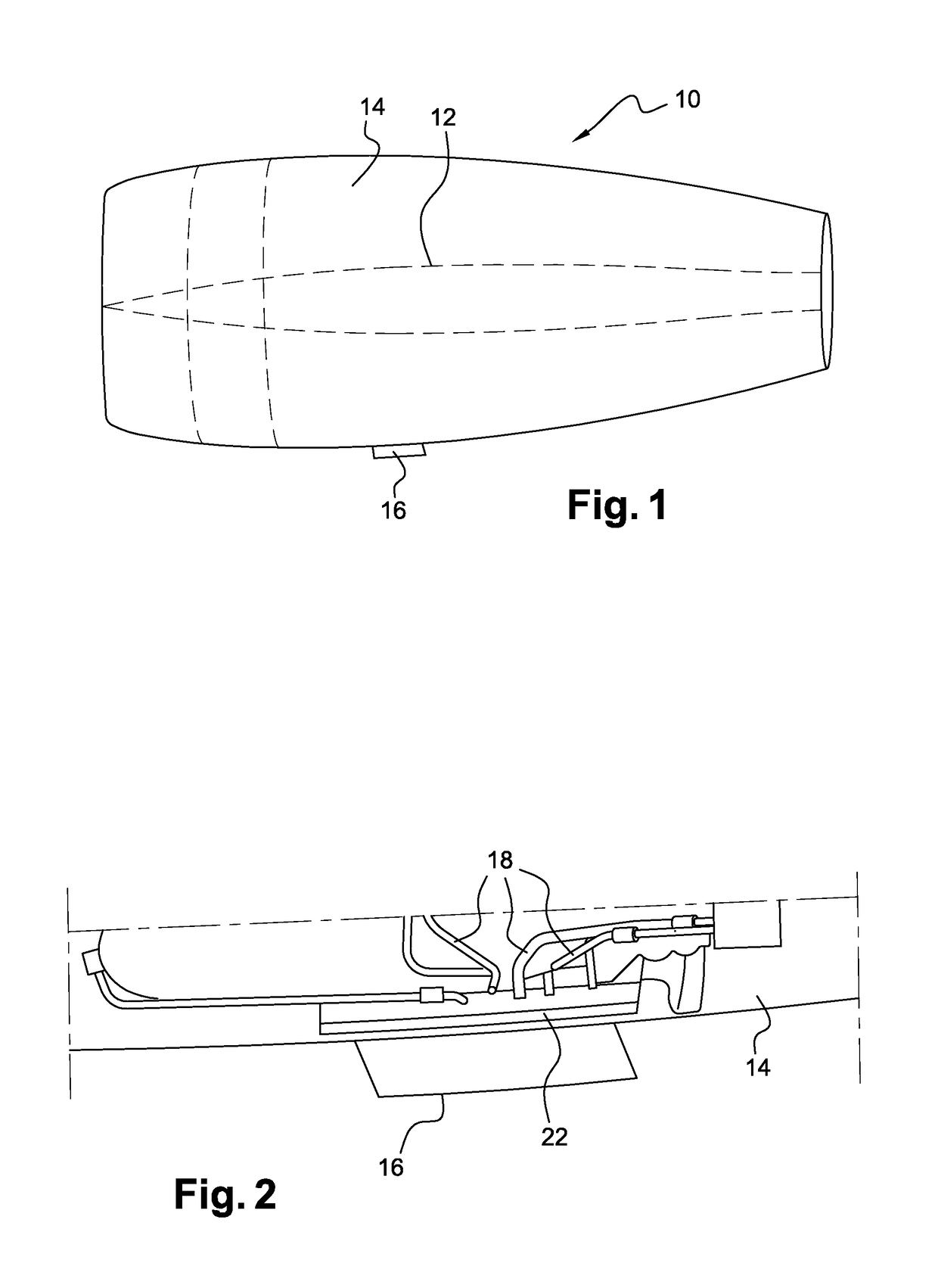

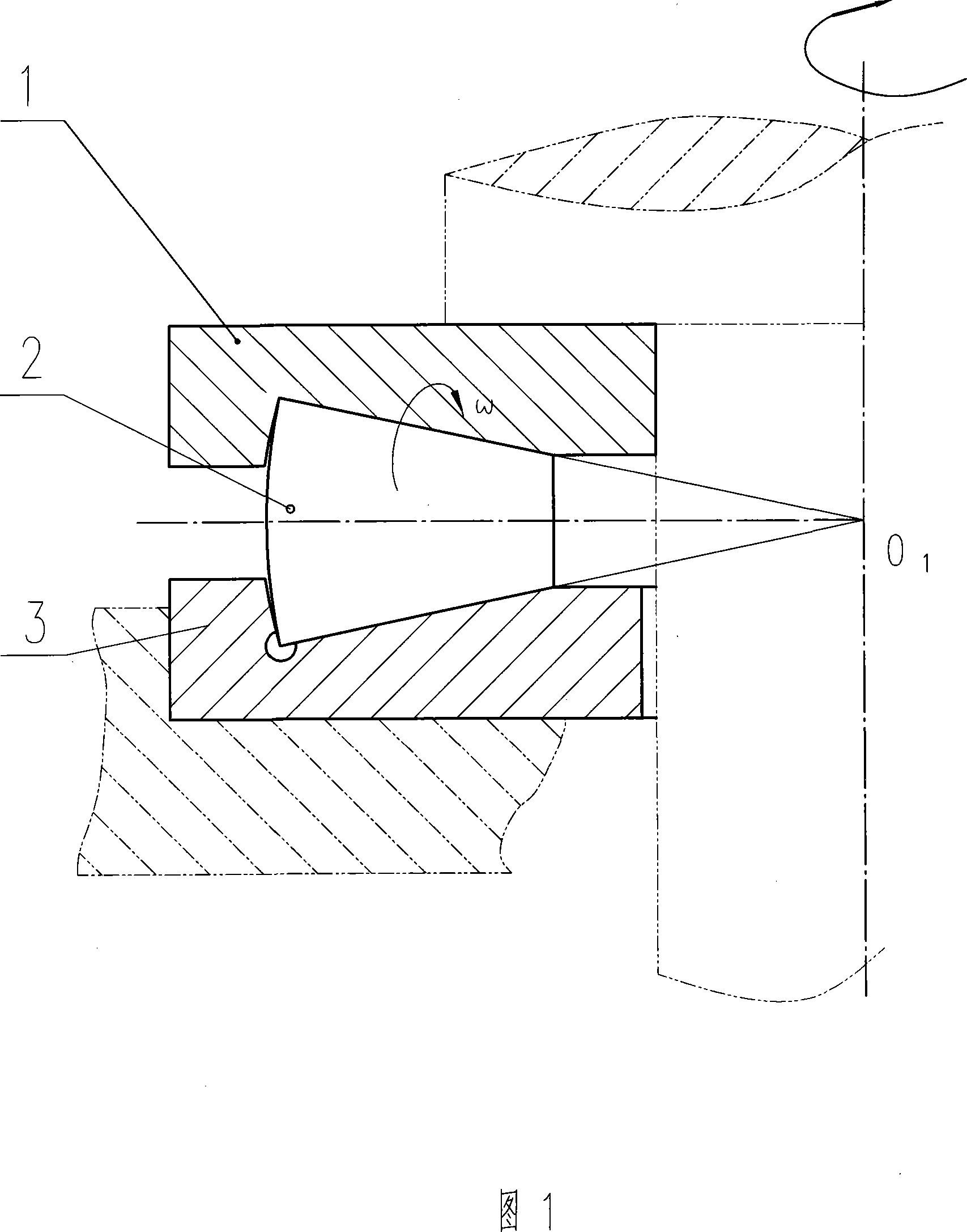

Wind power plant for generating energy

InactiveUS7118344B2Improve efficiencyIncrease airflowPropellersWind motor controlPeaking power plantPower station

A wind power system (1) for generating power is proposed, comprising a rotor which is axially flowed through, is rotatably held on a shaft (2) and is provided with blades (3), as well as a guide device (5) which accelerates the air flow through the rotor (4). In order to provide advantageous conditions for generating power it is proposed that the guide device (5) consists of several flow conduits (6) tapering in the direction of flow, which conduits are arranged on the rotor (4) in a distributed way in the manner of a rim around the shaft (2), that the blades (3) are associated with one flow conduit (6) each and that the rotor (4) comprises an outside jacket (7) enclosing the same.

Owner:GUDRUN WIESER

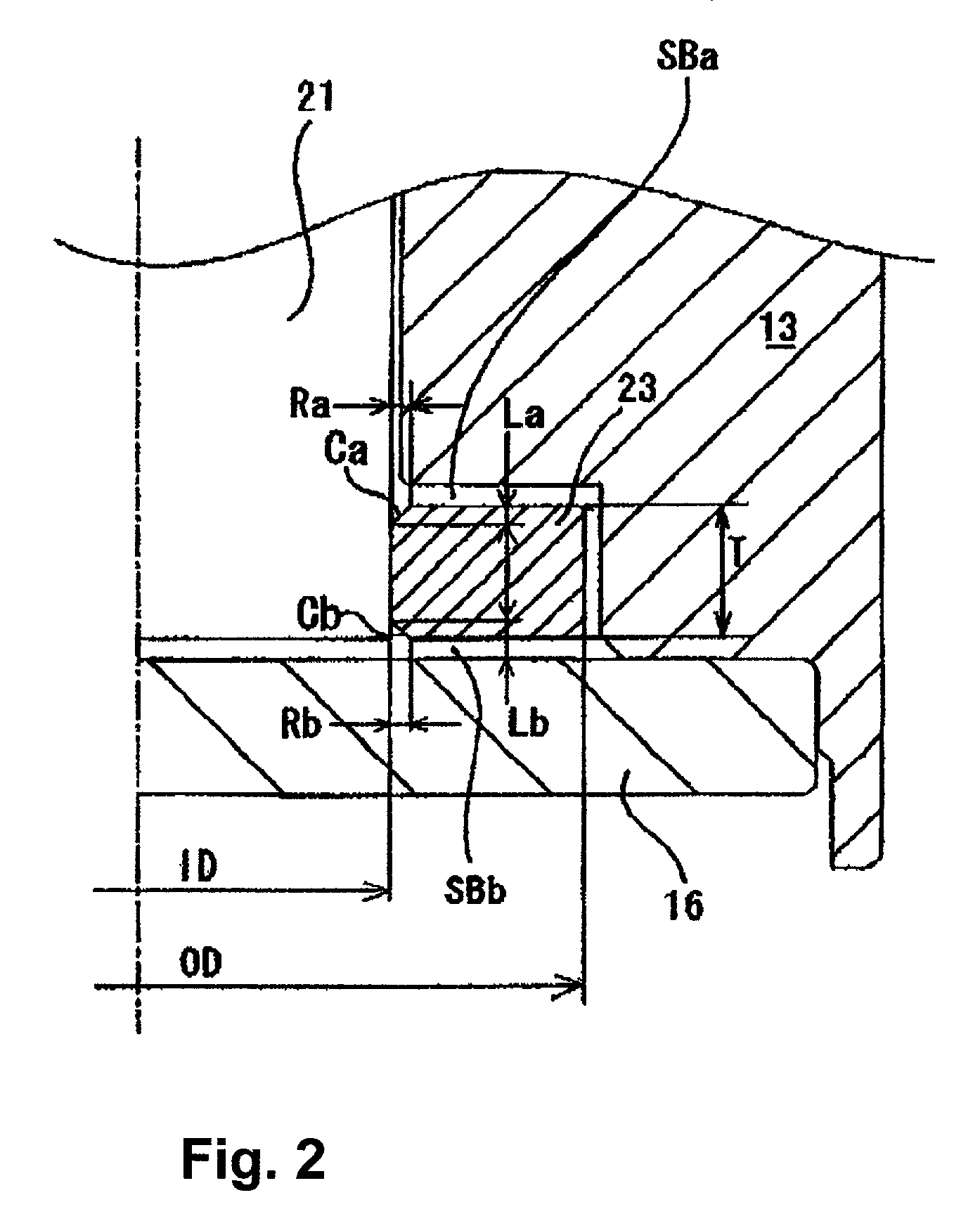

Thrust dynamic pressure bearing apparatus and method for manufacturing the same

InactiveUS20010006565A1Improve deformationSimple structureBearing componentsSliding contact bearingsShrink-fittingEngineering

A thrust dynamic pressure bearing apparatus includes a shaft member and a thrust plate having a fixing hole that is provided with chamfered sections Ca and Cb at the fixing hole. The shaft member is shrink fitted or pressure inserted in the fixing hole of the thrust plate. The chamfered sections Ca and Cb have axial lengths La and Lb in the axial direction. Dimensional relations of the axial lengths La and Lb in the chamfered sections Ca and Cb are set to be within a specified range to evenly distribute the bonding force of the thrust plate applied to the shaft member along the axial direction.

Owner:NIPPON DENSAN CORP

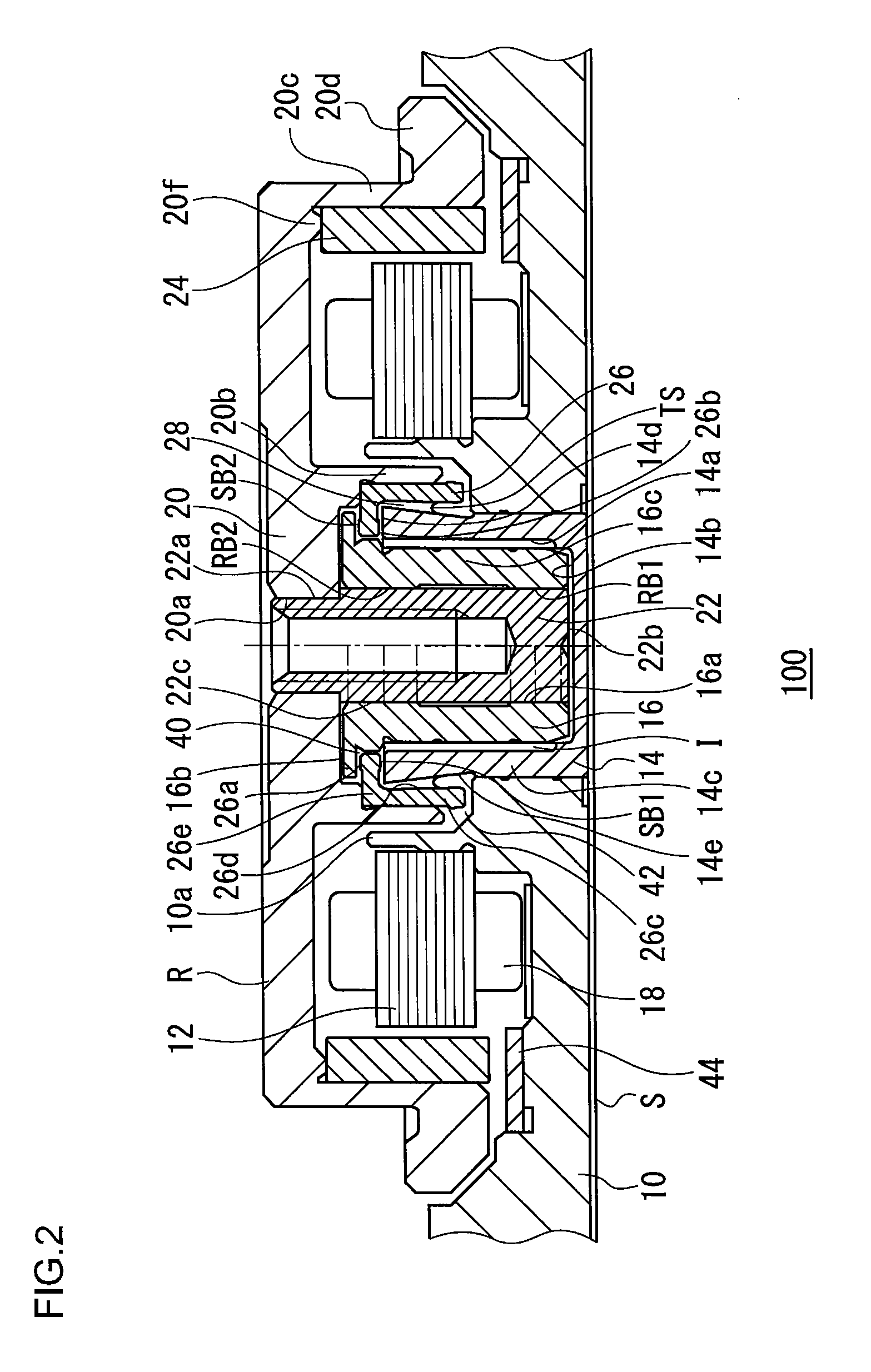

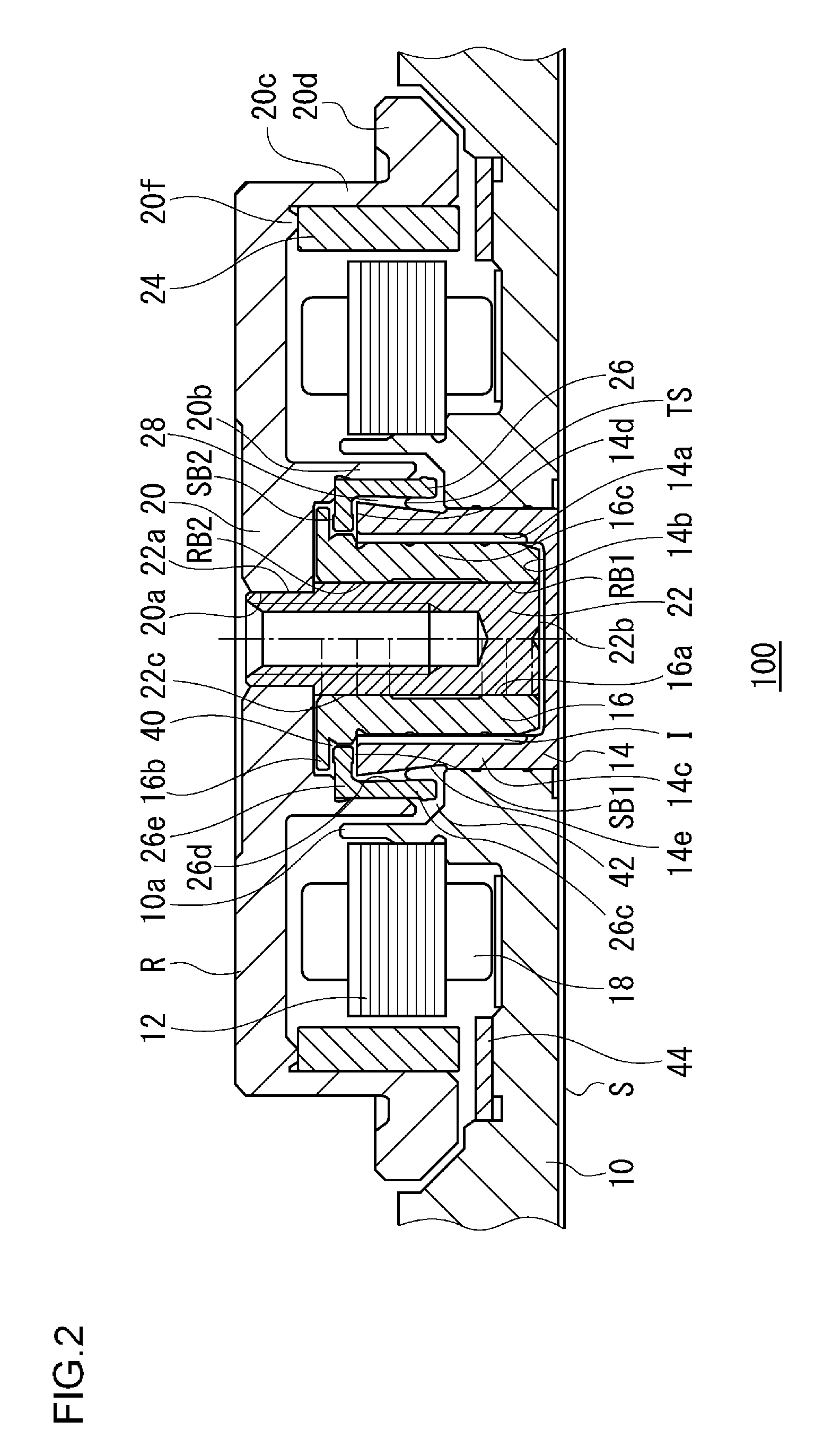

Disk drive device improved in Anti-vibration characteristic

InactiveUS20110033143A1StablyMaintain stiffnessShaftsRecord information storageRotational axisEngineering

A disk drive device includes a rotating body, a fluid dynamic bearing unit that rotatably supports the rotating body, and a drive unit. The fluid dynamic bearing unit has: a lubricant holding portion in which lubricant is held; a first thrust dynamic pressure groove with which a first thrust dynamic pressure generating portion for generating the dynamic pressure in the pump-in direction, which is oriented toward the inside of the lubricant holding portion, is structured; and a second thrust dynamic pressure groove with which a second thrust dynamic pressure generating portion for generating at least the dynamic pressure in the pump-out direction, is structured. The first thrust dynamic pressure generating portion and the second thrust dynamic pressure generating portion have dynamic pressure generation characteristics in which, when the rotating body is biased in the rotational axis direction from the state where the rotating body is floating in the lubricant, the sum of the changes in the dynamic pressure in the pump-out direction is larger than that of the changes in the dynamic pressure in the pump-in direction.

Owner:SAMSUNG ELECTRO MECHANICS JAPAN ADVANCED TECHNOLOGY CO LTD

Drained fluid evacuation stub for a propulsion assembly

ActiveUS10017238B2Controlling the riskHigh speedAircraft accessoriesAircraft power plant componentsEngineeringMechanical engineering

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

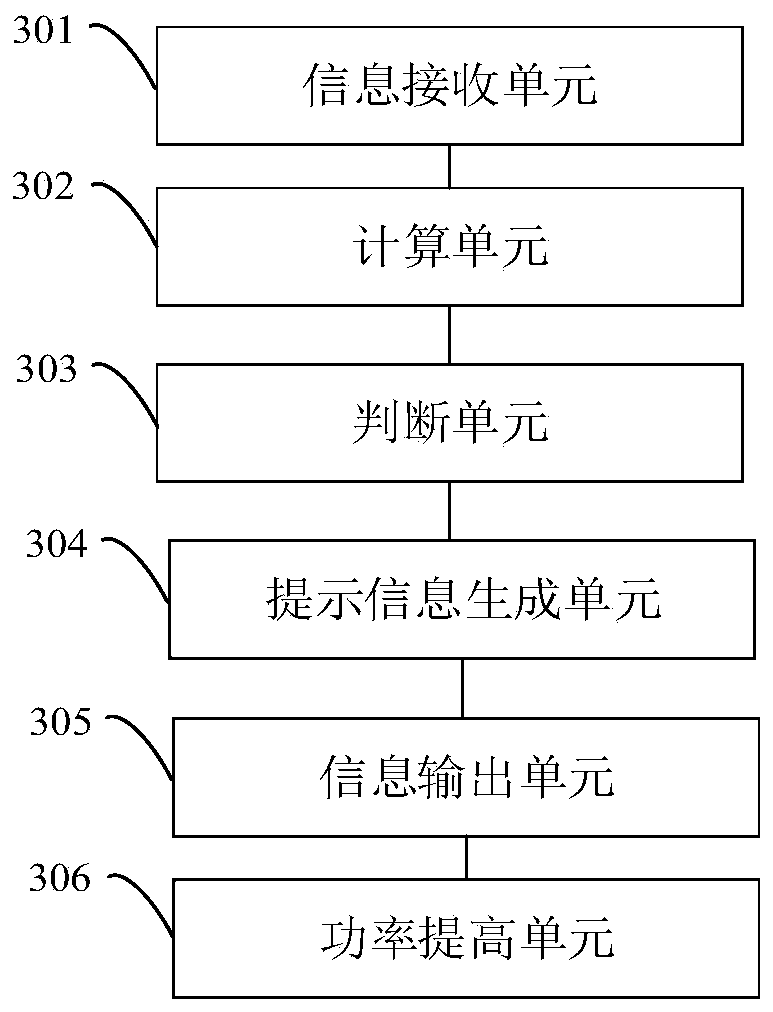

Air conditioner cleaning prompting generation method and device

The invention provides an air conditioner cleaning prompting generation method and device, and relates to the technical field of air conditioners. By means of the air conditioner cleaning prompting generation device, cleaning prompting information can be generated according to the acquired variation of the dynamic pressure relative to the pre-stored initial dynamic pressure. The principle of generating the cleaning prompting information is that when little dust accumulates on a filtering screen, the air output of an air conditioner is smooth, and therefore the static pressure can be low, the air speed can be high, and the dynamic pressure can be high; and when much dust accumulates on the filtering screen, the static pressure is improved, the air speed is low, the dynamic pressure is reduced, and therefore the dust accumulation degree can be fed back according to the change of the dynamic pressure of the air conditioner, and the accuracy and the reliability of the cleaning prompting information which is generated through the dust accumulation degree fed back according to the change of the dynamic pressure of the air conditioner are high.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

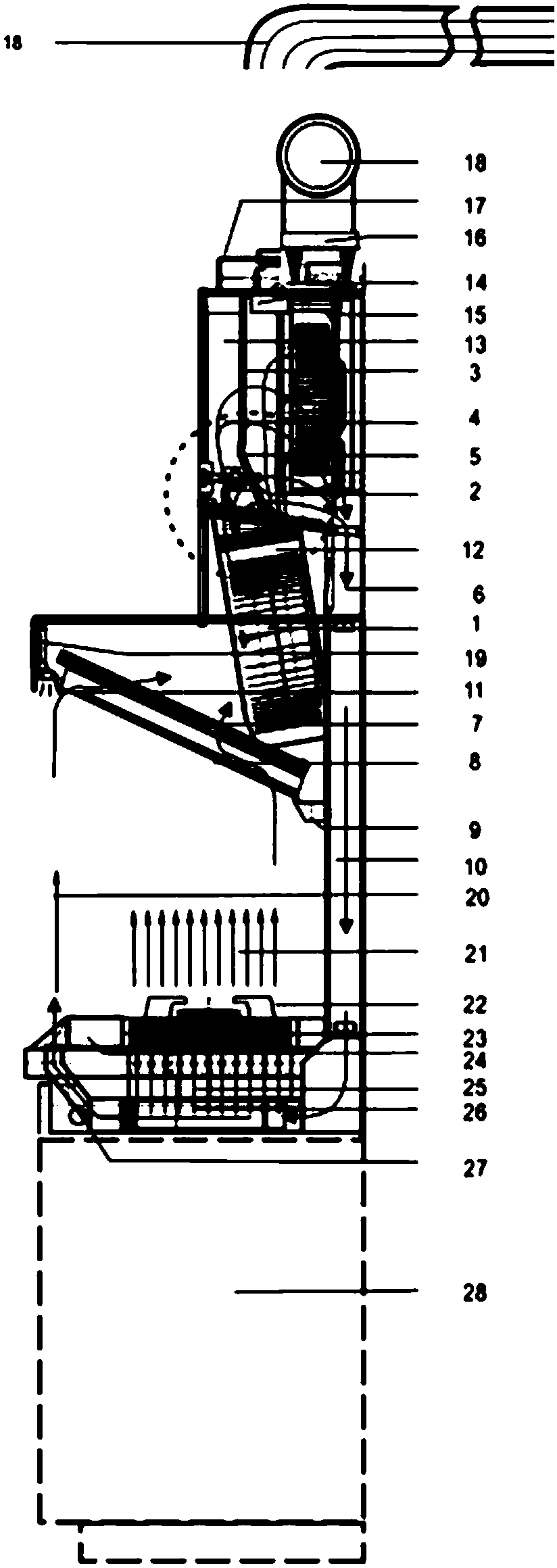

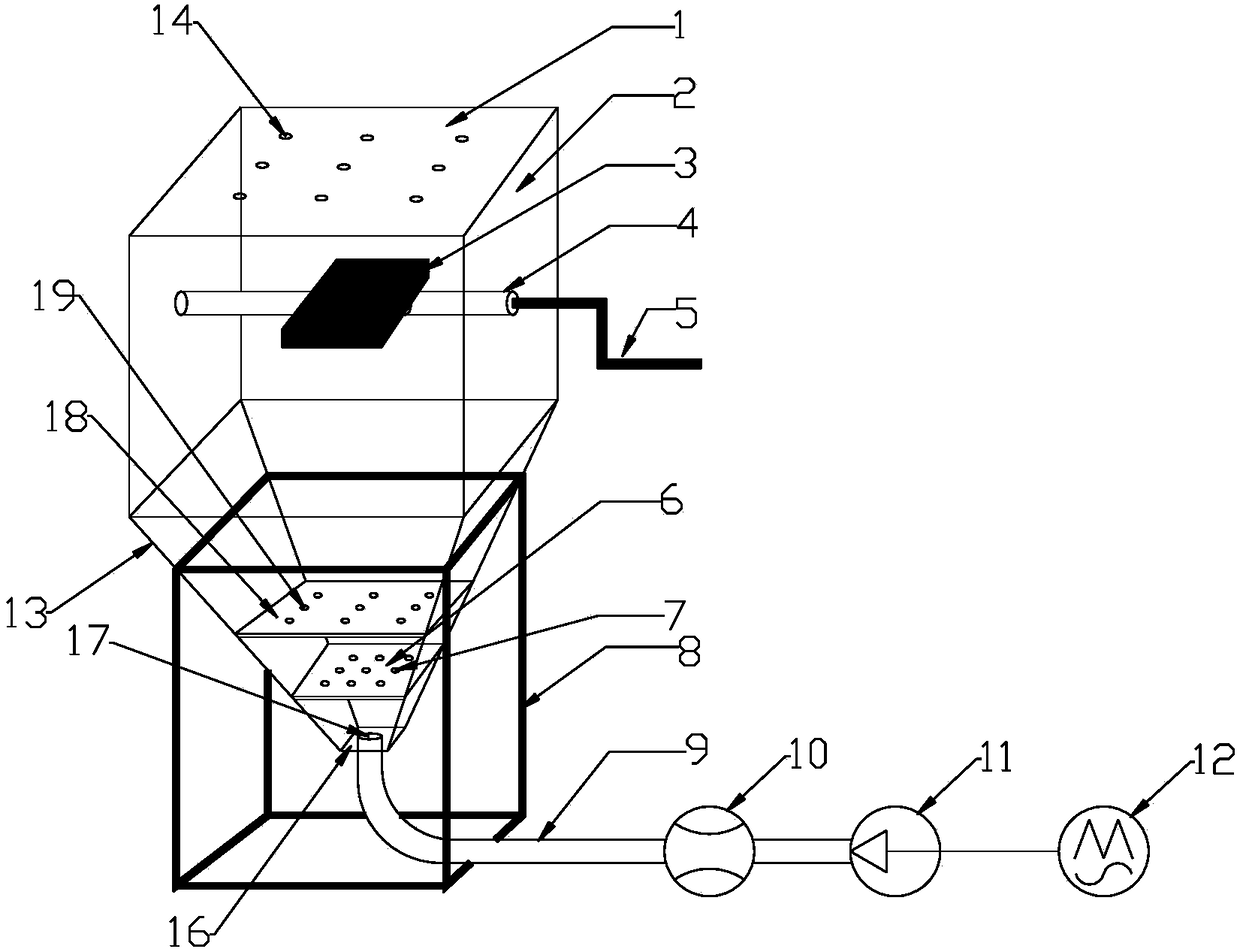

Zero-sum type low-carbon range hood and purification system

PendingCN107747754AExcellent range fume functionInhibited DiffusionDomestic stoves or rangesLighting and heating apparatusProcess engineeringExhaust pipe

The invention belongs to the technical field of cooking fume treatment devices, and discloses a zero-sum type low-carbon range hood. The zero-sum type low-carbon range hood comprises a cooking fume discharge system and an inner cycle cooking fume suction system. The cooking fume discharge system is composed of a condensation plate, a filter layer, a cooking fume suction fan, an air distribution adjuster, a pressurization box a pressurization fan, a non-return air valve and an exhaust pipe. The inner cycle cooking fume suction system is composed of the condensation plate, the filter layer, thecooking fume suction fan, the air distribution adjuster, a static-pressure box, a connecting air flue, an air curtain air outlet and an air curtain. The zero-sum type low-carbon range hood has the cooking fume suction function more excellent than that of a range hood and an integrated stove. Cooking fumes are filtered, the interior of a range hood body does not need to be cleaned, and pollution ofthe cooking fumes to the atmosphere is reduced; and the cooking fumes generated by cooking are wrapped to flow through a cooking fume filter screen and then are fed into the cooking fume suction fan,cooking fume diffusion is suppressed, cooking fume escape is avoided, and the cooking fumes are thoroughly exhausted. Comprehensive energy consumption is smaller than 1 / 10 of that of the range hood and the integrated stove, and healthier, more low-carbon, more environment-friendly and safer home life guarantees can be provided for wide users.

Owner:ZHONGSHAN CALCULUS SCI & TECH LTD

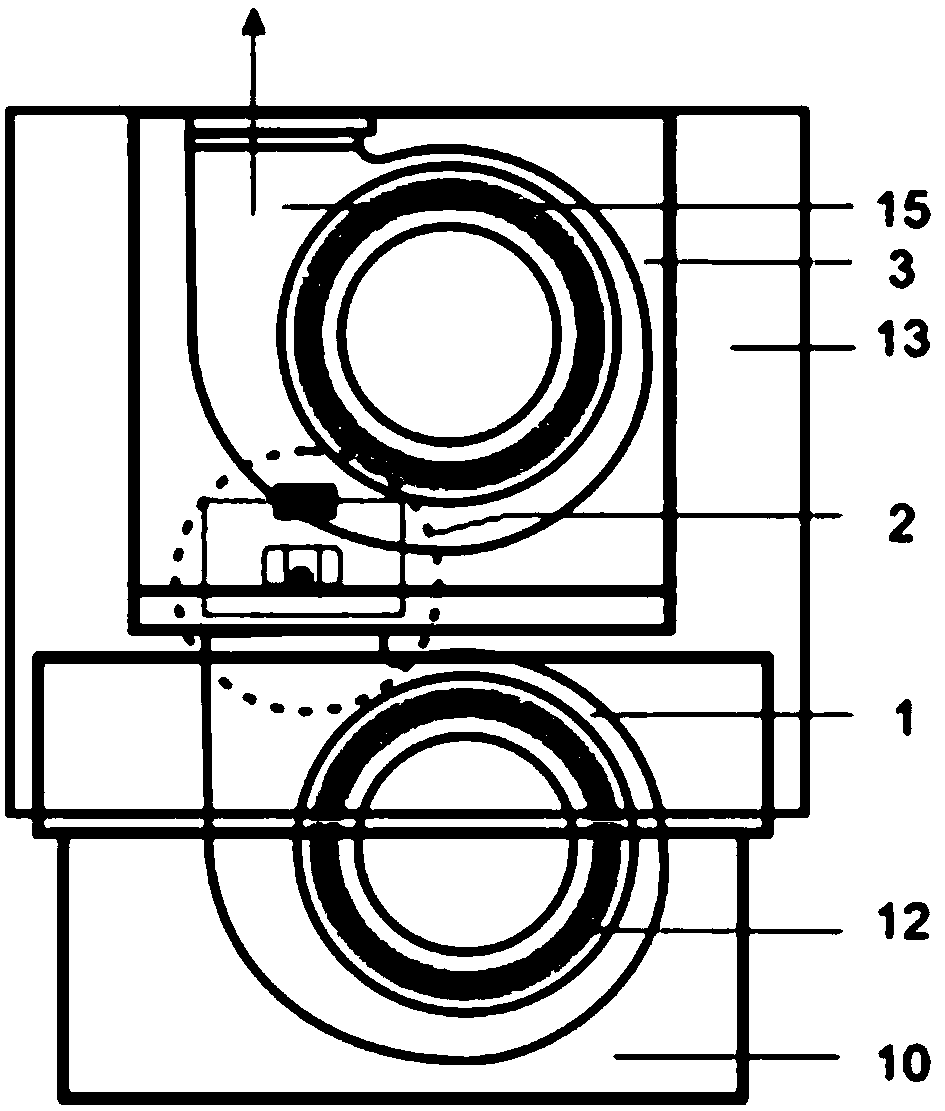

Induced fan

InactiveCN1508485AReduce construction costsLarge thrustLighting and heating apparatusVentilation systemsImpellerElectricity

The invention discloses a kind of guiding fan for ventilation in large location, the structure comprises chassis, snoot with variable angles, there sets electricity machine and cross-flow blade wheel connecting to the output shaft at the side of the chassis, its shaft direction corresponds to the shaft of the snoot. There has a guiding volute on the inner wall of chassis back of the blade wheel, there has a countercurrent resisting volute tongue, when the electricity machine drives the blade wheel to rotate, the air enters form the back of the chassis, through guiding volute, countercurrent resisting volute tongue and snoot, it uses high speed air to guide air to the fixed direction and region.

Owner:北京新安特风机有限公司

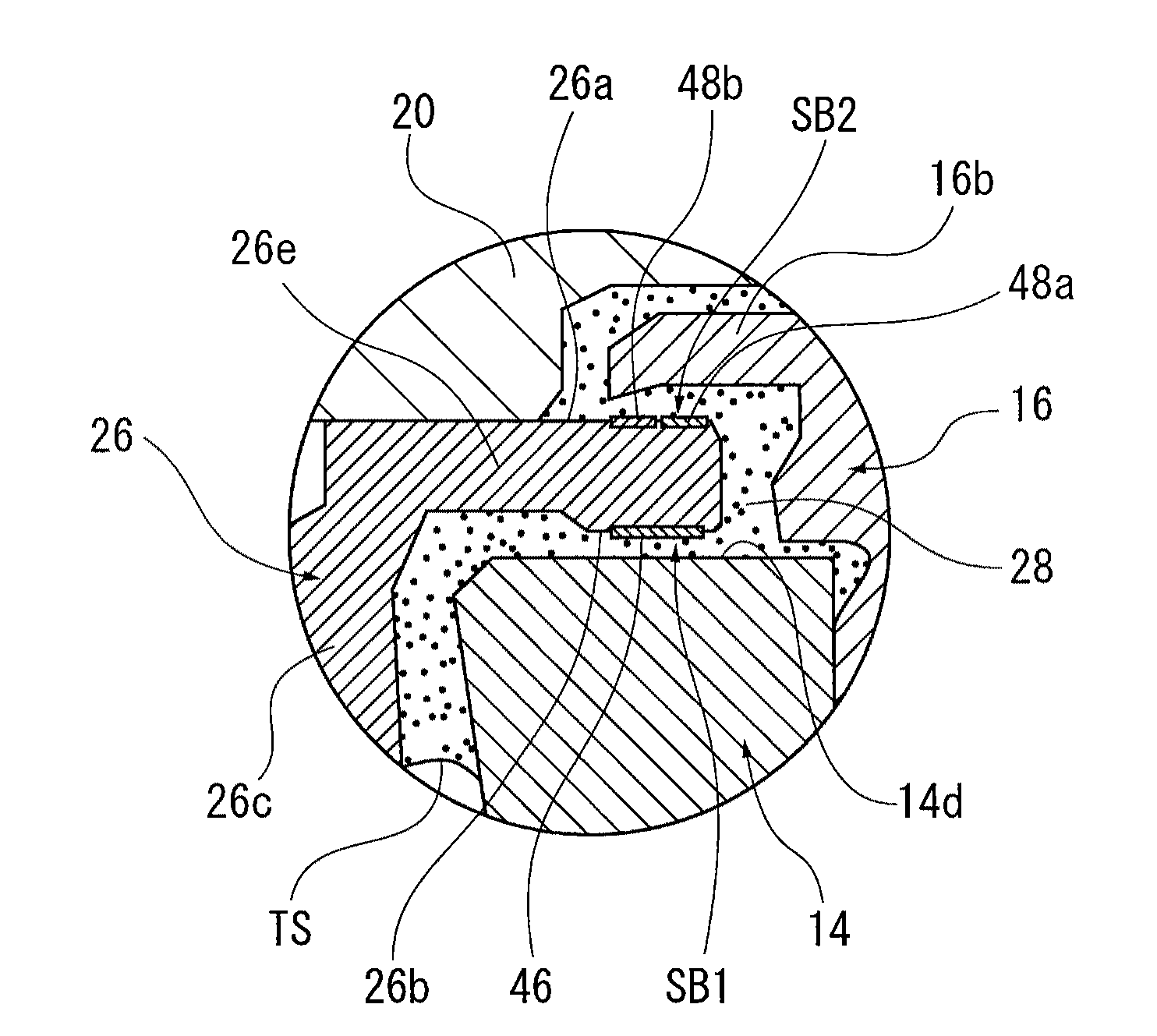

Rotating device

InactiveUS20130181558A1Improve impact resistanceImprove radial stiffnessShaftsBearing componentsEngineeringLubricant

A rotating device comprises a stator configured to rotatably support a rotor via a lubricant. A first zonal region is formed on an inner surface of a sleeve. A plurality of grooves along a direction that crosses the first zonal region are formed on the first zonal region from each of both sides of the first zonal region. A groove formed from one side of the first zonal region is formed so that the closer a position in the groove is to the other side of the first zonal region, the shallower and the narrower the groove at the position will be. A groove formed from the other side is formed so that the closer a position in the groove is to the one side, the shallower and the narrower the groove at the position will be.

Owner:SAMSUNG ELECTRO MECHANICS JAPAN ADVANCED TECHNOLOGY CO LTD

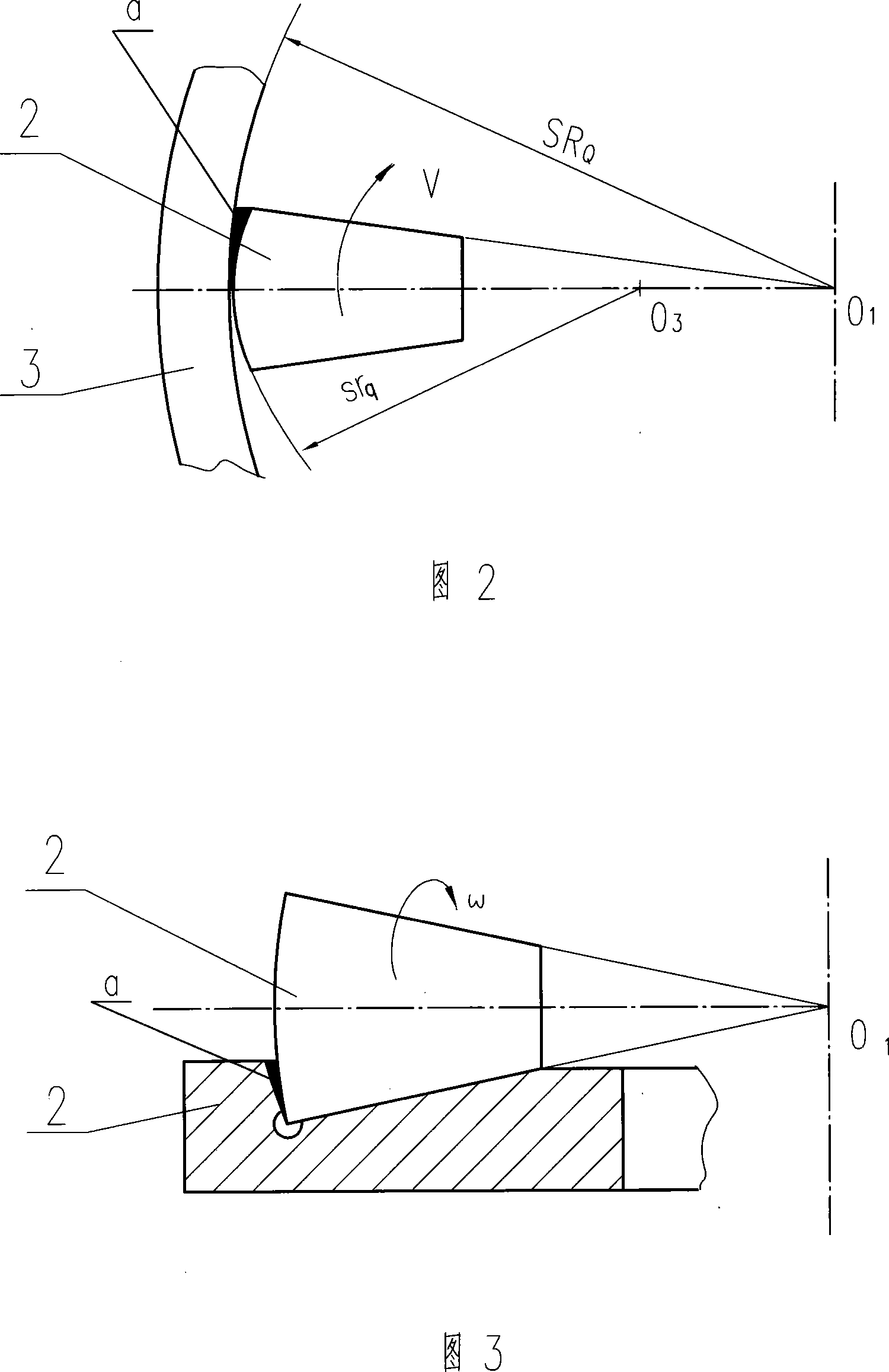

Oil film lubrication method between large-end face of taperroller and capped edge of housing washer in thrush bearing

InactiveCN101092992AImprove performanceRich design methodBearing componentsRolling-element bearingThrust bearing

This invention discloses a film lubrication method for thrust bearing roller cone races and ribs, which forms a wedge clearance between the large end surface of a roller and inside wall of a ring rib and fills it with lubrication oil, when the shape, size of the clearance and axial load, glide speed and viscosity of the oil are matched to each other, a dynamic pressure film is formed between the two surfaces, in which the wedge clearance is formed by cone roller spherical large end surface and the ring rib spherical ring, so it's easy to form a dynamic pressure film by selecting race SRQ of the inner surface of the race and axis ring and srq of the cone large end surface reasonably.

Owner:郭溪泉

Production method of rotating device having thrust dynamic pressure generating site on which a thrust pressure pattern is formed and rotating device produced by said production method

InactiveUS20110154875A1Improve efficiencyReduce gapBearing assemblyMetal-working feeding devicesEngineeringDynamic pressure

A thrust dynamic pressure pattern is marked on a rotating member or fixed member set on a rest table. A pressure for marking is applied to a member to be marked in a cycle of applying and releasing the pressure, and a supplemental force for keeping the member to be marked, still is separately applied. According to the present embodiment, a rotating device can be provided that narrows down a bearing gap and improves the efficiency of raking up a lubricant so as to increase the dynamic pressure by reducing the deformation of the shape of the protrusions of a thrust dynamic pressure pattern and the variation in the height of the protrusions when forming the thrust dynamic pressure pattern in a method of producing a rotating device.

Owner:SAMSUNG ELECTRO MECHANICS JAPAN ADVANCED TECHNOLOGY CO LTD

Disk drive device improved in stiffness of fluid dynamic bearing

InactiveUS8315011B2Lower performance requirementsSmall sizeFilamentary/web record carriersRecord information storageFlangeEngineering

A disk drive device includes a bearing unit and a drive unit. The bearing unit includes: a shaft; a sleeve configured to allow relative rotation, with the shaft as the axis; a flange projected in the radial direction of the shaft and configured to rotate integrally with the shaft; a flange housing space portion provided continuously from the sleeve and configured to rotatably house the flange; a counter plate structured with both a first surface, which faces the end surface in the axial direction of the flange and seals the flange housing space portion, and a second surface that is opposite to the first surface. The projected dimension of the flange is designed to be larger than the wall thickness of the flange surrounding wall portion in the radial direction of the flange, the flange surrounding wall portion defining the flange housing space portion.

Owner:SAMSUNG ELECTRO MECHANICS JAPAN ADVANCED TECHNOLOGY CO LTD

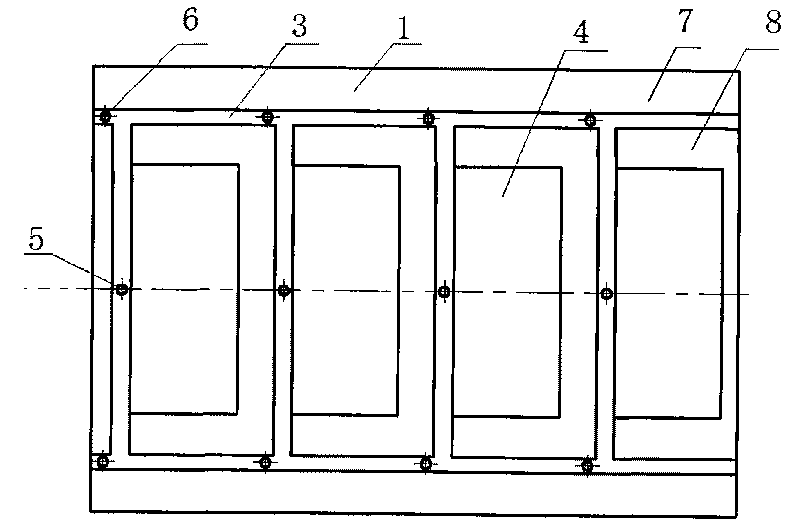

Device and method for preparing fiber reinforced silica sol composite shell through airflow laying

InactiveCN108213344AConsistent performanceImprove air permeabilityFoundry mouldsFoundry coresDiameter ratioAirflow

The invention discloses a device and a method for preparing a fiber reinforced silica sol composite shell through airflow laying. The device comprises a fiber laying chamber, a fiber storage chamber,an air supply unit and a support, wherein the fiber laying chamber is a hollow cube and is composed of four side vertical plates and an upper bottom surface exhaust hole plate and an upper bottom surface exhaust hole plate, and an exhaust hole is formed in the upper bottom surface exhaust hole plate; a rotating shaft used for bearing the shell sample is installed in the fiber laying chamber; the fiber storage chamber is of a hollow inverted quadrangular frustum shape formed by four side plates and a lower bottom surface air inlet plate, a fiber storage rack is arranged in the fiber storage chamber, and airflow guide holes are formed in the fiber storage rack; and the fiber spreading chamber is located right above the fiber storage chamber, the side length of the side vertical plate of thefiber spreading chamber is equal to the side length of the side plate of the fiber storage chamber, and the four side vertical plates and the four side plates are fixedly connected in a one-to-one correspondence manner. According to the device and the method, the fibers can be uniformly distributed in the shell, the fibers can be laid on the shell in a quantitative mode, so that the performance ofthe prepared shell is consistent, and the fiber with the large length-diameter ratio can also be added into the shell.

Owner:INNER MONGOLIA UNIV OF TECH

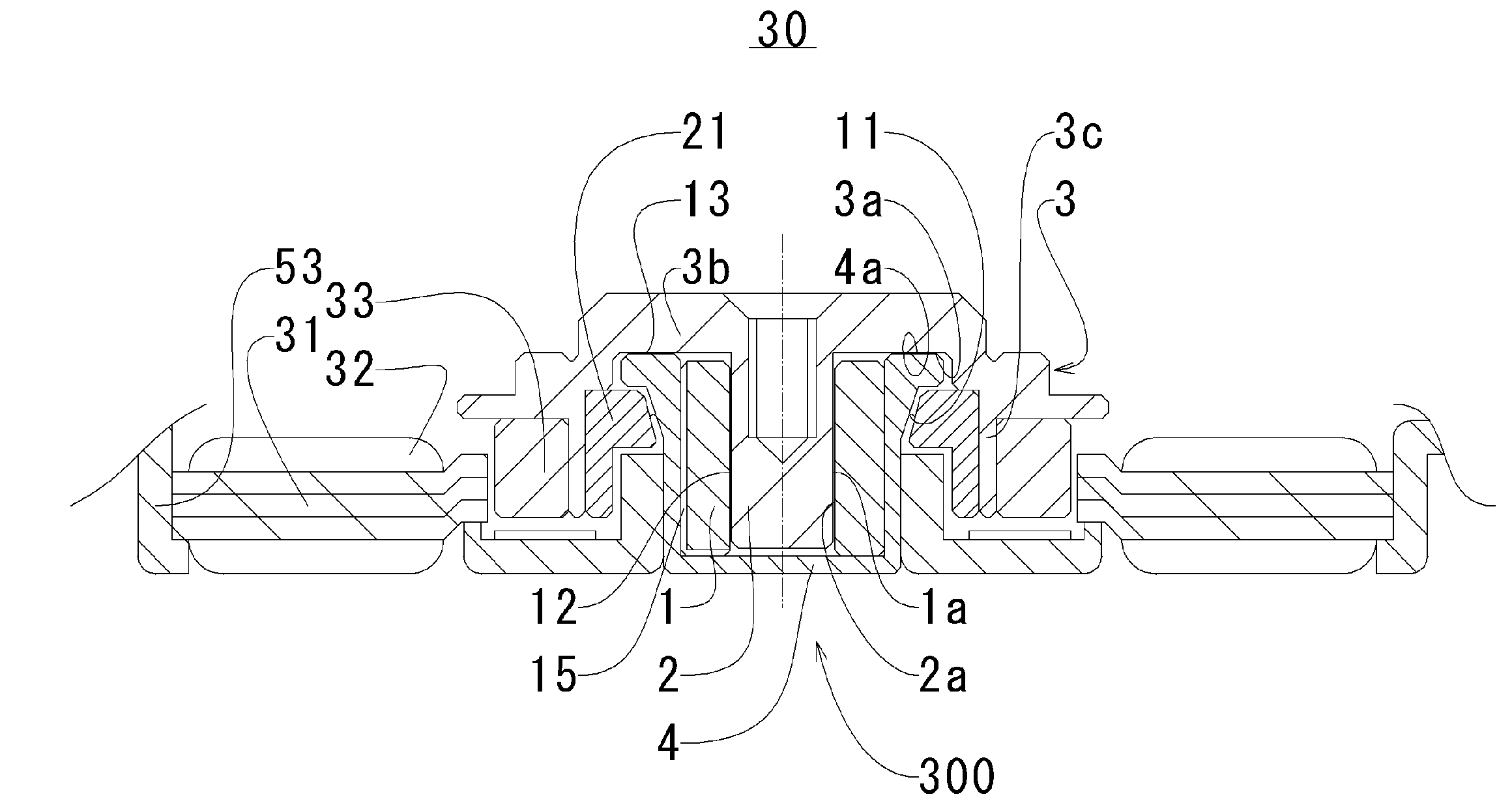

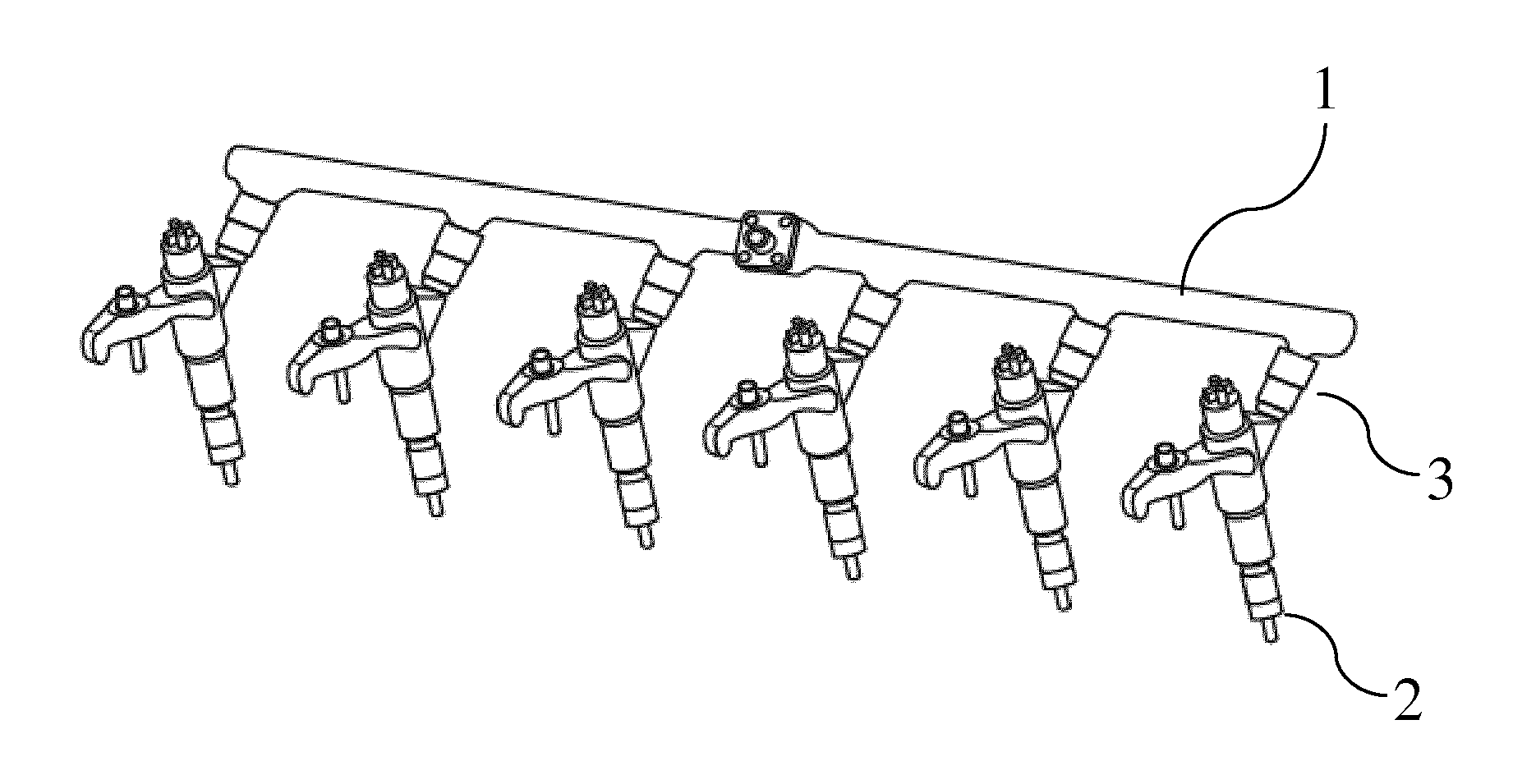

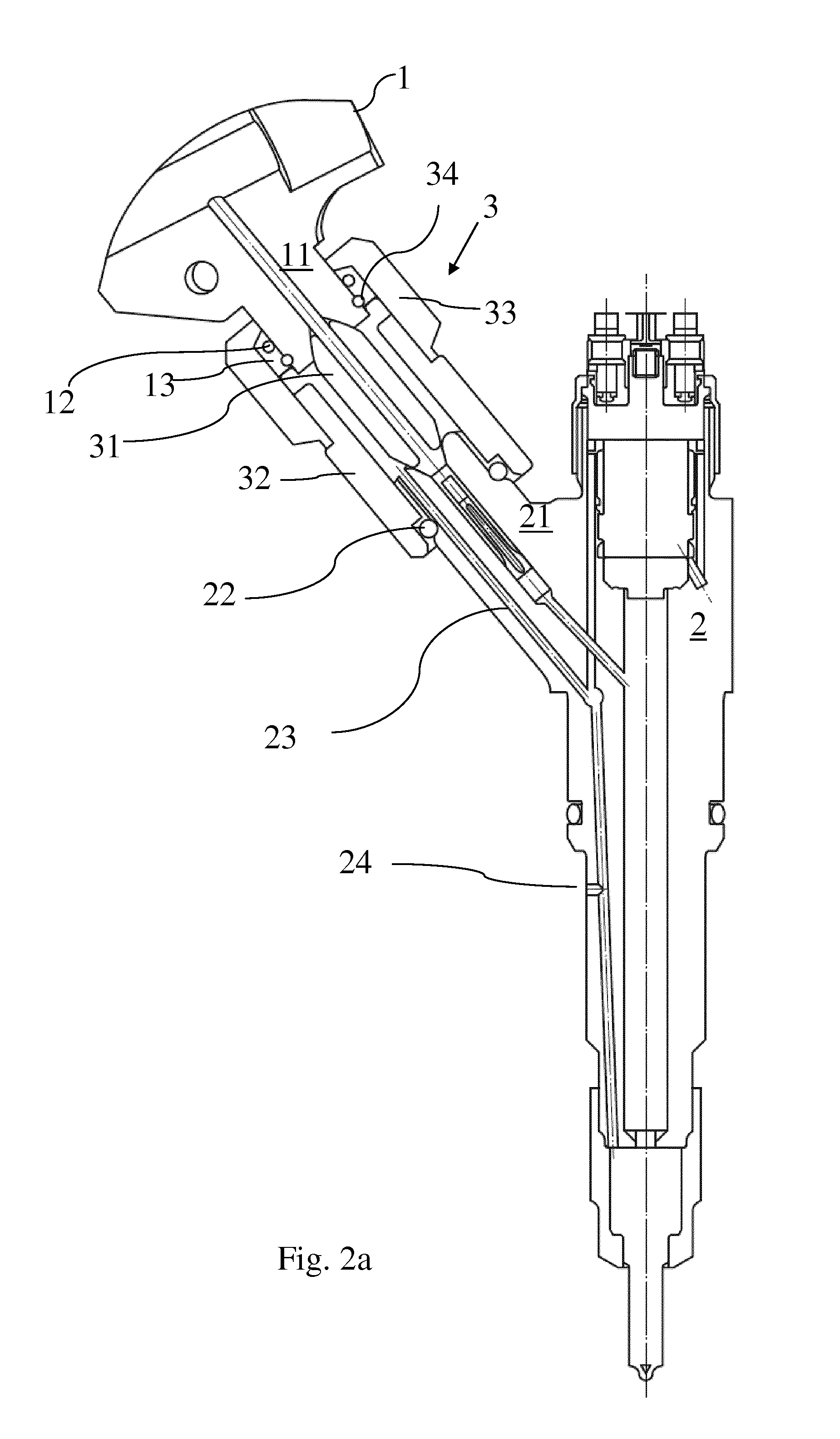

Fuel piping arrangement in common rail type fuel supply systems

ActiveUS20160102641A1Improve securityImprove leakageLow-pressure fuel injectionMachines/enginesCommon railFuel supply

The present invention provides for a fuel piping arrangement in common rail type fuel supply systems, the supply system comprising at least one common rail and at least one respective injector, wherein the common rail is connected with the at least one injector directly, by means of only one joint.

Owner:FPT MOTORENFORSCHUNG

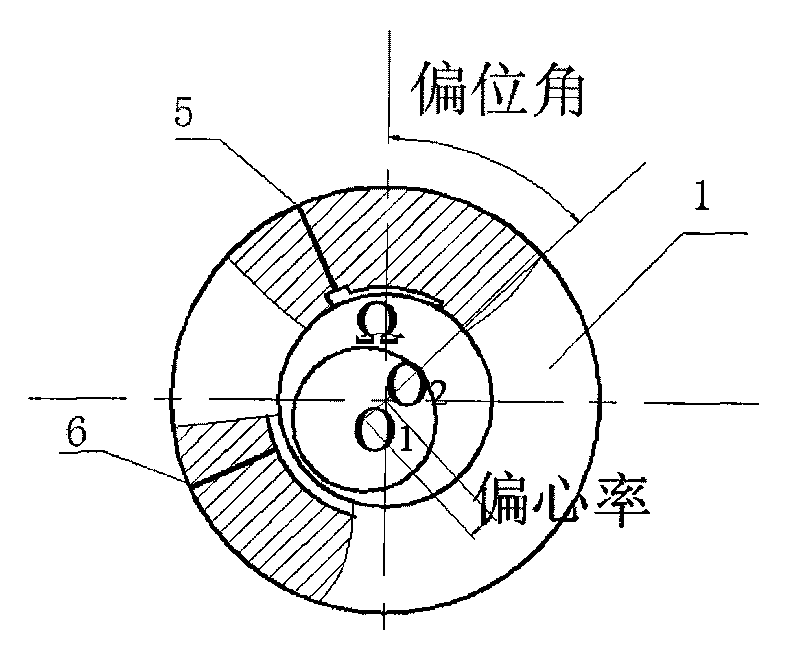

Water lubrication dynamic and static pressure ladder groove step bearing

InactiveCN101696714AImprove bearing capacityIncrease stiffnessBearing coolingBearingsLubricationOil supply

The invention relates to a water lubrication dynamic and static pressure ladder groove step bearing, comprising a bearing pad and a main shaft arranged in the bearing pad. The inner wall of the bearing pad which is also the oil sealing surface of a bearing is provided with an annular ladder-shaped groove; the bearing pad is separated into a plurality of mutually communicated areas by the annular ladder-shaped groove; the annular ladder-shaped groove is internally provided with shallow cavities; and the bearing pad is also provided with oil inlet holes and cooling holes which are both communicated with the annular ladder-shaped groove. In the invention, the oil sealing surface of the bearing is provided with the ladder-shaped deep groove for dividing the surface of the bearing into a plurality of areas, and the shallow cavities with depth less than that of the groove are arranged in the areas surrounded by the ladder-shaped groove. The shallow cavities surrounded by the ladder-shaped groove can enhance the dynamic pressure and improve the bearing capability and rigidity of the bearing. A plurality of oil supply holes and cooling holes are arranged in the ladder-shaped groove so that high-pressure lubricating medium can be pumped into the gaps of the bearing through the small holes, the flow rate of the surface of the bearing pad is improved, the temperature raising is reduced, and the continuity of the oil film is ensured.

Owner:XI AN JIAOTONG UNIV

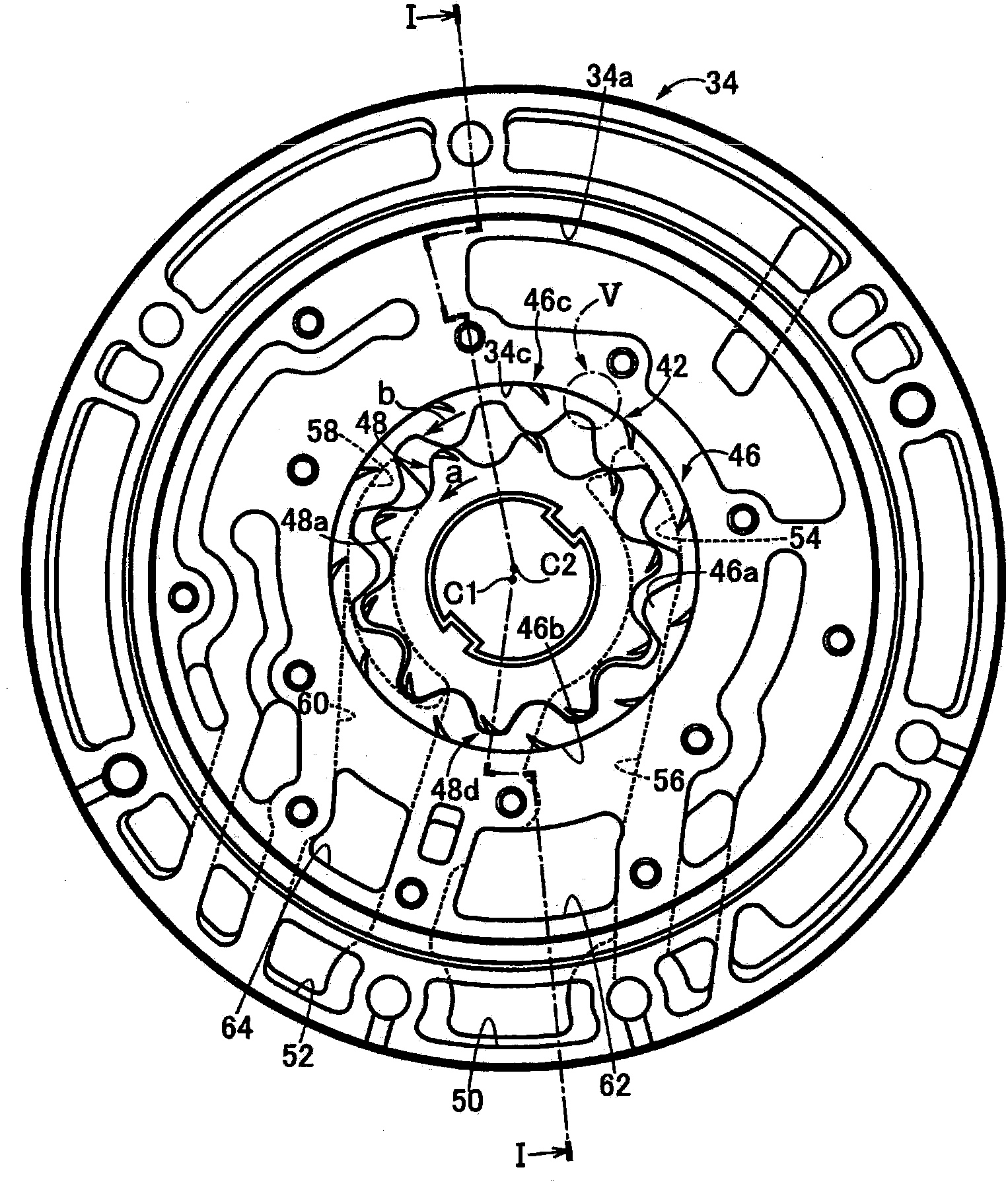

Internal-gear-type oil pump for vehicle

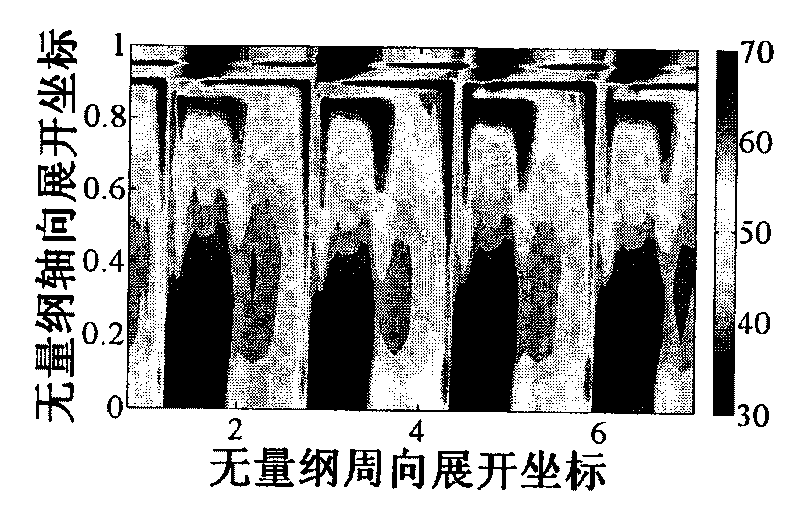

InactiveCN103917785AInhibit fluid friction increaseSuppresses fluid friction coefficient increaseRotary piston pumpsRotary piston liquid enginesMechanical engineeringDynamic pressure

Provided is an internal-gear-type oil pump for a vehicle, the oil pump being provided with a driven gear in which the self-aligning effect of the driven gear can be obtained while preventing the fluid friction acting on the driven gear from increasing. First dynamic pressure generation grooves (46c) that concave are formed on the outer circumferential surface (46b) of a driven gear (46). The depths (D1) of said grooves are set such that the gap ratio (m1) of a gap (H1) extending from the deepest part of the first dynamic pressure generation grooves (46c) to the inner circumferential surface (34c) of a pump body (34) relative to a gap (H2) extending from the outer circumferential surface (46b) of the driven gear (46) to the aforementioned inner circumferential surface (34c) is within a predetermined range including the maximum value of the dynamic pressure (P1) generated by means of the first dynamic pressure generation grooves (46c) and the minimum value of a fluid friction coefficient (mu1) acting by means of the first dynamic pressure generation grooves (46c). As a consequence, the fluid friction coefficient (mu1) acting on the driven gear (46) is reduced to a minimum and the dynamic pressure (P1) generated by means of the first dynamic pressure generation grooves (46c) reaches a maximum, thereby obtaining a self-aligning effect of the driven gear (46) while preventing the fluid friction acting on the driven gear (46) from increasing.

Owner:TOYOTA JIDOSHA KK

Thrust dynamic pressure bearing, spindle motor using the same, and information recording and reproducing apparatus using them

InactiveUS7160031B2Increased durabilityImprove reliabilityShaftsRecord information storageAir liquid interfaceEngineering

In order to prevent lubricating oil leakage due to bubbles in a thrust dynamic pressure bearing having herringbone grooves, and to stabilize the bearing performance, and enhance the reliability and durability, auxiliary grooves deeper than pump-in type herringbone grooves for generating dynamic pressure are provided. The bearing inner periphery and bearing outer periphery are linked by a pressure gradient descending slowly, and therefore bubbles present in the bearing inner periphery can be guided to the bearing outer periphery through the auxiliary grooves, and discharged outside of the bearing from the air-liquid interface, so that lubricating oil leakage due to bubbles can be prevented.

Owner:PANASONIC CORP

Fluid dynamic pressure bearing and recording disk drive device comprising the same

InactiveUS7380989B2Increase dynamic pressureEffective supportRolling contact bearingsShaftsEngineeringMechanical engineering

In a radial minute gap between a substantially columnar shaft and an inner peripheral face of a substantially cylindrical sleeve, oil is retained and a radial dynamic pressure bearing is formed. A plurality of recessed portions are arranged in a circumferential direction on at least one of an outer peripheral face of the shaft and the inner peripheral face of the sleeve and a first hill portion is provided to an axial end portion of each the recessed portion. Thus, it is possible to achieve a dynamic pressure bearing with which sufficient radial shaft support can be obtained in spite of a short axial length.

Owner:NIDEC CORP

Disk drive device improved in anti-vibration characteristic

InactiveUS8506168B2StablyMaintain stiffnessShaftsRecord information storageRotational axisPressure generation

A disk drive device includes a rotating body, a fluid dynamic bearing unit that rotatably supports the rotating body, and a drive unit. The fluid dynamic bearing unit has: a lubricant holding portion in which lubricant is held; a first thrust dynamic pressure groove with which a first thrust dynamic pressure generating portion for generating the dynamic pressure in the pump-in direction, which is oriented toward the inside of the lubricant holding portion, is structured; and a second thrust dynamic pressure groove with which a second thrust dynamic pressure generating portion for generating at least the dynamic pressure in the pump-out direction, is structured. The first thrust dynamic pressure generating portion and the second thrust dynamic pressure generating portion have dynamic pressure generation characteristics in which, when the rotating body is biased in the rotational axis direction from the state where the rotating body is floating in the lubricant, the sum of the changes in the dynamic pressure in the pump-out direction is larger than that of the changes in the dynamic pressure in the pump-in direction.

Owner:SAMSUNG ELECTRO MECHANICS JAPAN ADVANCED TECHNOLOGY CO LTD

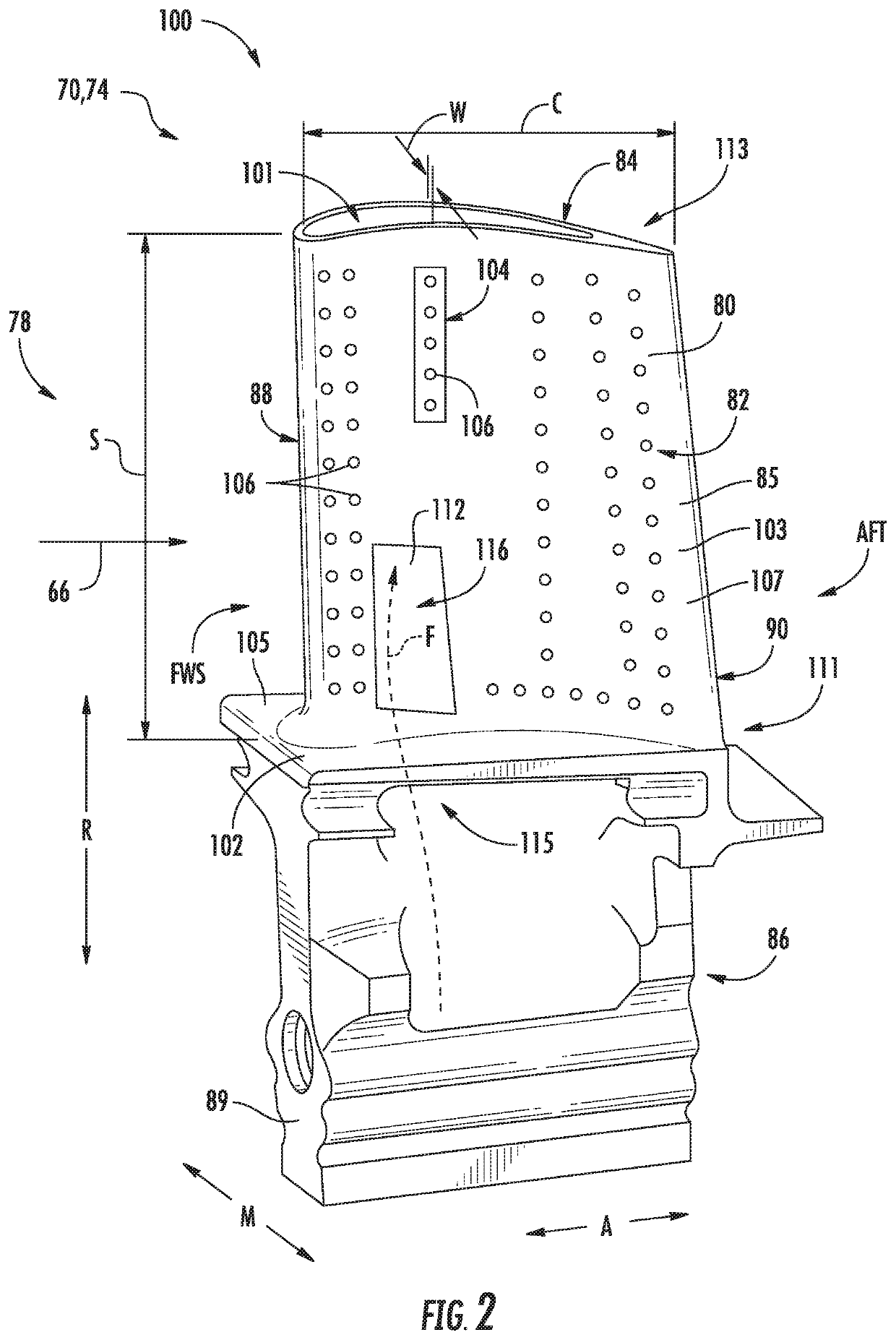

CMC Component Cooling Cavities

ActiveUS20200080425A1Reduce the temperatureIncrease dynamic pressureEngine fuctionsBlade accessoriesEngineeringGas turbines

A component for a gas turbine engine including a core and an outer enclosure. The core includes an exterior surface extending along a length between a first end and a second end and at least partially defines a cooling cavity on the exterior surface extending from the first end along at least a portion of the length. The cooling cavity is fluidly coupled to an air supply at the first end. The outer enclosure includes an outer surface. The outer enclosure is positioned outside the core and extends from the first end of the core along at least a portion of the length of the core and at least partially defines the cooling cavity.

Owner:GENERAL ELECTRIC CO

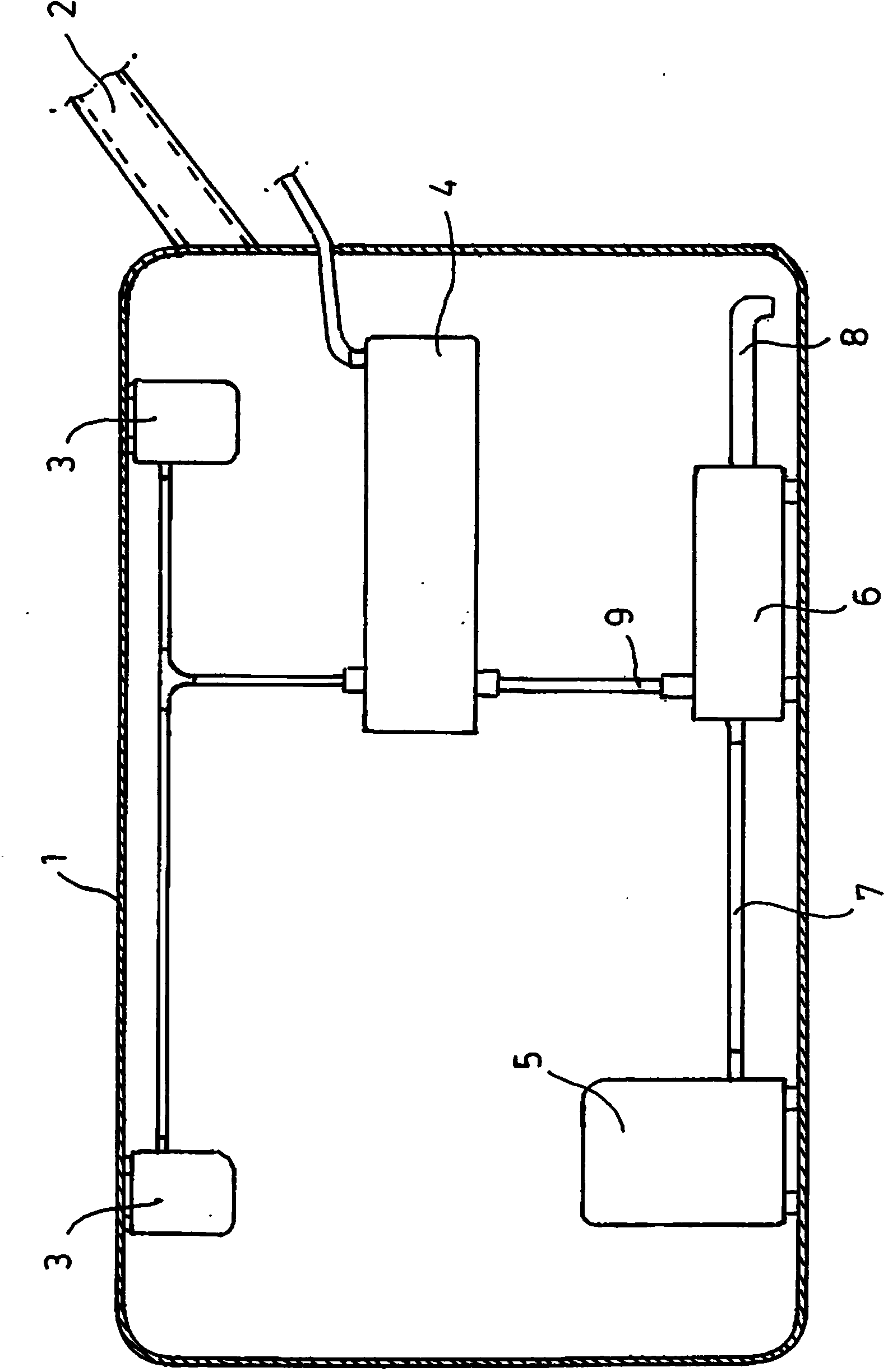

Device for pressure-dependent opening of a suction intake

ActiveCN103619629AImprove efficiencySmall pressure lossLarge containersJet pumpsFeed pressureFuel tank

The invention relates to a device (6) for pressure- dependent opening of a suction intake (10), comprising a suction jet pump (11), comprising a feed line (12), an outlet line (13) and the suction intake (10); a valve body (15), displaceably arranged inside the feed line (12) in the delivery direction (14) of the suction jet pump (11) and having an effective area (16) exposed to the feed pressure of the suction jet pump (11); and a spring element (17), arranged between the feed line (12) and the valve body (15), for applying a force in opposition to the feed pressure inside the feed line (12); wherein the effective area (16) of the valve body (15), and the spring element (17) are designed so that the valve body (15) closes the suction intake (10) so that it is fluid-tight below a predefined pressure inside the feed line (12) and opens said intake when the predefined pressure inside the feed line (12) is exceeded. The invention further relates to a fuel tank, comprising a device (6) for pressure-dependent opening of a suction intake (10).

Owner:KAUTEX TEXTRON

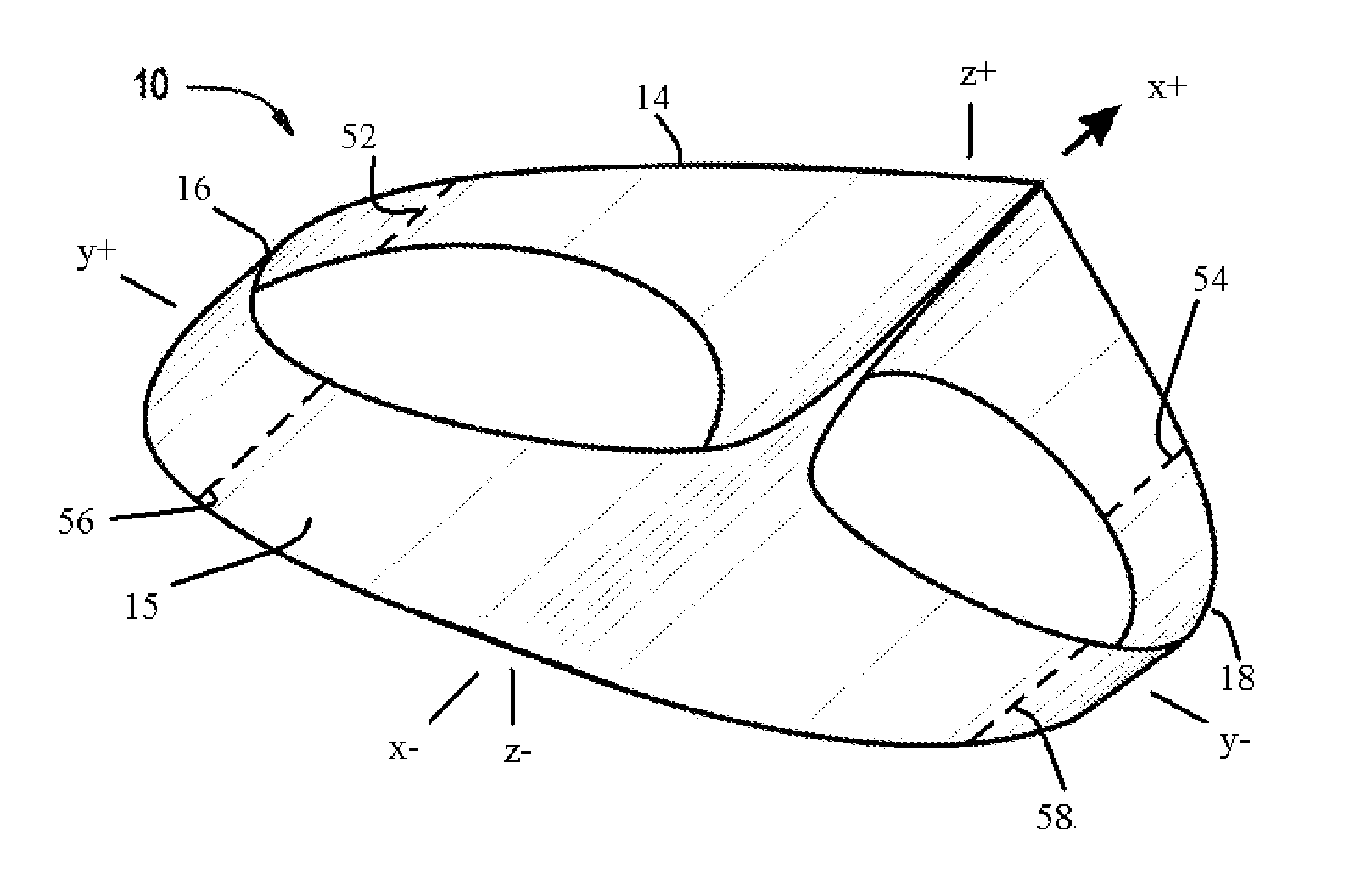

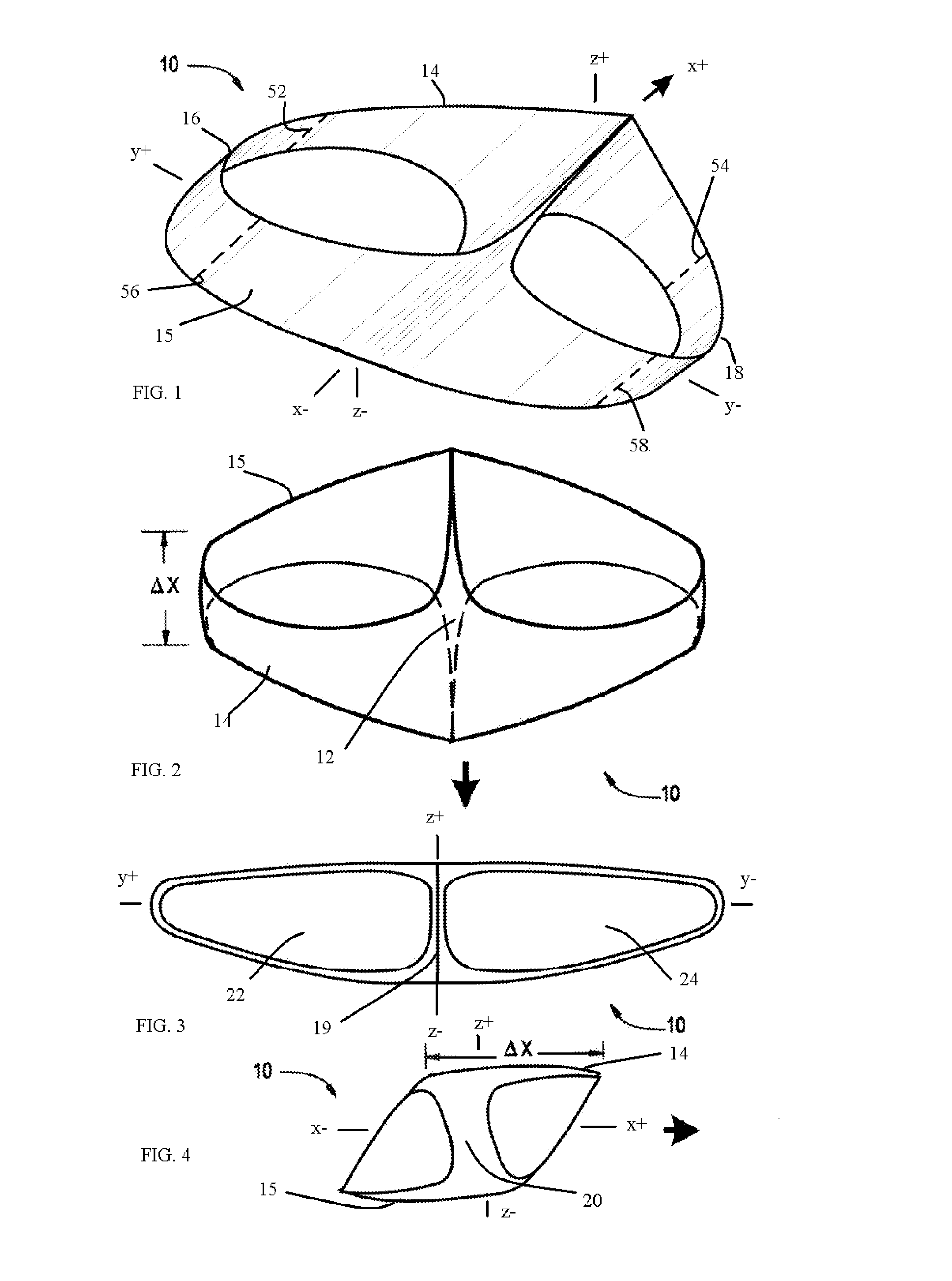

Lifting foil

ActiveUS8387912B2Avoid poor resultsImprove stabilityPropellersWing adjustmentsEngineeringMechanical engineering

Owner:HOUCK II RONALD G

Paddle-type flowmeter with magnetic coupling

ActiveUS8397587B2Minimize impactIncrease dynamic pressureVolume/mass flow by dynamic fluid flow effectCouplingDisplay device

The invention relates to a flow monitor for monitoring the flow of flowing media, wherein a paddle projecting into the flow transfers the rotating movement of the paddle onto a display device by means of a magnetic gear comprising a plurality of individual magnets corresponding with each other.

Owner:MASCHFAB REINHAUSEN GEBR SCHEUBECK GMBH & CO KG

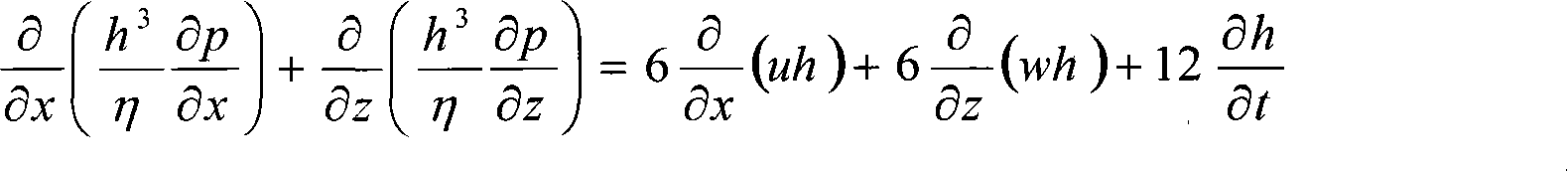

Dry gas seal slotting method and device based on slot bottom micro model design

ActiveCN107228197AEase of industrial applicationSimple structureGeometric CADEngine sealsDry gas sealEngineering

The invention discloses a dry gas seal slotting method and device based on slot bottom micro model design. A relatively reasonable and complete slot bottom interface roughness model is established, the mechanism of the reasonable roughness model design on sealing performance improving and slotting technology standard lowering is elucidated, accordingly an orderly model design method based on the dry gas seal slot bottom roughness microeffect is finally achieved, the dry gas seal performance is improved, and the slotting technology method is simplified.

Owner:山东双环密封科技有限公司

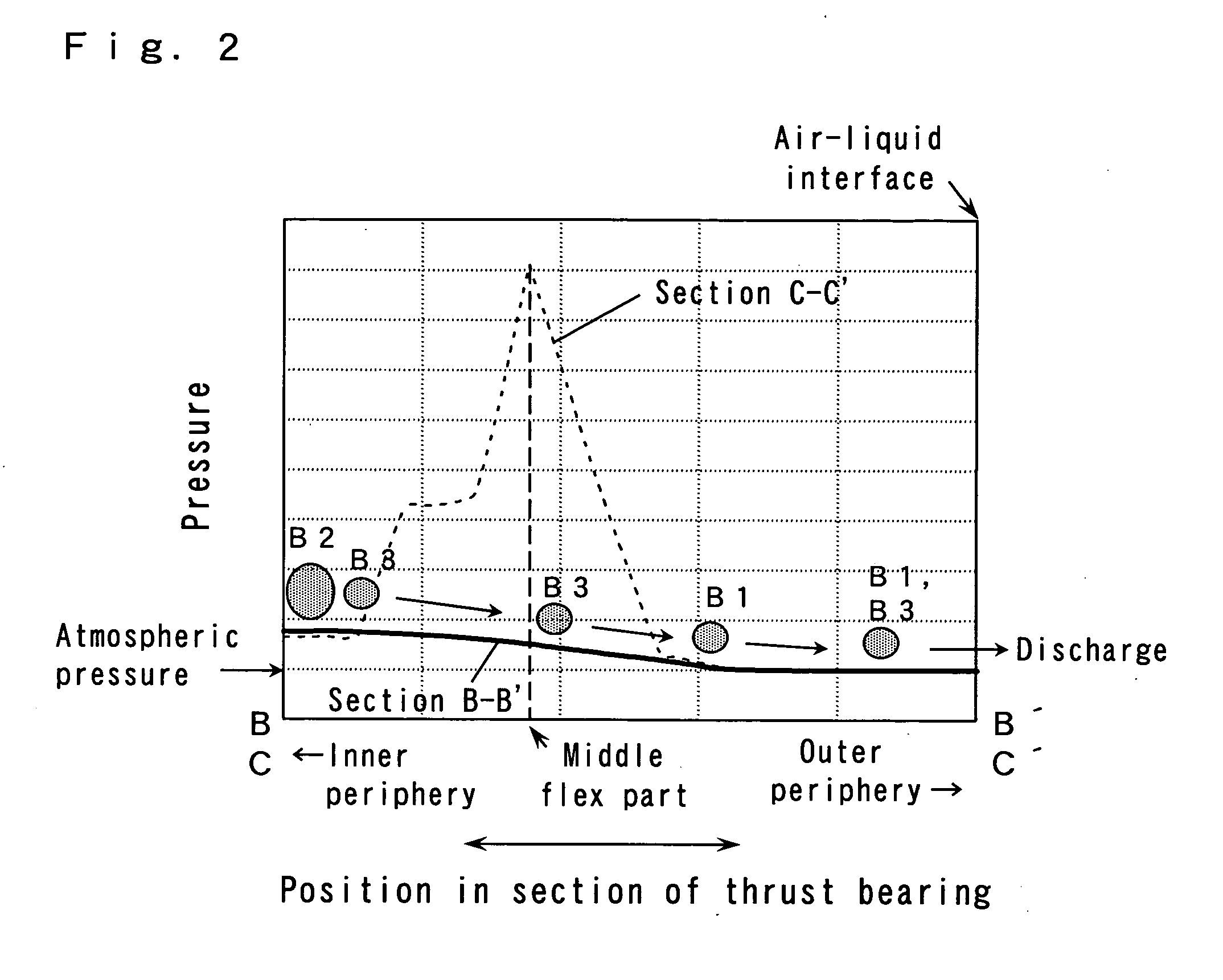

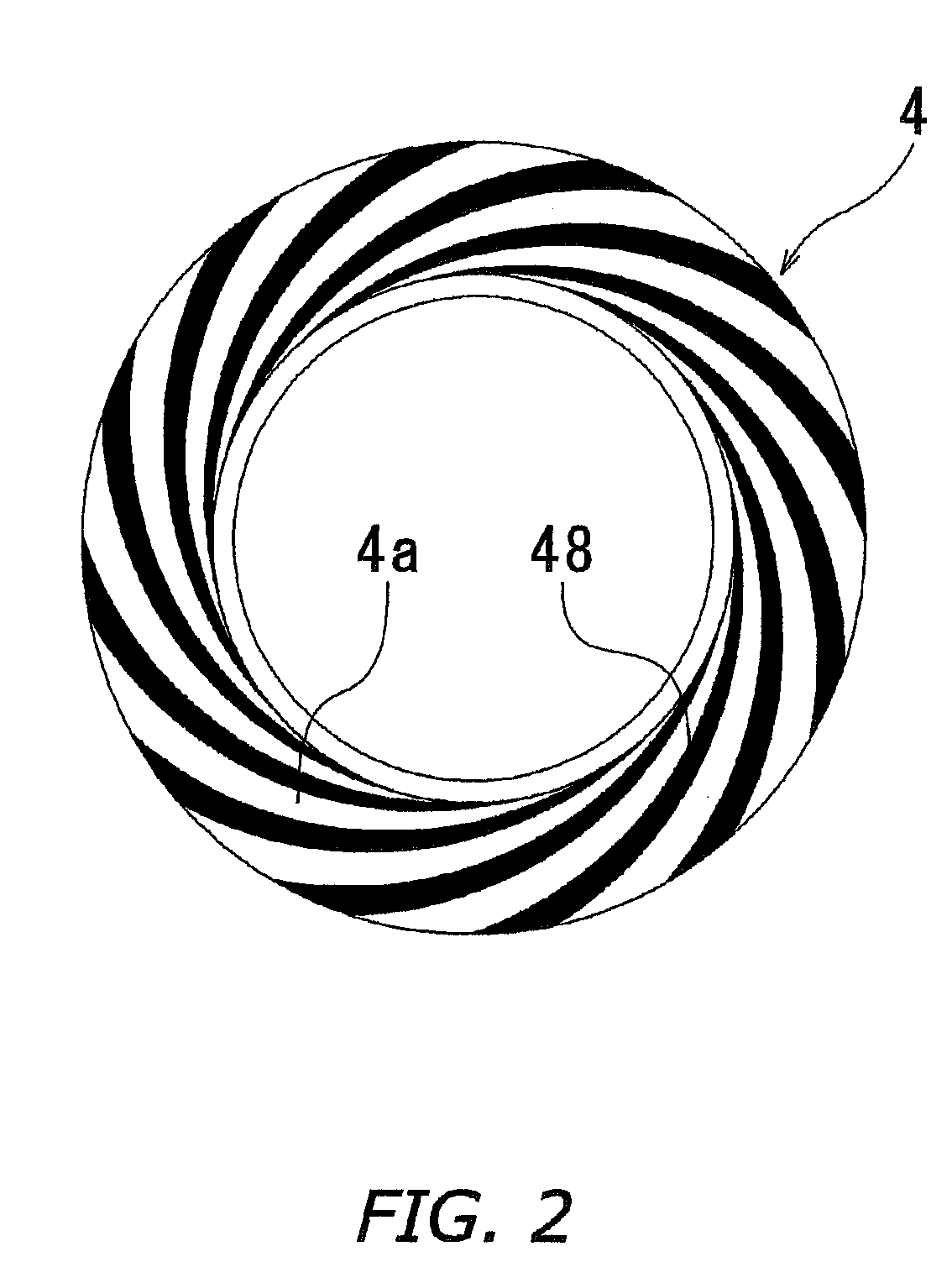

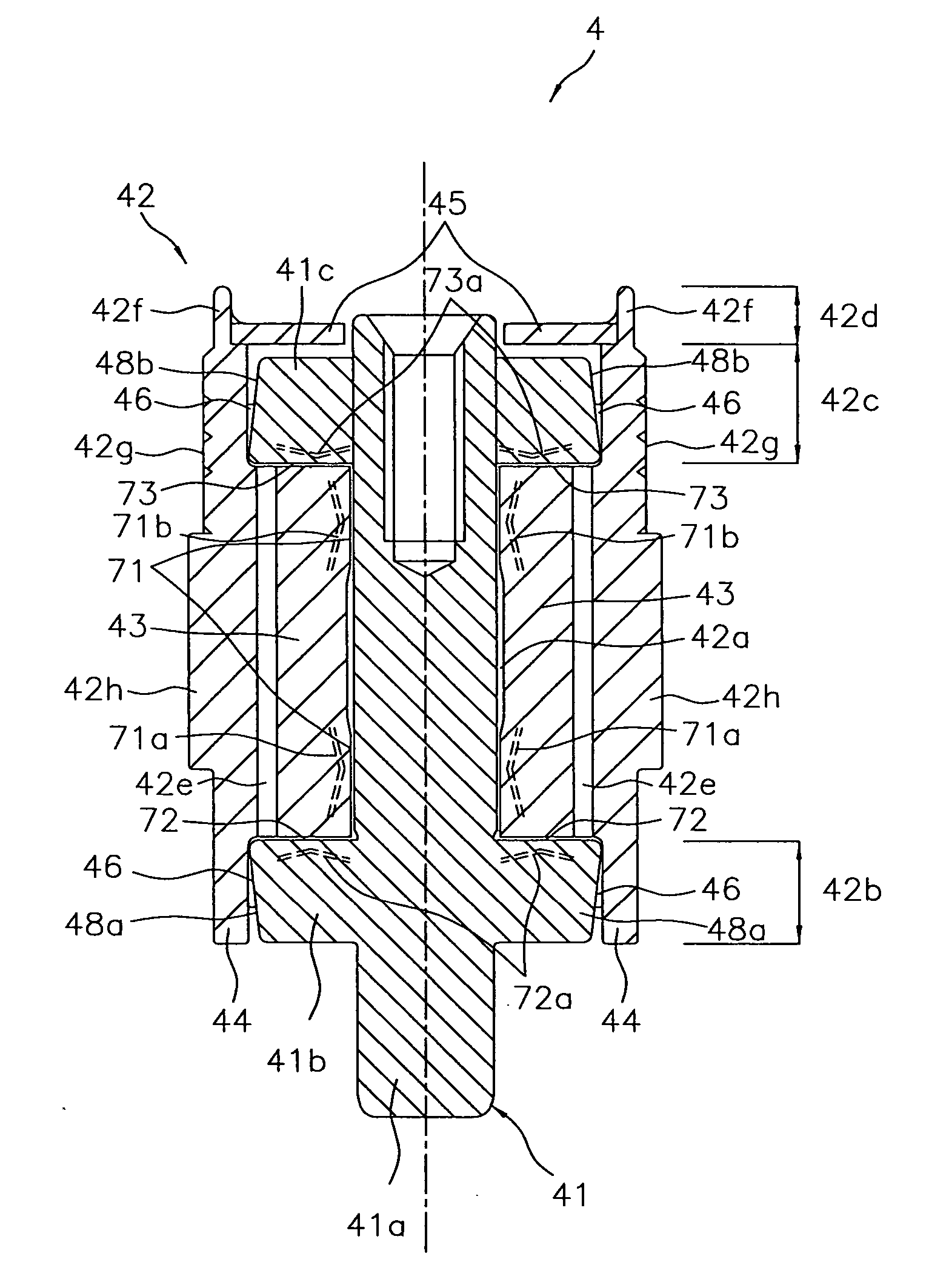

Hydrodynamic bearing device

ActiveUS20070071378A1Increase dynamic pressureSimple designBearing componentsSliding contact bearingsThrust bearingEngineering

A hydrodynamic bearing device which can improve reliability by stabilizing a balance of dynamic pressures generated at a thrust bearing portion. The spindle motor 1 includes a hydrodynamic bearing device 4 including a shaft 41, a sleeve 42, first and second thrust flanges 41b and 41c, first and second thrust bearing portions 72 and 73 and thrust dynamic pressure generating grooves 72a and 73a. The thrust dynamic pressure generating grooves 72a and 73a are formed such that a plurality of groove portions are connected without being isolated from each other, and the groove depth becomes greater from the inner periphery toward the outer periphery.

Owner:PHC HLDG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com