Dry gas seal slotting method and device based on slot bottom micro model design

A technology of dry gas sealing and slotting method, which is applied in the directions of engine sealing, design optimization/simulation, calculation, etc., to achieve the effect of reducing slotting technical requirements, reducing leakage, and optimizing slot structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with accompanying drawing, the present invention will be further described:

[0046] like Figure 1-8 As shown, a dry gas seal grooving method based on the micro-modeling design of the groove bottom is characterized in that it includes AR type two-dimensional digital filtering technology, and the steps are as follows:

[0047] Step 1: Rough surface method based on Gaussian distribution and linear autocorrelation function, using AR type two-dimensional digital filtering technology;

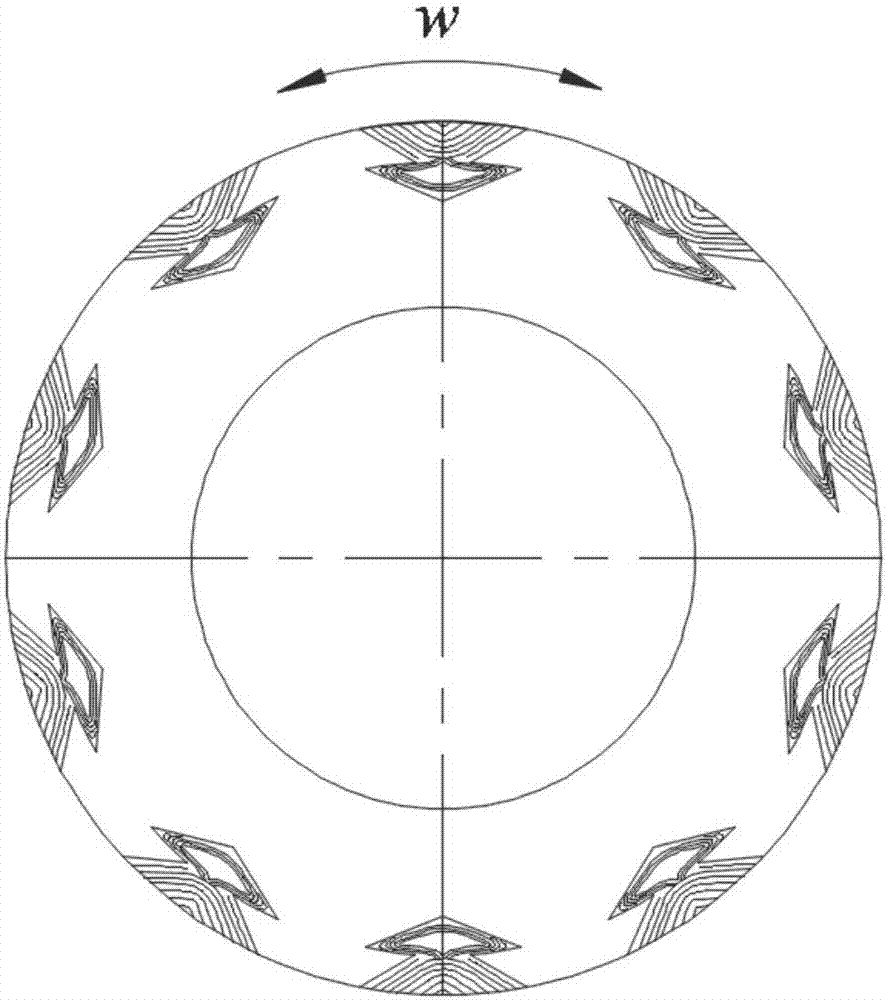

[0048] Step 2: Establish a model for simulating the microscopic random characteristics of the interface roughness of the groove bottom (such as figure 1 shown);

[0049] Step 3: Generate an autocorrelation function rough surface 3D model with corresponding random features based on the model in step 2 (such as figure 2 Shown) and establish functional relationship, described rough surface autocorrelation function is as follows:

[0050] R(τ x , τ y ) = σ 2 exp{-2.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com