Gold extraction method by pre-oxidation and cyanide leaching of refractory gold concentrate

A technology of cyanidation leaching and pre-oxidation, which is applied in the direction of improving process efficiency, can solve problems such as the extraction and smelting of gold ore that have not been seen, and achieve the effects of easy industrial application, low cost and strong adaptability of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

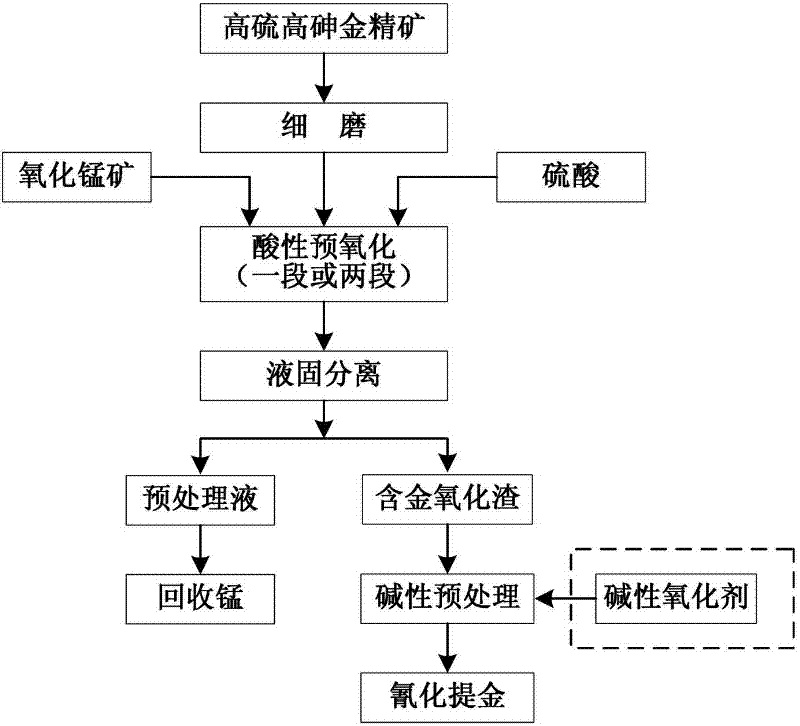

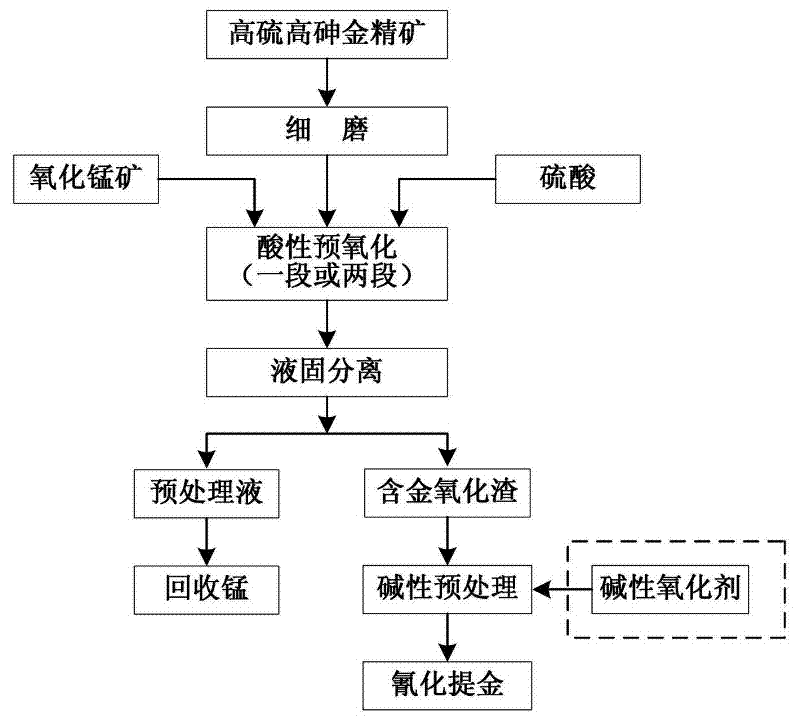

[0024] A kind of such as the present invention figure 1 The method of preoxidation-cyanidation leaching gold extraction of refractory gold concentrate shown, the main material in the selected refractory gold concentrate is pyrite / arsenopyrite wrapped type refractory gold concentrate, the yellow The Au content in the iron ore / arsenopyrite-wrapped refractory gold concentrate reaches 76.55g / t, the S content is 17.4% (the percentages in the composition ratio are all mass fractions unless otherwise specified), and the As content is 3.44 %, Fe is 21.95%, and its main steps are as follows.

[0025] 1. Fine grinding: Mix 50g of the above-mentioned refractory gold concentrate with 0.5g sodium lignosulfonate, and use a mill (rod mill, ball mill, tower mill or stirring ball mill) to fully grind the mixed material As fine as 95% through 25μm.

[0026] 2. Acidic pre-oxidation: the oxidant pyrolusite (MnO in the main component 252%, Fe 5.72%) and the finely ground material in step 1 are ...

Embodiment 2

[0031] A kind of such as the present invention figure 1 The method of preoxidation-cyanidation leaching gold extraction of refractory gold concentrate shown, the main material in the selected refractory gold concentrate is pyrite / arsenopyrite wrapped type refractory gold concentrate, the yellow The Au content in the iron ore / arsenopyrite-wrapped refractory gold concentrate reaches 43.43g / t, the S content is 19%, the As content is 5.86%, and the Fe content is 21.90%. The main steps are as follows.

[0032] 1. Fine grinding: Mix 50g of the above-mentioned refractory gold concentrate with 0.75g sodium lignosulfonate, and use a mill (rod mill, ball mill, tower mill or stirring ball mill) to fully grind the mixed material As fine as 95% through 45μm.

[0033] 2. Acidic pre-oxidation: mix the oxidant pyrolusite (composition of the manganese ore is the same as in Example 1) and the finely ground material in step 1 at a mass ratio of 2.4:1, and then mix the slurry with concentrated s...

Embodiment 3

[0038] A kind of such as the present invention figure 1 The method of preoxidation-cyanidation leaching gold extraction of refractory gold concentrate shown, the main material in the selected refractory gold concentrate is pyrite / arsenopyrite wrapped type refractory gold concentrate, the yellow The Au content in the iron ore / arsenopyrite-wrapped refractory gold concentrate reaches 64.34g / t, the S content is 31.1%, the As content is 10.81%, and the Fe content is 36.19%. The main steps are as follows.

[0039] 1. Fine grinding: Mix 50g of the above-mentioned refractory gold concentrate with 0.15g of sodium tartrate, and use a mill (rod mill, ball mill, tower mill or stirring ball mill) to fully grind the mixed material to 95 % through 38 μm.

[0040] 2. Acidic pre-oxidation: mix the oxidant pyrolusite (same composition as in Example 1) and the finely ground material in step 1 at a mass ratio of 3:1, and then mix and stir the prepared slurry with concentrated sulfuric acid. One...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com