Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

170 results about "Cyanide leaching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cyanide Leaching process is the main method of extracting gold from the ore and the concentrate in modern time. It includes some basic steps, such as cyanide leaching, leaching pulp washing filter, pulp cyanide solution or cyanide gold extraction and smelting of finished products.

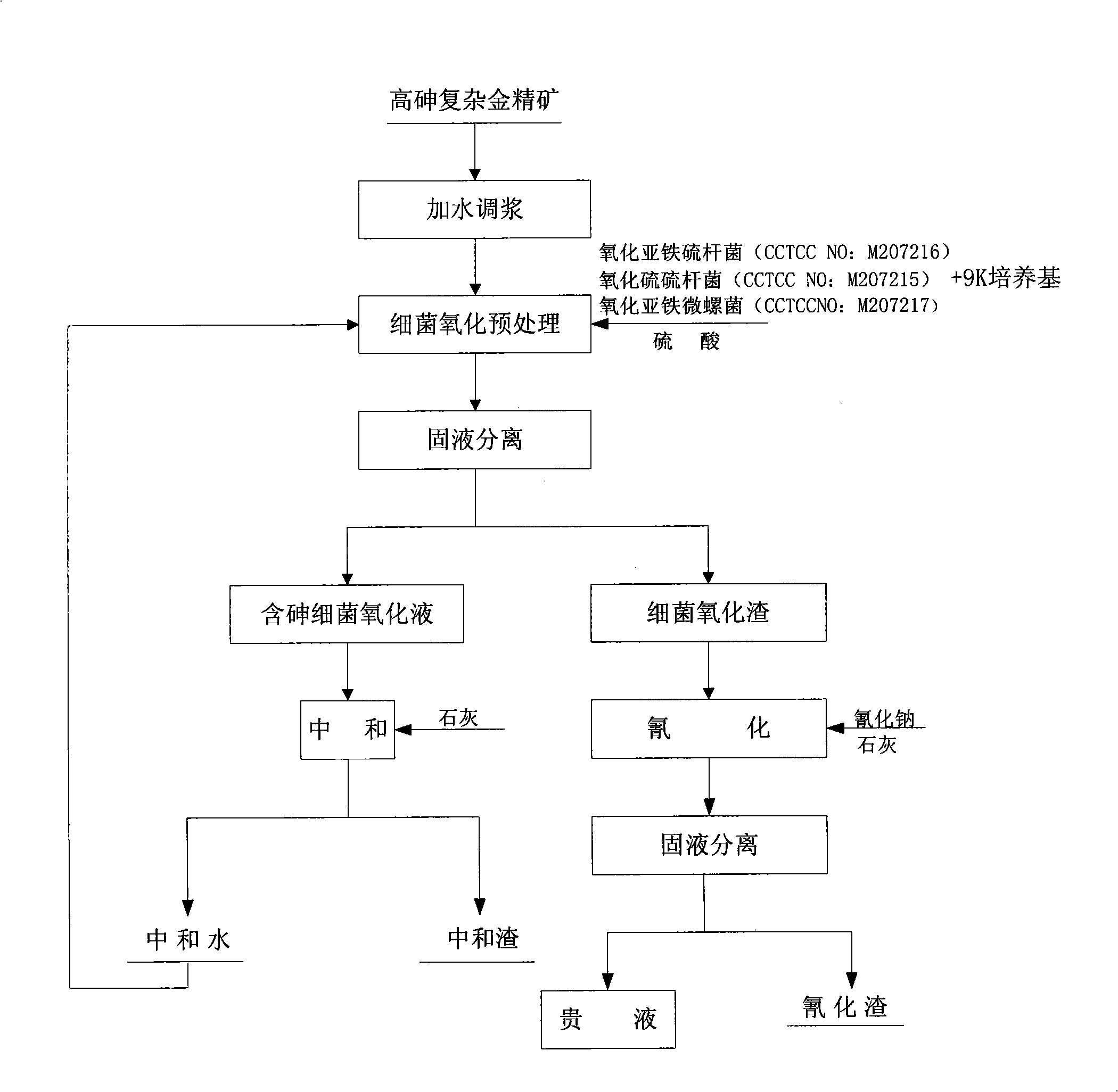

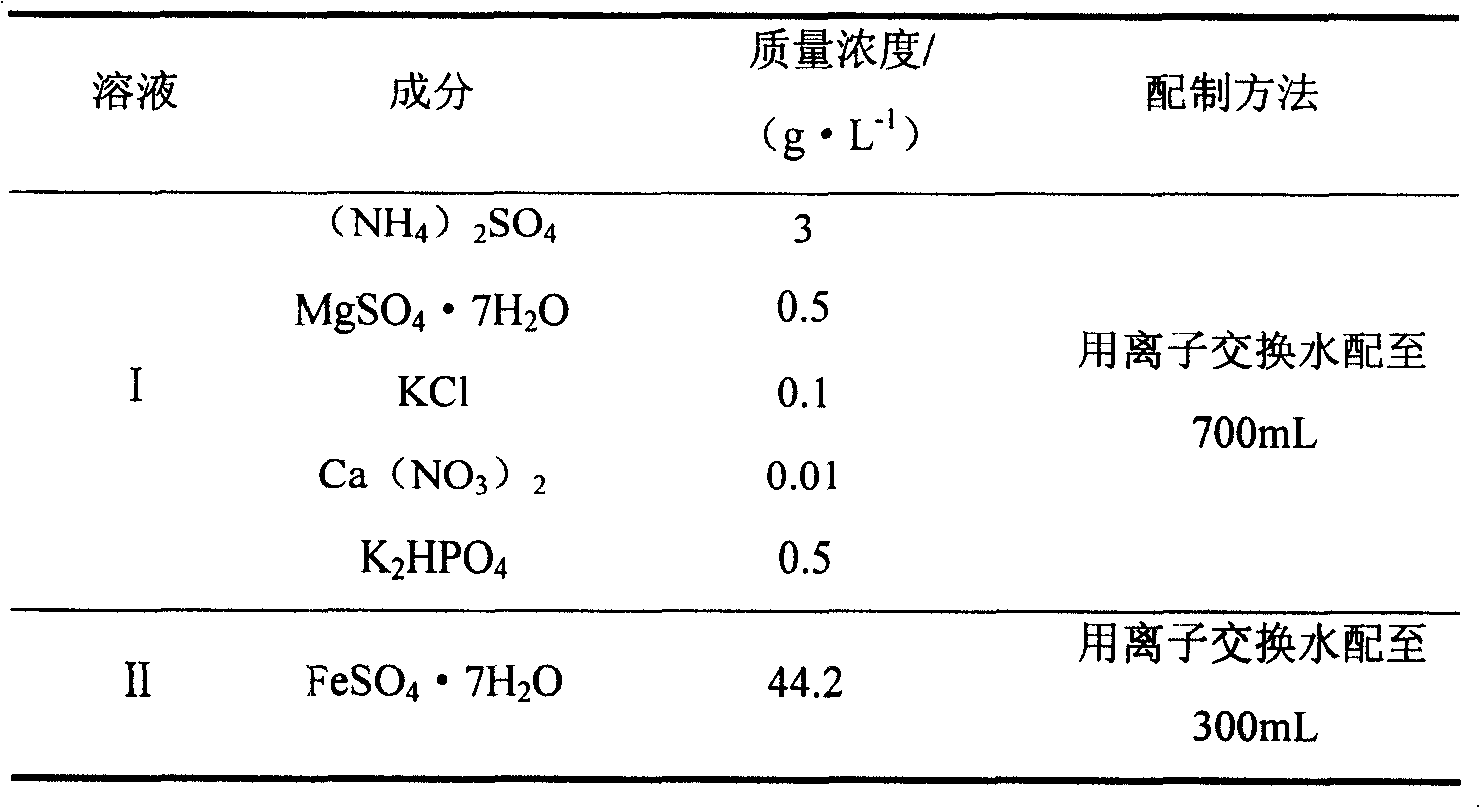

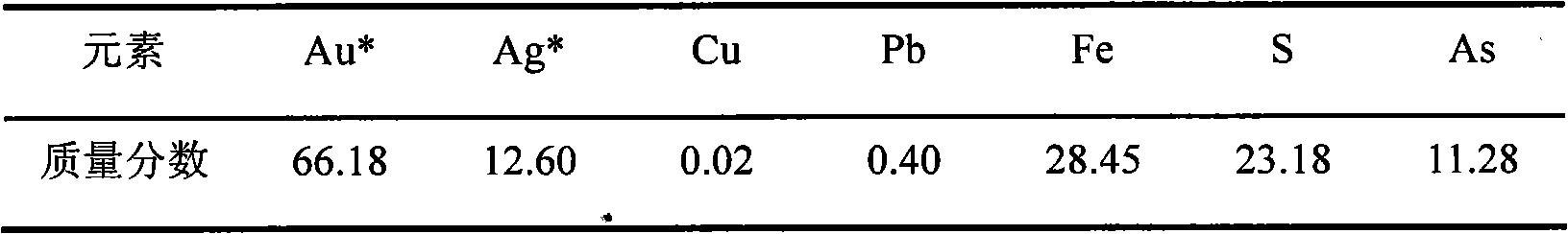

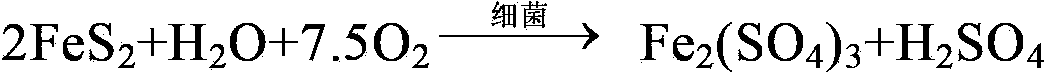

Cyanidation aurum-extracting method for preprocessing high-arsenic complex refractory gold ore by oxidation with arsenic resistant strains

InactiveCN101333599AIncrease growth temperatureStable temperatureProcess efficiency improvementThiobacillus ferrooxidansResistant strain

Disclosed is a cyaniding gold extraction method for pre-treating high-arsenic complex refractory gold ore by arsenic-resistant bacteria oxidation, comprising five steps of arsenic-resistant bacteria culture, flotation concentrate mixing, bacterial oxidation of flotation concentrates, solid-liquid separation and cyaniding gold extraction. The cyaniding gold extraction method adopts specific arsenic-resistant bacteria which are prepared by mixing Thiobacillus ferrooxidans, Thiobacillus thiooxidans and Leptospirillum ferrooxidans, and conducts oxidation pretreatment of high-arsenic complex refractory gold ore. The high-arsenic complex gold ore containing 8 to 20 percent of arsenic can be pretreated, and the arsenic removal rate is 85 to 98 percent. The leaching rate of gold is up to 90 to 95 percent after cyaniding leaching. The cyaniding gold extraction method adopts unique bacteria for leaching ores, greatly saves cooling cost, conducts direct oxidation of high-arsenic complex gold ore containing 8 to 20 percent of arsenic, and has advantages of being widely adaptable, simple in operation, environmentally friendly and remarkably beneficial.

Owner:NORTHEASTERN UNIV

Process for recovery of metal values from materials containing arsenic and/or antimony

InactiveUS20090019970A1Limiting copper contentReduced cyanide consumptionProcess efficiency improvementSlurryCyanide leaching

A method for the recovery of metal values from a metal value-bearing material containing arsenic and / or antimony and a source of sulphate ions such as sulphide ore or concentrate is disclosed. In one form the method comprises the steps of: (a) providing a feed stream comprising a metal value-bearing material containing arsenic and / or antimony and a source of sulphate ions; (b) subjecting the feed stream to oxidative conditions under elevated temperature and pressure conditions in the presence of at least one component selected to decrease the effective concentration of free acid generated during the pressure oxidation step and promote the formation of pH-stable iron (III) sulphate products, thereby forming a slurry comprising a metal value-containing leach solution and a solid leach residue containing pH-stable iron (III) sulphate products and environmentally stable iron-arsenic and / or iron-antimony products; (c) separating the metal value-containing leach solution from the solid leach residue; (d) recovering the metal value (s) from the metal value-containing leach solution; and (e) recovering precious metal values, if present, in the solid leach residue by cyanide leaching.

Owner:DUNDEE PRECIOUS METALS

Method for producing insulating bricks by utilizing aluminum-electrolyzed waste refractory materials

InactiveCN102059736AEmission reductionAdsorptiveCeramic shaping apparatusCyanide compoundAluminium electrolysis

The invention discloses a method for producing insulating bricks by utilizing aluminum-electrolyzed waste refractory materials, relating to a recovery technology of waste refractory materials during the aluminum electrolysis production, wherein the aluminum-electrolyzed waste refractory materials are mainly various refractory material mixture in which waste cathode carbon blocks and side silicon carbide are removed. The method adopts the following raw materials in percentage by weight: 5-30% of the aluminum-electrolyzed waste refractory materials, 10-50% of fly ash or fly ash drift beads, 15-30% of a cementing agent, 1-5% of additives, 3-8% of a pore-forming agent and 10-20% of water, and the method comprises the following steps of: preparing the raw materials, mixing the raw materials, extruding the mixture to mold, drying and sintering to produce the insulating bricks; and by utilizing innocuous treatment measures, the extraction contents of fluoride and cyanide of the produced insulating bricks are lower than 50mg / l and 1.0mg / l, the smoke gas is adsorbed by an aluminum oxide, and the solvable injurant and the smoke gas of the insulating bricks both meet the national environment protection emission standard; and the produced insulating bricks can be applied to the heat insulation of various pipelines and walls at a temperature lower than 1000 DEG C.

Owner:YICHUAN LONGHAI TECH INDAL

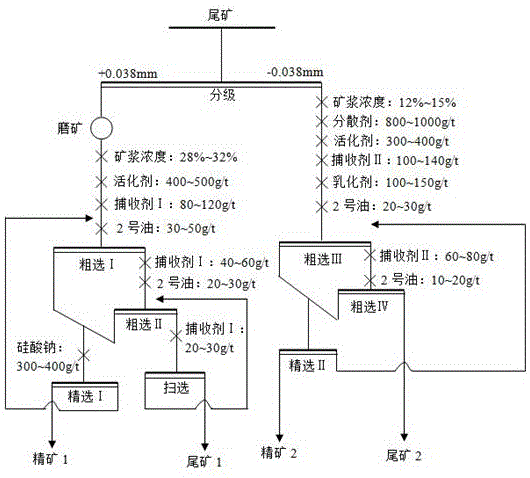

Method for recycling gold and micro-fine particle antimony minerals in antimony-containing gold ore flotation tailings

The invention discloses a method for recycling gold and micro-fine particle antimony minerals in antimony-containing gold ore flotation tailings. By the adoption of the method, the technical problem that if the antimony-containing gold ore flotation tailings are subjected to cyanide leaching directly, the cost is high, and the gold recovery rate is low is solved. Meanwhile, efficient recovery of associated antimony minerals can also be achieved. The method is characterized by comprising the steps that the tailings are rated, the tailings with the particle size being larger than 0.038 mm are subjected to regrinding and size mixing, copper sulfate, lead nitrate and ammonia carbonate are added sequentially as a mixed activating agent, sodium n-butylxanthate and ammonium butyl aerofloat serve as a collecting agent, No.2 oil serves as a foaming agent, and gold and the antimony minerals are recycled through flotation; and water is directly added into the tailings with the particle size being smaller than 0.038 mm for size mixing, grinding is not needed, sodium hexametaphosphate, copper sulfate, lead nitrate, ammonia carbonate, sodium n-butylxanthate, No.25 aerofloat, kerosene (or diesel oil) and No.2 oil are added in sequence, wherein the sodium hexametaphosphate serves a dispersing agent, the copper sulfate, lead nitrate and ammonia carbonate serve as an activating agent, the n-butylxanthate and No.25 aerofloat serve as a collecting agent, the kerosene (or diesel oil) serves an emulsifying agent, and the No.2 oil serves as a foaming agent, and gold and the micro-fine particle antimony minerals are recycled through flotation. The technique is reasonable, procedures are simple, the gold and antimony recovery rate is high, and industrialized implementation is easy.

Owner:KUNMING UNIV OF SCI & TECH

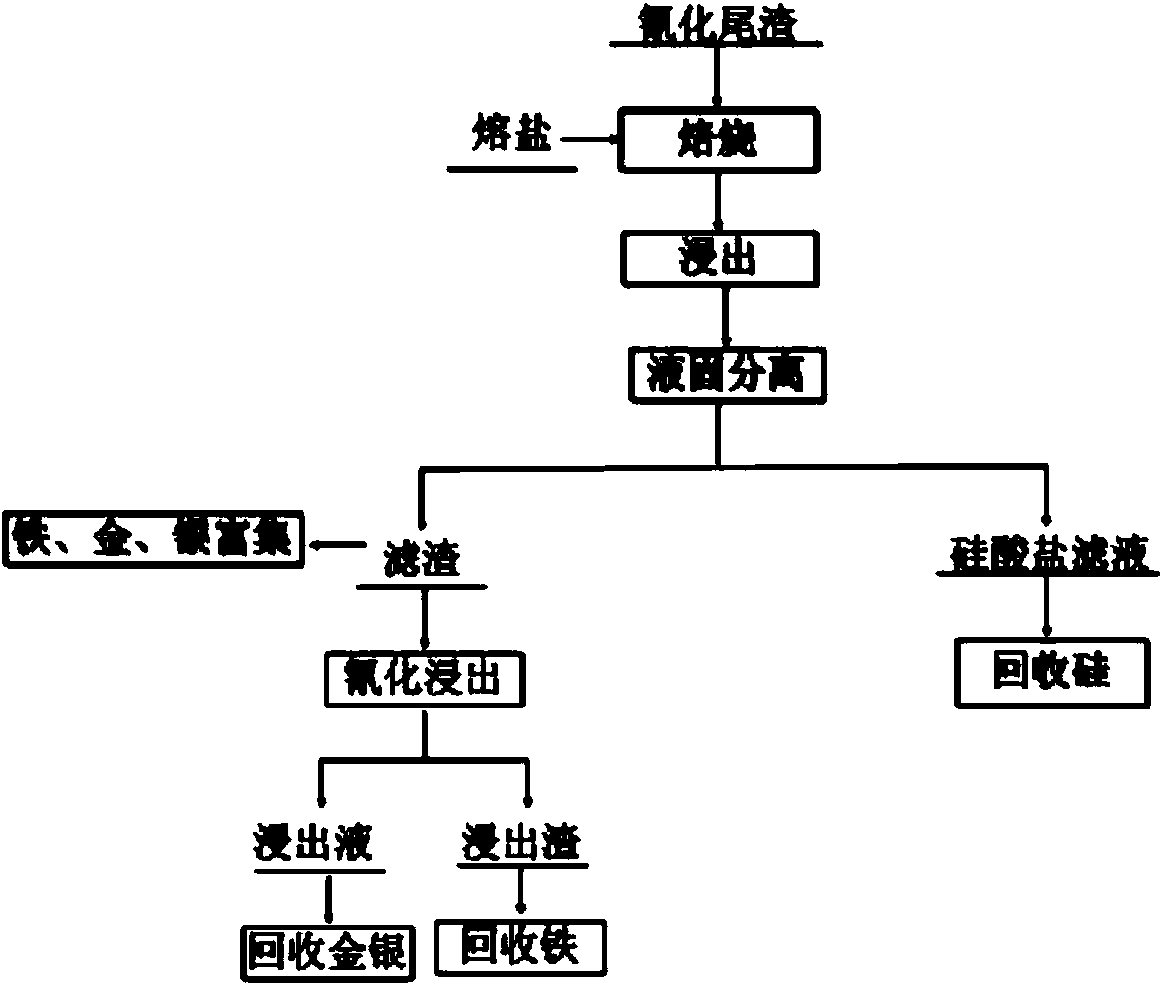

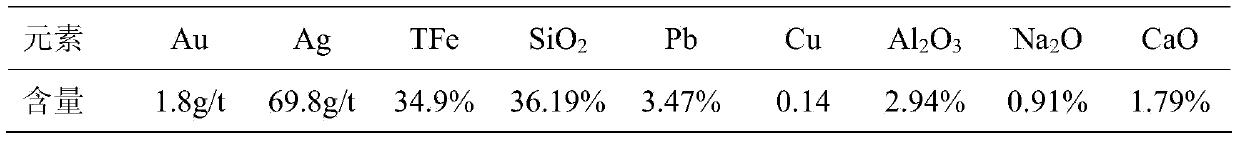

Comprehensive utilization method of cyanidation tailings

ActiveCN104046787ARealize comprehensive utilizationProcess efficiency improvementWater immersionMolten salt

The invention relates to a comprehensive utilization method of cyanidation tailings. The method comprises the steps of roasting cyanidation tailings in which molten salt is added to obtain a roasted product, wherein the molten salt is a mixture of NaOH, NaCl and NaNO3 or a mixture of NaOH, NaF and NaNO3; carrying out water immersion on the roasted product, and then, carrying out solid-liquid separation to obtain filtrate and filter residues; respectively recovering valuable elements in the filtrate and the filter residues. According to the invention, SiO2 in the cyanidation tailings is converted into soluble silicate in a roasting way by taking the cyanidation tailings as raw materials and the molten salt as a medium, so that the comprehensive utilization of a Si element in the cyanidation tailings is realized; meanwhile, the Au and Ag packages are opened, and the valuable elements such as Fe, Au, Ag and the like are enriched; in addition, the comprehensive utilization of all the valuable elements in the cyanidation tailings can be realized through conventional cyanide leaching and iron selection methods.

Owner:SHAANXI LONGMEN IRON & STEEL

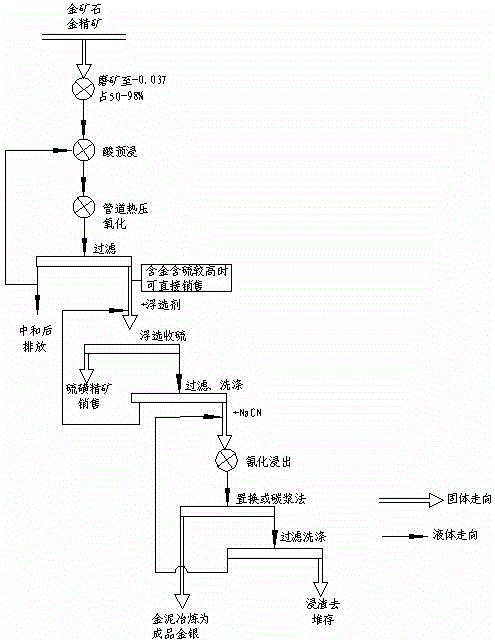

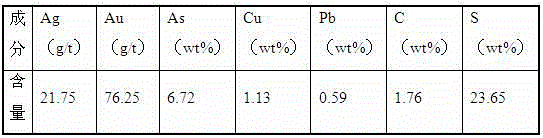

Method for recovering gold and silver from refractory gold ores

InactiveCN104818380AReduce pollutionAchieve recyclingProcess efficiency improvementBiological oxidationGold ore

The invention discloses a method for recovering gold and silver from refractory gold ores, and belongs to the field of metallurgy. The method includes two steps: firstly, pre-oxidizing and breaking inclusions of the gold and the silver in a hot-pressing manner, oxidizing organic carbon in the ores, and recovering sulfur in the ores; secondly, recovering the gold and the silver in presoaked residues by cyanidation or other non-cyanide leaching. The gold and the silver are recovered from the refractory gold ores by the method, the recovery rate of the gold and the silver is higher than 90% and increased by 40 percentage points as compared with that of a conventional cyanidation method, and the recovery rate of the sulfur is higher than 50%. By the aid of the scheme, production cost is about 400 Yuan / ton. Compared with biological oxidation, two-stage roasting and conventional hot-pressing oxidation processes, investment and the production cost can be reduced, the recovery rate is increased, multi-element comprehensive recovery is realized, environmental pollution is reduced, and economic and social benefits are obvious.

Owner:张伟晓

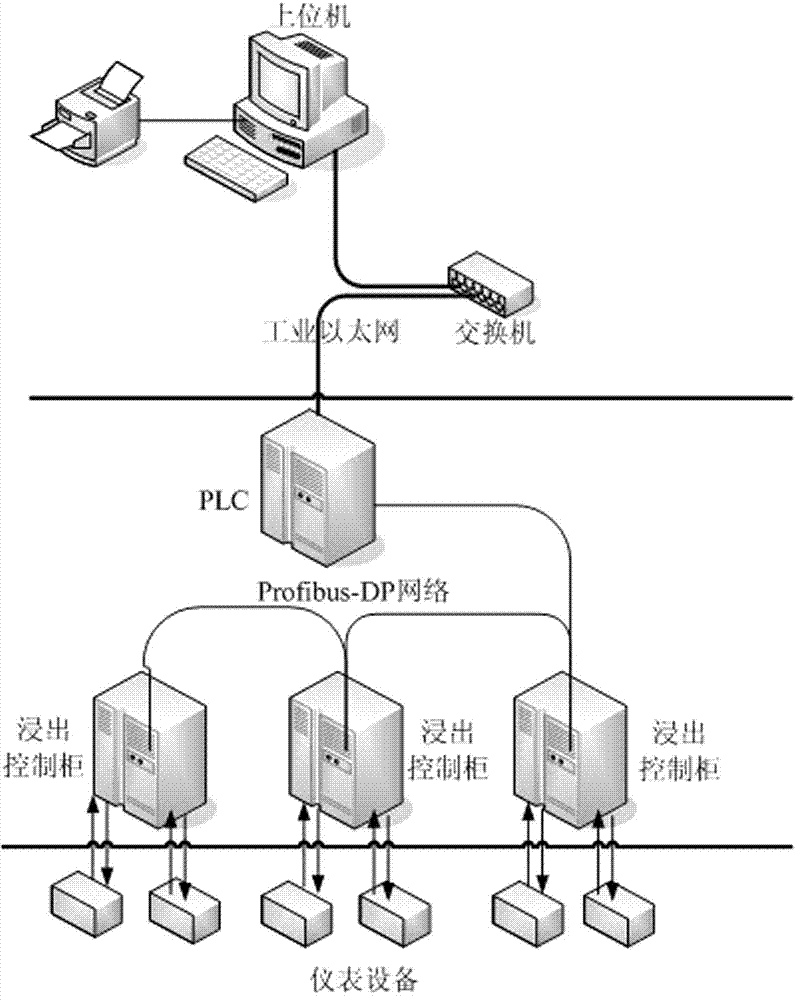

Hydrometallurgical gold cyanide leaching optimization method

ActiveCN104597755ASolve the insufficient additionSolve problems such as blindly adding too muchAdaptive controlProcess optimizationData acquisition

The invention discloses a hydrometallurgical gold cyanide leaching optimization method. By using the traditional hydrometallurgical gold cyanide leaching process and based on stable production and production index, the production cost is minimized. The method comprises the following process steps of: (1), data collection; (2), selection and data processing of auxiliary variables; (3), establishment of an optimization model; (4), solution of the optimization model; and (5), determining of operation guidance of the leaching process optimization. According to production requirements and production site conditions, additive amount of raw materials in the guidance production process is optimized, a reasonable production plan is developed, problems of insufficient additive amount of the raw materials and excessive additive amount in the production process are solved, the production requirements are ensured, and waste of the raw materials is avoided.

Owner:NORTHEASTERN UNIV

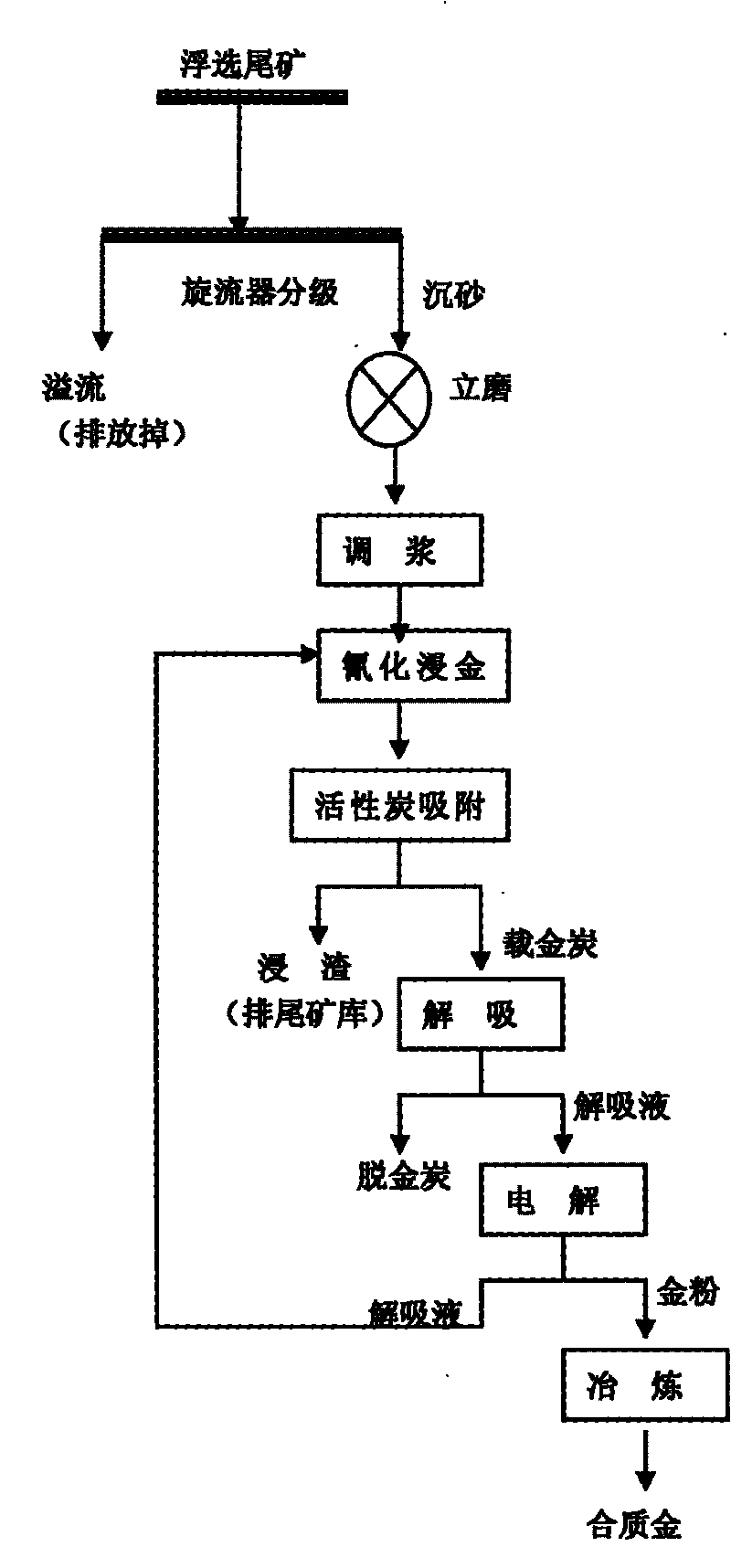

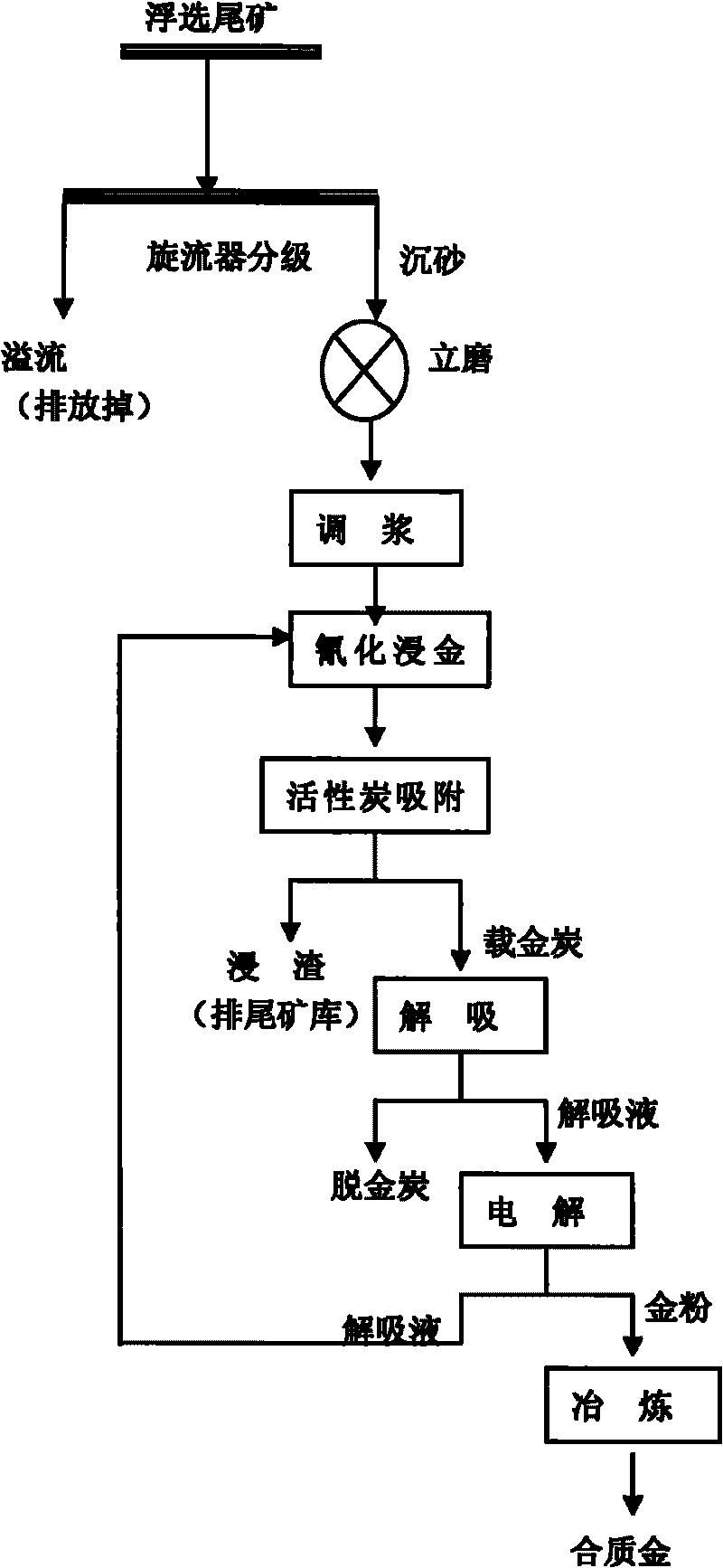

Technology for secondary recovery of gold from flotation tailings

InactiveCN101705506AImprove mineral processing recovery rateLow costProcess efficiency improvementCycloneDesorption

The invention particularly discloses a technology for the secondary recovery of gold from flotation tailings, which comprises the following steps: conducting cyclone classification on ore pulp of the flotation tailings, grinding the cyclone-classified grit as crude ore, conducting ore pulp mixing on the ground ore powder, conducting cyanide leaching of gold, absorbing the leached gold by active carbon, desorbing gold-loaded carbon after saturated adsorption, and electrolyzing the desorption solution after desorption, thus obtaining gold powder. Unlike conventional processes, the technology only needs investment on the power cost of equipment and material cost instead of implementing pit discharging and pit loading by staff and vehicles, therefore, compared with the conventional treatment method, the technology has the characteristics of low cost, large treatment quantity, continuous operation and the capability of enhancing the ore dressing recovery rate by floatation technology to the maximum extent.

Owner:LINGBAO CITY JINYUAN MINING

Gold extraction technique method for low-grade refractory gold ores

ActiveCN105039737ASolve the problem of resource recyclingLess investmentProcess efficiency improvementActivated carbonSulfide compound

The invention discloses a gold extraction technique method for low-grade refractory gold ores. The method comprises the following steps: raw ores or cyanide tailings containing micro-fine particle sulfide-encapsulated gold are finely grinded; the finely grinded raw ores or cyanide tailings are added into an intense agitation inflation reaction device, and are mixed with water to form pulp; under an ordinary pressure at a temperature of 10 DEG C-100 DEG C, air or oxygen is introduced and mixing is performed so as to perform pre-oxidation; calcium oxide is added into the above mentioned pre-oxidized pulp to perform adequate alkali treatment; NaCN is added into the pulp subjected to alkali treatment for cyanide leaching, and finally, gold extraction is performed by using activated carbon for adsorption. The method disclosed by the invention has the advantages of low investment, low cost, simple equipment, mild conditions, high resource recovery rate and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

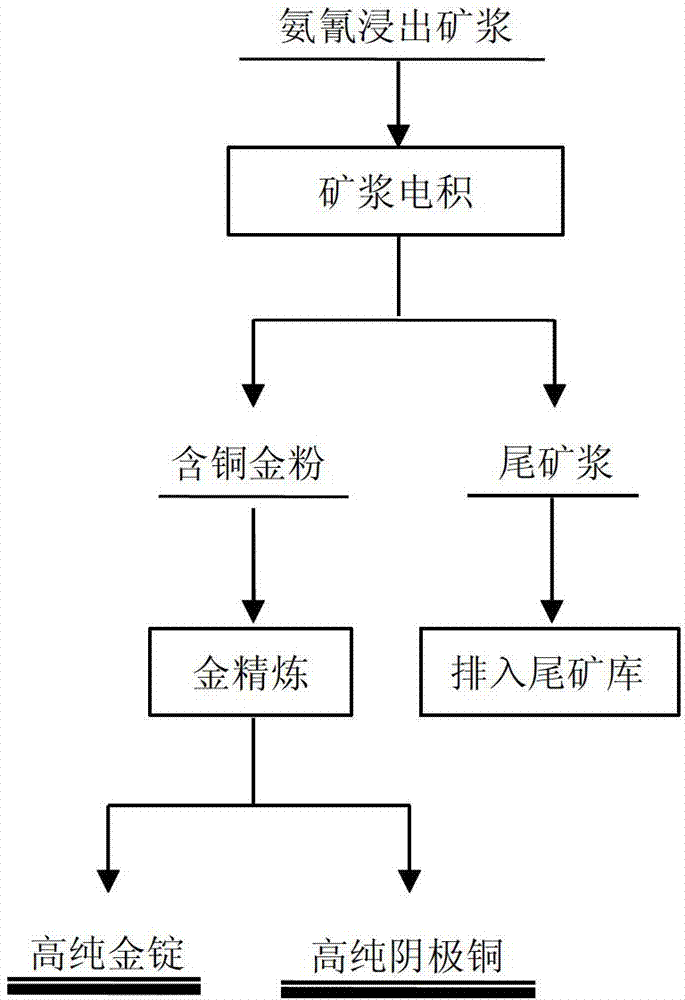

Process for extracting gold from low-grade, copper-containing and difficultly-treated goldmine ammonia cyanide leaching pulp via electrodeposition

ActiveCN103194770AHigh recovery rateShort processPhotography auxillary processesDesorptionCyanide leaching

The invention relates to a process for extracting gold from a low-grade, copper-containing and difficultly-treated goldmine ammonia cyanide leaching pulp via electrodeposition. The process comprises the following steps: diluting the low-grade, copper-containing and difficultly-treated goldmine ammonia cyanide leaching pulp to the proper pulp concentration; leading the pulp into an electrodeposition tank and performing the electrodeposition on the pulp; refining the copper-containing gold powder obtained from a cathode, thereby obtaining a high-purity gold ingot and high-purity cathode copper; and discharging the pulp after the electrodeposition into a tailings pond. The process has the advantages that the technological process is short; the gold recovery rate is high; the production cost is low; the comprehensive recovery of copper is realized; the steps of countercurrent washing, carbon adsorption, gold-carrying carbon desorption-electrodeposition and the like in the conventional gold leaching process are omitted; the investment cost is lowered greatly; and the like.

Owner:ZIJIN MINING GROUP

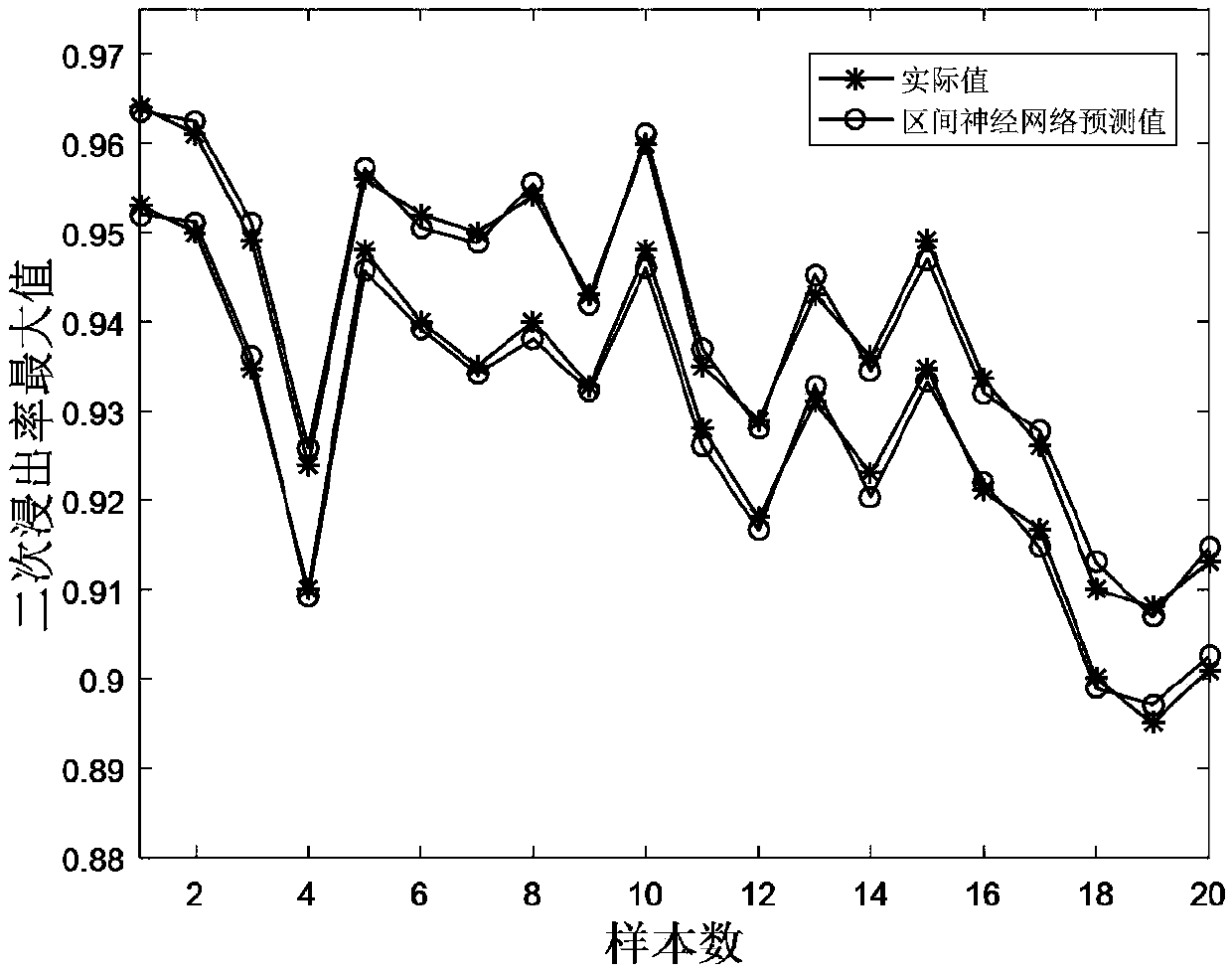

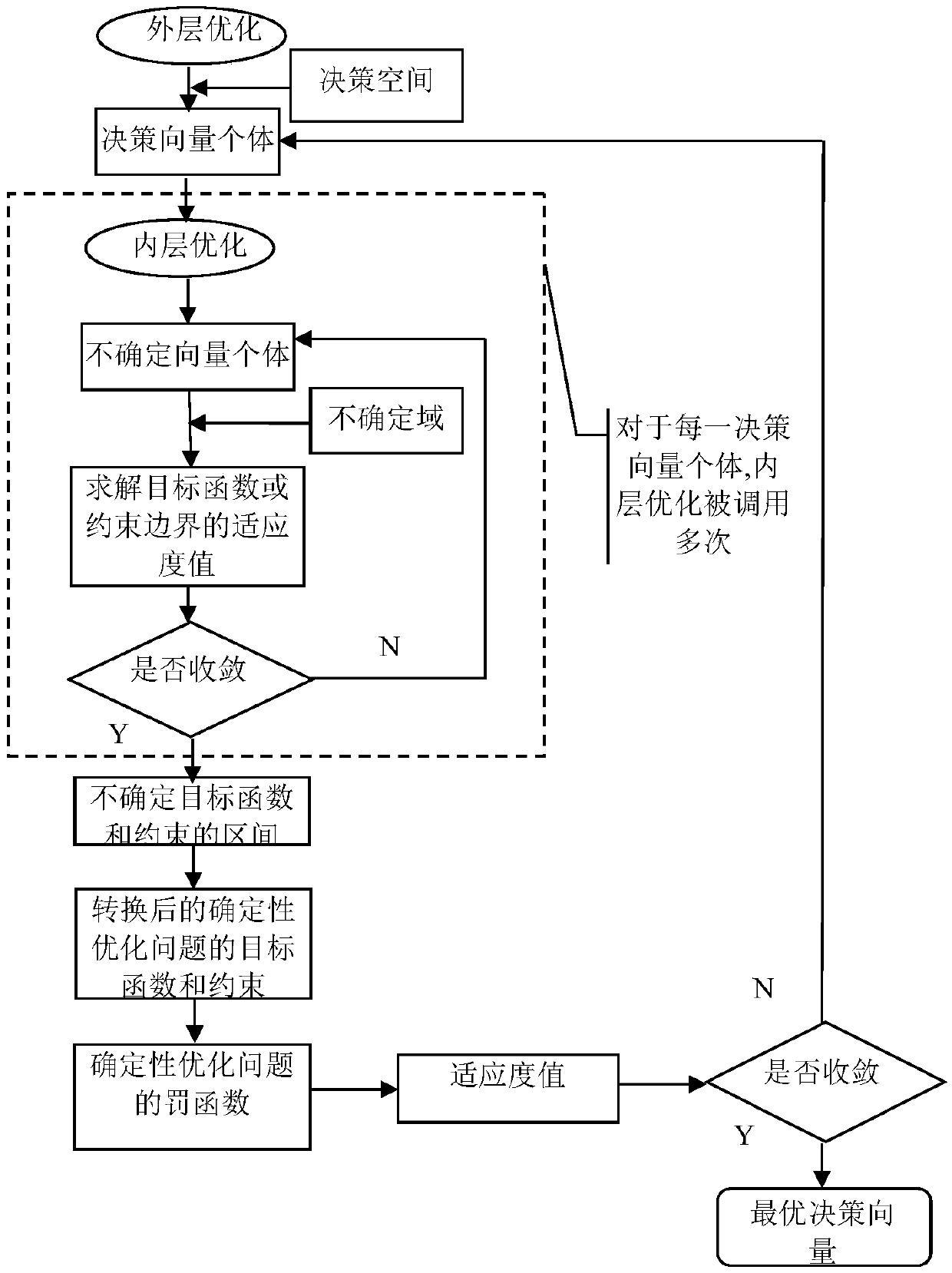

Wet metallurgy leaching process optimization method with interval uncertainty

ActiveCN108921352ACalculation speedHigh precisionForecastingDesign optimisation/simulationProcess optimizationEconomic benefits

The invention relates to a wet metallurgy leaching process optimization method with interval uncertainty. The ore pulp concentration is described by adopting an interval number; and according to the analysis on a reaction mechanism in a gold cyaniding leaching process, a mechanism model of the gold cyaniding leaching process is built by utilizing a material conservation equation and an interval analysis theory. On the basis of the mechanism model, an optimization model taking the maximum economic benefit of the two-stage gold cyaniding leaching process as a target and based on the interval number is built. For the uncertainty optimization model, a two-layer nested improved differential evolution and sequence quadratic programming hybrid optimization algorithm is adopted for performing solving. Finally the influence of the uncertainty level of the ore pulp concentration on the economic benefits of the leaching process is verified through simulation. The model can reflect actual situations of a production process more objectively compared with a traditional model; the adaptability of the model is improved; and therefore, the method has relatively good actual engineering significance.

Owner:NORTHEASTERN UNIV

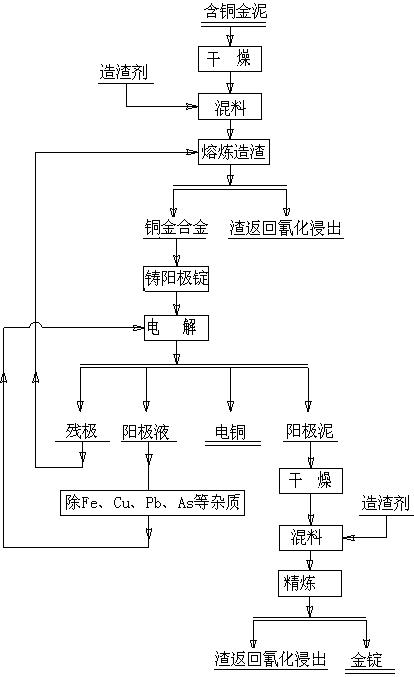

A kind of processing method of copper-containing gold mud

ActiveCN102286663AReduce consumptionIncrease the link of electrolytic copper removalPhotography auxillary processesProcess efficiency improvementElectrolysisSlag

The invention discloses a method for processing copper-contained gold mud, relating to a comprehensive recovering and processing method of copper-contained gold (silver or gold and silver) mud, in particular to copper-contained gold (silver or gold and silver) mud obtained by zinc powder replacement in the gold production process. The method is characterized by comprising the following steps in the processing process: (1) after the copper-contained gold mud is dried, smelting to obtain copper and gold copper and smelting slag; (2) casting the copper alloy obtained by smelting into an anode for electrolysis, and electrolyzing to obtain cathode copper; (3) after smelting to obtain smelted slag ore grinding, carrying out cyaniding leaching to recover gold and silver; (4) drying the anode mudobtained in step (2); adding slagging constituent to smelt to obtain a gold ingot and smelting slag; and (5) after carrying out ore grinding to the smelting slag obtained by smelting, recovering goldand silver by cyaniding leaching. With the method, the step of dissolving and removing copper by acid in the high copper-contained gold mud processing process is omitted by integrated innovation. Meanwhile, a link of electrolytic copper removal is added to realize zero wastewater emission and consume no medicines, such as sulfuric acid and the like, and meanwhile the electrolytic copper and the gold ingot can be obtained.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD +1

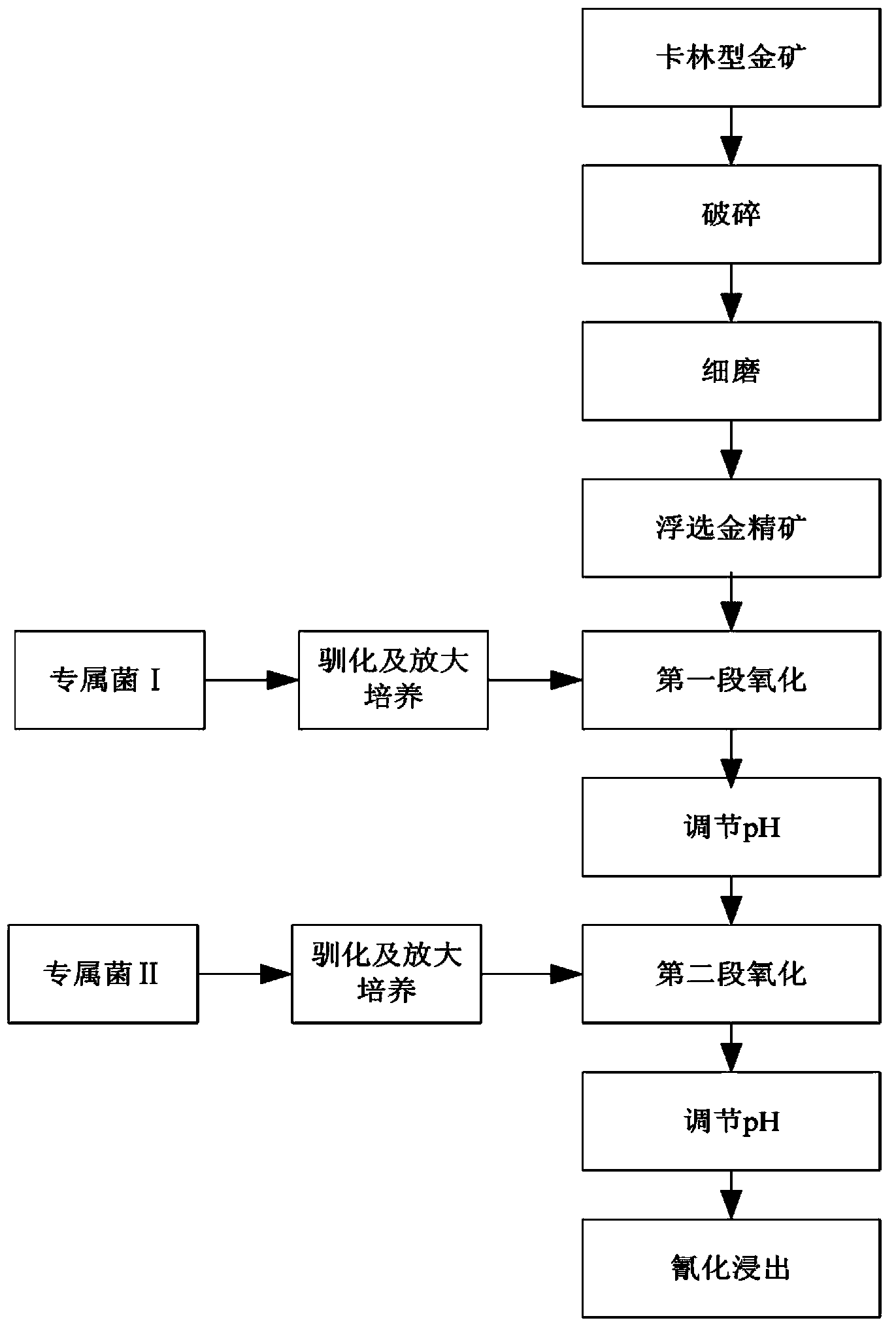

Two-stage biological pre-oxidation gold extraction process for Carlin-type gold deposit by two exclusive ore-leaching bacteria

ActiveCN103911509AImprove leaching rateBig economic interestsProcess efficiency improvementSlagBiology

The invention relates to a two-stage biological pre-oxidation gold extraction process for Carlin-type gold deposit by two exclusive ore-leaching bacteria. The process comprises the steps of: (1) subjecting the Carlin-type gold deposit to crushing, fine grinding and flotation to obtain flotation gold concentrate, and conducting drug removal treatment on the flotation gold concentrate; (2) employing an exclusive bacterium I to perform first-stage oxidation on the flotation gold concentrate obtained in step (1); (3) employing an exclusive bacterium II to perform second-stage oxidation on the gold concentrate oxidizing slag obtained in step (2); and (4) subjecting the oxidizing slag obtained in step (3) to cyaniding leaching. The exclusive bacterium I is Leptospirillum ferriphilum MJ-CL, and the exclusive bacterium II is Thermoanaerobacteriumsp. L-D. Being able to improve the gold recovery rate, the process provided by the invention has the advantages of small investment, low production cost, and no generation of exhaust gas, is especially suitable for the Carlin-type gold deposit, and can obtain greater economic, social and environmental benefits.

Owner:有研资源环境技术研究院(北京)有限公司

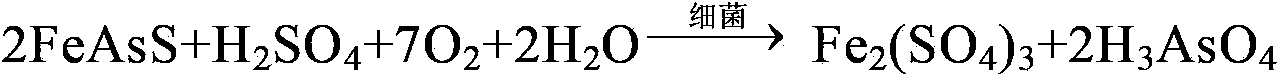

Method for comprehensively utilizing vanadium slag

InactiveCN104120269AReduce dosageShort processPhotography auxillary processesProcess efficiency improvementPregnant leach solutionSlag

The invention relates to a method for comprehensively utilizing vanadium slag, belongs to the field of resource reclamation, and aims to solve the technical problem of providing the method for comprehensively utilizing the vanadium slag. The method comprises the following steps: a, acid leaching at oxygen pressure, namely at oxygen pressure, adding sulfuric acid into the vanadium slag, stirring and filtering to obtain leaching liquid and leaching slag; b, leaching liquid extraction, namely regulating the pH value of the leaching liquid, and extracting to obtain extraction liquid and raffinate; c, vanadium-containing solution preparation, namely carrying out back extracting on the extraction liquid to obtain subnatant which is the vanadium-containing solution; d, electrolytic manganese preparation, namely regulating the pH value of the raffinate, adding ammonium sulfate and selenium dioxide, and electrolyzing to obtain the electrolytic manganese; and e, titanium dioxide preparation, namely adding sulfuric acid into the leaching slag which is obtained in the step a to perform secondary acid leaching, heating, reducing, freezing, crystallizing, filtering, hydrolyzing, filtering, washing, evaporatively crystallizing and calcining to obtain the titanium dioxide. The method can be used for comprehensively reclaiming and recycling vanadium slag.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

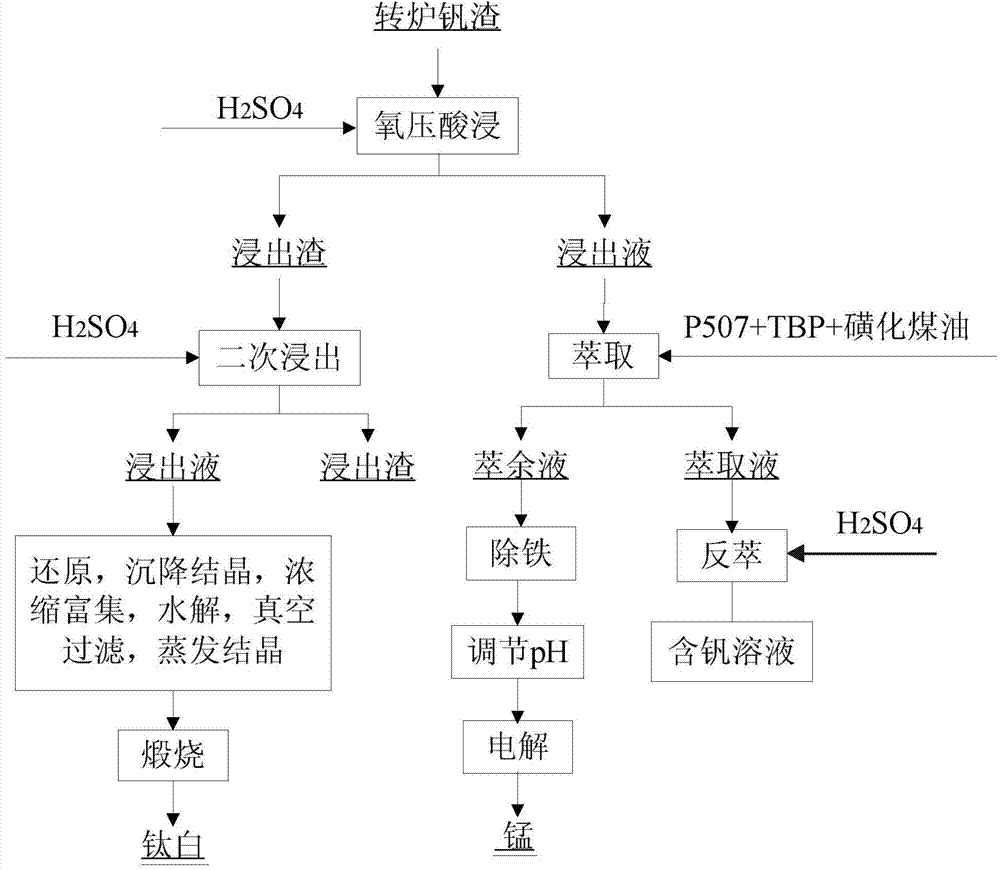

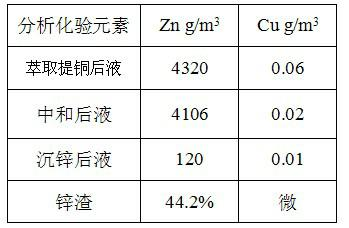

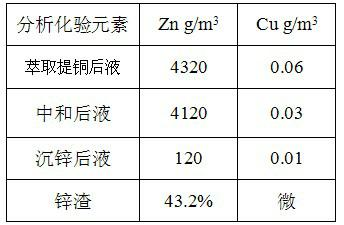

Method for recovering zinc from liquid obtained by calcining, acid leaching and copper extraction of gold concentrate containing zinc and copper

InactiveCN102399986AEfficient use ofFull recoveryProcess efficiency improvementChemical industryResource utilization

The invention relates to a method for recovering zinc from liquid obtained by calcining, acid leaching and copper extraction of gold concentrate containing zinc and copper, and belongs to the technical field of production processes for recovering zinc from the liquid obtained by calcining, acid leaching and copper extraction in metallurgical chemical industries. The method comprises the following steps of: performing acid leaching, extracting, extracting the copper by electrodeposition and adding sodium sulfide into zinc-containing filtrate to precipitate zinc. The method is simple and practicable; and the zinc serving as a valuable metal is recovered while valuable metals such as gold, silver, the copper and sulfur are recovered fully in a process for calcining gold concentrates, so multielement gold-containing gold concentrate resources are utilized effectively, wastes are turned into wealth, the utilization rate of the resources is improved further and the economic benefits of enterprises are increased.

Owner:SHANDONG GUODA GOLD

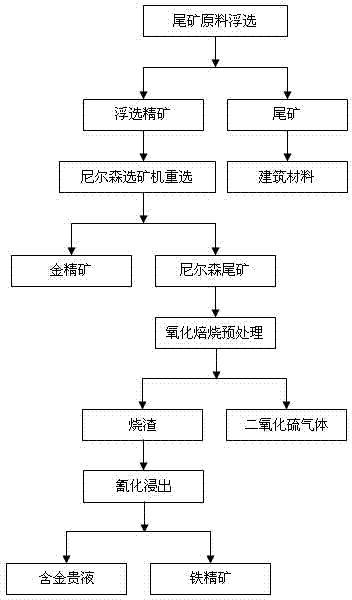

Method for recovering low-grade precious metals from mineral dressing tailings

ActiveCN104846195AHigh recovery rateIncrease profitProcess efficiency improvementLower gradeLow graded

The invention relates to the technical field of mineral dressing and discloses a method for recovering low-grade precious metals from mineral dressing tailings. The method comprises a tailing raw material floating step, a Knelson concentrator gravity concentration step, a Knelson tailing oxidizing roasting pretreatment step, a cinder cyanide leaching step and the like; golds are is enriched in flotation concentrate by tailing flotation; coarse grained golds in the flotation concentrate are recycled by adopting a Knelson concentrator gravity concentration method; Knelson tailings are subjected to oxidizing roasting pretreatment; treated cinder is processed by adopting a cyanide leaching technique to recover fine-grained golds lost in the Knelson tailings. According to the method disclosed by the invention, the recovery of the golds is realized by stages, so that the recovery rate of the golds is improved; the problem that as the flotation tailings are treated by adopting a traditional technique, the recovery rate of the precious metals is low is solved, and the recovery rate of the precious metals is improved; meanwhile, gold concentrate and iron concentrate are produced, so that the comprehensive utilization rate of the tailing is improved; zero discharge of solid waste is realized, the influence of a tailing pond on the surrounding environment is thoroughly avoided, and a pollution source and potential safety hazards are eliminated.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

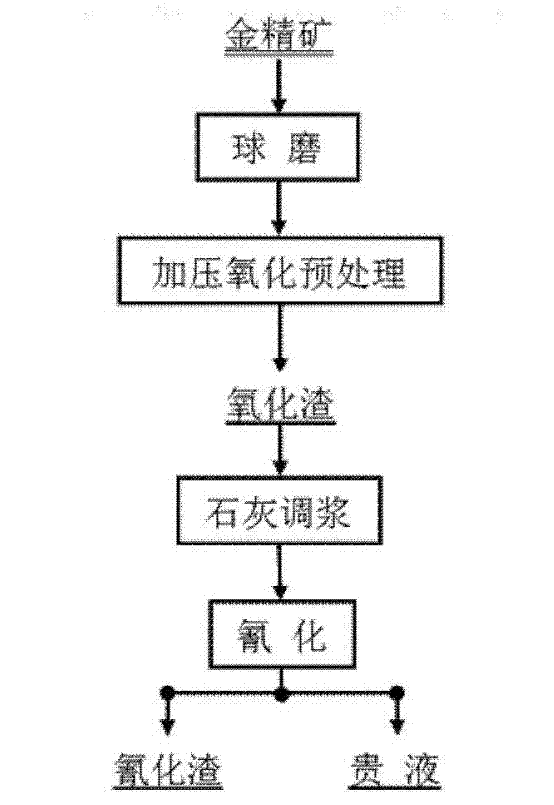

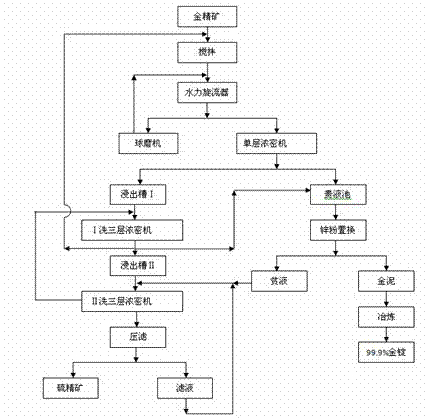

Pressurization, water immersion and oxidation preprocessing cyaniding gold extraction method for difficult-processing gold concentrates

InactiveCN102925716AReduce usageReduce maintenance costsProcess efficiency improvementWater immersionSulfur containing

The invention relates to a pressurization, water immersion and oxidation preprocessing cyaniding gold extraction method for difficult-processing gold concentrates, which aims at the gold concentrates with higher sulfur-containing, mainly containing iron pyrite, concomitant with copper pyrite, zinc blende and the like, and comprises the following steps: performing ball-milling on the raw material gold concentrates, performing size mixing, cyaniding for gold extraction after pressurization, water immersion and oxidation preprocessing to obtain a pregnant solution with gold-containing of 0.010 g / L-0.040 g / L, and the gold cyanide leaching rate reaches 96% of a smelting indicator. In the invention, the initial media are neutral, an acid or alkali reagent is not needed, and only the neutral additive lignosulphonate is needed, so that the process cost is reduced, and the extremely high gold recovery rate is realized at the same time.

Owner:YUNNAN GOLD MINING GRP

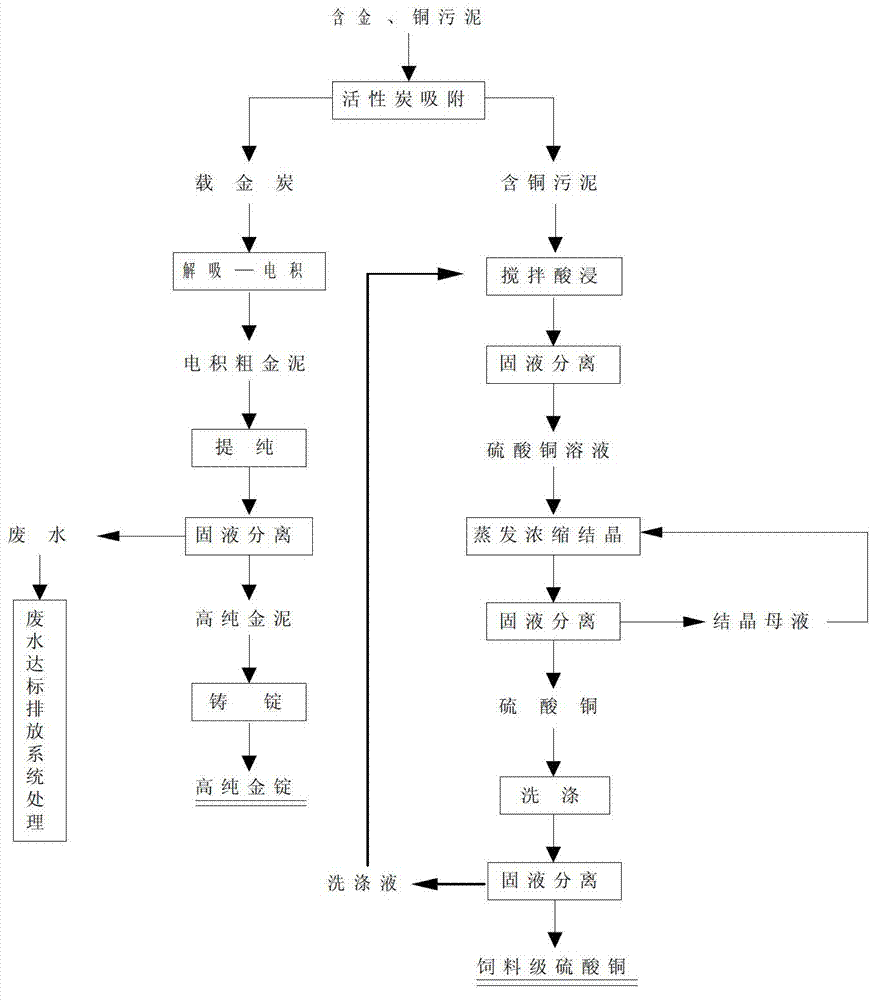

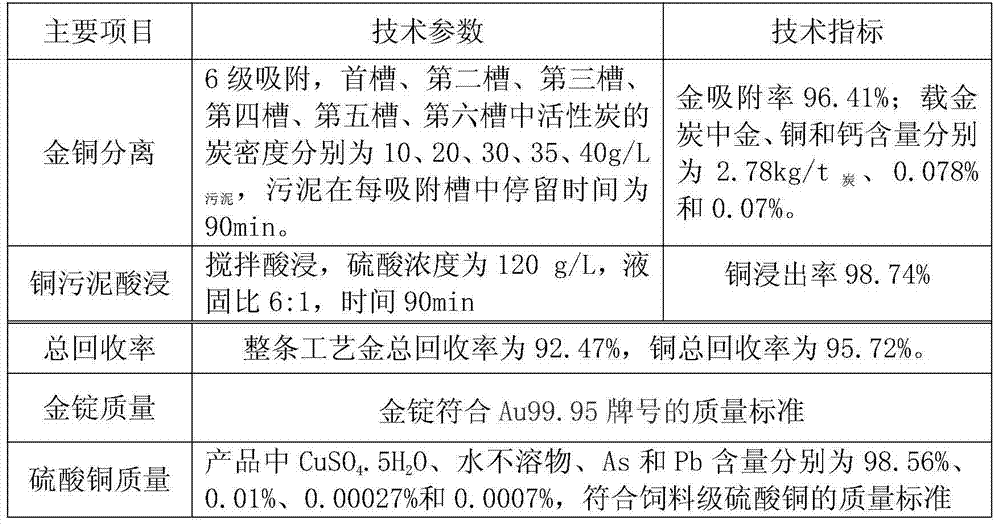

Method for producing high-purity gold and copper sulphate from gold-bearing copper sludge

ActiveCN103397190AEfficient separationAchieve reductionPhotography auxillary processesProcess efficiency improvementSludgeDesorption

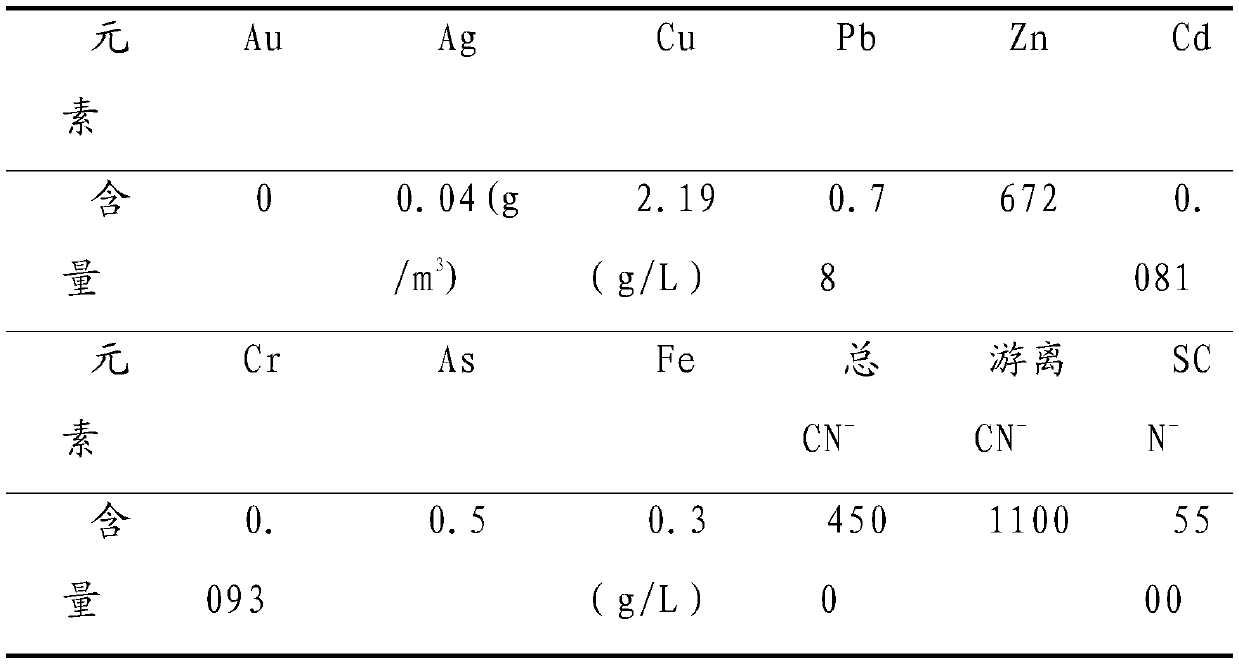

The invention relates to a method for producing high-purity gold and copper sulphate from gold-bearing copper sludge. The method comprises the process steps of gold-copper separation, high-purity gold production and feed-grade copper sulphate production; in the gold-copper separation, cyanided pregnant solution generated through cyanide leaching of copper-bearing gold ores or carbon adsorption barren solution is fed to a carbon absorption system by virtue of gold-bearing and copper-bearing sludge which has a water content of 90-98% and is generated during an oxidative cyanogen removal process, gold is absorbed by active carbon and finally gold and copper are separated; in the high-purity gold production, a finished gold ingot is mainly prepared by the steps of gold-bearing carbon desorption-electrodeposition, electrodeposition gold sludge purification and ingot casting; and in the feed-grade copper sulphate production, feed-grade copper sulphate and washing solution are prepared by the working procedures of stirring and acid-leaching, evaporation and concentration and crystallization, and copper sulphate impurity removal. The method has the advantages of low treatment cost, strong adaptability, environmental friendliness, capability of realizing reduced, resourceful and harmless treatment on the gold-bearing and copper-bearing sludge, and the like, and is applicable to process of copper-bearing gold ores of which the cyanide soluble copper content is 0.04-0.1%.

Owner:ZIJIN MINING GROUP

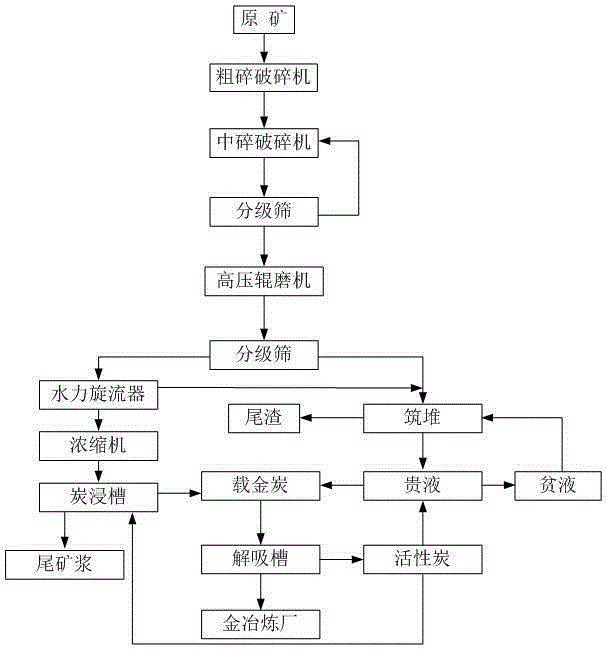

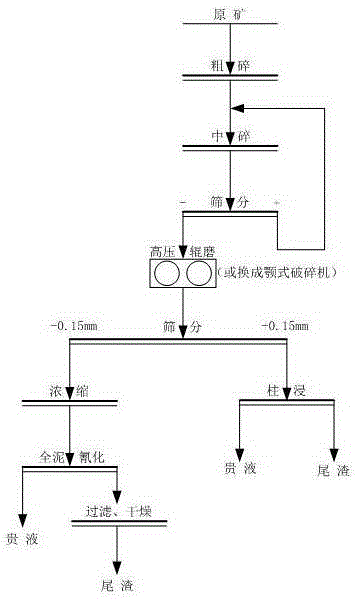

Low-grade gold ore pile soaking technology based on high-pressure roller smashing

InactiveCN105214831AFine particle sizeGood particle size distribution uniformityGrain treatmentsWet separationCrazingCyanide leaching

The invention discloses a low-grade gold ore pile soaking technology based on high-pressure roller smashing and belongs to the technical field of metallurgy. The low-grade gold ore pile soaking technology comprises the following steps that firstly, raw gold ore is coarsely smashed in an open circuit mode, the coarsely-smashed product is all fed into a medium smashing system and classified through a vibrating screen, coarse materials on a screen are returned to medium smashing equipment to continue to be smashed, and proper screened materials enter a high-pressure roller smashing machine; secondly, the proper screened materials are subjected to open circuit fine smashing through the high-pressure roller smashing machine, the product is subjected to combined action of a wet vibrating screen and classifying equipment, fine overflow products are fed into an all-slimed cyanide leaching system, settled sand and coarse grain materials are mixed with lime with properly-blended soda and then fed into a storage yard to be piled together, and the classifying leaching technology of gold ore materials is achieved; thirdly, a precious solution containing gold and tailings are obtained after leaching is completed. According to the low-grade gold ore pile soaking technology, high-pressure roller open-circuit fine smashing is adopted, the product granularity of the product is fine, surface micro cracks are rich, the gold leaching rate can be remarkably increased, consumption of a leaching agent can be reduced, and the piling leaching cycle can be shortened. The product with fine granularity grades is recycled while piling leaching is conducted.

Owner:FUZHOU UNIV

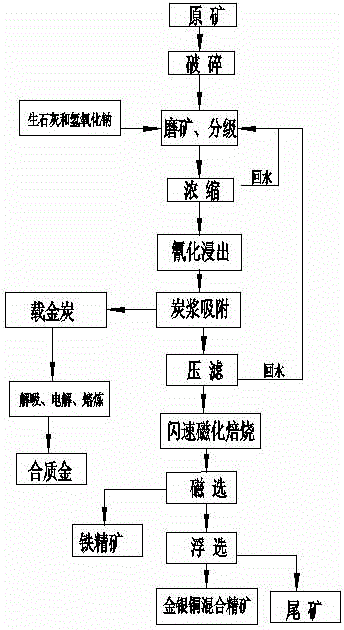

Process of comprehensively recovering various metals from limonite

The invention relates to a process of comprehensively recovering various metals from limonite and belongs to the technical field of comprehensively recovering various metals. The process comprises the following steps: crushing, ore grinding, classifying, concentrating, cyanide leaching, carbon-in-pulp adsorption, pressure filtration, flash magnetization roasting, magnetic separation and flotation, wherein in the magnetic separation phase, an iron concentrate is obtained; and in the flotation phase, a mixed concentrate of gold, silver and copper is obtained. According to the process disclosed by the invention, by adopting the combined concentration and smelting process flow, concomitant gold, silver, copper and iron in the limonite can be recovered, the recovery rates of the gold and the silver are above 75 percent, the recovery rate of the copper is above 40 percent, and the recovery rate of the iron is above 98 percent, so that the mineral resources are fully utilized, and the economical benefit of an enterprise is also increased.

Owner:河南黄金产业技术研究院有限公司

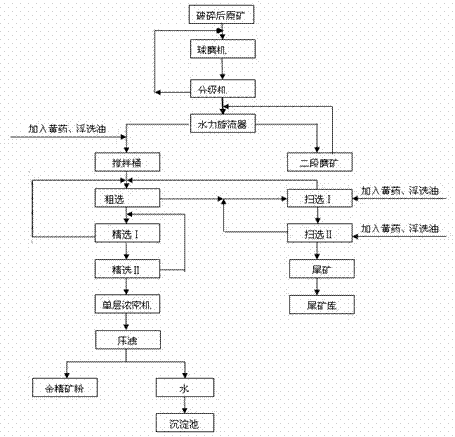

Method for improving gold mine flotation and flotation concentrate cyaniding leaching recovery rate

The invention discloses a method for improving gold mine flotation and flotation concentrate cyaniding leaching recovery rate. In gold mine flotation, when a gold mine is subjected to three flotation operations, i.e. the gold mine is milled through a ball mill, is classified through a classifier and is roughly floated, hot water is added, and the hot water temperature is 35-45 DEG C; in flotation concentrate cyaniding leaching, by a cyaniding leaching process, heating is performed in a single-layer thickener and a three-layer thickener, so that the temperature of cyaniding process water is 25-35 DEG C; the average temperature of the flotation process water in the prior art is 22 DEG C; average flotation tailings grade is 0.22g / t; after heat energy is utilized, the average flotation tailings grade is 0.1g / t; in gold concentrate powder cyaniding, before the heat energy is utilized, the average cyanide residue grade is 0.6g / t; and after the heat energy is utilized, the average cyanide residue grade is 0.4g / t. With the adoption of the heat energy, the gold mine flotation and flotation concentrate cyaniding leaching recovery rate is effectively improved, and gold mine resources are sufficiently utilized.

Owner:QINGDAO PINGDU JIUDIAN GOLD MINE

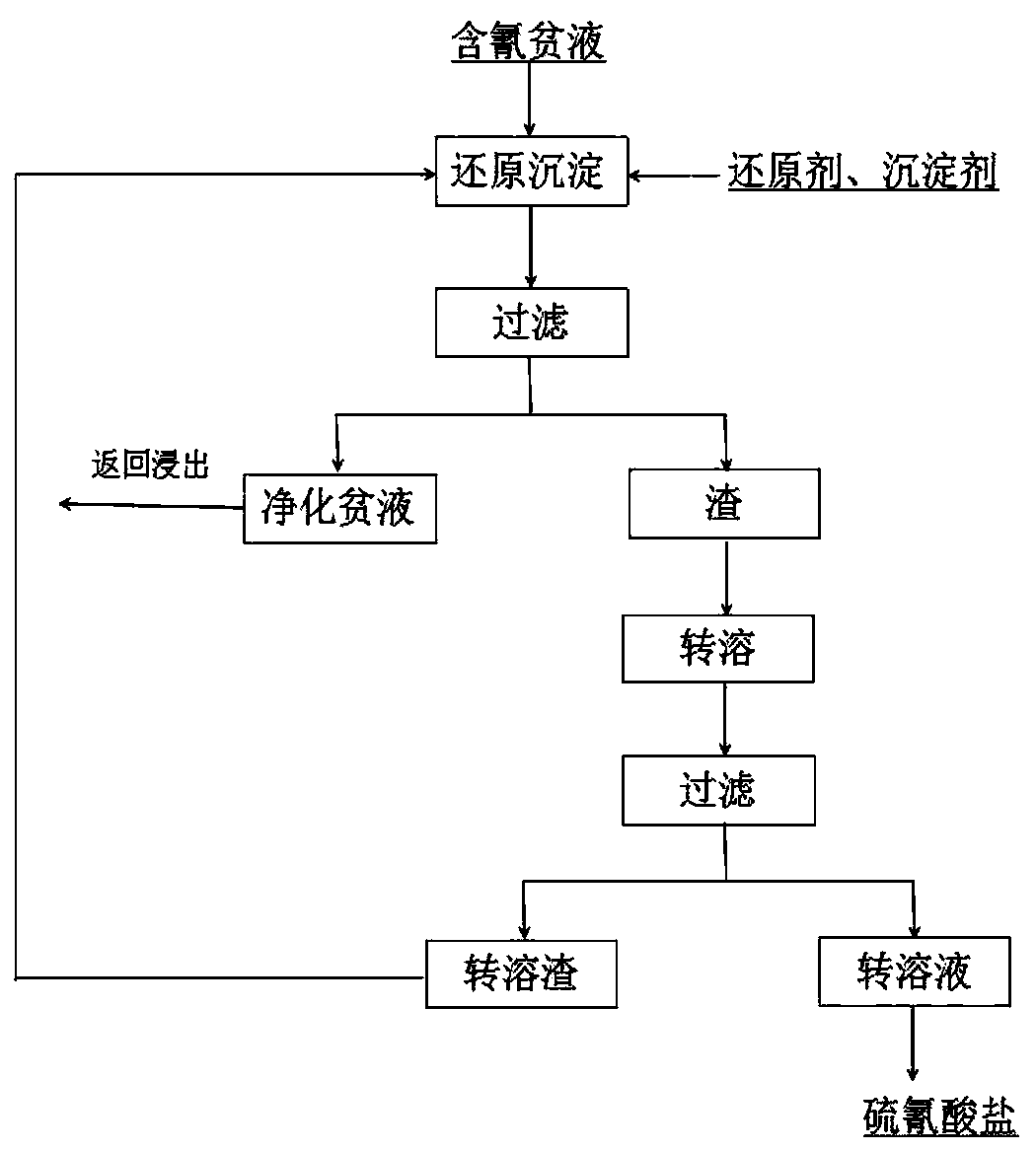

Method for realizing short-process and green cyclic utilization of cyanogen-containing barren solution

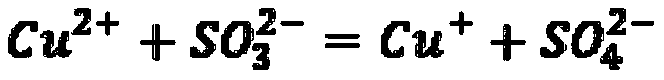

InactiveCN109735715AHigh dissolution rateReduce consumptionThiocyanic acidProcess efficiency improvementEconomic benefitsGold deposit

The invention provides a method for realizing short-process and green cyclic utilization of a cyanogen-containing barren solution. Firstly, reduction precipitation is carried out on the cyanogen-containing barren solution so as to enable SCN <-> and Cu<+> to precipitate to be enriched in residues; the purified barren solution is returned to be subjected to cyaniding leaching or follow-up oxidationtreatment to meet the standard to be discharged; then precipitated residues are transferred to be dissolved in alkali liquor through the alkali liquor so that the SCN<-> can be transferred into the alkali liquor to be used for leaching gold extracting from gold ore or cyaniding tailings, preparing thiocyanate and the like, and the dissolving-transferred residues are returned to the reduction precipitation step so as to reduce the consumption of precipitant, namely, copper salt. The method for realizing short-process and green cyclic utilization of the cyanogen-containing barren solution is high in economic benefit, small in pollution, and capable of protecting the environment.

Owner:NORTHEASTERN UNIV +1

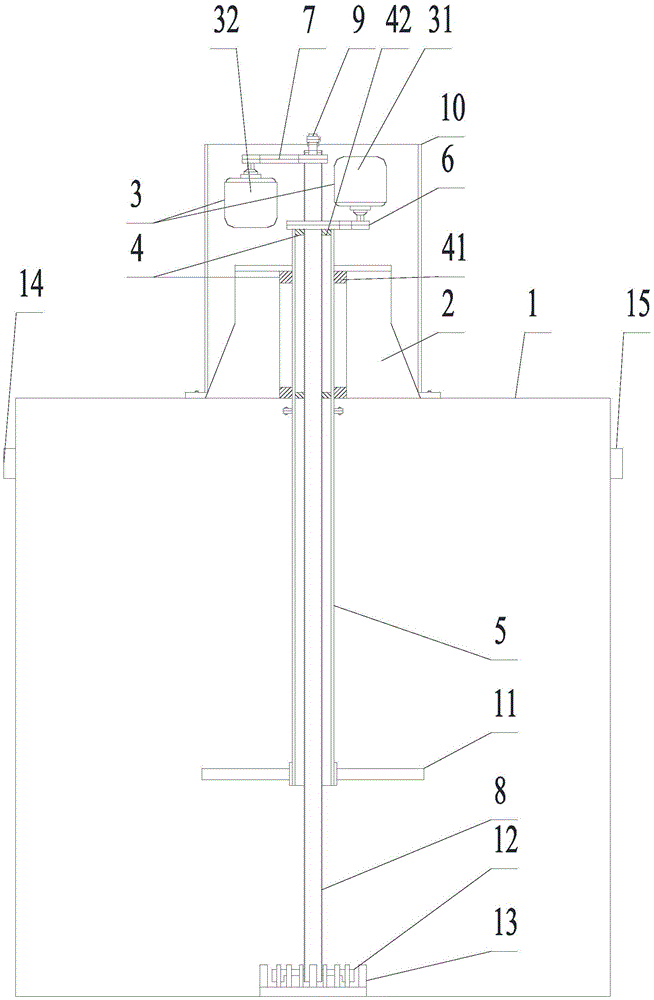

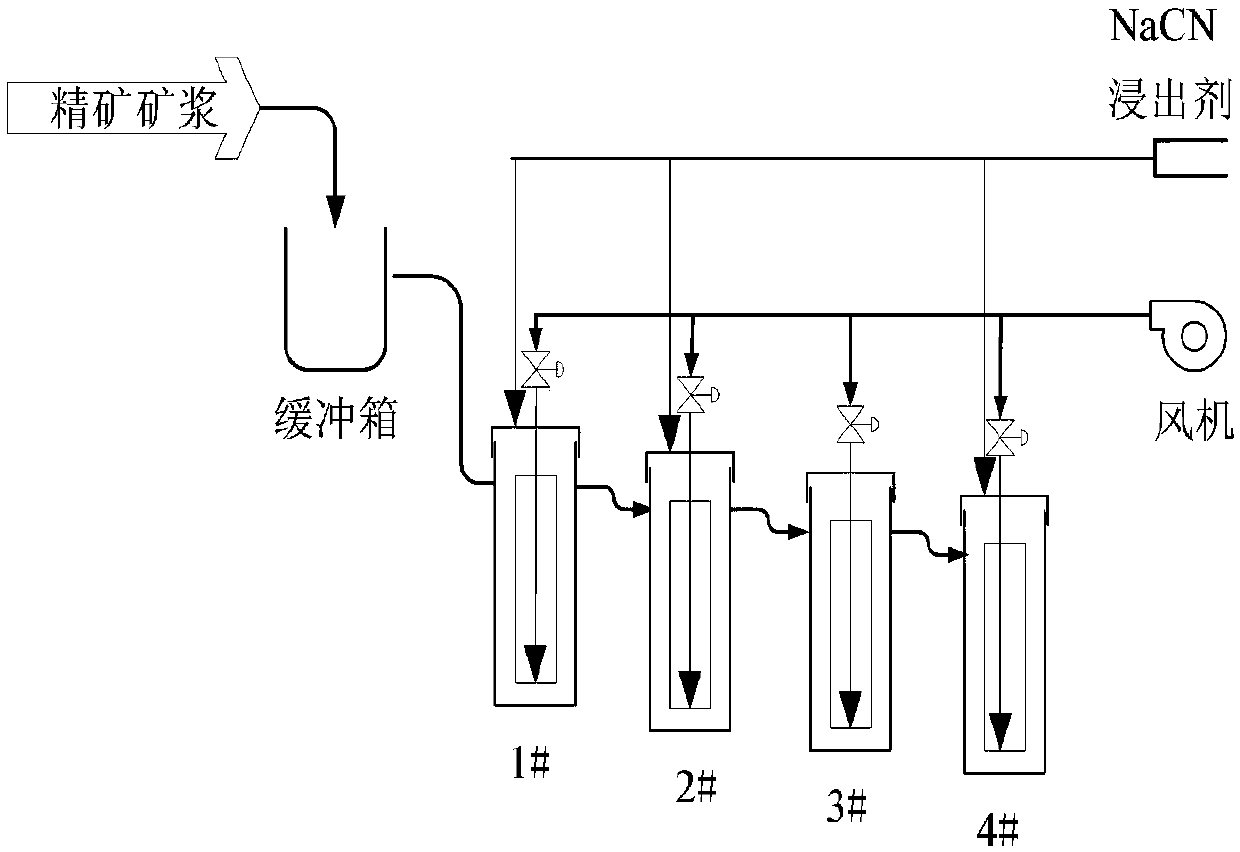

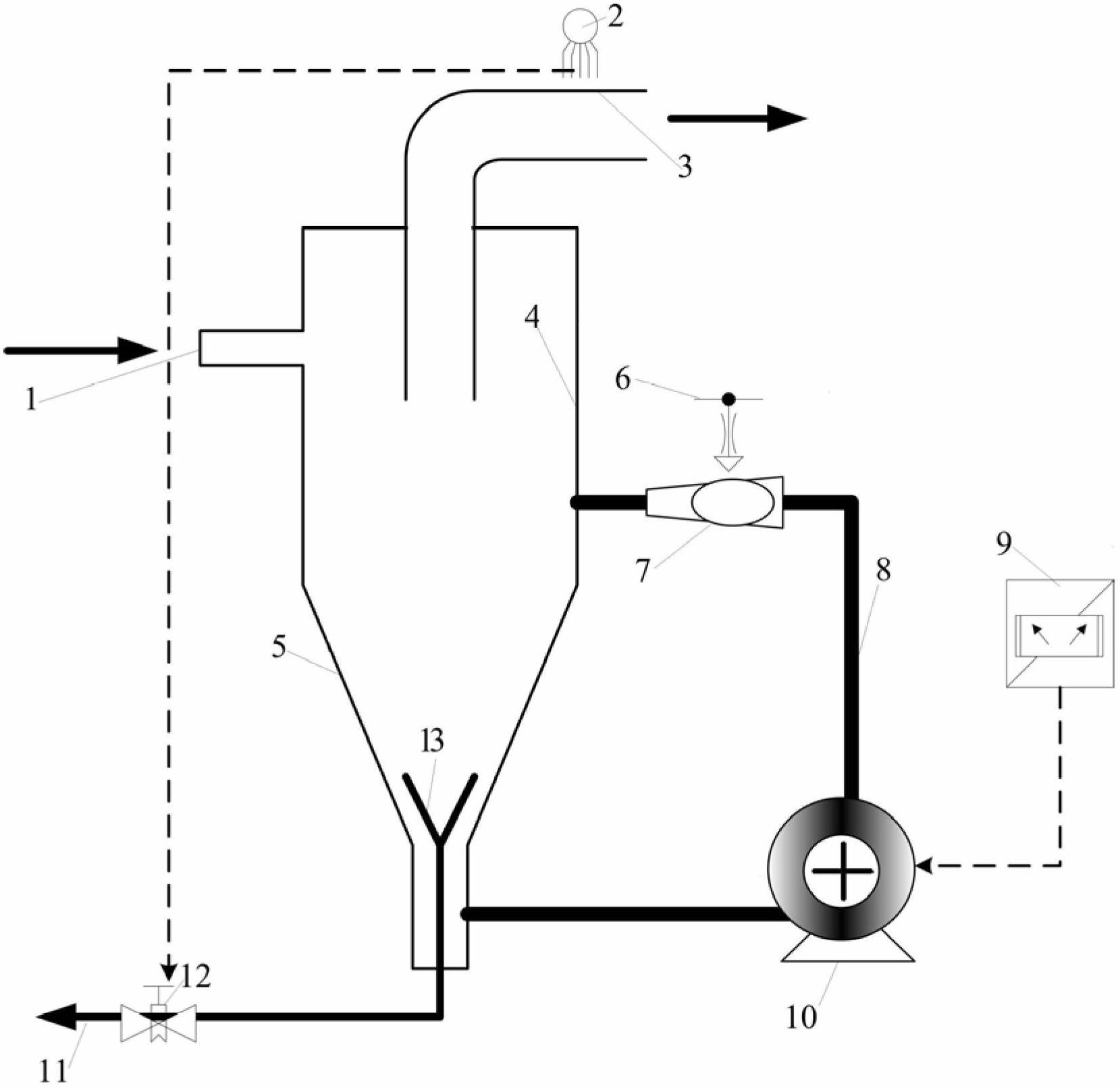

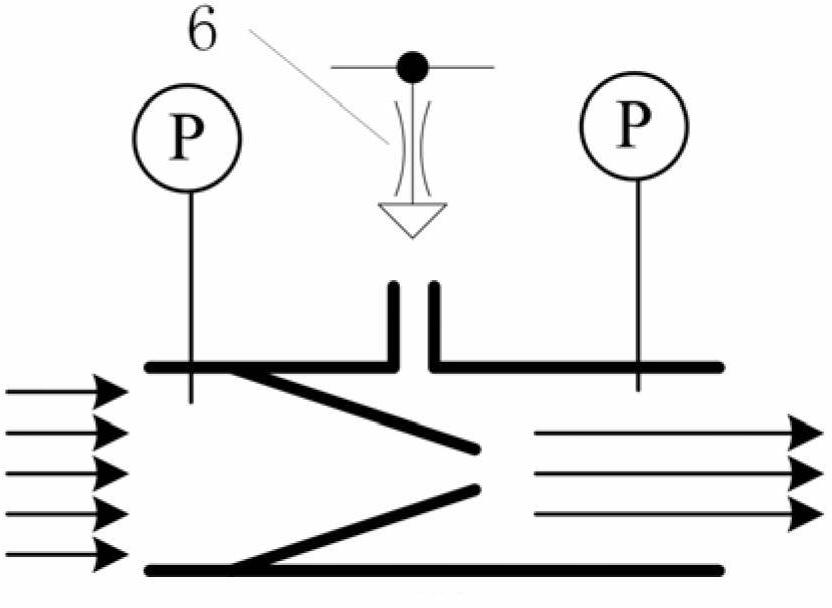

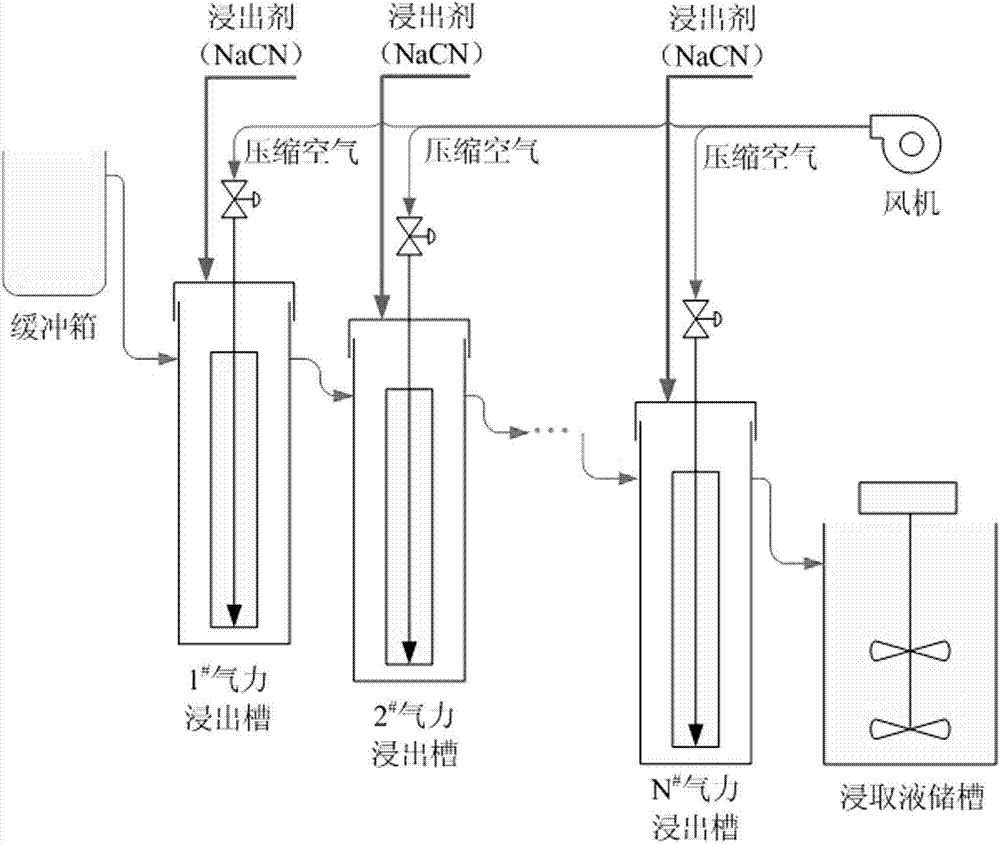

Cyanide leaching device for gold ore

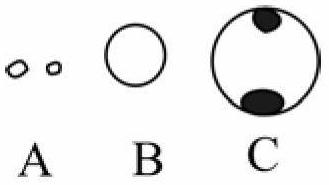

InactiveCN102660675AEnhanced cyanide leaching processImprove leaching rateProcess efficiency improvementCyanideHigh energy

The invention discloses a cyanide leaching device for gold ore. For overcoming the defects of small aeration quantity, dead zone existence, low leaching rate and high energy consumption in the currently-used agitation leaching groove, a leaching column is novel leaching equipment for combining cyclone separation with pipe flow strengthened leaching and achieving dual goals of grading and leaching in one equipment. According to the cyanide leaching device disclosed by the invention, the inspiratory capacity is increased and the turbulence level of gas, liquid and solid phases is improved by a bubble generator adopting a jet principle, so that the full air amount can be ensured and enough stirring strength is ensured. According to the pipe flow cycle intensifying leaching mode for a coarse fraction refractory leaching gold grain intergrowth body, strong pertinence is realized, the leaching rate of gold ore can be effectively increased and the cyanide leaching process of the gold ore is intensified.

Owner:CHANGAN UNIV

Method for leaching silver from oxidized manganese-silver ores difficult to dress and smelt

The invention relates to the technical field of mineral substance processing, and particularly relates to a method for leaching silver from oxidized manganese-silver ores difficult to dress and smelt. The method comprises the following steps: 1, crushing the manganese-silver ores, and carrying out coarse grinding on the obtained object, so that manganese-silver ore powder is obtained; 2, uniformly mixing the manganese-silver ore powder with a reductant in a mass rate of 1:2-4, so that an ore sample is obtained for standby application; 3, carrying out wet separation: reacting the ore sample prepared in the step 2 with sulfuric acid in a ratio of 1 g: 3-5 ml, and stirring constantly, and after solids and liquid are fully contacted, carrying out water bath reaction accompanied by occasional stirring for 2 hours at a water bath temperature of 80-90 DEG C, so that slurry is obtained for standby application; 4, carrying out solid-liquid separation: carrying out centrifugal separation on the slurry prepared in the step 3, and washing 1-2 times; and filtering and separating centrifugalized mother liquor by using fine filter paper, so that residues are obtained; and 5, extracting silver by cyanidation: leaching silver from the residues by using a sodium cyanide solution. According to the invention, the cyanide leaching rate of silver can be greatly improved while manganese is reduced and separated.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

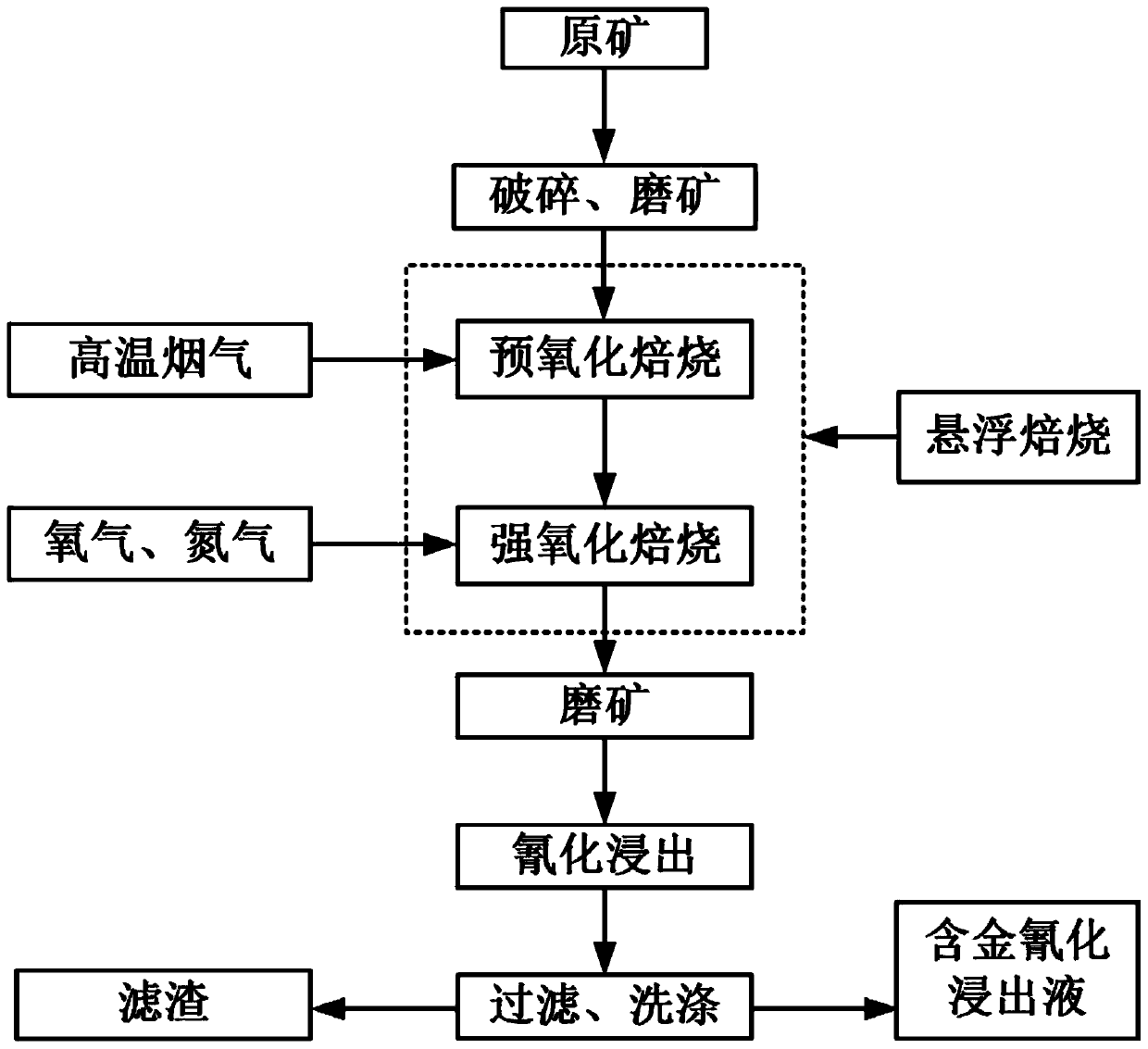

Method for increasing gold leaching rate through suspension roasting of carbon-containing gold ore

A method for increasing the gold leaching rate through suspension roasting of a carbon-containing gold ore includes the following steps of firstly, breaking and grinding the carbon-containing gold oreto obtain a fine ore; secondly, conveying the fine ore to a pre-oxidizing and suspension roasting furnace, making the fine ore at a suspension state under the action of gas flow and negative pressure, and heating the fine ore to 650-700 DEG C for dearsenification roasting to obtain pre-oxidized and roasted powder; thirdly, introducing the pre-oxidized and roasted powder into a strong-oxidizing and suspension roasting furnace, making the pre-oxidized and roasted powder at a suspension state under the action of gas flow, and performing strong-oxidizing and roasting at 550-600 DEG C to obtain strong-oxidized slag powder; fourthly, grinding the ore after cooling to obtain a secondary fine ore; and fifthly, adding water to prepare ore slurry, then adding sodium cyanide to be evenly stirred forcyanide leaching, and filtering a material subjected to leaching to obtain a liquid-phase gold-containing cyanide leaching solution. The method is high in production continuity and high in adaptability to different ores and equipment can be easily upsized and industrialized.

Owner:NORTHEASTERN UNIV

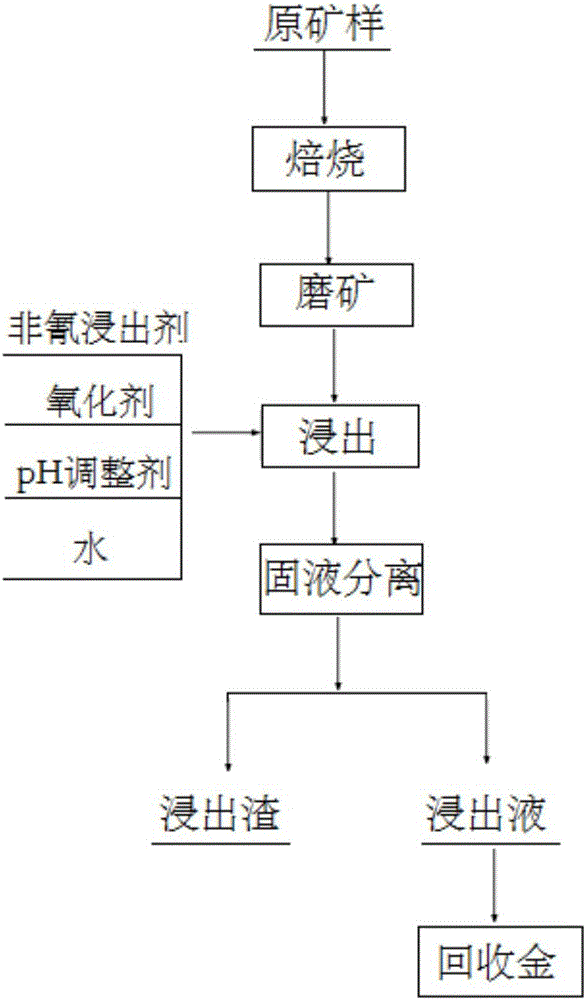

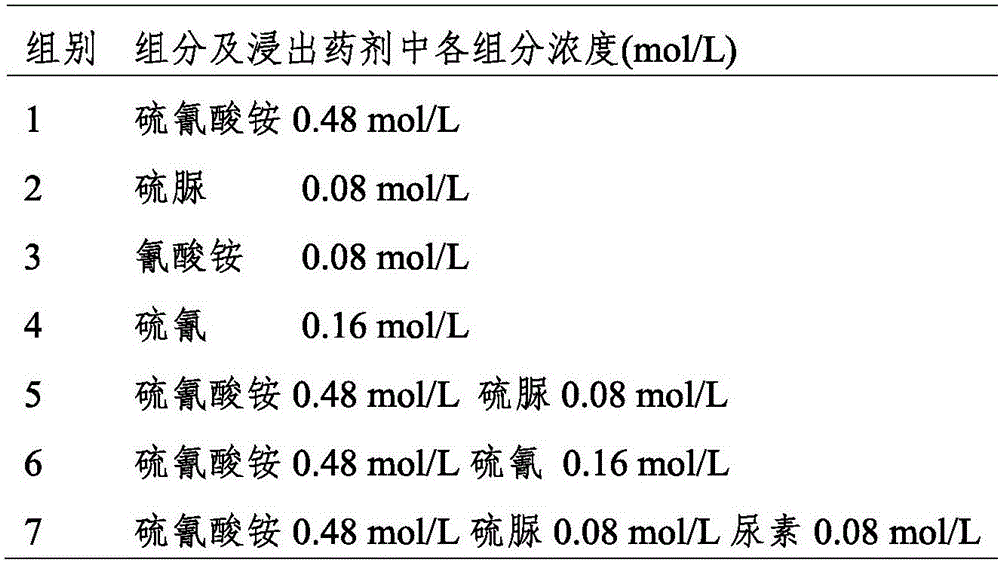

Non-cyanide leaching agent and method for gold mine leaching thereof

ActiveCN107435102AImprove leaching efficiencyGood leaching effectProcess efficiency improvementSulfurThiourea

Disclosed is a non-cyanide leaching agent. The non-cyanide leaching agent comprises thiocyanate, thiourea, thiocyanogen and cyanate. The molar ratio of each component is 4-8:0.5-1:0.5-3:1-2. The non-cyanide leaching agent has the advantages of being high in leaching rate, high in leaching speed, stable in performance, wide in applicable range, low in cost, high in adaptive capacity to environment and simple and convenient in technology, and the leaching rate of gold in sulfuration gold mine with high sulfur and high arsenic and difficult to process is improved to above 96%.

Owner:JIANGXI UNIV OF SCI & TECH

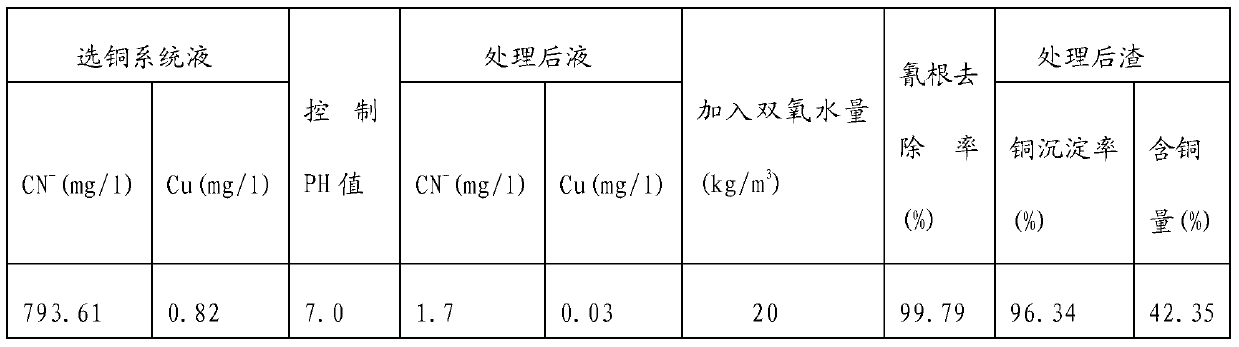

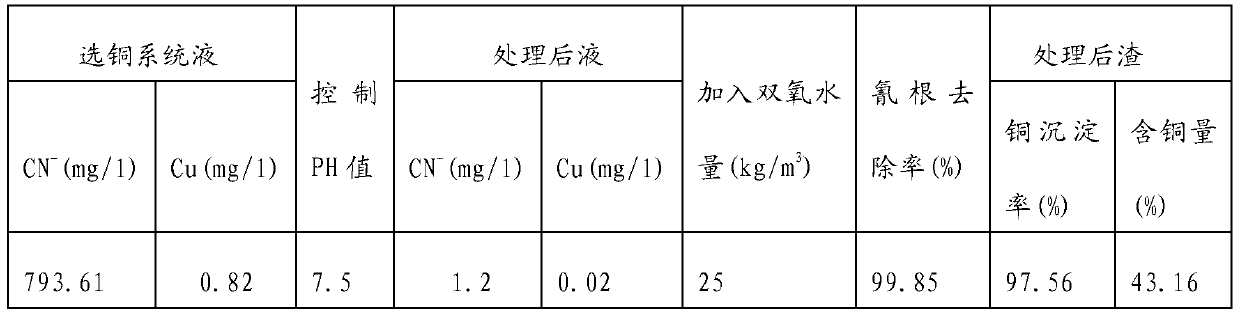

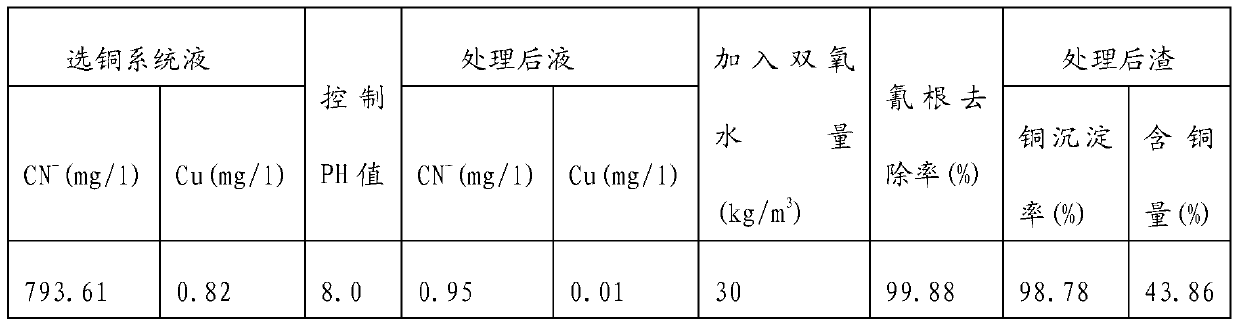

Method for recovering copper from copper flotation system liquids of tailings after cyaniding gold extraction

InactiveCN103276221AEfficient recyclingEliminate pollutionProcess efficiency improvementPollutionCyanide leaching

The invention relates to a method for recovering copper from a copper flotation system liquid of tailings after cyaniding gold extraction. The method comprises the steps of regulating the pH (potential of Hydrogen) value of the copper flotation system liquid produced through sequentially carrying out lead flotation and copper flotation on gold concentrate after being subjected to cyanide leaching and gold and silver extraction, enabling the copper flotation system liquid subjected to pH adjustment to react with hydrogen peroxide, decomposing cyanogen, and depositing and recovering copper. According to method disclosed by the invention, the copper flotation system liquid is comprehensively processed, the cyanogen is decomposed and the valuable element copper in the liquid is recovered, so that the pollution of cyanogen-containing waste water to the surrounding environment is eliminated, the liquid after being processed can serve as reclaimed water to return to the system for use, the comprehensive utilization rate of resources is increased, the economic benefit of enterprises is increased and environmental protection and social benefit are provided.

Owner:SHANDONG GUODA GOLD

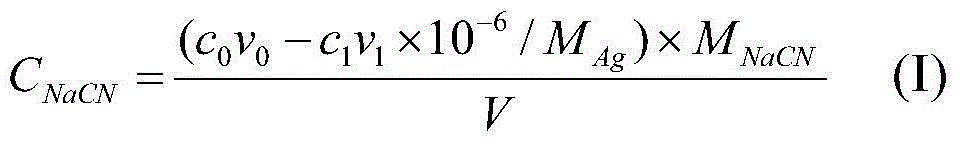

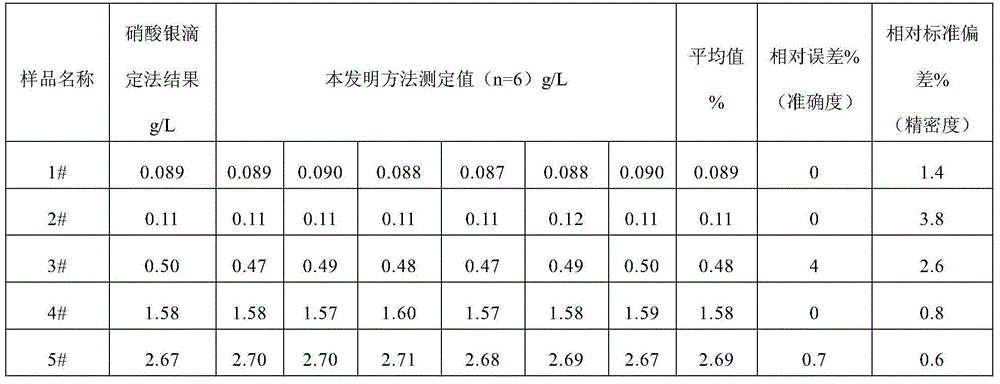

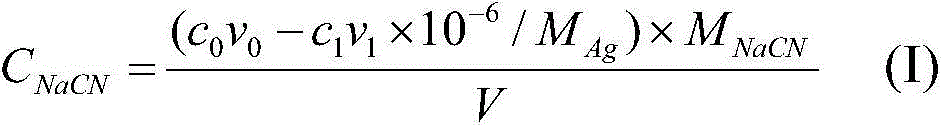

Rapid analysis method for concentration of cyanide in cyanide leaching solution of gold ore

InactiveCN105806788APrevent the occurrenceReduce pollutionColor/spectral properties measurementsDistillationBottle

The invention provides a rapid analysis method for the concentration of cyanide in a cyanide leaching solution of gold ore. The method comprises the following steps: accurately weighing 5.00 to 25.00 mL of the cyanide leaching solution of gold ore and putting the weighed cyanide leaching solution into a bottle with a volume of 100 mL; adjusting a pH value to 10 to 13; adding a quantified and excess standard silver solution, allowing a volume of the added solution to be fixed by using water and carrying out shaking-up; subjecting the obtained solution to dry filtering into a beaker; separately taking obtained filtrate and measuring the concentrations of silver ions in the solution by using atomic absorption spectrometry; and calculating the concentration of cyanide in the cyanide leaching solution according to a formula (I) which satisfies the equation that C<NaCN> = [(C<0>V<0>-C<1> v<1>*10<-6> / M<Ag>)*M<NaCN>] / V. The method provided by the invention omits a distillation apparatus and step, puts an end to generation of hydrogen cyanide, reduces operation dangers, mitigates environmental pollution and simplifies operation steps; only two inorganic reagents are used in the whole analysis process, and rapid determination of the concentration of cyanide in the cyanide leaching solution of gold ore is realized; and the method is applicable to determination of cyanide (in terms of sodium cyanide) with a concentration of 1 mg / L or above in the cyanide leaching solution, and obtained results are good in accuracy and precision.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

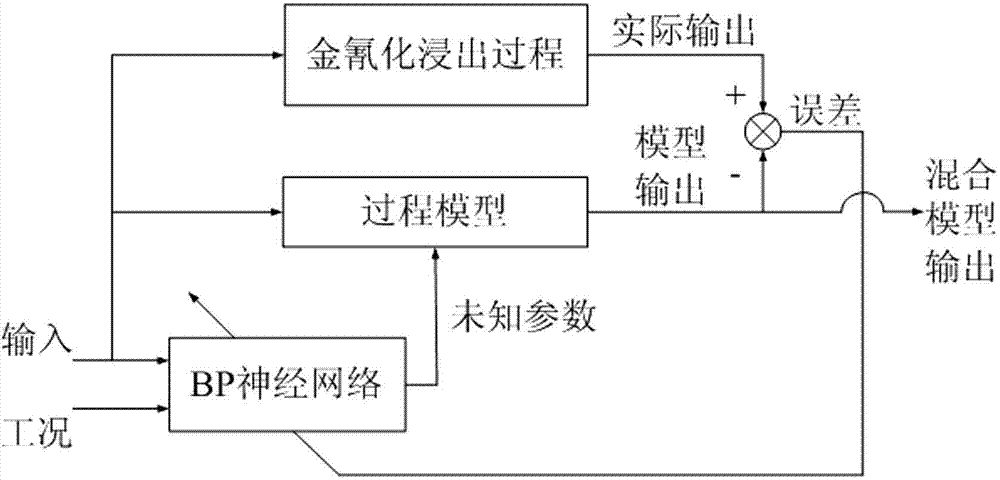

Leaching rate prediction method for wet metallurgy gold cyaniding leaching process

InactiveCN104199285ATimely and reasonable operation guidanceGuaranteed leaching rateAdaptive controlHydrometallurgyCyanide ion

The invention discloses a leaching rate real-time prediction method for a gold cyaniding leaching process on the basis of a serial mixed model, that is, a method for realizing online predication for a leaching rate. The prediction method has the following characteristics that: in the prediction method disclosed by the invention, a dynamic mechanism model for the complete gold cyaniding leaching process, that is, a gold and cyanide ion material conservation equation is established, and the mechanism model is taken as the core of the serial mixed predication model, in this way, the accuracy of a model trend can be ensured; in the prediction method disclosed by the invention, the dynamic reaction speed of the gold cyaniding leaching process is estimated on the basis of a Tikhonov regularization method, and the method is capable of effectively suppressing the influence of a measurement data noise on the estimation result. Unknown parameters in the mechanism model are estimated in a serial form by virtue of a BP neural network data model, thus improving the accuracy and popularization capacity of the model. The prediction method disclosed by the invention has the following advantages that: a serial fixed modelling method combining the mechanism model with a data model is adopted, the existing process priori knowledge is adequately utilized, the prediction accuracy and generalization capacity of the dynamic mechanism model are improved, and the prediction method has the advantages of being simple in structure, high in reliability, high in interpretability, good in popularization capacity, and the like.

Owner:NORTHEASTERN UNIV

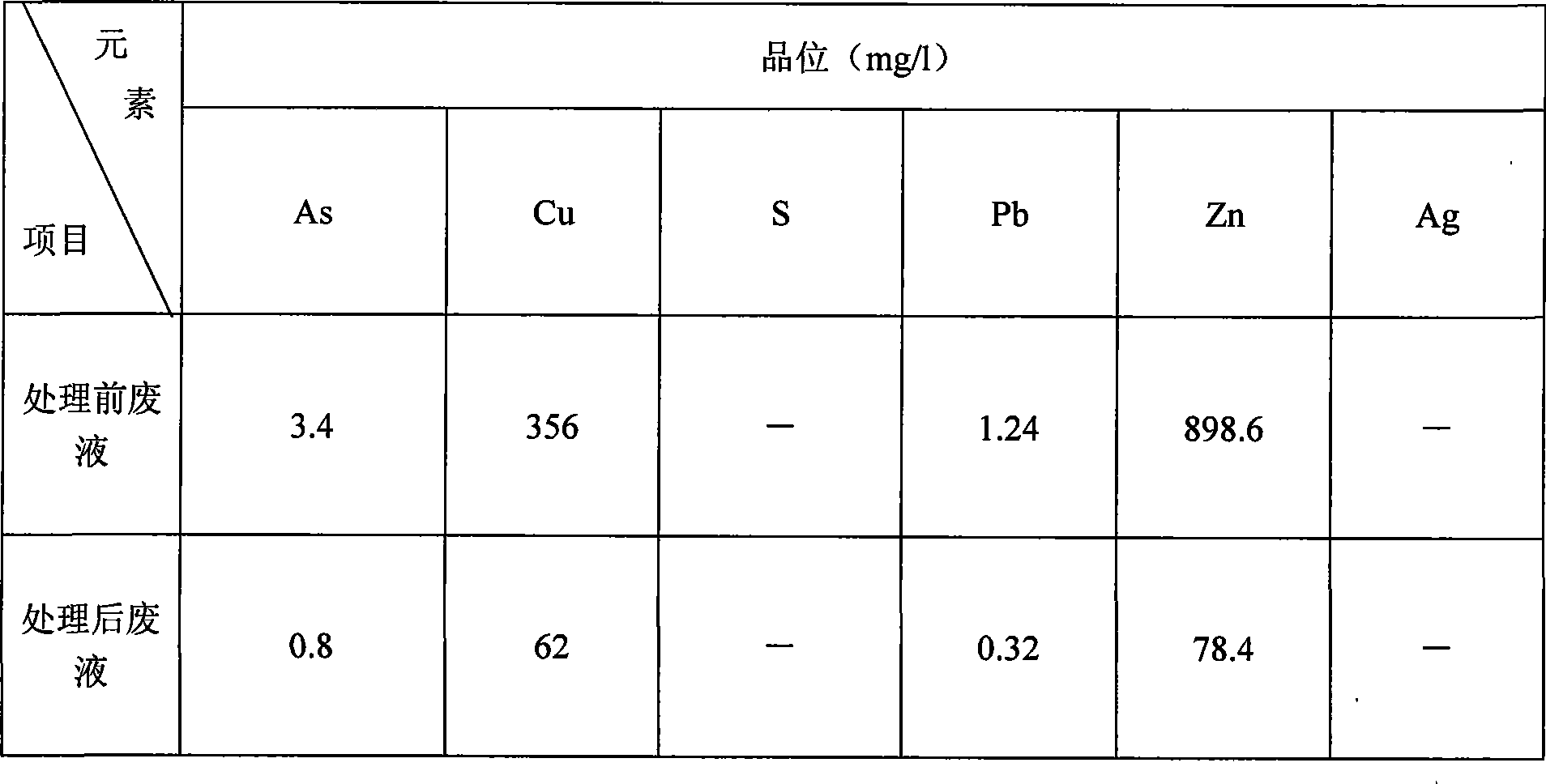

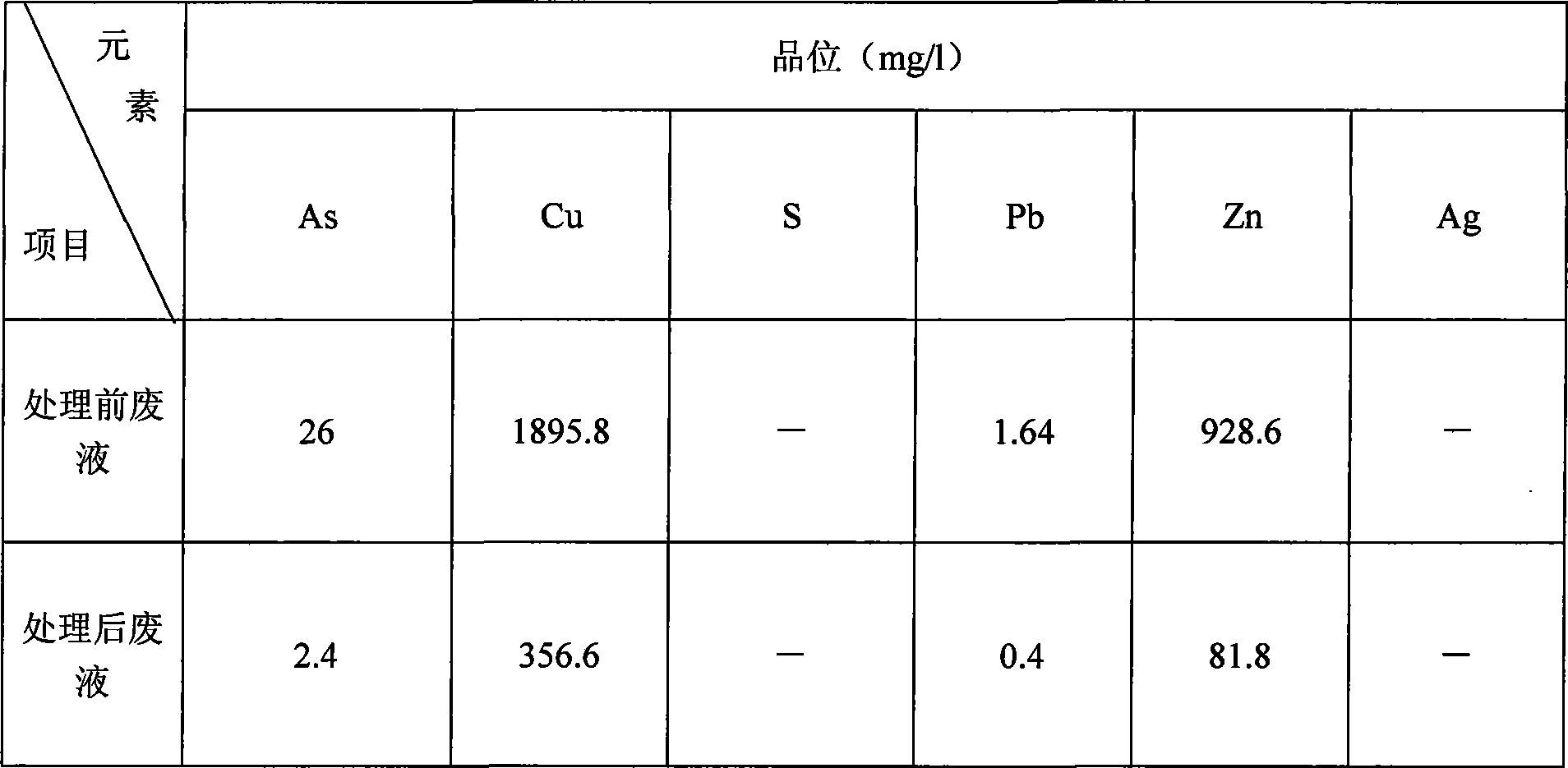

Method for treating cyaniding gold extraction waste water

ActiveCN101381175ASimple configurationEasy to operateMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationLiquid wasteWastewater

The invention discloses a method for treating cyanide gold-extraction wastewater, which comprises the following steps: a shell compound additive is directly added to alkaline cyanide gold-extraction waste liquid so as to remove various harmful impurities affecting the cyanide leaching of gold through a precipitation form; all filtrate is returned to a cyanide gold-extraction system for application through solid-liquid separation; and a filter cake is used for sale as copper concentrate. The method has the advantage of overcoming the defects that the prior acidification method for treating wastewater is long in process, high in cost and incapable of returning all wastewater for application.

Owner:SHANDONG HUMON SMELTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com