Method for increasing gold leaching rate through suspension roasting of carbon-containing gold ore

A suspension roasting and suspension roasting furnace technology, applied in the direction of improving process efficiency, can solve the problems of complex process, difficult product separation, poor roasting effect, etc., and achieve high heat and mass transfer efficiency, good continuity, and complete reaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

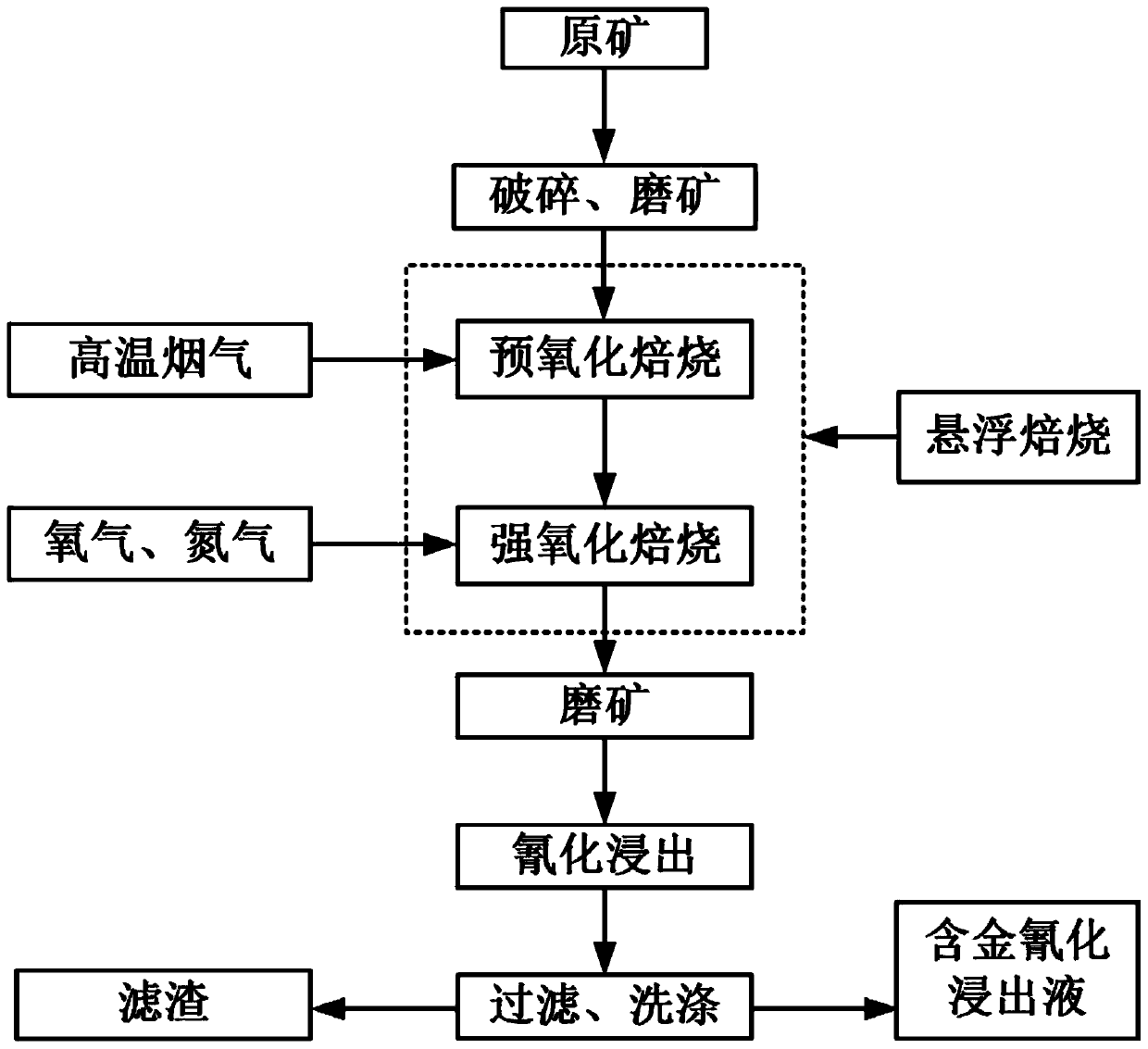

[0028] Process such as figure 1 shown;

[0029] The Au content of carbon-bearing gold ore is 5.74g / t, the mass percentage of C is 2.93%, the mass percentage of As is 0.15%, and the mass percentage of S is 5.82%;

[0030] Crush the carbon-containing gold ore to a particle size of 5-15 mm, and then grind the ore to a particle size of -0.074 mm, accounting for 90% of the total mass, to obtain fine ore;

[0031] The fine ore is transported to the pre-oxidation suspension roaster with a burner at the bottom, and the top of the pre-oxidation suspension roaster is connected to the induced draft fan through a pipeline; under the condition of the induced draft fan, the gas and air are ignited by the burner to generate High-temperature flue gas, high-temperature flue gas enters the pre-oxidation suspension roaster, and the fine ore is in a suspended state under the action of air flow and negative pressure, and is heated to 650°C for dearsenic roasting, and the As in the fine ore is con...

Embodiment 2

[0036] Method is with embodiment 1, and difference is:

[0037] (1) The Au content of carbon-bearing gold ore is 18.37g / t, the mass percentage of C is 15.37%, the mass percentage of As is 0.62%, and the mass percentage of S is 9.94%; %;

[0038] (2) The roasting temperature for dearsenicization is 680°C; the residence time of fine ore in the pre-oxidation roasting furnace is 18 minutes;

[0039] (3) The strong oxidation roasting temperature is 570°C; the amount of oxygen introduced is O 2 1.2 times the amount required for the complete reaction of C and S in the pre-oxidized roasted powder; the volume concentration of oxygen in the strong oxidation suspension roaster is 30%; the residence time of the pre-oxidized roasted powder in the strong oxidation suspension roaster 40min;

[0040] (4) Grinding to the part of particle size-0.074mm accounts for 93% of the total mass, and obtains the secondary powder ore; the secondary powder ore is added with water to make a slurry with a...

Embodiment 3

[0043] Method is with embodiment 1, and difference is:

[0044] (1) The Au content of carbon-bearing gold ore is 24.58g / t, the mass percentage of C is 8.66%, the mass percentage of As is 0.77%, and the mass percentage of S is 6.05%; %;

[0045] (2) Roasting temperature for arsenic removal is 700°C; the residence time of fine ore in the pre-oxidation roaster is 15 minutes;

[0046] (3) The strong oxidation roasting temperature is 600°C; the amount of oxygen introduced is O 2 1.3 times the amount required for the complete reaction of C and S in the pre-oxidized roasted powder; the volume concentration of oxygen in the strong oxidation suspension roaster is 20%; the residence time of the pre-oxidized roasted powder in the strong oxidation suspension roaster 30min;

[0047] (4) Grinding to a particle size of -0.074mm accounts for 90% of the total mass to obtain secondary powder ore; add water to the secondary powder ore to make a slurry with a mass concentration of 45%, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com