Method for recovering low-grade precious metals from mineral dressing tailings

A precious metal, low-grade technology, applied in the field of beneficiation, can solve problems such as low recovery rate of precious metal gold, and achieve the effects of improving economic benefits, solving impacts, and improving comprehensive utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

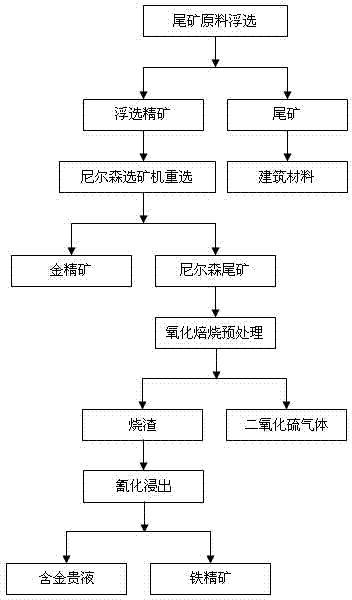

Image

Examples

Embodiment 1

[0023] The method of the present invention is used to recover low-grade precious metals from a certain flotation tailings in Jiangxi. The mass percentage content of sulfur in the tailings is 8.50%, and the mass ratio of precious metal gold to tailings is 0.20g / t.

[0024] Step 1, tailings raw material flotation, pulp the tailings raw material, the mass percentage concentration of the pulp is 25%, add copper sulfate and stir for 3 minutes after fully stirring, the mass ratio of copper sulfate and tailings raw material is 200g / t, in the slurry Then add isoamyl xanthate and terpineol oil and stir for 2 minutes. The mass ratio of isoamyl xanthate and tailings raw material is 200g / t, and the mass ratio of terpineol oil to tailings raw material is 50g / t; inflate the slurry Flotation, rough concentrate and tailings are obtained after one roughing and one sweeping, and the coarse concentrate is ground until the mass percentage of particles with a particle size of -0.074mm is 75%. ore ...

Embodiment 2

[0034] The method of the present invention is used to recover low-grade precious metals from a certain flotation tailings in Gansu. The mass percent content of sulfur in the tailings is 10.25%, and the content of precious metal gold is 0.45g / t.

[0035] Step 1, tailings raw material flotation, pulping the tailings raw material, the mass percentage concentration of the pulp is 30%, after fully stirring, add copper sulfate and stir for 3 minutes, the mass ratio of copper sulfate and tailings raw material is 200g / t, in the slurry Then add isoamyl xanthate and terpineol oil and stir for 2 minutes. The mass ratio of isoamyl xanthate and tailings raw material is 200g / t, and the mass ratio of terpineol oil to tailings raw material is 60g / t; inflate the slurry Flotation, rough concentrate and tailings are obtained through one roughing and one sweeping, and the coarse concentrate is ground until the mass percentage of particles with a particle size of -0.074mm is 80%. Mine and tailings...

Embodiment 3

[0045] The method of the present invention is used to recover low-grade precious metals from certain flotation tailings in Xinjiang. The mass percent content of sulfur in the tailings is 12.42%, and the content of precious metal gold is 0.78g / t.

[0046] Step 1, tailings raw material flotation, the tailings raw material is pulped, the mass percentage concentration of the pulp is 35%, after fully stirring, add copper sulfate and stir for 3 minutes, the mass ratio of copper sulfate and tailings raw material is 200g / t, in the slurry Then add isoamyl xanthate and terpineol oil and stir for 2 minutes. The mass ratio of isoamyl xanthate to tailings raw material is 250g / t, and the mass ratio of terpineol oil to tailings raw material is 60g / t; inflate the slurry Flotation, rough concentrate and tailings are obtained through one roughing and one sweeping, and the coarse concentrate is ground until the mass percentage of particles with a particle size of -0.074mm is 85%. Ore and tailing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com