Rapid analysis method for concentration of cyanide in cyanide leaching solution of gold ore

A technology of cyanide leaching and cyanide, which is applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of high airtightness of the distillation device, incomplete absorption of lye, cumbersome analysis steps, etc., so as to save the distillation device and steps , easy to master, and simplified operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

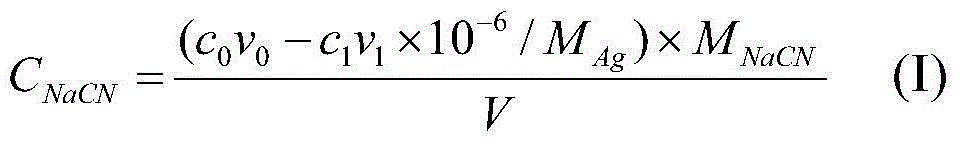

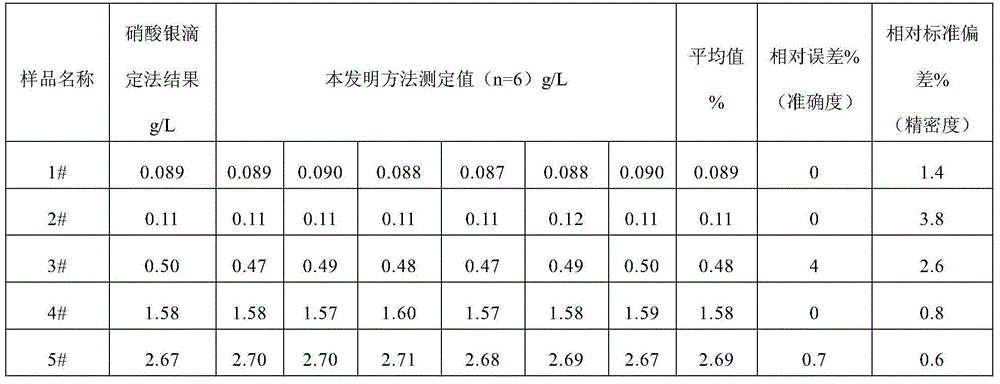

[0025] Accurately measure 20.00mL gold ore cyanide leachate sample 2 # In a 100mL volumetric flask, add 8 drops of 10% sodium hydroxide solution dropwise, add 10.00mL silver nitrate standard solution with a silver ion concentration of 1.00mg / mL, dilute to volume with water, shake well, dry filter (discard the initial filtrate ), divide and get 5.00mL filtrate in 100mL volumetric flask, with water constant volume, measure the content of silver in the solution with atomic absorption method to be 2.598 μ g / ml, calculate the concentration of sodium cyanide in the cyanide leachate with formula (1) as 0.11g / L.

Embodiment 2

[0027] Accurately measure 10.00mL gold ore cyanide leachate sample 3 # In a 100mL volumetric flask, add 5 drops of 10% sodium hydroxide solution dropwise, add 15.00mL silver standard solution with a silver ion concentration of 1.00mg / mL, dilute to volume with water, shake well, dry filter (discard the initial filtrate) , divide and get 5.00mL filtrate in 100mL volumetric flask, with water constant volume, measure the content of silver in the solution with atomic absorption method to be 2.309 μ g / ml, calculate the concentration of sodium cyanide in the cyanide leachate with formula (I) be 0.47 g / L.

Embodiment 3

[0029] Accurately measure 5.00mL gold ore cyanide leachate sample 4 # In a 100mL volumetric flask, add 8 drops of 10% sodium hydroxide solution dropwise, add 20.00mL silver nitrate standard solution with a silver ion concentration of 1.00mg / mL, dilute to volume with water, shake well, dry filter (discard the initial filtrate ), divide and get 5.00mL filtrate in 100mL volumetric flask, with water constant volume, measure the content of silver in the solution with atomic absorption method to be 1.292 μ g / ml, calculate the concentration of sodium cyanide in the cyanide leachate with formula (1) as 1.58g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com