Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33 results about "Silver cyanide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silver cyanide is the chemical compound with the formula AgCN. This white solid forms upon treatment of solutions containing Ag⁺ with cyanide. This precipitation step is used in some schemes to recover silver from solution. Silver cyanide is used in silver-plating.

Cyanide-free silver plating solution containing auxiliary complexing agent

InactiveCN102277601AGood binding and brightPlating solution is stableSupporting electrolyteContinuous use

The invention discloses cyanogen-free silver-plating electroplating liquid containing an auxiliary complexing agent. The cyanogen-free silver-plating electroplating liquid containing the auxiliary complexing agent is composed of a silver ion source material, a complexing agent, the auxiliary complexing agent, a supporting electrolyte, an electroplating additive, a pH adjusting agent and the like;the components of the electroplating liquid and the contents are as follows: 30-60 g / L of silver ion source material, 140-200 g / L of complexing agent, 10-50 g / L of auxiliary complexing agent, 10-30 g / L of supporting electrolyte, 100-800 mg / L of electroplating additive and 10-30 g / L of pH adjusting agent. The cyanogen-free silver-plating electroplating liquid containing the auxiliary complexing agent provided by the invention has the advantages that: the electroplating liquid is stable and has low toxicity, the anodic passivation in the electroplating process can be better inhibited, the anodeis normally dissolved, the electroplating liquid can be continuously utilized for long time, the electroplating layer has a good bonding force and is bright, and the electroplating liquid can be applied to multiple fields including decorative electroplating, functional electroplating and the like.

Owner:NANJING UNIV

A bright cyanide-free silver plating solution and preparation method thereof

The invention discloses non-cyanide bright silver electroplating bath, which consists of the following components in mass concentration: 50 to 800mg / L brightener, 25 to 60g / L silver ion source substance, 130 to 190g / L coordinating agent, 10 to 40g / L supporting electrolyte and 10 to 50g / L electroplating bath pH regulator, wherein the brightener is one or more kinds of amino acid compounds, imidazole, polyethylene glycol, quinoline derivatives and saccharin. Compared with the prior art, the non-cyanide bright silver electroplating bath has the outstanding advantages that: the electroplating bath is stable and low in toxicity; and an extremely small amount of brightener can obviously improve the performance of the electroplating bath and the quality of a coating. The coating has fine crystals, good bonding force, smooth and bright surface and high anti-tarnish property, can meet the requirement of application in multiple fields such as decorative electroplating, functional electroplatingand the like, has high practicability and can generate good economic and social benefits.

Owner:NANJING UNIV

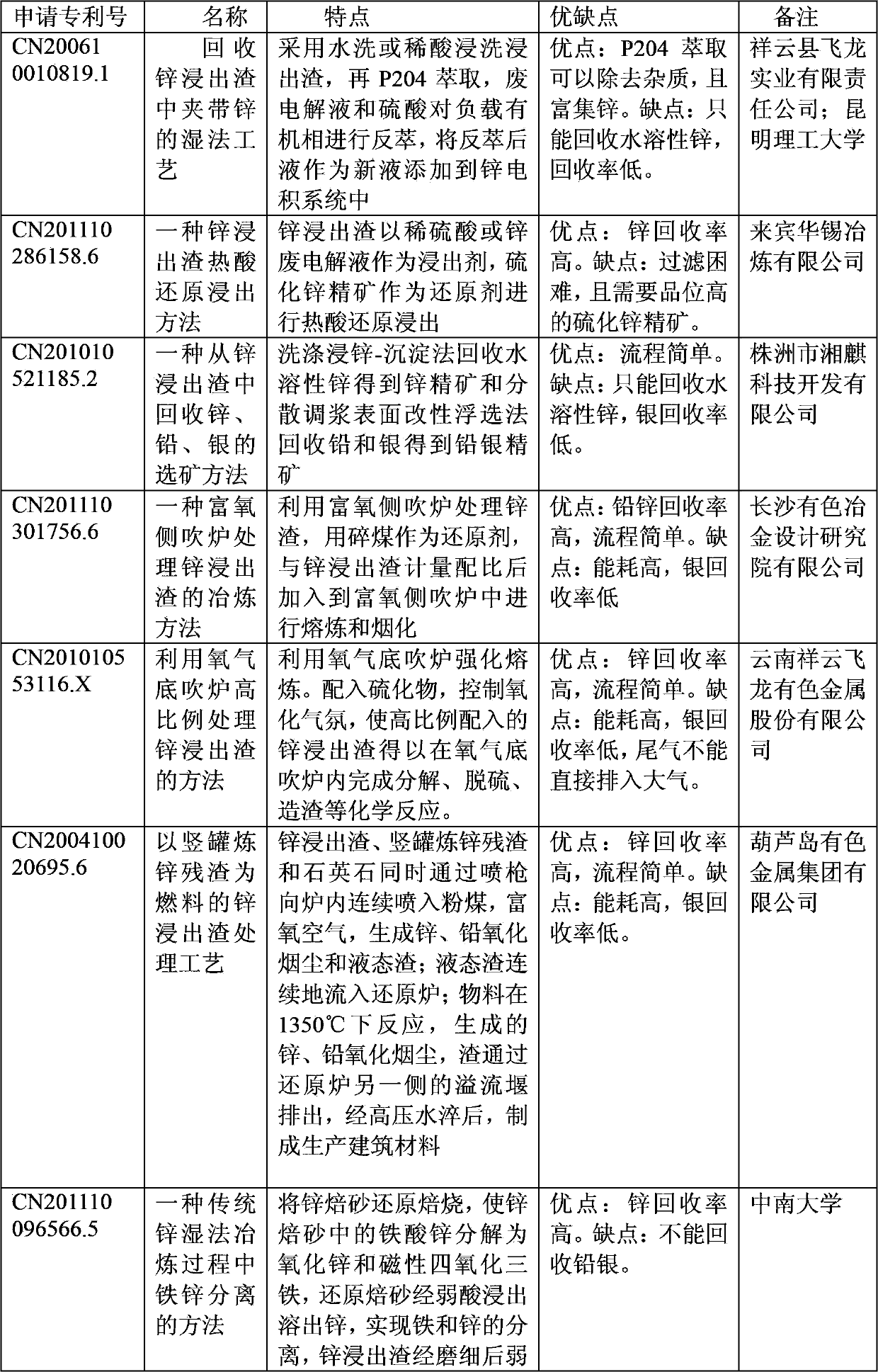

Technology for extracting zinc, lead and silver step by step by processing zinc-leached residues by full wet process

ActiveCN102719668AHigh extraction rateAchieve recyclingProcess efficiency improvementHigh concentrationSlurry

Owner:JIANGXI LONGTIANYONG NONFERROUS METAL CO LTD

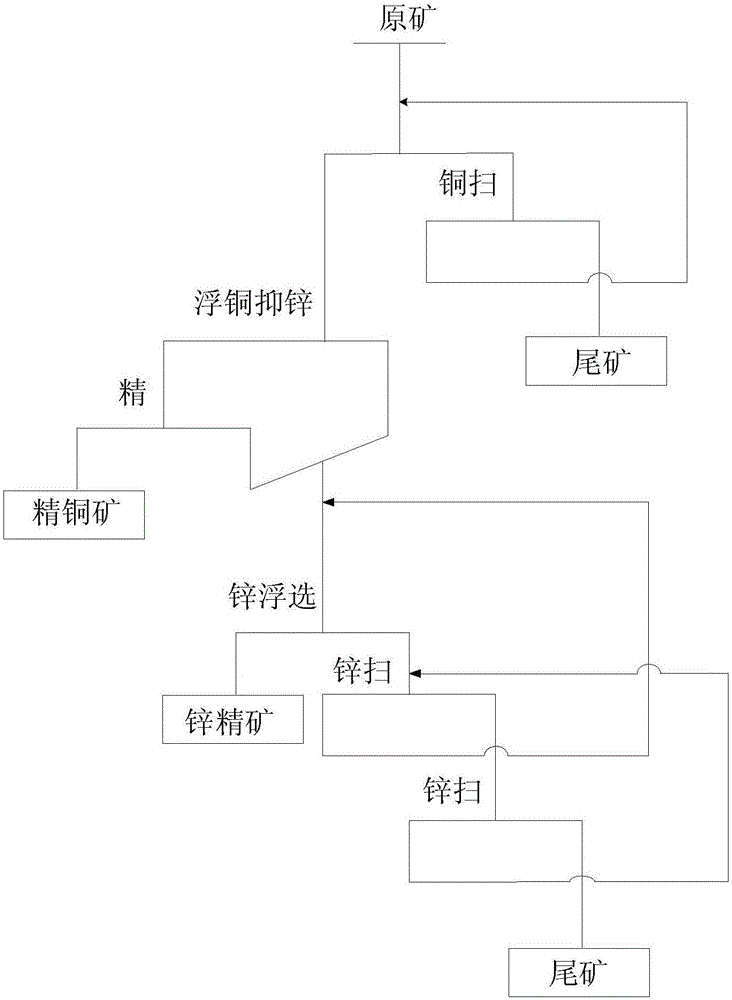

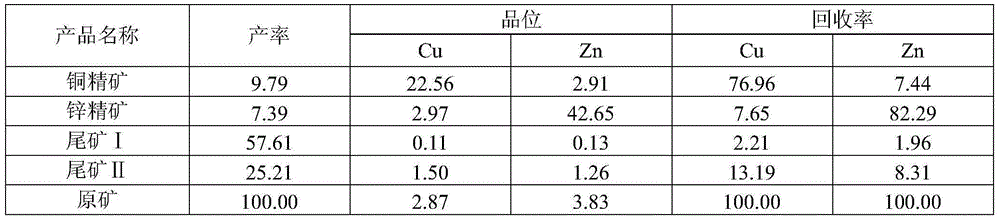

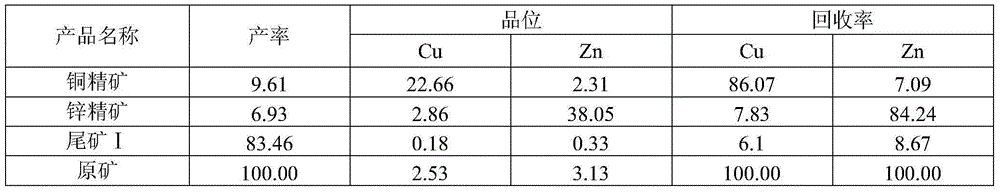

Method for recovering associated sulphide copper-zinc ore from cyaniding slag of gold-silver concentrate

The invention discloses a method for recovering associated sulphide copper-zinc ore from cyaniding slag of gold-silver concentrate and belongs to the technical field of flotation recovery of valuable metals in the gold smelting industry. The method comprises the steps of preparing pulp: preparing the cyaniding slag of the silver concentrate into the pulp with the concentration of 30-35% under the condition of the roughing concentration of ore flotation and injecting into a flotation machine, activating with LGY-01 as an activator for the floatation of sulphide copper-zinc ore, and obtaining copper-zinc mixed concentrate via single roughing and single scavenging by taking a combination of butyl xanthate and butylamine dithiophosphate at a weight ratio of 3:2 as a collecting agent and 2# oil as a foaming agent, wherein the activator LGY-01 is prepared from sodium pyrosulfite and sodium hydrosulfite at a weight ratio of 5:1. The method is a floatation technology for floatation recovery of the sulphide copper-zinc concentrate from the gold-silver cyaniding slag, increases a resource utilization rate, reduces environmental pollution and increases economic benefits of an enterprise.

Owner:JIANGXI UNIV OF SCI & TECH

Method for synthesizing metal cyanides by use of Fenton reagent

ActiveCN104556150ANo pollutionNot involved in the productionComplex cyanidesMetal/metal-oxides/metal-hydroxide catalystsPlatinumFenton reagent

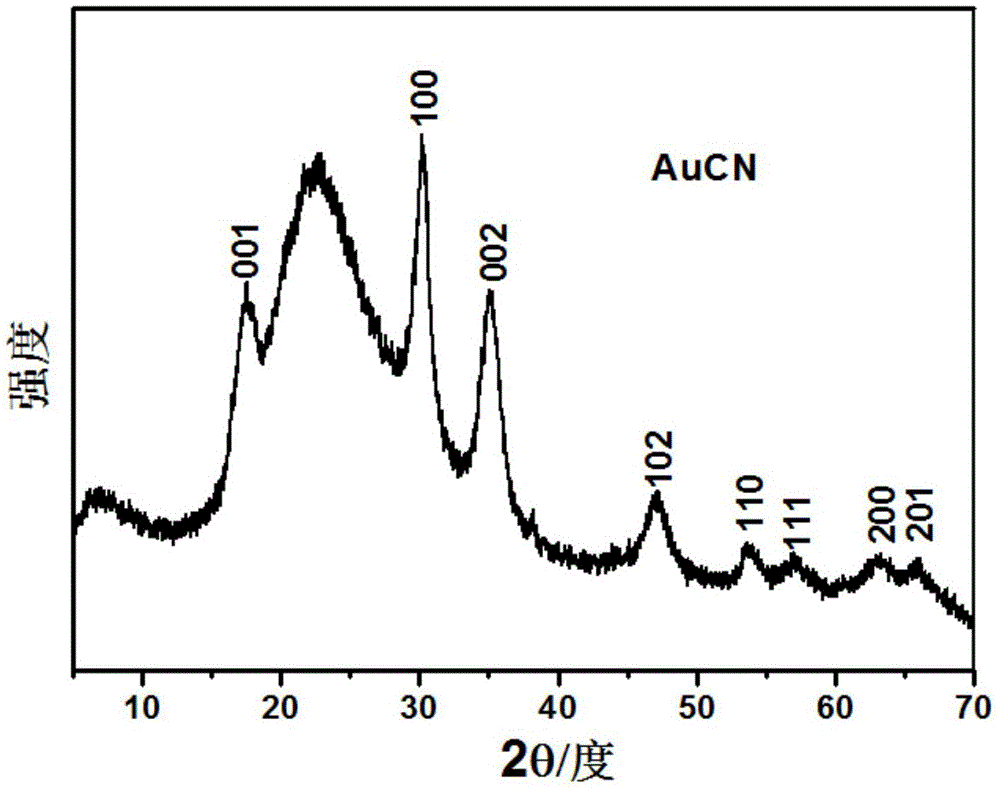

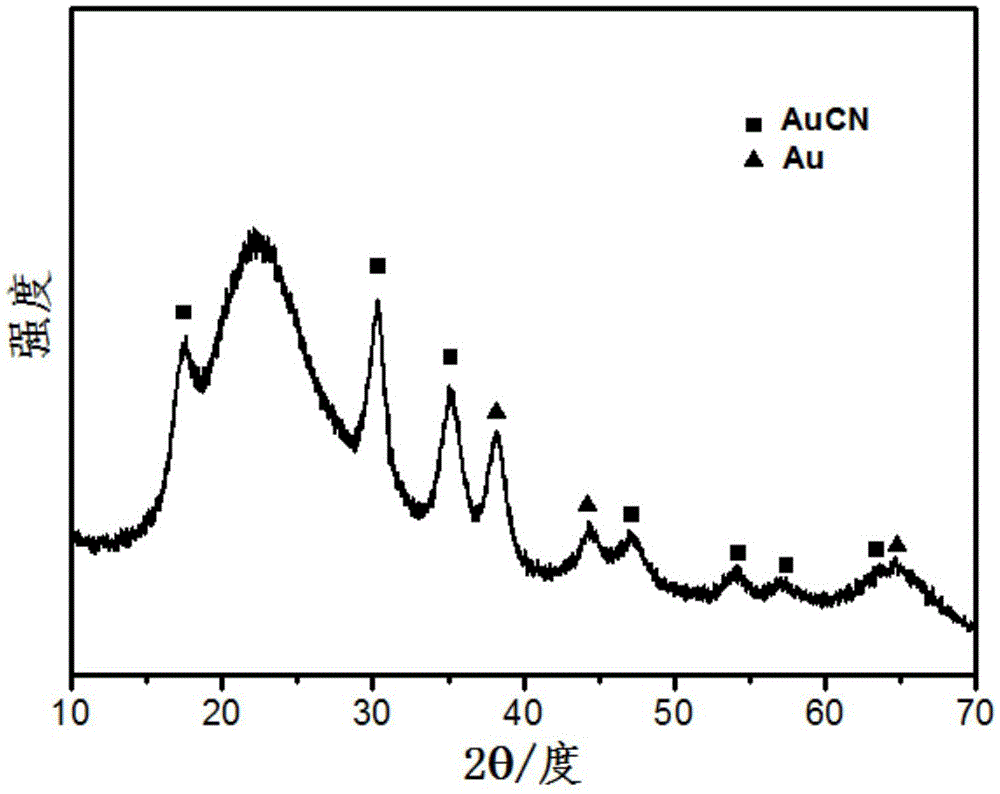

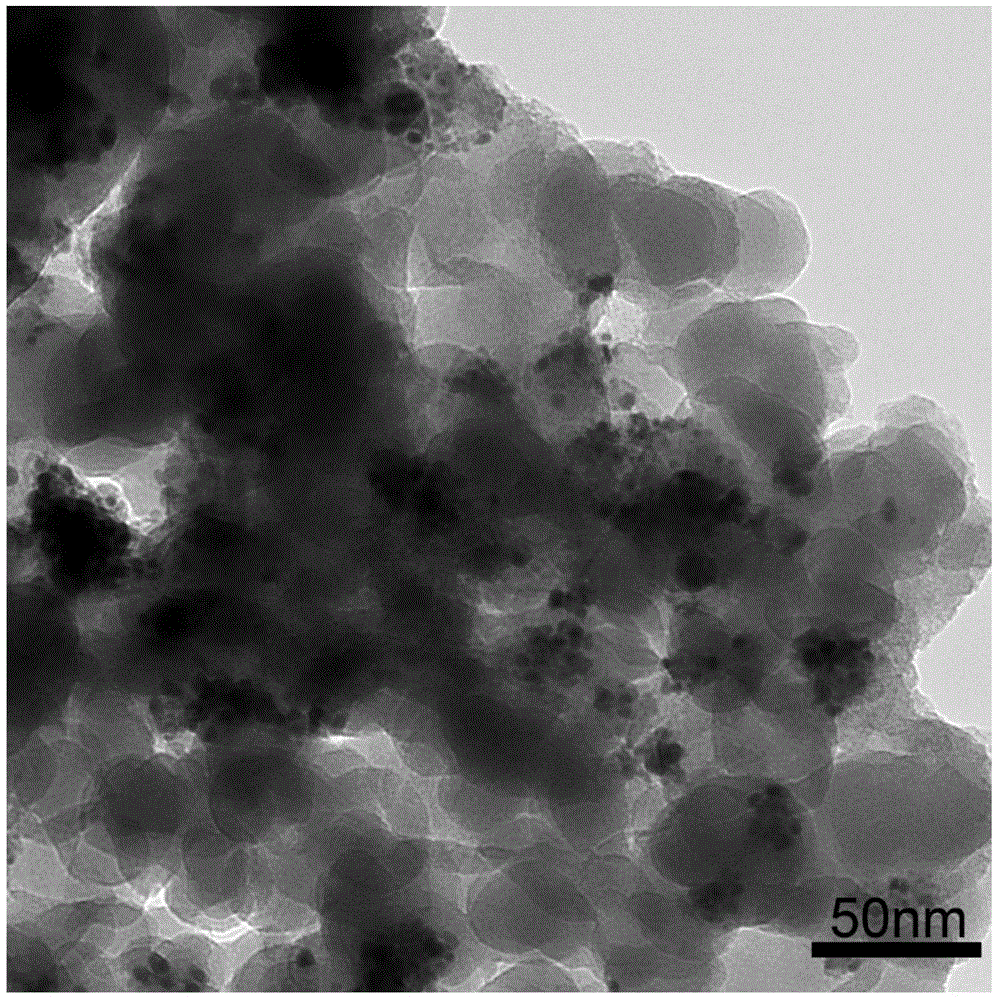

Provided is a preparation method of metal cyanide, comprising the following steps: 1) mixing supported metal nanoparticles, a Fenton reagent and nitrile to form suspension, and then stirring, the supported metal nanoparticles being a complex wherein the supporter supports nano metal supports nano metal, nano metal oxide or nano metal salt; and 2) centrifugalizing and drying a product after stirring to obtain the metal cyanide. Also provided are the prepared metal cyanide and the use of same in the fields of sensing, batteries, medicine, electroplating and catalysis. The preparation method does not relate to highly toxic substance CN -, does not require ultraviolet light, is an entirely green method for synthesizing metal cyanide, and applies to industrial production of a large scale.

Owner:ZHEJIANG UNIV

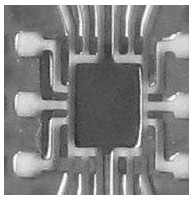

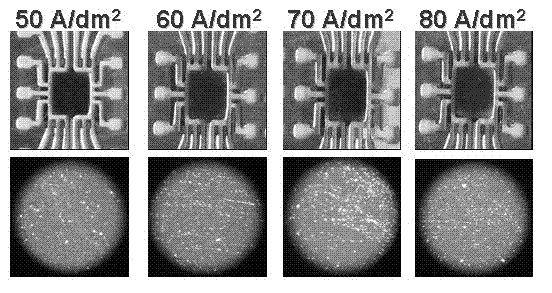

Method for electroplating silver on surface of printed circuit board through pulse current

The invention discloses a method for electroplating silver on the surface of a printed circuit board through pulse current. The method is low in cost, simple in process and controllable. The method comprises the steps of (1) preparing electroplate liquid containing silver salt and (2) carrying out the silver plating process. In the step (1), silver cyanide, sodium cyanide and sodium hydroxide are used as main salt, dimethylamine-borane and thiourea serve as supporting electrolytes, and an inorganic molten salt plating solution system is prepared. In the step (2), the silver plating process comprises the steps of grinding of the surface of the printed circuit board, chemical oil removal, water flushing, brush polishing, etching activation, pulse silver plating, washing and drying, wherein the pulse silver plating process is that electroplating is carried out at the temperature of 50-60 DEG C, and reverse pulse electroplating is adopted; pulse parameters are that forward current is 5-15 A, reverse current is 15 A, forward pulse time is 18-108 ms, reverse pulse time is 2 ms, and electroplating time is 60 min. The method can be applied to the field of metal materials.

Owner:ZHUHAI YUANSHENG ELECTRONICS SCI & TECH

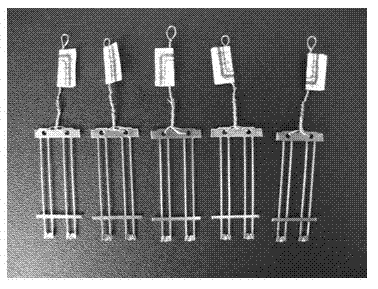

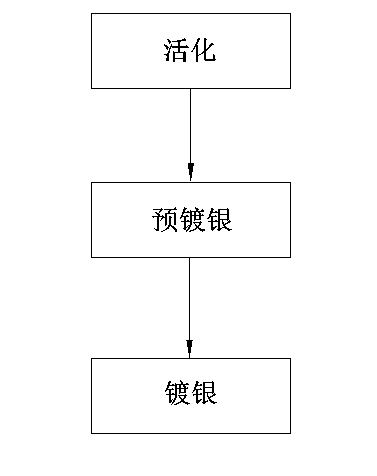

Nickel silvering process in process of electroplating LED (Light Emitting Diode) bracket

The invention discloses a nickel silvering process for replacing copper silvering in the process of electroplating an LED bracket; the nickel silvering process comprises the steps of activating, pre-silvering and silvering, wherein the mixed solution of editpotassium cyanide and potassium carbonate is adopted in the activating process; the concentrations of both editpotassium cyanide and potassium carbonate are 3-20 g / L; the mixed solution of editpotassium cyanide and silver cyanide is adopted in the pre-silvering process; the concentration of editpotassium cyanide is 120-160 g / L; the concentration of silver cyanide is 2.2-4 g / L; the mixed solution of editpotassium cyanide, silver cyanide and potassium hydroxide is adopted in the silvering process; the concentration of silver cyanide is 12-15 g / L; the concentration of editpotassium cyanide is 100-150 g / L; and the concentration of potassium hydroxide is 0.2-0.5 g / L. The nickel silvering process disclosed by the invention is simple in process; silvering is carried out after treating through the process disclosed by the invention; and the LED bracket is non-discolouring in the roasting process only by plating silver of lower thickness.

Owner:甘宁

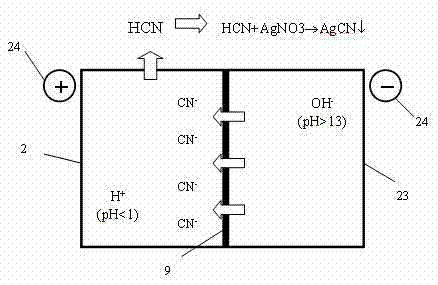

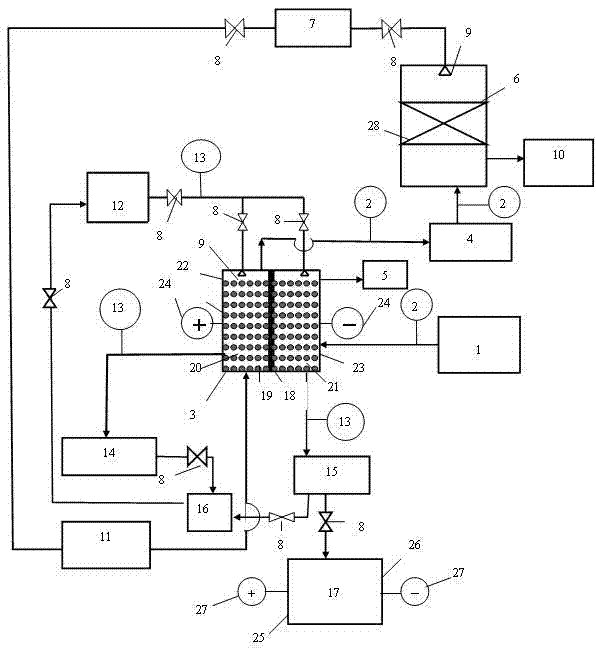

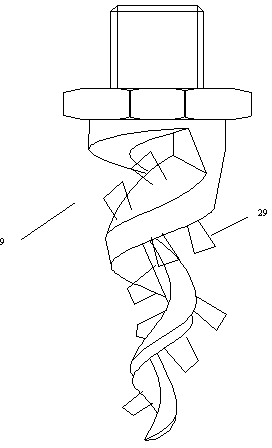

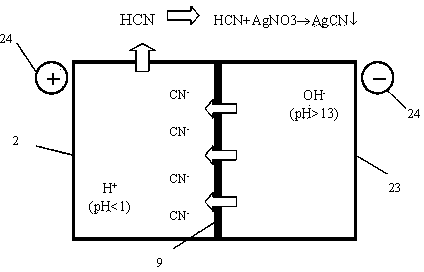

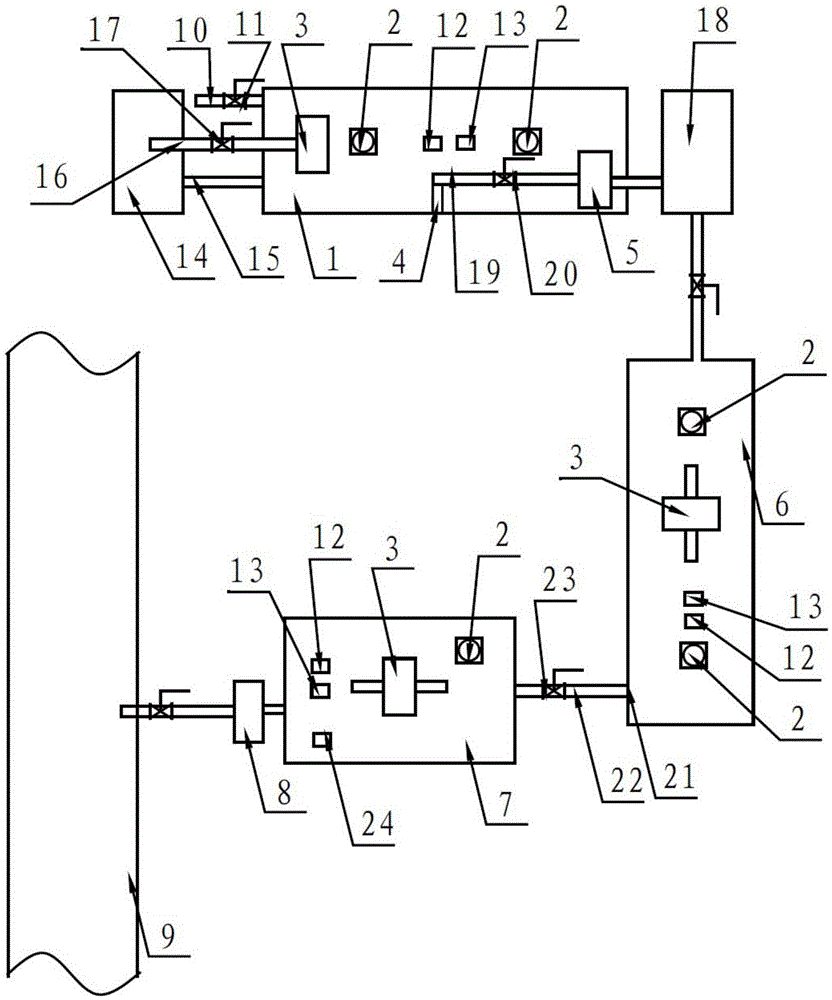

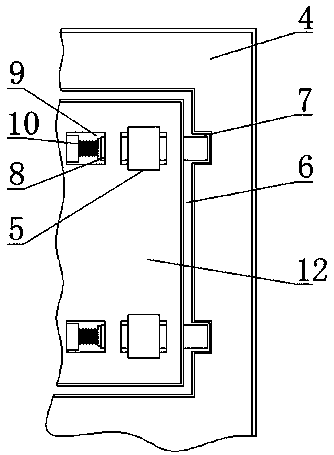

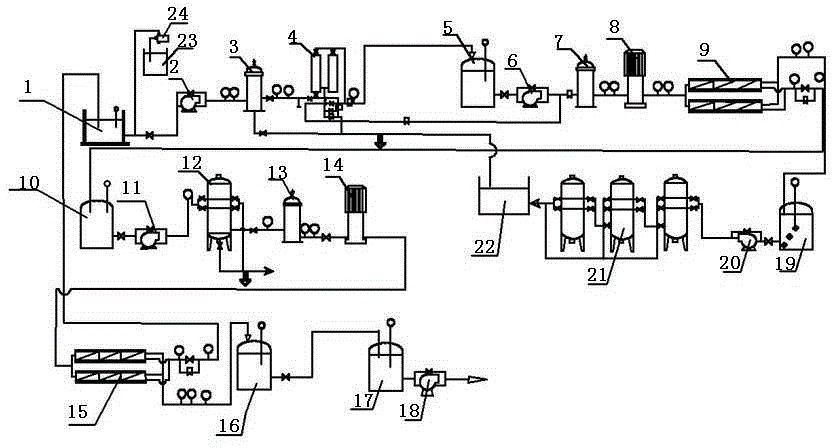

Device for preparing silver cyanide (AgCN) by recovering hydrogen cyanide (HCN) through electrodynamic migration and method for device

ActiveCN102895854APurification process is stableAchieve emissionsDispersed particle separationMetal cyanidesCarbon fibersAllyl cyanide

The invention discloses a device for preparing silver cyanide (AgCN) by recovering hydrogen cyanide (HCN) through electrodynamic migration. The device consists of an electric waste gas treatment device, a cathode electro-Fenton device and an HCN gas absorption device, wherein the electric waste gas treatment device consists of an anode chamber and a cathode chamber; the anode chamber and a cathode chamber is partitioned by an ion permselective membrane; voltages are respectively applied to both ends of the device; a waste gas is converted into a CN<-> form after entering the cathode chamber, and transmits an ion exchange membrane under the action of electromigration to enter the anode chamber; a high-concentration HCN gas is obtained in the anode chamber; the high-concentration HCN gas is collected in an HCN recovery storage tank; absorption liquid in an absorption liquid tank contains Ag<+>; and the Ag<+> reacts with HCN in an absorption tower. The device disclosed by the invention can be used for recovering HCN in various cyanogen-contained waste gases, such as a carbon fiber tail gas, an allyl cyanide gas, a calcium carbide furnace gas, a coke-oven gas, a yellow phosphorus tail gas and the like, and the HCN can be produced into an AgCN product.

Owner:ZHEJIANG UNIV

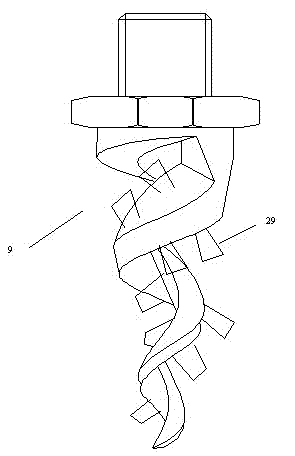

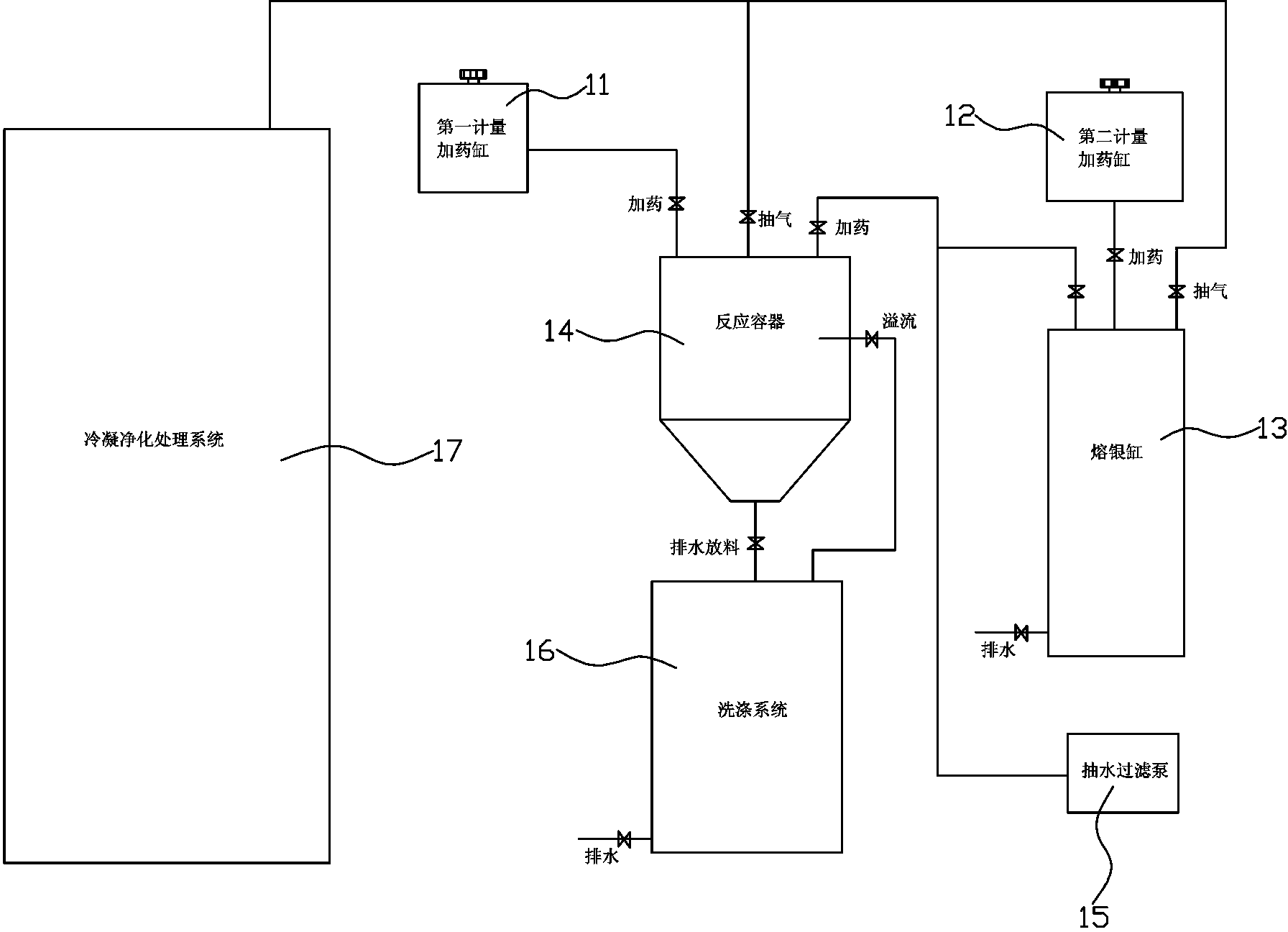

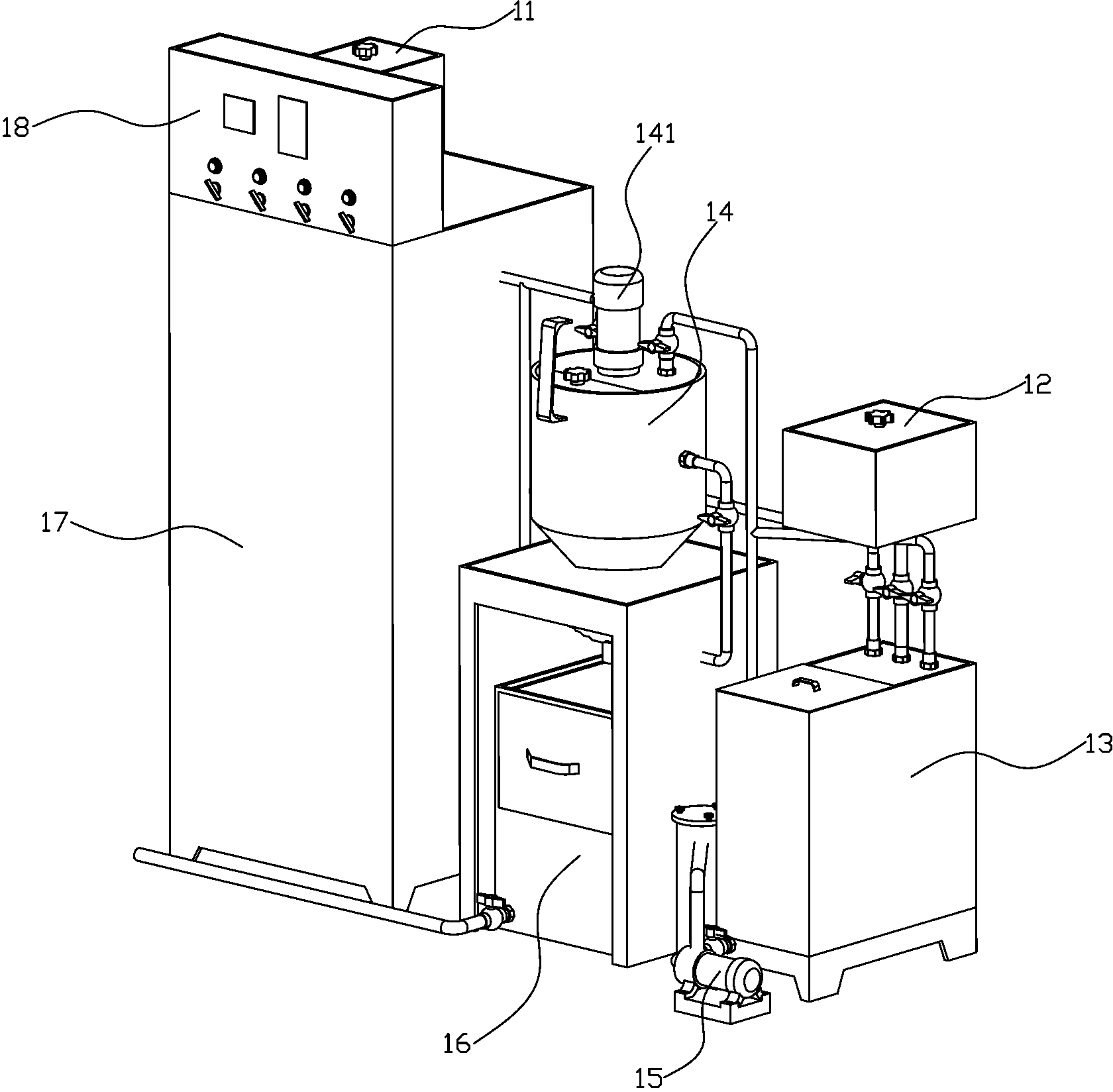

Silver cyanide manufacturing technology and equipment thereof

The invention belongs to the technical field of silver cyanide manufacture, and provides a silver cyanide manufacturing technology and equipment thereof. The technology comprises the steps as follows: firstly, nitric acid and silver are subjected to chemical reaction, so as to prepare a silver nitrate solution, then the silver nitrate solution and cyanide solution (such as an editpotassium cyanide solution or a sodium cyanide solution) are subjected to chemical reaction, so as to prepare silver cyanide and a nitrate solution (such as a potassium nitrate solution or a sodium nitrate solution), and finally the sodium nitrate solution are washed and separated from each other, so that the production of silver cyanide is accomplished. The technology is pollution-free, nonhazardous and low in sliver loss during the whole production process, is high in purity and good in quality of produced silver cyanide, improves the production efficiency, reduces the cost, and also realizes energy conservation and environment protection.

Owner:深圳市鑫鸿发环保设备有限公司

Technology for extracting zinc, lead and silver step by step by processing zinc-leached residues by full wet process

ActiveCN102719668BHigh extraction rateAchieve recyclingProcess efficiency improvementHigh concentrationSilver cyanide

The invention relates to a technology for extracting zinc, lead and silver step by step by processing zinc-leached residues by a full wet process, and belongs to the technical field of zinc-leached residue recycle. The technology comprises the following steps of: preparing sulfuric acid into an appropriate concentration, and performing two-stage acid leaching in an appropriate liquid-solid ratio and at a high temperature to obtain slurry; filtering and separating the slurry to obtain lead-silver residues and a zinc-containing solution; oxidizing, neutralizing and deironing the zinc-containing solution, and depositing zinc by using sodium sulphide; and eluting the lead-silver residues, blending with caustic lye at an appropriate concentration to obtain slurry at a certain concentration, reacting at a certain temperature and in a certain solid-liquid ratio, and filtering and separating to obtain a filter cake and a filtrate, wherein the filtrate is directly added with sodium sulphide for lead deposition and the filter cake returns to a silver cyaniding leaching process. The technology is short in process, simple in operation, low in cost and mild and loose in reaction conditions; an acid solution and an alkali solution at high concentrations are not required; requirements on equipment are low; the extraction rate of metal is higher than that in the conventional method; no additional waste solid, waste liquid and waste gas are discharged; the recycle of the eluate and the filtrate is realized; and environment pollution is avoided from the source.

Owner:JIANGXI LONGTIANYONG NONFERROUS METAL CO LTD

Silver cyanide drying method

PendingCN113188309AAchieve pre-shreddingImprove drying efficiencyDomestic cooling apparatusDrying gas arrangementsSilver cyanidePhysical chemistry

The invention relates to the technical field of silver cyanide drying, in particular to a silver cyanide drying method. The method comprises the following steps: 1, weighing quantitative metal silver and nitric acid through weighing equipment, then weighing quantitative water and quantitative sodium cyanide, and then respectively putting the weighed materials into respective placing containers; and 2, putting the weighed quantitative silver and nitric acid into a mixing container at the same time, completely dissolving the silver, then adding the quantitative water weighed in step 1 for dilution, adding the weighed quantitative sodium cyanide into the mixed solution after dilution, and closing a shielding cover of the mixing container after the reaction is completed. According to the device, silver cyanide is pre-crushed, the drying efficiency of the silver cyanide is improved, the phenomenon that the silver cyanide is attached to the outer sides of the containing containers and is inconvenient to clean is avoided to the maximum extent, meanwhile, waste of heat energy in the drying process is avoided to the maximum extent, and the safety of the silver cyanide during drying is guaranteed.

Owner:福建紫金贵金属材料有限公司

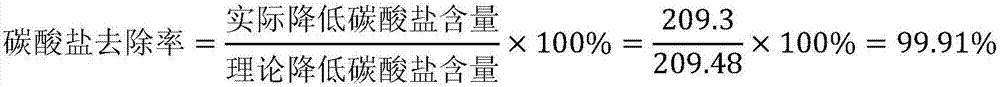

Method for removing carbonate in cyanide silver-plating bath solution

The present invention relates to a kind of method for removing carbonate in cyanide silver-plating bath solution, comprises a, confirms carbonate content: takes cyanide silver-plating bath solution, analyzes and determines wherein carbonate content; B, confirms precipitation agent adding Quantity: Calculate and prepare the carbonate precipitant that needs to be added according to the carbonate content in the cyanide silver plating bath; c. Carbonate precipitation: add the carbonate precipitant to the cyanide silver plating bath , stirred, allowed to stand, precipitated, filtered, and the filtrate was obtained. The invention has the advantages of high carbonate removal efficiency in cyanide silver plating bath liquid, short reaction time, more complete reaction and less potential safety hazard.

Owner:PLA NO 5719 FACTORY

Device for preparing silver cyanide (AgCN) by recovering hydrogen cyanide (HCN) through electrodynamic migration and method for device

ActiveCN102895854BPurification process is stableAchieve emissionsDispersed particle separationMetal cyanidesCarbon fibersHCN poisoning

The invention discloses a device for recovering hydrogen cyanide and preparing silver cyanide by electrodynamic migration. The device consists of an electric exhaust gas treatment device, a cathode electro-Fenton device, and an HCN gas absorption device. The electric exhaust gas treatment device is composed of an anode chamber and a cathode chamber, which are separated by an ion-selective permeable membrane, and a voltage is applied to both ends of the device. , the exhaust gas enters the cathode chamber and is converted into CN- form, and enters the anode chamber through the ion exchange membrane under the action of electromigration, and obtains high-concentration HCN gas in the anode chamber, which is collected by the HCN recovery storage tank, and the absorption liquid in the absorption liquid tank contains Ag+, react with HCN in the absorption tower to prepare the product AgCN. The device can recover HCN from various cyanide-containing waste gases (such as carbon fiber tail gas, acrylcyanide waste gas, calcium carbide furnace gas, coke oven gas, yellow phosphorus tail gas, etc.) and produce AgCN products.

Owner:ZHEJIANG UNIV

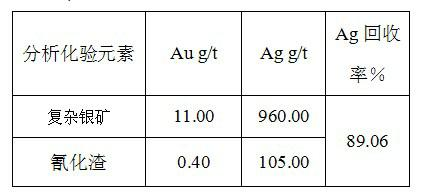

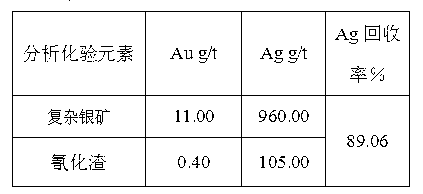

Method for raising leaching rate of silver cyanide

InactiveCN102492854AIncrease profitImprove leaching rateProcess efficiency improvementChemical industrySurge tank

The invention relates to a method for raising leaching rate of silver cyanide and belongs to the technical field of roasting-cyaniding silver extraction production processing technology in the gold smelting and chemical industry. The method provided by the invention contains the following steps of: 1, adding complex silver ore, sal glauberi and sodium carbonate according to the mass ratio of 1: (0.02-0.03): (0.02-0.03) into a surge tank, adjusting the pulp concentration to 65-70% by the addition of water, and continuously stirring at normal temperature and normal pressure for 3-5 hours; 2) carrying out fluidized sulfating roasting on the pulp obtained from the step 1); 3) carrying out acid leaching treatment; and 4) carrying out cyanide leaching. By the adoption of the method, recovery rate of silver can be effectively raised, and utilization rate of resources and enterprise economic benefits are raised.

Owner:SHANDONG GUODA GOLD

A method for synthesizing metal cyanides by fenton reagent

ActiveCN104556150BNo pollutionImprove responseComplex cyanidesMetal/metal-oxides/metal-hydroxide catalystsCyanide compoundPlatinum

The invention provides a simple, convenient and completely green synthesis method of metal cyanides. Mix nano-gold (or nano-silver, nano-silver oxide, silver nitrate, nano-platinum, nano-palladium, nano-ruthenium) loaded on a conventional carrier, Fenton's reagent and nitrile to form a suspension system, and synthesize metal cyanide in a certain temperature step . The product is uniformly dispersed and crystallized well. The present invention uses Fenton's reagent to synthesize metal cyanide for the first time, has obtained single metal cyanide such as gold cyanide, silver cyanide, palladium cyanide, ruthenium cyanide, platinum cyanide, and gold silver cyanide, cyanide Binary metal cyanides such as gold copper, silver copper cyanide, and copper cyanurate, and ternary metal cyanides such as gold silver copper cyanide. The synthesis process neither involves CN--a highly toxic substance, nor does it require the use of ultraviolet light. It is a completely green method for synthesizing metal cyanides, which is suitable for large-scale industrial production. The synthesized supported nano metal cyanide has broad application prospects in the fields of sensing, battery, medicine, electroplating and catalysis.

Owner:ZHEJIANG UNIV

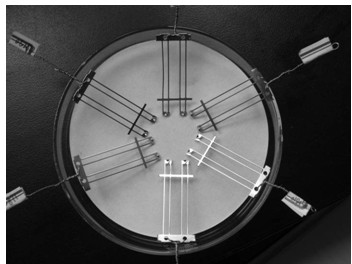

A kind of silver plating solution pre-dissolving process

ActiveCN103741199BSolve the problem of difficult concentration controlReduce use costCellsPotassium cyanideSilver cyanide

The invention discloses a silvering solution pre-dissolving process. The process comprises the following steps: adding pure water into a dissolving tank, starting a heater arranged in the dissolving tank and a circulating pump arranged on the dissolving tank; then adding potassium cyanide into the dissolving tank; under the circulating stirring action of the circulating pump, adding silver cyanide after potassium cyanide is dissolved fully into water; injecting the dissolved liquid medicine into a storing tank through a liquid outlet pipeline, a valve and an extracting pump which are arranged on the dissolving tank; after the liquid medicine is injected into the storing tank, starting the heater and a liquid medicine circulating pump which are arranged in the storing tank; introducing the liquid medicine in the storing tank into a titrating tank, and then starting the circulating pump and the heater which are arranged in the titrating tank, then starting a titration metering pump so as to add the liquid medicine into a plating bath with an appointed flow rate due to the adoption of the titration metering pump. Due to the adoption of the process, the thickness of a silver layer on the surface of a silvered product can be uniform without salient points, and furthermore, a large amount of silvering raw materials can be saved.

Owner:NINGBO KANGQIANG ELECTRONICS CO LTD

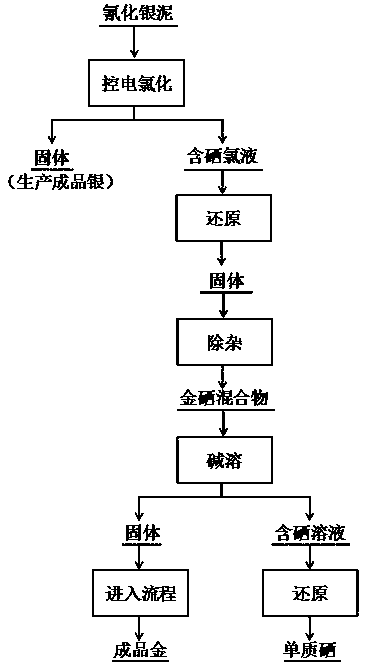

A kind of method that reclaims selenium from silver cyanide mud

ActiveCN107651653BAvoid wastingHigh recovery rateElemental selenium/telluriumSilver cyanideEconomic benefits

The invention belongs to the field of recycling of silver cyanide mud and particularly relates to a method for recycling selenium from the silver cyanide mud. Silver cyanide is treated by the aid of silver mud wetting method, gold and selenium in a selenium containing chlorine solution are reduced to be simple substances, bur picking is performed, a gold selenium mixture obtained after bur pickinghas the gold and the selenium separated with an alkali dissolution mode, the product obtained is then subjected to solid-liquid separation, solid obtained from separation enters a process to be produced to be finished gold, and the liquid is subjected to solid-liquid separation after reduction to obtain selenium powder. The method has the advantages of easy control of process conditions, brief procedure, simpleness in equipment, low cost, high product add-value, high recycling rate, low environment pollution and high economic benefit.

Owner:山东金创金银冶炼有限公司

Preparation method of silver potassium cyanide

The invention provides a brand-new preparation method of silver potassium cyanide, which can recycle nitrate and is environment-friendly. The preparation method of the silver potassium cyanide comprises the following steps of: reacting silver nitrate with carbonate or hydroxide to generate silver carbonate or silver hydroxide, and reacting the silver carbonate or silver hydroxide with potassium cyanide to obtain the silver potassium cyanide. According to the preparation method, in the production process of the silver potassium cyanide, the production process in which silver nitrate reacts with cyanide to generate silver cyanide is omitted. Silver nitrate reacts with carbonate and other alkaline substances to generate silver carbonate precipitates (insoluble in water), meanwhile, generated nitrate and the aqueous solution do not contain cyanide, and the aqueous solution can be concentrated to recycle the nitrate so that the nitrate can be utilized as a chemical raw material. The environment is protected, resource waste is reduced, and harm to human bodies caused by harmful gas possibly generated when acidic substances are in contact with potassium cyanide in the production process of the silver potassium cyanide is eliminated.

Owner:漯河瀚普环创环保科技有限公司

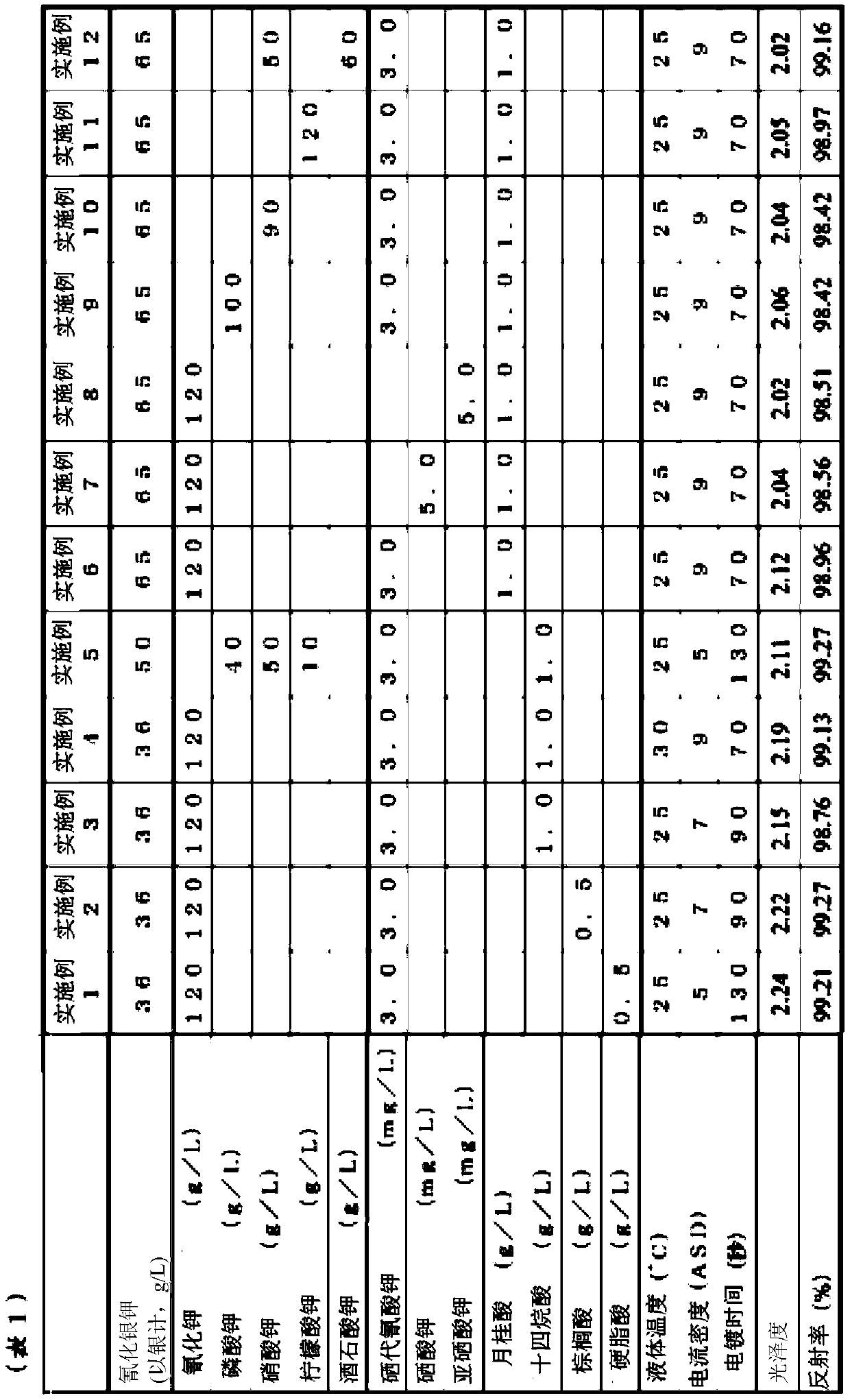

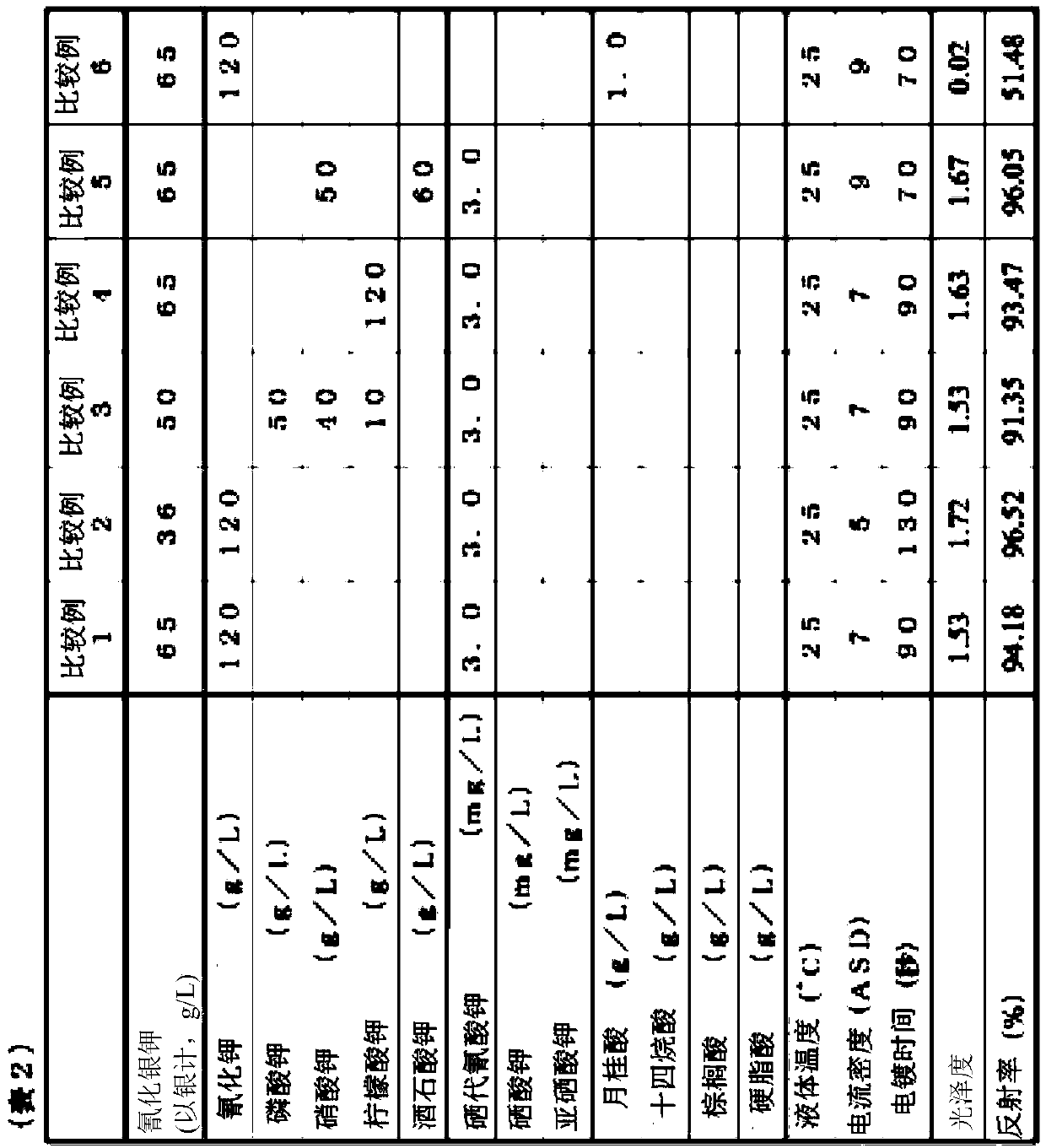

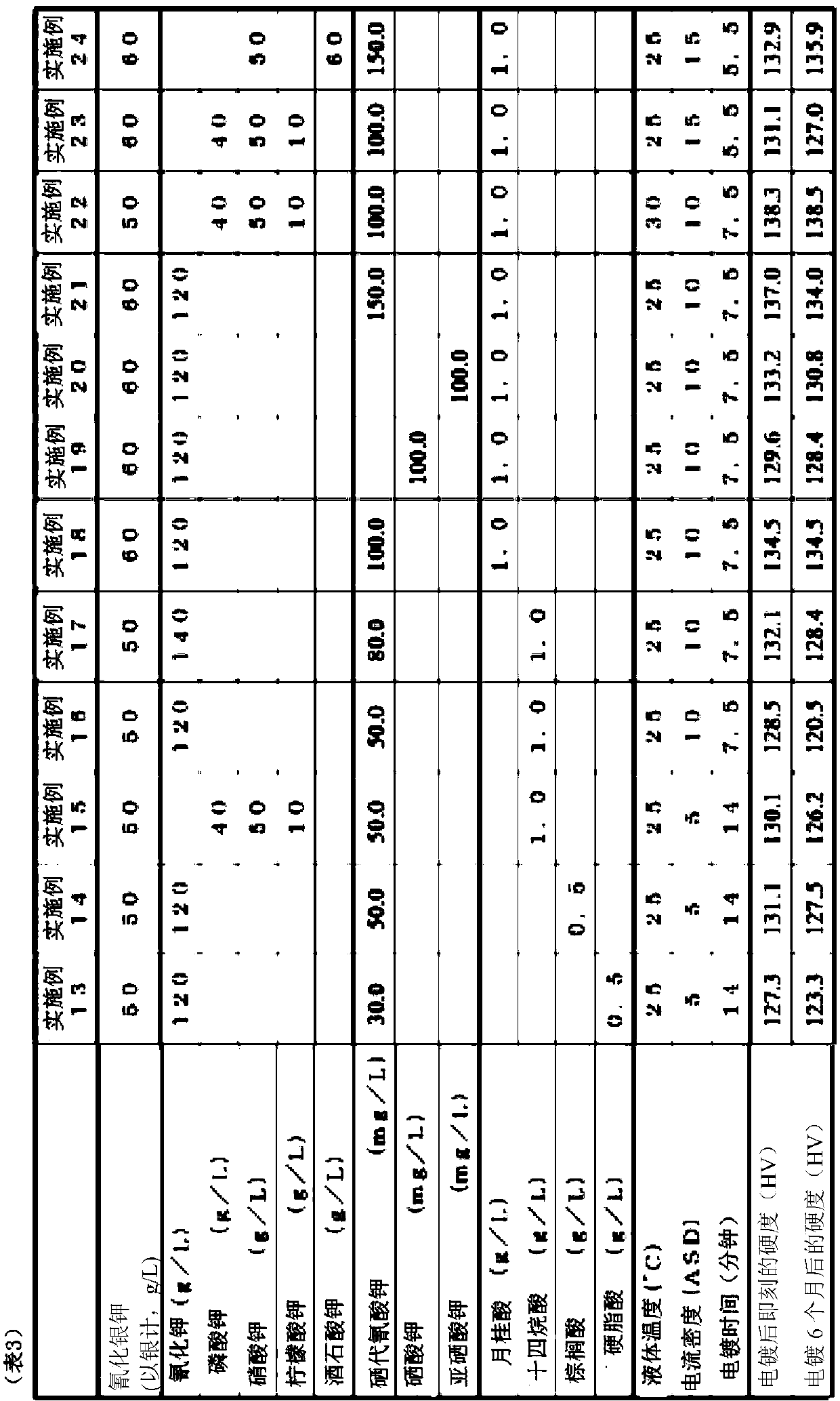

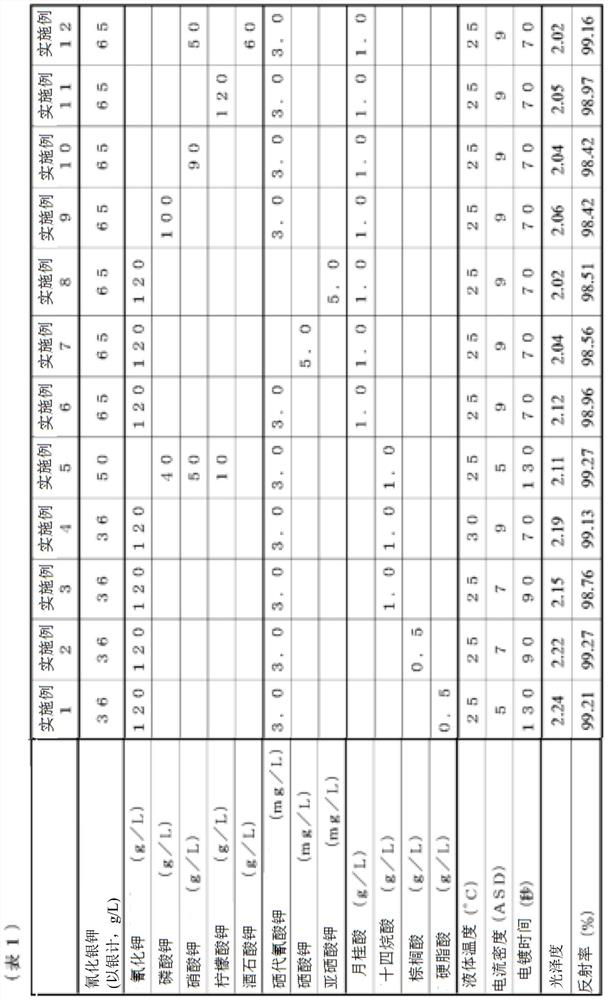

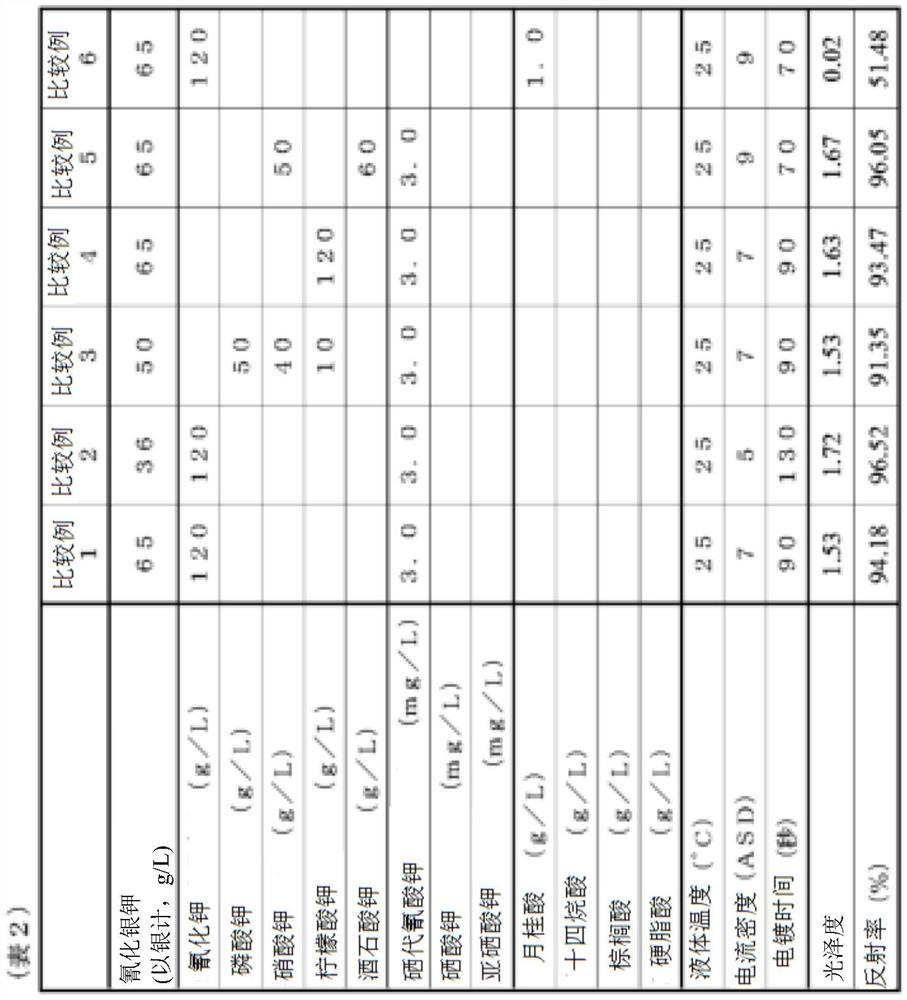

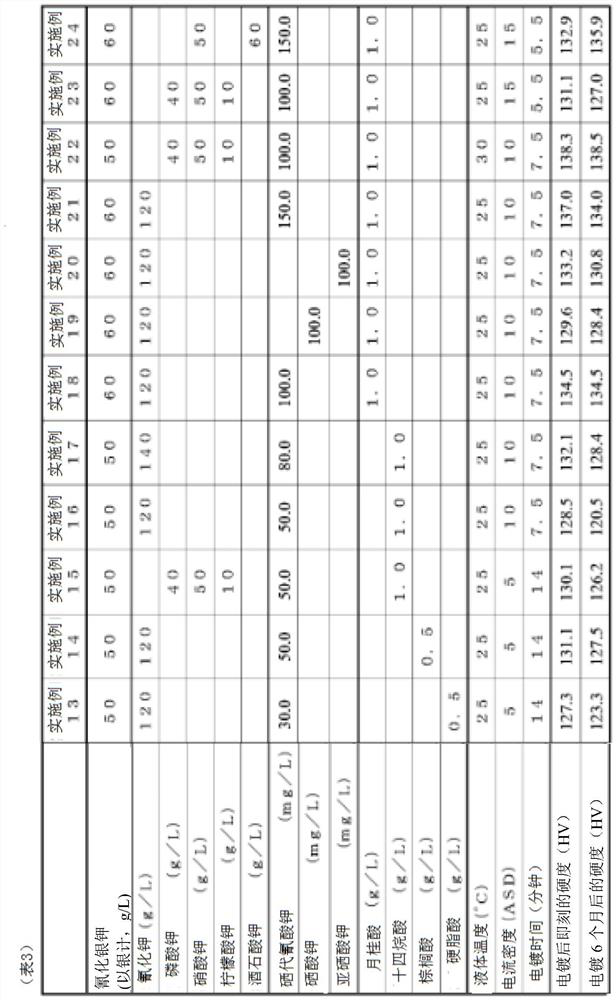

Electrolytic silver plating solution

According to the present invention, the present invention provides an electrolytic silver plating solution containing a silver cyanide complex, an electrically conductive salt, a selenium compound, asaturated fatty acid, and / or a salt thereof, and capable of forming a silver film with a high gloss and a high reflectance.

Owner:ELECTROPLATING ENGINEERS OF JAPAN LTD

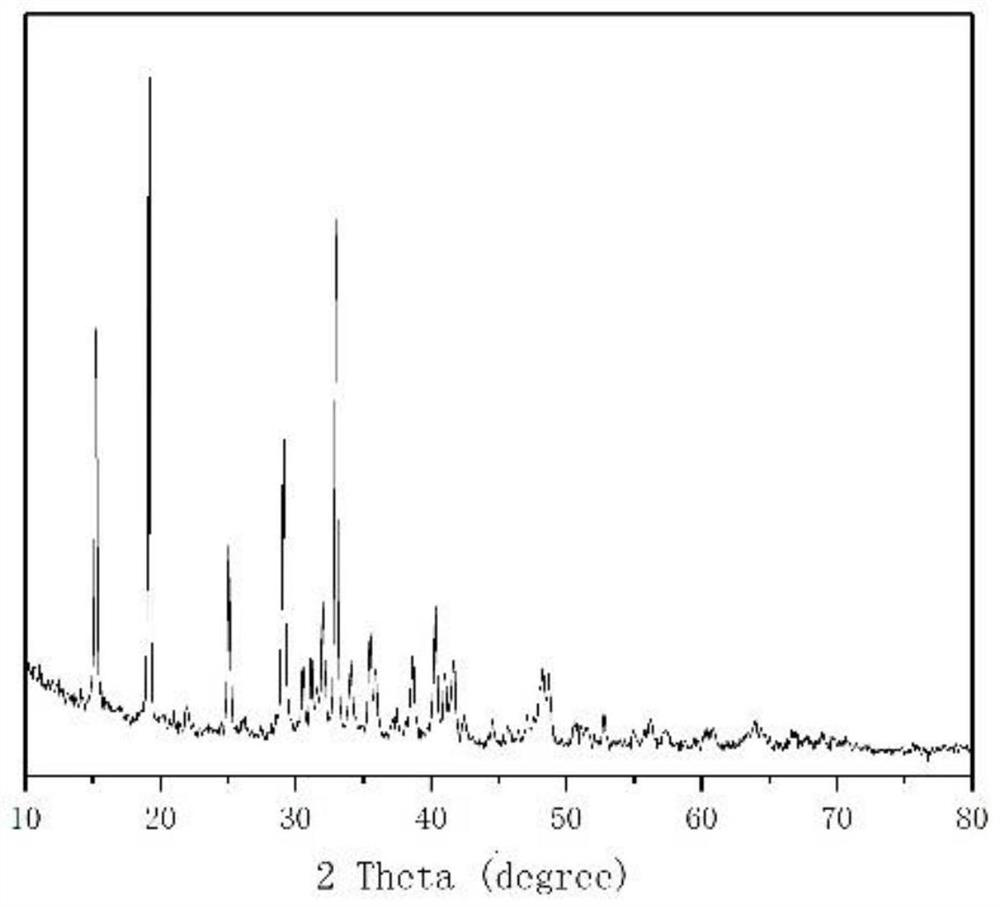

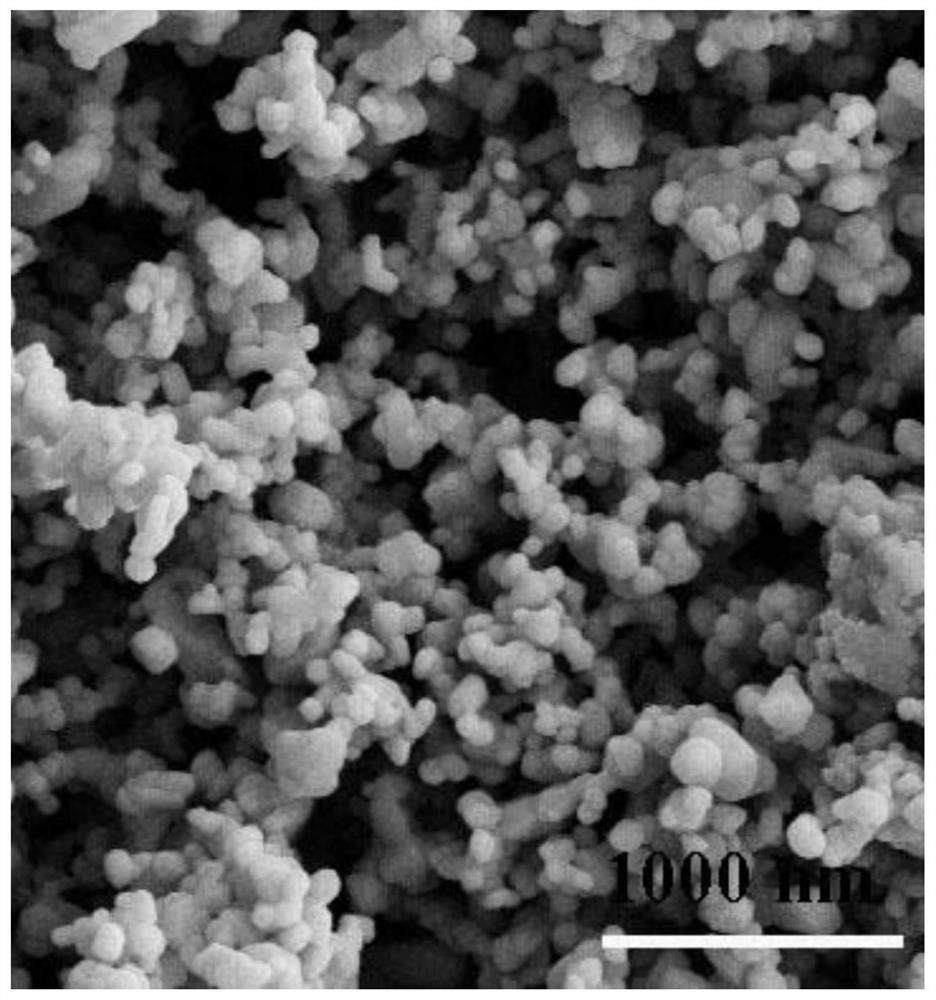

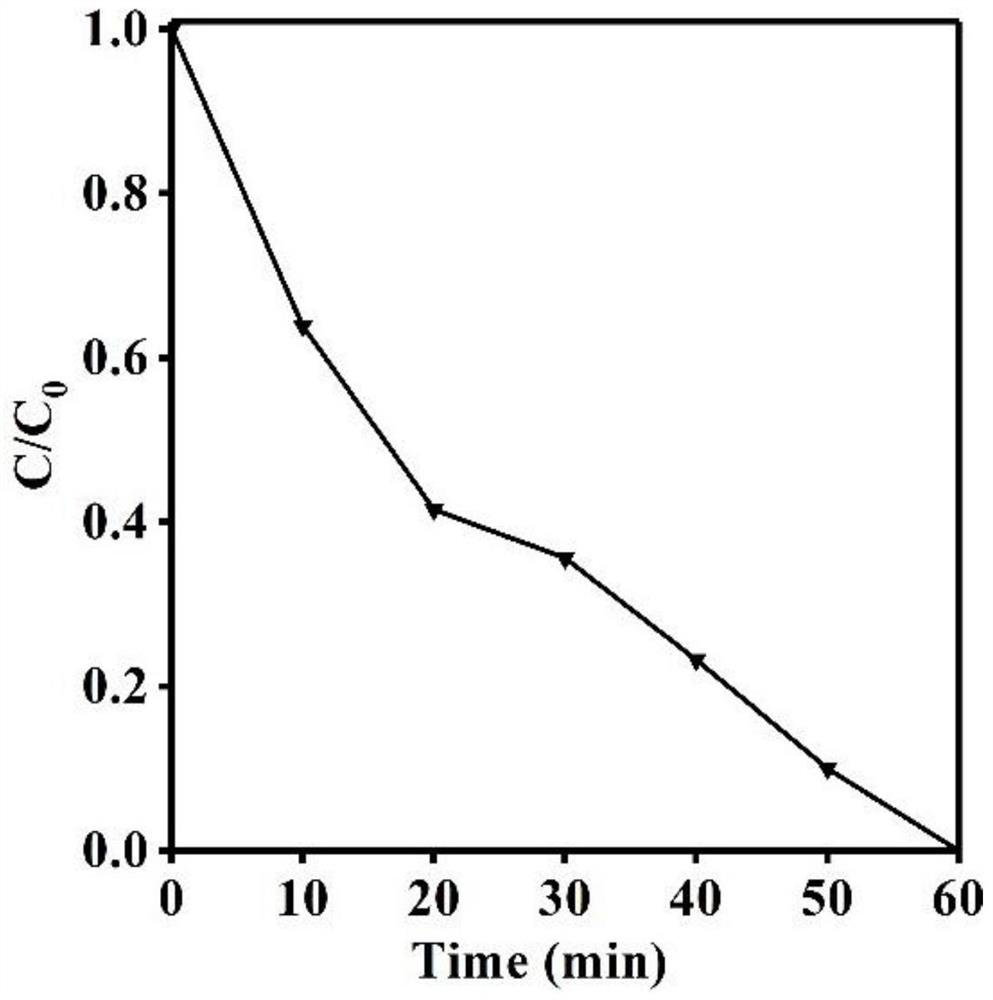

A kind of preparation method of silver thiocyanide/polyacid nanocomposite material

ActiveCN108745379BSolve the complex preparation processComposition is easy to controlWater/sewage treatment by irradiationWater treatment compoundsAlcoholSilver cyanide

The present invention is a method for preparing silver thiocyanide / polyacid nanocomposite materials, which belongs to the technical field of inorganic nanomaterial preparation. It includes the following steps: adding thiocyanic acid or thiocyanate and polyacid or polyacid into water; Form solution A; add silver salt to water to form solution B; mix solution A and B, then react for 0.5-5 hours, filter to obtain the product; wash the product with water or ethanol, and dry to obtain silver thiocyanide / polyacid nanocomposite Material. The present invention uses a simple one-step co-precipitation to prepare silver thiocyanide / polyacid nanocomposite materials. The composition and particle size are both controllable and solves the problem of complex composite material preparation processes. The preparation method and process are simple, environmentally friendly, and suitable for use. It is suitable for large-scale industrial production and has broad application prospects; the prepared silver thiocyanide / polyacid nanocomposite material has excellent performance and high structural stability.

Owner:JINING UNIV

Method of wet extraction of silver from cyanide silver mud

ActiveCN107794374AReduce separation and removal stepsEasy to operateProcess efficiency improvementSilver cyanideProcess conditions

Owner:山东金创金银冶炼有限公司

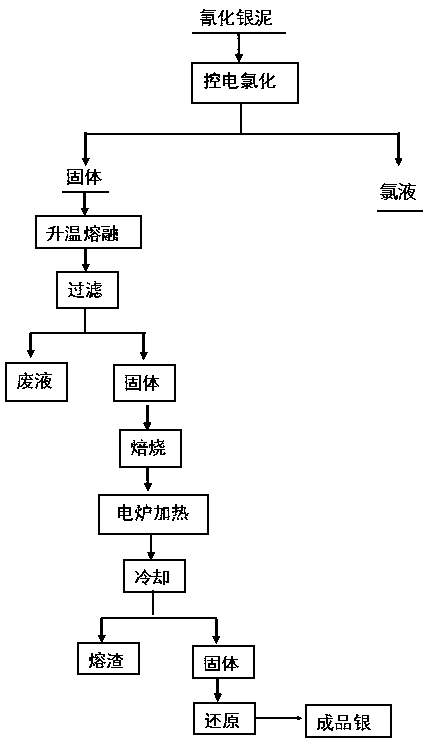

A kind of method of wet extraction silver from silver cyanide mud

ActiveCN107794374BReduce separation and removal stepsEasy to operateProcess efficiency improvementSilver cyanideProcess conditions

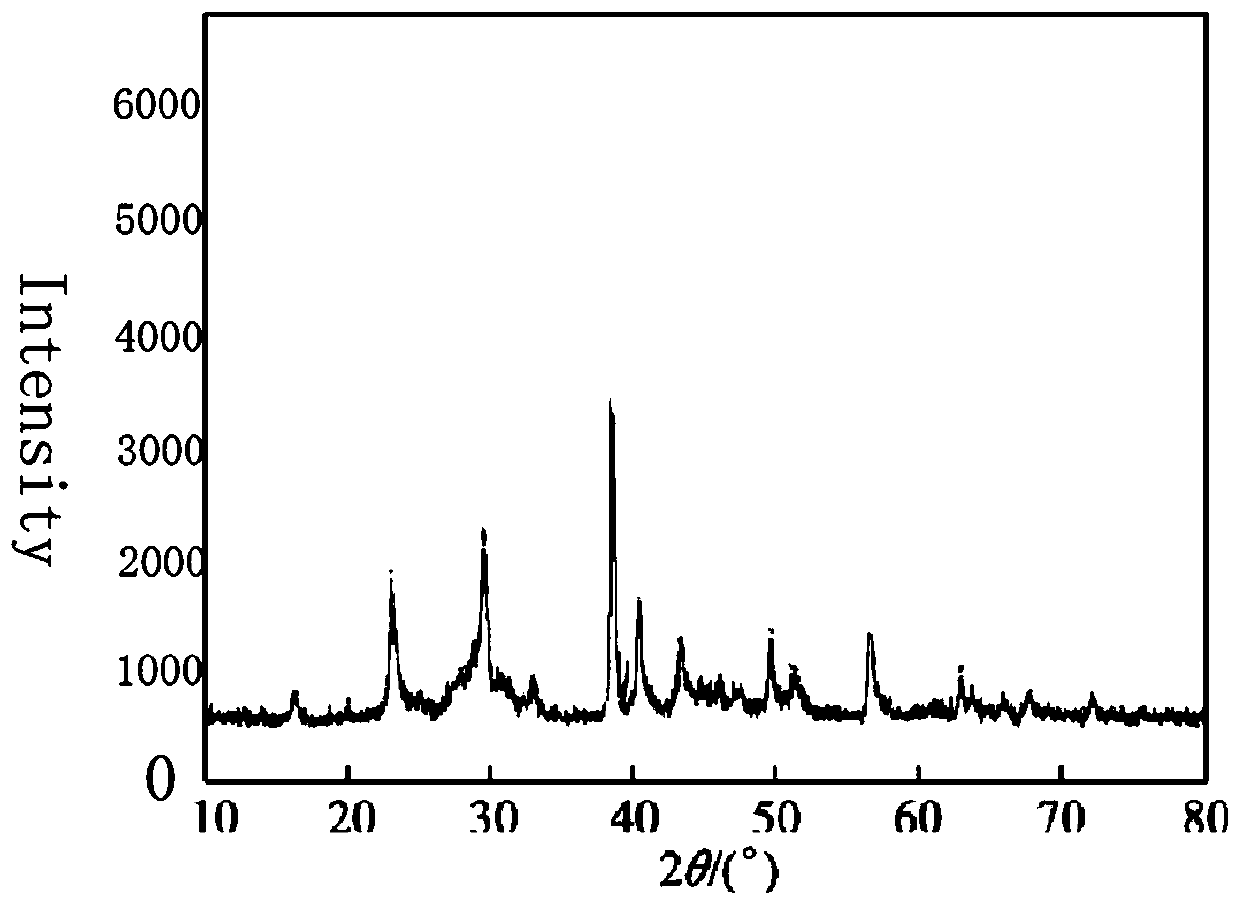

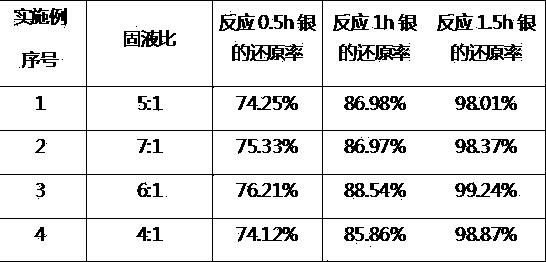

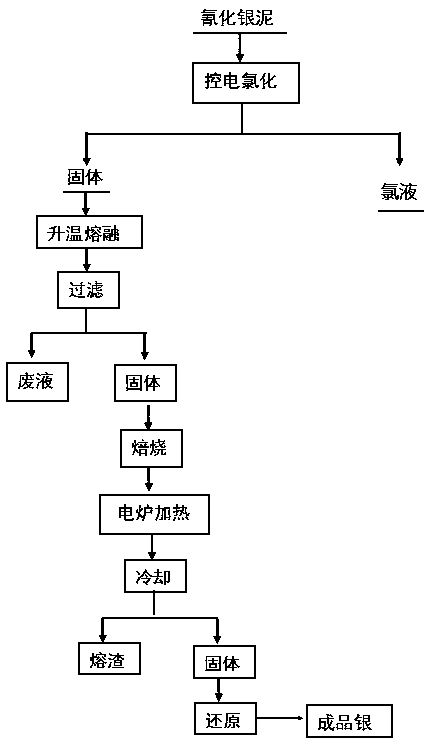

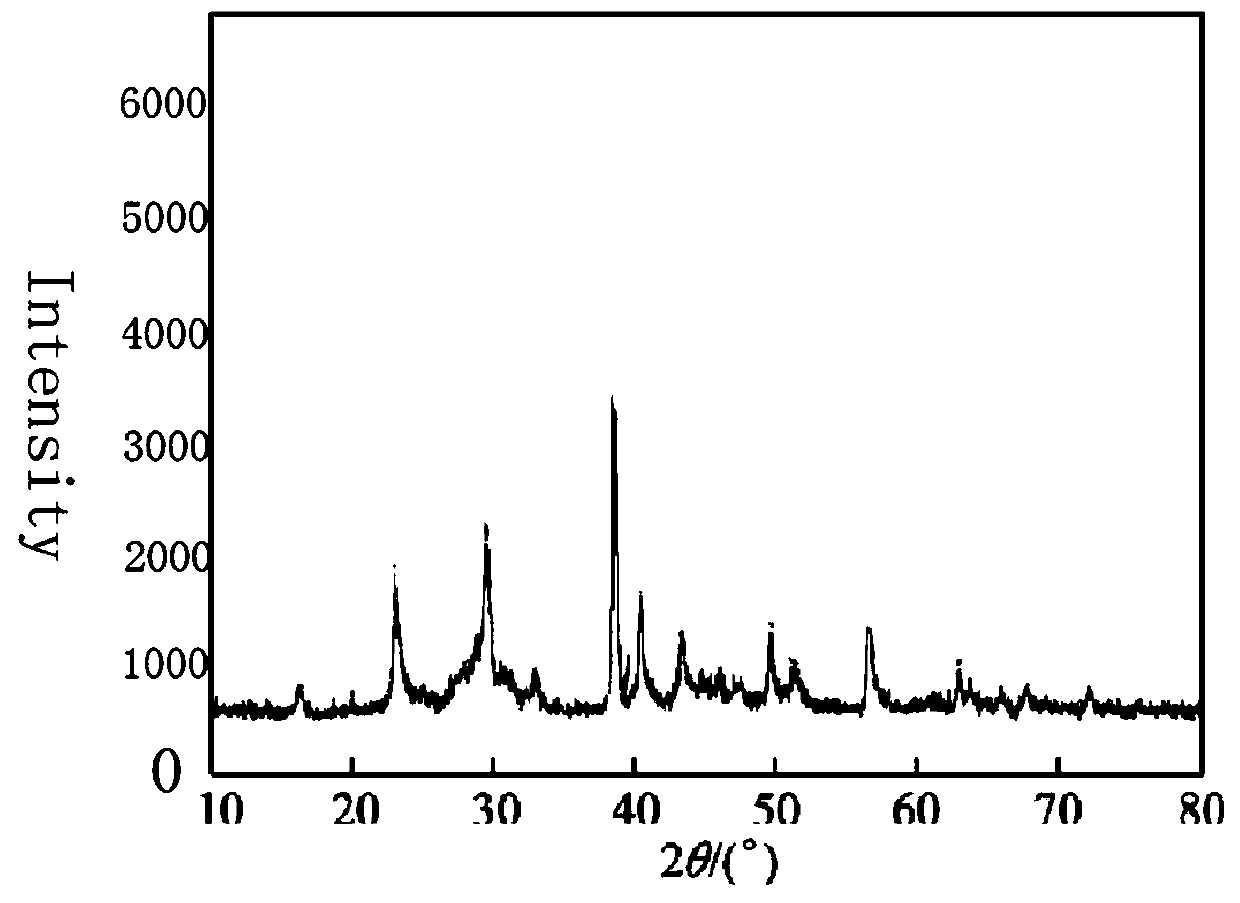

The invention belongs to the field of smelting of silver cyanide mud, and in particular relates to a method of wet extraction of silver from cyanide silver mud. The silver cyanide mud is treated through a medium-high potential wet method to be chloridized to become solid silver cyanide mud which continues to be treated by a series of steps of roasting, heating, cooling, reduction and the like to obtain elemental silver; with polyhydroxy aldehydes used for reduction, silver is quickly and efficiently reduced to the solid, and the elemental silver of high purity is obtained. The method of wet extraction of silver from the cyanide silver mud has the advantages of easy control of process conditions, simple equipment and low cost, high added value of products, high direct recovery efficiency, high safety, small environmental pollution and high economic efficiency.

Owner:山东金创金银冶炼有限公司

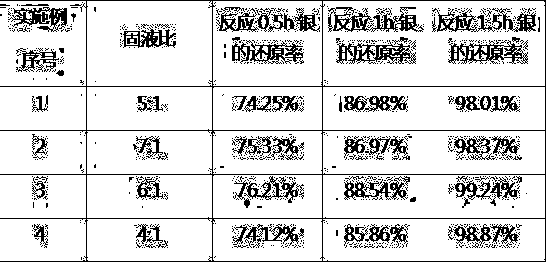

Method for raising leaching rate of silver cyanide

InactiveCN102492854BIncrease profitImprove leaching rateProcess efficiency improvementChemical industrySurge tank

The invention relates to a method for raising leaching rate of silver cyanide and belongs to the technical field of roasting-cyaniding silver extraction production processing technology in the gold smelting and chemical industry. The method provided by the invention contains the following steps of: 1, adding complex silver ore, sal glauberi and sodium carbonate according to the mass ratio of 1: (0.02-0.03): (0.02-0.03) into a surge tank, adjusting the pulp concentration to 65-70% by the addition of water, and continuously stirring at normal temperature and normal pressure for 3-5 hours; 2) carrying out fluidized sulfating roasting on the pulp obtained from the step 1); 3) carrying out acid leaching treatment; and 4) carrying out cyanide leaching. By the adoption of the method, recovery rate of silver can be effectively raised, and utilization rate of resources and enterprise economic benefits are raised.

Owner:SHANDONG GUODA GOLD

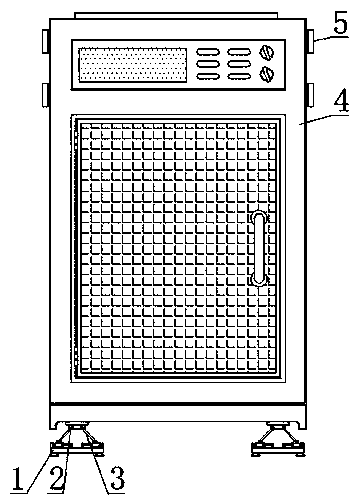

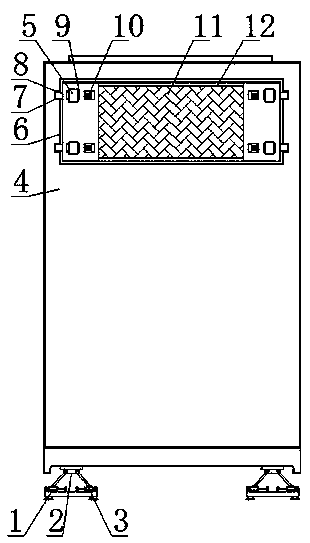

Drying device for silver cyanide production

PendingCN110030823ASolve the unstable placementChange heightDrying chambers/containersSilver cyanidePulp and paper industry

The invention discloses a drying device for silver cyanide production. The drying device comprises a drying device main body, wherein fixing heads are arranged at both ends of the lower surface of thedrying device main body; supporting rods are arranged at both ends of the fixing heads; first bolts are arranged at the joints between the supporting rods and the fixing heads; sliding heads are arranged at the ends of the supporting rods; second bolts are arranged at the joints between the sliding heads and the supporting rods; threaded rods penetrates through the insides of the sliding heads; and supporting bottom plates are arranged on the lower surfaces of the threaded rods. By designing the supporting rods at both ends of the fixing heads and designing the sliding heads at the ends of the supporting rods, the problem that the height of the supporting bottom plates is inconvenient to adjust before the drying device is used, so that the drying device is unstable to place when the ground is not even is avoided, the height of the supporting rods can be changed by sliding the sliding heads on the outer surfaces of the threaded rods, so that the height of the supporting bottom plates is changed, and the problem that the drying device is unstable to place because the height of the supporting bottom plates is inconvenient to adjust is solved.

Owner:三门峡朝阳科技有限公司

Electrolytic Silver Plating Solution

According to the present invention, an electrolytic silver electroplating solution is provided, which is an electrolytic silver electroplating solution containing silver cyanide complexes, conductive salts, selenium compounds, saturated fatty acids and / or salts thereof, which can form high-gloss, high-reflectivity Silver coating.

Owner:ELECTROPLATING ENGINEERS OF JAPAN LTD

Recovery device for wastewater containing silver cyanide

The invention discloses a recovery device for wastewater containing silver cyanide. The recovery device comprises a pretreatment system for wastewater containing silver cyanide, a first-stage membrane separation treatment system, a second-stage membrane separation treatment system and a conveying system which communicate with one another sequentially through a pipeline, wherein the first-stage membrane separation treatment system is connected with a silver recovery system through a pipeline, the pretreatment system for wastewater containing silver cyanide comprises a collection tank for wastewater containing silver cyanide, a raw water pump, a bag filter, an ultrafilter and a pretreatment water tank which communicate with one another sequentially through a pipeline, the first-stage membrane separation treatment system comprises a first-stage boosting pump, a first-stage fine filter, a first-stage high-pressure pump, a first-stage membrane separation device and a first-stage treatment water tank which communicate with one another sequentially through a pipeline, the conveying system comprises a recycling water tank and a conveying pump which communicate with each other sequentially through a pipeline, and the silver recovery system comprises a silver recovery treatment water tank, a silver recovery conveying pump and a silver recovery device. The recovery device has the advantages that the silver recovery ratio is high, and the operating cost is low.

Owner:TAIZHOU HUALONG ELECTRONICS

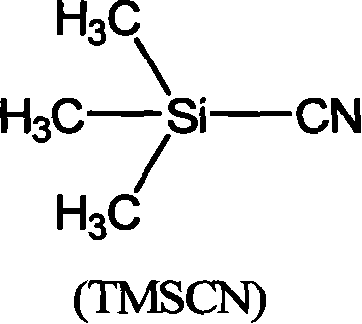

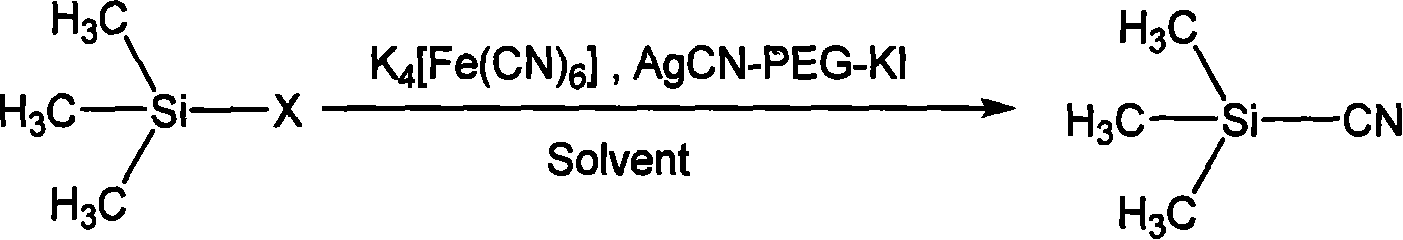

Method for preparing trimethylsilylcyanation

InactiveCN101250197BEasy to prepareMild preparation methodGroup 4/14 element organic compoundsOrganic solventPotassium cyanide

The invention discloses a preparation method of trimethyl silylcyanation (TMSCN), which comprises in organic solvent, using halogenated trimethyl silane and potassium ferrocyanide as raw materials and using silver cyanide-polyethylene-potassium iodide as catalyst to react for 2-12h at 40-200DEG C to prepare trimethyl silylcyanatio, wherein the mol ratio of halogenated trimethyl silane, potassium ferrocyanide, silver cyanide, polyethylene and potassium iodide is 1:0.1-1:0.01-0.1:0.01-0.1:0.01-0.1. The preparation method uses easily accessible potassium ferrocyanide as the resource of cyanide group, to avoid toxic cyanide as sodium cyanide and potassium cyanide or the like, reduce waste acid, dangerous operation and reduce the load on following treatment. The invention is simple, mild and green, which is suitable for preparing trimethyl silylcyanation in large scale.

Owner:NANJING TECH UNIV

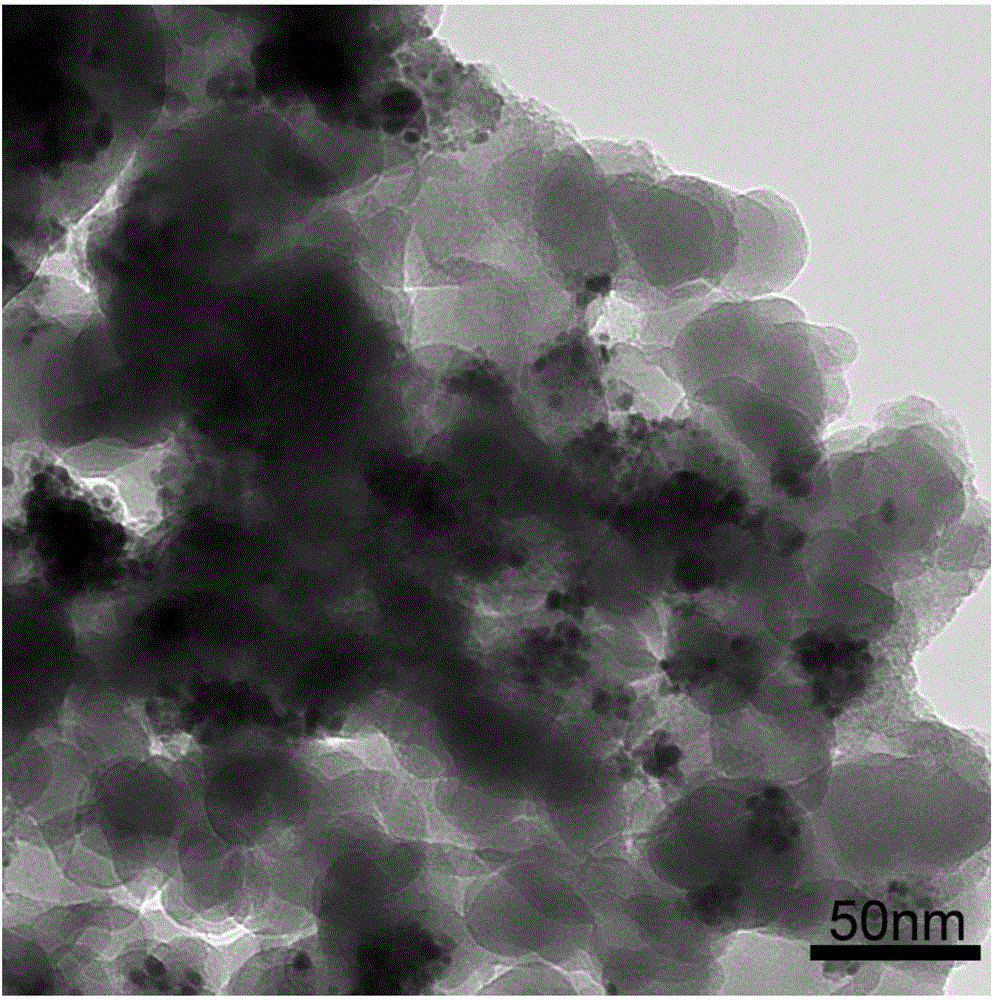

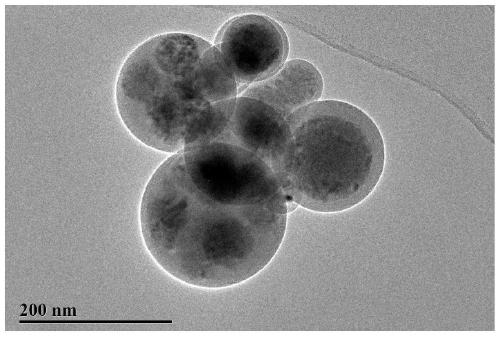

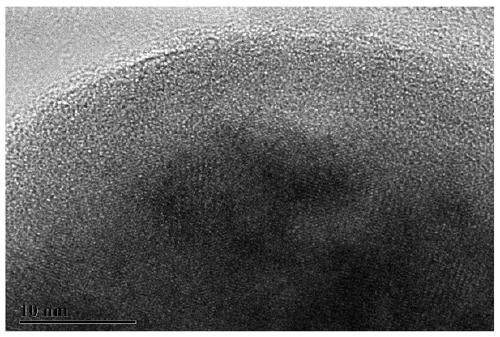

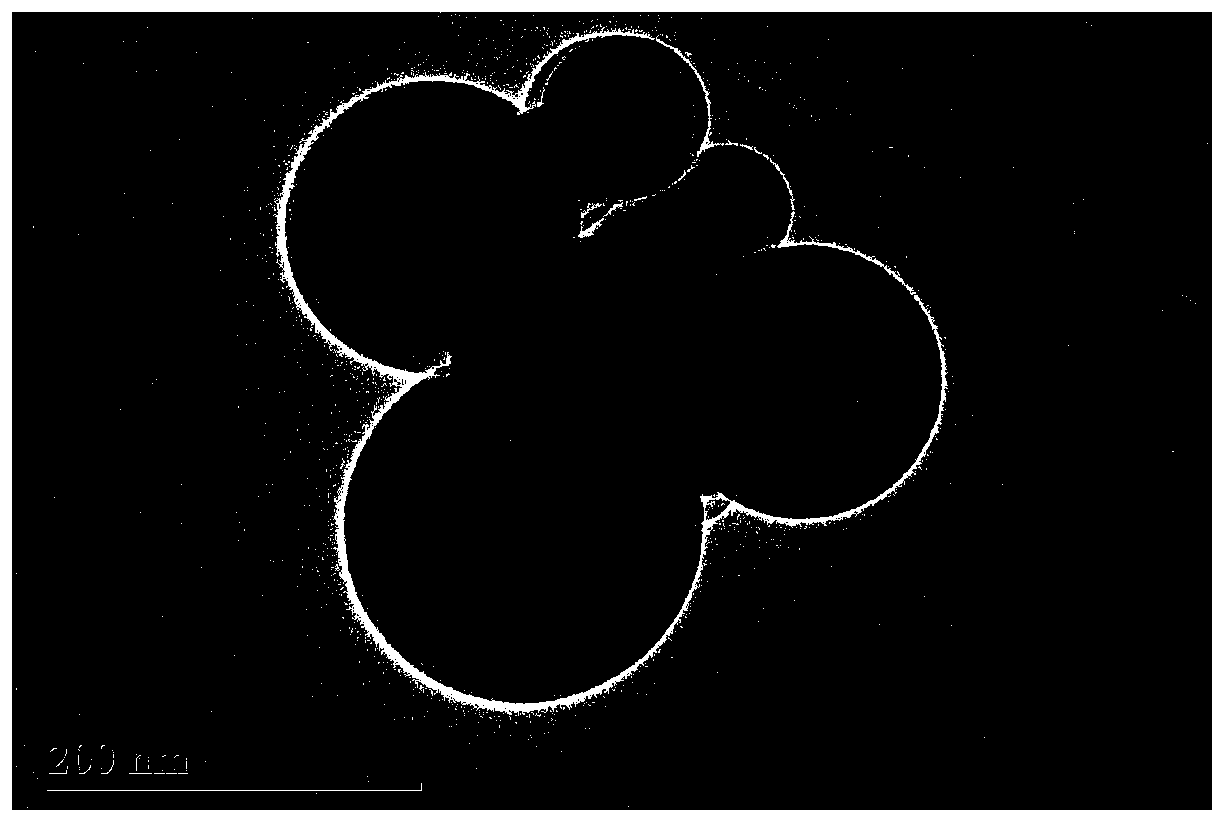

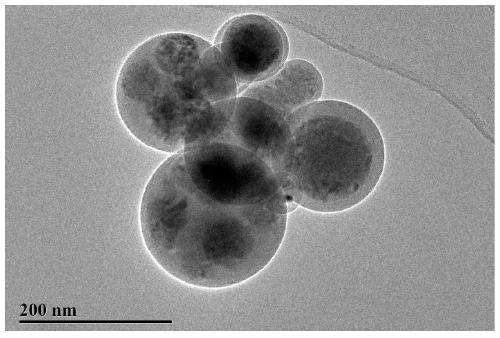

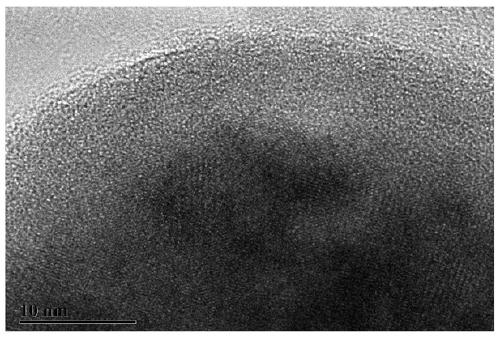

Method for preparing core-shell structure ferrous silver cyanide aluminum nano material

ActiveCN109911914AHigh degree of crystallinityIron cyanidesNanotechnologyAluminium chlorideMaterials preparation

The invention belongs to the technical field of nano material preparation and in particular relates to a method for preparing a core-shell structure ferrous silver cyanide aluminum nano material. Themethod comprises the following steps: simultaneously dropping a silver nitrate solution and an aluminum chloride solution into a ferrous silver cyanide solution, and carrying out a coprecipitation reaction, thereby obtaining the core-shell structure ferrous silver cyanide aluminum nano material. The method provided by the invention is simple in process, environmentally friendly in material, low incost, controllable in preparation process parameter, stable in product property and possible in on-scale production; the size of the core-shell structure ferrous silver cyanide aluminum nano materialprepared by using the method is 50-150nm, the ferrous silver cyanide aluminum nano material is of a core-shell structure, and the crystallization degree of a core is higher than that of a shell.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

A kind of preparation method of silver-aluminum ferrocyanide nanomaterial with core-shell structure

ActiveCN109911914BHigh degree of crystallinityIron cyanidesNanotechnologyAluminium chlorideSilver cyanide

The invention belongs to the technical field of nano material preparation and in particular relates to a method for preparing a core-shell structure ferrous silver cyanide aluminum nano material. Themethod comprises the following steps: simultaneously dropping a silver nitrate solution and an aluminum chloride solution into a ferrous silver cyanide solution, and carrying out a coprecipitation reaction, thereby obtaining the core-shell structure ferrous silver cyanide aluminum nano material. The method provided by the invention is simple in process, environmentally friendly in material, low incost, controllable in preparation process parameter, stable in product property and possible in on-scale production; the size of the core-shell structure ferrous silver cyanide aluminum nano materialprepared by using the method is 50-150nm, the ferrous silver cyanide aluminum nano material is of a core-shell structure, and the crystallization degree of a core is higher than that of a shell.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

Imitation gold electroplating solution

The invention discloses an imitation gold electroplating solution which is composed of the following raw materials: 80-85 parts of cuprous sulfate, 80-90 parts of cupric chloride, 10-15 parts of sodium cyanide, 10-12 parts of ammonium thiocyanate, 8-10 parts of potassium thiocyanate, 20-30 parts of potassium cyanide, 40-45 parts of potassium auric cyanide, 8-10 parts of zinc hydroxide, 15-20 parts of barium cyanide, 20-25 parts of calcium cyanide, 15-20 parts of silver cyanide, 5-6 parts of trisodium phosphate, 5-8 parts of sodium metaphosphate, 8-10 parts of citric acid, 8-10 parts of magnesium fluoride, 8-10 parts of barium fluoride, 6-10 parts of sodium fluosilicate and 8-10 parts of aluminum fluoride. The imitation gold electroplating solution has the advantages of low cost, high electroplating performance, wide raw material sources, simple preparation process, stable performance and favorable electroplating effect.

Owner:陈新棠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com