A bright cyanide-free silver plating solution and preparation method thereof

A cyanide-free silver plating and electroplating solution technology, which is applied in the field of electrochemical silver plating, can solve the problems that the process performance cannot meet the electroplating process, poor dispersibility of cyanide-free silver plating, inconvenient management and operation, etc., to improve the quality of the plating layer, combine Good power, good economic benefits and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A bright cyanide-free silver plating solution, the raw material formula is made up of each component of following mass concentration: 300 mg / L saccharin, 500 mg / L methionine, 30 g / L AgNO 3 , 180 g / L hydantoin, 17 g / L KNO 3 , 10 g / L NaOH.

[0025] The complexing agent hydantoin, supporting electrolyte KNO 3 Dissolve the pH regulator NaOH of the electroplating solution with part of the water, mix well; cool to room temperature, and then slowly add the silver ion source AgNO 3 , stir until the solution is clear; then add the brightener saccharin and methionine to it, and finally add the remaining water, stir evenly and let stand.

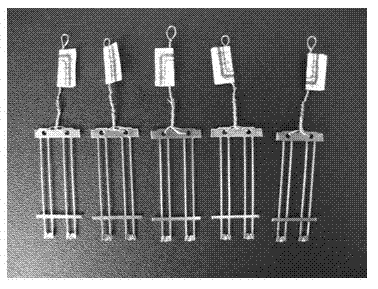

[0026] During the electroplating process, the bath was maintained at 50°C. Then, the pretreated metal substrate was connected to the circuit and immersed in the electroplating solution with a current density of 1 A / dm 2 , and the plating method was rack plating to obtain a silver-plated sample of a light-emitting diode lead frame. Rack plat...

Embodiment 2

[0028] A bright cyanide-free silver plating solution, the raw material formula is made up of each component of following mass concentration: 10 mg / L polyethylene glycol, 500 mg / L histidine, 42 g / L AgCl, 190 g / L 5 -Methylhydantoin, 24 g / L K 2 CO 3 , 14 g / L KOH.

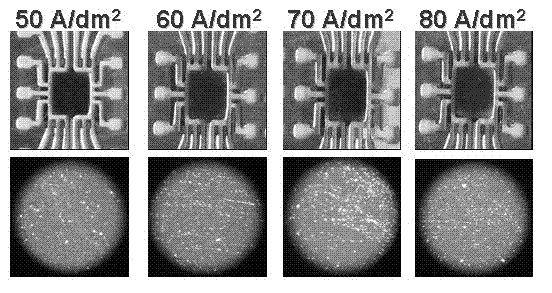

[0029] Adopt above-mentioned formula and adopt the preparation method of embodiment 1 to prepare, obtain bright cyanide-free silver plating electroplating solution, temperature control 10~80 ℃, at 50-80 A / dm 2 Under the current density, the silver-plated sample of the integrated circuit lead frame is sprayed by spraying. Morphology and microstructure of IC lead frame plated parts at different current densities, such as figure 2 As shown, the frame leads of integrated circuits generally require high-speed electroplating with a soft, matte silver layer of 1~5mm. The silver layer requires stable properties and good solderability. Utilizing the invention of the invention, the high-speed cyanide-free silver plating of ...

Embodiment 3

[0031] A bright cyanide-free silver plating solution, the raw material formula is made up of each component of following mass concentration: 200 mg / L imidazole, 450 mg / L tryptophan, 25 g / L AgNO 3 , 160 g / L 5,5-dimethylhydantoin, 20 g / L K 2 CO 3 , 18 g / L NaOH.

[0032] Adopt above-mentioned formula and adopt the preparation method of embodiment 1 to prepare, obtain bright cyanide-free silver plating electroplating solution, temperature control 40 ℃, at 5 A / dm 2 Under the current density, rack plating of wire silver plating samples was carried out by rack plating.

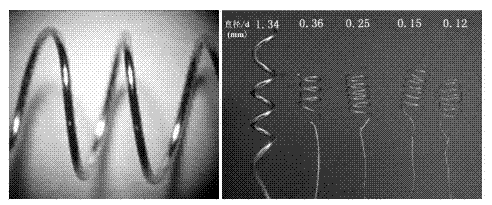

[0033] Photos of silver-clad copper wires and electroplating effects of copper wires of different thicknesses, such as image 3 As shown, in the electronic industry, especially in the field of high-frequency communication, it is necessary to provide functional silver-plated wires with high conductivity due to the miniaturization of devices. The invention perfects the cyanide-free silver plating process on copper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com