Method for separating aluminum and iron in high-iron bauxite

A technology of high-iron bauxite and bauxite, which is applied to the separation of minerals and the field of separating aluminum and iron in high-iron bauxite, can solve the problems of comprehensive utilization of aluminum and iron, and achieve low cost and high production efficiency. The effect of high efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] High-speed iron bauxite in a province in China: Al 2 o 3 Content 49.76%, SiO 2 Content 4.9%, A / S=10.16, Fe 2 o 3 Content 28.23%;

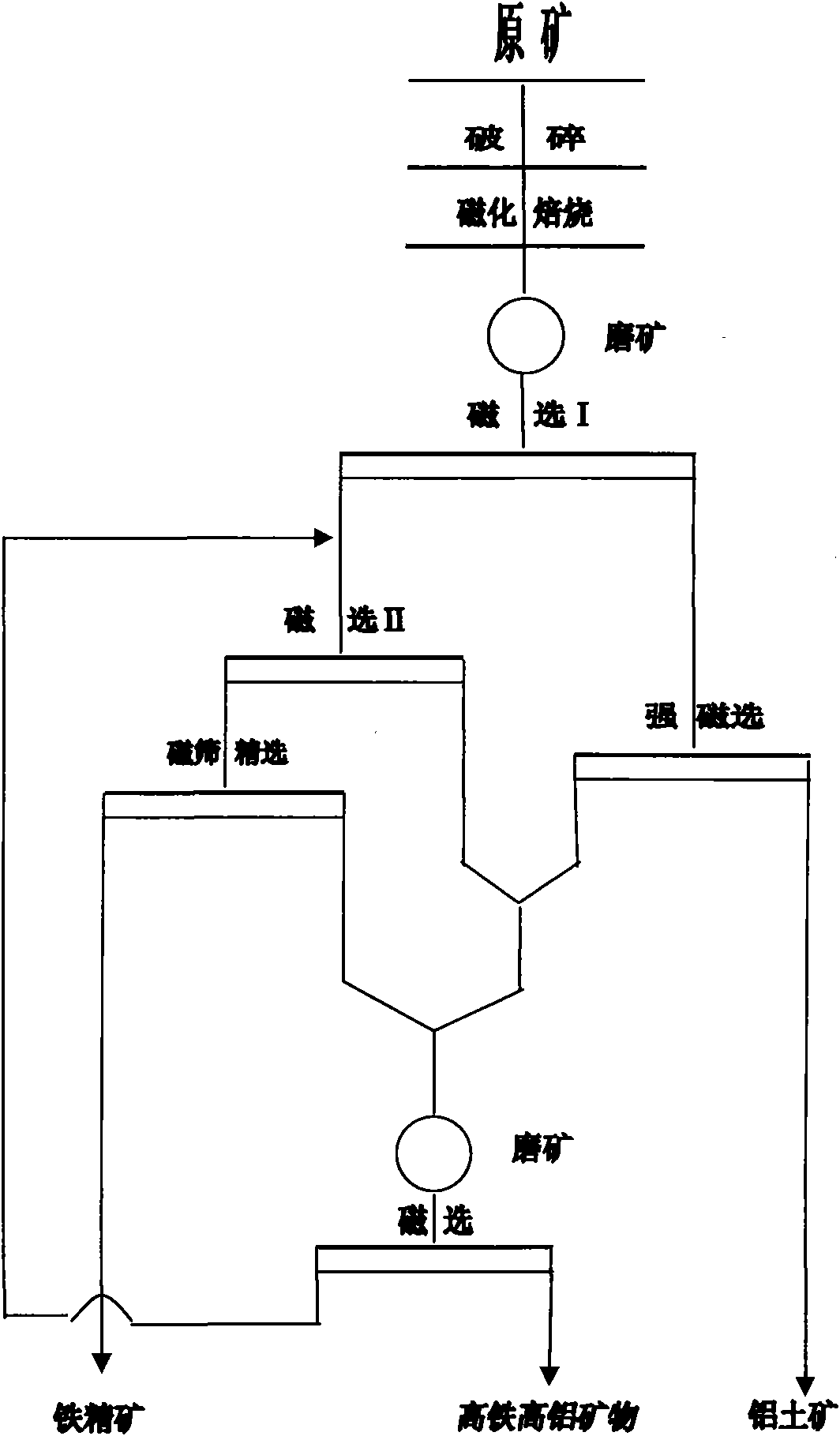

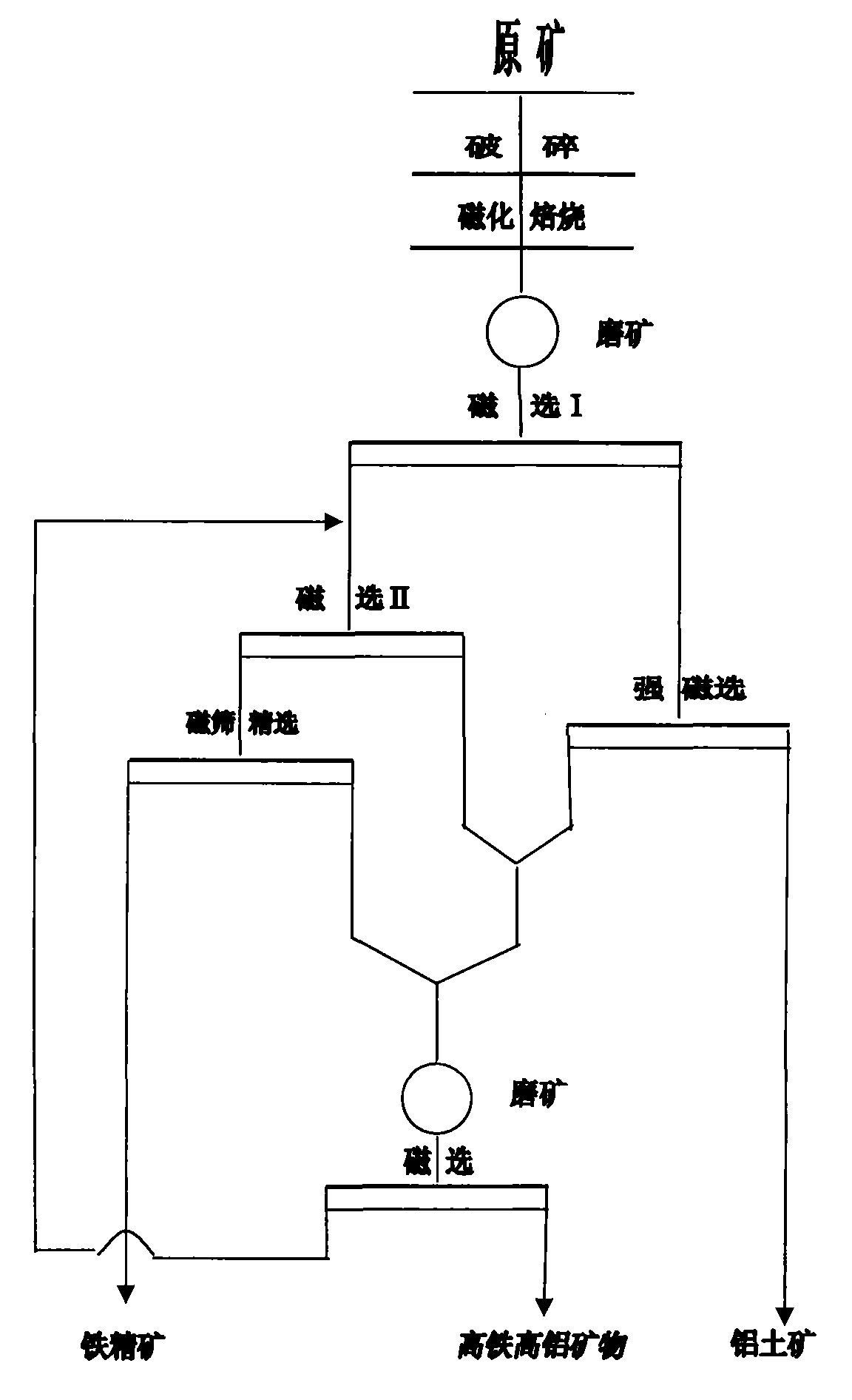

[0019] The high-iron bauxite is crushed until the total particle size of the ore is less than 5mm, and then magnetized roasting is carried out. The conditions of magnetized roasting are: the weight of coke added is 25% of the total weight, the roasting temperature is 1030 ° C, and the roasting time is 4.5 hours; The roasted high-iron bauxite is ground until the ore particle size is less than 200 mesh and the weight accounts for 90% of its total weight; the magnetic field strength of the first stage of magnetic separation is 127.4 kA / m, and the bauxite and iron minerals are separated; The separated bauxite is subjected to strong magnetic separation under the condition of strong magnetic separation with a magnetic field strength of 717 kA / m, and the iron minerals are completely removed to obtain qualified bauxite; the separated iron concen...

Embodiment 2

[0022] High-speed iron bauxite in a province in China: Al 2 o 3 Content 51.06%, SiO 2 Content 4.15%, A / S=12.30, Fe 2 o 3 Content 29.01%;

[0023] The high-iron bauxite is crushed until the total particle size of the ore is less than 5mm, and then magnetized roasting is carried out. The condition of the magnetized roasting is 25% coke, the roasting temperature is 1030 ° C, and the roasting time is 4.5 hours; the magnetized roasted high-iron bauxite is processed by The ore is ground until the ore particle size is less than 200 mesh and the weight accounts for 90% of its total weight; the magnetic field strength of the first stage of magnetic separation is 160 kA / m, and the bauxite and iron minerals are separated; the separated bauxite is in the magnetic field Strong magnetic separation is carried out under the condition of strong magnetic separation with a strength of 1095 kA / m, and the residual iron minerals are removed again to obtain qualified bauxite; the separated iron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com