Silver cyanide manufacturing technology and equipment thereof

A manufacturing process and technology of silver cyanide, applied in metal cyanide and other directions, can solve the problems of polluted air, large loss of silver, low purity of silver cyanide, etc., and achieve the effect of improving production efficiency, reducing cost and reducing silver loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A kind of silver cyanide manufacturing process that the embodiment of the present invention provides is characterized in that comprising the following steps:

[0018] (1) Chemically react the silver plate with nitric acid solution, the concentration of nitric acid is 60% to 80%, to make silver nitrate solution;

[0019] (2) Chemically react silver nitrate solution with cyanide solution to make silver cyanide and nitrate solution, wherein the concentration of cyanide solution is 120~135g / L, and the cyanide solution is potassium cyanide solution or sodium cyanide solution;

[0020] (3) Wash and separate silver cyanide and nitrate solution, thus completing the production of silver cyanide.

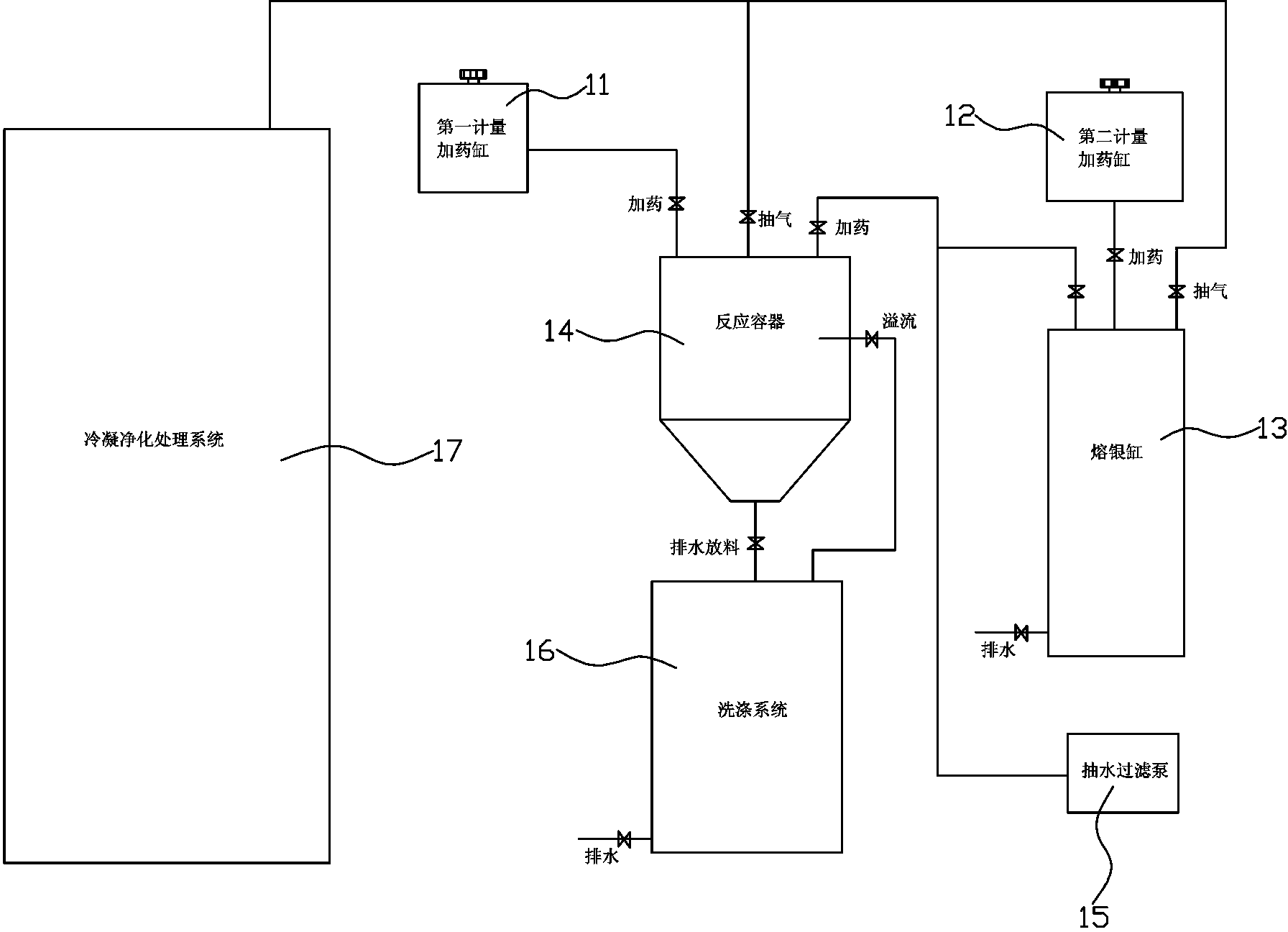

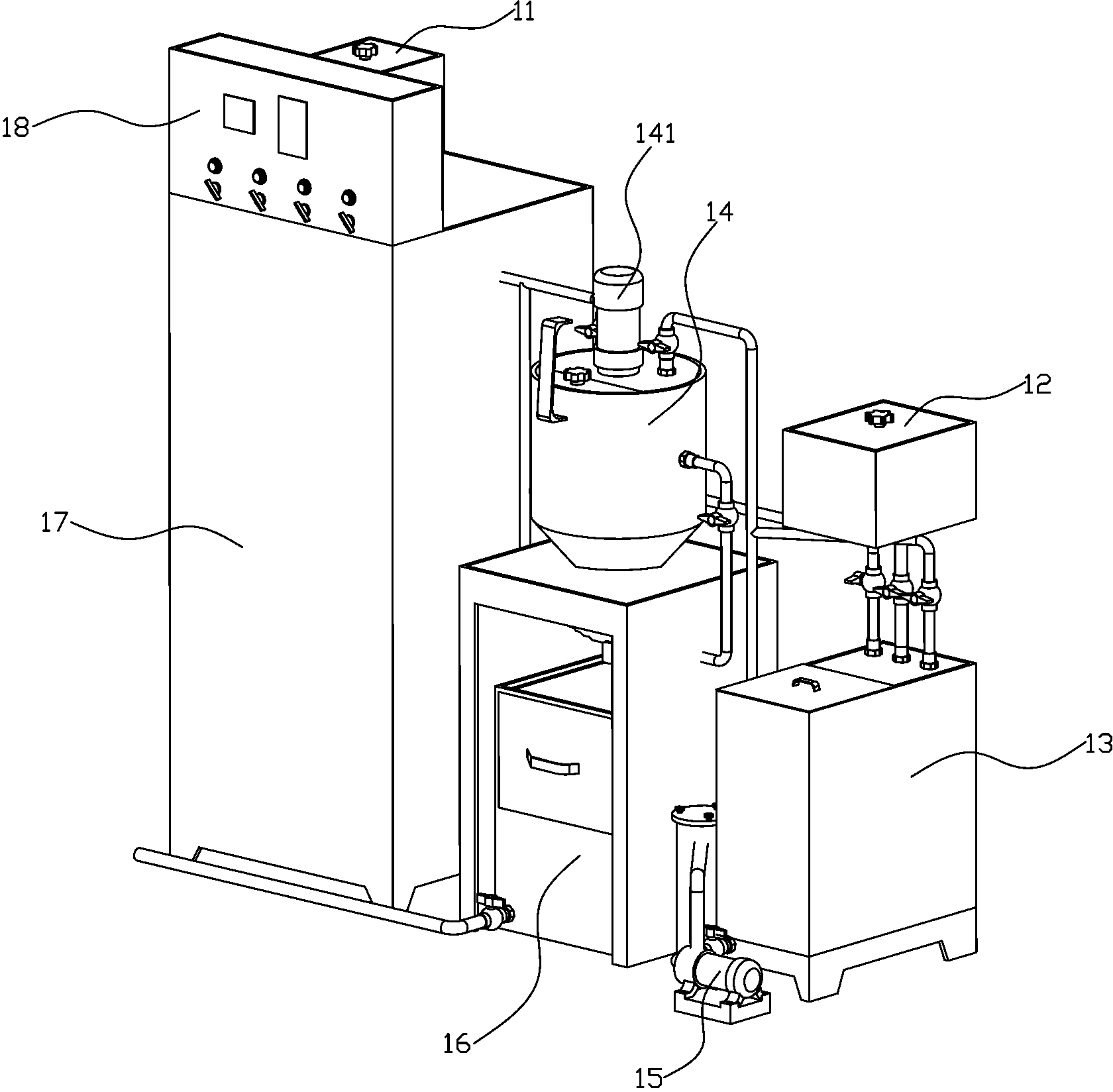

[0021] Such as figure 1 with figure 2 As shown, the equipment used in the above-mentioned silver cyanide manufacturing process provided by the embodiment of the present invention includes a first metering and dosing cylinder 11, a second metering and dosing cylinder 12, a silver me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com