Nickel silvering process in process of electroplating LED (Light Emitting Diode) bracket

A technology of LED bracket and silver process, applied in the field of silver-on-nickel process, can solve the problems of waste, LED bracket discoloration, affecting the function and effect of LED bracket, etc., and achieve the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

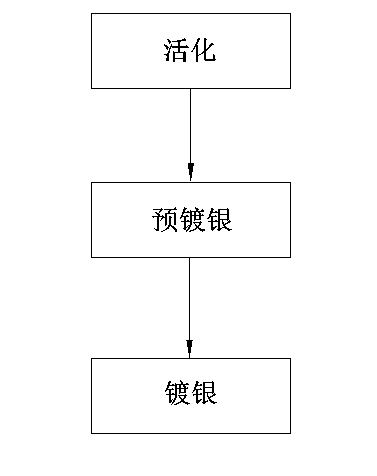

[0015] Such as figure 1 As shown, the process of the process of plating silver on nickel for LED stent electroplating provided by the present invention is: activation→pre-plating silver→silver plating.

[0016] Activation is to first pass a current of 0.5A / d㎡ to the LED bracket, and then move it to a mixed solution of potassium cyanide with a concentration of 10g / L and potassium carbonate with a concentration of 15g / L to clean the surface of the nickel-plated layer. Organic film, and remove the oxide layer on the surface of the nickel layer.

[0017] The pre-plating of silver is to first pass a current of 2A / d㎡ to the LED bracket, and then move it to a mixed solution of silver cyanide with a concentration of 3g / L and a concentration of 140g / L at a temperature of 20℃. Electroplating prevents the replacement of silver in the nickel layer and increases the bonding force between the silver layer and the nickel layer.

[0018] Silver plating is to first pass a current of 1A / d㎡ to the LE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com