A kind of method of wet extraction silver from silver cyanide mud

A silver cyanide and wet process technology, applied in the field of silver cyanide mud recycling, can solve the problems of the danger of hydrogen-explosive silver compounds, no practical value, etc., so as to increase melt fluidity, reduce separation and impurity removal steps, and avoid reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

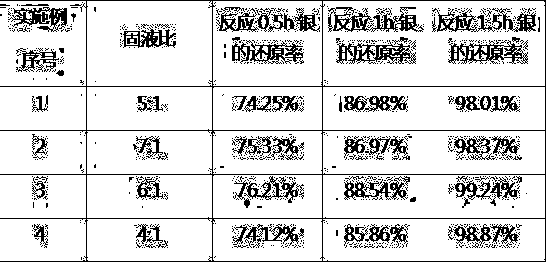

Embodiment 1

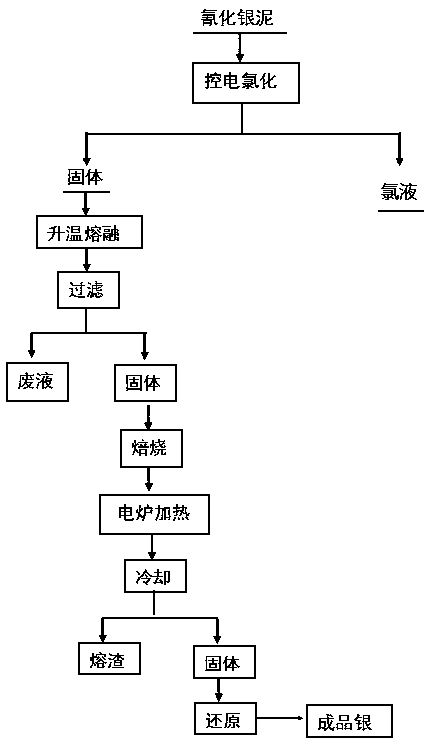

[0031] This embodiment includes the following steps:

[0032] ① Put silver cyanide mud into the reaction kettle according to a certain solid-liquid ratio, control the potential, make it chlorinated in the medium of sulfuric acid and sodium chloride, make all the copper, selenium and part of the gold enter the solution, and control the sulfuric acid and chlorine The ratio of sodium chloride mixture to silver cyanide mud is 4:1, and the concentration of sulfuric acid is 10%;

[0033] ②Add a certain proportion of starch and iron powder mixed solution to the silver-containing mixed solid obtained from solid-liquid separation in step ①, heat up to 1200°C for 10 minutes, cool to 900°C, and filter;

[0034] ③ adding the hydrotalcite and fluorite soaked in the ethanol solution containing the mercapto functional group for 35 hours to the solid obtained by filtering in step ②, roasting together, and cooling;

[0035] ④ Add zinc powder, carbon powder and glass powder to the cooled slag ...

Embodiment 2

[0039] This embodiment includes the following steps:

[0040] ① Put silver cyanide mud into the reaction kettle according to a certain solid-liquid ratio, control the potential, make it chlorinated in the medium of sulfuric acid and sodium chloride, make all the copper, selenium and part of the gold enter the solution, and control the sulfuric acid and chlorine The ratio of sodium chloride mixture to silver cyanide mud is 5:1, and the concentration of sulfuric acid is 8%;

[0041] ②Add a certain proportion of starch and iron powder mixed solution to the silver-containing mixed solid obtained from solid-liquid separation in step ①, heat up to 1200°C for 13 minutes, cool to 900°C, and filter;

[0042] ③ adding the hydrotalcite and fluorite soaked in the ethanol solution containing the mercapto functional group for 30 hours to the solid obtained by filtering in step ②, roasting together, and cooling;

[0043] ④ Add zinc powder, carbon powder and glass powder to the cooled slag o...

Embodiment 3

[0047] This embodiment includes the following steps:

[0048] ① Put silver cyanide mud into the reaction kettle according to a certain solid-liquid ratio, control the potential, make it chlorinated in the medium of sulfuric acid and sodium chloride, make all the copper, selenium and part of the gold enter the solution, and control the sulfuric acid and chlorine The ratio of sodium chloride mixture to silver cyanide mud is 7:1, and the concentration of sulfuric acid is 9%;

[0049] ②Add a certain proportion of starch and iron powder mixed solution to the silver-containing mixed solid obtained from solid-liquid separation in step ①, heat up to 1200°C for 15 minutes, cool to 900°C, and filter;

[0050] ③ adding the hydrotalcite and fluorite soaked in the ethanol solution containing the mercapto functional group for 33 hours to the solid obtained by filtering in step ②, roasting together, and cooling;

[0051] ④ Add zinc powder, carbon powder and glass powder to the cooled slag o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com