Method for preparing trimethylsilylcyanation

A technology of trimethylsilicon cyanide and trimethylsilane, which is applied in the field of preparation of high-efficiency trimethylsilicon cyanide, can solve the problems of environmental hazard, unfavorable operation and high cost, and achieves reduction of waste acid hazard, green process method and operation. risk reduction effect

Inactive Publication Date: 2011-01-05

NANJING TECH UNIV

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Alkali metal cyanide is selected as the cyanide source. Under special catalytic conditions, trimethylsilyl cyanide can be easily obtained, but there is highly toxic hydrocyanic acid in the process, which is harmful to the environment and is not conducive to operation. The special catalyst It is not suitable for large-scale industrial use, and the cost is relatively high, which does not conform to the principle of economy

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

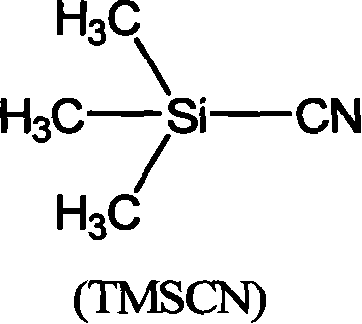

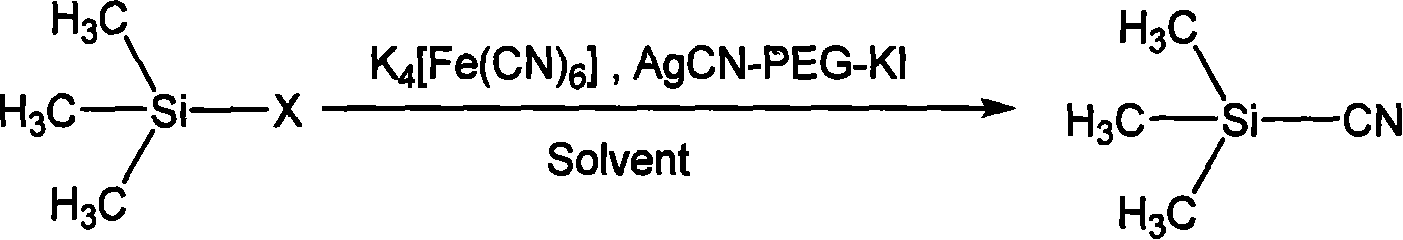

Login to View More Abstract

The invention discloses a preparation method of trimethyl silylcyanation (TMSCN), which comprises in organic solvent, using halogenated trimethyl silane and potassium ferrocyanide as raw materials and using silver cyanide-polyethylene-potassium iodide as catalyst to react for 2-12h at 40-200DEG C to prepare trimethyl silylcyanatio, wherein the mol ratio of halogenated trimethyl silane, potassium ferrocyanide, silver cyanide, polyethylene and potassium iodide is 1:0.1-1:0.01-0.1:0.01-0.1:0.01-0.1. The preparation method uses easily accessible potassium ferrocyanide as the resource of cyanide group, to avoid toxic cyanide as sodium cyanide and potassium cyanide or the like, reduce waste acid, dangerous operation and reduce the load on following treatment. The invention is simple, mild and green, which is suitable for preparing trimethyl silylcyanation in large scale.

Description

A kind of preparation method of trimethylsilyl cyanide technical field The invention relates to a preparation method of high-efficiency trimethylsilyl cyanide (TMSCN). Background technique Trimethylsilylcyanide is an important intermediate in organic synthesis and an important chemical raw material, and it is widely used in many reactions, such as the corresponding selective addition reaction with aromatic aldehydes, the asymmetric addition reaction with aldehydes, especially , its nucleophilic addition to the C=O double bond is the main method to generate carbon-carbon bonds and obtain chiral cyanohydrins. As early as 1952, J.J.MCBRIDE, JR. etc. just reported adopting trimethylsilyl halide and silver cyanide to prepare trimethylsilyl cyanide (J.J.MCBRIDE, JR.andH.C.BEACHE, J.Am.Chem. Soc, 1952, 5, 5247-5250.), this work and the similar work after that mostly adopt comparatively expensive silver cyanide as the cyanide source, and react for a long time under the condition ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C07F7/18

Inventor 李振江孙颖杰宋国伟周继新

Owner NANJING TECH UNIV

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com